Patents

Literature

58 results about "Oxygen converter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for directly producing austenitic stainless steel by utilizing oxide nickel

ActiveCN101445845AImprove dephosphorization efficiencyHigh yieldBlast furnace detailsElectric arc furnaceFerrochrome

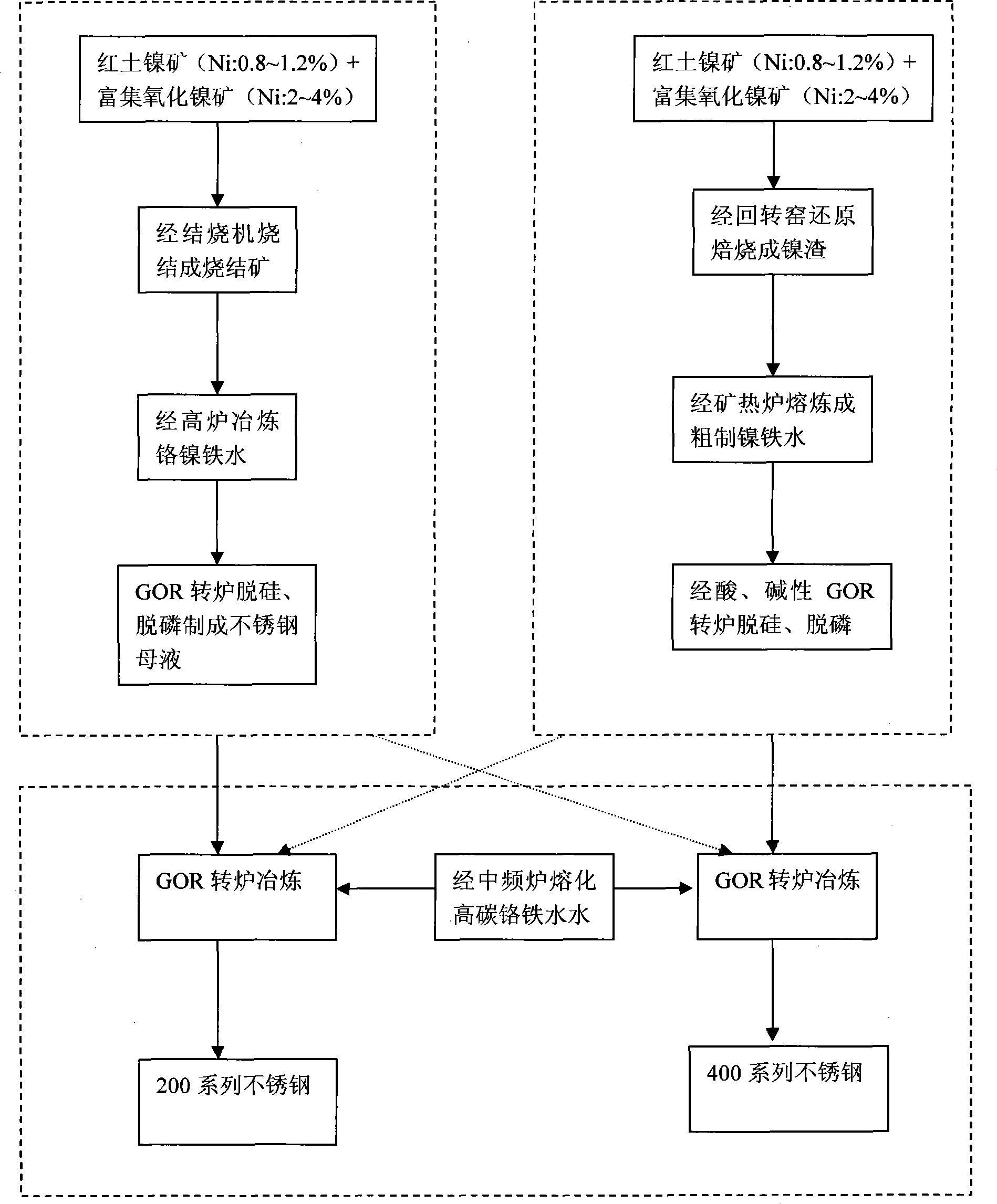

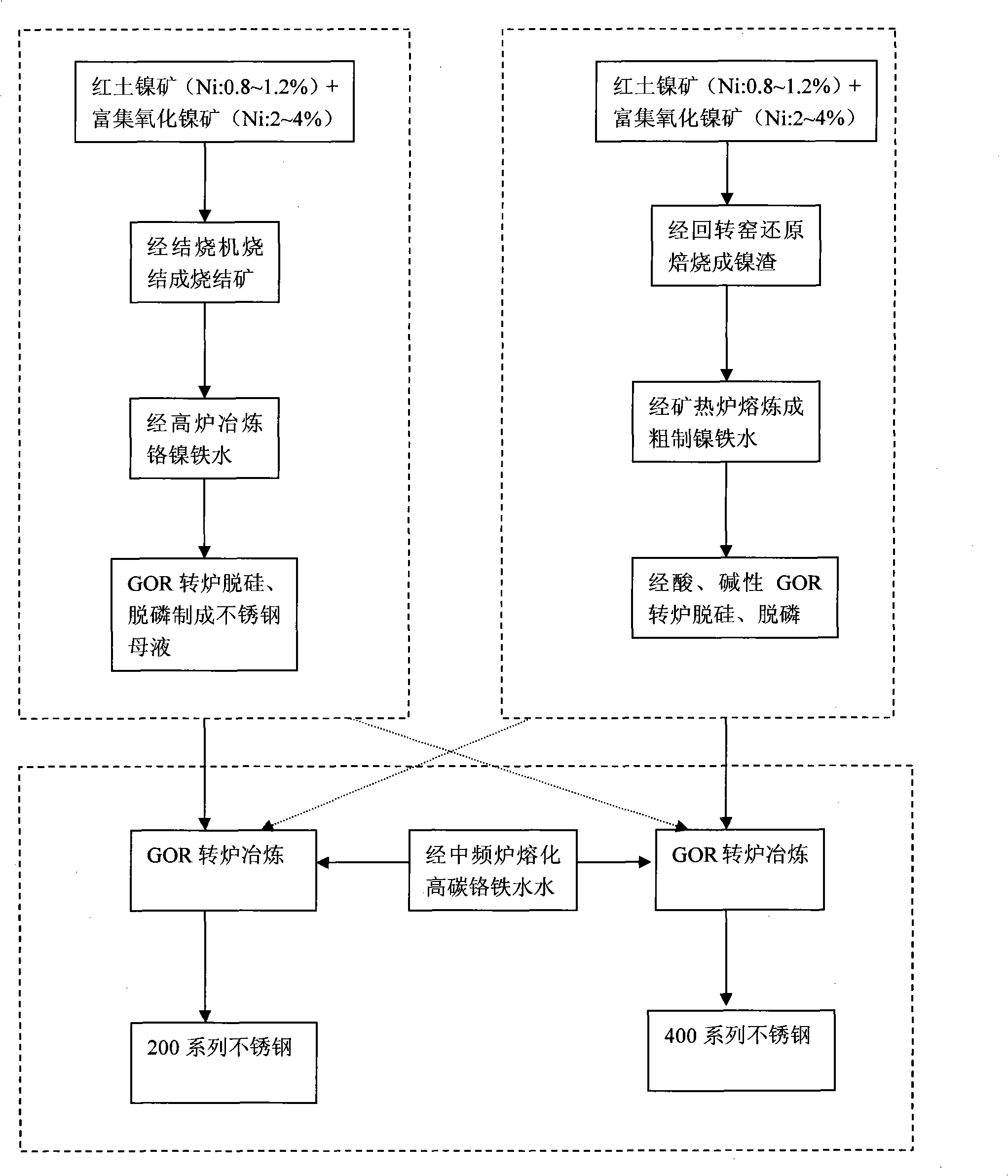

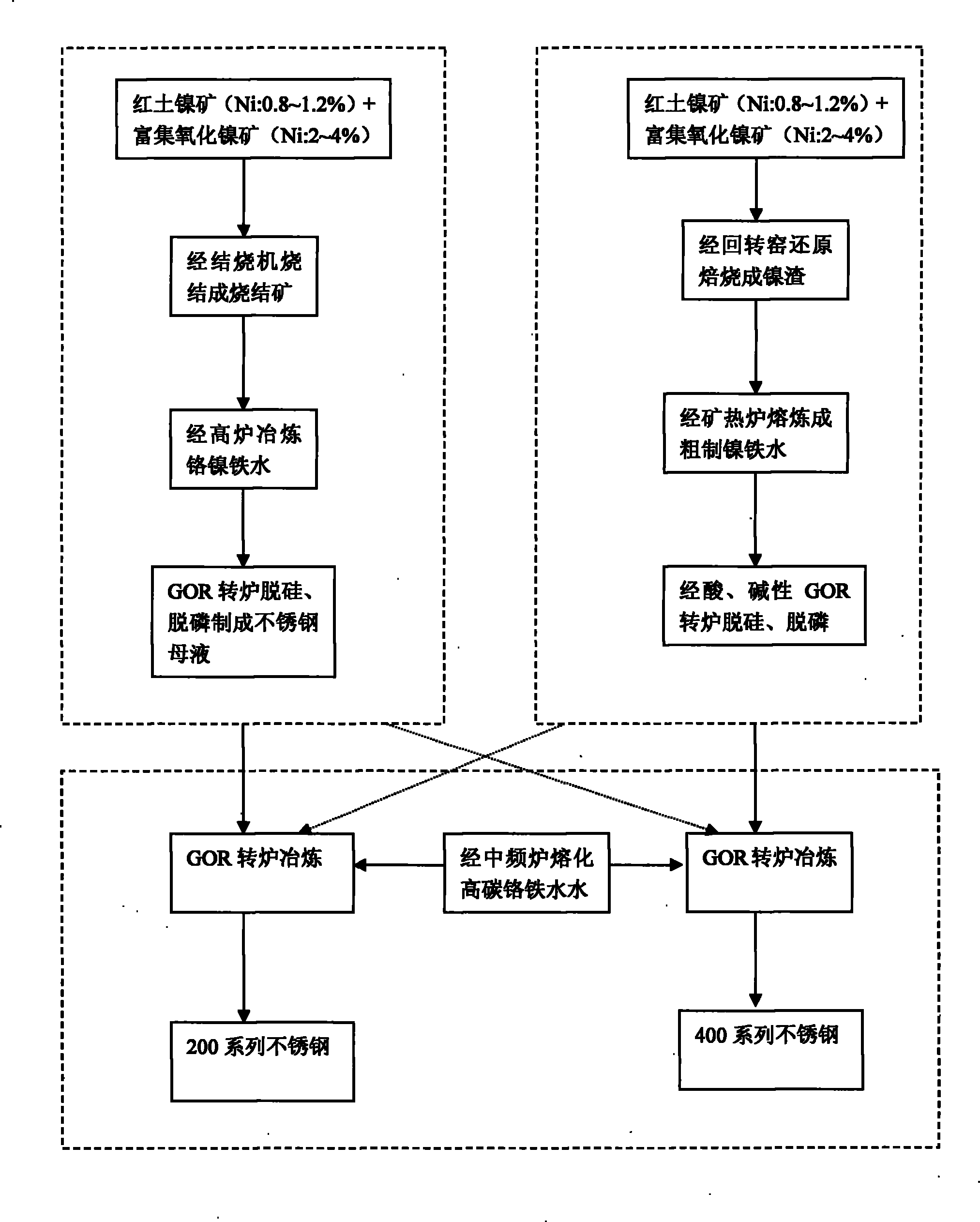

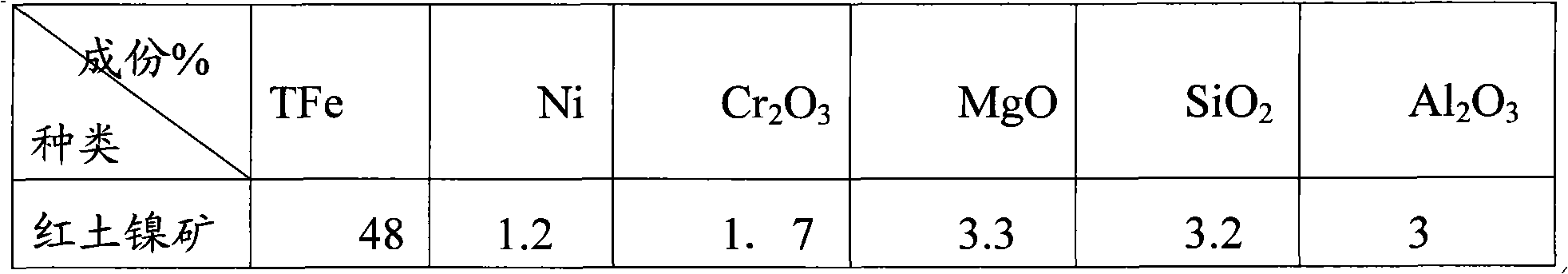

The invention relates to a technological process for stainless steel smelting, in particular to a process for directly producing austenitic stainless by utilizing oxide nickel. The process has the following advantages: oxide nickel of various grades is adopted to obtain different ingredients of molten nickel iron by smelting in a blast furnace and a submerged arc furnace, an electric arc furnace is cancelled as a melting unit, the chemical heat of the molten iron is utilized to melt all or part of chromium and manganese alloy, and a bottom-blowing argon-oxygen converter is utilized to dephosphorize so as to improve the dephosphorization efficiency of molten chromium iron and the obtainment yield of chromium, thereby the following series and trademarks of products, i.e. 200 series of 201, 202, J4, and the like, 300 series of 304,304L, 316,321,329, and the like, are produced; and meanwhile, all links in the whole production flows are organically combined, and various energy sources, such as coal gas, steam, afterheat, and the like are fully utilized and recycled, thereby the energy consumption is low, the secondary waste gas discharge amount not great, the production cost and the raw material cost are low, and the investment and the occupied area are not great.

Owner:陈法官 +1

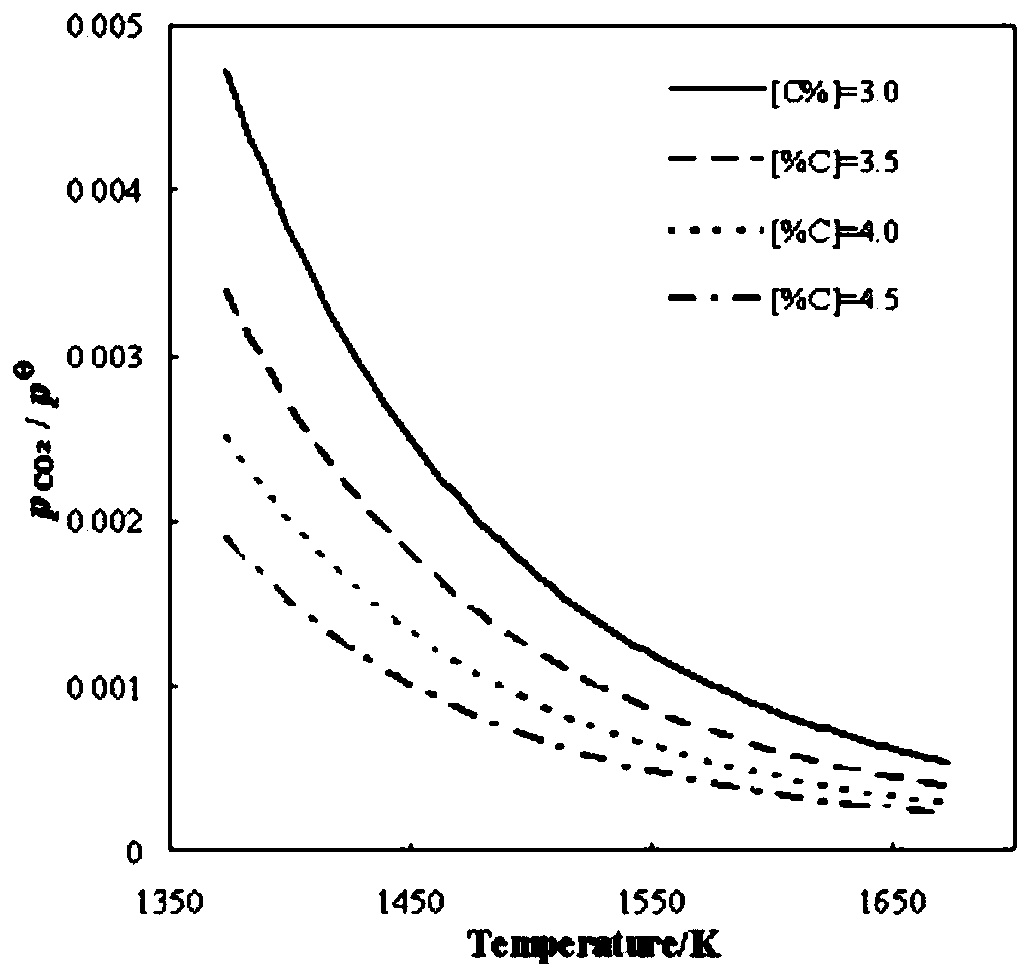

Steel-making method for prolonging service life of bottom-blowing oxygen converter through CO2

ActiveCN105907914ALower furnace bottom temperatureExtended service lifeManufacturing convertersThermodynamicsHydrocotyle bowlesioides

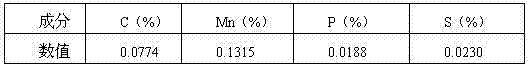

The invention belongs to the field of the metallurgy technology, and relates to a steel-making method for prolonging the service life of a bottom-blowing oxygen converter through CO2. According to the method, mixed gas of O2 and CO2 serves as bottom main blowing gas, mixed gas of hydrocarbon and CO2 serves as protective gas, and the CO2 mixing proportion in the bottom-blowing mixed gas of O2 and CO2 and the mixed gas of hydrocarbon and CO2 is controlled according to different smelting stages of the bottom-blowing oxygen converter; and by means of the characteristics that CO2 reacts with iron and carbon to absorb heat, and CO2 does not contaminate molten steel, the outlet temperature of a bottom-blowing nozzle is reduced, consumption of hydrocarbon is reduced, the quality of molten steel is improved, and therefore the service life of the bottom-blowing oxygen converter is prolonged, and the smelting cost is reduced. The steel-making method is suitable for the bottom-blowing oxygen converter of 30-350 tons; and by means of the steel-making method, the bottom service life of the bottom-blowing oxygen converter can be prolonged by 300-600, the smelting cost of steel per ton can be reduced by 2-3 yuan, and the end-point molten steel carbon-oxygen equilibrium can be reduced by 0.0002-0.0004.

