High-temperature high-pressure wedge-shaped expansion load presplitting grain stress corrosion test device

A high-temperature, high-pressure, stress-corrosion technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of long process, no technical public report, and influence of test results, so as to ensure reliability, realize continuous measurement, Ease of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

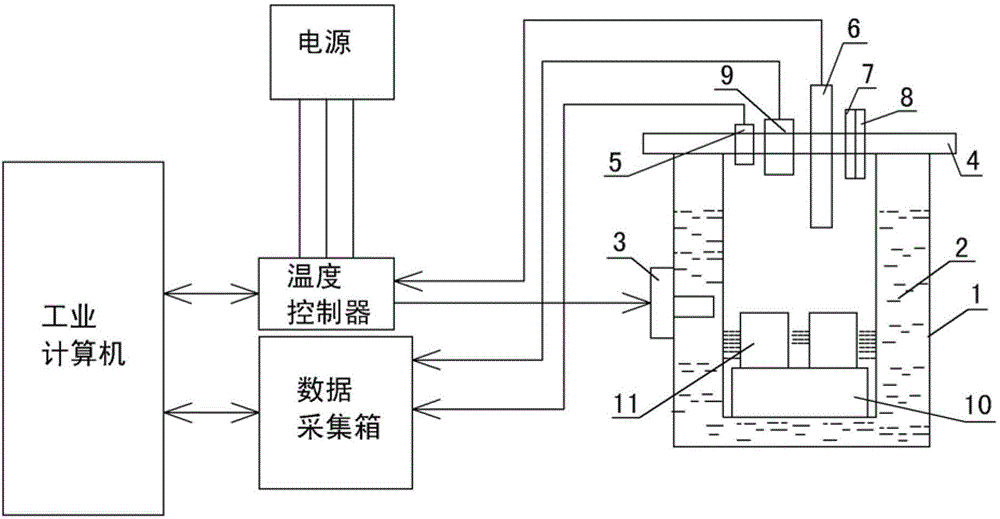

[0019] see figure 1 , the high-temperature and high-pressure wedge-shaped opening loading pre-crack stress corrosion test device in this embodiment is composed of a high-temperature and high-pressure container, a sealed lead joint, a data acquisition box, a temperature controller and an industrial computer;

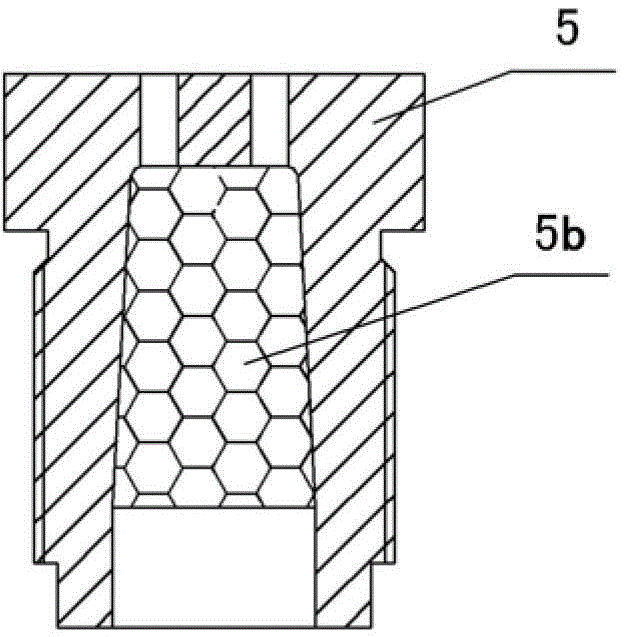

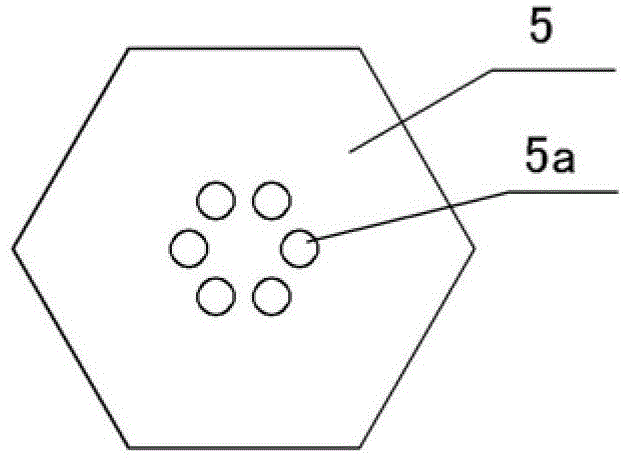

[0020] The high-temperature and high-pressure container is a closed container 1 with a jacket structure welded by steel plates. The jacket is filled with heat transfer oil 2, and an electric heating device 3 is provided for the heat transfer oil 2; the top cover of the airtight container 1 is set as a flange cover 4 , install the sealing lead connector 5 on the flange cover 4, and set the temperature sensor 6, the safety valve 7, the pressure gauge 8 and the pressure transmitter 9 respectively; set the sample holder for placing the WOL sample 11 inside the airtight container 10; lead the strain gauge signal on the WOL sample out of the airtight container with the sealed l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com