Patents

Literature

35results about How to "Guaranteed heat sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

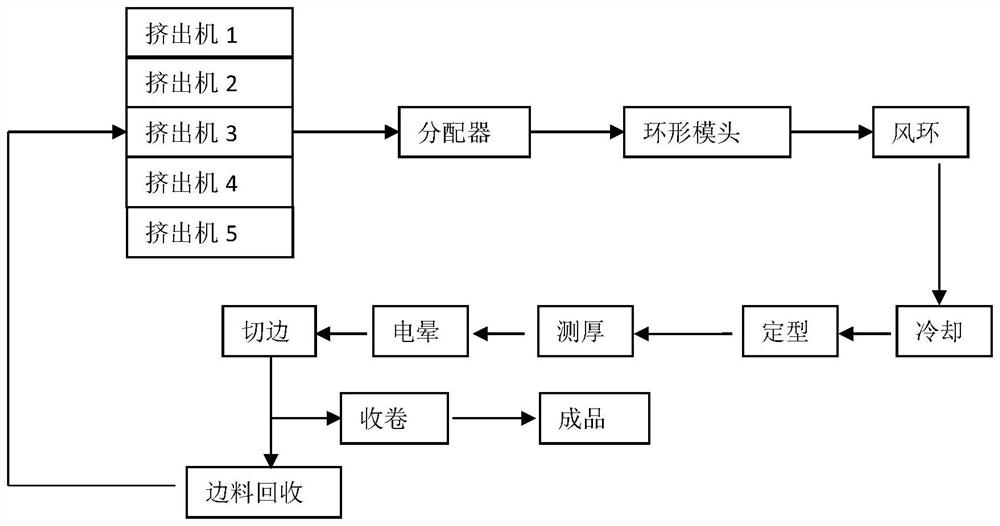

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

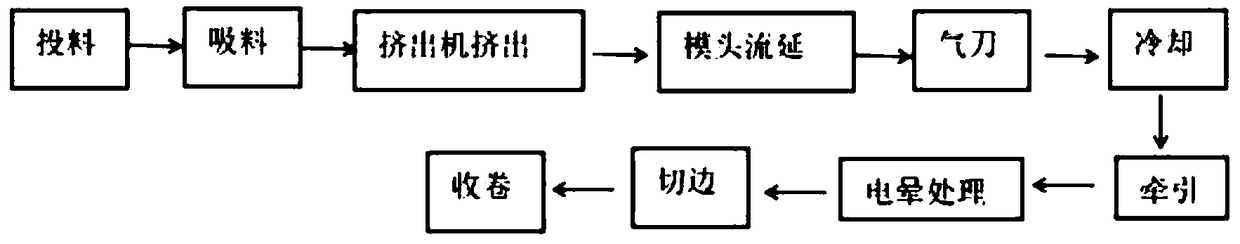

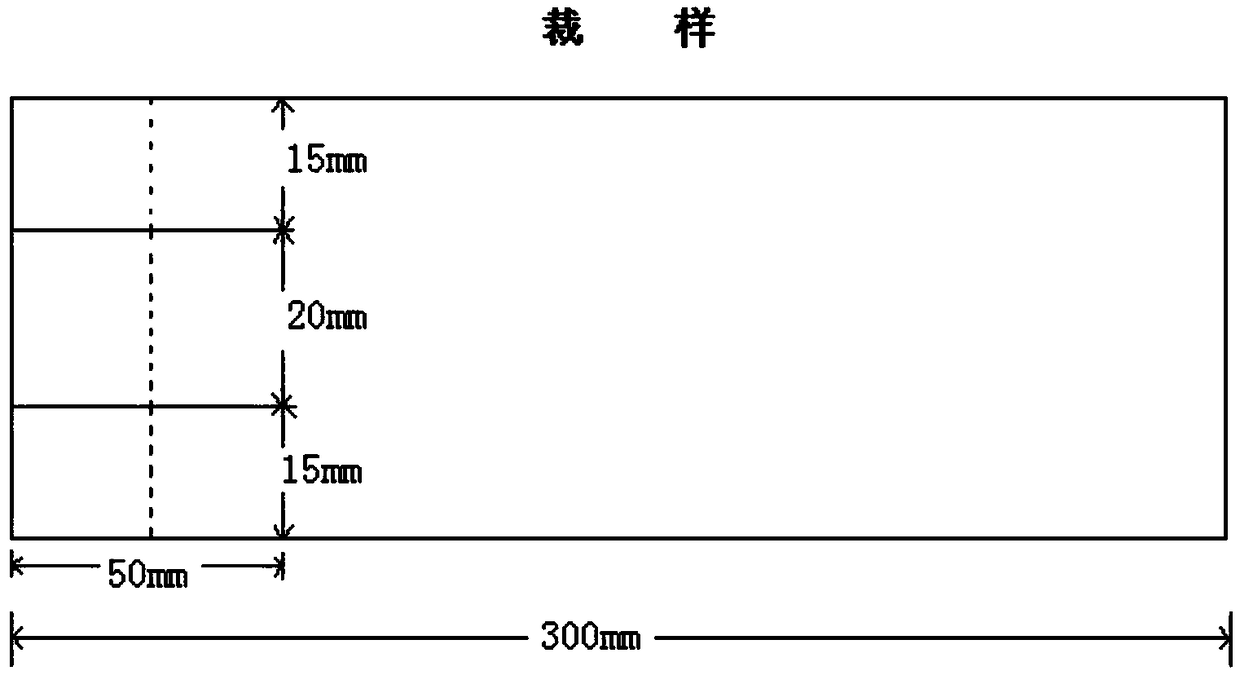

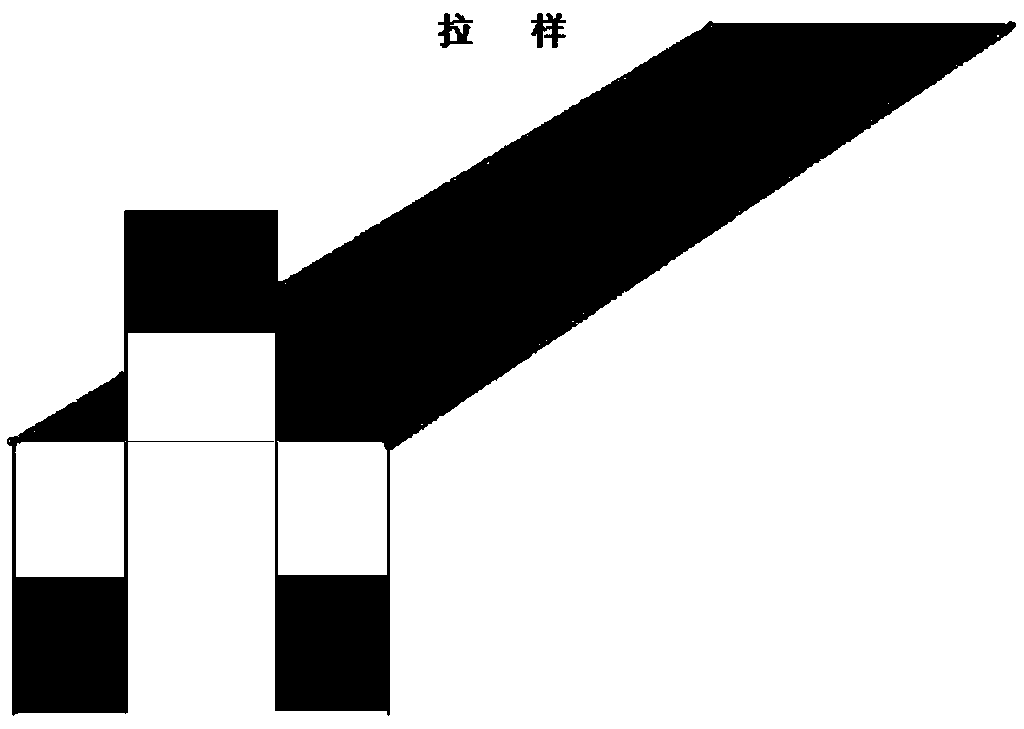

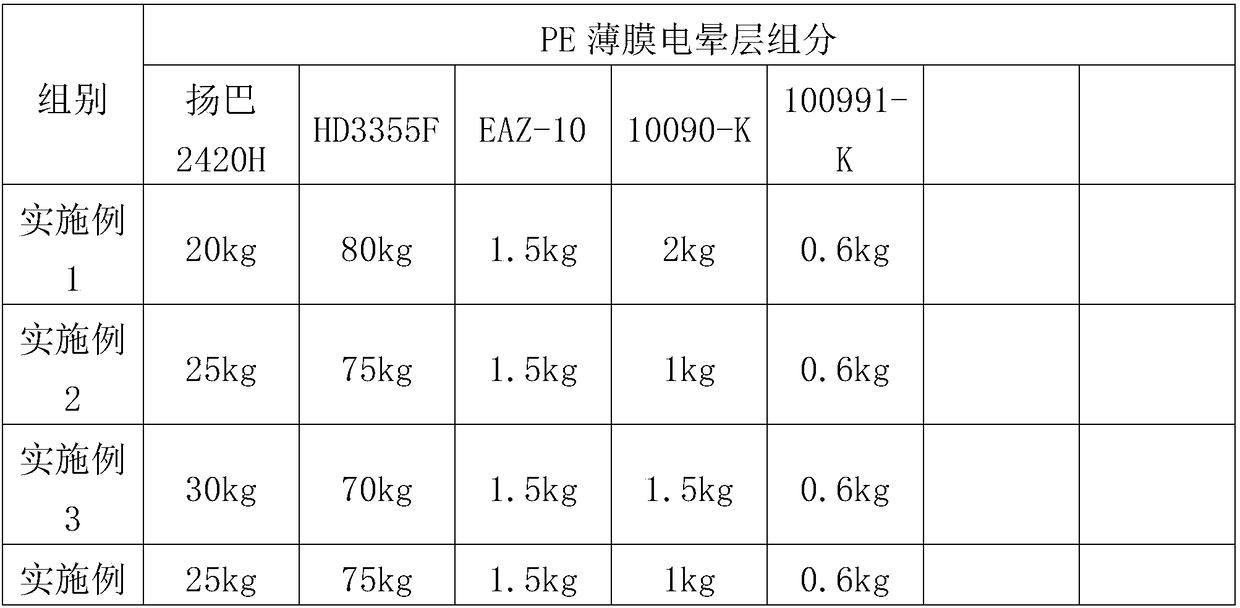

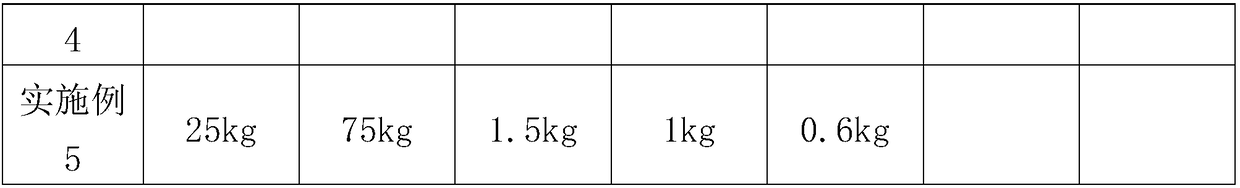

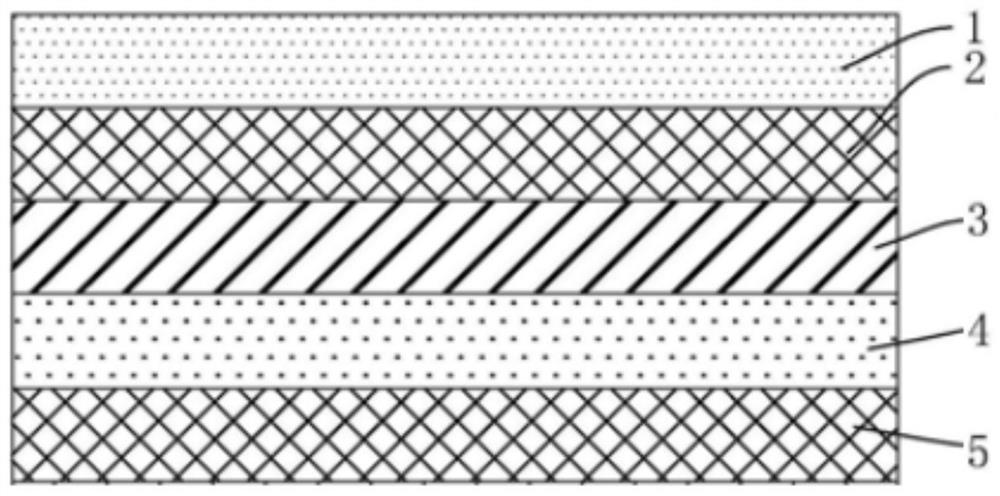

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

Metal can packing material and method of manufacturing the same

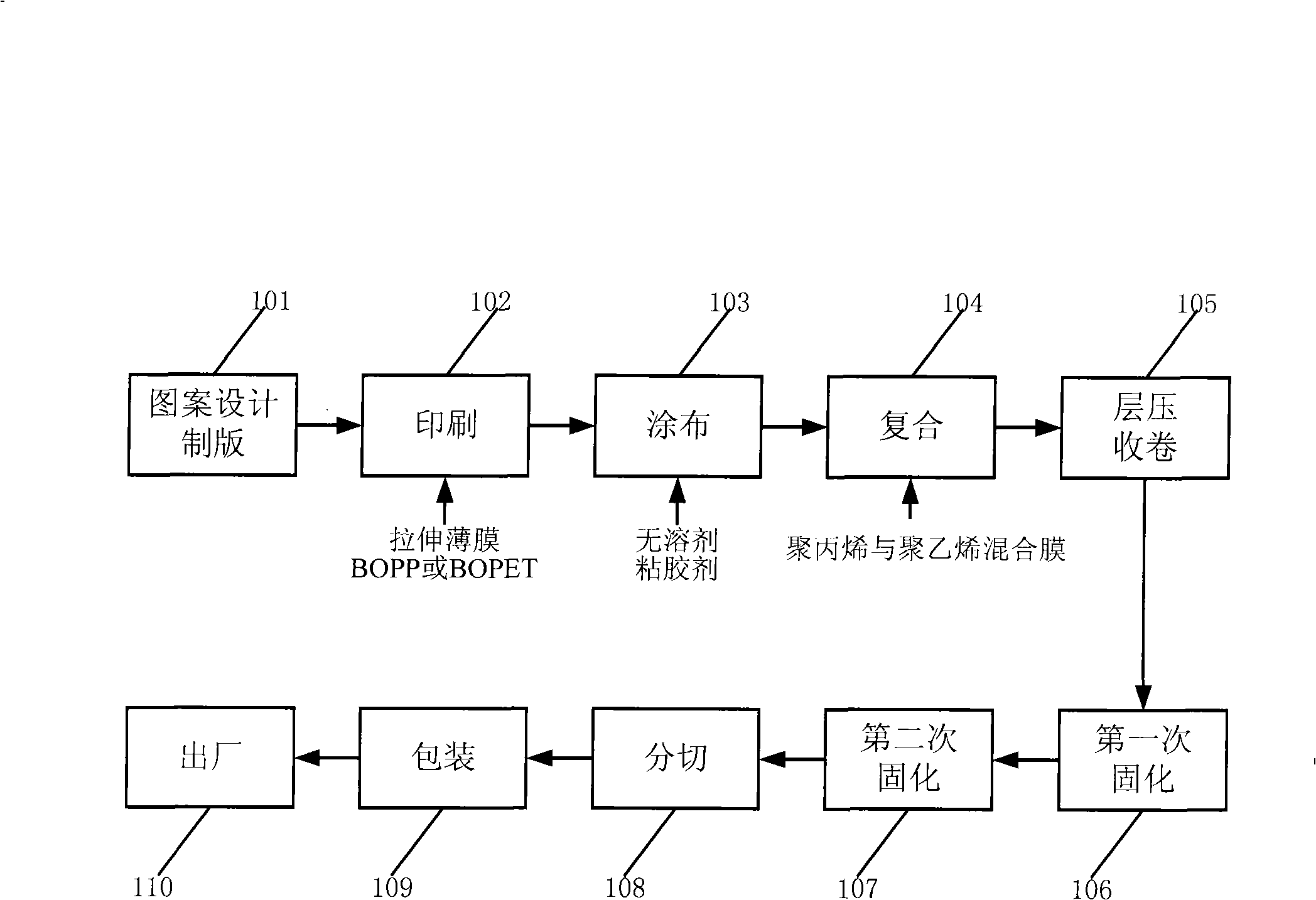

The invention relates to a metal tank packing material and a manufacturing method thereof, which comprises the following steps that: (a) a pattern after the design and the plate making is printed on basic material, the basic material adopts a two-way stretch BOPP or a two-way stretch BOPET; (b) solvent-free adhesive is applied on the basic material, the applied quantity is 1.2 to 1.5 g / m <2>; (c) the basic material is preheated, bonded and compounded; the preheating temperature is 50 to 65 DEG C, a polypropylene mixed film or a polyethylene mixed film is bonded and compounded on the basic material; the compound speed is 90 to 120 m per minute; (d) the laminating and the recovery-furl are performed; (e) the preheating temperature is 40 to 60 DEG C, the delivery-furl tension is 2 to 10 kg, the recovery-furl tension is 15 to 25 kg; (f) the curing is carried out; (g) the cutting and the packing are performed. The method makes the direct printing on the packing material, as a standard film, the packing material is directly packed on the unprinted metal tank for packaging, and has the effect of realistic metal sense.

Owner:上海人民塑料印刷厂有限公司

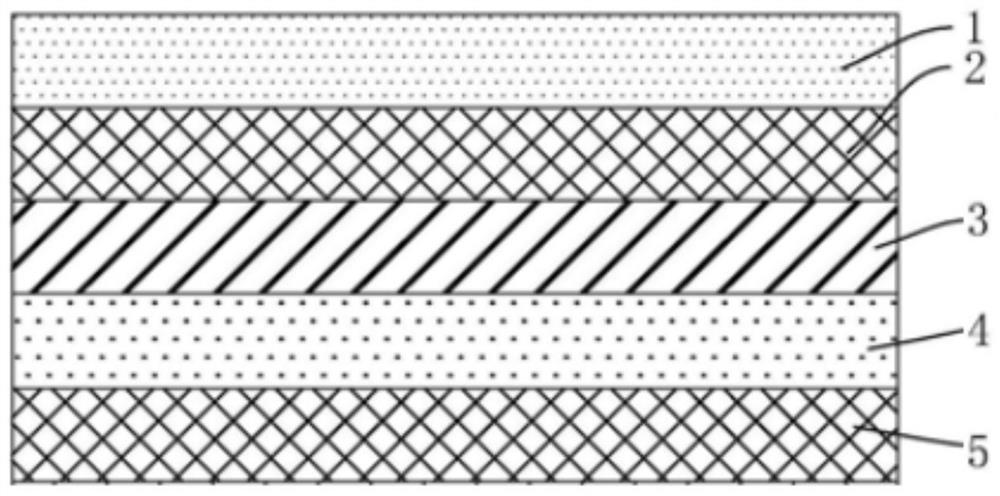

Heat-seal interface easily-torn PE thin film and preparation method thereof

InactiveCN108943949AImprove aging resistanceGood acid and alkali resistanceFlexible coversWrappersLow-density polyethylenePolyester

The invention discloses a heat-seal interface easily-torn PE thin film, which is formed by coextruding a corona layer, a middle layer and an inner layer, wherein the corona layer contains low-densitypolyethylene resin and high-density polyvinyl resin; the middle layer contains low-density polyethylene resin and high-density polyvinyl resin; the inner layer contains coated low-density polyethylene, high-density polyvinyl resin, polybutylene resin and polyester modified organosilicone. The coated low-density polyethylene is added into the inner layer, so that the thin film has good heat seal property, and the polyester modified organosilicone added into the inner layer has heat seal property, so that the heat-seal intensity value of the thin film is controlled within certain range and is easily torn off a heat-seal surface without complete damage or filament raising, and therefore, the PE thin film is suitable for being used as an easily-torn seal cup lid film, easily-torn mask productpackages and easily-torn medical dressing packages.

