Double laser-double-wire bypass electric arc compound welding method

A bypass arc and welding method technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high cost, poor weldability of high reflectivity materials, and low energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

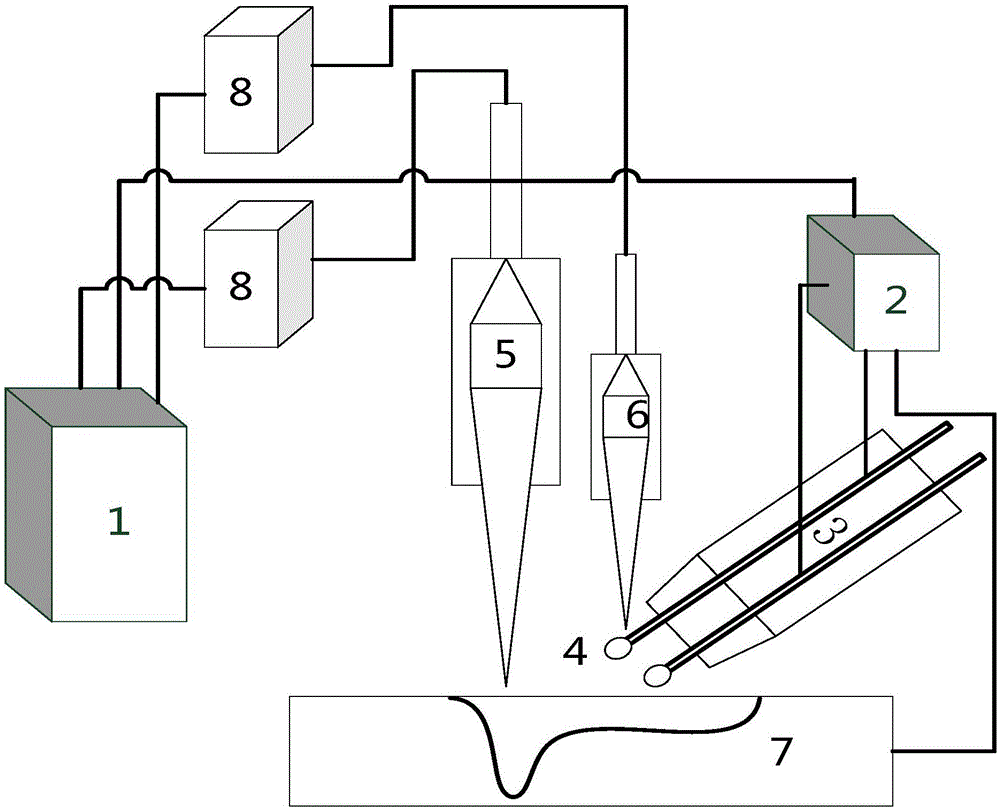

[0020] The embodiment of the present invention provides a double laser-double wire bypass arc combined welding method, the method adopts equipment such as figure 1 As shown, it includes: a computer control system 1, an arc length adjustment system 2, a continuous laser beam 5 and a pulsed laser beam 6. The computer control system 1 can control the arc height according to the voltage change value collected by the arc length adjustment system 2, so that the pulsed laser beam can be accurately incident on the necking position of the droplet; the base material 7 is Q235 low carbon steel with a thickness of 10 mm, and the laser frequency is 10-500 Hz.

[0021] The specific double laser-double wire bypass arc combined welding method includes the following steps:

[0022] 1. Adjust the spatial positions of the continuous laser beam 5, the pulsed laser beam 6, and the twin-wire welding torch 3, so that the continuous laser beam 5 acts on the base material 7, and the pulsed laser beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com