Patents

Literature

94results about How to "Achieve real-time recording" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

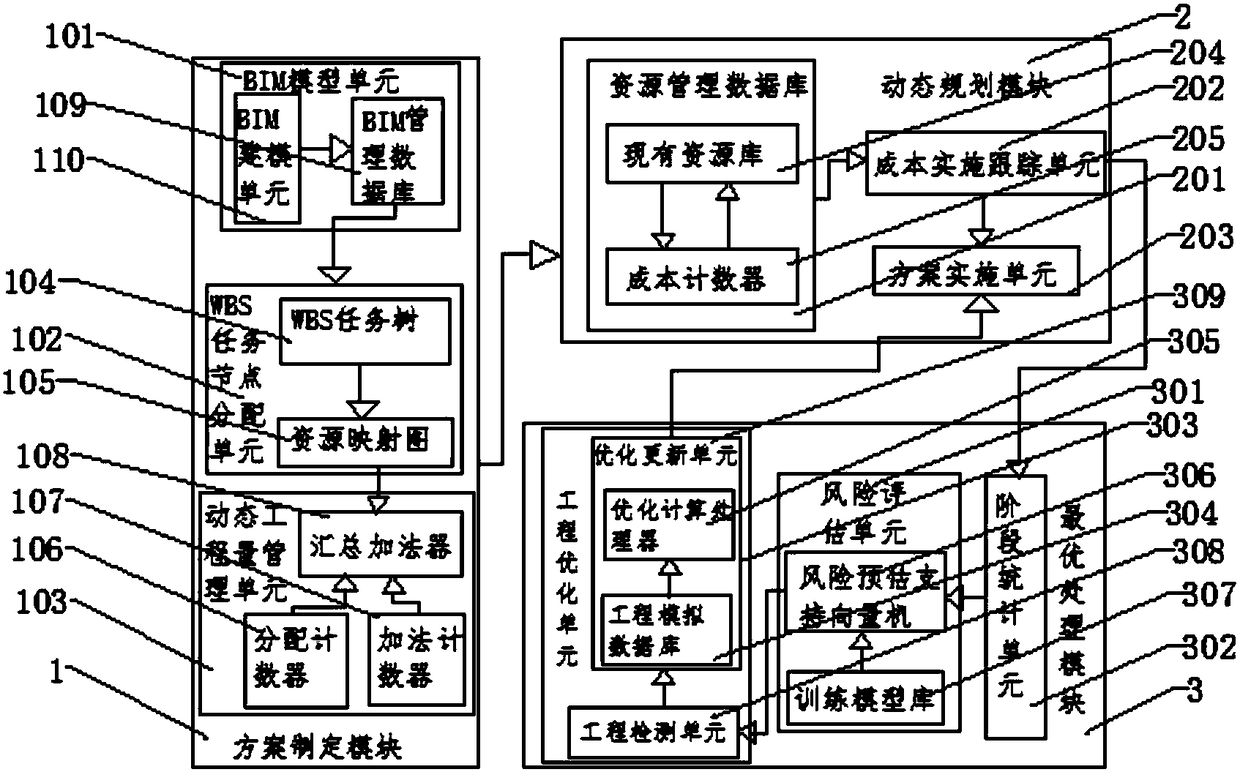

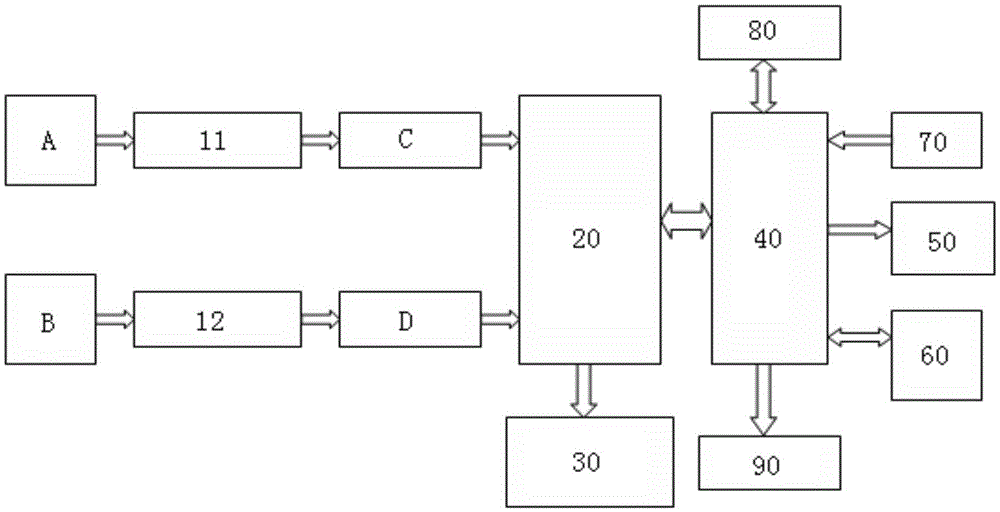

BIM-based building scheme project management system

InactiveCN108537440AReduce error rateEasy programming and automatic planning managementGeometric CADResourcesManagement unitDynamic planning

The invention discloses a BIM-based building scheme project management system. The system comprises a scheme formulation module and a dynamic planning module; an optimal processing module is connectedbetween the ports of the scheme formulation module and the dynamic planning module; the scheme formulation module comprises a BIM project unit and a WBS task node allocation unit; the output of the WBS task node allocation unit is connected with a dynamic project quantity management unit; the dynamic planning module comprises a resource management database; the data read-write end of the resourcemanagement database is connected with a cost implementation tracking unit; the input end of the cost implementation tracking unit is connected with a scheme implementation unit; the optimal processing module includes a risk assessment unit and a stage statistics unit; and the data output end of the stage statistics unit is connected with a project optimization unit. With the BIM-based building scheme project management system of the invention adopted, the full digital processing of large building projects is realized; task scheduling and project cost statistics can be carried out conveniently; and dynamic optimization processing can be carried out according to an implementation condition, so that project optimization can be realized.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE OF COMM

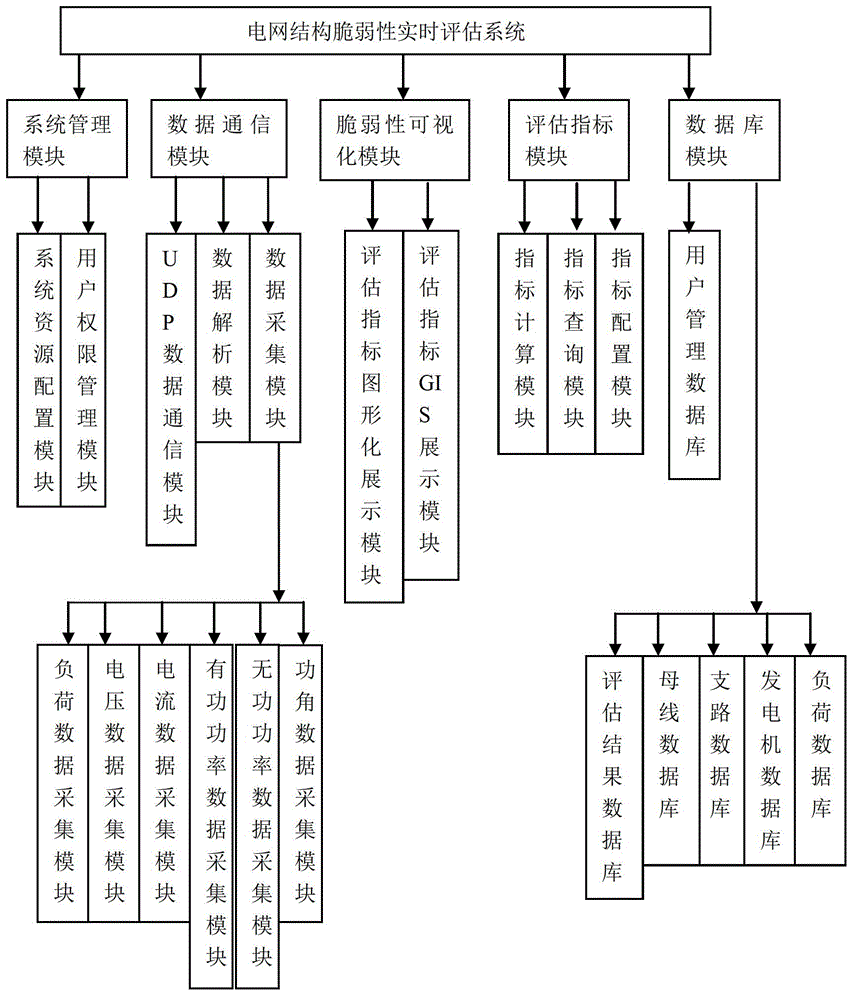

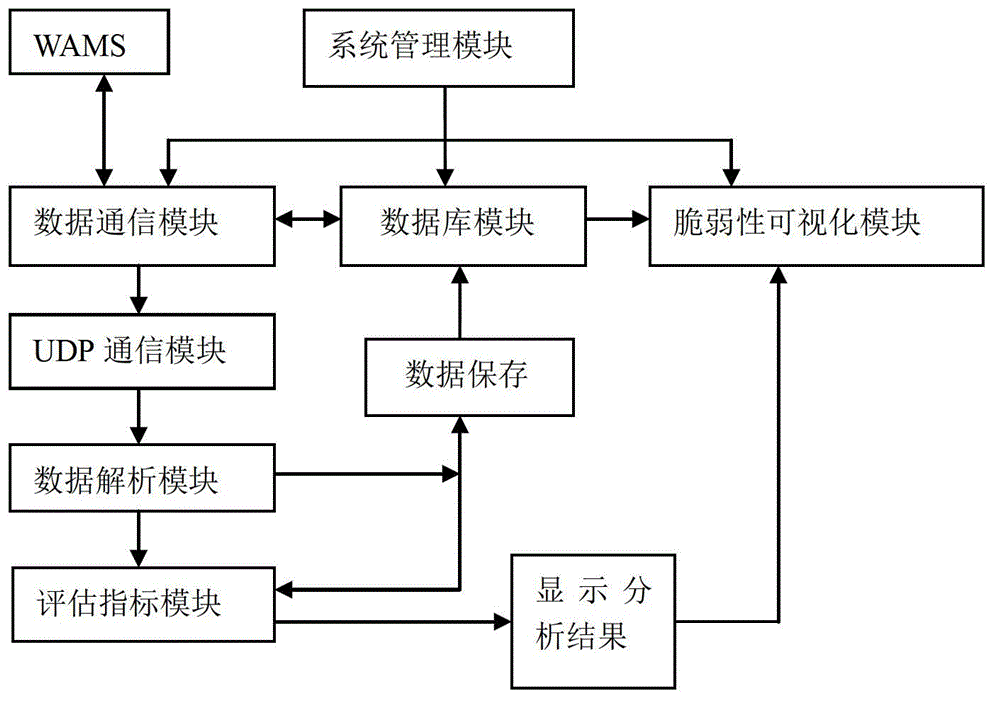

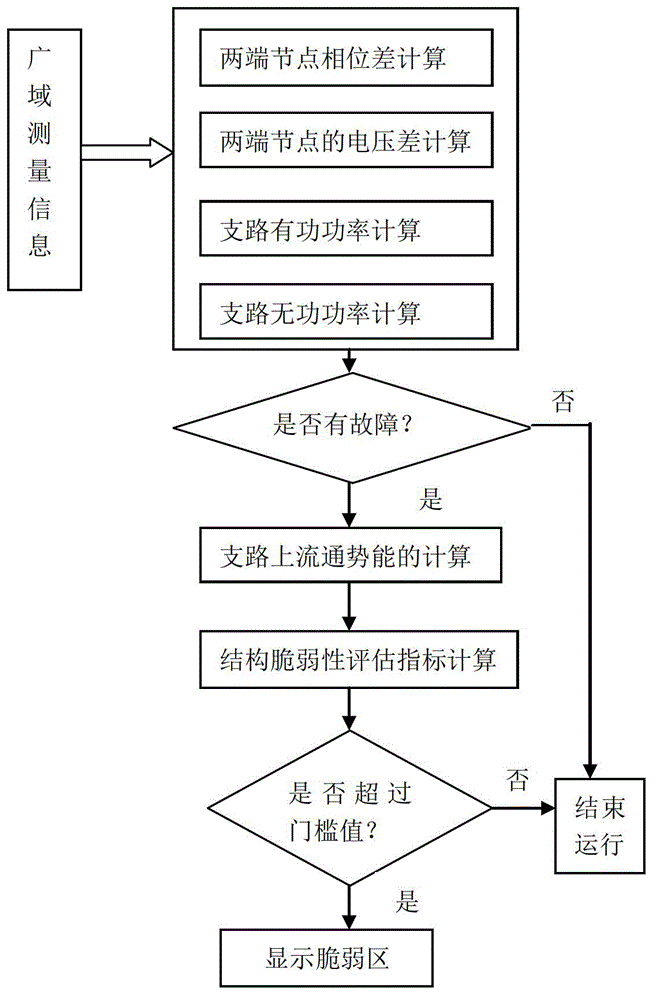

Electric network structure vulnerability real-time evaluation system

InactiveCN103150687ARealize the structureAchieve real-time recordingData processing applicationsState parameterSystems management

The invention relates to an electric network structure vulnerability quantification and visualization display technology and discloses an electric network structure vulnerability real-time evaluation system for carrying out real-time evaluation and analysis on the electric network structure vulnerability. The electric network structure vulnerability real-time evaluation system has the technical scheme that the electric network structure vulnerability real-time evaluation system comprises a system management module, a data communication module, a vulnerability visualization module, an evaluation indicating module and a database module. The electric network structure vulnerability real-time evaluation system is based on the wide area measurement information, the electric network structure vulnerability is evaluated in real time, and the functions of the structure vulnerability evaluation, the real-time display, the real-time recording and the like of operation parameters in an electric network are realized. On one hand, the receiving of dynamic data transmitted by a WAMS (wide area measurement system) is realized, in addition, the dynamic structure and the state information are analyzed, and the real-time recording of the electric network operation state parameter is realized; and on the other hand, the electric network structure vulnerability evaluation and result display is realized, and basis is provided for improving the safe operation of the electric network.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