Owner:HUANGSHAN NOVEL

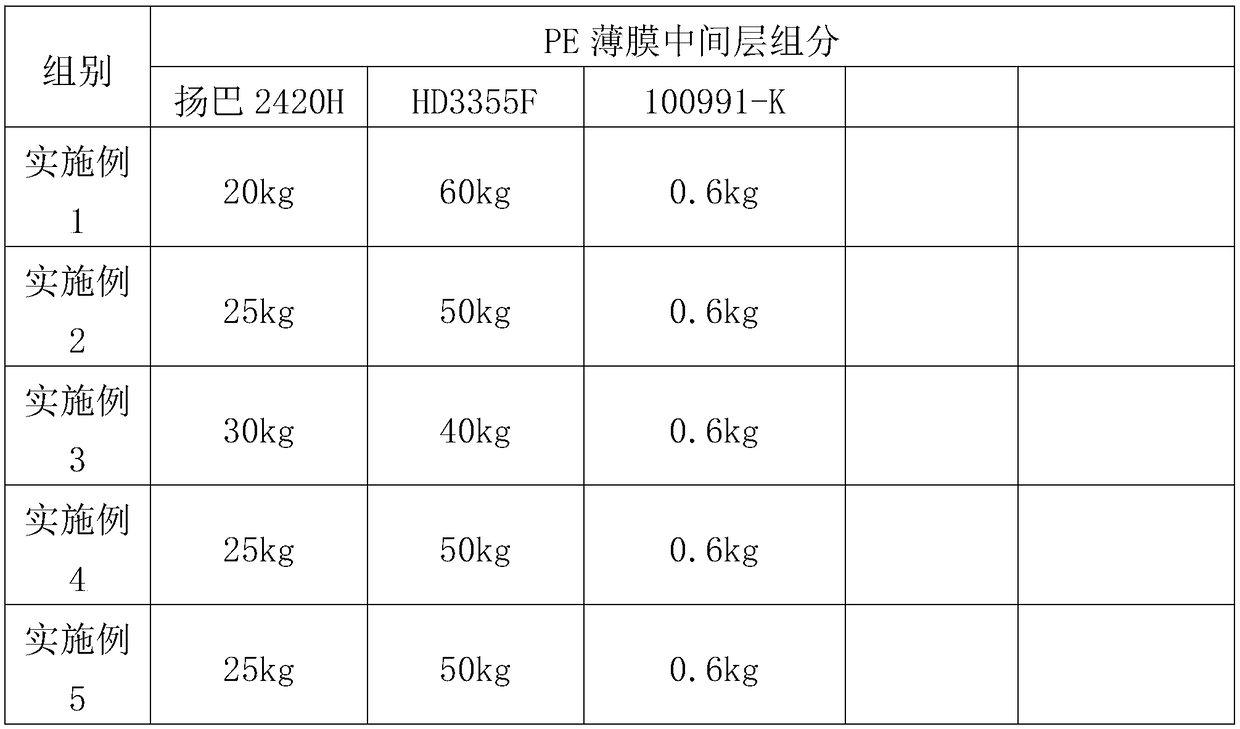

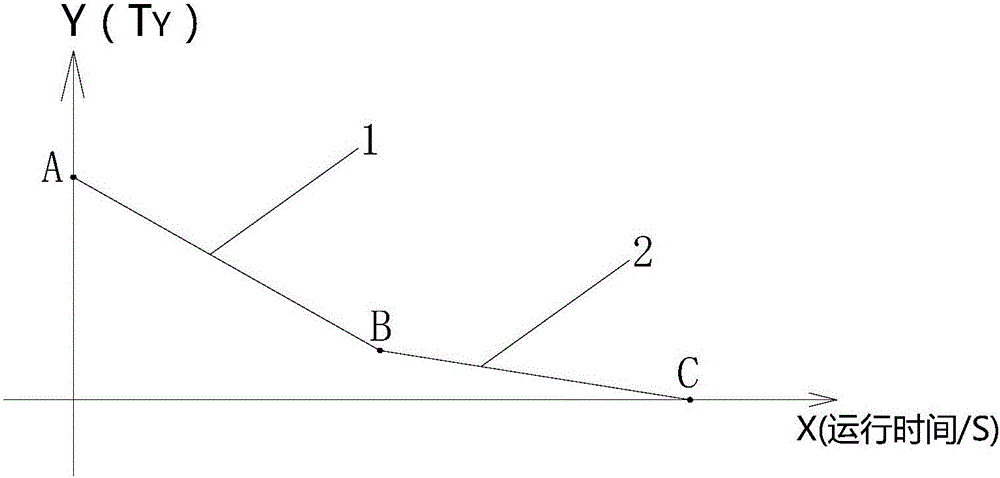

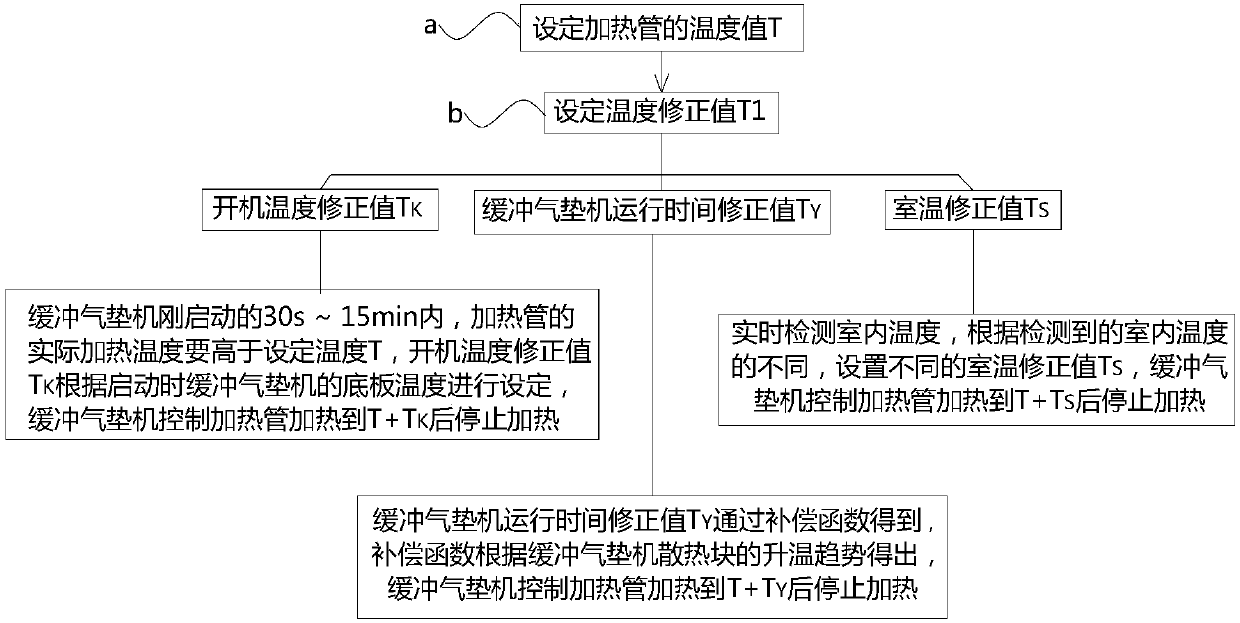

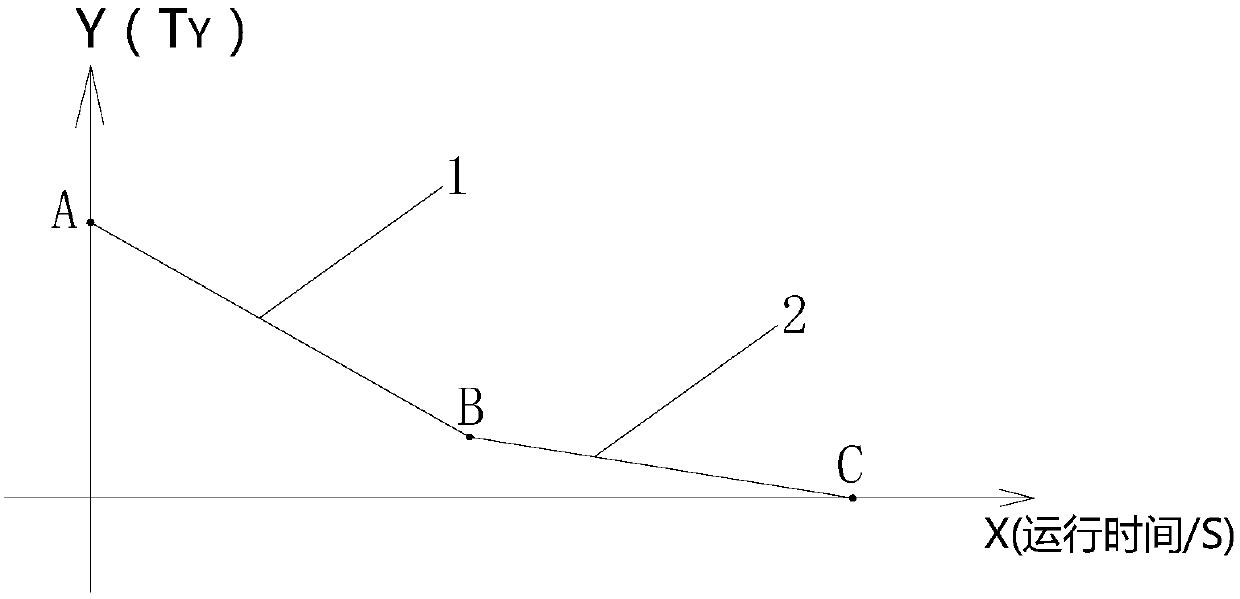

Temperature compensation method for buffering air cushion machine

ActiveCN106217847AInfluence of heat sealing effectGuaranteed heat sealing performanceMachine controlRoom temperature

The invention discloses a temperature compensation method for a buffering air cushion machine. In the temperature compensation method, the temperature value T of a heating pipe is set, the starting temperature correction value TK is set according to the temperature of a bottom plate when the buffering air cushion machine is started, the room temperature correction value TS is set according to the detected indoor temperature of the position where the buffering air cushion machine is located, and the running time correction value TY of the buffering air cushion machine can be obtained in real time according to the compensation function; and in the actual operation, on the basis of the temperature value T of the heating pipe, at least one of the starting temperature correction value TK, the room temperature correction value TS and the running time correction value TY of the buffering air cushion machine can be offset, heating is stopped after the buffering air cushion machine controls the heating pipe to conduct heating till the sum of T and at least one of the TK, the TS and the TY is achieved, and therefore the situation that when the buffering air cushion machine conducts heat sealing on an air cushion film, the heat sealing effect is affected by the room temperature, the temperature of a heating block during starting, the running time of the buffering air cushion machine and other factors can be avoided, and the heat sealing effect of the air cushion film is ensured.

Owner:HANGZHOU BINGJIA TECH

Biodegradable high-barrier paper-plastic packaging composite film and preparation method thereof

ActiveCN113619242AGreat print lookImprove display effectFlexible coversWrappersElastomerPolymer science

The invention provides a biodegradable high-barrier paper-plastic packaging composite film and a preparation method thereof. The biodegradable high-barrier paper-plastic packaging composite film sequentially comprises an ink layer, a paper layer, a barrier coating, a bonding layer and a PLA layer from outside to inside, wherein the PLA layer is modified by a thermoplastic elastomer, and after modification, the temperature resistance and toughness of the PLA layer can be improved, heat sealing performance is ensured, and the packaging requirements of different contents and different weights are met; and the barrier coating can ensure that a final finished product has good barrier property and prolongs the shelf life of the contents. The biodegradable high-barrier paper-plastic packaging composite film has the advantages of being exquisite in printing appearance, good in display effect and the like, is made of degradable materials, can be biodegraded after being used, and is free of pollution to the environment.

Owner:JIANGSU LEATER GREEN PACKAGING CORP LTD

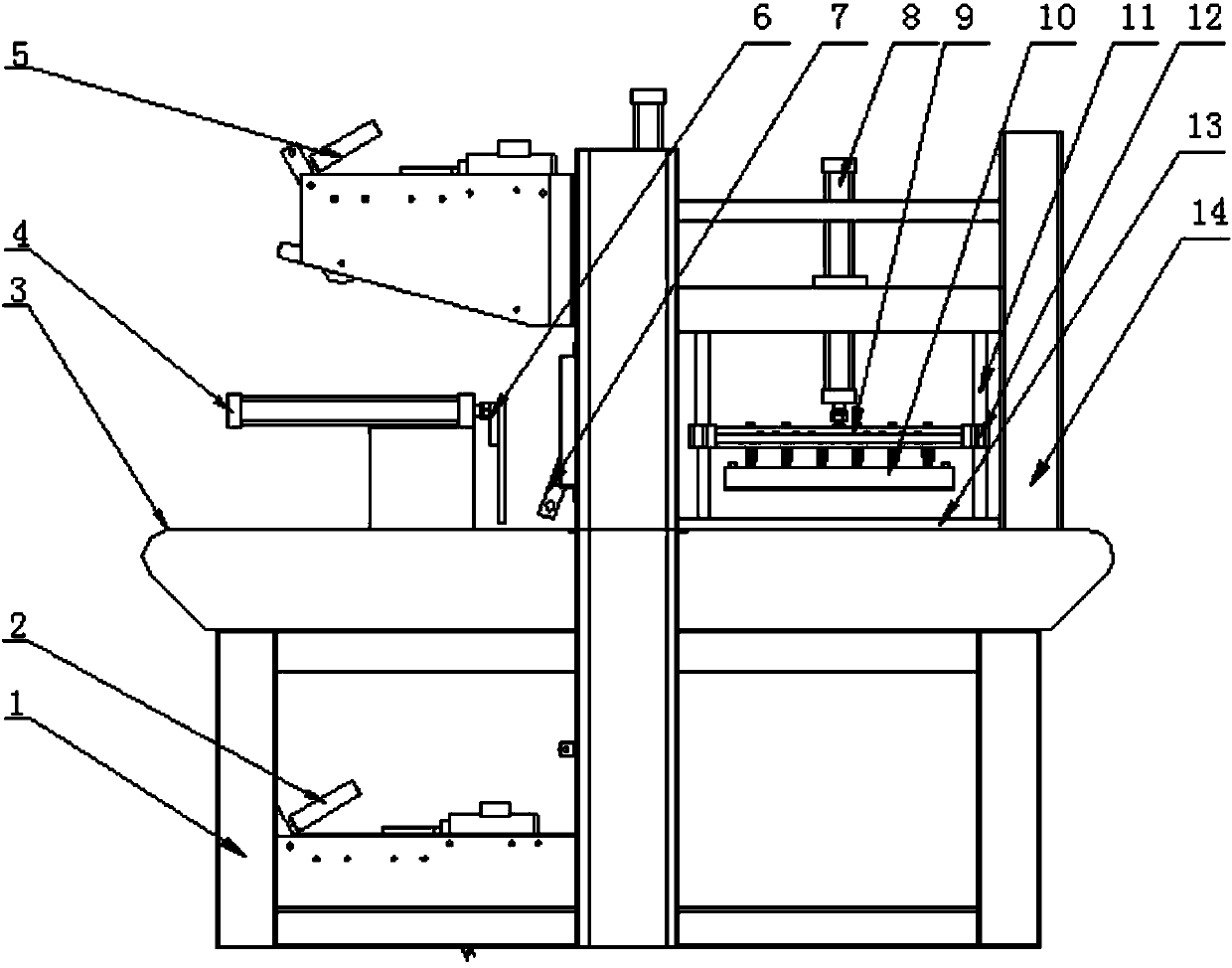

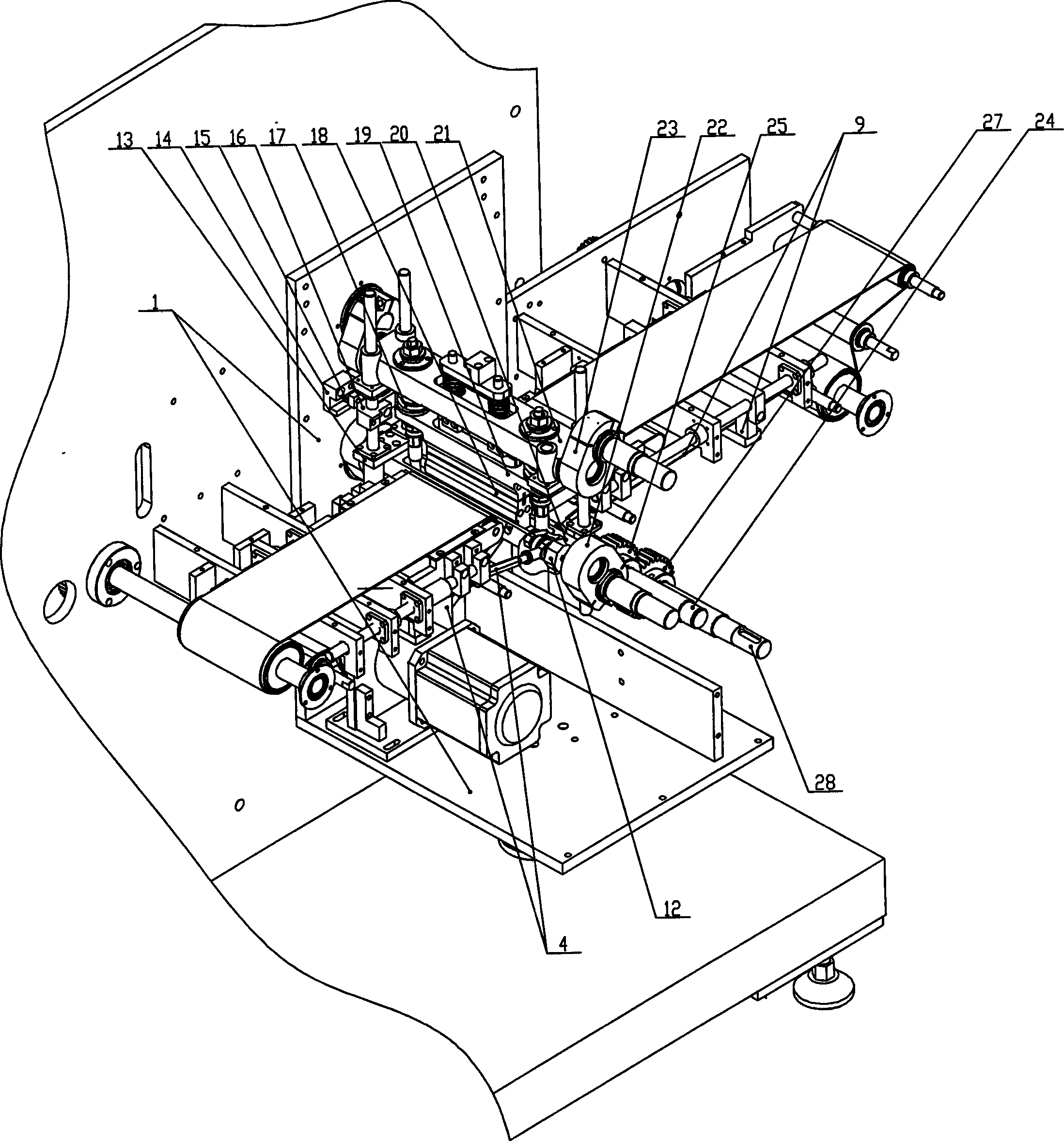

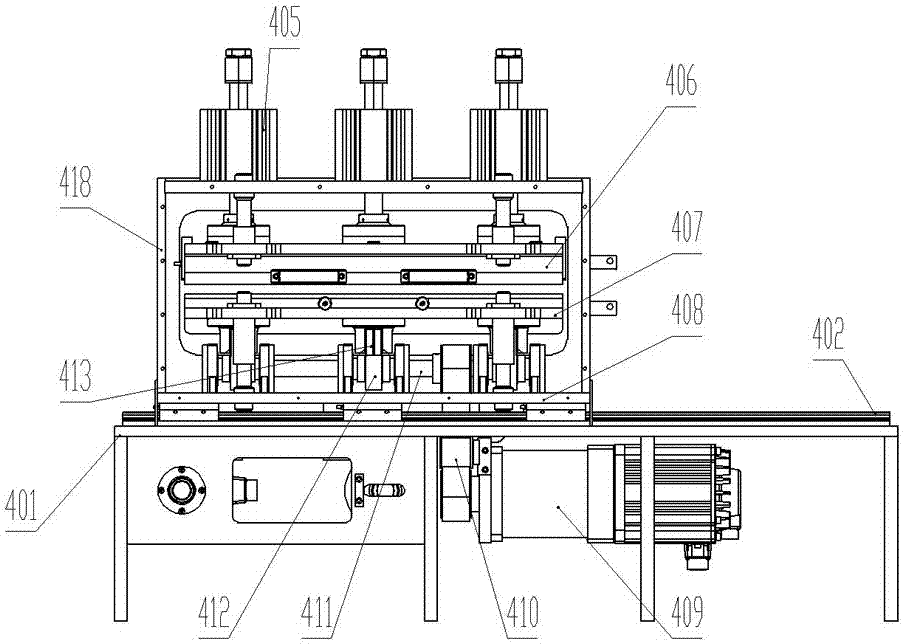

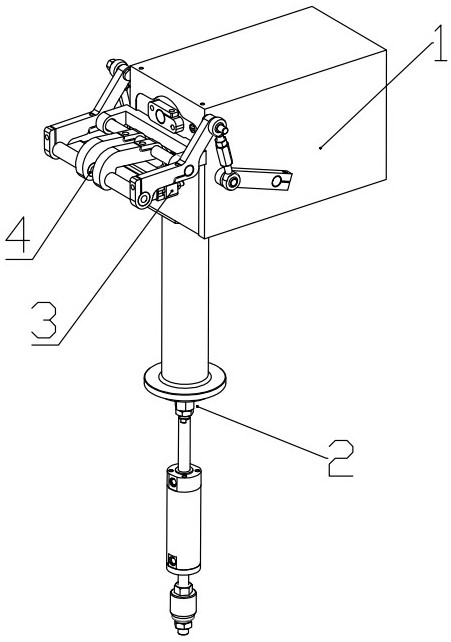

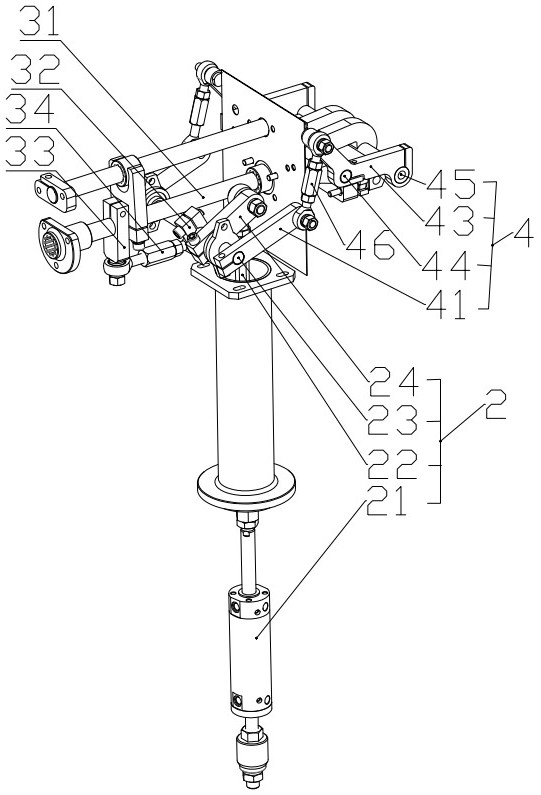

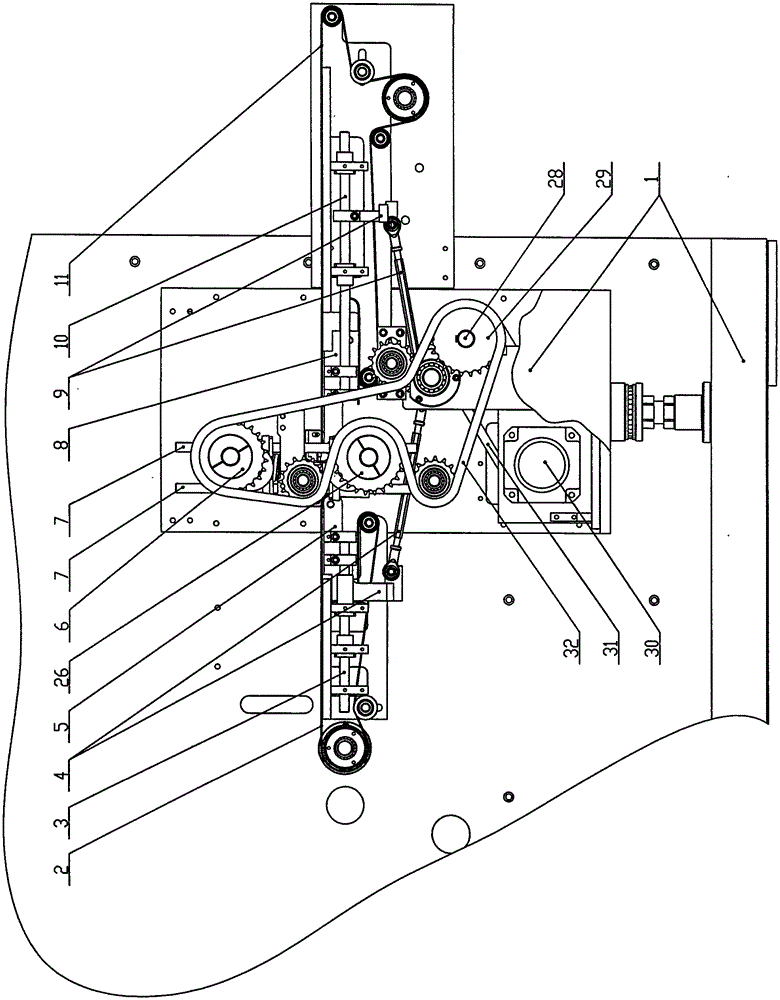

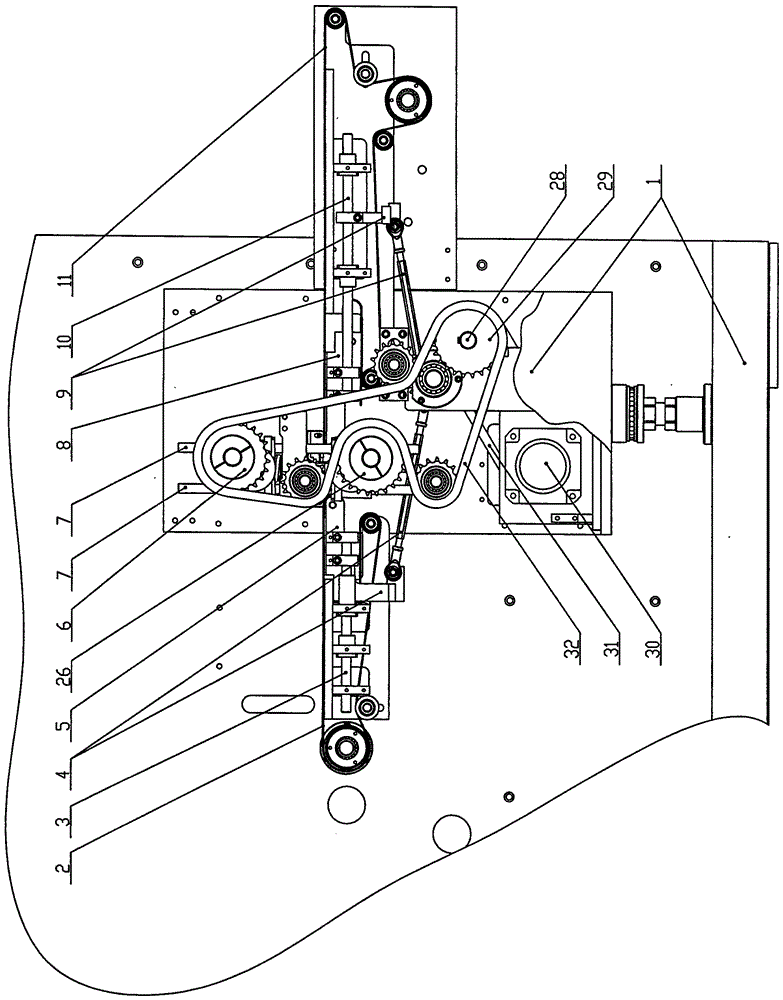

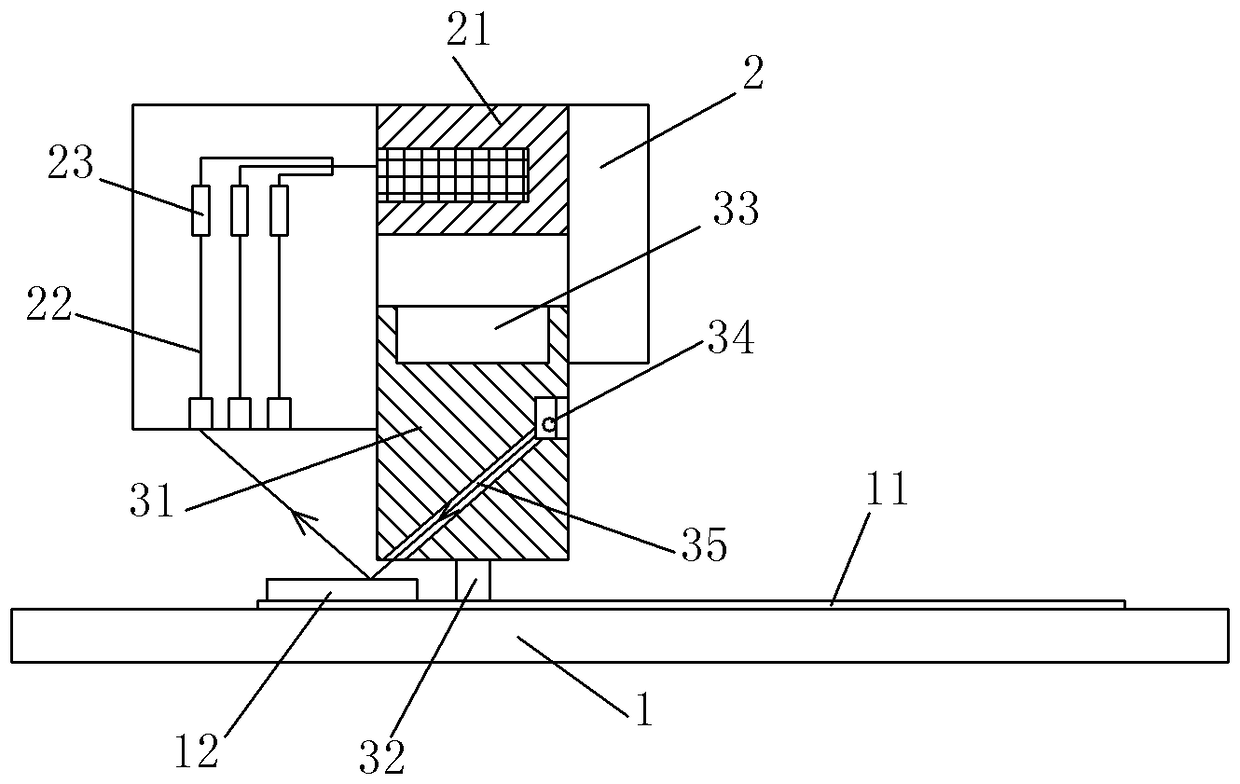

Thermal sealing device for two ends of welding rod packaging production line packaging bag

InactiveCN103991584APrevent moistureRealization of heat sealingWrapper twisting/gatheringProduction lineEngineering

The invention relates to a thermal sealing device for two ends of a welding rod packaging production line packaging bag. The thermal sealing device comprises a rack, a conveying mechanism, a film discharge mechanism, a film feed mechanism, a material push mechanism and a longitudinal thermal sealing tool mechanism, and the conveying mechanism is horizontally arranged on the rack. The thermal sealing device is characterized in that two symmetric transverse thermal sealing tool mechanisms are further arranged on the rack, the two transverse thermal sealing tool mechanisms are arranged on the two sides of the conveying direction of the conveying mechanism, each transverse thermal sealing tool mechanism is composed of a thermal sealing support, an upper thermal sealing tool air cylinder, an upper thermal sealing tool and a thermal sealing bottom plate, the upper thermal sealing tool air cylinders are arranged on the rack through the thermal sealing supports, the upper thermal sealing tools are arranged on the lower portions of push rods of the upper thermal sealing tool air cylinders, and the thermal sealing bottom plates are fixedly arranged on the two sides of the conveying mechanism. The device is scientific and reasonable in structural design, and has the advantages of being stable and reliable in machining, high in efficiency and good in quality, leakproofness of welding rod paper box plastic bag package is guaranteed, and the thermal sealing device is high in innovativeness.