Owner:UNIV OF SCI & TECH BEIJING

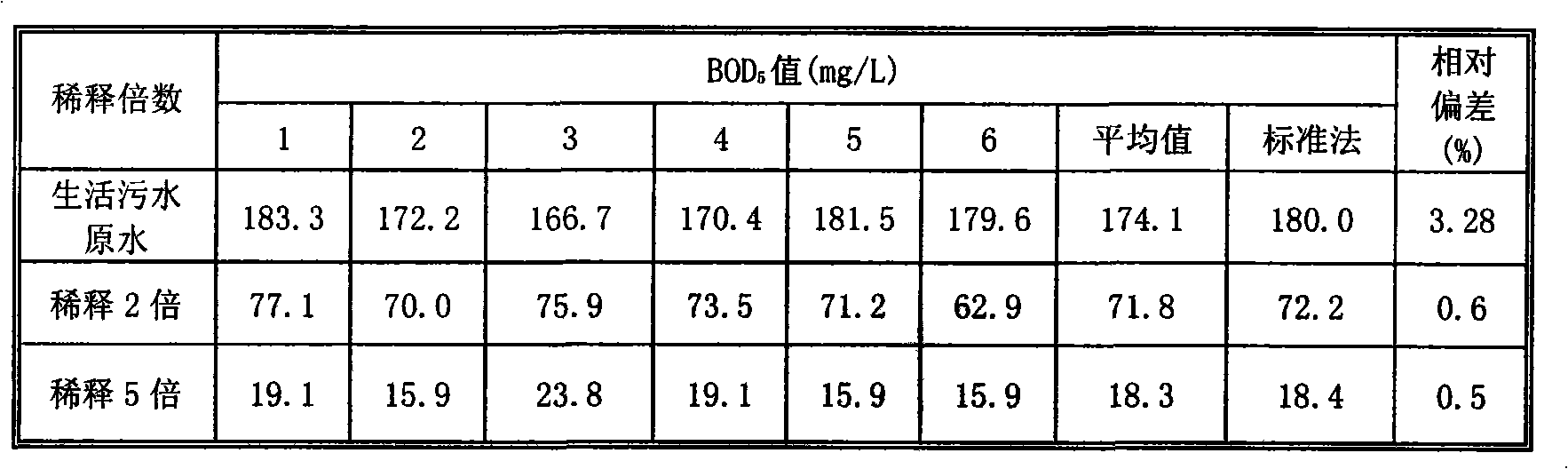

Reactor type BOD rapid measuring method and measuring instrument

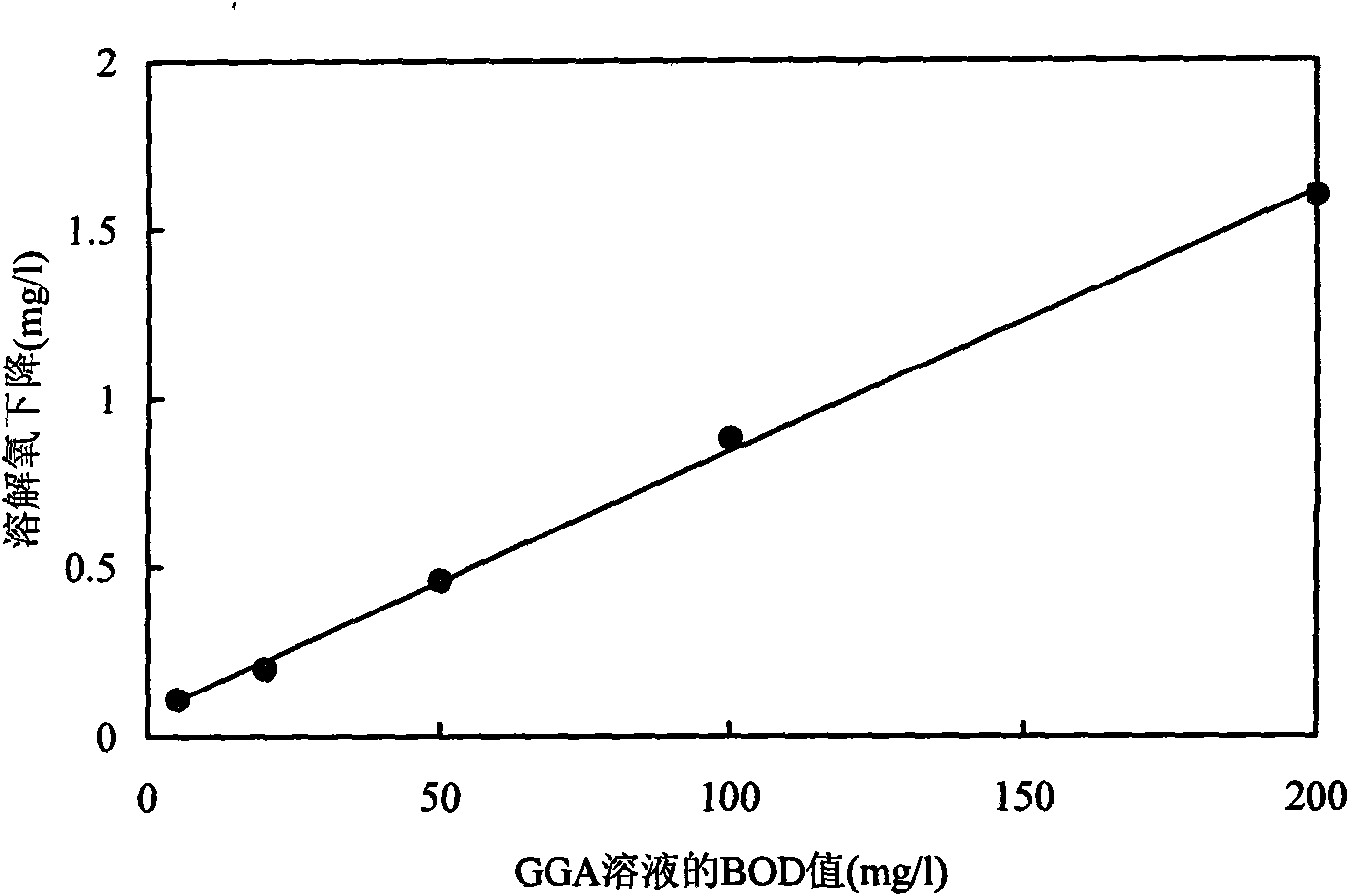

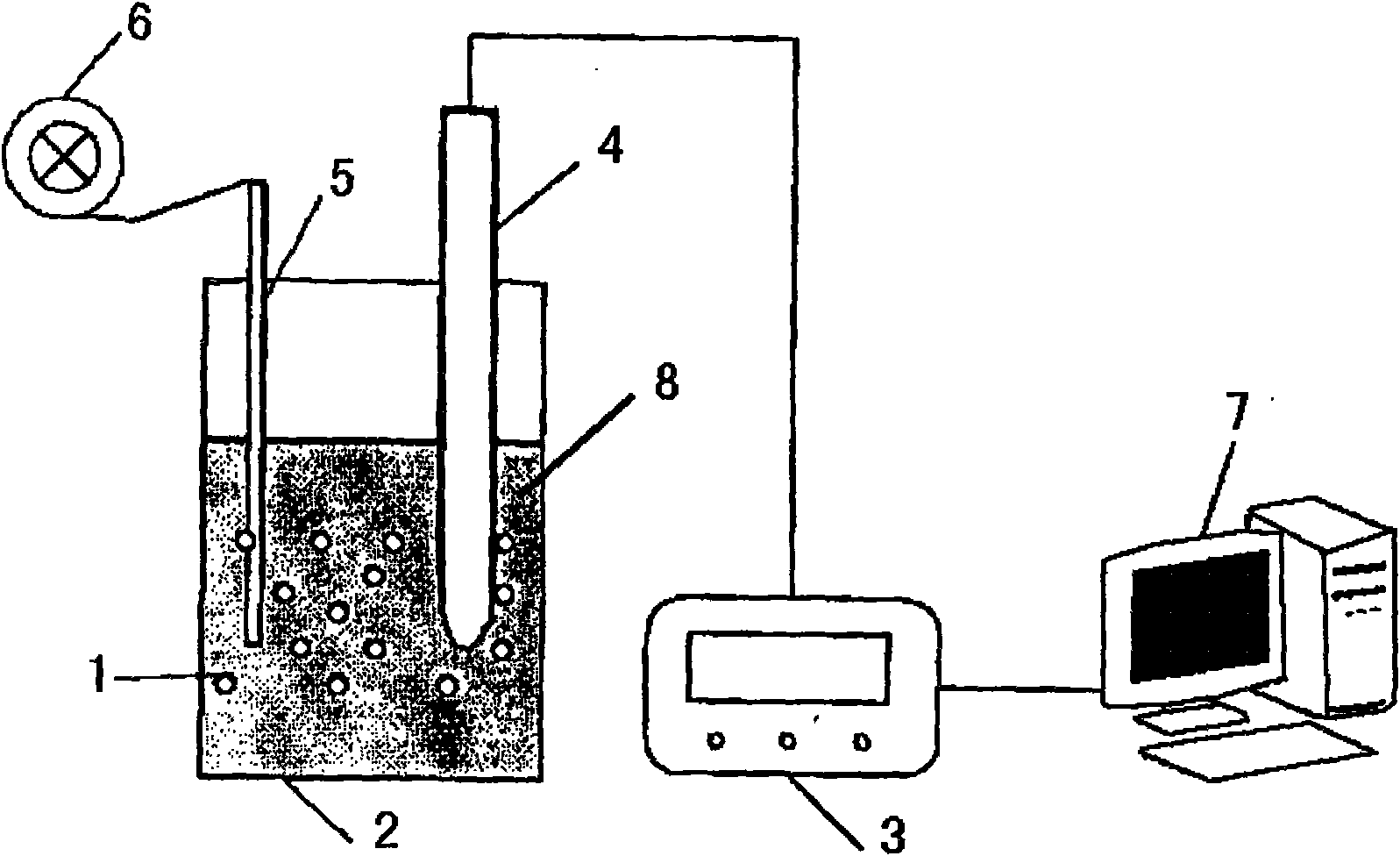

InactiveCN101639472AEasy to manufactureCan be stored for a long timeTesting waterMeasuring instrumentInstability

The invention discloses a reactor type BOD rapid measuring method and a measuring instrument, belonging to the field of environmental pollution monitoring. The measuring instrument comprises a hybridbiochemical reactor, an aeration system connected therewith, a dissolved oxygen converter and a computer data processing system, wherein, a dissolved oxygen electrode and an aeration pipe are arrangedin the hybrid biochemical reactor. Sewage and immobilized microorganism particles to be measured are mixed, stirred and aerated in a measuring chamber, heating and temperature control are carried out, thereby leading the immobilized microorganism particles to degrade biodegradable organic pollutants in a water body, constantly reducing the concentration of dissolved oxygen and then calculating the BOD value of a water sample to be measured through a standard curve according to the difference value of the dissolved oxygen between two stable states. The measuring instrument solves the problemsof instability, poor reproducibility of the measurement result and the like of the traditional biological membrane type BOD rapid measuring instrument. The reactor type BOD rapid measuring instrumenthas the advantages of good stability, wide linear range of measurement, good reproducibility, low requirement on precision of a dissolved oxygen instrument and the like.

Owner:TSINGHUA UNIV

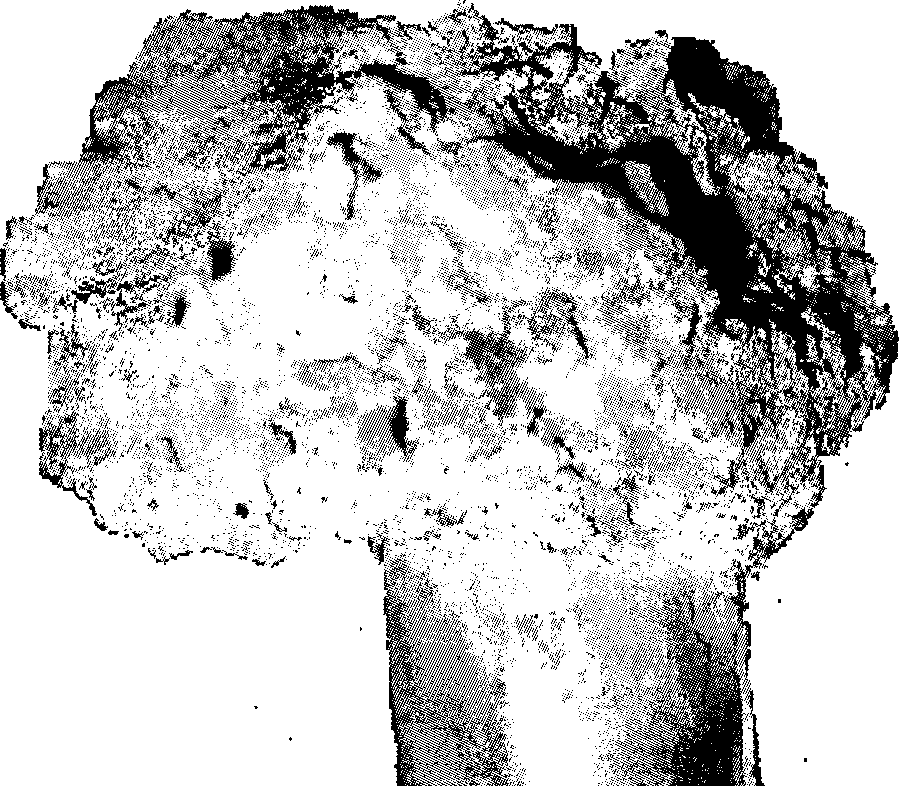

Method for improving combined blown converter campaign length by metal furnace cinder composite mushroom

Owner:CENT IRON & STEEL RES INST

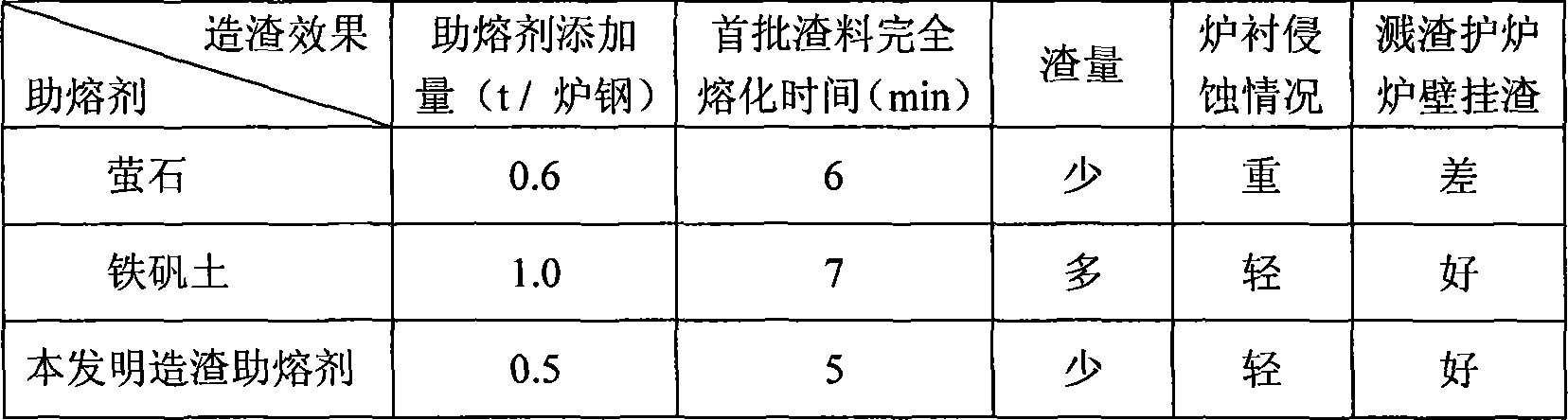

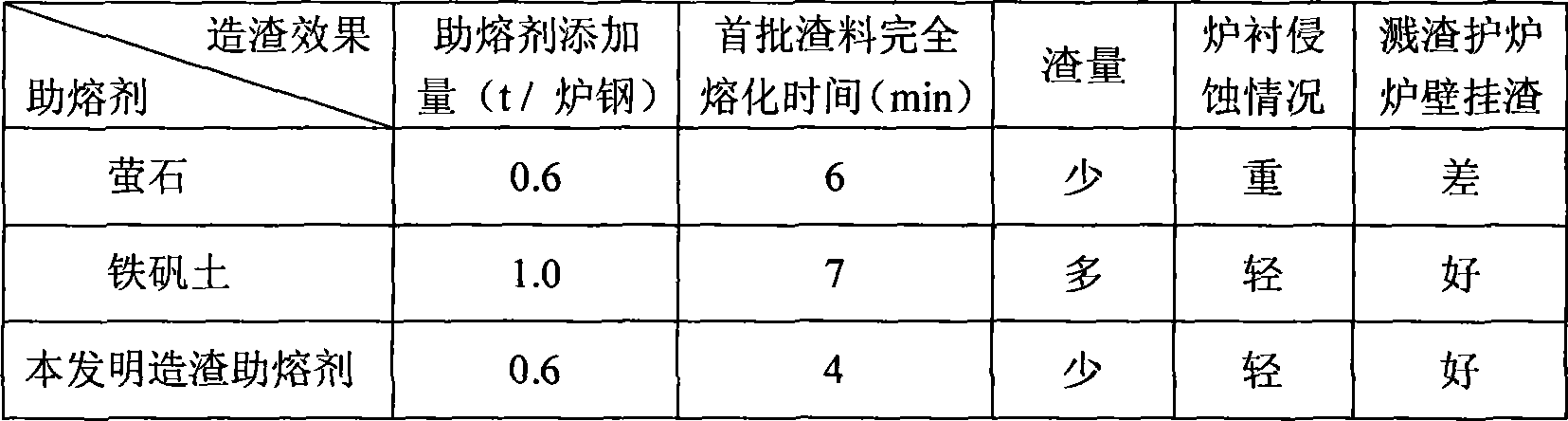

Alkaline oxygen converter steelmaking slagging fluxing agent and its preparing method and slagging method

InactiveCN101033496ASpeed up meltingReduce consumptionManufacturing convertersOxygen converterMetallurgy

The invention relates to the slagging flux of oxygen converter steelmaking and its preparation methods as well as slagging method. The slagging flux contains by percentage of quality as follow: 5~10% of B2O3, 45~50% of CaO, 20~25% of MgO, 15~20% of Al2O3, 10~15% of Fe2O3. The slagging flux is added for slagging in accordance with the ratio of 2~10kg / ton steel, and the slagging flux is added into the furnace with slagging materials in batches, i.e. it adds the first batch of slagging materials (usually the slagging materials is expected to be half of the total) and prescriptive half of the slagging flux, that is, 1~5kg / t steel, when the gun starts oxygen blowing oxygen. It adds the second batch of slagging materials and the remaining part of the slagging flux at the time of the interim blowing.

Owner:JIANGSU UNIV

Adding method of steelmaking slag charge of oxygen converter

ActiveCN104774995AEasy to optimizeOptimal Endpoint ControlManufacturing convertersOxygen converterDolomite

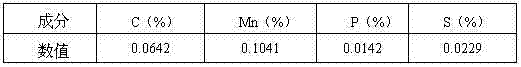

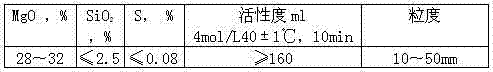

Provided is an adding method of steelmaking slag charge of an oxygen converter. Selected raw materials include limestone, lime, light-burned magnesian limestone, ferric-oxide dust pellets and steelmaking iron ore, wherein the limestone contains 53%-55% of CaO, the lime contains 90%-92% of CaO and not more than 2.5% of SiO2, the light-burned magnesian limestone contains 28%-32% of MgO and not more than 2.5% of SiO2, the ferric-oxide dust pellets contain 52%-56% of T and Fe, and the steelmaking iron ore contains 61%-63% of T and Fe. The slag charge comprises, by weight, 12%-14% of the limestone, 28%-30% of the lime, 26%-28% of the light-burned magnesian limestone, 14%-16% of the ferric-oxide dust pellets and 15%-17% of the iron ore, and the raw materials of the slag charge are added in batches. Through batch adding of the optimized lime, the optimized dolomite and the other slag charge, the adding method optimizes the process and end point control of slag, reduces the phenomena of process splashing and smoking, and can obviously reduce smelting costs.

