Biodegradable high-barrier paper-plastic packaging composite film and preparation method thereof

A biodegradable, high-barrier technology, applied in the field of packaging materials, can solve problems such as the need to control the degradation rate, increase the cost of raw materials, lack of elasticity and flexibility, achieve good printing performance and appearance, control production and processing costs, and good composite fastness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

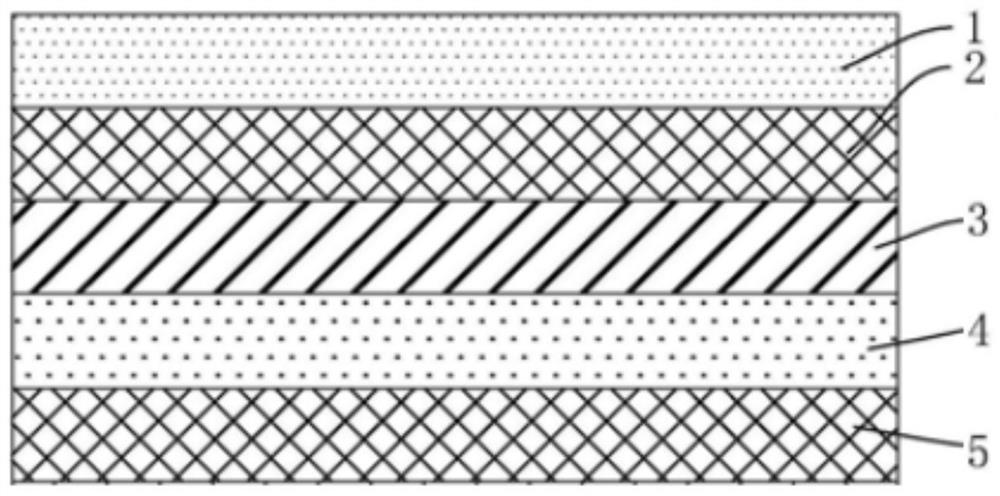

[0050] The preparation method of the biodegradable high-barrier paper-plastic packaging composite film provided by the present invention comprises the following steps:

[0051] 1) According to the mass fraction, add 50 parts of PVA powder, 15 parts of plasticizer sorbitol and 3 parts of heat stabilizer laurate into 70 parts of deionized water at 90 ° C, mix well, and configure PVA solution; remove PVA solution Soak, cool down, filter and extrude to obtain a solution; apply the solution on the paper layer (2) at 40°C with a wet film thickness of 300 microns, dry at 60°C for 5 minutes, and heat press with a flattening roller Flatten the paper to obtain a barrier coating (3);

[0052] 2) Use gravure printing technology to print degradable water-based ink on the other side of the kraft paper;

[0053] 3) In parts by weight, add 55 parts of PLA particles and 1 part of bifunctional compatibilizer KT20 into the casting machine, mix for 20 minutes and then raise the temperature to 17...

Embodiment 2

[0056] The preparation method of the biodegradable high-barrier paper-plastic packaging composite film provided by the present invention comprises the following steps:

[0057] 1) According to the mass fraction, add 60 parts of PVA powder, 10 parts of plasticizer triethanolamine and 5 parts of heat stabilizer laurate into 60 parts of deionized water at 95 ° C, mix well, and configure PVA solution; PVA solution Extrude after defoaming, cooling, and filtering to obtain a solution; apply the solution on the paper layer (2) at 50°C with a wet film thickness of 400 microns, then dry it at 100°C for 1 minute, and heat it with a flattening roller. Flatten the paper to obtain a barrier coating (3);

[0058] 2) Use gravure printing technology to print degradable water-based ink on the other side of wood pulp paper;

[0059] 3) In parts by weight, add 58 parts of PLA particles and 2 parts of compatibilizer EsunBio5004K into the casting machine, mix for 30 minutes and then heat up to 17...

Embodiment 3

[0062] The preparation method of the biodegradable high-barrier paper-plastic packaging composite film provided by the present invention comprises the following steps:

[0063] 1) According to the mass fraction, 80 parts of PVA powder, 20 parts of plasticizer triethanolamine and 10 parts of heat stabilizer zinc stearate are added to 80 parts of deionized water at 80 ° C, mixed evenly, and configured into a PVA solution; PVA The solution is defoamed, cooled, filtered, and then extruded to obtain a solution; the solution is coated on the paper layer (2) at 60°C with a wet film thickness of 500 microns, then dried at 80°C for 3 minutes, and flattened with a flattening roller heat-pressed flattened paper to obtain a barrier coating (3);

[0064] 2) Use gravure printing technology to print degradable water-based ink on the other side of the glassine paper;

[0065] 3) In parts by weight, add 60 parts of PLA particles and 0.5 parts of BASF epoxy chain extender ADR 4468 into the casti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com