Patents

Literature

122results about How to "Fit tight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

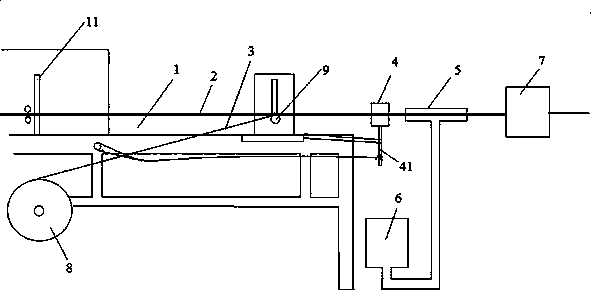

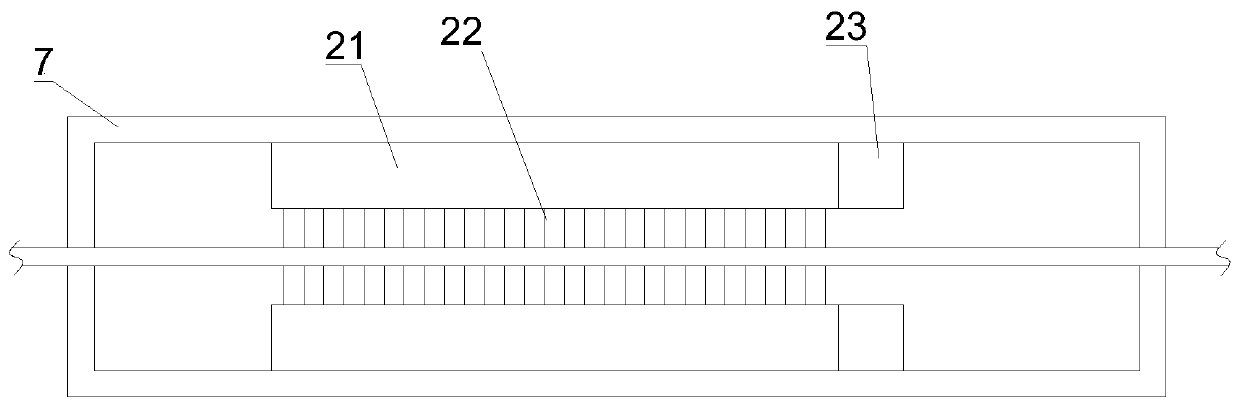

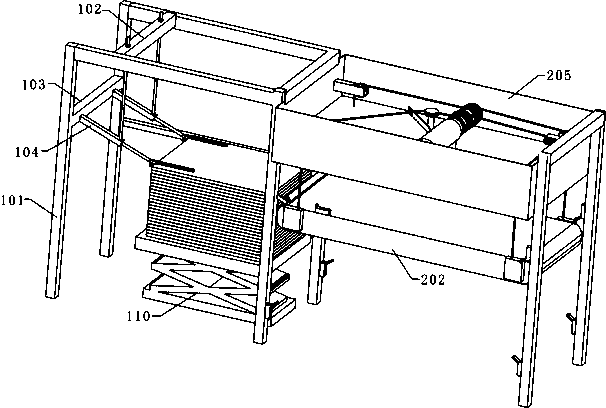

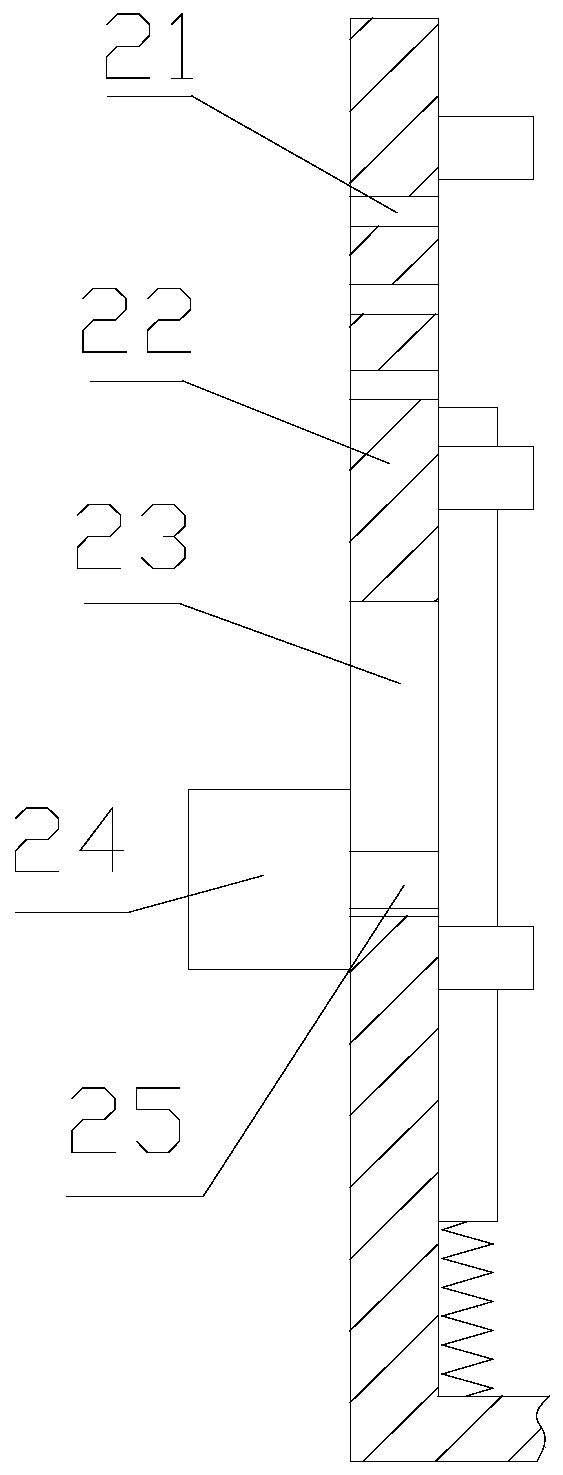

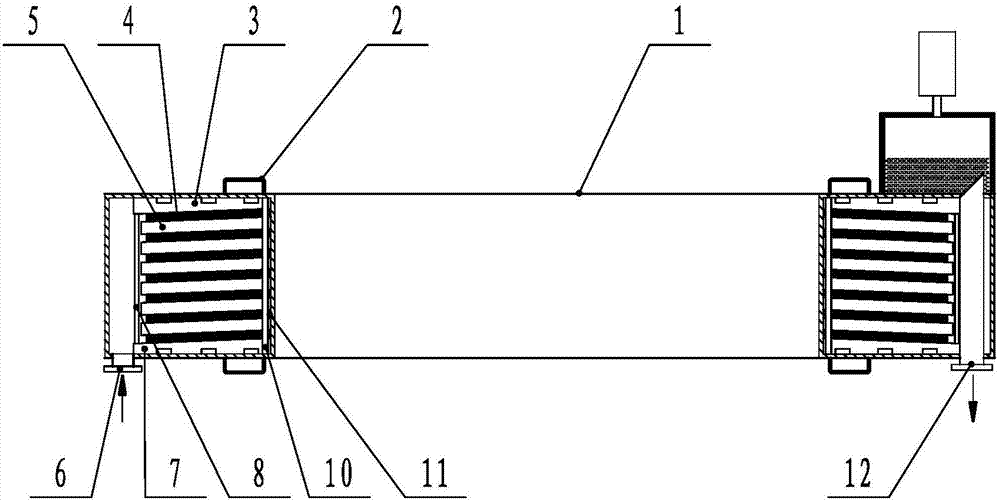

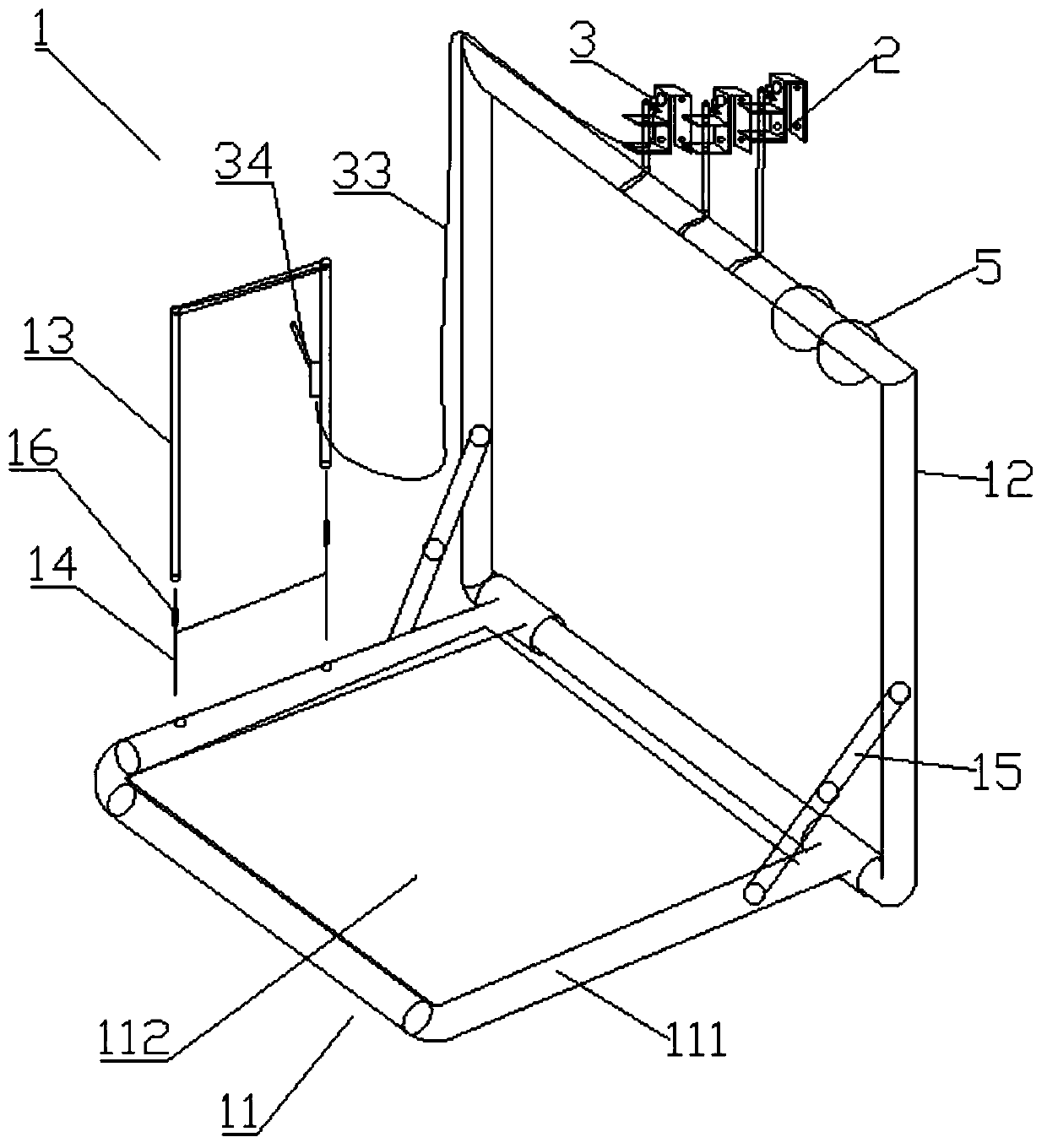

Equipment for longitudinally wrapping cable paper on cable

ActiveCN103714918AImprove packaging efficiencySave materialCable/conductor manufactureEngineeringElectrical and Electronics engineering

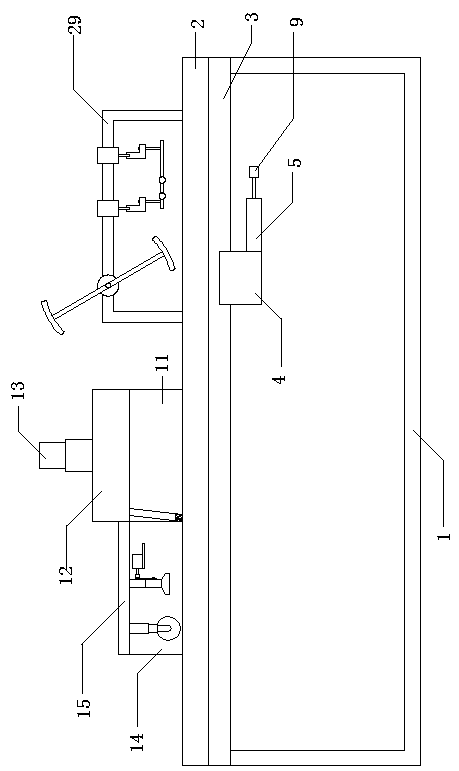

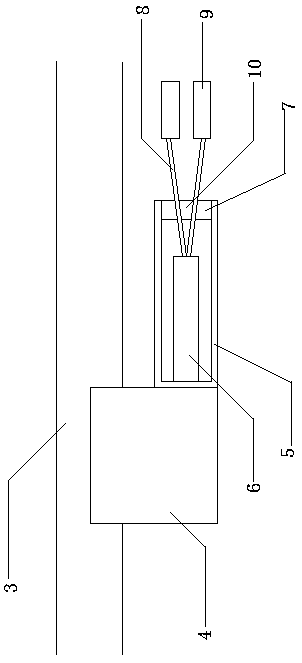

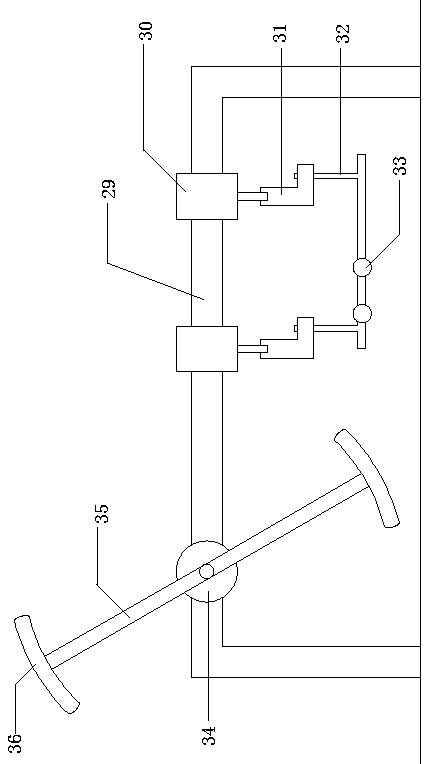

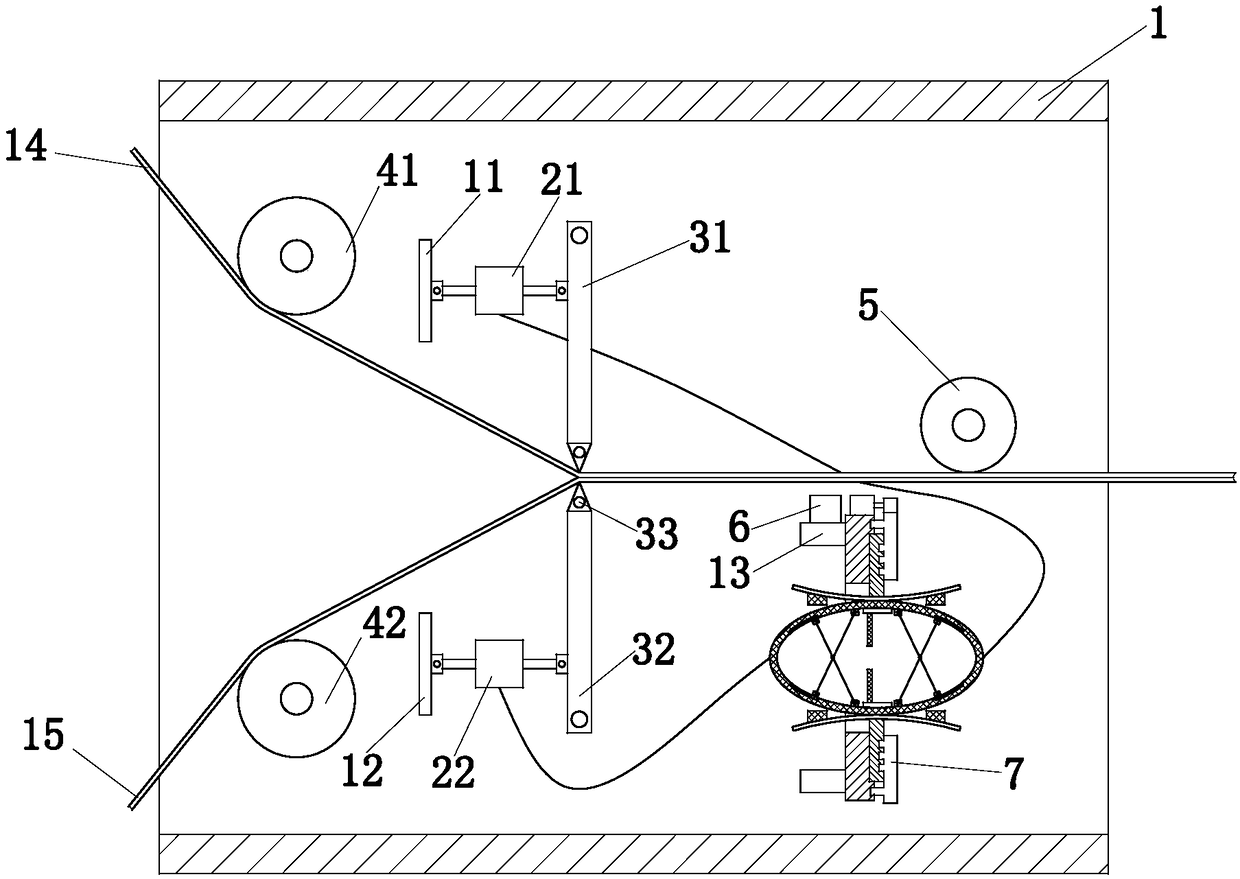

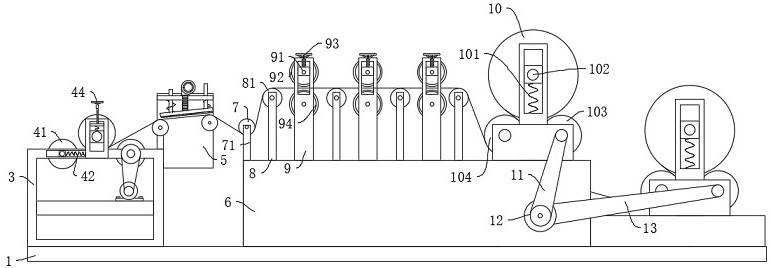

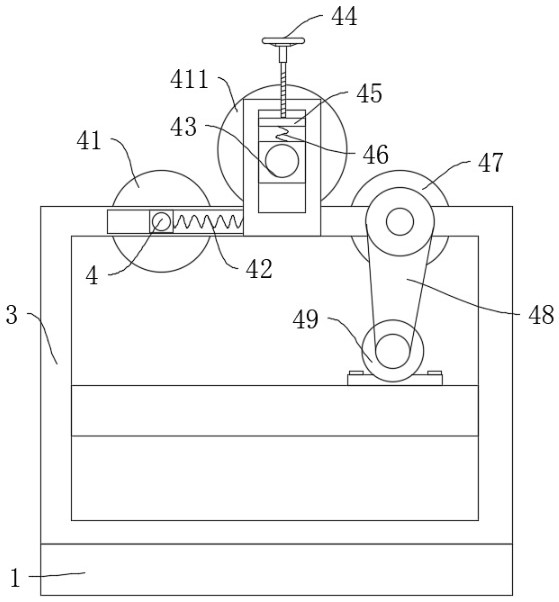

The invention discloses equipment for longitudinally wrapping cable paper on a cable. The equipment comprises a stand, a draw gear, a collecting structure and a furling and wrapping structure, wherein the draw gear is arranged on the stand, and the cable and the cable paper pass through the collecting structure and the furling and wrapping structure by being synchronously drawn by the draw gear; the furling and wrapping structure comprises a first furling part and a second furling part, a first furling through hole is formed in the first furling part, the diameter of the first furling through hole meets the requirement that the cable and the cable paper which are collected on the same straight line can pass through the first furling through hole, the cable paper is wrapped on the cable under the constraint of the first furling through hole, and a second furling through hole is formed in the second furling part which further comprises a vacuum structure used for forming negative pressure of the second furling through hole. The equipment solves the problem that wrapping efficiency is low because a winding mode is adopted for equipment for wrapping cable paper on a cable in the prior art, and improves the wrapping efficiency by 30%-40%.

