Patents

Literature

41results about How to "Composite fastness is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

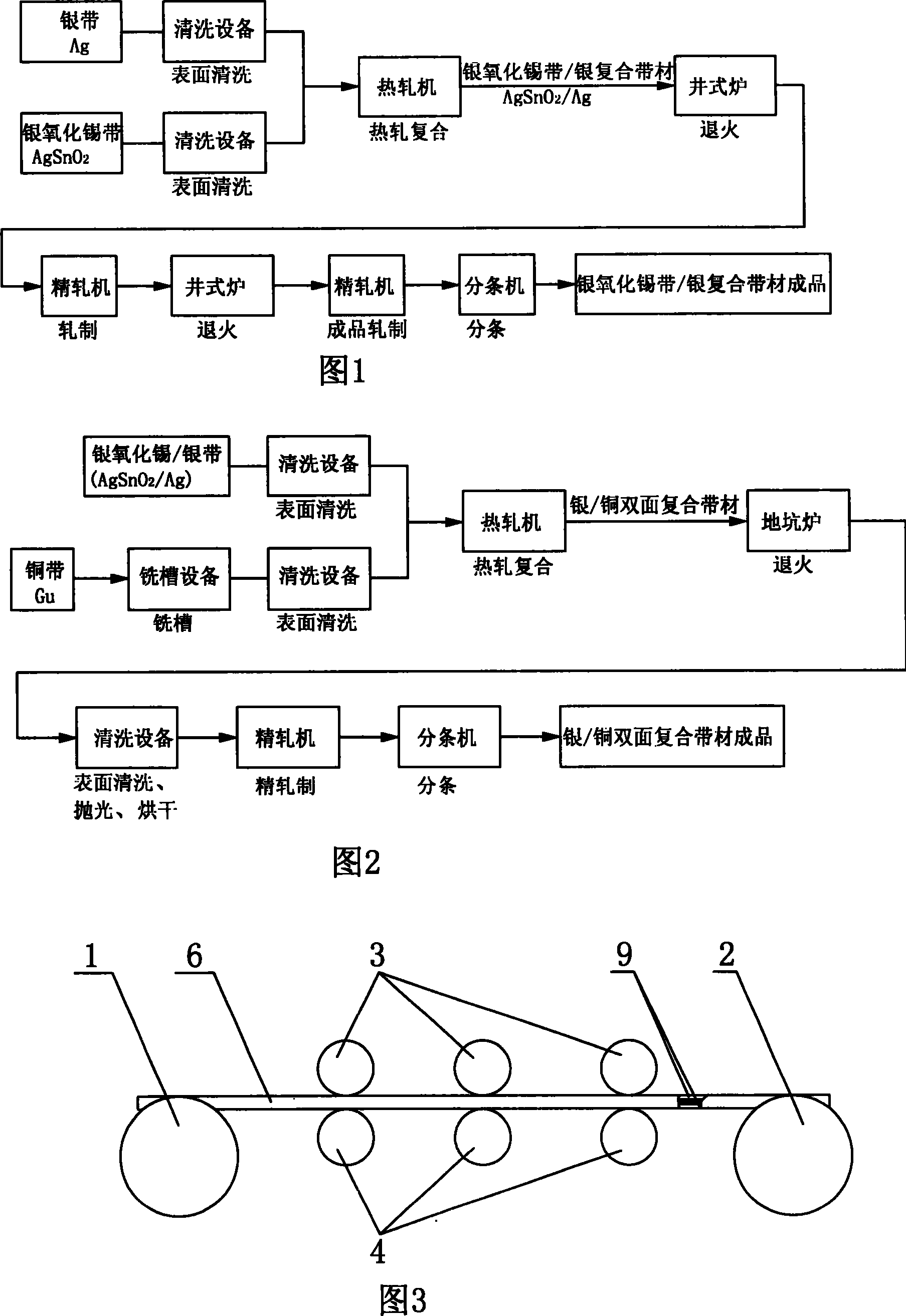

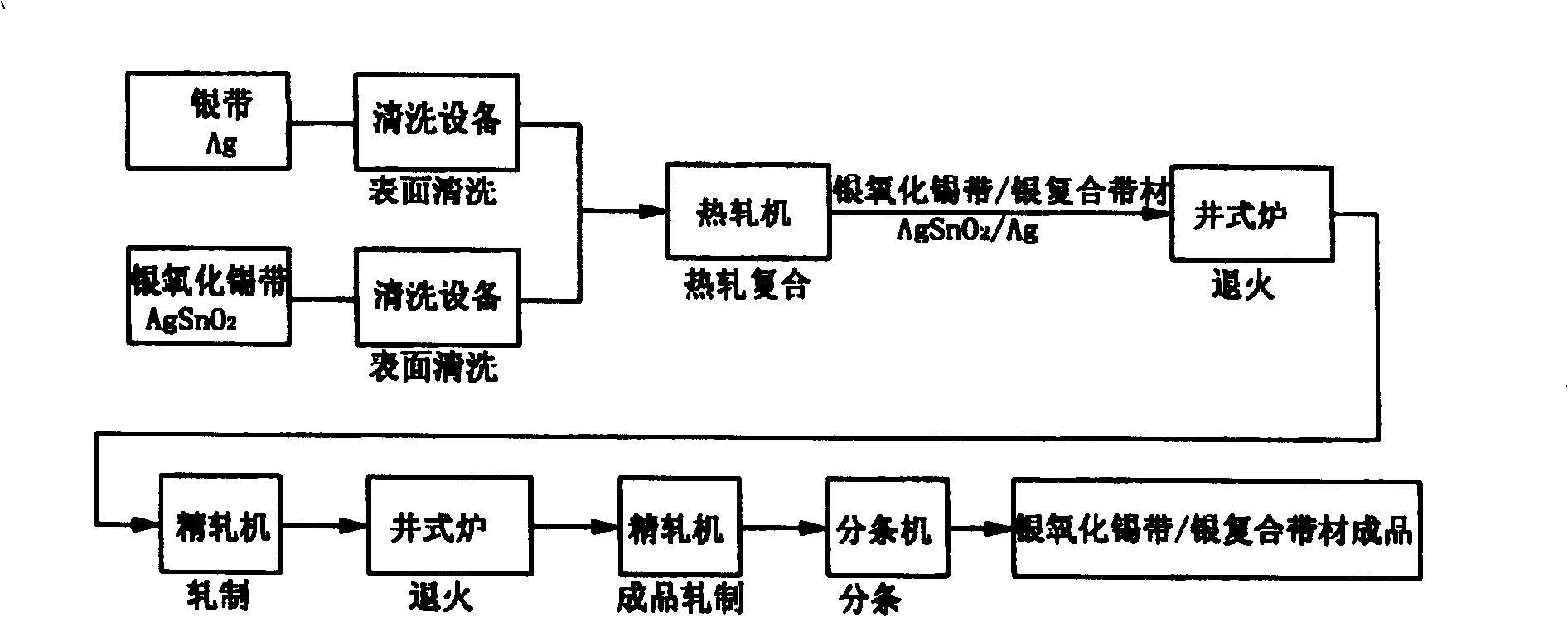

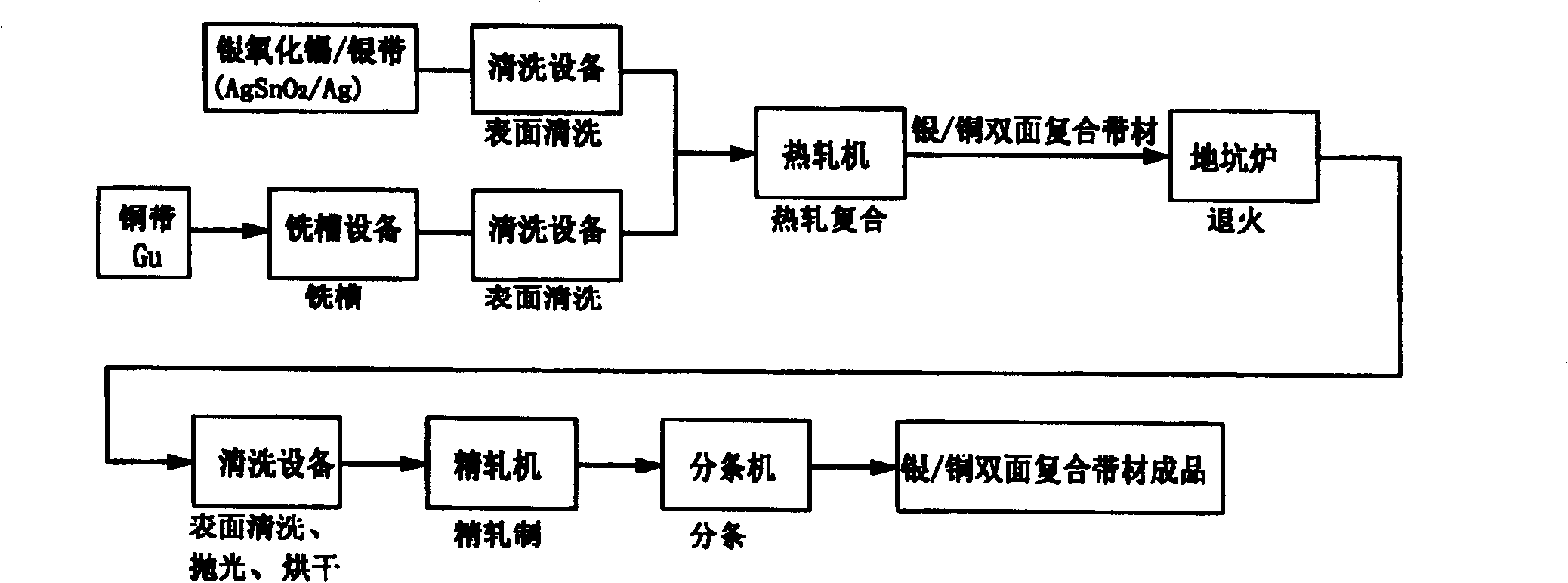

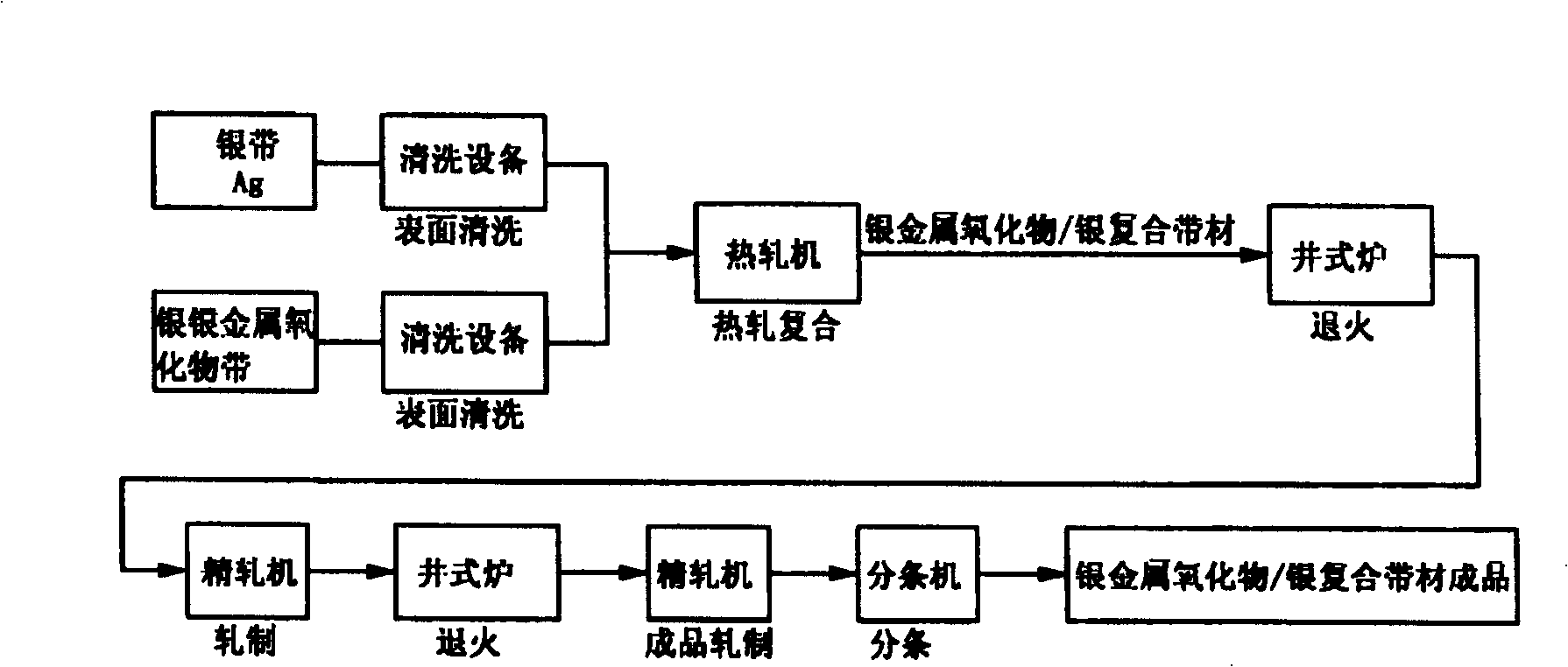

Machining technique of silver/copper double composite strip material

This invention relates to electricity materials technique field and to one silve to copper double compound band process method, which comprises the following steps: firstly grinding the silver metal oxidation with one thin siver band to form silver metal oxidation or silver compound materials; grinding silver metal oxidation and silver compound band through its top silver band layer and copper band heat grinding through heat compound band for annealing.

Owner:东莞市中一合金科技有限公司

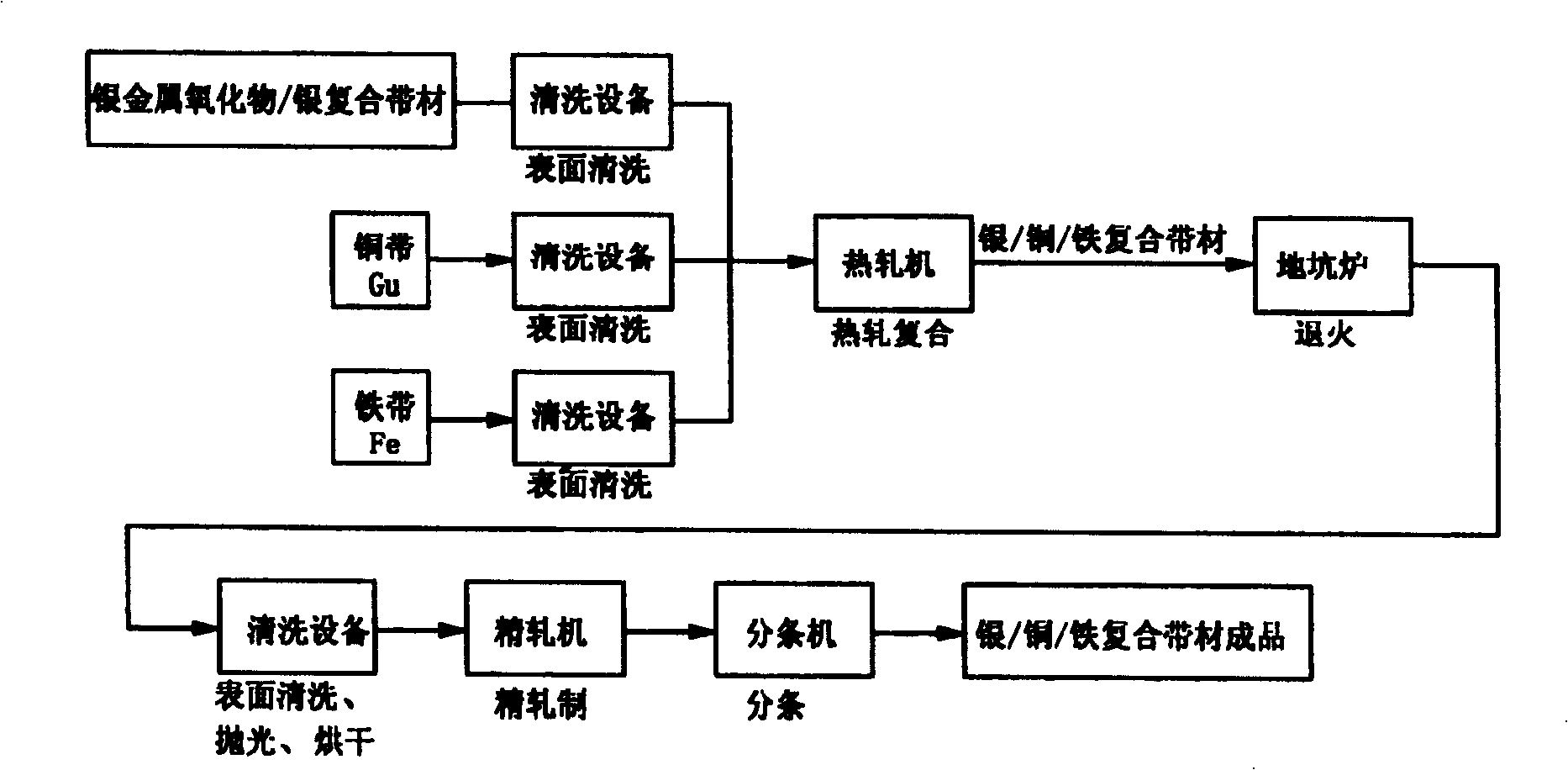

Machining technique of silver/copper/iron composite strip material

This invention relates to compound materials technique field to process electricity probe and especially to one silver and copper and iron compound process method, which comprises the following steps: firstly grinding the silver metal oxidation and one film of pure silver materials for combination; then grinding the copper band and iron band to process this invention silver, copper and iron compound band.

Owner:东莞市中一合金科技有限公司

Dry composite water-thined adhesive in soft package and its prepn

The present invention discloses one kind of dry composite water-thinned adhesive in soft package and its preparation process. The water-thinned adhesive may be used in combining plastics. The preparation process of the water-thinned adhesive includes the following steps: polymerizing acrylate emulsion in dispersed self-emulsifying polyurethane liquid to obtain hybridized polyurethane / acrylate emulsion; adding mildew inhibitor and defoaming agent; and packing in soft package. The present invention uses water as dispersing medium, has no volatile organic solvent and is environment friendly.

