Composite silver tape manufacturing method and manufacturing equipment

A manufacturing method and composite tape technology, applied in the direction of electrical components, electric switches, contact materials, etc., can solve the problems of non-continuous processing, poor bonding strength, and low efficiency, and achieve good composite fastness, high bonding strength, and avoid The effect of the reduction reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in combination with specific embodiments and accompanying drawings.

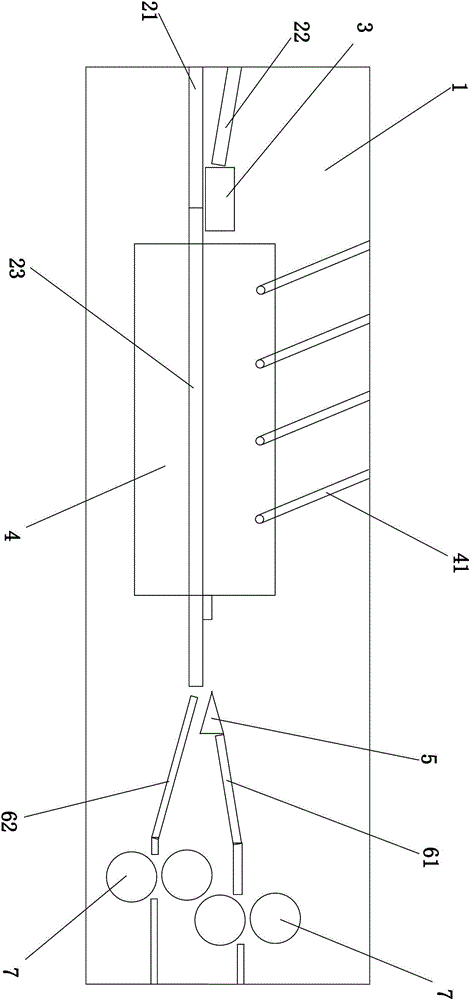

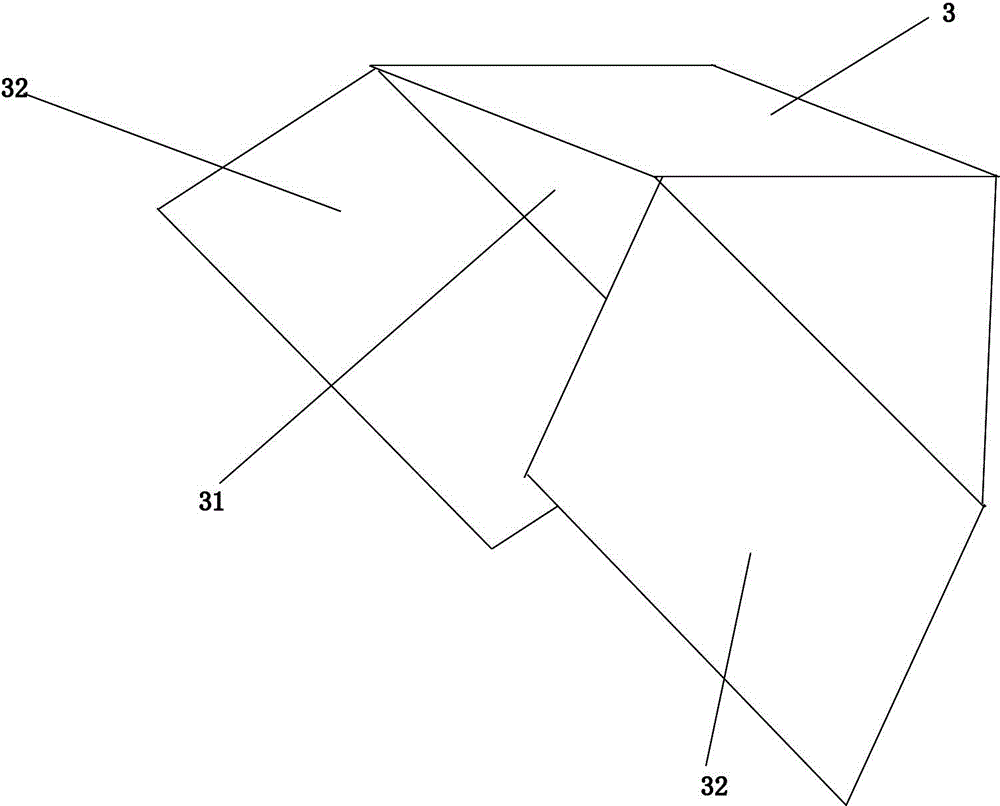

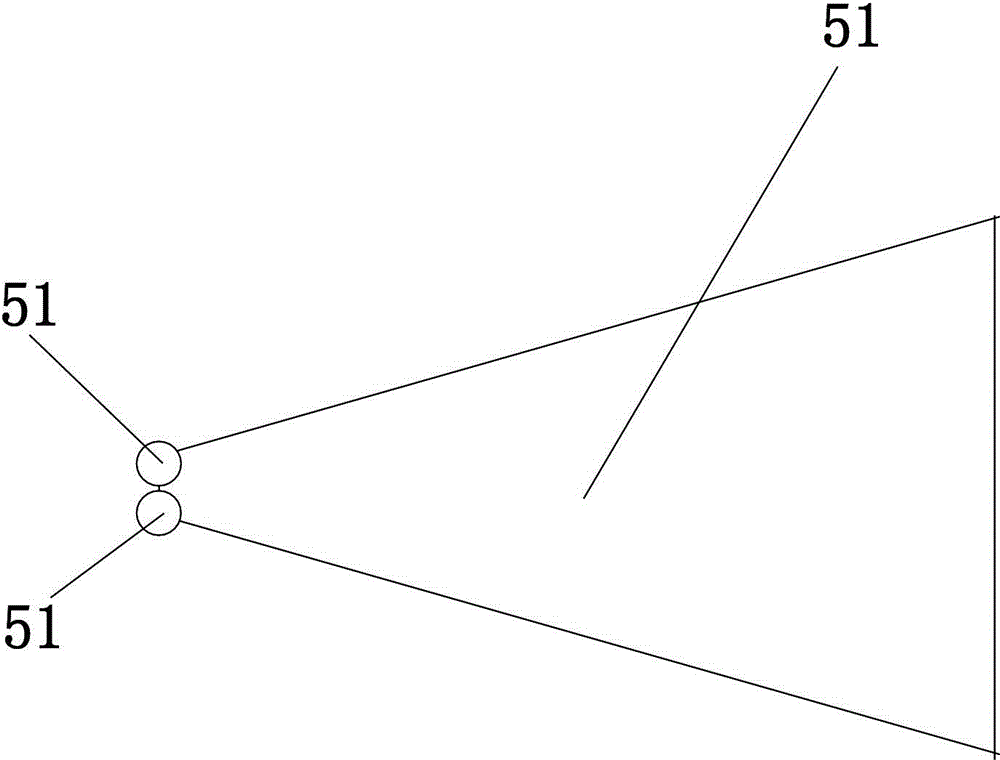

[0020] Such as figure 1 , figure 2 , image 3 As shown, a hot composite rolling mill includes a conveying device, a heating device, a separating device 5 and a pressure roller device 7. The heating device is a continuous heating furnace 4 connected with several gas pipes 41. Described delivery device comprises A conveyor belt 21, B conveyor belt 22 and C conveyor belt 23, and described A conveyor belt 21 and described B conveyor belt 22 connect described C conveyor belt 23 by described combiner 3 , the combiner 3 has an inclined surface 31 facing the second conveyor belt 22 and having a width suitable for the copper belt, guide plates 32 are provided on both sides of the inclined surface 31, and the first conveyor belt 21 is positioned at directly below the slope 31 . Described C conveyor belt 23 connects described separating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com