Owner:QINGDAO RIKEN WIRE & CABLE

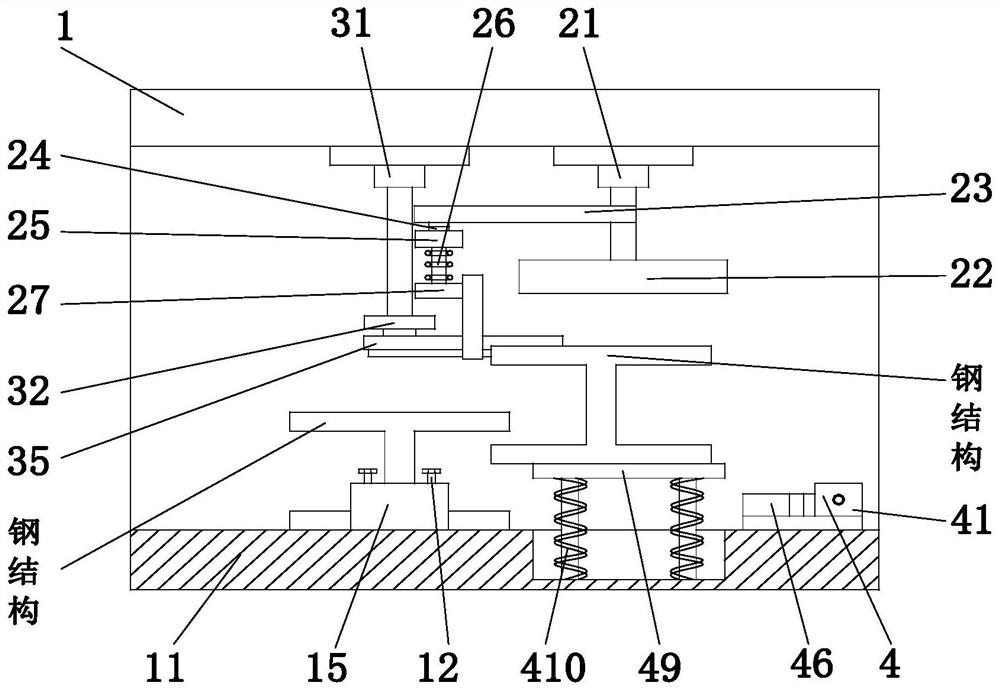

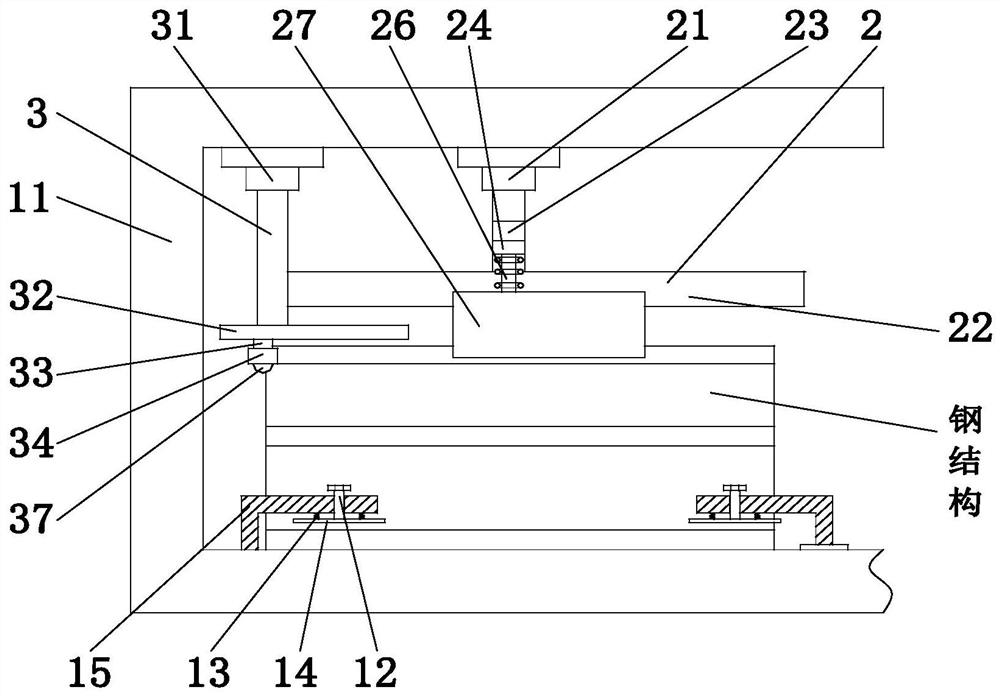

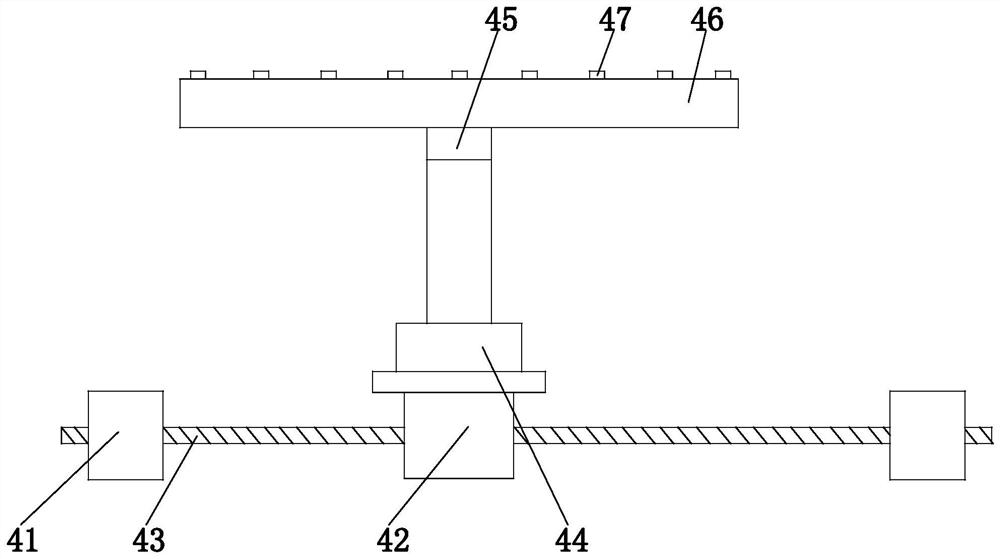

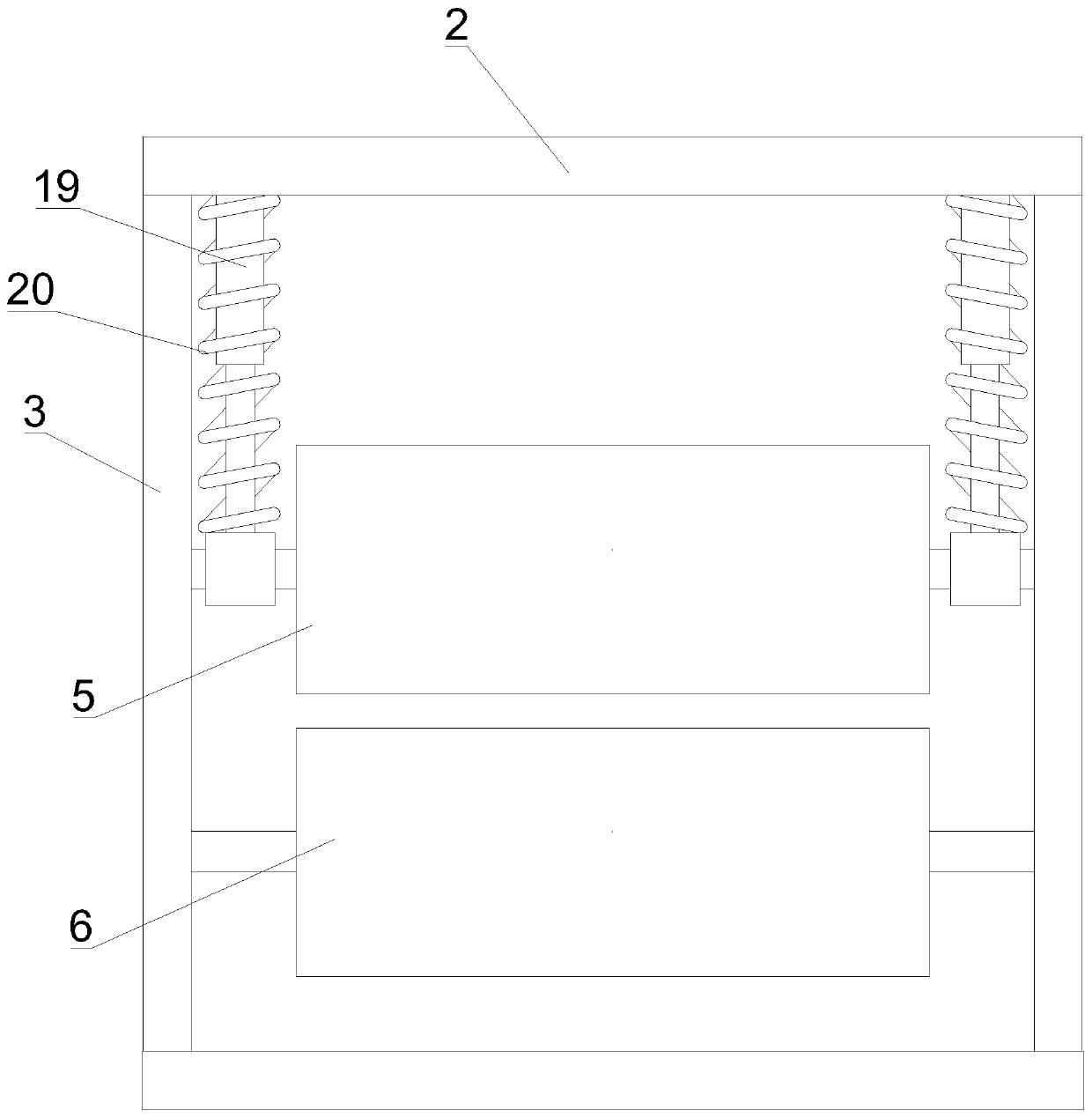

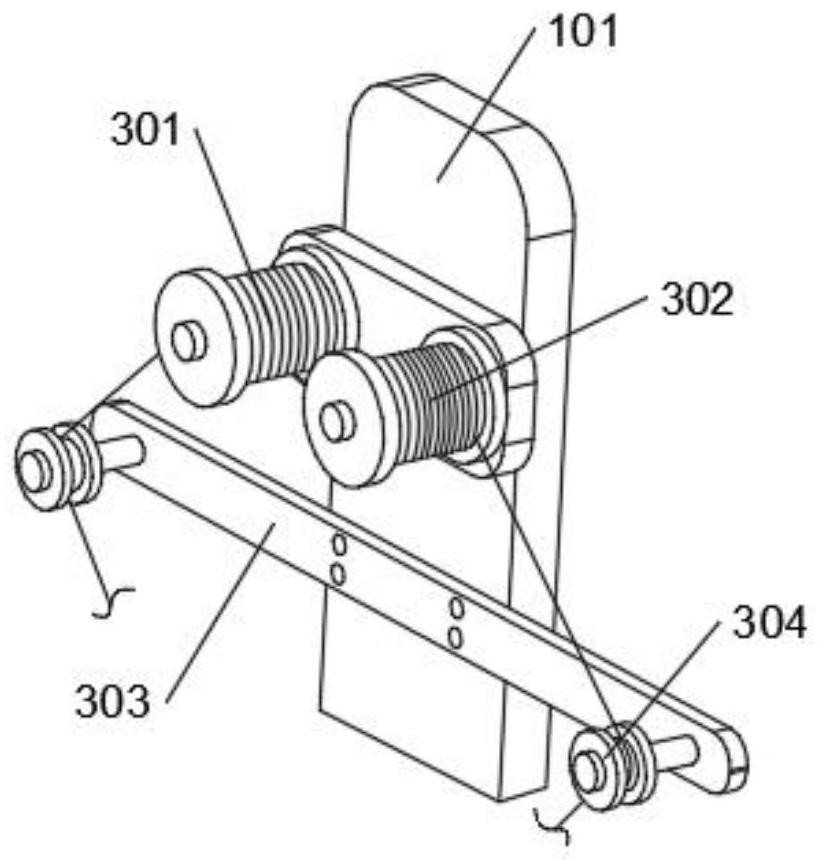

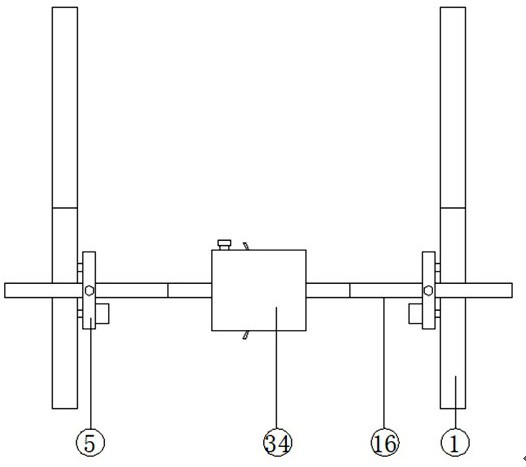

Automatically-assembled welding clamp with steel structure

ActiveCN111644797AAvoid damageIncrease the fixed areaWelding/cutting auxillary devicesAuxillary welding devicesIndustrial engineeringWelding process

The invention relates to an automatically-assembled welding clamp with a steel structure. The automatically-assembled welding clamp comprises a welding rack, an aligning mechanism, a rolling levelingmechanism and an adjusting mechanism. The problems in the welding process of the steel structure can be solved and are as follows: a, in the traditional welding process, the clamping specification forthe steel structure is fixed, the clamp of one specification can only respond to one steel structure, as for steel structures of different specifications in practical production, in the welding process, clamps need to be frequently replaced, a process is tedious, and the production cost is high; b, in the traditional welding process, the problems that weldments are aligned incompletely, and weldsurfaces are not uniform probably exist, and using of steel structures after welding is influenced; and c, in the traditional welding process, the weldments are only attached together, after welding is completed, the problem that weld joints are prone to being broken probably exists, and the welding effect is poor.

Owner:江苏恒智重工制造有限公司

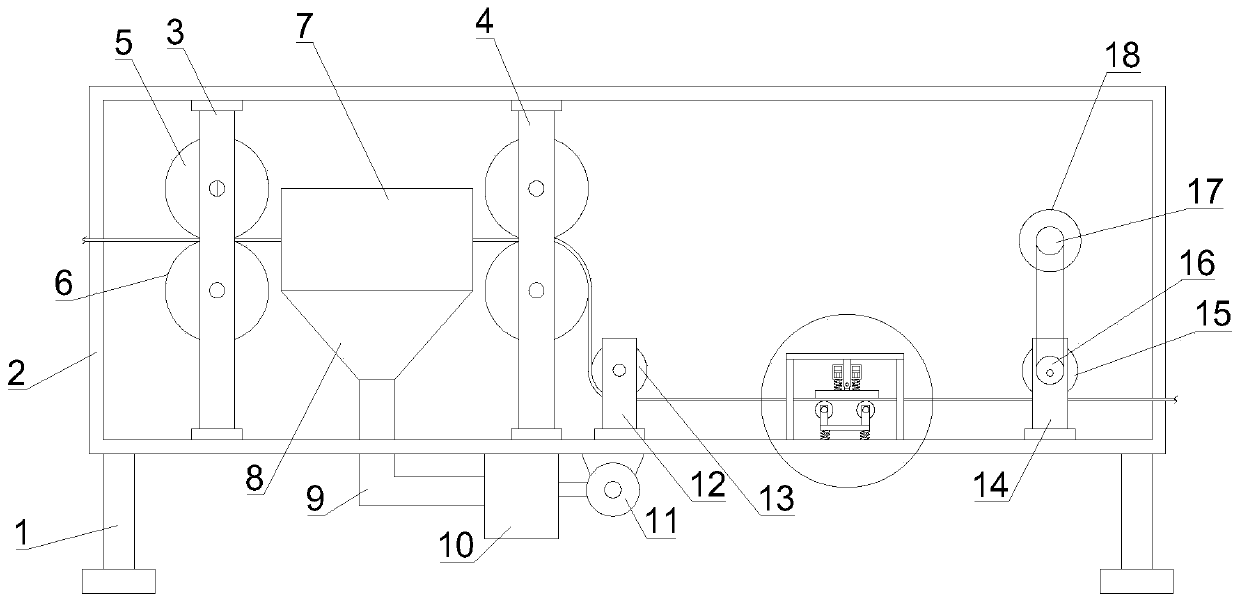

Blended yarn impurity removal and transporting mechanism

The invention discloses a blended yarn impurity removal and transporting mechanism which comprises a box body, a transporting mechanism body and an impurity removal mechanism, wherein landing legs are arranged at the bottom of the box body; the transporting mechanism body and the impurity removal mechanism are arranged in the box body; a first support plate and a second support plate are in sliding fit with a yarn feeding press roller through a first connecting shaft; a sleeve is arranged on the first connecting shaft in a sleeving manner; the sleeve is connected with the bottom end of a telescopic rod; the top end of the telescopic rod is connected with the top surface of the box body; a first spring is arranged on the telescopic rod in a sleeving manner; the first support plate and the second support plate are rotatably connected with a yarn feeding rotary roller through a second connecting shaft; the yarn feeding press roller is right above the yarn feeding rotary roller; a third support plate is rotatably connected with a yarn guiding rotary roller through a third connecting shaft; and a fourth support plate is rotatably connected with a driving rotary roller through a fourth connecting shaft. The blended yarn impurity removal and transporting mechanism can compress and transport blended yarn to enable the blended yarn to be fully unfolded during the transporting process and ensure the transporting broad width of the blended yarn, is cleaner and more comprehensive in blended yarn impurity removal and higher in efficiency.

Owner:徐州嘉搏纺织股份有限公司

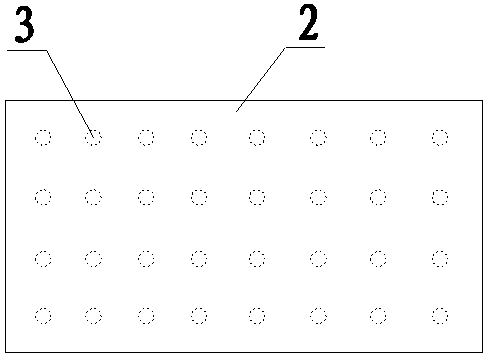

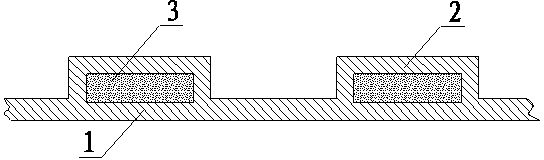

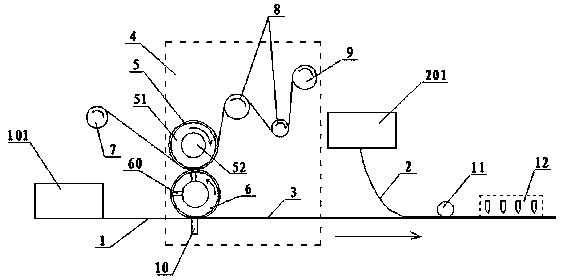

Printed non-woven fabric and processing method and device thereof

ActiveCN103409943AEasy to produceSimplify the production process and shorten the processing cycle of printed non-woven fabricsTextile decorationNon-woven fabricsMolding machineEngineering

The invention relates to a printed non-woven fabric which is not prone to color fading, is simple and environmentally friendly in manufacturing process and has patterns of the watermark effect and a processing method and device for the printed non-woven fabric. The printed non-woven fabric is composed of two fiber net layers which are tangled and fixed mutually and a plurality of patterned sheets which are fixed between the two fiber net layers at intervals. The processing method for the printed non-woven fabric comprises the steps of firstly, conveying the plurality of patterned sheets to the bottom fiber net layer, then covering the bottom fiber net layer with the upper fiber net layer, coating the patterned sheets between the two fiber net layers, performing water-jet entangling fixing on the two fiber net layers, and finally, performing drying treatment to produce a non-woven fabric product. The processing device of the printed non-woven fabric comprises two molding machines, a conveying device for the sheets and a water-jet device, wherein the conveying device comprises an unwinding mechanism, a tension roller, a shearing mechanism, a sucking moving mechanism and an adsorption mechanism.

Owner:HANGZHOU NBOND NONWOVENS

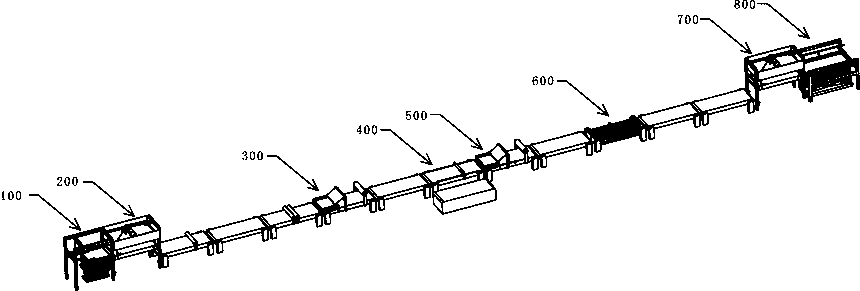

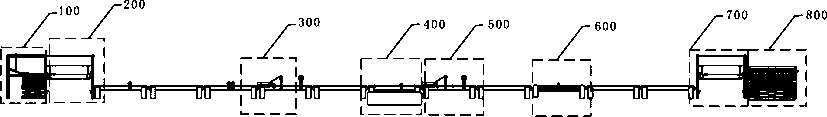

Production line of building board

PendingCN109808053AImprove production efficiencyQuality improvementCeramic shaping plantsFeeding arrangmentsProduction lineEngineering

The invention discloses a production line of a building board. The production line comprises a base board conveying device, a base board transfer device, a first layer mortar laying device, an insulating layer laying device, a second layer mortar laying device, a board cutting device, a board transfer device and a board stacking device, wherein the base board conveying device is located at the front end; the base board transfer device is adjacent to the rear end of the base board conveying device; the first layer mortar laying device is connected with the rear end of the base board transfer device through a conveying belt; the insulating layer laying device is connected with the rear end of the first layer mortar laying device through the conveying belt; the second layer mortar laying device is located at the rear end of the insulating layer laying device; the board cutting device is connected with the rear end of the second layer mortar laying device through the conveying belt; the board transfer device is connected with the rear end of the board cutting device through the conveying belt; and the board stacking device is located at the rear end of the board transfer device. The production line is reasonable in design, simple in structure and convenient to use. Through the reasonable layout, the board production efficiency of the production line for producing the building boardis better, and the quality is more stable and reliable.

Owner:成都福仕特科技有限责任公司

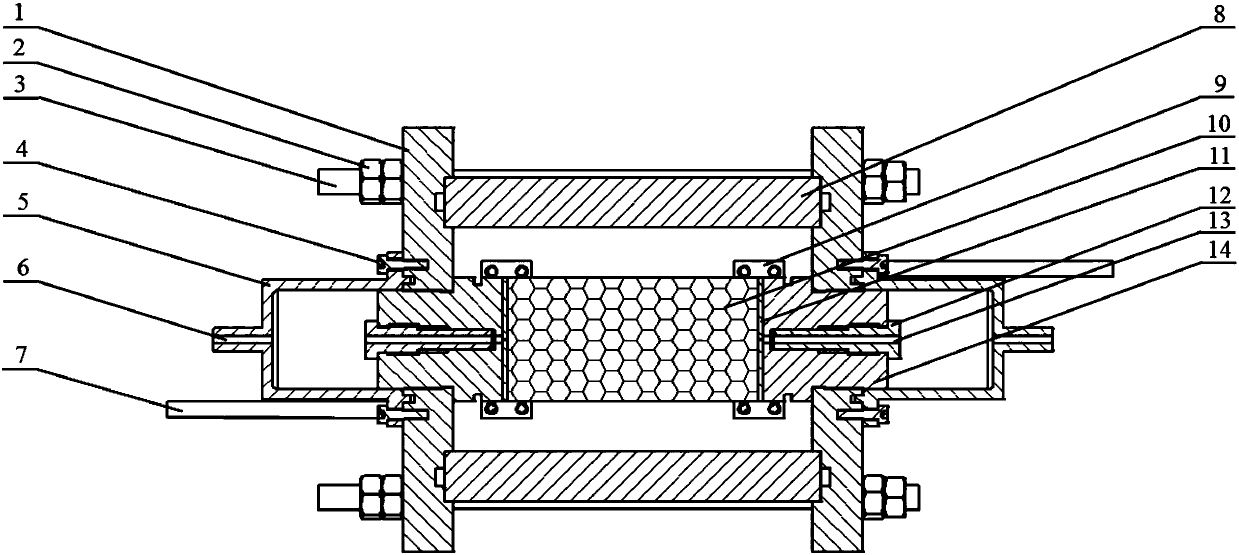

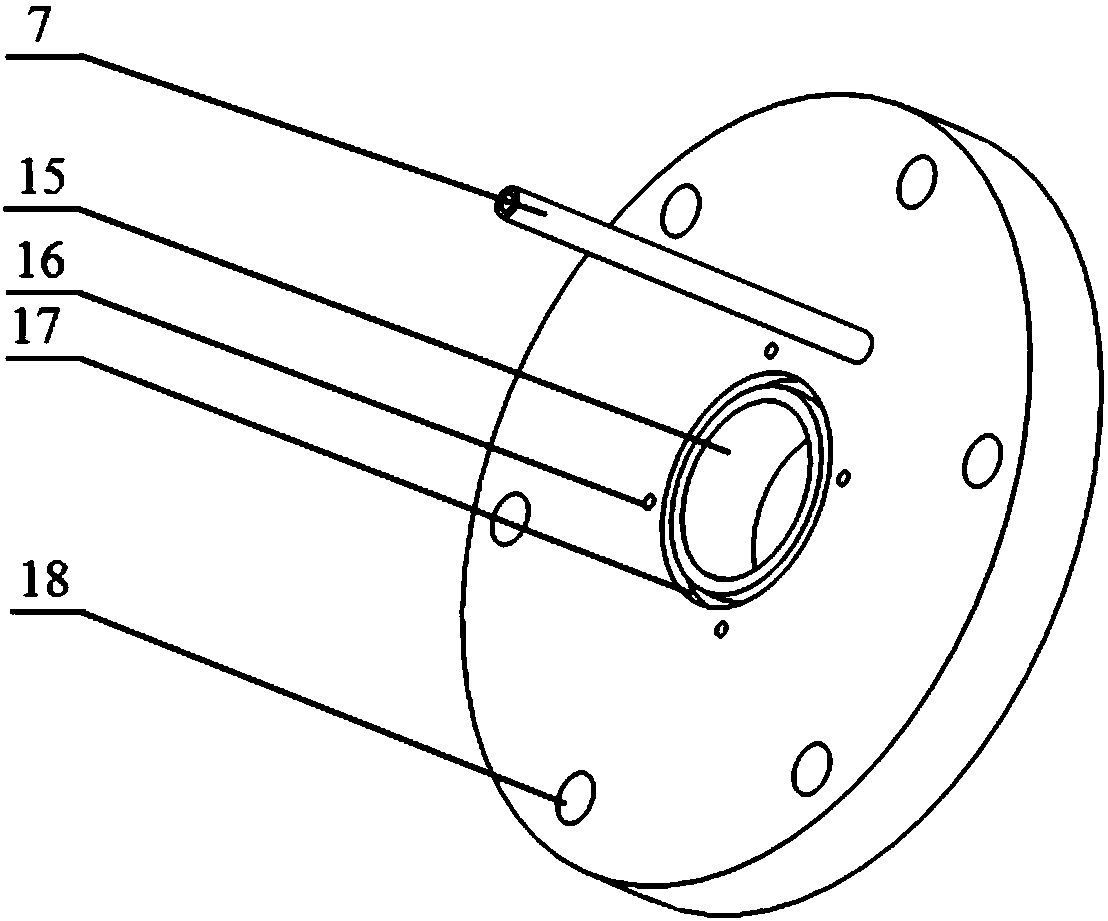

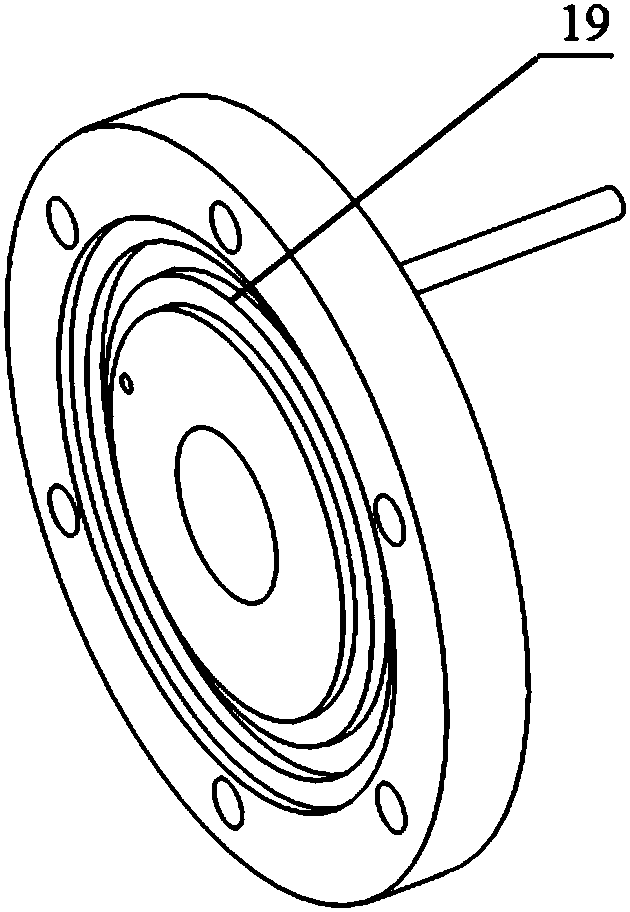

Rock-soil medium horizontal seepage simulation device with adjustable size of sample pool

ActiveCN109991143AGuaranteed reliabilityReduce adsorptionPermeability/surface area analysisLiquid mediumEngineering

The method is widely applied to the fields of research of seepage behaviors of gas and liquid media in a rock-soil medium, research of migration behaviors of solutes in a rock-soil medium, and the like, and discloses a rock-soil medium horizontal seepage simulation device with an adjustable size of a sample pool; sample bases are arranged at the two ends of the device respectively, wherein a gas or liquid sample inlet pipe is fixed in each base center through a rotary plug connector; the device comprises a front stainless steel base and a rear stainless steel base; a gas inlet pipe connector is arranged near the center of the base; the interior of a barrel body is connected with a gas steel cylinder through the gas inlet pipe connector; a stainless steel sealing cap is arranged at each ofthe front and rear ends of the device separately, and a gas or liquid sample inlet pipe is arranged at the top of the device; a shaft shoulder matched with a first groove is machined on the inner sideof the bottom of each cap brim, and four sixth threaded holes are uniformly engraved in the cap brim; and the sealing caps are arranged on the periphery of the base in a sleeving mode and are tightlyfixed on the base. The rock-soil medium horizontal seepage simulation device is convenient to use and reliable in result.