Owner:YANGCHUN NEW STEEL CO LTD

Extremely-thick low-alloy steel plate with low compression ratio and preparation method thereof

The invention relates to an extremely-thick low-alloy steel plate with a low compression ratio. The steel plate is 150-180 mm thick, and consists of the following components in percentage by mass: 0.10-0.17% of C, 0.15-0.45% of Si, 1.18-1.40% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.10-0.20% of Ni, 0.010-0.040% of Nb and the balance Fe and inevitable impurities; and meanwhile, the content of the corresponding elements meets the following relation: Ceq less than or equal to 0.39%, [C]+[Mn] greater than or equal to 1.35% but less than or equal to 1.50%. A melting process comprises the following steps: oxygen converter smelting, ladle furnace refining, vacuum degassing treatment, continuous casting for slab with thickness being 370 mm or greater, casting blank cover-cooling, casting blank heating, rolling control, cooling control, stacking and slow-cooling, flaw detection and performance examination. The steel plate has the characteristics of being high in strength, excellent in low-temperature toughness, excellent in weldability and the like, and is wider in scope of application.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

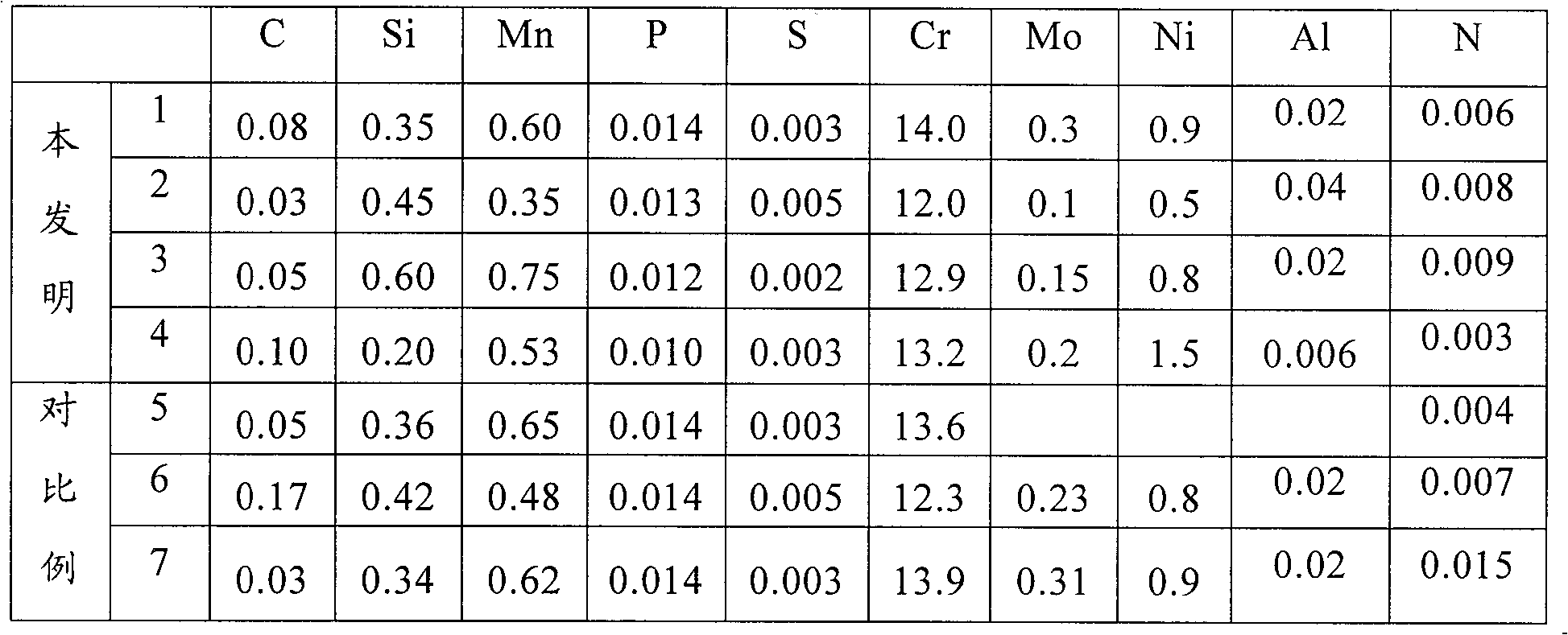

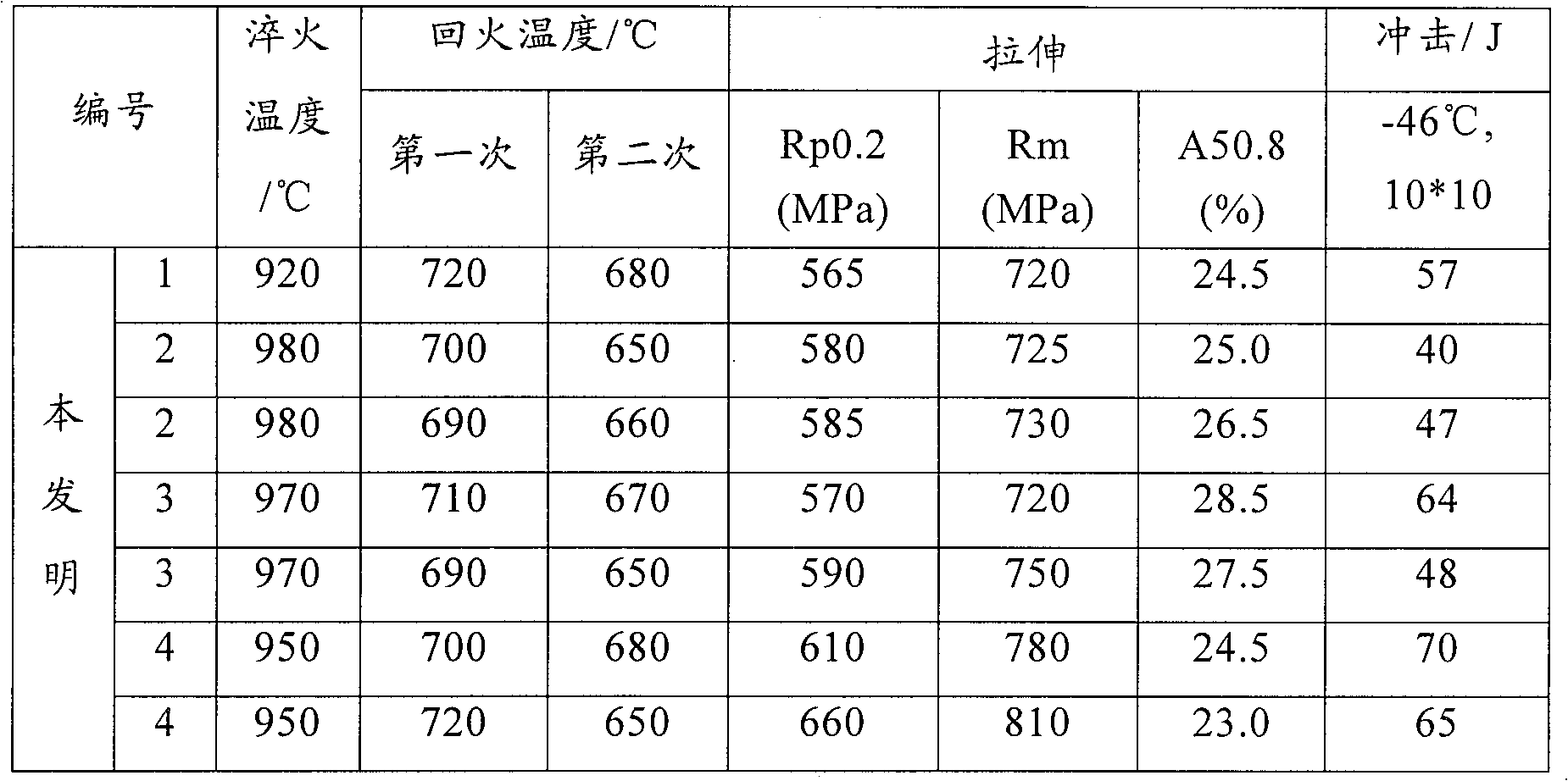

High-toughness corrosion-resistant steel and manufacturing method thereof

ActiveCN102839331AImprove manufacturabilitySufficient marginElectric arc furnaceChemical composition

Owner:BAOSHAN IRON & STEEL CO LTD +1

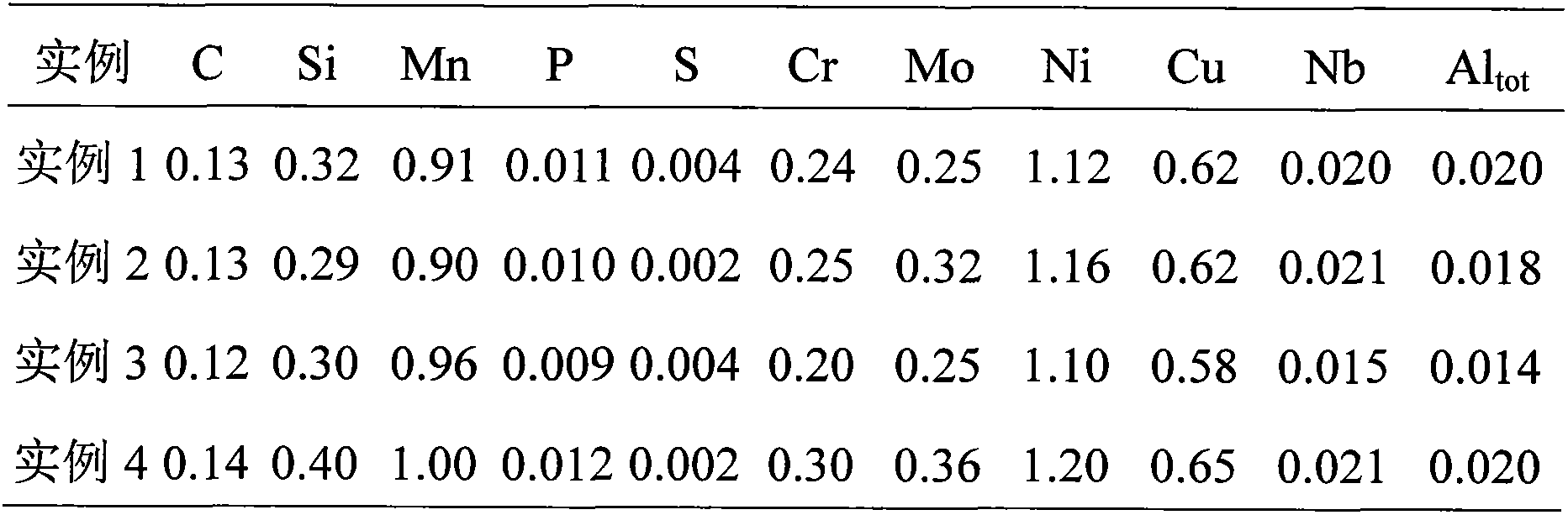

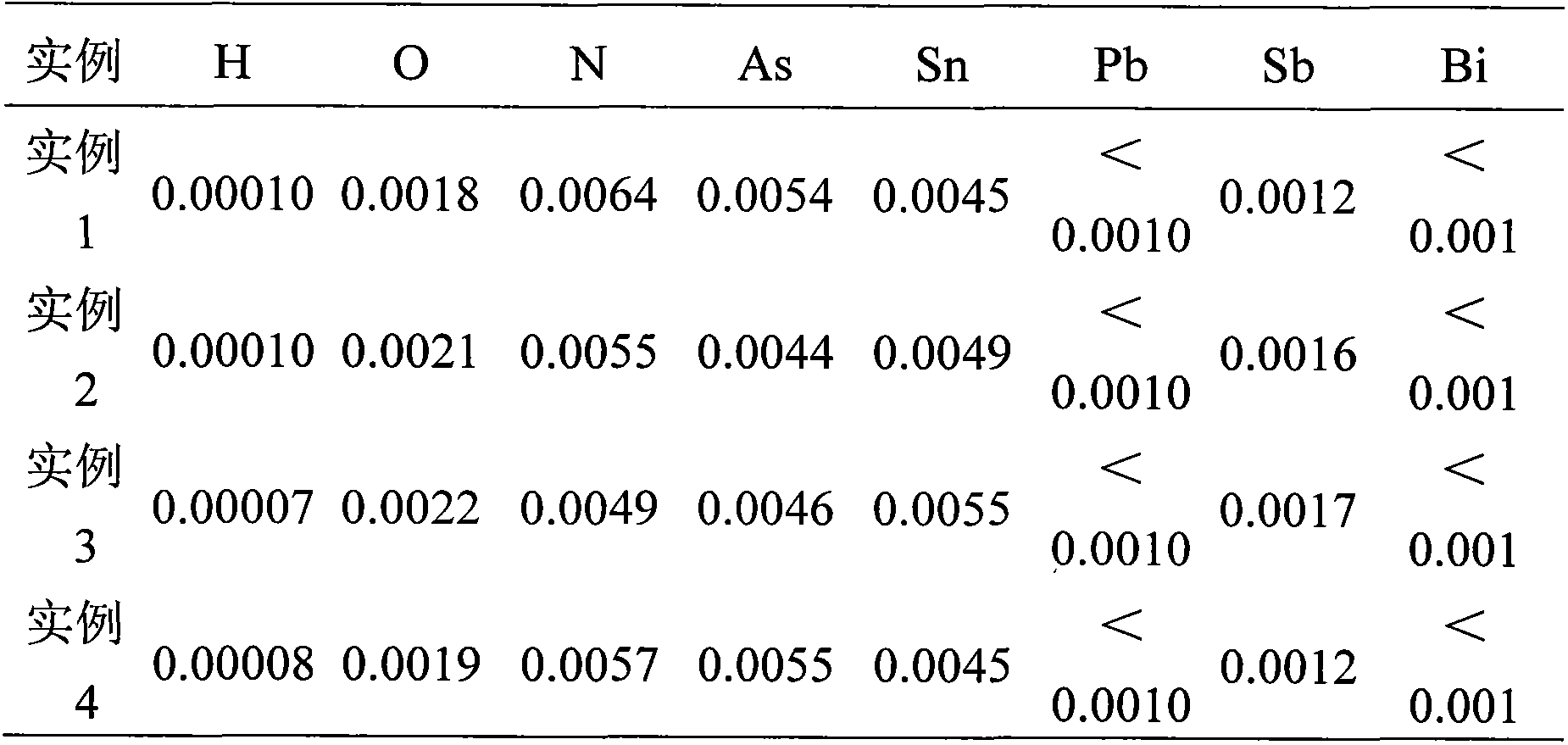

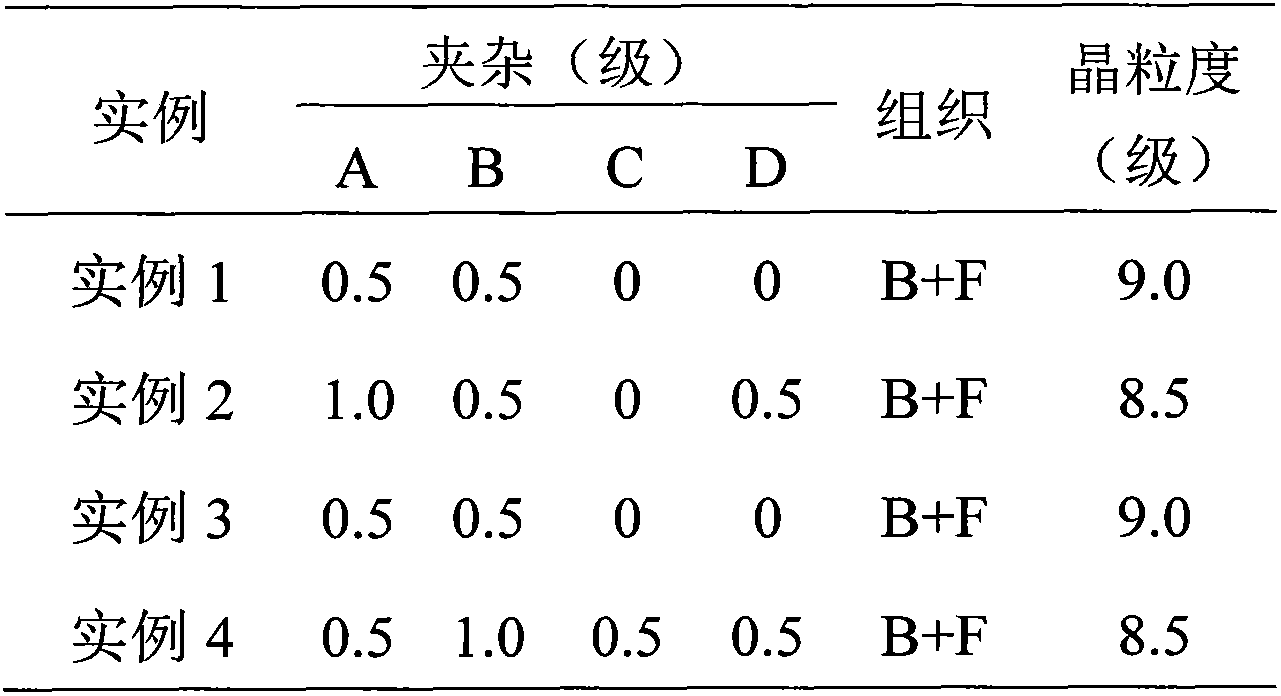

Cu-contained and Cr-controlled seamless steel tube for nuclear power station and production method for Cu-contained and Cr-controlled seamless steel tube

The invention relates to a Cu-contained and Cr-controlled seamless steel tube for a nuclear power station and a production method for the seamless steel tube. The seamless steel tube comprises the following chemical components in weight percentage: 0.10-0.15 percent of C, 0.90-1.20 percent of Mn, 0.20-0.45 percent of Si, not greater than 0.015 percent of P, not greater than 0.005 percent of S, 0.20-0.30 percent of Cr, 0.25-0.40 percent of Mo, 1.10-1.25 percent of Ni, 0.55-0.65 percent of Cu, 0.015-0.025 percent of Nb, not greater than 0.02 percent of Altot, not greater than 0.008 percent of N, not greater than 0.0002 percent of H, not greater than 0.003 percent of O, not greater than 0.012 percent of As and Sn, not greater than 0.020 percent of As, Sn, Pb, Sb and Bi and the balance Fe and inevitable impurities. According to the production method for the seamless steel tube, steel for a round tube blank is treated by adopting an oxygen converter through external refining and vacuum refining, and the round tube blank is produced by adopting a continuous casting method. The invention has the advantages that through adding alloying elements, such as Cu and Cr, the round tube blank with high purity, low gas content and low impurity content is obtained through strictly controlling harmful elements, and moreover, a reasonable reheating schedule, a rolling technology and a heat treating regime are formulated, so that the steel grade has much higher strength than carbon steel and is good in flow accelerated corrosion (FAC) resistance, is capable of saving wall thickness, is safe and reliable and is suitable for the demanding seamless steel tube for the nuclear power station.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

