Method for finely grinding main shaft necks of crankshaft

A main journal and crankshaft technology, applied in the field of crankshaft processing, can solve problems such as difficulty in improving machining accuracy, affecting grinding quality, cracks or breakage, etc., and achieve the effect of improving coaxiality, easy operation, and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

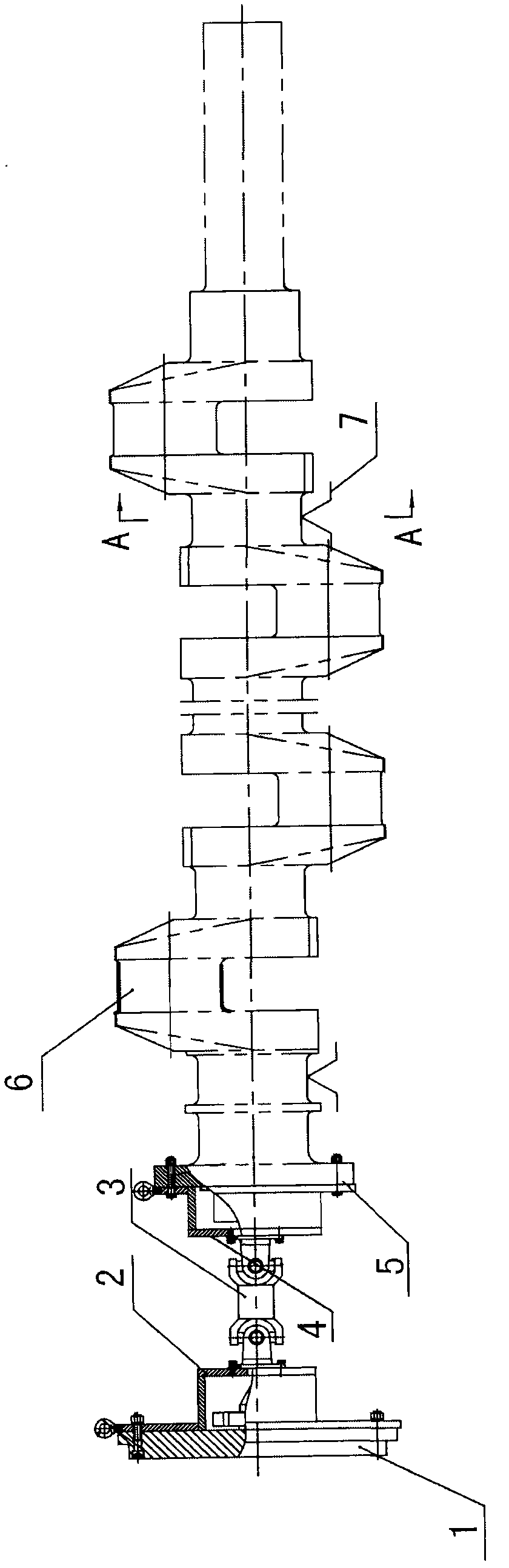

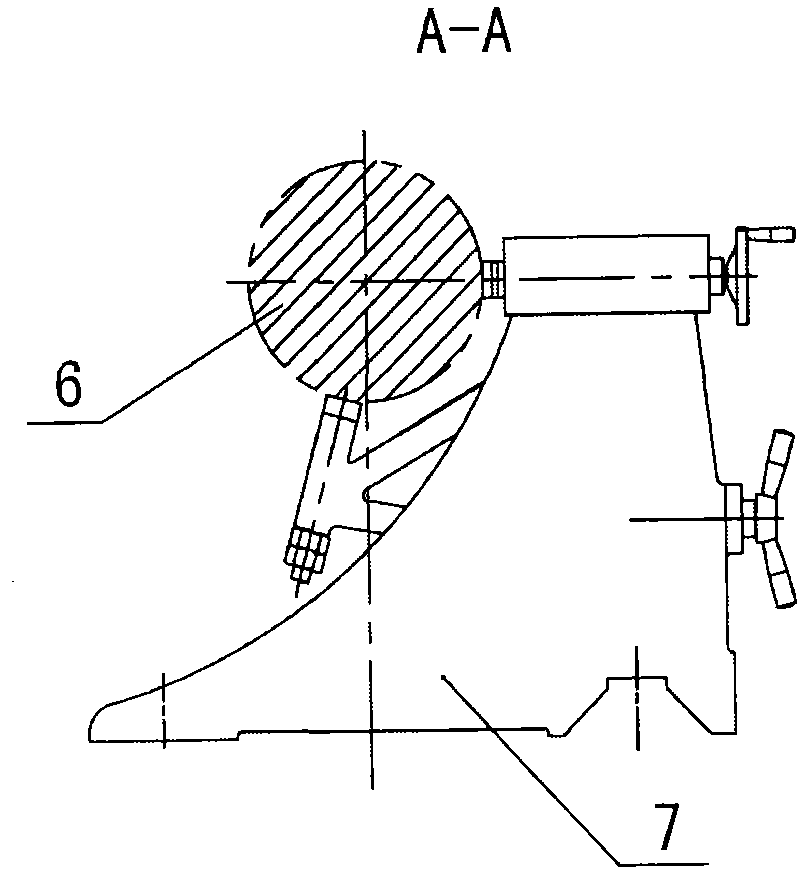

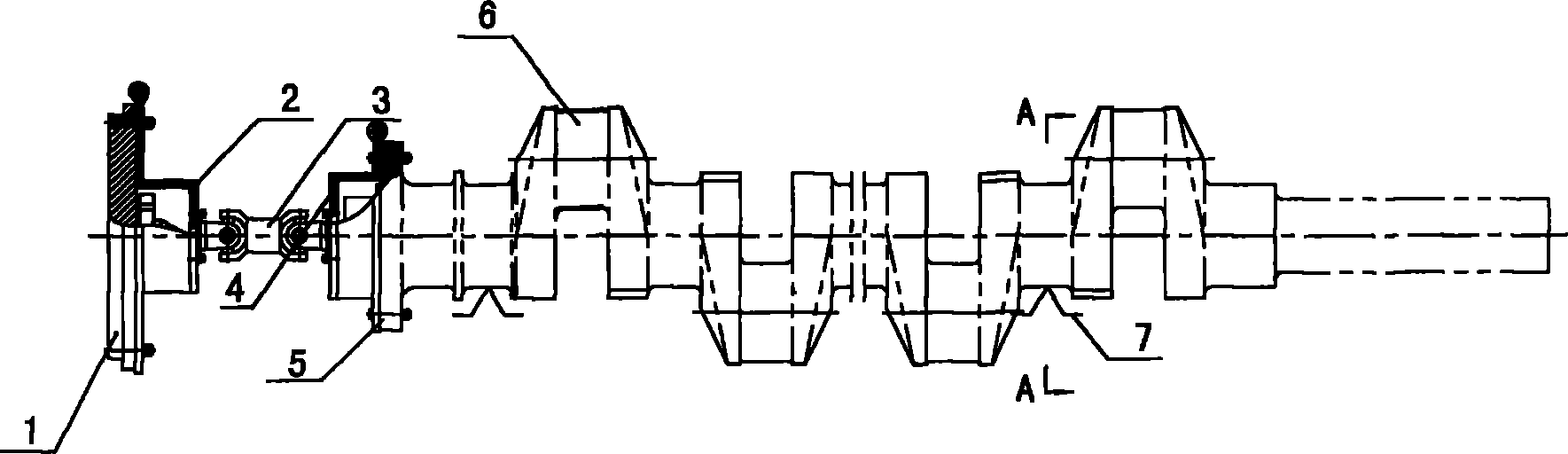

[0017] refer to Figure 1-Figure 2 , first place the main journal of the crankshaft 6 on the grinding machine center frame 7, the specific placement method is: place the center frame under the first main journal, and then place a center frame every other main journal; the left end of the universal coupling 3 The left connecting disc 2 is connected with the grinding machine headstock chuck 1, and the right end of the universal coupling is connected with the crankshaft through the right connecting disc 4 and crankshaft flywheel end flange 5; the crankshaft is located on the main journal on the center frame and the side bus bar Straightness ≤ 0.03mm, to determine the axis reference; start grinding, first grind the position of the main journal supported by each center frame, and then grind the rest of the main journals, in order, and then grind the support of the center frame and the remaining main journals until required Size, during the grinding process, adjust the steady rest t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com