Converter and finery steelmaking on-line continuous detection system

A detection system and refining furnace technology, applied in the direction of furnaces, furnace components, manufacturing converters, etc., can solve the problems of inability to realize fully automatic steelmaking, lack of online continuous detection means, etc., and achieve the effect of continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

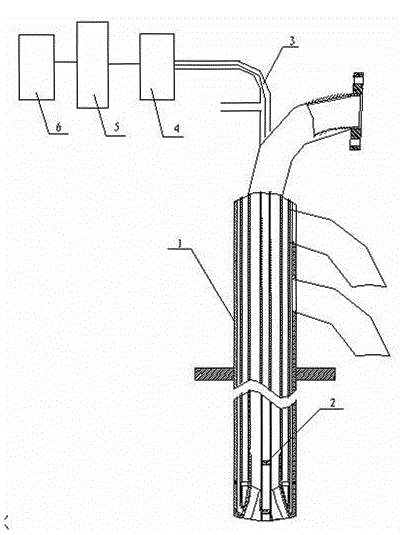

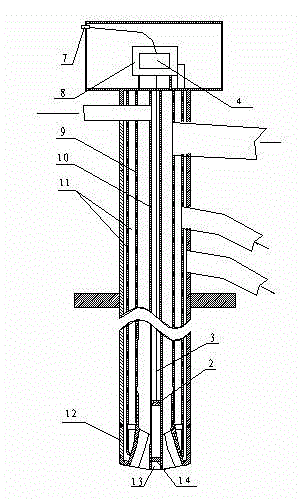

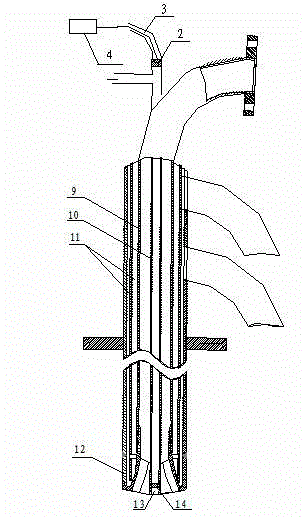

[0019] see figure 1 , this converter and refining furnace steelmaking on-line continuous detection system is composed of oxygen lance 1, light transmission lens 2, optical fiber 3, spectrometer 4, computer 5, oxygen lance 1 is equipped with light transmission lens 2, and light transmission lens 2 is connected through optical coupling One end of the optical fiber 3 is connected to the optical fiber 3, and the other end of the optical fiber 3 is connected to the light entrance of the spectrometer 4 outside the furnace through an optical coupler. The spectrometer 4 is equipped with a grating spectrometer and a CCD array detector. The light entrance is irradiated on the grating spectroscopic device, and the grating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com