Magnetoelectric loop wire test method for continuously applying scanning magnetic field and device thereof

A test device, magnetoelectric technology, applied in the direction of hysteresis curve measurement, magnetic performance measurement, etc., can solve the problem of slow test speed, and achieve the effect of fast measurement, simple operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

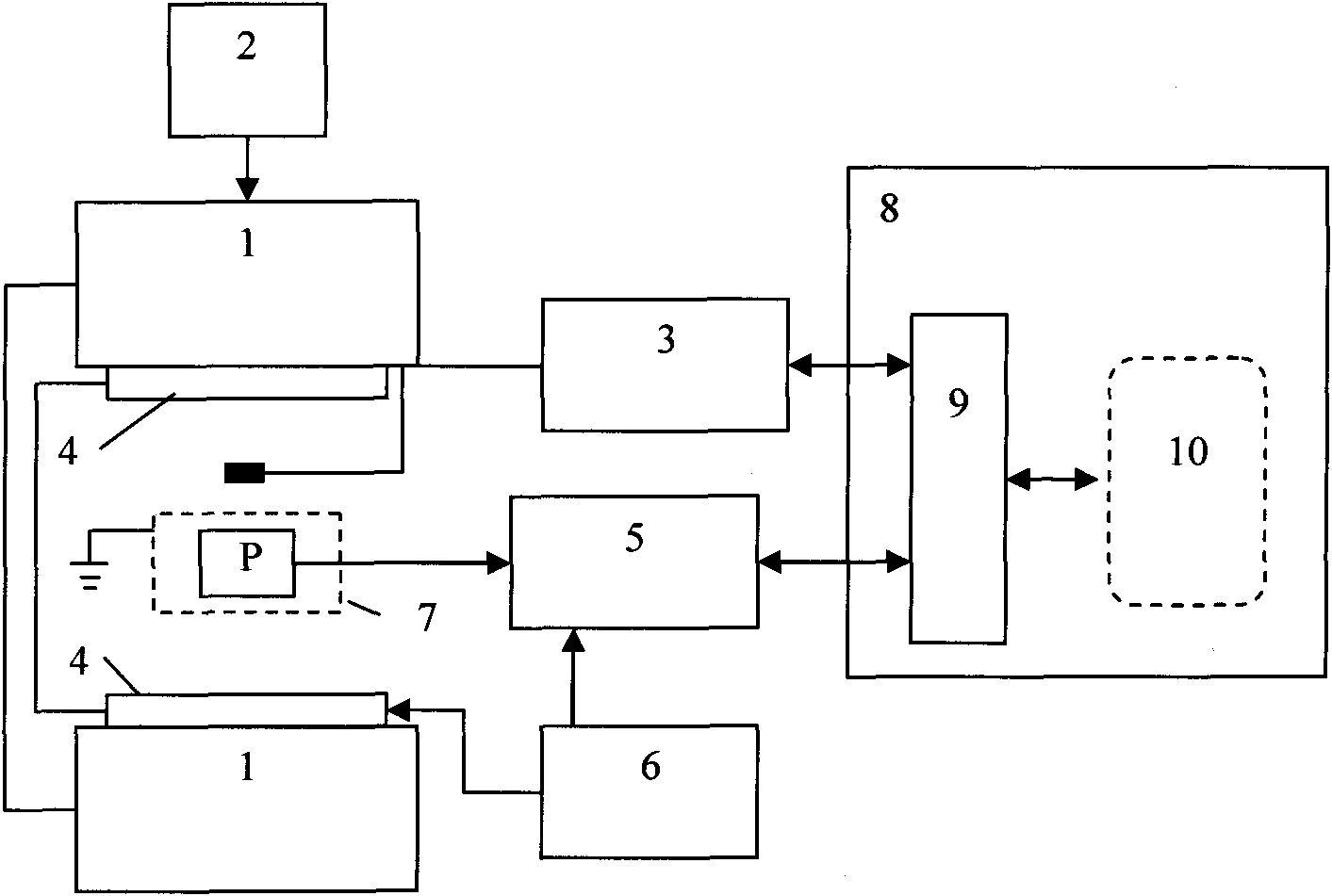

[0071] according to figure 1 The test device is connected in the same way, and an electromagnet 1 (model U-85) is driven by a DC power supply 2 (model U85D). The magnetic field intensity generated by the electromagnet 1 is measured by a Tesla meter 3 (model YL1020) with a communication port, and the Hall probe of the Tesla meter 3 is placed in the uniform strength area of the electromagnet 1. The Helmertz coil 4 is placed in the electromagnet 1, and the center of the uniform intensity area of the coil coincides with the center of the uniform intensity area of the electromagnet. The sample P is placed in the center of the uniform intensity area, surrounded by a grounded shield 7 . The voltage output terminal of the function signal generator 6 (model DG2012A) is connected to the Helmertz coil 4, and outputs an AC voltage with a frequency from 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com