Owner:TIANJIN VOCATIONAL INST

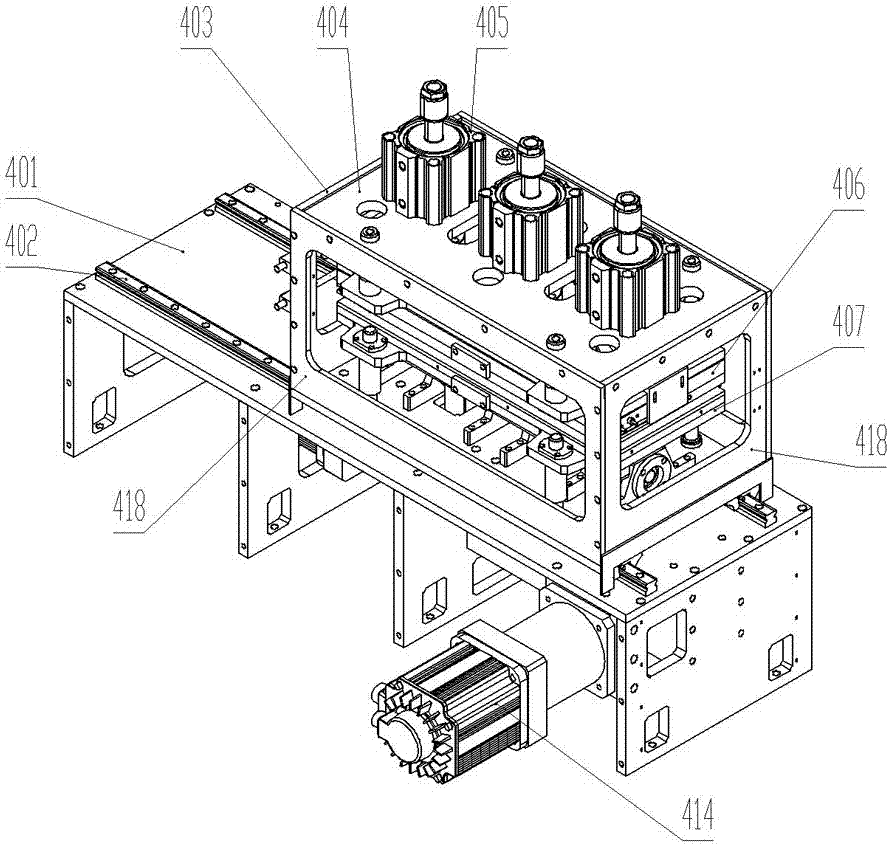

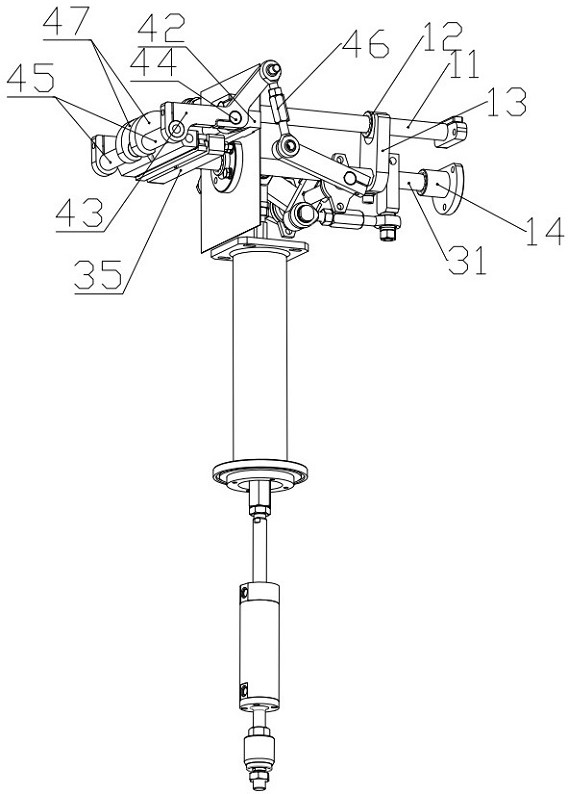

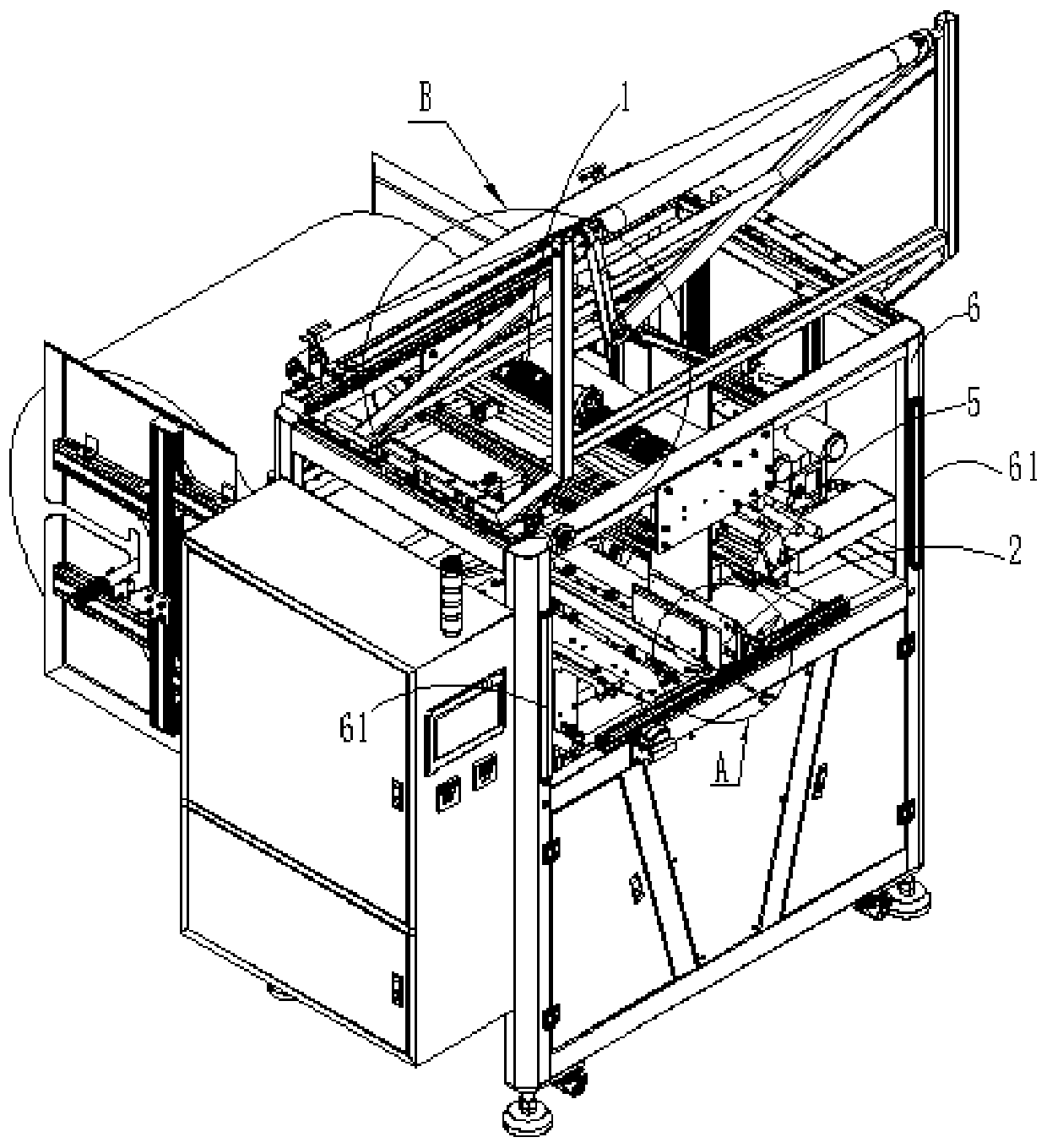

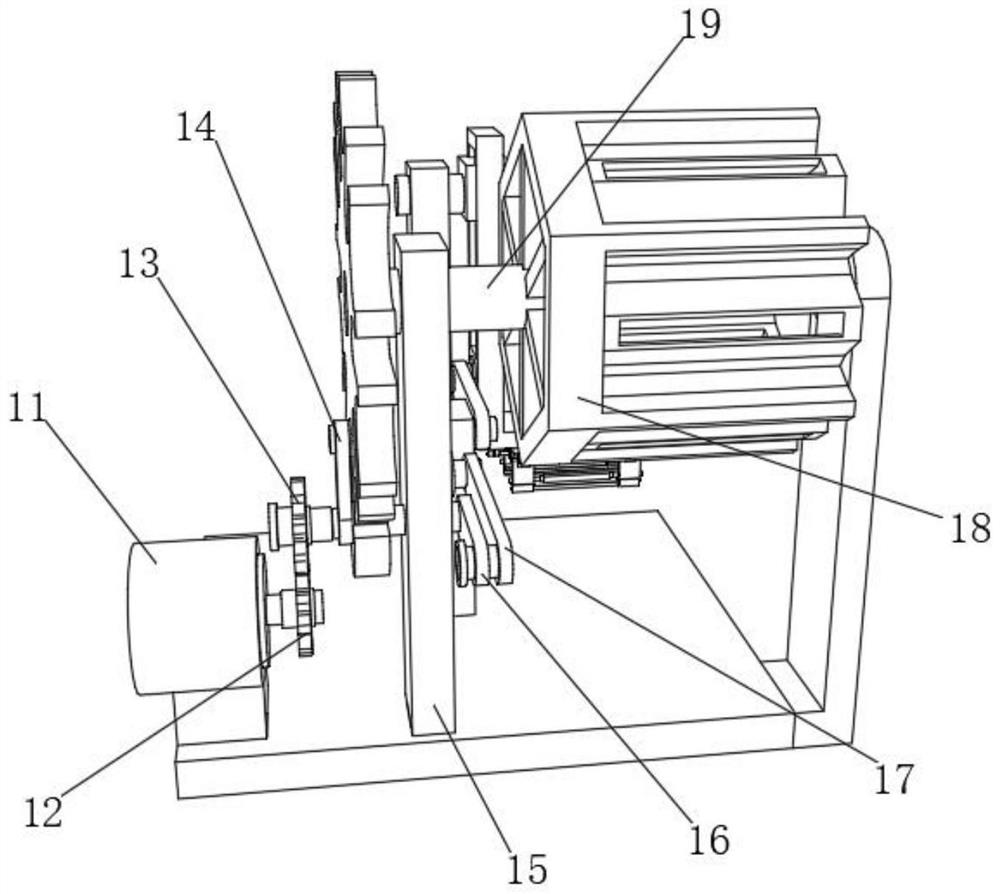

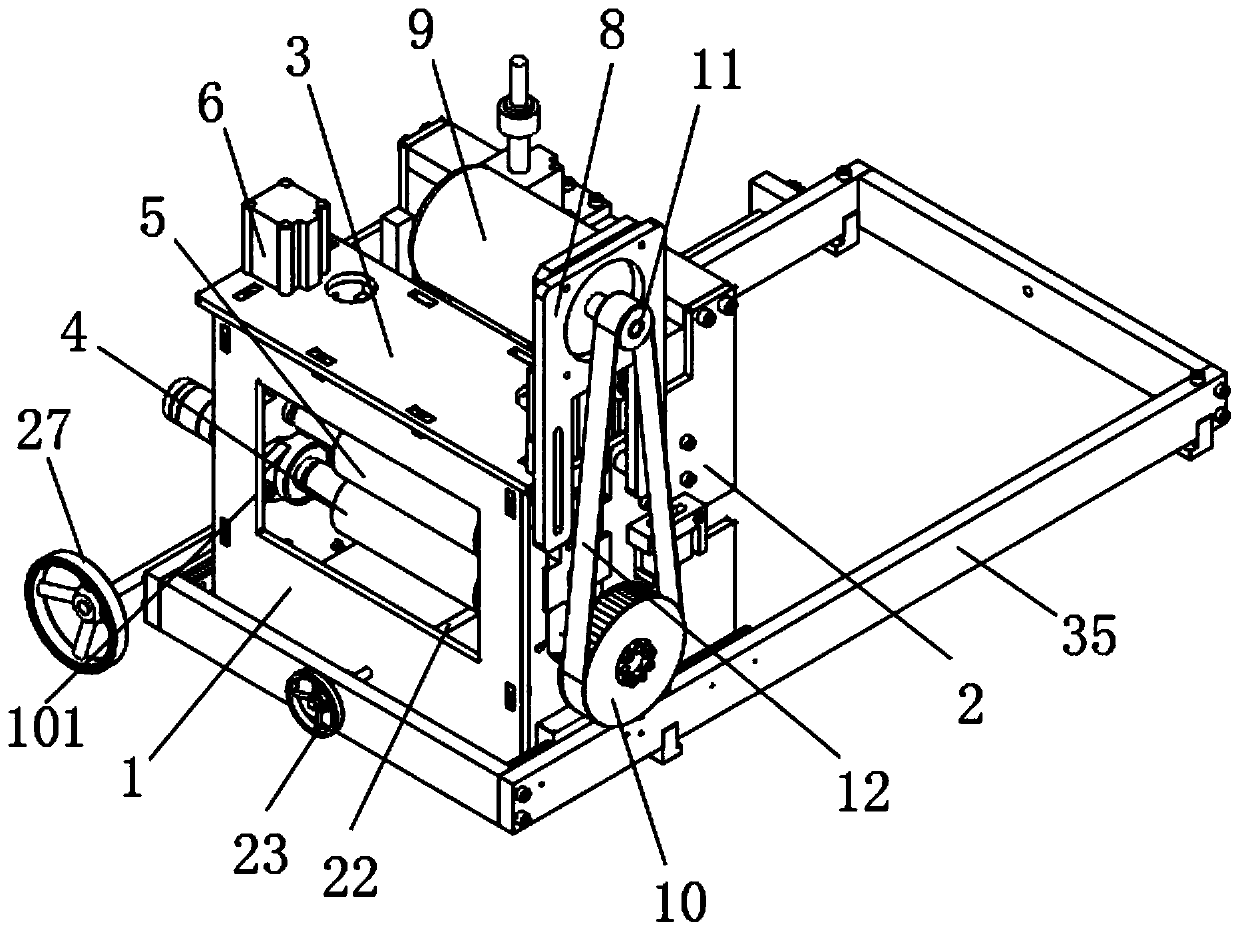

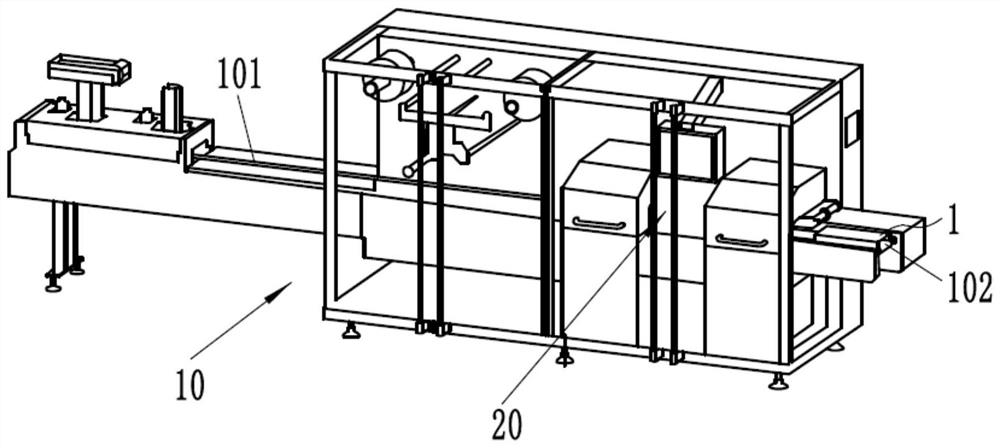

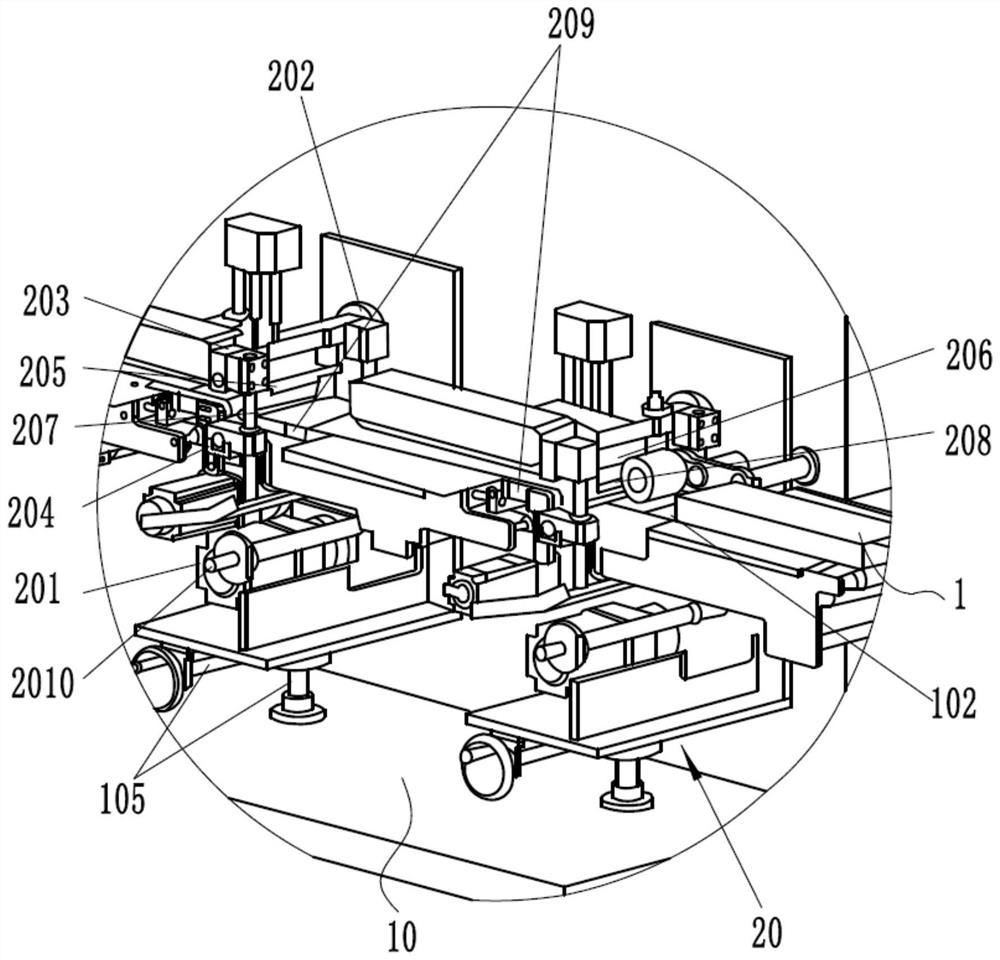

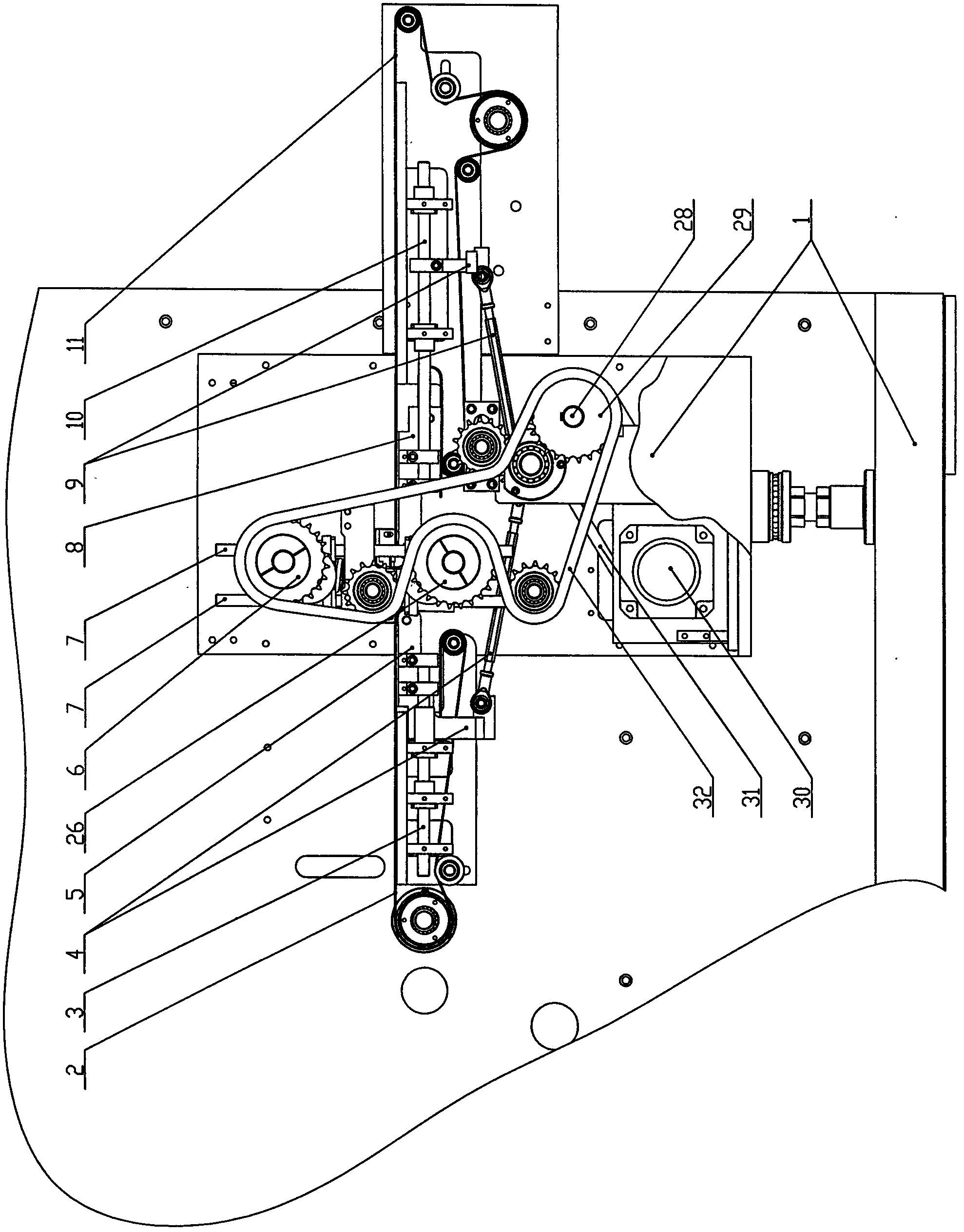

High-speed displacement type sealing and cutting assembly

ActiveCN104229217AGuaranteed heat sealing effectImprove the overall sealing and cutting speedWrapper twisting/gatheringEngineeringLow transmission

The invention discloses a high-speed displacement type sealing and cutting assembly applied to a pillow type packaging machine. The high-speed displacement type sealing and cutting assembly comprises a machine frame (1), an upper cutter shaft (21) and a lower cutter shaft (20), wherein upper transmission eccentric discs (23) are arranged at the two ends of the upper cutter shaft, and lower transmission eccentric discs (22) are arranged at the two ends of the lower cutter shaft. The upper transmission eccentric discs and the lower transmission eccentric discs respectively do eccentric rotation, further, a sealing and cutting upper cutter, a sealing and cutting lower cutter and pillow packaging bags hot sealed between the sealing and cutting upper and lower cutters are driven to respectively and firstly move towards the left side and then move towards the right side for a certain distance, and the hot sealing is kept and lasts for a certain time for ensuring the hot sealing effect. Therefore the integral sealing and cutting speed can be accelerated, the packaging speed can reach more than 180 pieces per minute, in addition, the conveyance is fast and smooth, and the production efficiency is high.

