Metal can packing material and method of manufacturing the same

A packaging material and manufacturing method technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of high cost, poor material flatness, insufficient rigidity and stiffness, etc., achieve low production cost, wide application fields, The effect of high product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

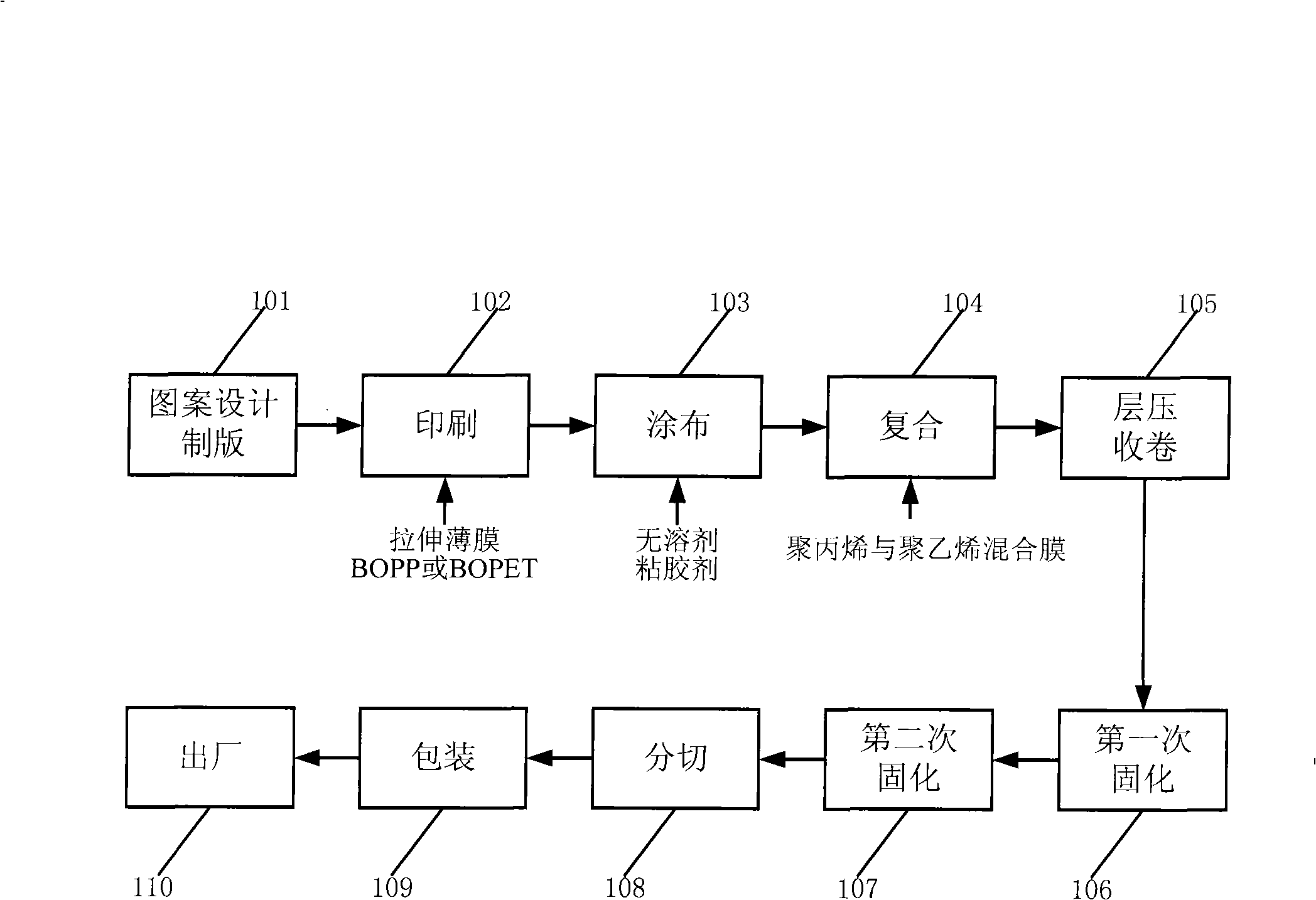

Method used

Image

Examples

Embodiment 1

[0042] Heat seal layer material: Milky white polypropylene: polyethylene = 35:65;

[0043] The composite speed is 95m / min, the preheating temperature is 45°C, the unwinding tension of the fabric is 2.2kg, the unwinding tension of the inner layer is 2.2kg, the winding tension is 12.6kg, the trolley pressure is 4%, and the coating weight is 1.2g / m 2 , the slope is 20%, and the inner material is preheated to 50°C.

Embodiment 2

[0045] Heat seal layer material: milky white polypropylene: polyethylene = 40:60;

[0046] The composite speed is 105m / min, the preheating temperature is 50°C, the unwinding tension of the fabric is 3kg, the unwinding tension of the inner layer is 3kg, the winding tension is 16kg, the trolley pressure is 4.5%, and the coating amount is 1.3g / m 2 , the slope is 25%, and the inner material is preheated to 58°C.

Embodiment 3

[0048] Heat seal layer material: Milky white polypropylene: polyethylene = 43:67;

[0049] The composite speed is 115m / min, the preheating temperature is 60°C, the unwinding tension of the fabric is 3.2kg, the unwinding tension of the inner layer is 3.2kg, the winding tension is 17kg, the trolley pressure is 7%, and the coating amount is 1.5g / m 2 , the slope is 36%, and the inner material is preheated to 65°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com