High-performance light-weight PE heat shrinkage film and preparation method thereof

A heat-shrinkable film and lightweight technology, applied in the field of film materials, can solve the problems of high recycling pressure and high cost, and achieve the effects of large lateral shrinkage, high clamping force and good visual effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

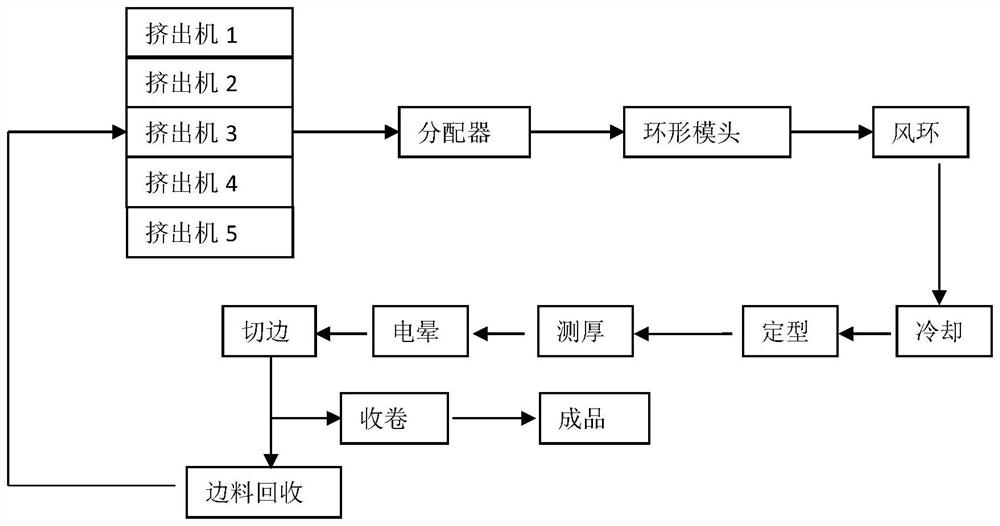

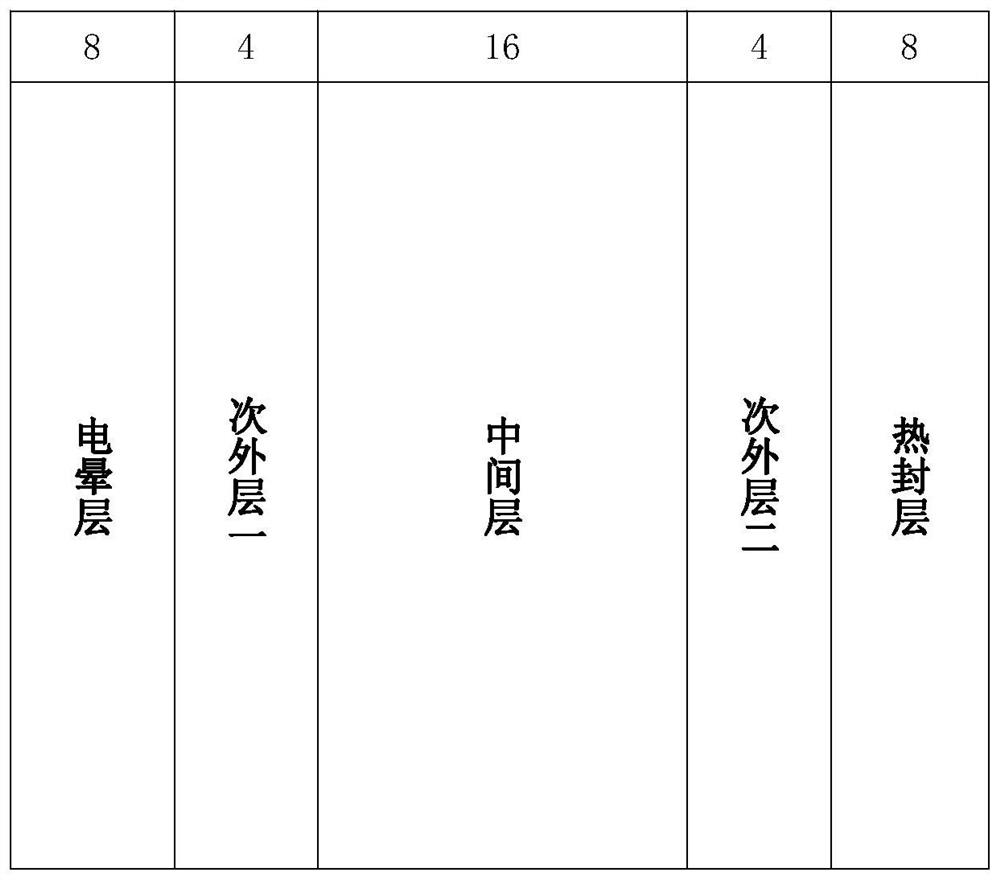

[0052] A kind of preparation method of high-performance lightweight PE heat-shrinkable film of the present invention, comprises the following steps:

[0053] Step 1, extrusion: put the raw materials of the corona layer, sub-outer layer 1, middle layer, sub-outer layer 2 and heat-sealing layer into the German WH five-layer co-extrusion blown film machine in sequence according to the above component ratio requirements After being heated into a melt through the trough barrel, barrel 1 zone, barrel 2 zone, barrel 3 zone, barrel 4 zone, screen changing zone, and flange zone, it is extruded into a tube through a die; extrusion parameters : The temperature of the trough-type barrel is 50°C, the temperature of the barrel 1 zone is 185°C, the temperature of the barrel 2 zone, the barrel 3 zone, the barrel 4 zone, the screen changing zone, and the flange zone are all 195°C, the die head temperature is 200°C; the extrusion rate is 560kg / h;

[0054] Step 2, film blowing: After the tube l...

Embodiment 2

[0059] The preparation method is the same as in Example 1, only the formulation of each film layer is adjusted, specifically: the corona layer includes the first metallocene polyethylene resin, high-pressure low-density polyethylene resin and Fluoride processing aid; the heat-sealing layer includes the first metallocene polyethylene resin, high-pressure low-density polyethylene resin, fluoride processing aid and slippery agent with a mass ratio of 82:18:0.2:1; the The second outer layer one and the second outer layer both include the second metallocene polyethylene resin, the low-pressure high-density resin, the third metallocene polyethylene resin and a fluoride processing aid with a mass ratio of 42:33:27:0.3; The middle layer includes the second metallocene polyethylene resin, low-pressure high-density resin, high-pressure low-density polyethylene resin and fluoride processing aid in a mass ratio of 42:38:20:0.2.

Embodiment 3

[0061] The preparation method is the same as in Example 1, only the formulation of each film layer is adjusted, specifically: the corona layer includes the first metallocene polyethylene resin, high-pressure low-density polyethylene resin and Fluoride processing aid; the heat-sealing layer includes the first metallocene polyethylene resin, high-pressure low-density polyethylene resin, fluoride processing aid and slippery agent with a mass ratio of 78:22:0.2:1; the The second outer layer one and the second outer layer both include the second metallocene polyethylene resin, the low-pressure high-density resin, the third metallocene polyethylene resin and the fluoride processing aid with a mass ratio of 38:37:23:0.3; The middle layer includes the second metallocene polyethylene resin, low-pressure high-density resin, high-pressure low-density polyethylene resin and fluoride processing aid in a mass ratio of 38:42:20:0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com