Owner:瑞安市海创机械有限公司

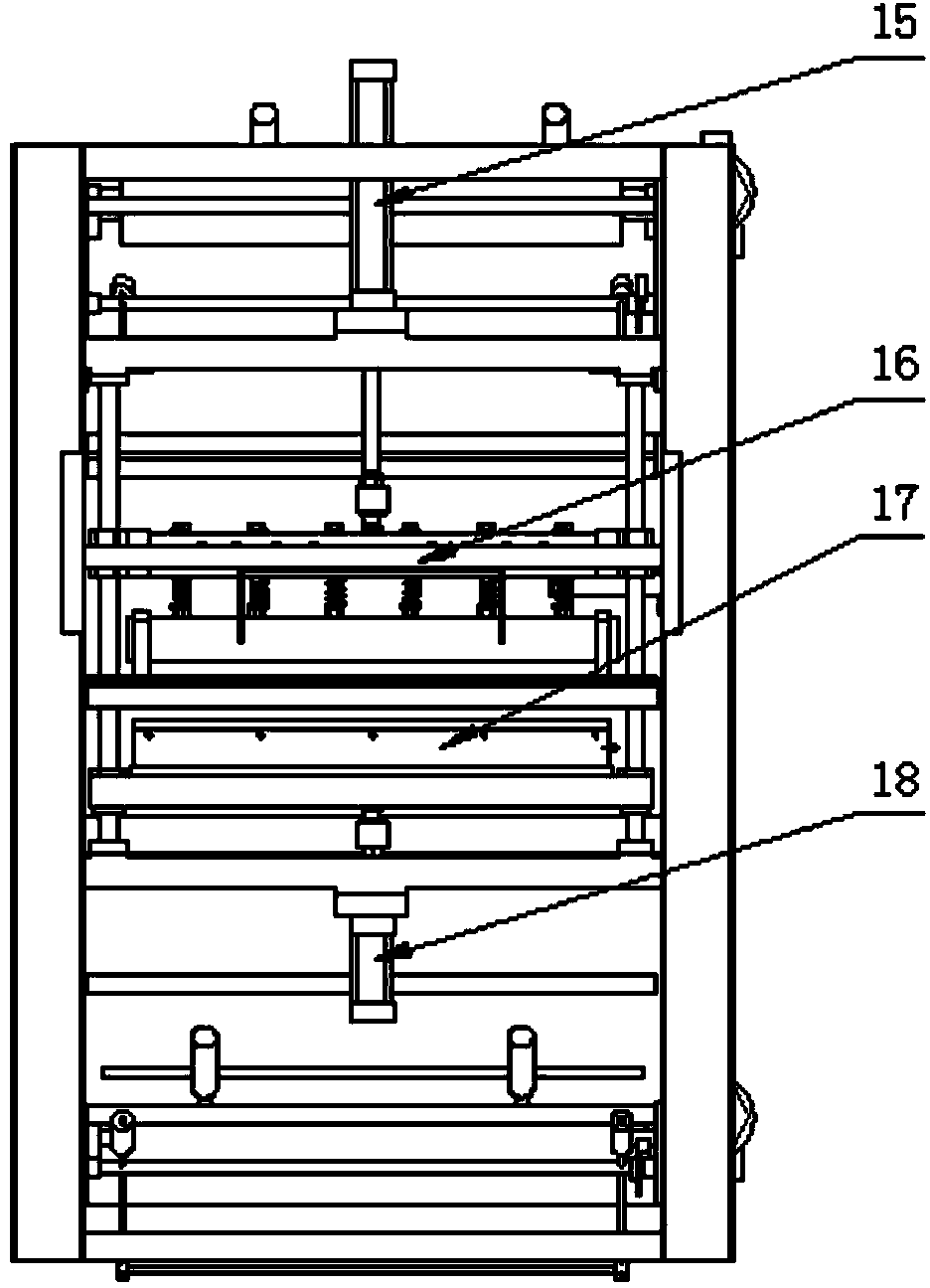

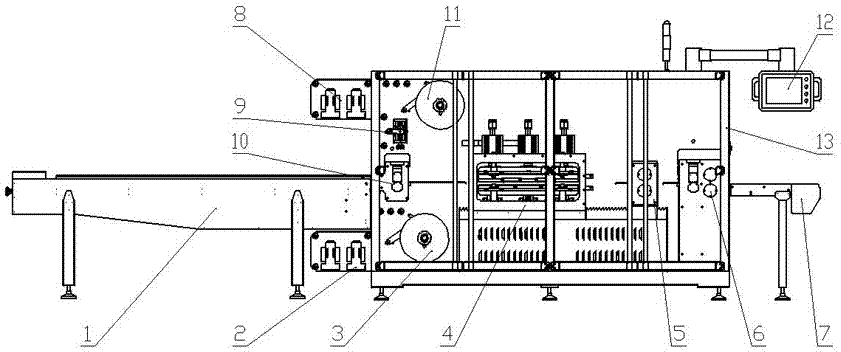

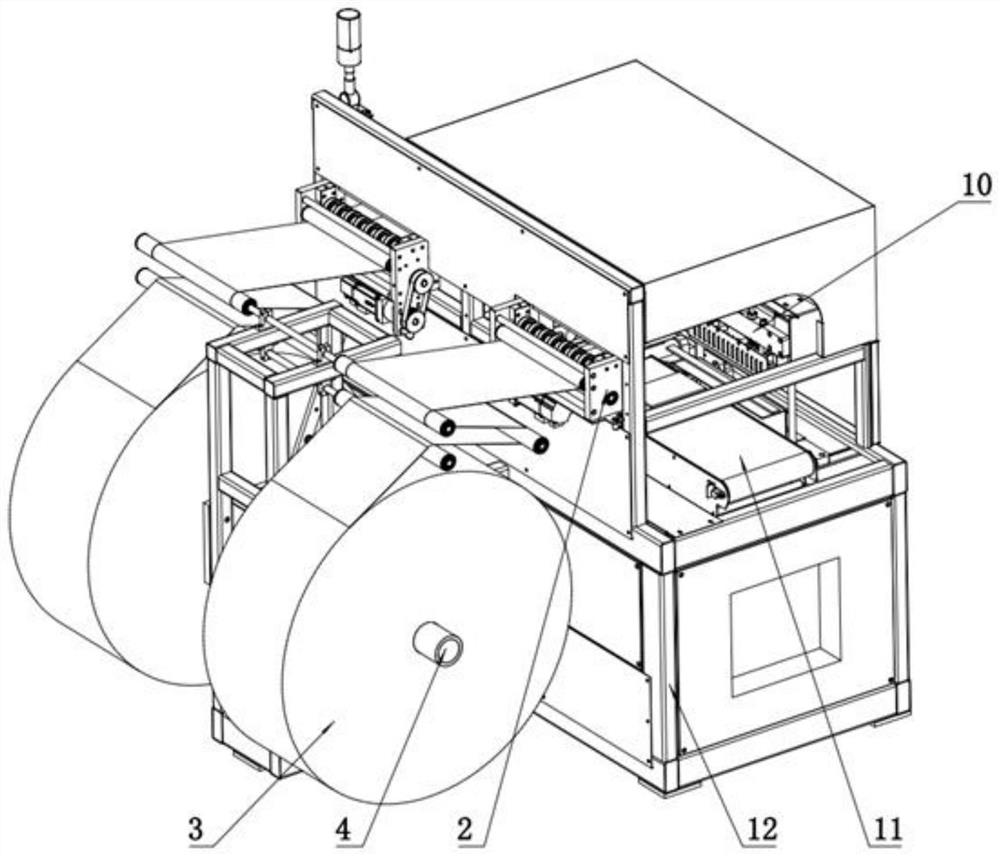

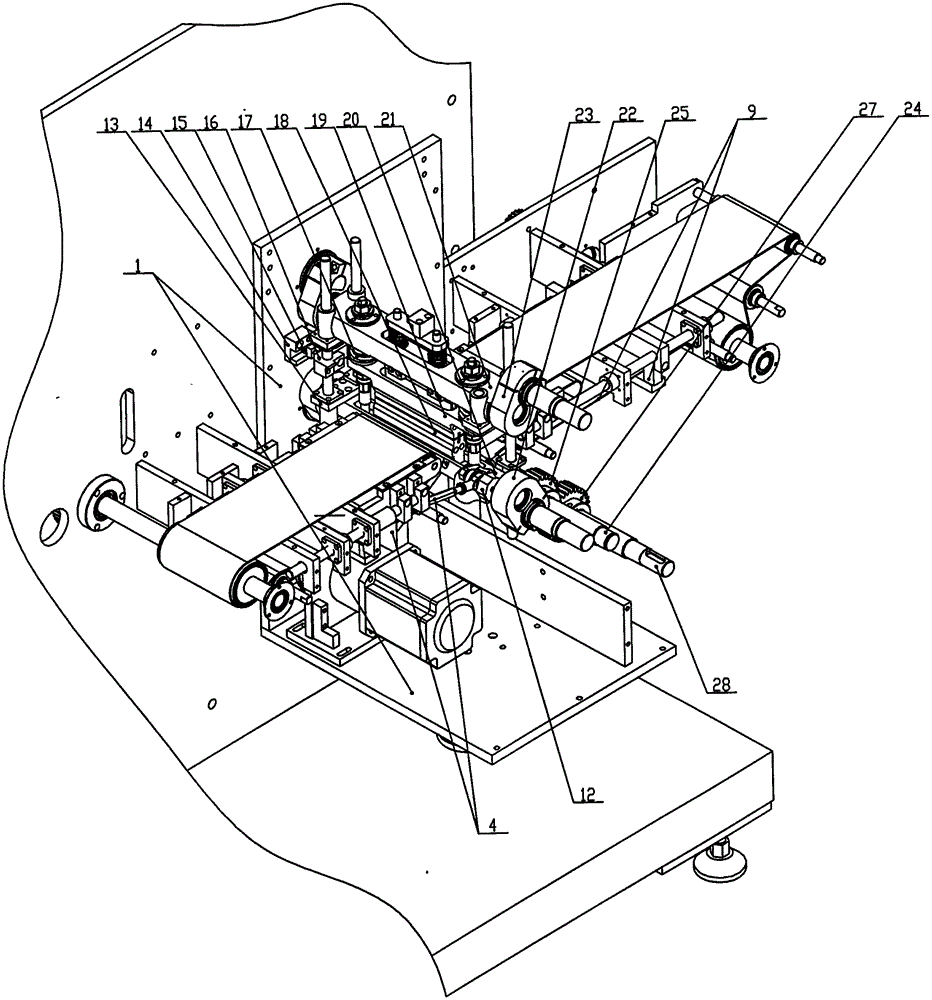

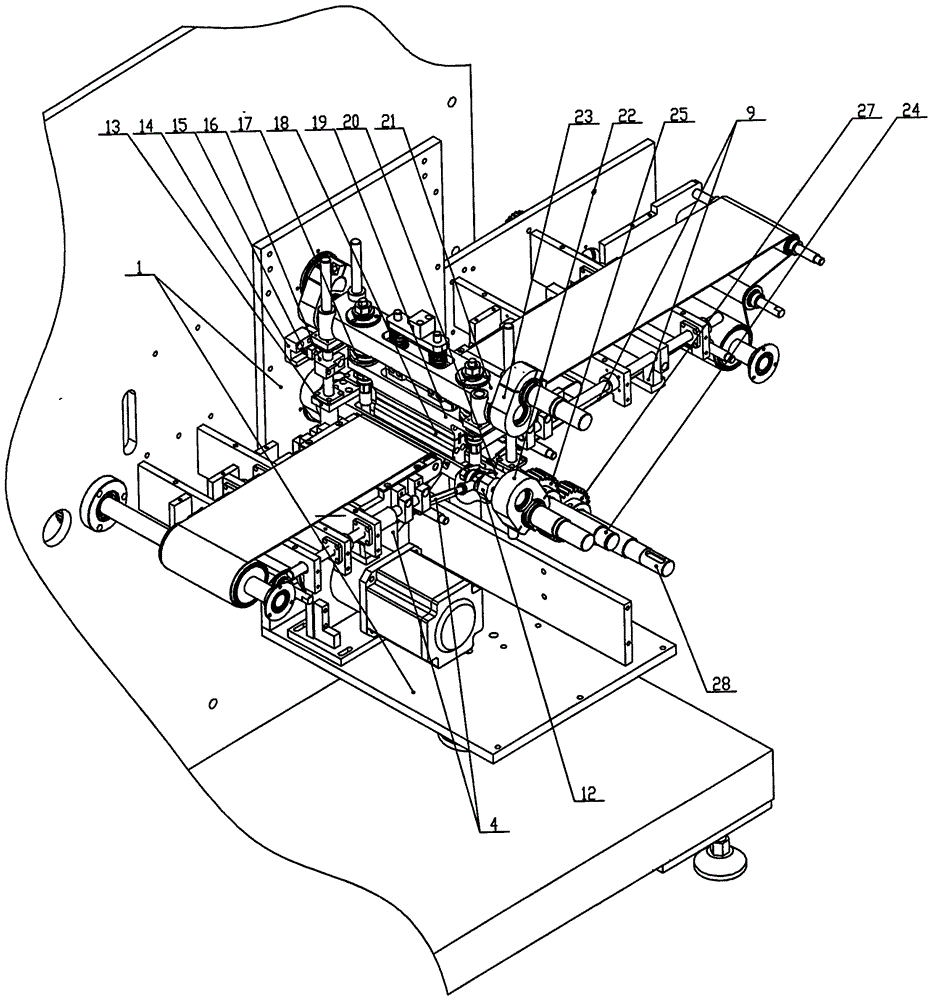

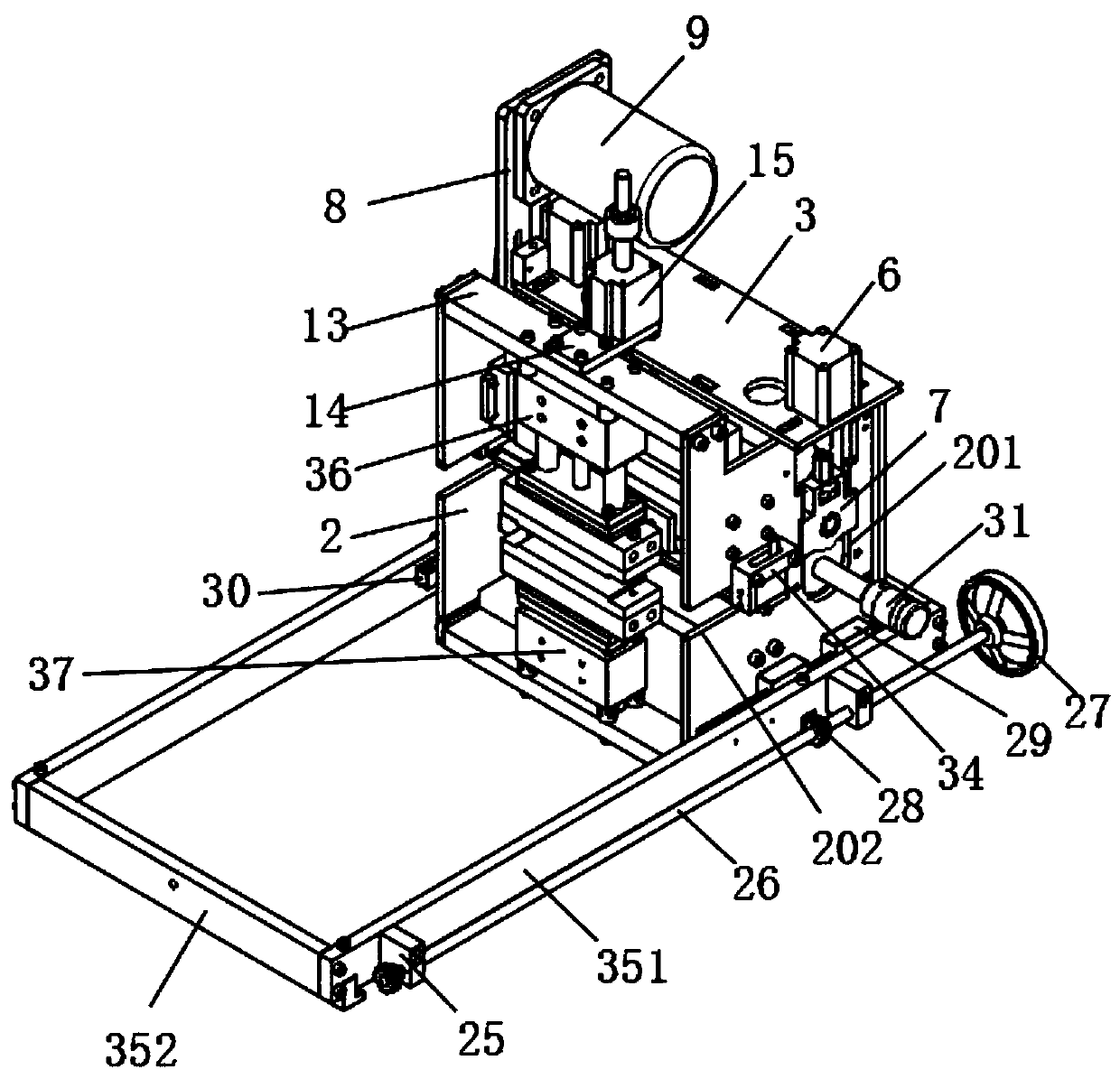

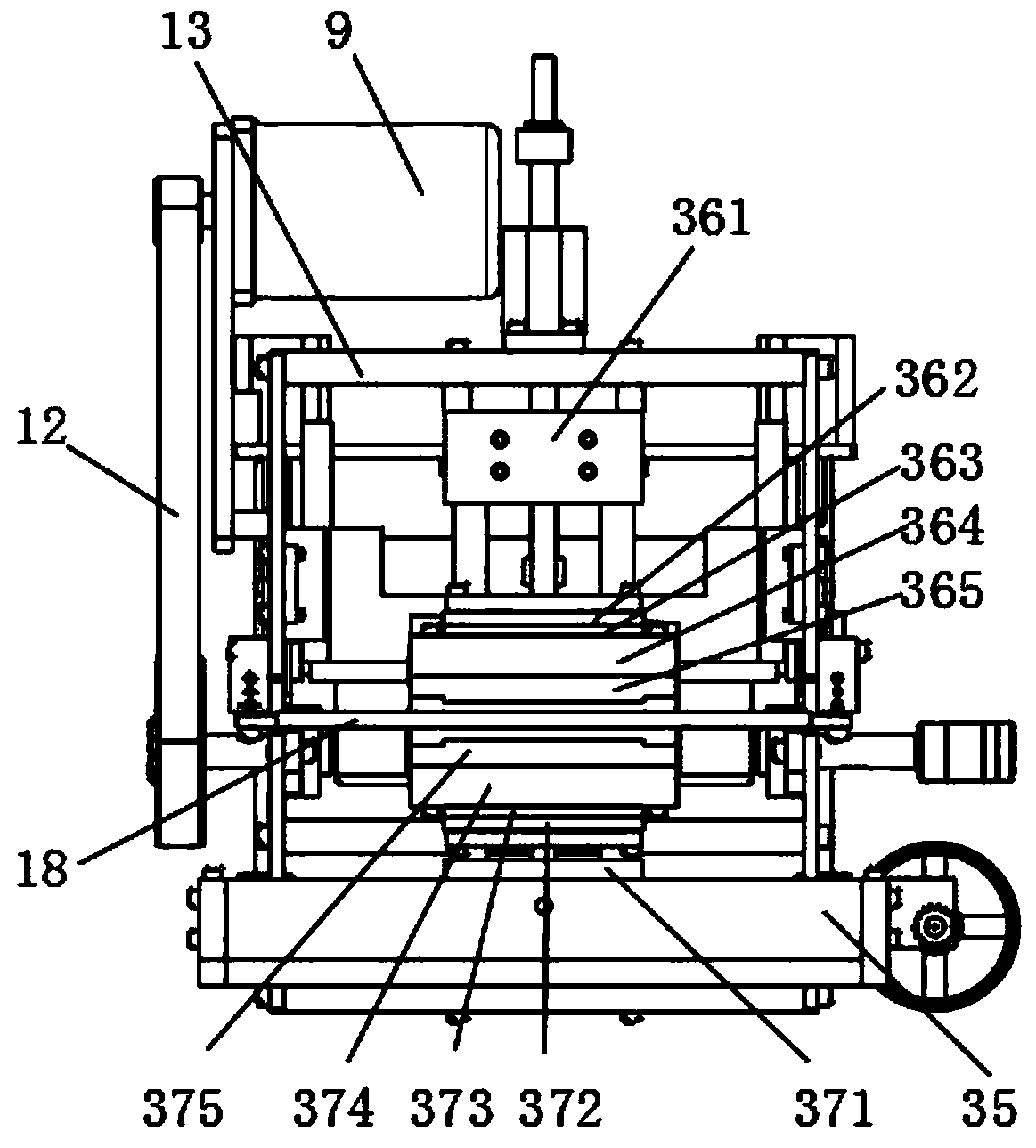

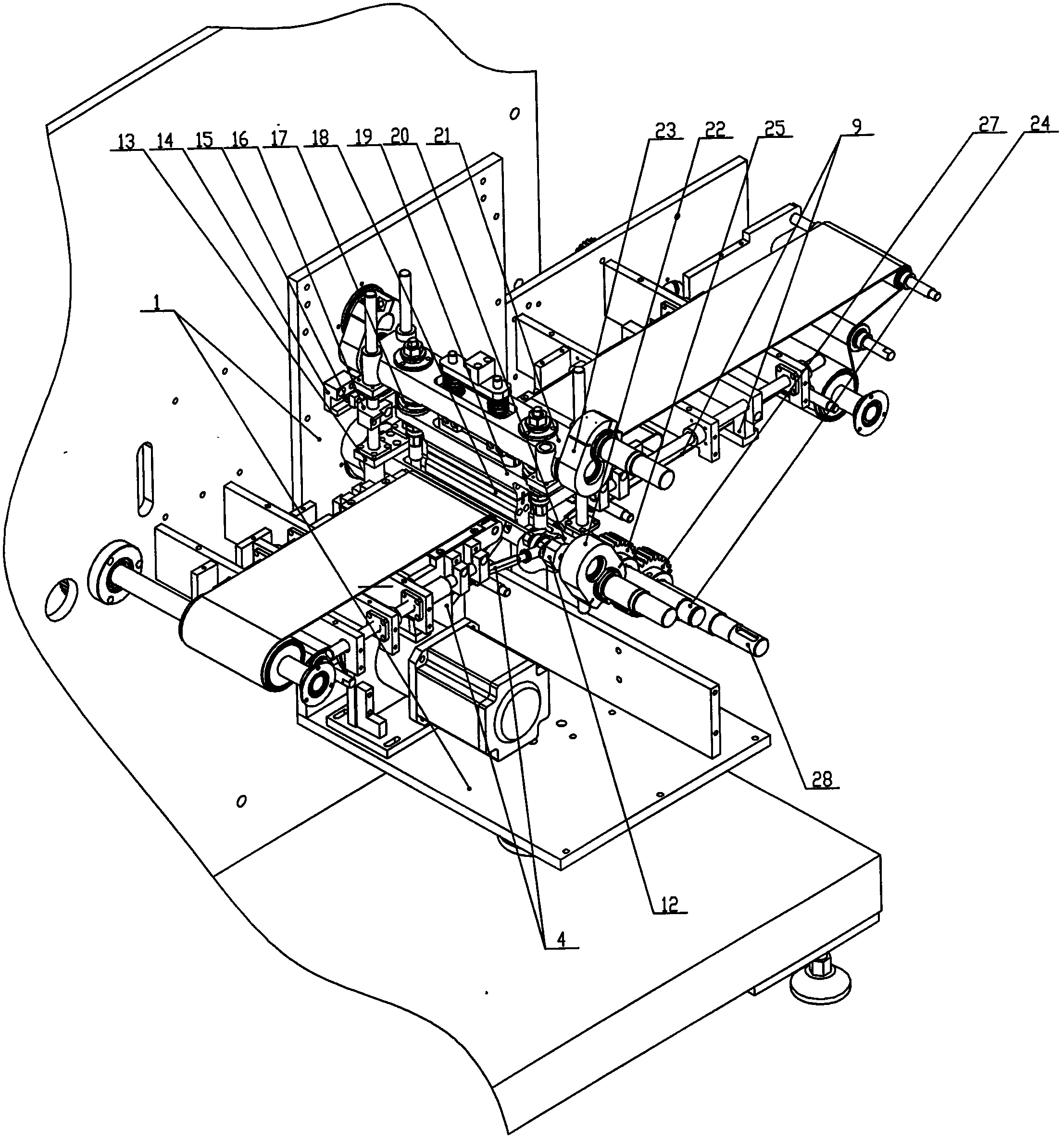

Full-automatic continuous four-side sealing packaging machine

InactiveCN106945886AGuaranteed heat sealing performanceExpanded range of specificationsWrapper twisting/gatheringMotor driveElectric machinery

The invention discloses a full-automatic continuous four-side sealing packaging machine. The full-automatic continuous four-side sealing packaging machine is characterized in that a heat sealing mechanism comprises a heat sealing frame and a heat sealing assembly; a second servo motor, a synchronous pulley I and a synchronous pulley II are arranged on the heat sealing frame; a synchronous belt II is wound on the synchronous pulley I and the synchronous pulley II; the second servo motor and the synchronous pulley I are linked; linear rails are further arranged on the heat sealing frame; the heat sealing assembly is provided with a top plate and a bottom plate; an upper module and a lower module are arranged between the top plate and the bottom plate; the bottom plate is mounted on sliding blocks of the linear rails; the synchronous belt II is linked with the bottom plate; a first servo motor is further fixedly mounted on the bottom surface of the bottom plate; a spindle is arranged on the top surface of the bottom plate; a plurality of eccentric wheels are arranged on the spindle at equal intervals; the first servo motor drives the spindle through a synchronous belt I; the upper module is connected with cylinders arranged on the top plate; and rollers which correspond to the eccentric wheels and are in contact with the eccentric wheels are arranged on the bottom surface of the lower module. According to the full-automatic continuous four-side sealing packaging machine, structure is simple, arrangement is convenient, the heat sealing effect is good, and continuous operation of the entire machine is achieved.

