Patents

Literature

158 results about "Neck position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

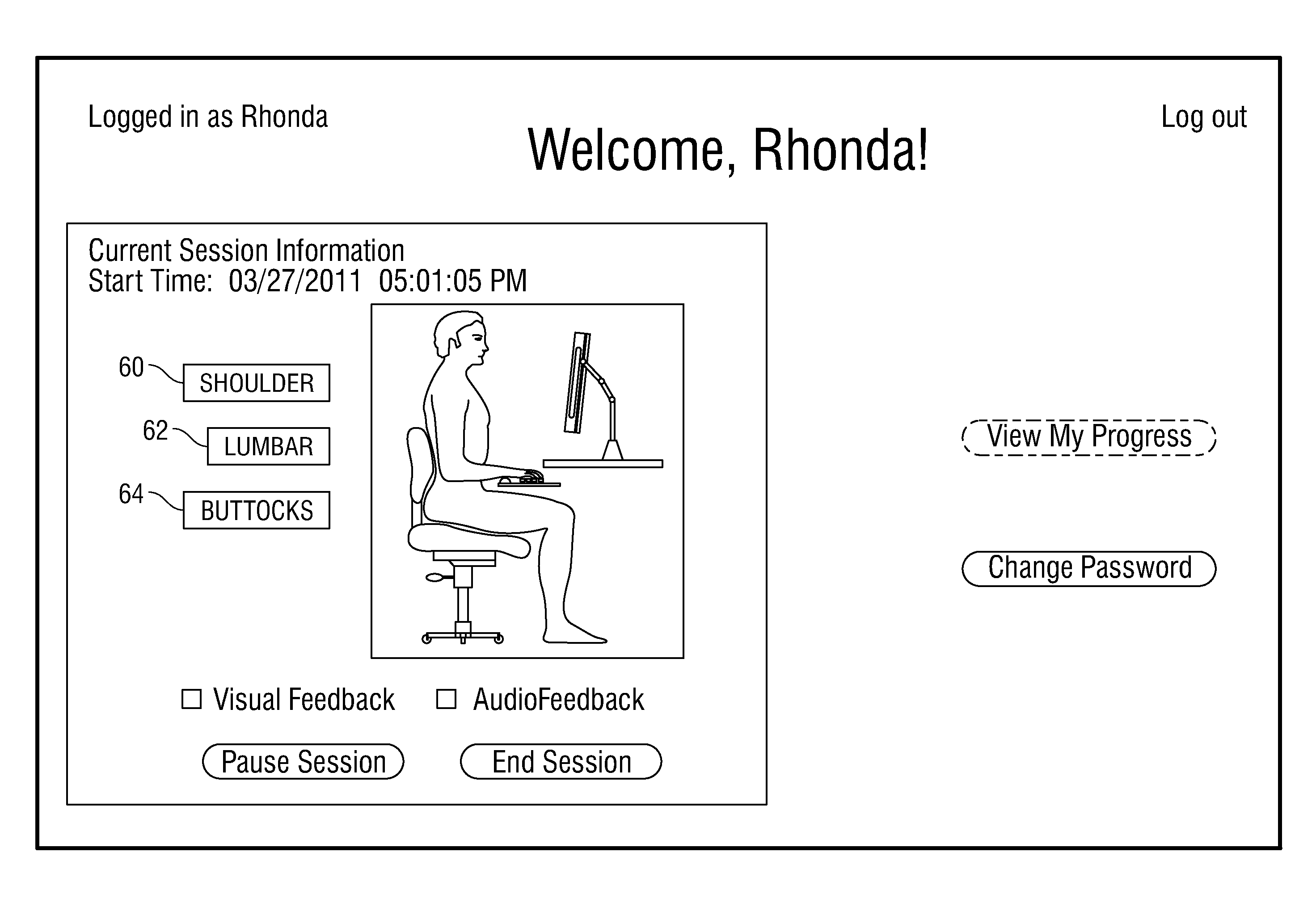

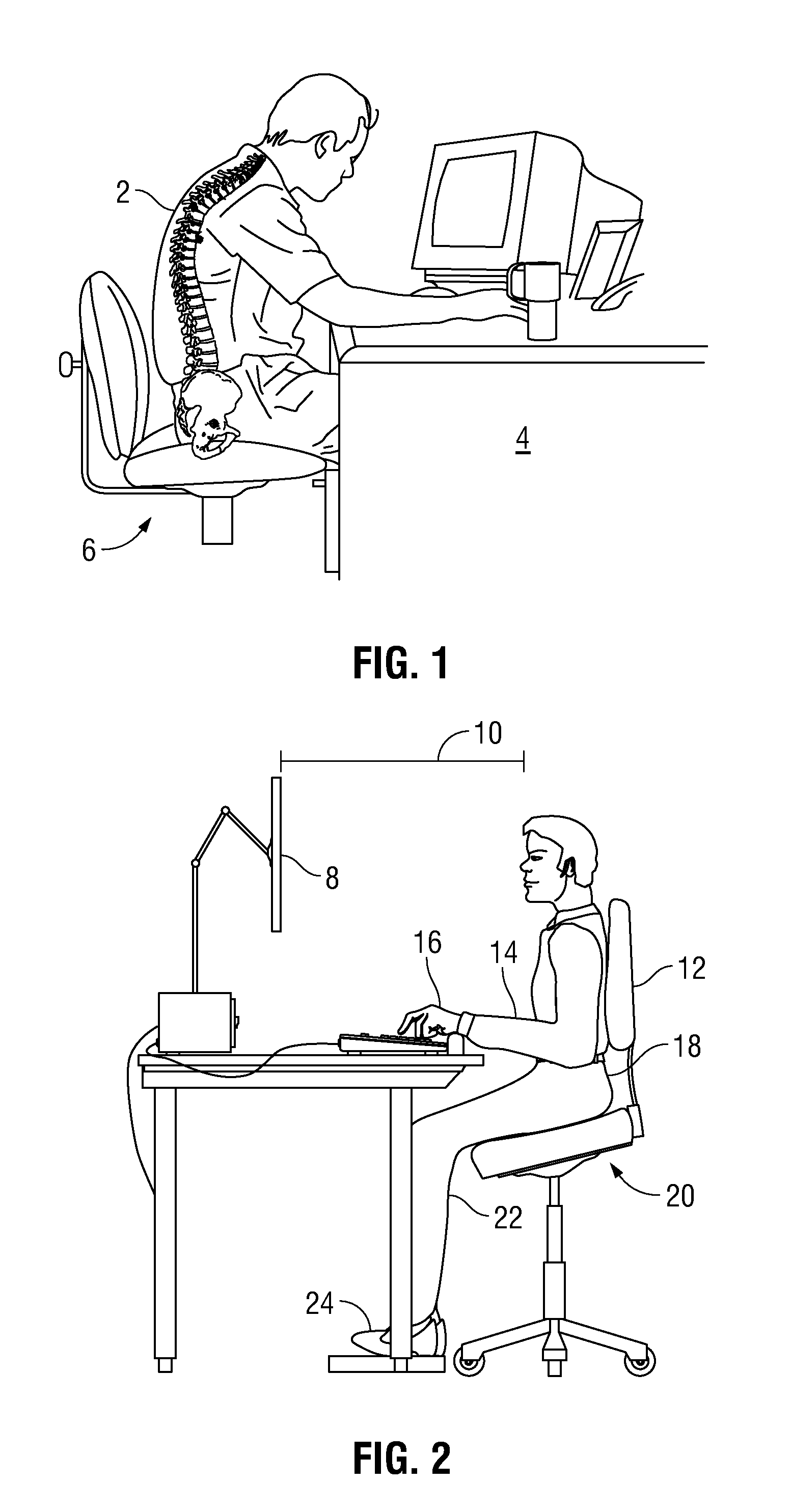

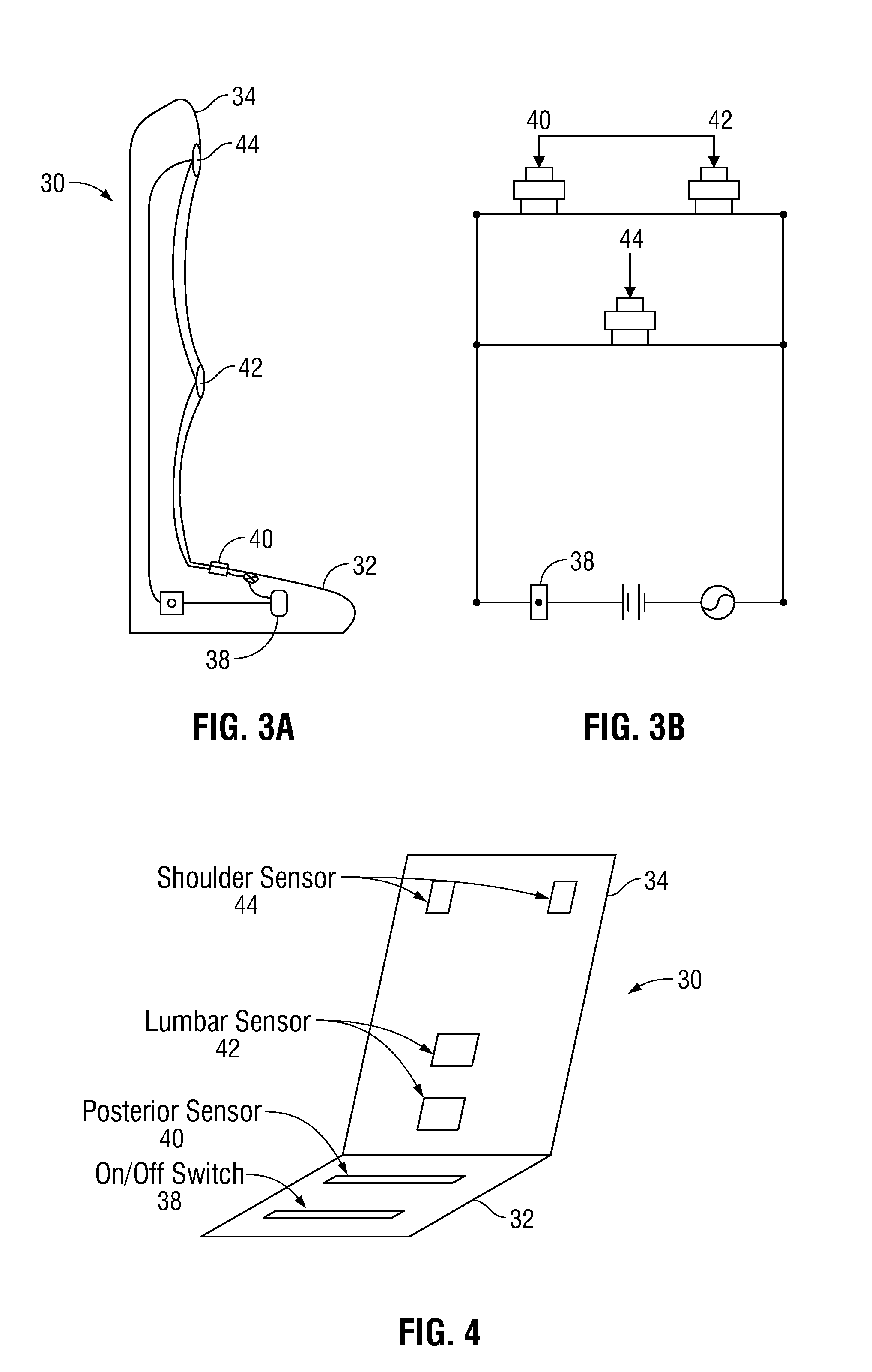

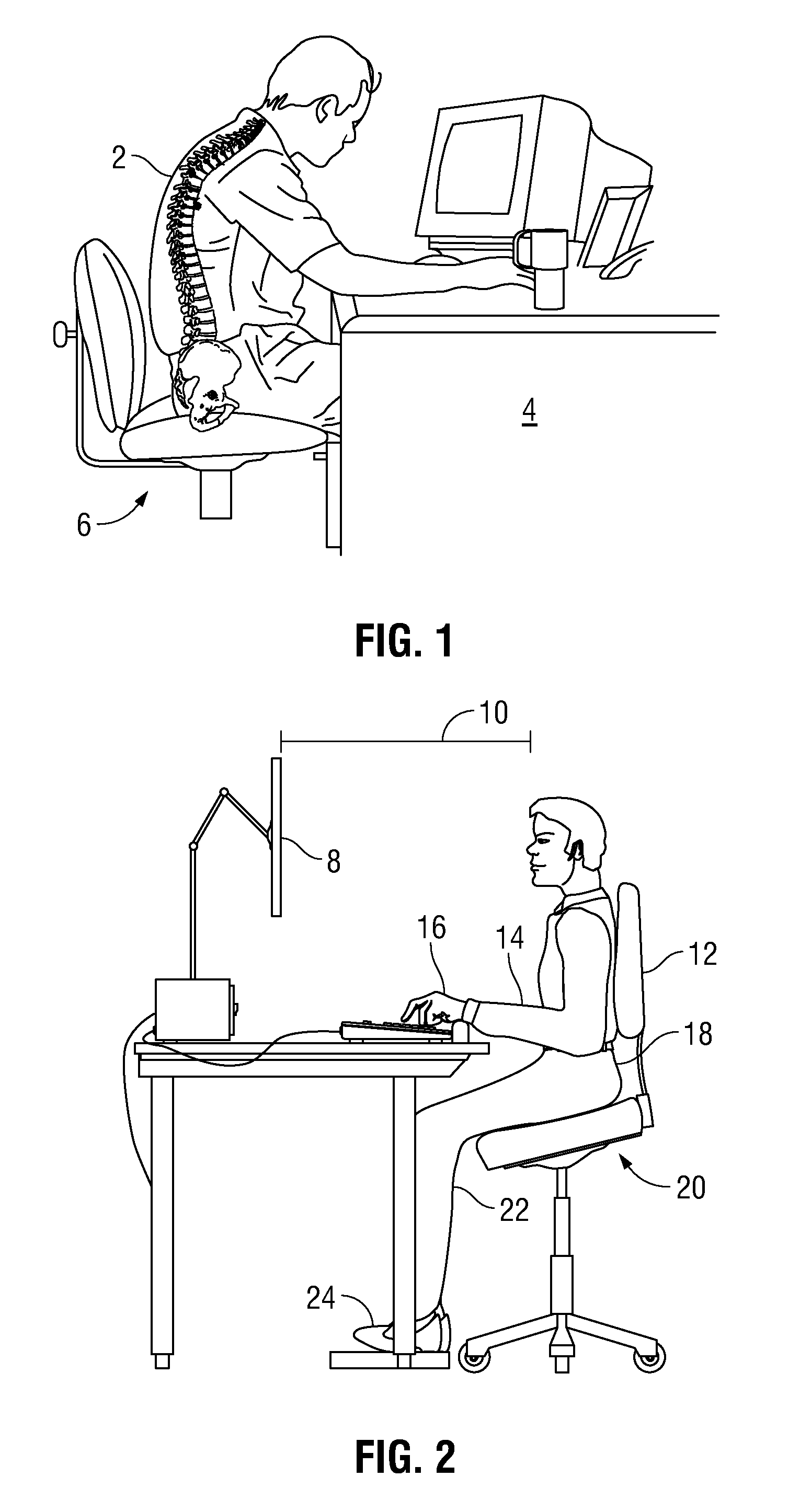

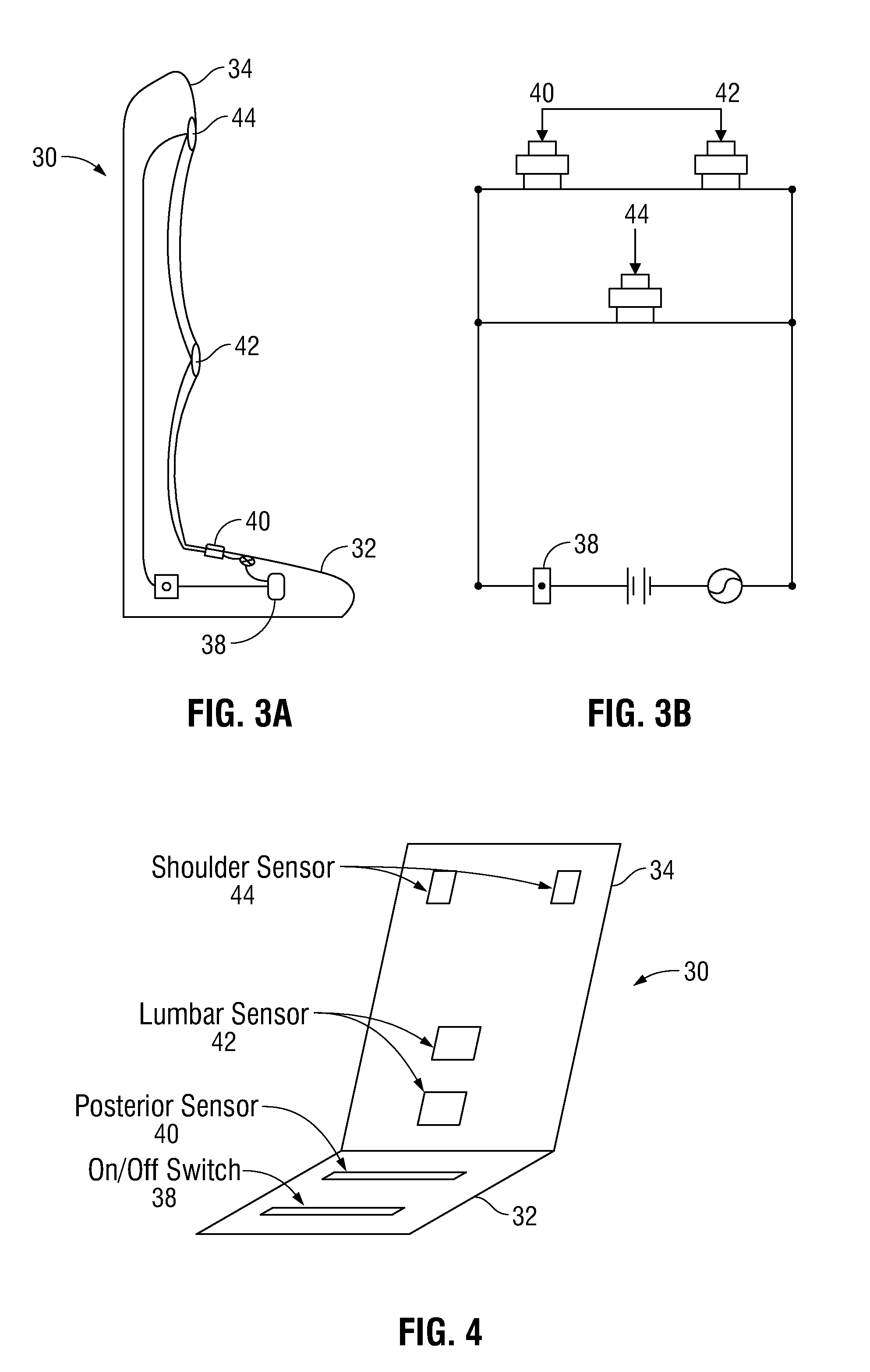

Ergonomic Sensor Pad with Feedback to User and Method of Use

ActiveUS20110275939A1Avoid developmentPrecise alignmentCosmonautic condition simulationsPerson identificationEngineeringPersonal computer

A portable system is provided for sensing and training a user to maintain correct posture while seated in a chair with a seat portion and a back portion. The system includes a first pad attachable to the seat portion of a chair, said first pad having a front area and a rear area, and a second pad attachable to the back portion of a chair and having a lower area and an upper area. There is a first sensor located in the first pad capable of sensing that a user is seated in the seat portion of the chair, a second sensor located in the first pad capable of sensing whether the lower posterior portion of the user's body is in contact with the rear area of the first pad, a third sensor operably attached to the lower area of the second pad capable of sensing whether the user's lumbar region is in contact with the second pad, a fourth sensor operably attached to the upper area of the second pad capable of sensing the distance between the user's upper back and the upper area of the second pad and a neck-position sensor operably attached to the second pad and capable of sensing the distance between the neck-position sensor and the user's neck. The system also includes a microprocessor operably connected to the first sensor, second sensor, third sensor, fourth sensor and neck-position sensor and capable of collecting data from each of the first sensor, second sensor, third sensor, fourth sensor and neck position sensor. The system also includes software for a personal computer, which configures the personal computer to receive the data from the microprocessor and to display the data received from the microprocessor, so that the user can utilize the ergonomic seat pad to receive feedback regarding his posture and over time, improve his posture.

Owner:WALSH MICHAEL C +9

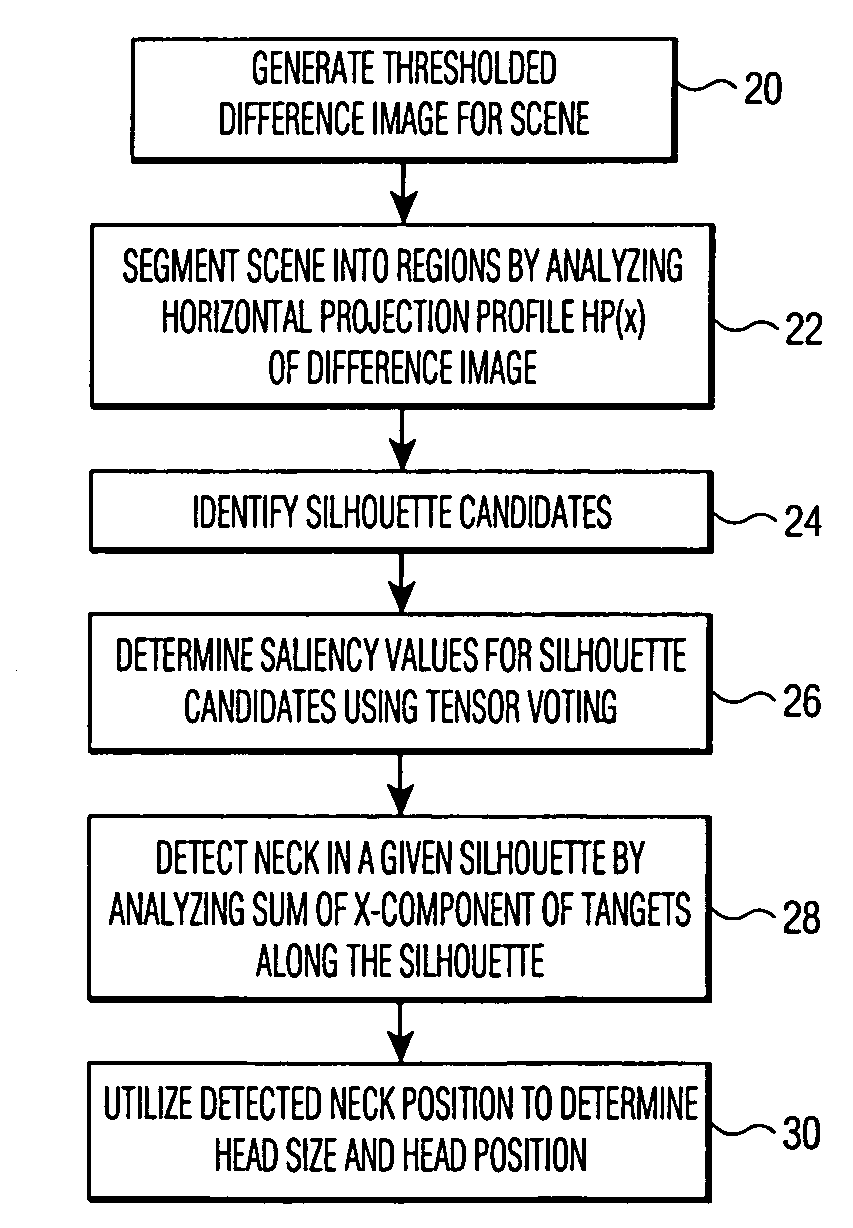

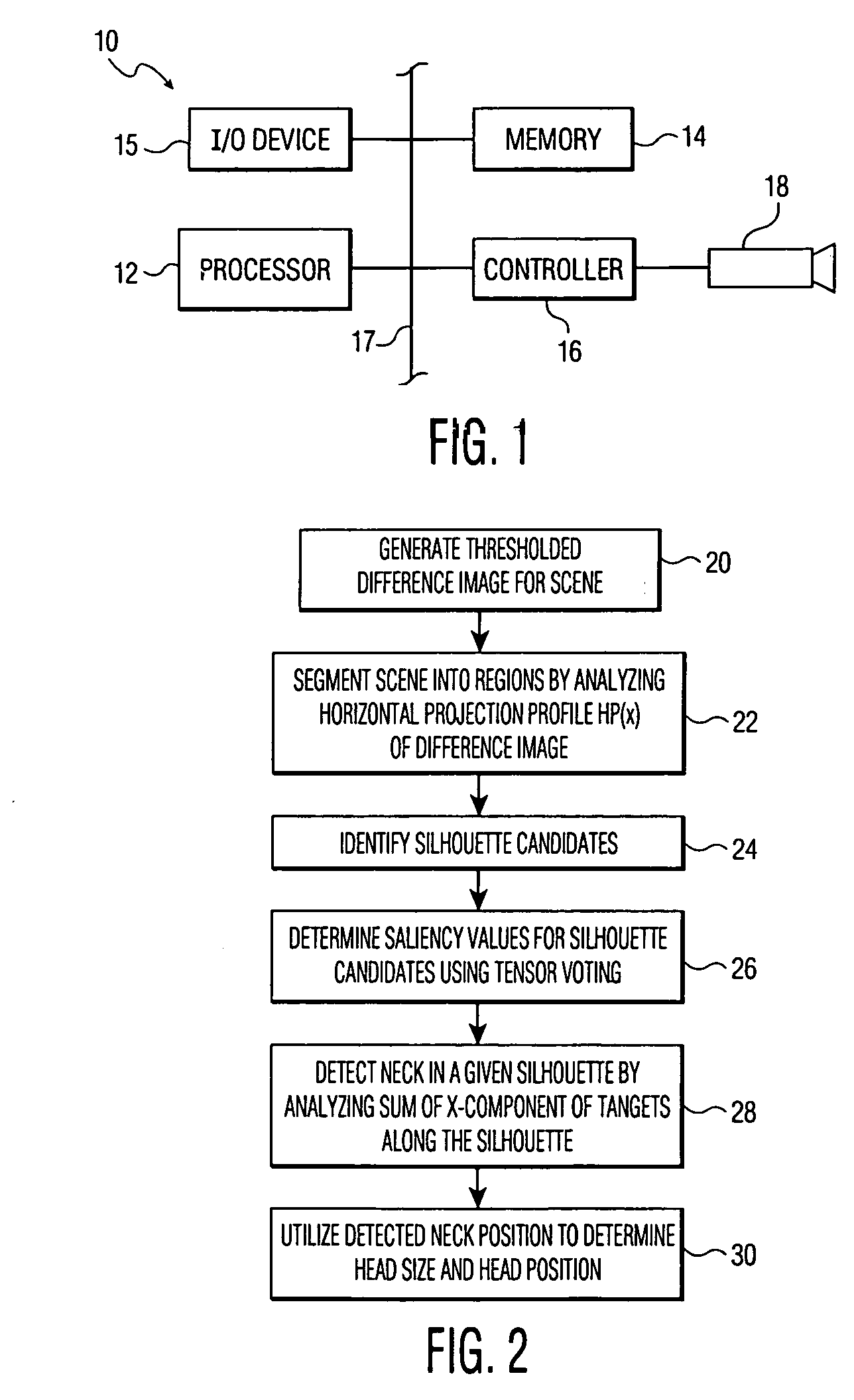

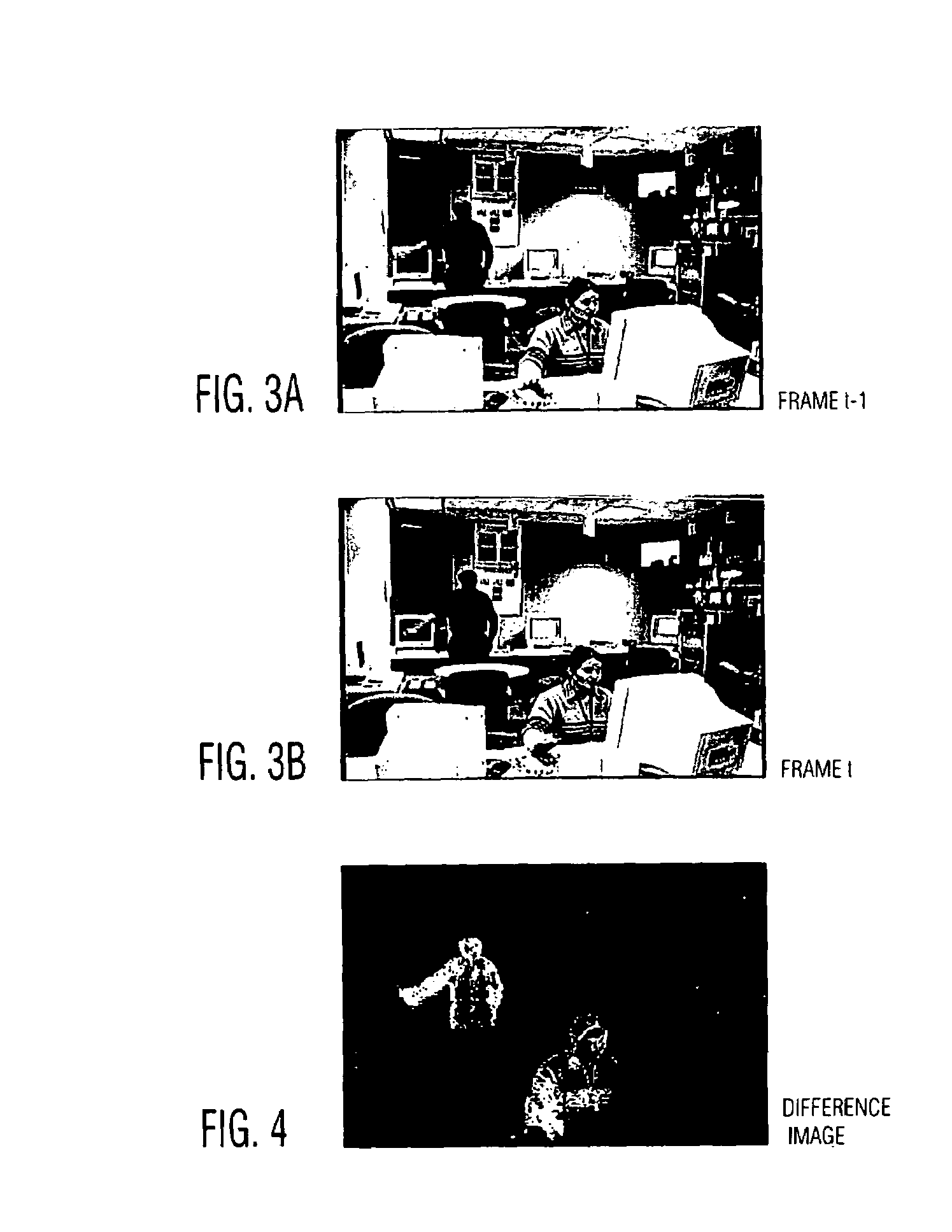

Method and apparatus for detecting moving objects in video conferencing and other applications

InactiveUS7123745B1Noise robustLess computationally expensiveImage enhancementTelevision system detailsHead sizeImaging processing

An image processing system detects a moving person or other object of interest. The system generates a thresholded difference image by processing a video signal or other type of image signal received from a camera. The difference image is then segmented into regions bounded by vertical lines passing through the image, and silhouette candidates are identified in one or more of the regions. Tensor voting is used to determine saliency values and corresponding tangents for each of the silhouette candidates, and the resulting values and tangents are used to detect the object of interest. In an embodiment in which the object of interest is a moving person, a neck position of the moving person may be detected by analyzing a sum of x-components of tangents along a corresponding silhouette. The detected neck position may then be utilized to determine a head position and a head size for the moving person.