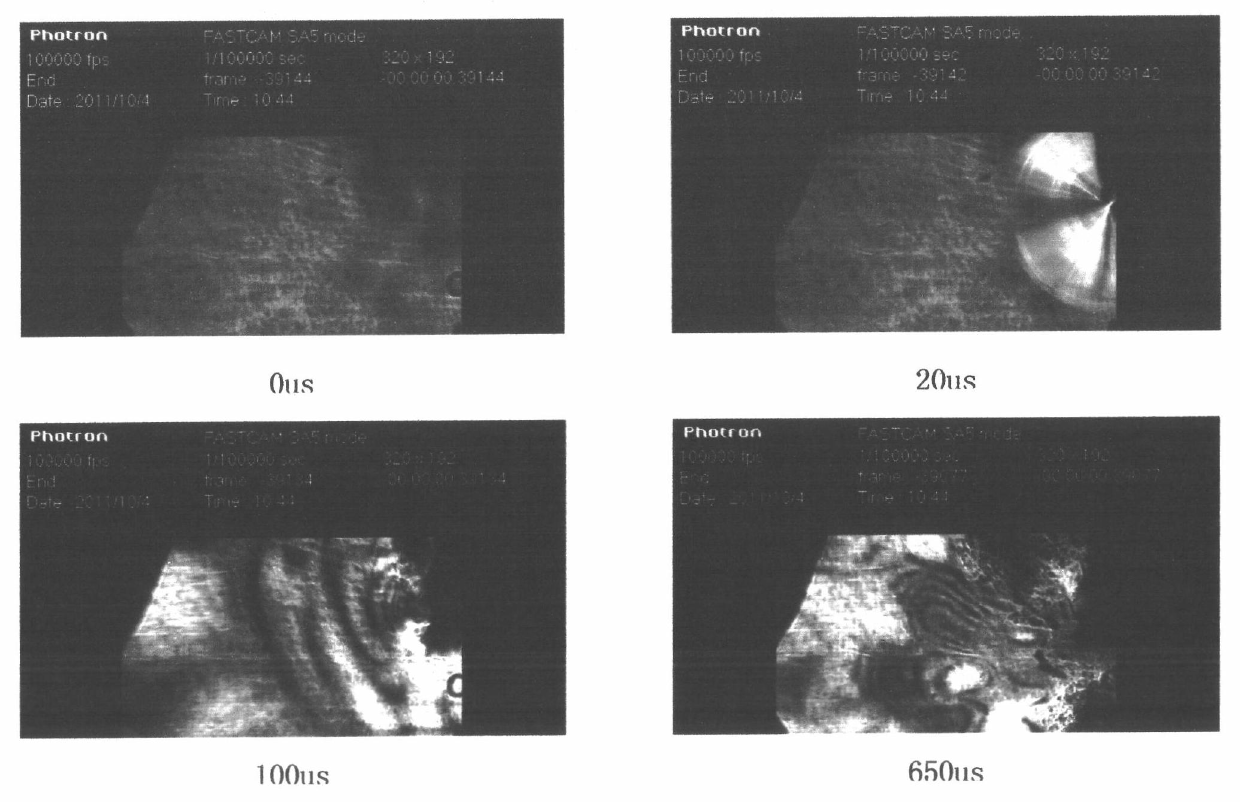

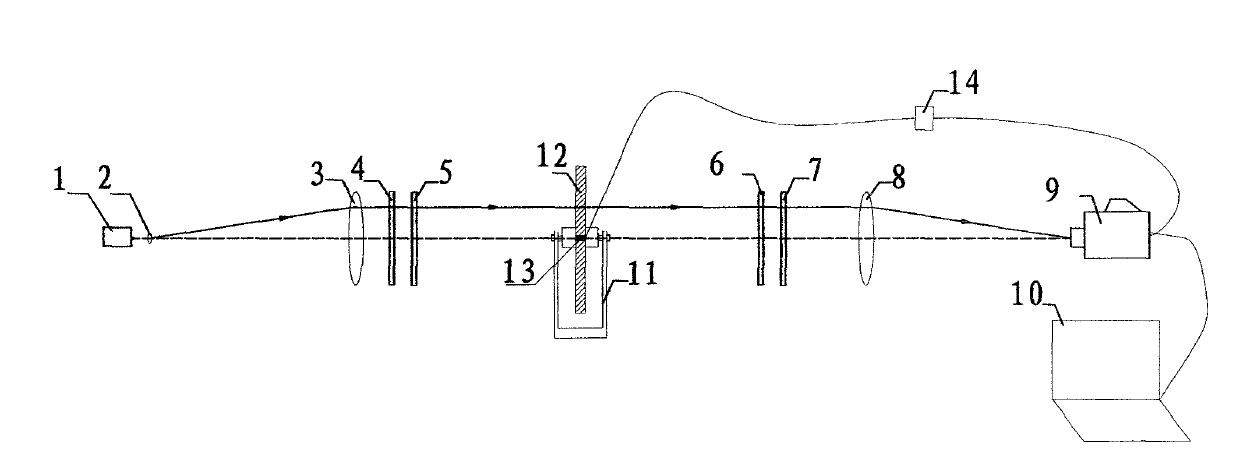

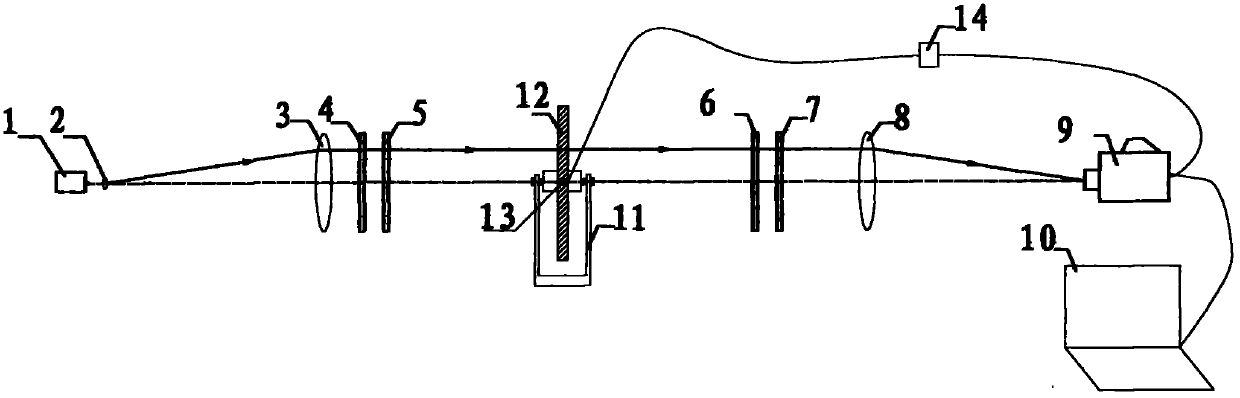

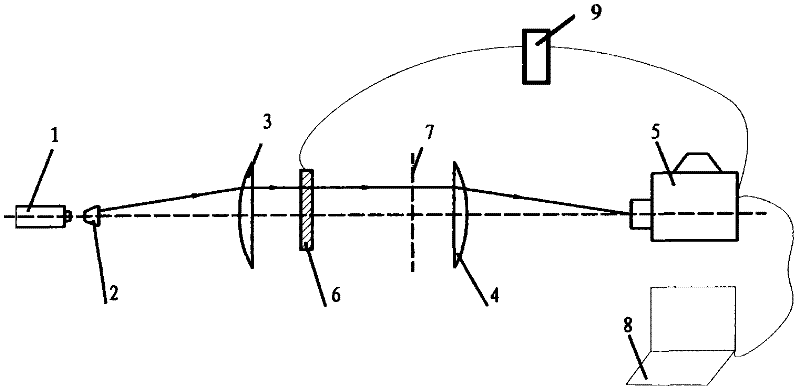

Digital laser explosion loading dynamic photoelastic experiment system

InactiveCN102589766AImprove controllabilityHigh precisionForce measurement by measuring optical property variationTest sampleLight beam

The invention discloses a digital laser explosion loading dynamic photoelastic experiment system, which comprises a laser, a beam expanding mirror, a field lens combination, a left 1 / 4 wave plate, a right 1 / 4 wave plate, an analyzer, an explosion loading device, an exploder, a digital high speed video camera and a computer. The laser sends out continuous line beams which are converted into circularly polarized light through the beam expanding mirror, a field mirror and the 1 / 4 wave plate to be illuminated on a test sample of the explosion loading device, the circularly polarized light are converged through the right 1 / 4 wave plate, the analyzer and the field mirror to be illuminated into a lens of the digital high speed video camera, and finally, the circularly polarized light is exploded by the exploder and shot by starting the digital high speed video camera to form an explosion loading image. The system record and analyze the broadcast information including process of stress saves in the test sample under explosion loads, stress time and space distribution and the like, an optical path is simple, requirements for experiment environment and experiment cost are low, period is short, precision is high, and continuous observation of the whole fracture process is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

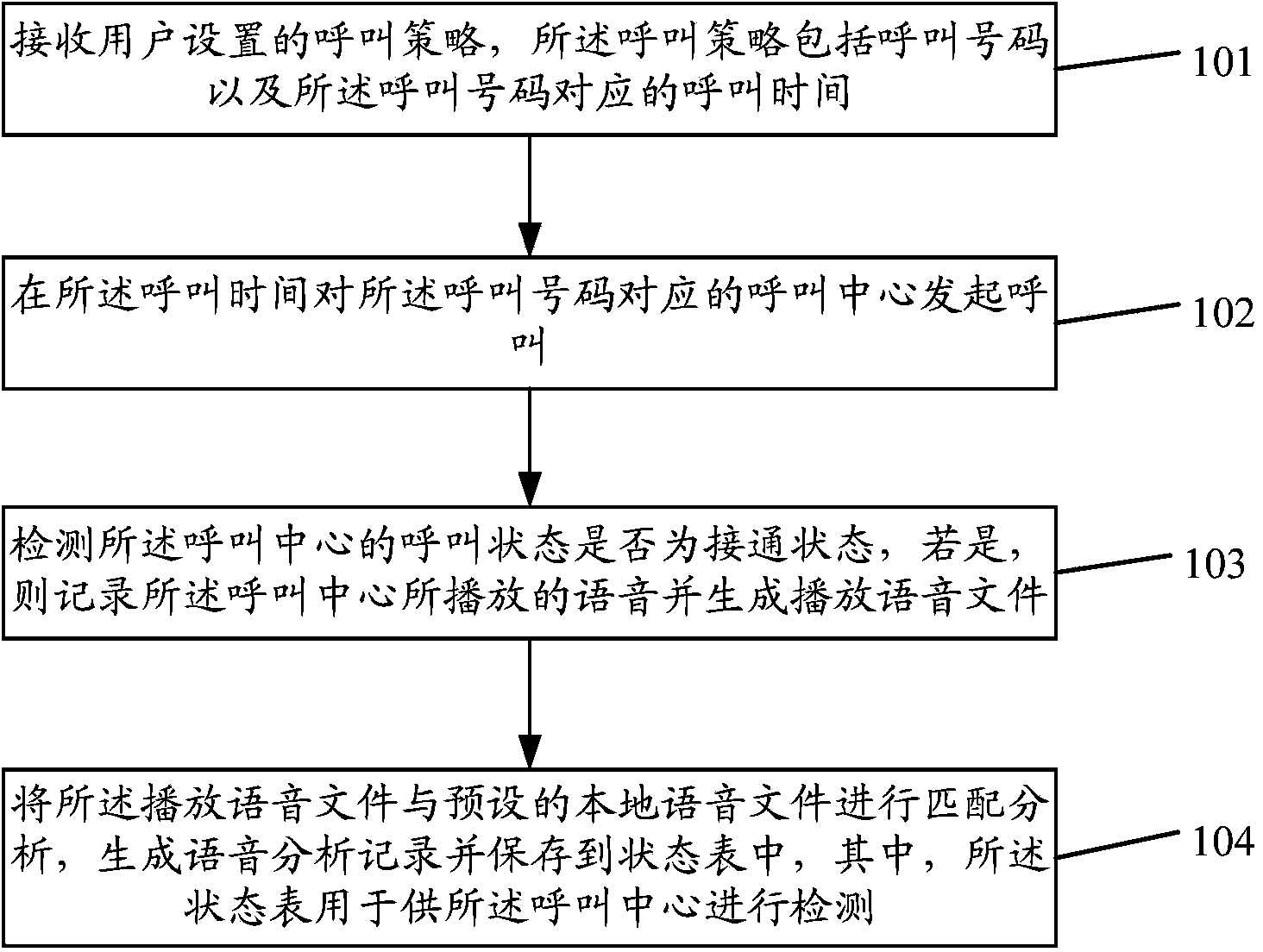

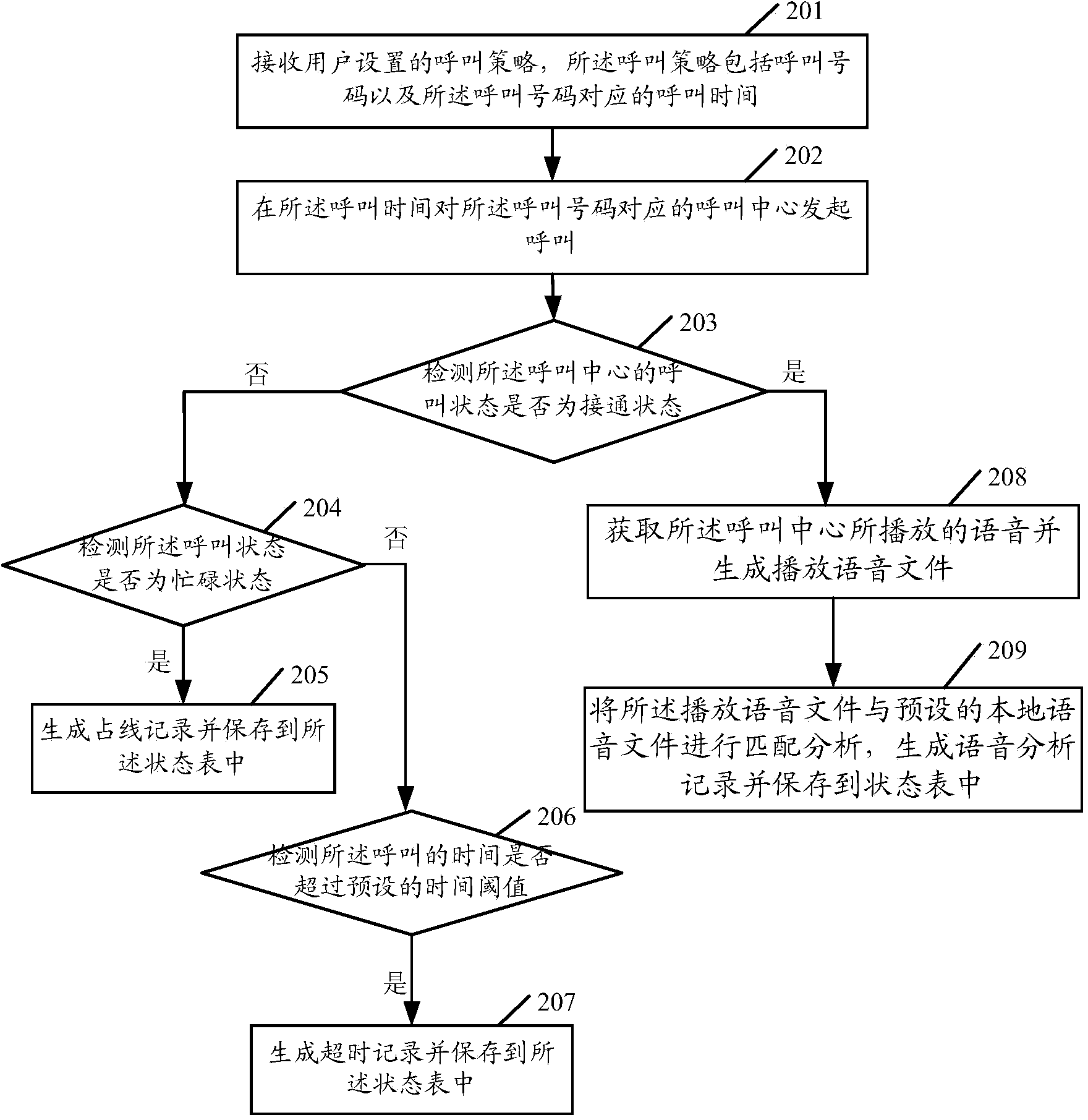

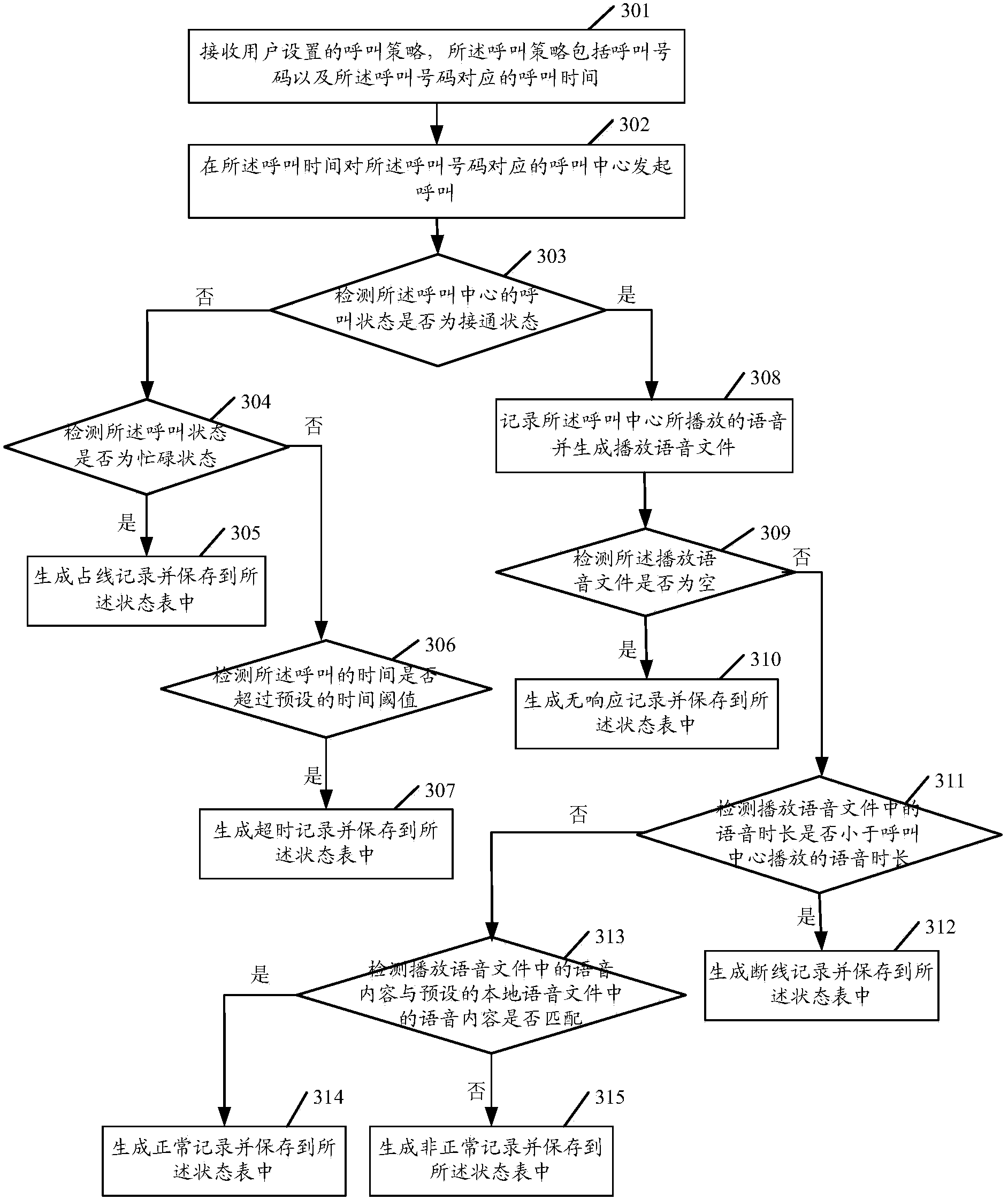

Detecting method and device for call center

ActiveCN104363354AEasy to maintainReduce workload and complexitySpecial service for subscribersSupervisory/monitoring/testing arrangementsSpeech analyticsSpeech sound

An embodiment of the invention discloses a detecting method and device for a call center. The method includes: receiving a call strategy set by a user, wherein the call strategy includes a call number and call time corresponding the call number; calling the call center corresponding to the call number at the call time; detecting whether the calling state of the call state is communicated or not, if so, acquiring the voice played by the call center and generating a voice playing file; performing matching analysis on the voice playing file and a local voice file to generate a voice analyzing record, and saving the voice analyzing record into a state table, wherein the state table is used for allowing the call center to perform testing. By the method, a server can automatically call and test the call center, and the problem that the call center is high in testing task load and high in testing task complexity is solved.