Owner:瑞安市华源包装机械厂

Novel packaging machine and using method thereof

PendingCN114229111AReduce adhesionAvoid stickingWrapping material feeding apparatusWrappingThermodynamicsProcess engineering

The invention relates to a novel packaging machine which comprises a conveying device for conveying a product, an upper film and a lower film which are positioned above the conveying device, and a heat-sealing cutting device arranged on the conveying device, and further comprises a first film releasing device for conveying the upper film to the position above the product, and a second film releasing device for conveying the lower film to the position between the product and the conveying device. Through the arrangement of the conveying device, the heat sealing and cutting device, the first film releasing device and the second film releasing device, a packaging bag is replaced by a packaging film, and manual work is replaced by a machine, so that the production cost is saved; through the arrangement that the first driving device is driven to drive the rotating roller to rotate, different positions on the circumferential surface of the rotating roller are matched with the heat-sealing cutter, so that the pressure-bearing surface matched with the heat-sealing cutter is continuously changed, the heat-sealing frequency of the heat-sealing cutter is increased, meanwhile, the rotating roller rotates to provide stable forward conveying power for products, collision of the products is prevented, and the production efficiency is improved. And normal production is ensured.

Owner:济南聚隆兴机电科技有限公司

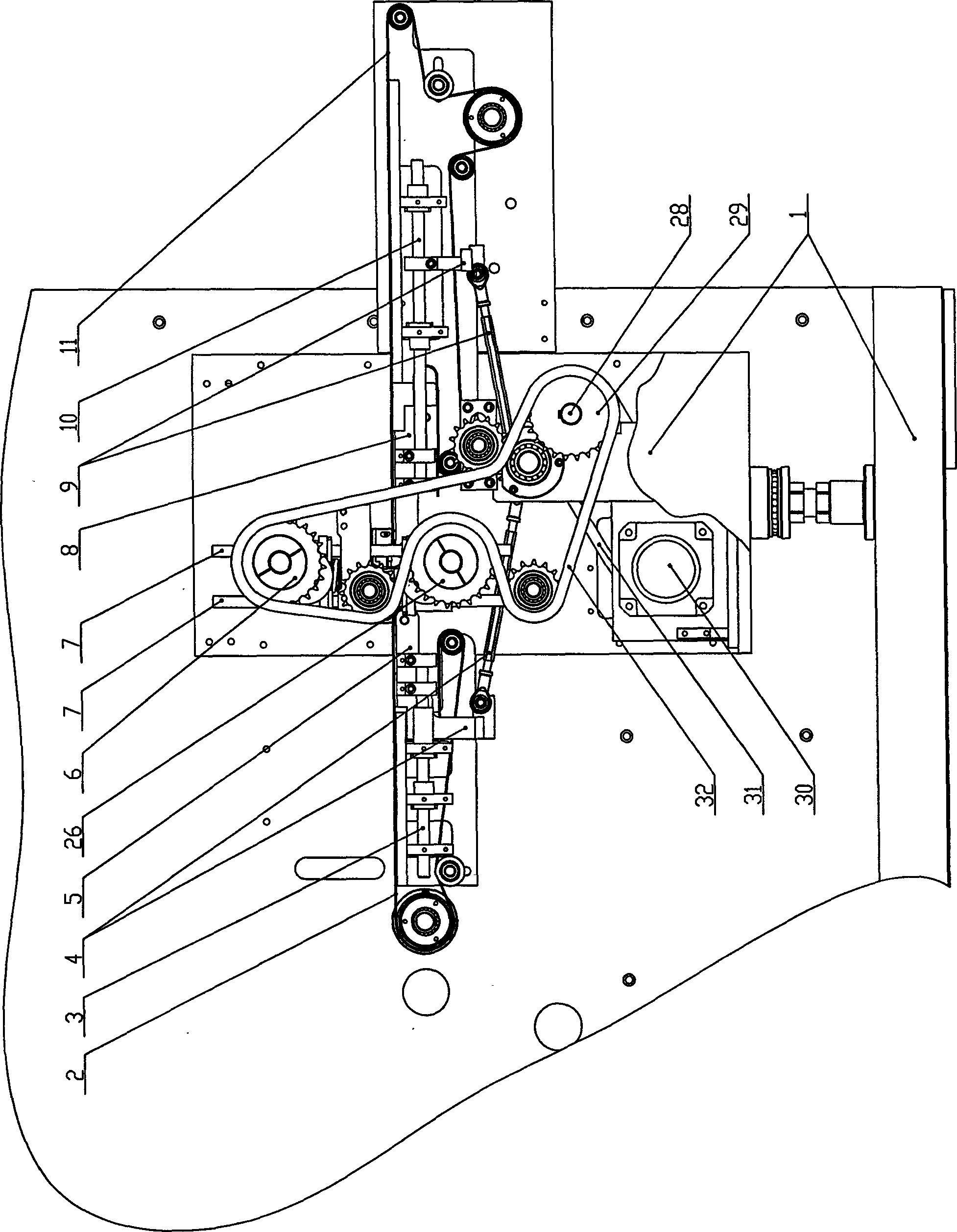

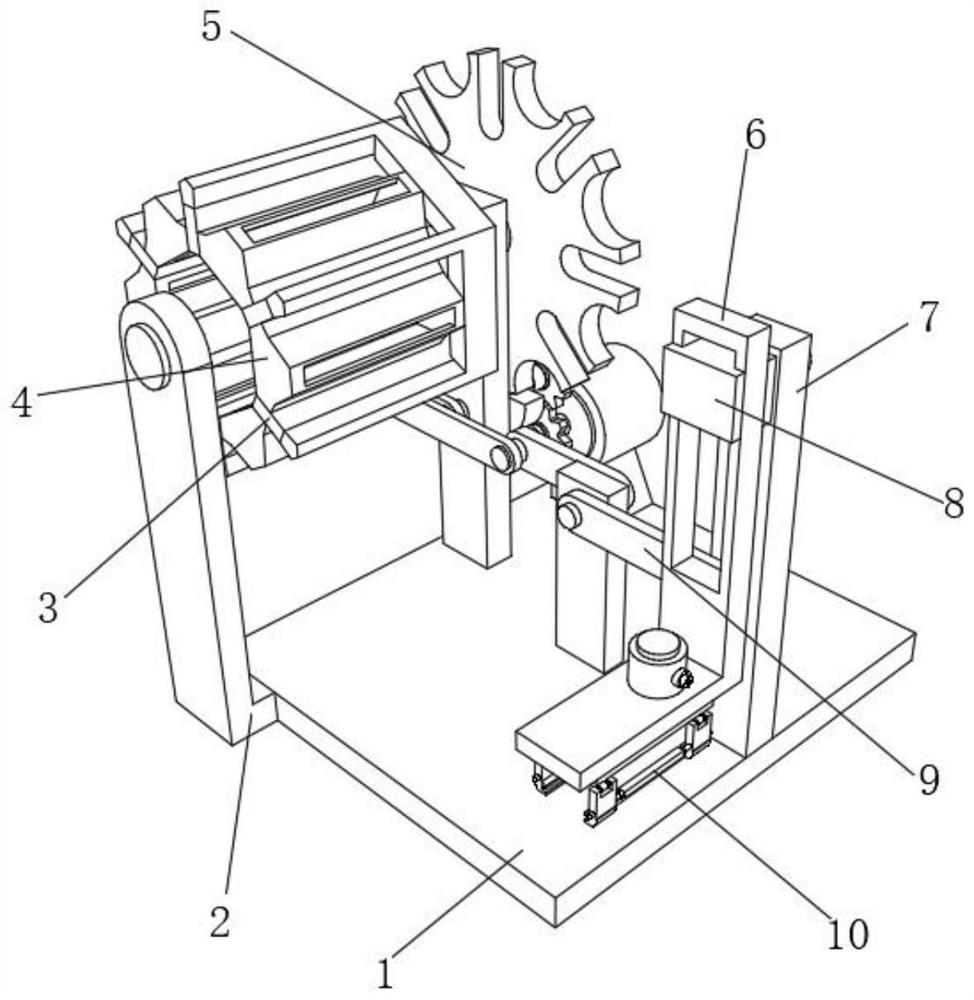

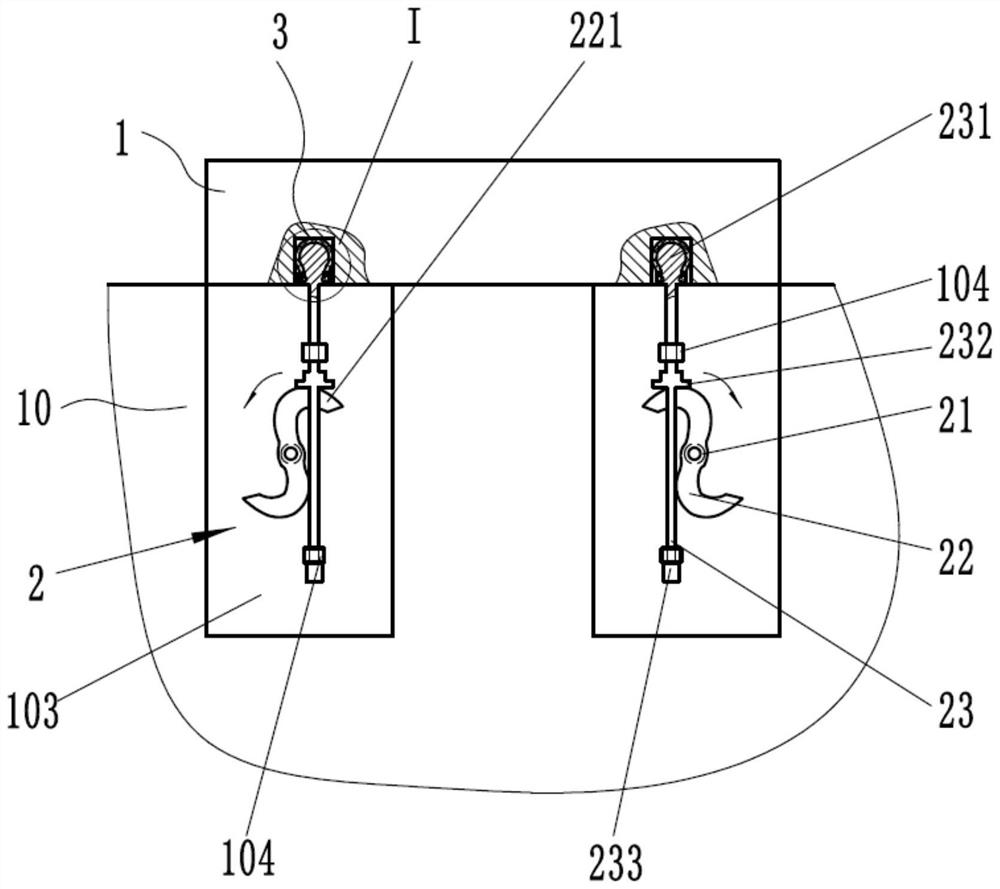

Bottom edge heat seal mechanism for cigarette sealing and packaging

InactiveCN105752413AGuaranteed heat sealing performanceReasonable designWrapper twisting/gatheringEngineeringTower

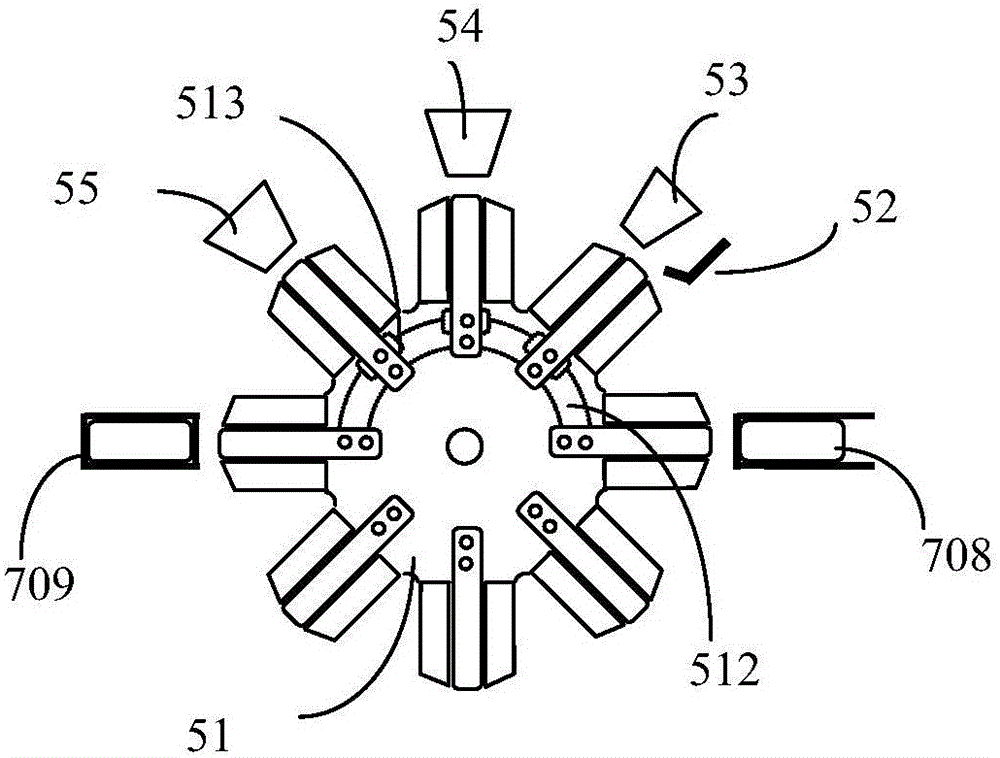

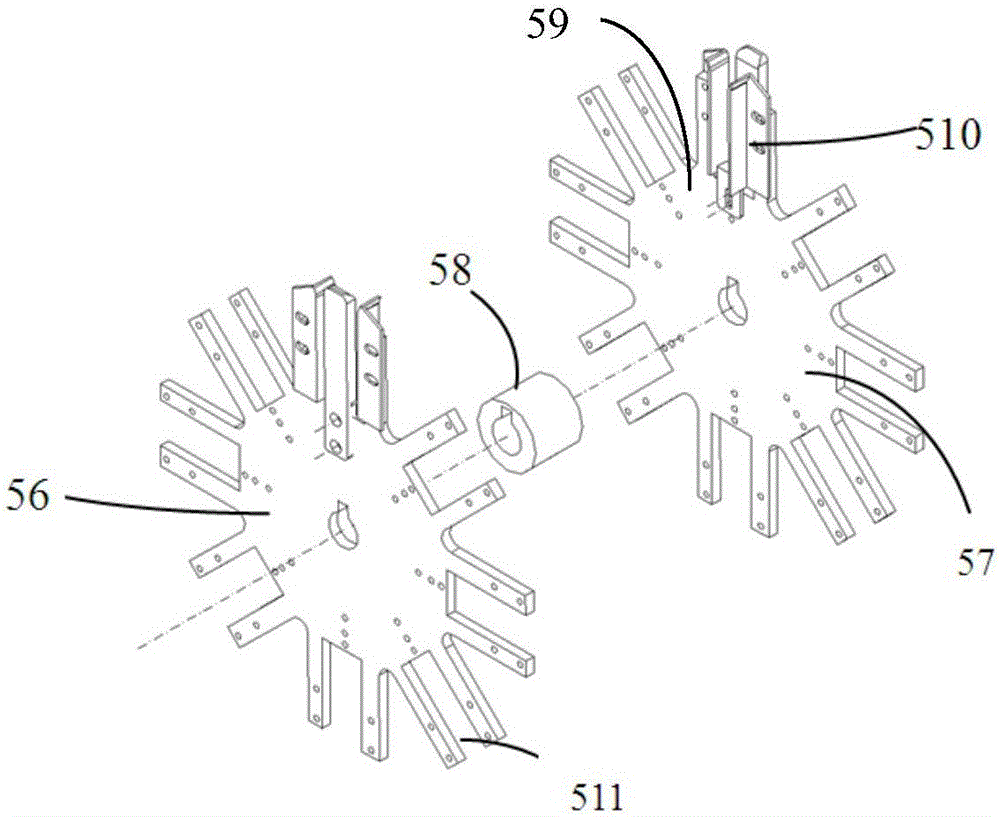

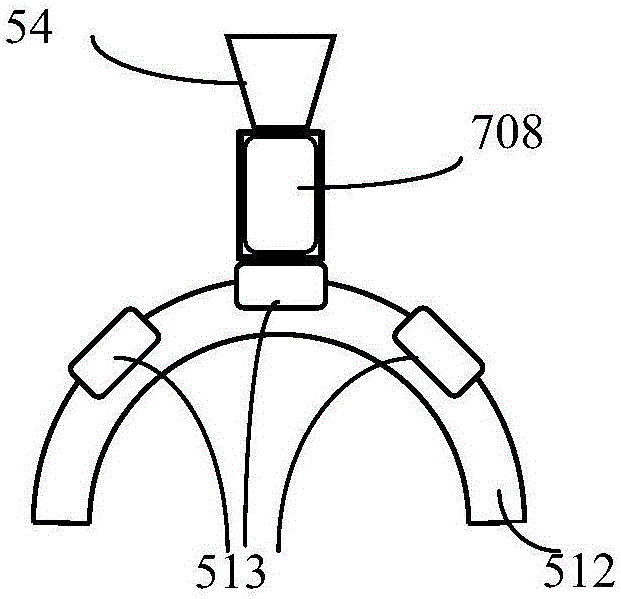

The invention discloses a bottom edge heat seal mechanism for cigarette sealing and packaging. The bottom edge heat seal mechanism comprises an octagonal rotary tower, a bottom edge folder, a bottom edge pre-sealing solder iron and a bottom edge heat seal solder iron, wherein the octagonal rotary tower comprises eight stations which are a station I, a station II, a station III, a station IV, a station V, a station VI, a station VII and a station VIII in sequence from the right side anticlockwise; the bottom edge folder, the bottom edge pre-sealing solder iron and the bottom edge heat seal solder iron are arranged at the corresponding station II, station II and station III of the octagonal rotary tower respectively; the octagonal rotary tower rotates anticlockwise; the octagonal rotary tower comprises a left rotary plate and a right rotary plate which are arranged in a mirror symmetry manner; the left rotary plate is connected with the right rotary plate through a rotary shaft; the left rotary plate or the right rotary plate comprises a rotary plate and a rotary tower mould box; a clamping groove is formed in the rotary plate; and the rotary tower mould box is matched with the clamping groove. The bottom edge heat seal mechanism is reasonable in design and simple in structure; and through the mechanism, the folding of the bottom edge and the heat seal treatment of a folded lapping hole in sealing and packaging can be effectively finished and the bottom edge heat seal effect of cigarette sealing and packaging can be ensured.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Temperature Compensation Method for Cushion Air Cushion Machine

ActiveCN106217847BInfluence of heat sealing effectGuaranteed heat sealing performanceMachine controlRoom temperature

The invention discloses a temperature compensation method for a buffering air cushion machine. In the temperature compensation method, the temperature value T of a heating pipe is set, the starting temperature correction value TK is set according to the temperature of a bottom plate when the buffering air cushion machine is started, the room temperature correction value TS is set according to the detected indoor temperature of the position where the buffering air cushion machine is located, and the running time correction value TY of the buffering air cushion machine can be obtained in real time according to the compensation function; and in the actual operation, on the basis of the temperature value T of the heating pipe, at least one of the starting temperature correction value TK, the room temperature correction value TS and the running time correction value TY of the buffering air cushion machine can be offset, heating is stopped after the buffering air cushion machine controls the heating pipe to conduct heating till the sum of T and at least one of the TK, the TS and the TY is achieved, and therefore the situation that when the buffering air cushion machine conducts heat sealing on an air cushion film, the heat sealing effect is affected by the room temperature, the temperature of a heating block during starting, the running time of the buffering air cushion machine and other factors can be avoided, and the heat sealing effect of the air cushion film is ensured.

Owner:HANGZHOU BINGJIA TECH

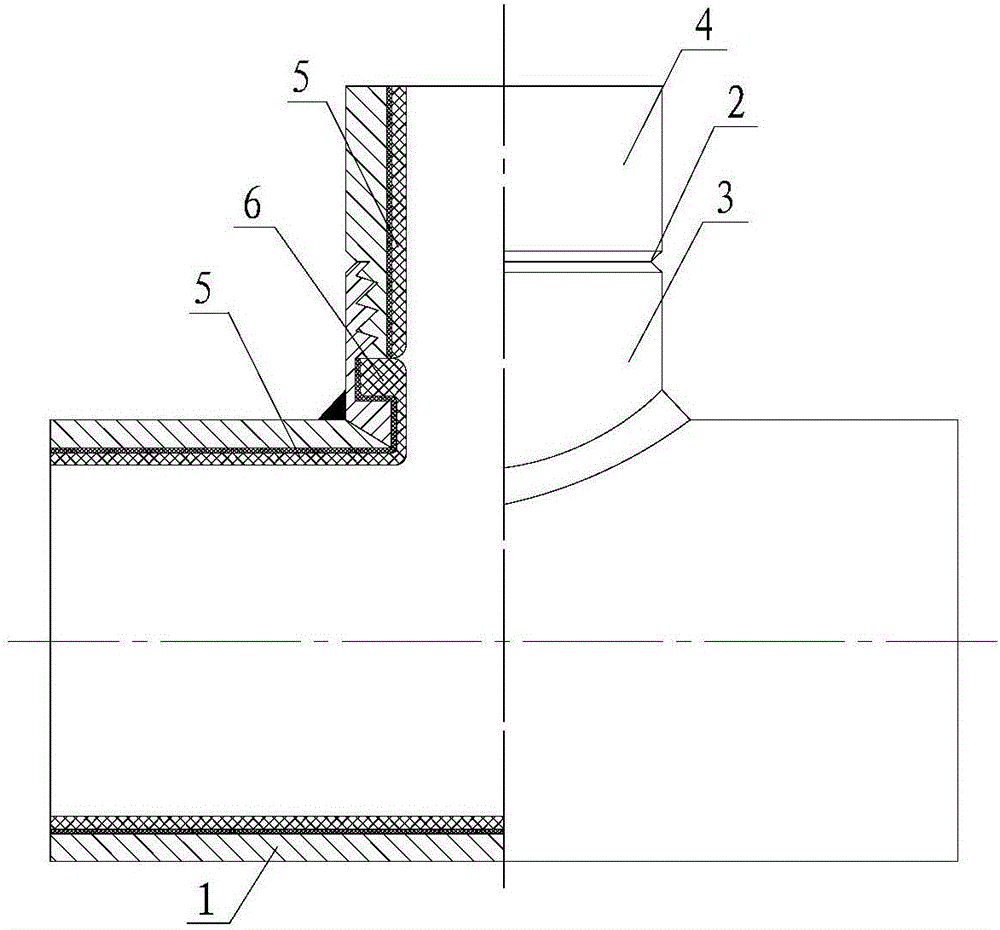

Method for fabricating plastic lining steel tee joint pipe fitting

ActiveCN105114740AGuaranteed heat sealing performanceBranching pipesRigid pipesManufacturing technologyPipe fitting

The invention discloses a method for fabricating a plastic lining steel tee joint pipe fitting and belongs to the technical field of composite steel tube design and manufacturing. The method for fabricating the plastic lining steel tee joint pipe fitting is applicable to various calibers and can guarantee the heat seal effect of plastic lining layers to the greatest extent. The fabrication method comprises the following steps of firstly, preparing a parent tube which constitutes a branch tube and a branch tube extension section; then welding the parent tube to a branch tube joint of a straight tube; subsequently, conducting integrated hot melting plastic lining on the straight tube and the parent tube, and meanwhile lining a composite layer transitional structure out of the tail end of a connection structure of the parent tube; then, installing the branch tube extension section where the plastic lining layer is completed to the tail end of the parent tube through the connection structure, and sealing the plastic lining layer at the inner side of the branch tube extension section and the plastic lining layer at the inner side of the parent tube through the composite layer transitional structure. By the mode, the plastic lining composition work for a plastic lining composite tee joint steel tube is completed.