Owner:UNILOC 2017 LLC

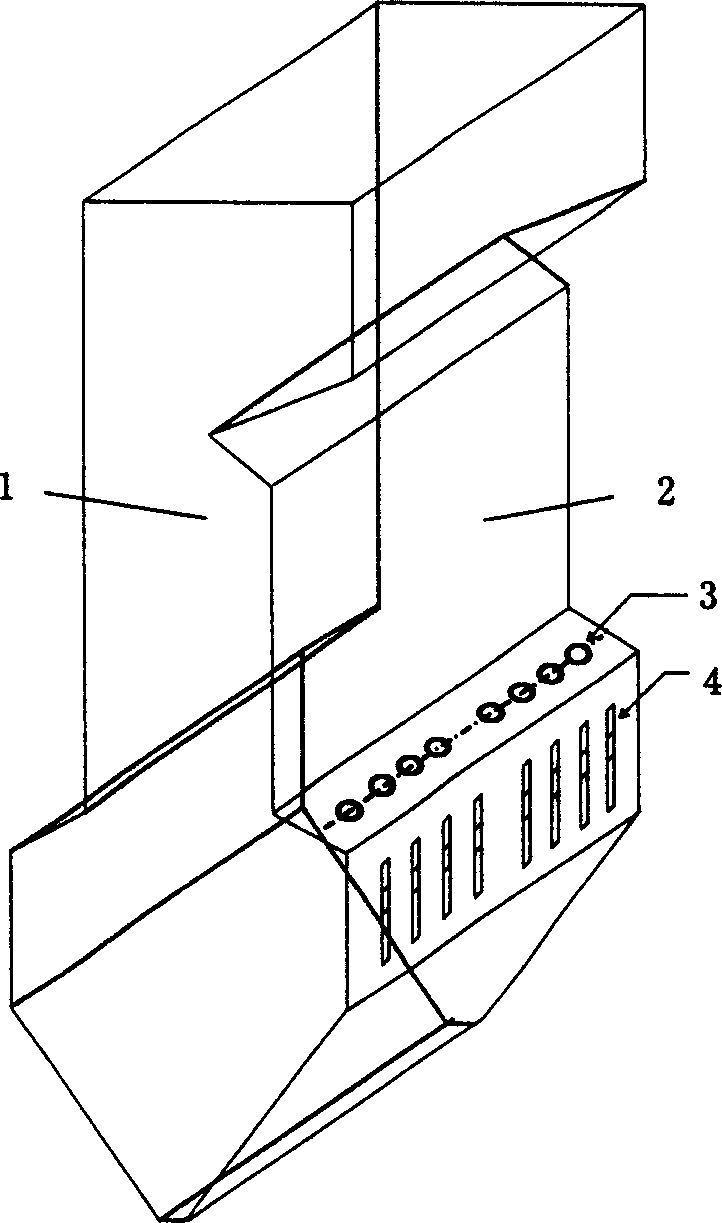

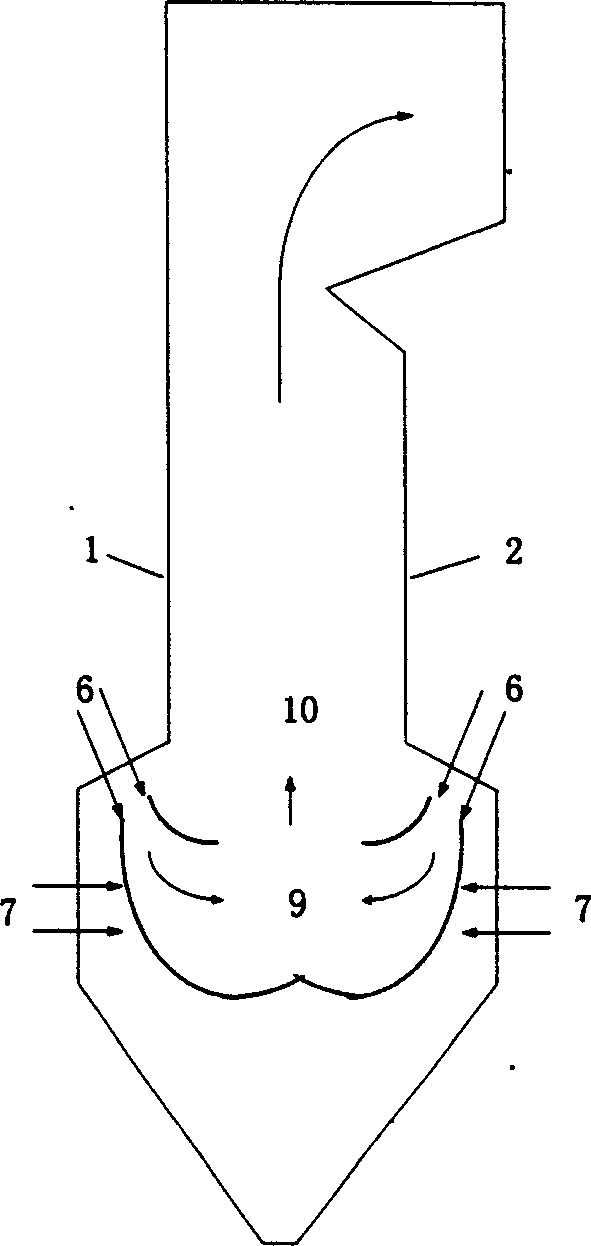

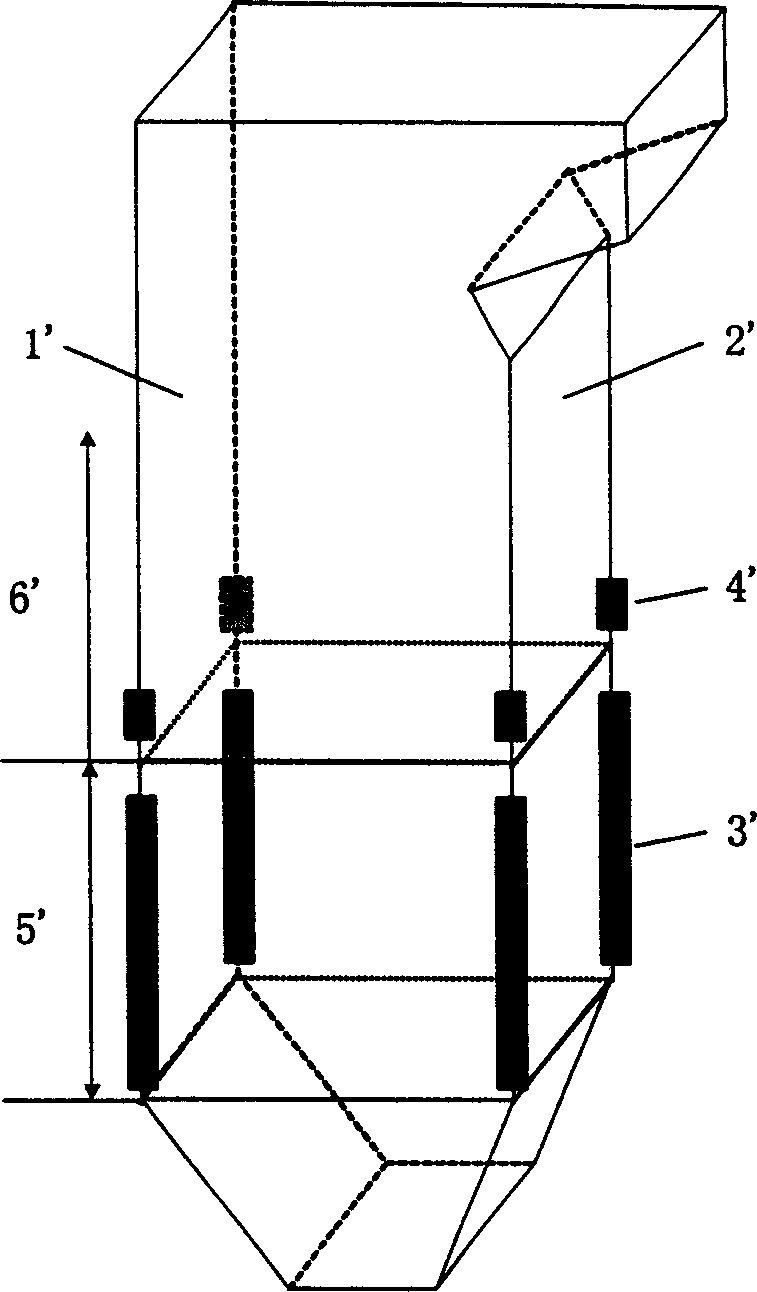

Device and method for w shape flame boiler completely burning

Owner:HUAZHONG UNIV OF SCI & TECH

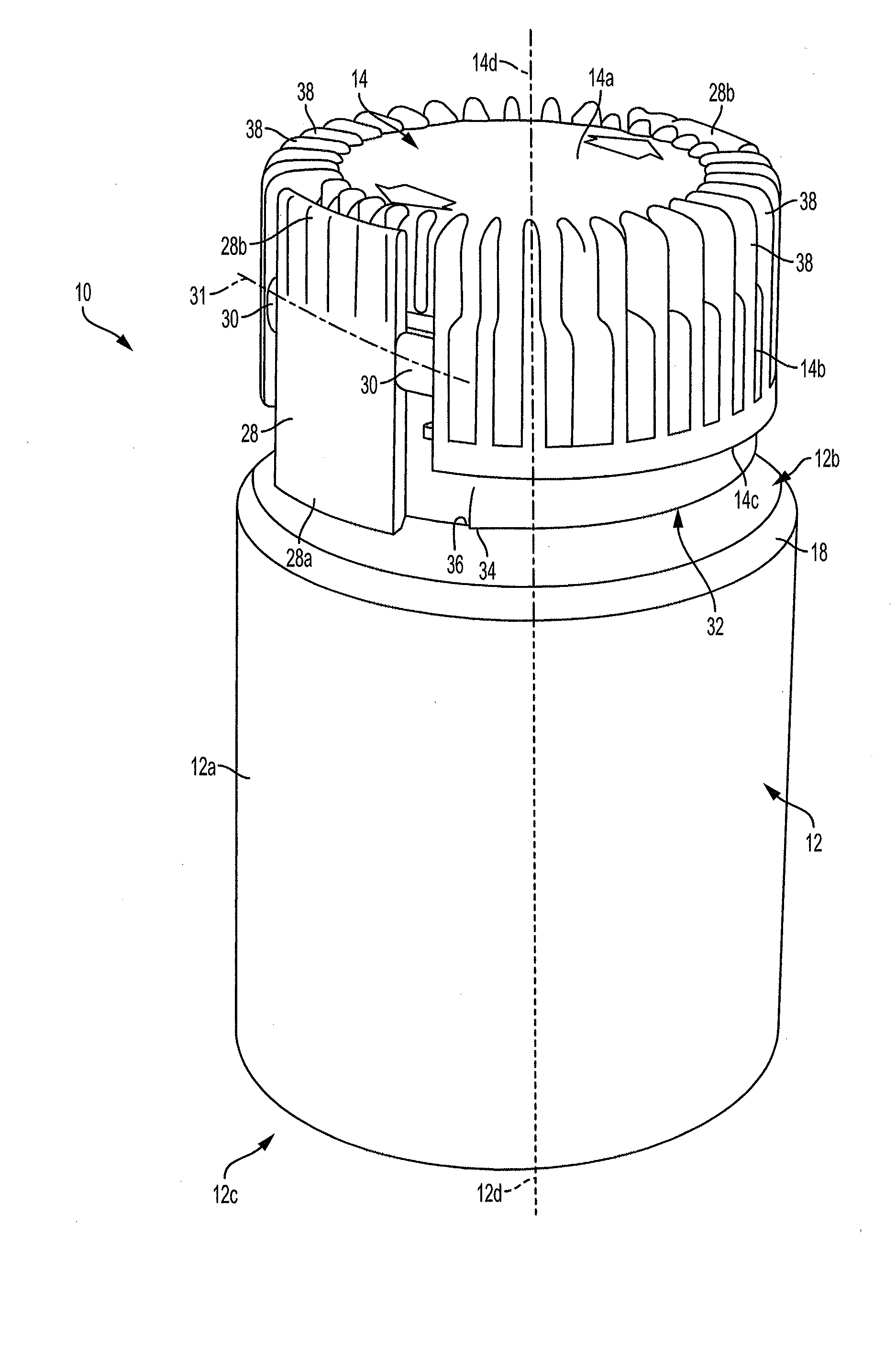

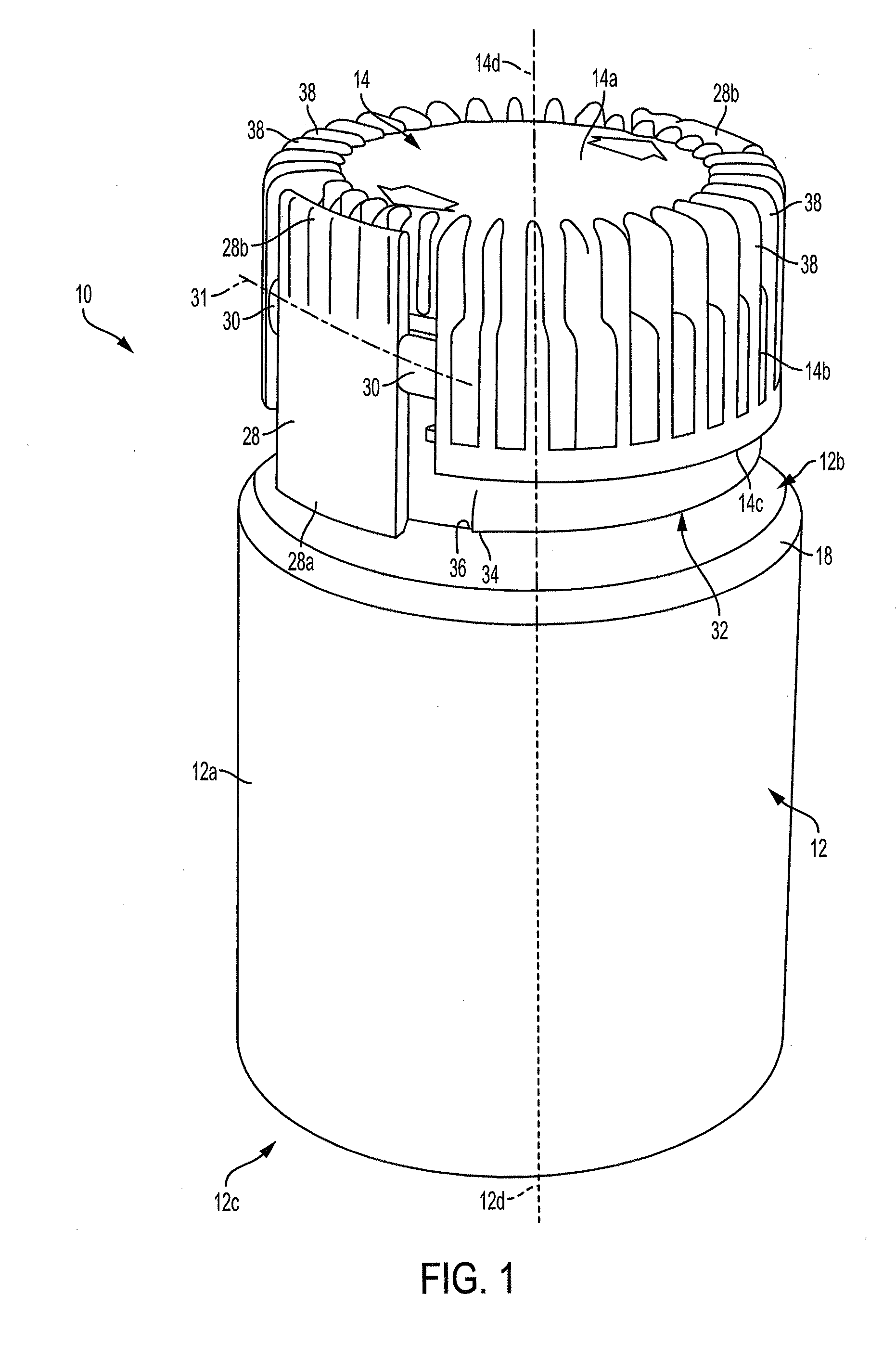

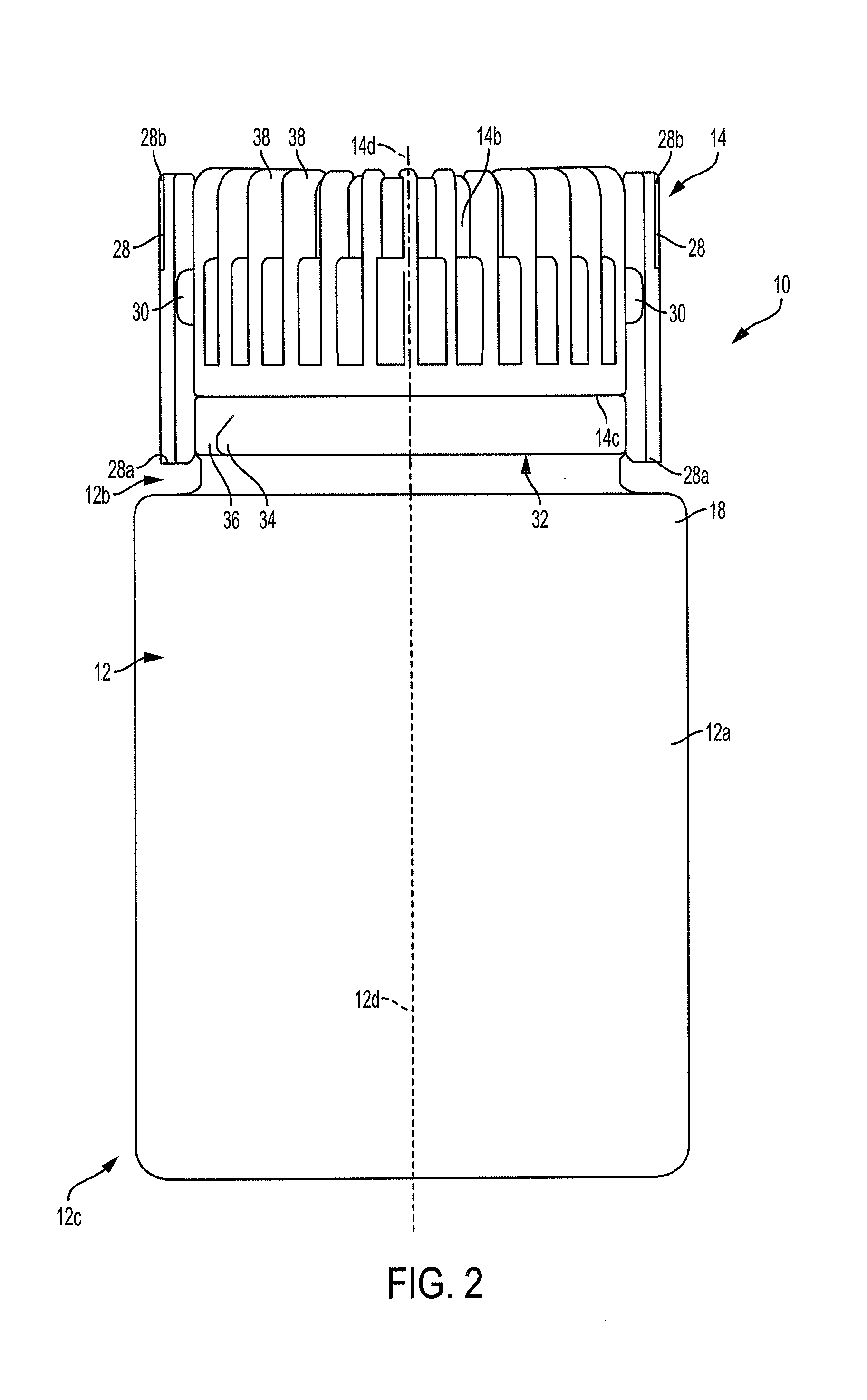

Child-resistant cap and container assembly

A child-resistant container assembly for selectively storing materials is provided. The child-resistant container assembly includes a cap and a container. The cap has a top wall and a sidewall. First and second levers are positioned in respective gaps in the sidewall and are pivotably connected thereto via hinges. The container includes a neck positioned at an upper end thereof, having a radially outwardly extending, circumferentially tapering locking rib. The locking rib defines at least one locking edge, at a largest diameter of the locking rib, and at least one base edge, at a smallest diameter of the locking rib. To remove the cap from the container, the first and second levers are manually pivoted to clear the at least one locking edge, in order to permit sufficient rotation of the cap relative to the container to remove the cap from the container.

Owner:DRUG PLASTIC & GLASS

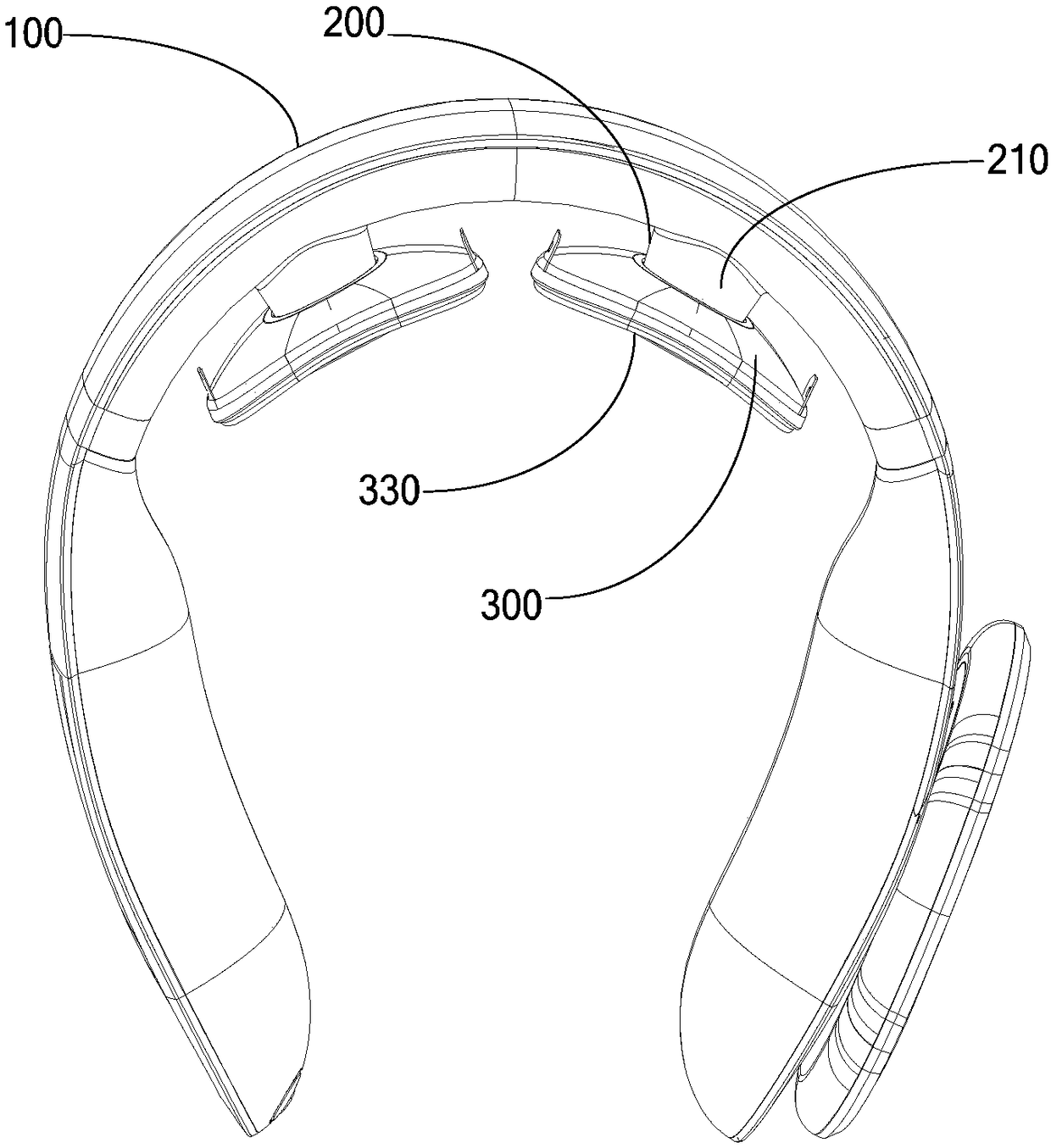

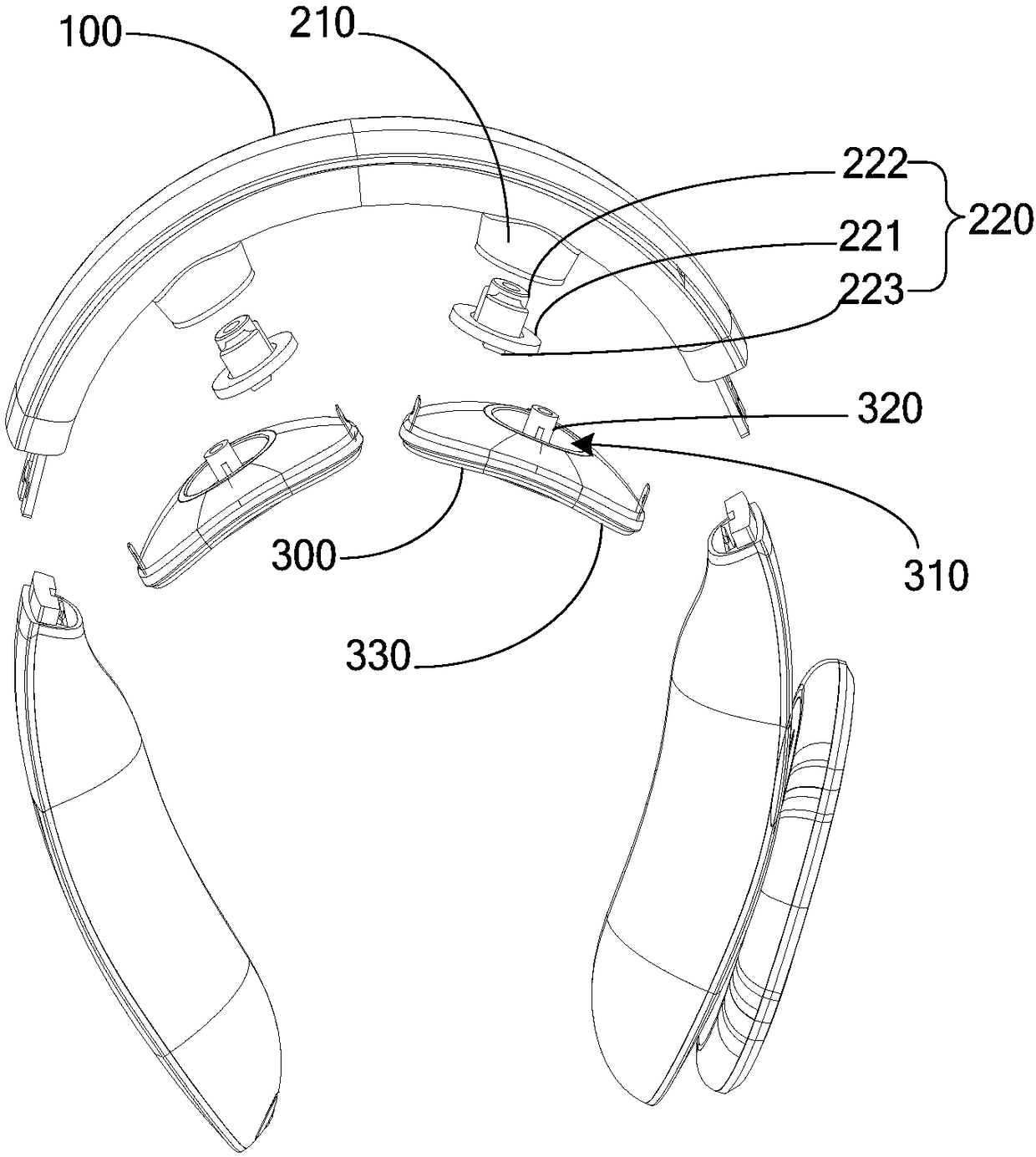

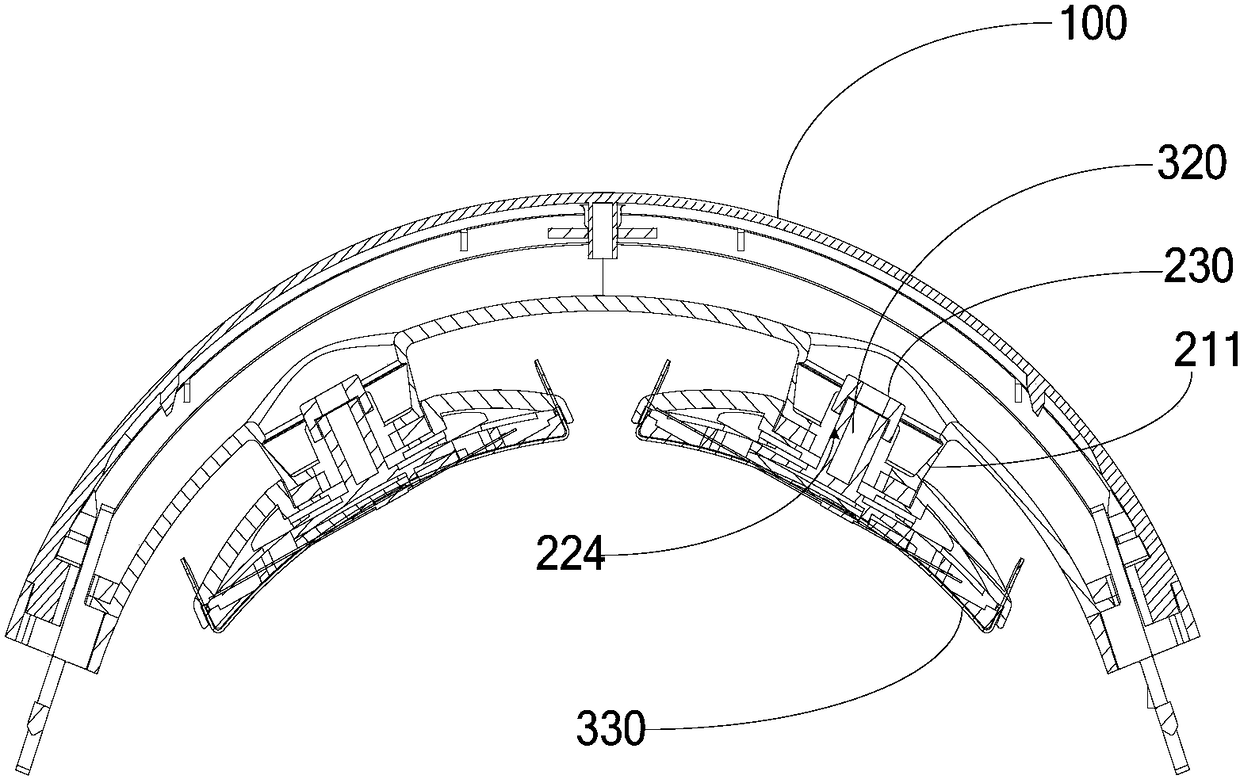

Neck massage device

PendingCN108379738ASolve technical problems that cannot adjust the position as neededElectrotherapyArtificial respirationMassagePhysical therapy