Owner:63653 FORCES PLA

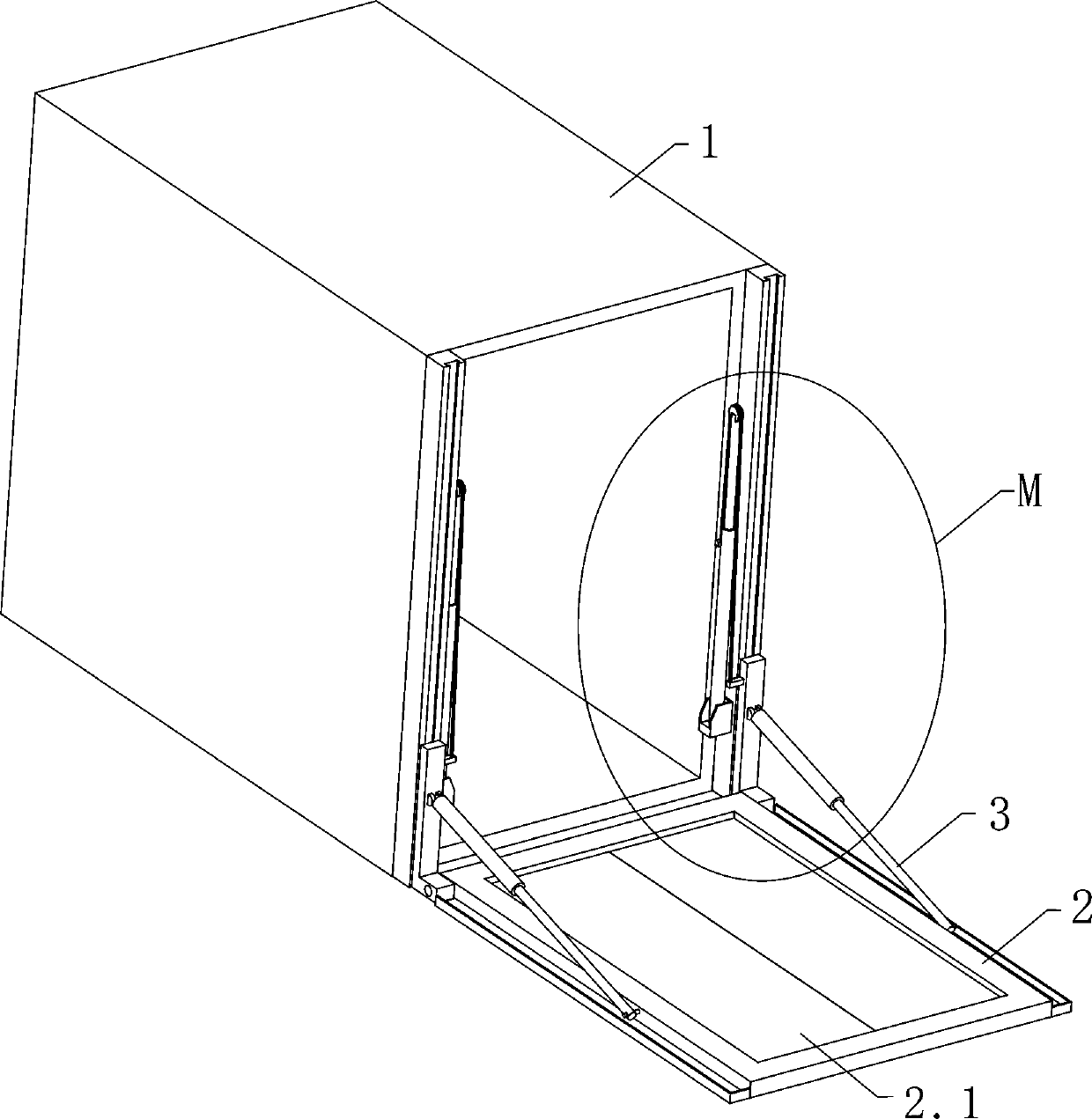

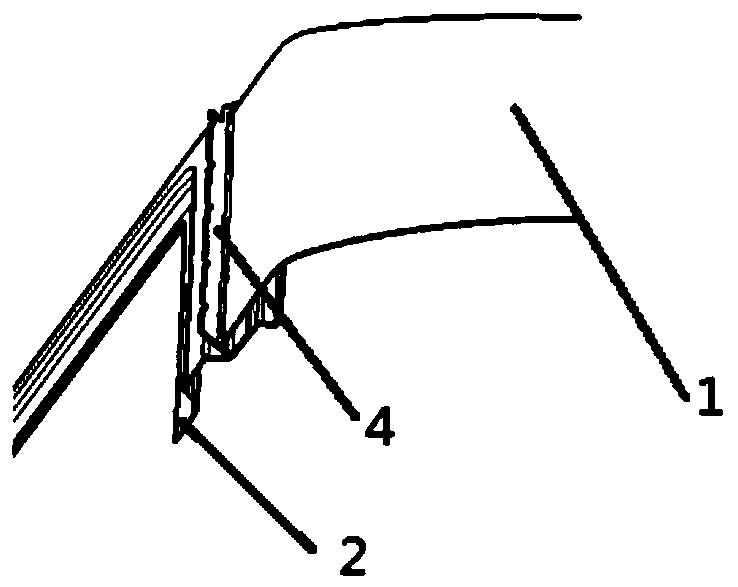

Door-in-door on tail part of carriage

PendingCN110435402AEasy loadingEasy to unloadVehicle with raised loading platformVehicle with loading gatesEngineeringJamb

The invention discloses a door-in-door on the tail part of a carriage. The door-in-door includes a door plate, the door plate is installed on a door frame on the tail part of the carriage through a sliding block, the sliding block is connected with the door plate through a pin shaft, the door plate can be overturned with a rotating shaft as the axis, a vertical power device driving the sliding block to move up and down on the door frame is fixedly installed in the door frame, and meanwhile, a turnover power device driving the door plate to overturn is arranged at the front end of the sliding block. According to the door-in-door, design is reasonable, the structure is simple, use is convenient, the door-in-door installed on the tail part of the carriage is arranged, the door plate is reasonably designed, a cargo door capable of being opened and closed is further arranged in the door plate, the door plate can be overturned and moved up and down to facilitate loading and unloading by staff, especially the height can be adjusted, loading or unloading of high-level goods in the carriage are convenient, the door plate can drive objects to move upwards or downwards, and the inconvenienceof the staff when loading or unloading in the carriage is overcome.

Owner:朱从伟

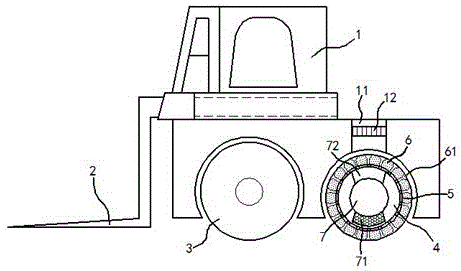

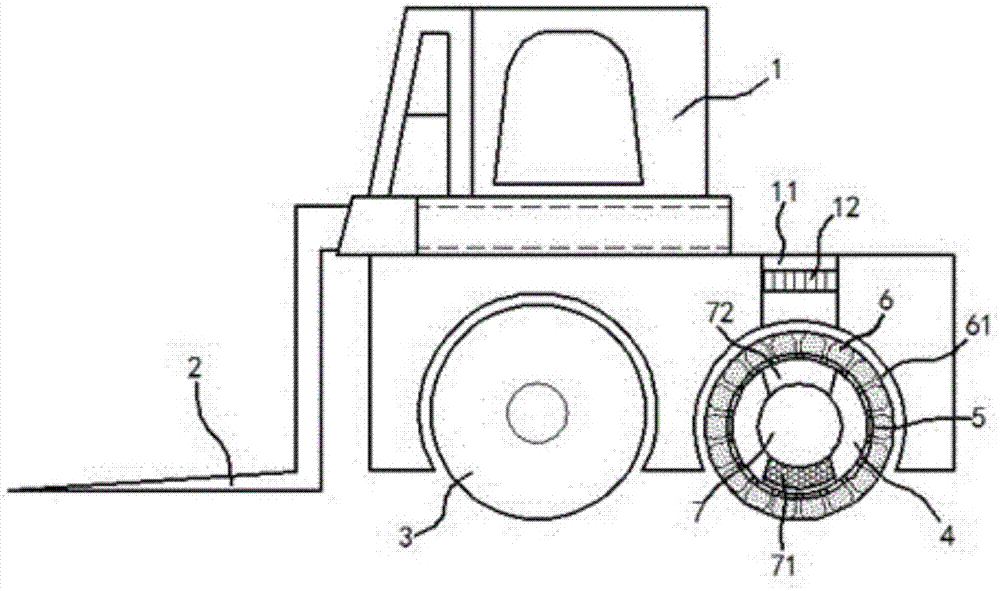

Negative-pressure forklift

ActiveCN105600706AFlexible steeringFlexible moving processLifting devicesCounterweightsDrive wheelEngineering

The invention relates to a negative-pressure forklift which comprises a forklift body, a fork leg, driving wheels and a counterweight wheel, wherein the fork leg device is arranged on the front end of the forklift body, and the counterweight wheel is arranged at the rear part of the forklift body; the counterweight wheel comprises a wheel rim capable of rotating freely around an axle; the exterior of the wheel rim is sleeved by a tire; sucking disc components are arranged at equal intervals in the circumferential direction of the tire; the disc surfaces of the sucking disc components face outwards, and necks of the sucking disc components extend towards the axle along the radial direction of the wheel rim; air guide holes opposite to the positions of the necks are formed at equal intervals in the wheel rim; the wheel rim is internally provided with a sucking pump; the sucking end of the sucking pump is airtightly clung to the inner wall of the wheel rim in a manner of facing downwards in the vertical direction; the wheel rim can rotate freely relative to the sucking pump. The forklift is relatively light in self weight, can turn and move flexibly, is capable of effectively improving the carriage efficiency and further can operate stably and safely.

Owner:NANTONG ELITE MARINE EQUIP & ENG

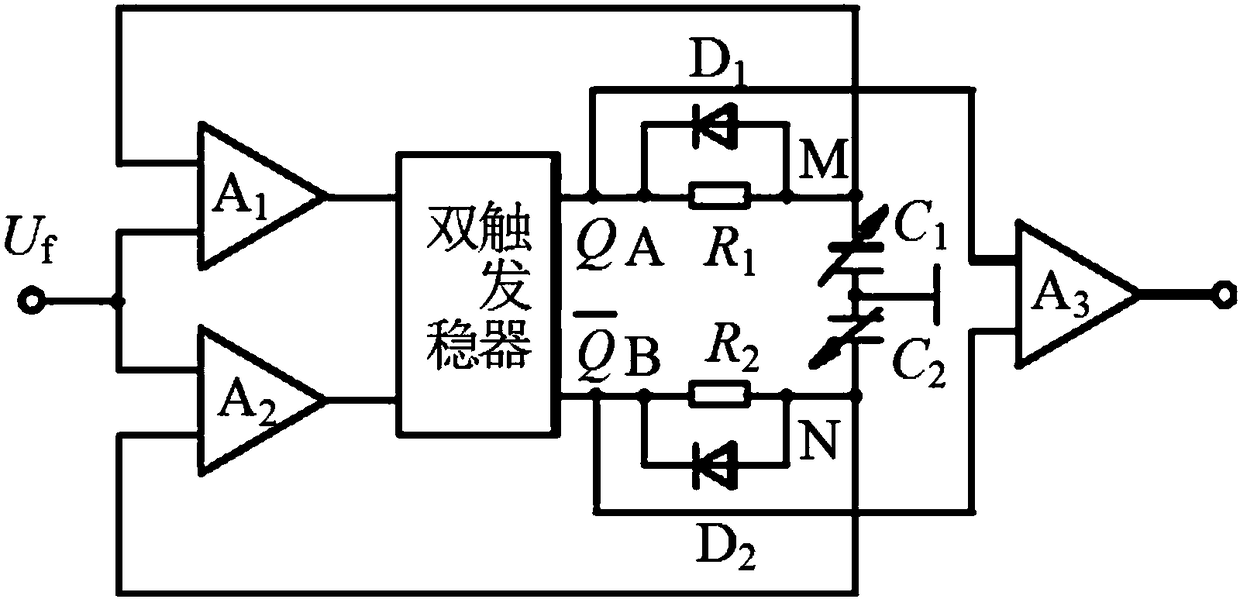

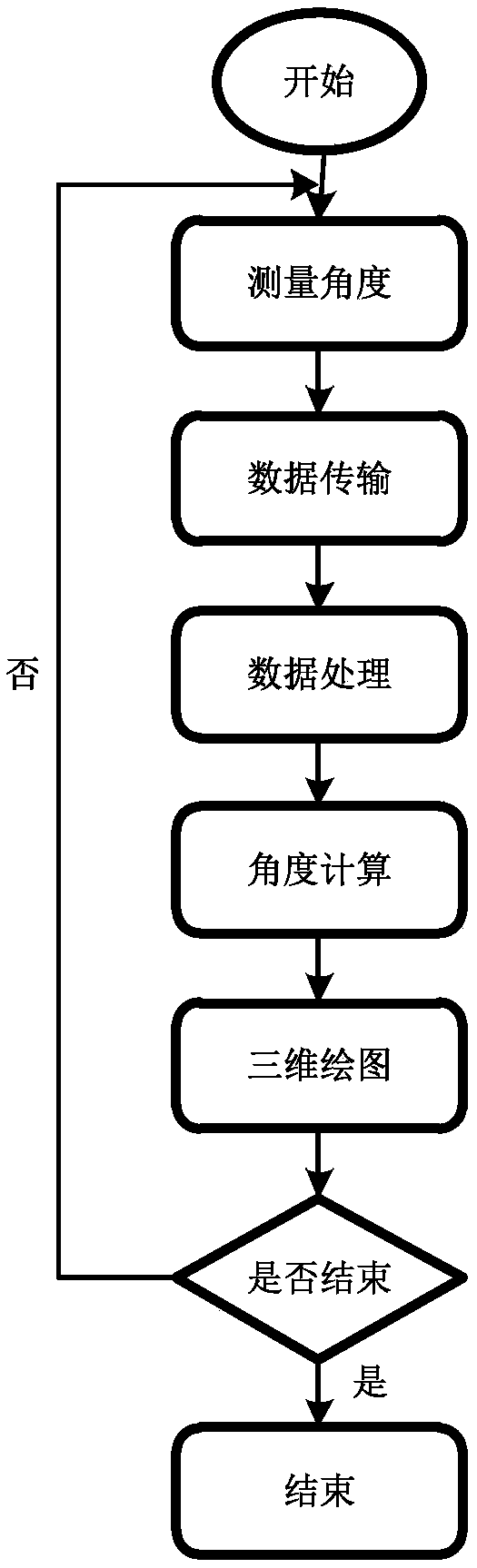

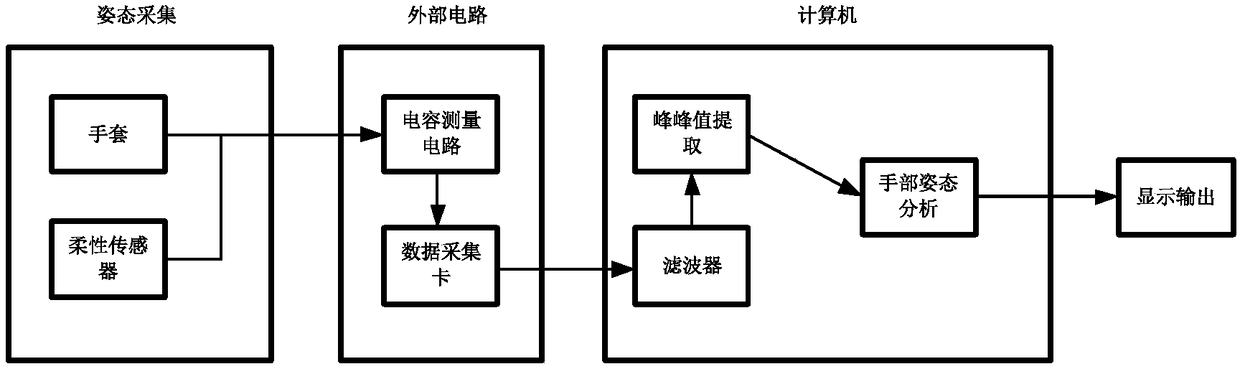

Hand posture measurement system and method based on flexible large deformation sensor

The invention discloses a hand posture measurement system and method based on a flexible large deformation sensor, and the hand posture measurement system can measure and display a human hand motion in real time. The hand posture measurement system comprises three parts: a glove part, an external circuit part and a computer. The glove part is responsible for obtaining a hand posture mainly information of the bending angle of each finger joint in the motion; the external circuit is responsible for collecting a signal obtained by a capacitive flexible dielectric sensor and performing low-pass filtering on a power supply noise. The computer is responsible for processing data and converting the data obtained by the sensor into angle information, and the received real-time human posture can bedisplayed by a drawing program. The system can be, but is not limited to, used in hand posture collection for wearable devices and physician assessment of patient's hand rehabilitation during rehabilitation medical procedures.

Owner:XI AN JIAOTONG UNIV

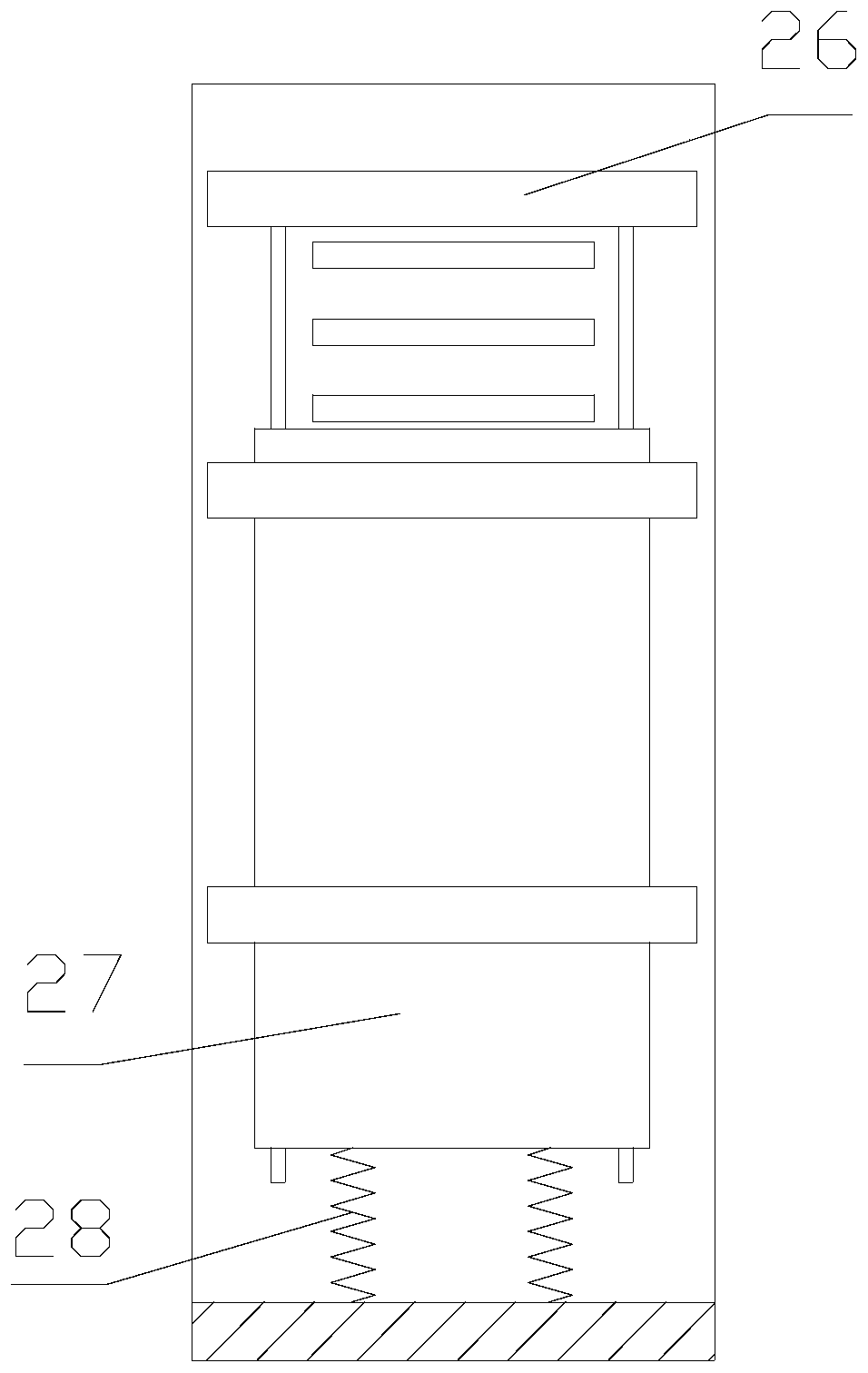

Power box with function of closing cavity in flood

ActiveCN110011198AAvoid electric shockAvoid enteringSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringRed light

The invention provides a power box with the function of closing a cavity in flood. The power box comprises a closed top cover, a power box body, threaded holes, a fixed base, a service door switch, connection hinges and maintenance doors. A lower end of the closed top cover is welded to an upper side of the power box body, the closed top cover is set above the fixed base, and the threaded holes and the fixed base are an integrated structure. A floating block mechanism floats upward due to buoyancy in flood, a waterproof baffle mechanism is driven to move upward to close a heat dissipation holeon the power box body, and water is prevented from flowing into the inside of the power box. When the power box is completely submerged, a small floating block on the floating block mechanism floatsto a water surface, a glass plate on the small floating block and a mercury layer reflect red light, the water is prevented from flowing into the inside of the power box to cause short circuit, the electric shock of a passing person caused by the electrical conduction of the water is prevented, a submerged position of the power box can be determined, and power workers can find and treat in time.

