Organic silicon modified styrene-acrylic emulsion for ceramic tile back adhesive and preparation method thereof

A technology of styrene-acrylic emulsion and silicone, which is applied in the direction of adhesives, adhesive types, hydrocarbon copolymer adhesives, etc., can solve the problems of slow drying speed and inability to meet the brush-and-stick process, so as to improve the drying speed , the effect of high tensile bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

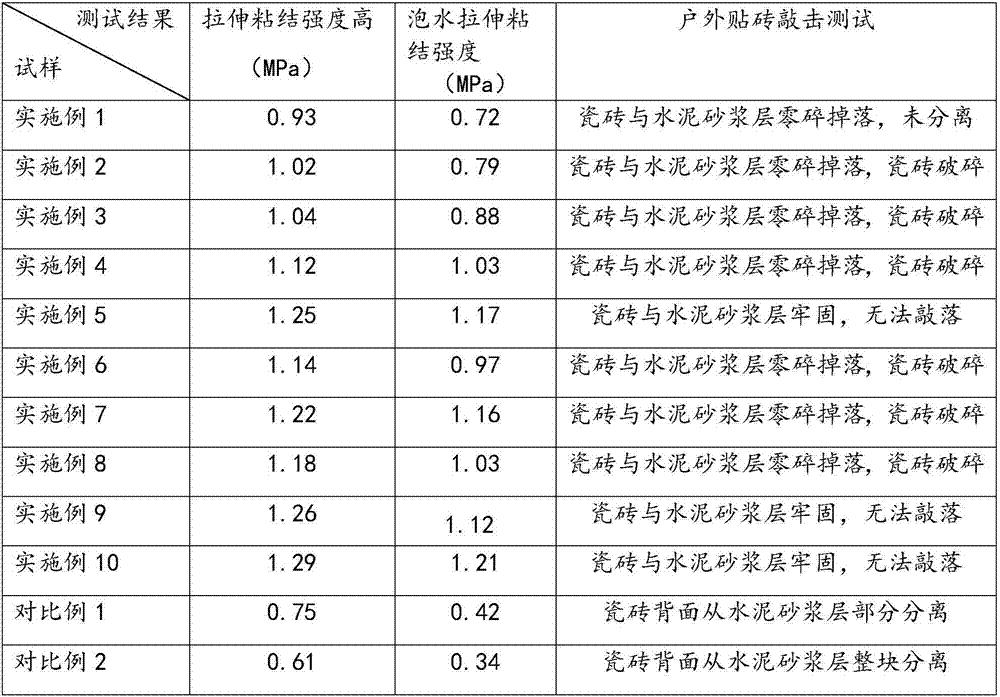

Examples

preparation example Construction

[0056] On the other hand, the embodiment of the present invention also provides a method for preparing a silicone-modified styrene-acrylic emulsion for tile back adhesive, which may include the following steps:

[0057] Emulsion preparation: add deionized water to the emulsification tank, put the first part of the emulsifier into the emulsification tank and stir and disperse for 10-30 minutes, then slowly add unsaturated carboxylic acid and functional cross-linking monomer, and continue stirring for 10-30 minutes, Then add styrene, alkyl acrylate, silicone modified monomer, stir for 10 to 60 minutes to obtain emulsion, set aside;

[0058] Preparation of reaction tank bottom material: add deionized water to the reaction tank, raise the temperature to 60-70°C in the reaction tank, add the second part of emulsifier to obtain the reaction tank bottom material;

[0059] The water-soluble peroxide initiator is divided into two parts, which are recorded as initiator A and initiator B...

Embodiment 1

[0084] Silicone-modified styrene-acrylic emulsion for ceramic tile back glue, consisting of the following raw materials in parts by weight: 15 parts of styrene; 10 parts of ethyl acrylate; 25 parts of n-butyl acrylate; 0.6 parts of acrylic acid; 0.8 parts of acrylamide; 0.8 part of oxysilane; 1.5 parts of emulsifier, wherein the weight ratio of anionic emulsifier and nonionic emulsifier is 1:2, anionic emulsifier is allyl fatty alcohol polyoxyethylene ether ammonium sulfate, nonionic emulsifier Isomerized alcohol polyoxyethylene; 0.3 parts of potassium persulfate; 0.2 parts of tert-butyl hydroperoxide-sodium bisulfite; 56.5 parts of deionized water.

[0085] The preparation method is as follows:

[0086] 1. Emulsion preparation: Add 25% of the total weight of deionized water into the emulsification tank, put 65% of the total weight of the emulsifier into the water in the emulsification tank, stir and disperse at high speed for 30 minutes, slowly add acrylic acid and acrylamide...

Embodiment 2

[0095] Silicone-modified styrene-acrylic emulsion for tile back adhesive, which is composed of the following raw materials in parts by weight: 15 parts of styrene; 25 parts of n-butyl acrylate; 10 parts of isooctyl acrylate; 0.6 parts of acrylic acid; 0.8 parts of acrylamide; 1.2 parts of trimethoxysilane; 1.5 parts of emulsifier, wherein the weight ratio of anionic emulsifier and nonionic emulsifier is 1:2, and the anionic emulsifier is 3-allyloxy-2 hydroxy-1-propanesulfonic acid Sodium salt, non-ionic emulsifier is fatty alcohol polyoxyethylene ether; 0.3 parts of sodium persulfate; 0.2 parts of tert-butyl hydroperoxide-sodium bisulfite; 56.5 parts of deionized water; 0.1-5 parts of 1-propanol.

[0096] The preparation method is as follows:

[0097] 1. Emulsion preparation: Add 25% of the total weight of deionized water to the emulsification tank, put 65% of the total weight of the emulsifier into the water in the emulsification tank, stir and disperse at high speed for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com