Owner:SUN YAT SEN UNIV

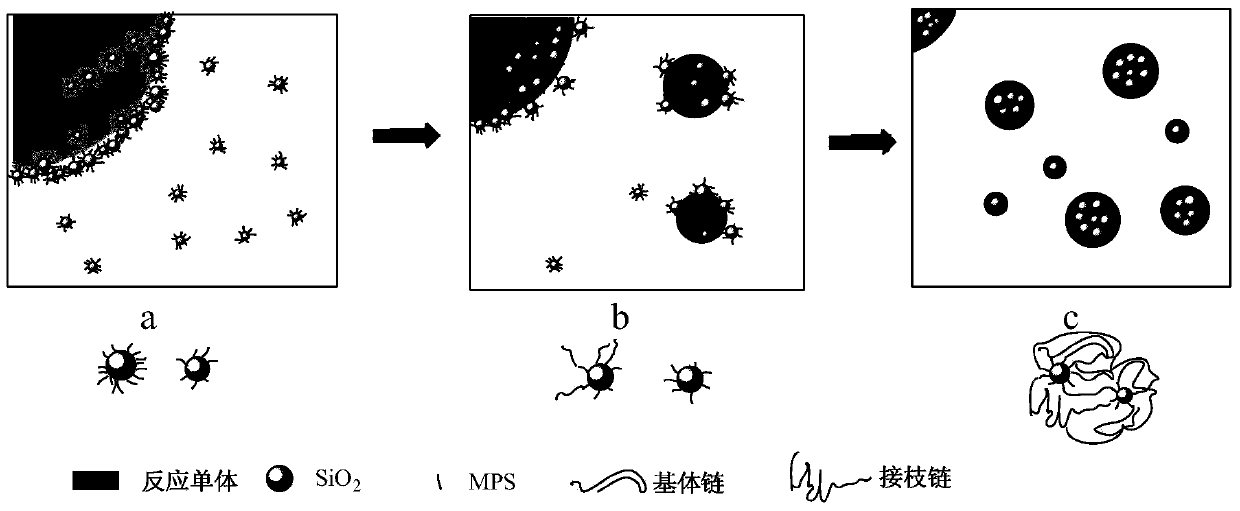

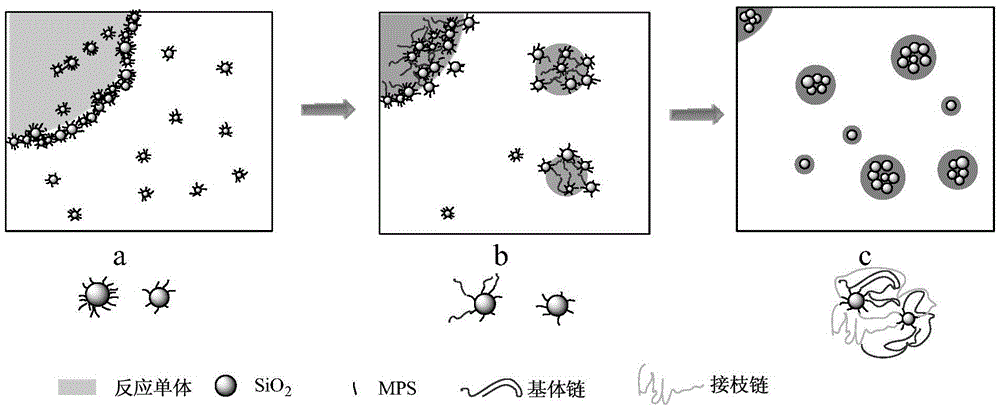

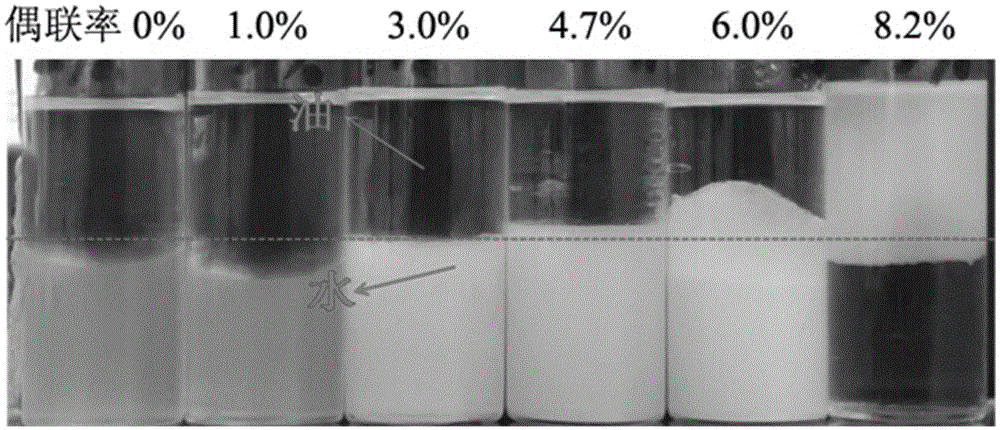

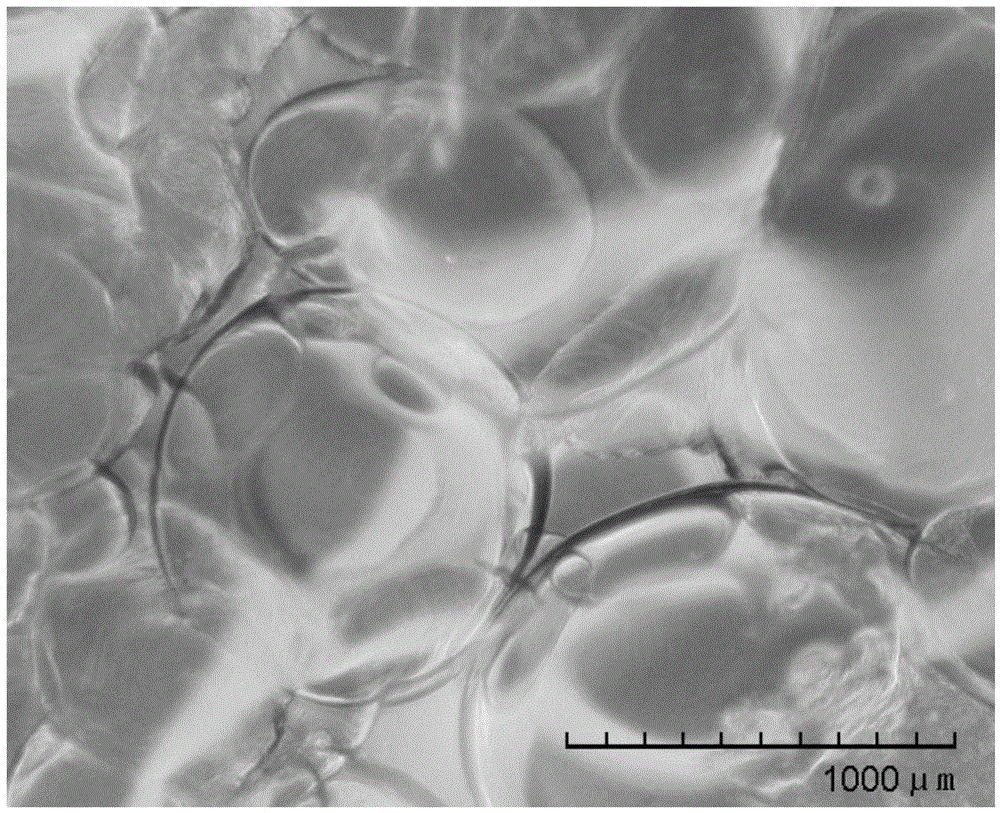

Preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres

The invention discloses a preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres, which comprises the following steps: mixing an aqueous dispersion solution of silicon dioxide modified by proper amount of double-bond silane coupling agent in a coupling method with a phenylpropyl monomer, anionic emulsifier, non-anionic emulsifier and water, and stirring simply, so that a milky emulsified liquid is obtained; adding initiator to perform emulsion polymerization in the presence of silicon dioxide, so that the pomegranate-shaped organic-inorganic nano-composite microspheres with multiple silicon dioxide particles wrapped in phenylpropyl emulsion particles are obtained finally and are stably dispersed in the emulsified liquid. The preparation method has the advantages that the sources of the raw materials are extensive, the raw materials are easy to obtain, the preparation process is simple, and moreover, in the prepared pomegranate-shaped organic-inorganic nano-composite microspheres, the wrapping rate of silicon dioxide is high, the structure is neat and the placement stability is good. The adhesion property and the film forming performance of the composite microsphere particles are adjustable, the adhesive force and the transparency of the corresponding glue film are good, and the organic-inorganic nano-composite microspheres can be applied to the fields of coating, textile, rubber, plastics, biology, medicine and the like.

Owner:杭州华利实业集团有限公司

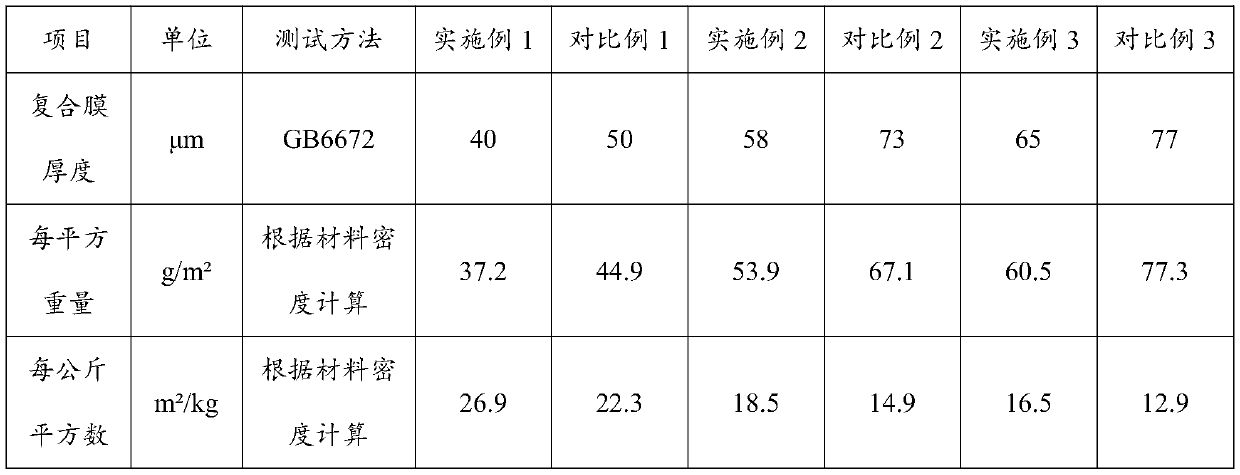

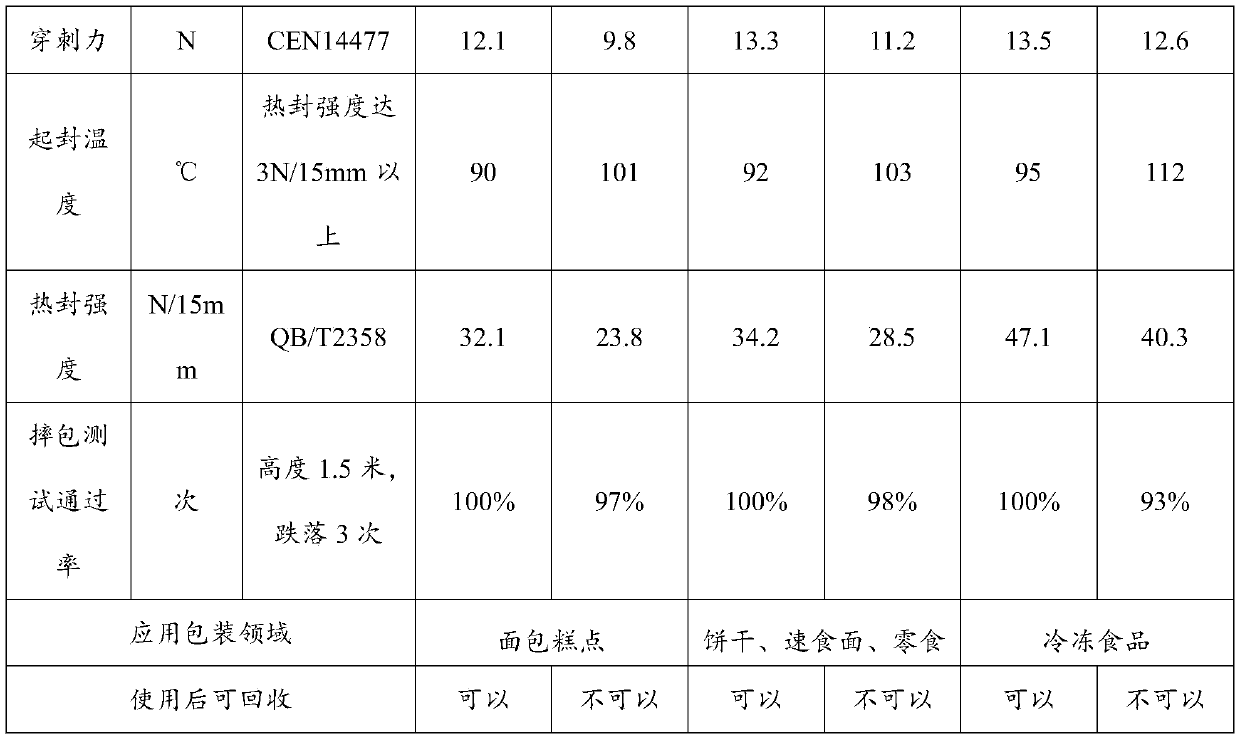

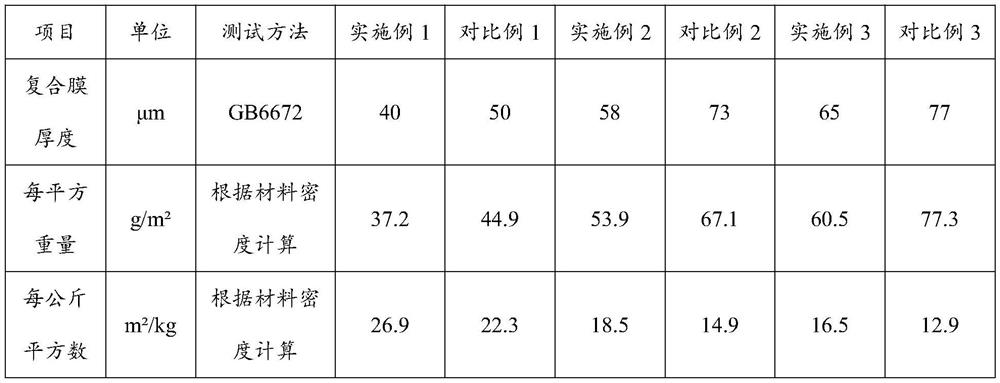

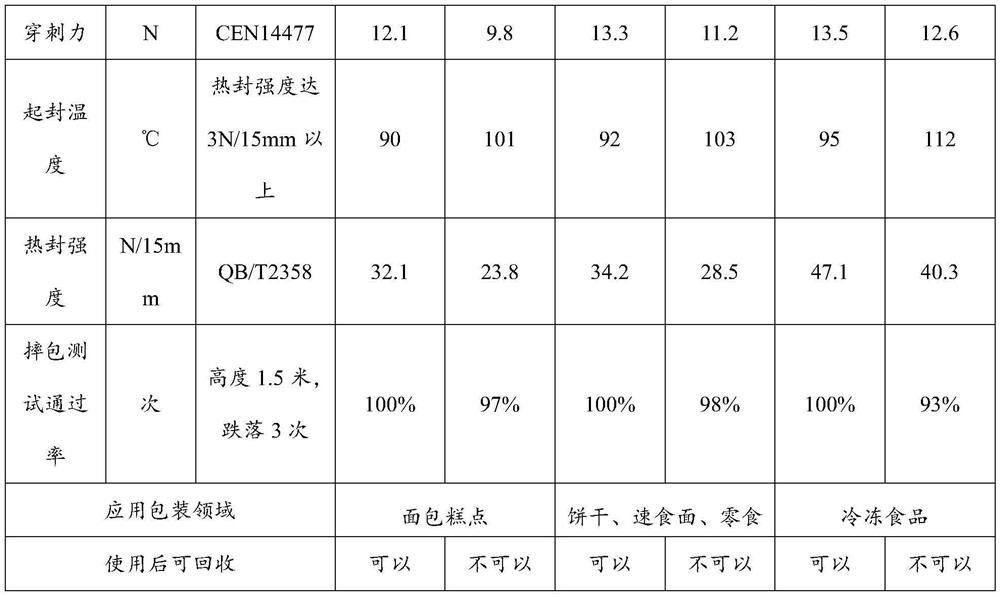

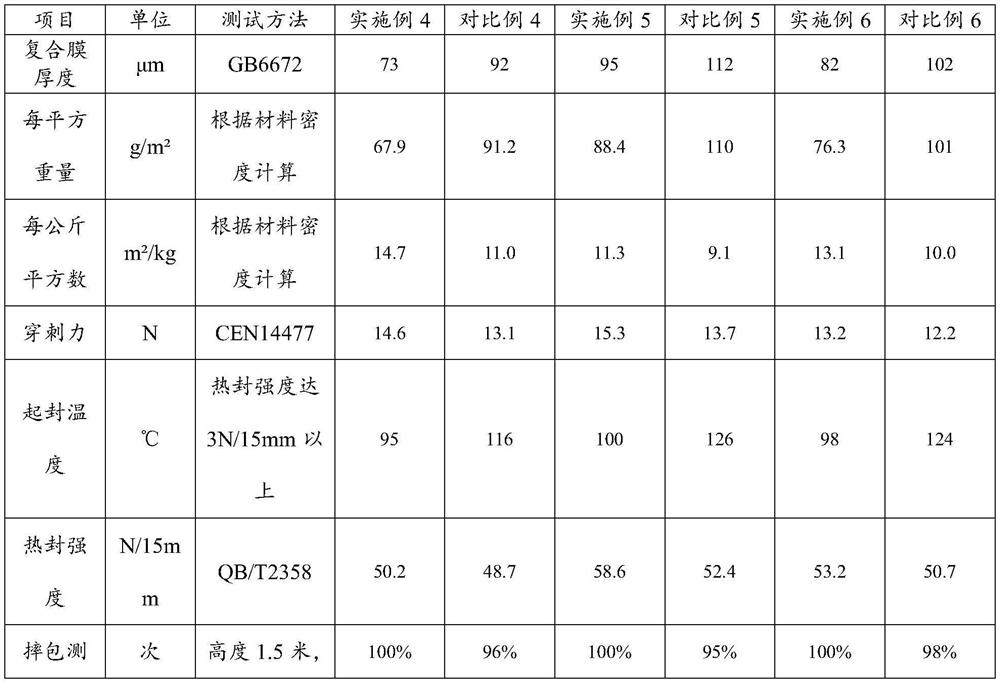

Polyethylene composite film capable of 100% recovery as well as preparation method and application thereof