Owner:CHINA CONSTRUCTION BANK

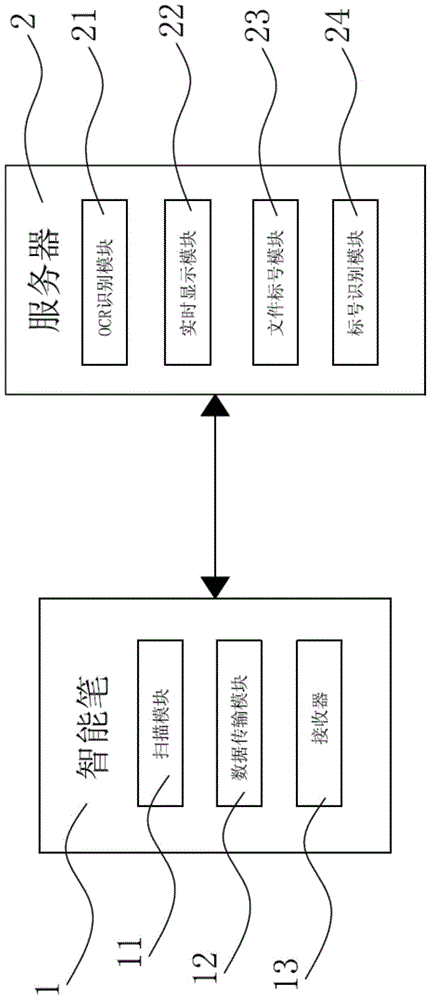

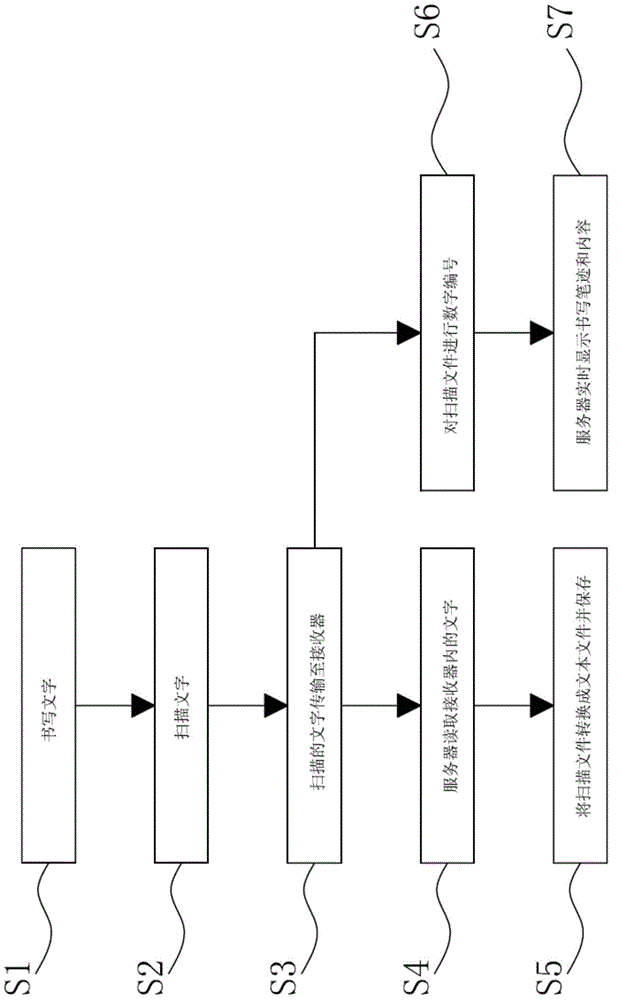

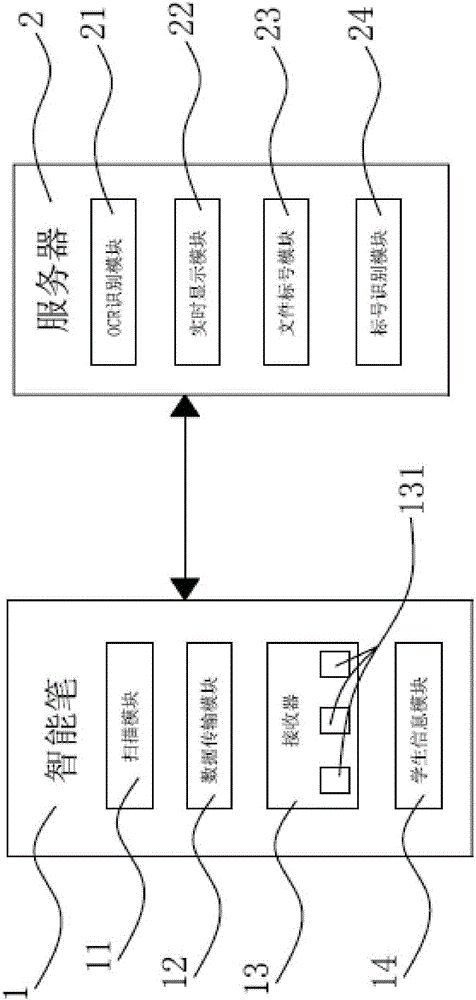

Intelligent pen system and operation method thereof

InactiveCN105096222ARealize scanningReal-timeData processing applicationsCharacter and pattern recognitionData transmissionFile transfer

The invention discloses an intelligent pen system. The system comprises an intelligent pen, a track record module, a data transmission module, a receiver and an OCR identification module, wherein a writing pen core is arranged in the intelligent pen and is used for writing characters; the track record module is used for recording a track of writing in real time during writing and generating a track file; the data transmission module is used for transmitting a character scanning file to the receiver; the receiver carries out data connection with a server and the server reads a cache page in the receiver; the OCR identification module is arranged in the server and is used for converting the cache page into a text file. The invention simultaneously discloses an intelligent pen system operation method. By using the system and the method of the invention, real-time records of classroom notes of a student and character writing can be realized and the records can be uploaded to the server so that recording and uploading efficiency of character information is greatly increased.

Owner:SUZHOU D&T EDUCATION TECH

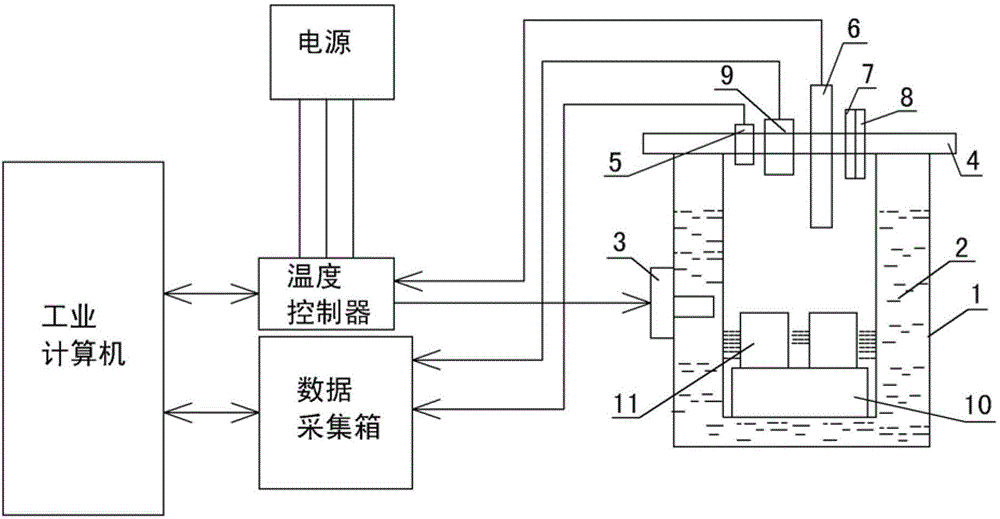

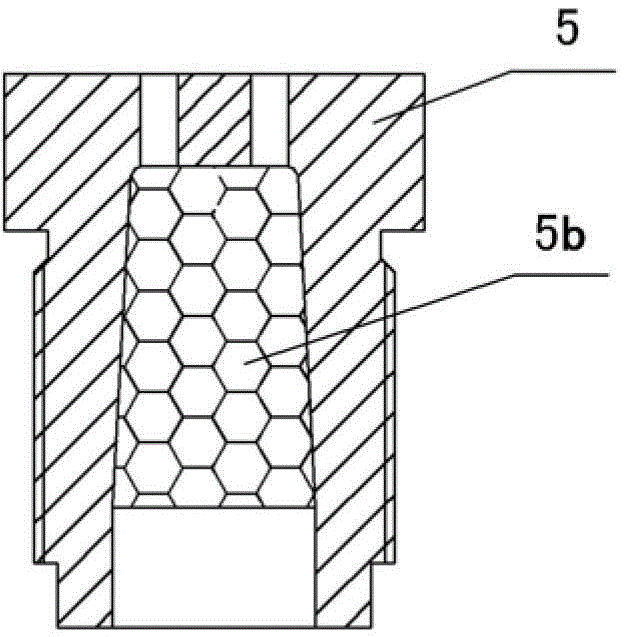

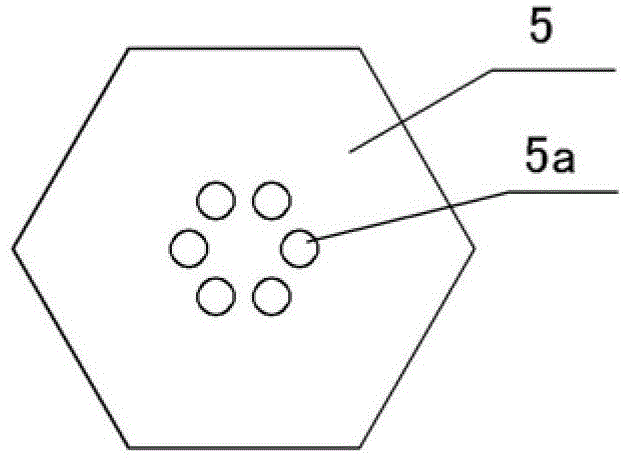

High-temperature high-pressure wedge-shaped expansion load presplitting grain stress corrosion test device

InactiveCN102944482AImplementing Stress Corrosion TestingRealize continuous measurementMaterial strength using tensile/compressive forcesSignal onData acquisition

The invention discloses a high-temperature high-pressure wedge-shaped expansion load presplitting grain stress corrosion test device which is characterized by being composed of a high-temperature high-pressure container, a sealing wire joint, a data acquisition box, a temperature controller and an industrial computer, wherein the high-temperature high-pressure container is a closed container with a jacket structure, and the closed container is formed by welding steel plates; conduction oil is filled in the jacket; aiming at the conduction oil, an electric heater is arranged; the top cover of the closed container is a flange cover; the flange cover is provided with the sealing wire joint and respectively provided with a temperature sensor and a pressure transmitter; a sample holder for placing a WOL sample is arranged in the closed container; the sealing wire joint is used for guiding a strain gauge signal on the WOL sample out of the closed container; and the industrial computer controls the internal temperature and pressure ranges of the closed container. The device disclosed by the invention can be used in a high-temperature environment of a simulated field and can be used for continuously performing a stress corrosion test.

