Patents

Literature

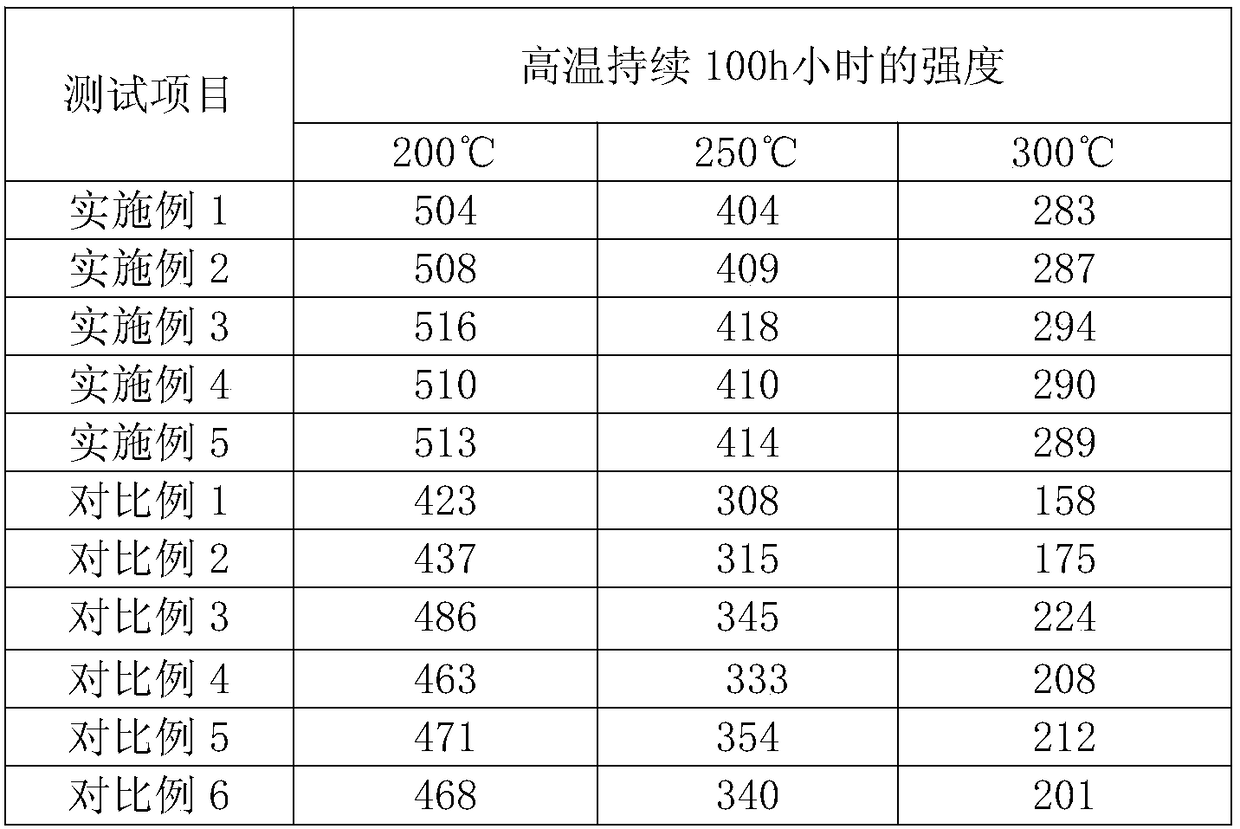

34results about How to "Facilitates atomic diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diffusion and connection method for ceramic and steel by adding active intermediate alloy

InactiveCN1721121AReduce microscopic gapIncrease contact areaNon-electric welding apparatusAlloyUltimate tensile strength

This invention discloses diffusion link method for ceramics and steel by adding active intermediate alloy with main character as follows: add active intermediate alloy between the contact surfaces of ceramics and steel needed welding, use upper and lower pressure heads to press the needed welding ceramics / steel workpiece; put into vacuum chamber to take expansion link with technical parameters of heat temperature 1060~1180Deg, heat preservation time 25~60min, pressure 8~16MPa, and vacuum degree 2.5í‡10-4í½1í‡10-5Pa. It solves efficiently the expansion link and obtains jointing with shear strength as high as 140MPa fit to use require for complex structure. The invention has advantages of low cost, simple and convenient technique, high applicability and easy to spread.