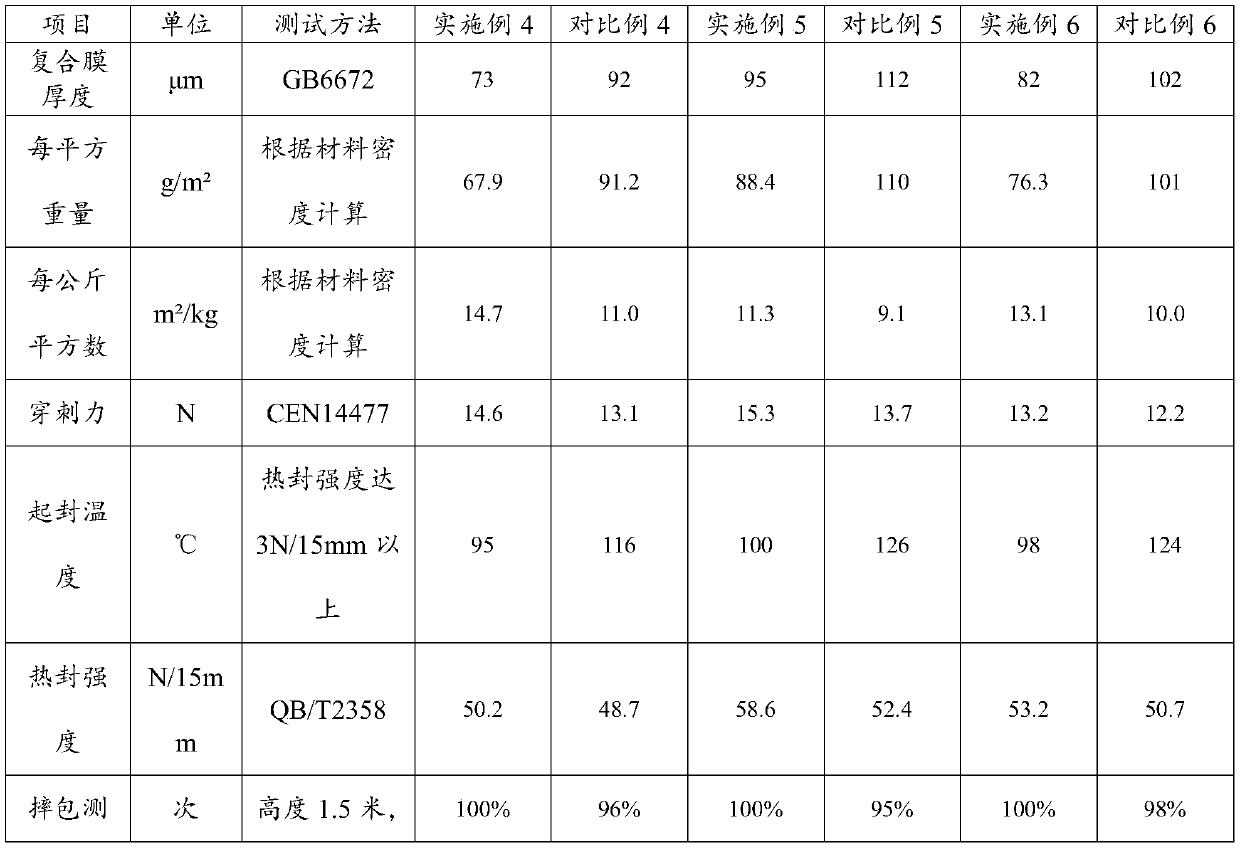

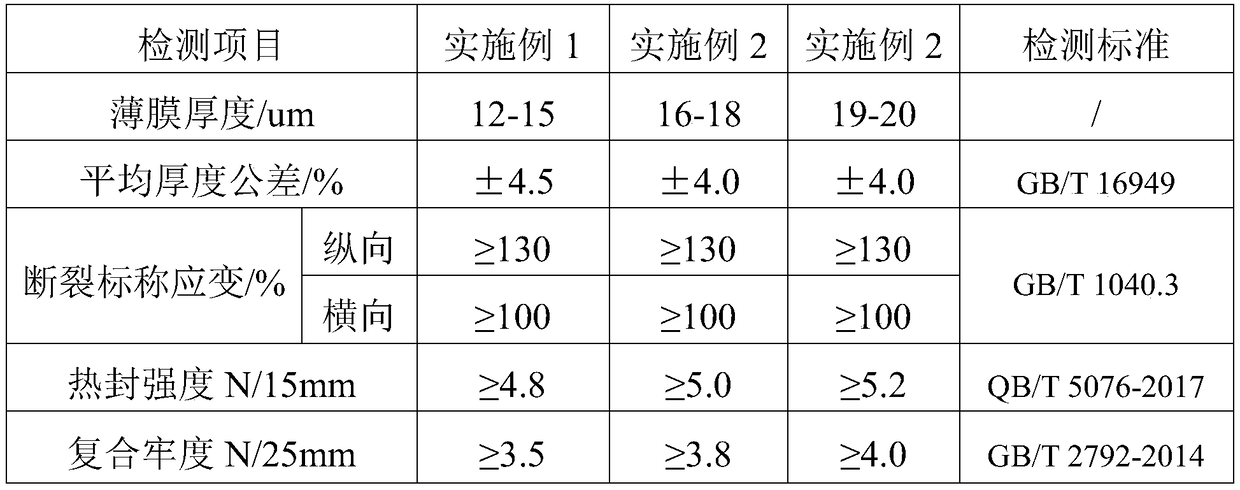

ActiveCN111531991AGood printabilityGood optical performancePackage recyclingFlexible coversLow-density polyethylenePolymer science

The invention belongs to the technical field of polyethylene materials, and particularly relates to a polyethylene composite film capable of 100% recovery as well as a preparation method and application thereof. The provided polyethylene composite film comprises a composite printing layer, a bonding layer and a composite heat-seal layer which are bonded in sequence, wherein the composite printinglayer is a longitudinally-stretched polyethylene printing film; the direction from the composite printing layer to the composite heat sealing layer is from outside to inside, and the composite printing layer comprises a printing layer outer layer, a printing layer middle layer and a printing layer inner layer in sequence; the bonding layer is a low-density polyethylene film or a solvent-free gluelayer; the composite heat-seal layer is a multi-layer co-extrusion polyethylene heat-seal film and comprises a heat-seal layer outer layer, a heat-seal layer middle layer and a heat-seal layer inner layer in sequence. Experimental results show that the polyethylene composite film capable of 100% recovery can be recycled by 100%, and has the characteristics of small thickness, low density, punctureresistance and low unsealing temperature.

Owner:江门市华龙膜材股份有限公司

Manufacturing process for heat transfer film

InactiveCN105479962AGood dimensional stabilityRich layersDuplicating/marking methodsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a manufacturing process for a heat transfer film. The manufacturing process comprises the steps of preparing a raw material, unreeling, coating a mold releasing agent, coating printing ink and coating glue agent. Polyethylene terephthalate (PET) is selected for a raw material substrate thin film which has the characteristics of being good in dimensional stability, uniform in tension and good in heat-resisting effect and mold releasing property. The solid content of the mold releasing agent is controlled to be 20%-25%, so that the defect that the volatile speed of solvent in the mold releasing agent is high and the drawback that the transferring effect is not obvious are overcome. Hot melt glue is selected for the glue agent, after the glue agent is coated and dried to form a film, the film texture is transparent, the surface where the mold releasing agent and the printing ink are coated has the excellent composite fastness and the distinguished flexibility, and the capacity of resisting friction, water, acid, alkali and other mediums is high. According to the transfer film produced through the process, multi-color patterns can be mapped at a time, color registering is not needed, layers of printed patterns are rich, and the color difference is small.

Owner:丹阳市华兴纸箱有限公司

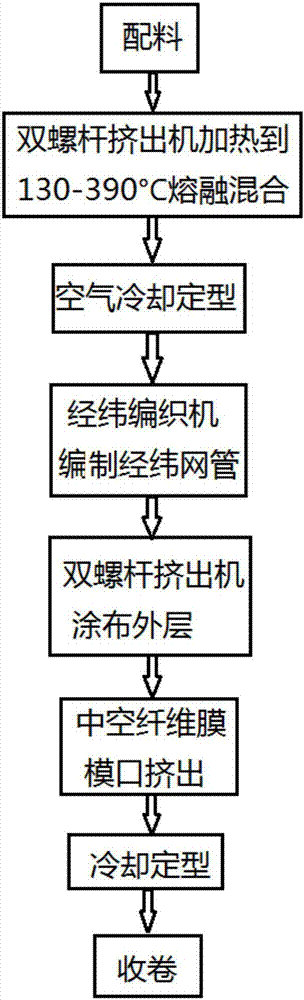

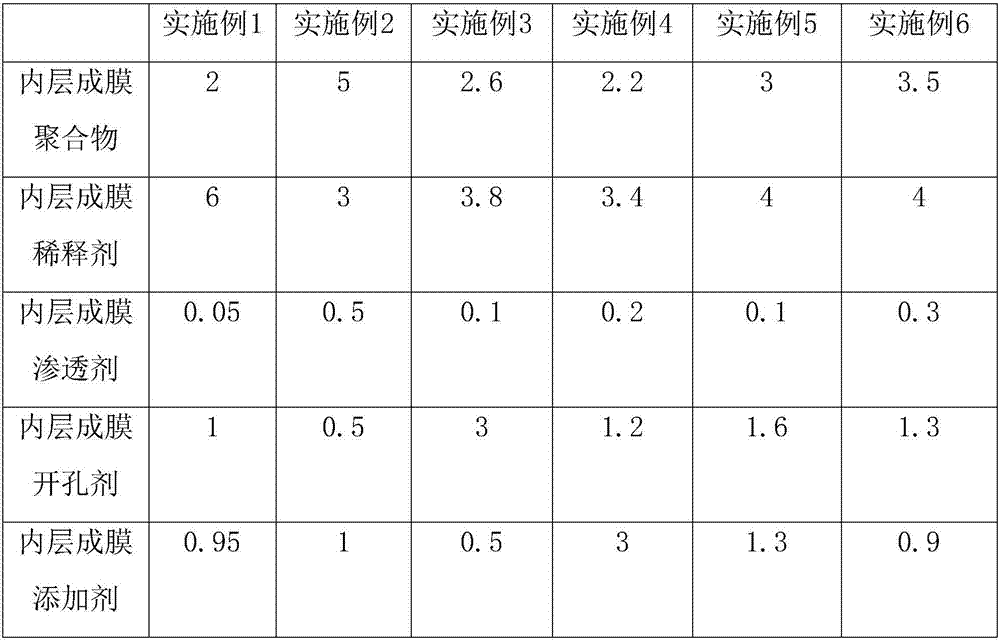

Manufacturing method of inner pressure pipe type multilayer composite film

InactiveCN107308825AImprove efficiencyExtended service lifeSemi-permeable membranesInternal pressureComposite film

The invention discloses a manufacturing method of an inner pressure pipe type multilayer composite film. The manufacturing method comprises: a, uniformly mixing a film forming polymer, a film forming diluent, a film forming penetrant, a film forming pore forming agent and a film forming additive according to a certain mass percentage ratio, heating to a temperature of 130-390 DEG C with an extrusion molding machine through a thermally induced phase separation method, melting, uniformly mixing, extruding with a pipe type film inner film mold, and cooling to obtain the inner layer film of a pipe type film; b, weaving a warp and weft mesh pipe outside the inner layer film by using a warp and weft weaving machine, wherein it is ensured that the warp and weft mesh pipe is tightly attached to the surface of the inner layer film; c, coating the inner layer film outer layer attached to the warp and weft mesh pipe with a layer of an outer layer film; and d, extracting the prepared inner pressure pipe type multilayer composite film semi-finished product by using ethanol or isopropanol to obtain the inner pressure pipe type multilayer composite film finished product. According to the present invention, the inner pressure pipe type multilayer composite film has advantages of good separation performance, good compounding fastness and good mechanical property, the area of the effective filtration membrane can be increased, and the breaking of the film pipe and the damage caused by the separating and the layering between the filtration membrane layer and the support layer can be effectively avoided, such that the use efficiency and the service life of the film can be improved.

Owner:李月玲

BOPET film for metal compounding and preparation method thereof

ActiveCN109251485AComposite fastness is goodImprove efficiencySynthetic resin layered productsBoPETBottle

The invention relates to a BOPET film for metal compounding and a preparation method thereof. The BOPET film for metal compounding consists of an upper surface layer, a core layer and a lower surfacelayer. The core layer is composed of: 60%-80% of PET polyester chips, 10%-20% PBT polyester chips and 10%-20% of neopentylene glycol copolymerization modified PET polyester chips. The upper surface layer is composed of: 40%-60% of bottle grade PET polyester chips and 40%-60% of PET polyester anti-stick masterbatch. The lower surface layer is methyl methacrylate graft copolymerization modified PETGheat-seal chip. Compared with the traditional BOPET films and BOPET heat-seal films, the BOPET film for metal compounding provided by the invention has excellent performance in terms of heat sealing,fracture nominal strain, heat shrinkage, etc., and can achieve good compounding fastness after hot lamination with metals. Through hot pressing lamination with iron plates, steel plates, aluminum plates and other metals, the BOPET film can be used for production and manufacturing of chemical tanks, food cans and capacitors. Compared with the traditional iron printing process, the products produced by thermal lamination of the BOPET film with metals have more advantages in performance, material cost, production cost, environmental protection, energy consumption and other aspects.

Owner:ANHUI GUOFENG PLASTIC

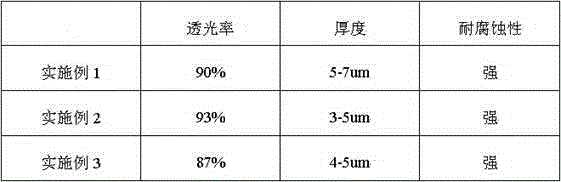

Lithium battery packaging film with high barrier, acid resistance and alkali resistance

InactiveCN101774450AImprove corrosion resistanceImprove buffering effectFlexible coversWrappersPolypropyleneHeat treated

The invention discloses a lithium battery packaging film with high barrier, acid resistance and alkali resistance, which is manufactured through the following steps of: using a special aluminum alloy aluminum layer as an intermediate base layer, thermally processing the aluminum alloy aluminum layer, respectively plating a layer of functional nanometer silicon material on the upper and lower surface layers of the aluminum alloy aluminum layer, thermally processing through a special process, processing an inner layer and an outer layer with a nanometer barrier and an insulating coating liquid twice; and attaching a layer of high-strength nylon layer to the outer layer of the aluminum alloy aluminum layer, and attaching a layer of polypropylene layer made from nanometer macromolecular materials to the inner layer of the aluminum alloy aluminum layer. By adequately adopting the extreme flexibility, ductility performance, extremely high corrosion resistance and barrier performance of alloy aluminum foil after the alloy aluminum foil is functionally processed, the manufactured lithium battery packaging film has excellent performances such as excellent insulation, cold punching resistance, corrosion resistance, high barrier, high strength and the like.

Owner:SUZHOU JUNYUE NEW MATERIAL TECH

Biodegradable high-barrier paper-plastic packaging composite film and preparation method thereof

ActiveCN113619242AGreat print lookImprove display effectFlexible coversWrappersElastomerPolymer science

The invention provides a biodegradable high-barrier paper-plastic packaging composite film and a preparation method thereof. The biodegradable high-barrier paper-plastic packaging composite film sequentially comprises an ink layer, a paper layer, a barrier coating, a bonding layer and a PLA layer from outside to inside, wherein the PLA layer is modified by a thermoplastic elastomer, and after modification, the temperature resistance and toughness of the PLA layer can be improved, heat sealing performance is ensured, and the packaging requirements of different contents and different weights are met; and the barrier coating can ensure that a final finished product has good barrier property and prolongs the shelf life of the contents. The biodegradable high-barrier paper-plastic packaging composite film has the advantages of being exquisite in printing appearance, good in display effect and the like, is made of degradable materials, can be biodegraded after being used, and is free of pollution to the environment.

Owner:JIANGSU LEATER GREEN PACKAGING CORP LTD

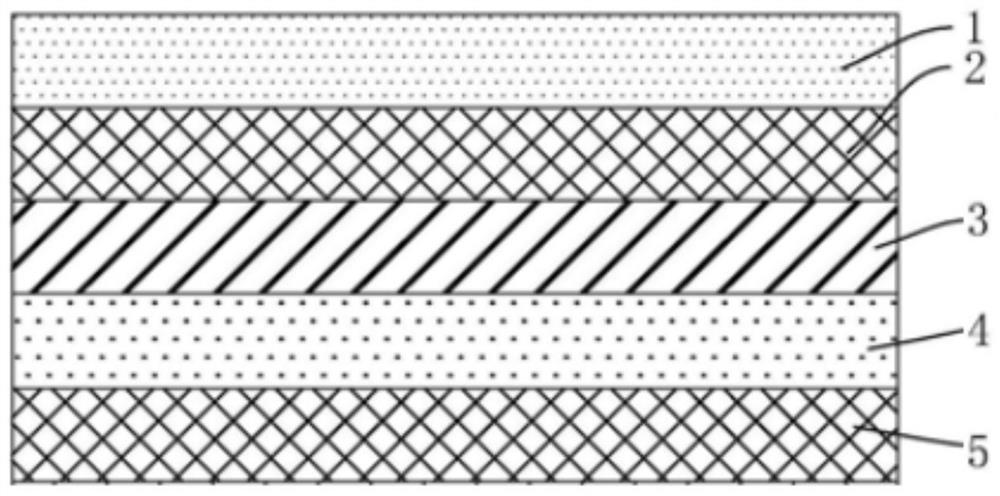

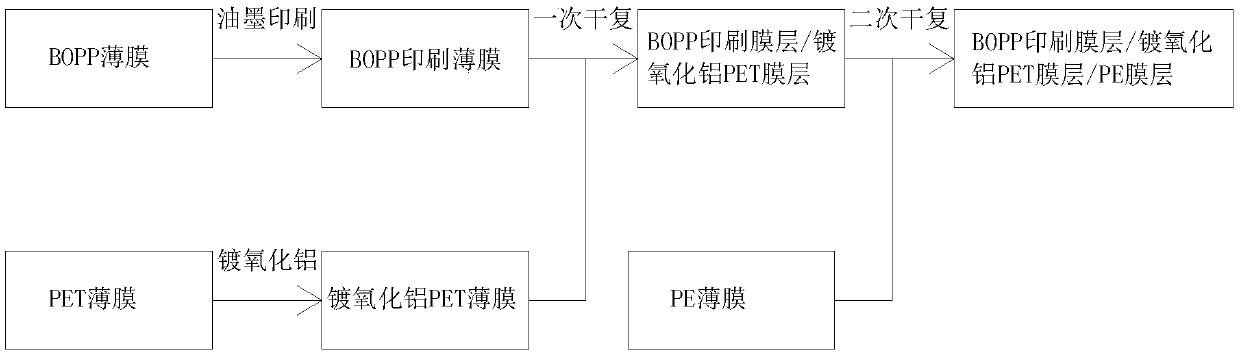

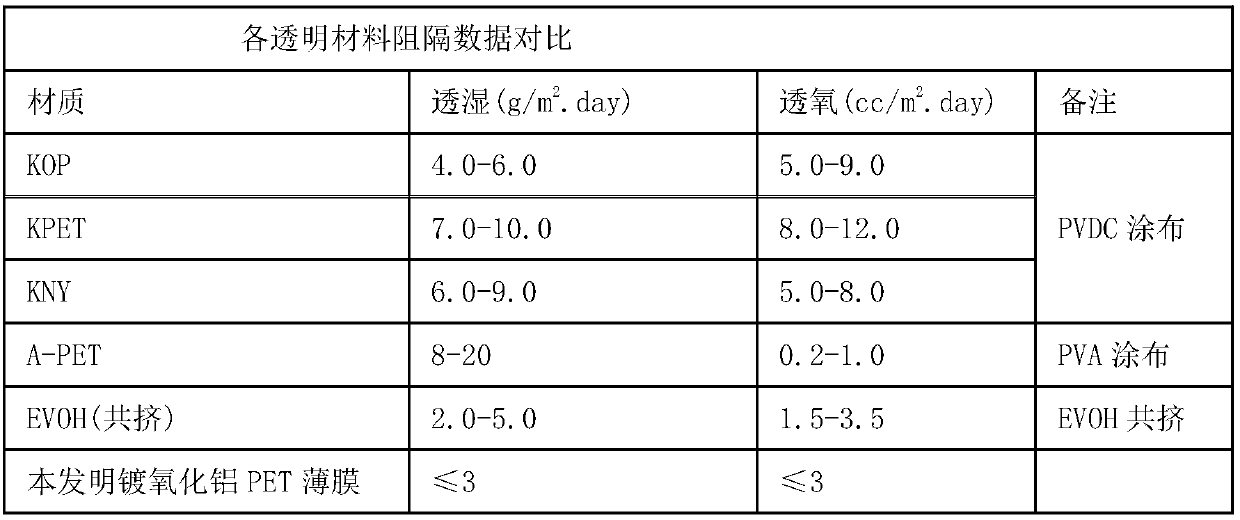

Transparent high-barrier film applicable to high-speed automatic packaging and production method thereof

InactiveCN108673989AImprove barrier propertiesExcellent odor barrierPolyureas/polyurethane adhesivesSynthetic resin layered productsWater vaporMicrometer

The invention relates to a transparent high-barrier film applicable to high-speed automatic packaging and a production method thereof. The material structure of the transparent high-barrier film comprises a BOPP printing film layer, an aluminum oxide plated PET film layer and a PE film layer, wherein the aluminum oxide coating of the aluminum oxide plated PET film layer is compounded with a printed surface of the BOPP printing film layer; the thickness of the aluminum oxide coating is 0.15 to 0.25 micrometers; the thickness of the BOPP printing film layer is 18 to 20 micrometers; the thicknessof the aluminum oxide plated PET film layer is 12 to 14 micrometers; the thickness of the PE film layer is 30 to 35 micrometers. The transparent high-barrier film not only has barrier property on oxygen and water vapor, but also has excellent odor barrier property, has fragrance keeping function, and further has excellent transparency and heat sealing strength.