Owner:HEFEI GENERAL MACHINERY RES INST

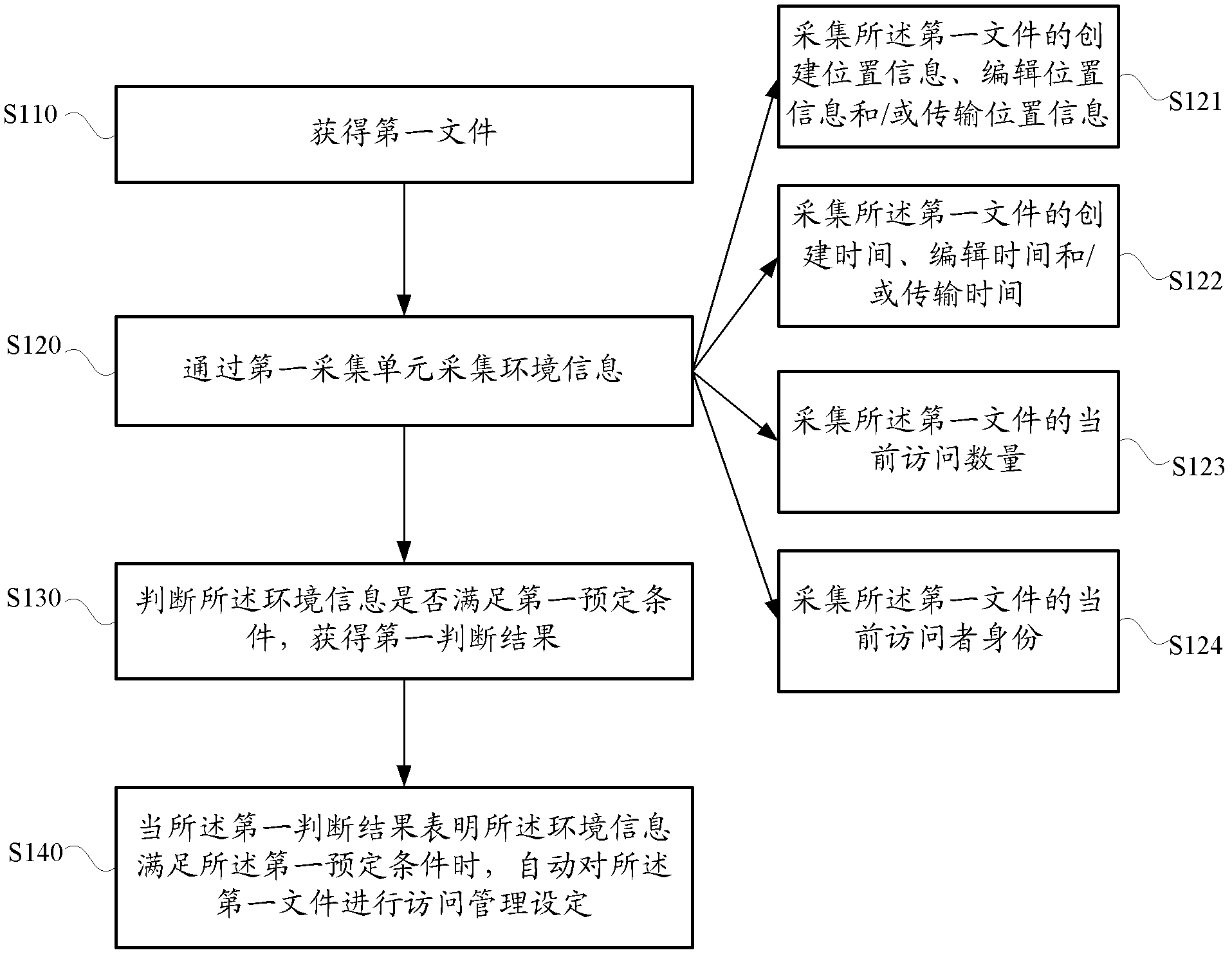

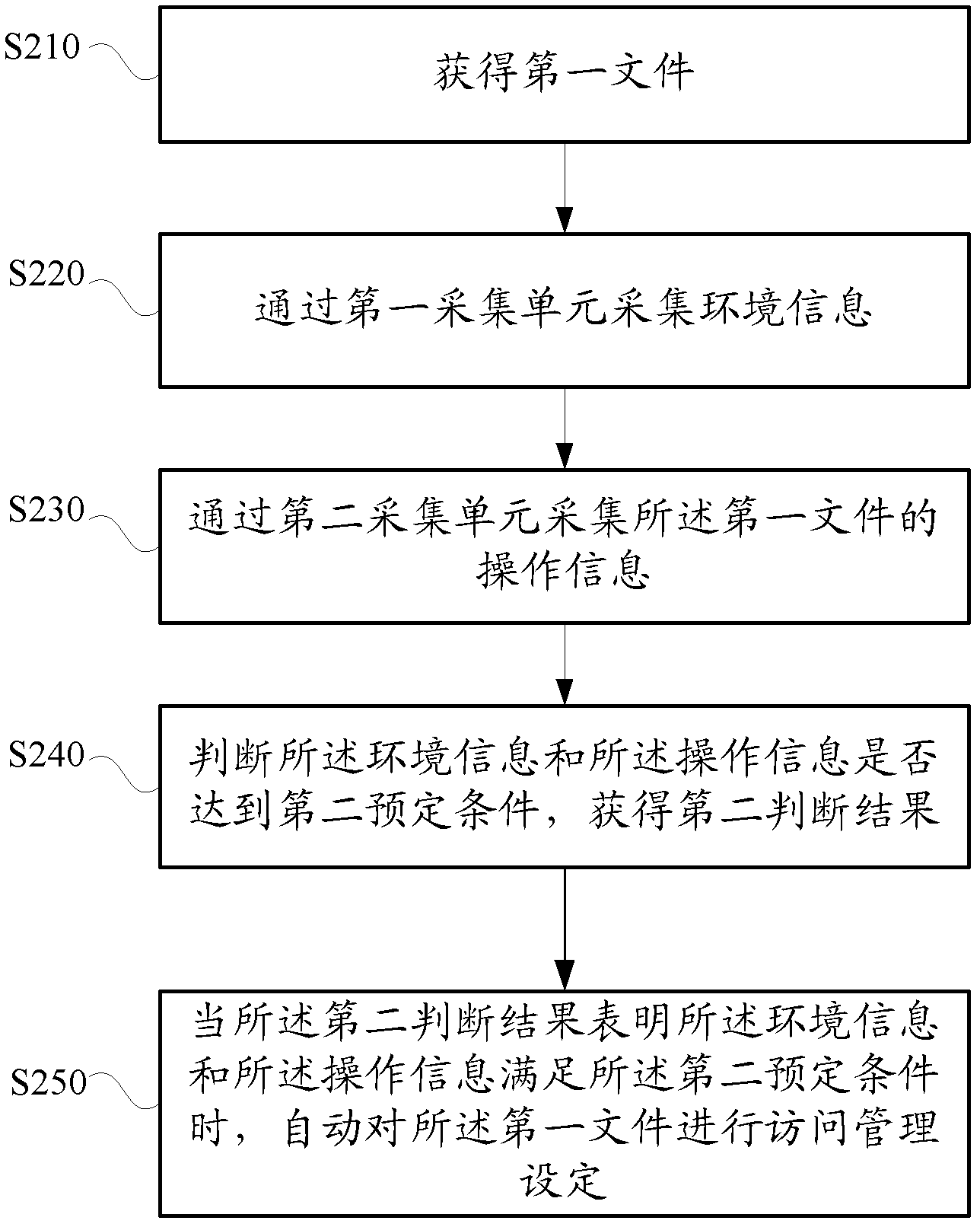

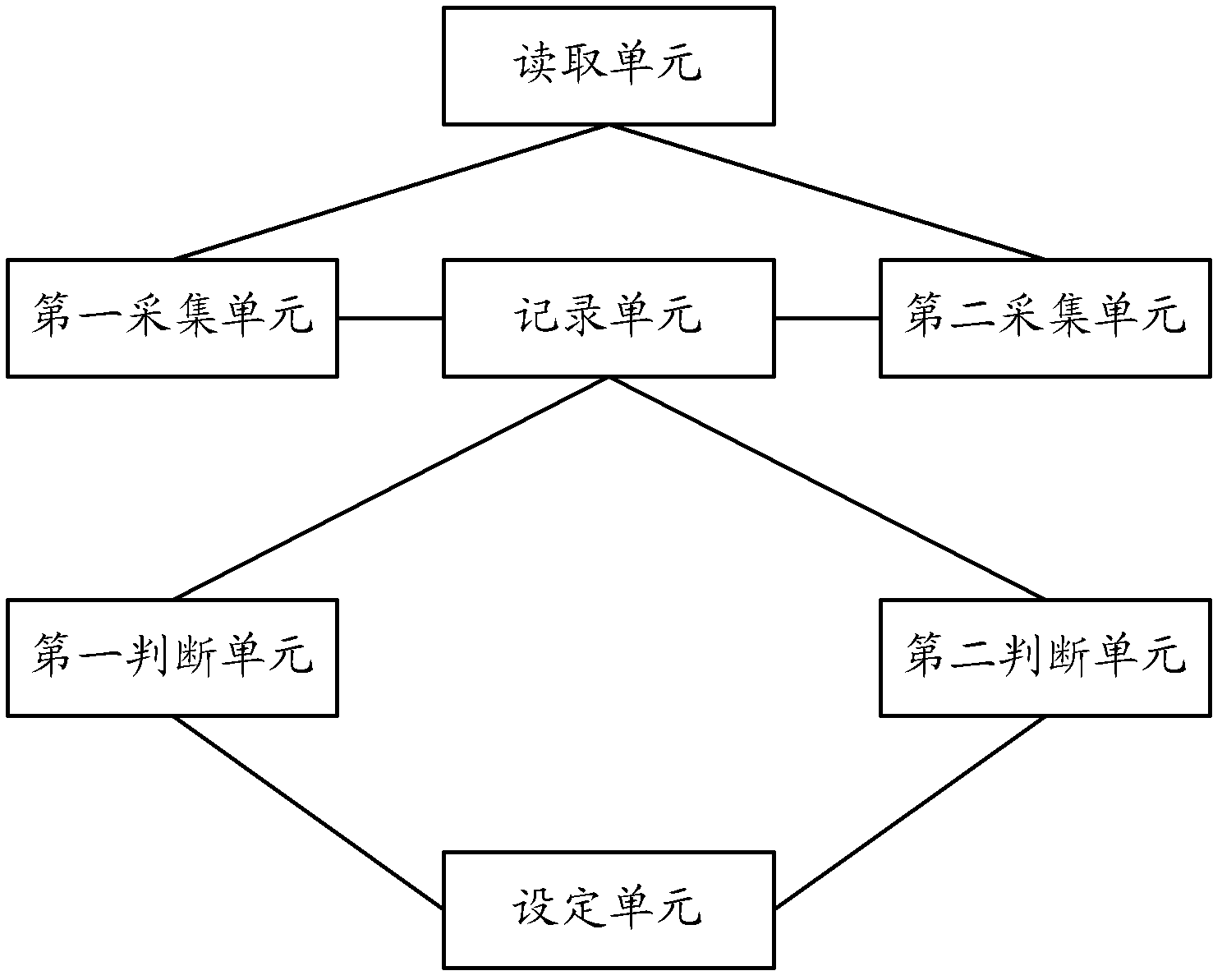

File management method and file management system

ActiveCN102999729APrevent security access settingsSimple applicationDigital data protectionFile managementAccess management

The invention provides a file management method and a file management system. The file management method comprises the following steps of: acquiring a first file; acquiring environmental information through a first acquisition unit; judging whether the environmental information satisfies a first predetermined condition to obtain a first judged result; and when the first judged result indicates that the environmental information satisfies the first predetermined condition, performing access management setting on the first file. According to the file management method and the file management system, access management setting can be performed automatically on files which meet the requirement of secrecy, so that security access setting on important files is prevented from being missed or forgotten.

Owner:LENOVO (BEIJING) CO LTD

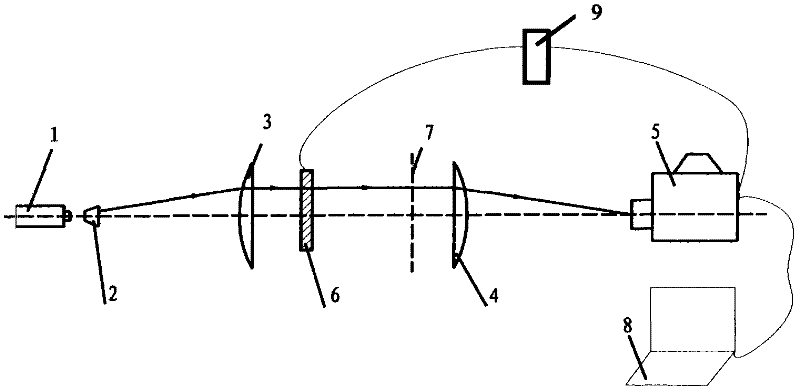

Digital laser dynamic caustics experiment method and system thereof

InactiveCN102539254AImprove controllabilityHigh precisionMaterial strength using single impulsive forceCamera lensSynchronous control

The invention discloses a digital laser dynamic caustics experiment method and a system thereof. The system comprises a laser device, a beam expanding mirror, a field lens assembly, an uploading device, a synchronous control switch, a digital high speed camera and a computer. A continuous line beam is emitted by the laser device, converted into plane beam through the beam expanding mirror, converted into parallel beams through the field lens to shoot on the surface of a test piece and finally converged to be conveyed in a camera lens of the digital high speed camera. With starting of the uploading device, the digital high speed camera is synchronously controlled to be started to finish dynamic record of crack expanding processes on the test piece, namely, digital dynamic caustics record is finished. The system can be used for optical measurement mechanics analysis in dynamic broken experiment processes like impact, explosion and the like and is simple in light path system, convenient to operates, low in experiment cost, short in period and capable of continuously detecting the whole broken processes and improving experiment accuracy.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

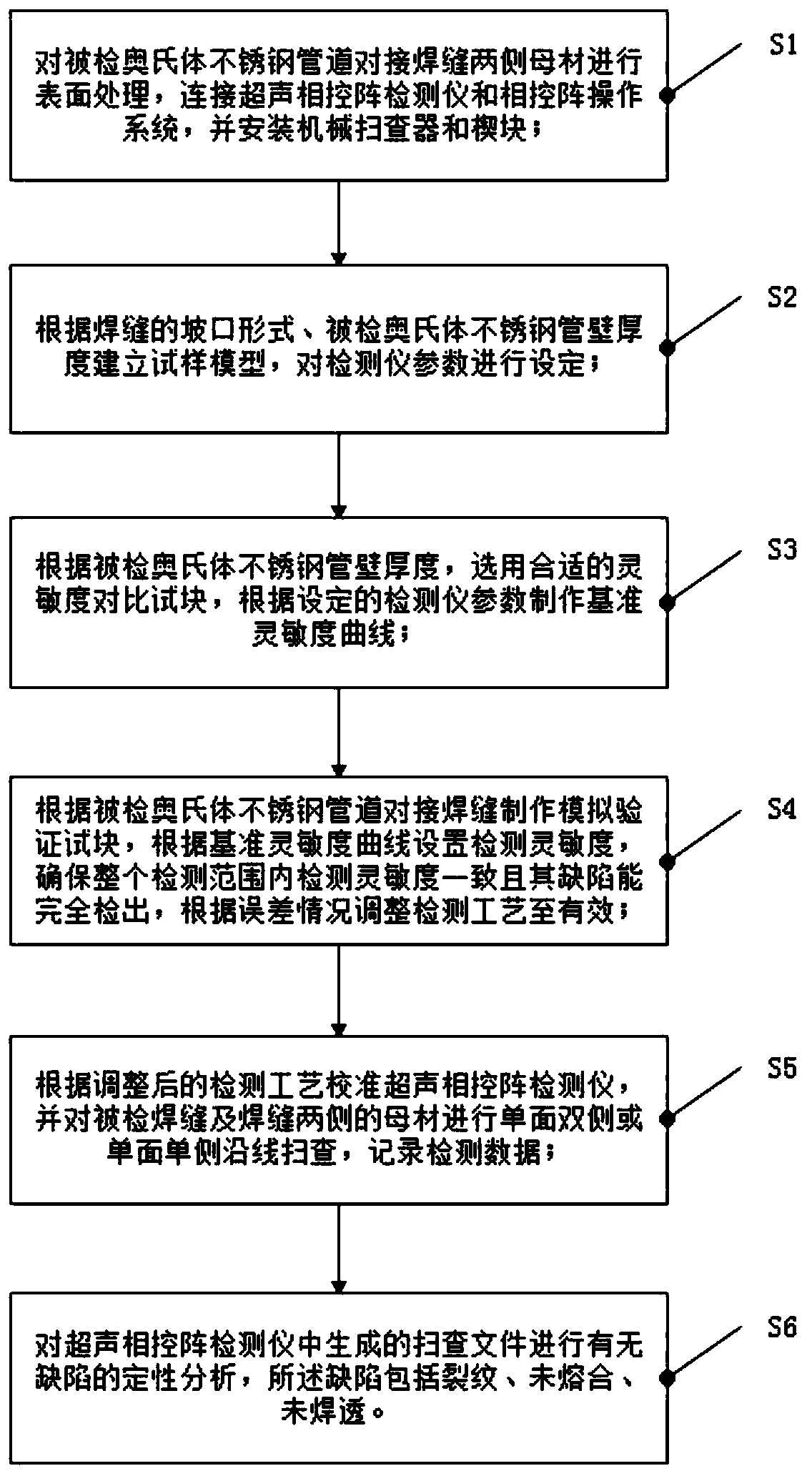

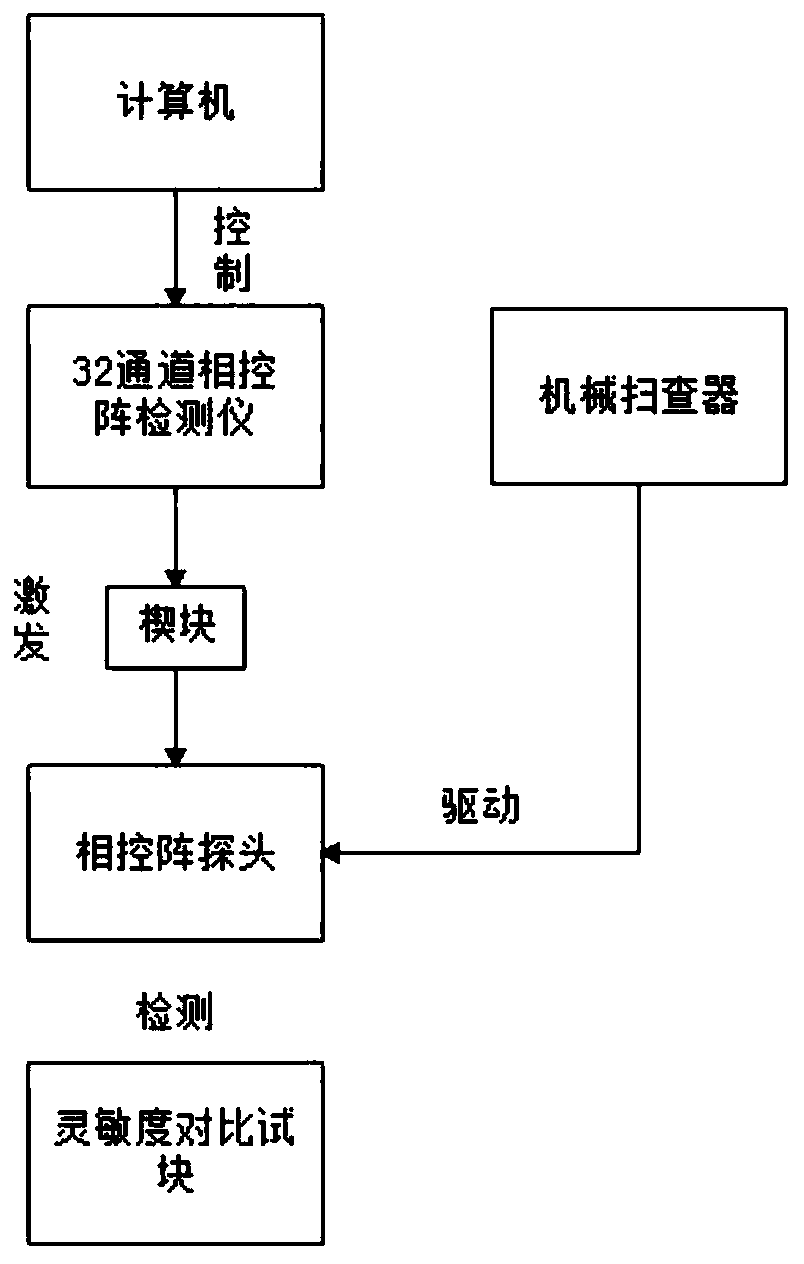

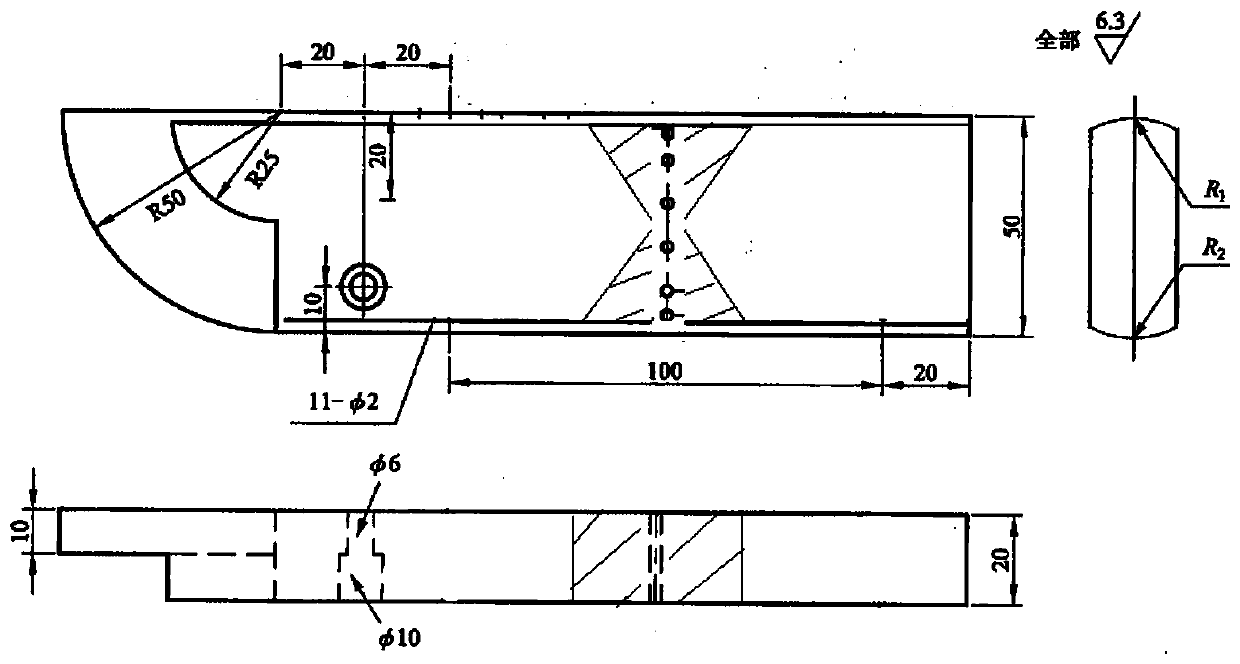

Phased array detection method for austenite stainless steel pipeline butt weld joint

InactiveCN110261476AReduce processing costsAddress specificityAnalysing solids using sonic/ultrasonic/infrasonic wavesPhased arrayMaterials science

The invention discloses a phased array detection method for an austenite stainless steel pipeline butt weld joint. With the phased array detection method adopted, the defects of the austenite stainless steel pipeline butt weld joint can be recorded; the defect detection rate of the austenite stainless steel pipeline butt weld joint is high; detection is safe; and cost is low. According to the technical schemes of the invention, the method comprises the following steps that: pre-detection preparation work is performed for a workpiece to be detected, and a detection instrument is installed; a sample model is established according to the groove form and detection thickness of the weld joint, detection equipment parameters are set; a sensitivity comparison test block is selected, and a sensitivity reference curve is drawn; a simulation verification test block is produced, detection sensitivity is set, and the defect of the simulation verification test block is detected, and whether a detection process is effective or not is verified; single-side double-side detection is performed on any surface of the weld joint according to the verified detection process, and detection data are recorded; and defects existing in the detection data are analyzed.

