Process for directly producing austenitic stainless steel by utilizing oxide nickel

A technology of austenitic stainless steel and laterite nickel ore, which is applied in the production process field of direct production of austenitic stainless steel by using laterite nickel ore, can solve the problems of polluting the environment, increasing secondary emissions, and increasing smelting costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

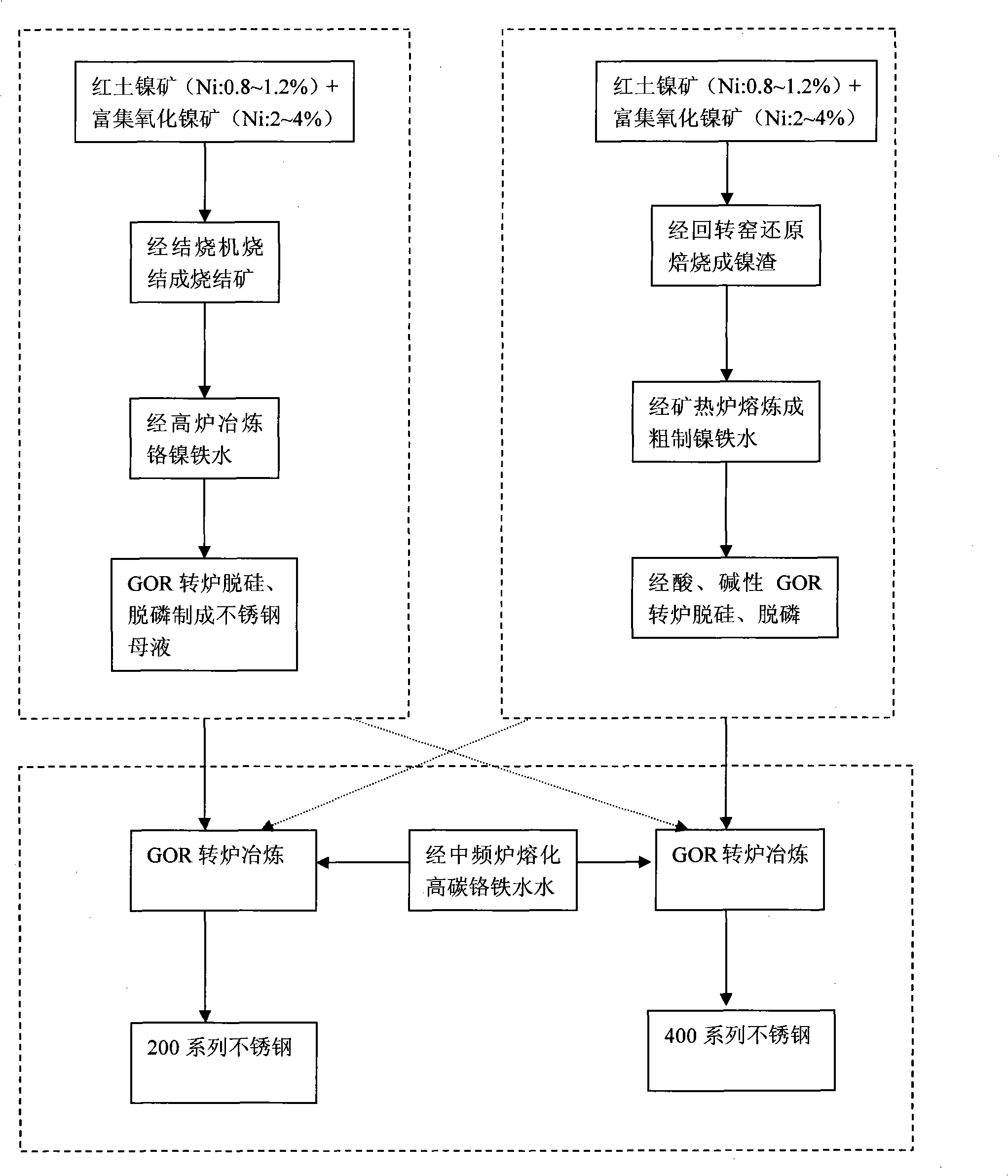

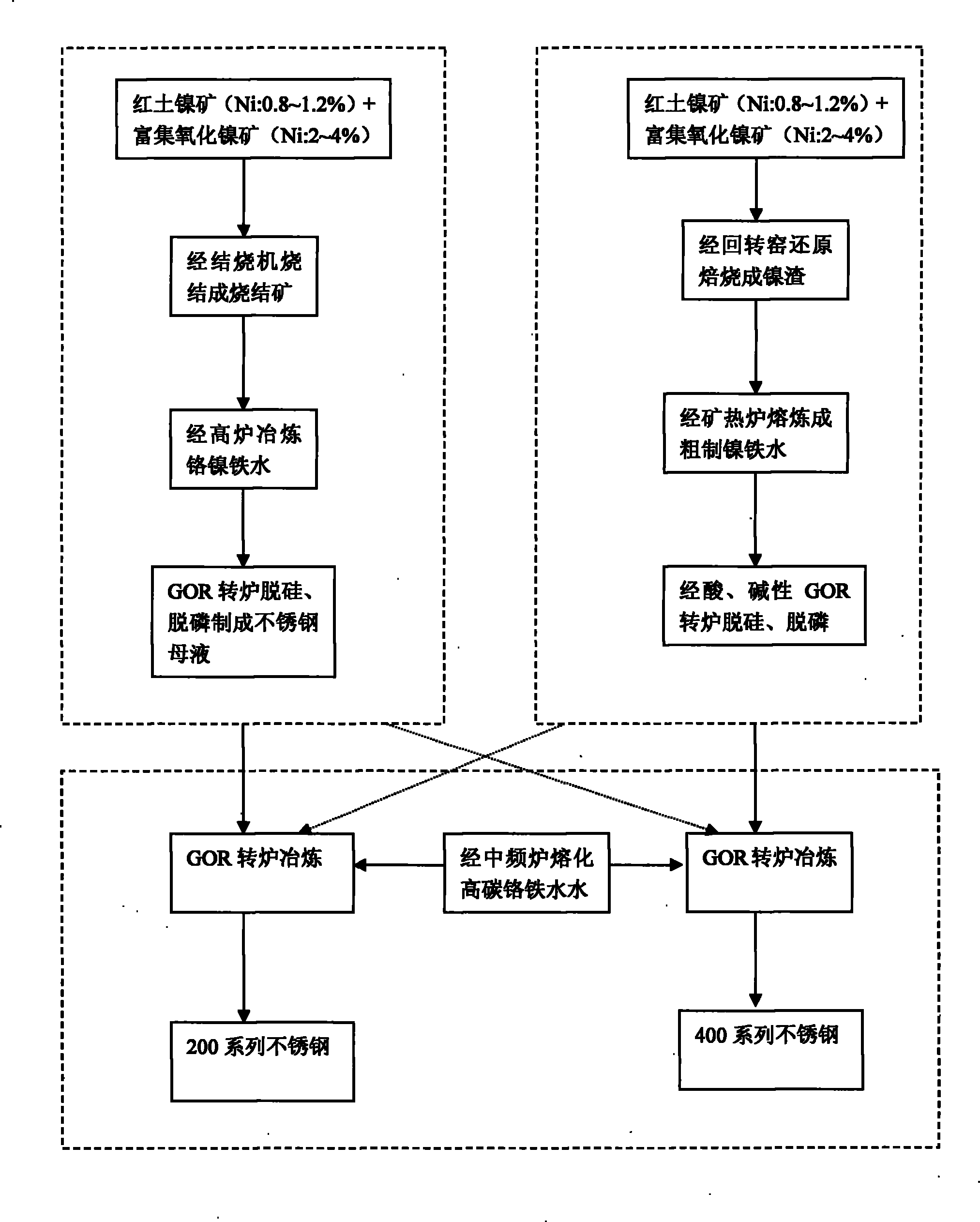

Method used

Image

Examples

Embodiment Construction

[0052] Best practice:

[0053] A production process using laterite nickel-iron to directly produce austenitic stainless steel is used to produce 201 and 304 stainless steel production examples:

[0054] 1. Main equipment:

[0055] Blast furnace hot metal preparation: 1 set of 180m2 sintering machine + 1 set of 600m3 blast furnace

[0056] Preparation of stainless steel mother liquor: one 80-ton GOR converter

[0057] Preparation of molten nickel iron: one 75m*4.85m rotary kiln + 25000KVA submerged arc furnace + two 15-ton GOR refining furnaces.

[0058] Stainless steel production: one 80-ton GOR converter

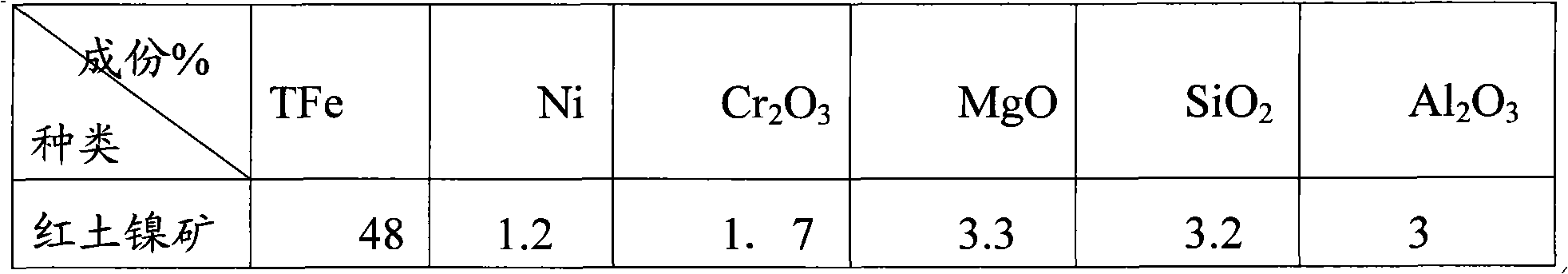

[0059] 2. The chemical composition of the finished product

[0060] Chemical composition % of 201 stainless steel:

[0061] C≤0.15, Si≤1.0, Mn: 5.50~7.50, P≤0.06, S≤0.03, Cr: 16~18, Ni: 3.5~5.5, N: ≤0.25

[0062] Chemical composition % of 304 stainless steel:

[0063] C≤0.07, Si≤1.0, Mn:≤2.0, P≤0.045, S≤0.03, Cr: 17~19,

[0064] Ni: 8.0~10.0

[0065] 3. Main proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com