Owner:诸暨市凯腾广告设计有限公司

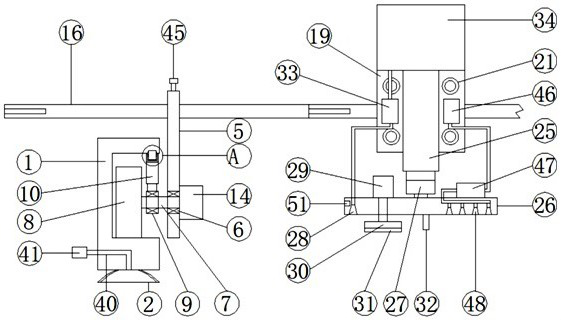

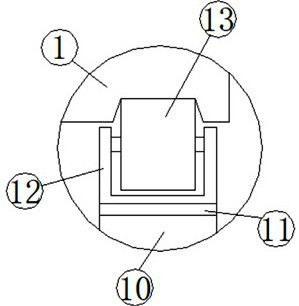

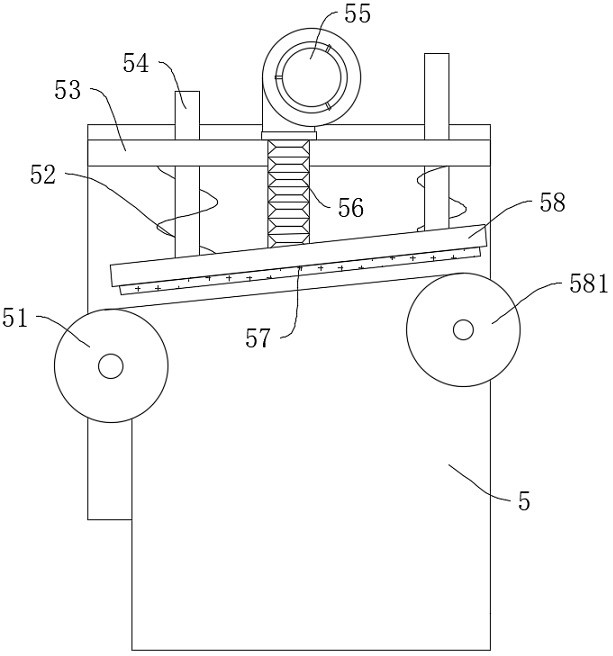

Processing device for blending wool and tree fiber into yarn

PendingCN113584658ASolve the problem of winding gapsReduce tensionContinuous wound-up machinesYarnYarnFiber

The invention relates to the technical field of spinning, in particular to a processing device for blending wool and tree fiber into yarn. The processing device comprises a base, a support A, a support B, a support C, a support D and a yarn guide block A. The support A is fixedly installed on one side of the upper surface of the base. Through the structural cooperation of an extrusion assembly and a transmission assembly, the problems that in the prior art, cotton threads are always in a loose and soft state after being wound and unwound from a bobbin, and relatively large winding gaps can be formed between processed yarns are solved; in combination with the upward movement of a toothed plate and the upward movement of an extrusion slope block in the device, a connecting frame is elastically pressed to be compressed, meanwhile, the slope end of the slope block extrudes the surface of a rotating sleeve, the rotating sleeve and the slope block are in rolling extrusion, a sliding block drives tree fiber cotton threads and wool cotton threads to move towards the two sides along a guide column A, and a spring A is elastically compressed; and the tension of the cotton threads is increased by increasing traction force, so that no relatively large gaps exist in the twisting process of the cotton threads, and the processed yarn is more compact and fit.

Owner:HEFEI ANLUYI TECH CO LTD

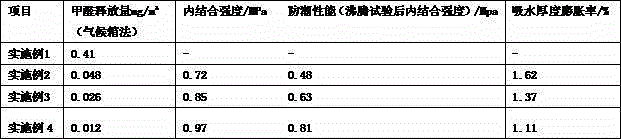

Production method for damp-proof ceiling decoration density board

InactiveCN105150353ALow residual formaldehydeAvoid it happening againNon-macromolecular adhesive additivesWood working apparatusNatural ventilationWear resistant

The invention provides a production method for a damp-proof ceiling decoration density board. The production method includes the steps that broken wood materials or broken gains such as various types of straw and nutshells which are generated after crops are harvested and damp-proof urea-formaldehyde resin adhesives are mixed and pressed into a board, and the board and melamine-soaked paper or aluminium oxide wear-resistant paper are pressed and attached at a high temperature to form the damp-proof ceiling decoration density board. Three times of cold pressing, three times of hot pressing and two times of heat dissipation regimens are adopted for board forming. The cold pressing temperature is the room temperature, the cold pressing pressure is 2.5 MPa, and the hot pressing pressure is 1.5-2.0 MPa. The temperature of the first time of hot pressing is 130-135 DEG C. The temperature of the second time of hot pressing is 125-130 DEG C. The temperature of the third time of hot pressing is 120-125 DEG C. The heat dissipation regiments are achieved by lowering the temperature of a constant temperature room to the room temperature through natural ventilation cooling, and the time ranges from 3 h to 4 h. The melamine-soaked paper or the aluminium oxide wear-resistant paper is attached to the surface of the board at a temperature of 150 DEG C and under the pressure of 1.5 MPa.

Owner:钱秀英

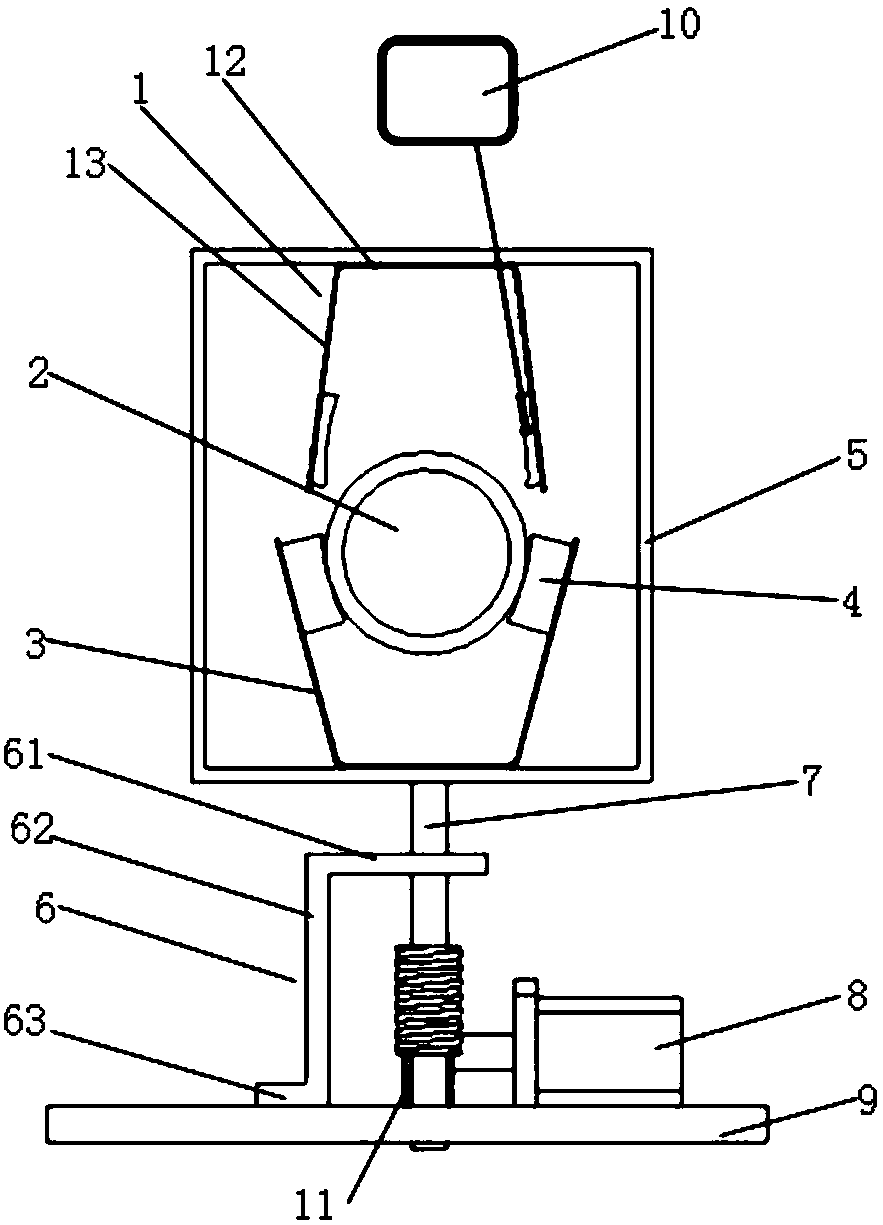

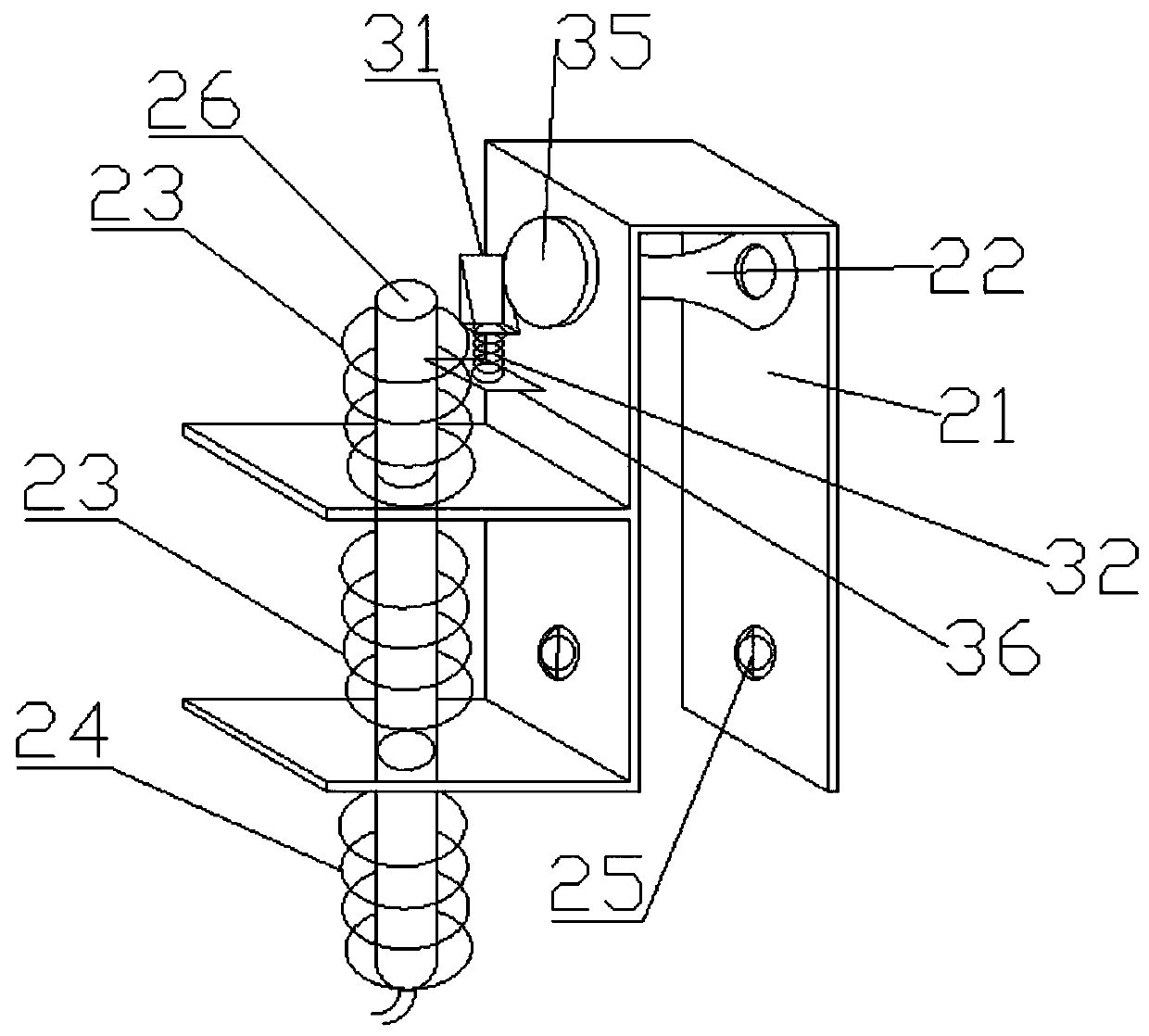

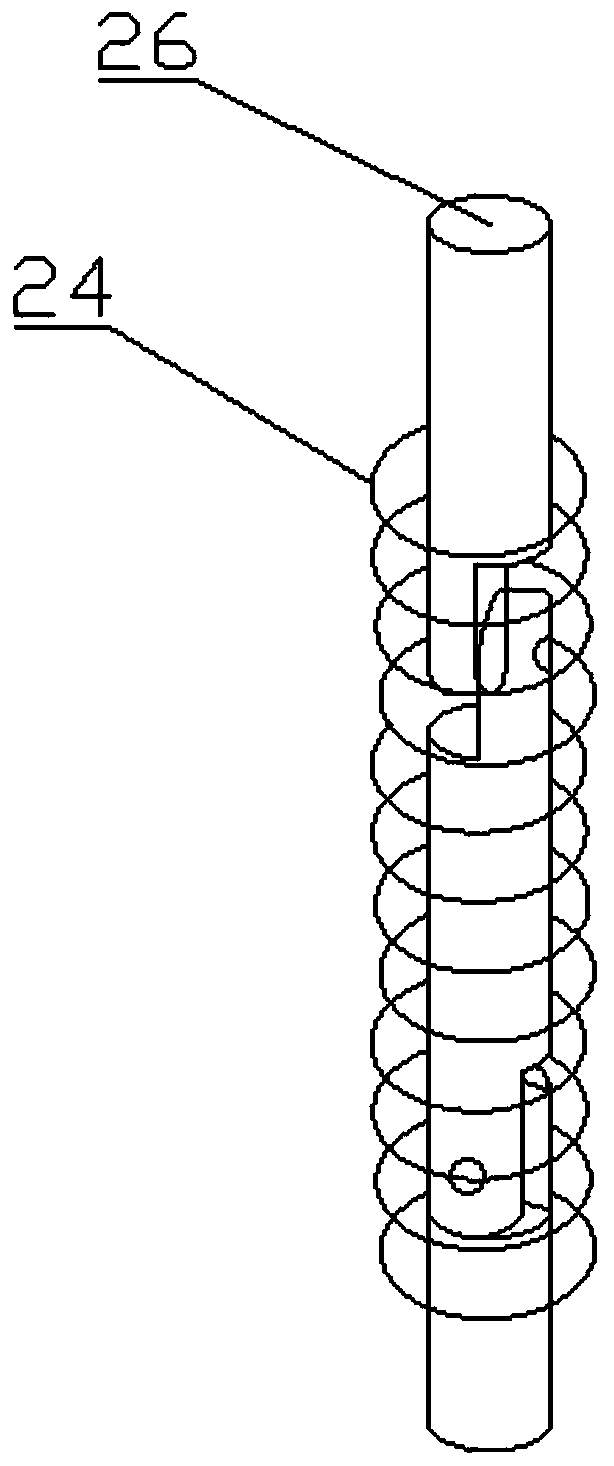

Conductive sliding ring brush holder system capable of automatic switching and working method thereof

The invention discloses a conductive sliding ring brush holder system capable of automatic switching, comprising an electric brush, a conductive ring, a backup electric brush, a wear thimble, a movable frame, a screw rod fixing frame, a screw rod, a motor, a support plate, an upper computer and a gear. The electric brush is connected with the backup electric brush. The wear thimble is disposed atend portions, away from the conductive ring, of the electric brush and the backup electric brush. The electric brush is connected with the upper end surface of the movable frame. The backup electric brush is connected with the lower end surface of the movable frame. The lower end portion of the screw rod fixing frame is fixed on the support plate. The upper end surface of the screw rod is fixed onthe outer wall of the movable frame, and the lower end portion of the screw rod passes through the screw rod fixing frame and the support plate in sequence. The gear meshes with the screw rod. The motor is connected with the gear. The upper computer is connected with the wear thimble through a signal line. The working method of the conductive sliding ring brush holder system capable of automaticswitching according to the invention is simple and easy, the conductive sliding ring does not need to be removed for maintenance, the time is greatly saved, and the work efficiency is improved.

Owner:浙江恩碧技创新科技有限公司

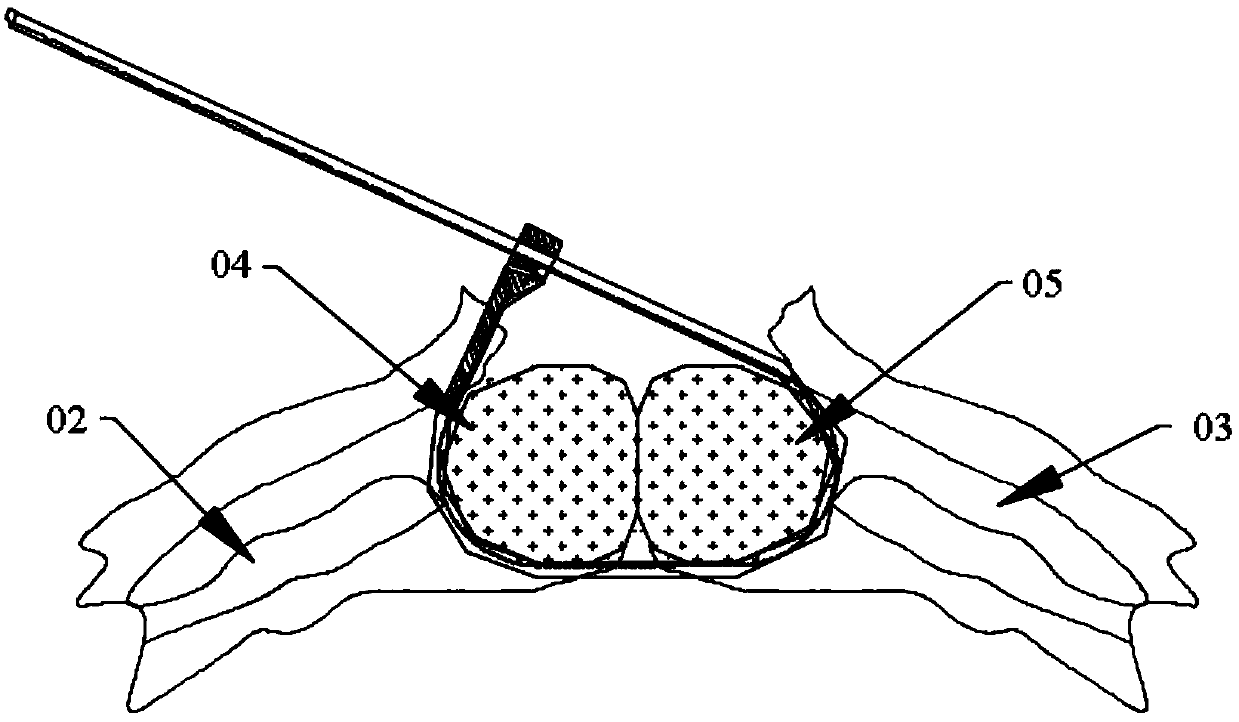

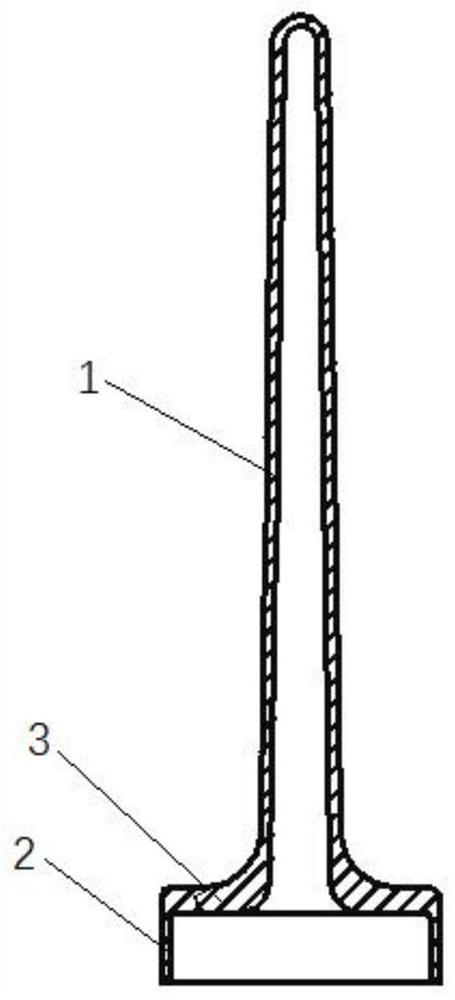

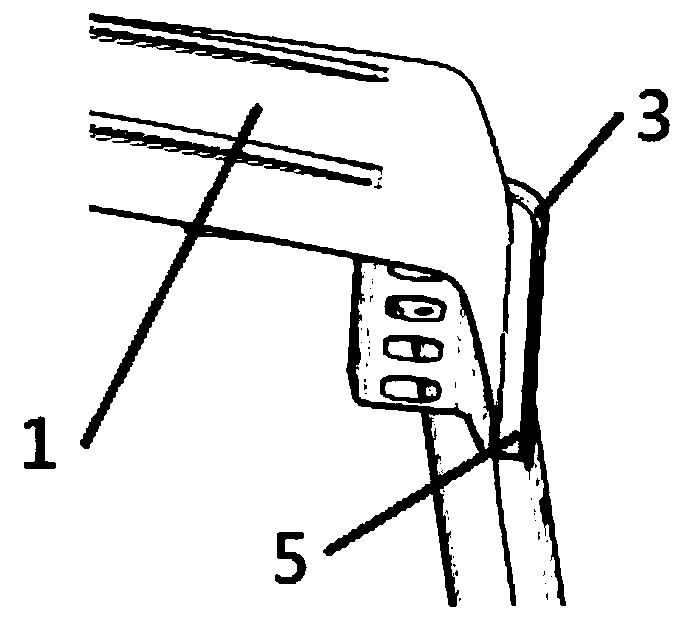

Medical orthopedic implantation bundling strap

PendingCN107638206ANot easy to slipEasy to insertInternal osteosythesisFastenersInterference fitEngineering

The invention discloses a medical orthopedic implantation bundling strap which comprises a puncture section, a threading section, a lock tooth section, a locking ring and a lock plate which are sequentially arranged. The threading section, the lock tooth section and the locking ring are integrally formed, a puncture head is arranged at one end of the puncture section, and the other end of the puncture section is fixedly connected with the threading section; a plurality of lock teeth are continuously arranged on a bone clinging surface of the lock tooth section; the locking ring comprises a lock hole, the threading section and the lock tooth section can penetrate the lock hole, a side of the periphery of the lock hole is connected with the lock tooth section, and the two end surfaces of thelocking ring are connected with the bone clinging surface and the other surface of the lock tooth section; an armature spring is arranged in the lock hole, one end of the armature spring is connectedwith a side wall of the lock hole, the other end of the armature spring is a free end, and accordingly a variable gap is reserved between the armature spring and the connected side wall of the lock hole; more than one armature spring lock tooth which can mesh with the lock teeth on the lock tooth section is arranged on the side, which is far away from the variable gap, of the armature spring; theshape of the lock plate is adaptive to the shape of the variable gap when the lock teeth on the lock tooth section mesh with the armature spring lock teeth, so that the lock plate can be inserted inthe variable gap in an interference fit manner.