Owner:SHANDONG UNIV

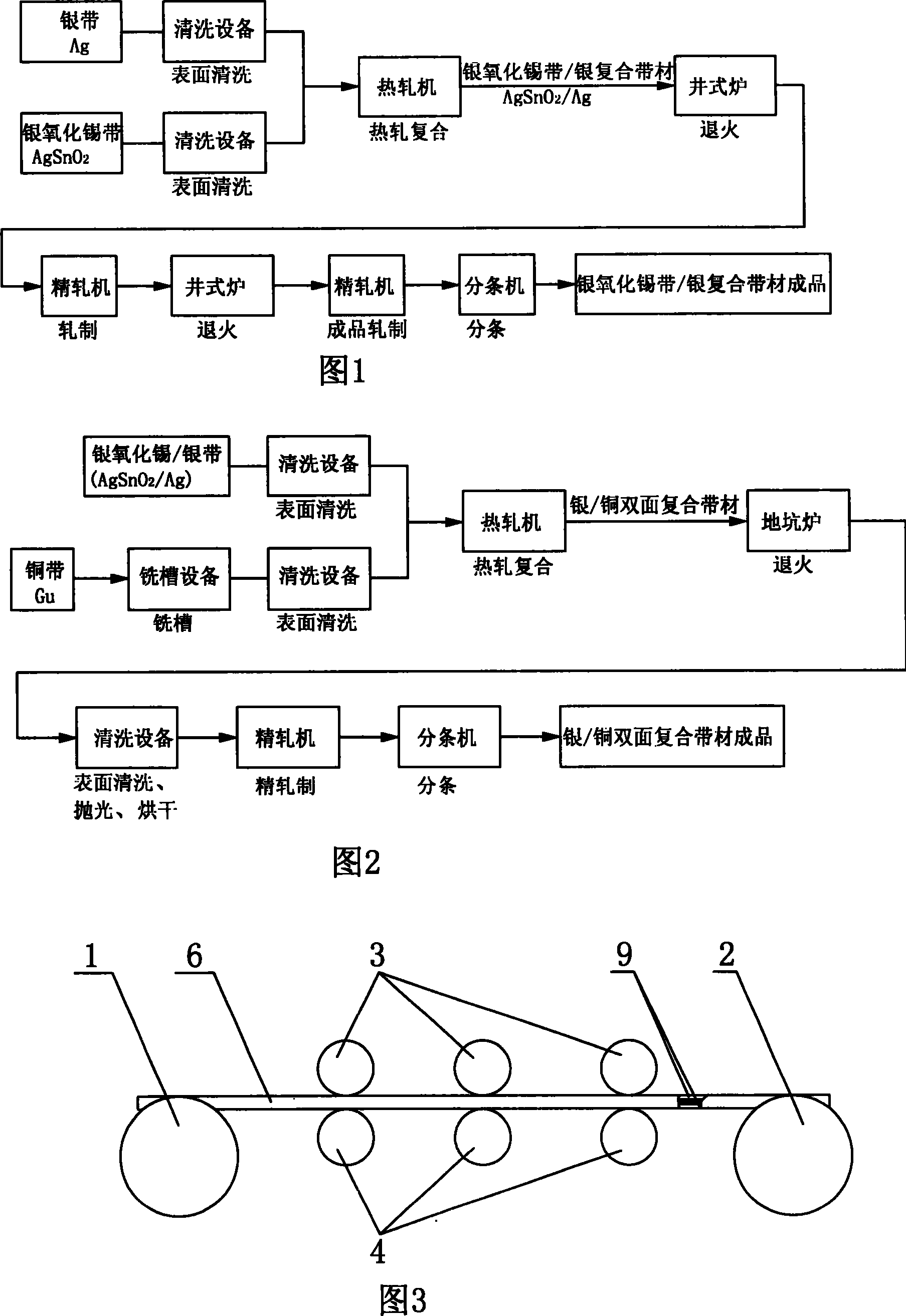

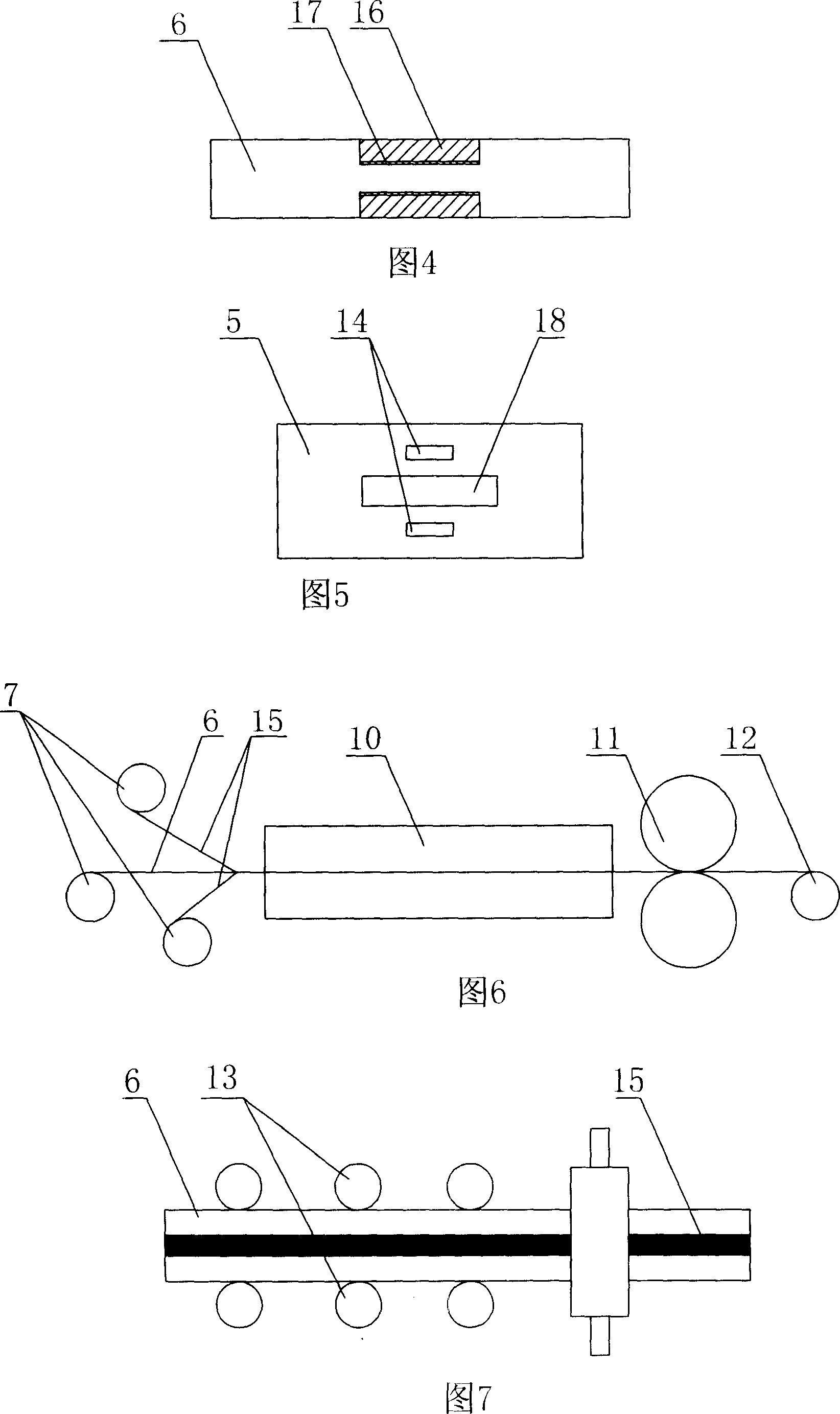

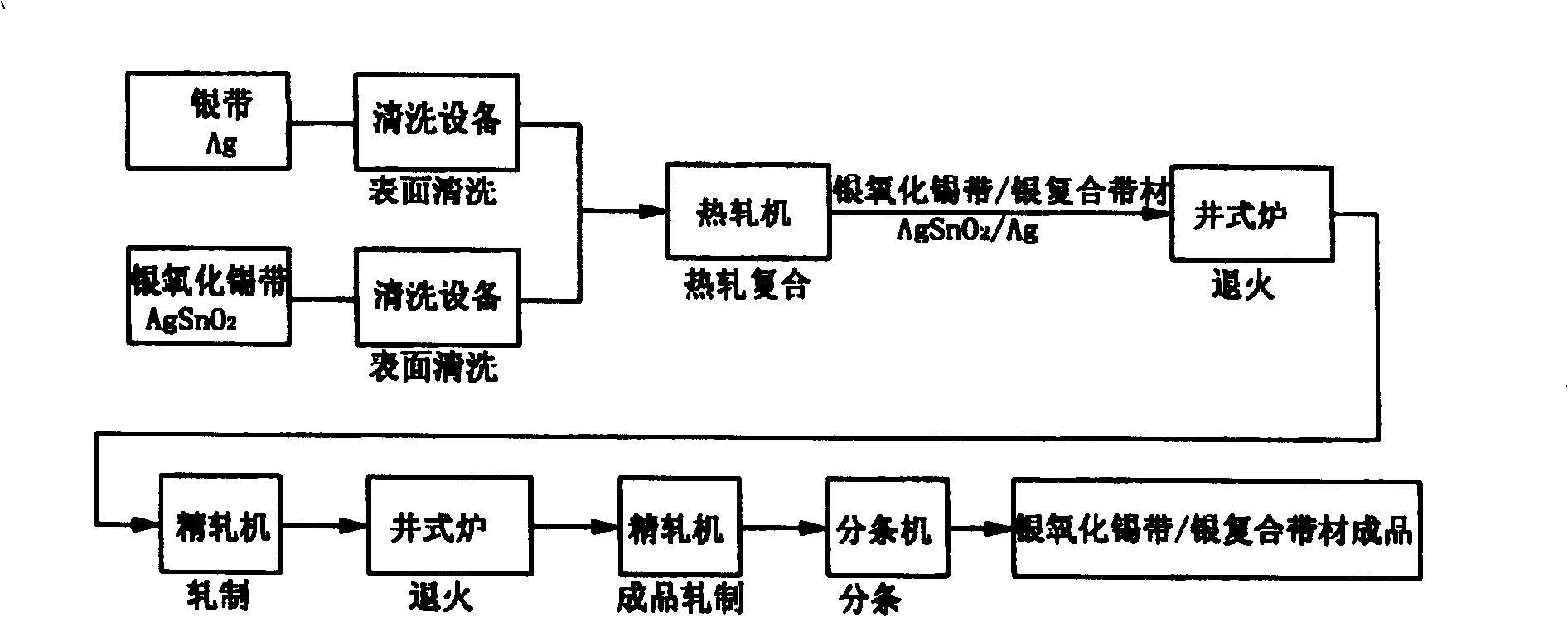

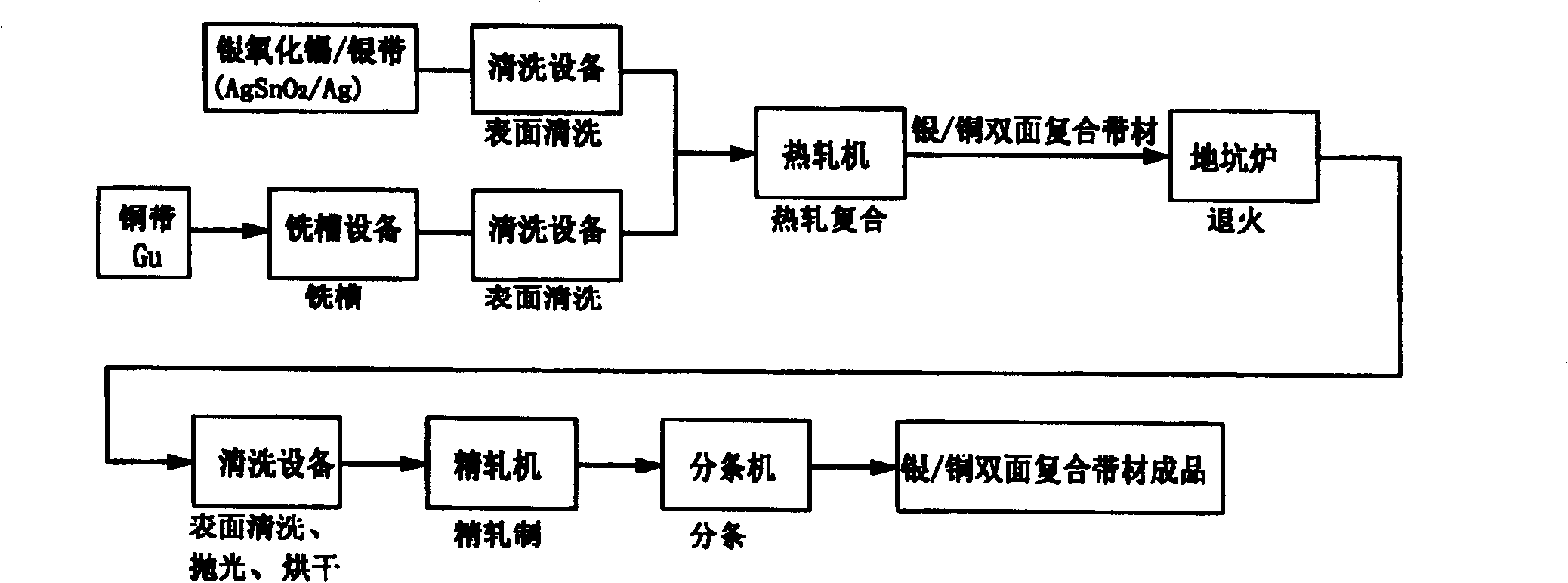

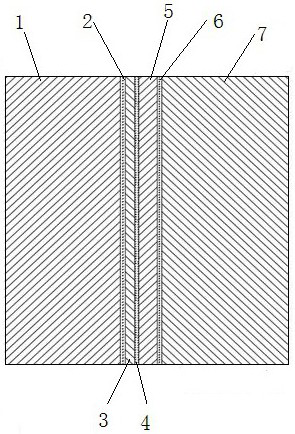

Machining technique of silver/copper double composite strip material

This invention relates to electricity materials technique field and to one silve to copper double compound band process method, which comprises the following steps: firstly grinding the silver metal oxidation with one thin siver band to form silver metal oxidation or silver compound materials; grinding silver metal oxidation and silver compound band through its top silver band layer and copper band heat grinding through heat compound band for annealing.

Owner:东莞市中一合金科技有限公司

Brazing clad material used for metal surface

ActiveCN104907725AWon't fall offReduce stressWelding/cutting media/materialsSoldering mediaEpoxyAtomic diffusion

The invention discloses a brazing clad material used for a metal surface, wherein the clad material is powder particles that is constituted of the follow components with weight percent; Ni tungsten carbide powder ( WC-10 Ni) is within 48 percent to 62 percent; Ni powder is within 7 percent to 11 percent; NiCrBSi alloyed powder (AWS BNi-2) is within 27 percent to 45 percent; binder occupies the rest percentage; the size of the Ni tungsten carbide powder particle is within 5 to 15 micro-meter; the size of the Ni powder particle is within 30 to 45 micro-meter; the NiCrBSi alloyed powder particle is within 25 to 35 micro-meter; and the degree of the metal bonding phase between Ni tungsten carbide powder particles is less or equal to 0.3 micro-meter. According to the invention, under the effect of the organic silicon resin binding material and the epoxy resin binding material, the component of the brazing material is uniform and has specific binding property; and the brazing clad material won't be fell off, thus facilitating to the atomic diffusion and the interface reaction during the high temperature connection process and improving the wetting ability of the clad material and the performance of the metal surface.

Owner:无锡腾达海川新材料有限公司

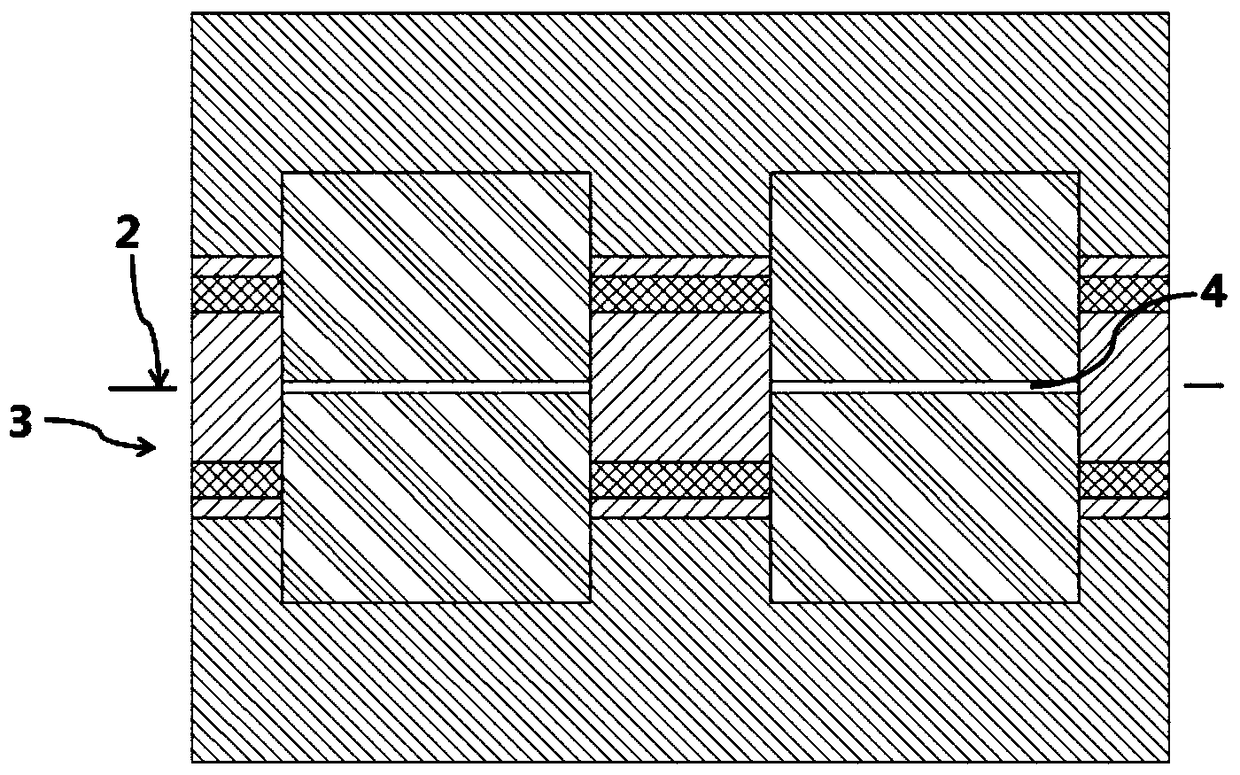

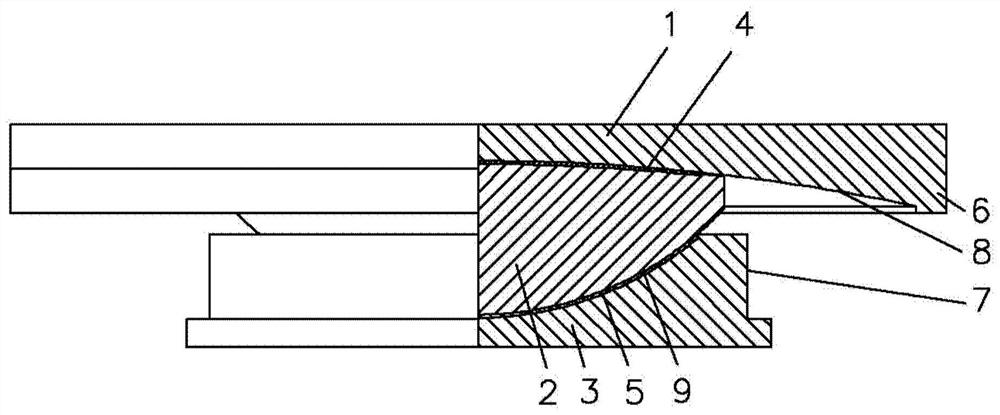

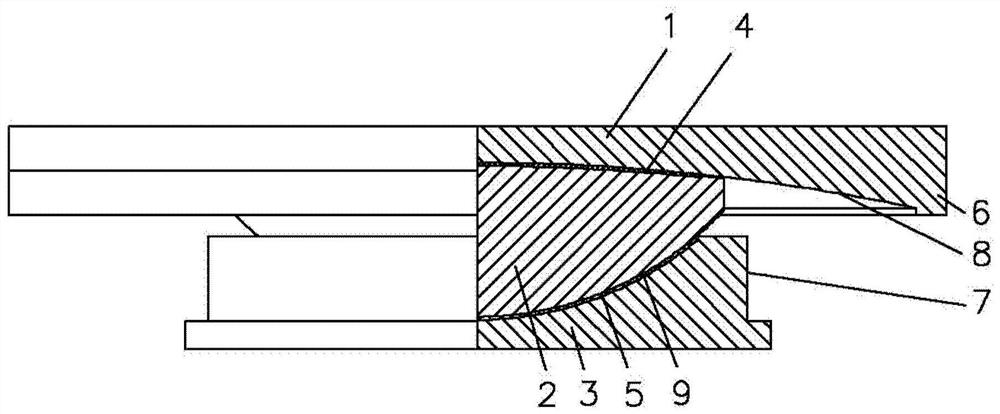

Diffusion bonding method of silicon carbide ceramics and ferritic stainless steel

InactiveCN103273155ADiffuse join implementationFacilitates atomic diffusionSoldering apparatusAlloyVacuum chamber

The invention relates to a diffusion bonding method of silicon carbide ceramics and ferritic stainless steel. Al-Si intermediate alloy is added between the contact faces, to be connected, of the silicon carbide ceramics and stainless steel, and the silicon carbide ceramics and a ferritic stainless steel plate workpiece to be connected are tightly pressed through an upper pressing head and a lower pressing head of diffusion bonding equipment, are arranged in a vacuum chamber and are connected in a diffusion bonding mode. According to technological parameters, heating temperature is 500 DEG C to 540 DEG C, heat preservation time is 25min to 50min, pressure is 40MPa to 90MPa, and a vacuum degree is 1.33 *10-3Pa to 1.33*10-2Pa. Then cooling, cleaning and drying are carried out to achieve diffusion bonding. The Al-Si alloy foil is added, a transition liquid phase is formed on a contact surface in a diffusion bonding process, and the diffusion bonding of the silicon carbide ceramics and the stainless steel is achieved. The melting temperature of the Al-Si alloy foil is greatly lower than the softening temperature of the ferritic stainless steel, and the method is beneficial for accelerating a silicon carbide ceramics / stainless steel interface to form good diffusion bonding.

Owner:SHANDONG UNIV

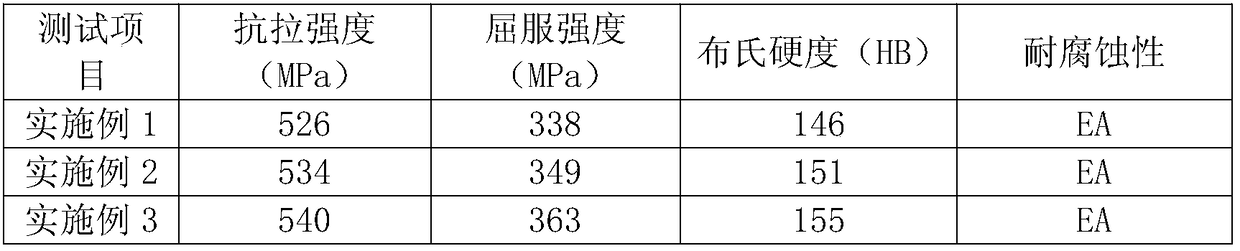

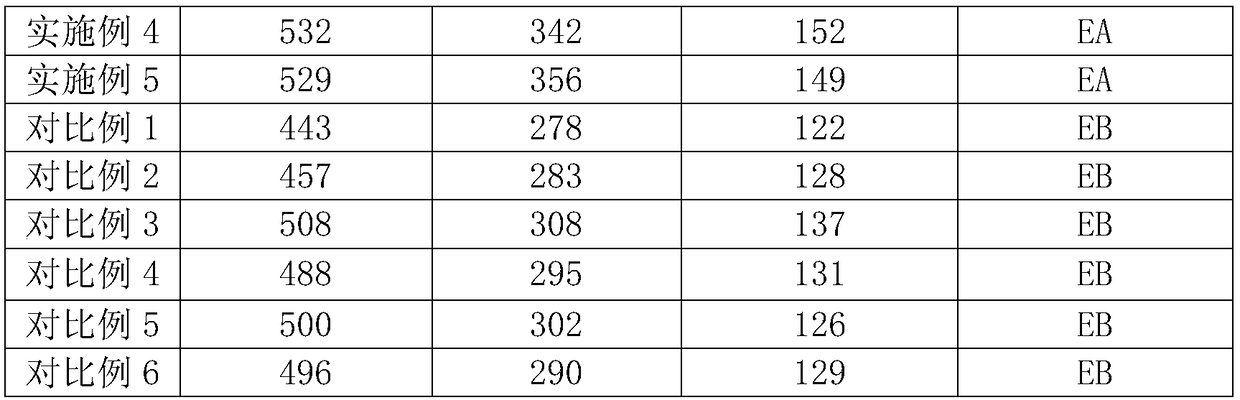

Machining method of a window and door aluminium alloy

The invention discloses a machining method of a window and door aluminium alloy. The window and door aluminium alloy comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn,0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare earth element RE and the balance of Al. The window and door aluminium alloy is prepared by using the steps of melting, slagging-off, heat preservation and standing, online refining, alloying, refining, on-line degassing, casting, homogenizing annealing, extrusion forming, heat treatment, shading, sealing treatment and the like. According to the machining method of the window and door aluminium alloy, by optimizing alloy components, a mixing ratio and a machining process, a problem that the strength and the casting performance of the aluminium alloy contradict each other can be effectively solved; and problems of large hot cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminium alloy are solved.

