A kind of process method of in-situ leaching ore injection of ionic rare earth ore

The invention relates to an ionic rare earth ore and a process method, which are applied in the field of in-situ leaching and liquid injection of ionic rare earth ore, and can solve problems such as the recovery rate of rare earth from geological disasters, and achieve the advantages of improving labor productivity, reducing leaching time, and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

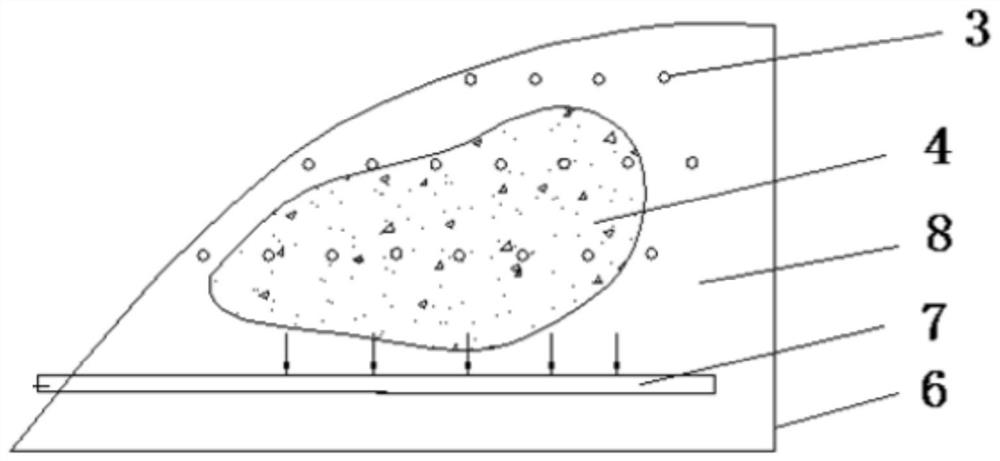

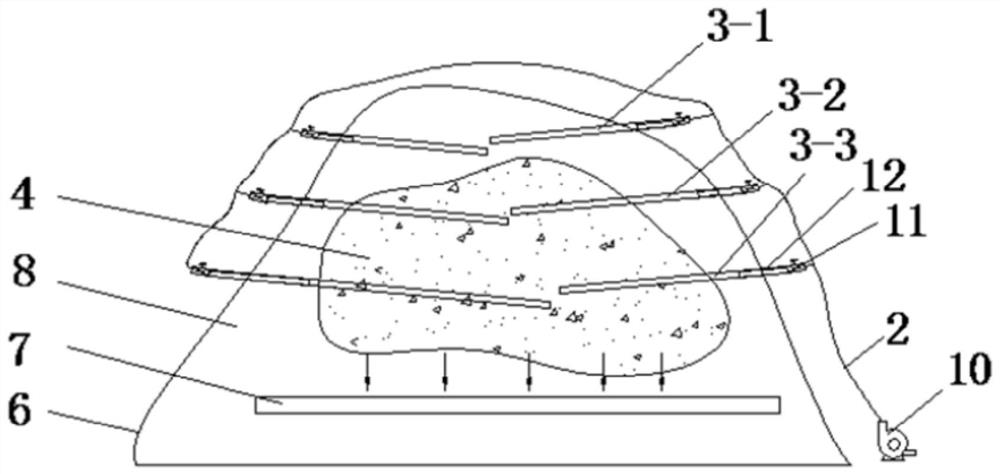

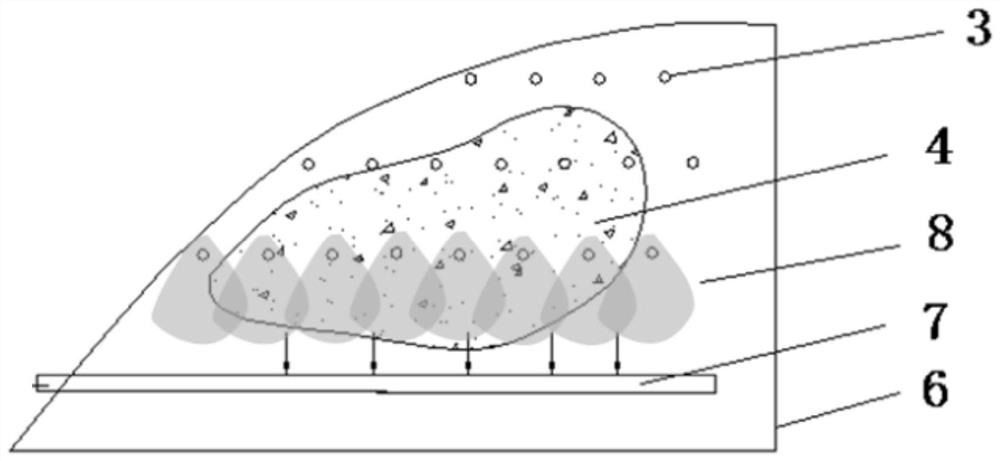

[0035] This embodiment provides a process method for in-situ leaching and liquid injection of ionic rare earth ore, such as Figure 1-3 As shown, the process method includes the following steps:

[0036] S1. Drilling: Drill a plurality of lateral injection holes 3 at intervals on the 4 sides of the ionic rare earth ore body. the center of the ore body 4; a plurality of the lateral liquid injection holes 3 are distributed in multiple layers in the height direction of the ore body 4, and the plurality of lateral liquid injection holes 3 located in the same layer are distributed at intervals in the horizontal direction;

[0037] S2. Intubation: insert a rigid elongated object into each of the lateral liquid injection holes 3, and then insert a connecting pipe 12 into the lateral liquid injection hole 3 along the rigid elongated object;

[0038] S3. Liquid injection and leaching: inject the leaching agent into the lateral liquid injection hole 3 through the connecting pipe 12, th...

Embodiment 2

[0042] As in the process method described in Embodiment 1, the process method further includes a purification step S5 after the step S4: the rare earth leachate collected in the step S3 and the rinsed water collected in the step S4 are subjected to a purification and enrichment process, and processed into rare earth products.

[0043] In the leached water collected in step S4, some of the leached water contains a relatively high concentration of rare earths, and this part of the leached water with a relatively high concentration of rare earths is subjected to a purification and enrichment process, and some of the water after leaching has a relatively low concentration of rare earths, This part of the leaching water with a lower concentration of rare earth is returned to prepare the leaching agent.

[0044] The purification and enrichment process may include a separation step of separating the leaching agent and the water after leaching, and the rare earth primary product can b...

Embodiment 3

[0046] Process method as described in embodiment 1, as Figure 1-3 As shown in the figure, the horizontal injection holes 3 of the upper and lower adjacent layers are staggered; the vertical distance between the horizontal injection holes 3 of the upper and lower adjacent layers is 3-5 meters, and the horizontal injection holes of the same layer The horizontal distance between two adjacent lateral injection holes 3 in 3 is 3-5 meters; the distance between the lateral injection holes 3 located on the bottom layer and the bottom of the ore body 4 is 4-6 meters;

[0047] The depth of the lateral liquid injection holes 3 in each layer covers the lower ore body, the lateral liquid injection holes 3 are slightly inclined downward along the extending direction, and the diameter of the lateral liquid injection holes 3 is 80-120 mm.

[0048] The horizontal spacing of the lateral injection holes 3 is determined according to the density of the ore soil. The loose spacing of the ore soil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com