Owner:YANGJIANG NUCLEAR POWER +2

Intelligent pen answering system and method

InactiveCN105160958AAchieve real-time recordingTransmissionElectrical appliancesData connectionComputer science

The invention discloses an intelligent pen answering system. The system comprises an intelligent pen which is internally provided with a writing pen core for writing characters; a receiver which is in data connection with a server, is also provided with multiple buttons each representing an option, internally generates corresponding option results after students press the buttons and transmits the results to the server in which teachers check the answering number and answering correctness conditions of the students; and a student information module which is connected with the receiver for associating the receiver with information of the students so that the teachers can identify the information of the corresponding answering students according to the receiver. The invention also discloses an intelligent pen answering method. According to the invention, a function of real-time answering in a classroom and uploading answers to the server by the students is realized, and at the same time, the teachers can also check the answering conditions in the server in real time.

Owner:SUZHOU D&T EDUCATION TECH

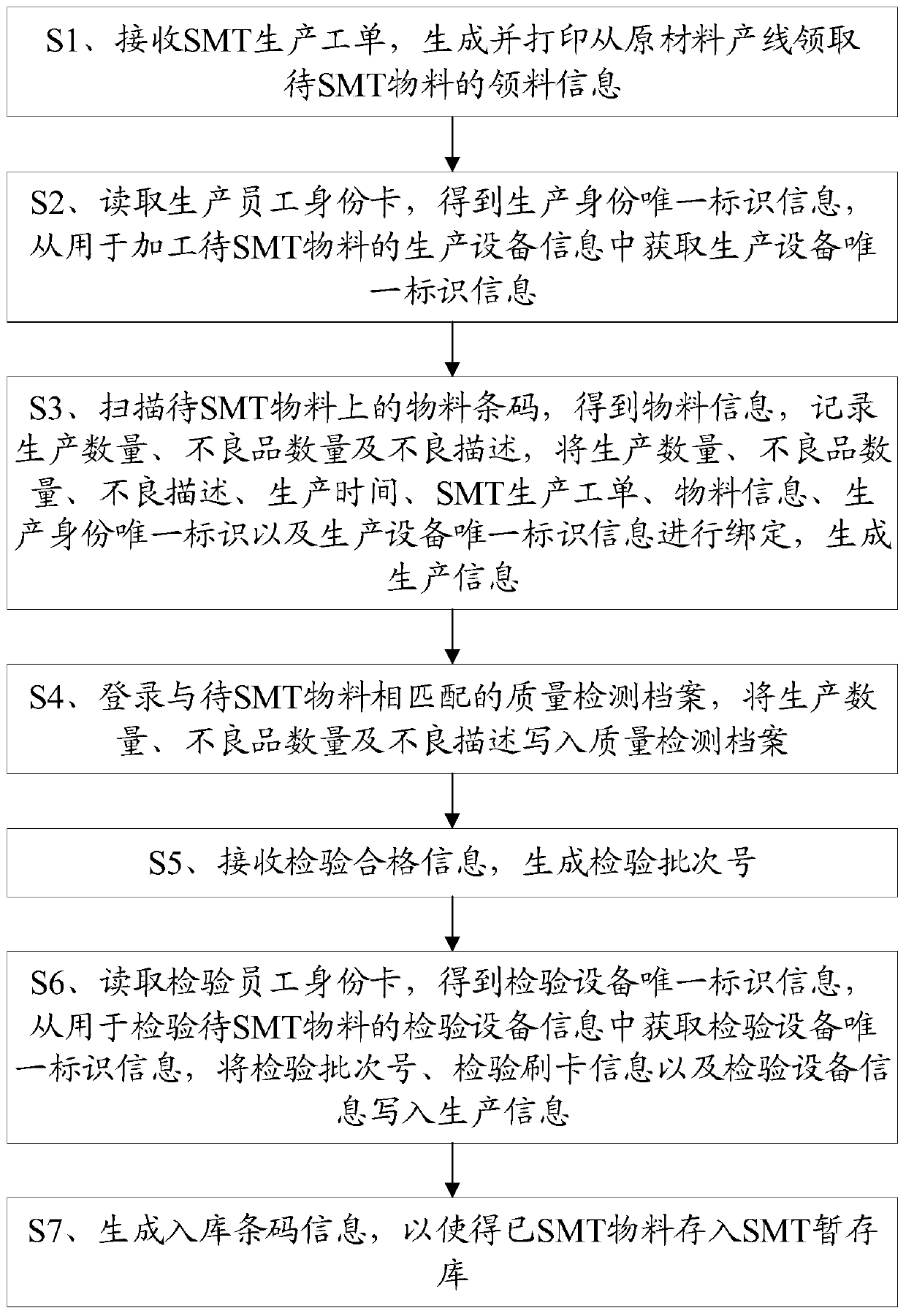

An SMT production line management method and a manufacturing end

ActiveCN109840572AAchieve real-time recordingEnsure "transparent" managementData processing applicationsCo-operative working arrangementsProduction lineRaw material

The invention discloses an SMT production line management method and a manufacturing end, and the method comprises the steps: receiving an SMT production work order, and generating and printing material receiving information for receiving a to-be-SMT material from a raw material production line; Reading a production staff identity card to obtain unique production identity identification information, and obtaining unique production equipment identification information from production equipment information for processing the to-be-SMT material; Scanning material bar codes on the to-be-SMT materials to obtain material information, recording production quantity and bad data, and binding all the information to generate production information; Logging in a quality detection file matched with theto-be-SMT material, and writing the production number, the number of defective products and the defective description into the quality detection file; And writing the data related to the inspection into production information, and generating warehousing bar code information, so that the SMT material is stored in an SMT temporary storage library. According to the invention, a complete product tracing system is formed, transparent management of production is ensured, and subsequent bad analysis is facilitated, so that the production yield is improved.

Owner:JIANGXI YINHE METER CO LTD

General-purpose plane vertical crash test device and test method

The invention discloses a general-purpose plane vertical crash test device and a general-purpose plane vertical crash test method. The general-purpose plane vertical crash test device comprises a fixing bracket, a test piece which is fixed on the fixing bracket through suspension steel cables, a crash platform which is arranged on the ground and is parallelly opposite to the fixing bracket, a plurality of guide steel cables which are arranged between the fixing bracket and the crash platform and penetrate the test piece, a scale plate, and a camera which is arranged in a manner that the camera directly faces the scale plate. With the general plane vertical crash test device and test method provided by the invention, the stability of the attitude of the plane test piece in a free fall process can be ensured, and it can be ensured that the test piece cannot deviate from the guide steel cables in crash and bounce, and therefore, the safety of personnel and equipment can be guaranteed; and the scale plate and the camera are used in cooperation, and therefore, real-time recording of the deformation and displacement of the test piece in the crash process can be realized, and whether the test piece is tilted in the fall process can be verified. The general-purpose plane vertical crash test device and test method of the invention are advantageous in accurate test results, simple operation, safety and feasibility.

Owner:JIANGXI HONGDU AVIATION IND GRP

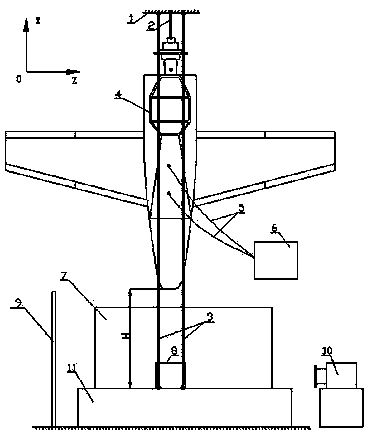

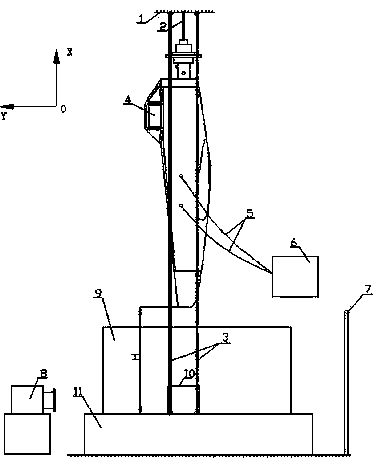

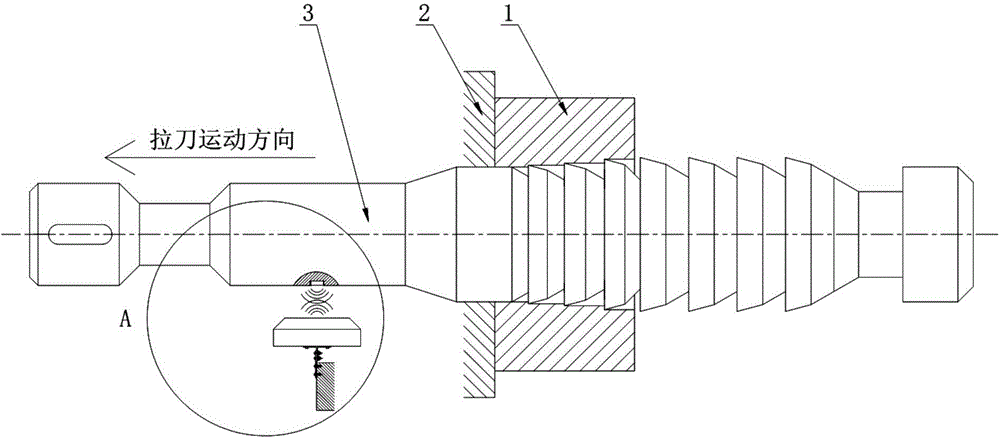

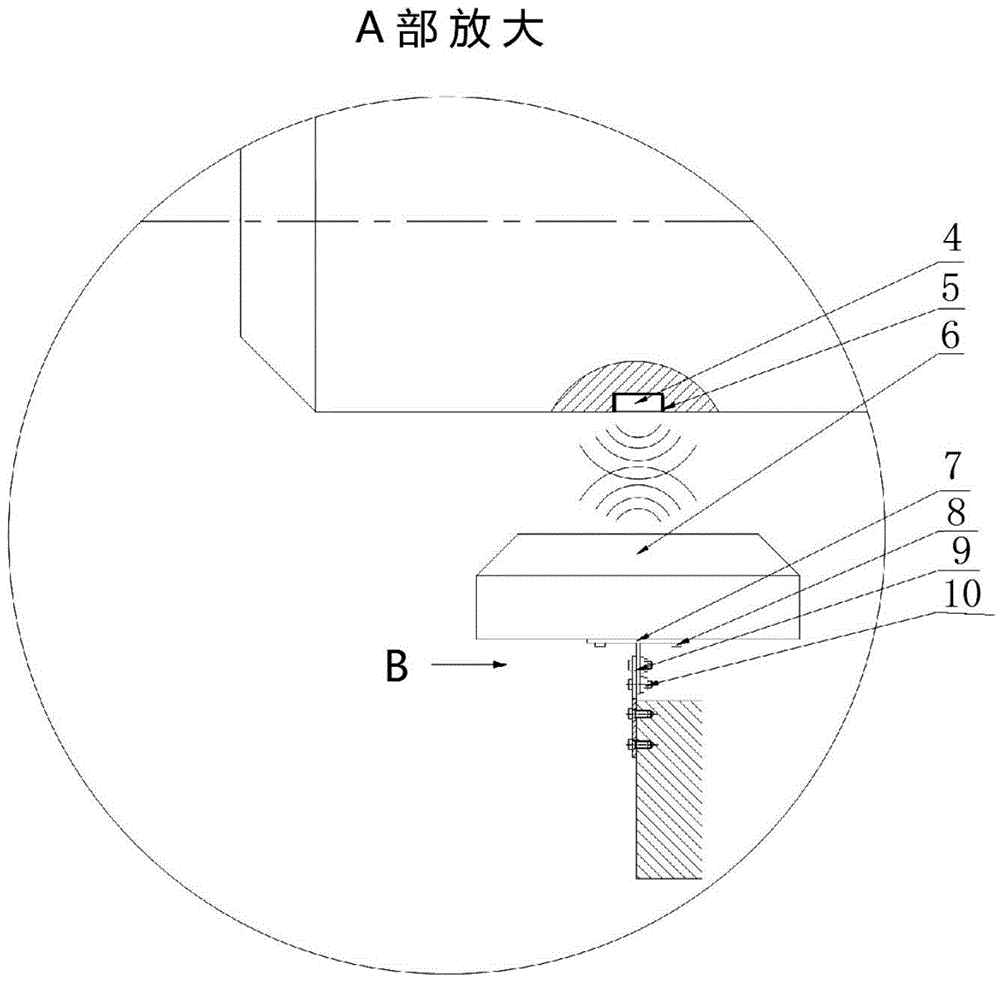

On-line monitoring device and method for motion state of broach

ActiveCN104889824AAchieve real-time recordingDoes not affect normal workAutomatic card filesMeasurement/indication equipmentsRecording durationEngineering

Provided is an on-line monitoring device and a method for the motion state of a broach. The on-line monitoring device comprises an RFID anti-metal tag, a reader-writer and a support assembly of a motion monitoring device. The RFID anti-metal tag is mounted to a broach handle. The reader-writer is fixed onto a machine tool by means of the support assembly of the motion monitoring device and capable of adjusting the direction thereof within the certain angle range in order to ensure normal communication between reader-writer and the RFID anti-metal tag. The reader-writer transmits an electromagnetic wave signal with frequency band ranging from 901 to 928 MHZ. When the RFID anti-metal tag enters the region of a magnetic field with the broach, the RFID anti-metal tag receives the electromagnetic wave signal ad obtains energy for sending the electromagnetic wave signal from the interior. The reader-writer receives interior information sent out by the RFID anti-metal tag and writes in information on broaching frequency of the broach to the RFID anti-metal tag such that on-line and active accurate monitoring of the broaching frequency of the broach is achieved. The on-line monitoring device and method for the motion state of the broach has following beneficial effects: real-time and on-line monitoring of the total number of machined workpieces during the whole service lifetime of the broach is realized; characteristics such as non-contact and long recording duration are obtained; and the on-line monitoring device and method are suitable for broaches with different kinds of specifications.