The present invention discloses a neck massage device. The device comprises an elastic support and a silica gel pedestal. The silica gel pedestal is arranged on the elastic support, one side, far awayfrom the elastic support, of the silica gel pedestal is provided with electrode slices configured to have a massage effect on a human body's neck. In the technical scheme of the invention, the electrode slices are fixed on the massage head, and is fixedly installed on a mounting base through the massage head, the flexibility of the silica gel pedestal itself is employed to allow the massage headto regulate the angle and the position according to the real-time neck position to allow the electrode slices to be attached to the neck all the time so as to solve the technical problem that the electrode slices of a traditional neck massage device cannot regulate positions as required.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

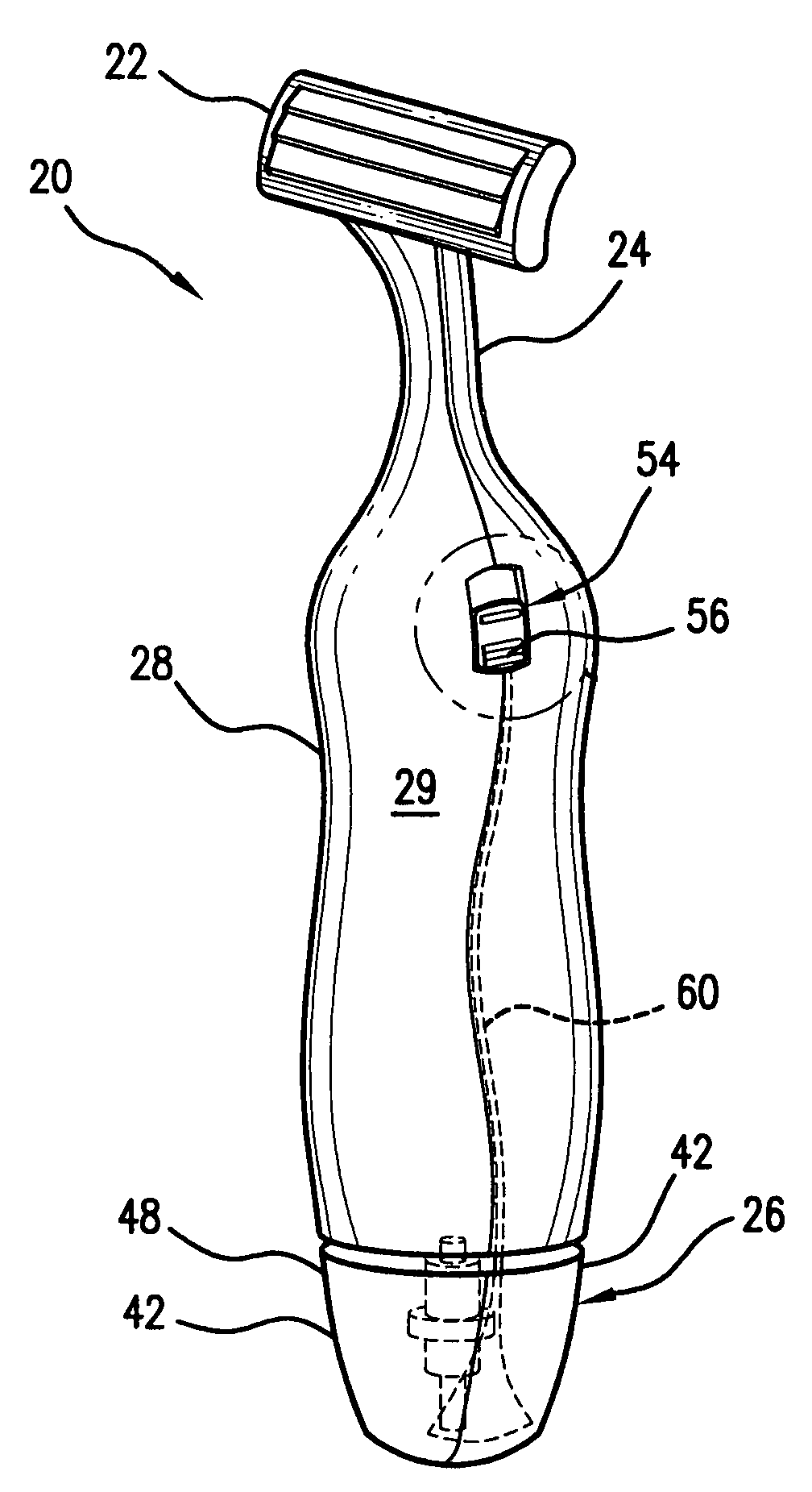

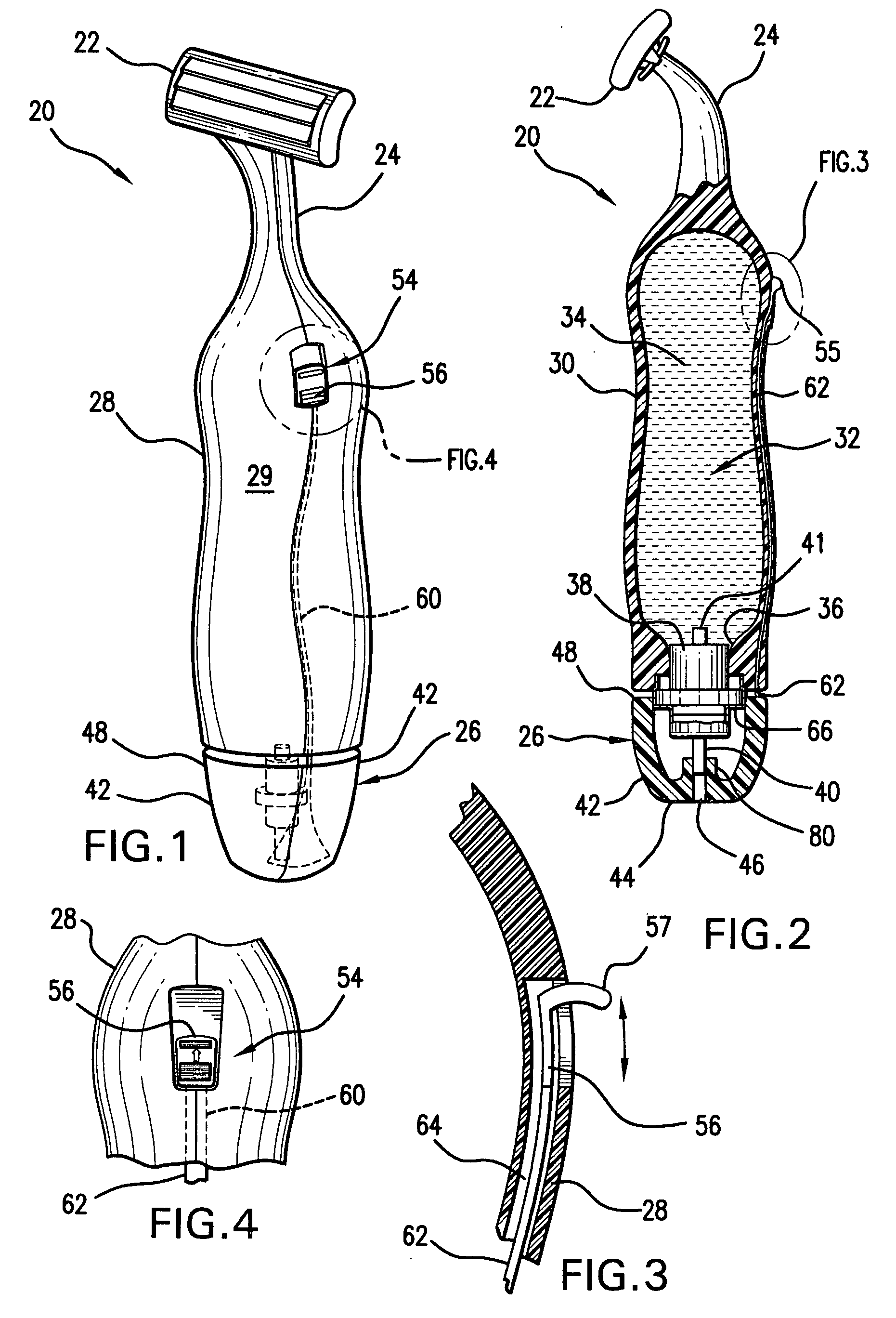

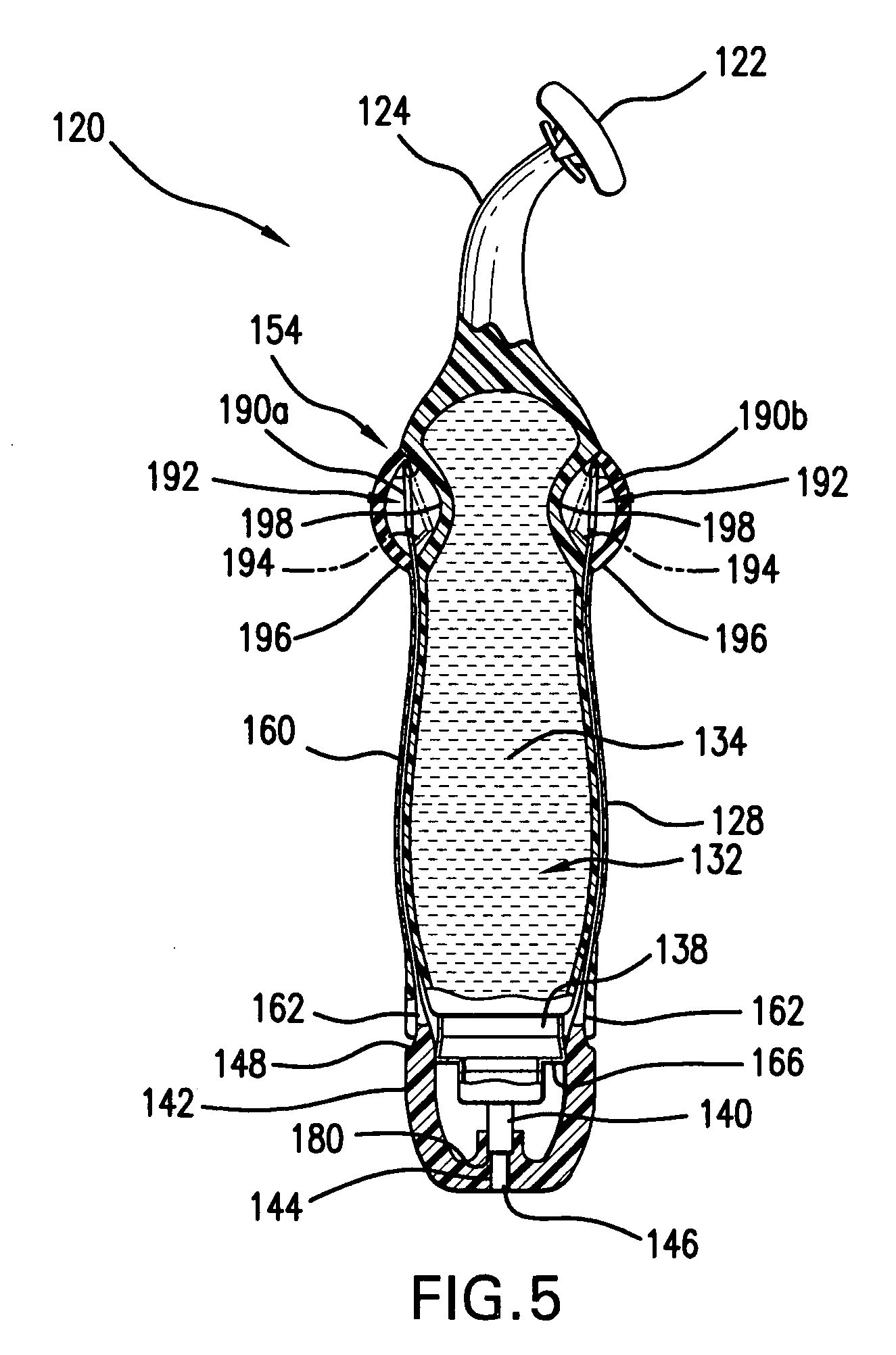

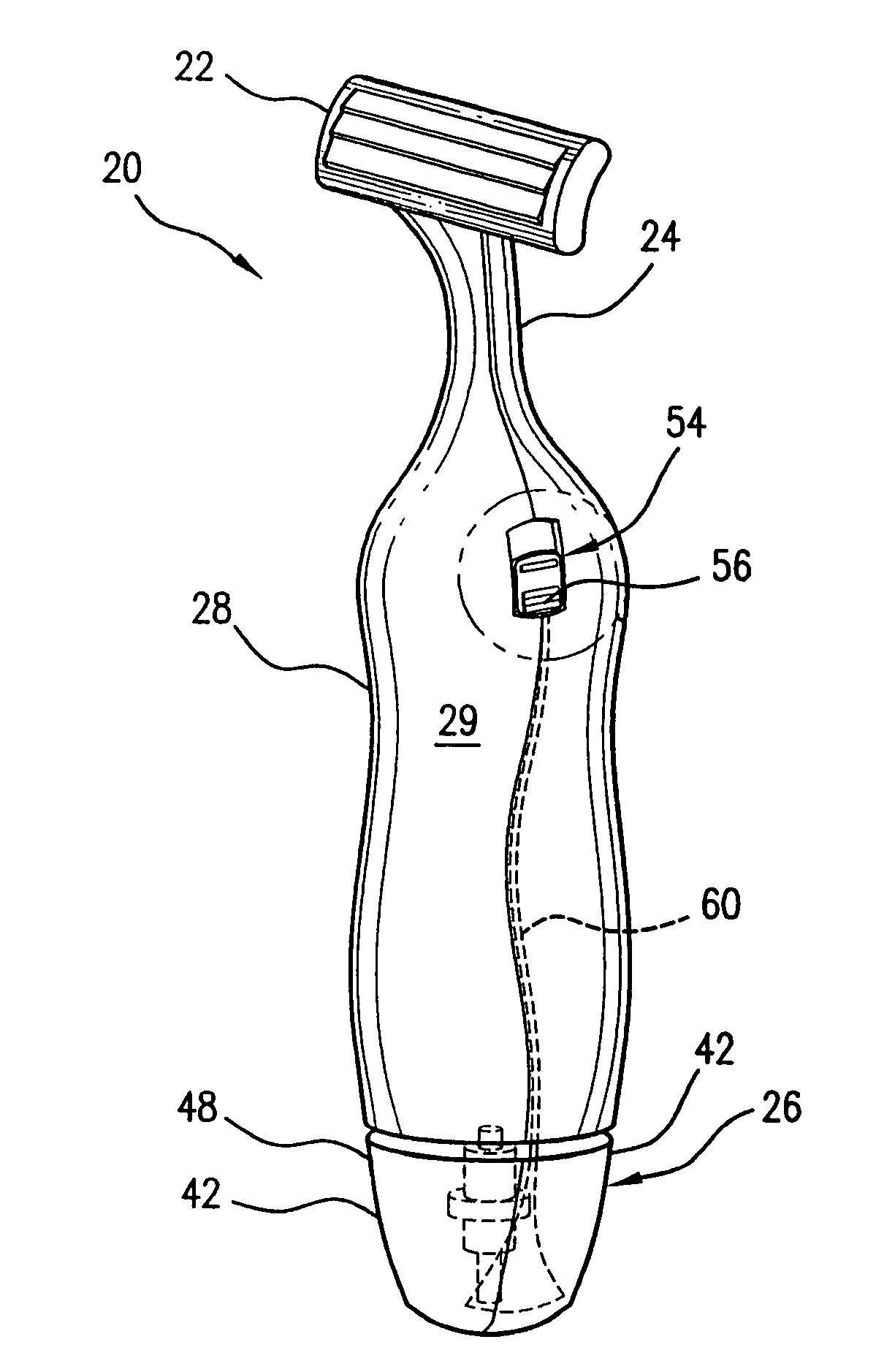

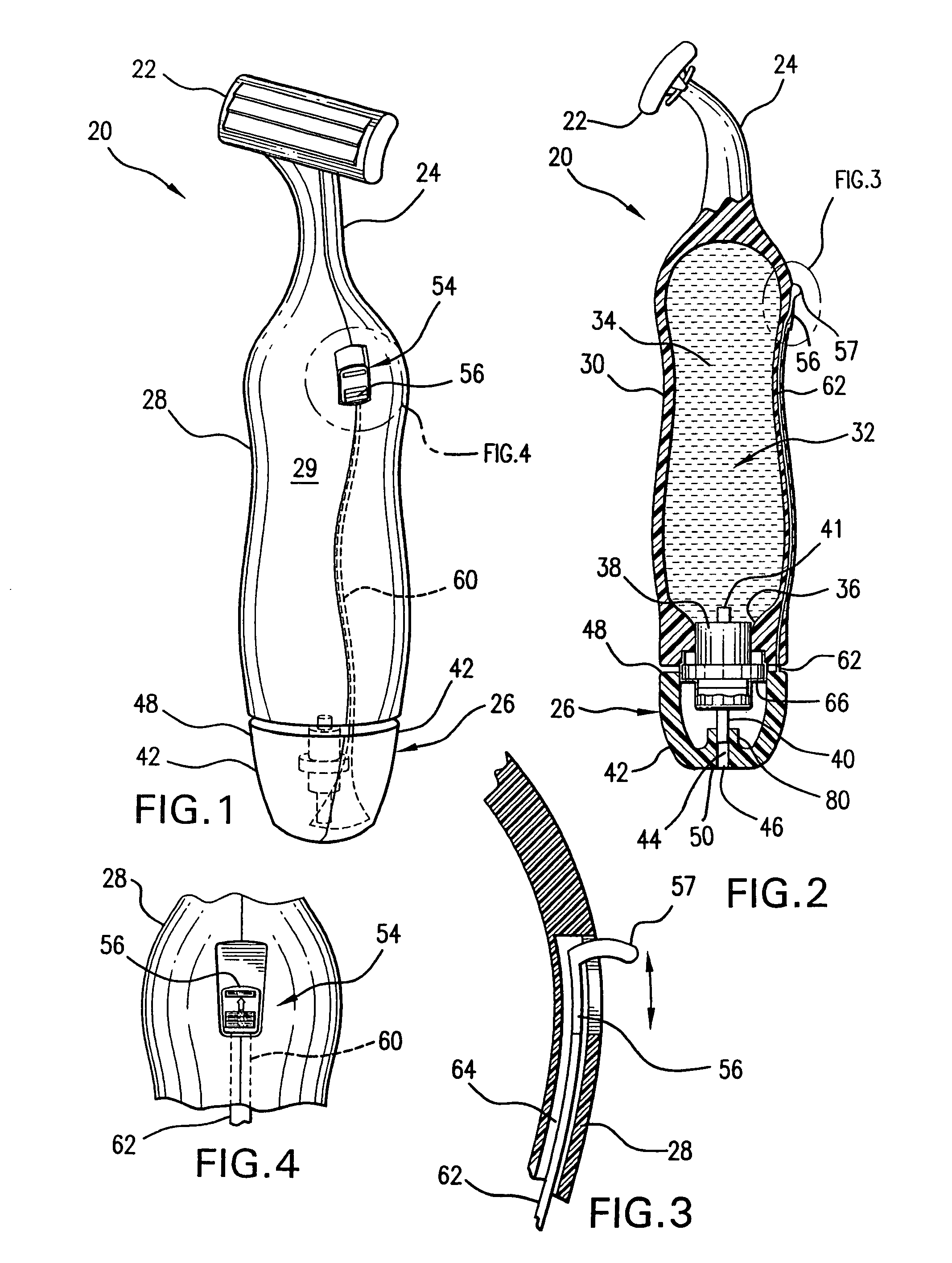

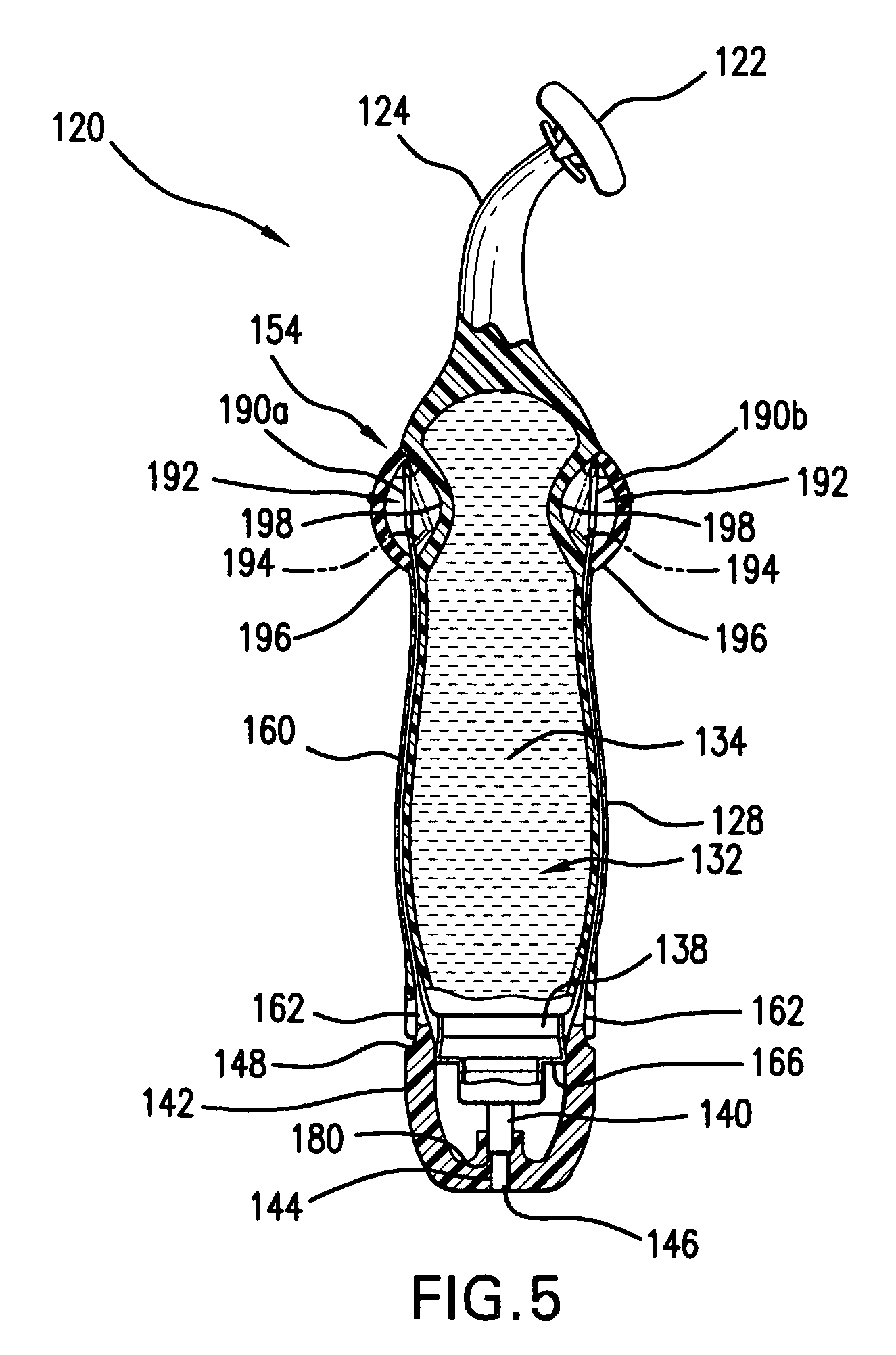

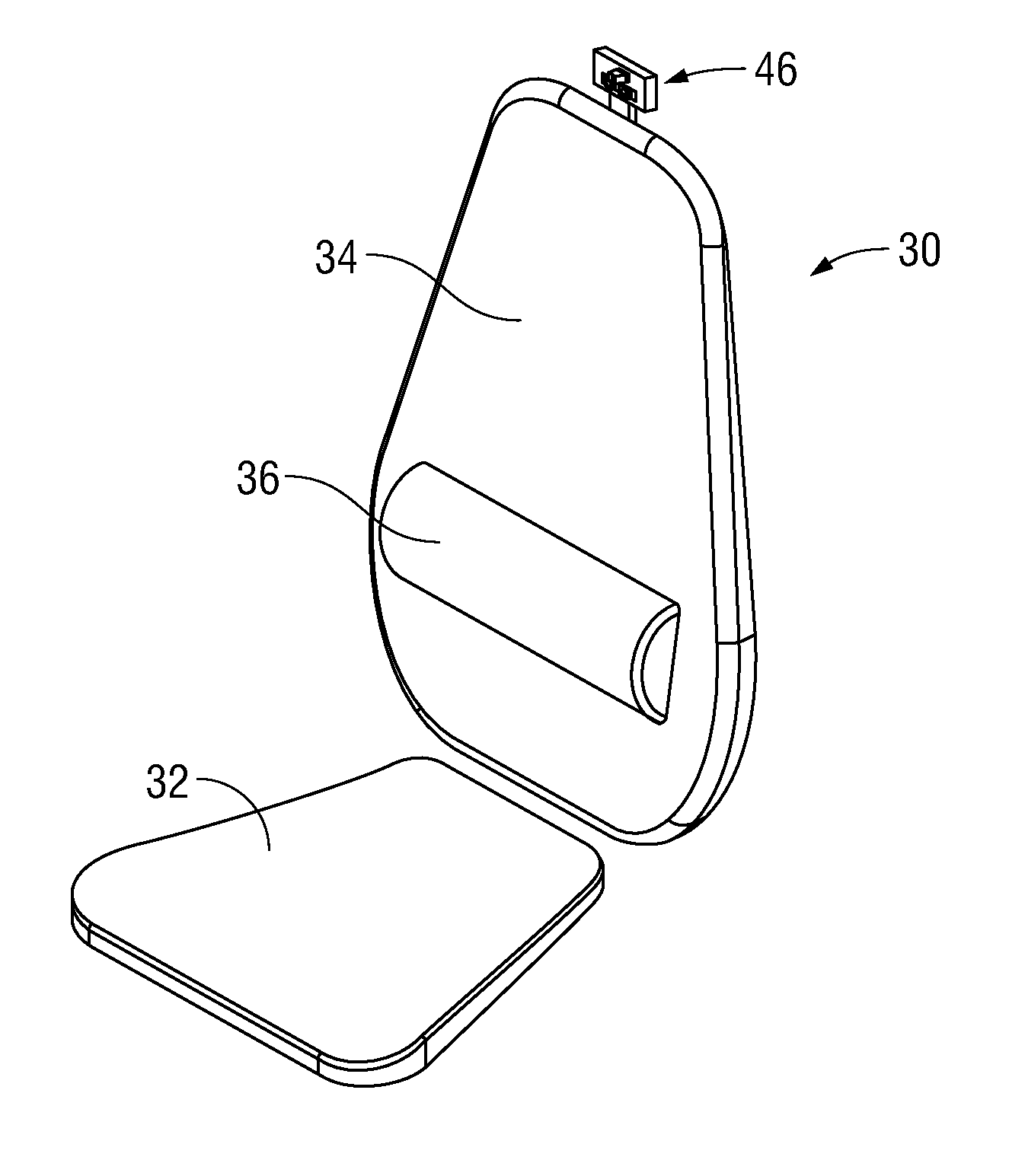

Disposable razor with integrated shaving cream dispenser

ActiveUS20090126197A1MiniaturizationDispensing apparatusMetal working apparatusShaving creamNeck position

A disposable safety razor having an integral shaving conditioner dispenser includes a neck to which a blade cartridge is affixed at a top end thereof and a handle extends downwardly therefrom. The handle is ergonomically shaped and has an exterior wall that defines a pressure cavity therein for receiving a shaving conditioning compound and a pressurized dispensing gas. The handle has an opening at its bottom and a valve received in the opening. The valve is configured to dispense the shaving conditioning compound down-wardly through the valve with the razor held upright. A dispensing cap covers the valve and is engaged therewith such that movement of the dispensing cap causes release of the shaving conditioning compound downwardly through the valve and out from a discharge opening in the cap while holding the razor upright with the blade cartridge and neck positioned higher than the handle bottom and dispensing cap.