Owner:成都共同制管有限公司

Biodegradable high-barrier paper-plastic packaging composite film and preparation method thereof

PendingCN113619241AGood barrierExtended shelf lifeFlexible coversWrappersPaper sheetPolymer chemistry

The invention provides a biodegradable high-barrier paper-plastic packaging composite film and a preparation method thereof. The biodegradable high-barrier paper-plastic packaging composite film sequentially comprises an ink layer, a paper layer, a bonding layer, an aluminized layer and a PLA layer from outside to inside, wherein the PLA layer is modified through a thermoplastic elastomer, and after modification, the temperature resistance and toughness of the PLA layer can be improved, the heat sealing performance of the PLA layer is guaranteed, and the packaging requirements of different contents and different weights are met; and the aluminized layer can ensure that a final finished product has good barrier property and prolong the shelf life of the contents. The biodegradable high-barrier paper-plastic packaging composite film has the advantages of being exquisite in printing appearance, good in display effect and the like, is made of degradable materials, can be biodegraded after being used, and is free of pollution to the environment.

Owner:JIANGSU LEATER GREEN PACKAGING CORP LTD

Heat sealing mechanism of packaging machine

PendingCN112830023ANo interferenceImprove work efficiencyPackaging by pressurising/gasifyingWrapper twisting/gatheringHeat sealerReciprocating motion

The invention discloses a heat sealing mechanism of a packaging machine, and relates to the field of packaging equipment. The heat sealing mechanism of the packaging machine comprises a rack, a driving assembly, a first heat sealing assembly and a second heat sealing assembly, the first heat sealing assembly and the second heat sealing assembly are oppositely arranged and do synchronous opposite separation movement, the driving assembly is in linkage connection with the first heat sealing assembly and the second heat sealing assembly, drives the first heat sealing assembly to do linear reciprocating motion, and synchronously drives the second heat sealing assembly to do reciprocating swing motion, and an avoiding space is formed in the middle section of the second heat sealing assembly. The heat sealing mechanism has the advantages of being good in heat sealing effect and high in working efficiency.

Owner:WENZHOU KEDI MACHINERY

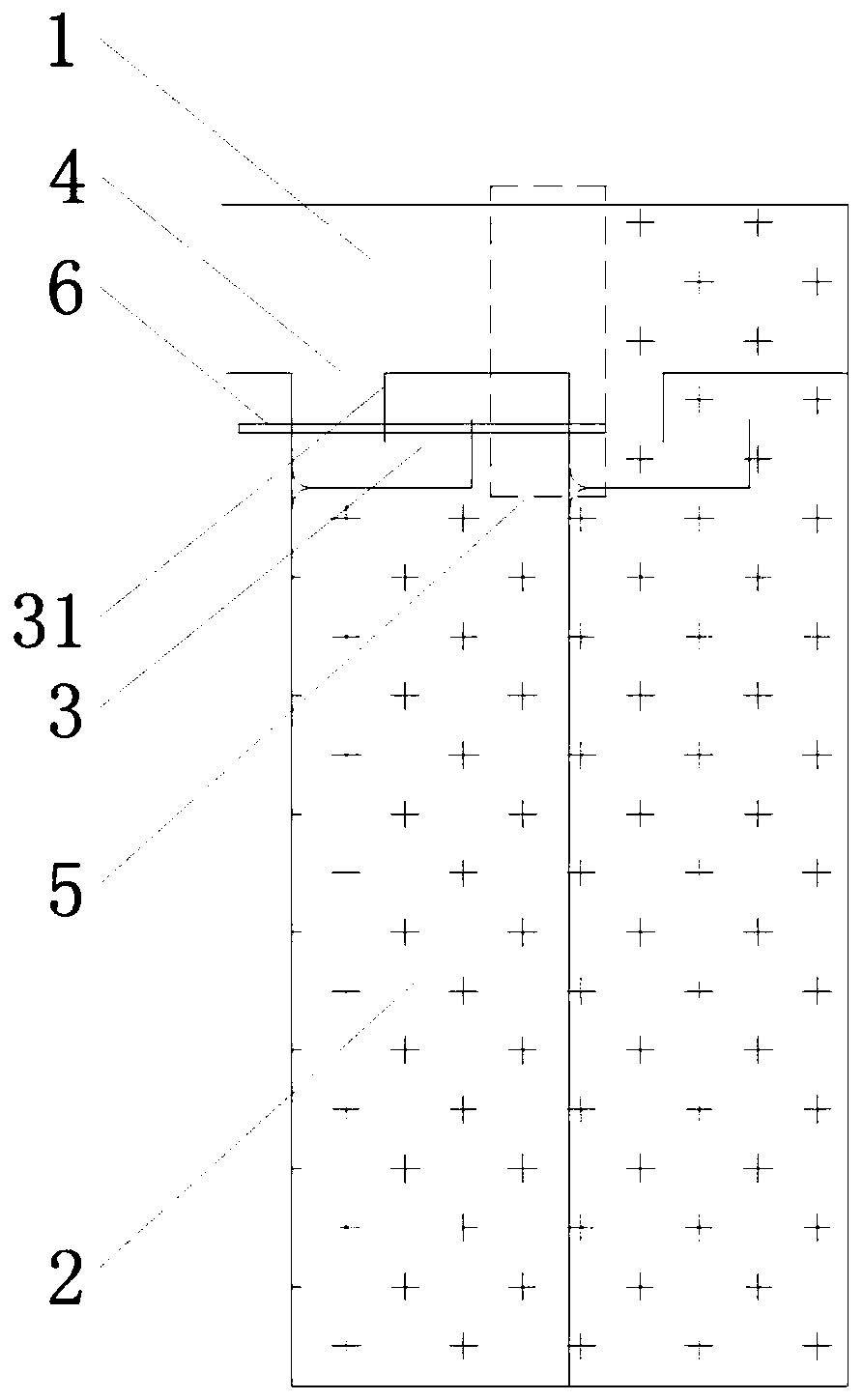

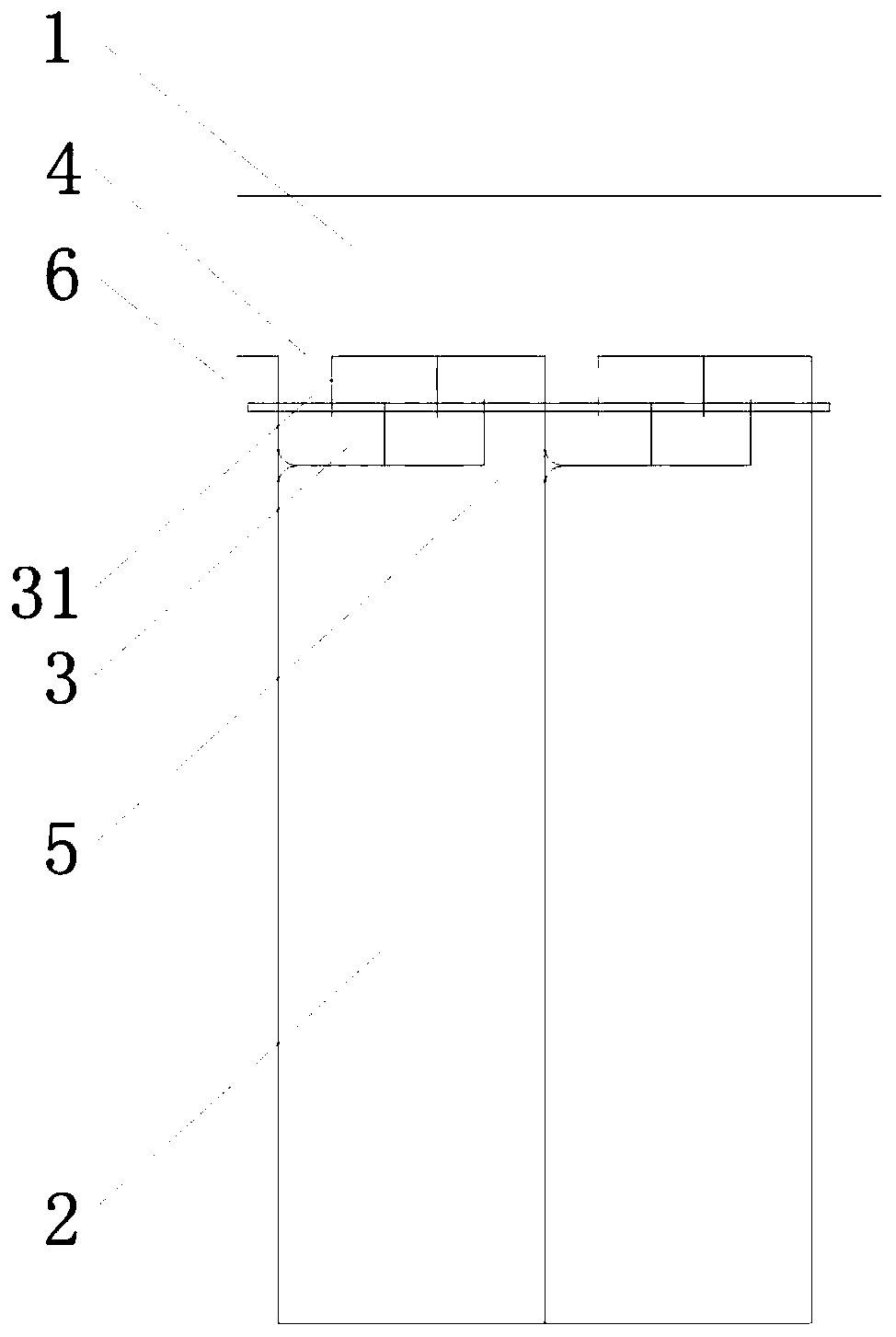

High-speed continuous sealing and cutting device

ActiveCN104229218BGuaranteed heat sealing performanceIncrease sealing and cutting speedWrapper twisting/gatheringEngineeringDisplacement control

The invention discloses a high-speed continuous sealing and cutting device applied to a pillow packaging machine. An upper transmission eccentric disc (23) is installed at both ends of an upper cutter shaft, and a lower transmission eccentric disc (23) is installed at both ends of a lower cutter shaft. disc (22); between its input belt assembly and output belt assembly, it is connected successively through the input displacement transmission rod (4), displacement eccentric seat (12), and output displacement transmission rod (9). On the control shaft (24), the displacement control shaft is connected with the main drive assembly. The invention makes the upper transmission eccentric disk and the lower transmission eccentric disk rotate eccentrically, and then drives the upper sealing and cutting knife and the lower sealing and cutting knife, as well as the heat-sealed pillow-type packaging bag between them, to first shift to the left and then to the right Displace a certain distance and keep heat sealing for a certain period of time to ensure the heat sealing effect. Therefore, the overall sealing and cutting speed can be improved, reaching more than 180 pieces per minute, and the transportation is fast and smooth, and the production efficiency is high.

Owner:浙江海众机械有限公司

Highly wear-resistant biodegradable material for mobile phone shell and preparation method thereof

The invention discloses a highly wear-resistant biodegradable material for a mobile phone shell. The highly wear-resistant biodegradablematerial comprises the following raw materials in parts by weight: 10-20 parts of straw, 50-70 parts of polylactic acid, 0.5-3 parts of a titanate coupling agent, 3-10 parts of a wear-resistant additive, 3-10 parts of a flame retardant, 3-10 parts of an antibacterial agent, and 1-4 parts of graphene. A preparation method comprises the following steps: washing, oven-drying and crushing the straw; adding the wear-resistant additive, the flame retardant, and theantibacterial agent to the treated straw short fibers for stirring and mixing treatment; then adding the titanate coupling agent for coupling treatment; and adding polylactic acid and graphene to thecoupling treated material, sending the mixture into a mixing stirrer for blending and kneading, and directly producing the highly wear-resistant biodegradable material after the kneading treatment iscompleted. The product can be automatically degraded under natural conditions, the product is environmentallyfriendly, safe, and non-toxic, and has good wear resistance, softness, antistatic ability and antibacterial ability, and all performance indicators reach national standards.

Owner:刘辉

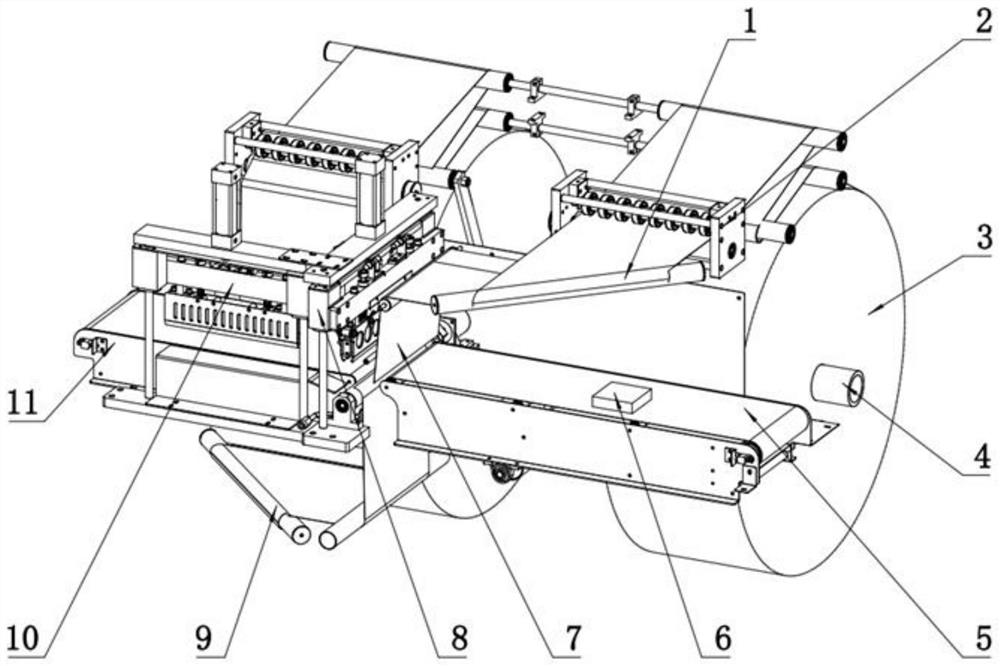

Plastic film packing machine

PendingCN110217416AEasy feedingGuaranteed heat sealing performanceWrapping material feeding apparatusWrapper twisting/gatheringEngineeringPlastic film

The invention provides a plastic film packing machine, and relates to the technical field of packing devices. The plastic film packing machine comprises a film supply mechanism, a charging mechanism and a bag making mechanism which are installed on a bracket; the film supply mechanism is used for conveying plastic films downwards; the charging mechanism is located below the film supply mechanism and used for expanding the plastic films; the bag making mechanism is located below the charging mechanism, can seal a side opening of the plastic films and can cut off and seal the opening formed in the cutting-off positions of the plastic films; and the bag making mechanism comprises a driving assembly, an elastic assembly, a heat sealing cutter and a base plate, the elastic assembly is arrangedbetween the driving assembly and the heat sealing cutter, and / or, the elastic assembly is arranged between the driving assembly and the base plate. The technical problems that in the prior art, afteropenings of plastic films are subjected to heat sealing through a plastic film packing machine, the heat sealing positions are irregular, poor in sealing stability and inaesthetic are solved.

Owner:BLUESWORD INTELLIGENT TECH CO LTD

Cigarette packet transparent paper heat-sealing soldering iron and using method thereof

PendingCN113978845AGrowth Size LengthExtend heat sealing timeWrapper twisting/gatheringMetallurgyMaterials science

The invention discloses a cigarette packet transparent paper heat-sealing soldering iron and a using method thereof. The cigarette packet transparent paper heat-sealing soldering iron comprises two sets of soldering iron bodies which are symmetrically arranged, heat-sealing grids and soldering iron protruding blocks are arranged on the inner side faces of the two sets of soldering iron bodies, the heat-sealing grids are arranged at one ends of the soldering iron bodies, the soldering iron protruding blocks are arranged in the middles of the soldering iron bodies, threaded holes are formed in the outer side faces of the soldering irons, and the two sets of soldering irons are installed at the two ends of a cigarette packet output channel of the packaging machine through the threaded holes respectively. According to the cigarette packet transparent paper heat-sealing soldering iron, the size and length of the soldering iron are increased, the transparent paper heat-sealing time is prolonged, and the heat-sealing effect is guaranteed; by designing the grid shape at the tail part of the soldering iron, the heat sealing time of the soldering iron is prolonged, and meanwhile, the transparent paper can be prevented from being damaged and wrinkled due to long-time heat sealing through heat dissipation; and the protrusion is designed in the middle of the soldering iron, key heat sealing can be conducted on a transparent paper lap joint, the heat sealing effect is guaranteed, and the air tightness of cigarette packet transparent paper is guaranteed.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

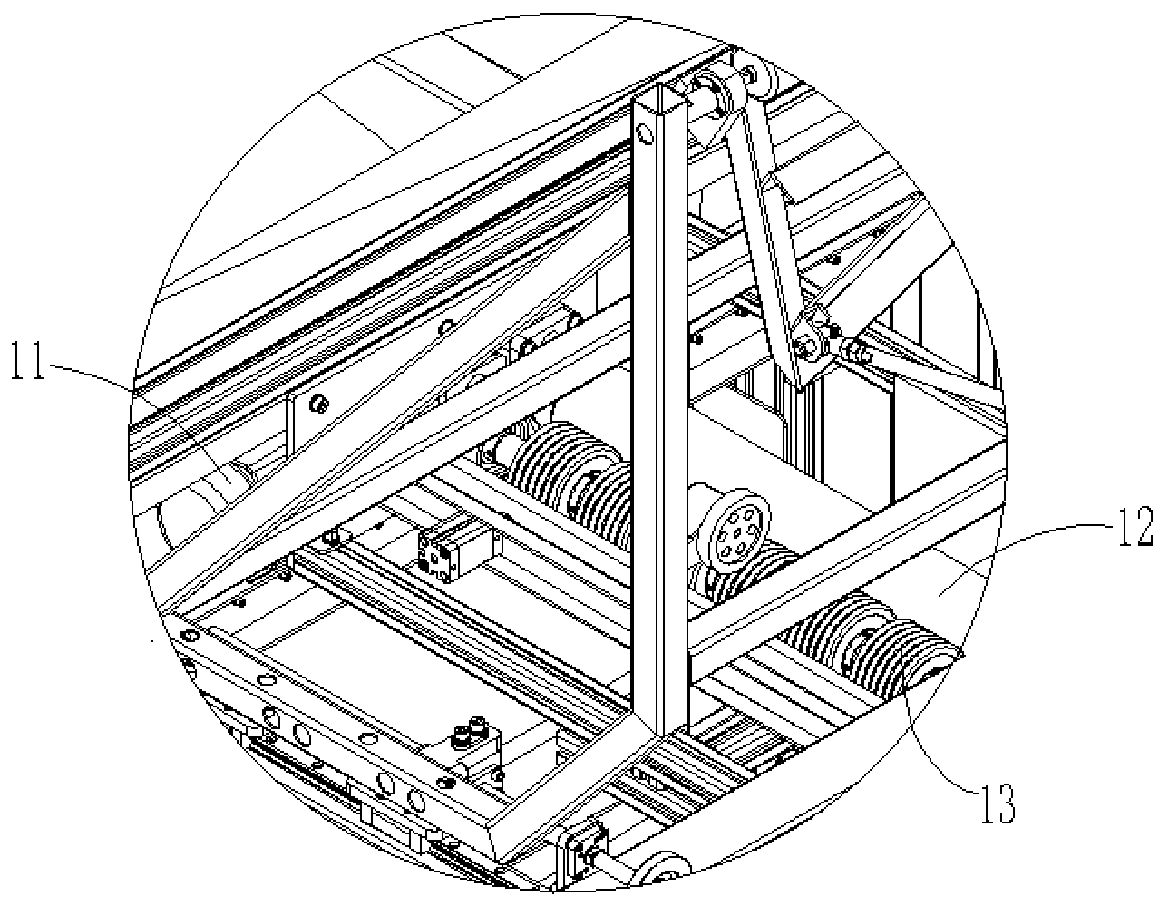

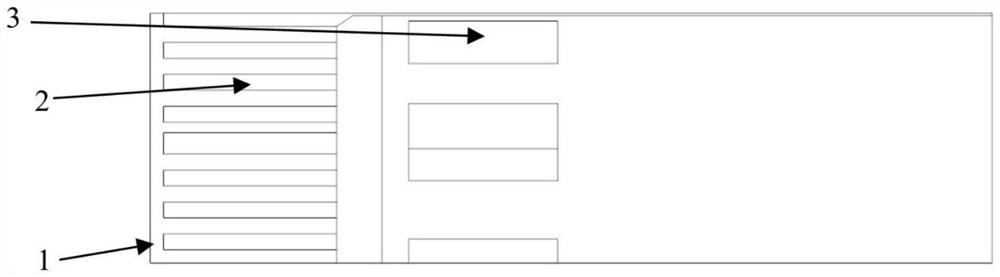

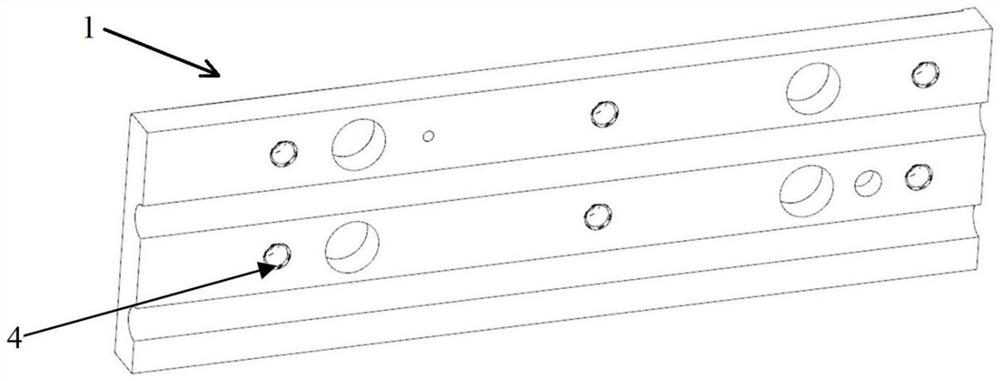

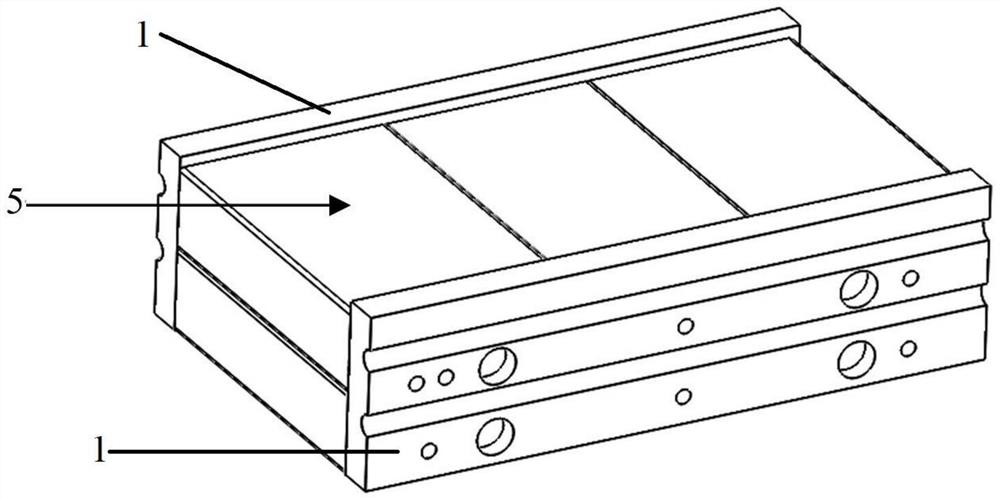

Mobile conveyor unit for high-speed sealing and cutting devices

ActiveCN104229201BGuaranteed heat sealing performanceIncrease sealing and cutting speedWrapper twisting/gatheringEngineeringDisplacement control

The invention discloses a mobile conveying assembly applied to a high-speed sealing and cutting device of a pillow packaging machine, comprising a frame (1), an input belt (2), and an output belt (11). Between the bottom and the bottom are connected successively through the input displacement transmission rod (4), the displacement eccentric seat (12), and the output displacement transmission rod (9). The displacement eccentric seat is installed on the displacement control shaft (24), and the displacement control shaft (24) Connect with the main drive assembly. In the present invention, the input displacement transmission rod and the output displacement transmission rod are driven by the displacement eccentric seat, so that the input belt and the output belt are firstly displaced to the left, and then to the right to make a lateral displacement, so as to realize the movable type of conveying to match the continuous sealing and cutting of the movement. , keep the heat seal for a certain period of time to ensure the heat seal effect. In this way, the overall sealing and cutting speed can be improved, reaching more than 180 pieces per minute, and the transportation is fast and smooth, and the production efficiency is high.