Owner:SHANGHAI JIAO TONG UNIV +1

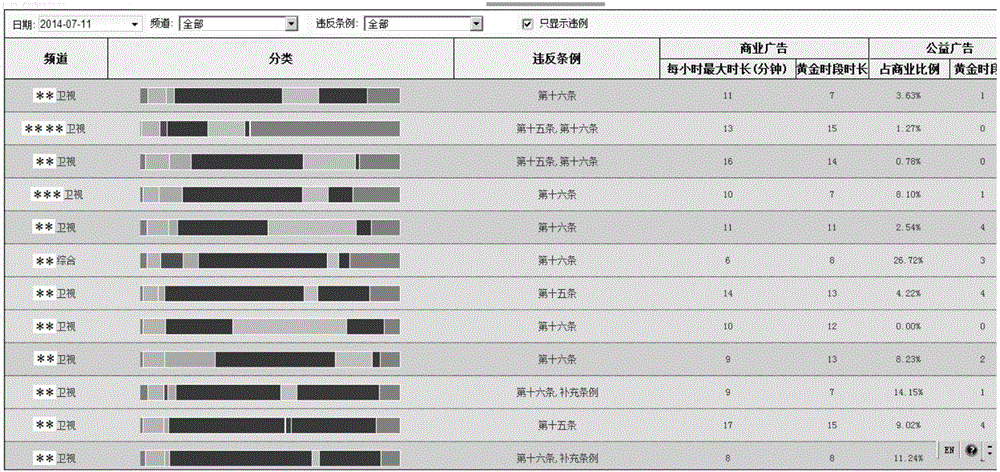

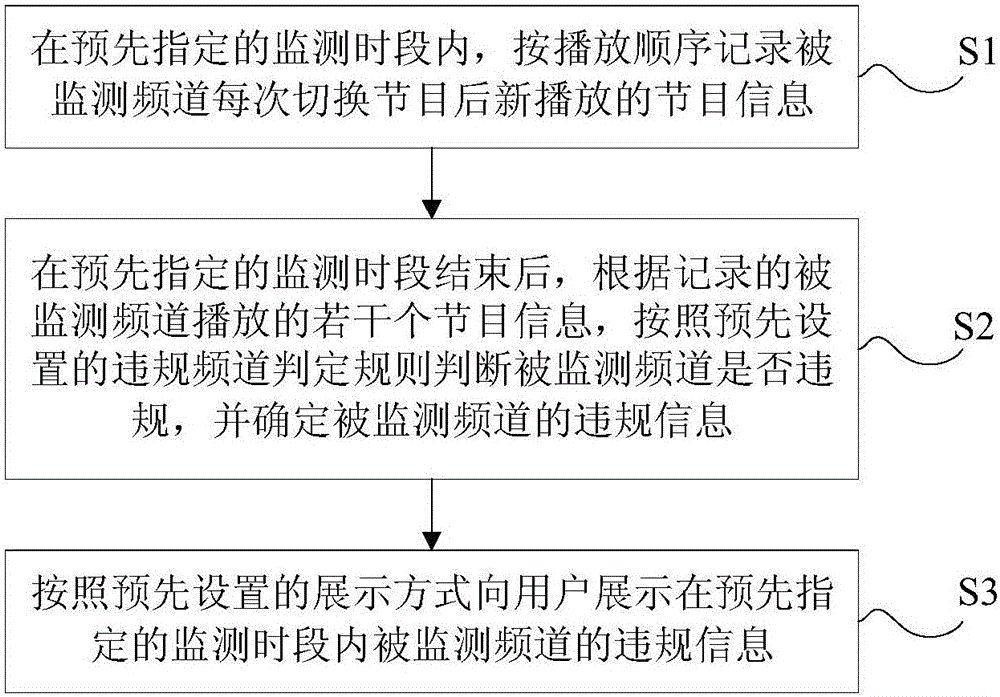

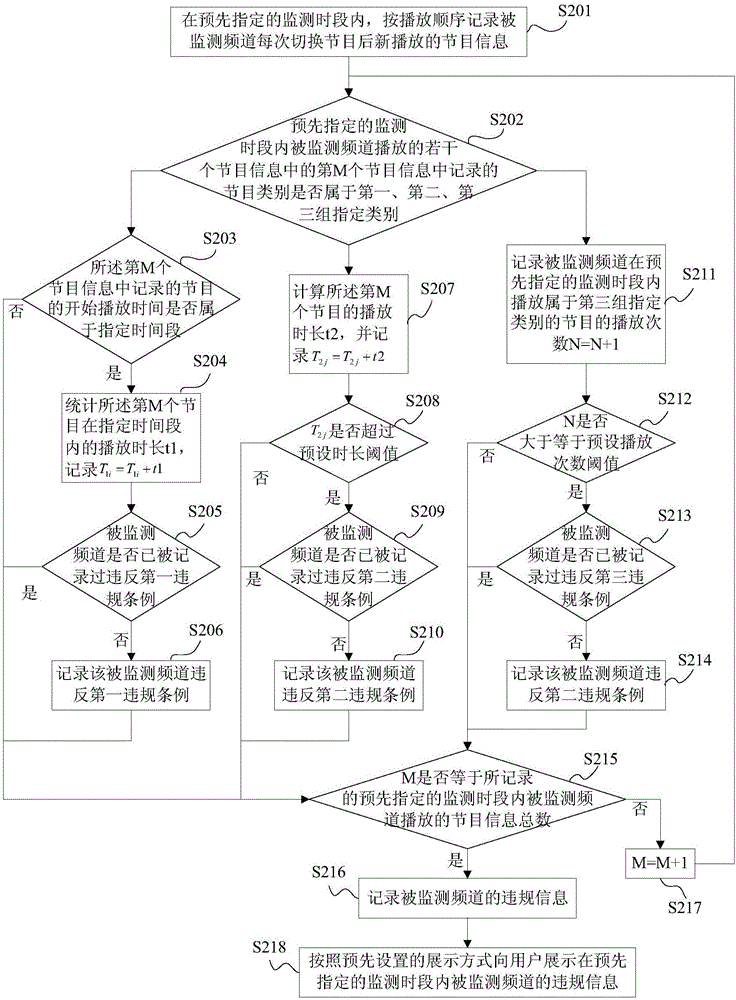

Rule-violating channel monitoring method and rule-violating channel monitoring device

InactiveCN105163179AEffective supervisionAchieve real-time recordingSelective content distributionNon complianceTime cost

The invention discloses a rule-violating channel monitoring method and a rule-violating channel monitoring device, which is a scheme used for carrying out automatic monitoring on programs played by channels so as to realize effective supervision for rule-violating channels which play programs in a non-compliance mode. The rule-violating channel monitoring method comprises the steps of recording information of a newly played program of a monitored channel after each time of program switching according to a playing sequence in a predetermined monitoring time period; judging whether the monitored channel violates rules or not according to preset rule-violating channel judgment rules on the basis of the recorded information of a plurality of programs played by the monitored channel in the predetermined monitoring time period at the end of the predetermined monitoring time period, and determining rule-violating information of the monitored channel when the monitored channel is determined to violate the rules; and displaying the rule-violating information of the monitored channel in the predetermined monitoring time period to users according to a preset display mode. The method disclosed by the invention is simple to implement, can realize automatic supervision for the rule-violating channels which play programs in the non-compliance mode, and saves the manpower cost and the time cost of artificial supervision.

Owner:WUXI TVMINING MEDIA SCI & TECH

Session process recording system and method

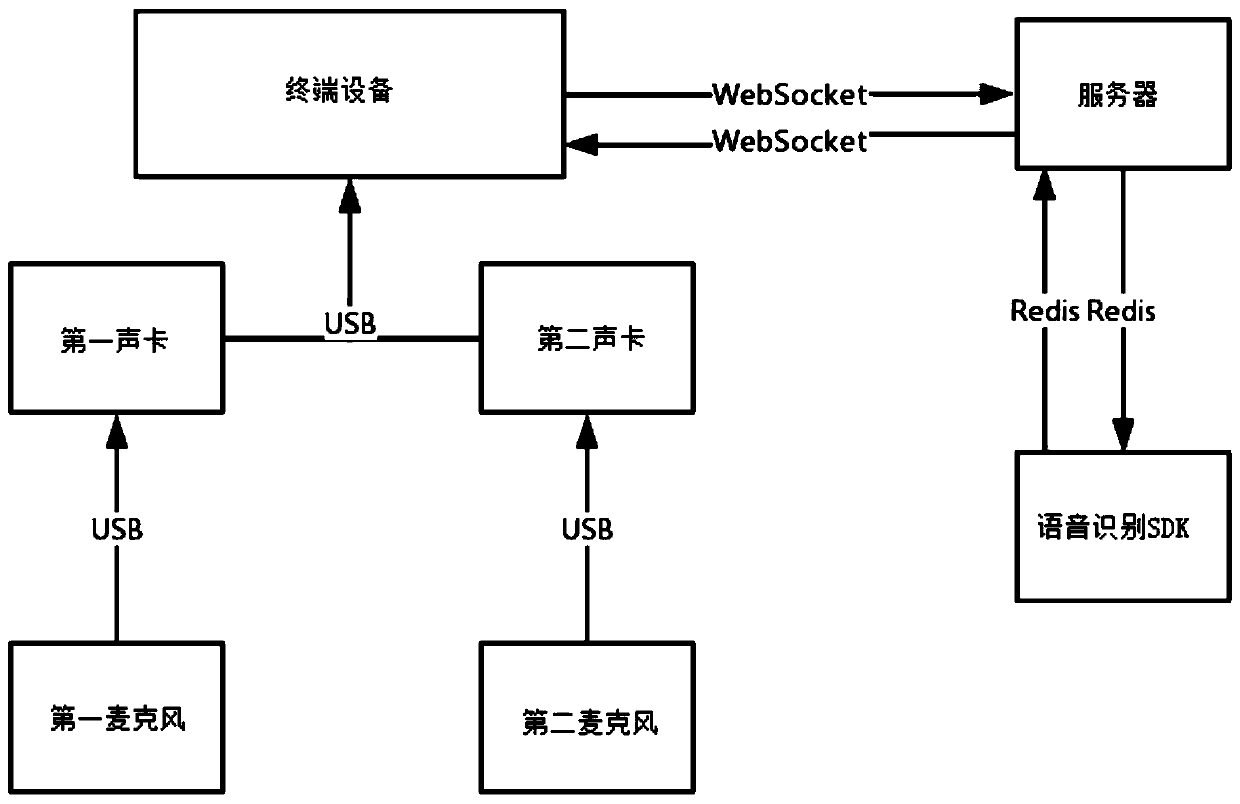

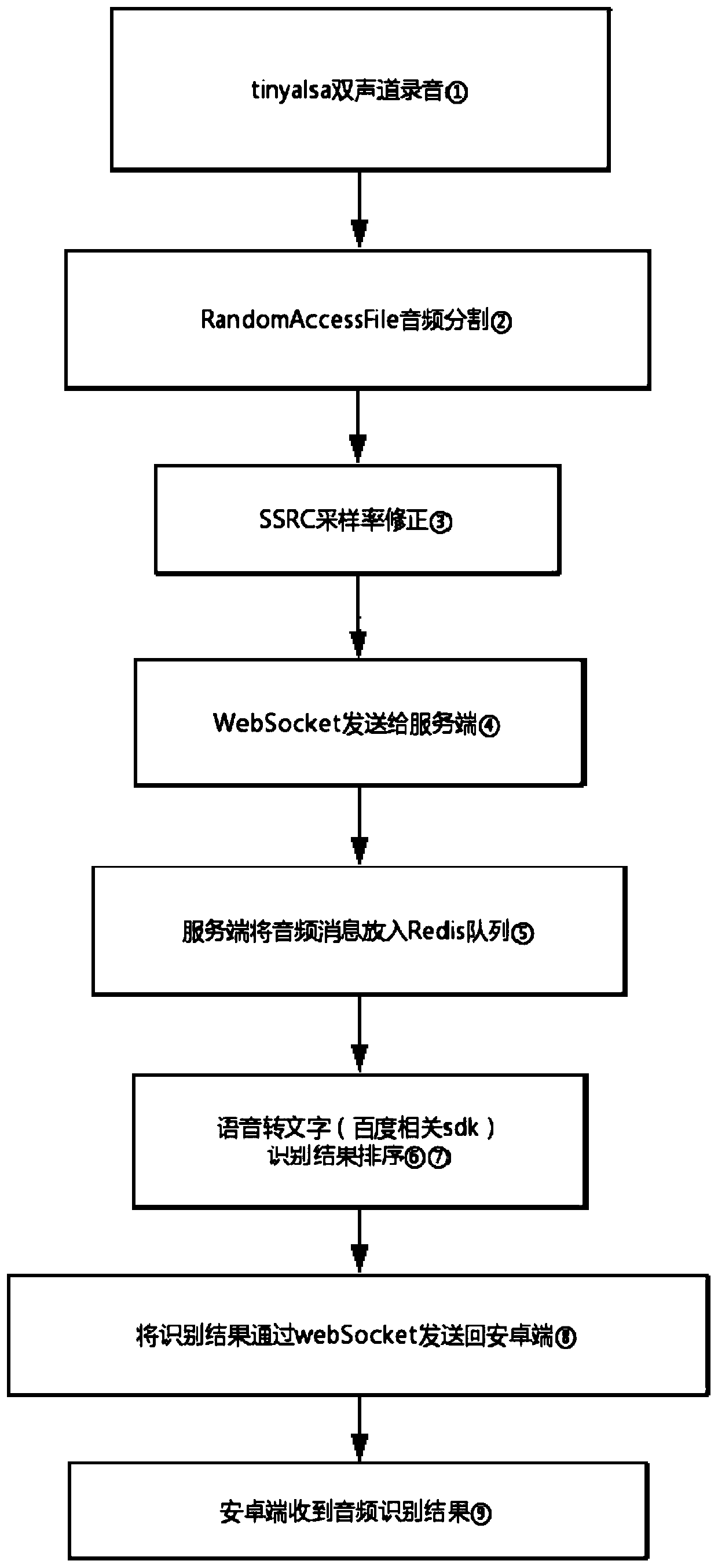

InactiveCN110648665AAchieve real-time recordingMeet application needsSpeech recognitionComputer hardwareInformation processing

The invention belongs to the field of voice information processing, and discloses a session process recording system and method. The system comprises a terminal device, a plurality of voice acquisition devices and a server, wherein the voice acquisition devices are suitable for simultaneously acquiring multiple sections of voice information and correspondingly forming a plurality of audio files; the audio files are sent to the server through the terminal device; the voice information in the audio files is converted into text information through a voice recognition SDK; and the text informationis stored in the server and fed back to the terminal device. According to the session process recording system and method, the multiple sections of voice information acquired simultaneously is converted into the text information, so that real-time recording of multi-role session processes is realized and application requirements of specific scenes of multi-person sessions are met.