Owner:TOMASSETTI LOUIS D

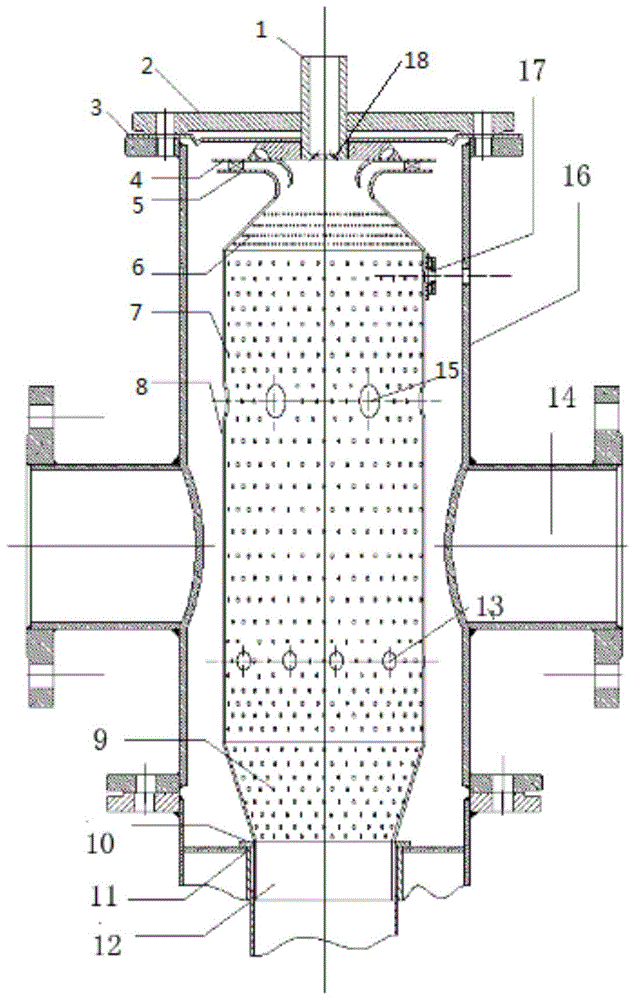

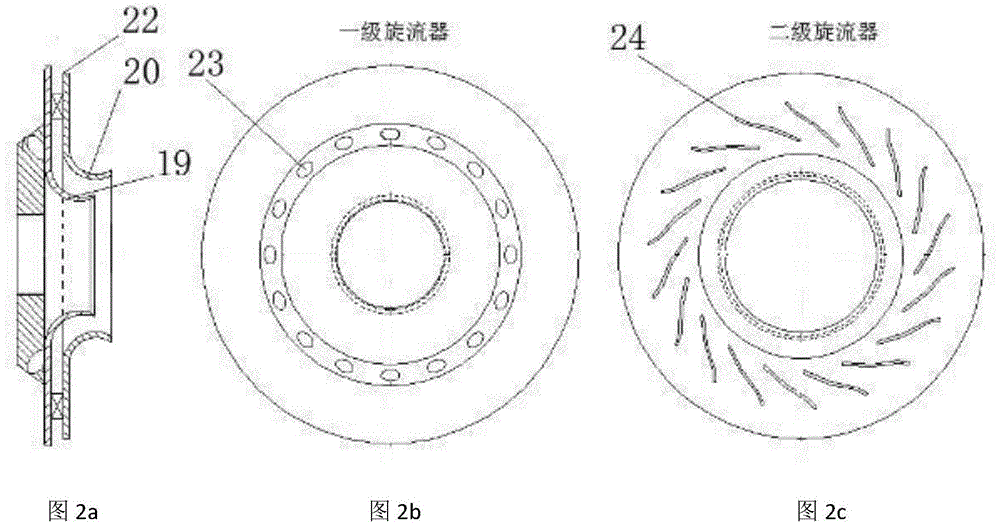

Single-tube combustor device of ground combustion gas turbine

The invention provides a single-tube combustor device of a ground combustion gas turbine. The single-tube combustor device of the ground combustion gas turbine comprises a casing and a flame tube arranged in the casing. A natural gas inlet pipeline is arranged on the top of the flame tube in an externally connected mode. A first-stage beveling hole whirlcone and a second-stage radial whirlcone which are opposite in rotation direction are arranged in the neck position of the flame tube sequentially from top to bottom. The first-stage beveling hole whirlcone is of a circular truncated cone structure and provided with a through hole enabling the side wall and the bottom face to communicate. The two stages of whirlcones are each provided with a Venturi tube. An igniter assembly, a main combustion hole and a mixing hole are formed in the side wall of the flame tube sequentially from top to bottom. A plurality of tiny full-coverage air film cooling holes are formed in the surface of the flame tube. A pair of symmetrical air inlets are formed in the side wall of the casing, and a convergence outlet is formed in the tail of the flame tube. By arranging the two stages of whirlcones on the neck of the flame tube and arranging the main combustion hole, the mixing hole and the tiny cooling holes in the flame tube, reasonable distribution of a combustion flow field, outlet temperature and wall temperature and reasonable temperature rise of a combustor can be achieved, and the service life of the flame tube is prolonged.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

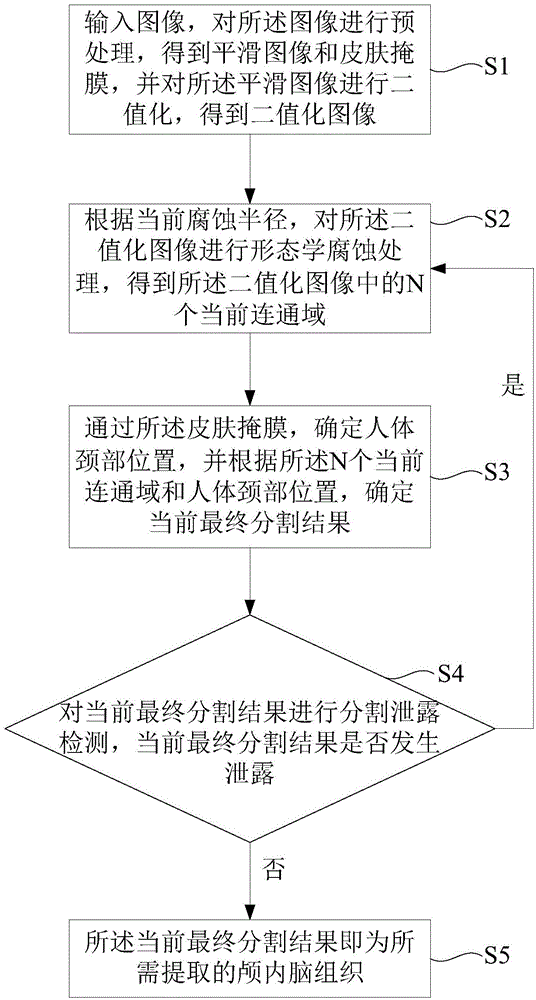

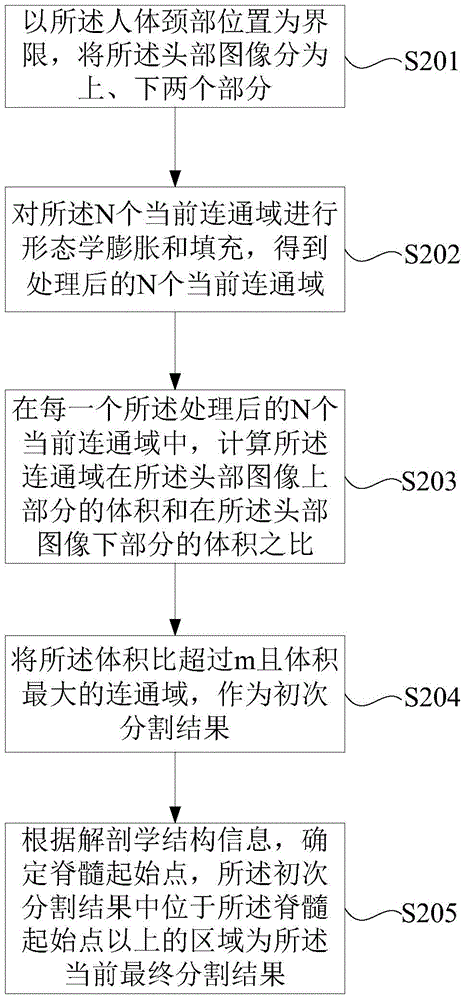

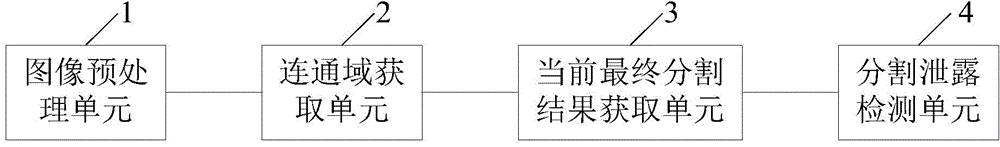

Method and device for extracting intracerebral brain tissue

The invention provides a method and a device for extracting an intracerebral brain tissue. The method comprises the following steps: (1) inputting an image, preprocessing the image for obtaining a smooth image and a skin mask, and performing binarization on the smooth image for obtaining a binary image; (2) according to a current corrosion radius, performing morphological erosion on the binary image for obtaining N current connected domains; (3) determining a human neck position through the skin mask, and determining a current final dividing result according to the N current connected domains and the human neck position; and (4) performing dividing leakage detection on the current final dividing result, if a leakage occurs in the current final dividing result, enlarging the current corrosion radius and returning to the step (2); and if no leakage occurs in the current final dividing result, determining the current final dividing result as the intracerebral brain tissue which requires extraction. The method and the device can be used for automatically and accurately extracting the intracerebral brain tissue and furthermore have advantages of low realizing complexity and high computing speed.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Disposable razor with integrated shaving cream dispenser

A disposable safety razor having an integral shaving conditioner dispenser includes a neck to which a blade cartridge is affixed at a top end thereof and a handle extends downwardly therefrom. The handle is ergonomically shaped and has an exterior wall that defines a pressure cavity therein for receiving a shaving conditioning compound and a pressurized dispensing gas. The handle has an opening at its bottom and a valve received in the opening. The valve is configured to dispense the shaving conditioning compound downwardly through the valve with the razor held upright. A dispensing cap covers the valve and is engaged therewith such that movement of the dispensing cap causes release of the shaving conditioning compound downwardly through the valve and out from a discharge opening in the cap while holding the razor upright with the blade cartridge and neck positioned higher than the handle bottom and dispensing cap.

Owner:TOMASSETTI LOUIS D

Ergonomic sensor pad with feedback to user and method of use

ActiveUS9196175B2Avoid developmentPrecise alignmentCosmonautic condition simulationsPerson identificationEngineeringPersonal computer

Owner:WALSH MICHAEL C +9

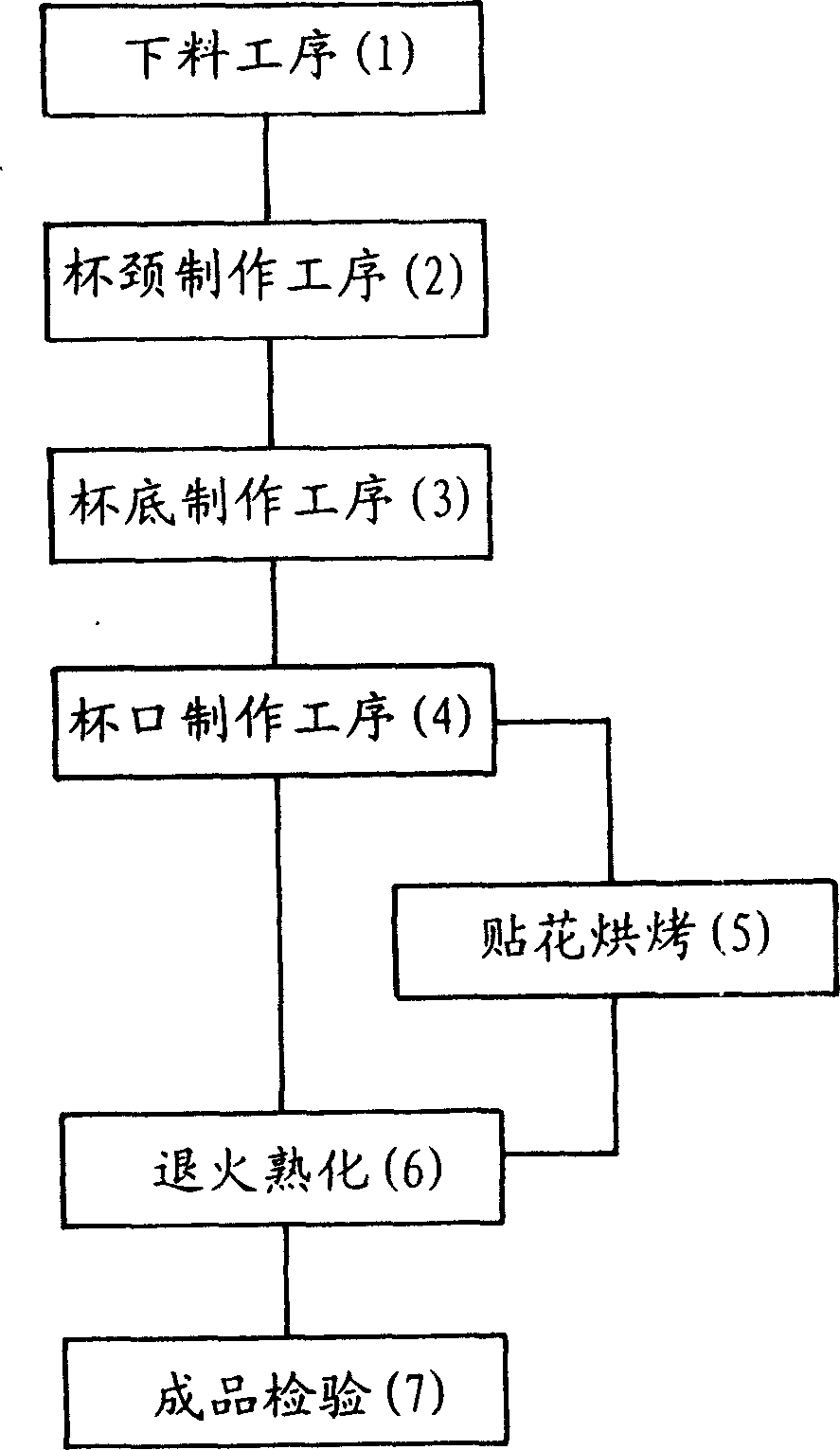

Method for producing goblet by using glass tube

InactiveCN1634781AIncrease brightnessSimple production processGlass reforming apparatusEngineeringNeck position

The present invention discloses a method for making goblet by using glass tube, which comprises the following steps: A. blanking procedure: cutting a glass tube into glass tube sections; B. cup neck making procedure: air blowing and warming up the cup neck gradually until the glass tube is softened, then pressing the cup neck die on the cup neck position to make the glass tube contract and distort towards the inside, separating the cup neck pressing die and going on with air blowing and warming up until the glass is melted to a column shape, then doing annealing treatment; C. cup bottom making procedure: air blowing and warming up the cup bottom to make the glass tube contract and distort towards the inside until it is melted and cut off, the cup bottom forms a flat bottom; D. cup mouth making procedure: polishing the blank cup mouth and warming it up to form a circle. The invention has the advantages of simple production process, convenient operation, high yield, etc.

Owner:陈则明

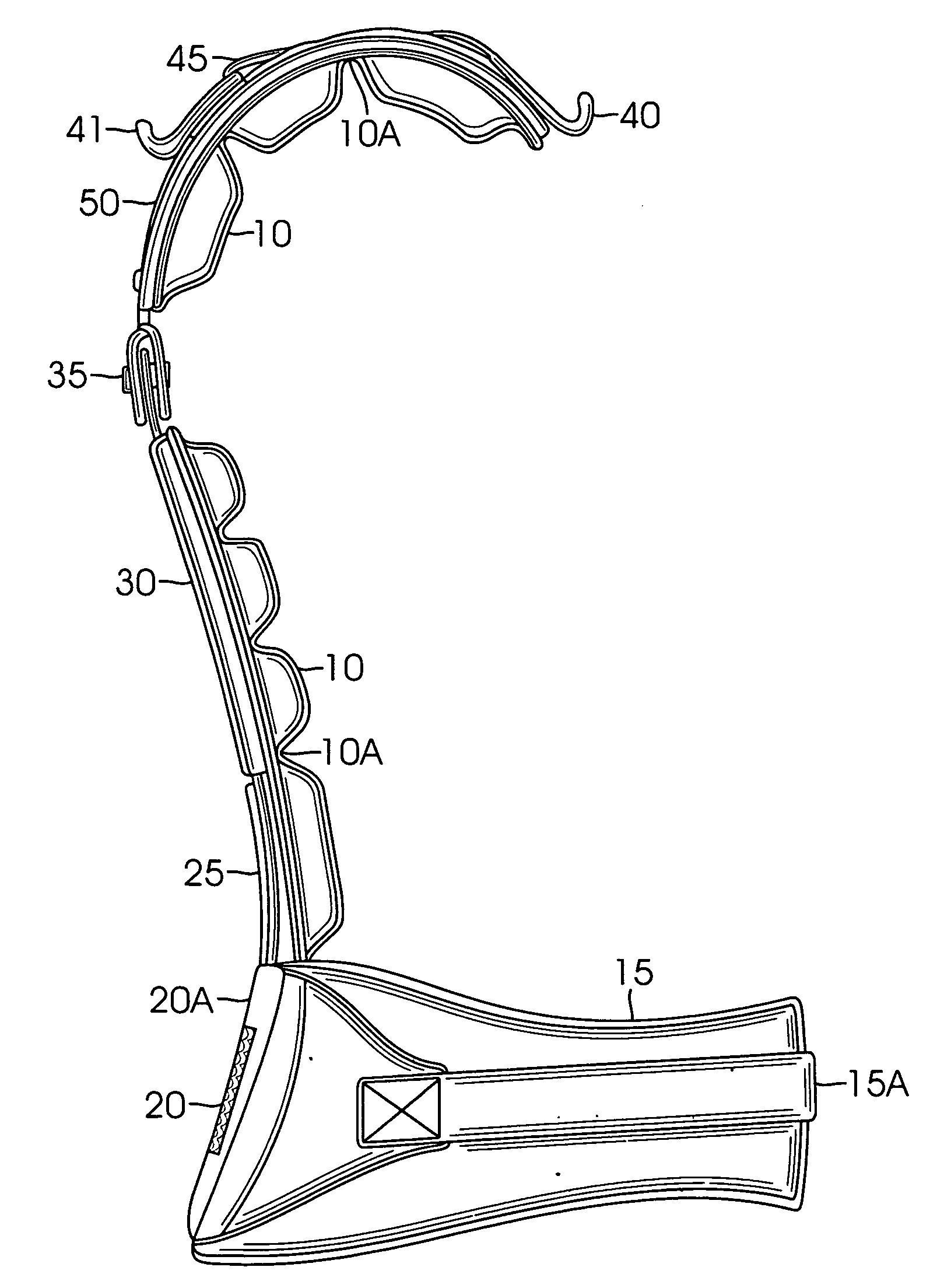

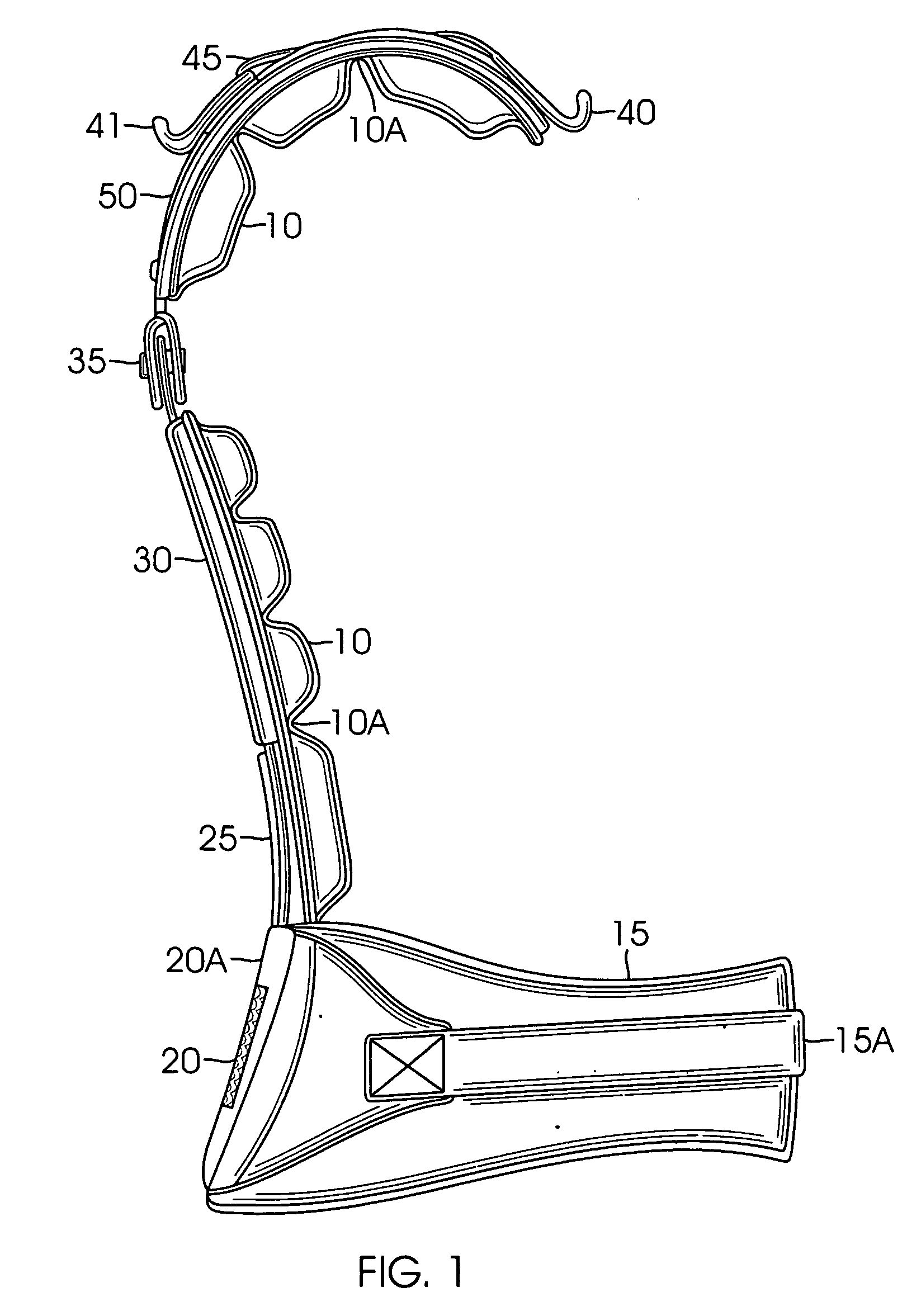

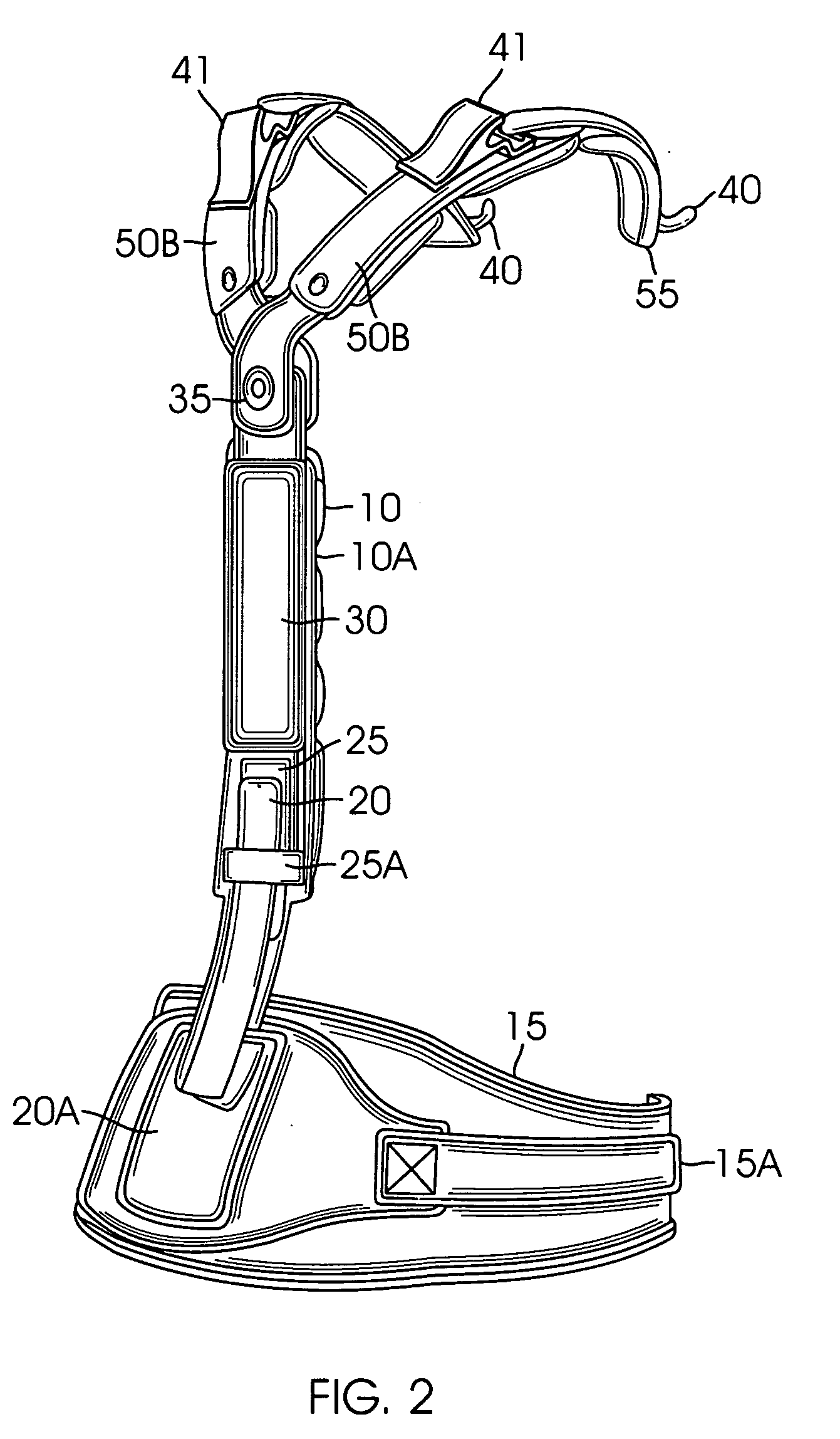

Harness apparatus for squatting exercises

A harness apparatus for a user engaging in freestanding leg exercises with a weightlifting bar is presented. The apparatus has at least two shoulder harness straps shaped for resting on the users shoulders. Front hooks are positioned on the front of the shoulder harness straps and configured for holding the weightlifting bar when the user places the weightlifting bar on a chest position. Back hooks are positioned on the back of the shoulder harness straps and configured for holding the weightlifting bar when the user places the weightlifting bar on a behind the neck position. A vertical spine blade attachable to the shoulder harness straps is provided for assisting the user in maintaining an upright position of the users upper torso during the exercises. A weightlifting belt attachable to the vertical spine blade provides support to the users lower back and waistline during the exercises.

Owner:THOMAS LINDA P

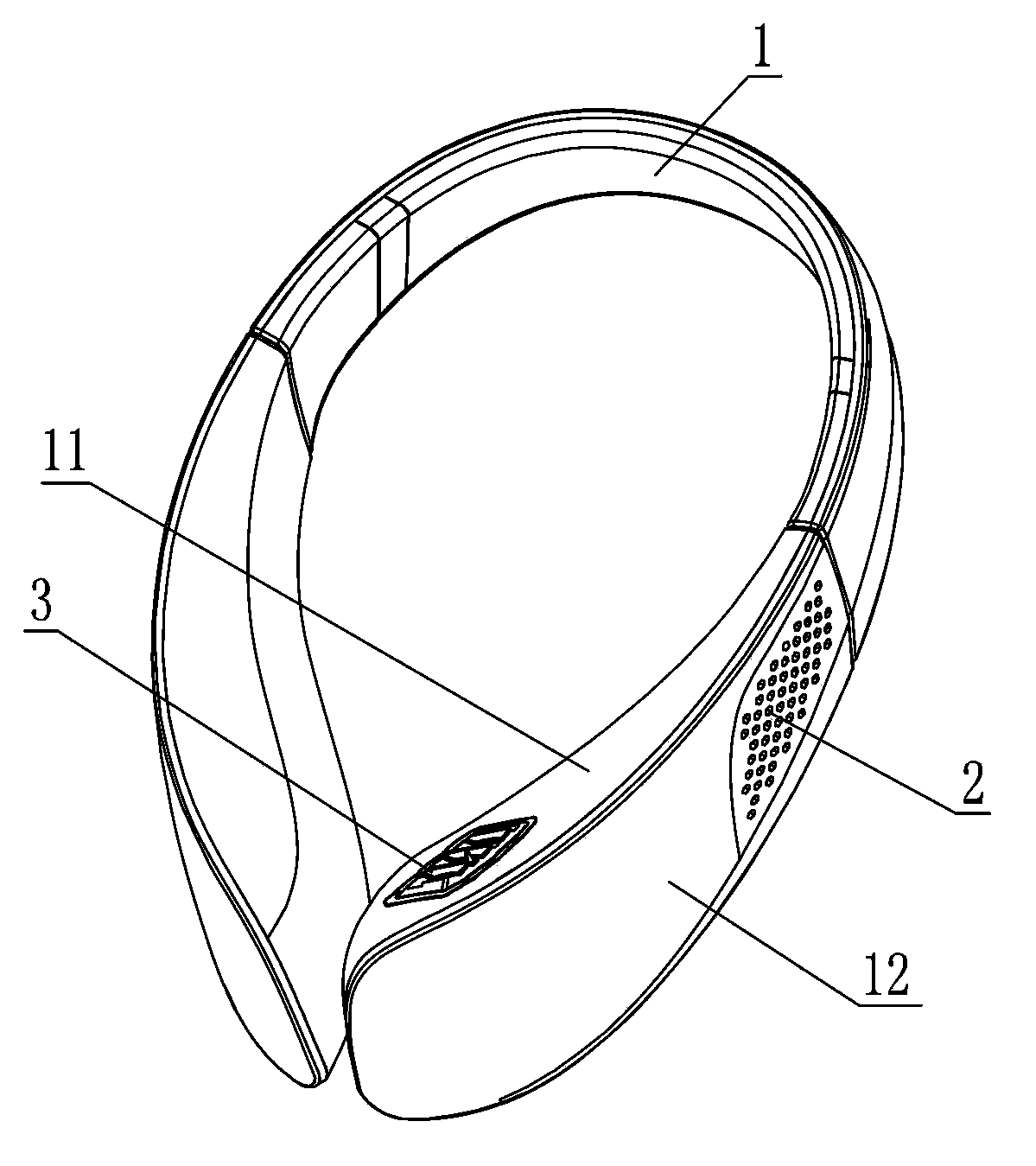

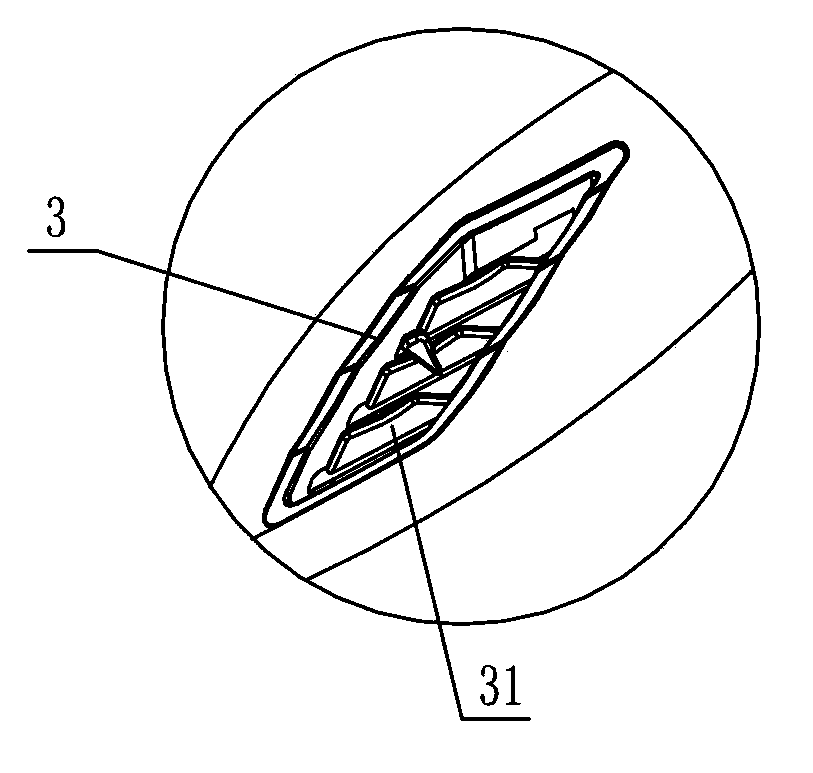

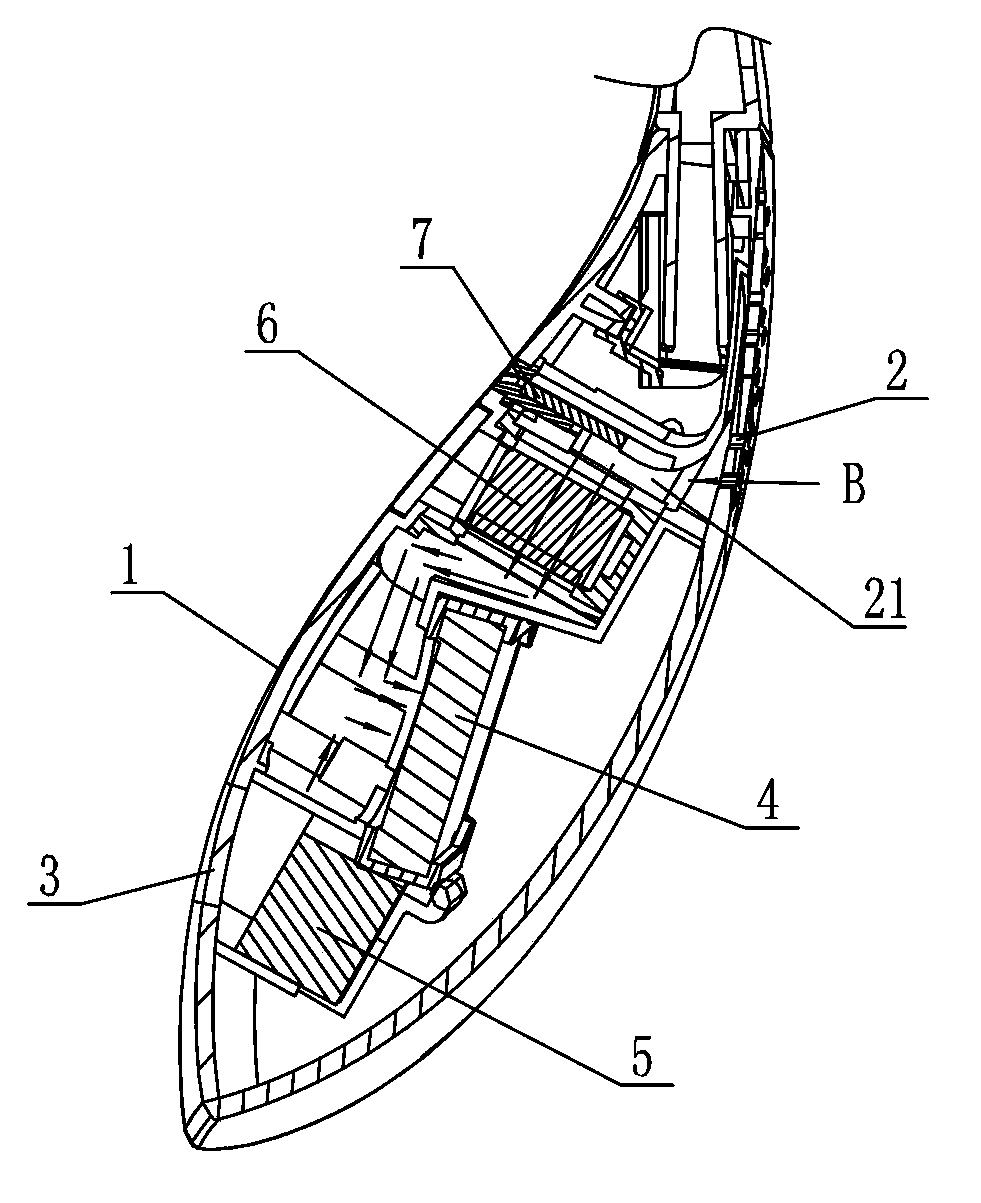

Portable air purifier

ActiveCN103868162ABeautiful and fashionable appearanceAchieve evolutionCombination devicesLighting and heating apparatusHuman bodyEngineering