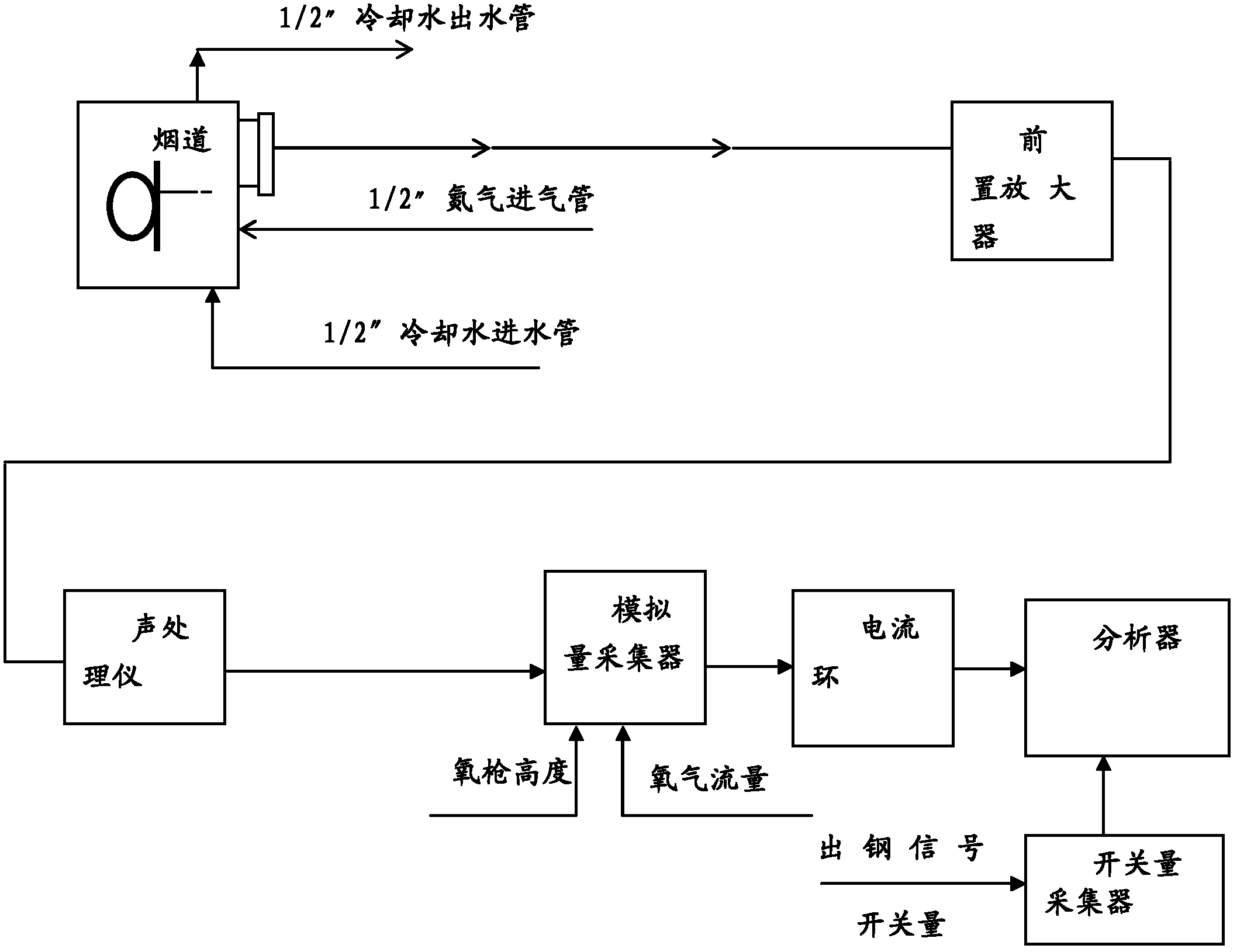

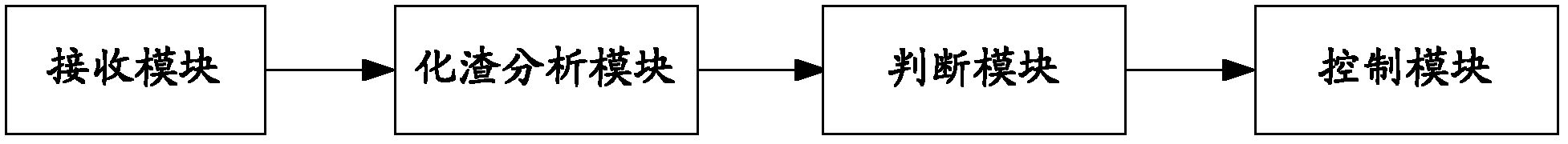

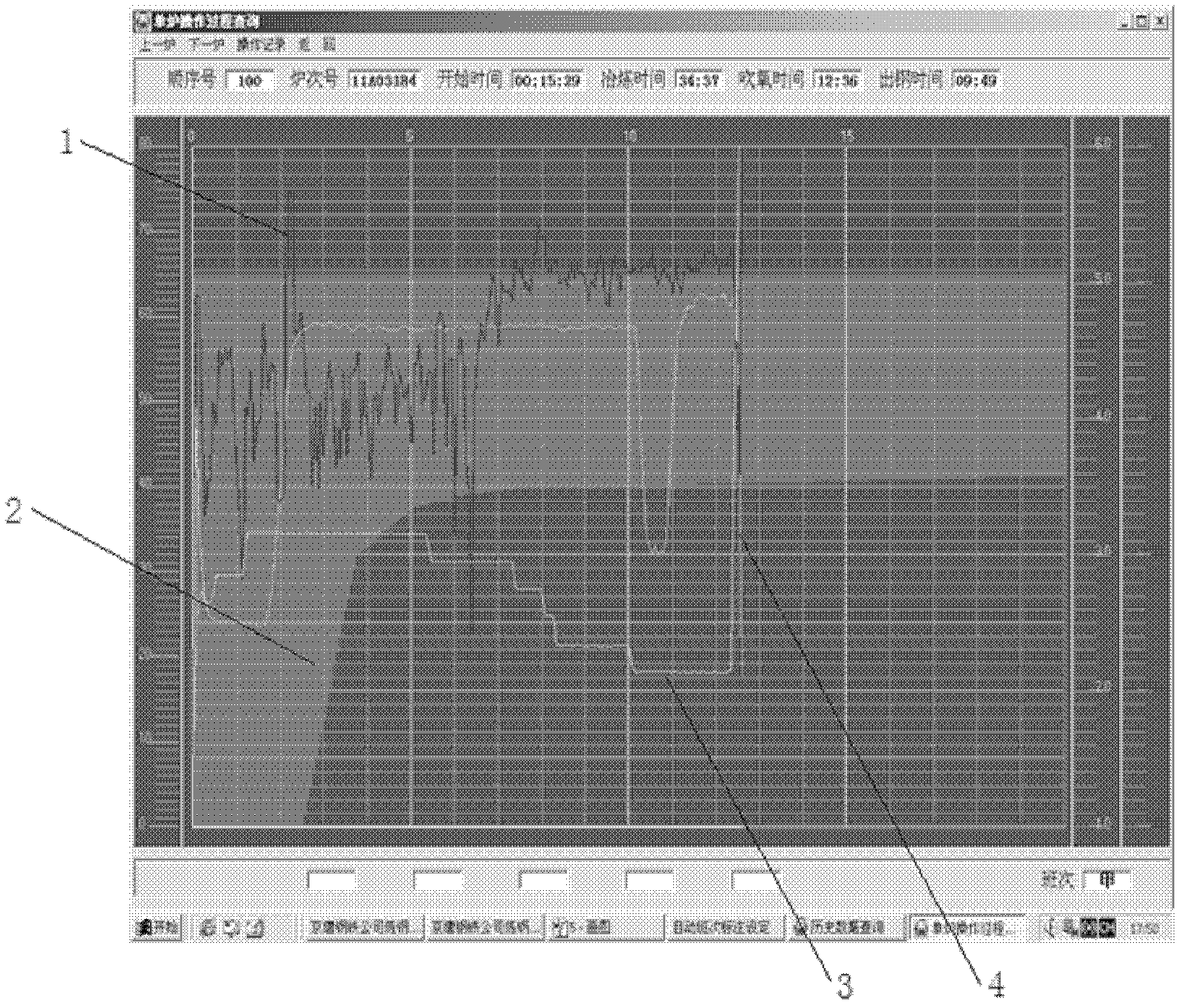

Sonar slagging analysis apparatus and method based on flue sound picking

The invention provides a sonar slagging analysis apparatus based on flue sound picking. The apparatus comprises a noise acquisition device, an analog quantity gatherer and an analyzer. The invention also provides a sonar slagging analysis method based on flue sound picking. The method comprises the following steps: acquiring noise information at a platform flue sampling opening; acquiring oxygen lance height information and oxygen flow information; and analyzing slagging situation according to the noise information, the oxygen lance height information and the oxygen flow information. The sonar slagging analysis apparatus and the sonar slagging analysis method based on flue sound picking provided in the invention can detect and process noise generated in the process of slagging of an oxygen converter, monitor the situation of changing of slag, display a variation curve of sound intensity in the slagging process and guidance information and operation records related to operation on a color monitor of a computer, forecast abnormal furnace conditions like splashing, redrying, etc., and provide visual and striking scientific guidance and management information for operation personnel in front of the converter.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

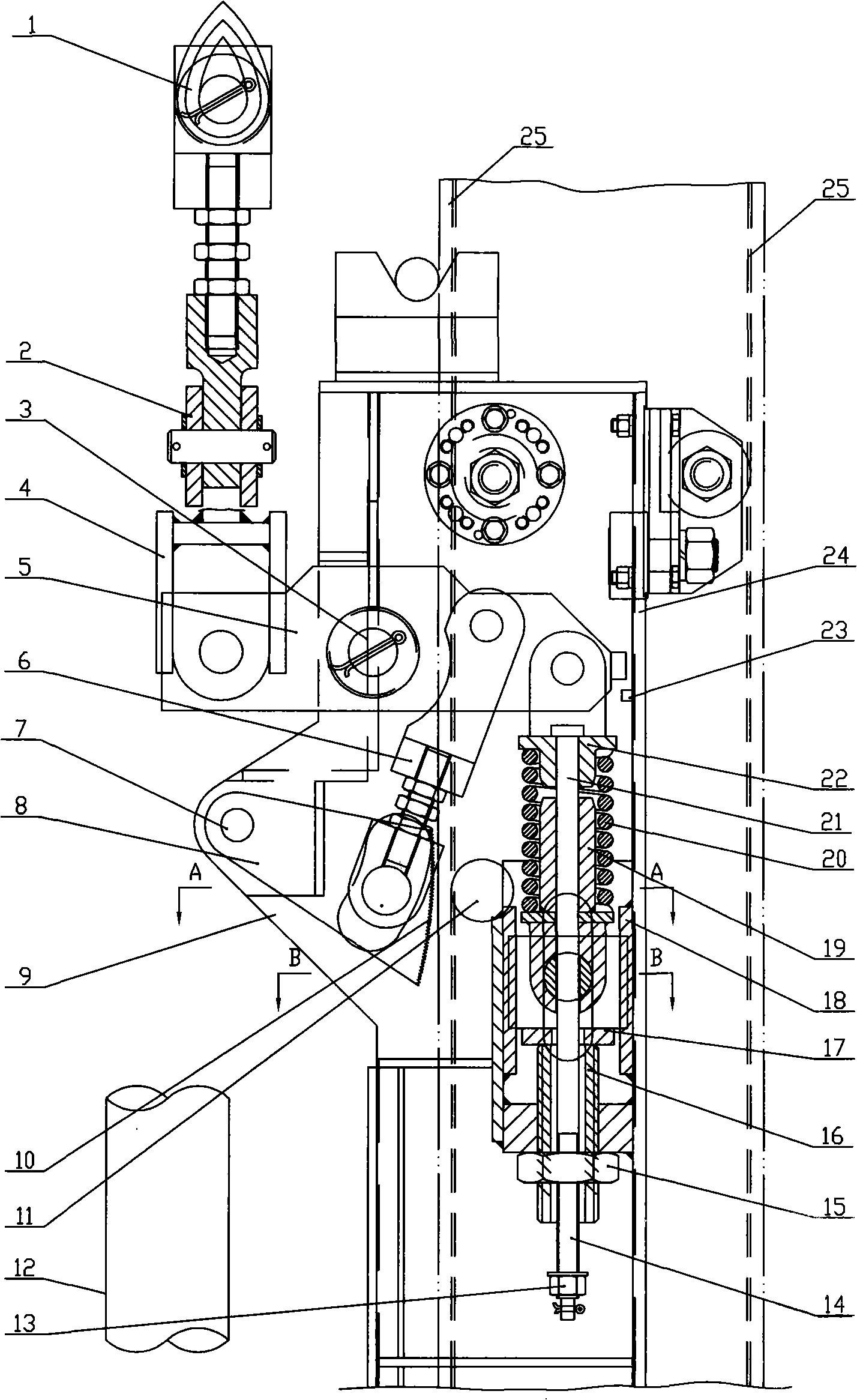

Sublance trolley anti-falling mechanism

InactiveCN101285110APrevent fallingReduce tensionManufacturing convertersVehicle frameOxygen converter

Owner:WISDRI ENG & RES INC LTD

Method for regenerating metal furnace cinder composite mushroom and shimming permeable furnace bottom

ActiveCN101487071AAchieve regenerationGuaranteed breathabilityManufacturing convertersThree stageGranularity

Owner:CENT IRON & STEEL RES INST

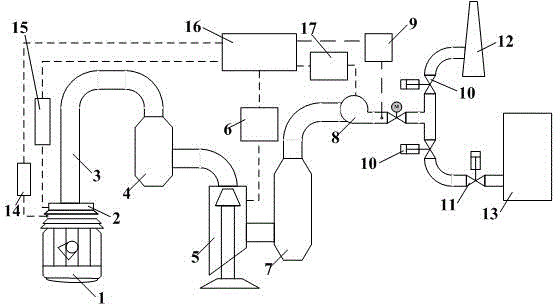

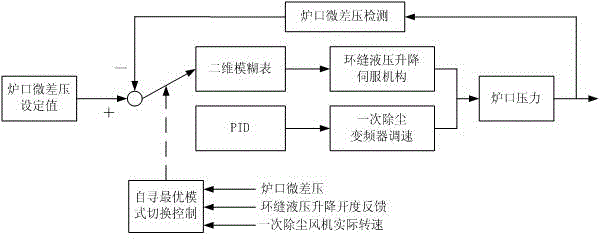

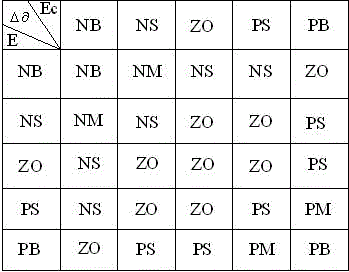

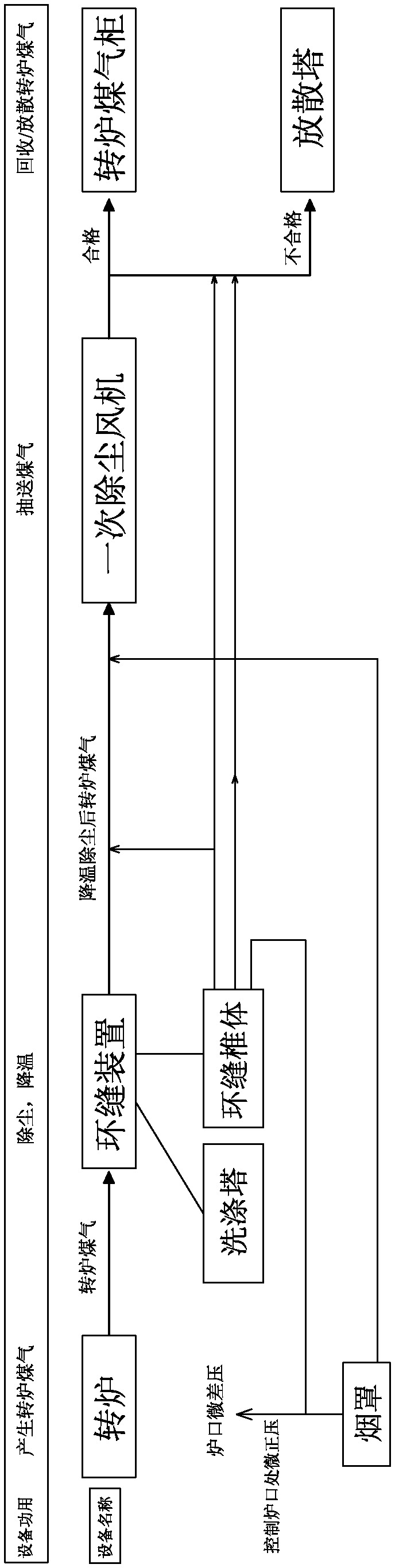

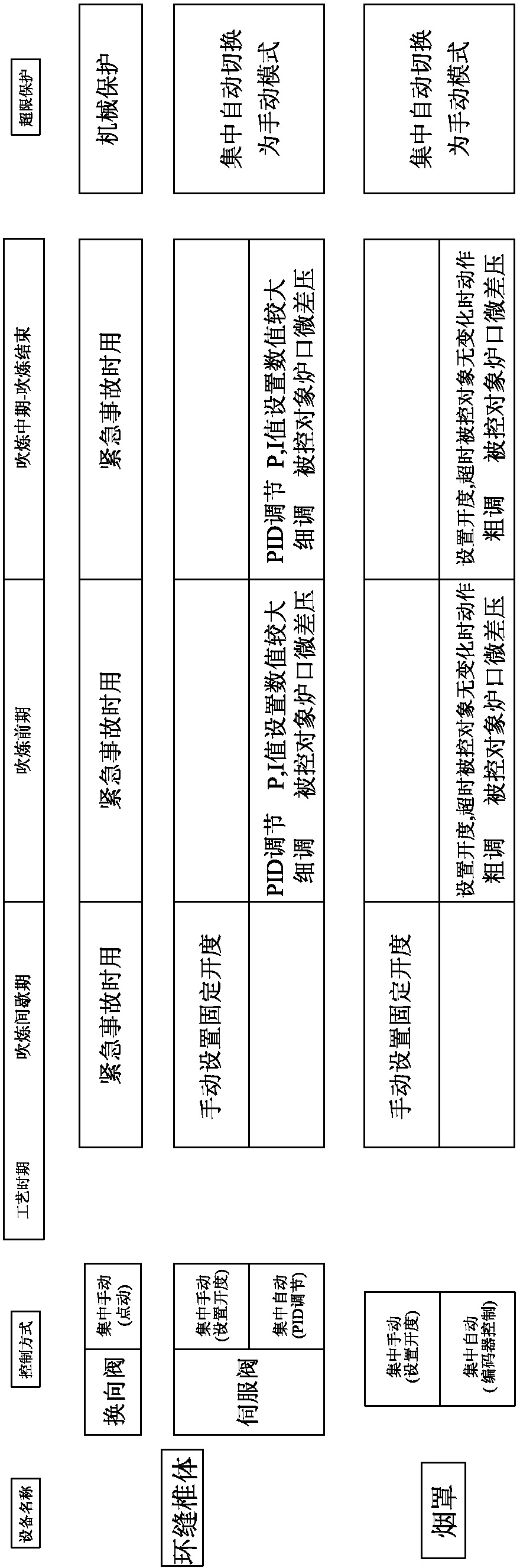

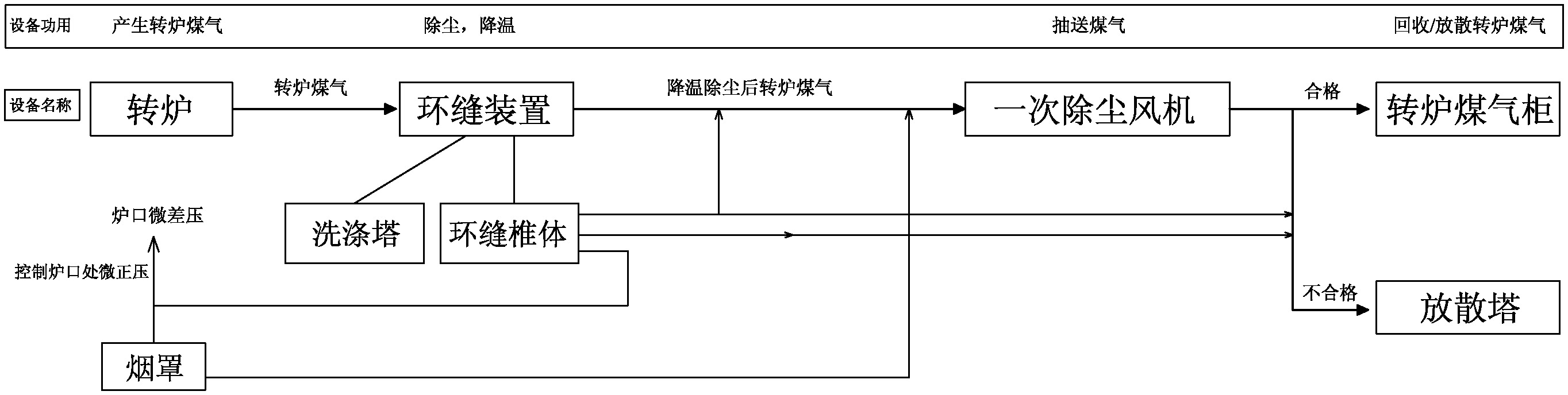

Control method for improving gas recovery of new OG (Oxygen Converter Gas Recovery) converter

InactiveCN102978331AEasy to recycleMeet collection requirementsManufacturing convertersStable stateDifferential pressure

The invention provides a control method for improving gas recovery of a new OG (Oxygen Converter Gas Recovery) converter. The control method comprises the following steps: 1) feeding back a pressure signal of micro differential pressure of a converter mouth, a position signal of an annular gap scrubbing tower and rotation speed of a dust exhausting fan to a PLC (Programmable Logic Controller); 2) detecting the content of gas and the content of CO through a gas analyzing instrument, and igniting and diffusing the gas in a diffusing tower when the contents do not meet the recovery condition; 3) adjusting the micro differential pressure of the converter mouth by self-optimizing model switch control; and 4) starting to recover the gas when the gas analyzing instrument detects that the gas meets the requirement on collection. According to the control method for improving gas recovery of the new OG converter, a movable smoke hood, an annular gap hydraulic control device and the dust exhausting fan are coordinated and controlled by the PLC, the self-optimizing switching control mode is adopted, so that the micro differential pressure of the converter mouth in blowing can quickly reach the range of 0 to 10Pa and the stable state during blowing, and as a result, the content of the gas and the content of CO in of the converter can meet the requirement on collection within a short time, and the purpose of improving the recovery rate of the gas of the converter can be realized.