Owner:阜阳力佳门业有限公司

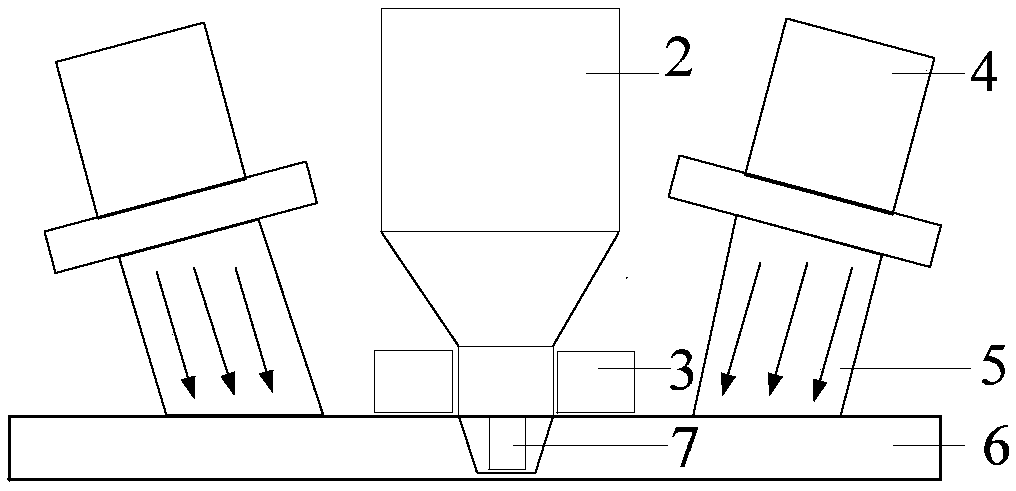

Method for preparing titanium alloy/hydroxylapatite gradient composite coating

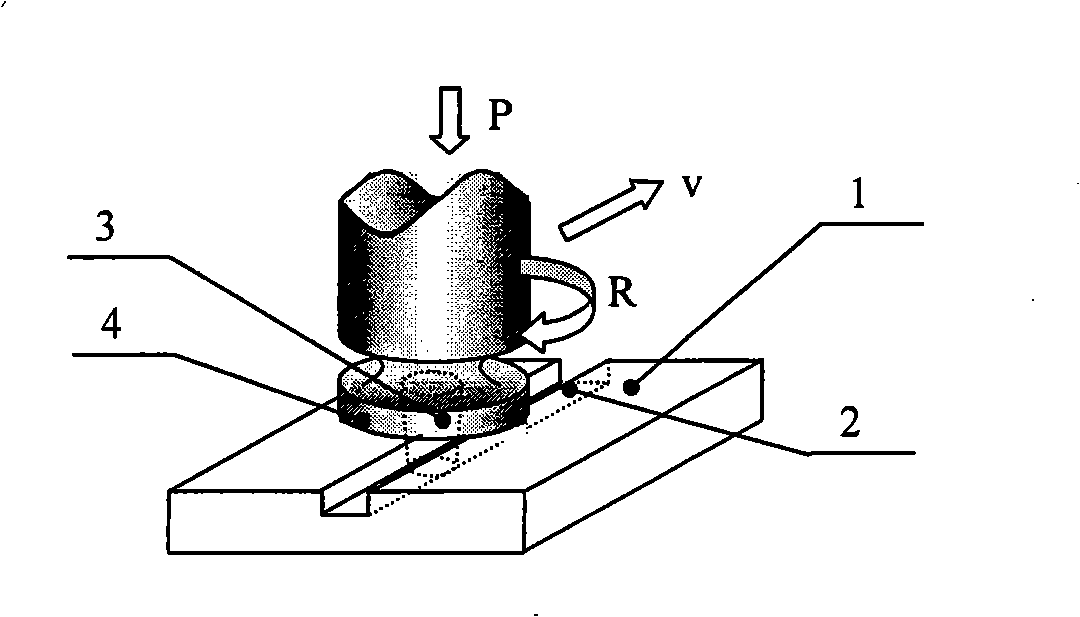

InactiveCN101327337AFacilitates atomic diffusionHigh tensile bond strengthCoatingsProsthesisMachine partsHydroxylapatite

The invention discloses a gradient compound coating of a titanium alloy / hydroxyapatite and a preparation method thereof. The surface of the titanium alloy to be made is polished, cleaned and baked; 2 to 10 perforated flutes of 2mm multiplied by 2mm to 4 mm multiplied by 4mm are processed on the surface of the titanium alloy every 12mm; all the flutes are parallel to each other and are filled with powder; the titanium alloy filled with powder is placed on a tool with a heating device and is fixed and clamped; the titanium alloy is stirred by friction under the conditions that the room temperature rises to 350 DEG C to 500 DEG C, the rotation speed of a stirrer head ranges from 450 r / min to 850 r / min; the horizontal speed ranges from 28 mm / min to 90 mm / min, with an angle of inclination of 2.5 DEG. The rear area of a stirring area is provided with a cooling device, with the machining parts protected by argon gas. By a stirring method, the HA powder is stirred on the surface of the titanium alloy, thus forming viscoplasticity, speeding up the atom proliferation between the titanium alloy and the HA powder, and generating a chemical bond. The tensile-bonding strength is raised from 24.8MPa in the prior art to ranging from 65 MPa to 103MPa.

Owner:NANTONG MING YU NEW MATERIAL TECH CO LTD +1

Metalized materials for Si3N4 ceramic surface and preparation method as well as brazing technique

ActiveCN105057919AEvenly heatedReduce stress concentrationNon-macromolecular adhesive additivesEster polymer adhesivesInterfacial reactionAdhesive

The invention discloses metalized materials for Si3N4 ceramic surface and a preparation method as well as brazing technique. Silver-based materials are of powder particles, which are prepared from the following components in percentage by weight: 20 to 25 percent of Cu, 3 to 5 percent of Ti, 2 to 3 percent of Ni, 0.1 to 0.3 percent of Ce, 0.2 to 0.3 percent of Sc, 0.5 to 0.6 percent of Re, and the balance of Ag; a particle size of the Ag, the Cu, the Ti and the Ni is 40 mu. m to 55 mu. m, the particle size of the Ce, Sc and Re is 15 mu. m to 25 mu. m. The silver-based materials provided by the invention are of flexible fibrous metal cloth materials, which are prepared by the pressure roller under the effect of a special adhesive; the composition of Ag-base alloy materials are uniform and the Ag-base alloy materials have a certain adhesive property; the Ag-base alloy materials are conductive to the local binding of ceramic parts in various complex parts, can ensure that the metalized materials for the Si3N4 ceramic surface do not fall off and the distribution of the surface metal is uniform under the condition of brazing, are conductive to the atomic diffusion and the interfacial reaction in a brazed connection process, can improve the wettability of the metalized materials for a surface, and are conductive to a good connection between the ceramic and a metal.

Owner:JIANGSU UNIV OF SCI & TECH

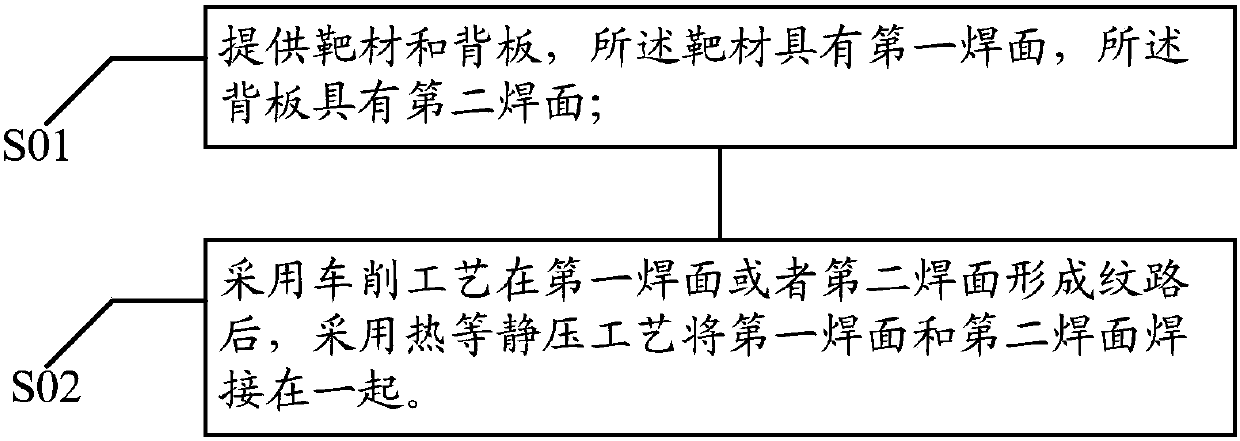

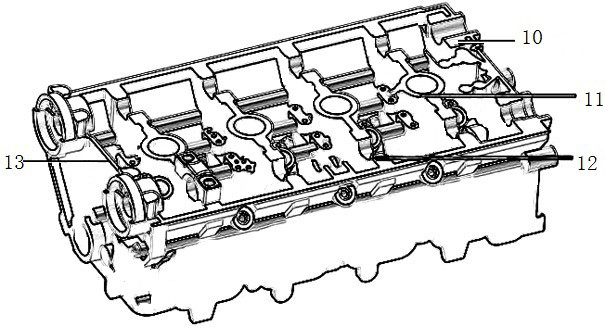

Welding method of target assembly

InactiveCN107552939AImprove welding strengthIncrease roughnessNon-electric welding apparatusEngineeringWeld strength

Disclosed is a welding method of a target assembly. The method comprises the steps of providing a target material and a back plate, wherein the target material is provided with a first welding face, and the back plate is provided with a second welding face; adopting a turning process to form lines on the first welding face or the second welding face, and adopting the hot isostatic pressure processto enable the first welding face and the second welding face to be welded together. According to the welding method of the target assembly, the lines are formed on the first welding face so as to increase roughness of the first welding face, or the lines are formed on the second welding face to increase roughness of the second welding face; in the hot isostatic pressure process, the lines on thefirst welding face can be embedded on the back plate or the lines on the second welding face can be embedded in a target material; atom diffusion between the target material and the back late is facilitated in the hot isostatic pressure process, and welding strength of the target assembly is improved.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

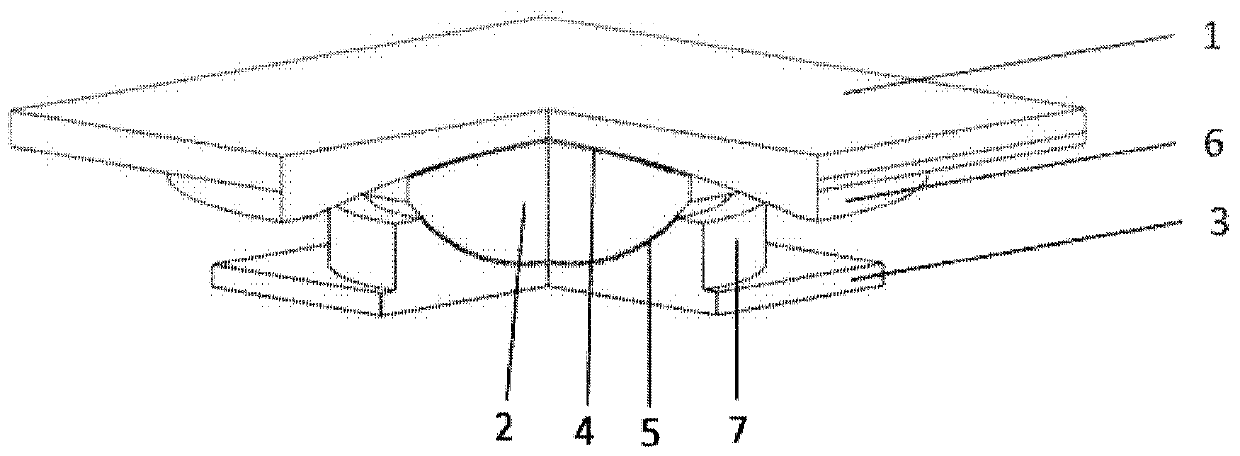

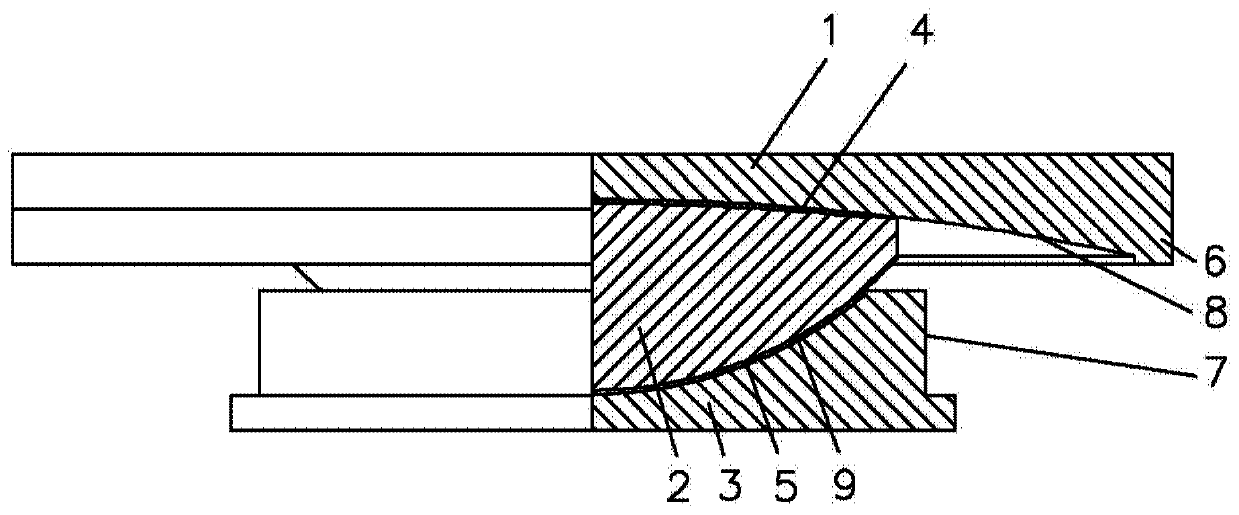

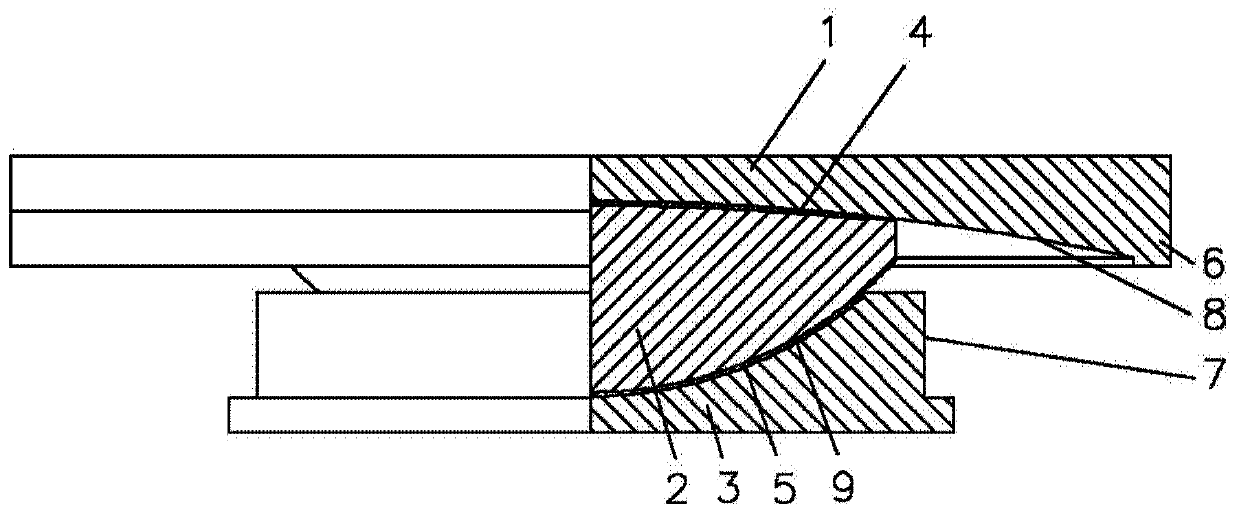

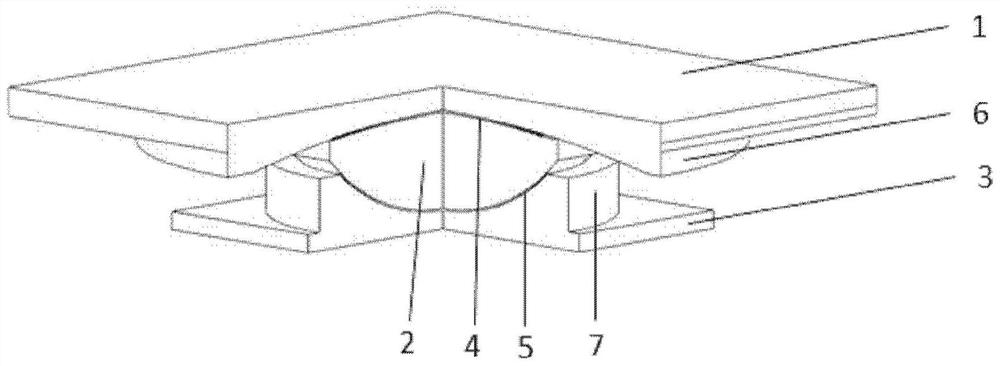

Ellipsoidal anisotropy friction simple pendulum support

InactiveCN111021238AHigh design strengthIncreased durabilityBridge structural detailsProtective buildings/sheltersEngineeringMechanical engineering

