Pulse current auxiliary cutting machining system and machining method

A cutting and pulse current technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of work hardening, tool wear, etc., to improve cutting performance, improve production efficiency, and ensure stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

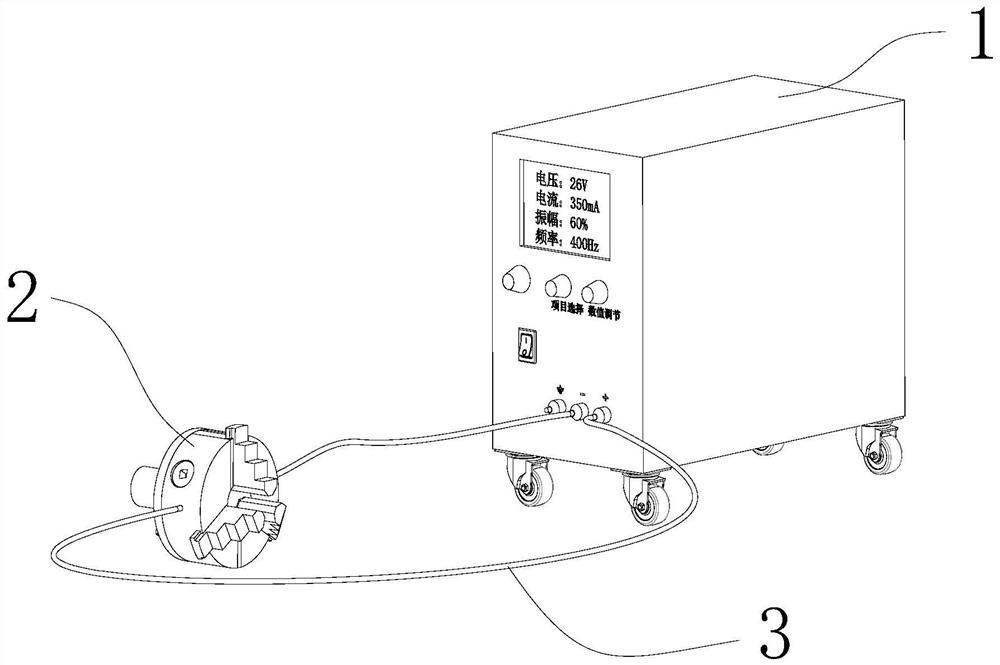

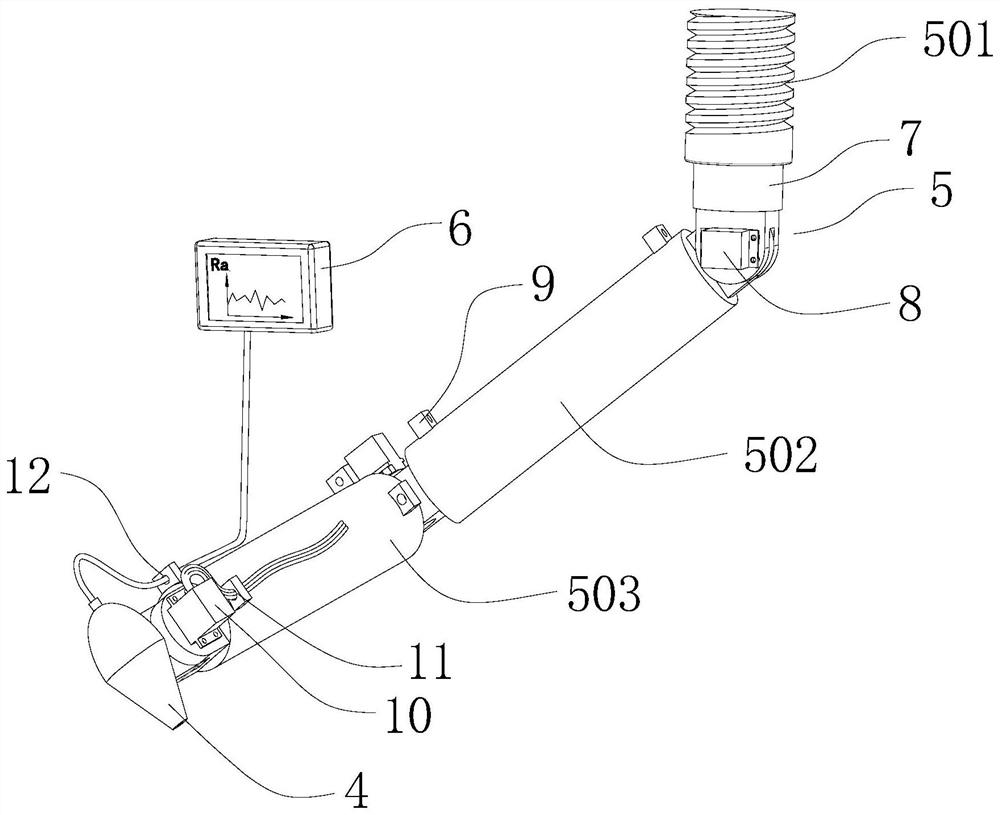

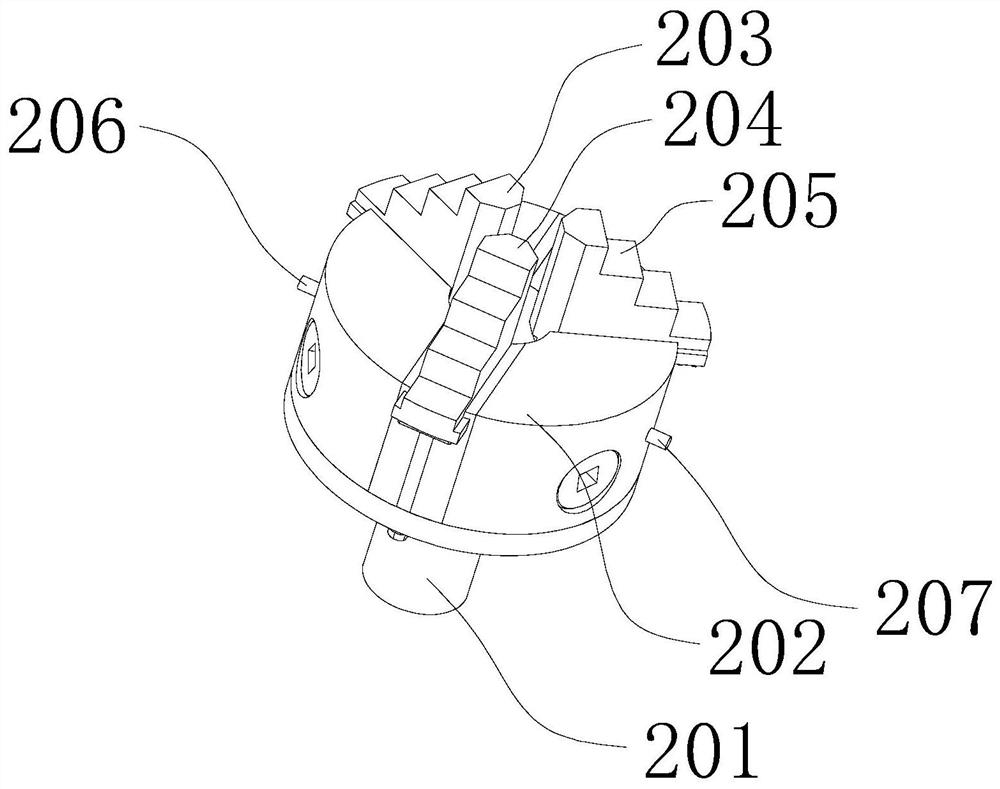

[0034] Such as figure 1 and figure 2 As shown, this embodiment provides a pulse current assisted cutting processing system, including an electric pulse assisted processing device and a laser surface roughness on-line detection device, the electric pulse assisted processing device includes a high-frequency pulse generator 1 and a fixture 2, and the high-frequency The pulse generator 1 is connected to the fixture 2 through the wiring cable 3, and the fixture 2 is clamped on the fixture of the five-axis machining center; the laser surface roughness online detection device includes the laser roughness detection head 4, the holder 5 and the oscilloscope 6, and the holder 5 is fixed on the tool magazine of the five-axis machining center, the laser roughness detection head 4 is clamped on the top of the holder 5, and the focus points to the processed surface of the workpiece, and the laser roughness detection head 4 is connected to the oscilloscope 6 through a signal line.

[0035]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com