Owner:CISDI ENG CO LTD +1

Circular seam control device and process for novel converter one-time dedusting OG (Oxygen Converter Gas Recovery) system

InactiveCN102534100AEasy to recycleEasy to controlManufacturing convertersDifferential pressureProgrammable logic controller

The invention discloses a circular seam control device and process for a novel converter one-time dedusting OG (Oxygen Converter Gas Recovery) system. The circular seam control process comprises the following steps of: accessing a position feedback signal of the circular seam control device to a PLC (Programmable Logic Controller) and accessing a signal output from the PLC to a servo valve; in a blowing intermission, concentratedly manually operating a circular seam cone and a smoke hood and manually setting openness; in the initial blowing stage, enabling a three-way valve to be at a diffusion side, igniting and discharging coal gas of a converter, keeping the position of the smoke hood fixed, and enabling the circular seam control device to be in an concentrated and automatic state of the servo valve; in the intermediate blowing stage, enabling the three-way valve to be at a recovery side, roughly adjusting the height and the micro-differential pressure of the smoke hood, reducing the fluctuation of the micro-differential pressure, and setting the circular seam control device to be in a concentrated and automatic state of the serve valve. The circular seam control device comprises the circular seam cone, a hydraulic station and the PLC. The smoke hood is used for matching control over the circular seam control device; the hydraulic station is used for supplying power; the PLC is used for transmitting the signal to the servo valve and controlling the servo valve to actuate; the servo valve is used for driving and controlling the circular seam cone; and an absolute encoderis additionally arranged on the smoke hood. The circular seal control device and process disclosed by the invention have the advantages of reduced number of installation equipment, increase of energyrecovery, low investment and high system precision.

Owner:WISDRI ENG & RES INC LTD

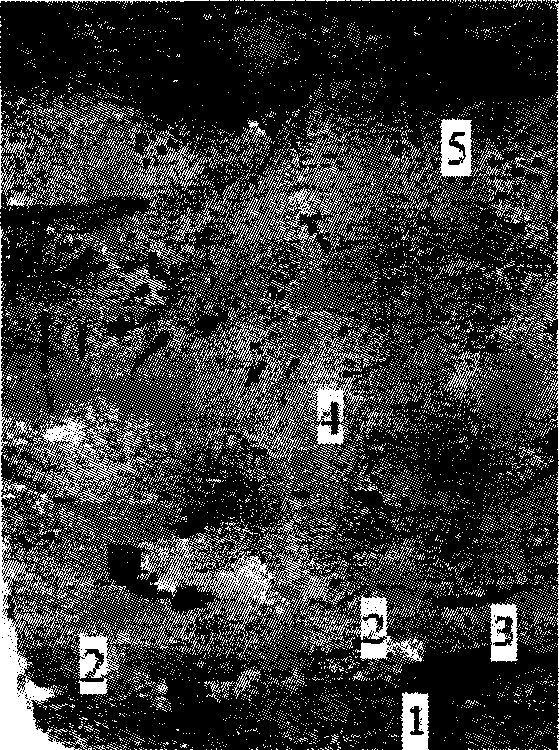

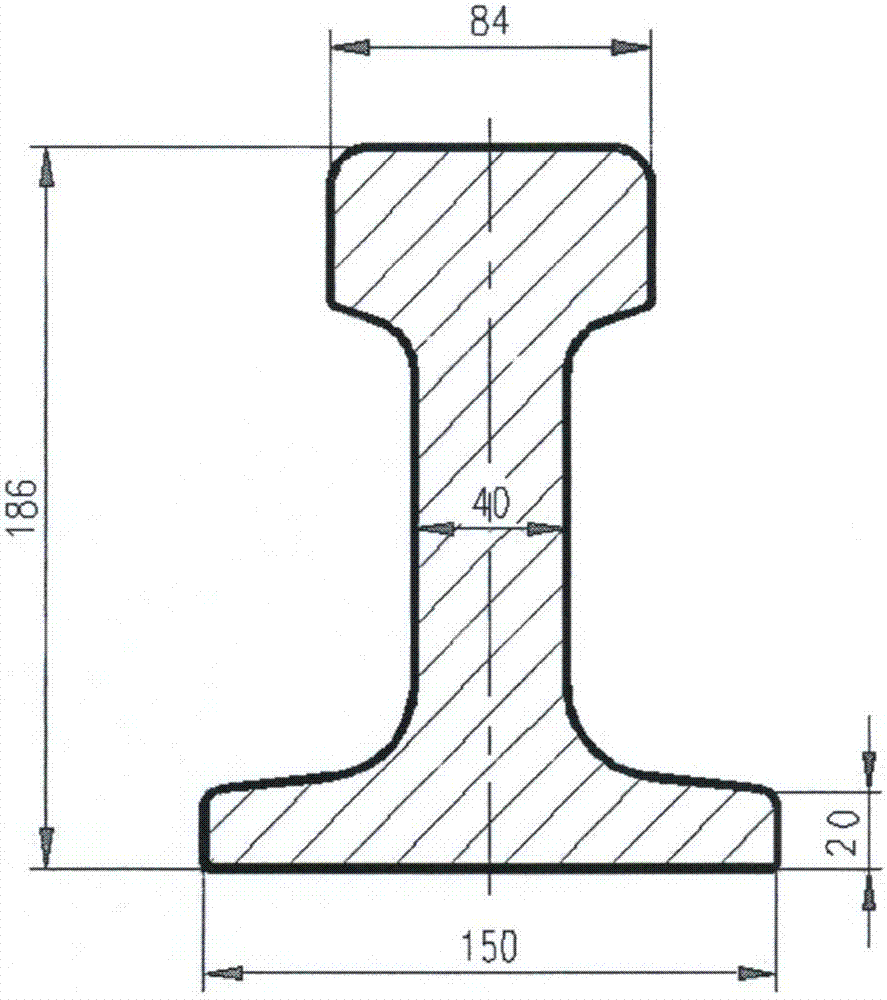

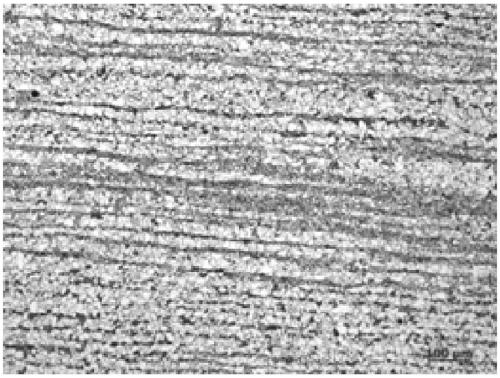

Bainite steel frog and manufacture method thereof by three-stage cooling after rolling

ActiveCN102732804AReduce the amount of machiningIdeal organizationRail switchesFurnace typesChemical compositionThree stage

The invention discloses a bainite steel frog, comprising 0.18-0.23 wt% of C, 1.0-2.0 wt% of Mn, 0.4-0.7 wt% of Al, 0.6-1.0 wt% of Ni, 1.4-2.0 wt% of Cr, 1.0-1.6 wt% of Si, less than 0.01 wt% of Ti, less than 0.0005 wt% of B, less than 0.03 wt% of V, less than 0.01 wt% of Nb, less than 0.0016 wt% of O, less than 0.0001 wt% of H, less than 0.01 wt% of S, and less than 0.01wt% of P, and the balance of Fe A method for manufacturing the bainite steel frog comprises the following steps: smelting in an oxygen converter; then conducting external refining; and then forming sectional form by continuous casting and hot rolling to obtain a railway frog blank material, wherein the rolling ratio is larger than 9; after rolling, directly conducting three-stage cooling to room temperature; and finally heating up to 310-330 DEG C, preserving the heat for 50-70min, and then conducting air cooling to room temperature. According to the invention, the advantages of simple process, low cost, energy saving performance and material saving performance are achieved, and the bainite steel frog has excellent welding performance.

Owner:YANSHAN UNIV

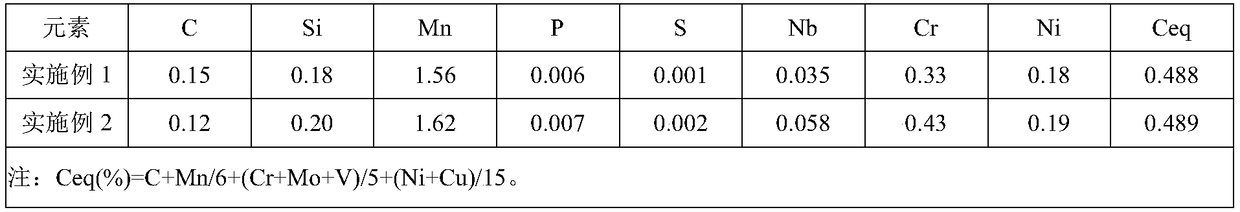

8-25mm thickness type low-yield-ratio and high-strength steel sheet for tank truck and manufacturing method thereof

The invention relates to an 8-25mm thickness type low-yield-ratio and high-strength steel sheet for a tank truck. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck solves the shortages such as high yield ratio, low welding performance and high production cost of a current steel sheet. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck is characterized in that a C+Mn+Cr and Nb and Ni microalloying system is adopted; the steel comprises the following chemical components in percentage by weight: 0.08-0.15% of C, 0.05-0.20% of Si, 1.50-2.00% of Mn, not greater than 0.012% of P, not greater than 0.005% of S, 0.32-0.45% of Cr, 0.10-0.20% of Ni, 0.02-0.07% of Nb, and the balance Fe and inevitable impurity elements; and the formula (seeing the description) is met. A normalizing technology is carried out for production; the mechanical performance meets the condition that the yield strength is not less than 400MPa;the tensile strength Rm is not less than 600MPa; the ductility A50 is not less than 32%; the yield ratio is not greater than 0.75; the transverse impact energy KV2 at below 50 DEG C is not less than 47J; the technical processes include preparing molten iron through a blast furnace, performing KR treatment on the molten iron, performing smelting in a 120-160t oxygen converter, performing refining in an LF (ladle furnace), performing treatment (refining) in an RH vacuum furnace, performing continuous casting, heating a casting blank, performing controlled rolling, performing normalizing, detecting cracks, and inspecting. The 8-25mm thickness type low-yield-ratio and high-strength steel sheet for the tank truck has the characteristics of being low in yield ratio, high in strength, outstandingin low-temperature toughness and plasticity, and high in welding performance; and in addition, the production cost is low; and the operability is high.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

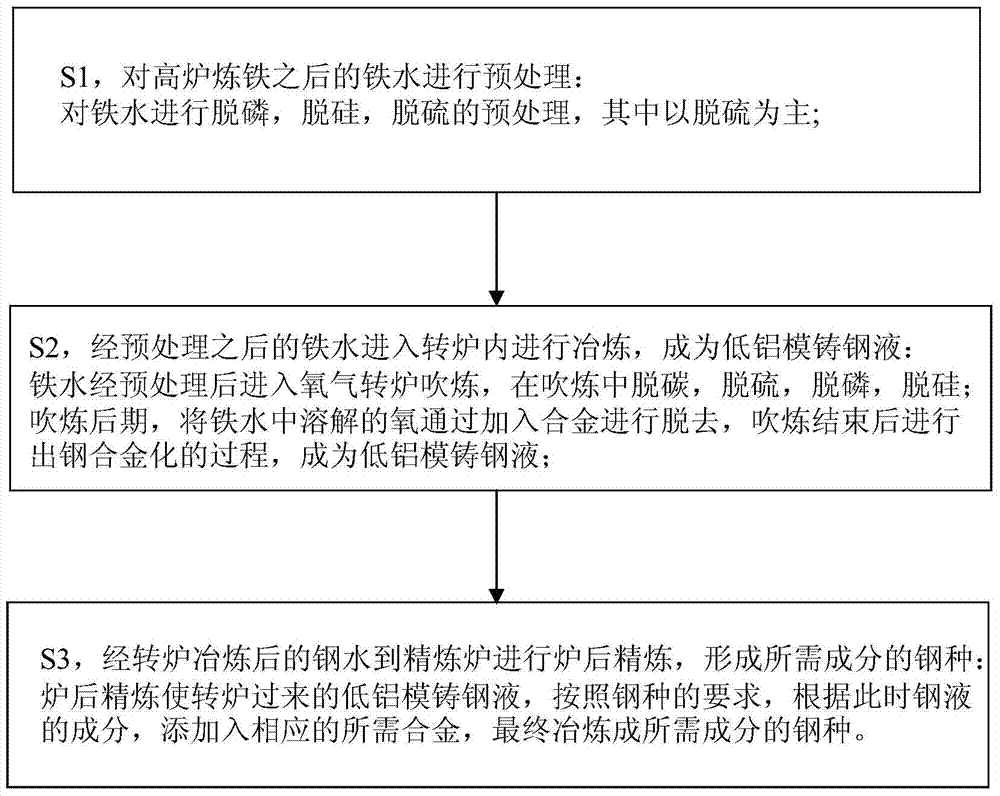

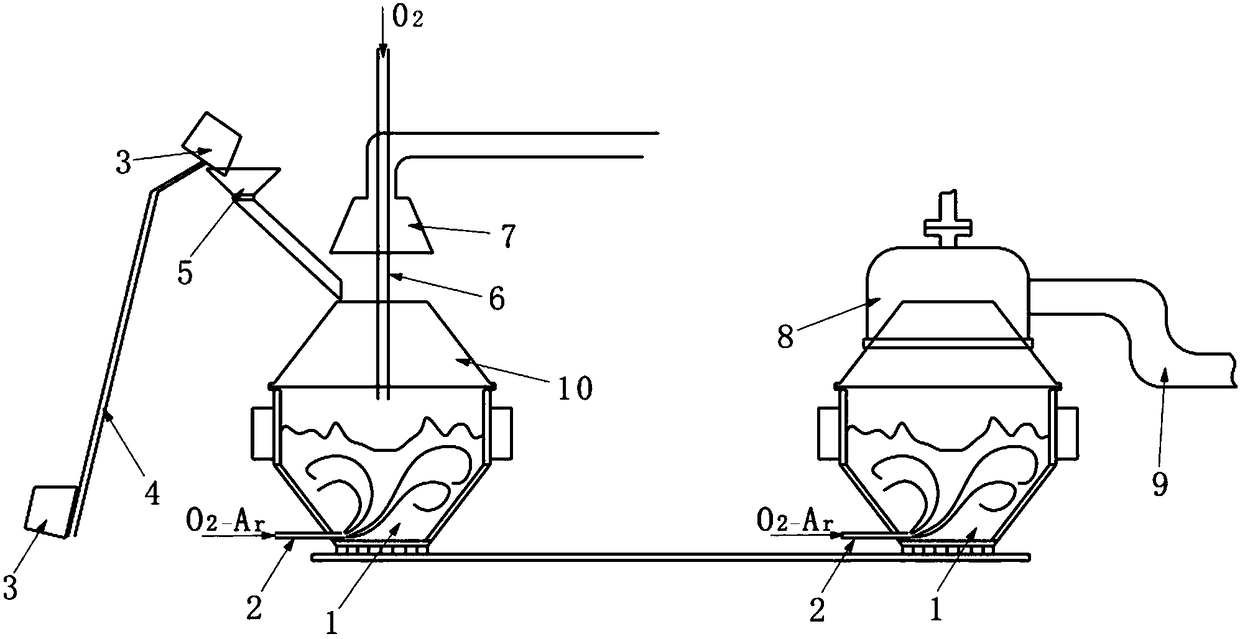

Method for smelting low-aluminium moulded steel

ActiveCN104846150ASolve the problem of out-of-range ingredientsStable controlManufacturing convertersLower limitSmelting process

The invention provides a method for smelting low-aluminium moulded steel, and relates to iron and steel smelting methods. The problem of component pattern breaking in existing low-aluminium moulded steel is solved. The method comprises the steps that molten iron after blast furnace ironmaking is subjected to pretreatment, wherein desulfuration is conducted mainly; the molten iron which is subjected to pretreatment enters a converter to be smelted, oxygen converter blowing is adopted, decarbonization, desulfuration, dephosphorization and desilicication are conducted in the blowing process, oxygen dissolved in the molten iron is removed in the later period of blowing, the process of steel tapping and alloying is conducted after blowing is completed, alloy is added according to steel grade demands, and low-aluminium moulded steel liquid is formed; the molten iron which is smelted by the converter enters a refining furnace to be subjected to the refining process of out of the converter, and a steel grade with the needed components is formed. The method can be widely applied to the smelting of the steel grade, in which temperature rising by blowing oxygen cannot be conducted in refining, and a low limit requirement for aluminium is asked, and the method is particularly applied to moulded steel with a low-aluminium requirement. According to the method, the components of the low-aluminium moulded steel are stably controlled, the problem of component pattern breaking in the low-aluminium moulded steel smelting process is solved, and component steel changing is avoided.

Owner:BAOSHAN IRON & STEEL CO LTD

42Mn wide steel stripe for knife die and manufacturing method thereof

The invention discloses a 42Mn wide steel stripe for a knife die and a manufacturing method of the wide steel stripe. The wide steel stripe comprises the chemical components by weight percent: 0.39%-0.46% of C, 0.80%-0.95% of Mn, 0.18%-0.35% of Si, 0.10-0.30% of Cr, 0.010%-0.050% of Ti, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.010%-0.050% of Alt, and the balance of Fe and inevitable impurity elements. The manufacturing method comprises the processes of: a steelmaking process: smelting by adopting a top-bottom combined blowing oxygen converter, refining molten steel by an LF (ladle furnace); and conveying the molten steel to a continuous casting workshop to carry out continuous casting to form a plate blank; a heating process: heating the plate blank to be at 1190-1250 DEG C, and controlling the total heating time according to 0.7-1.0min / mm; and a rolling process: controlling and rolling the heated plate blank by using a hot rolling mill, and coiling to form the steel strip, wherein the hot continuous rolling finishing temperature range is within 850-920 DEG C, and the coiling temperature range is within 640-720 DEG C. The 42Mn brand wide strip produced by using the method replaces a 30CrMo brand narrow steel strip to be supplied to a knife die factory for manufacturing the knife die, and the demands of the knife die manufacturing industry on purchase cost, width, precision, performance and surface quality of the steel strip are met.