The invention discloses an ellipsoidal anisotropy friction simple pendulum support which comprises an upper base plate the top surface of which is a plane and the bottom surface of the which is an ellipsoidal concave surface; a lower base plate the bottom surface of which is a plane and the top surface of which is a concave spherical curved surface; a hinge sliding block arranged between the upperbase plate and the lower base plate, wherein the top surface of the hinge sliding block is an ellipsoidal convex surface matched with the ellipsoidal concave surface, and the bottom surface of the hinge sliding block is a convex spherical curved surface matched with the concave spherical curved surface. According to the ellipsoidal anisotropy friction simple pendulum support, the lower portion ofthe hinge sliding block and a groove in the upper portion of the lower base plate are spherical surfaces, and the hinge sliding block rotates in any horizontal direction through the spherical surfaces; a vertical rotating gap is formed between the hinged sliding block and a groove in the upper portion of the lower base plate, vertical rotation of the hinged sliding block is achieved when the upper base plate of the support swings horizontally, then anisotropic seismic mitigation and absorption design in the longitudinal and transverse bridge directions of a bridge is achieved, and the performance of the support is good under a rapid shearing friction test with the speed larger than or equal to 500 mm / s.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT +1

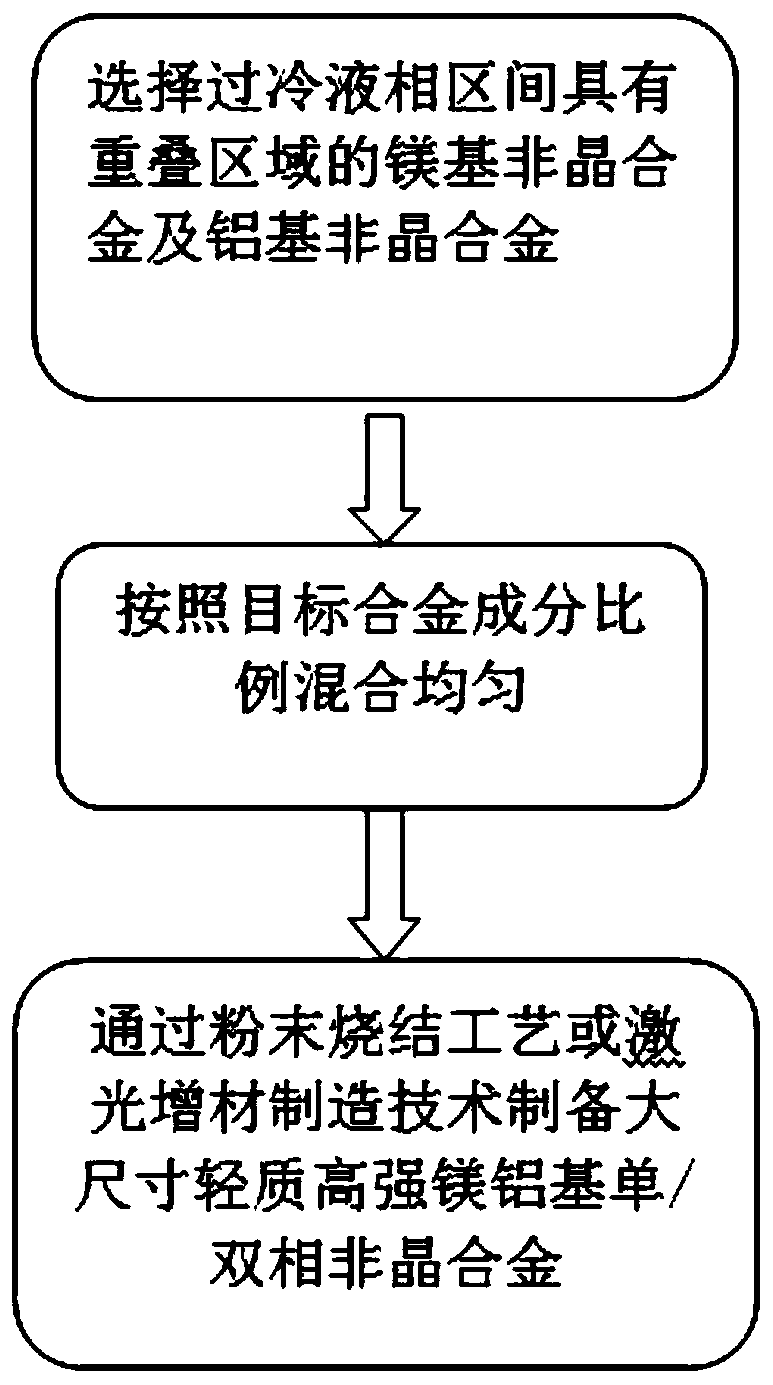

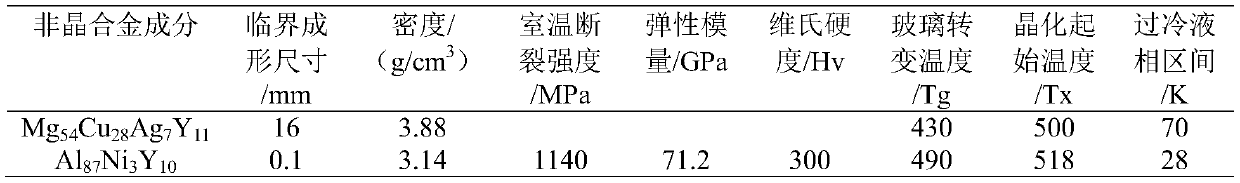

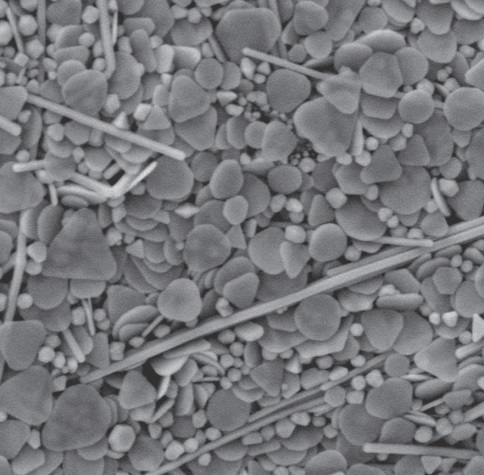

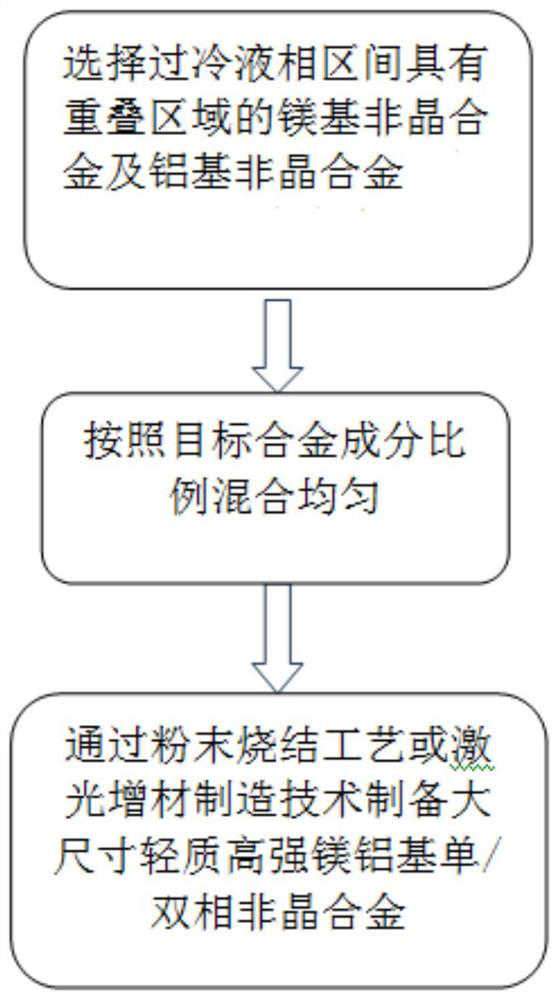

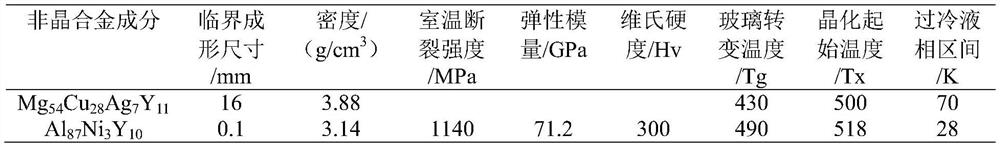

Preparation method for large-dimension light magnesium-aluminum based amorphous alloy

ActiveCN110724885AHigh strengthGood plasticity at room temperatureLaser additive manufacturingAlloy composition

The invention belongs to the field of amorphous alloys, and particularly relates to a preparation method for a large-dimension light magnesium-aluminum based amorphous alloy. The preparation method comprises the following steps: weighing powered magnesium based amorphous alloy and aluminum based amorphous alloy according to a target alloy component proportion, and uniformly mixing the magnesium based amorphous alloy with the aluminum based amorphous alloy to obtain magnesium-aluminum based amorphous alloy mixed powder; enabling a super-cooling liquid phase zone of the magnesium based amorphousalloy to be superposed with a super-cooling liquid phase zone of the aluminum based amorphous alloy; and preparing magnesium-aluminum based amorphous alloy through a powder sintering process or a laser additive manufacturing technology. The preparation method utilizes aluminum based amorphous alloy as a toughening phase to improve room-temperature plasticity of the magnesium based amorphous alloyor utilizes magnesium based amorphous alloy as a reinforcing phase to improve strength of the aluminum based amorphous alloy; and large-dimension light high-strength magnesium-aluminum based amorphous alloy is prepared by the powder sintering process or the laser additive manufacturing technology, so that the technical problem that the prepared composite material is not high in performance as relatively great difference exists between a crystal second phase and an amorphous matrix internal structure, deformation mode difference is relatively great, and interface metallurgical bonding is difficult is solved.

Owner:HUAZHONG UNIV OF SCI & TECH

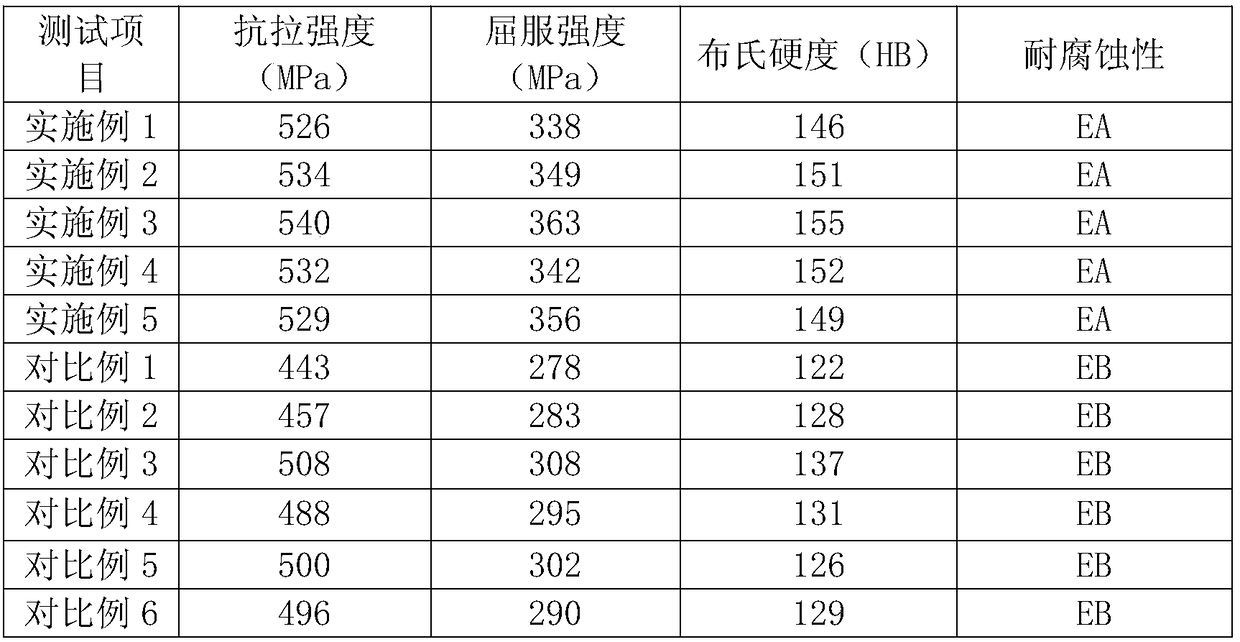

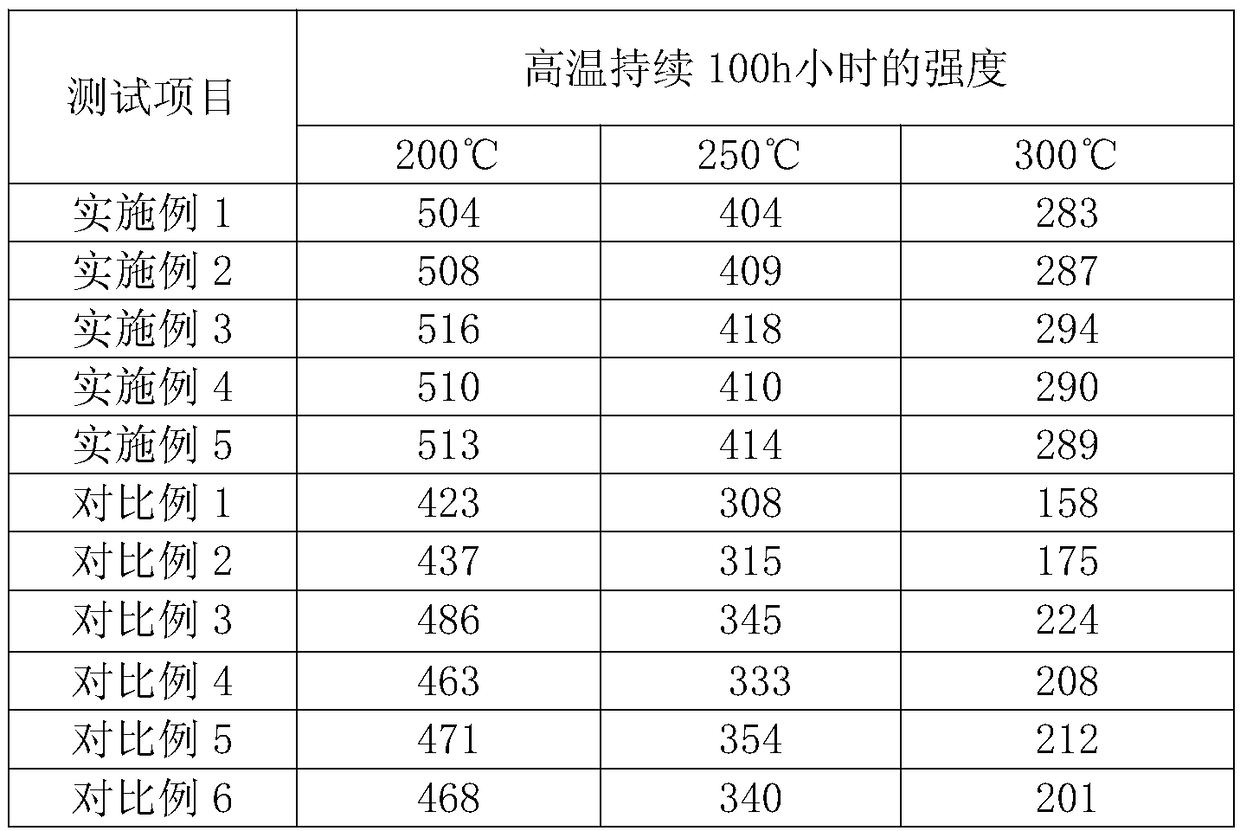

Aluminum alloy for high-strength corrosion-resistant doors and windows and preparation method thereof

InactiveCN109161746AImprove toughnessAccelerated corrosionSurface reaction electrolytic coatingRare-earth elementUltimate tensile strength

The invention discloses an aluminum alloy for high-strength corrosion-resistant doors and windows, which comprises 6.50-10.50% of Zn, 2.50-3.50% of Cu, 2.10-2.50% of Mg, 0.40-0.60% of Mn, 0.34-0.38% of Si, 0.19-0.25% of Cr, 0.11-0.15% of Ti, 0.02-0.05% of Mo, 0.22-0.26% of B, 0.05-0.09% of rare-earth element Re, and the balance of Al. The aluminum alloy is prepared by the steps of melting, slag-off, heat preservation, standing, on-line refining, proportioning, refining, on-line degassing, casting, uniform annealing, extrusion molding, heat treatment, coloring and pore sealing. By optimizing the composition, proportion and processing technology of the alloy, the contradiction between the strength and the casting performance of the aluminum alloy can be effectively solved, and the problems of large thermal cracking tendency, poor corrosion resistance and poor high temperature strength of the aluminum alloy are solved.