A portable air purifier comprises a body (1), wherein an air inlet (2) and an air outlet (3) are formed in the body (1), a fan (4) and an air purification portion (6) are arranged inside the body (1), and air enters the air inlet (2) under the effect of the fan (4), passes through the air purification portion (6) and then is discharged out of the air outlet (3). At least a part of body (1) is in a surrounding mode, and the body (1) is positioned on the neck of a user in the surrounding mode. The portable air purifier is fashionable and attractive in appearance, can be directly worn on the neck position of the human body, at least a part of the body of the portable air purifier is in the surrounding mode to enable the body to be positioned on the neck of a user in the surrounding mode so as to enable a distance between the air outlet position of the purifier and the human body nose to be kept constant, the air speed is slow, the air direction is adjustable, thorough purification of air nearby the nose is effectively achieved, and the portable air purifier is simple in structure and convenient to wear and use.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

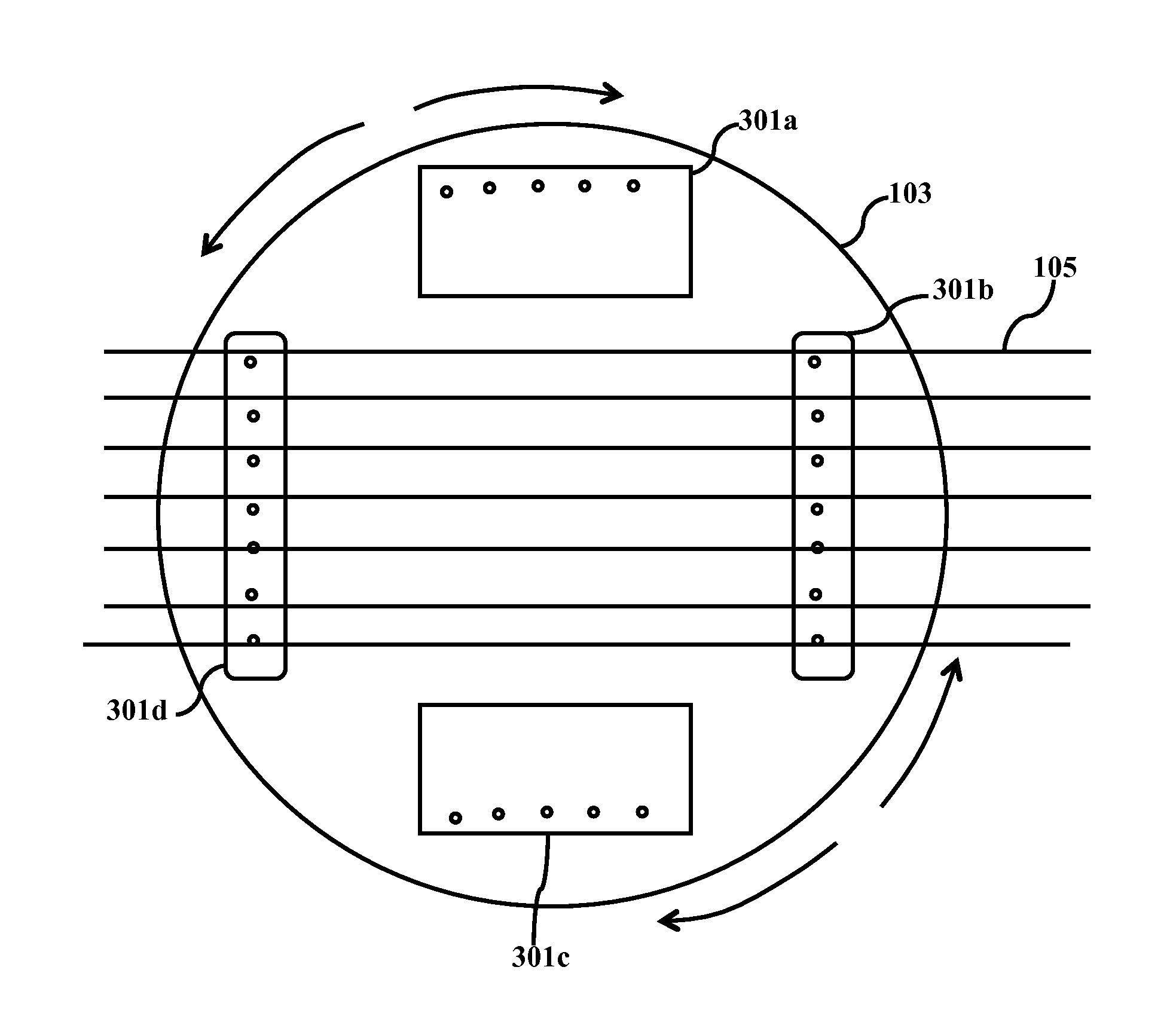

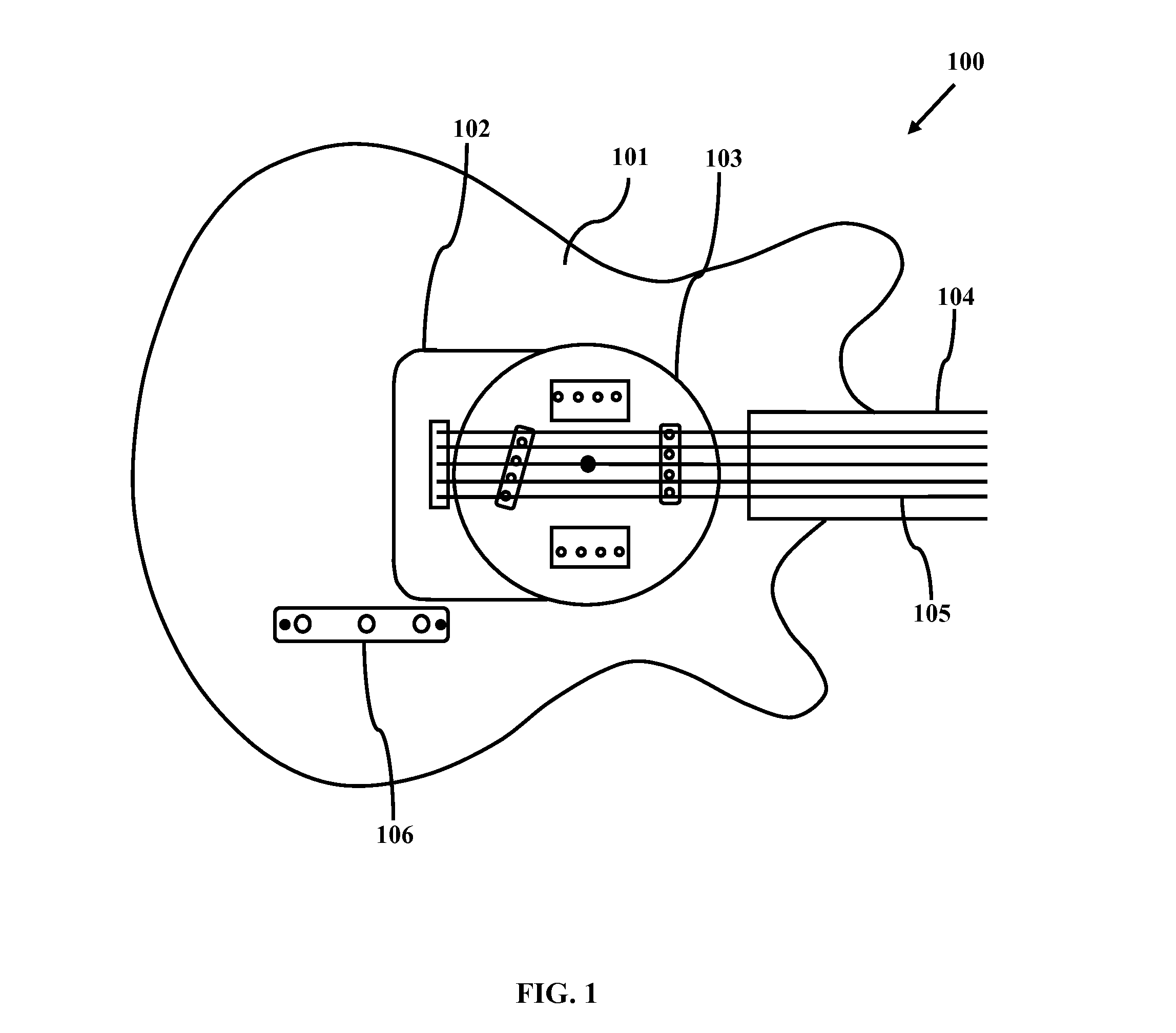

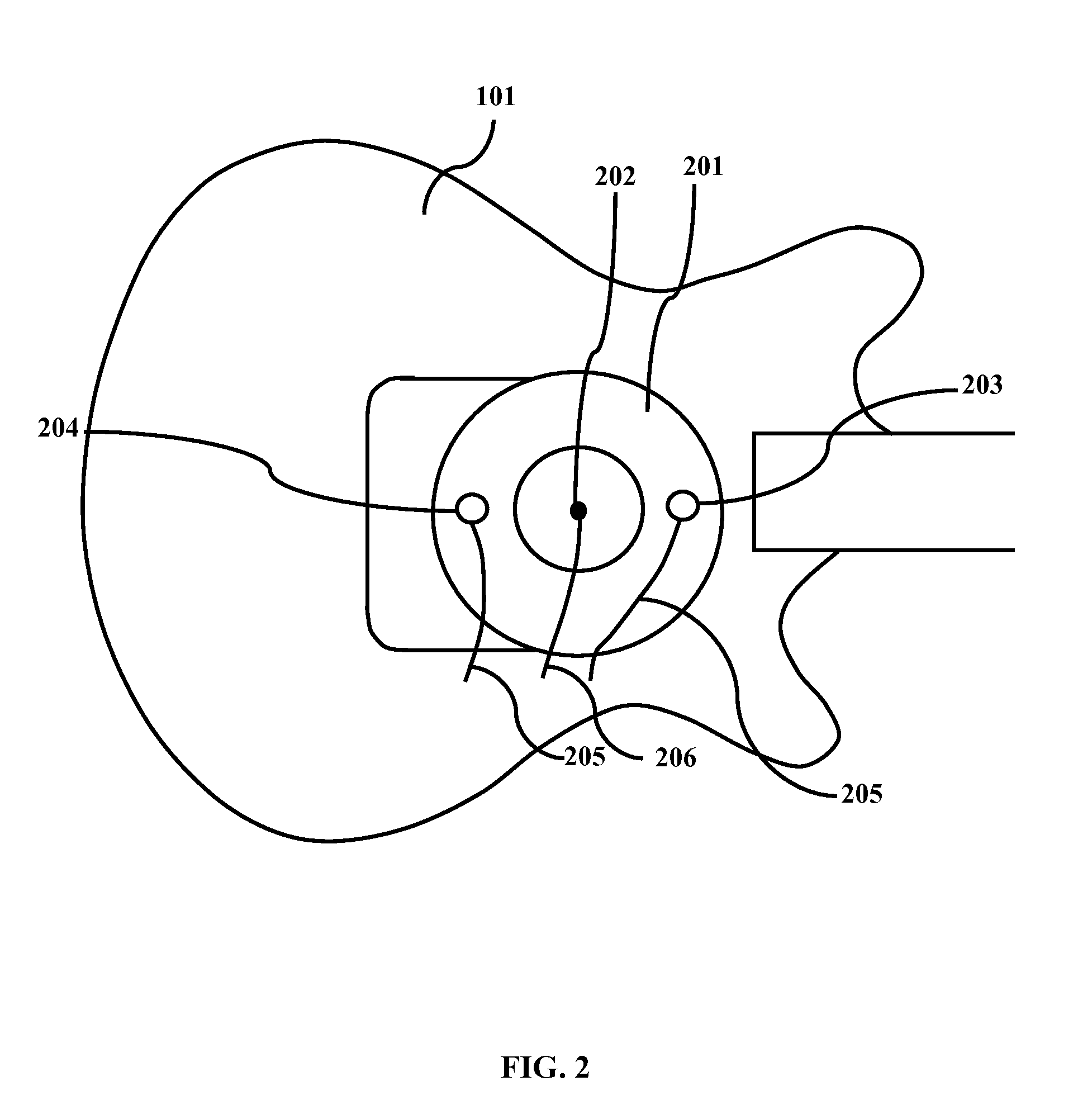

System and method for switching sound pickups in an electric guitar using a spin wheel arrangement

InactiveUS20150294659A1Well formedElectrophonic musical instrumentsGuitarsBridging positionElectricity

The embodiments herein provide a system and method for instantly switching sound pickups in an electric guitar using a spin wheel arrangement in the middle of a song. The spin wheel houses a pickup assembly with multiple pickups. The spin wheel allows a guitar player to easily roll neck pickup to bridge position and bridge pickup to neck position in middle of a song by rotating the spin wheel. A click stop arrangement halts wheel rotation after completing a semi-circular rotation around a center screw. The backend portion of pickups is connected to spring loaded plunger. The contact pads at bottom portion of guitar body establishes electrical connections between pickups and control components. The pickups under the strings get activated. The spin wheel arrangement allows a guitar player to add favorite pickups for generating various tonalities beyond the limit of a single guitar.

Owner:CHAPMAN JOSEPH

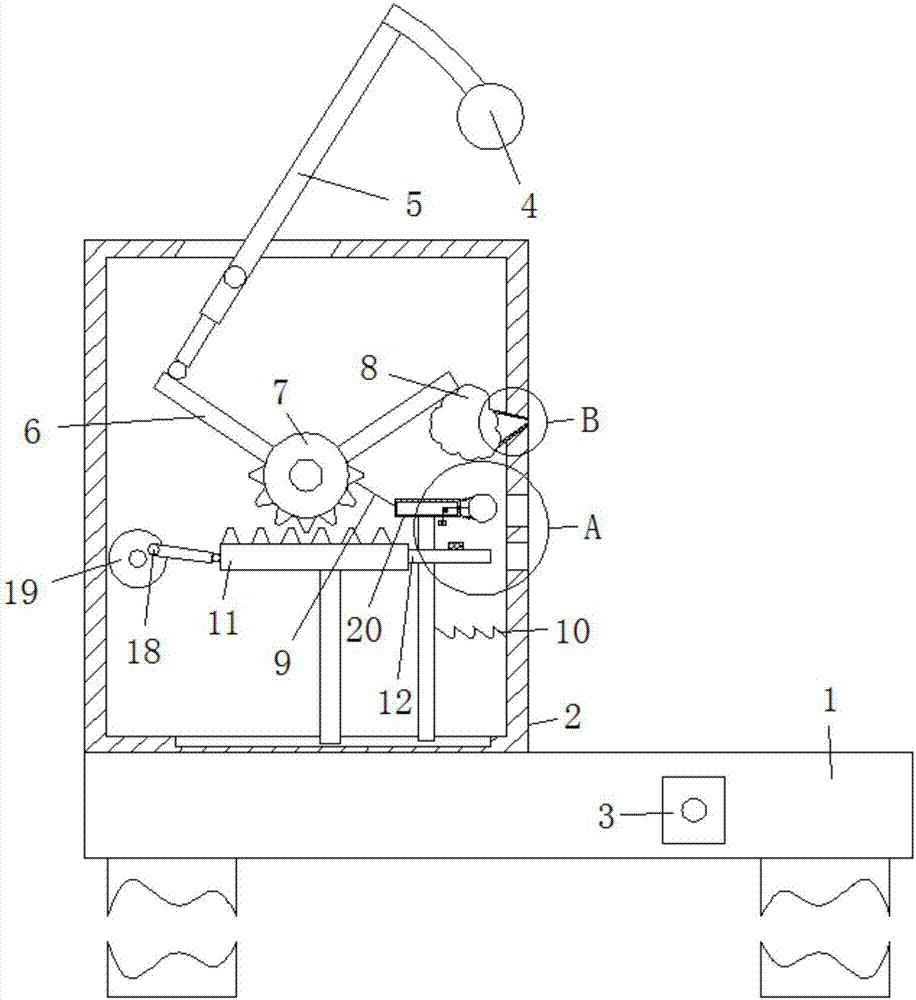

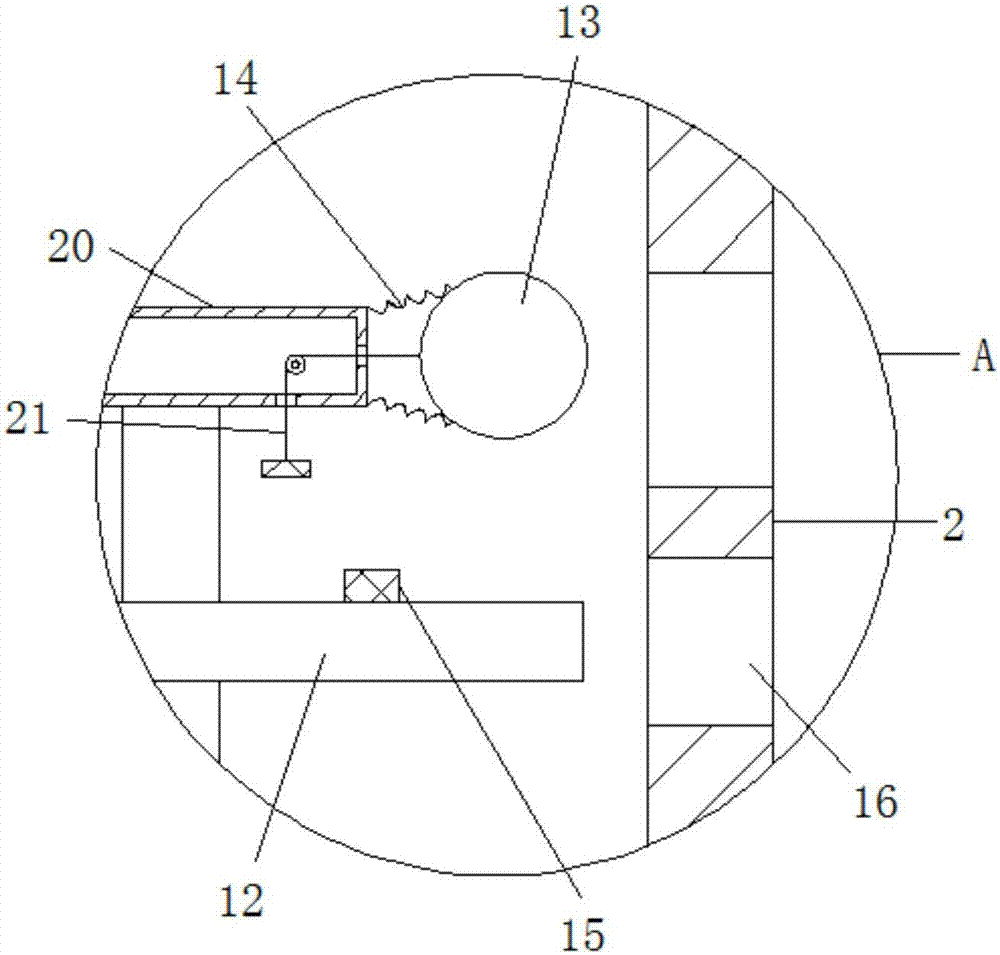

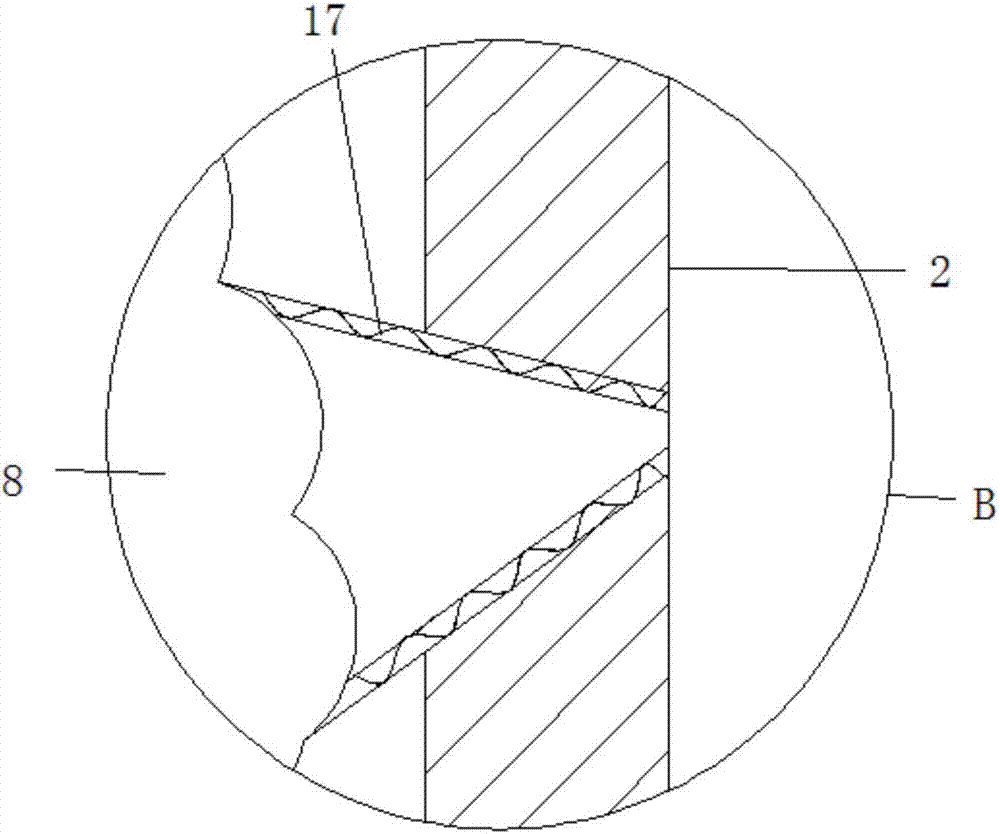

Multifunctional chair

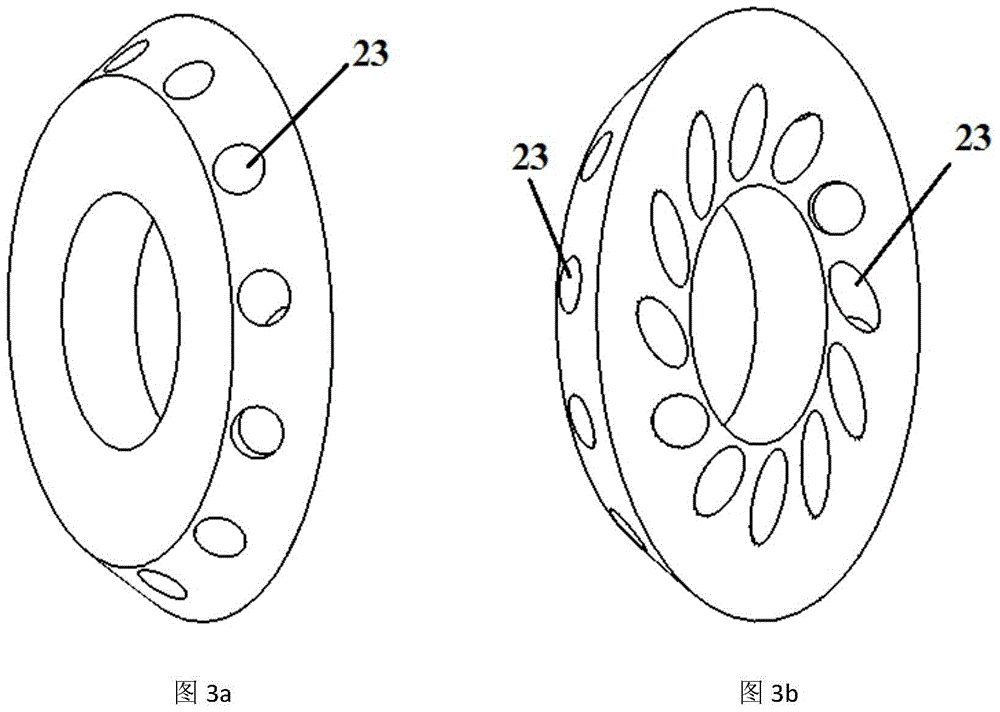

InactiveCN107969840ASimple structurePoor airflowVibration massageRoller massageCircular discGear wheel

The invention discloses a multifunctional chair, which comprises a chair seat, wherein a push button switch is connected onto the front side wall of the chair seat. The multifunctional chair has the advantages that the structure is simple; a circular disc is driven to rotate by a motor; a rack does horizontal movement to and fro through a steel wire rope; a massage rod performs knocking massage onthe back of people through a first through hole; meanwhile, the rack is engaged with a round flaw gear, so that a first rotating rod and a second rotating rod swing to and fro; the telescopic rod isdriven to rotate through the first rotating rod; the knocking massage is performed on the neck position of people through a knocking ball; in addition, the round flaw gear and a turntable are coaxially arranged; when the rack rightwards moves, the turntable anticlockwise rotate to wind a first pull rope; the massage ball leftwards moves; otherwise, the rack leftwards moves, the massage ball rightwards moves, so that a first magnet and a second magnet intermittently attract each other; under the effect of a second spring, the massage ball performs massage in a vibration shape through the secondthrough hole; the massage efficiency is improved.

Owner:郭姗姗

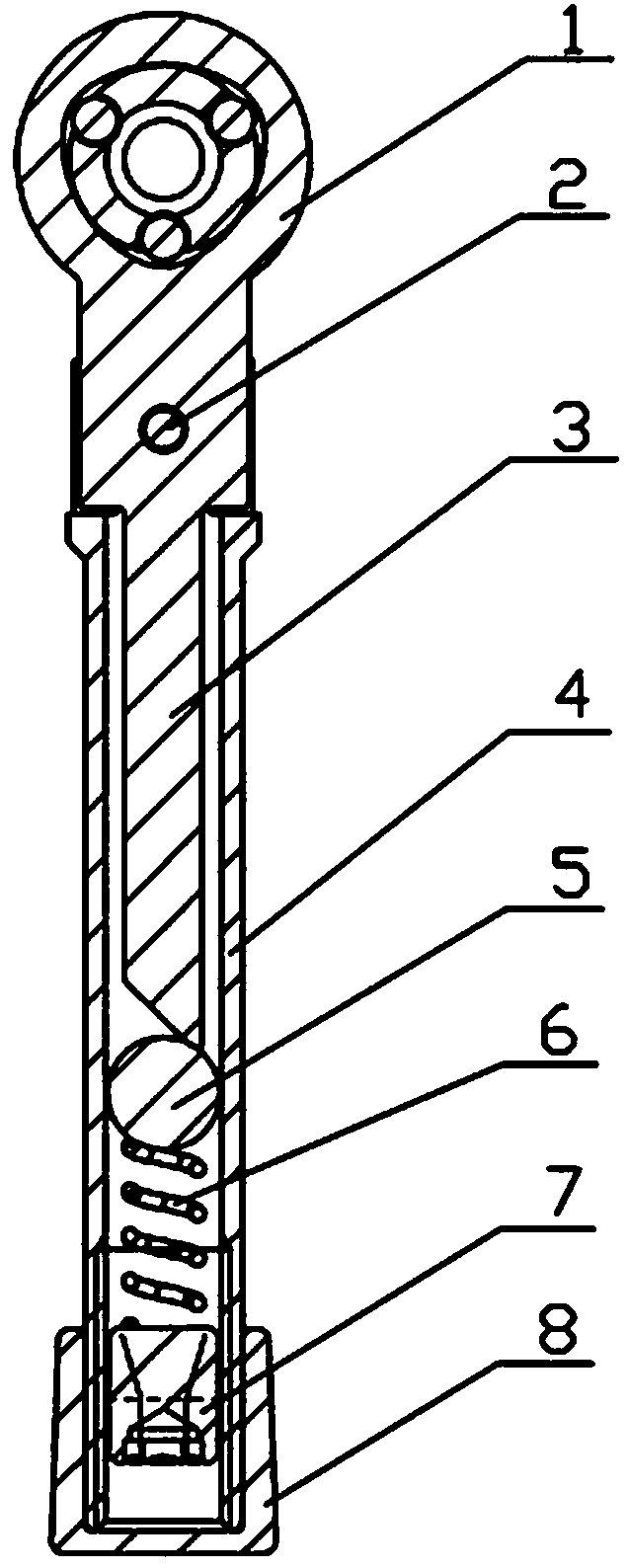

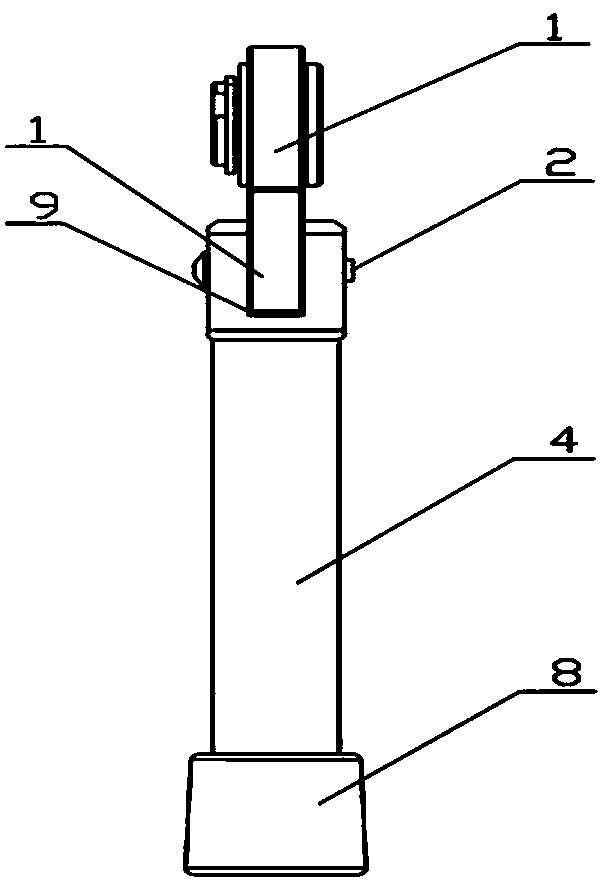

Detection tool for steering knuckle

InactiveCN104634208AAchieve positioningEasy to operateMechanical diameter measurementsEngineeringNeck position

The invention provides a detection tool for a steering knuckle. The detection tool is simple to operate and quick in detection, and improves the detection efficiency. The detection tool comprises a base, and is characterized in that a positioning device and a hole position detecting device are arranged on the base; the positioning device comprises a support shaft neck positioning device and a lower lug pin hole positioning device; the support shaft neck positioning device comprises a reference seat, a positioning sleeve I and a quick clamp; the reference seat is fixed on the base; the positioning sleeve I is inserted onto and fixed on the reference seat; the positioning sleeve I is provided with a positioning hole I corresponding to a support shaft neck; the lower lug pin hole positioning device comprises a positioning pin; the hole position detecting device comprises a detecting seat and a detecting pin; and the detecting seat is fixed on the base and is provided with a detecting hole which is in sliding matching connection with the detecting pin.