Owner:新余钢铁股份有限公司

Composite reinforced producing method for high strength steel

InactiveCN1900325AImprove purityMeet persistent security requirementsTemperature control deviceManufacturing convertersRebarAustenite

The production process of compositely reinforced steel includes the steps of smelting, tapping, deoxygenating and alloying, blowing argon, continuous casting, finishing, heating, rolling, cooling, etc. The production process features smelting in oxygen converter with final carbon content controlled in 0.08-0.12 %, controlling the chemical components of the steel product, deoxygenating and alloying via adding SiMnFe, MnFe, SiFe, SiAlCaBa and NbFe, bottom blowing argon in the ladle, continuous casting at 1020-1060 deg.c, and rolling in the austenite re-crystallization region. The steel bar product of the present invention has high toughness, good weldability, good earthquake resistant performance, high strength, low cost and high comprehensive performance.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

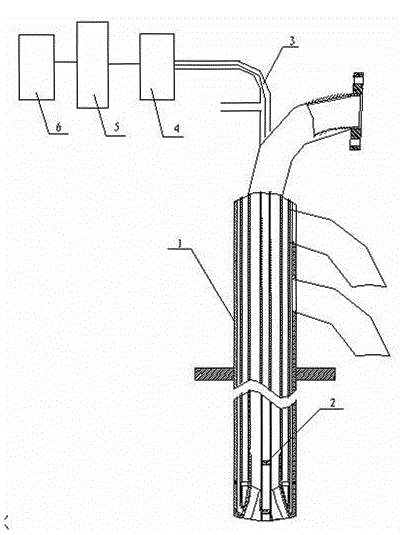

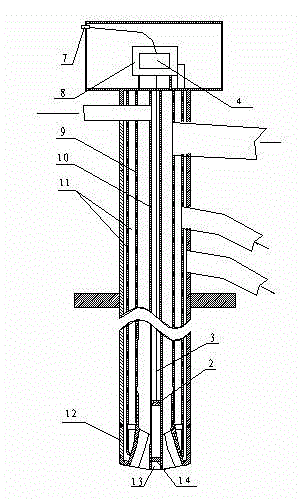

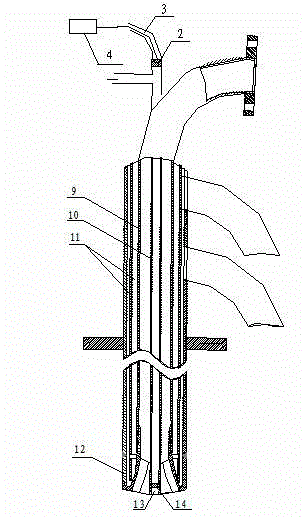

AOD+VOD duplex smelting process and device for low-carbon ferrochrome

The invention discloses an AOD+VOD duplex smelting process and device for low-carbon ferrochrome. The device comprises a movable AOD argon-oxygen converter with a top oxygen lance, wherein a bottom (side) oxygen lance is arranged at the bottom of the argon-oxygen converter, the top oxygen lance, a gas collecting hood and a feeding device are arranged above the argon-oxygen converter, a vacuum hoodis arranged above a VOD vacuum station, the vacuum hood is connected with a vacuumizing device, and a feeding device is arranged at the upper end of a furnace opening. A process of AOD+VOD duplex smelting of low-carbon ferrochrome comprises a molten ferrochrome preparation process, a rapid decarburization AOD refining process, a cooling process by adding a cooling material, a vacuum negative pressure bottom oxygen decarburization VOD refining process, a vacuum negative pressure carbon deoxidation refining process, a reduction refining process and a detection and warehousing process. Accordingto the process provided by the invention, a new process of hot charging of molten ferrochrome is adopted, and oxygen, nitrogen or argon, and a mixed gas of nitrogen and oxygen or argon and oxygen areblown in through special refining equipment to directly smelt low-carbon ferrochrome; and the process has the advantages of short smelting period, no power consumption, good product quality, less impurities, energy conservation, environmental protection and the like.

Owner:CHENGDU HAOSHENG STEEL +1

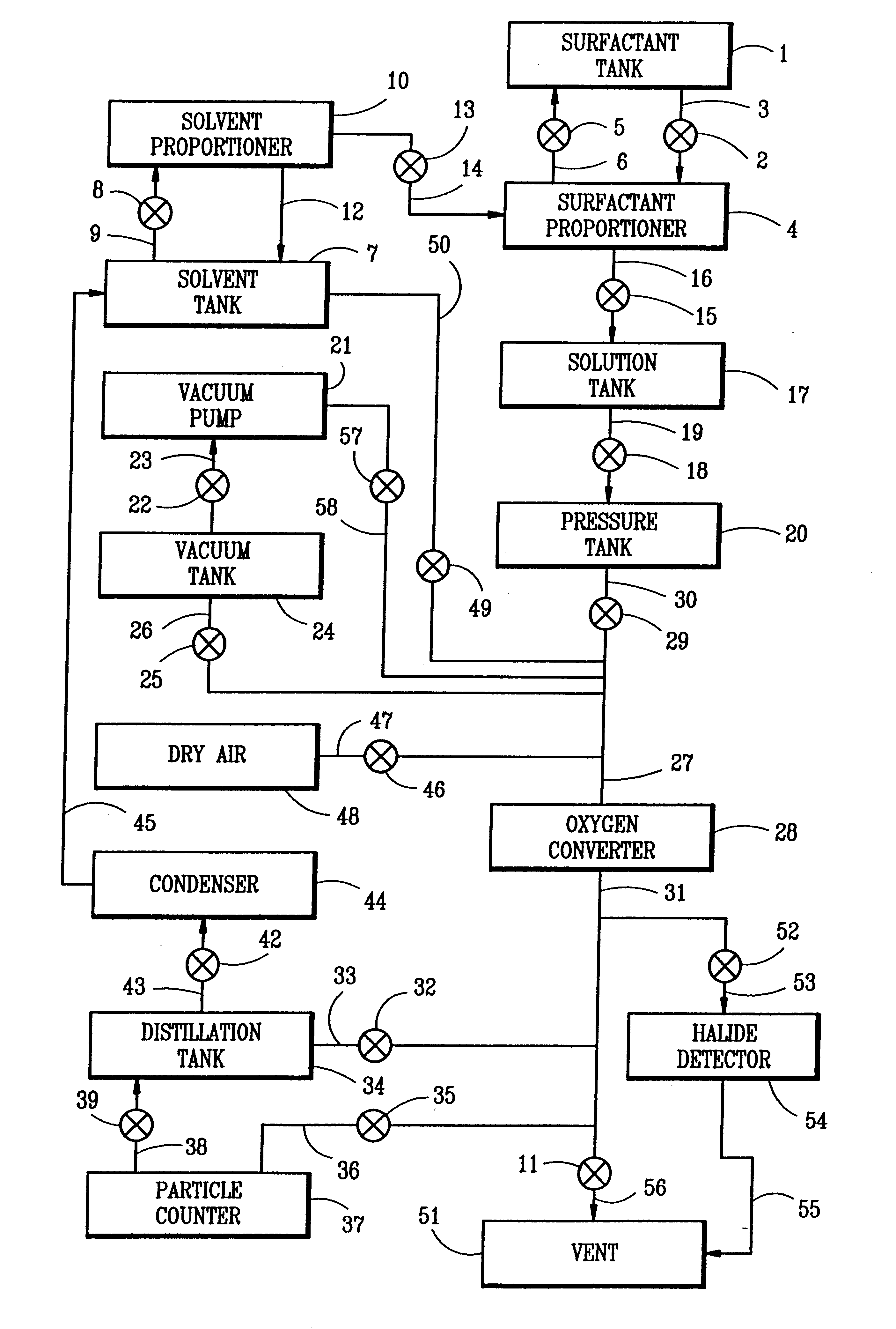

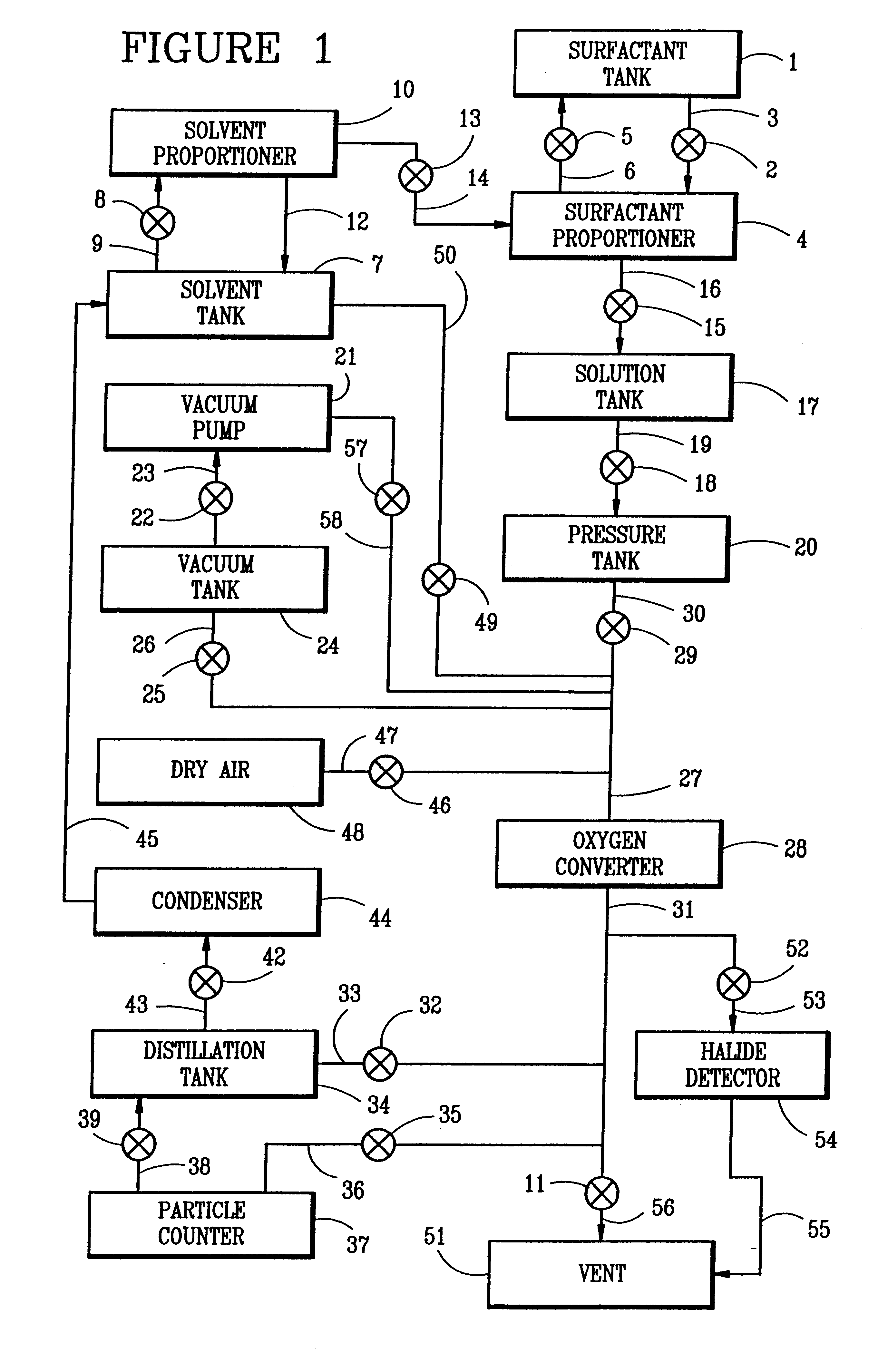

Methods, compositions and apparatus for cleaning surfaces

InactiveUS6676768B2Lighting and heating apparatusHollow article cleaningOxygen converterFluorocarbon

The present invention comprises methods, compositions and apparatus for cleaning the surfaces within vessels that have restricted points of entry, and in particular, the surfaces within oxygen converters and oxygen cylinders. These oxygen converters and oxygen cylinders are components of the onboard oxygen supply systems of aircraft. A surfactant and a solvent are mixed to form a cleaning composition that is boiled at reduced pressure and increased temperature within the oxygen converter or oxygen cylinder. The oxygen converter or oxygen cylinder is rinsed with pure solvent, and the rinse fluid is measured to determine the level of contaminants. Dry air is forced through the oxygen converter or oxygen cylinder to remove remaining solvent. The cleaning composition may comprise a fluorocarbon solvent and a fluorosurfactant.

Owner:VERSAR

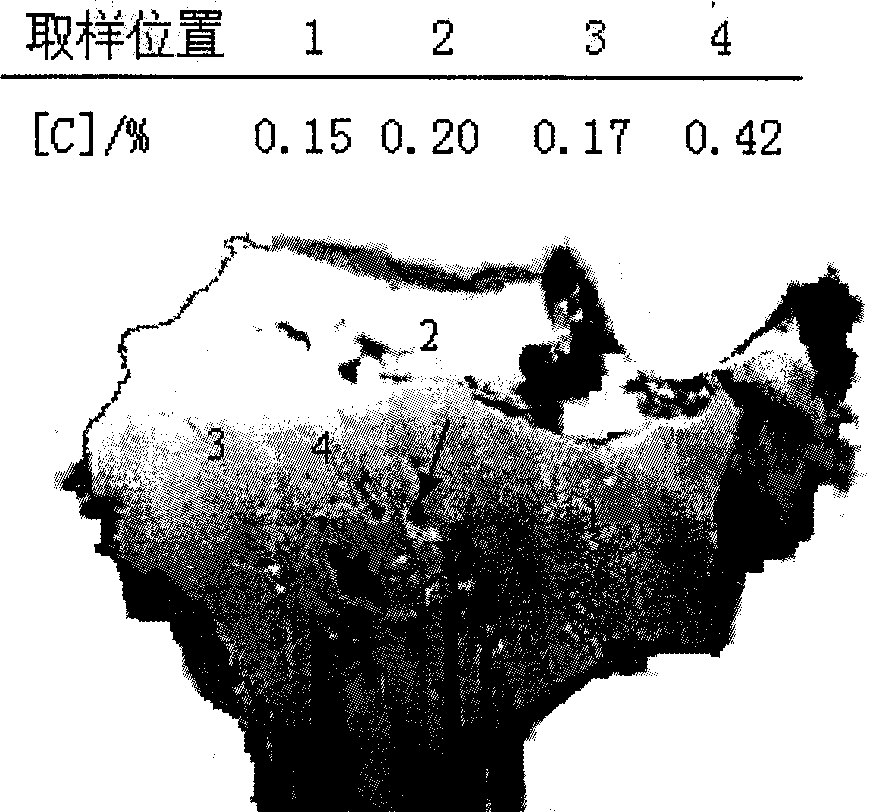

A kind of low compression bit thickness low alloy steel plate and its manufacturing method

The invention relates to an extremely-thick low-alloy steel plate with a low compression ratio. The steel plate is 150-180 mm thick, and consists of the following components in percentage by mass: 0.10-0.17% of C, 0.15-0.45% of Si, 1.18-1.40% of Mn, less than or equal to 0.010% of P, less than or equal to 0.003% of S, 0.10-0.20% of Ni, 0.010-0.040% of Nb and the balance Fe and inevitable impurities; and meanwhile, the content of the corresponding elements meets the following relation: Ceq less than or equal to 0.39%, [C]+[Mn] greater than or equal to 1.35% but less than or equal to 1.50%. A melting process comprises the following steps: oxygen converter smelting, ladle furnace refining, vacuum degassing treatment, continuous casting for slab with thickness being 370 mm or greater, casting blank cover-cooling, casting blank heating, rolling control, cooling control, stacking and slow-cooling, flaw detection and performance examination. The steel plate has the characteristics of being high in strength, excellent in low-temperature toughness, excellent in weldability and the like, and is wider in scope of application.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Process for directly producing austenitic stainless steel by utilizing oxide nickel

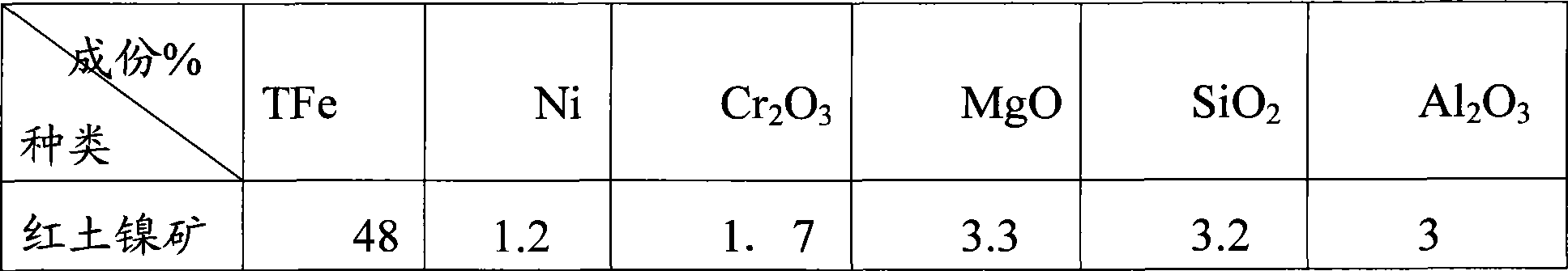

ActiveCN101445845BImprove dephosphorization efficiencyHigh yieldBlast furnace detailsElectric arc furnaceLaterite

The invention relates to a technological process for stainless steel smelting, in particular to a process for directly producing austenitic stainless by utilizing oxide nickel. The process has the following advantages: oxide nickel of various grades is adopted to obtain different ingredients of molten nickel iron by smelting in a blast furnace and a submerged arc furnace, an electric arc furnace is cancelled as a melting unit, the chemical heat of the molten iron is utilized to melt all or part of chromium and manganese alloy, and a bottom-blowing argon-oxygen converter is utilized to dephosphorize so as to improve the dephosphorization efficiency of molten chromium iron and the obtainment yield of chromium, thereby the following series and trademarks of products, i.e. 200 series of 201, 202, J4, and the like, 300 series of 304,304L, 316,321,329, and the like, are produced; and meanwhile, all links in the whole production flows are organically combined, and various energy sources, such as coal gas, steam, afterheat, and the like are fully utilized and recycled, thereby the energy consumption is low, the secondary waste gas discharge amount not great, the production cost and the raw material cost are low, and the investment and the occupied area are not great.