Owner:阜阳力佳门业有限公司

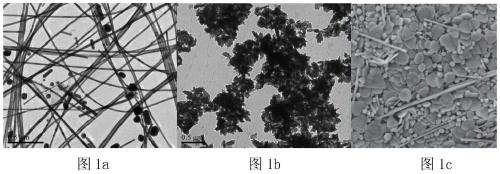

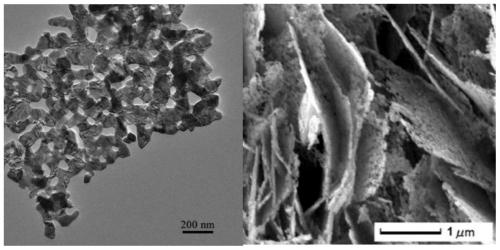

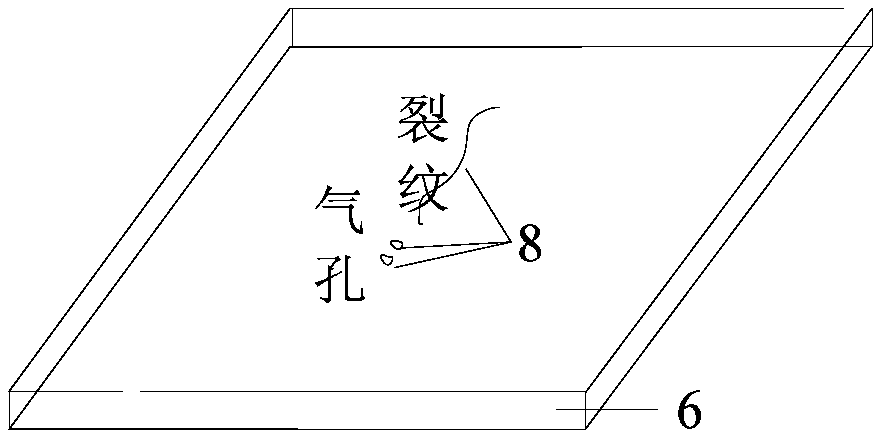

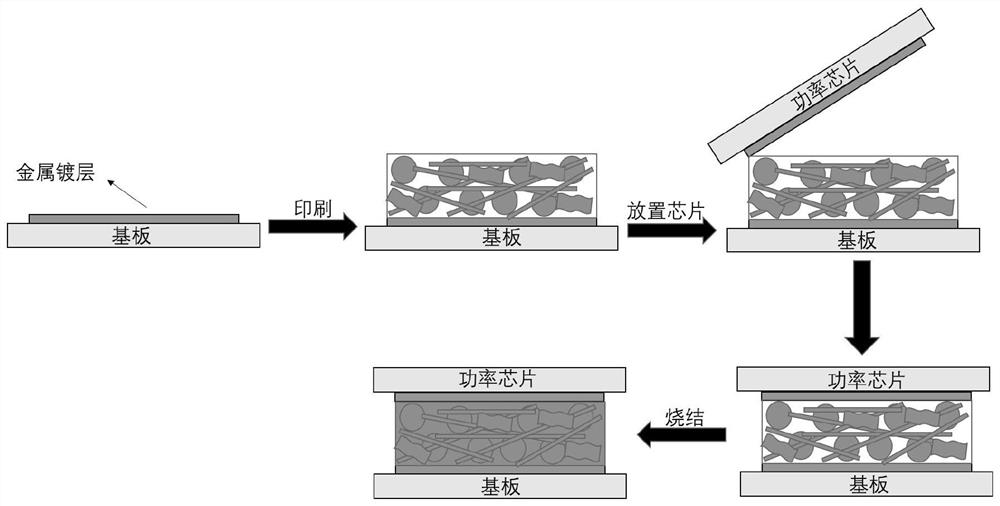

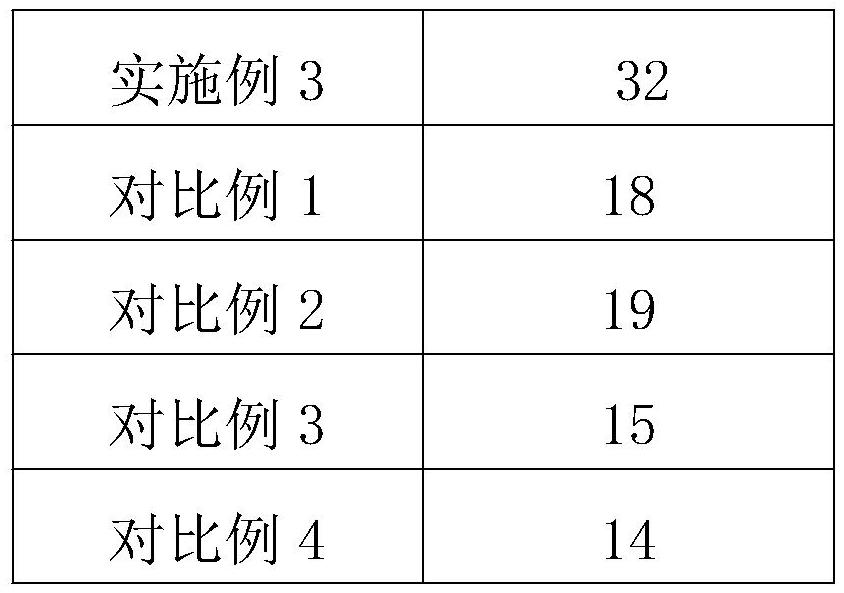

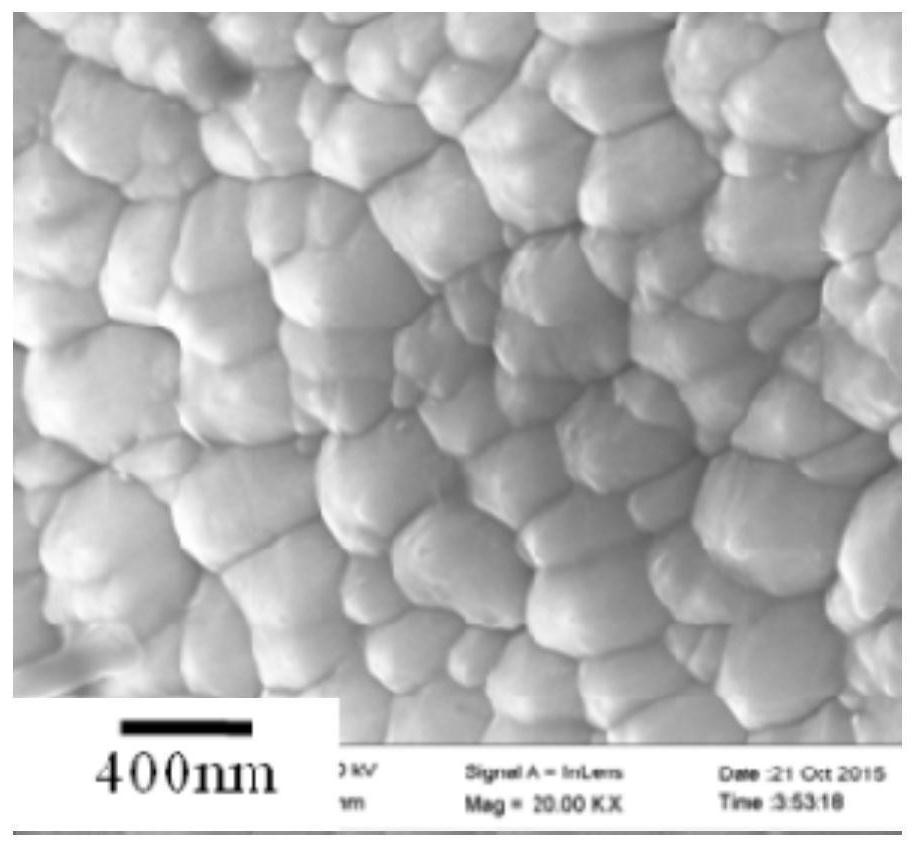

Packaging paste based on multi-dimensional nano material and preparation method of packaging paste

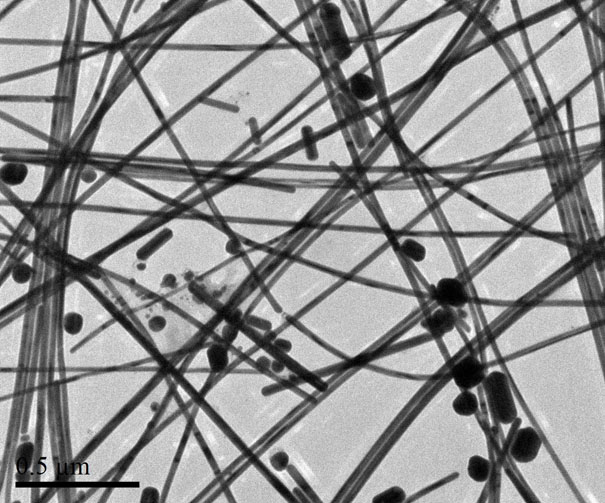

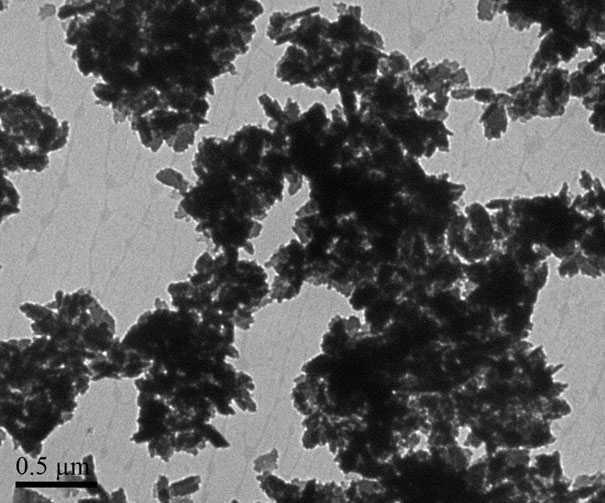

ActiveCN111354514ASimple processMild execution conditionsMaterial nanotechnologyWelding/cutting auxillary devicesMetal sheetNanomaterials

The invention provides packaging paste based on a nano material and a preparation method of the packaging paste. The nano material comprises at least two nano metals with different dimensions, and isprepared by the following steps: step 1, etching holes in the surface of a first nano metal wire and / or a first nano metal sheet to form a second nano metal wire and / or a second nano metal sheet, wherein the diameter of each hole is 10nm-40nm; 2, cleaning the first nano metal particles, the second nano metal wire and / or the second nano metal sheet by adopting a first solvent to obtain second nanometal particles, a third nano metal wire and / or a third nano metal sheet; 3, mixing the second nano metal particles, a third nano metal wire and / or a third nano metal sheet to obtain a first mixture,and mixing the first mixture with a second solvent to obtain a second mixture; and 4, concentrating the second mixture to obtain the packaging paste. The method is simple in process, mild in executioncondition and suitable for large-batch low-cost production.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Machining technique of silver/copper double composite strip material

Owner:东莞市中一合金科技有限公司

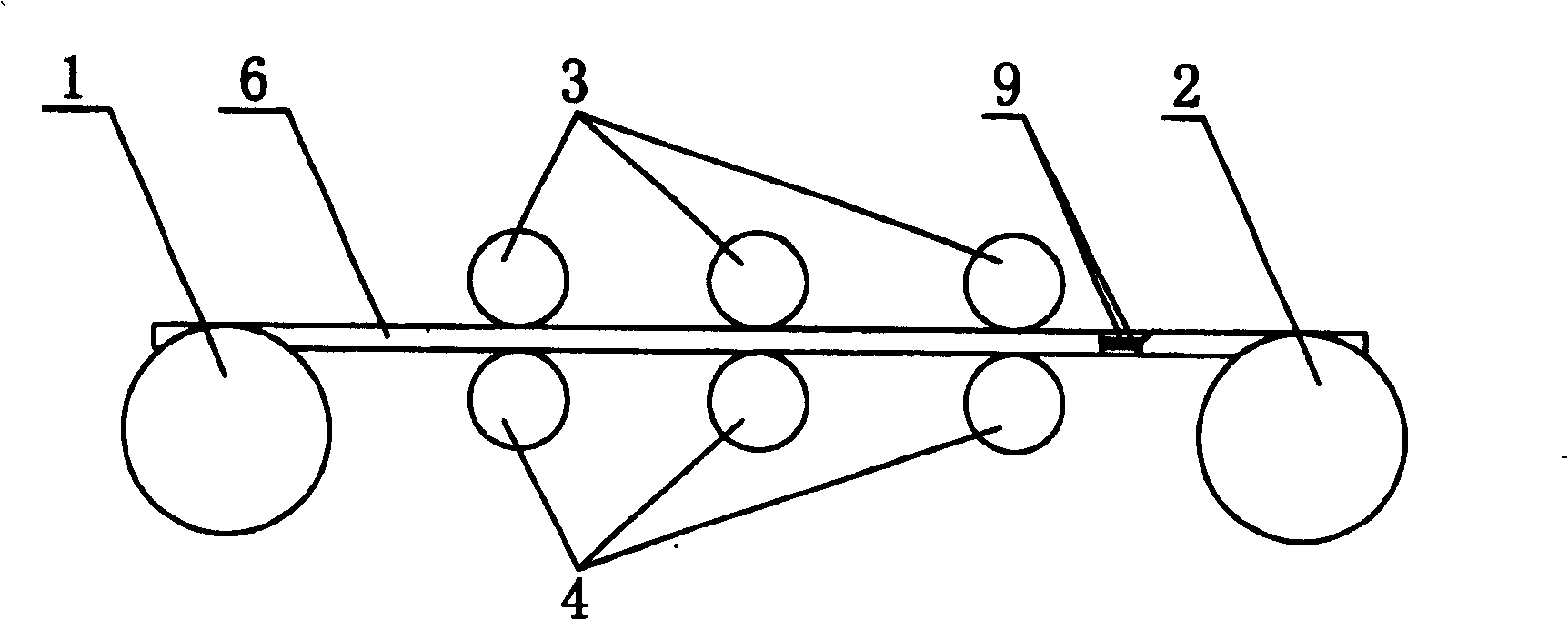

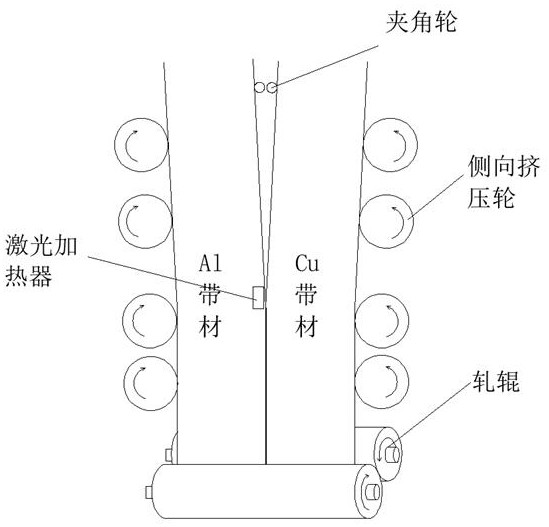

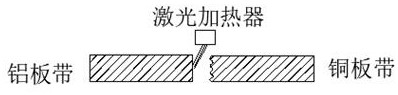

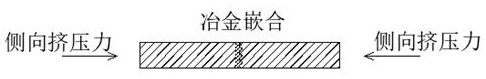

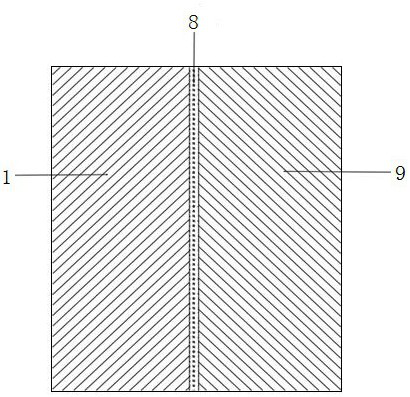

Preparation method of copper-aluminum composite plate strip with composite side edges