Owner:苏州爱宝利恩精密器械科技有限公司

Application of industrial textile

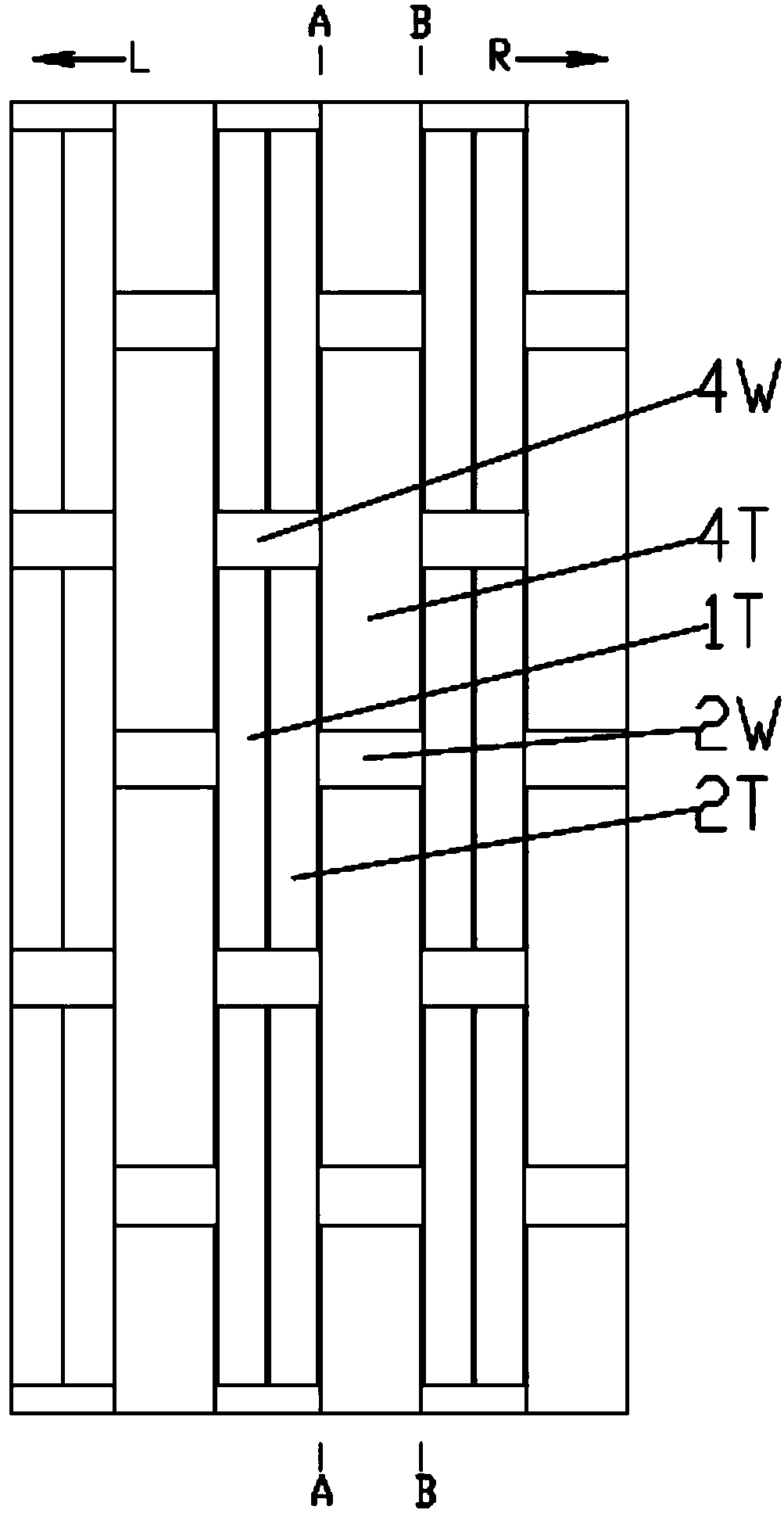

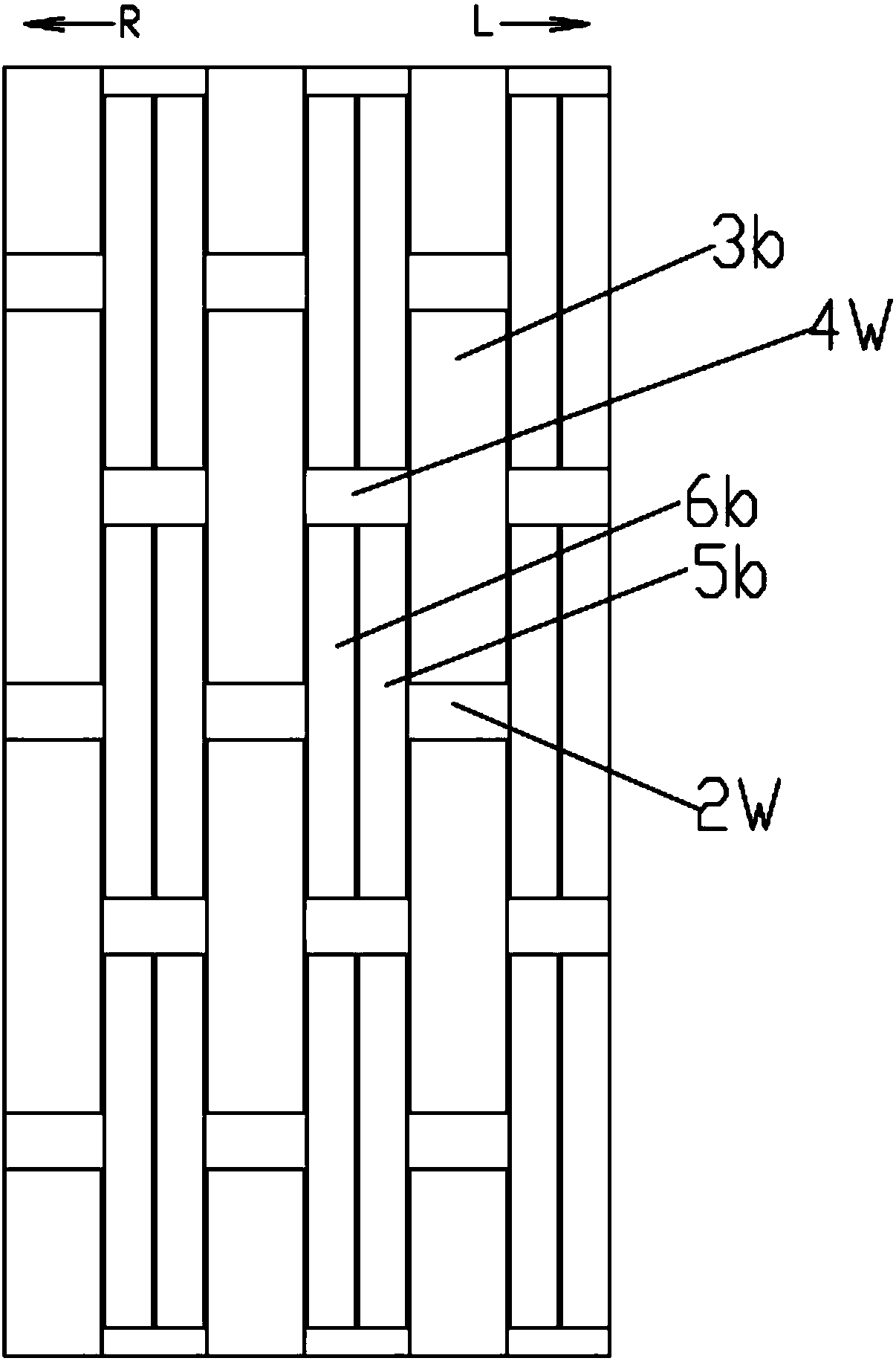

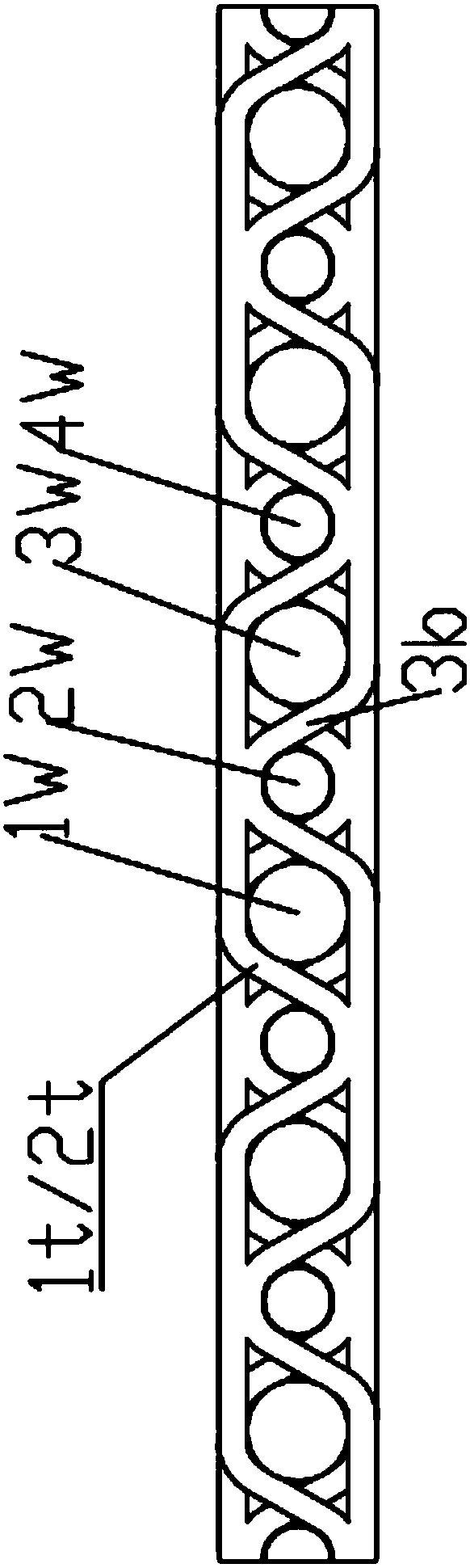

InactiveCN107627743APrecise size controlFit tightMulti-ply fabricsOpen work fabricsImage resolutionPulp and paper industry

The invention provides application of an industrial textile, and relates to the technical field of printers. The industrial textile is a net woven with single-filament material warps and single-filament material wefts; a warp structure or texture of the net is a double-layer structure; an upper layer of warps are woven with the wefts on the upper layer; a lower layer of warps are woven with the wefts on the lower layer; the upper layer of warps do not intersect with the lower layer of wefts; one warp basic unit comprises four sub units with two sub units on the upper layer and the other two sub units on the lower layer; the net is an end net, and the color of the net is common black; the application relates to application as a printer net belt. By adopting the application of the industrialtextile, the problems of a spiral net conveying belt in the prior art that size cannot be controlled precisely; stability is poor; clinging is not close; and high-speed, high-distinguishability and high-quality printing cannot be finished are solved. The application of the industrial textile has the characteristics that the size of the conveying belt is easy to control precisely; operation stability is good; a printing medium closely clings to the net belt; and high-speed, high-distinguishability and high-quality printing can be finished.

Owner:ANPING XINPENG MESH BELT LTD

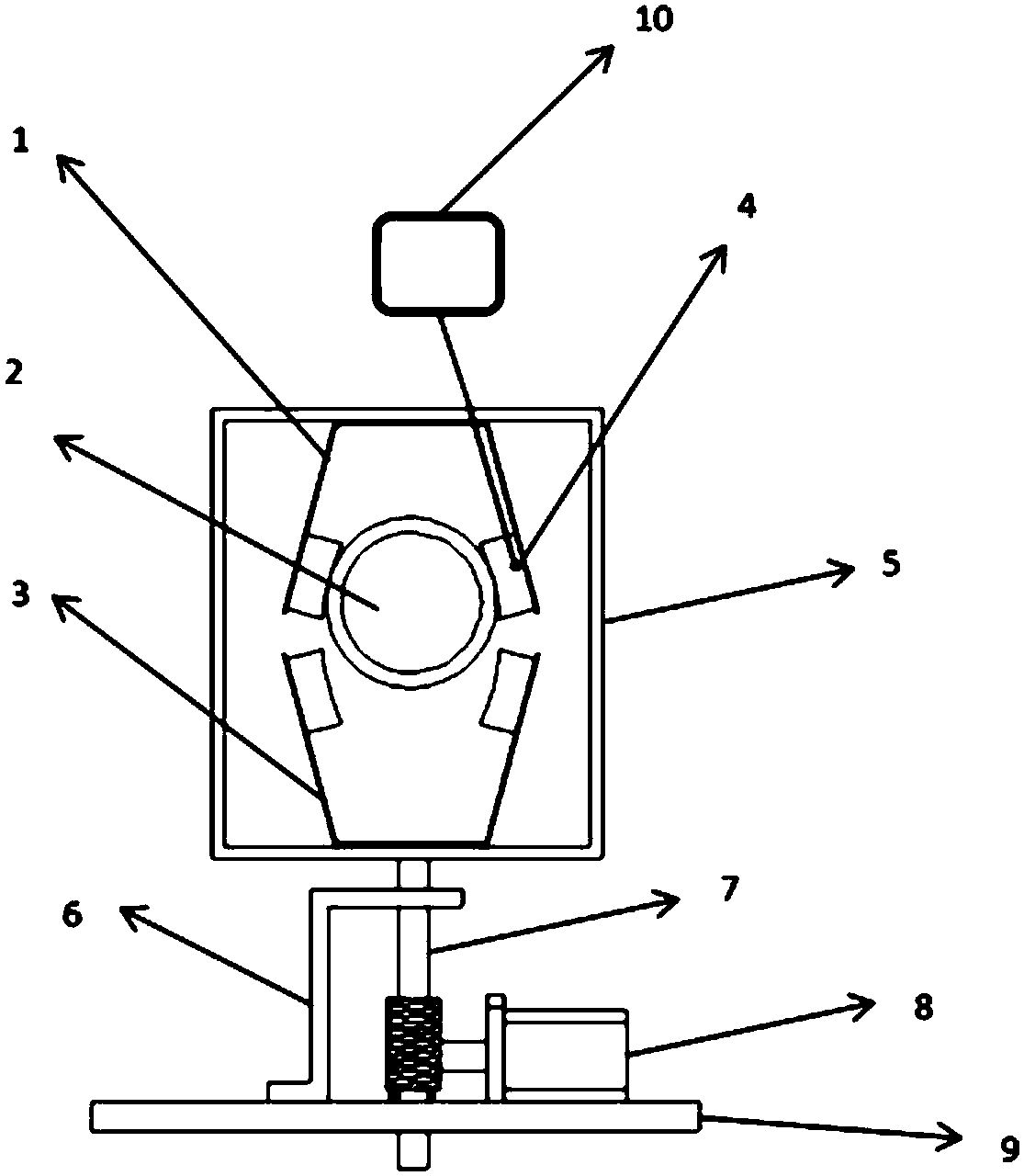

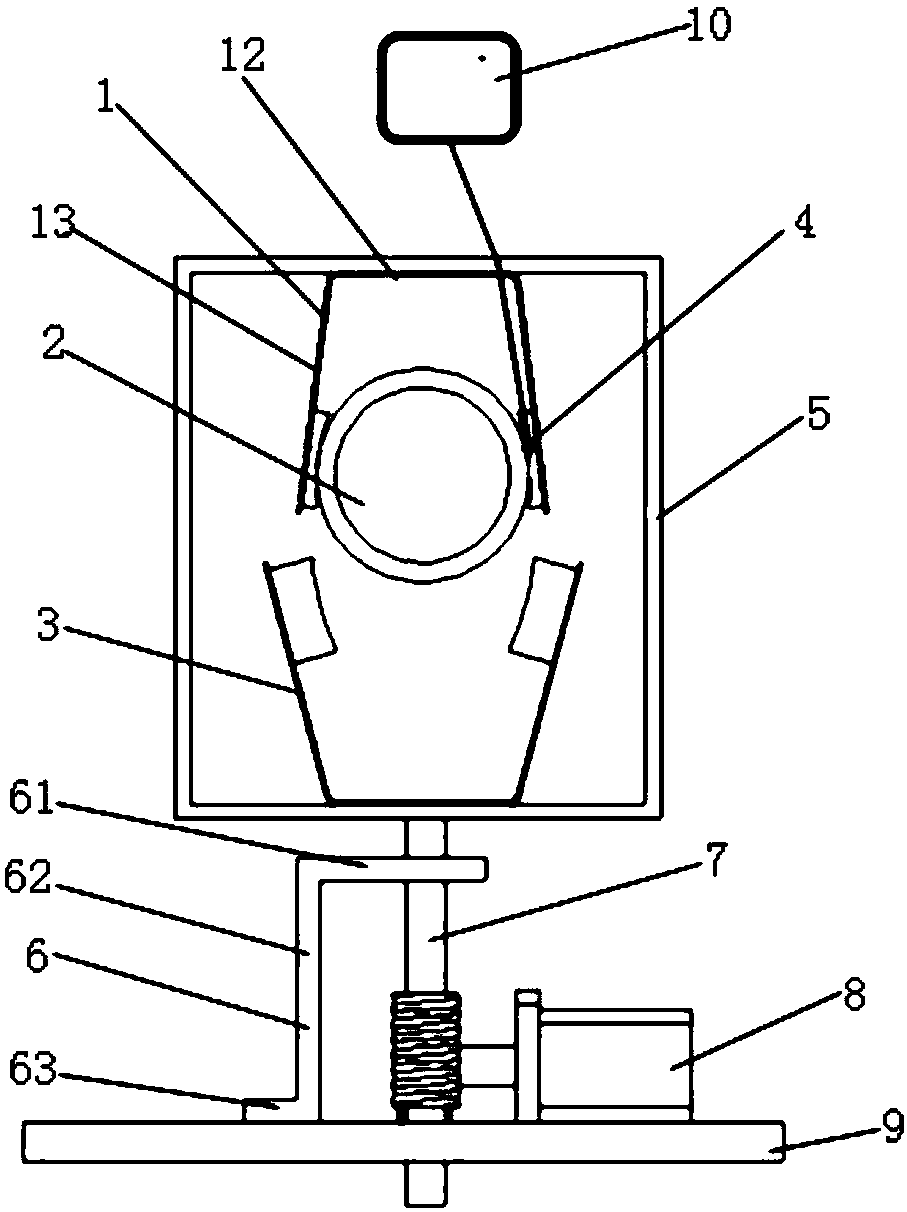

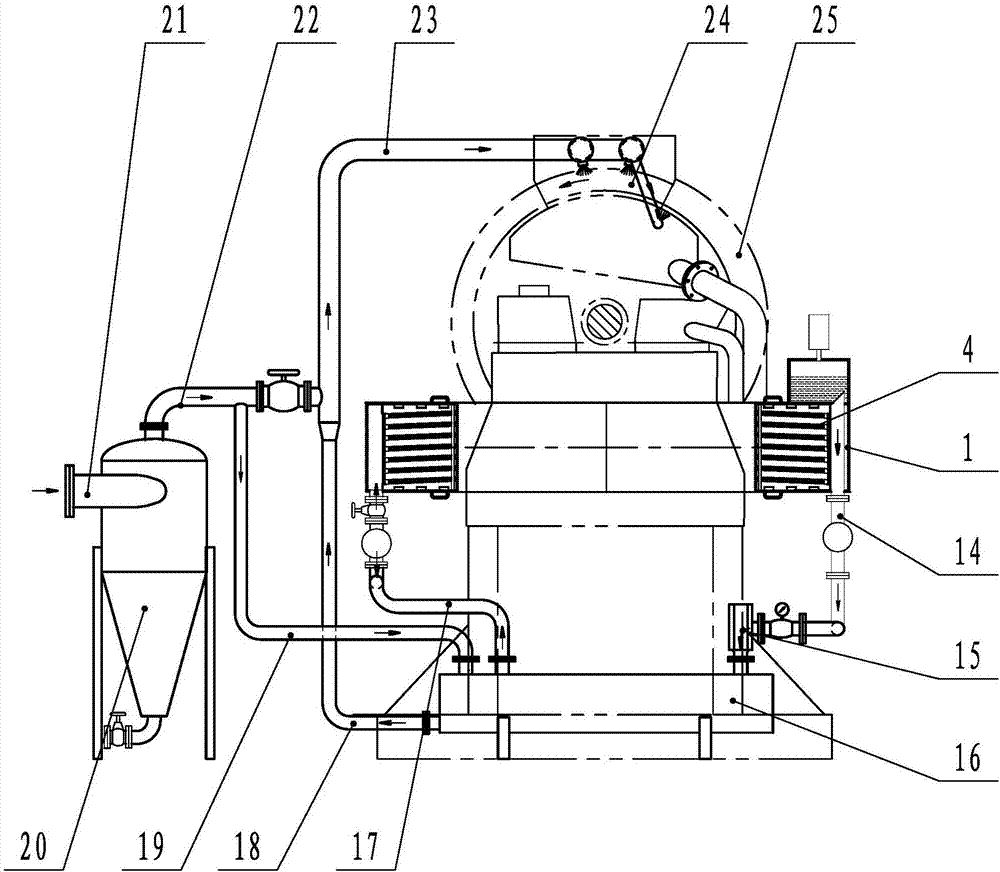

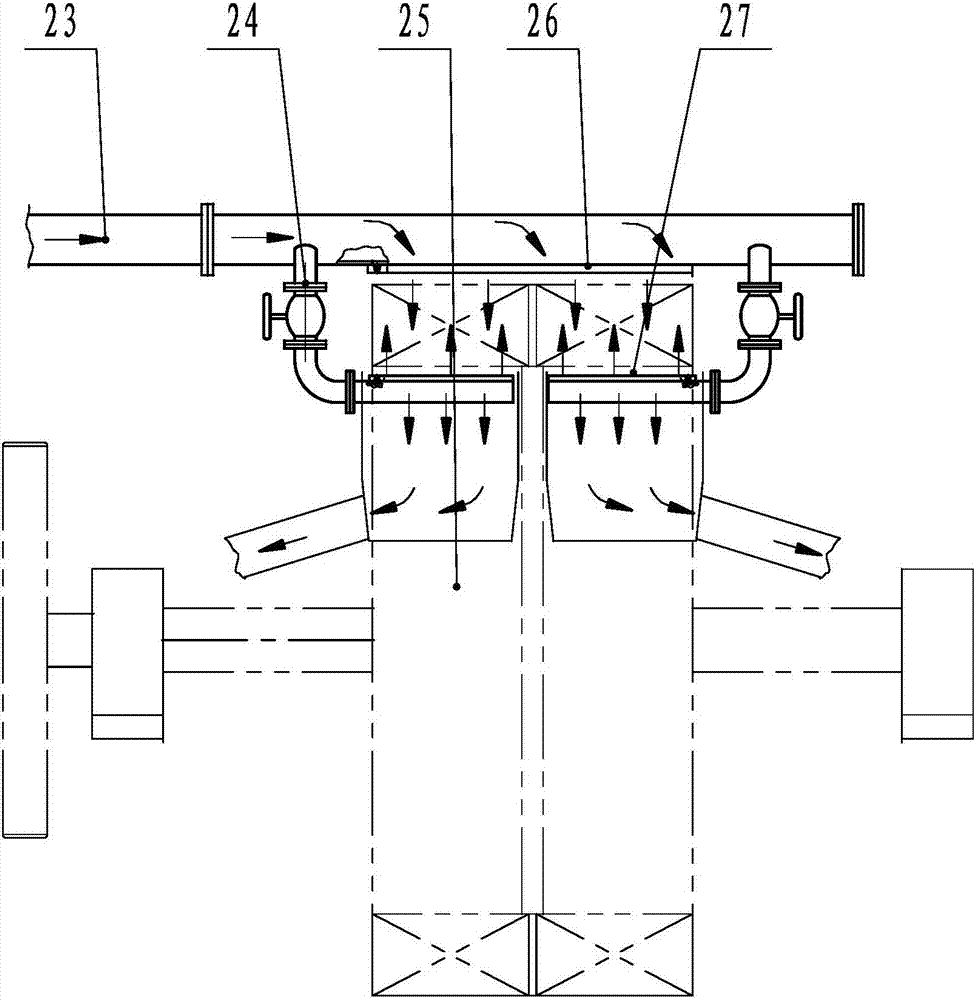

Vertical-ring high-gradient magnetic separator

ActiveCN107042156AIncrease ascent speedEasy dischargeHigh gradient magnetic separatorsMagnetic separatorWater pipe

The invention discloses a vertical-ring high-gradient magnetic separator which comprises a cooling system and a mineral flushing system; the cooling system comprises a magnet exciting coil, an oil pump and a cooler; the mineral flushing system comprises a filter and a mineral flushing water pipe; the mineral flushing water pipe comprises a positive mineral flushing water pipe located on the outer side of the upper part of a revolving ring, and a negative mineral flushing water pipe located on the inner side of the upper part of the revolving ring; the magnet exciting coil comprises magnet exciting wire coils arranged in an inner cavity of a coil case; each magnet exciting wire coil is obliquely arranged in a vertically multilayer manner; the outer circumference of each magnet exciting wire coil is higher than the inner circumference of the magnet exciting wire coil; interlayer insulation filler strips are arranged among gaps of each magnet exciting wire coil in a spaced manner, and interlayer cooling liquid channels are formed; inner holes of the coil case are in waist drum shapes; and two oil inlets are formed in one end of the coil case and two oil outlets are formed in the other end of the coil case. The vertical-ring high-gradient magnetic separator is high in oil flowing speed, good in heat dissipation effect, and good in mineral flushing effect; the problem that vibration friction is generated when the magnet exciting coil is electrified is solved; the stability and the service life of the magnet exciting coil is improved and prolonged; and the requirements of the large vertical-ring high-gradient magnetic separator are met fully.