Owner:陈法官 +1

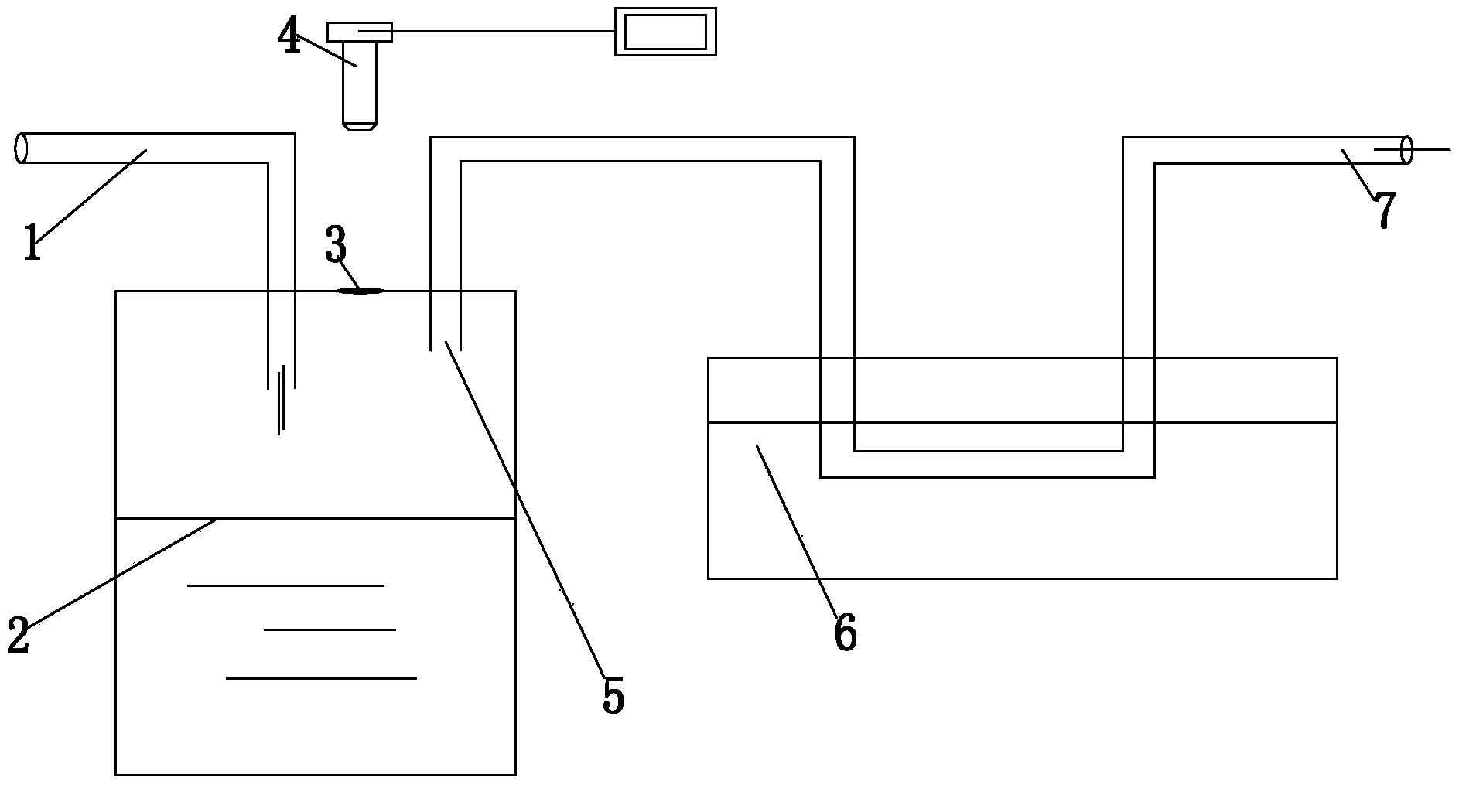

Converter and finery steelmaking on-line continuous detection system

InactiveCN102978335ARealize continuous measurementRealize fully automatic controlFurnace componentsManufacturing convertersAutomatic controlAutomated control system

The invention relates to full-automatic converter steelmaking, and particularly relates to a converter and finery steelmaking continuous detection system. The system comprises an oxygen lance, a light transmission lens and an optical fiber and further comprises a spectrometer and a computer, wherein the oxygen lance is provided with the light transmission lens; the light transmission lens is connected with one end of the optical fiber through an optical coupler; the other end of the optical fiber is connected with a light inlet of an external spectrometer through the optical coupler; a photoelectric conversion signal of the spectrometer is connected with a signal input port of the computer through an output end; and a signal output port of the computer is connected with a converter automatic control system. According to the invention, a means of detecting internal reaction conditions on line is provided; and based on the detection data, the continuous measurement of oxygen converter steelmaking and the full-automatic control on converting process can be realized through spectral analysis instead of sublance and flue gas analysis.

Owner:吕良玮

Thermosetting red mud block and preparation method thereof

The invention discloses a thermosetting red mud block and a preparation method thereof and belongs to the technical field of recycling of iron-containing solid waste resources in iron and steel enterprises. The thermosetting red mud block comprises the following raw materials in percentage by weight: 65 to 75 percent of steelmaking oxygen converter gas recovery sludge (OG), 1.5 to 2.5 percent of bentonite and the balance of scale; and the thermosetting red mud block comprises the following final chemical components in percentage by weight: 1 to 5 percent of MgO, 0 to 0.5 percent of P2O5, 65 to 85 percent of iron oxide, 5 to 15 percent of CaO, 2 to 8 percent of SiO2, 0 to 0.5 percent of S, 1 to 3.5 percent of Al2O3, 1 to 3.5 percent of MnO, and the balance of inevitable impurities. The compressive strength of the thermosetting red mud block is 100 to 200kg / cm<2>. The thermosetting red mud block and the preparation method thereof have the advantages that the defects of complexity of processing process and high preparation cost in the prior art can be overcome, the solid waste produced in a production process in iron and steel enterprises can be recycled, and the ore consumption of a converter can be avoided. Moreover, the thermosetting red mud block also has the characteristics of reducing environmental pollution, along with high quality and the like.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

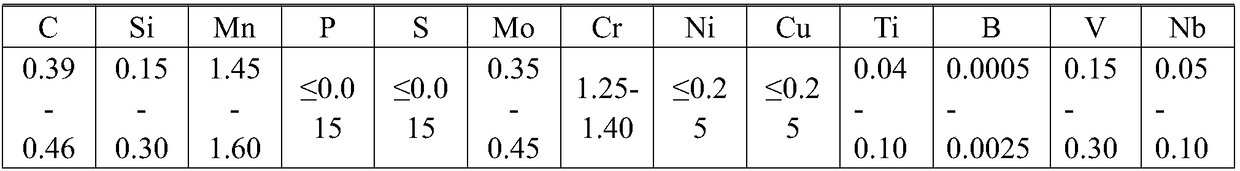

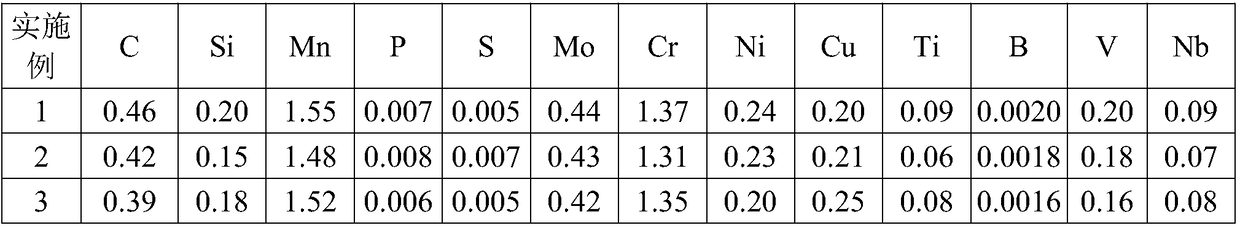

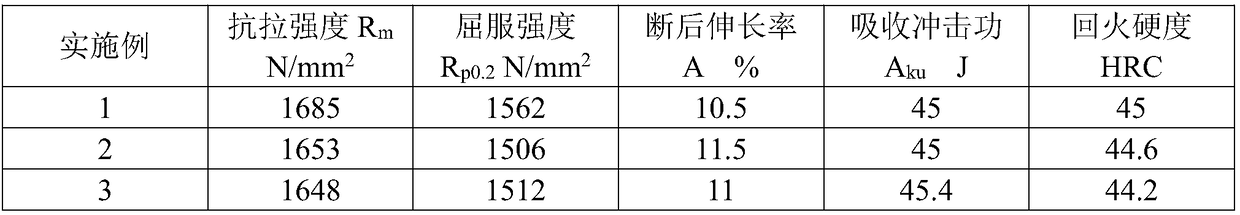

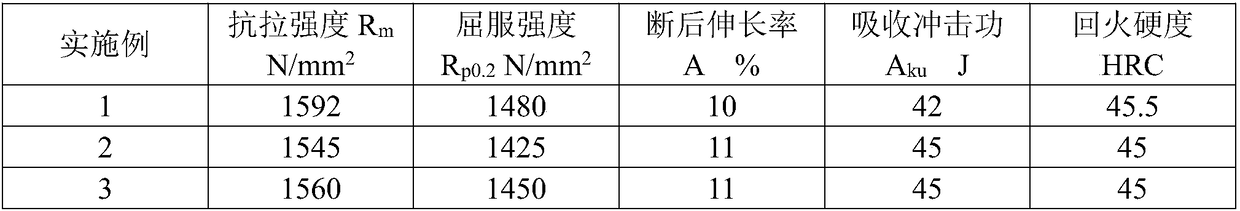

Vanadium-titanium-boron steel material for high-strength bolt and preparation method of vanadium-titanium-boron steel material

The invention discloses a vanadium-titanium-boron steel material for a high-strength bolt. The vanadium-titanium-boron steel material comprises the following chemical element components of, by mass percent, 0.39-0.46% of carbon, 0.15-0.30% of silicon, 1.45-1.60% of manganese, less than or equal to 0.015% of phosphorus, less than or equal to 0.015% of sulfur, 0.35-0.45% of molybdenum, 1.25-1.40% ofchromium, less than or equal to 0.25% of nickel, less than or equal to 0.25% of copper, 0.04-0.10% of titanium, 0.0005-0.0025% of boron, 0.15-0.30% of vanadium, 0.05-0.10% of niobium and the balanceiron. The vanadium-titanium-boron steel material has good machinability and hardenability, various elements act synergistically, and the strength and toughness of steel can be improved effectively. The invention also discloses a preparation method of the vanadium-titanium-boron steel material. By adopting top-blown oxygen converter smelting and furnace external refining, with a continuous castingtechnology, the chemical components of the vanadium-titanium-boron steel material can be controlled within the ranges of design.

Owner:湖南铂固科技股份有限公司

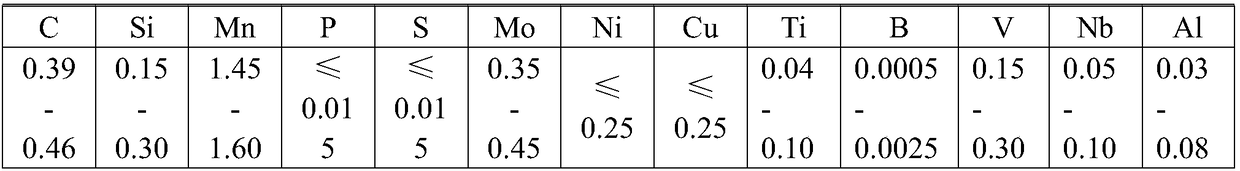

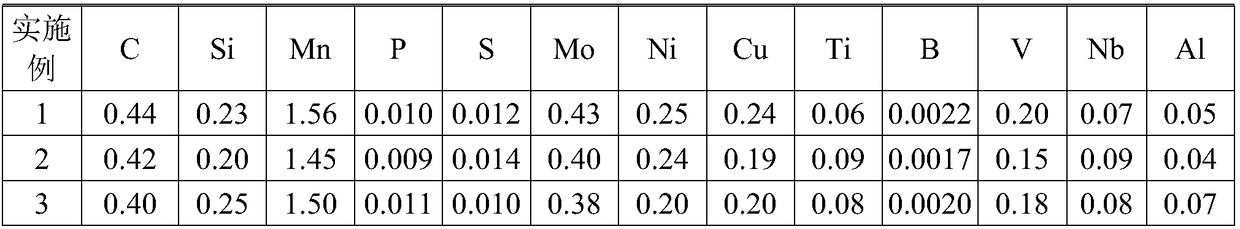

Manganese-molybdenum-vanadium steel material for high-strength bolt and preparation method of manganese-molybdenum-vanadium steel material

The invention discloses a manganese-molybdenum-vanadium steel material for a high-strength bolt. The manganese-molybdenum-vanadium steel material comprises the following chemical element components of, by mass percent,0.39-0.46% of carbon, 0.15-0.30% of silicon, 1.45-1.60% of manganese, less than or equal to 0.015% of phosphorus, less than or equal to 0.015% of sulfur, 0.35-0.45% of molybdenum, less than or equal to 0.25% of nickel, less than or equal to 0.25% of copper, 0.04-0.10% of titanium, 0.0005-0.0025% of boron, 0.15-0.30% of vanadium, 0.05-0.10% of niobium, 0.03-0.08% of aluminum and the balance iron. The manganese-molybdenum-vanadium steel material has good machinability and hardenability, various elements act synergistically, and the strength and toughness of steel can be improved effectively. The invention also discloses a preparation method of the manganese-molybdenum-vanadium steel material. By adopting top-blown oxygen converter smelting and furnace external refining, with a continuous casting technology, the chemical components of the manganese-molybdenum-vanadium steel material can be controlled within the ranges of design.