Owner:浙江海众机械有限公司

Automatic packaging and bag sealing device for food processing

The invention discloses an automatic packaging and bag sealing device for food processing, and relates to the technical field of food processing. The problem of food packaging efficiency is solved. The device specifically comprises a base, a support is arranged on the outer wall of one side of the base, a fixing plate, a mounting frame and a supporting frame are arranged on the outer wall of one side of the top of the base, a rotating rod is fixed to the opposite sides of the support and the mounting frame through bearings, and a guide frame is connected to one side of the rotating rod through a connecting plate; one side of the guide frame is connected with storage racks circumferentially distributed at equal intervals through supporting plates, a first motor is fixed to one side of the top of the base through a supporting block, the output end of the first motor is sleeved with a main gear, the end of the rotating rod is sleeved with a ratchet wheel, and the outer wall of one side of the back face of the mounting frame is rotationally connected with a secondary gear and a semi-ring wheel through a guide shaft. According to the food packaging machine, the food packaging efficiency is improved, the food packaging amount is increased, the food packaging automation is promoted, and meanwhile the heat sealing accuracy is improved.

Owner:安徽柏睿农业科技有限公司

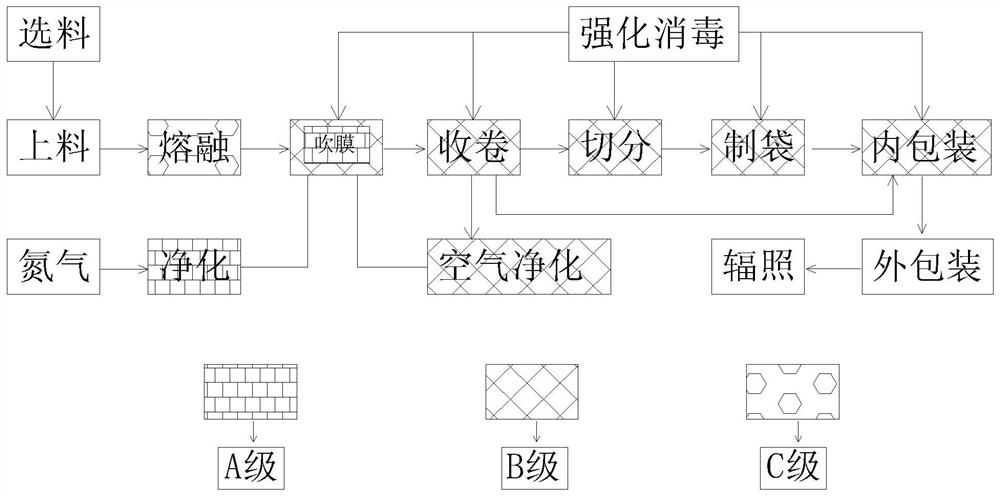

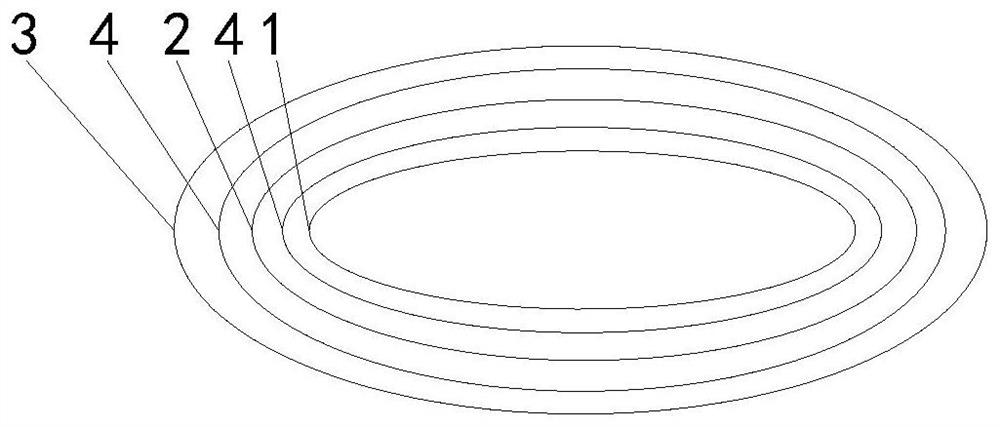

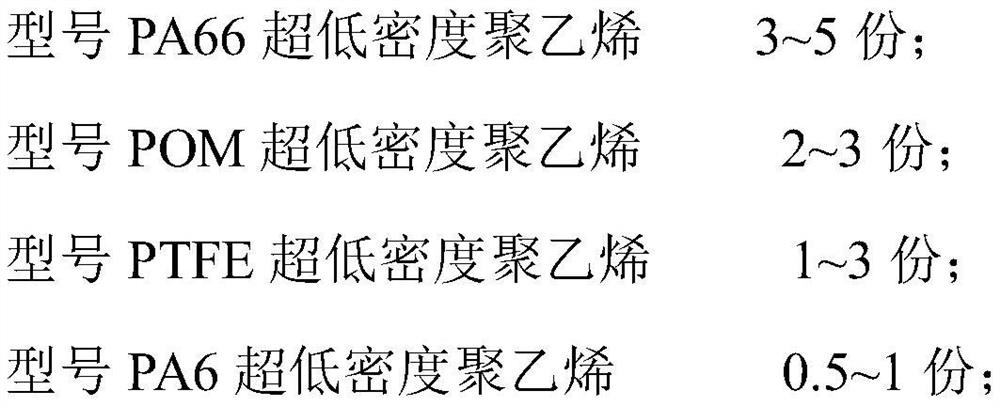

Special membrane for disposable bioreactor and preparation method thereof

ActiveCN109677071BLow running costReduce use costBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyLow-density polyethylene

The invention discloses a special membrane for a disposable bioreactor, which comprises an ultra-low-density polyethylene layer placed in the innermost layer of the membrane body, a low-density polyethylene layer placed in the outermost layer, and an ethylene / ethylene layer in the middle of the membrane body. An alcohol copolymer layer, and an adhesive layer arranged between two adjacent layers. The special membrane obtained for disposable bioreactors has high strength, good stability, and excellent pollution resistance, and can block the penetration of microorganisms, pathogenic bacteria, and sludge. The preparation method of the special film for the disposable bioreactor of the present invention ensures the smooth progress of the plasticizing reaction by controlling the head temperature of the film blowing machine to produce a special film with excellent performance. The preparation method is simple and efficient, and the disposable bioreactor is reduced The use cost of the reactor has significant economic benefits.

Owner:石家庄育才药用包装材料股份有限公司 +1

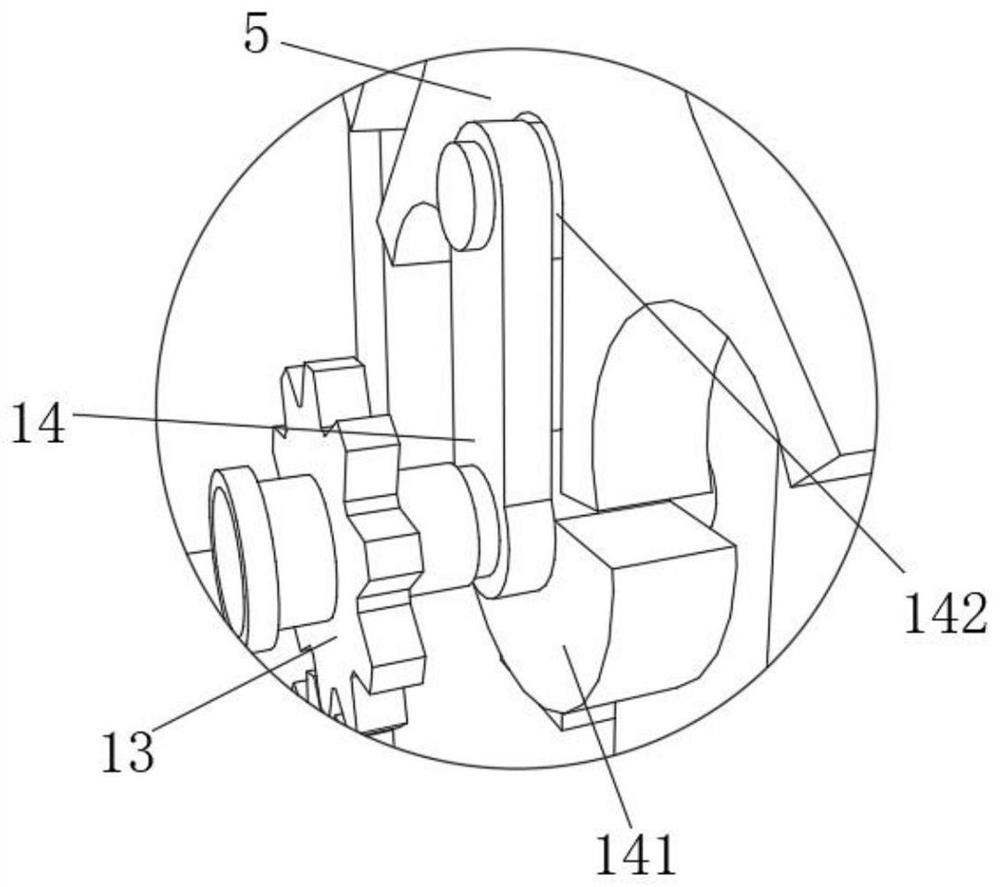

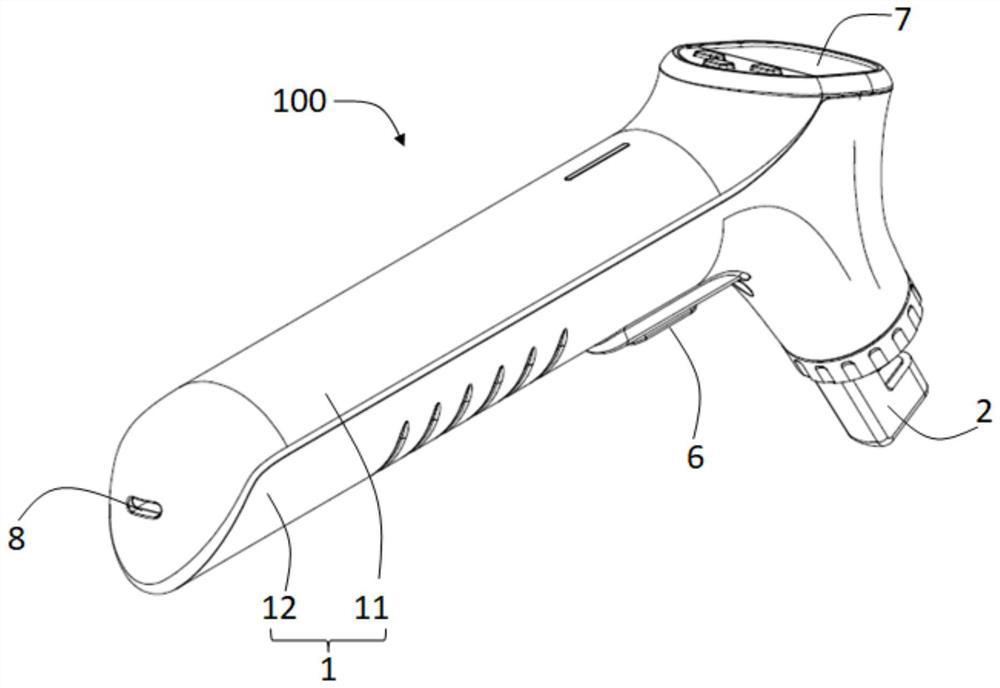

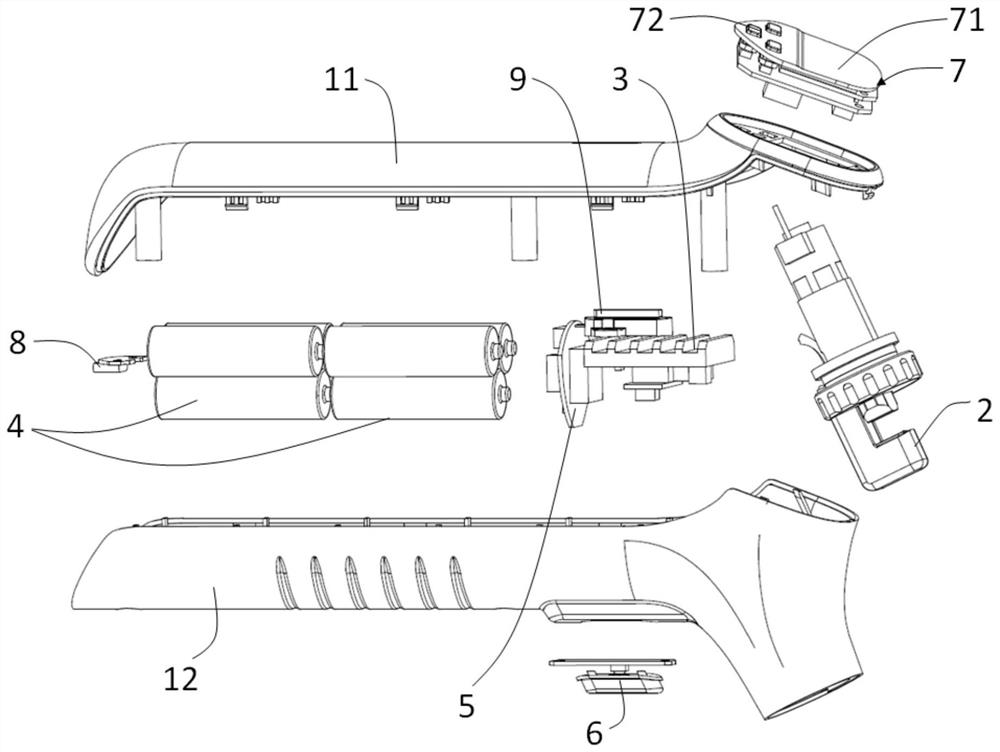

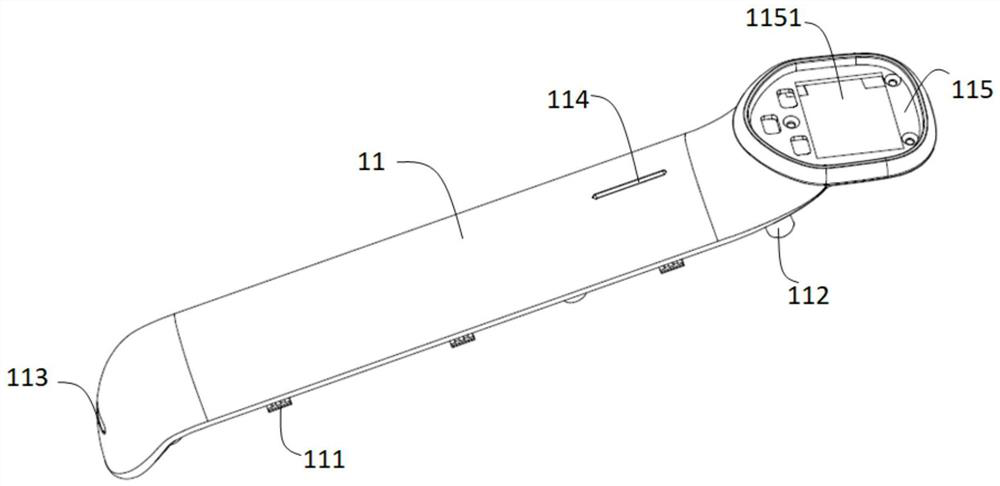

Handheld Sealing Guns and Sealing Devices

Owner:安徽美格医生物科技有限公司

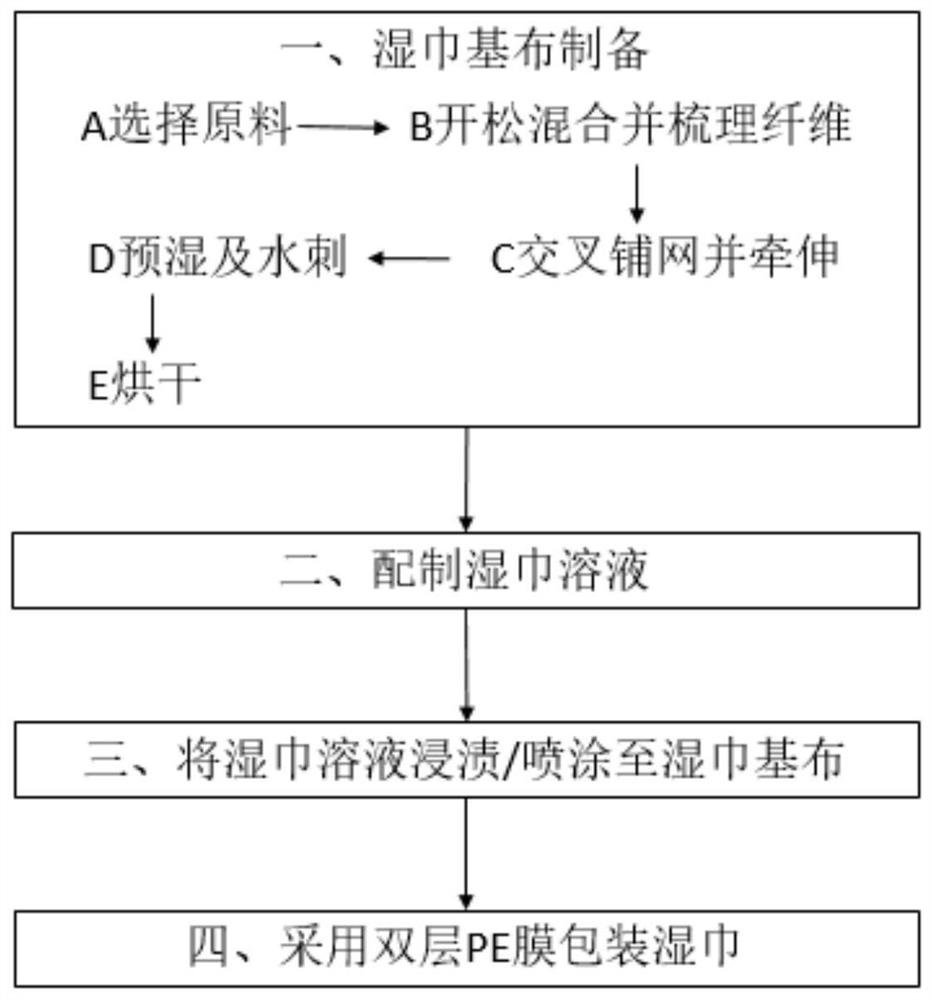

A kind of degradable wet wipes production process and wet wipes, packaging film for the wet wipes

ActiveCN112760810BAchieve degradationImprove mechanical propertiesCosmetic preparationsFlexible coversPolymer scienceWet wipe

The invention discloses a production process of degradable wet wipes, wet wipes, and a packaging film for the wet wipes. The wet wipe base fabric of the invention adopts degradable wood pulp, polylactic acid staple fiber, Viscose staple cellulose fibers are formed by wet laying and hydroentanglement curing and drying technology, and then dipping or spraying the solution to form a wet tissue product with a certain amount of liquid. The wet tissue in the present invention is degradable. In addition, in the present invention, a double-layer PE film is also proposed for the packaging of the degradable wet wipes as its envelope. The surface layer of the double-layer film PE is biaxially stretched PE, and the inner layer is a metallocene modified PE film. Polyethylene can be recycled due to its single thermoplastic material. The present invention obtains degradable wet wipes with good mechanical properties by screening suitable cellulose fiber types and proportions, and optimizing the fiber opening and carding process; meanwhile, the packaging film used for the wet wipes meets the requirements of barrier performance and heat-sealing performance. At the same time, it can be recycled and used, which meets environmental protection requirements.

Owner:FUJIAN HENGAN HLDG CO LTD +1

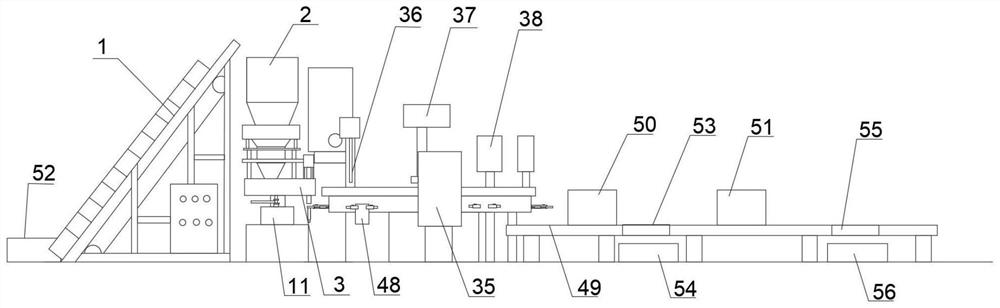

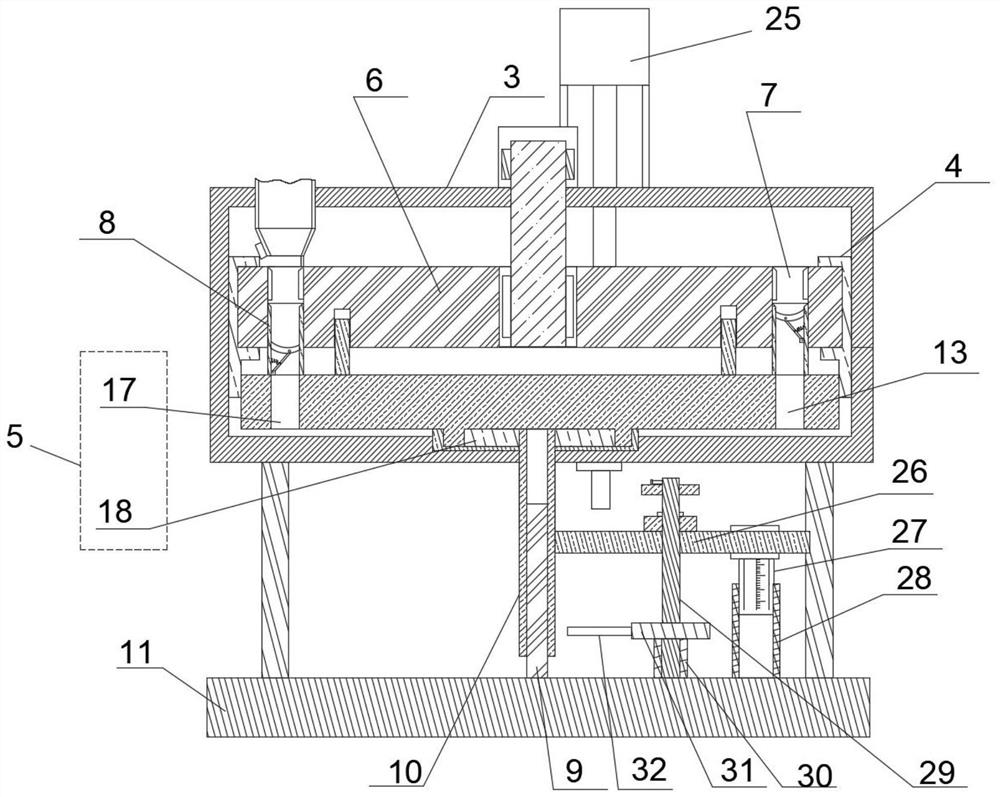

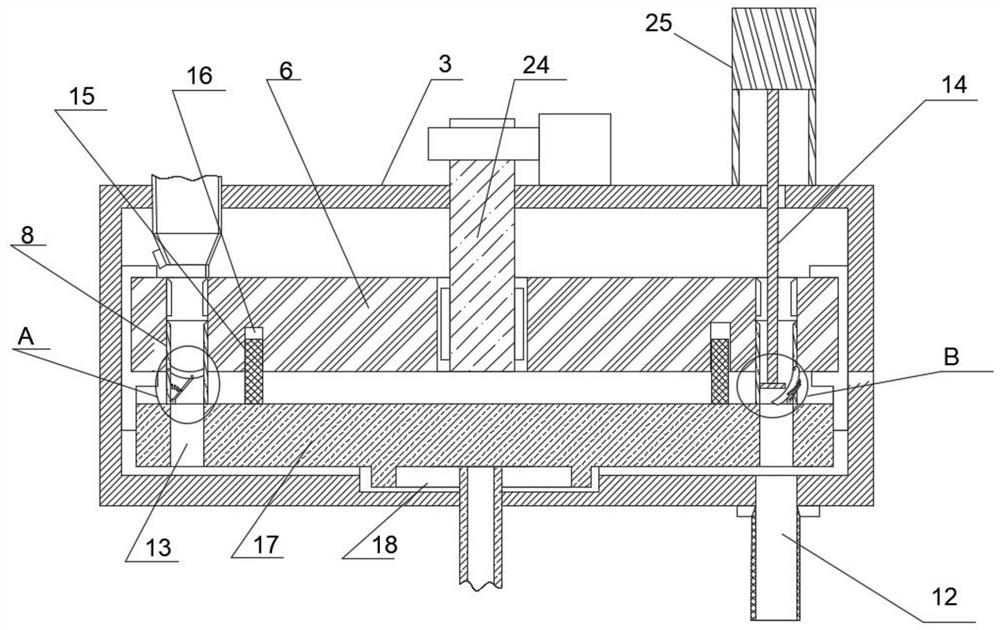

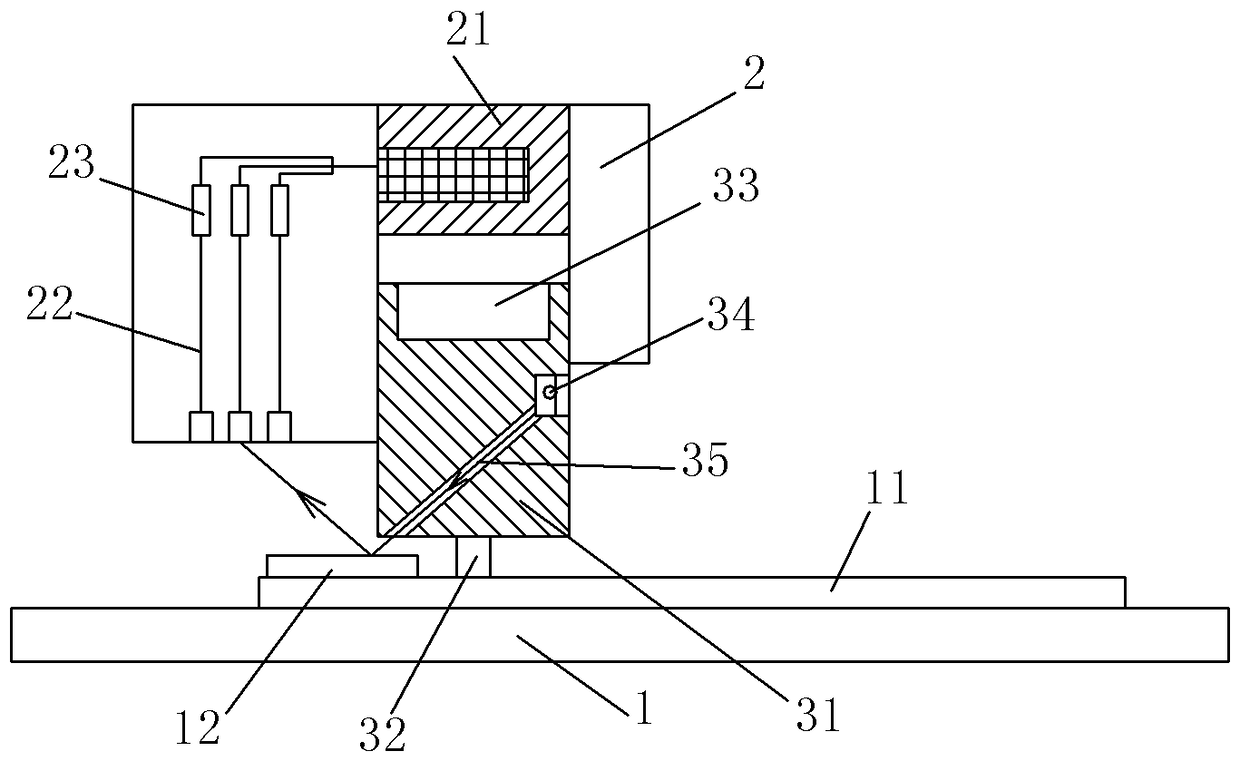

Full-automatic multi-specification sauce bag filling equipment and production process