Owner:SHANDONG HUATE MAGNET TECH

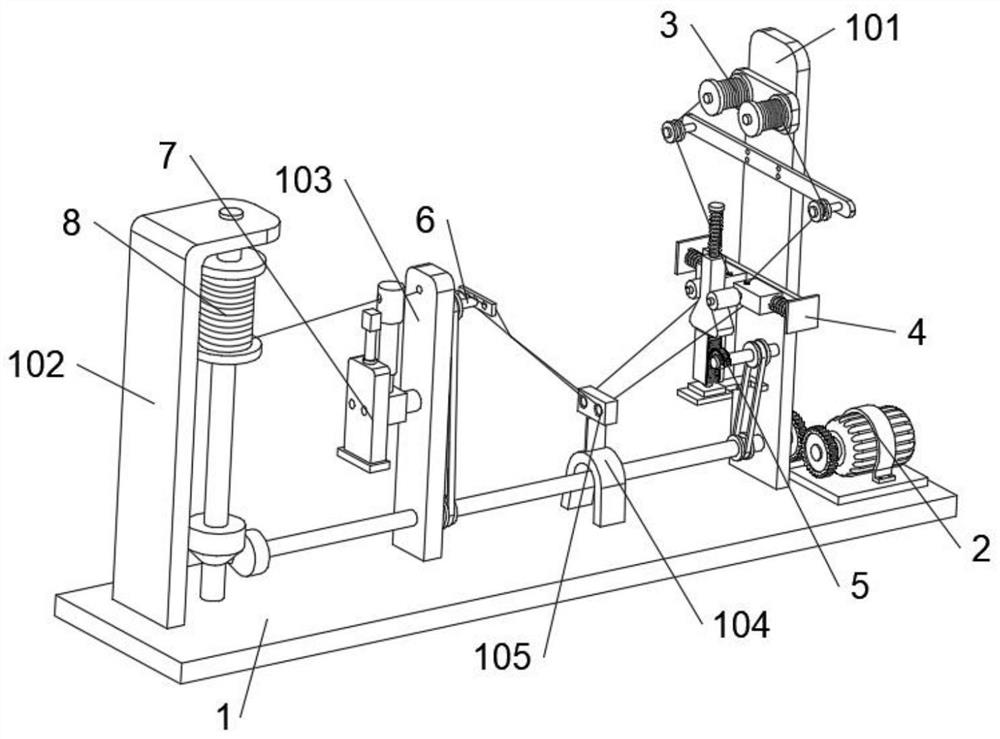

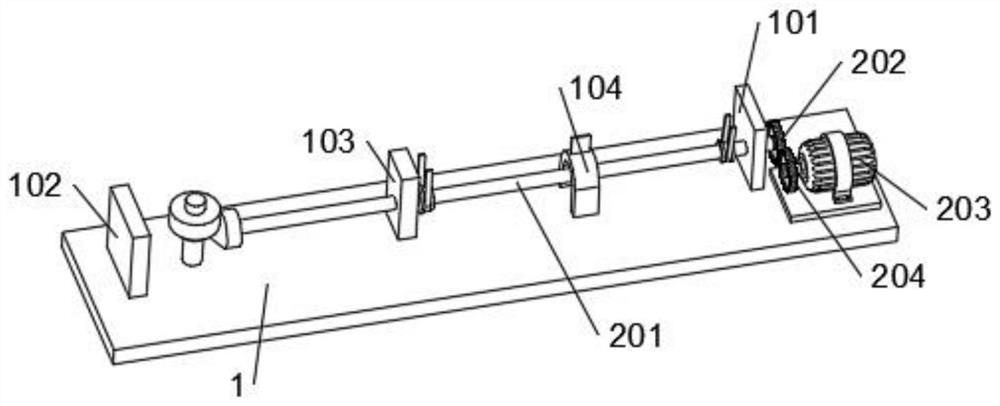

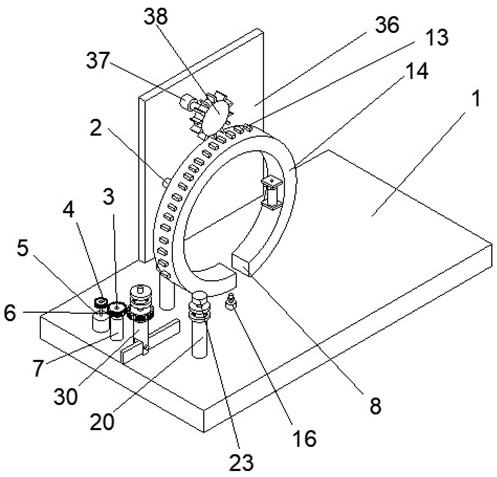

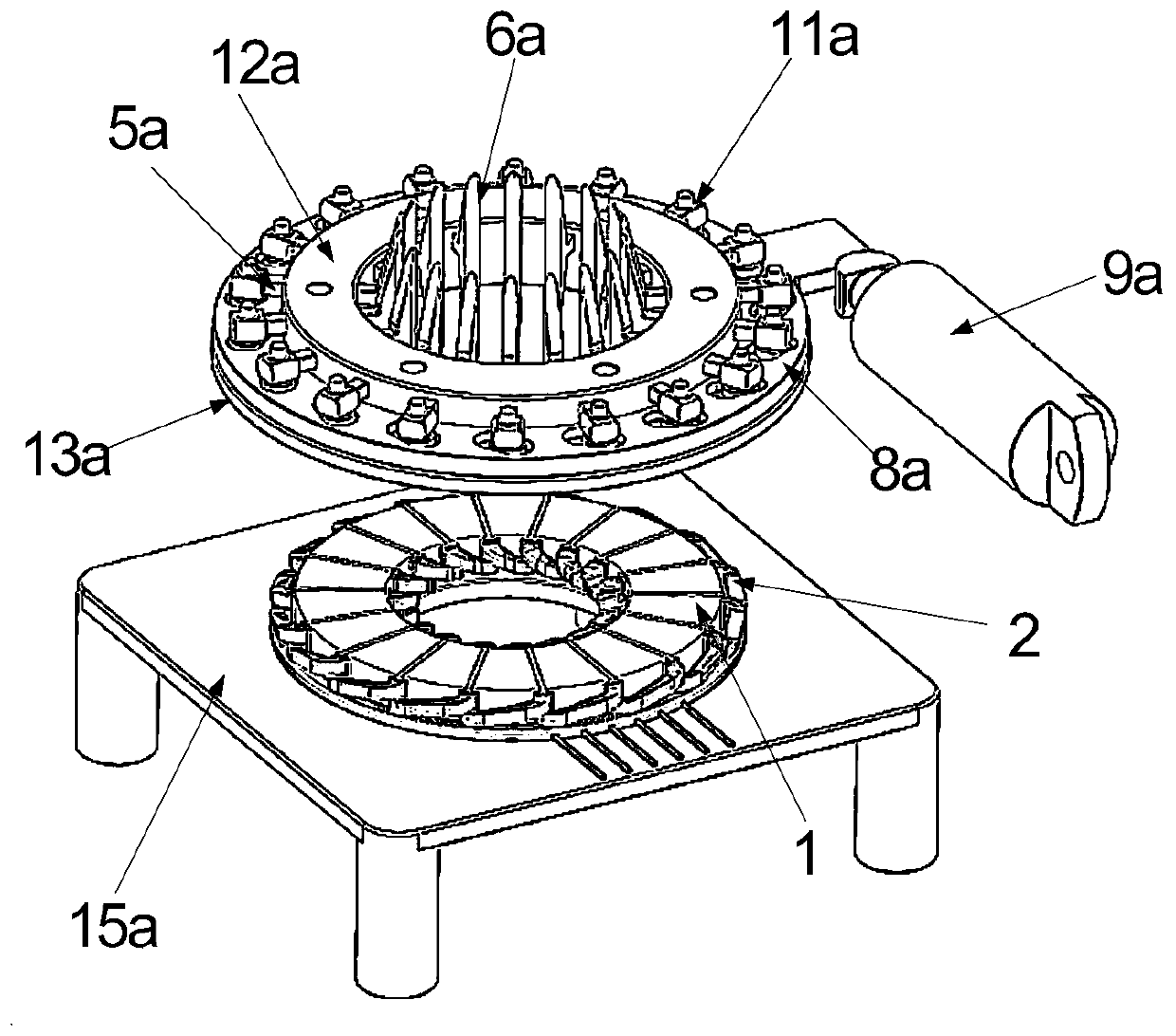

Annular inductor automatic winding equipment

ActiveCN112289580AEasy to put inImprove efficiencyCoils manufactureInductor windingsPower transmission

The invention relates to the technical field of inductors, and discloses annular inductor automatic winding equipment, which comprises a bottom plate, and an inductor rotating power structure is arranged at the left end of the top face of the bottom plate and used for providing power for rotation of an inductor; an inductor rotating power transmission structure is arranged at the left end of the top face of the bottom plate and used for transmitting power; a stabilizing plate is fixedly installed in the center of one side of the top face of the bottom plate, and an inductor winding power structure is arranged in the center of the top of the side wall, facing the bottom plate, of the stabilizing plate and used for providing power for inductor winding; side columns are fixedly installed at the left end and the right end of the side, facing the bottom plate, of the stabilizing plate correspondingly, and inductor winding supporting structures are arranged at the front ends of the side columns and used for supporting the inductor winding structures; and a limiting strip is fixedly installed in the center of the left end of the top face of the bottom plate, and inductor rotating supporting structures are arranged on the limiting strip and the top face of the bottom plate and used for supporting and rotating the inductor.

Owner:通友智能装备(江苏)有限公司

Piezoelectric acceleration sensor

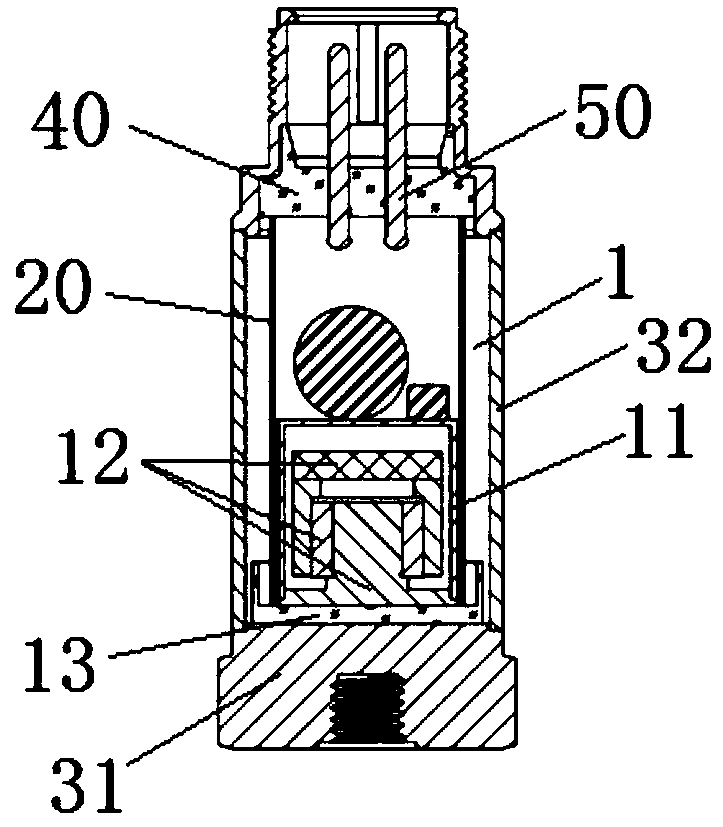

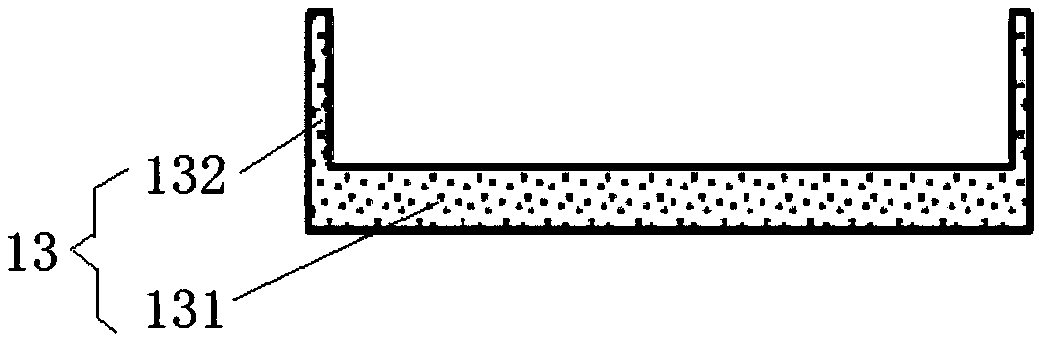

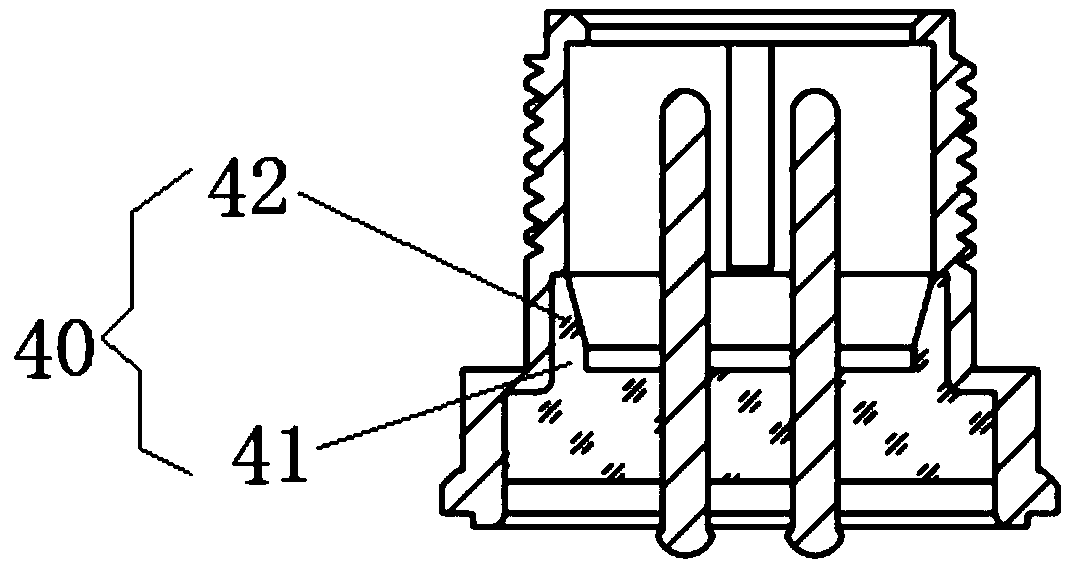

PendingCN109324211AImprove pressure resistanceImprove insulation performanceAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsEngineeringHigh voltage

The invention provides a piezoelectric acceleration sensor, which comprises an outer assembly, an inner assembly and an insulating hood. A containing cavity is formed in the outer assembly; the innerassembly is arranged in the containing cavity and comprises a shielding hood and a sensor core arranged in the shielding hood; and the insulating hood is arranged in the containing cavity and attachedto the peripheral wall of the shielding hood. The piezoelectric acceleration sensor provided by the invention has good pressure resistance and insulation, and is not prone to breakdown when encountering lightning or abnormal high-voltage input.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

Improved steel jacket and preparation method thereof

InactiveCN108179307AHigh hardnessImprove high temperature resistanceBearing componentsInterference fitSteel jacket

The invention discloses an improved steel jacket and a preparation method thereof. The steel jacket comprises a steel outer jacket and a copper alloy inner jacket. The copper alloy inner jacket comprises copper, tin and phosphorus. The mass of the tin accounts for 3%-6.5% of that of the copper, and the mass of the phosphorus accounts for 0.2%-1% of that of the copper. The copper alloy inner jacketcan further comprise nickel with the mass accounting for 0.05%-0.1% of that of the copper. The preparation method includes the steps that the steel outer jacket is heated to 300-480 DEG C, and then the copper alloy inner jacket is squeezed into the steel outer jacket. The copper alloy inner jacket and the steel outer jacket are in interference fit. According to the improved steel jacket and the preparation method thereof, the hardness and high-temperature resistance of a copper alloy shaft sleeve are further improved by adjusting the contents of the tin and the phosphorus in copper alloy; andmeanwhile, the proper steel outer jacket is adopted to replace the copper alloy, the using amount of the copper is decreased, cost is reduced and the strength of the shaft sleeve can be better increased through the steel outer jacket.

Owner:封安钰

Semi-automatic paper bag bottom pasting machine

ActiveCN109318536AGuarantee product qualityNovel structureBag making operationsPaper-makingSemi automaticPulp and paper industry

The invention provides a semi-automatic paper bag bottom pasting machine comprising a paper bag feeding mechanism. The paper bag feeding mechanism is sequentially provided with bag bottom spreading mechanisms, an adhesive spraying mechanism and a bottom pasting and compacting mechanism according to the paper bag advancing sequence. The bag bottom spreading mechanisms are symmetrically arranged onthe two sides of the upper portion of a feeding channel. Each bag bottom spreading mechanism sequentially comprises a spreading mechanism and an initial compacting mechanism which are sequentially installed on a bag bottom spreading machine frame. The paper bag feeding mechanism comprises a feeding base, feeding support plates and a feeding clamping mechanism. The bottom pasting and compacting mechanism comprises bottom pasting and compacting supporting plates, a bottom pasting and compacting installation plate, a bottom pasting mechanism and a compacting mechanism. The semi-automatic paper bag bottom pasting machine is novel in structure, production and manufacturing are convenient and rapid, and batch bottom pasting and compacting of paper bags can be achieved through a low production cost; in the bottom pasting and compacting process, a reinforcing paper sheet is accurately pasted to the bottom of the paper bag, press fitting and compacting of the reinforcing paper sheet are conducted, and therefore the production quality of the paper bag is guaranteed; and operation is stable, and the semi-automatic paper bag bottom pasting machine is suitable for use and popularization among small and medium-sized enterprises.

Owner:江苏宇驰包装股份有限公司

Foam cotton adhesive attaching device

ActiveCN109016786ASqueeze fullyIncrease the air supplyLaminationLamination apparatusAdhesiveGas cylinder

The invention belongs to the technical field of attaching strip splitting machinery, and particularly relates to a foam cotton adhesive attaching device. The foam cotton adhesive attaching device comprises a machine frame, an upper support frame, a lower support frame, an upper gas cylinder, a lower gas cylinder, a gas guide pipe, an upper scraping plate, a lower scraping plate, an adhesive tape roller, a foam cotton rolling wheel, a cutting cutter, an installing frame, a control unit and a gas supply device, wherein the gas is simultaneously supplied to the upper gas cylinder and the lower gas cylinder through the gas supply device; the simultaneous action of the upper scraping plate and the lower scraping plate can be realized; the foam cotton attaching precision is improved. By controlling the gas supply quantity of the gas supply device on the upper gas cylinder and the lower gas cylinder, the swinging angle of the upper scraping plate and the lower scraping plate is adjustable, sothat the gap between the upper scraping plate and the lower scraping plate is adjustable; the goal of producing different specifications of foam cotton is achieved; raw materials of various specifications are processed by using one kind of equipment, so that the production cost is reduced; the production efficiency is improved.

Owner:SUZHOU KECHUAN ELECTRONICS TECH

Robot used for cleaning building curtain wall and capable of widening applicable guide range

ActiveCN112056979AHigh degree of automationGood cleaning effectCarpet cleanersFloor cleanersRobotyWind power

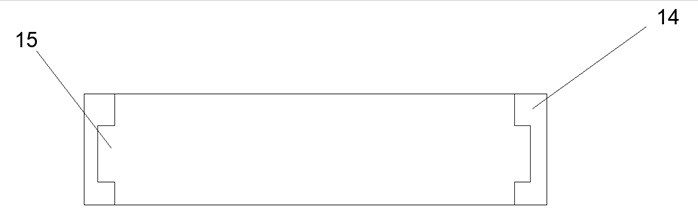

The invention discloses a robot used for cleaning a building curtain wall and capable of widening the applicable guide range. The robot comprises two longitudinal guide rail assemblies, a longitudinaldriving device, a transverse guide rail assembly, a transverse driving device and a cleaning device, wherein the two longitudinal guide rail assemblies are arranged in parallel; the longitudinal guide rail assembly is formed by connecting and splicing a plurality of longitudinal guide rails end to end; a groove is formed in one side of each longitudinal guide rail; a plurality of suction cups arefixedly arranged at the bottom end of each longitudinal guide rail; and two first clamping grooves are formed in one end of each longitudinal guide rail. The robot has the beneficial effects that therobot can be more stable in a cleaning process, is less affected by wind power and is high in automation degree and good in cleaning effect, and the transverse and longitudinal guide ranges can be changed by adding or reducing the longitudinal guide rails and the transverse guide rails, so that the robot can be suitable for cleaning operation of glass curtain walls of different sizes.