PendingCN114558886ASimple configurationLarge processing tolerance capacityWork heating devicesMetal rolling arrangementsThick plateNew energy

The invention relates to a preparation method of a side edge compounded copper-aluminum composite plate strip, and belongs to the technical field of new energy batteries, the preparation method comprises the following steps: forming a corrugated groove in the side edge of a copper plate strip, not forming a notch in an aluminum plate strip, cleaning and polishing the surfaces of the copper plate strip and the aluminum plate strip, performing laser heating on one side of the aluminum plate strip to a molten crystal state, and then performing heat treatment on the aluminum plate strip; laterally extruding with a copper plate strip with a corrugated groove to carry out metallurgical embedding; and after the temperature is regulated and controlled, multi-pass rolling is carried out, and then high-temperature heat treatment is carried out to obtain the copper-aluminum composite plate strip. The preparation method is simple in technological process, easy to implement and suitable for both thin and thick plate strips, the prepared copper-aluminum plate strip is good in interface bonding quality and excellent in performance, and the preparation method has remarkable application value.

Owner:长沙市泰润粉末材料有限公司

A kind of encapsulation paste based on multidimensional nanomaterial and preparation method thereof

ActiveCN111354514BSimple processMild execution conditionsMaterial nanotechnologyWelding/cutting auxillary devicesMetal sheetSurface etching

The present invention provides a packaging paste based on nano-materials and a preparation method thereof, the nano-materials include at least two nano-metals of different dimensions, including the following preparation steps: the first step: in the first nano-metal wire, and / Or etching holes on the surface of the first nano-metal sheet to form a second nano-metal wire, and / or the second nano-metal sheet, the diameter of the hole is 10nm to 40nm; the second step: using the first solvent to clean the first nano-metal particle , the second nano metal wire, and / or the second nano metal sheet, to obtain the second nano metal particle, the third nano metal wire, and / or the third nano metal sheet; the third step: mixing the second nano metal particle, the second nano metal particle The three nanometer metal wires and / or the third nanometer metal sheet obtain a first mixture, and mix the first mixture with a second solvent to obtain a second mixture; the fourth step: concentrate the second mixture to obtain an encapsulation paste. The method has simple process and mild execution conditions, and is suitable for mass production at low cost.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

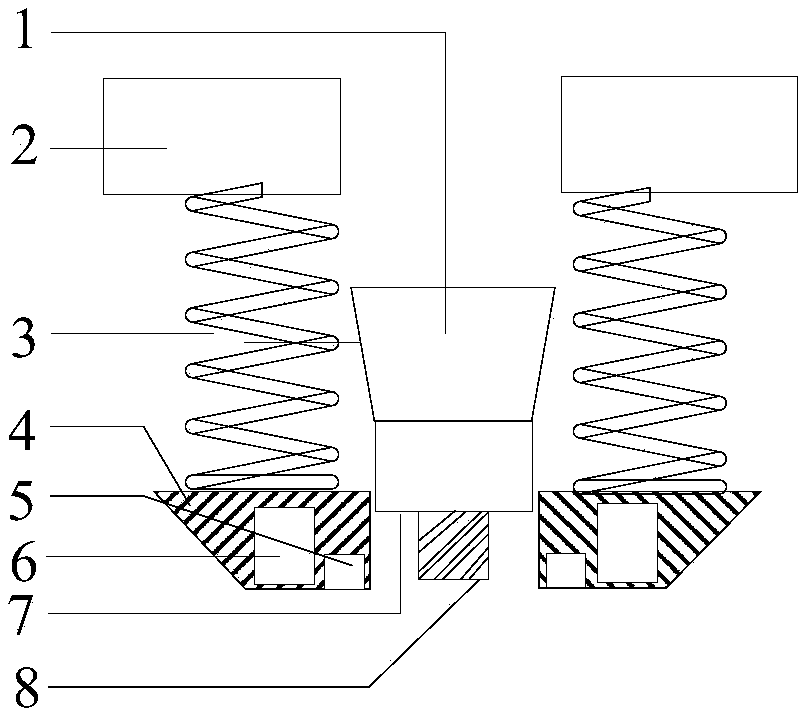

Transient liquid phase diffusion bonding process of molybdenum copper alloy and stainless steel

InactiveCN103252572BImprove interfacial wettabilityDiffusion fastNon-electric welding apparatusUltimate tensile strengthVacuum chamber

The invention discloses a transient liquid phase diffusion bonding process of molybdenum copper alloy and stainless steel. The transient liquid phase diffusion bonding process comprises the following steps that (1) before welding, the surfaces to be welded of the molybdenum copper alloy and the stainless steel are cleaned, wiped and blown to be dry until the surfaces to be welded show metallic luster; (2) a composite middle layer is added between contacting surfaces to be welded of the molybdenum copper alloy and the stainless steel, and then a workpiece to be welded is put in a vacuum chamber and is pressed tightly through an upper pressing head and a lower pressing head; (3) when the vacuum chamber is vacuumized until the vacuum degree reaches 10-4 Pa, transient liquid phase diffusion welding is carried out on the assembled workpiece made of the molybdenum copper alloy and the stainless steel; (4) cooling is carried out after welding, and the welding workpiece made of the molybdenum copper alloy and the stainless steel is taken out. The transient liquid phase diffusion bonding process of the molybdenum copper alloy and the stainless steel completely achieves diffusion bonding between the molybdenum copper alloy and the stainless steel, can obtain a diffusion bonding connector made of the molybdenum copper alloy and the stainless steel with the shearing strength reaching 120 M Pa, can meet the use requirements of a composite structure made of the molybdenum copper alloy and the stainless steel, and has the advantages of being low in cost, simple, convenient, high in applicability, convenient to popularize and apply and the like.

Owner:SHANDONG UNIV

A kind of preparation method of large size lightweight magnesium-aluminum base amorphous alloy

ActiveCN110724885BHigh strengthGood plasticity at room temperatureLaser additive manufacturingUltimate tensile strength

The invention belongs to the field of amorphous alloys, and more specifically relates to a preparation method of a large-sized light-weight magnesium-aluminum-based amorphous alloy. Weigh the powdered magnesium-based amorphous alloy and aluminum-based amorphous alloy according to the target alloy composition ratio, and mix them uniformly to obtain magnesium-aluminum-based amorphous alloy mixed powder; The liquid phase interval overlaps; the magnesium-aluminum-based amorphous alloy is prepared by powder sintering process or laser additive manufacturing technology. The invention uses aluminum-based amorphous as a toughening phase to improve the room temperature plasticity of magnesium-based amorphous alloys or uses magnesium-based amorphous as a reinforcing phase to improve the strength of aluminum-based amorphous, and adopts powder sintering technology or laser additive manufacturing technology to prepare large Lightweight and high-strength magnesium-aluminum-based amorphous alloys in size, thereby solving the problem that the existing technology uses a large difference in the internal structure of the crystal second phase and the amorphous matrix, the deformation mode is quite different, and the interface metallurgical bonding is difficult to achieve, resulting in the preparation of composite materials. Technical issues with poor material performance.

Owner:HUAZHONG UNIV OF SCI & TECH

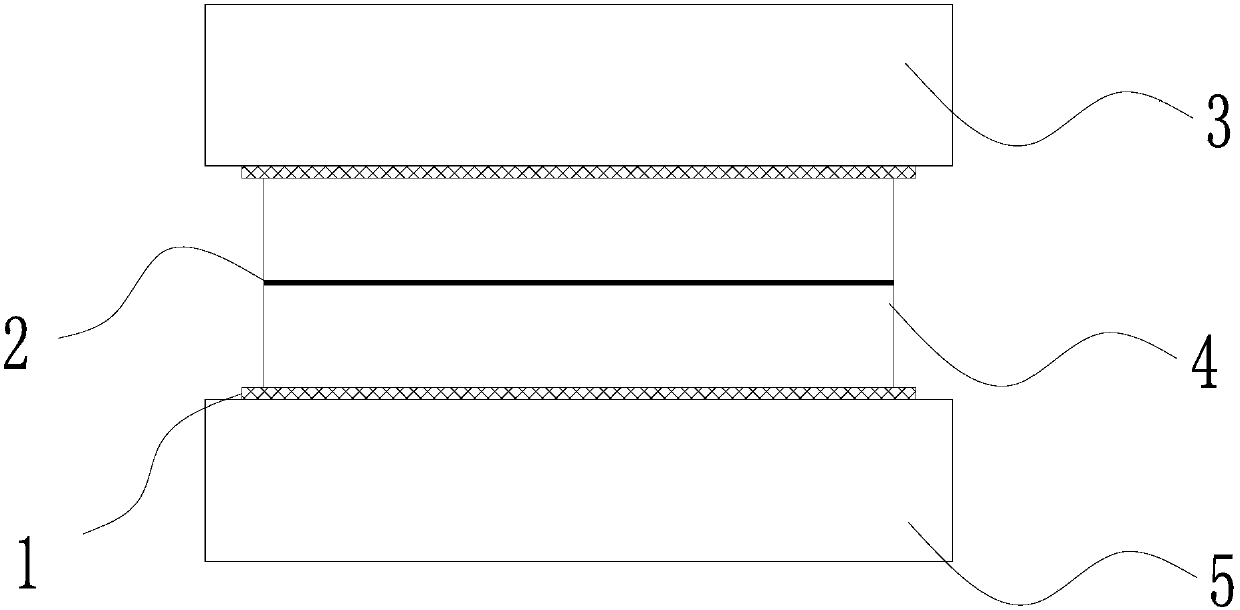

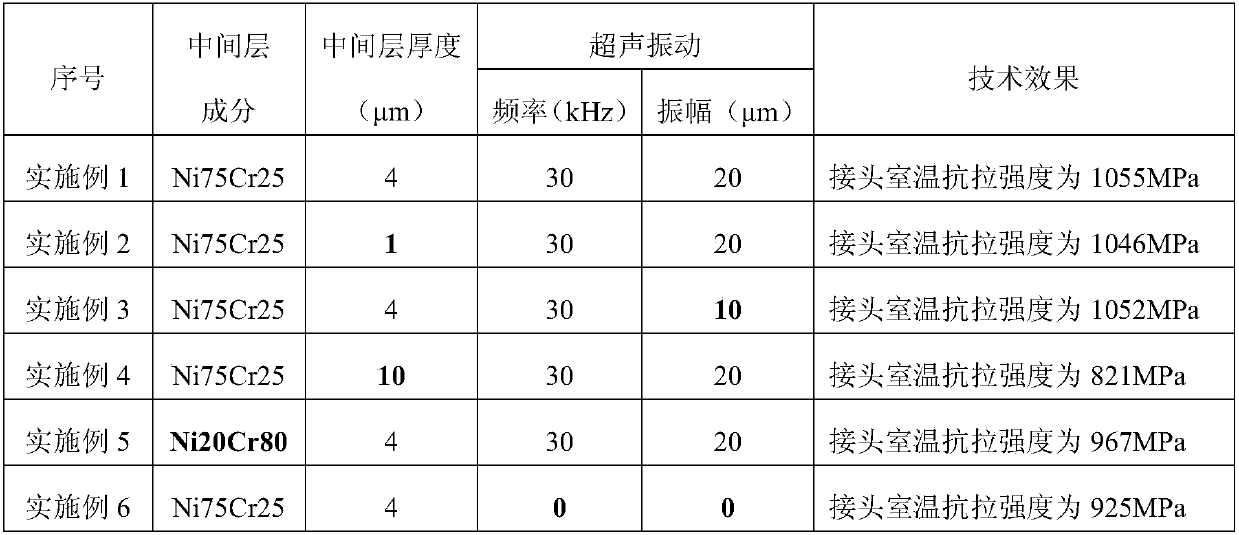

A Diffusion Welding Method for Improving the Strength of gh4099 Welded Joints

ActiveCN105665918BInhibited DiffusionReduce the impact of performance degradationWelding/soldering/cutting articlesNon-electric welding apparatusCold airSolder mask

The invention provides a diffusion welding method for improving the strength of GH4099 welding joints. The diffusion welding method comprises the steps that a nichrome foil and the to-be-welded surfaces of the GH4099 welding joints are firstly polished and cleaned and are blow-dried with cold air for standby application, the treated nichrome foil is put between the two GH4099 welding joints, and a welded workpiece is formed; then the welded workpiece is put between an upper press head and a lower press head of a diffusion welding furnace, solder mask layers are arranged between the upper press head and the welded workpiece and between the lower press head and the welded workpiece, then pre-pressure is applied, and a furnace door is closed; and finally, the diffusion welding furnace is vacuumized, supersonic vibration is adopted, axial welding pressure is applied, heat preservation is carried out, then the pressure and vibration are unloaded, furnace cooling is carried out, and welding is completed. According to the diffusion welding method, the time needed for diffusion connection can be greatly shortened, the production efficiency can be improved, and the influence of the too long time on performance degradation of a base material can be reduced; and mutual diffusion between the base material and an interlayer element is facilitated, and the structural constituents of the base material and the interlayer element are similar after welding.

