A counter weight wheel

A technology of counterweight wheels and rims, which is applied in the direction of lifting devices, etc., can solve the problems of forward leaning of the car body, high energy consumption, heavy weight, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

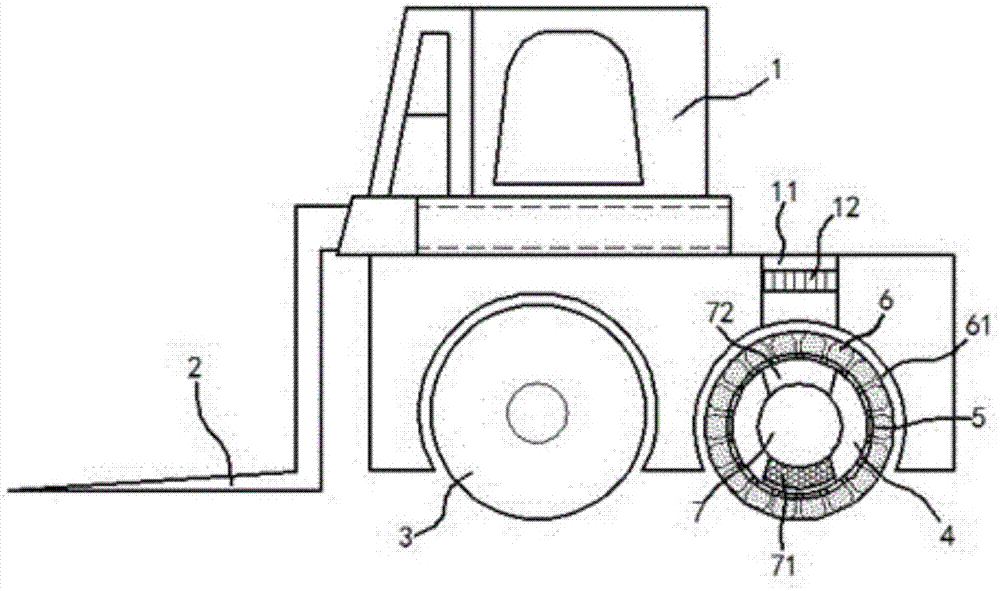

[0016] exist figure 1 In the shown embodiment, this negative pressure forklift comprises car body 1, fork foot 2, driving wheel 3 and counterweight wheel 4; 4 is installed at the rear of the car body 1; the counterweight wheel 4 includes a rim 5 that can rotate freely around the wheel shaft, and the rim 5 is made of a hard magnetic material; Tires 6 are provided; suction cup assemblies 61 are equidistantly installed on the circumferential direction of the tire 6 , the disk faces of each of the suction cup assemblies 61 are outward, and the necks of each of the suction cup assemblies 61 are directed toward the wheel shaft along the radial direction of the rim 5 . Extend; On the said rim 5 equidistantly set with the air guide holes facing the position of said neck; Inside said rim 5, an air suction pump 7 is also installed; The suction end 71 of said air suction pump 7 Vertically downward and airtight close to the inner wall of the rim 5, the suction end 71 is made of hard foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com