Owner:青岛环城建工集团有限公司

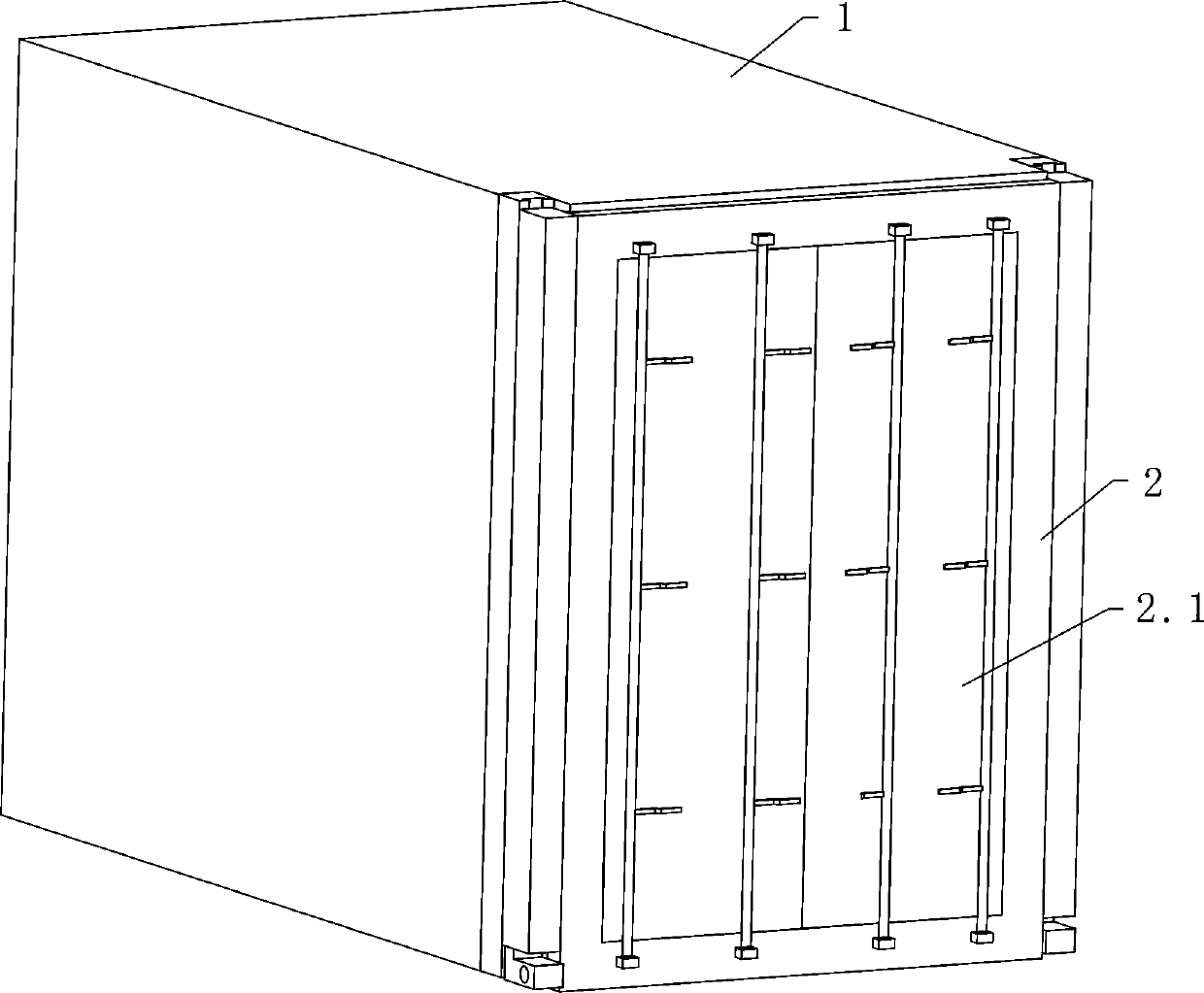

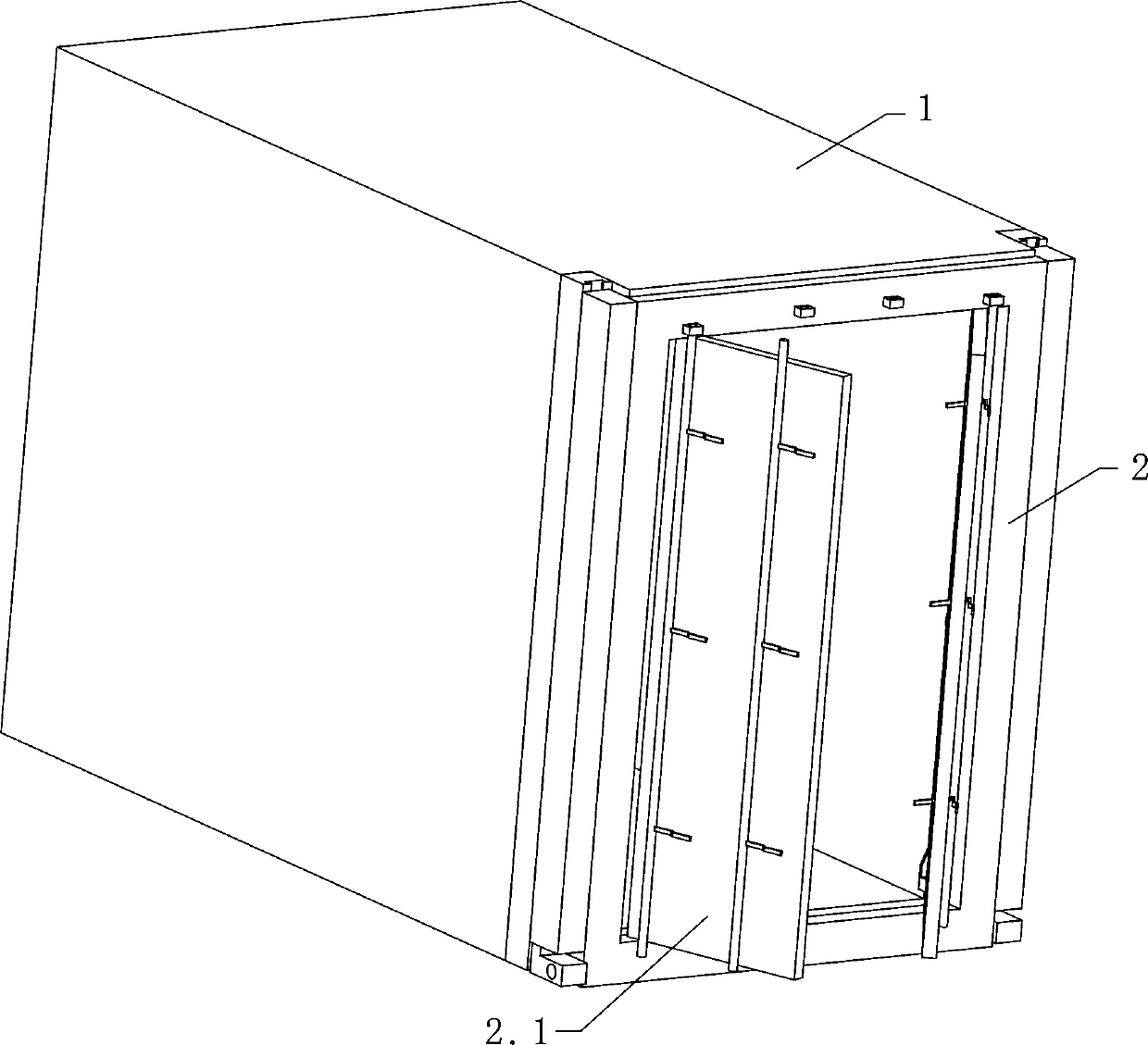

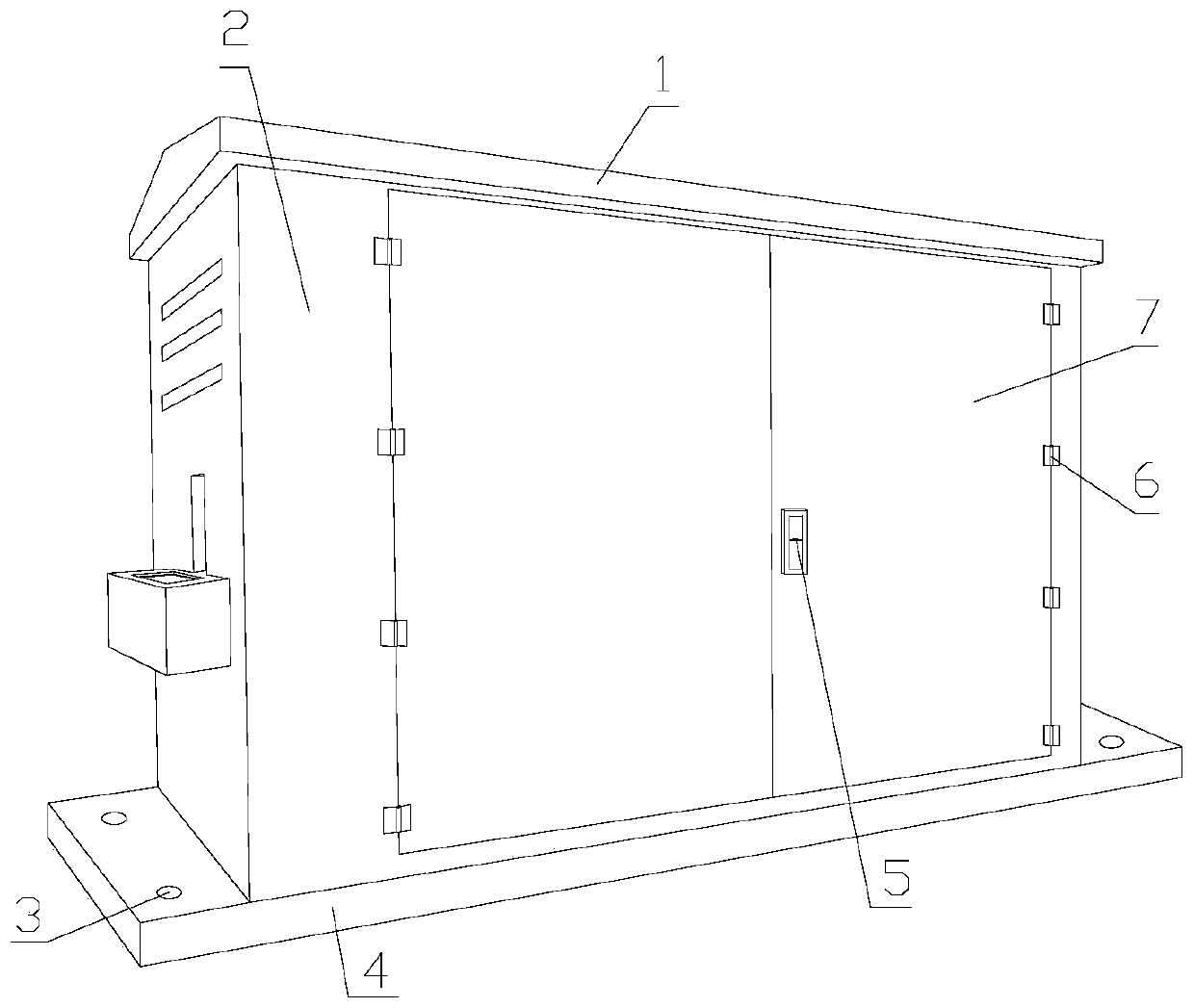

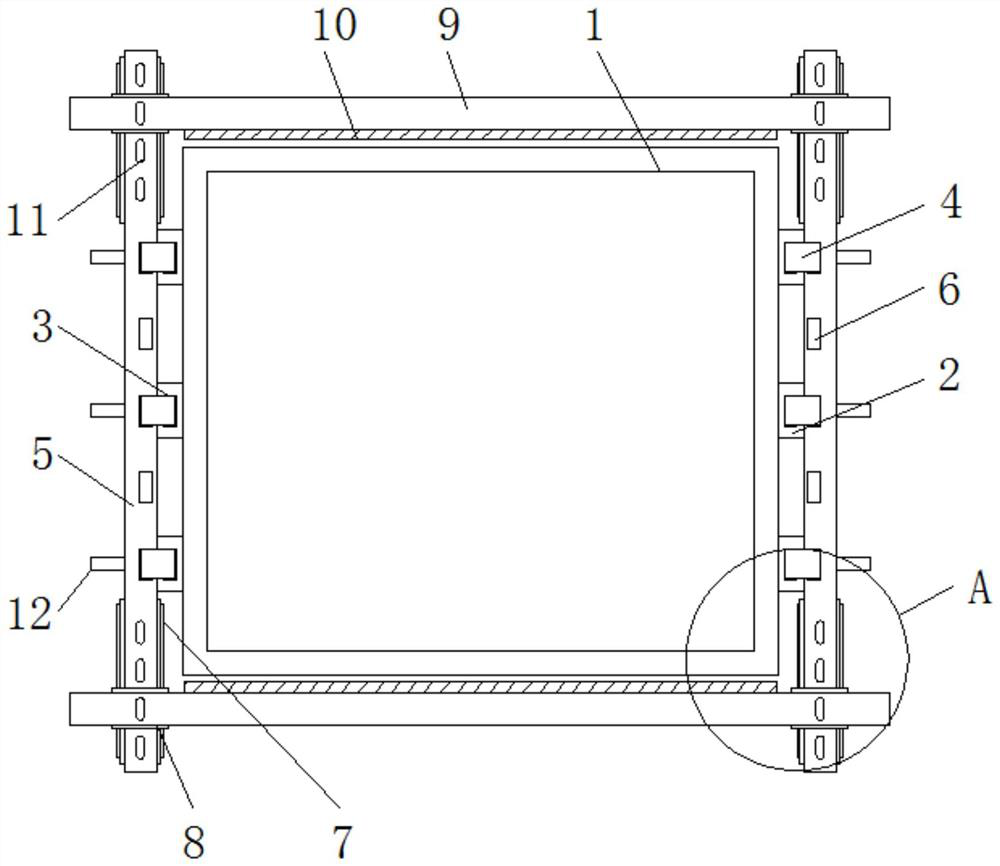

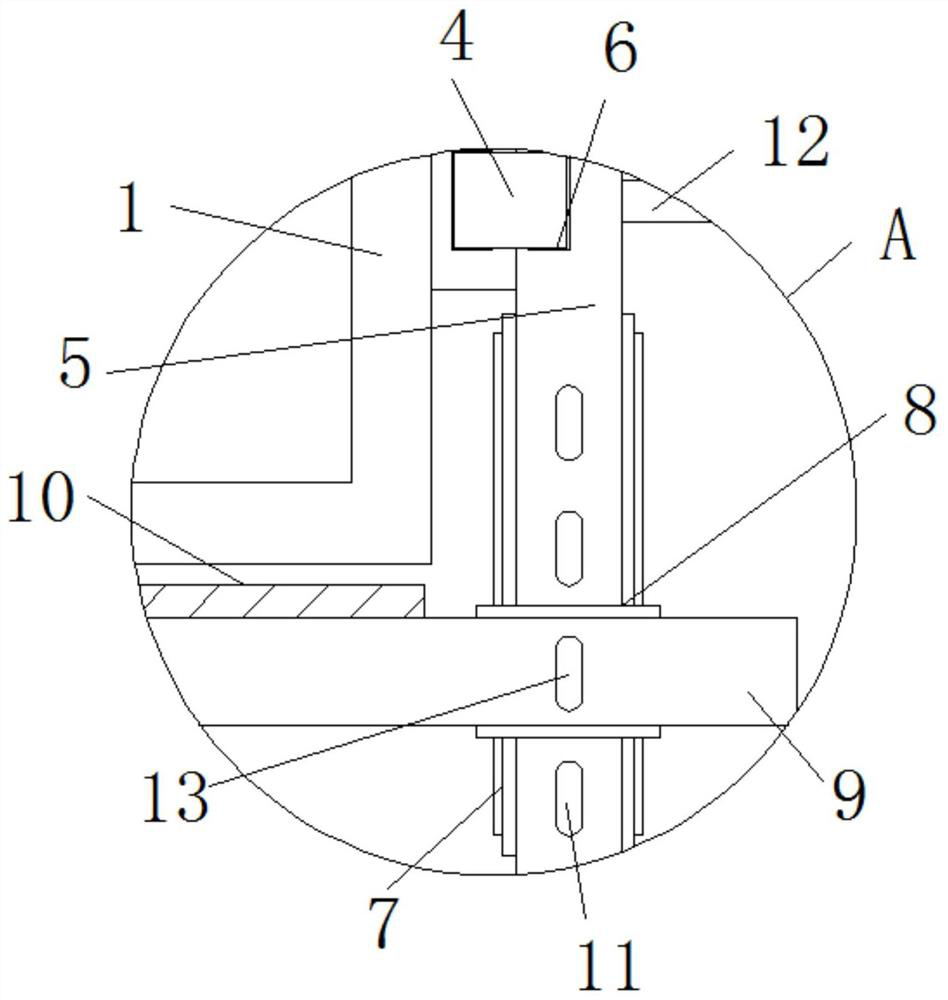

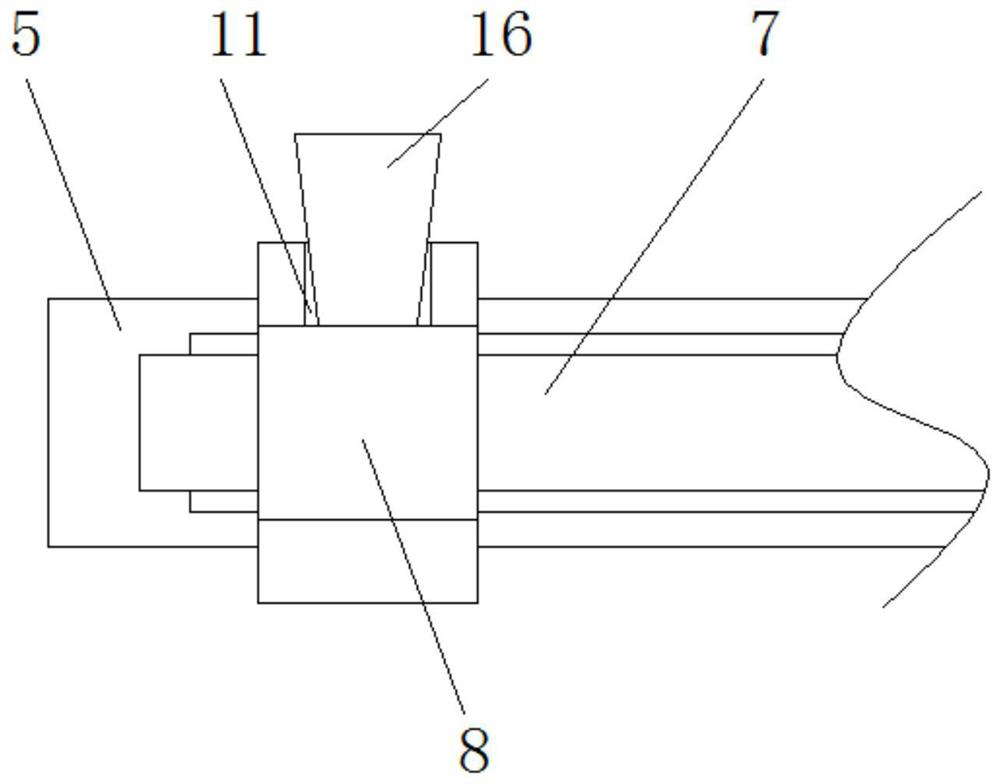

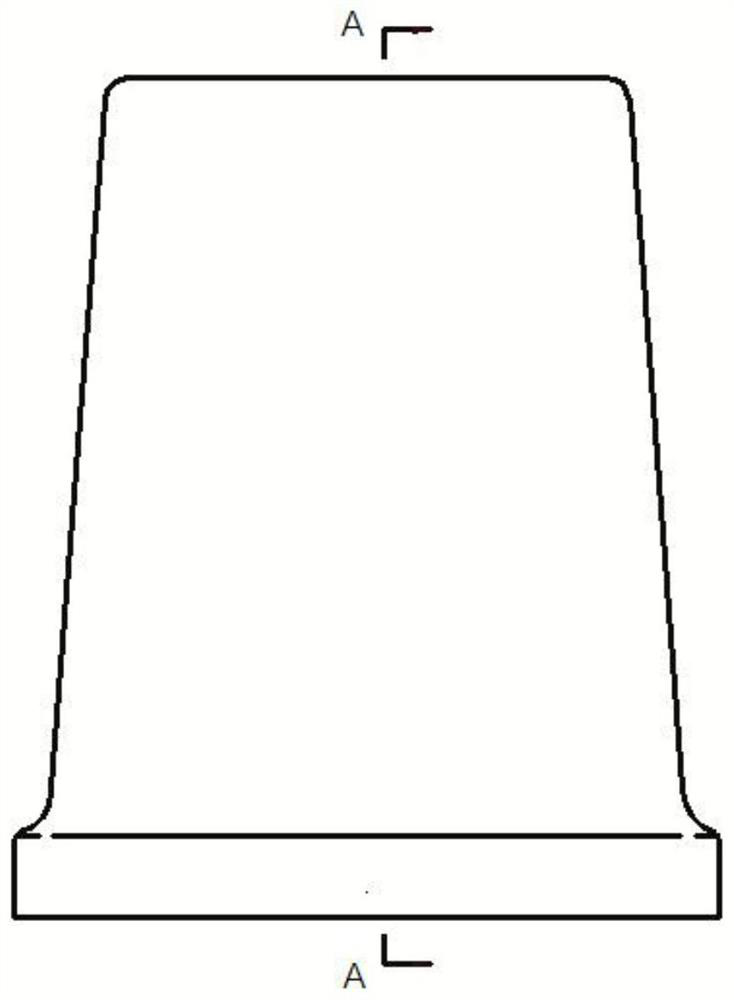

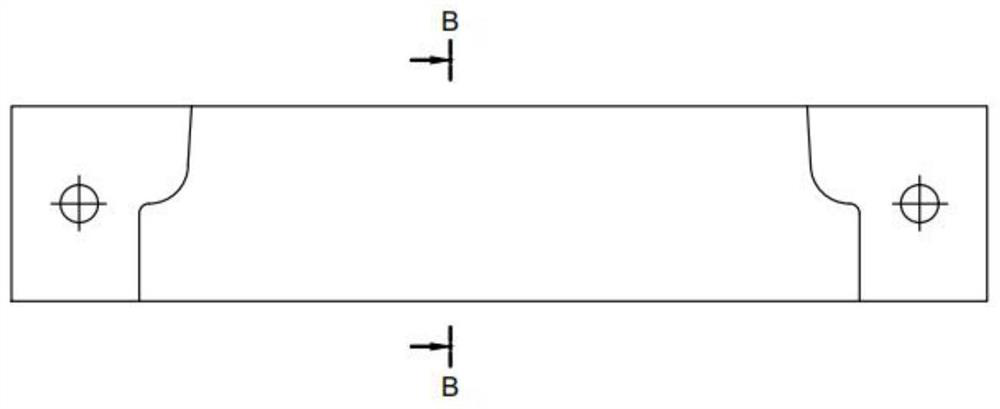

Square coupler template reinforcing device easy to disassembly and assembly

ActiveCN111779264AImprove stabilityImprove practicalityForms/shuttering/falseworksStructural engineeringMechanical engineering

The invention discloses a square coupler template reinforcing device easy to disassembly and assembly. The square coupler template reinforcing device easy to disassembly and assembly comprises a framebody (1), longitudinal main arrises (5) and transverse main arrises (9); a plurality of lateral transverse arrises (2) are connected to the end surfaces of the two ends of the frame body (1) in a spaced manner; one pair of longitudinal main arrises (5) is detachably connected to the plurality of lateral transverse arrises (2) at the two ends of the frame body (1), respectively; the two ends of the transverse main arrises (9) are connected between one ends of the pair of longitudinal main arrises (5) in a slideable manner, respectively; the pair of transverse main arrises (9) can slide in thelength directions of the longitudinal main arrises (5) and stick to the end surfaces of the two sides of the frame body (1); and the pair of longitudinal main arrises (5) and the pair of transverse main arrises (9) are movably connected to form a rectangular frame structure tightened around the frame body (1). The square coupler template reinforcing device easy to disassembly and assembly has theadvantages that the square coupler template reinforcing device easy to disassembly and assembly can be adaptively adjusted according to the dimension of a building template; the strength of a connection node is high; and the stability of the building template can be guaranteed so that the working efficiency is enhanced; the assembling and disassembling are convenient and fast; the practicability is high; the university is high and so on.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

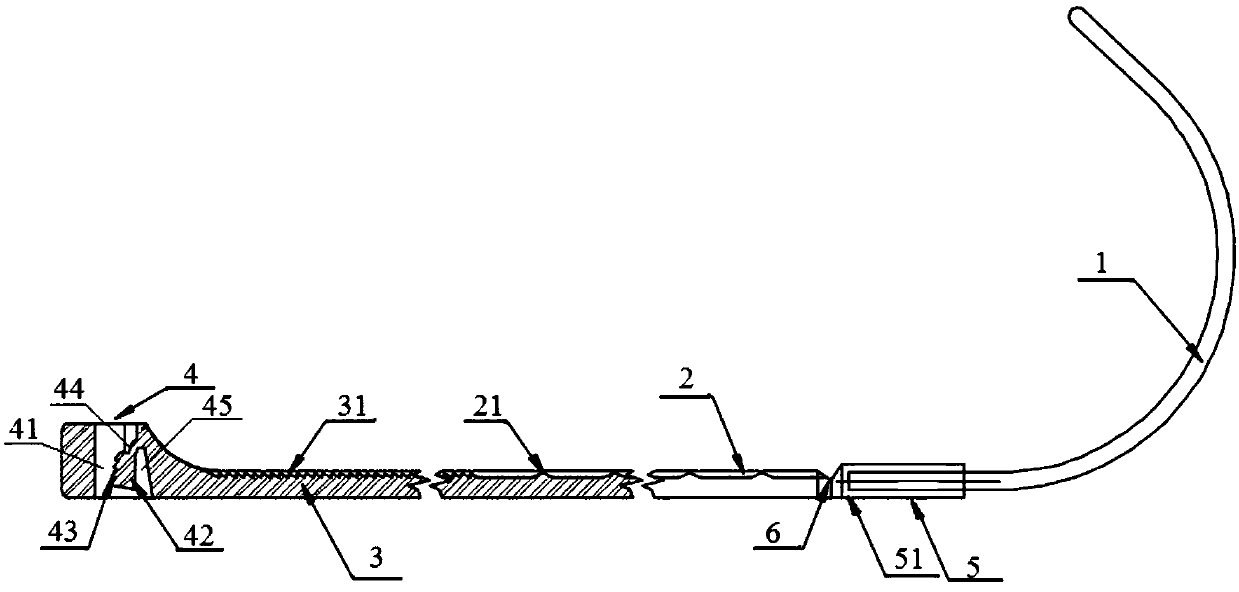

Compression molding method of antenna housing and pre-compaction mold

The invention relates to a compression molding method of an antenna housing and a pre-compaction mold, and belongs to the technical field of composite material compression molding. The problems that in the existing compression molding process, when a female mold and a male mold are assembled, fiber extrusion, protrusions or cavities and material shortage are generated at the mold assembling position, so that fiber breakage is caused, and the mechanical strength of the mold assembling position is influenced are solved. The compression molding method of the antenna housing includes the followingsteps: 1, analyzing the structure of a workpiece, and determining a portion prone to go wrong during compression molding of the workpiece; 2, designing a plurality of thickness gradients according tothe thickness of the portion with larger thickness of the workpiece; 3, designing the pre-compaction mold; 4, conducting laying and pre-compaction; and 5, conducting mold assembling and curing molding. The pre-compaction mold is used for local compaction multiple times, the situations of fiber extrusion, protrusions or cavities and material shortage at the mold assembling position are avoided, then fiber breakage is avoided, and the mechanical strength of the mold assembling position is guaranteed.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

A counter weight wheel

The invention provides a counter weight wheel which is arranged on the rear portion of a vehicle body. The counter weight wheel comprises a rim capable of rotating freely around an axle; a tire is put around the rim; the tire is provided with sucker components circumferentially in an equally-spaced manner; sucker surfaces of the sucker components face outward; necks of the sucker components extend to the axle in the radial direction of the rim; the rim is provided with air guide holes, which right face the neck positions, in an equally-spaced manner; the rim is internally provided with an air pump; an air pumping end of the air pump faces downward vertically and is attached to the inner wall of the rim in a hermetic manner; the rim can rotate freely relative to the air pump. A forklift has lighter weight, enables sensitive turning and moving, effectively increases the carrying efficiency, and operates stably and safely.

Owner:JIANGSU SIDA HEAVY IND

High-rise escape combination device

The invention discloses a high-rise escape combination device. The high-rise escape combination device comprises a rail escalator, an escape trolley, a braking mechanism and a pulley supporting mechanism; the rail escalator and the escape trolley are connected through the pulley supporting mechanism, and the escape trolley is located below the inner side of the rail escalator; the pulley supporting mechanism is arranged above the escape trolley and is clamped on the rail escalator; the braking mechanism is arranged on the escape trolley and the pulley supporting mechanism; and the high-rise escape combination device is light and convenient, does not occupy space, can be quickly unfolded when being used, and is convenient to take. According to the high-rise escape combination device, the centrifugal force is buffered through a centrifugal force movable joint, so that the escape personnel can be ensured to be tightly attached to the escape trolley. The high-rise escape combination devicedoes not need to be frequently maintained and is high in reliability.