PendingCN113320769AMeet volume requirementsAchieve rotationWrapper twisting/gatheringPackaging automatic controlEngineeringMaterial storage

The invention discloses full-automatic multi-specification sauce bag filling equipment and a production process, and belongs to the field of sauce bag filling. The full-automatic multi-specification sauce bag filling equipment comprises a feeding unit, a quantifying unit, a filling unit and a detecting unit, wherein the feeding unit comprises an inclined conveying frame and a multi-layer storage tower, an upper-layer box shell is mounted below the multi-layer storage tower, the upper-layer box shell is connected with the multi-layer storage tower, and an upper mounting plate and a lower lifting plate are mounted in the upper-layer box shell; the upper mounting plate is fixedly connected with the upper-layer box shell, a rotating disc is mounted in the upper mounting plate, a material storage cavity is formed in the rotating disc, a material storage barrel is mounted on the lower lifting plate, the material storage barrel is mounted in the material storage cavity, and a closing piece is mounted in the material storage barrel; the closing piece is suitable for limiting the size of materials stored in the material storage cavity and the material storage barrel, a center shaft is mounted in the rotating disc, and a first driving piece is mounted outside the center shaft and suitable for driving the center shaft to rotate. According to the full-automatic multi-specification sauce bag filling equipment, the problems that solid materials are quantified and the practicability is poor due to the fact that the material storage space is single are solved.

Owner:JINCAIDI FOOD CO LTD

Plastic bag heat sealing machine

ActiveCN106697430BImprove processing efficiencyAvoid the influence of heat sealing effectWrapper twisting/gatheringElectrical resistance and conductanceElectricity

The invention discloses a plastic bag heat sealing machine, which comprises a base and a lens. A heat seal base is arranged above the base; a heat seal cutter is slidably connected into the heat seal base, and comprises a cutter body and a cutter bit; a permanent magnet is arranged on the cutter body; an installation hole is further formed in the side wall of the cutter body; a light source is arranged at the installation hole part; an obliquely formed light transmission hole is further formed in the cutter body; the center of the light source is located on a central axis of the light transmission hole; an electromagnetic block repulsive to the permanent magnet is further arranged on the heat seal base; a magnet exciting coil is sleeved on the electromagnetic block; a plurality of optoelectronic switches are further arranged on the heat seal base, and are electrically connected with resistances with different resistance values; the resistance values of the resistances corresponding to the optoelectronic switches are increased along with the increase of the distances between the optoelectronic switches and the heat seal base; and the resistances are connected in parallel so as to be electrically connected with the magnet exciting coil. According to the scheme provided by the invention, when plastic bags with different thicknesses are heat-sealed, heat sealing pressure acted on the plastic bags can be automatically adjusted.

Owner:CHONGQING RUITING PLASTIC

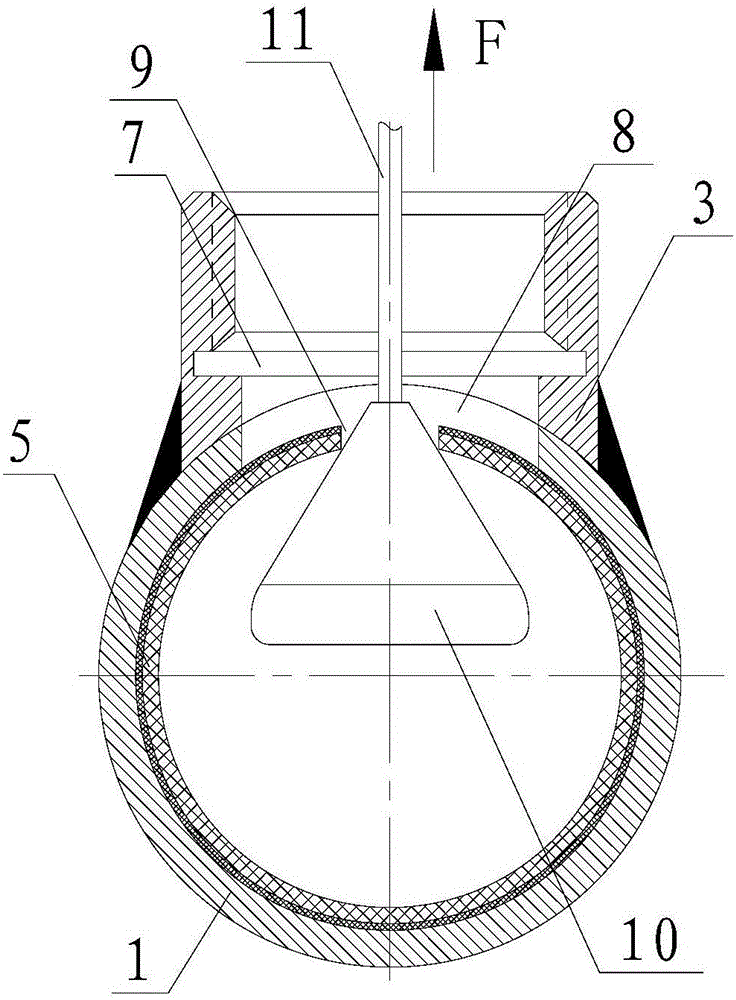

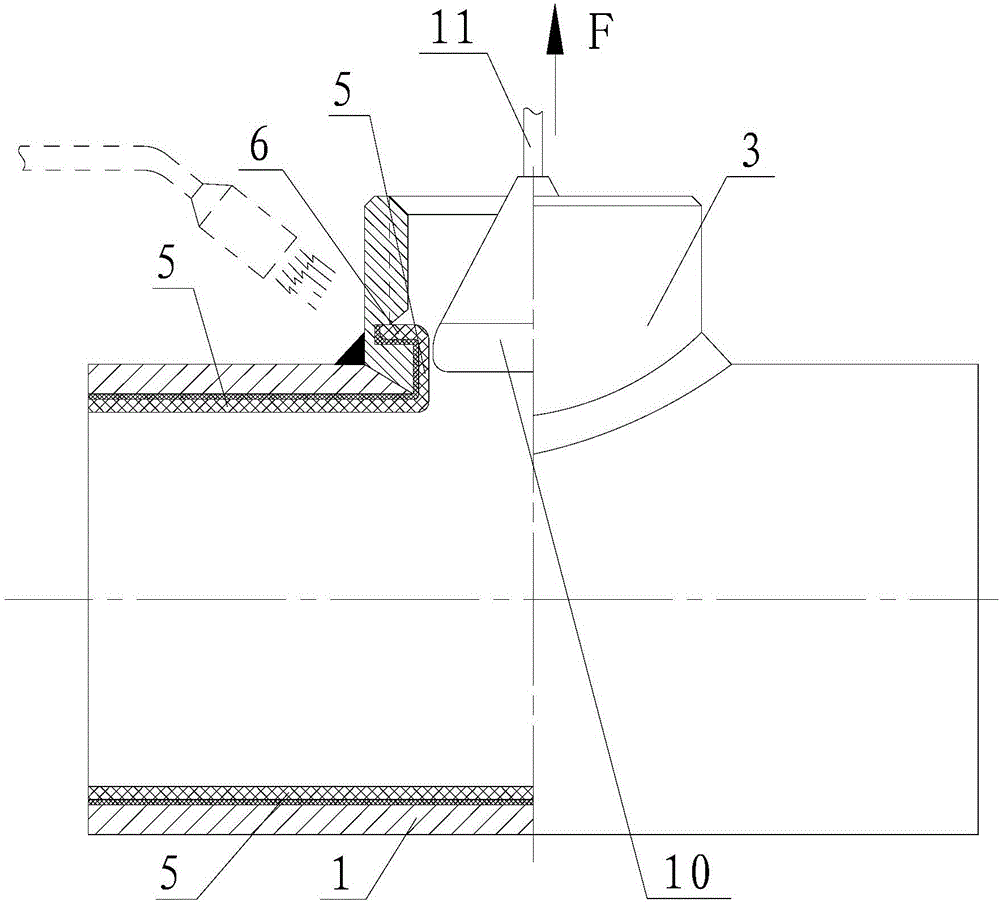

Novel air inlet nozzle runner and air column bag

PendingCN110979997AGuaranteed air tightnessGuaranteed heat sealing performanceContainers to prevent mechanical damageAir tightnessMechanics

The invention discloses a novel air inlet nozzle runner and an air column bag. The air inlet nozzle runner comprises an inlet and an outlet. The air inlet nozzle runner is divided by sealing lines toform a plurality of bends. The air column bag comprises the air inlet nozzle runner and further comprises an air inlet channel formed by heat sealing of an upper membrane and a lower membrane and a plurality of air column bag units. The inlet and the outlet of the air inlet nozzle runner communicate with the air inlet channel and the air column bag units respectively. The novel air inlet nozzle runner has the advantages of being good in airtightness and stable in heat sealing effect.

Owner:HANGZHOU BINGJIA TECH

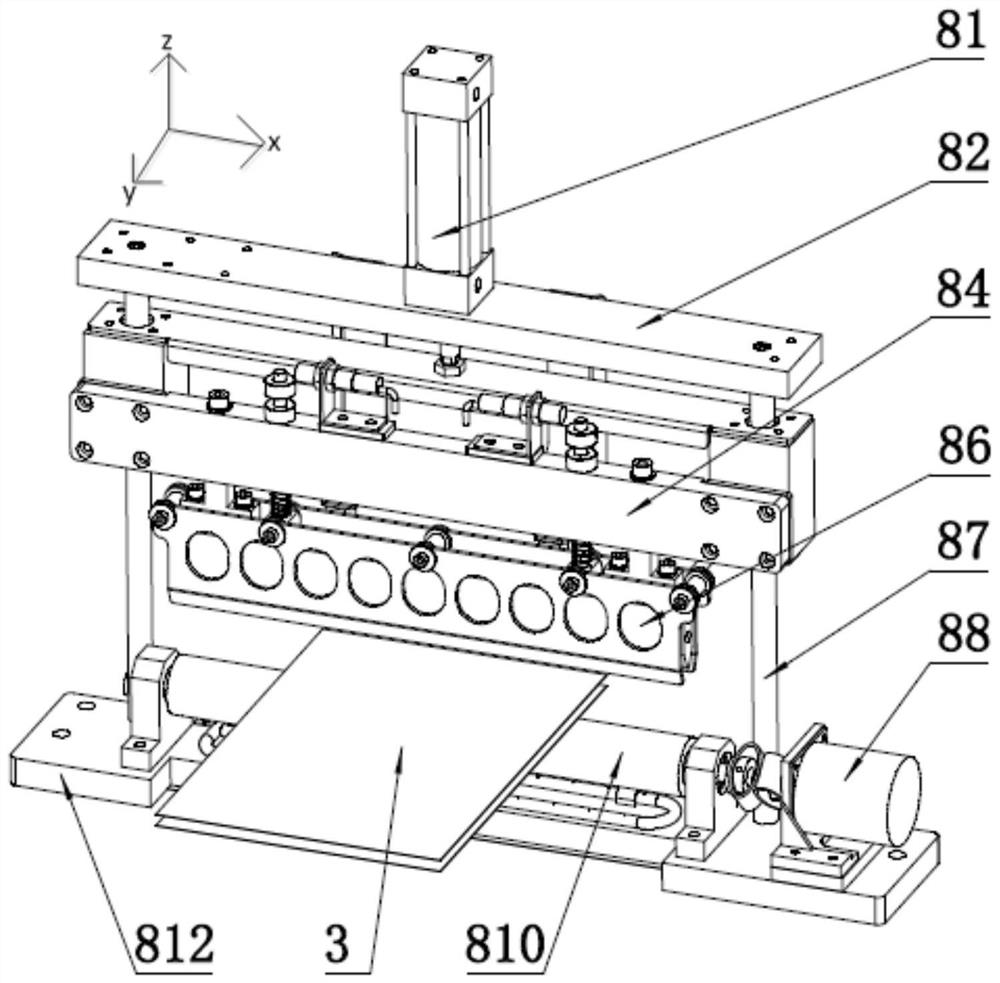

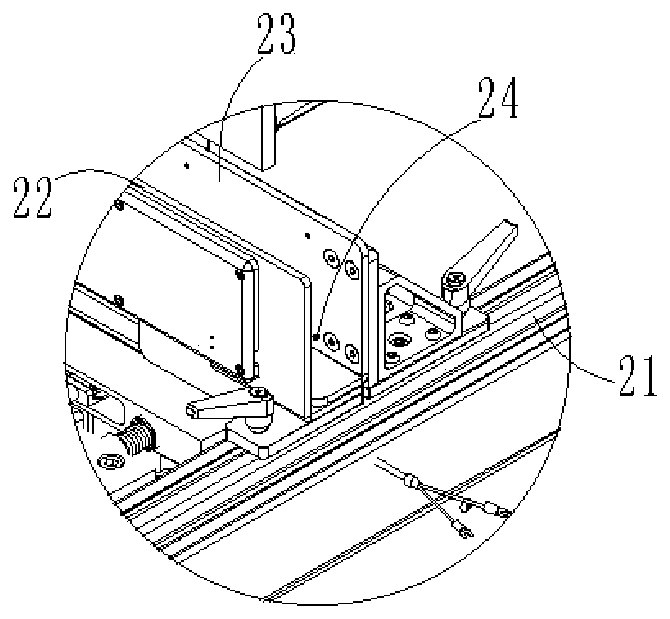

Transverse sheet supplementing device of bag making machine

ActiveCN110481100ASolve the technical problem of poor heat sealing effectSolve the technical problems of inconvenient adjustment and poor cutting effectBag making operationsPaper-makingFilm materialMechanical engineering

The invention discloses a transverse sheet supplementing device of a bag making machine. The device comprises a front wall plate and a movable seat, and a traction lower rubber roller and a traction upper pressing roller are arranged between side plates; an upper cutter is arranged between the two side plates, wherein a lower cutter is arranged below the upper cutter; an upper sealing module is installed on the bottom surface of an upper mounting rod, and a lower sealing module is installed on a lower mounting rod; one short rod is provided with an adjusting screw, wherein one end of the adjusting screw is provided with a first adjusting hand wheel; one end of an adjusting hand wheel shaft is fixedly provided with a second adjusting hand wheel, wherein a gear is fixedly installed on the adjusting hand wheel shaft. According to the sheet supplementing device, adjusting can be carried out in the front, rear and transverse directions, so that a feeding position of a main film material canbe accurately reached; and adjusting is flexible, the traction upper pressing roller can be conveniently controlled, and meanwhile adjusting is convenient, and heat sealing effects are good; and in addition, by adjusting the front and rear positions of the lower cutter, the knife edge of the lower cutter is aligned with the knife edge of the upper cutter, and therefore cutting effects of sheet supplementing materials are guaranteed.

Owner:GUANGDONG ZHONGBAO MACHINE

High-performance light-weight PE heat shrinkage film and preparation method thereof

ActiveCN114083855ACompliant with \"Plastic Reduction\"Meet the requirementsPackage recyclingFlexible coversThermodynamicsPack material

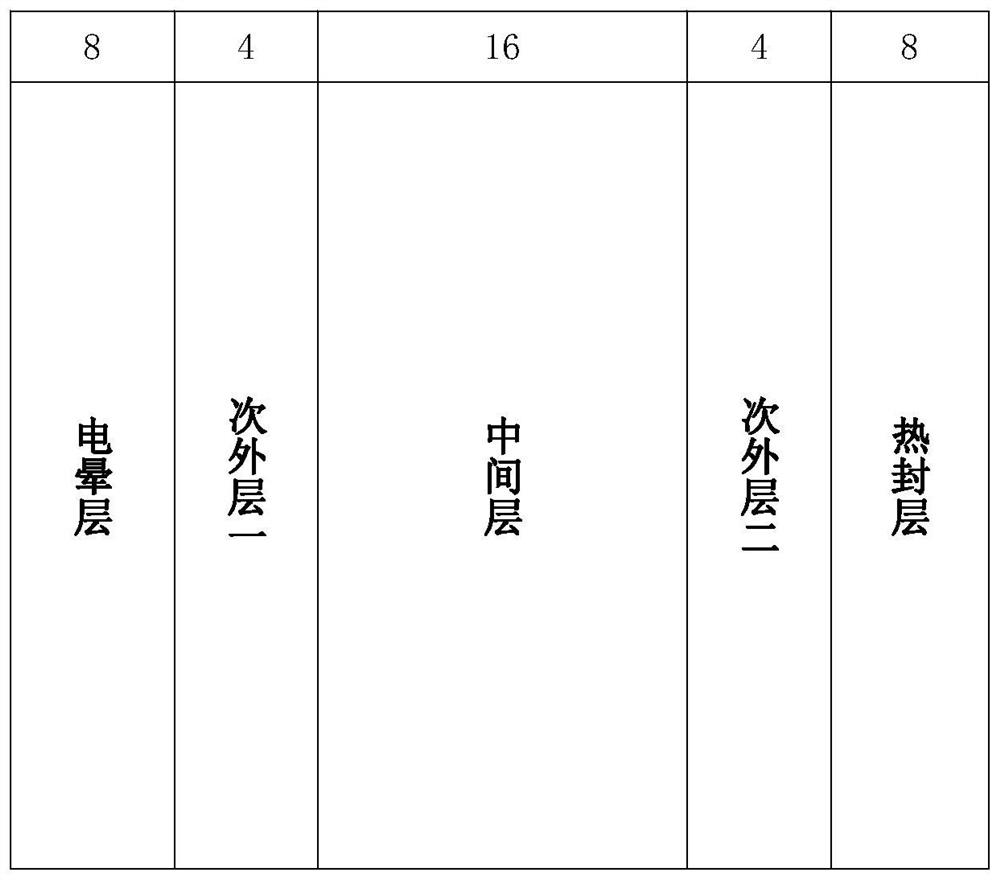

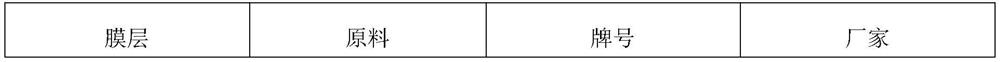

The invention belongs to the technical field of packaging materials, and particularly relates to a high-performance light-weight PE heat shrinkage film and a preparation method thereof. The PE heat shrinkage film comprises a corona layer, a first secondary outer layer, a middle layer, a second secondary outer layer and a heat sealing layer, wherein the formula of the corona layer is basically the same as that of the heat sealing layer, and the formula of the first secondary outer layer is the same as that of the second secondary outer layer. According to the invention, a five-layer film blowing symmetrical structure formula is adopted, a particle formula and process parameters are reasonably designed, so that the performance difference caused by thickness reduction is made up, the packaging requirements of customers are met while the weight is reduced, and the whole packaging material has the advantages of being small in thickness, high in transverse and longitudinal shrinkage rate, high in clamping force, free of springback, high in tensile strength and high in puncture resistance and tearing resistance; the optical performance is good; and the film has the advantages of moderate and stable dynamic and static friction coefficients, favorable thickness uniformity, favorable flatness, favorable printing adaptability and favorable heat-sealing stability and is suitable for automatic packaging equipment, and a packaged product has favorable fitting property and neat bull eyes.

Owner:HUANGSHAN NOVEL

A packaging machine with a double-end seal synchronous sealing and cutting system

ActiveCN109760890BReduce volumeSmall turning radiusWrapper twisting/gatheringReciprocating motionEngineering

The invention discloses a packaging machine with a double end seal synchronous seal cutting system. A rack is included and provided with a feeding conveying belt, a discharging conveying belt and a double end seal synchronous seal cutting mechanism located between the feeding conveying belt and the discharging conveying belt. The double end seal synchronous seal cutting mechanism comprises a pairof servo motors arranged on the rack, the servo motors drive corresponding eccentric discs to rotate, and the eccentric discs drive corresponding upper tool shafts and corresponding lower tool shaftsto rotate, wherein one upper tool shaft drives a first upper seal tool to reciprocate, the other upper tool shaft drives a second upper seal tool to reciprocate, one lower tool shaft drives a first lower seal tool to reciprocate, and the other lower tool shaft drives a second lower seal tool to reciprocate. Due to adoption of the above structure, on the premise that the heat seal effect of the packaging machine is guaranteed, the running speed of the whole machine is increased, conveying is rapid and smooth, the production efficiency is improved, and the packaging effect is more excellent.

Owner:东岱(济南)智能技术有限公司

High-speed continuous sealing and cutting device

ActiveCN104229218AGuaranteed heat sealing performanceIncrease sealing and cutting speedWrapper twisting/gatheringDisplacement controlEngineering

The invention provides a high-speed continuous sealing and cutting device applied to a pillow type packaging machine. The two ends of an upper cutter shaft are provided with upper transmission eccentric discs (23), the two ends of a lower cutter shaft are provided with lower transmission eccentric discs (22), an input belt assembly and an output belt assembly are connected sequentially through an input displacement transmission rod (4), a displacement eccentric seat (12) and an output displacement transmission rod (9), the displacement eccentric seat is arranged on a displacement control shaft (24), and the displacement control shaft is connected with a main driving assembly. The upper transmission eccentric discs and the lower transmission eccentric discs respectively do eccentric rotation, further, a sealing and cutting upper cutter, a sealing and cutting lower cutter and a pillow type packaging bag hot sealed between the sealing and cutting upper and lower cutters are driven to firstly move towards the left side and then move towards the right side for a distance, and the continuous hot sealing is kept and lasts for a certain time for ensuring the hot sealing effect. Therefore the integral sealing and cutting speed can be accelerated, the packaging speed can reach more than 180 pieces per minute, in addition, the conveyance is fast and smooth, and the production efficiency is high.

Owner:瑞安市海创机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com