Owner:MT PRECISION MACHINERY MFG

Torque spanner

Disclosed is a torque spanner. The torque spanner comprises a spanner end, a spanner bar and a stress application loop bar. The stress application loop bar refers to a hollowed shell, and a connectinggroove is formed in the upper end of the stress application loop bar. The spanner end and the spanner bar are of an integrated structure. A boss is arranged at the necking position of the lower end of the spanner end. A connecting groove of the spanner bar abuts against the boss surface of the spanner end. The spanner bar and the stress application loop bar are movably connected together througha rotating shaft. A steel ball and a spring are further arranged inside the stress application loop bar. A diagonal plane is arranged at the lower end of the spanner bar and further abuts against theouter surface of the steel ball. The lower end of the steel ball is connected with the spring, and the lower end of the spring is connected with an adjusting jackscrew. The adjusting jackscrew is in threaded connection with the inner wall of the lower end of the stress application loop bar. The torque spanner is simple in structure, a nut can stretch into a bayonet inside the spanner end in the using process, the stress application loop bar is twisted, the steel ball can touch the inner wall of the stress application loop bar and a clear alarm can be raised when a set torque value is reached,vibrations can be felt on the stress application loop bar, and locking can be stopped at the moment. Operation is convenient, time and labor are saved and the torque can be adjusted.

Owner:山东乐乐机械有限公司

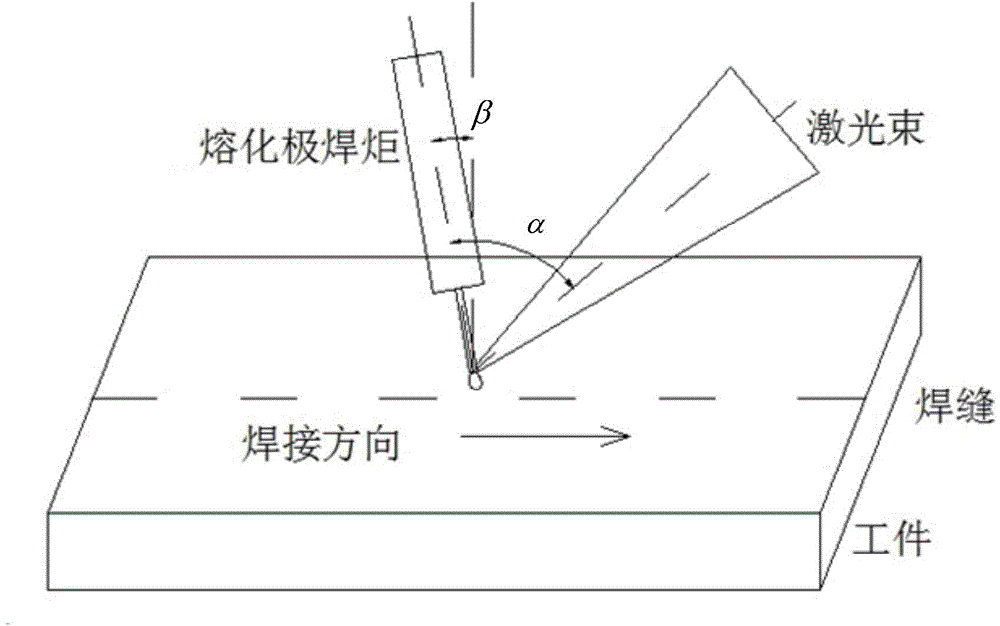

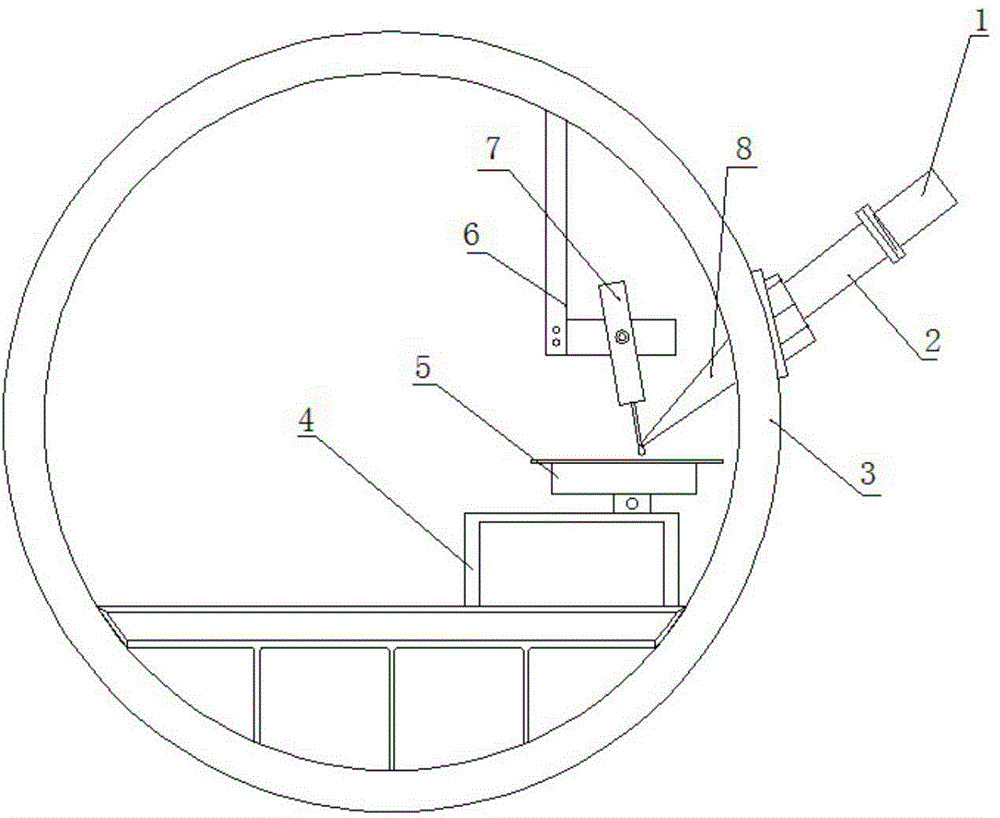

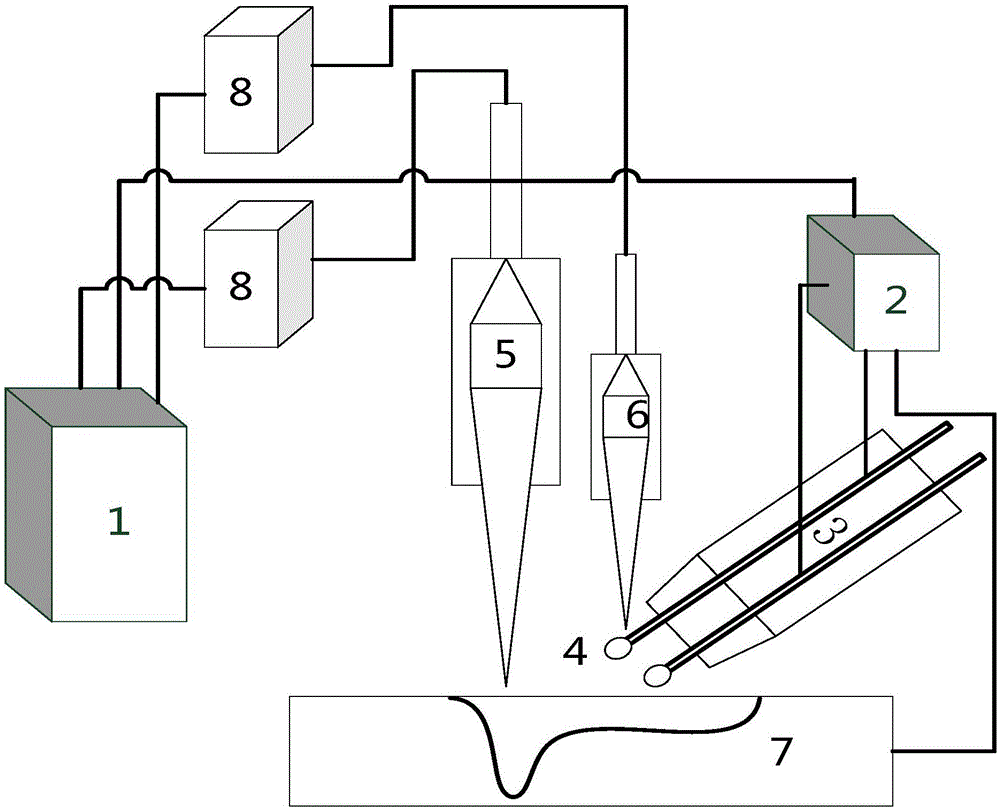

Laser-enhanced underwater GMAW droplet transfer control method

ActiveCN104551391AArc stabilizationImprove stabilityLaser beam welding apparatusMarine engineeringWeld seam

The invention discloses a laser-enhanced underwater GMAW droplet transfer control method. The method comprises the steps: placing a fusion electrode welding torch inside an underwater welding device, and placing a laser outside or inside the underwater welding device; leading a laser beam emitted by the laser into a GMAW welding droplet transfer necking position inside the underwater welding device, ensuring the laser beam and the fusion electrode welding torch to form an angle and to be arranged on the same straight line along the welding direction. By adopting the method, the orientated jet transfer state with stable arc and uniform droplet under the low welding current condition can be realized, the underwater welding droplet transfer time can be precisely controlled, the fusion penetration of a weld seam and the appearance shape of a weld pool can be controlled by freely selecting current under a wider condition, and the good weld seam formation can be realized on the premise of not obviously increasing the additional heat input.

Owner:北京三帝科技股份有限公司

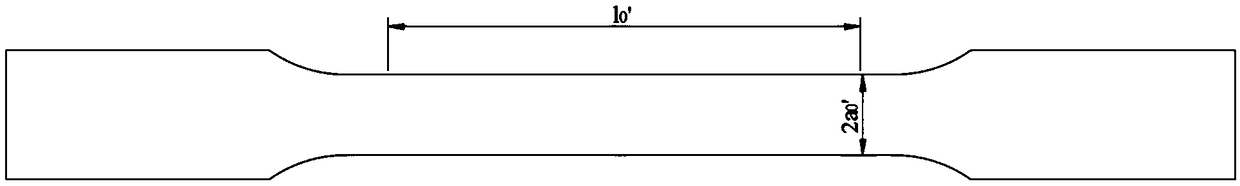

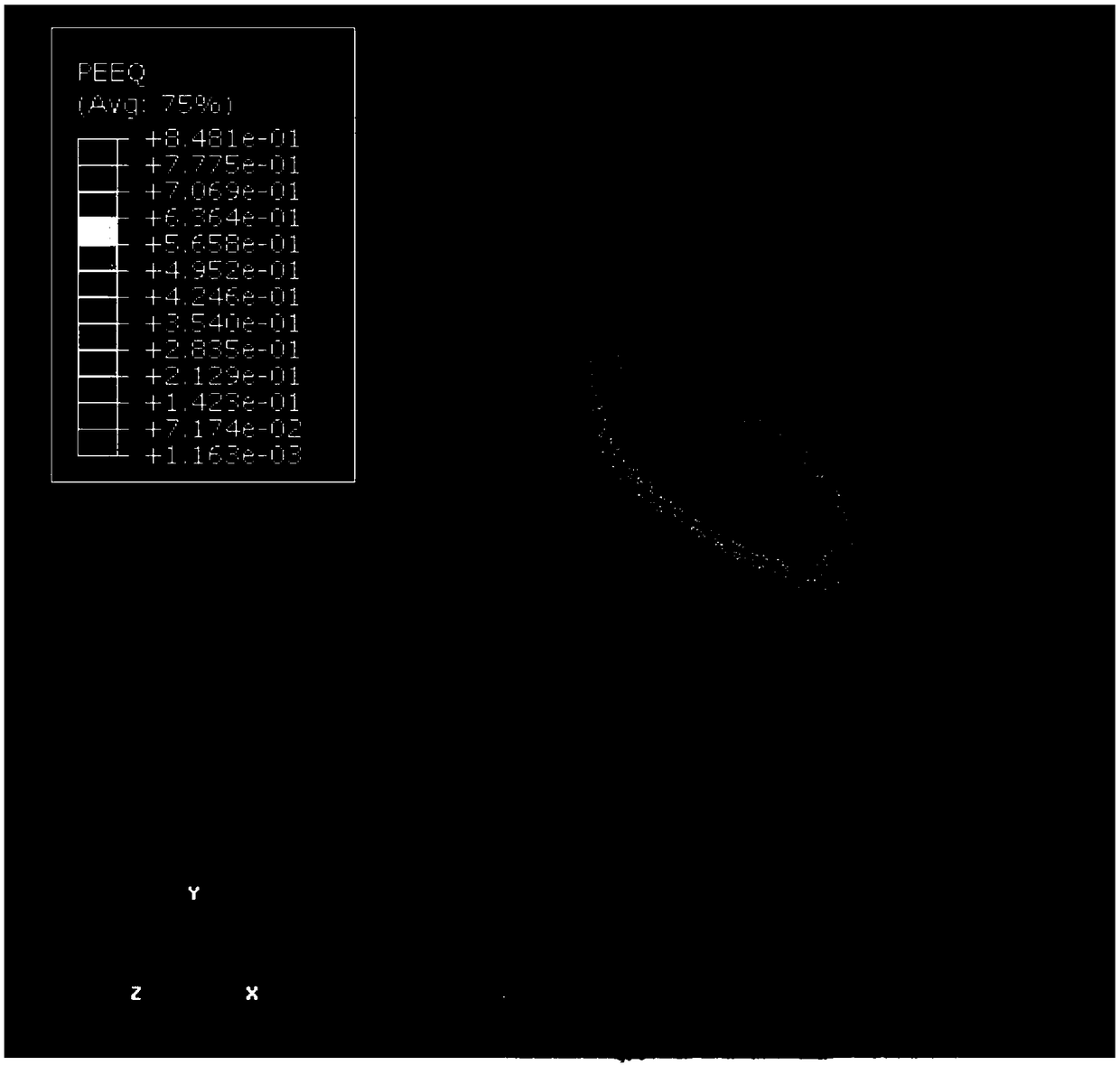

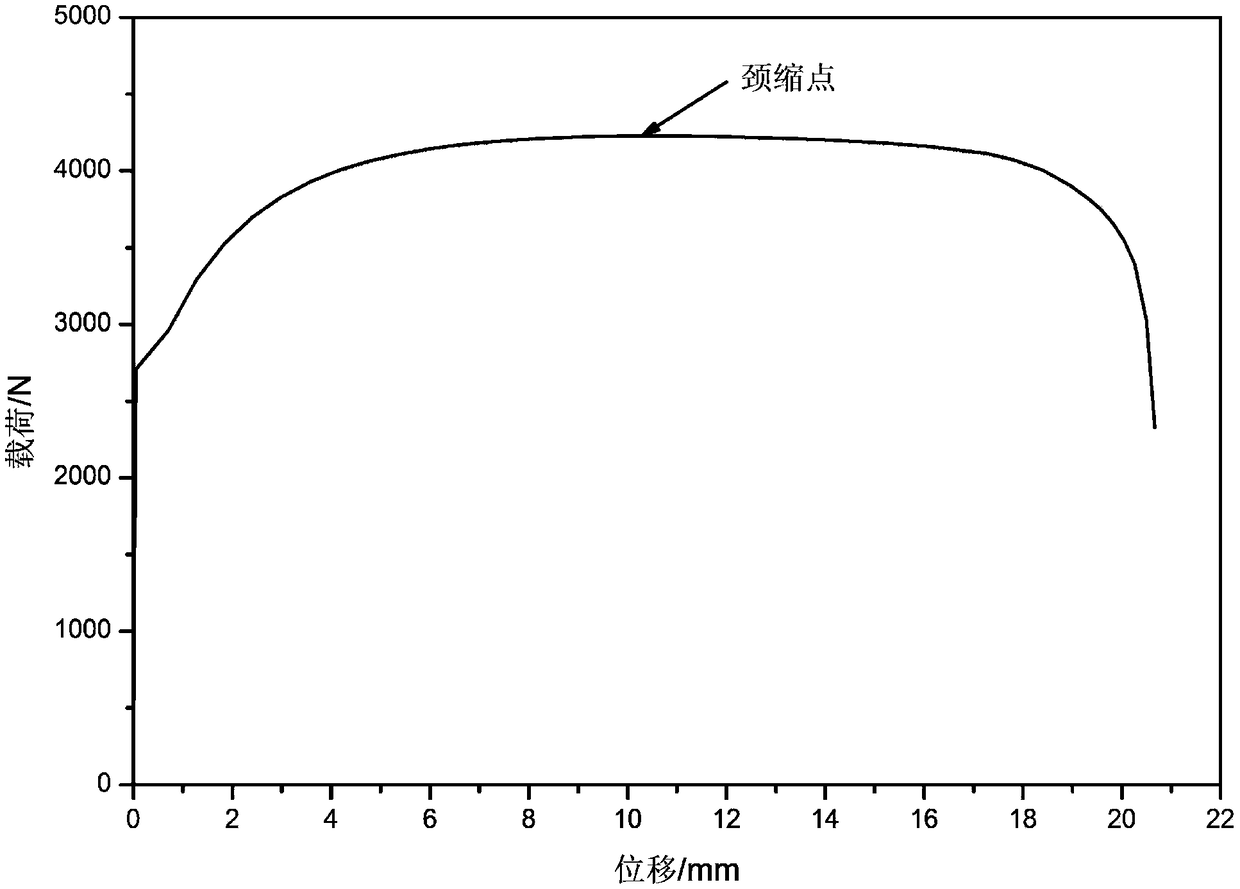

Method for measuring large-stress range stress strain in uniaxial tensile test of metal plate sample

InactiveCN108982222AEliminate cumbersome measurement linksSave time and costMaterial strength using tensile/compressive forcesBridgman methodStress–strain curve

The invention relates to a method for measuring the large-stress range stress strain in a uniaxial tensile test of a metal plate sample. The method comprises the following steps: building a step modelfor gradual expansion of unstable necking of uniaxial tension of the metal plate sample; measuring the instant gauge length and the minimum sectional width at a necking position of the plate sample after extension instability; building an interpolation curve expression of the necking profile on the basis of necking step coordinates of the necking step model at each moment; solving the parametersof the necking step model according to the mechanical relationship of necking in the width direction and the thickness direction and the principle of volume conservation; finally calculating the actual stress and actual strain at the moment through a Bridgman method. By adopting the method, the test measuring link for the necking outer profile curvature radius in the existing method is omitted, and the measuring accuracy of a large-strain range stress-strain curve is improved, so that the method has important significance to the mechanical performance test of metal materials.

Owner:JILIN UNIV

Double laser-double-wire bypass electric arc compound welding method

InactiveCN106624366ASpeed up meltingFacilitate droplet transferLaser beam welding apparatusNeck positionElectric arc

The invention discloses a double laser-double-wire bypass electric arc compound welding method. The double laser-double-wire bypass electric arc compound welding method includes that continuous laser beams act on parent metal, and pulse laser acts at a necking position of a welding wire molten drop solid-liquid interface at the upper end of a double-wire welding gun; a welding wire is heated by electric arcs to form molten drops, and the sizes of the molten drops increase gradually while a pulse laser beam emits a specific frequency of laser on the welding wire molten drops at the upper end to exert a specific frequency of laser evaporation recoil force on the molten drops; the laser evaporation recoil force 'cuts' the molten drops, and change of the pulse frequency makes the sizes, transition frequency, flying direction and track of the molten drops change to promote the molten drops to complete transition; the molten drops are isolated from the welding wire under bombardment of the laser evaporation recoil fore and are promoted to enter a molten pool by means of transition, so that deposition efficiency is improved; a computer control system achieves closed-loop control of fixed arc length by detecting change of electric arc voltage. The double laser-double-wire bypass electric arc compound welding method is capable of achieving high-efficiency high-quality great-fusion-depth low-spattering welding with narrow heat-affected zones at a high welding speed.

Owner:BEIJING UNIV OF TECH

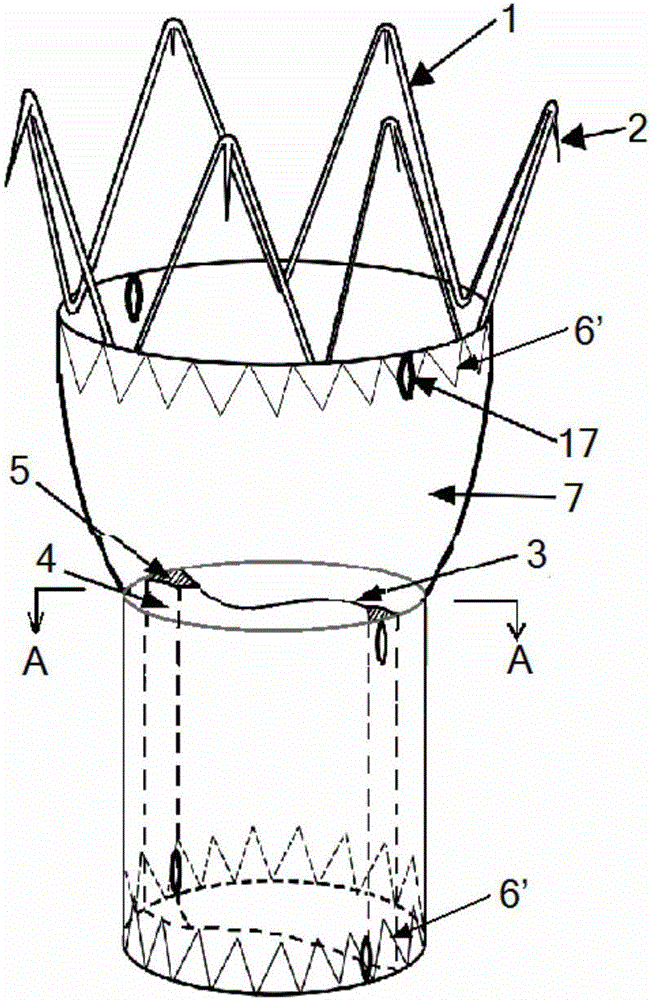

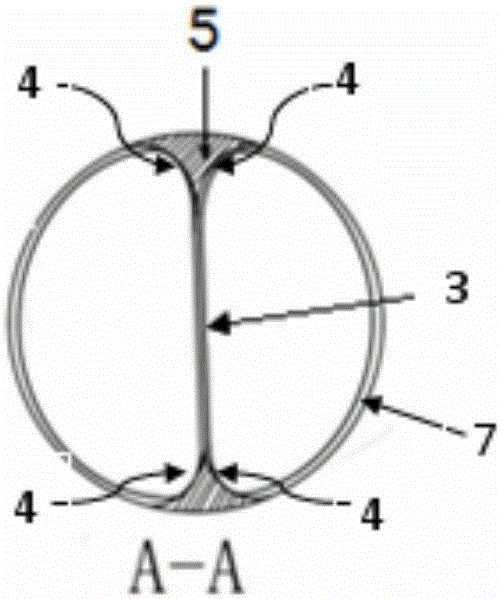

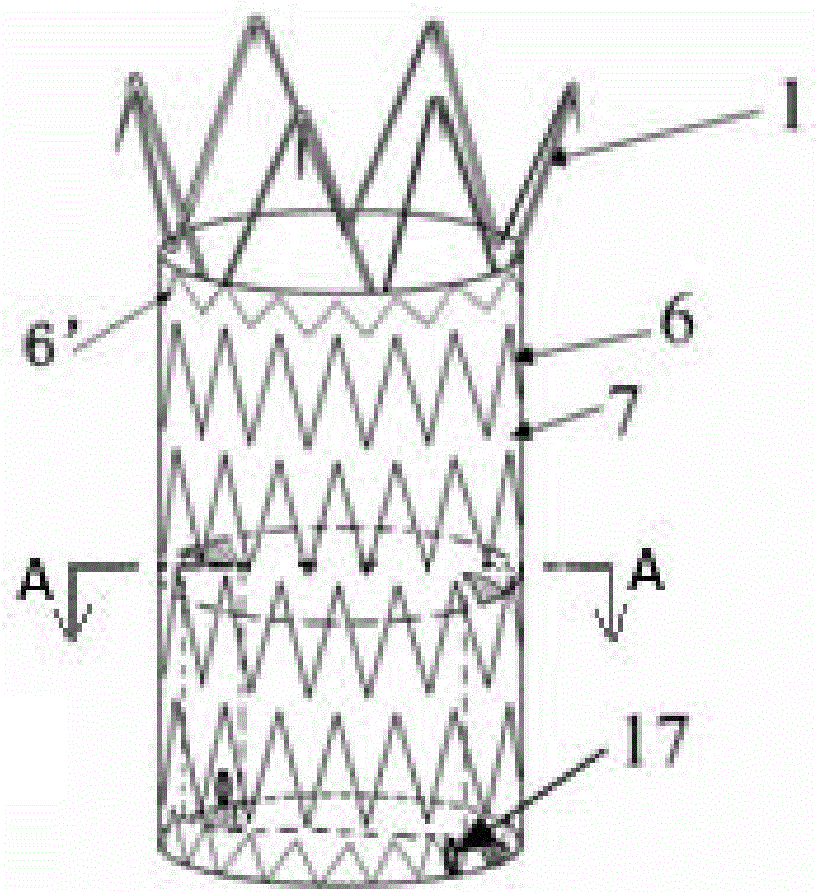

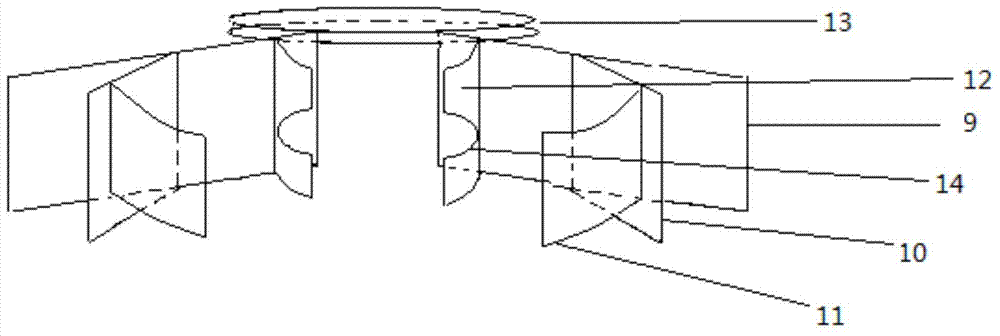

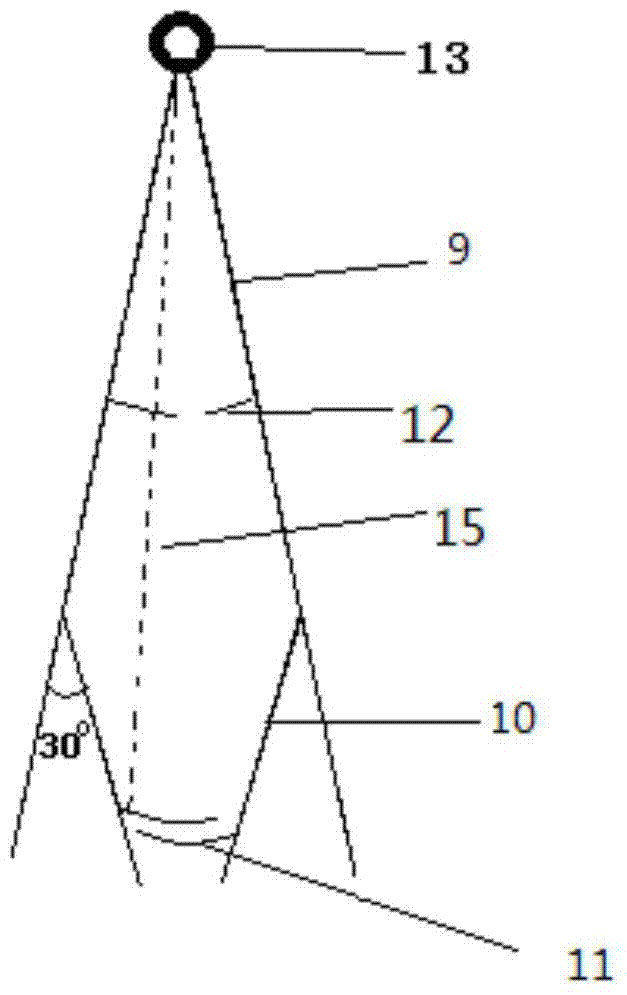

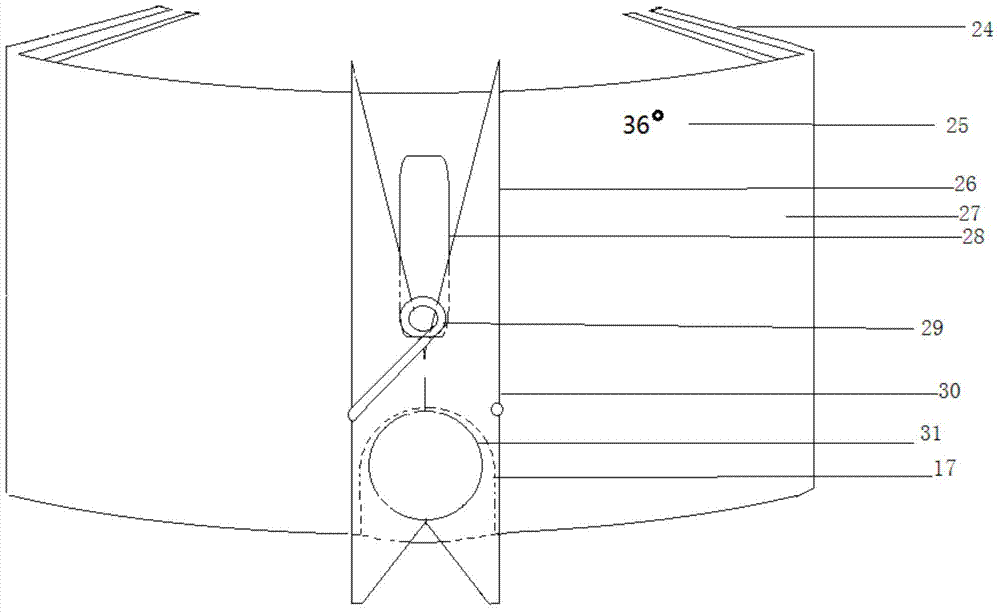

Combined abdominal aorta covered stent system and utilization method thereof

A combined abdominal aorta covered stent system and a utilization method thereof are applied to surgeries for endovascular interventional treatment of abdominal aortic aneurysm. The system comprises a body covered stent and a pair of branch covered stents, and each of the stent is cylindrical and provided with a delivery system. The near end of the body covered stent is a bare stent with barbs, a covered section comprises an upper half portion in a single-cavity cylinder shape and a lower half portion with a fixed outer diameter, and the lower half portion is averagely partitioned into two cavities by a longitudinal partition. Small-waveband stent rings are designed at near and far ends of the covered section of the body covered stent, and other covered parts can be either provided with stent rings or not. The upper half portion of the covered section is implanted at a neck position of infrarenal aortic aneurysm, and the lower half portion is suspended in an aneurysm cavity. The branch covered stents parallelly and internally sleeve the two cavities of the body covered stent, near ends of the branch covered stents are flush with the near end of the lower half portion of the body covered stent and fill the cavities of the body covered stent in a self-adoption manner, and far ends of the branch covered stents are implanted into iliac artery branches to better adapt to arterial aneurysms excessive in aneurysm neck torsion.

