High-elongation two-component silicone structural adhesive and preparation method thereof

A high elongation, two-component technology, used in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of bonding and sealing, and the inability to use super high-rise glass building curtain wall structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

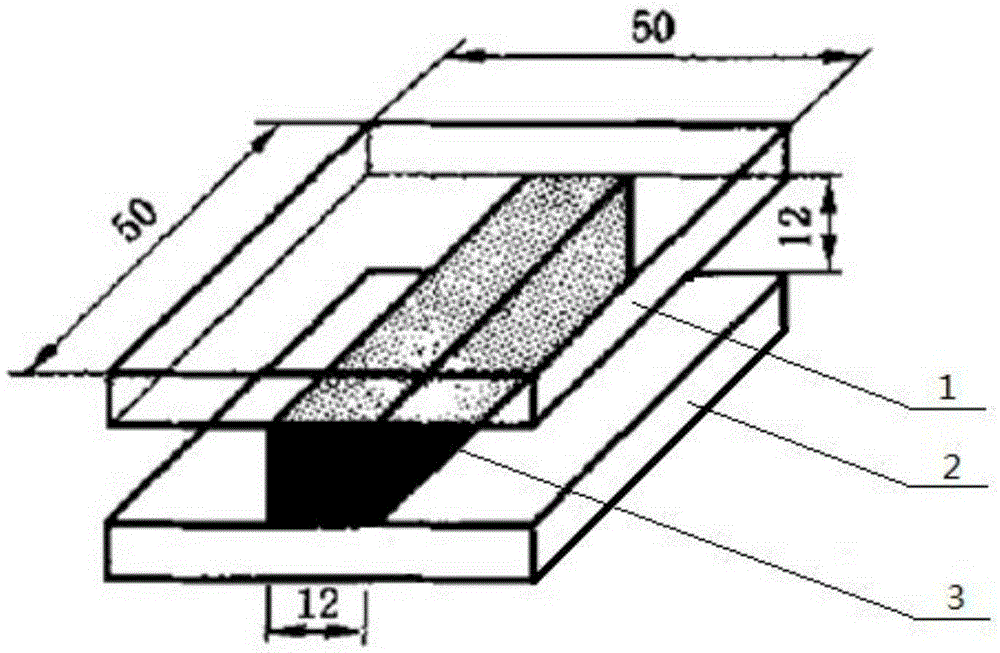

Image

Examples

preparation example Construction

[0041] The embodiment of the present invention also provides a method for preparing the above-mentioned high-elongation two-component silicone structural adhesive, which includes the following steps:

[0042] Prepare component A and component B, the sequence of preparing component A and component B is not limited, component A can be prepared first, component B can be prepared first, component A and component B can also be prepared at the same time;

[0043] The preparation process of component A is as follows:

[0044] In terms of parts by mass, input the ratio of 40-100 parts of base polymer, 40-80 parts of nano-calcium carbonate, 0.5-2 parts of ultraviolet absorber, and 5-10 parts of polydimethylsiloxane into twin-screw extrusion Machine control system, electronic metering of feeding amount, feeding, production through twin-screw extruder, control vacuum degree in the production process to -0.07 ~ -0.09MPa, material temperature 80 ° C ~ 100 ° C, to obtain A component;

[00...