Owner:HUANGSHAN NOVEL

Water-borne paper-plastic laminating adhesive and preparation method thereof

InactiveCN102250566AImprove the finishImprove protectionMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerAdhesive

The invention discloses a water-borne paper-plastic laminating adhesive and a preparation method thereof. The laminating adhesive comprises 30 to 50 parts of butyl acrylate, 40 to 50 parts of vinyl acetate, 3 to 10 parts of acrylic acid, 2 to 3 parts of crosslinking monomer and 0 to 3 parts of other functional monomers. The invention hast the advantages that: the water-borne paper-plastic laminating adhesive is safe, nontoxic, non-combustible and nonexplosive, and has good weatherability and good laminating fastness; and a laminated product has high finishment and good performance.

Owner:范会生

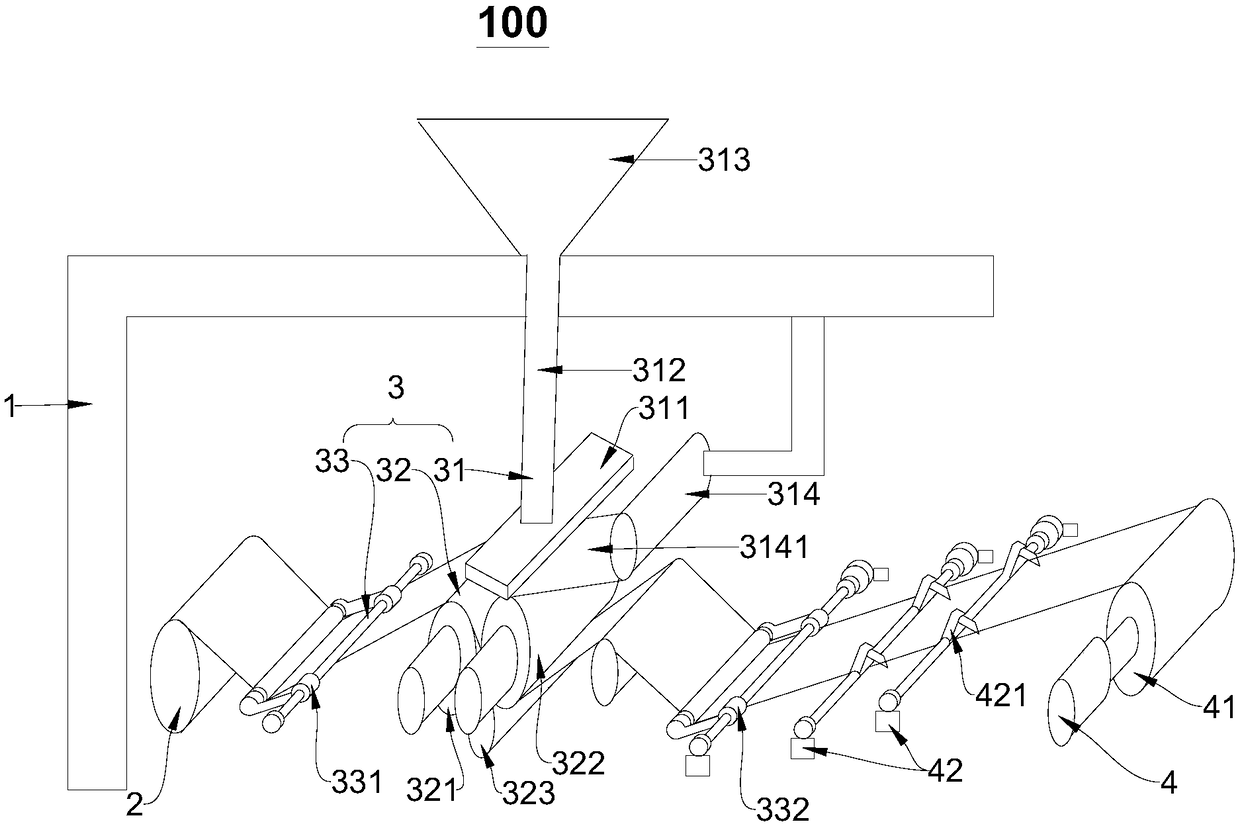

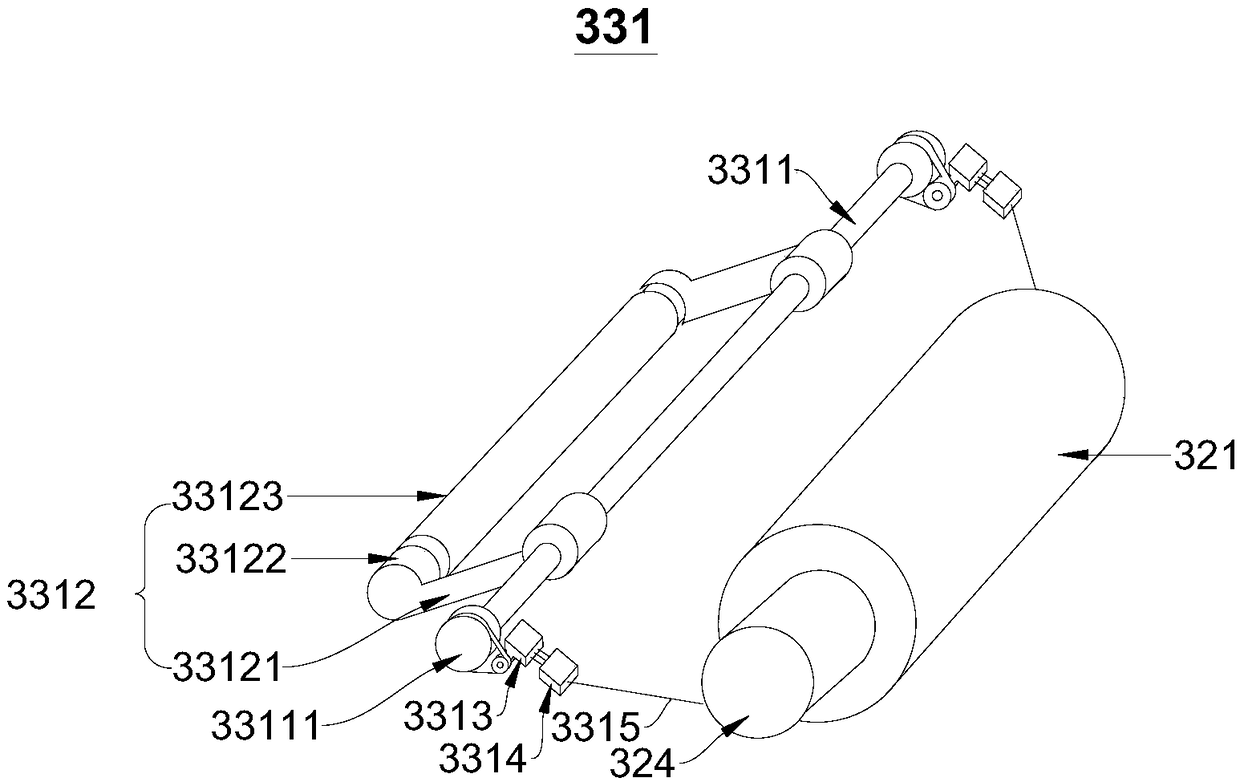

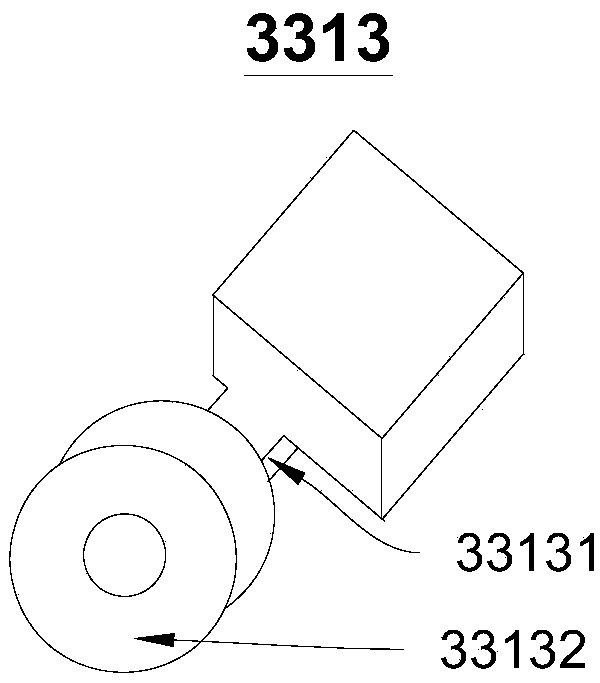

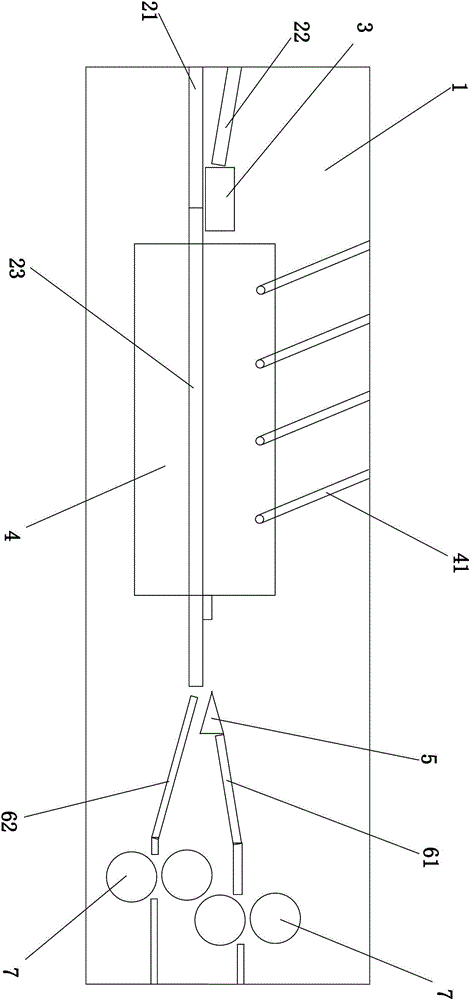

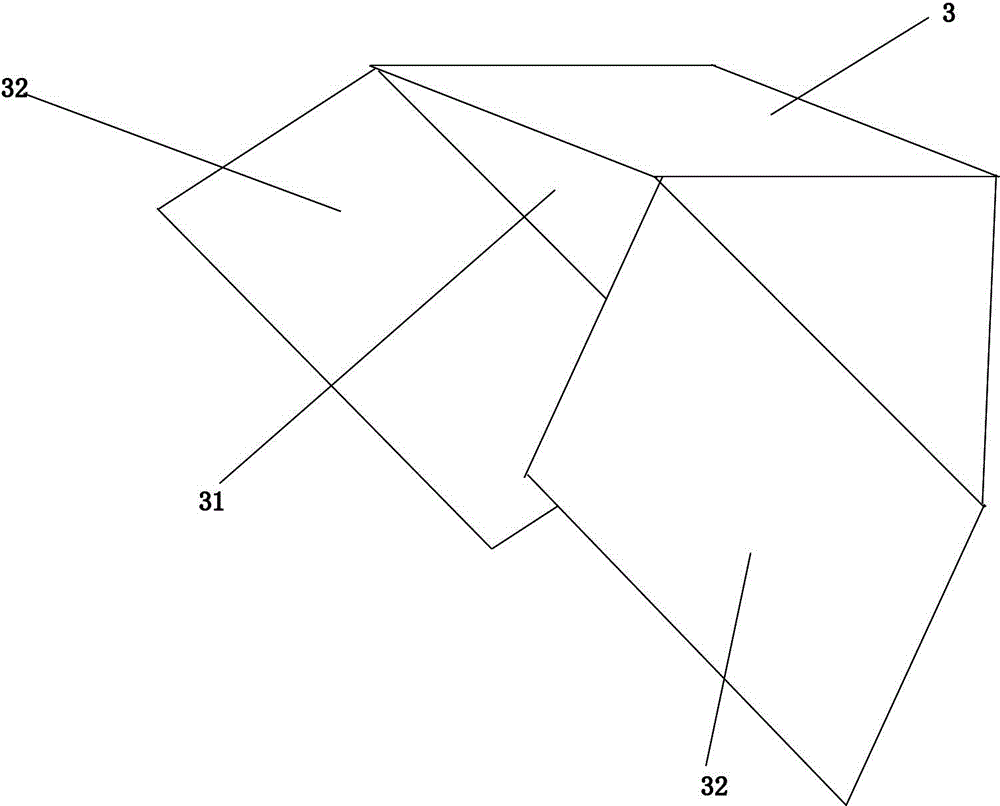

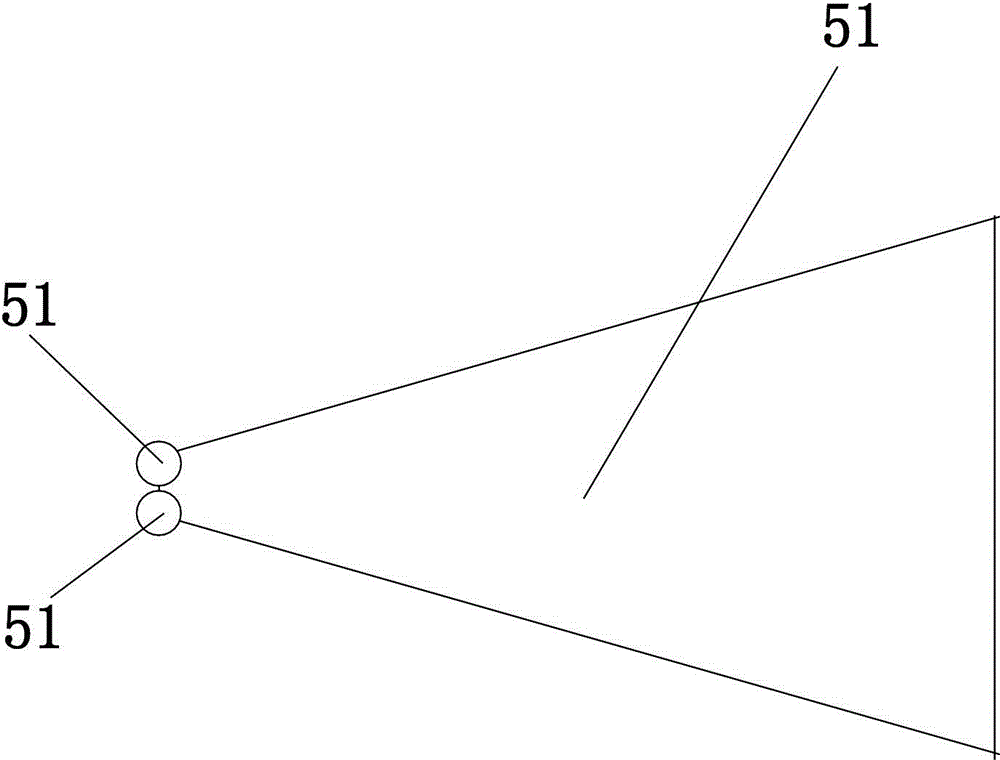

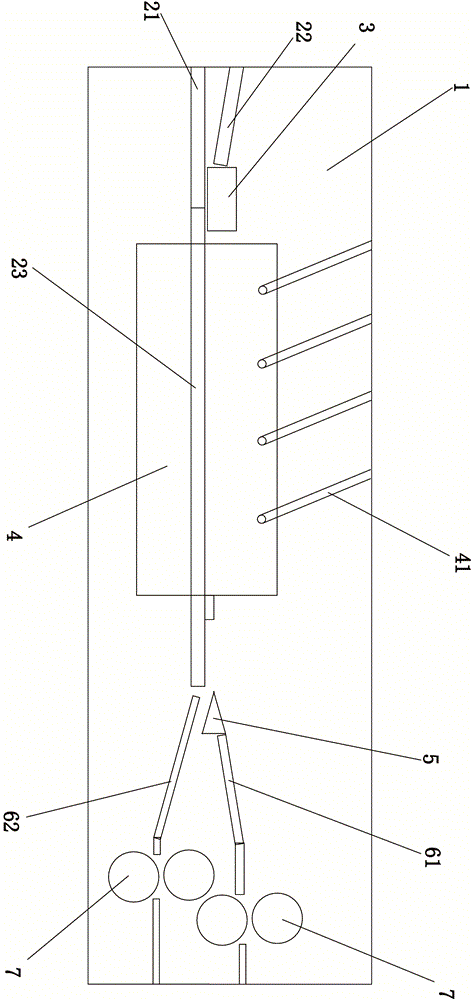

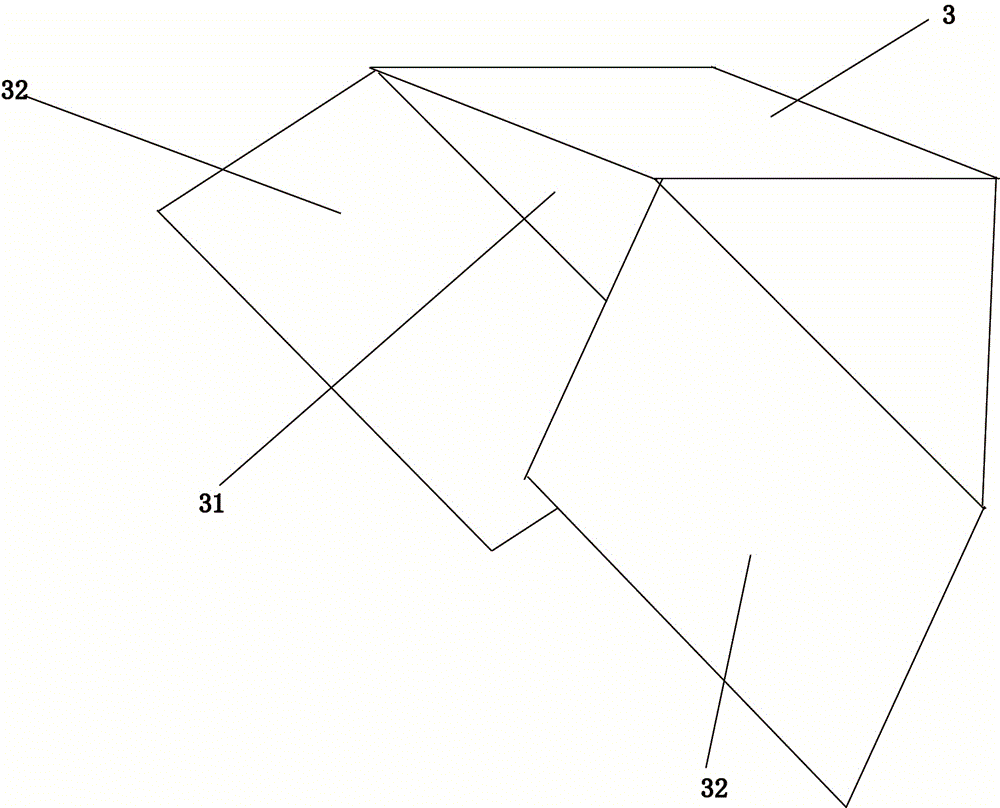

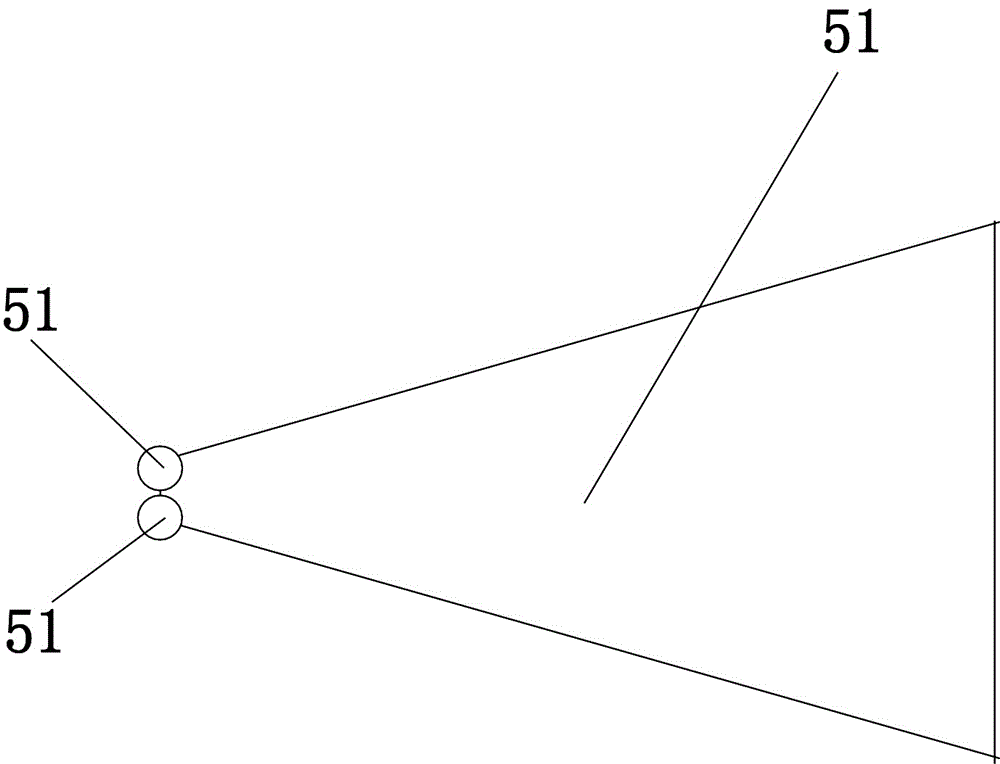

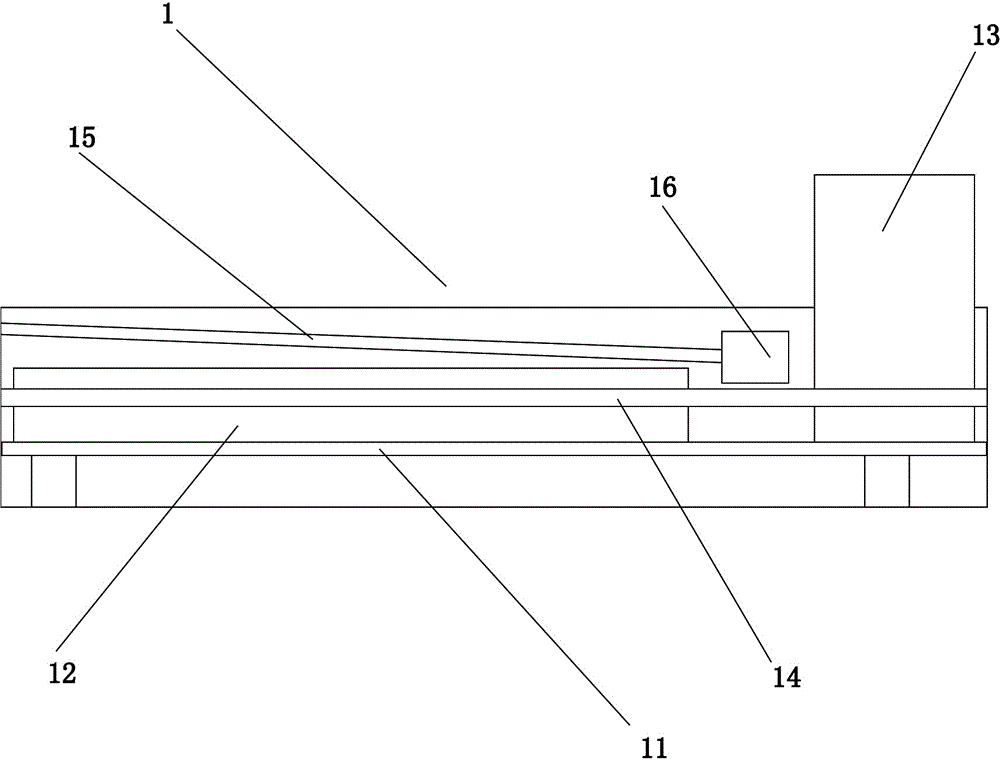

Online laminating equipment and laminating machine for packing bag production

PendingCN108993825AImprove compound level stabilityImprove efficiencyLiquid surface applicatorsLaminationEngineeringMechanical engineering

The invention provides online laminating equipment and a laminating machine for packing bag production and relates to the field of laminating equipment. The online laminating equipment comprises a non-woven fabric forming machine, the laminating machine, a rolling machine and a support. The laminating machine is arranged between the non-woven fabric forming machine and the rolling machine, and thetop end of the laminating machine is fixed to the support. The laminating machine comprise a composite device, a laminating device and a swinging roller device. The swinging roller device comprises afront swinging roller device used for controlling composite smooth of non-woven fabrics and a rear swinging roller device used for controlling the perimeter of the laminated non-woven fabrics to be stable. The non-woven fabrics on the non-woven fabric forming machine sequentially pass through the front swinging roller device, the composite device and the rear swinging roller device to be connected with the rolling machine. According to the online laminating equipment, the production efficiency is improved, the labor cost is reduced, the yield of materials is increased, and the quality is morestable. The invention further provides the laminating machine for packing bag production. The composite smooth stability of the materials is improved.

Owner:四川省开璞环保包装制品有限公司

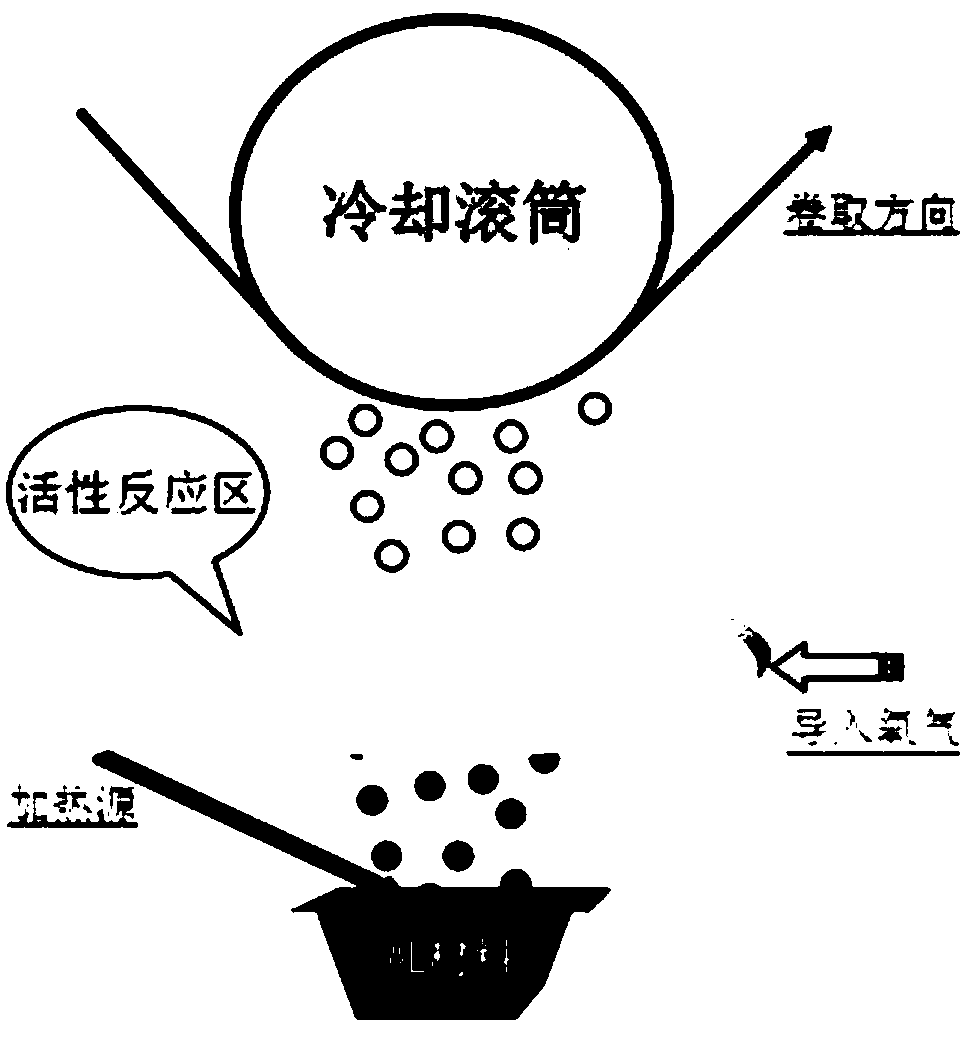

Plastic blown film compounding and manufacturing method