Owner:北京有卓正联医疗科技有限公司

Fixing device for mouse caudal intravenous injection

InactiveCN103610515AEasy to operateConvenient and reasonable division of laborAnimal fetteringEngineeringNeck position

The invention discloses a fixing device for mouse caudal intravenous injection. The fixing device comprises two baffle assemblies arranged symmetrically, a rotatable base plate, a fixing clamp and a rotatable base plate driving shaft. The two baffle assemblies are arranged on the rotatable base plate, each baffle assembly comprises a side wall plate, a rear side baffle, a head fixing plate and a tail fixing plate, one end of each rear side baffle is fixedly connected with one side wall plate, the other end of the rear side baffle is fixedly connected with one tail fixing plate, and a neck positioning groove is formed in each head fixing plate. The neck positioning grooves in the head fixing plates in the two the baffle assemblies are matched to clamp the neck of a mouse and limit the head of the mouse, the tail fixing plates in the two baffle assemblies are matched to limit the tail of the mouse, and a channel for the tail of the mouse to penetrate through is formed in the lower portion of each tail fixing plate. The fixing clamp comprises a fixing clamp baffle, a mouse tail clamp and a fixing clamp clamping groove, and the fixing clamp clamping groove is respectively connected with the rear side baffles in the two baffle assemblies in an inserted mode. The fixing device for mouse caudal intravenous injection is convenient to operate and used for mouse caudal intravenous injection in batch, and can improve efficiency.

Owner:TIANJIN UNIV OF COMMERCE

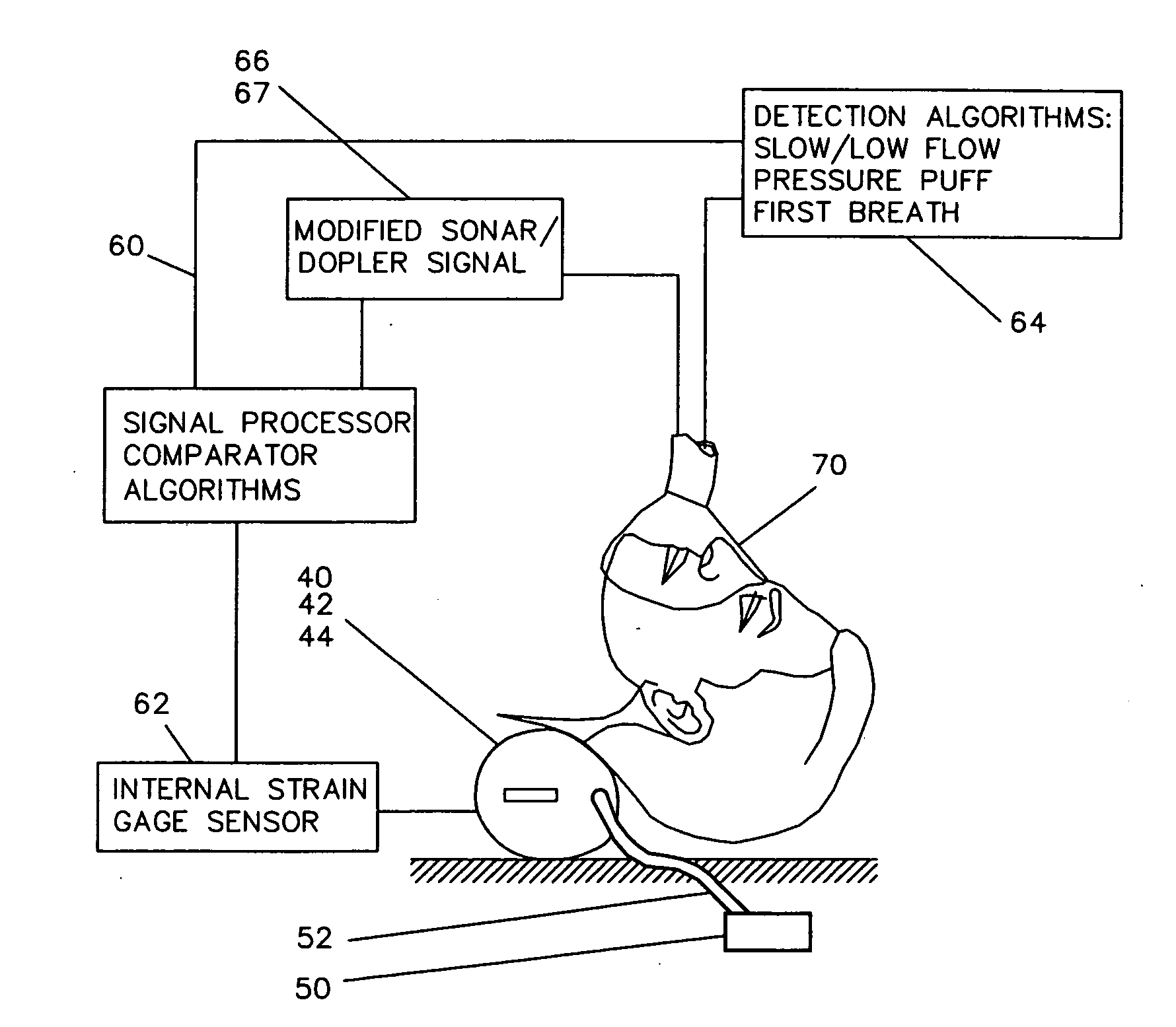

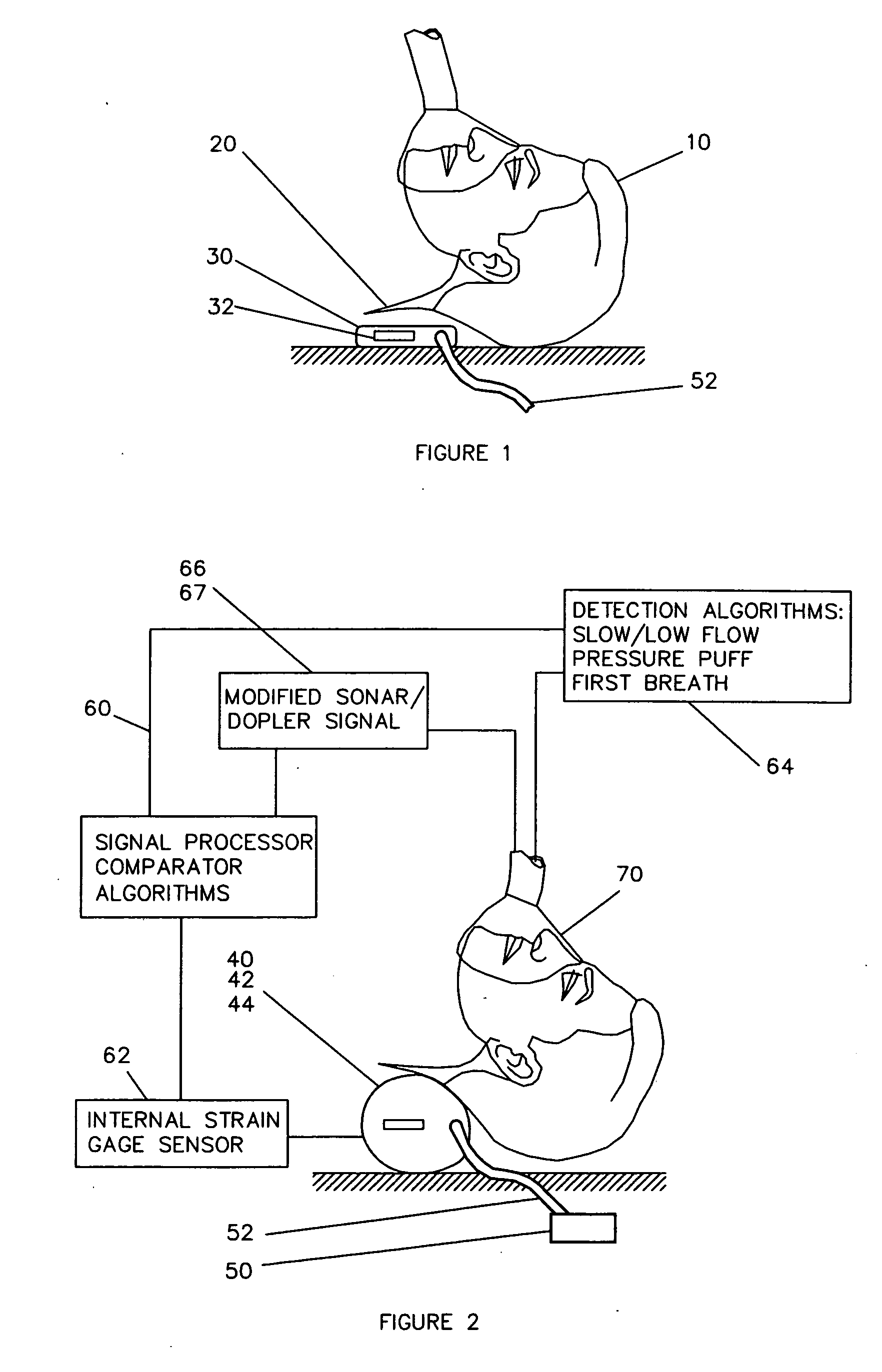

Neck positioning device for mechanical ventilator

InactiveUS20060249152A1Operating means/releasing devices for valvesRespiratory device testingMechanical ventilatorsCervical pillows

An airway opening system has an autoinflating hyperextension cervical pillow. The pillow is placed under the next of the non-breathing victim, and is inflated in a manner that opens the airway. In preferred embodiments, the pillow is automatically inflated using air pressure from a ventilator.

Owner:CPAIR

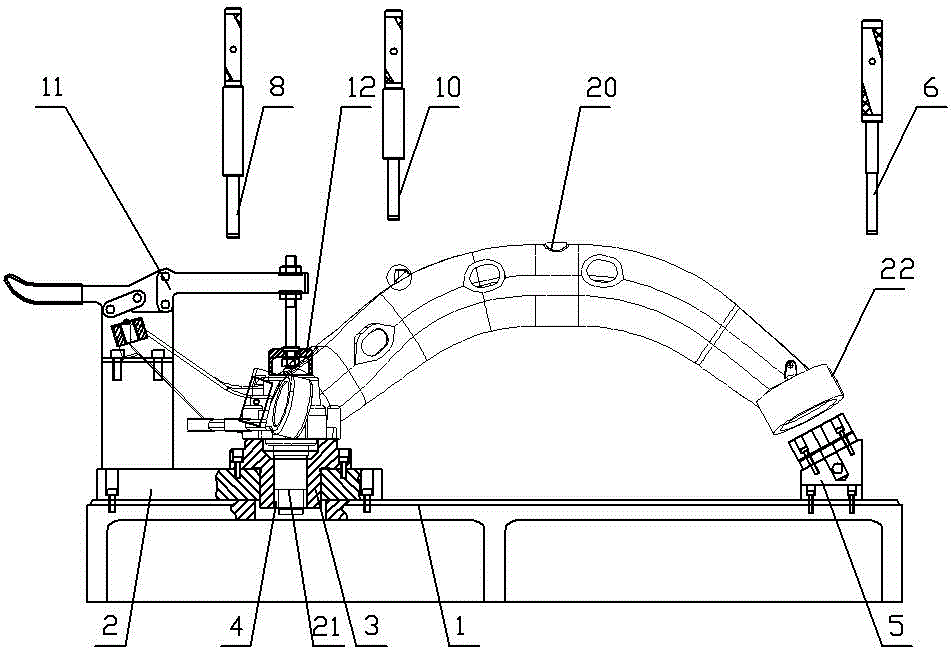

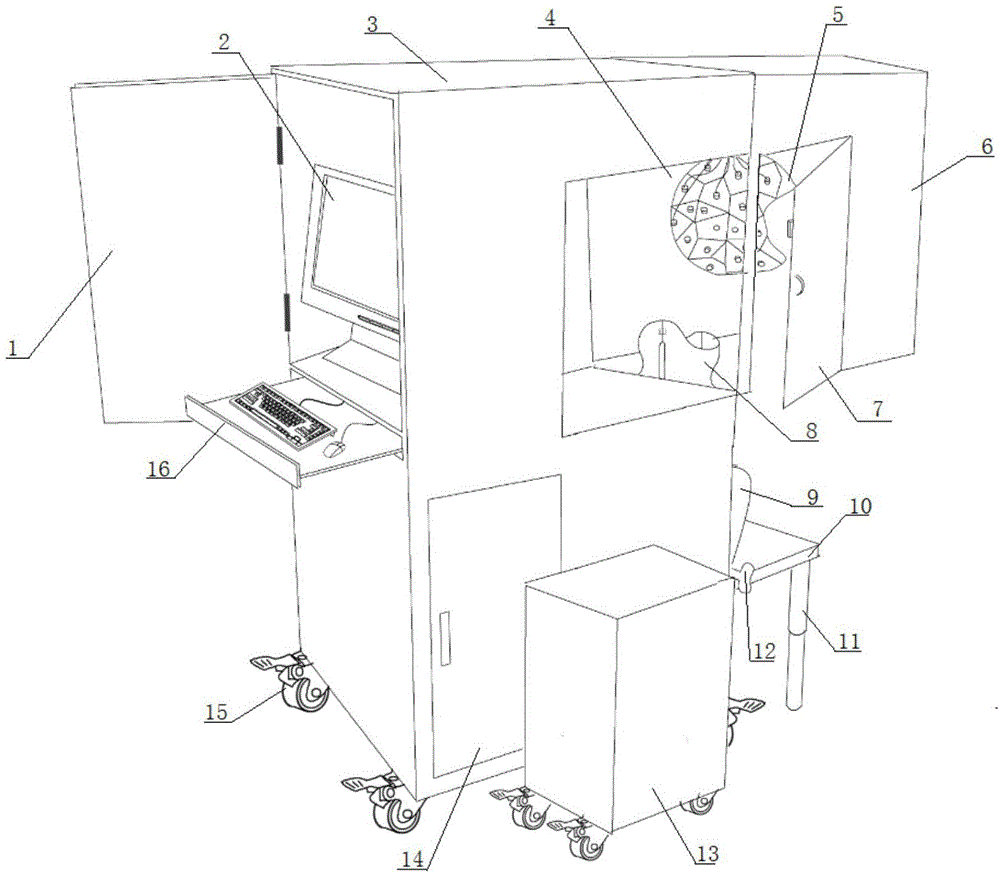

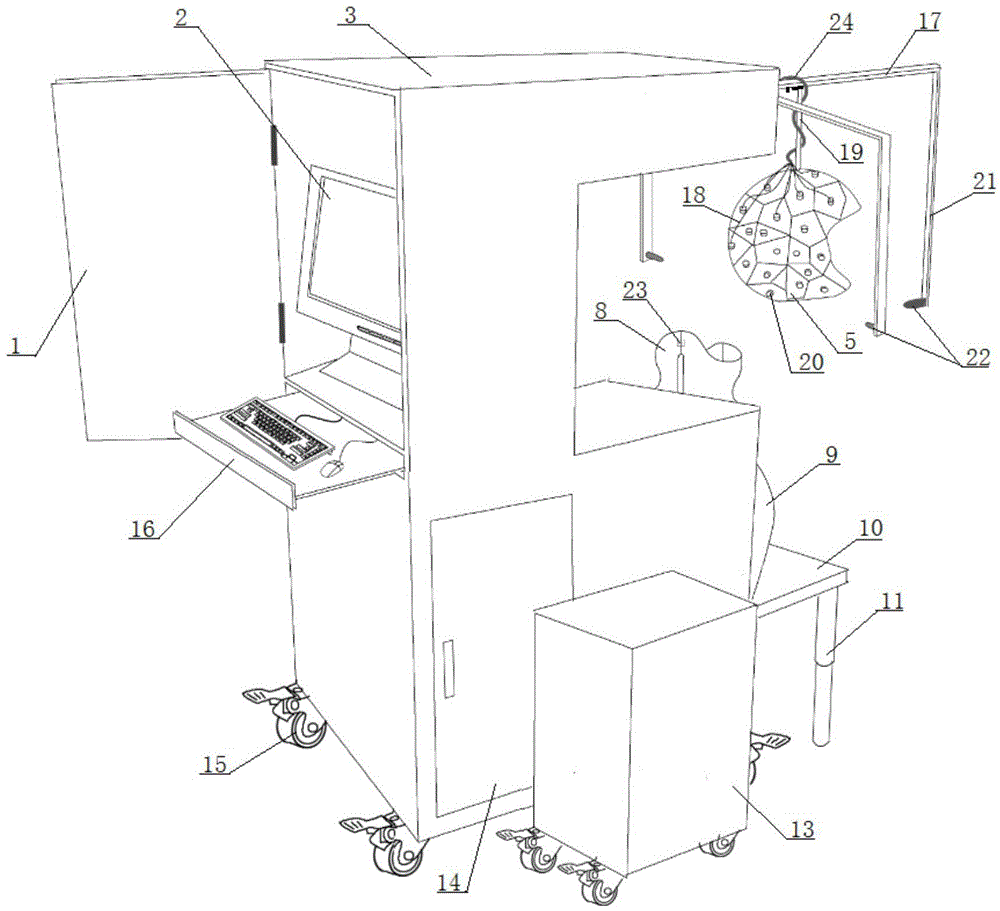

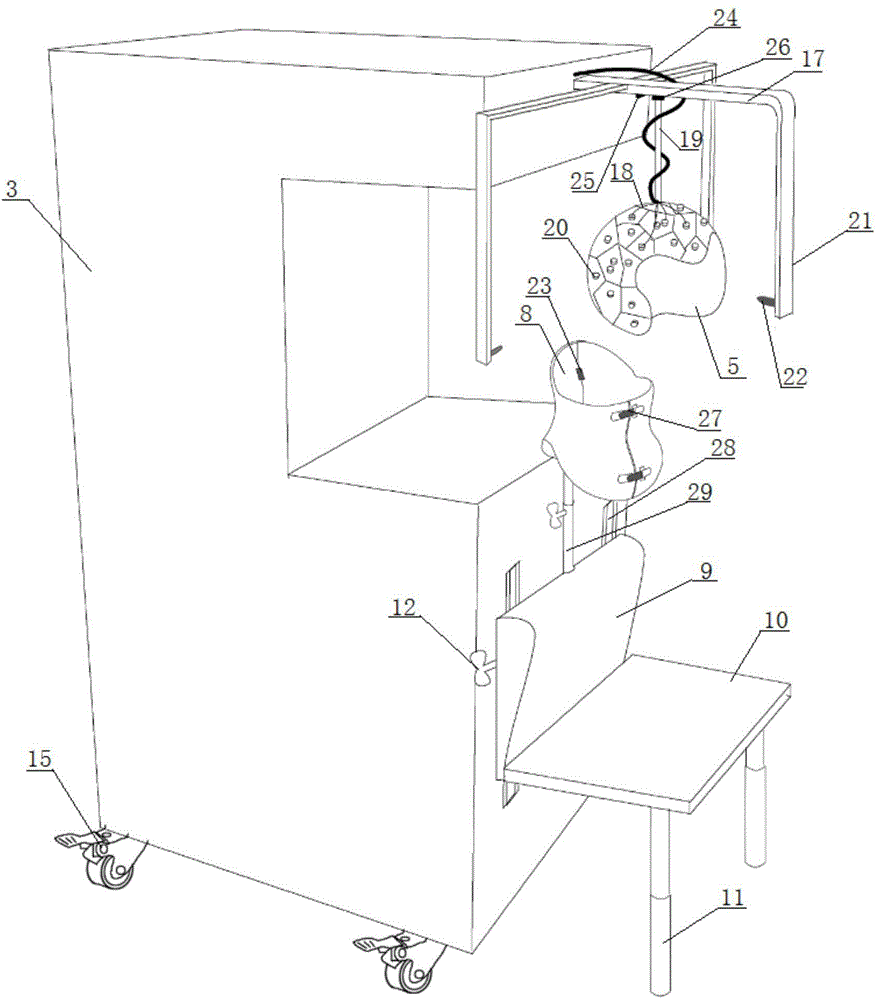

Multi-point multi-frequency three-dimensional transcranial magnetic stimulation system and intracranial and extracranial coordinate conversion method

ActiveCN104474636AGood effectAdjustable frequencyElectrotherapyDiagnostic recording/measuringAnatomyNeck position

The invention discloses a multi-point multi-frequency three-dimensional transcranial magnetic stimulation system and an intracranial and extracranial coordinate conversion method. The system comprises a fixing device, a stimulation device and an auxiliary positioning device, wherein the fixing device fixes the neck position of a patient, the stimulation device carries out fixed point magnetic stimulation on the patient, and the auxiliary positioning device is used for determining a positioning point in an auxiliary way for realizing the intracranial and extracranial coordinate conversion. Meanwhile, the coordinate conversion method provided by the invention can conveniently and fast realize the intracranial and extracranial coordinate conversion, and is matched with the system, and an all-around automatic transcranial magnetic stimulation treatment scheme is provided. The device has the advantages that the structure is simple, the function is practical, an effective device is provided for transcranial magnetic stimulation treatment, and a novel study idea is provided.

Owner:苏州脑控脑科学技术有限公司

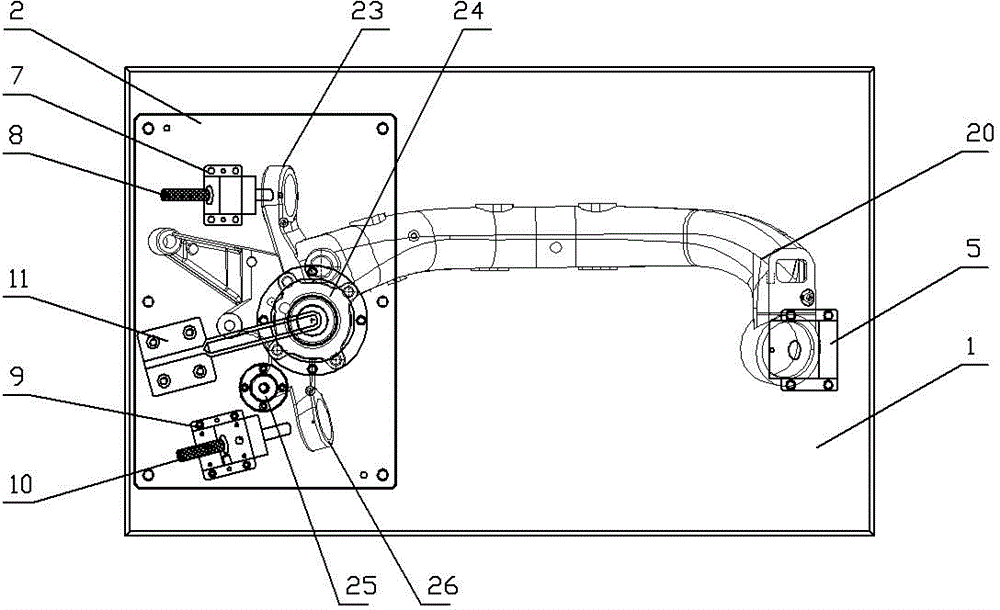

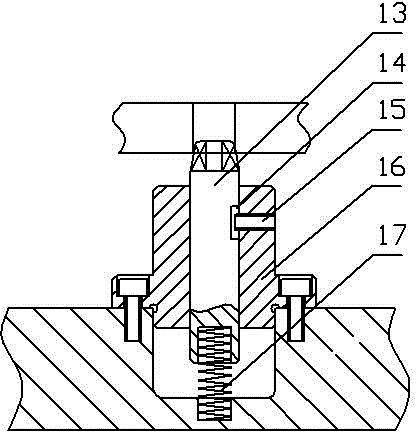

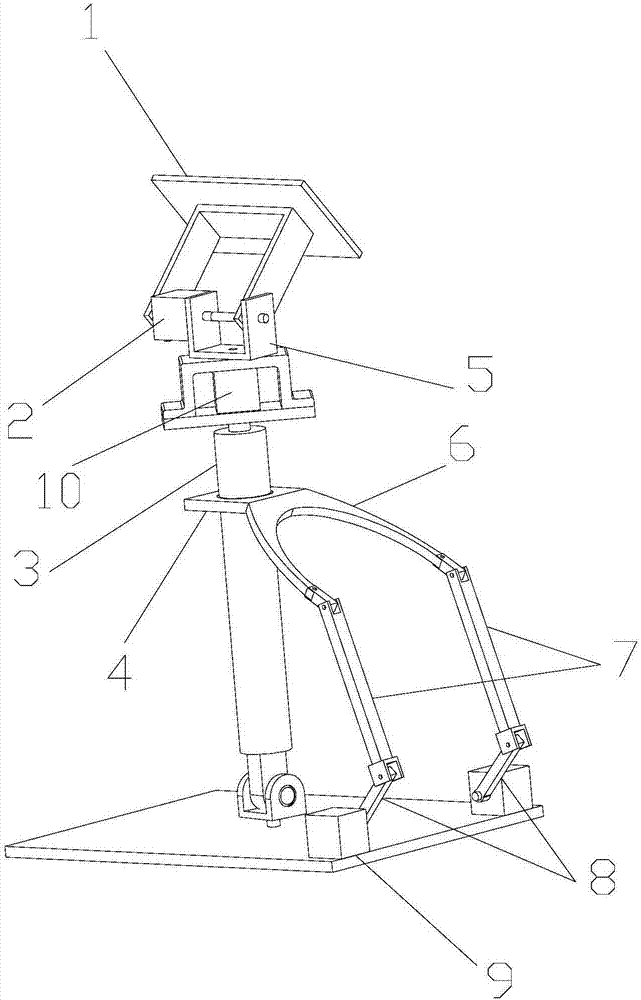

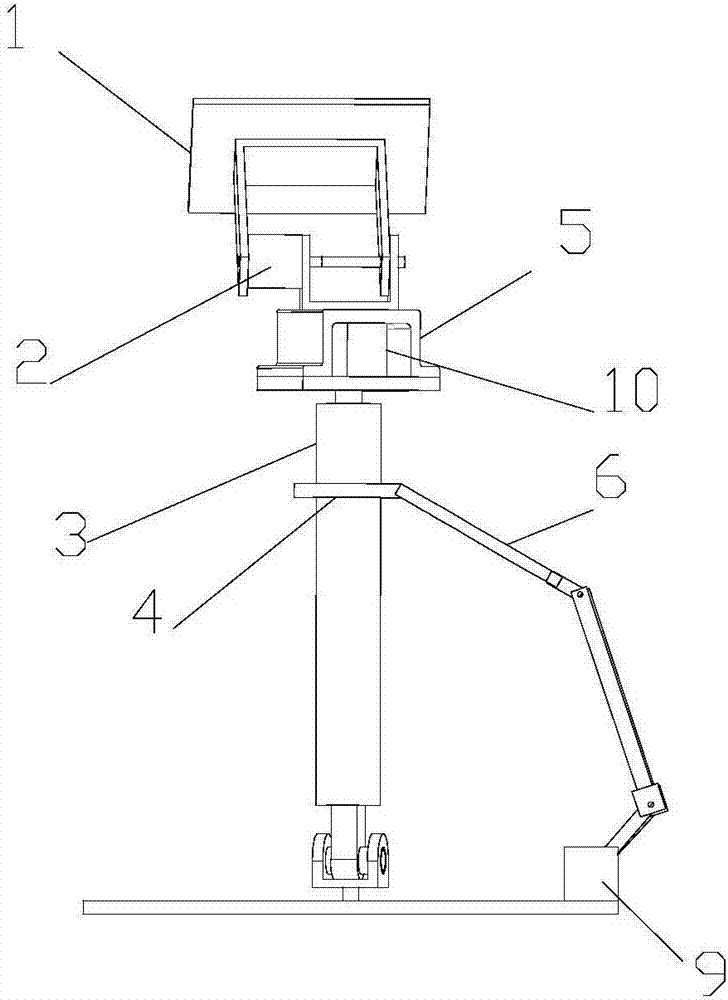

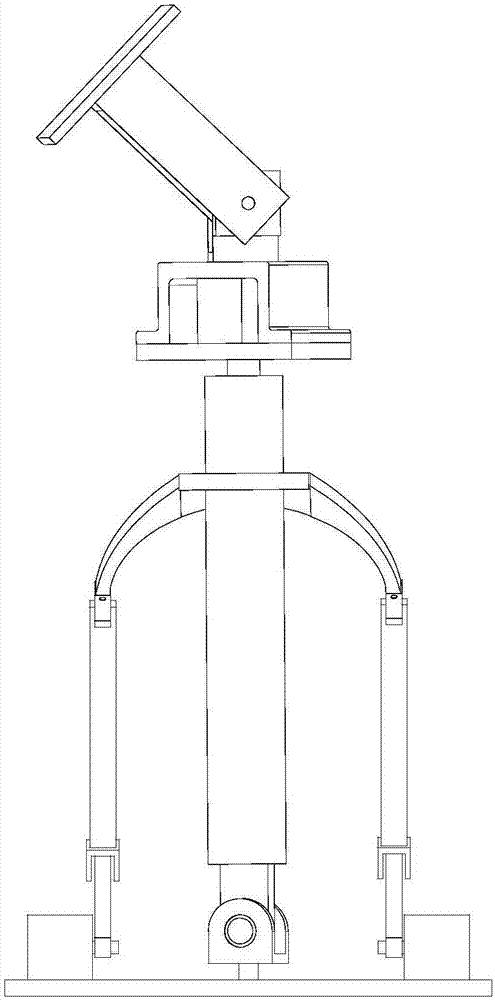

Multi-connecting-rod robot head and neck control mechanism

The invention discloses a multi-connecting-rod robot head and neck control mechanism. The mechanism comprises a base fixed with a body of a robot, a head support plate for fixing a head of the robot, a neck positioned between the head support plate and the base, and a neck control mechanism for controlling the neck to act; the lower end of the neck is hinged with the base through an universal hinge; and the neck control mechanism comprises at least two multi-connecting-rod mechanisms connected with the neck, and at least two motors I for correspondingly controlling the multi-connecting-rod mechanisms to act one to one. The mechanism is simple in structure, can flexibly and really simulate the head and neck actions of children, and enables the robot to be accepted by the aged more easily.

