Compensating automatic measurement system and method of soil surface evaporation capacity

An automatic measurement and evaporation technology, which is applied in the field of measurement systems, can solve the problems of large environmental impact on farmland, time-consuming and laborious, and difficult soil loading, and achieve the effect of small environmental impact on farmland, convenient and flexible operation, and continuous measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

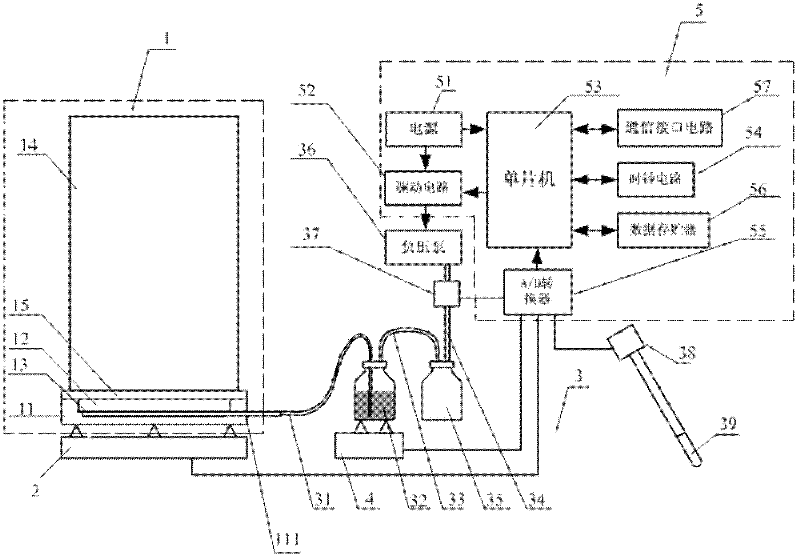

[0017] Such as Figure 1~3 As shown, the compensation type automatic measurement system of the present invention includes a soil measuring device 1 (in the virtual frame on the left), an evaporation load cell 2, a negative pressure compensation device 3, a compensation load cell 4 and a control device 5 (in the virtual box on the right).

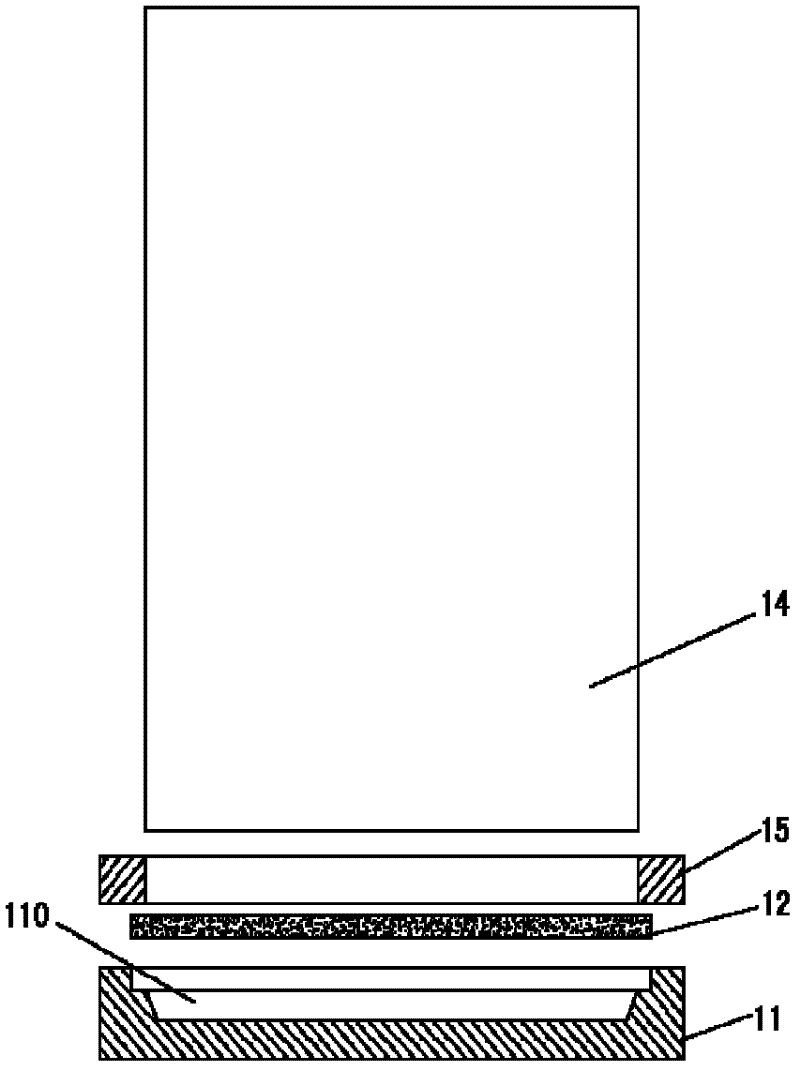

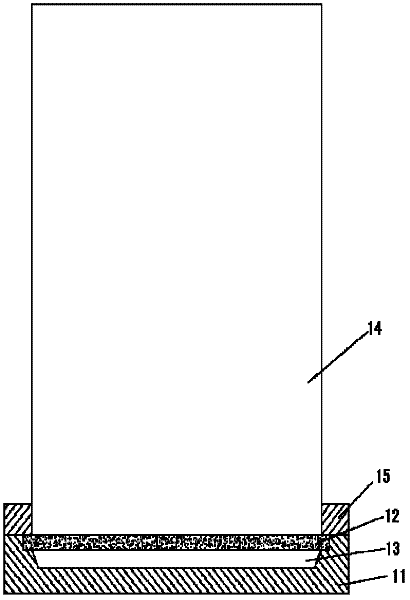

[0018] The soil measuring device 1 of the present invention includes a chassis 11 , a disc-shaped clay plate 12 , a water guide area 13 , a ring-shaped soil cylinder 14 and a pressure plate 15 . Wherein, the chassis 11 is provided with a stepped groove 110 (such as figure 2 shown). When it is necessary to measure the soil body, the clay plate 12 is first placed in the stepped groove 110 of the chassis 11, and the top surfaces of the clay plate 12 and the chassis 11 are flush, and a gap is formed between the clay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com