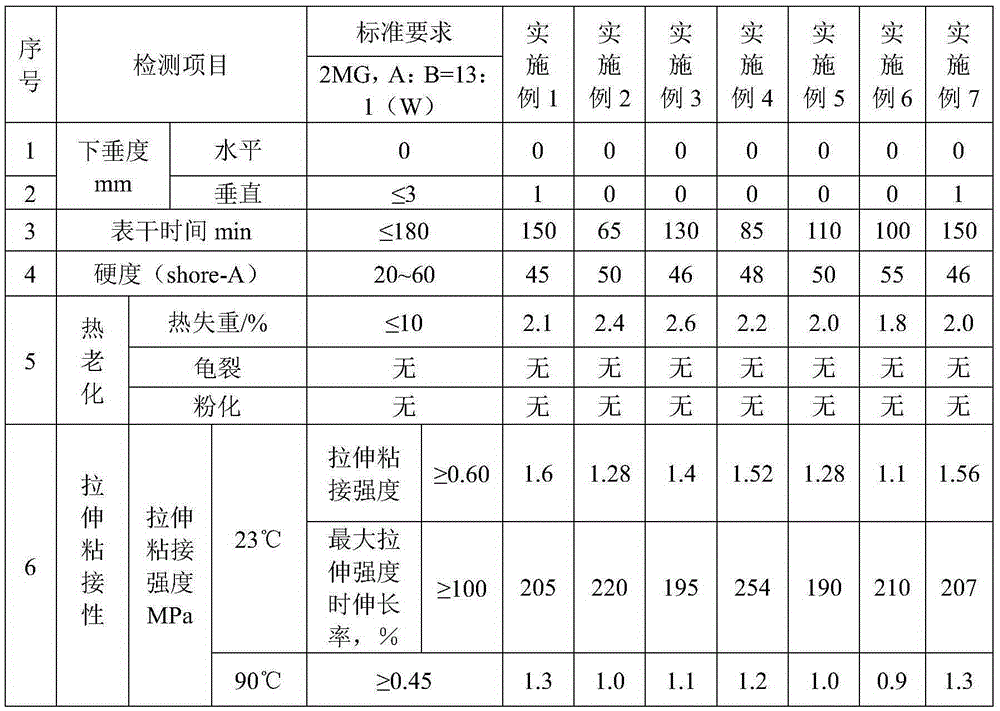

Embodiment 1

[0065] The high-elongation two-component silicone structural adhesive provided in this example includes components A and B, in parts by mass, and component A includes 90 parts of α, ω-dihydroxy polydimethylsiloxane alkane, 50 parts of nano-calcium carbonate, 1 part of benzotriazole UV stabilizer, 5 parts of polydimethylsiloxane; component B includes 50 parts of color paste, 10 parts of methyldimethoxysilyl poly Propylene oxide ether, 0.5 parts of p-toluenesulfonyl isocyanate, 40 parts of methyltriethoxysilane, 30 parts of γ-aminopropyltriethoxysilane, 10 parts of mercaptopropyltrimethoxysilane, 0.2 parts of dibutyl Tin dilaurate, wherein the color paste includes: 100 parts of polydimethylsiloxane, 50 parts of high-structure carbon black, 5 parts of fumed silica; components A and B are mixed in a mass ratio of 9:1.

[0066] The preparation method of the above-mentioned high-elongation two-component silicone structural adhesive comprises the following steps:

[0067] Preparatio...

Embodiment 2

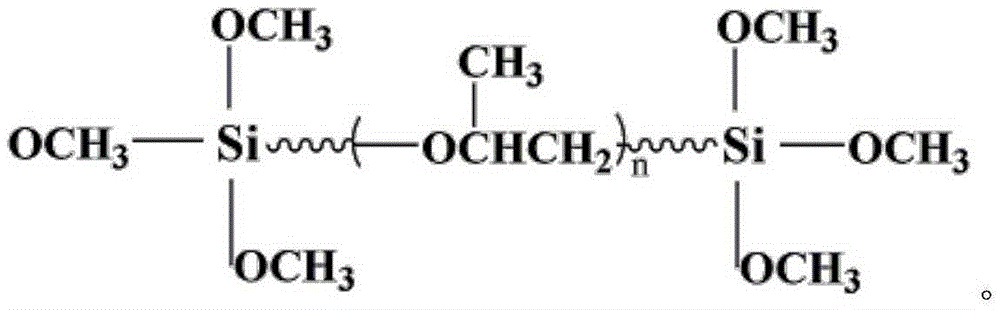

[0071] The high-elongation two-component silicone structural adhesive provided in this example includes components A and B, in parts by mass, and component A includes 100 parts of α, ω-dihydroxy polydimethylsiloxane alkane, 80 parts of nano-calcium carbonate, 2 parts of benzotriazole UV stabilizer, 10 parts of polydimethylsiloxane; component B includes 100 parts of color paste, 23 parts of trimethoxysilyl polyoxypropylene ether , 0.7 parts of vinyltrimethoxysilane, 80 parts of methyltrimethoxysilane, 30 parts of γ-aminopropyltriethoxysilane, 20 parts of γ-(2,3-epoxypropoxy)propyl trimethyl Oxysilane, 3 parts of dioctyltin dilaurate, the color paste includes: 100 parts of polydimethylsiloxane, 50 parts of high structure carbon black, 5 parts of fumed silica; A component, B component Mix according to the mass ratio of 13:1.

[0072] The preparation method of the above-mentioned high-elongation two-component silicone structural adhesive comprises the following steps:

[0073] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com