The invention discloses a plastic blown film compounding and manufacturing method which comprises the following steps: performing melt extrusion on plastic raw materials by virtue of an extrusion unit, and allowing the raw materials to enter a co-extrusion die head; extruding the melted materials from the co-extrusion die head, performing air inflation, upwards pulling and cooling to form film bubbles, exhausting the film bubbles by virtue of a cooling traction device, and cooling and flattening by virtue of a flattening roller to obtain film; trimming, separating the film into two pieces, performing hot-pressing on each film and a base film unwound by a composite unwinding device by virtue of a composite hot-pressing system, and laminating the film and base film to form a composite film; and winding the finished composite film by virtue of a slitting and winding system. According to the method disclosed by the invention, an adhesive is not adopted, use of a solvent can be effectively avoided, the manufacturing process is simple, and the compound fastness is high.

Owner:佛山市联塑万嘉新卫材有限公司

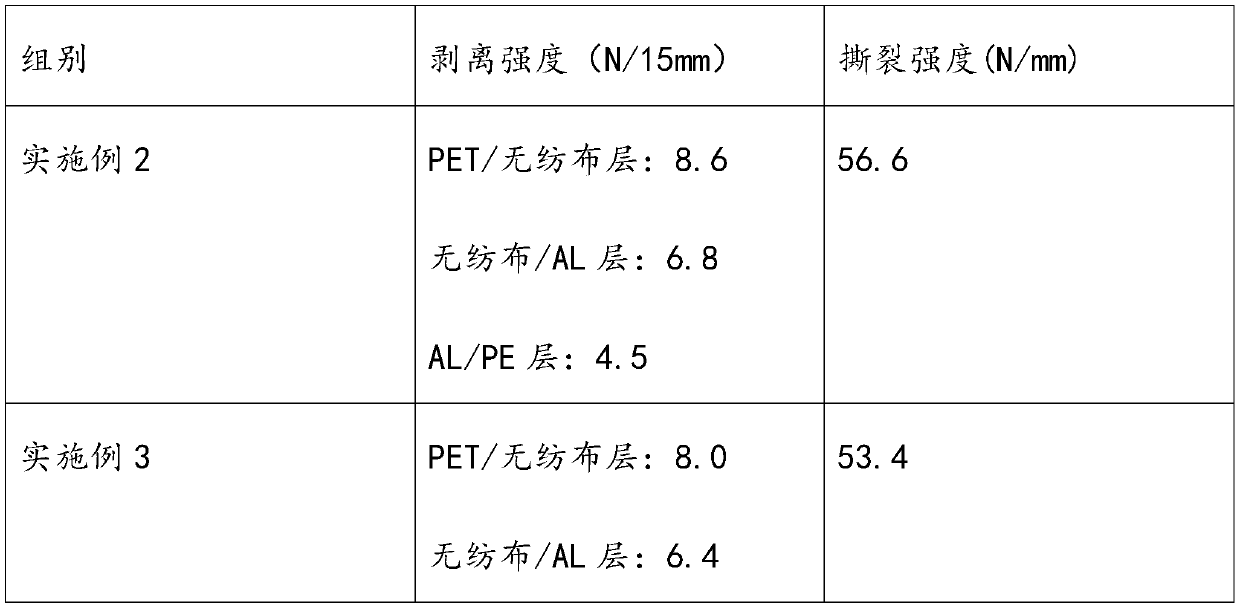

Composite bag made of non-woven fabric material

PendingCN110421916AMoisture-proofBreathablePackage recyclingSynthetic resin layered productsCombustionDecomposition

The invention relates to the field of packaging materials, and in particular relates to a composite bag made of a non-woven fabric material, the composite bag comprises a surface printing layer, a reinforcing layer, a barrier layer and an inner film layer which are sequentially arranged, wherein the reinforcing layer is the non-woven fabric; the reinforcing layer is made of the non-woven fabric, the reinforcing layer is arranged in the composite bag; the non-woven fabric has the advantages of moisture resistance, ventilation, flexibility, light weight, no combustion supporting, easy decomposition, no toxicity, no irritation, rich colors, low price and recyclability; and the non-woven fabric has better tear resistance, so that the tear resistance of the composite bag can be improved.

Owner:ZHEJIANG GOLDSTONE PACKING

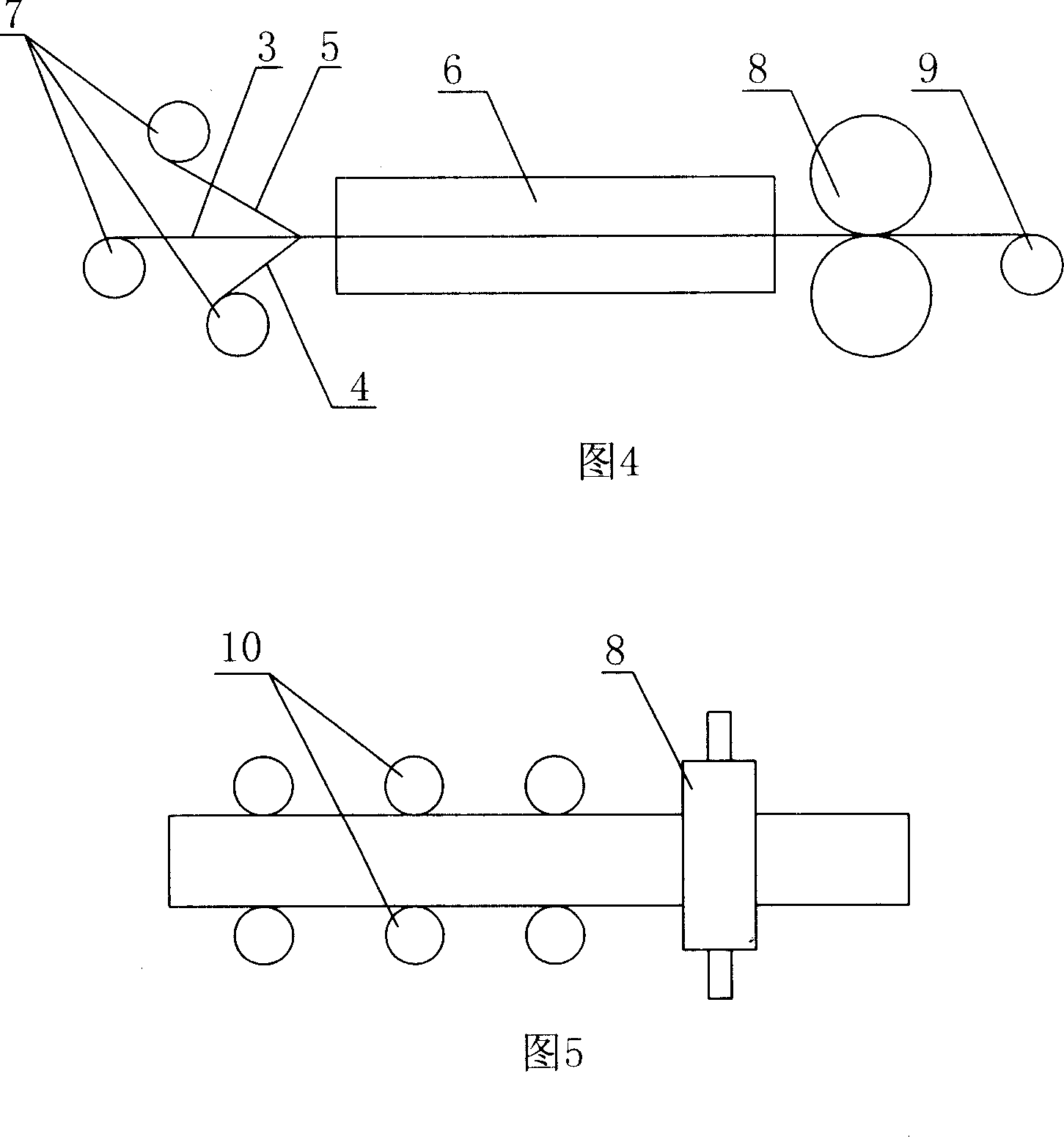

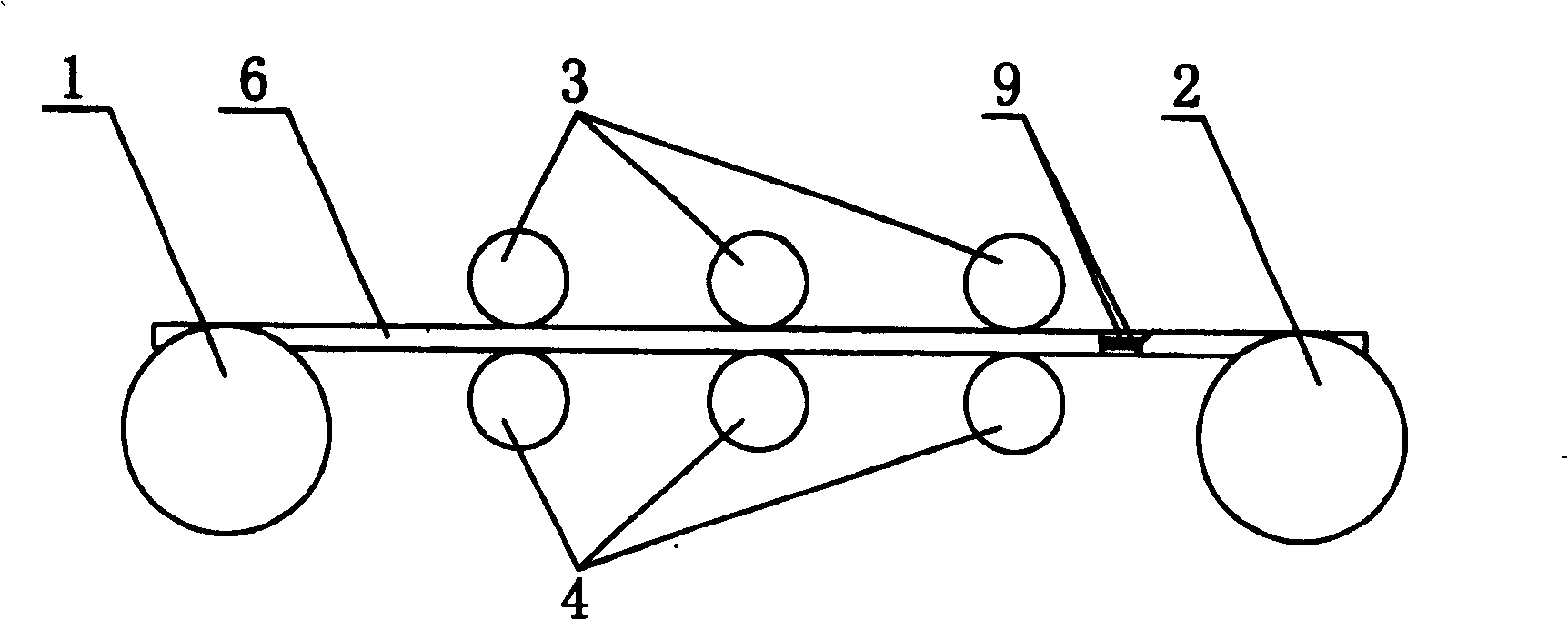

Composite silver tape manufacturing method and manufacturing equipment

The invention discloses a composite silver tape manufacturing method and a piece of manufacturing equipment, and relates to an electric contact material manufacturing method and equipment. The working process of the method comprises the steps of silver metal oxide tape and copper tape pre-processing, silver metal oxide tape and copper tape heating, silver oxide tape and copper tape compositing, composite tape annealing, composite tape precision-rolling, composite tape stress eliminating, composite tape anti-oxidation, composite tape slitting, composite tape inspection, and the like. Compared with the prior art, the beneficial effect is that the silver metal oxide tape can be prevented from contacting the outside in the heating process, and the problem that the silver metal oxide is reduced and the performance of the composite silver tape is lowered due to reduction reaction between the protective atmosphere and the silver metal oxide tape is avoided. Moreover, the silver metal oxide tape is put in a slot arranged on the copper tape and hot-rolled, which makes the bonding strength of the composite silver tape higher and compositing fastness higher.