Owner:CHONGQING UNIV

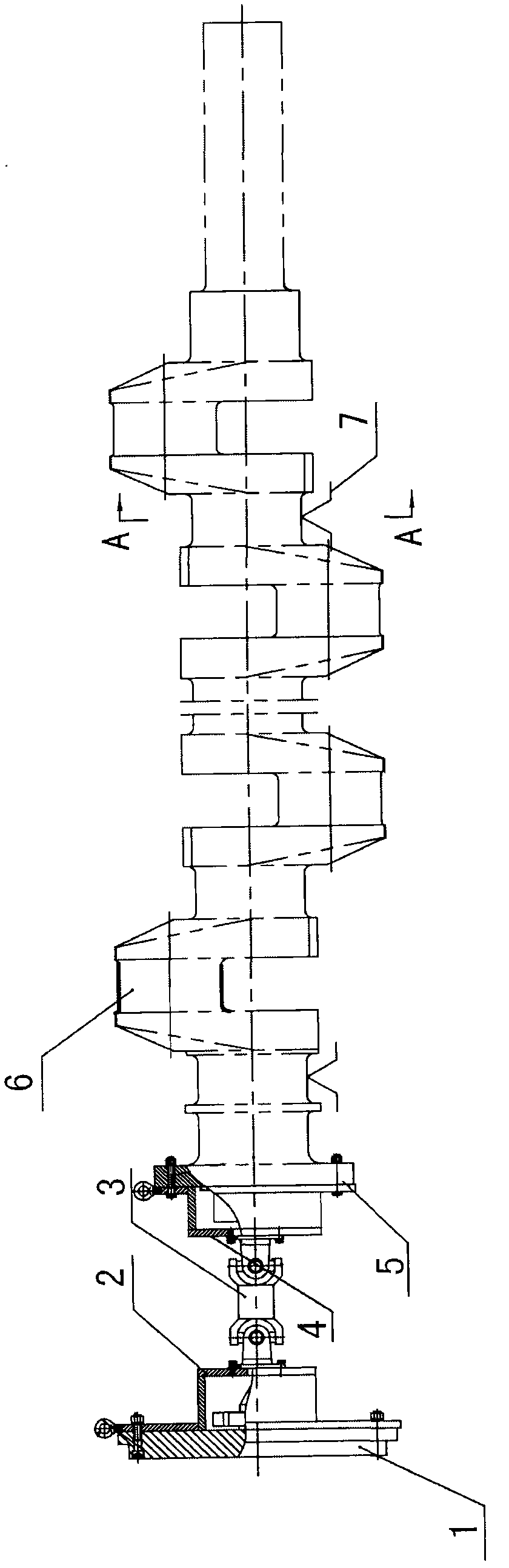

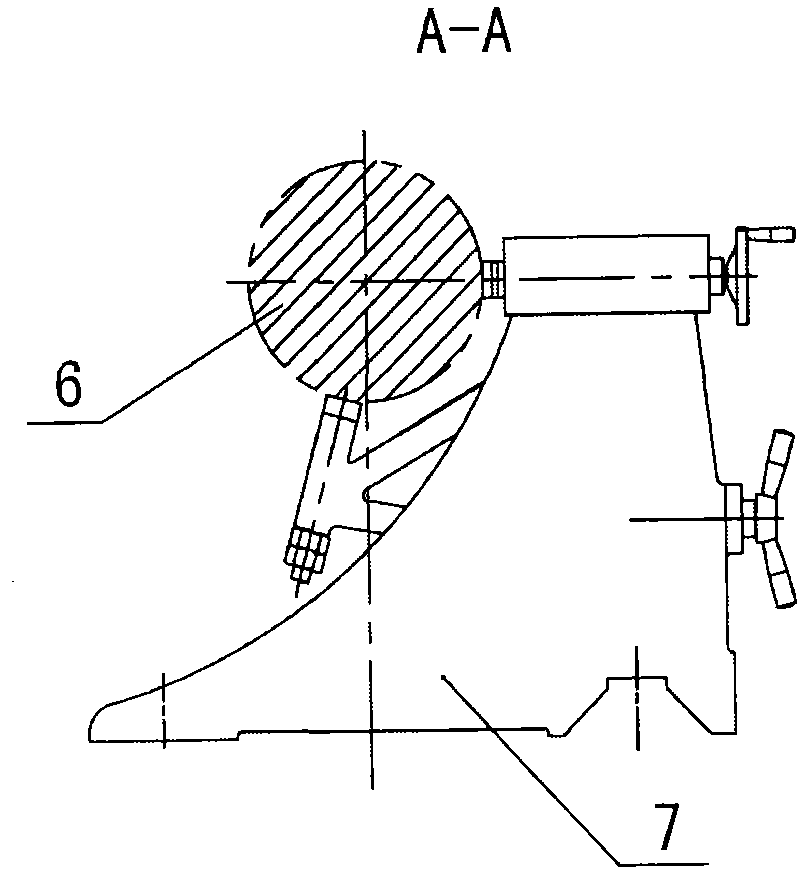

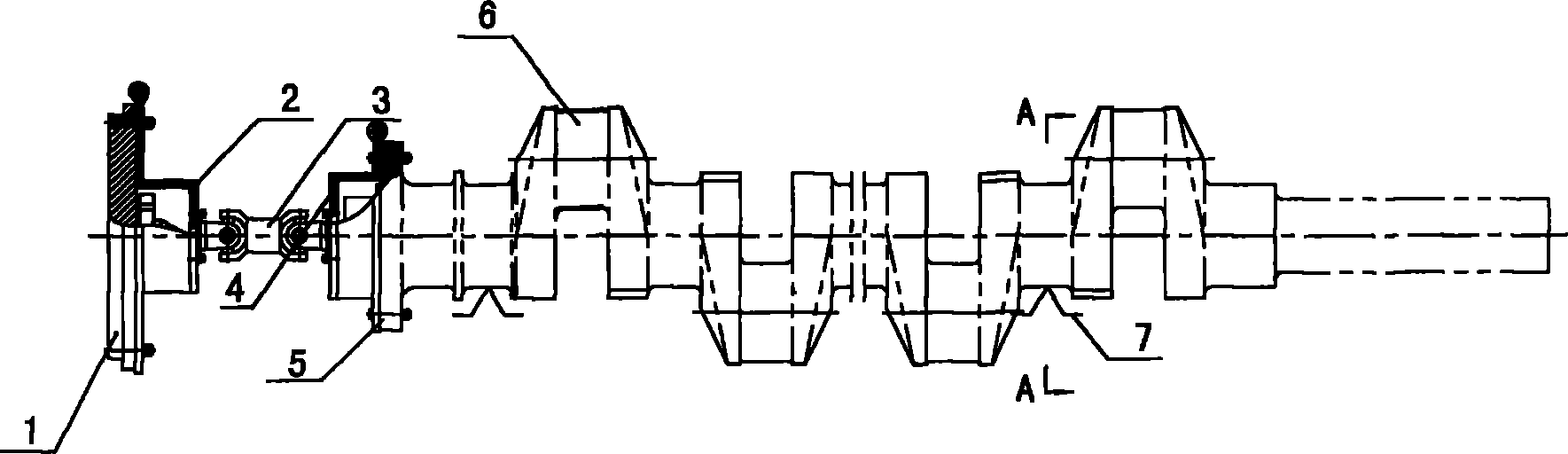

Method for finely grinding main shaft necks of crankshaft

InactiveCN102152180AEliminate Grinding Quality EffectsSimple and fast operationGrinding machine componentsRevolution surface grinding machinesNeck positionEngineering

The invention discloses a method for finely grinding main shaft necks of a crankshaft. The method comprises the following specific steps: putting the main shaft necks of the crankshaft on central frames of a grinding machine; connecting a main shaft box of the grinding machine with one end of a universal coupling, and connecting the other end of the universal coupling with one end of the crankshaft, wherein the free end of the crankshaft is not in contact with the top of a tail stock of the machine tool; aligning the axis of the crankshaft, and taking the axis of the crankshaft as the reference; and firstly grinding all the main shaft neck positions supported by all the central frames, and then grinding the other main shaft necks. By using the processing method, the influence of the accuracy error of the machine tool on the grinding quality can be effectively eliminated, the operation is simple and convenient, the reliability is high, and the coaxiality value of the crankshaft can be improved by one accuracy level as compared with the tolerance designed in a drawing.

Owner:青岛淄柴博洋柴油机股份有限公司

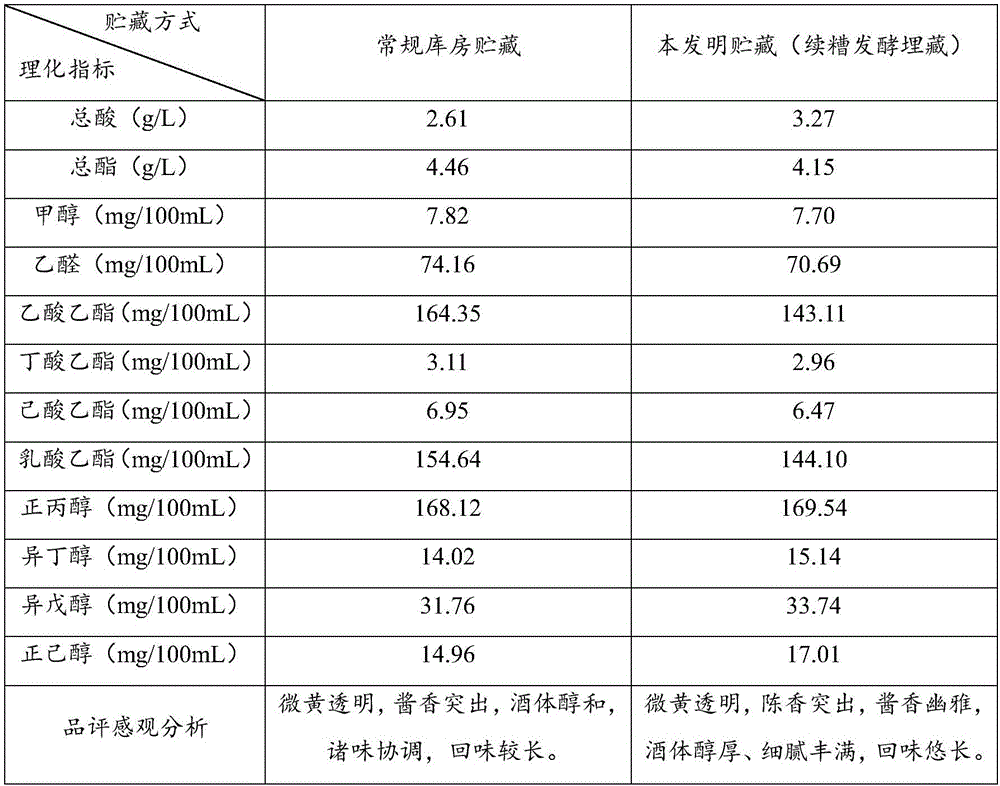

Maotai-flavor baijiu continuous mixed fermentation burying method

InactiveCN105695235ASimple operation processGood cellaring effectAlcoholic beverage preparationAdditive ingredientPurplish red

The invention belongs to the technical field of brewing and particularly relates to a Maotai-flavor baijiu continuous mixed fermentation burying method. The method includes steps: performing combinational primary blending of fresh baijiu; naturally ageing in a baijiu storehouse, performing secondary combination, blending and flavoring; proportionally mixing, and carrying out stacking fermentation for baijiu burying in pits; transferring blended finished baijiu into jars in the pits, covering the jars with lids, hermetically tying with kraft paper and waterproof cloth, and filling each jar with fermented grains subjected to stacking fermentation to a neck position; completely sealing the jars and the pits with unique purplish red mud in Maotai Town, and burying for two years; taking original baijiu from fermented grains in the pits as flavoring liquor, and adding into long-time stored baijiu according to different proportions, so that finished baijiu products are obtained. The defects of large ageing quality difference, long storage time and slow capital turnover of existing baijiu storage methods are overcome, aroma, flavor and medicinal ingredients of baijiu are increased, and baijiu quality is improved while healthcare value of baijiu is increased.

Owner:MOUTAI INST +2

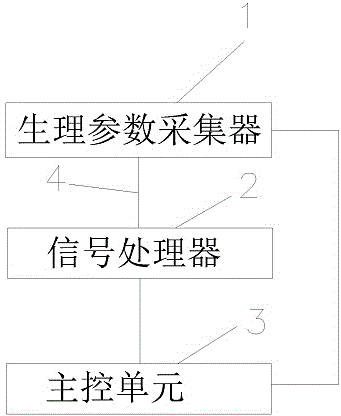

Wearable physiological parameter acquisition system

InactiveCN104605842AAccurate and comprehensive multi-point data collectionAuscultation instrumentsSensorsEngineeringNeck position

The invention relates to the technical field of medical instruments, in particular to a wearable physiological parameter acquisition system comprising physiological signal acquirers, a signal processor, a master control unit and conductive fibers disposed on traditional clothing fabric; the master control unit is electrically connected with the physiological signal acquirers and the signal processor through the conductive fibers; the physiological signal acquirers are further electrically connected with the signal processor; the physiological signal acquirers are disposed on the traditional clothing fabric and at least distributed at human armpit, human heart, human abdomen and human neck positions. The wearable physiological parameter acquisition system can be implanted in clothing fabrics such as wearable clothes and trousers; the wearable physiological parameter acquisition system is a multiple lattice-point acquisition system, and human physiological parameters are all-directionally monitored, accurately and completely.

Owner:巫立斌

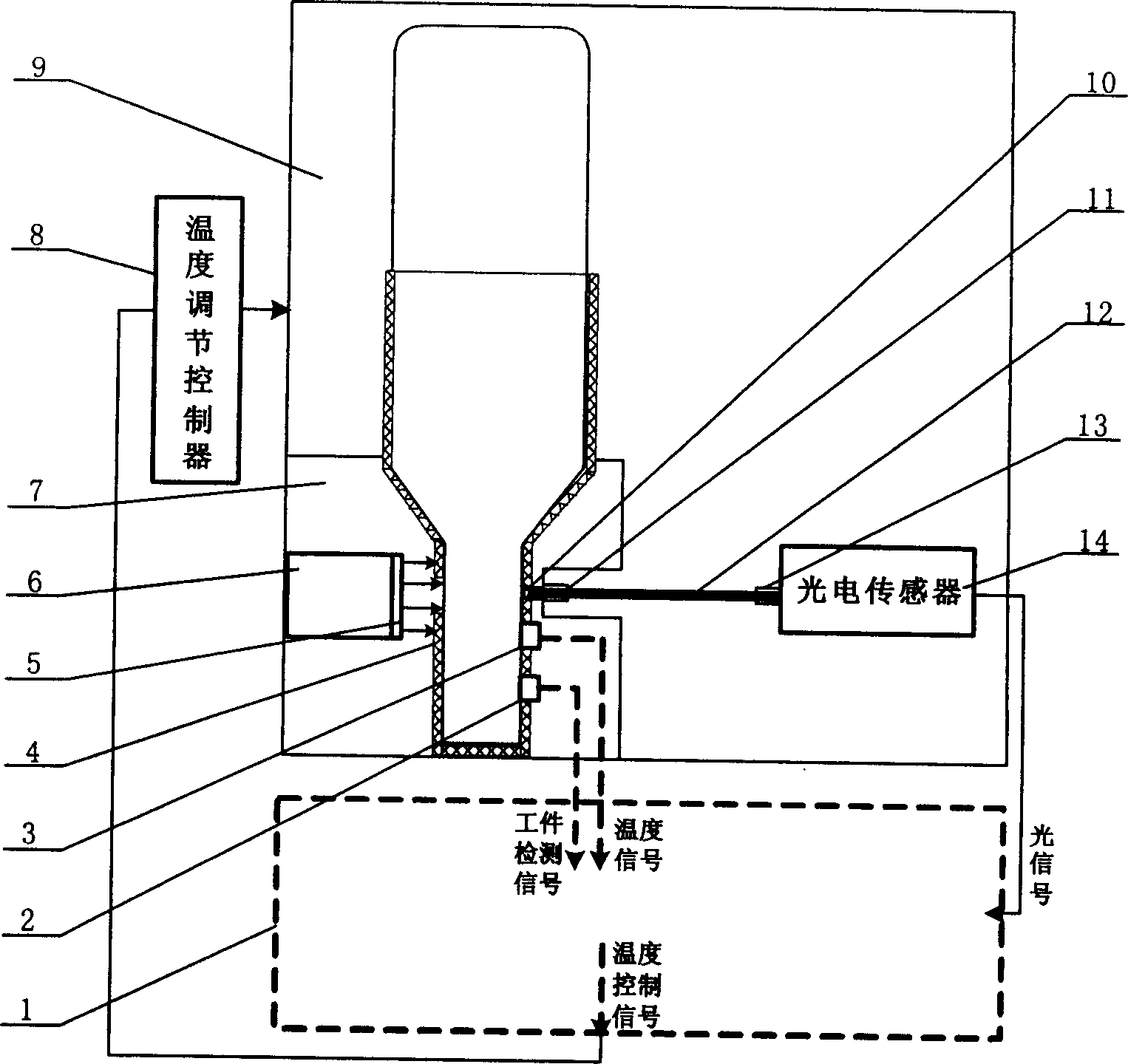

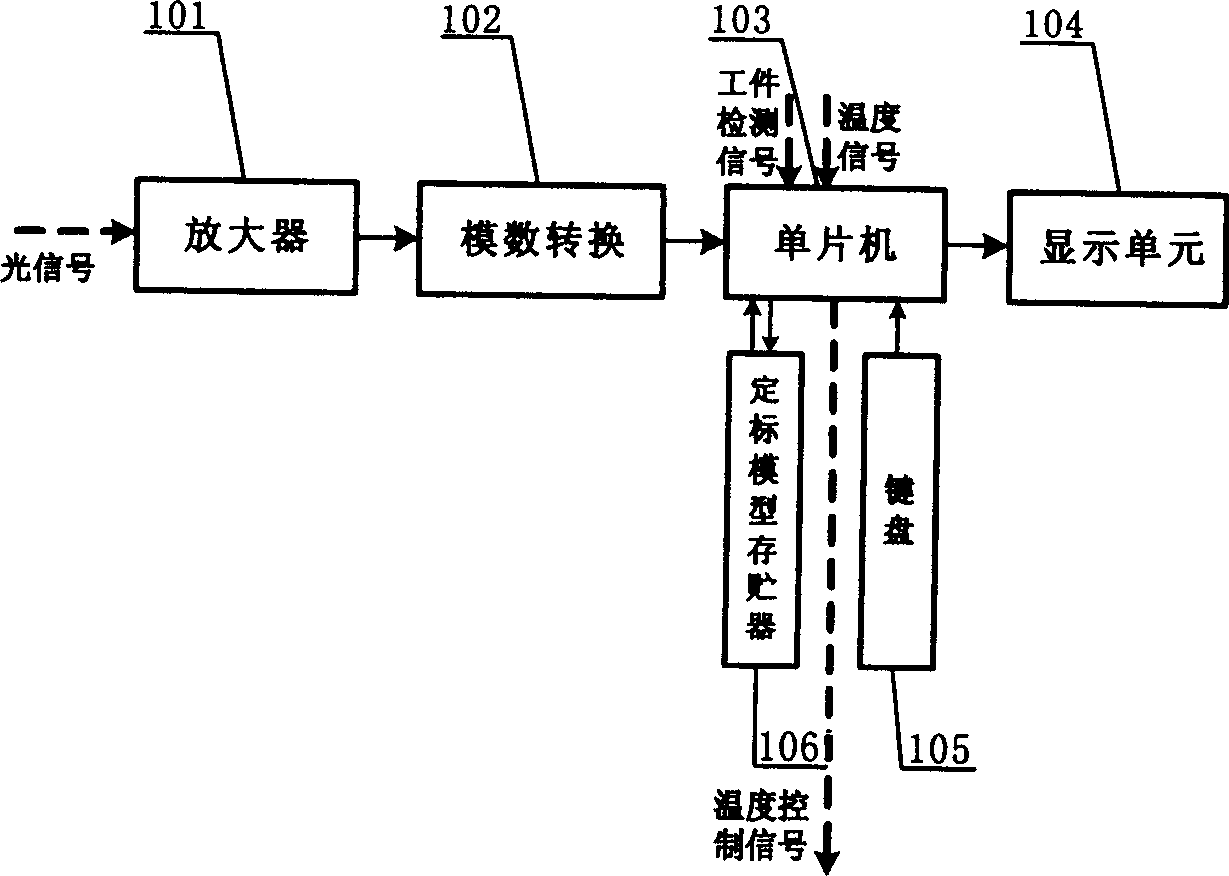

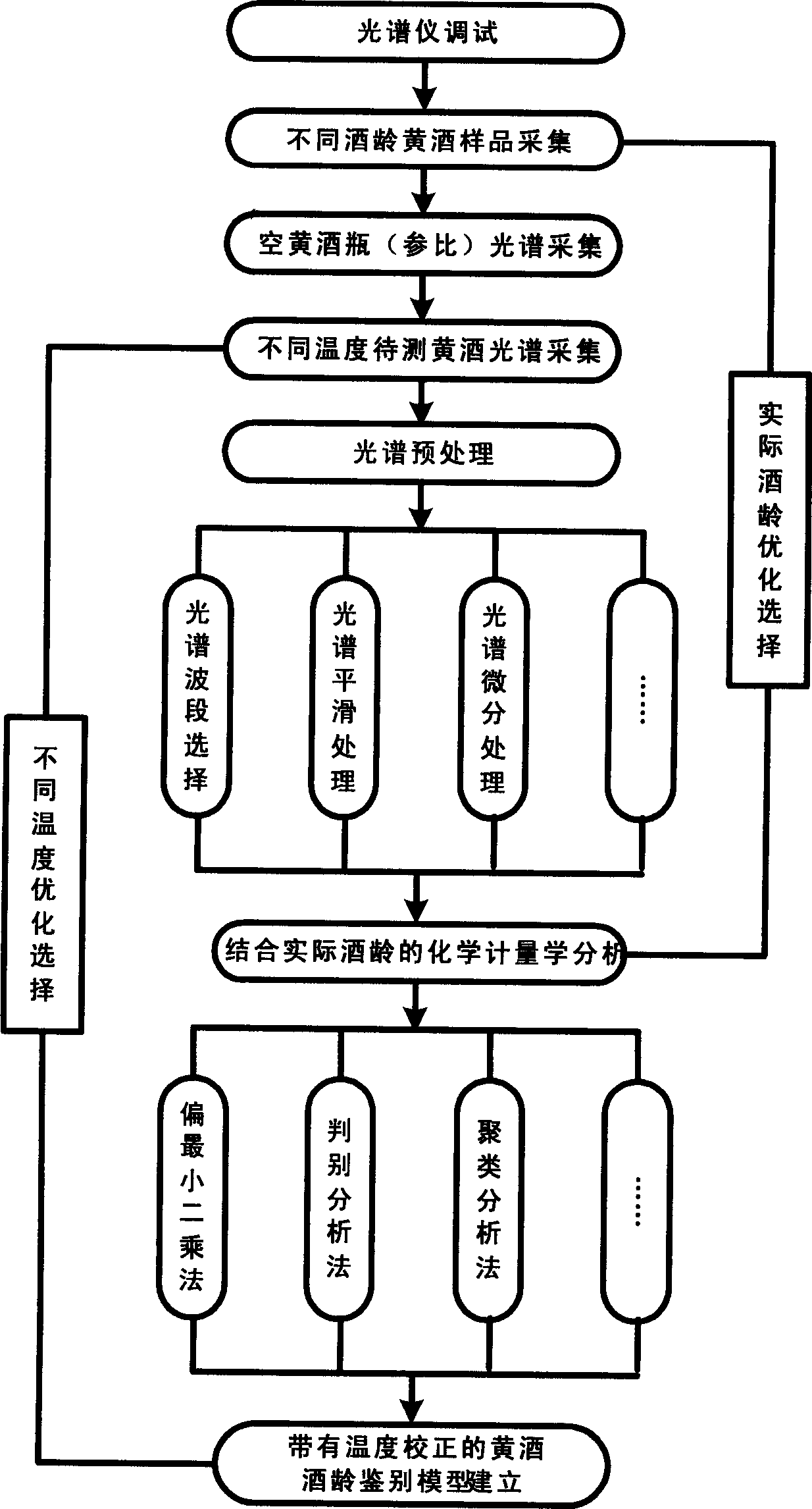

Intelligent device for quickly identifying age of Chinese rice wine based on near infrared spectrum

InactiveCN1789981ASolve the rotation problemSolve inaccurateMaterial analysis by optical meansField analysisIdentification device

The invention discloses an intelligent identification device of yellow rice wine age based on near-infrared spectra, which is characterized by the following: placing the photoelectric sensor and detecting platform with detecting clamp in the incubator; setting the light source and filter piece of near-infrared luminescent diode on the left side of detecting clamp at the neck position; placing the optical lens at the right side of detecting clamp; opposing the exit face of optical lens to the receiving face of optical fiber; connecting the exit end of optical fiber with the input end of photoelectric senor; setting the exit face of filter piece to oppose the receiving face of optical lens at the same axle through the detecting clamp; loading the temperature sensor and workpiece detector on the side of detecting clamp from the bottom of optical lens sequently. The invention solves the problem of inaccurate wine age identification result when the light splitter rotates in different temperature conditions.

Owner:ZHEJIANG UNIV

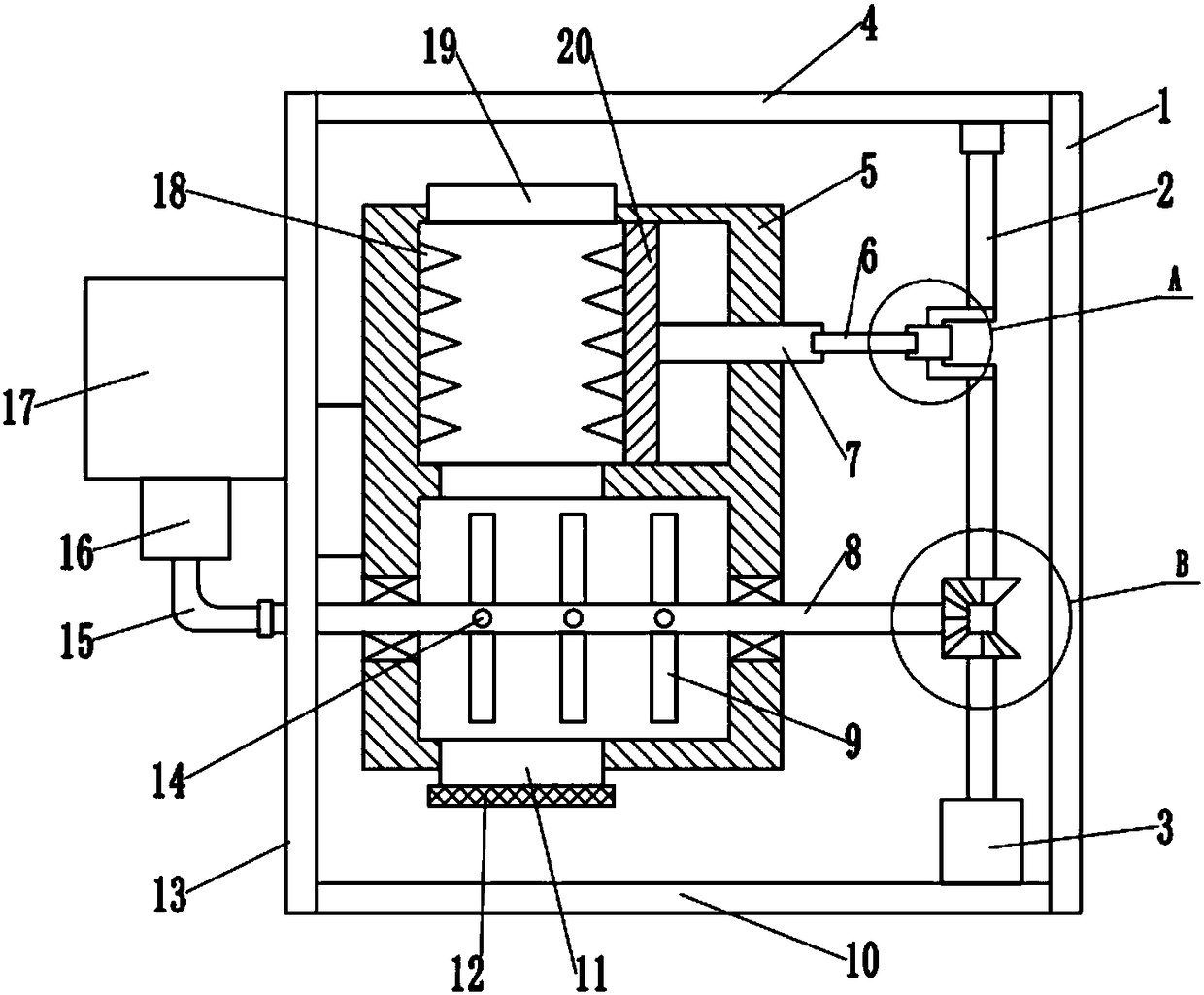

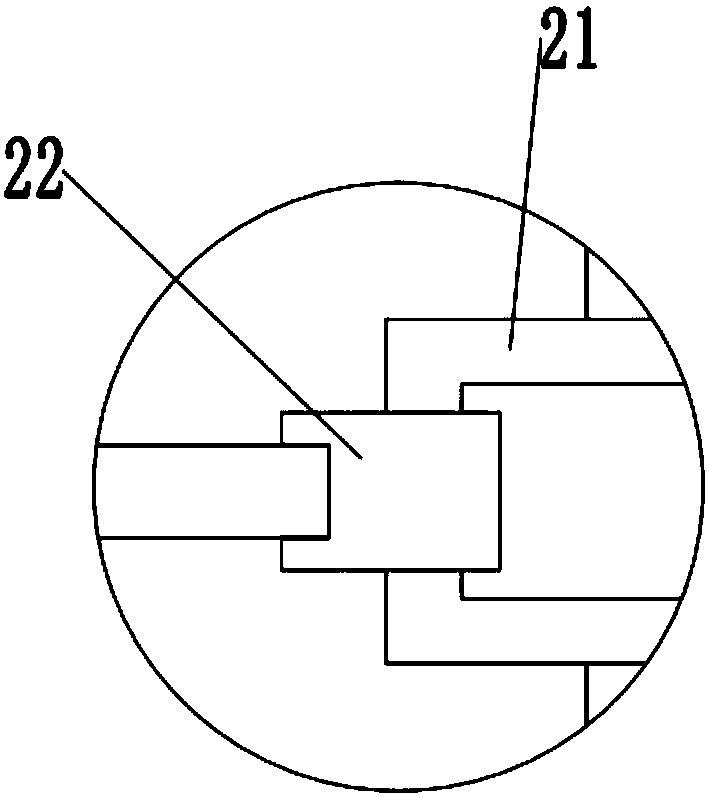

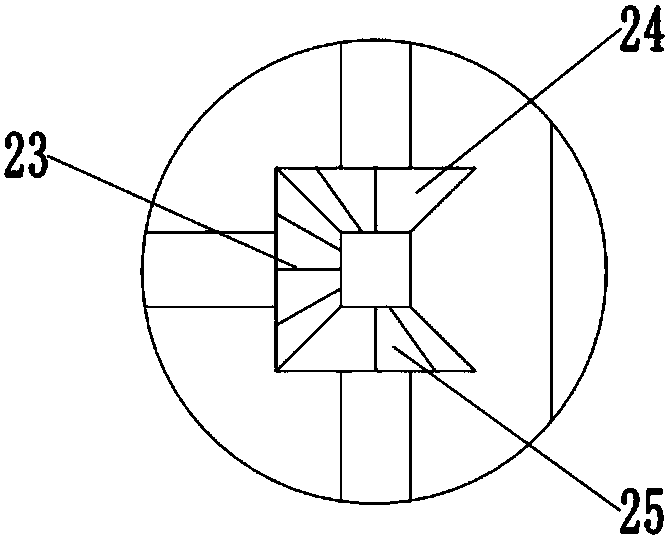

Glass garbage pulverizing, cleaning and granulating device

InactiveCN108579855AImprove crushing effectReduce crushing timeCleaning using liquidsGrain treatmentsDrive motorEngineering

The invention discloses a glass garbage pulverizing, cleaning and granulating device. The glass garbage pulverizing, cleaning and granulating device comprises a box and a bottom plate. A rotation rodis arranged on the right side of the bottom plate, and the upper end of the rotation rod is fixedly connected with a top plate. The lower end of the rotation rod is provided with a drive motor for driving the rotation rod to rotate. The box is fixedly arranged on the inner side of a left side plate, a feeding port is formed in the upper side of the box, and a discharging port is formed in the lower side of the box. A crankshaft is arranged on the upper side of the rotation rod, a rotation sleeve is rotationally arranged at the shaft neck position of the crankshaft, and a connecting rod is rotationally arranged on the left side of the rotation sleeve. The inner wall of the right side of an upper cavity is provided with a push rod in a sliding manner. The right end of the push rod is rotationally connected with the connecting rod, and a grinding plate is fixedly arranged at the left end of the push rod. The crankshaft is driven to rotate through rotation of the rotation rod, the left-right movement of the grinding plate is driven through the connecting rod and the push rod, so that the grinding plate constantly crushes glass added in the box, and the glass crushing effect is improved.

Owner:惠安思奕生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com