Owner:北京左医科技有限公司

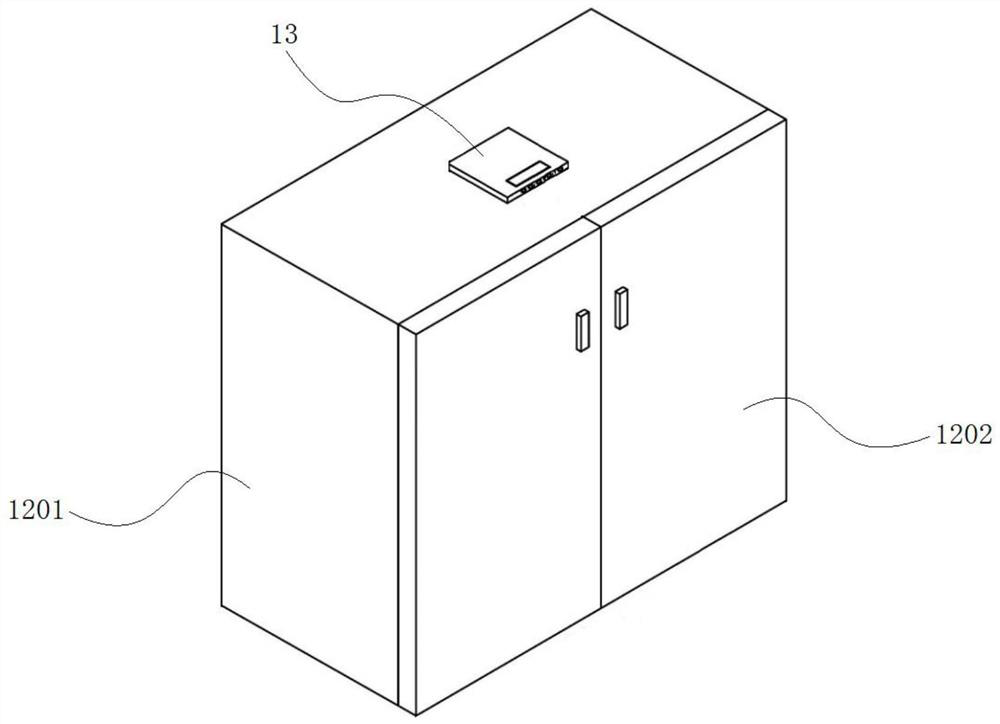

Mixed gas supply type visual natural gas hydrate experiment system

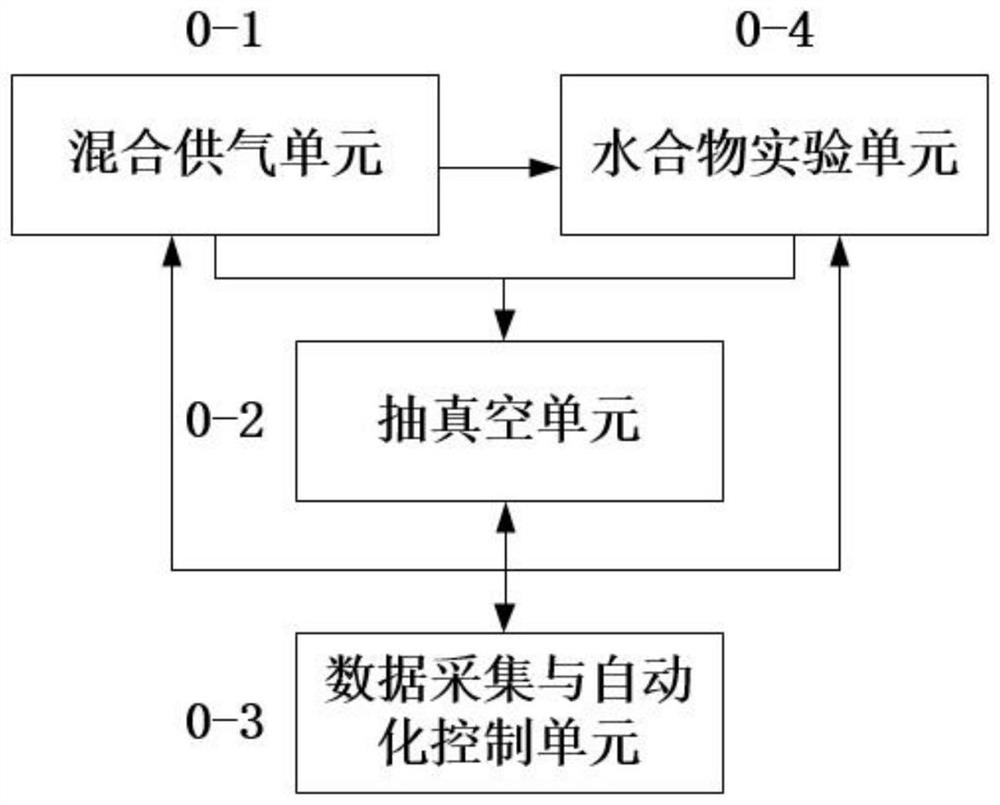

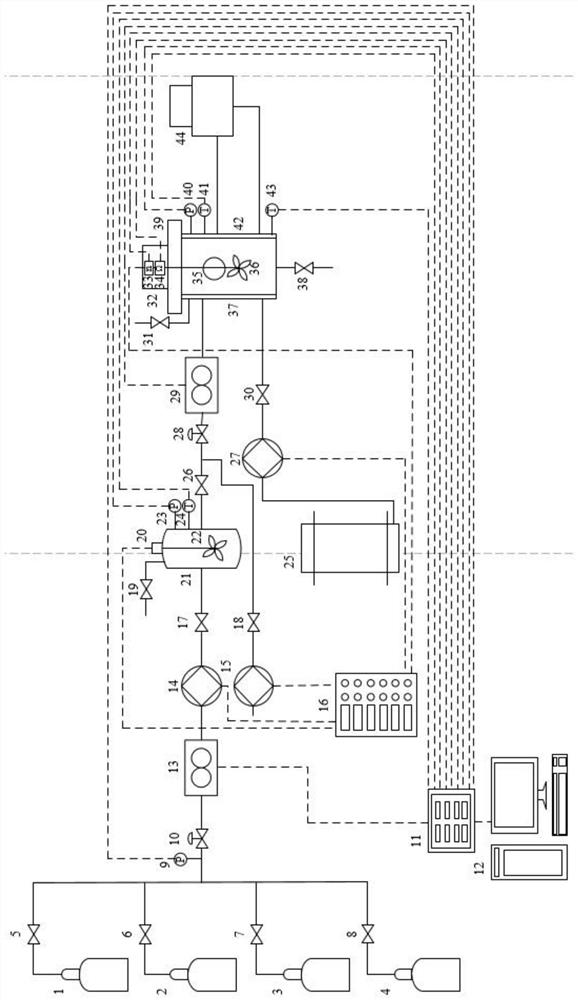

InactiveCN112834697ARealize visualizationEasy to sampleMaterial analysisWater bathsAutomatic control

The invention relates to a mixed gas supply type visual natural gas hydrate experiment system which mainly comprises a single-component gas cylinder, a data collector, a computer, a gas flowmeter, a gas booster pump, a vacuum pump, a control cabinet, a gas distribution tank, a liquid adding barrel, an injection pump, a high-pressure reaction kettle, a circulating water bath box, a pressure regulating valve, various sensors and pipeline matching valves. The system can be divided into a mixed gas supply unit, a vacuumizing unit, a data acquisition and automatic control unit and a hydrate experiment unit. The mixed gas supply unit is used for preparing multi-component high-pressure mixed gas; the vacuumizing unit is used for vacuumizing the system; the data acquisition and automatic control unit is used for monitoring parameters of each sensor in real time and remotely controlling the pump and the stirrer; the hydrate experiment unit is used for conducting hydrate experiments. According to the invention, the functions of multi-component gas input, hydrate generation visualization, gas or liquid experimental material sampling and the like can be realized, and various natural gas hydrate experiments can be carried out.

Owner:SOUTHWEST PETROLEUM UNIV

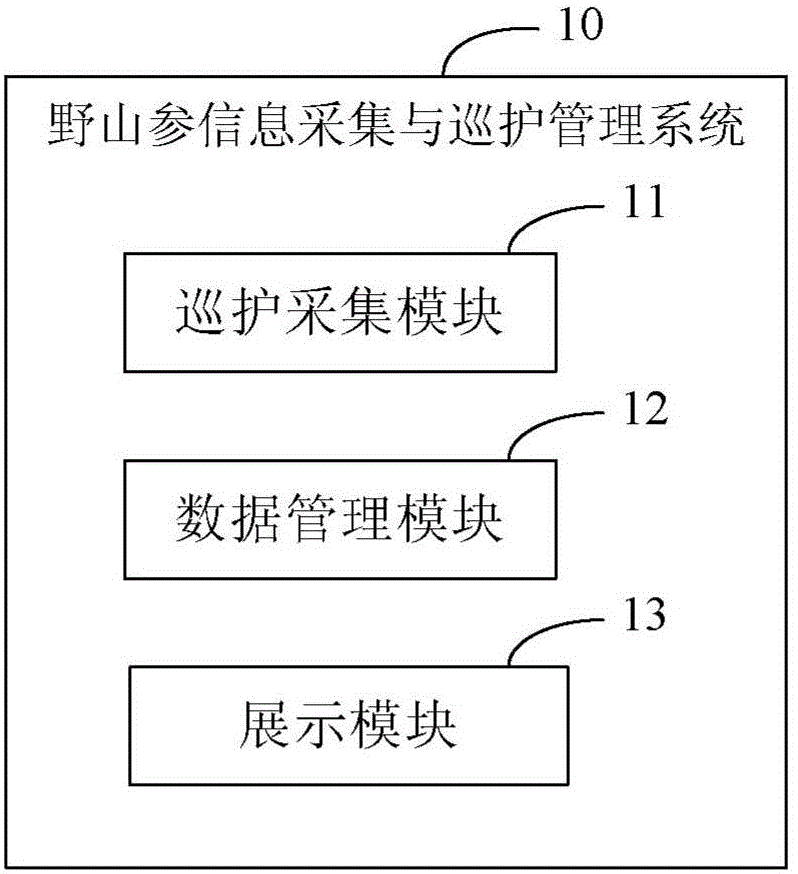

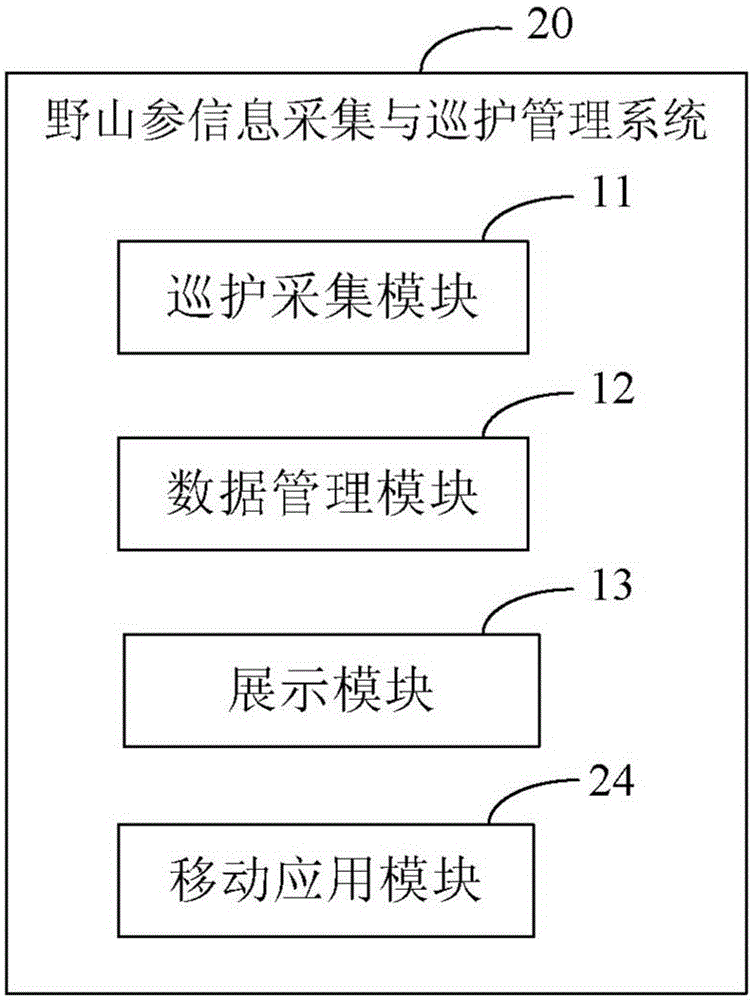

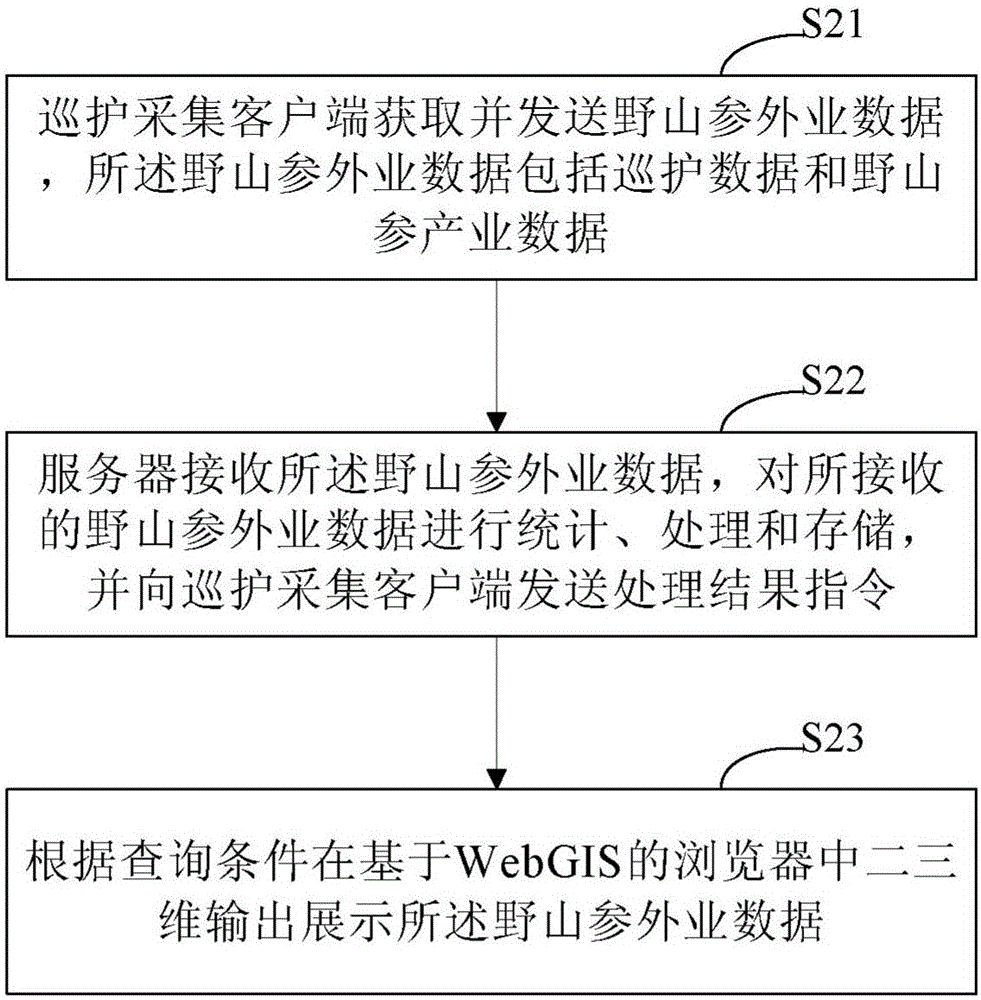

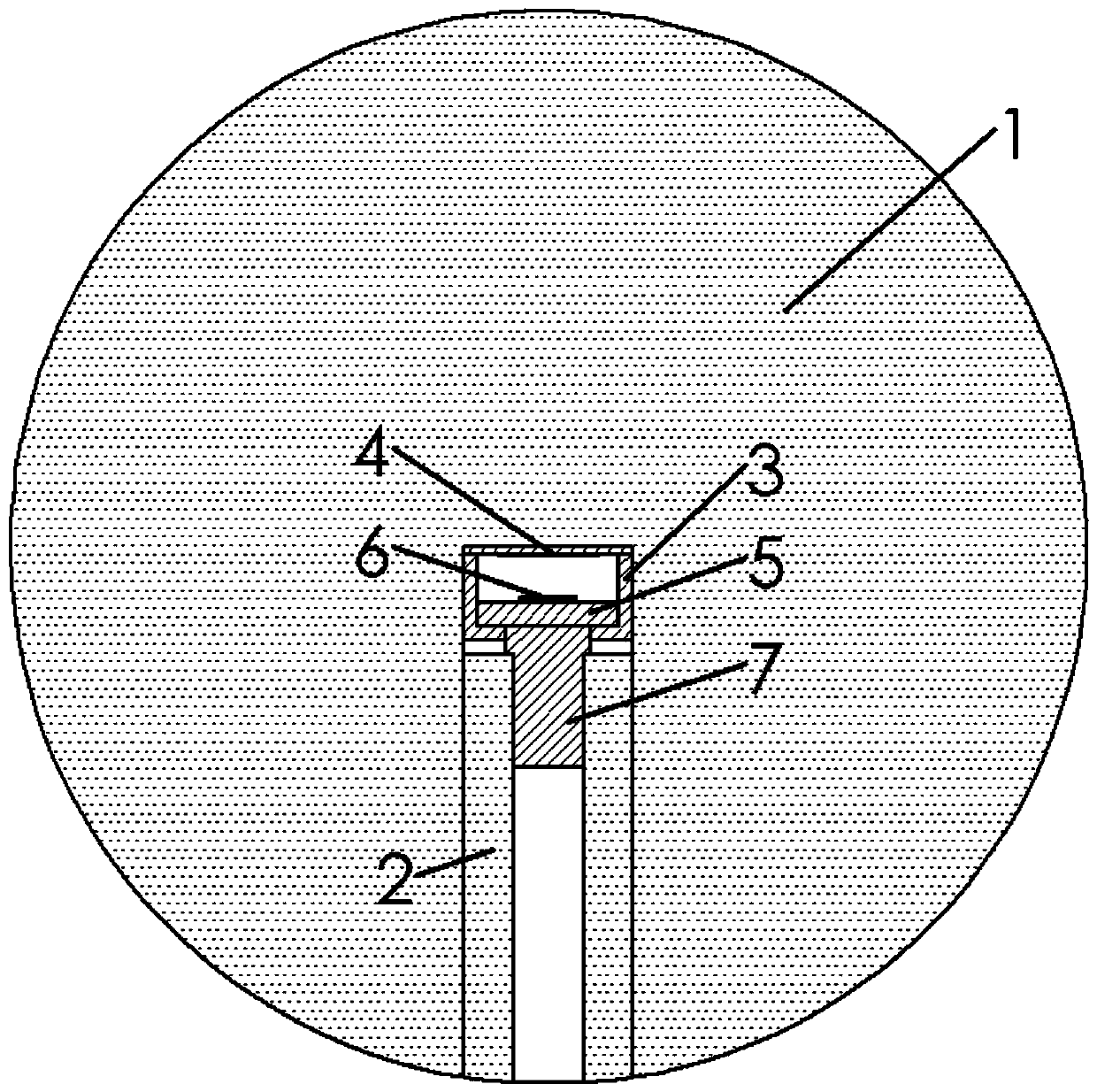

System and method for information acquisition and patrol management of wild ginseng

InactiveCN105023306AAchieve real-time recordingSave in timeChecking time patrolsData processing applicationsField dataData management

The invention provides a system and method for information acquisition and patrol management of wild ginseng. By the adoption of the system and method, automatic acquisition of wild ginseng industrial data and automatic recording of the patrol path can be achieved synchronously, acquisition of wild ginseng field data is facilitated, and wild ginseng field patrol work can be supervised timely and effectively. The system comprises a patrol acquisition module used for acquiring and sending wild ginseng field data, a data management module used for receiving the wild ginseng data, conducting statistics, processing and storage on the received wild ginseng field data, and sending a processing result instruction to the patrol acquisition module, and a display module used for outputting and displaying the wild ginseng field data in a two-dimensional or three-dimensional mode, wherein the wild ginseng field data include patrol data and wild ginseng industrial data.