Owner:宁波科扬贵金属合金科技有限公司

Special copper-aluminum alloy foil composite moistureproof and heatproof film

InactiveCN108336254AImprove buffering effectIncrease elasticityMaterial nanotechnologyCells cooling/heatingNano al2o3Alloy

The invention discloses a special copper-aluminum alloy foil composite moistureproof and heatproof film. The film is formed by using a copper-aluminum alloy foil as a middle base layer, attaching a second nano Al2O3 layer on the upper surface of the copper-aluminum alloy foil, attacking a polypropylene and nylon copolymer film on the upper surface of the second nano Al2O3 layer, attacking a firstnano Al2O3 layer on the lower surface of the copper-aluminum alloy foil and attaching a polypropylene layer on the lower surface of the first nano Al2O3 layer; each of the first nano Al2O3 layer and the second nano Al2O3 layer is formed by coating the copper-aluminum alloy foil with nano Al2O3, heating for treatment and coating the outer surface of the copper-aluminum alloy with nano blocking andinsulating coating liquid. The special copper-aluminum alloy foil composite mmoistureproof and heatproof film has excellent insulativity, resistance to cold stamping and corrosion, high blocking performance and high strength.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

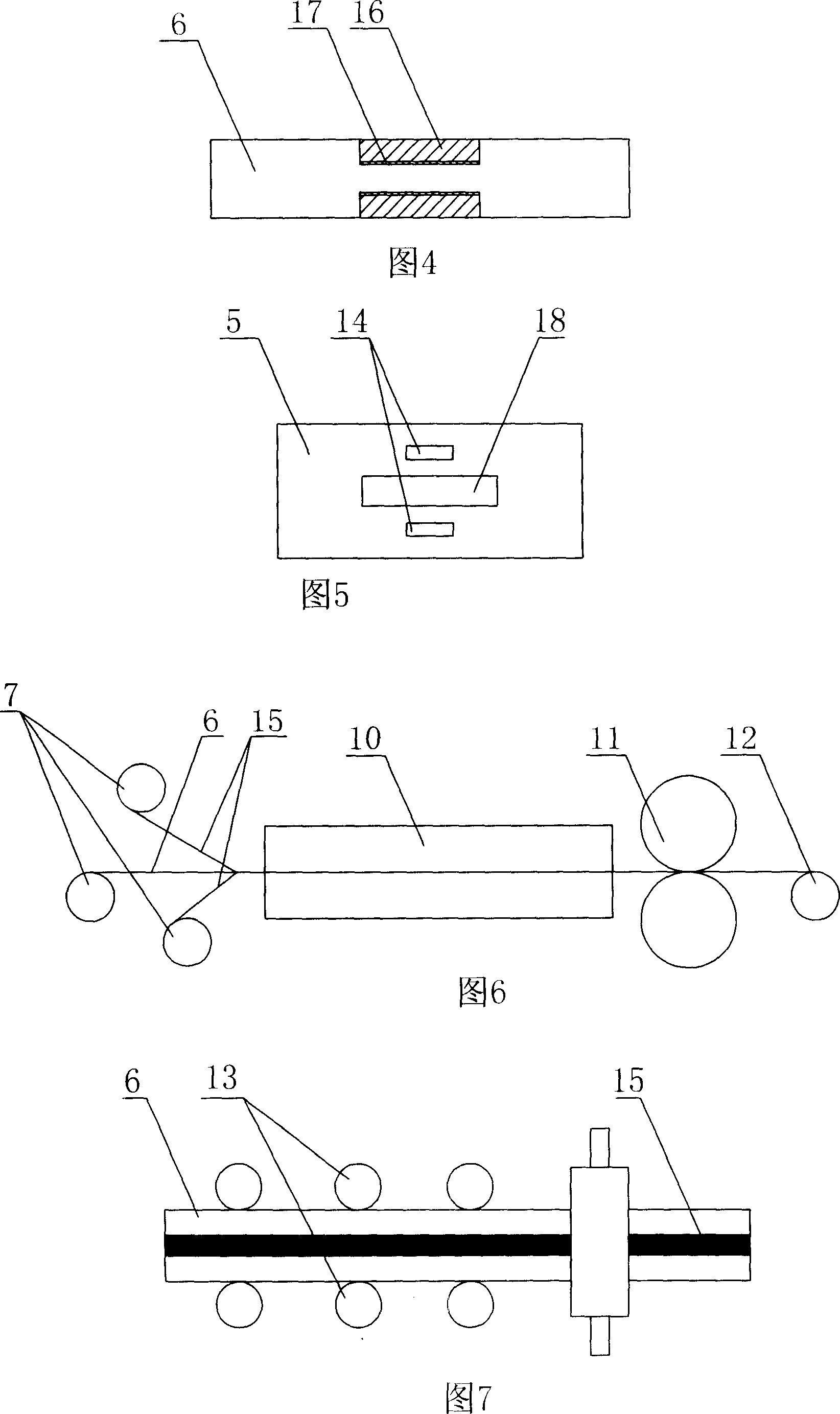

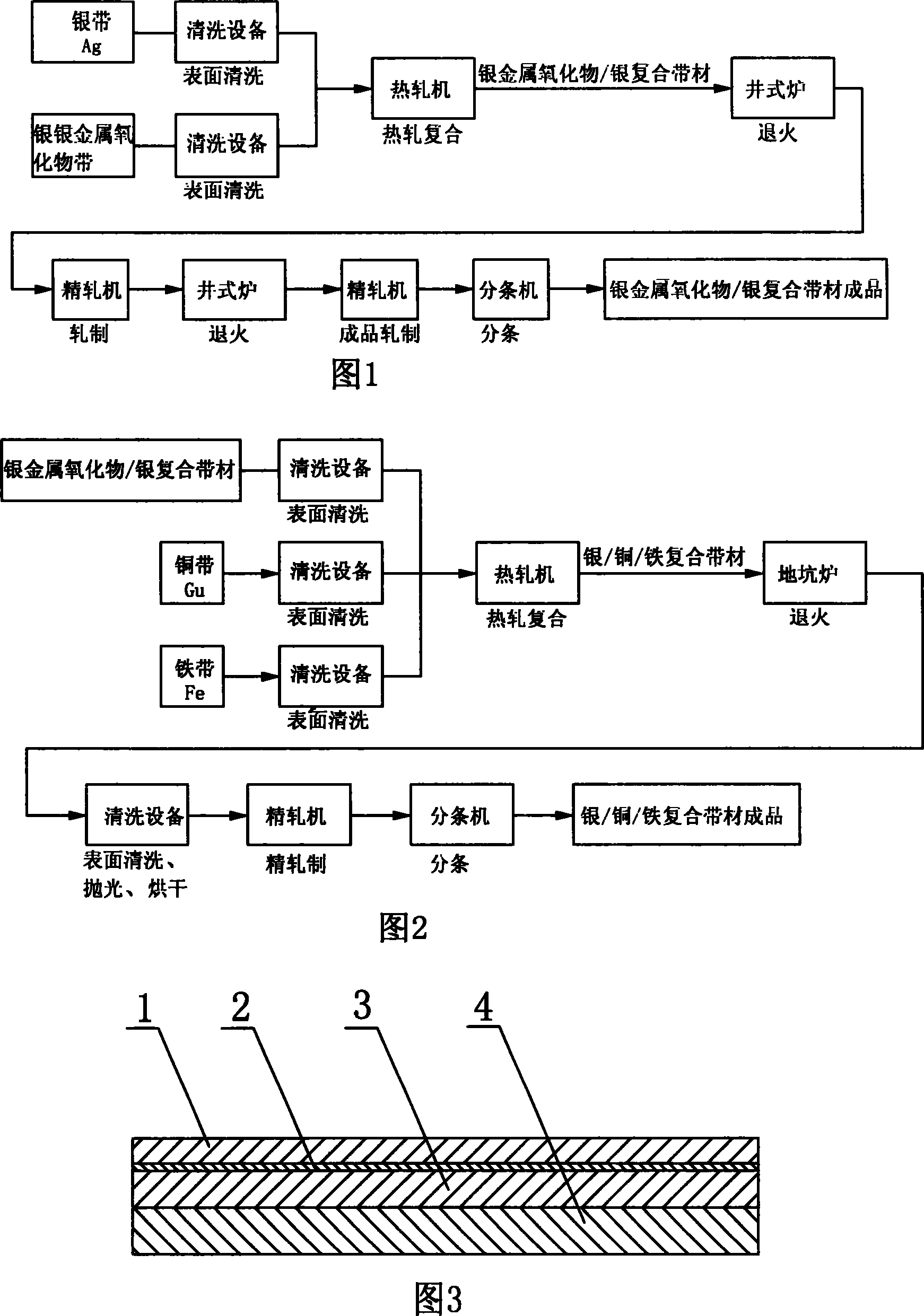

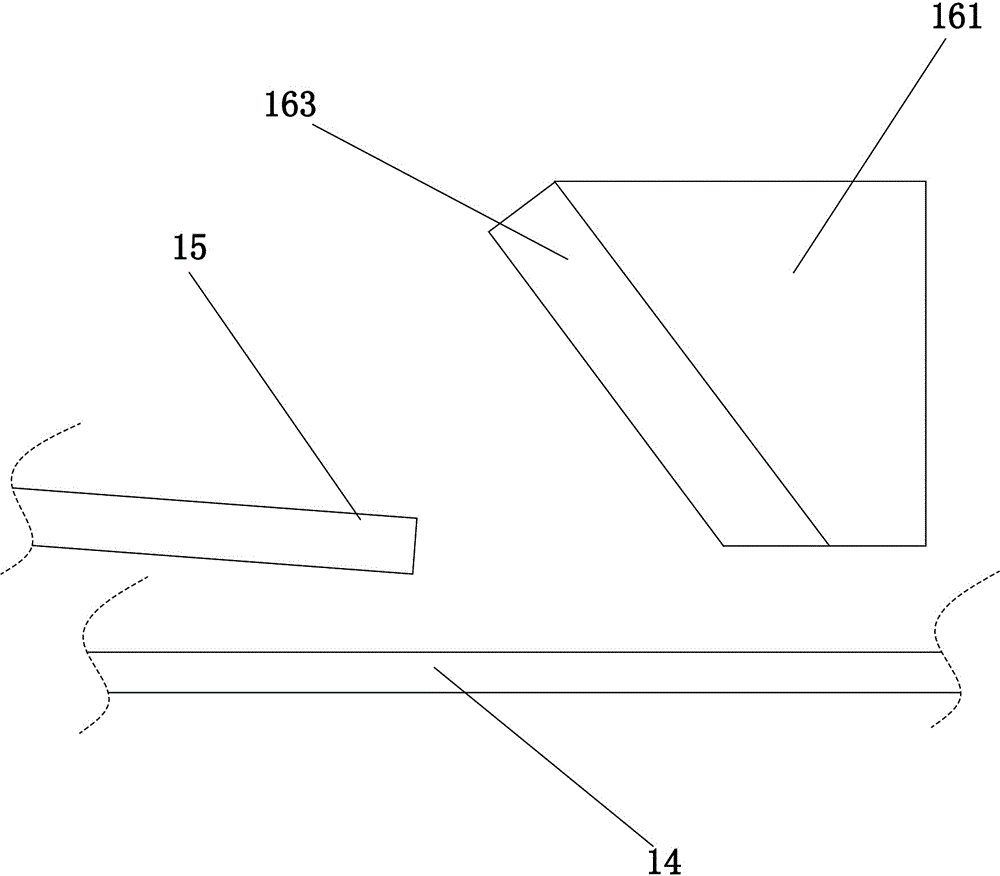

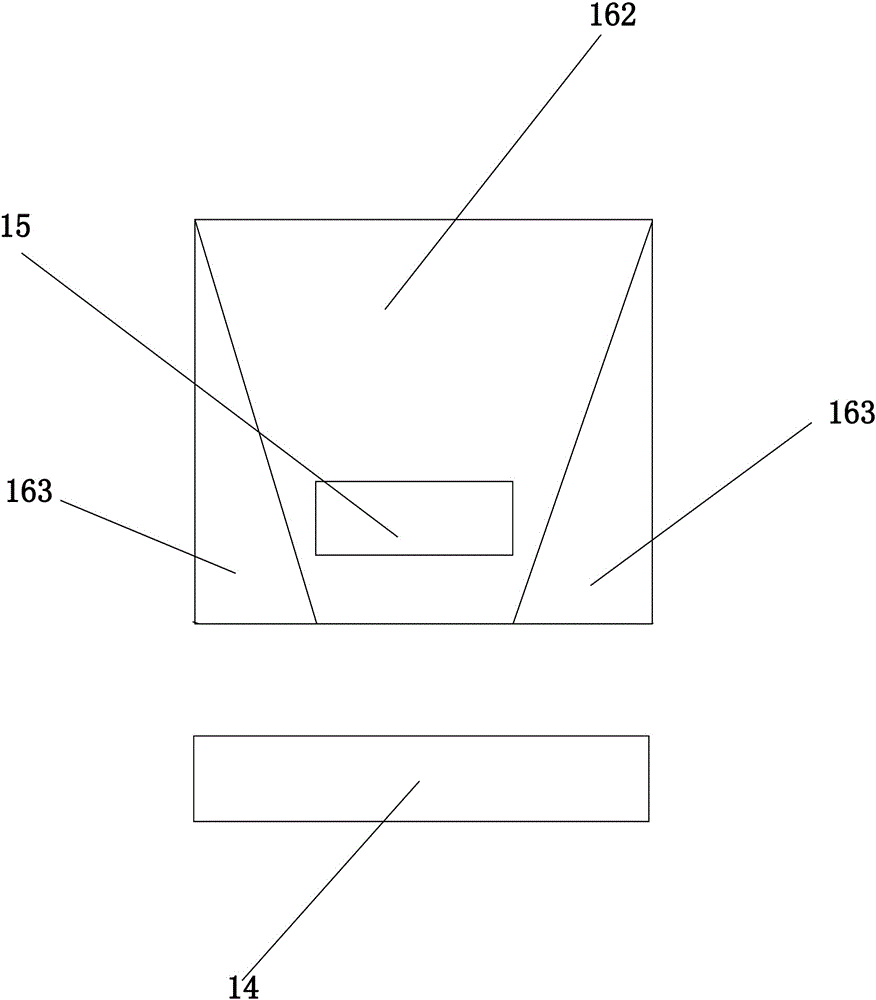

Manufacturing method and manufacturing equipment of composite silver strip

ActiveCN105047455AImprove bindingComposite fastness is goodElectric switchesMetal rolling arrangementsStress relievingOxidation resistant

The invention discloses a manufacturing method and manufacturing equipment of a composite silver strip, and relates to manufacturing methods and manufacturing equipment of electrical contact materials. The method comprises the following working processes: early treatment of a silver metal oxide strip and a copper strip, heating of the silver metal oxide strip and the copper strip, compounding of a silver oxidation strip and the copper strip, annealing of a composite strip, finish-rolling of the composite strip, stress removal of the composite strip, antioxidation of the composite strip, striping of the composite strip, and testing of the composite strip. Compared with the prior art, the manufacturing method and the manufacturing equipment have the beneficial effects that the silver metal oxide strip can be prevented from contacting the outside in the heating process; the problems that protective atmosphere and the silver metal oxide strip are subjected to reduction reaction, so that the silver metal oxide is reduced and the performance of the composite silver strip is reduced are avoided; and meanwhile, the silver metal oxide strip is put into a groove in the copper strip and then is subjected to heat press-rolling, so that the composite silver strip is relatively high in bonding strength and relatively good in compound fastness.