Owner:江苏博联硕焊接技术有限公司

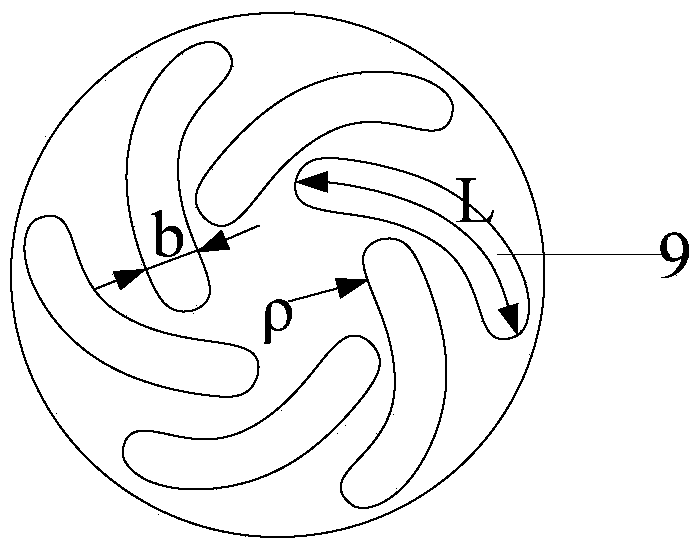

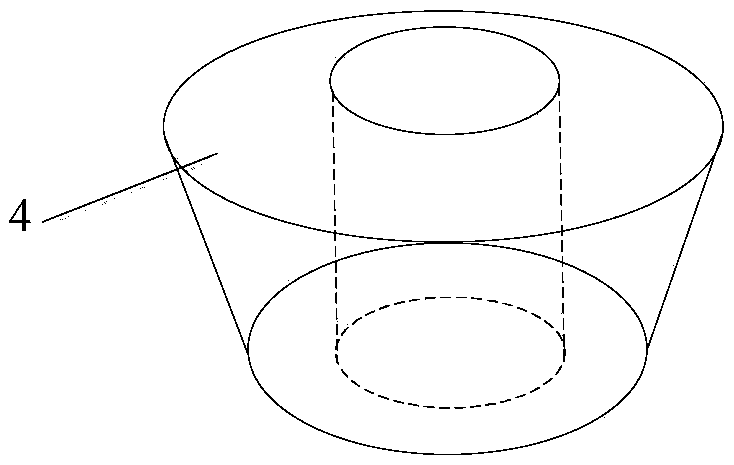

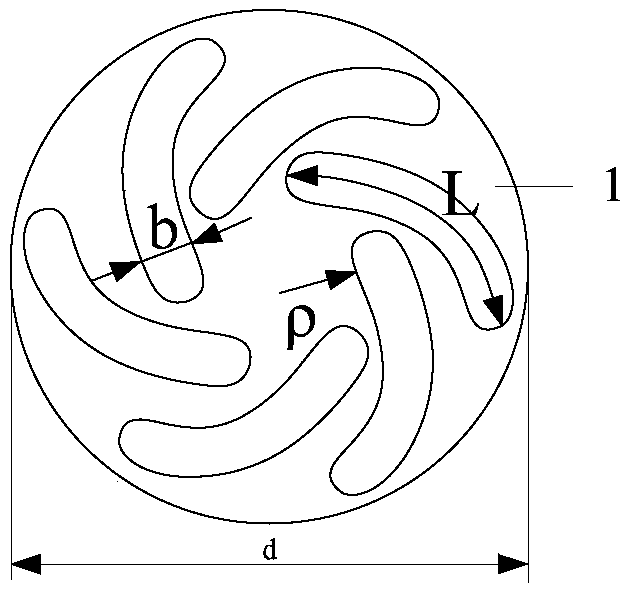

Friction stir welding tool and method for repairing keyhole defects using the tool

ActiveCN106670642BFlow is easy to controlImprove bindingNon-electric welding apparatusElectricityStress concentration

The invention discloses a friction-stir welding tool which is characterized in that a six-helix groove is formed in the bottom surface of a stirring needle of a stirring head; a stationary shaft shoulder is connected with shaft shoulder fixing blocks through springs; the shaft shoulder fixing blocks are fixedly arranged on a welding machine; an electric heating device and a cooling medium passage are arranged and formed in the stationary shaft shoulder; and the electric heating device is arranged inside, close to the stirring head and the cooling medium passage is outside the electric heating device. When the friction-stir welding tool is used to repair a key hole defect, a key hole of a to-be-repaired workpiece is processed to be cylindrical, then continuous filling repair is carried out on the cylindrical key hole by using the stirring heads, the stationary shaft shoulders and filling pieces in different sizes. Compared with the prior art, the friction-stir welding tool has the beneficial effects that the grain size of a repair area is fined, the metallurgical bonding property and the mechanical property are good, the strength is high, the thickness of the repair area is not reduced, no material is spilled, the stress concentration phenomenon is few, and the friction-stir welding tool is free from defect depth limitation and is wide in application scope.

Owner:青岛新动航空科技发展有限公司

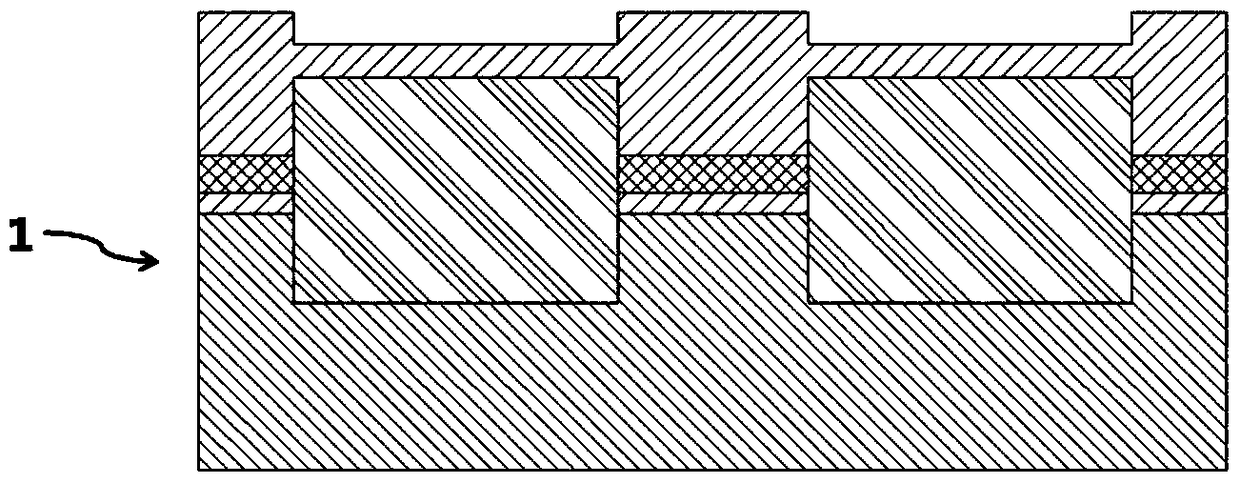

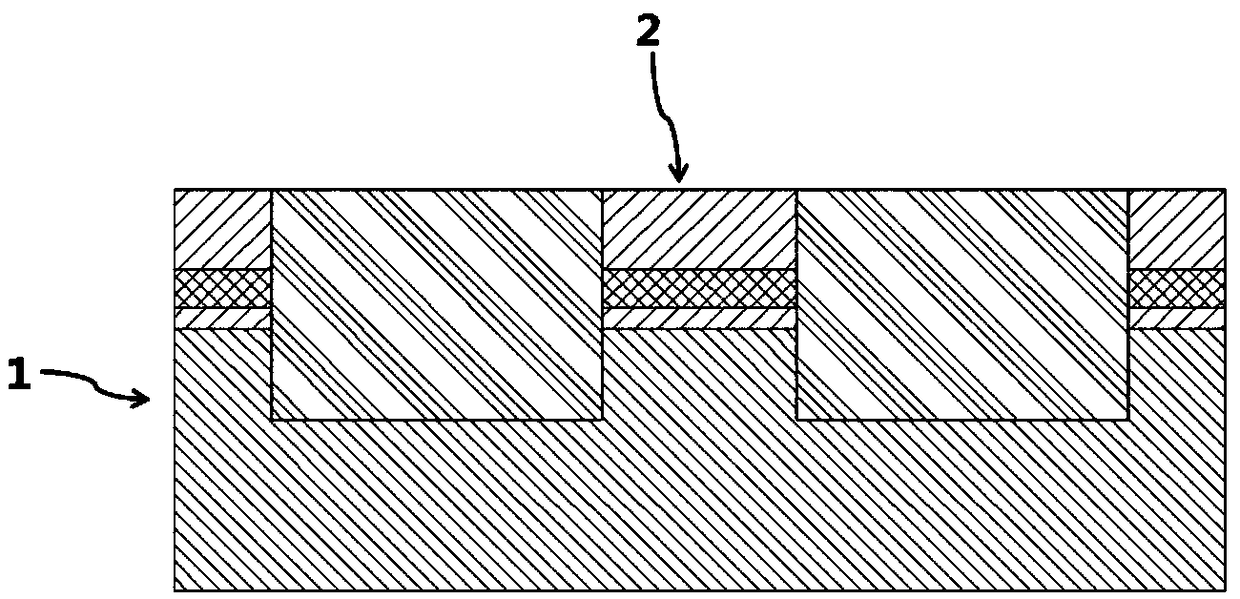

Lamination and connection process of wafers in 3d NAND flash memory structure

ActiveCN107611131BIncrease interface bonding forceReduce contact resistanceSolid-state devicesSemiconductor devicesElectrical resistance and conductanceEngineering

The invention provides a superimposed connection process for wafer connection in a 3D NAND flash memory structure, which includes the following steps: providing two wafer structures; performing preprocessing, specifically on the superimposed connection surfaces of the two wafer structures. Preprocessing is performed to roughen the overlay connection surface; overlay the overlay connection surfaces of the two wafer structures and connect the two wafer structures into an integrated structure. By performing plasma treatment on the overlay connection surface, a relatively rough overlay connection surface is obtained to increase the interfacial bonding force after the overlay connection; ion implantation is used to ion-dope the overlay connection surface to reduce the overlay connection surface The contact resistance of the conductive medium between them; by annealing the integrated structure after the lamination and connection, the atomic diffusion at the interface is accelerated, thereby increasing the interface bonding force after the lamination and connection; through the above process of the present invention, multiple laminations can be enhanced It combines the bonding force of the wafer connection interface to improve the product performance of the 3D NAND flash memory structure.

Owner:YANGTZE MEMORY TECH CO LTD

Secondary composite casting bimetal forming method

The invention discloses a secondary composite casting bimetal forming method, and belongs to the technical field of bimetal casting. The method comprises the following steps: arranging a bonding material on the surface of a metal matrix, putting the matrix of the bonding material into a casting mold or a sand mold, pouring the molten aluminum alloy into the casting mold or the sand mold to bond the aluminum alloy with the matrix, then putting the metal matrix into a casting mold or a sand mold used for secondary casting, pouring the molten aluminum alloy to form a secondary composite casting part, and finally performing heat treatment on the secondary composite casting part. According to the method of the invention, through secondary pouring, a second bonding interface of the same metal is further formed outside a bonding interface of dissimilar metal; and aluminum-aluminum same metal bonding is formed through secondary casting, better atomic diffusion can be achieved to form metallurgical bonding compared with traditional dissimilar metal bonding, and the problem that the bonding performance of a dissimilar metal bonding interface is low is solved.

Owner:ZHONGBEI UNIV

A brazing cladding material for metal surfaces

ActiveCN104907725BWon't fall offReduce stressWelding/cutting media/materialsSoldering mediaEpoxyBound property

The invention discloses a brazing clad material used for a metal surface, wherein the clad material is powder particles that is constituted of the follow components with weight percent; Ni tungsten carbide powder ( WC-10 Ni) is within 48 percent to 62 percent; Ni powder is within 7 percent to 11 percent; NiCrBSi alloyed powder (AWS BNi-2) is within 27 percent to 45 percent; binder occupies the rest percentage; the size of the Ni tungsten carbide powder particle is within 5 to 15 micro-meter; the size of the Ni powder particle is within 30 to 45 micro-meter; the NiCrBSi alloyed powder particle is within 25 to 35 micro-meter; and the degree of the metal bonding phase between Ni tungsten carbide powder particles is less or equal to 0.3 micro-meter. According to the invention, under the effect of the organic silicon resin binding material and the epoxy resin binding material, the component of the brazing material is uniform and has specific binding property; and the brazing clad material won't be fell off, thus facilitating to the atomic diffusion and the interface reaction during the high temperature connection process and improving the wetting ability of the clad material and the performance of the metal surface.