Owner:束楠

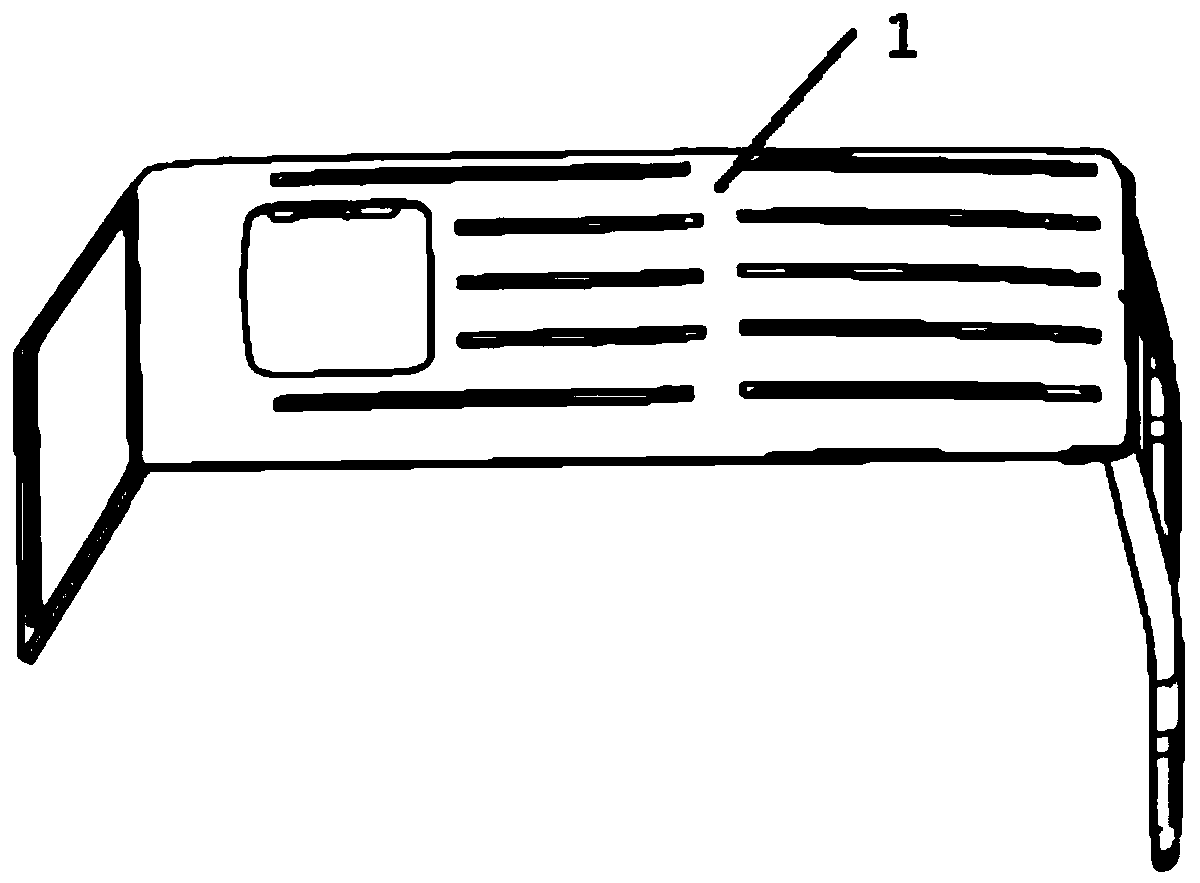

Dividing and cutting machine for non-woven fabric production line

InactiveCN112160151AFit tightMechanical cleaningPressure cleaningStructural engineeringNonwoven fabric

The invention discloses a dividing and cutting machine for a non-woven fabric production line, and relates to the technical field of non-woven fabrics. The dividing and cutting machine comprises a bottom plate, a feeding mechanism frame is fixedly connected to one side of the top of the bottom plate, an auxiliary sliding block is slidably connected to one side of the top of the feeding mechanism frame, and a pressing spring is fixedly connected to one end of the auxiliary sliding block; and an auxiliary feeding roller is rotationally connected to the middle of the auxiliary sliding block, a force adjusting screw is rotationally connected to the middle of the top of the feeding mechanism frame, and a pressing plate is rotationally connected to the bottom of the force adjusting screw. A cleaning mechanism frame fixedly connected to one side of the feeding mechanism frame is arranged, and a limiting plate is located at the top of the cleaning mechanism frame. A sliding rod is slidably connected to the limiting plate in the vertical direction, a cleaning brush on a cleaning plate fixedly connected to the bottom of the sliding rod is tightly attached to the upper surface of the non-woven fabric under the action of a pressing spring to clean the non-woven fabric, and meanwhile air generated by a draught fan can be transmitted to the bottom of the cleaning plate through a telescopic pipe to assist in cleaning the upper surface of the non-woven fabric.

Owner:董亚

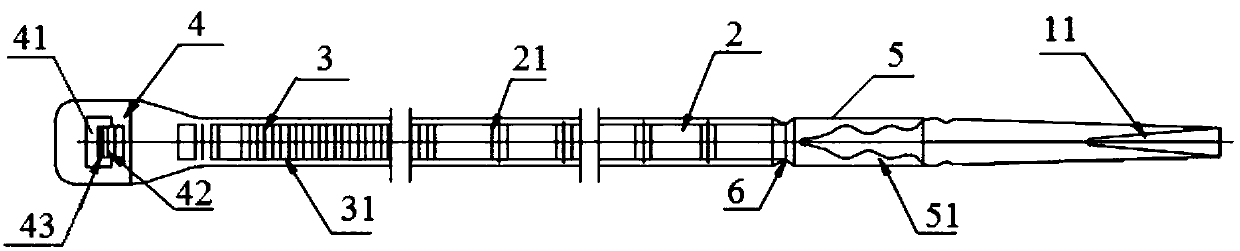

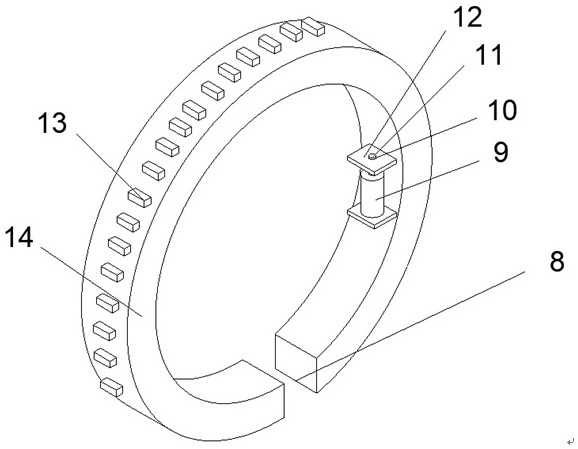

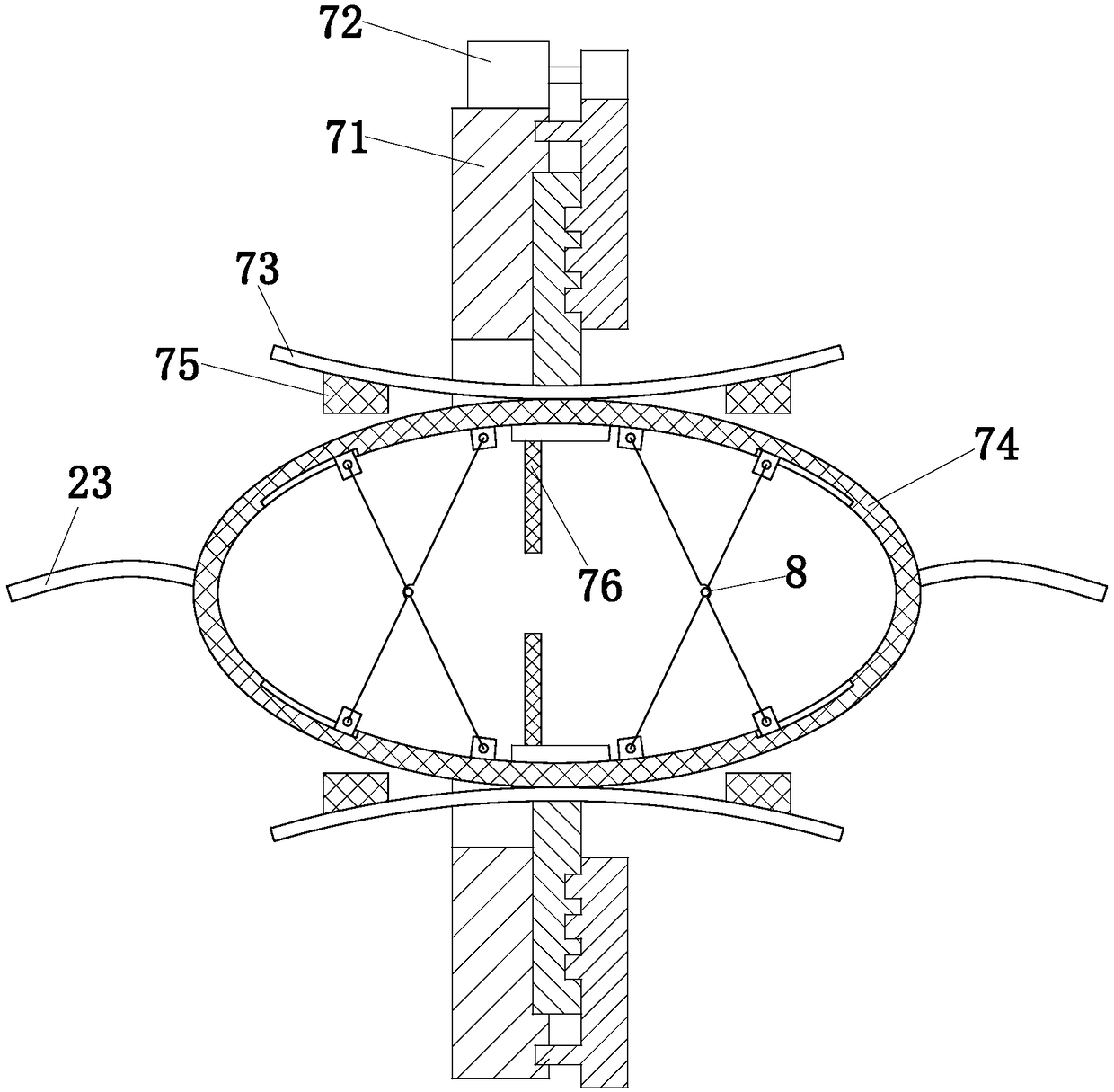

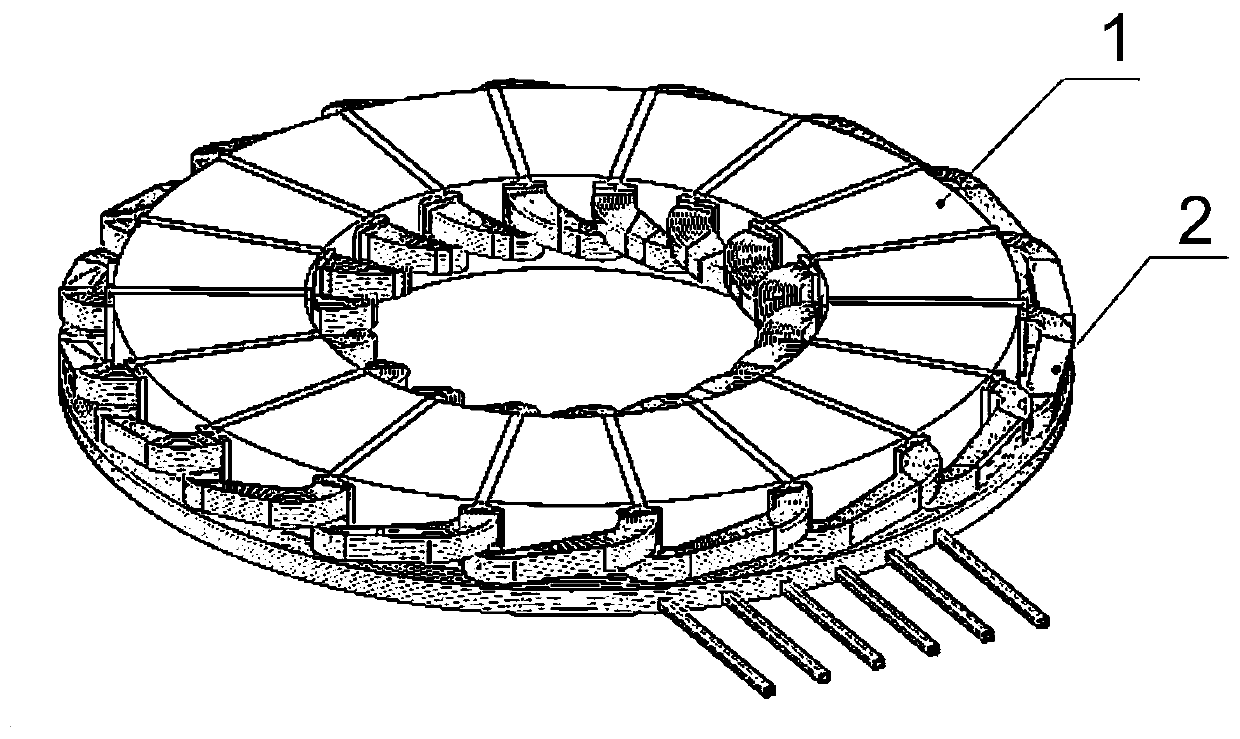

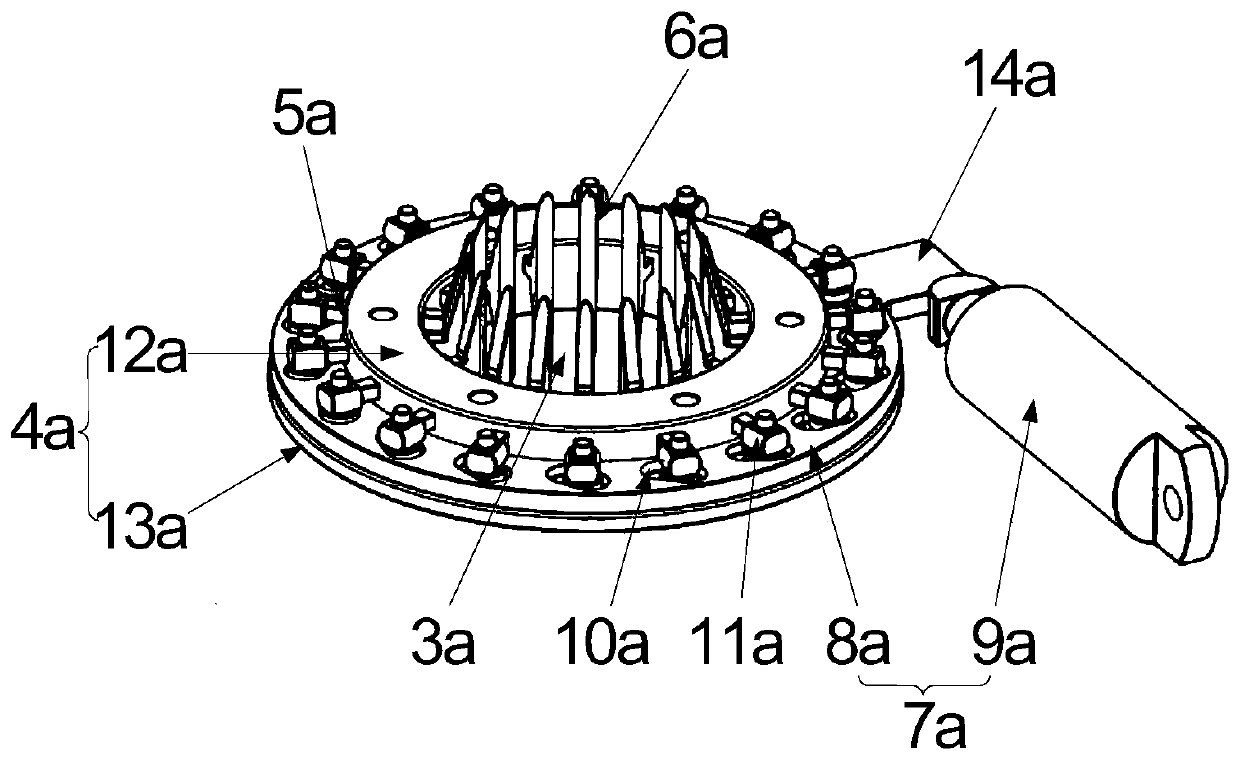

Coil shaping device and method for wire stator

PendingCN110719003AOuter ring leveling specificationTo achieve the purpose of plastic surgeryManufacturing dynamo-electric machinesElectric machineryControl theory

The invention discloses a coil shaping device and method for a wire stator, which are used for shaping the coil of the wire stator of an axial magnetic field motor. The coil shaping device includes atraction mechanism and an outer ring shaping mechanism. The traction mechanism can drive various traction arms to enable a coil located on a stator core outer ring and the stator core outer ring to betightly attached, so as to achieve the purpose of shaping the coil outer ring of the wire stator. A driving component is configured to move various pressing arms toward the axis of a circular throughhole in the radial direction such that various pressing blocks can press the circumferential outer surface of the coil. During the shaping process, no sliding friction exists between the pressing blocks and the coil, which can effectively avoid wire damage during the shaping of the coil. In addition, through the stepwise operation or synchronous operation of the traction mechanism and the outer ring shaping mechanism, the outer ring of the coil of the wire stator can be made more flat and standardized.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

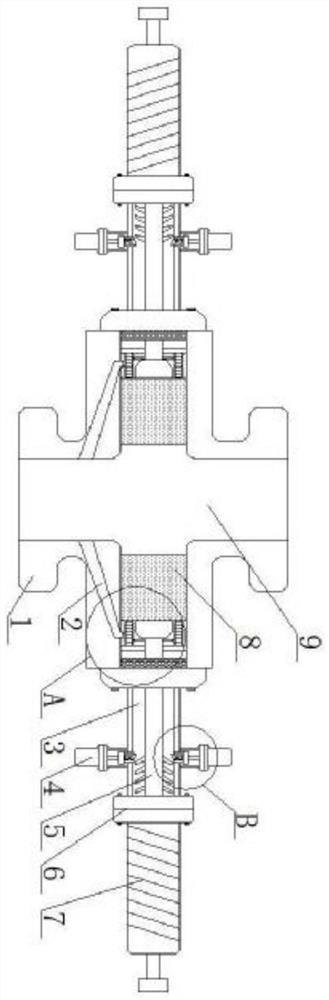

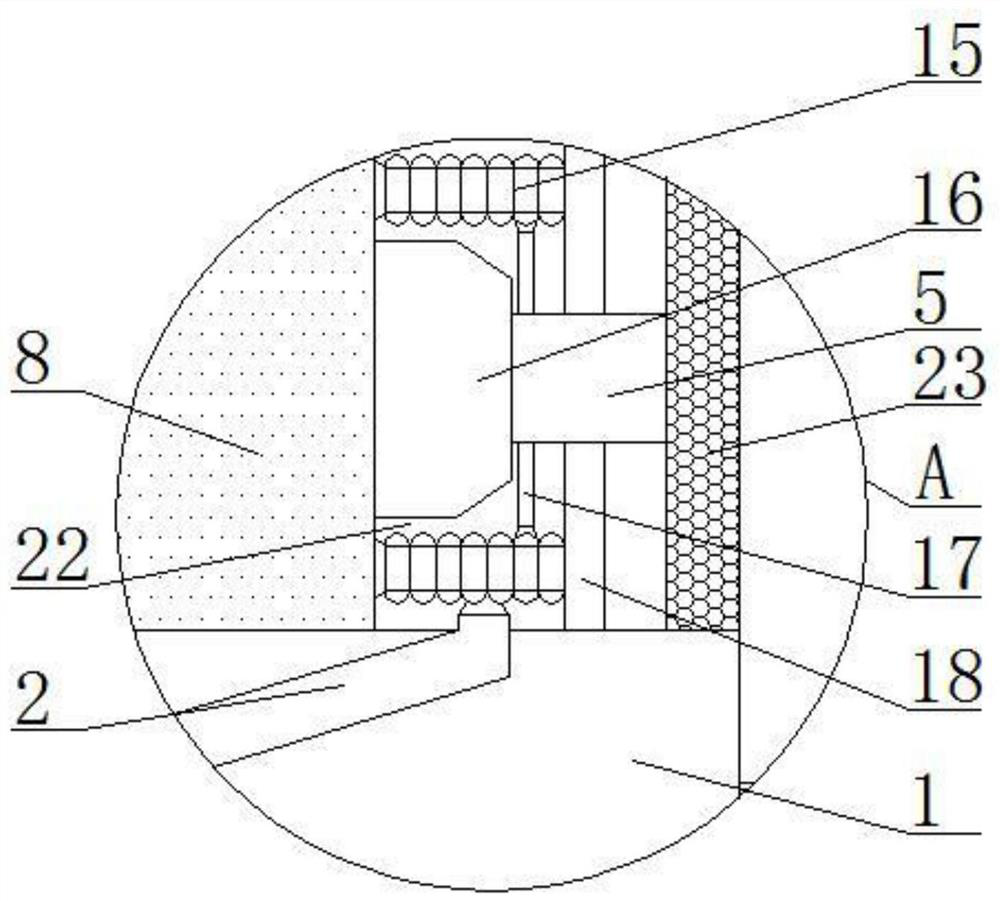

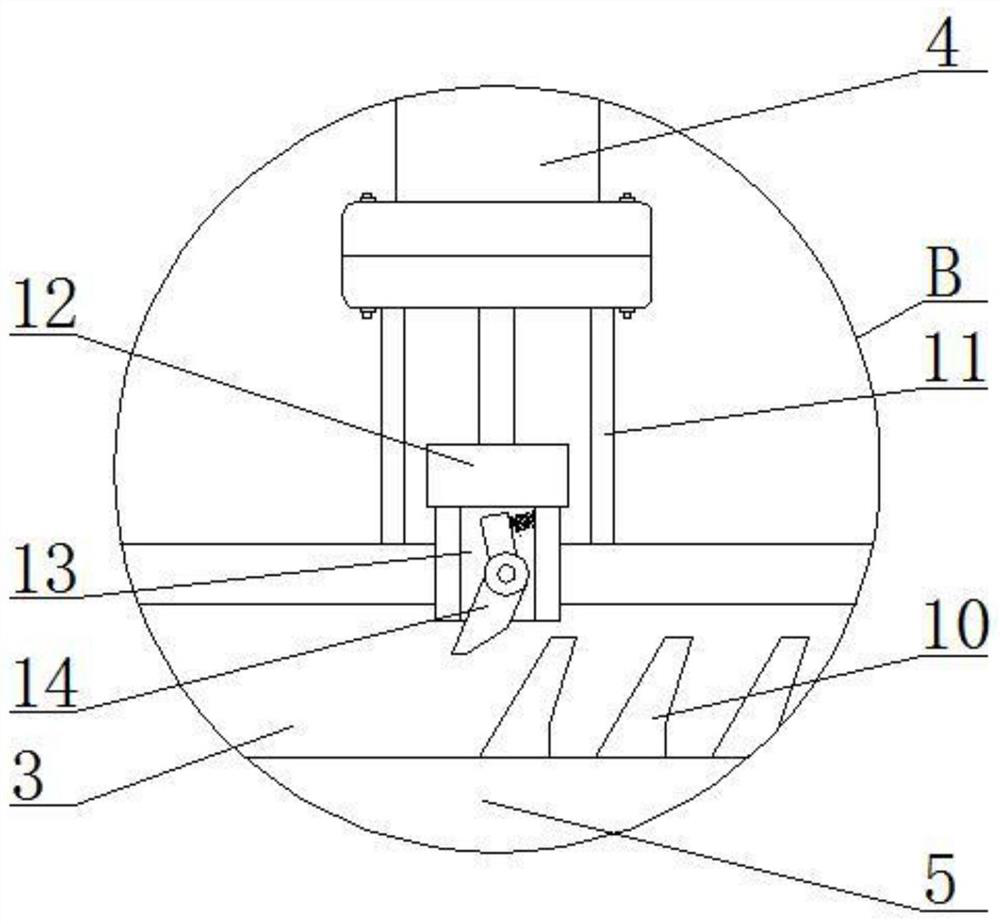

Ram blowout preventer for well control device

The invention relates to the technical field of oil field equipment, and discloses a ram blowout preventer for a well control device, which includes a device housing, a central communication cavity is opened inside the device housing, and a side surface of the device housing is provided with The side sealing cavity, the outer side of the device casing is located on the side of the side sealing cavity, and a connection chamber is fixedly installed. The ram blowout preventer used in the well control device can ensure that the sealing ram is self-locked when the sealing ram is sealed by setting the second hydraulic cylinder, movable seat, oblique clamping plate and clamping ring. Then the first hydraulic cylinder is released to increase the service life of the first hydraulic cylinder. At the same time, when it needs to be unlocked, the second hydraulic cylinder can be implemented. Through the cooperation of the communication hole, the rubber spring, the side support plate and the middle connecting hose, it can be used The pressure of the oil well is stamped into the inside of the rubber spring, and then deformed, which makes the sealing ram fit tightly and enhances the self-locking effect.

Owner:濮阳市轮通机械设备修造有限公司

Automobile roof cover outer plate and automobile

ActiveCN110979468ANo collisionBump won't happenSuperstructure subunitsStructural engineeringMechanical engineering

The embodiment of the invention provides an automobile roof cover outer plate and an automobile. The roof cover outer plate comprises a roof cover outer plate, and the front end and the rear end of the roof cover outer plate are respectively welded with a front air window assembly of an automobile body and a roof cover rear cross beam upper connecting plate so as to be fixed on the automobile body; at least two front positioning turnups with corresponding structures are arranged at the front end of the roof cover outer plate, the bottoms of the front positioning turnups and the front end of the roof cover outer plate are integrally formed, and the tops of the front positioning turnups extend in the direction away from the roof cover outer plate; and at least two rear positioning turnups with corresponding structures are arranged at the rear end of the roof cover outer plate, the bottoms of the rear positioning turnups and the rear end of the roof cover outer plate are integrally formed, and the tops of the rear positioning turnups extend in the direction away from the roof cover outer plate.

Owner:BAIC GRP ORV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com