Owner:宁波科扬贵金属合金科技有限公司

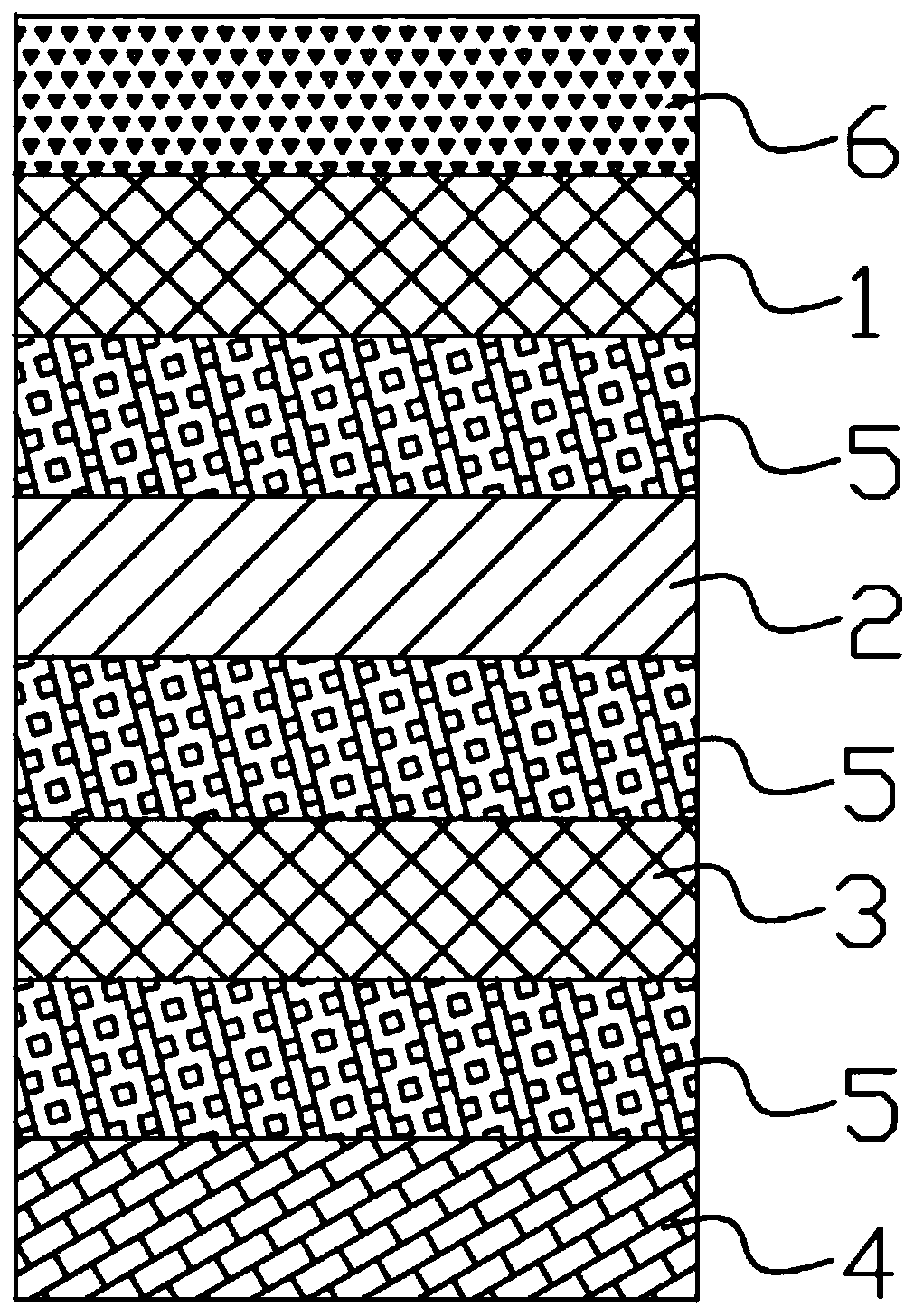

Aluminum foil woven fabric and preparation method thereof

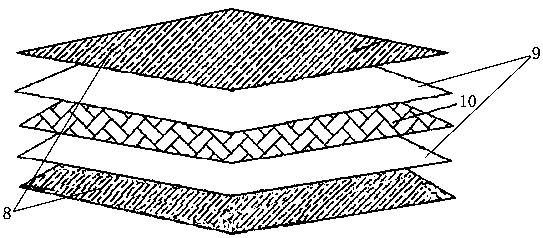

PendingCN107244107AImprove flame retardant effectComposite fastness is goodFlexible coversWrappersWoven fabricCalcium carbonate

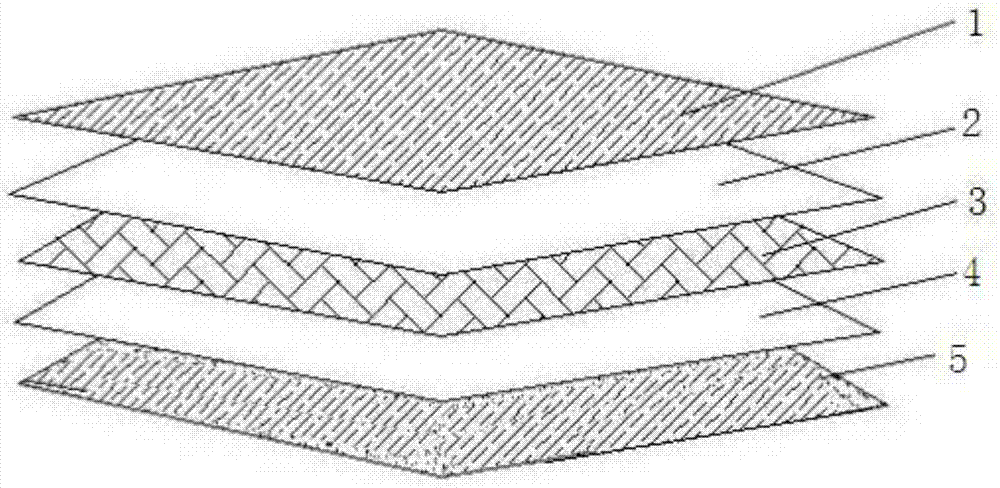

The invention discloses an aluminum foil woven fabric which consists of an upper aluminum foil layer, a flame retardant adhesive layer, a flame retardant woven fabric layer, a film lamination layer and a lower aluminum foil layer which are arranged in sequence from top to bottom, wherein the upper and lower aluminum foil layers are high-purity aluminum foils with the aluminum content of 99 percent; the flame retardant adhesive layer is calcium carbonate-added polyurethane composite glue; the flame retardant woven fabric layer is a low-pressure high-density polyethylene woven fabric; the film lamination layer consists of low-density polyethylene particles; the upper surface of the flame retardant woven fabric layer is compounded with the upper aluminum foil layer through the polyurethane composite glue; the lower surface of the flame retardant woven fabric layer is compounded with the lower aluminum foil layer through the melted low-density polyethylene particles in an adhered manner. According to the aluminum foil woven fabric prepared through the method, on the premise of not affecting the compound fastness and the physical performance of the material, the flame retardancy of the whole material is improved, and heat insulation and preservation of buildings home and abroad and flame retardancy of special packaging materials are met; the aluminum foil woven fabric is heat-insulated, waterproof, breathable and reflexible, can meet a heat insulation requirement, and is wide in application range and high in economical benefit.

Owner:ZHEJIANG PENGYUAN NEW MATERIAL TECH GRP CO LTD

Machining technique of silver/copper double composite strip material

Owner:东莞市中一合金科技有限公司

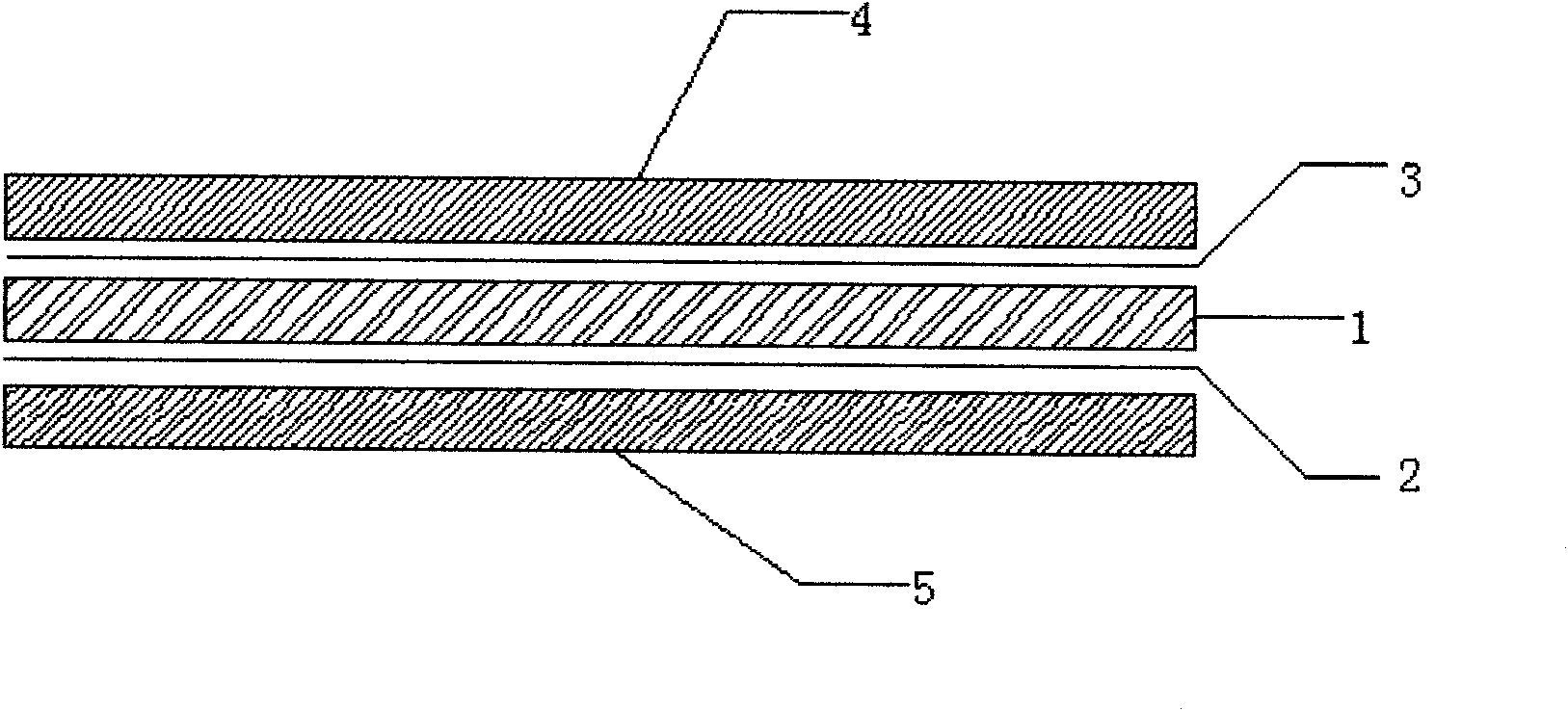

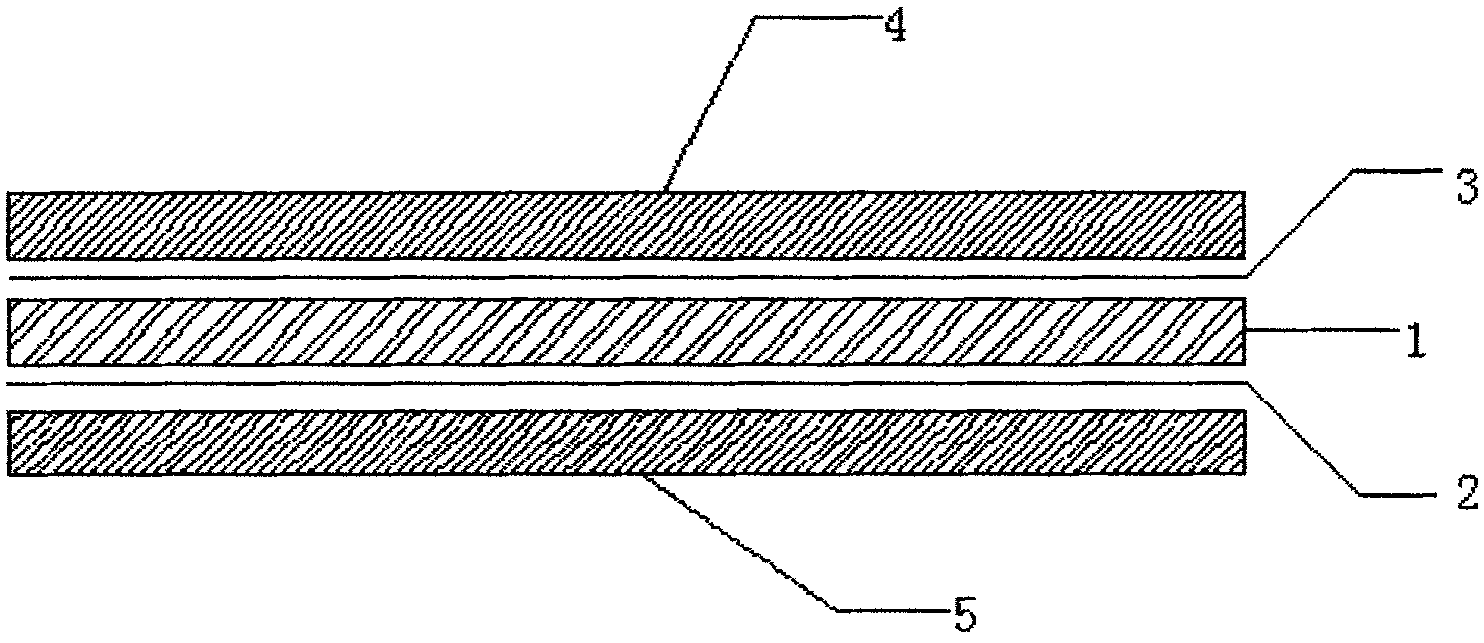

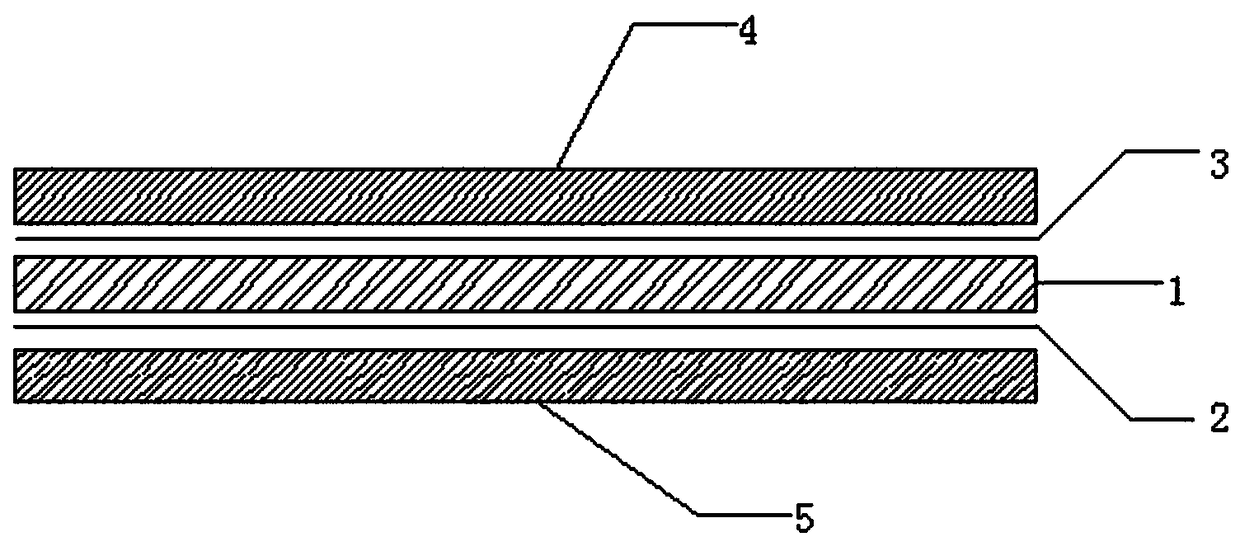

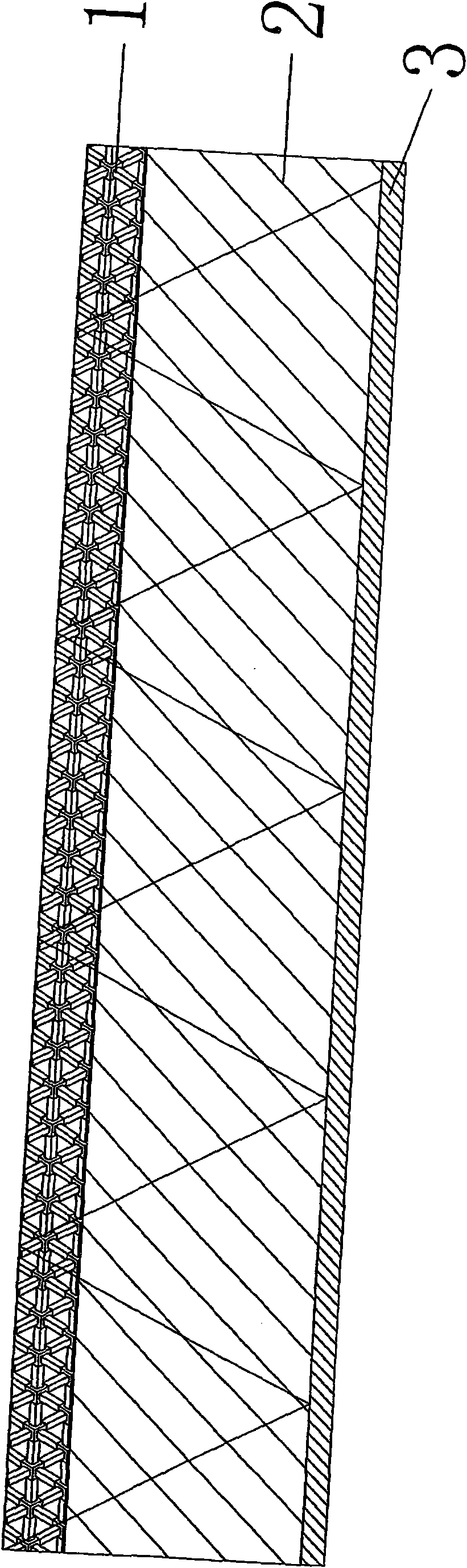

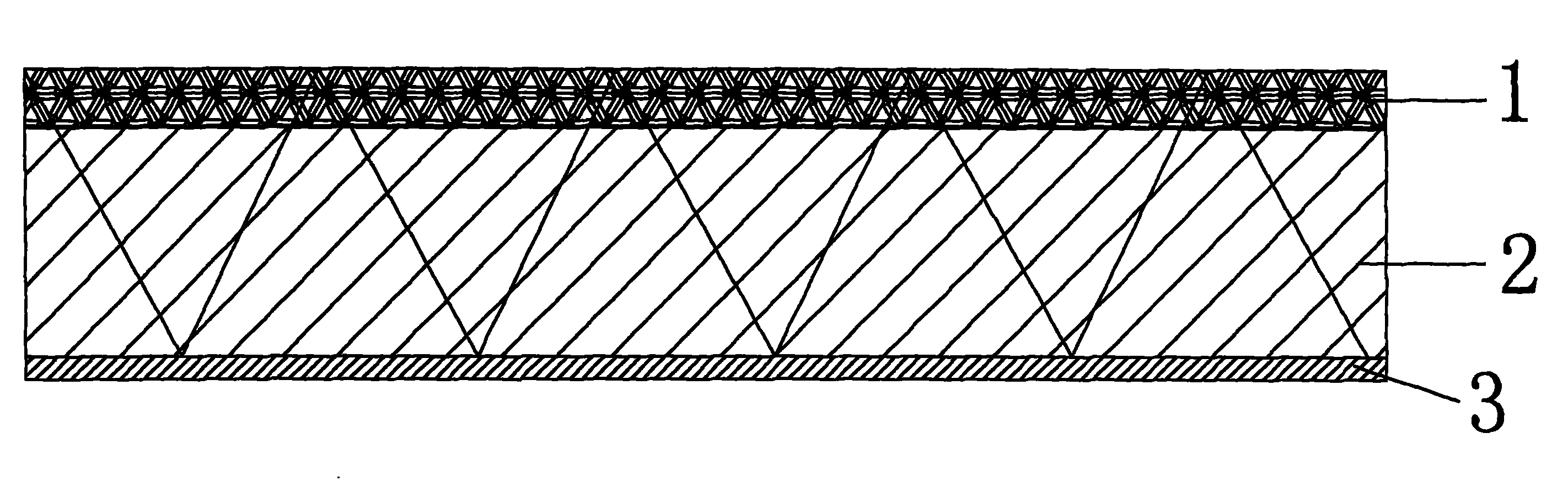

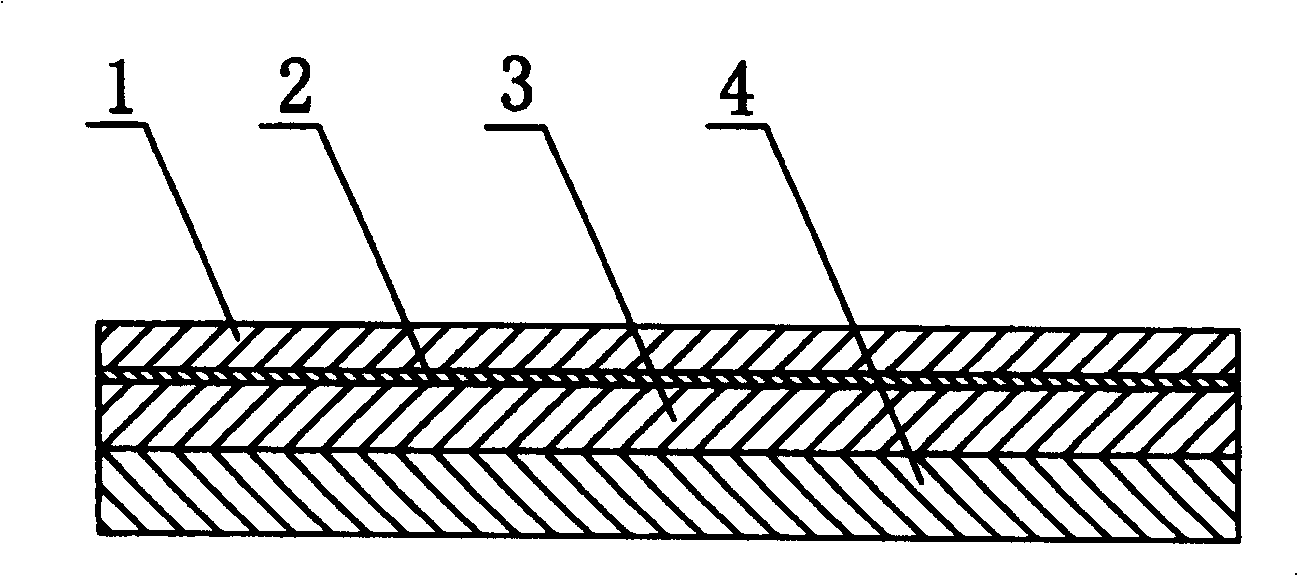

Wool knit and lace composite fabric

InactiveCN102048275AGorgeous and fashionable flower patternAvoid defects that feel hardLayered productsProtective garmentEngineeringMechanical engineering

The invention relates to a wool knit and lace composite fabric which is mainly used for high-level fashionable autumn / winter clothes for women, belonging to the industry of textile products. The invention is characterized in that the composite fabric is formed by quilting a lace layer (1) with a wool knit layer (2) in a stacking way, and combining a lining layer (3) in the back surface of the wool knit layer (2). In the invention, the composite fabric has the characteristics of gorgeous and fashionable as well as dignified and graceful flower types of the lace fabric, and has the characteristics of plainness, massiness and suitability for winter of the wool knit fabric, and the lace layer and the wool knit layer are quilted in a stacking way, so as to avoid the disadvantage of hard hand feeling of the fabric due to bonding. Moreover, the composite fastness is strong, therefore, the wool knit and lace composite fabric is quite suitable for the high-level fashionable autumn / winter clothes for women.