Owner:湖南铂固科技股份有限公司

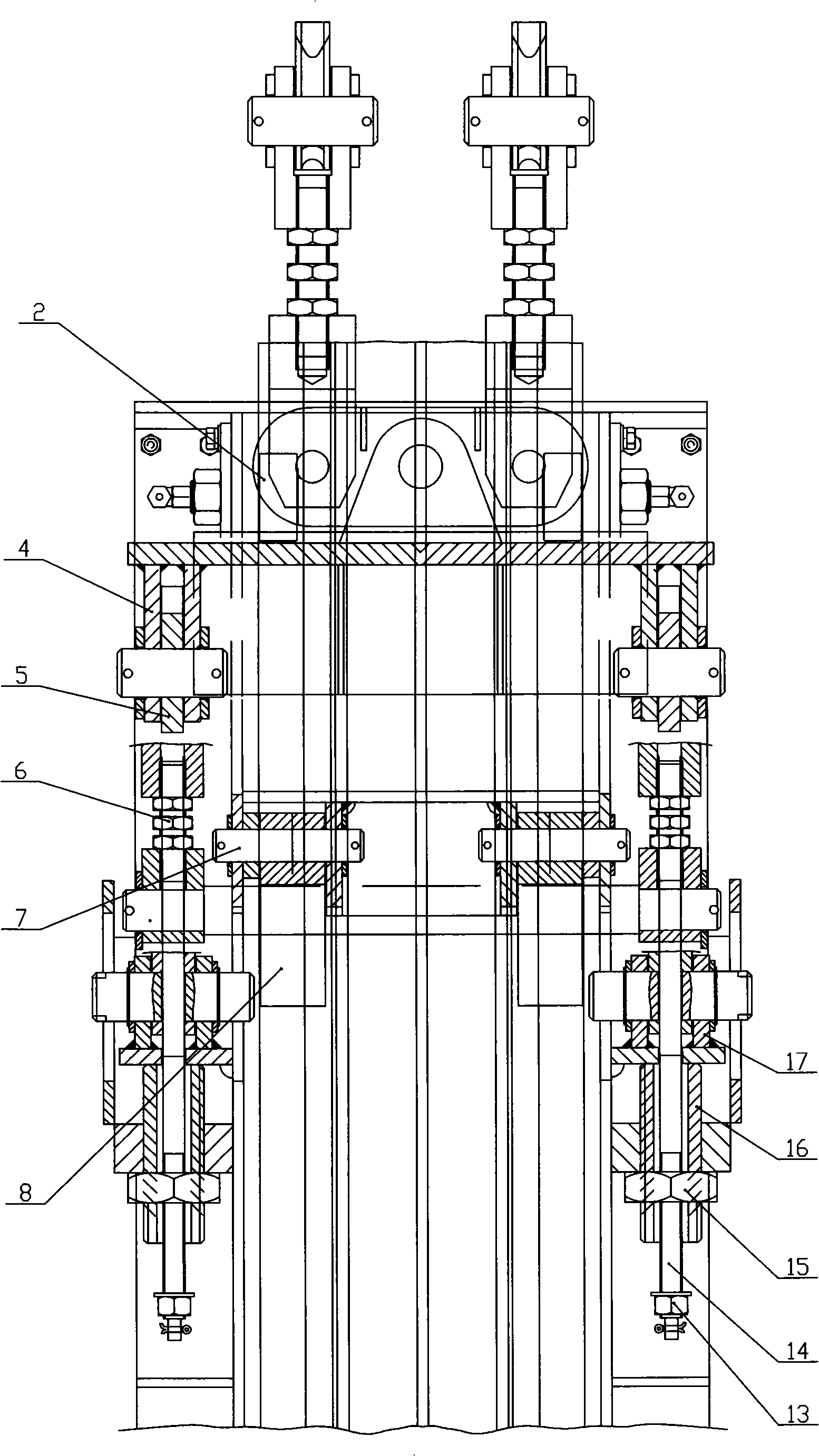

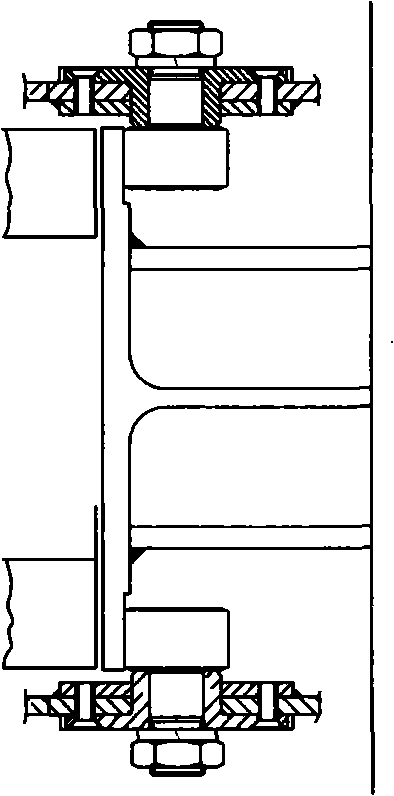

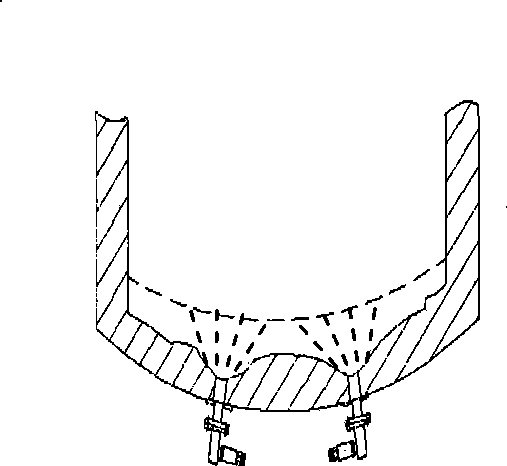

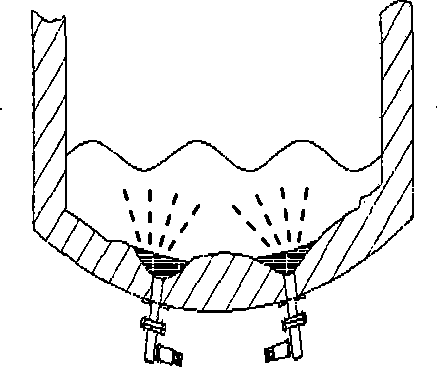

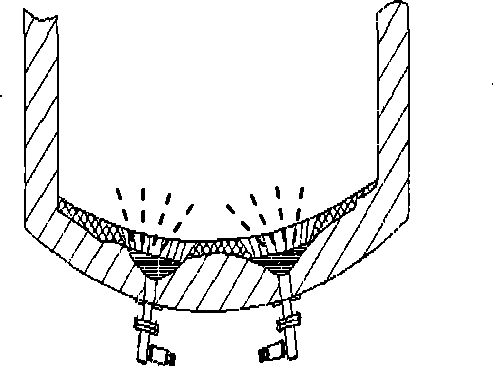

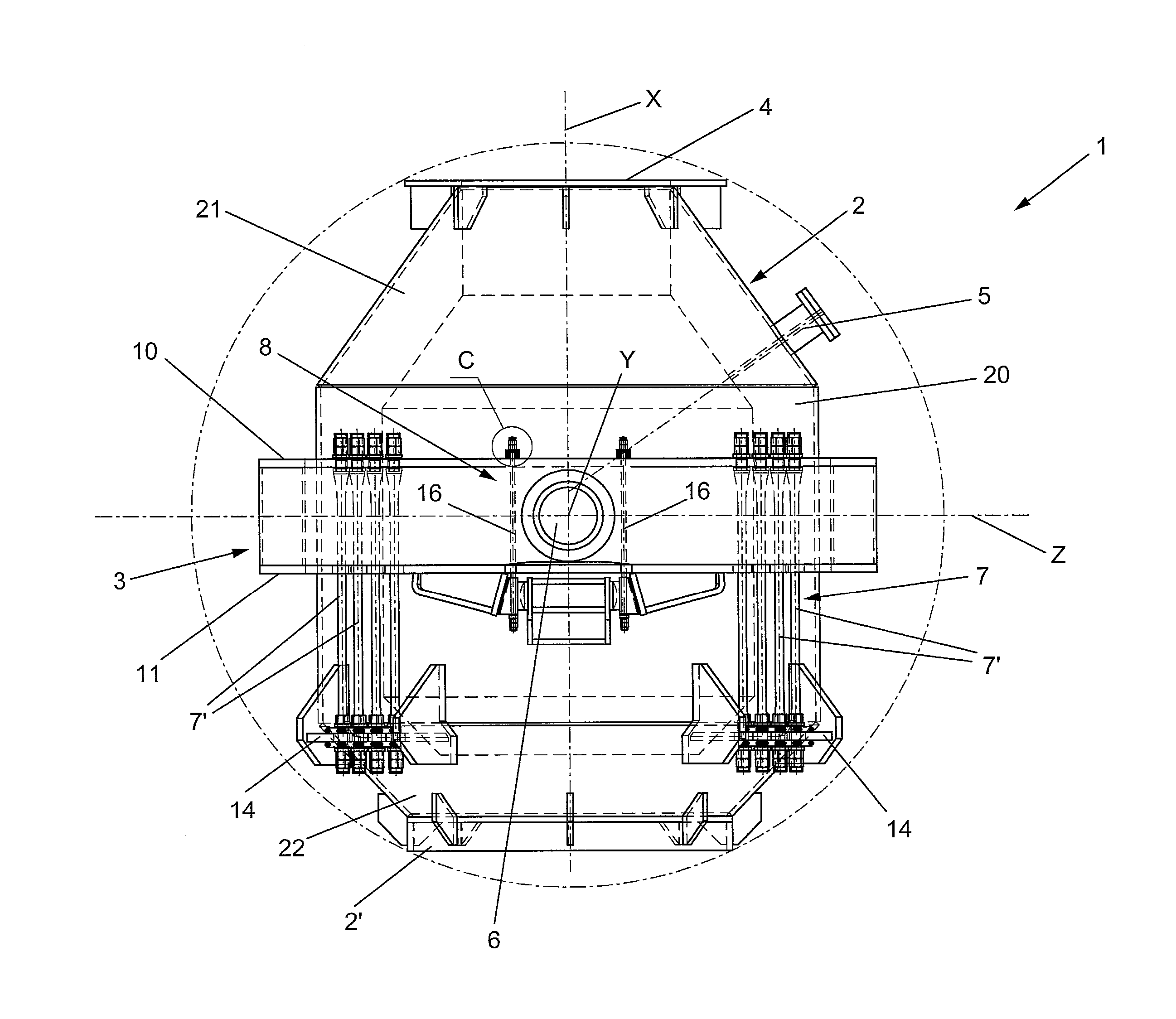

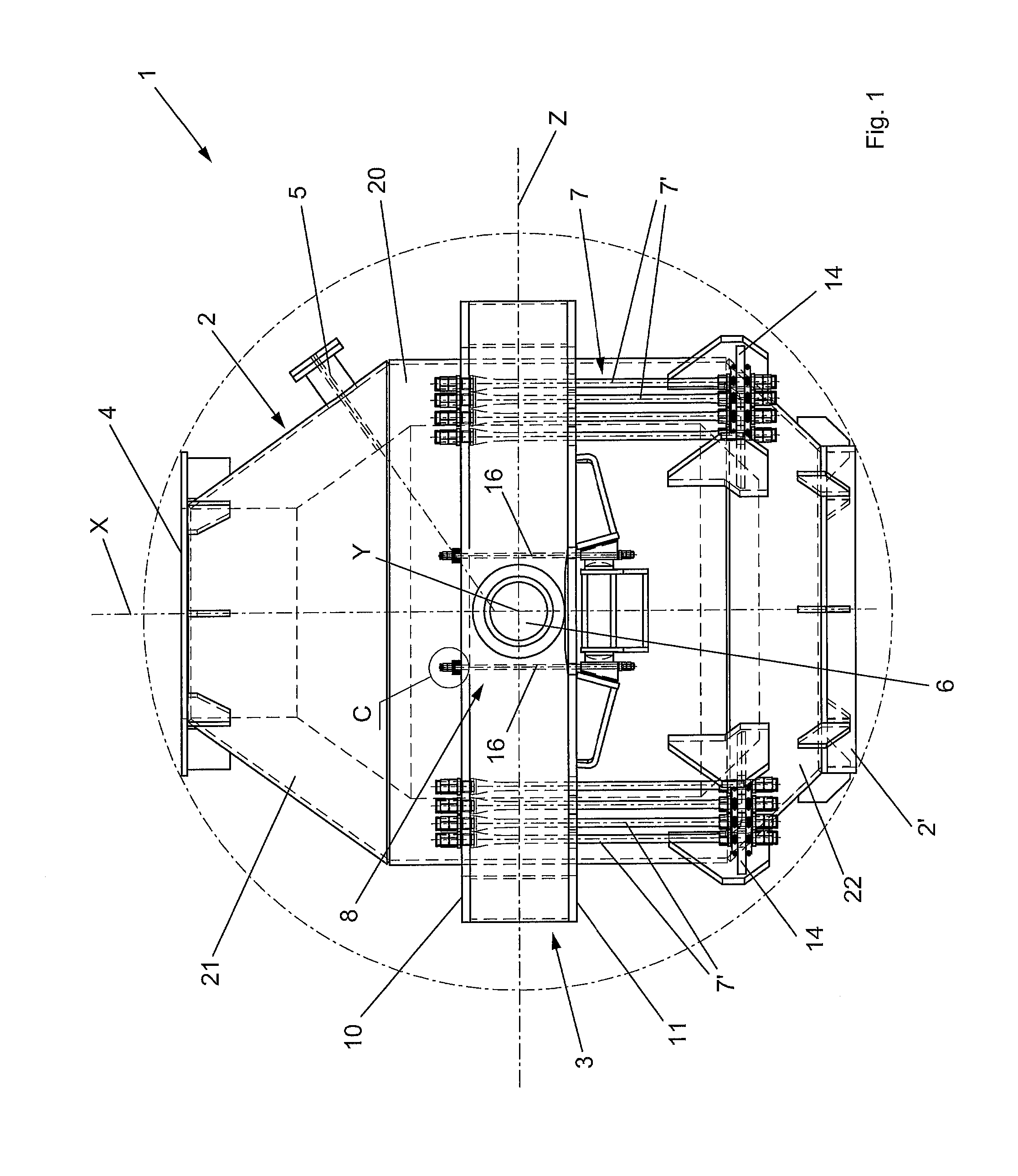

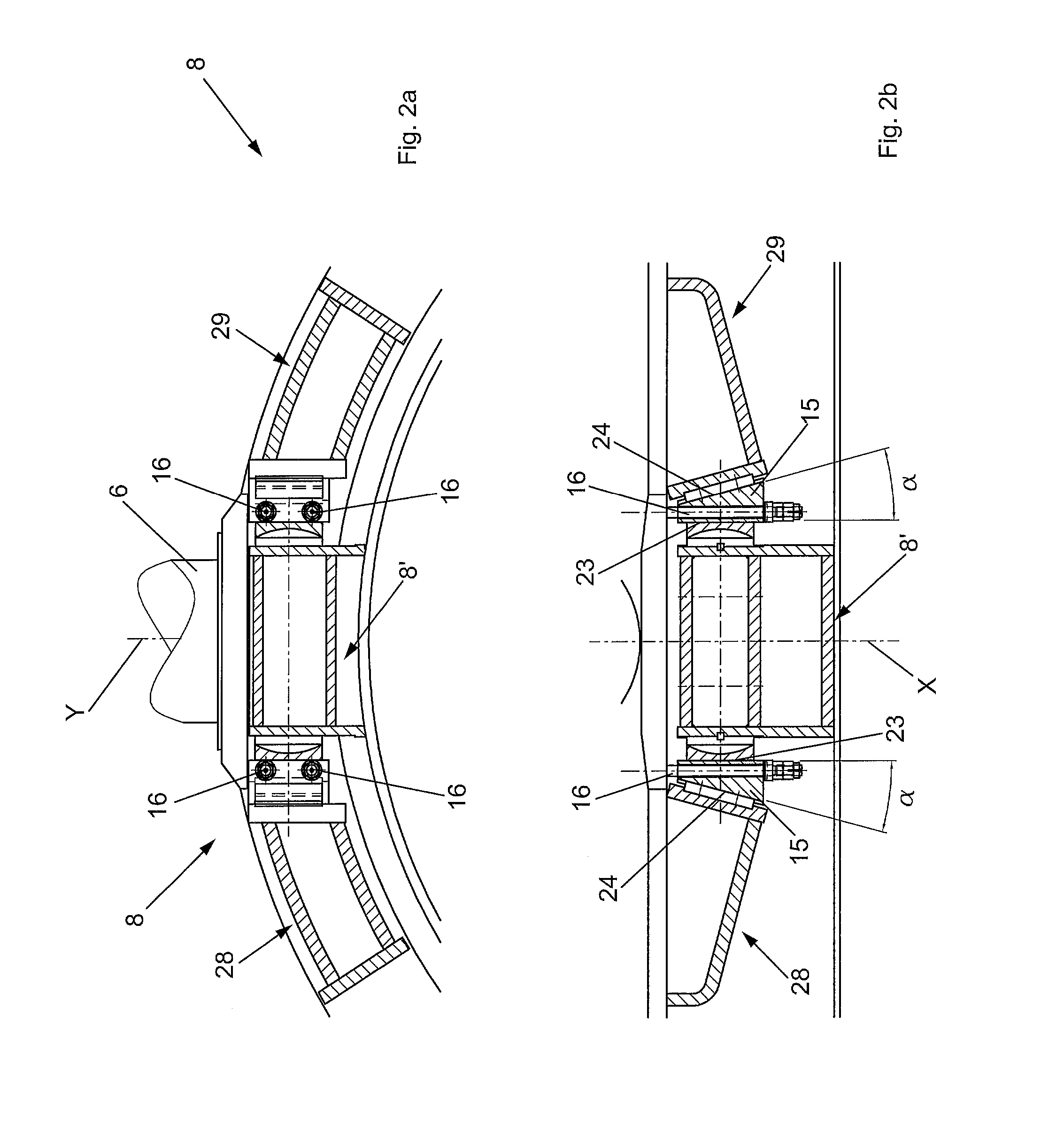

Suspension device for tilting oxygen converters and converter provided with said suspension device

InactiveUS20150152514A1Prevent overloadAvoid creatingManufacturing convertersOxygen converterEngineering

Owner:DANIELI & C OFF MEC SPA

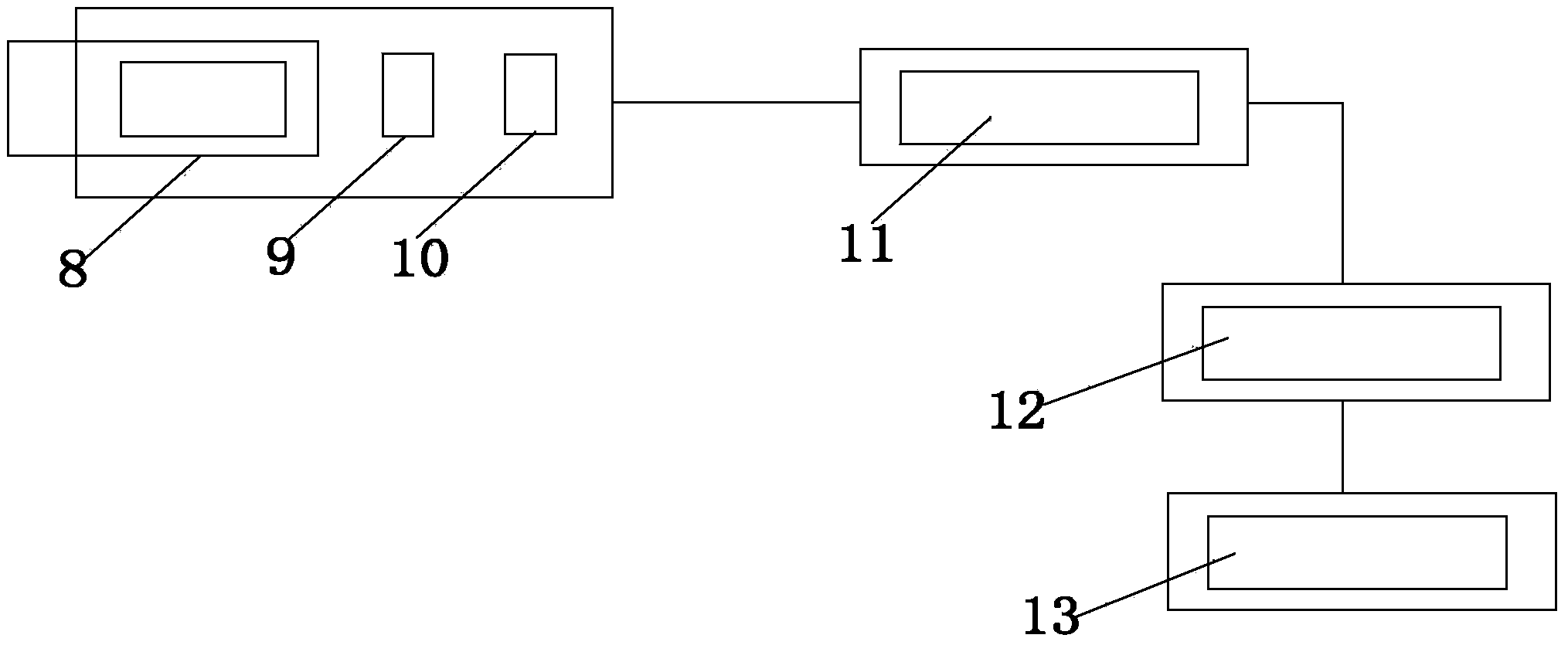

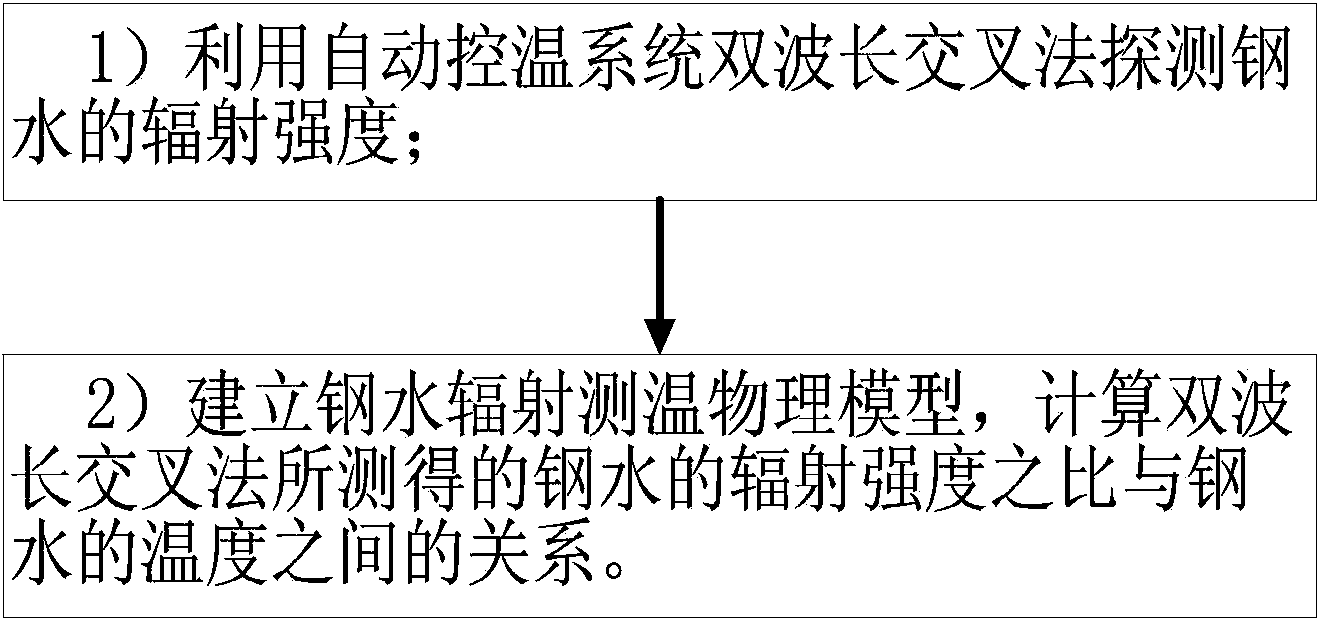

Automatic temperature control system for top blowing oxygen converter steel-making and use method of automatic temperature control system

InactiveCN104232832AHigh temperature control accuracyWide range of temperature controlRadiation pyrometryManufacturing convertersTemperature controlAutomatic Generation Control

The invention discloses an automatic temperature control system for top blowing oxygen converter steel-making and a use method of the automatic temperature control system. The automatic temperature control system for top blowing oxygen converter steel-making comprises an optical receiving system, a double-color cross light path, a photoelectric conversion unit, an A / D analog to digital conversion unit, an information processing unit and an automatic control system, wherein a temperature measuring window is formed in the position between an oxygen blowing conduit and a waste gas collecting conduit on the top of a top blowing oxygen converter; the automatic temperature control system is positioned right above the temperature measuring window. The automatic temperature control system is high in temperature control precision and wide in temperature control range, can automatically control the temperature in an in-situ severe steel-making environment, can avoid operation accident and is worthy of popularization.

Owner:河北新武安钢铁集团文安钢铁有限公司

Oxygen converter high-pressure injection limestone powder slagging and dephosphorization method

InactiveCN109929964AEfficient use ofLow investment costManufacturing convertersOxygen converterDecomposition

The invention relates to the technical field of steel metallurgy, in particular to an oxygen converter high-pressure injection limestone powder slagging and dephosphorization method. According to thescheme, the method comprises the following steps that S1, the following raw materials of, by weight, 20-80 parts of iron raw material (iron powder, pig iron and ladles) and 2-8 parts of limestone powder are prepared; S2, the iron raw materials are placed in a molten iron container, molten iron is formed, and the temperature of the molten iron is controlled to be 1350 DEG C to 1500 DEG C; S3, the 2-8 parts of limestone powder is injected into the molten iron through an oxygen lance with carrier gas as a carrier, and the injection time is 0.5 min to 30 min; and S4, a finished product is subjected to temperature measurement and sampling analysis. Through the decomposition characteristics of limestone and advantages of injection metallurgy, products formed by decomposition after the limestoneis rapidly heated are effectively utilized, CaO participates in the slagging and dephosphorization process, CO2 and C, Si, Mn and other elements in the molten iron react, generate CO and can be continuously used, and thus the method has the advantages of low investment cost and high efficiency.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com