Reinforcing agent for bonding bricks

A bonding enhancer and enhancer technology, applied in the field of construction mortar materials, can solve the problems of short service life of adhesives, poor aging resistance, waste of manpower and material resources, etc., achieve good brushing performance, and reduce large-area hollowing Or fall, guarantee the effect of construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of powder components, taking the preparation of 1000kg powder components as an example:

[0032] Mix 350kg of 42.5 ordinary Portland cement, 615kg of 30-60 mesh quartz sand, 30kg of redispersible latex powder VAE type and 5kg of hydroxypropyl methyl cellulose ether with a viscosity of 40000 / mPa·s and stir evenly.

[0033] Preparation of liquid components, taking the preparation of 500kg liquid components as an example:

[0034] Pour 200kg of acrylic emulsion into the container, then add 300kg of water and stir evenly.

[0035] The liquid component and the powder component are prepared according to the ratio of liquid: powder of 1:2, and stirred evenly to obtain the brick adhesion enhancer.

Embodiment 2

[0037] Preparation of powder components, taking the preparation of 100kg powder components as an example:

[0038] Mix 35 kg of 42.5 ordinary Portland cement, 62.5 kg of 30-60 mesh quartz sand, 2 kg of redispersible latex powder VAE, and 0.5 kg of hydroxypropyl methylcellulose ether and mix them evenly.

[0039] Preparation of liquid components, taking the preparation of 50kg liquid components as an example:

[0040] Add 25 kg of acrylic emulsion to 25 kg of water and stir evenly.

[0041] The liquid component and the powder component are prepared according to the ratio of liquid: powder of 1:2, and stirred evenly to obtain the brick adhesion enhancer.

Embodiment 3

[0043] Preparation of powder components, taking the preparation of 500kg powder components as an example:

[0044] Mix 175 kg of 42.5 ordinary Portland cement, 318.5 kg of 30-60 mesh quartz sand, 5 kg of redispersible latex powder VAE, and 1.5 kg of hydroxypropyl methyl cellulose ether and mix well.

[0045] Preparation of liquid components, taking the preparation of 250kg liquid components as an example:

[0046] Add 150 kg of acrylic emulsion to 100 kg of water and stir evenly.

[0047] The liquid component and the powder component are prepared according to the ratio of liquid: powder of 1:2, and stirred evenly to obtain the brick adhesion enhancer.

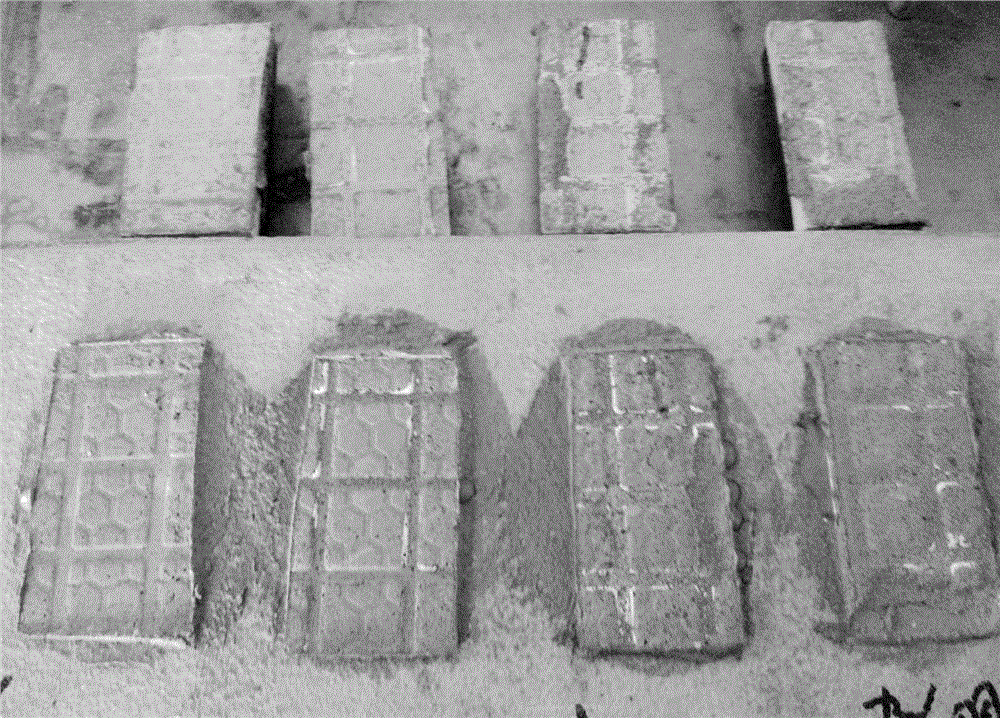

[0048] The present invention prepared in the above examples is brushed on the back of the same vitrified brick, and after drying, it is pasted on the base concrete slab with a cement-based adhesive, and its tensile bond strength is tested after 7 days of maintenance in a standard laboratory. size and damage (Table 1).

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com