Owner:王瑞雪

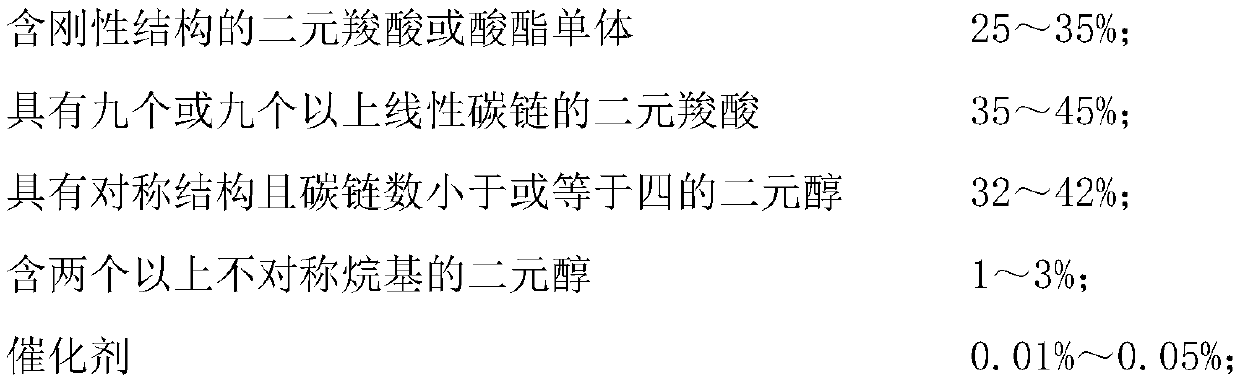

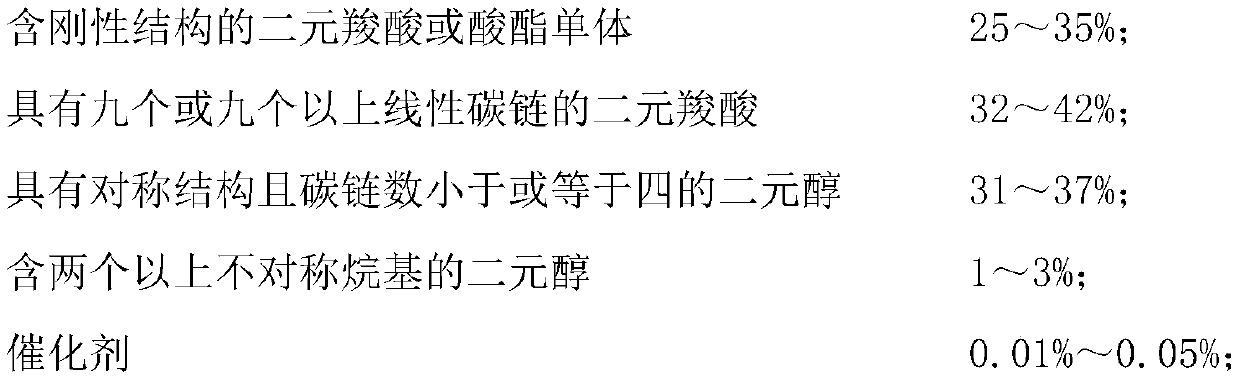

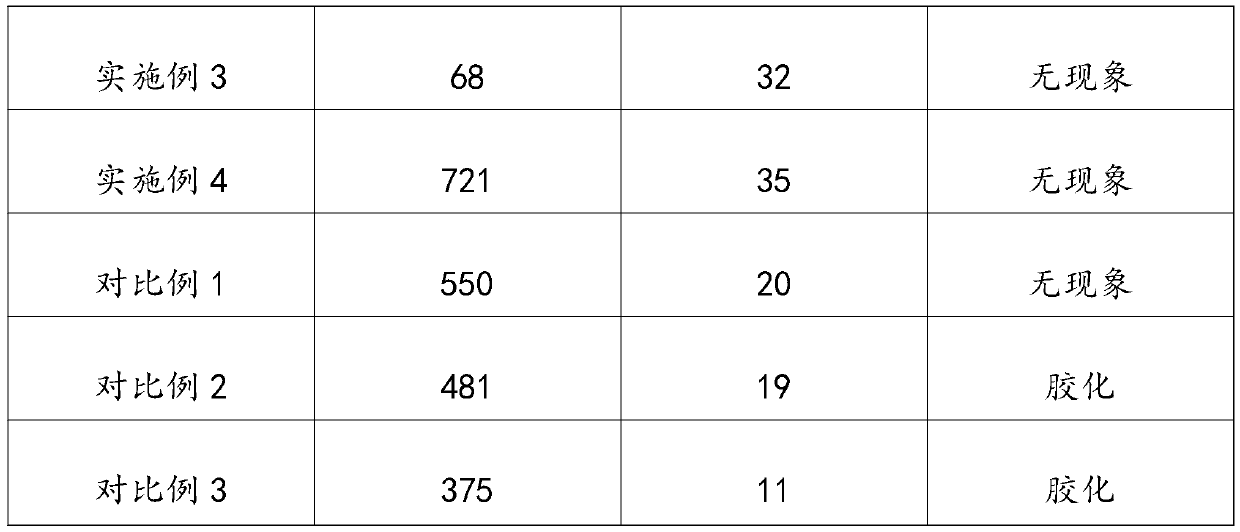

High-toughness stamping-resistant polyester resin for compounding aluminum-plastic film of lithium battery

ActiveCN111116875ATensile Yield Strength AdvantageAdvantages of elongation at breakAdhesivesPolymer sciencePtru catalyst

The invention discloses a high-toughness stamping-resistant polyester resin for compounding an aluminum-plastic film of a lithium battery. The polyester resin is prepared through the following steps:putting 25-35% of a dicarboxylic acid or acid ester monomer containing a rigid structure, 32-42% of dicarboxylic acid with a C9 or more chain, 31-37% of dihydric alcohol with a symmetrical structure and a carbon chain number of less than or equal to 4 and 1-3% of dihydric alcohol containing two or more asymmetric alkyl groups into a reaction container, and performing heating and stirring; adding 0.01-0.05% of a catalyst, and heating to react; vacuumizing when the esterification rate of the material in the reaction container is measured to be more than 94%, and gradually increasing the vacuum degree until the hydroxyl value of the material in the reaction container is 46 + / -4 mgKOH / g; and heating to 260 + / -5 DEG C, vacuumizing, gradually increasing the vacuum degree to be 300Pa or below, and controlling the hydroxyl value of the material in the reaction container to be 4 + / -0.5 mgKOH / g. Toughness related indexes of the resin have advantages; and the impact test yield is high, and the maximum deep drawing depth is tested to reach up to 15 mm.

Owner:SHANGHAI WEIKAI CHEM +2

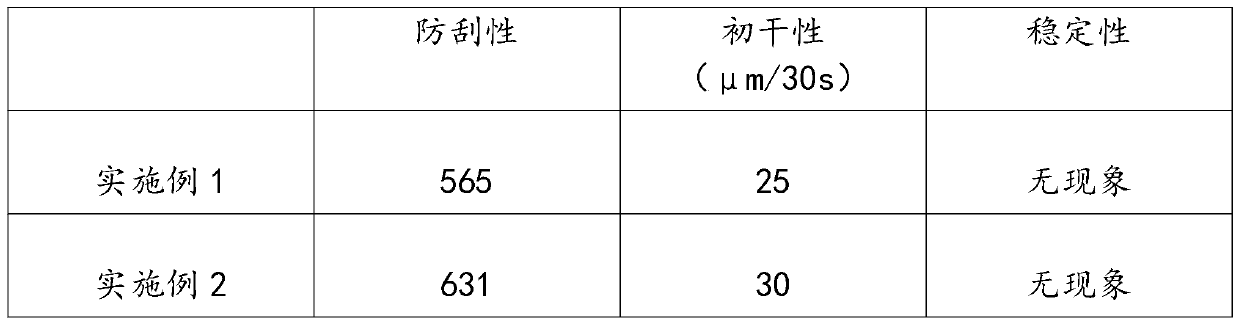

Scratching-resistant aqueous ink and preparation method thereof

InactiveCN110183905AStrong stabilityExcellent stability and scratch resistanceInksEthyl EthersChemistry

The invention discloses a scratching-resistant aqueous ink which is prepared from the following raw materials in parts by weight: 30-40 parts of modified polyurethane, 35-50 parts of a modified acrylic resin liquid, 5-10 parts of a pigment, 15-20 parts of titanium dioxide, 5-8 parts of a thickening agent, 10-15 parts of a dispersant, 3-8 parts of benzoin ethyl ether and 35-55 parts of absolute ethyl alcohol. The invention further discloses a preparation method of the scratching-resistant aqueous ink. The modified polyurethane and the modified acrylic resin liquid are used in the preparation process of the scratching-resistant aqueous ink, the modified polyurethane disclosed by the invention has good stability, acid-base resistance and wearing resistance, and the finally prepared scratching-resistant aqueous ink has excellent stability and scratching resistance; due to adoption of the modified acrylic resin liquid, the ink has good adhesion solidness and compounding fastness; in addition, the scratching-resistant aqueous ink disclosed by the invention is high in glossiness, attractive in appearance and applicable to multiple fields.

Owner:张小清

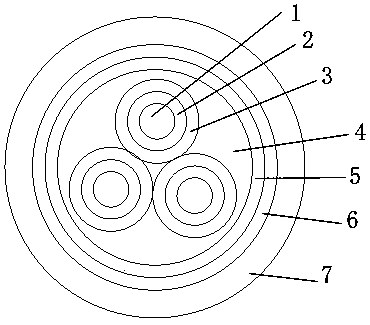

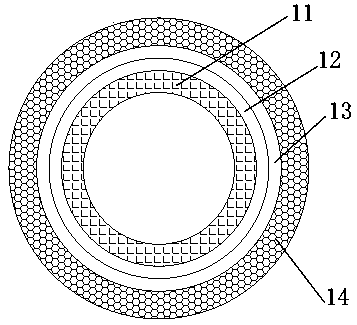

Copper core cross-linked polyethylene-insulated non-magnetic metal band low-smoke zero-halogen flame-retardant cable

PendingCN108461194AImprove fire resistanceNo damageInsulated cablesInsulated conductorsElectrical conductorInsulation layer

The invention discloses a copper core cross-linked polyethylene-insulated non-magnetic metal band low-smoke zero-halogen flame-retardant cable. The cable comprises a cable core which is formed by twisting three flame-retardant insulated wire cores; the gap of the cable core is filled with a refractory expansion band, a second aluminum foil woven fabric flame retarding layer is arranged outside thecable core, a non-magnetic metal band is arranged outside the second aluminum foil woven fabric flame retarding layer, and a flame-retarding cable pipe is arranged outside the non-magnetic metal band; and each flame-retardant insulated wire core is formed by an aluminum conductor, a cross-linked polyethylene insulation layer wrapping the aluminum conductor in an extruding mode and a first aluminum foil woven fabric flame retarding layer arranged outside the cross-linked polyethylene insulation layer. The cable has the performances of flame retarding, fire proofing and the like.

Owner:JIANGSU LONG E CABLE

A kind of 100% recyclable polyethylene composite film and its preparation method and application

ActiveCN111531991BGood printabilityGood optical performancePackage recyclingFlexible coversLow-density polyethylenePolymer science

The invention belongs to the technical field of polyethylene materials, and in particular relates to a 100% recyclable polyethylene composite film and its preparation method and application. The 100% recyclable polyethylene composite film provided by the present invention comprises a sequentially bonded composite printing layer, an adhesive layer and a composite heat-sealing layer; The direction to the composite heat-sealing layer is from outside to inside, and the composite printing layer includes the outer layer of the printing layer, the middle layer of the printing layer and the inner layer of the printing layer in sequence; the adhesive layer is low-density polyethylene film or solvent-free glue layer; the composite heat-sealing layer is a multi-layer co-extruded polyethylene heat-sealing film, and the composite heat-sealing layer includes an outer layer of a heat-sealing layer, a middle layer of a heat-sealing layer and an inner layer of a heat-sealing layer in sequence. Experimental results show that the 100% recyclable polyethylene composite film provided by the invention can be 100% recyclable, and has the characteristics of thin thickness, low density, puncture resistance and low sealing temperature.

Owner:江门市华龙膜材股份有限公司

Machining technique of silver/copper/iron composite strip material

This invention relates to compound materials technique field to process electricity probe and especially to one silver and copper and iron compound process method, which comprises the following steps: firstly grinding the silver metal oxidation and one film of pure silver materials for combination; then grinding the copper band and iron band to process this invention silver, copper and iron compound band.

Owner:东莞市中一合金科技有限公司

Water-soluble composite adhesive and preparation method therefor

InactiveCN110628376AReduce moisture contentDry fastNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyolWeather resistance

The invention belongs to the field of composite adhesives and discloses a water-soluble composite adhesive. The water-soluble composite adhesive is prepared from the following raw materials in parts by weight: 30-50 parts of polyisocyanate, 15-25 parts of water-soluble high polymer, 10-20 parts of polyol, 4-8 parts of emulsifier, 3-6 parts of stabilizer, 2-4 parts of initiator, 15-25 parts of kaolin and the balance of deionized water. The water-soluble composite adhesive disclosed by the invention is low in moisture content, high in drying speed, difficult in deformation and low in dosage andis not absorbed by adhered objects, and thus, the production cost is reduced greatly; the water-soluble composite adhesive prepared by a preparation method disclosed by the invention is stable in performance, excellent in weather resistance and good in compounding fastness; the water-soluble composite adhesive prepared by taking the polyisocyanate, the water-soluble high polymer, the polyol, the kaolin and the like as main raw materials has relatively high bond strength and impact toughness; and the kaolin has a relatively good thickening effect, so that the precipitation of the prepared water-soluble composite adhesive is avoided, and the kaolin can exert a dispersing action.

Owner:常州天南化工有限公司

A kind of preparation method of pomegranate-shaped organic-inorganic nanocomposite microspheres

The invention discloses a preparation method of pomegranate-shaped organic-inorganic nano-composite microspheres, which comprises the following steps: mixing an aqueous dispersion solution of silicon dioxide modified by proper amount of double-bond silane coupling agent in a coupling method with a phenylpropyl monomer, anionic emulsifier, non-anionic emulsifier and water, and stirring simply, so that a milky emulsified liquid is obtained; adding initiator to perform emulsion polymerization in the presence of silicon dioxide, so that the pomegranate-shaped organic-inorganic nano-composite microspheres with multiple silicon dioxide particles wrapped in phenylpropyl emulsion particles are obtained finally and are stably dispersed in the emulsified liquid. The preparation method has the advantages that the sources of the raw materials are extensive, the raw materials are easy to obtain, the preparation process is simple, and moreover, in the prepared pomegranate-shaped organic-inorganic nano-composite microspheres, the wrapping rate of silicon dioxide is high, the structure is neat and the placement stability is good. The adhesion property and the film forming performance of the composite microsphere particles are adjustable, the adhesive force and the transparency of the corresponding glue film are good, and the organic-inorganic nano-composite microspheres can be applied to the fields of coating, textile, rubber, plastics, biology, medicine and the like.

Owner:杭州华利实业集团有限公司

Manufacturing method of composite silver ribbon

ActiveCN103730279BThe amount of deformation is determinedPrevent restoreElectric switchesStress relievingOxidation resistant

The invention discloses a method for manufacturing a compound silver band and relates to a method for manufacturing electric contact materials. The method for manufacturing the compound silver band comprises the working process that a silver oxidization band and a copper band are treated at the earlier stage; the copper band is heated; the silver oxidization band and the copper band are compounded; a compounded band is annealed; the compounded band is precisely rolled; the stress of the compounded band is eliminated; oxidation resistance of the compounded band is achieved; the compounded band is split; the compounded band is detected. Compared with the prior art, in the machining process, the silver metallic oxidization band and the copper band do not need to be heated at the same time, so that a reduction reaction generated by a protective atmosphere and the silver metallic oxidization band in the heating process is avoided, and silver metallic oxide is prevented from being reduced. Meanwhile, the silver metallic oxidization band is placed in a groove formed in the copper band and then rolled, the combination strength is higher, and the compounding firmness is better. When the method is used for manufacturing the compound silver band, the requirement for manufacturing devices is low, machining is easy, the band is long, automatic convenient machining and manufacture in large bathes are achieved, and therefore cost is greatly reduced.

Owner:ZHEJIANG KEYANG NEW MATERIAL TECH

A kind of manufacturing equipment and manufacturing method of composite silver belt

ActiveCN103722041BAvoid reduction reactionAvoid safety accidentsElectric switchesMetal rolling arrangementsStress relievingManufactured apparatus

The invention discloses manufacturing equipment and method of a compound silver belt, and relates to manufacturing equipment and methods of electric contact materials. The method comprises the following work flows: carrying out pre-treatment on a silver oxidization belt and a copper belt; heating the copper belt; compounding the silver oxidization belt and the copper belt so as to obtain a compound belt; annealing the compound belt; carrying out finish rolling on the compound belt; relieving stress on the compound belt; carrying out antioxidation on the compound belt; stripping the compound belt; and verifying the compound belt. The manufacturing equipment is a hot compound mill which can automatically attach the high-temperature copper belt and the silver oxidization belt. Compared with the prior art, according to the method, in the processing process, the silver metal oxidization belt is not heated while the copper belt is heated, and thus, silver metal oxide is prevented from being reduced due to reduction reaction of a protective atmosphere and the silver metal oxidization belt in the heating process. Meanwhile, the silver metal oxidization belt is placed in a slot of the copper belt, and then is rolled, so that the combining strength is relatively high and the compounding fastness is relatively good.

Owner:ZHEJIANG KEYANG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com