Bottom edge heat seal mechanism for cigarette sealing and packaging

A technology of sealing packaging and bottom edge, applied in the directions of packaging, transportation packaging, transportation and packaging, etc., can solve the problems of not involving the sealing packaging packaging method and packaging equipment, etc., to achieve the effect of simple structure, reasonable design, and ensure the effect of heat sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated and described below in conjunction with the accompanying drawings and embodiments of the present invention.

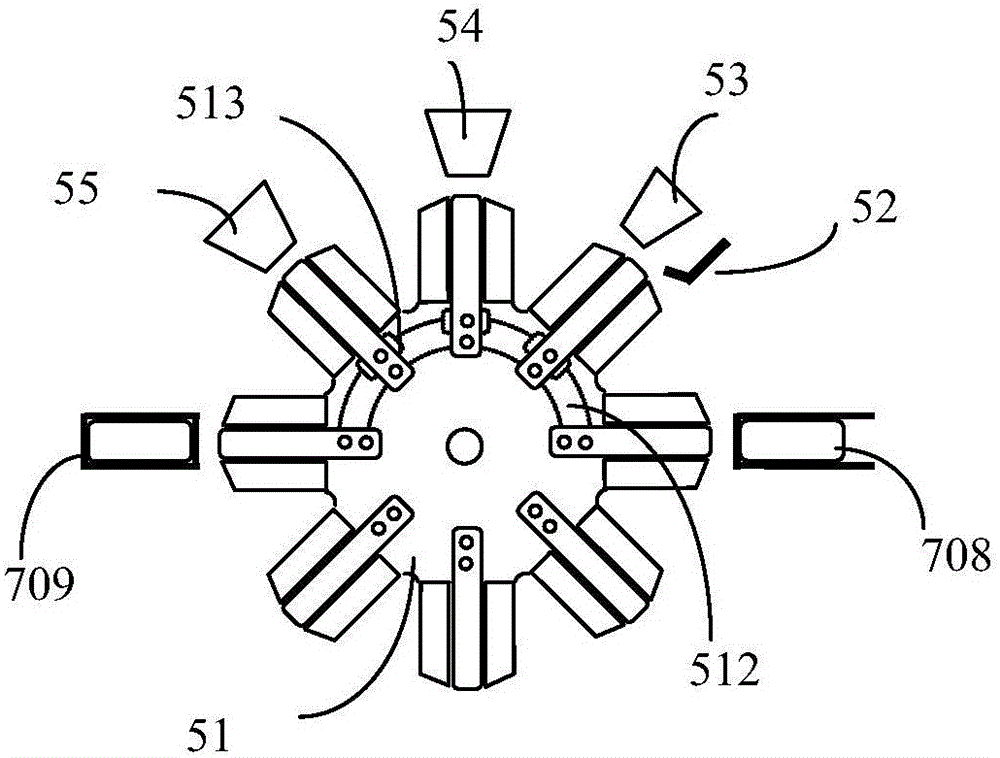

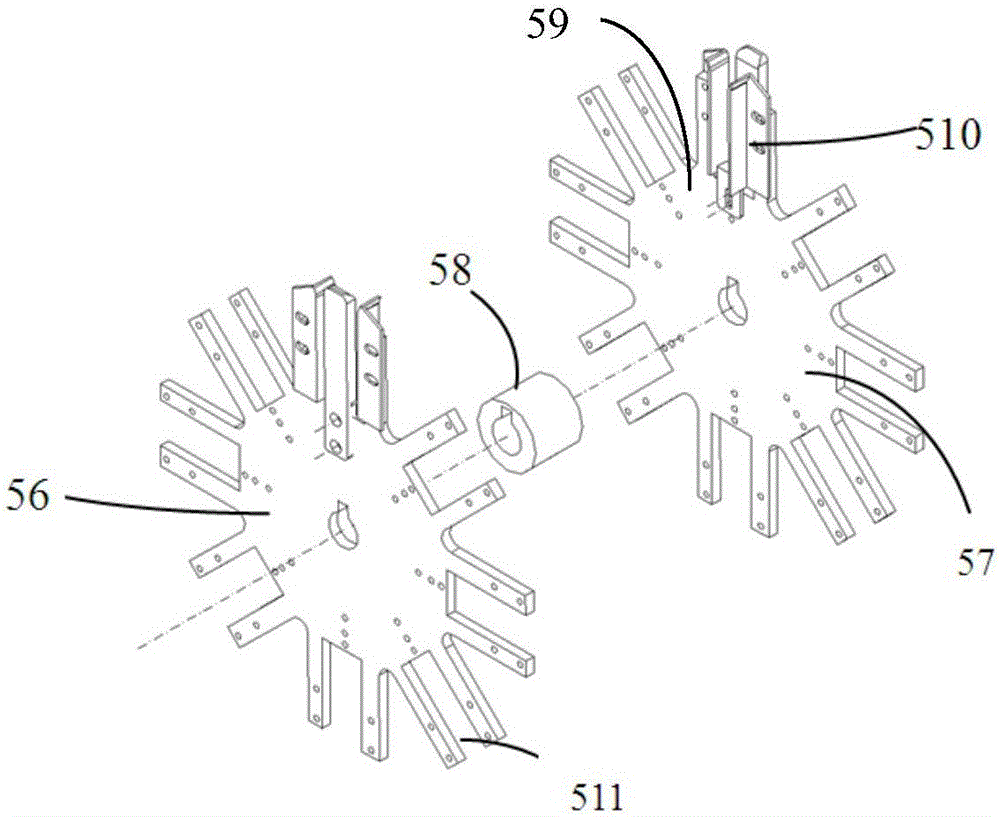

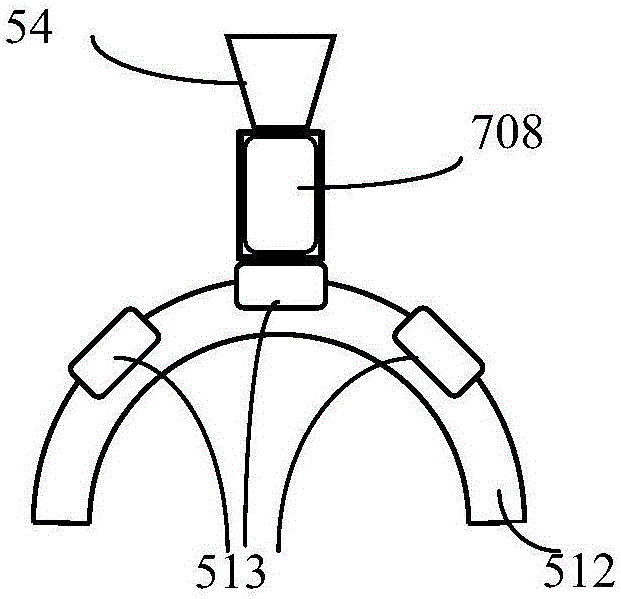

[0017] to combine Figure 1-3 , a bottom edge heat-sealing mechanism for cigarette sealing packaging, comprising an octagonal turret 51, a bottom edge folding device 52, a bottom edge pre-sealing soldering iron 53, and a bottom edge heat-sealing soldering iron 54, and the octagonal turret 51 includes 8 working Stations, starting from the right and counterclockwise are No. 1, No. 2 ... No. 7, and No. 8 stations. The bottom edge folding device 52, the bottom edge pre-sealing soldering iron 53, and the bottom edge heat-sealing soldering iron 54 are respectively set at The No. 2 station, No. 2 station and No. 3 station corresponding to the octagonal wheel turret 51, the octagonal wheel turret 51 rotates counterclockwise, and the octagonal wheel turret 51 includes a mirror-symmetrical left turntable 56 and a right turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com