Owner:无锡腾达海川新材料有限公司

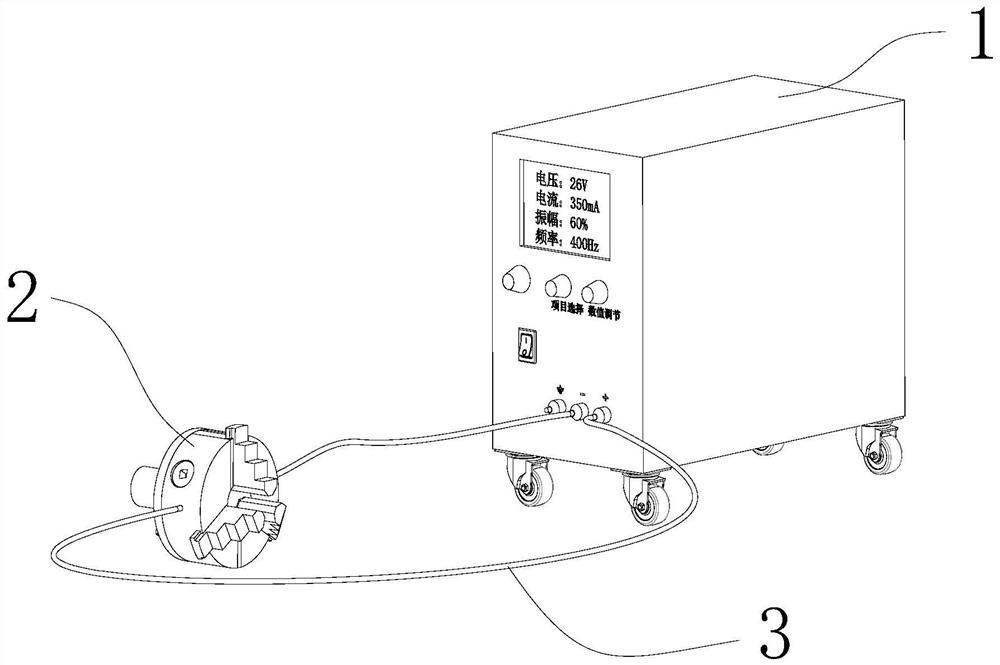

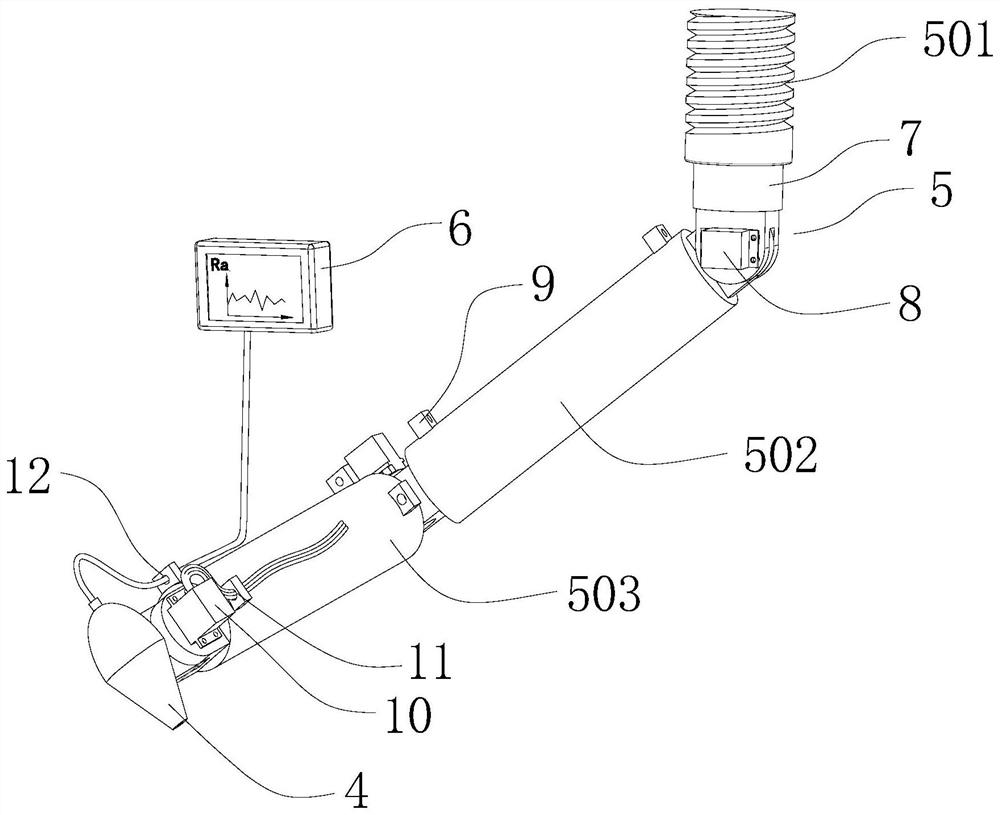

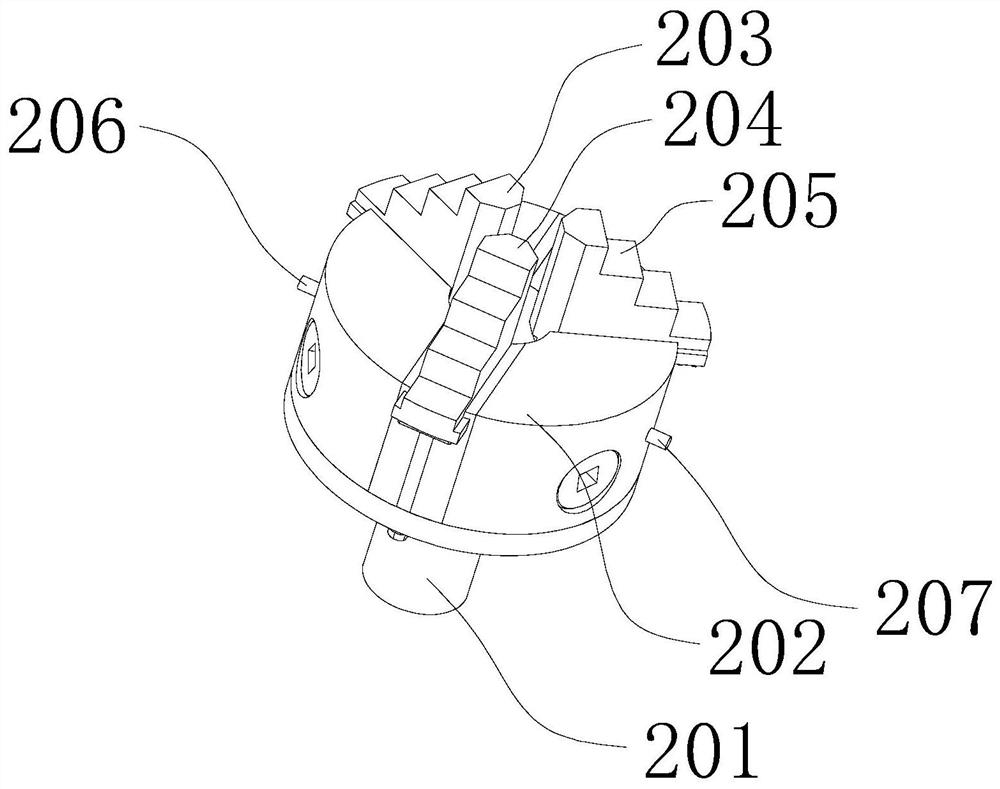

Pulse current auxiliary cutting machining system and machining method

PendingCN113814745AImprove plasticityFacilitates atomic diffusionMeasurement/indication equipmentsChucksMachined surfaceEngineering

The invention discloses a pulse current auxiliary cutting machining system and a machining method. The pulse current auxiliary cutting machining system comprises an electric pulse auxiliary machining device and a laser surface roughness online detection device. The electric pulse auxiliary machining device comprises a high-frequency pulse generator and a clamp, the high-frequency pulse generator is connected with the clamp through a wiring cable, and the clamp is clamped on a five-axis machining center clamp; and the laser surface roughness online detection device comprises a laser roughness detection head, a holder and an oscilloscope, the holder is fixed on a five-axis machining center tool magazine, the laser roughness detection head is clamped at the top end of the holder, a focus point points to a machined surface of a workpiece, and the laser roughness detection head is connected with the oscilloscope through a signal line. By means of the pulse current auxiliary cutting machining system, the problems of work hardening, severe tool abrasion and the like in the current titanium alloy machining process are solved, meanwhile, the stability of the product quality can be effectively guaranteed, and the production efficiency of titanium alloy components is improved.

Owner:SOUTH CHINA UNIV OF TECH

for si 3 no 4 Ceramic surface metallization material and preparation method and brazing process

ActiveCN105057919BEvenly heatedReduce stress concentrationNon-macromolecular adhesive additivesEster polymer adhesivesInterfacial reactionAdhesive

Owner:JIANGSU UNIV OF SCI & TECH

Ellipsoidal anisotropic friction simple pendulum support

PendingCN113981812AHigh design strengthIncreased durabilityBridge structural detailsProtective buildings/sheltersClassical mechanicsEngineering

The invention discloses an ellipsoidal anisotropic friction simple pendulum support, which comprises: an upper base plate, wherein the top surface of the upper base plate is a plane and the bottom surface is an ellipsoidal concave surface; a lower base plate, wherein the bottom surface of the lower base plate is a plane, and the top surface is a concave spherical curved surface; and a hinged sliding block which is arranged between the upper base plate and the lower base plate, wherein the top surface of the hinged sliding block is an ellipsoidal convex surface matched with the ellipsoidal concave surface, and the bottom surface of the hinged sliding block is a convex spherical curved surface matched with the concave spherical curved surface. According to the ellipsoidal anisotropic friction simple pendulum support, the lower portion of the hinged sliding block and a groove in the upper portion of the lower base plate are spherical surfaces, and the hinged sliding block can rotate in any horizontal direction through the spherical surfaces; and a vertical rotating gap is formed between the hinged sliding block and the groove in the upper portion of the lower base plate, vertical rotation of the hinged sliding block is achieved when the upper base plate of the support swings horizontally, then anisotropic seismic mitigation and isolation design in the longitudinal and transverse bridge directions of a bridge is achieved, and the performance of the support is good under a rapid shear friction test with the speed larger than or equal to 500 mm / s.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT +1

A method of repairing long-volume defects in metal components by friction stir welding

ActiveCN106583916BSolve the technical problems of long-volume defect repairSolve technical problemsNon-electric welding apparatusNeedle freeFriction welding

The invention discloses a method for repairing long volume type defects in a metal component by utilizing friction stir welding. The method comprises the following steps of: 1, digging irregular long volume type defects of a to-be-repaired metal component to form long-strip-shaped grooves, and filling the grooves with homogeneous or heterogeneous metal; 2, putting the metal component onto a base plate for being fixed, and enabling a to-be-repaired area to be in a horizontal state; 3, using a needle-free stirring head to fix filling metal into long-strip-shaped grooves of the metal component through friction stir welding; 4, using a stirring head with a stirring needle and a static shaft shoulder which is matched with the stirring head to carry out friction stir welding on filling metal and the metal component; and 5, after friction stir welding is completed, carrying out re-vibrating on the to-be-repaired area by utilizing ultrasonic vibrating. The method disclosed by the invention can solve the technical problem in repairing of long volume type defects of the metal component, and has the advantages of being good in metallurgical bonding with the to-be-repaired area, high in strength, flat and smooth in surface and small in internal stress.

Owner:SHENYANG AEROSPACE UNIVERSITY

A paste based on multi-dimensional metal nanomaterials and its interconnection process

ActiveCN111415767BConducive to dense interconnectionIncreased shear strengthMaterial nanotechnologySemiconductor/solid-state device manufacturingNanowireSemiconductor chip

The invention provides a multi-dimensional metal nanomaterial paste and an interconnection process thereof. The multi-dimensional metal nanomaterial paste includes: zero-dimensional nanospheres, one-dimensional nanowires and / or two-dimensional nanosheets; the one-dimensional nanometer The surface of the wire and the two-dimensional nanosheet is provided with holes, and the diameter of the holes ranges from 10 nm to 40 nm. The interconnection process of the multi-dimensional metal nanomaterial provided by the present invention has the advantages of simple process and gentle adjustment, and can realize the interconnection between chips and substrates in high-power devices under low temperature and no pressure. The introduction of several nano-metals of different dimensions in the paste and the appearance of related etching holes are beneficial to atomic diffusion and dense interconnection between particles during sintering, which improves the shear strength of the sintered paste and can reduce the sintering. temperature to achieve low temperature sintered interconnects. The interconnection process based on the method of the present invention can be widely used in many emerging microelectronic interconnection fields such as flexible electronic packaging, third-generation semiconductor chip device packaging and the like.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Diffusion and connection method for ceramic and steel by adding active intermediate alloy

InactiveCN100434224CReduce microscopic gapIncrease contact areaNon-electric welding apparatusAlloyUltimate tensile strength

This invention discloses diffusion link method for ceramics and steel by adding active intermediate alloy with main character as follows: add active intermediate alloy between the contact surfaces of ceramics and steel needed welding, use upper and lower pressure heads to press the needed welding ceramics / steel workpiece; put into vacuum chamber to take expansion link with technical parameters of heat temperature 1060-1180Deg, heat preservation time 25-60min, pressure 8-16MPa, and vacuum degree 2.5x10-4-1x10-5Pa. It solves efficiently the expansion link and obtains jointing with shear strength as high as 140MPa fit to use require for complex structure. The invention has advantages of low cost, simple and convenient technique, high applicability and easy to spread.

Owner:SHANDONG UNIV

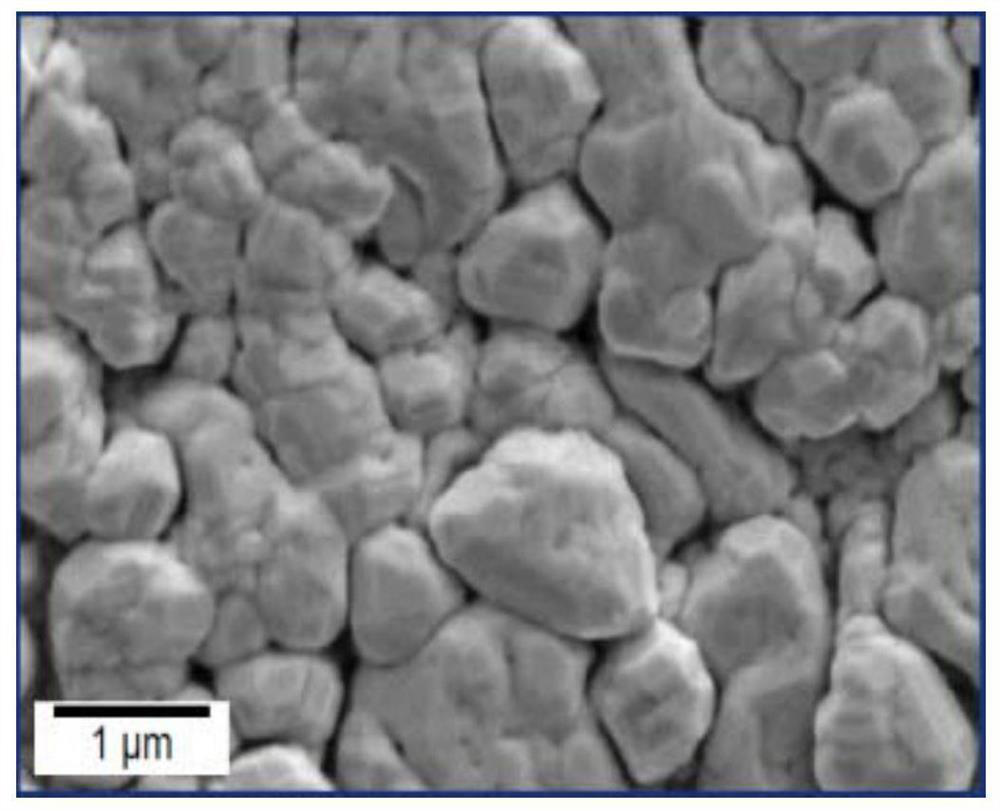

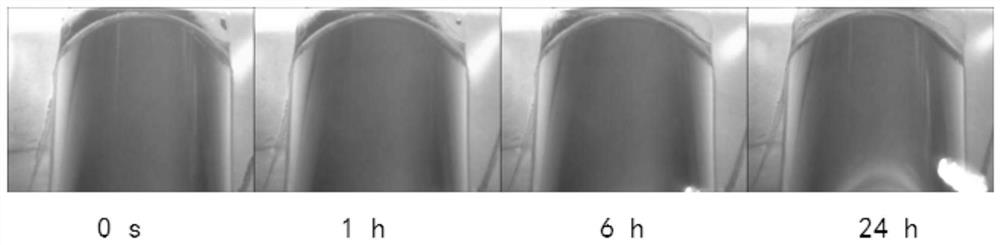

A method for preparing a dense copper protective layer on the surface of an aluminum mold core

ActiveCN109913800BAvoid defects caused by sputtering onto the core surfaceGood bondingVacuum evaporation coatingSputtering coatingCopper platingPhysical chemistry

The invention discloses a method for preparing a compact copper protection layer on the surface of an aluminum mold core, belongs to the field of inertial confinement fusion target preparation, and particularly relates to a method for preparing a high-compactness copper protection layer. The method aims at solving the problems that at present, a copper protection layer prepared on the surface of an aluminum mold core is not compact, and the binding force of the copper protection layer and the aluminum mold core is poor. The method for preparing the compact copper protection layer on the surface of the aluminum mold core comprises the steps that firstly, a copper target is pretreated; secondly, the aluminum mold core is assembled; thirdly, vacuum heating degassing treatment and ion etchingcleaning are carried out; fourthly, magnetron sputtering deposition is carried out on a first copper plated layer; fifthly, in-situ heat treatment is carried out; sixthly, a copper plated layer is etched and deposited; and seventhly, operation of the sixth step is repeated two times, and an aluminum-copper composite core shaft is obtained. The method has the beneficial effects that the surface roughness RMS is smaller than 60 nm, residual stress is reduced to 58 MPa+ / -20 MPa, and the corrosion resisting time in a NaOH solution of 3 mol / L exceeds 24 h. The method is mainly used for preparing the aluminum-copper composite core shaft.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Diffusion bonding method of silicon carbide ceramics and ferritic stainless steel

InactiveCN103273155BDiffuse join implementationFacilitates atomic diffusionSoldering apparatusAlloyVacuum chamber

The invention relates to a diffusion bonding method of silicon carbide ceramics and ferritic stainless steel. Al-Si intermediate alloy is added between the contact faces, to be connected, of the silicon carbide ceramics and stainless steel, and the silicon carbide ceramics and a ferritic stainless steel plate workpiece to be connected are tightly pressed through an upper pressing head and a lower pressing head of diffusion bonding equipment, are arranged in a vacuum chamber and are connected in a diffusion bonding mode. According to technological parameters, heating temperature is 500 DEG C to 540 DEG C, heat preservation time is 25min to 50min, pressure is 40MPa to 90MPa, and a vacuum degree is 1.33 *10-3Pa to 1.33*10-2Pa. Then cooling, cleaning and drying are carried out to achieve diffusion bonding. The Al-Si alloy foil is added, a transition liquid phase is formed on a contact surface in a diffusion bonding process, and the diffusion bonding of the silicon carbide ceramics and the stainless steel is achieved. The melting temperature of the Al-Si alloy foil is greatly lower than the softening temperature of the ferritic stainless steel, and the method is beneficial for accelerating a silicon carbide ceramics / stainless steel interface to form good diffusion bonding.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com