Owner:SHEN XIAN YUAN GINSENG CO LTD

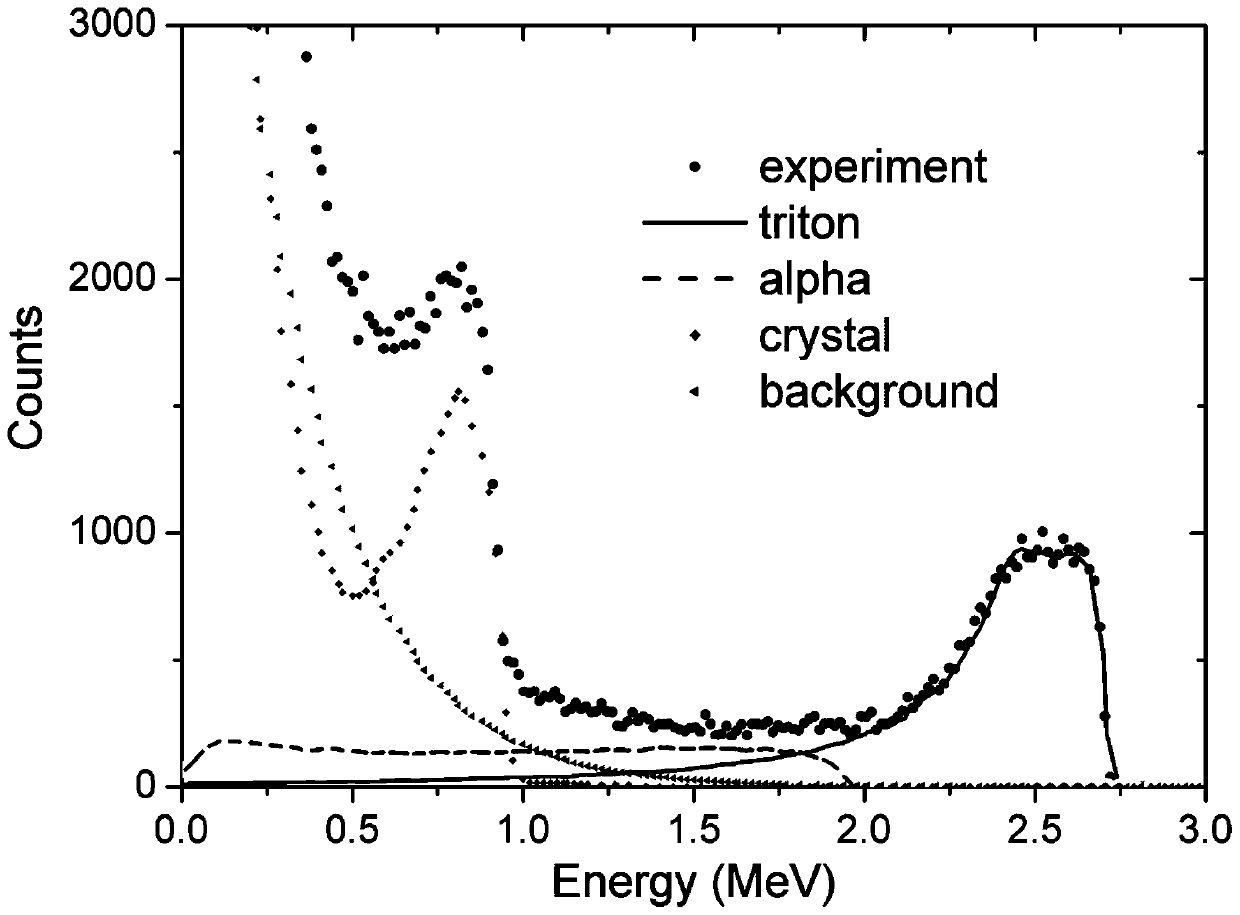

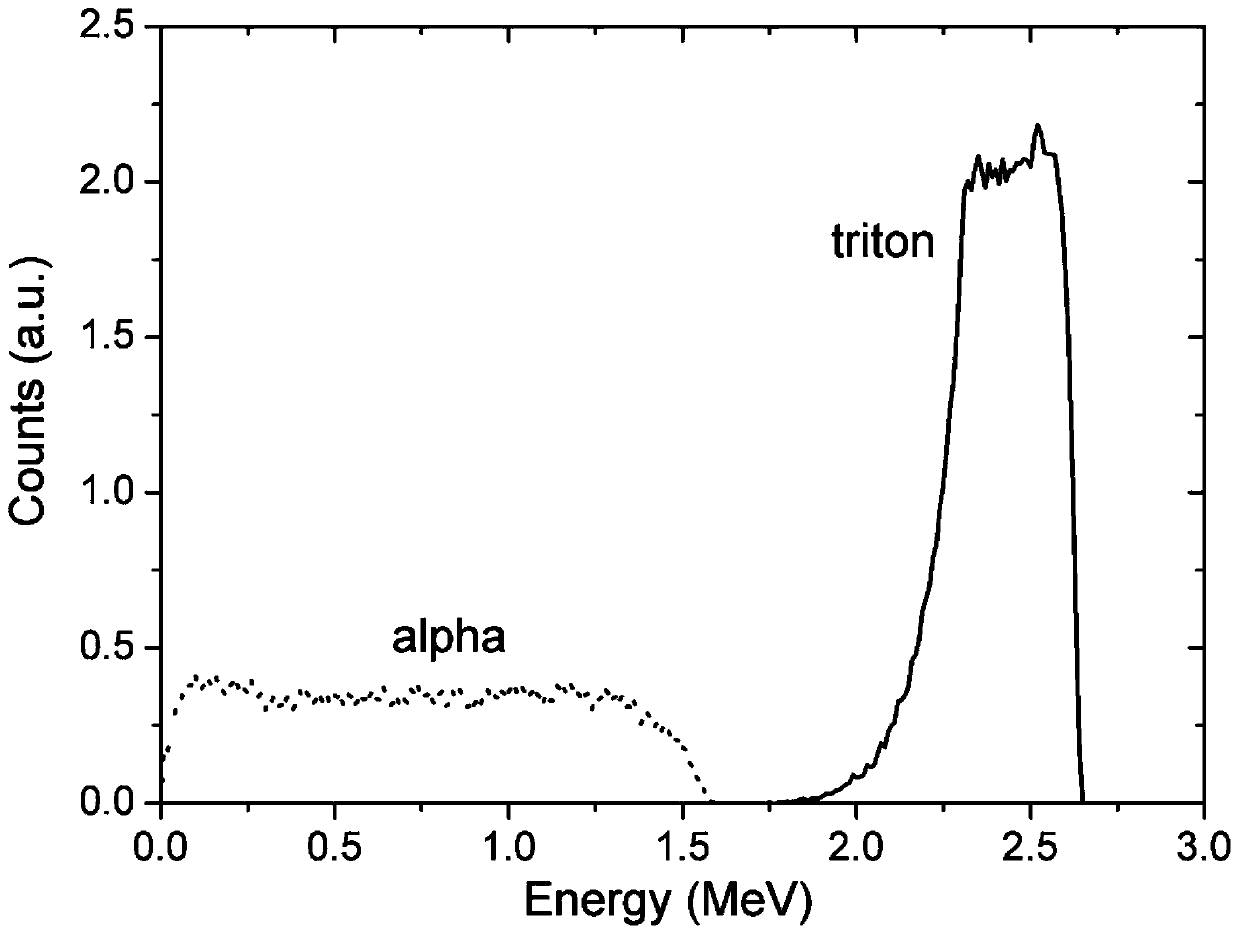

Neutron energy spectrum measuring device and Bonner sphere spectrometer system

ActiveCN109799527AImprove counting effectAccurate countNeutron radiation measurementNeutron converterBonner sphere

The invention provides a neutron energy spectrum measuring device and a Bonner sphere spectrometer system. A diamond detector is adopted as a thermal neutron counter, the advantage that the diamond detector is low in thermal neutron detection efficiency and quick in response is utilized, data real-time recording can be realized, the problem of detector counting saturation in a strong neutron fieldis avoided, and the device has the advantages of a real-time data recording function that existing active Bonner sphere spectrometers have and an anti-saturation function in a high-throughput neutronfield. A gap is formed between a diamond sensitive unit and a 6LiF neutron converter, so that alpha and tritium particles obtained by thermal neutrons and 6Li reaction can be separated, and tritium particle counting is more accurate. In addition, only one diamond detector is arranged in each spherical moderator, so that electronics and a data collection system are enabled to become simple and bemore convenient for operation, and subsequent data processing is made simple and convenient.

Owner:PEKING UNIV

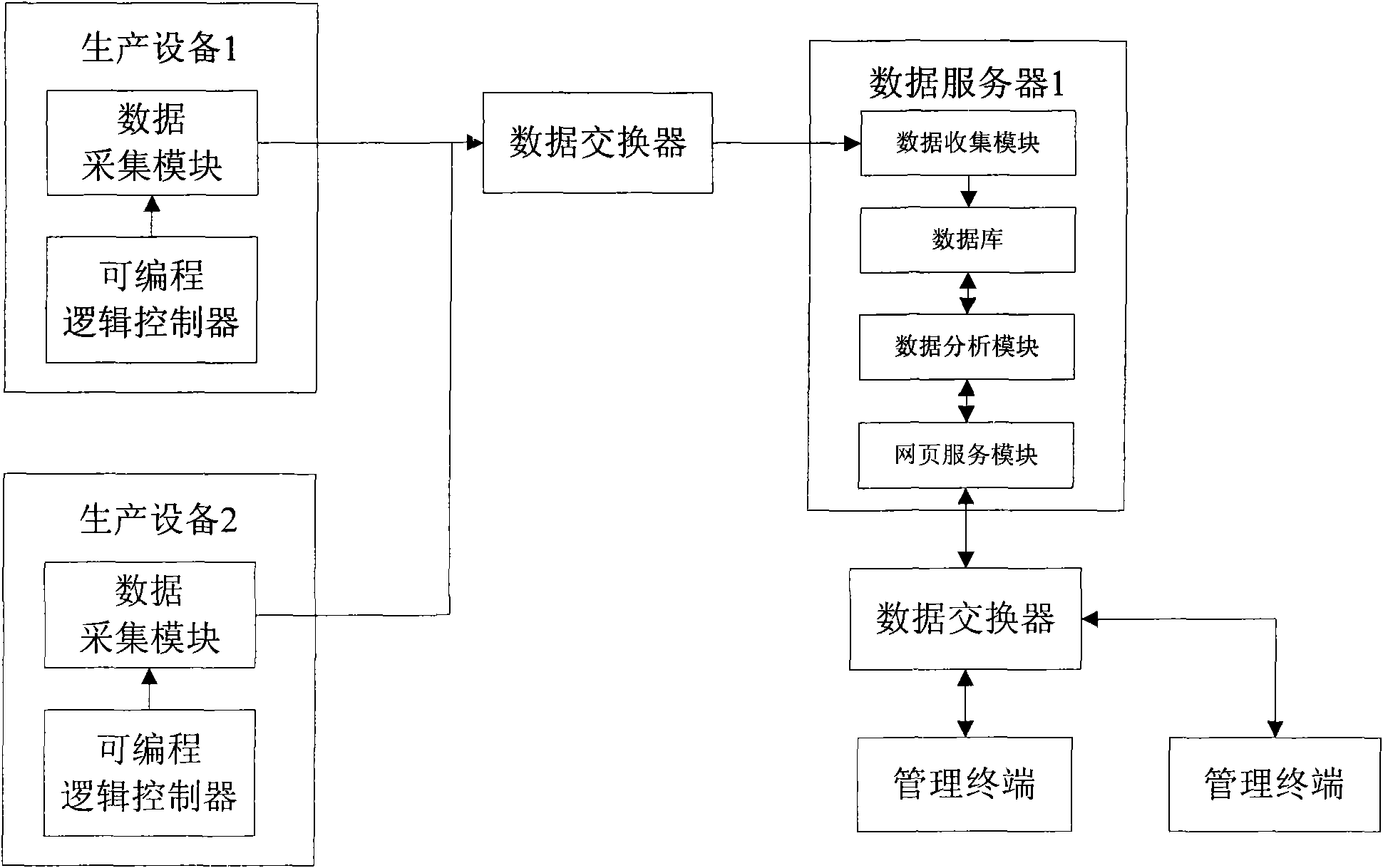

Automobile production information managing system

InactiveCN101639683AAchieve real-time recordingAchieve real-time displayTotal factory controlProgramme total factory controlCountermeasureIdle time

The invention provides an automobile production information managing system. The system comprises one or more programmable controllers which are arranged on production equipment and used for controlling the production process and a data server, wherein each programmable controller is connected with a data acquisition module used for acquiring production time, fault time and idle time; and the dataserver comprises a data collection module which is connected with the data acquisition module and used for obtaining the information from the data acquisition module, a data base used for storing theinformation collected by the data collection module and a data analysis module used for analyzing the information in the data base. The automobile production information managing system replaces an original manual record mode and avoids the faults in the manual record. In addition, the system also realizes the functions of real-time record and real-time demonstration, so that the production management staff can find faults according to accurate data in the first time and then take right measures.

Owner:SHANGHAI AUTOMOTIVE BRAKE SYST

A method for recording the maintenance operation process of a substation based on wearable equipment

InactiveCN109242113AAchieve real-time recordingImprove work efficiencyData processing applicationsInformation technology support systemTablet computerSmart substation

The invention relates to a method for recording the maintenance process of a substation based on wearable equipment, which comprises the following steps: (1) a maintenance task work order and a work ticket are received; (2) operation tools, operation tablet computers and operation glasses are assigned to the overhaul operation through the intelligent substation management platform; (3) the intelligent substation management platform pushes the maintenance work ticket to the operation terminal; (4) Overhaul personnel carries out overhaul operations; 5) the maintenance responsible person recordsthe work ticket and synchronously uploads the work ticket to the application serv; 6) during that operation, the positioning server receives the positioning information of the personnel and calculateswhether the personnel crosses the line or not; (7) The operation glasses is prompted to use and record the inspection and repair operation instruction card and relevant safety specifications; (8) Fordangerous points, the tablet computer compulsorily records the picture and text information; (9) the homework is Finished. The invention realizes the recording of the work order, the recording of pictures and texts of the key processes, and the prompting and recording of the violation behaviors, so as to facilitate the real-time synchronization and the post-statistical analysis.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

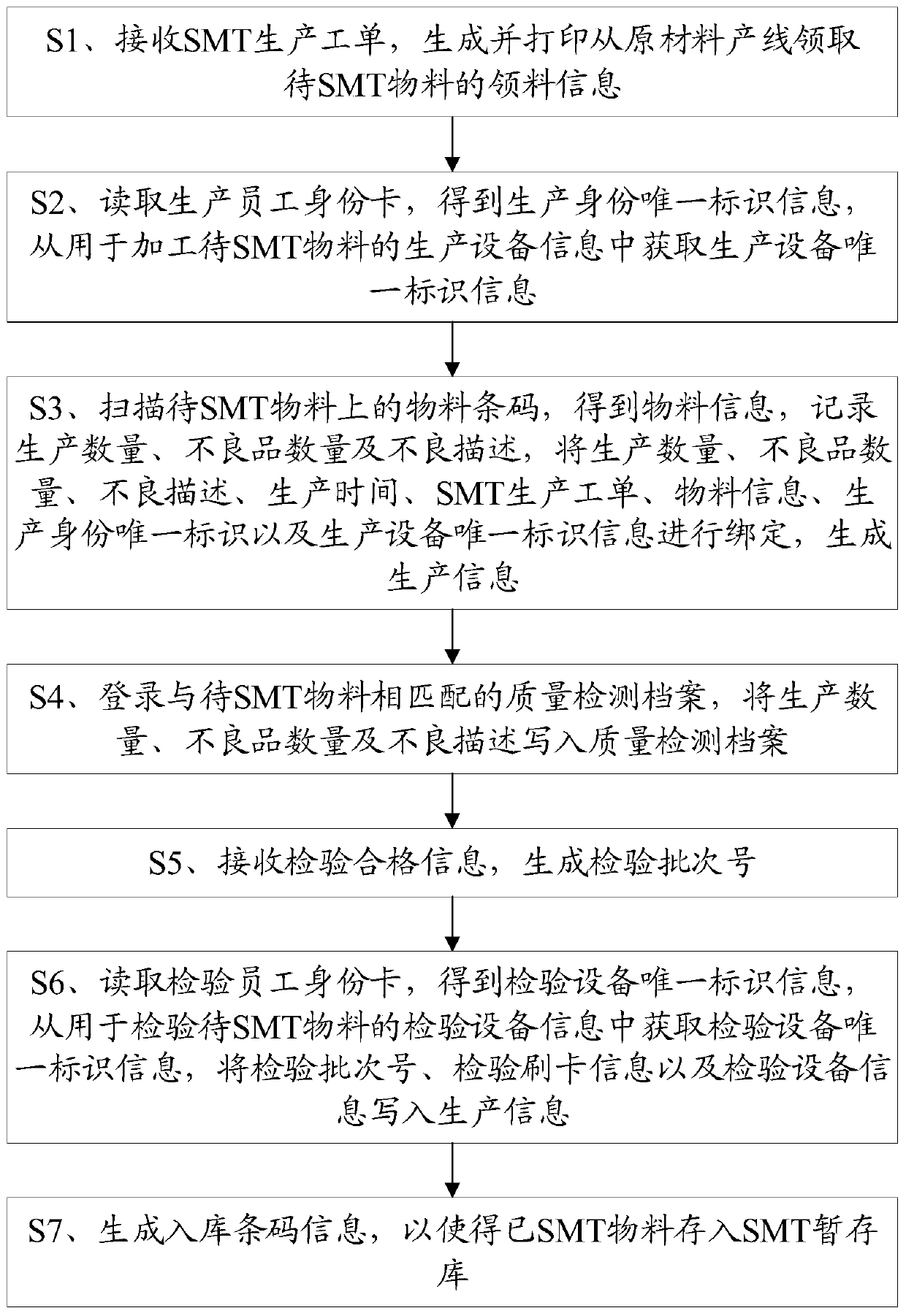

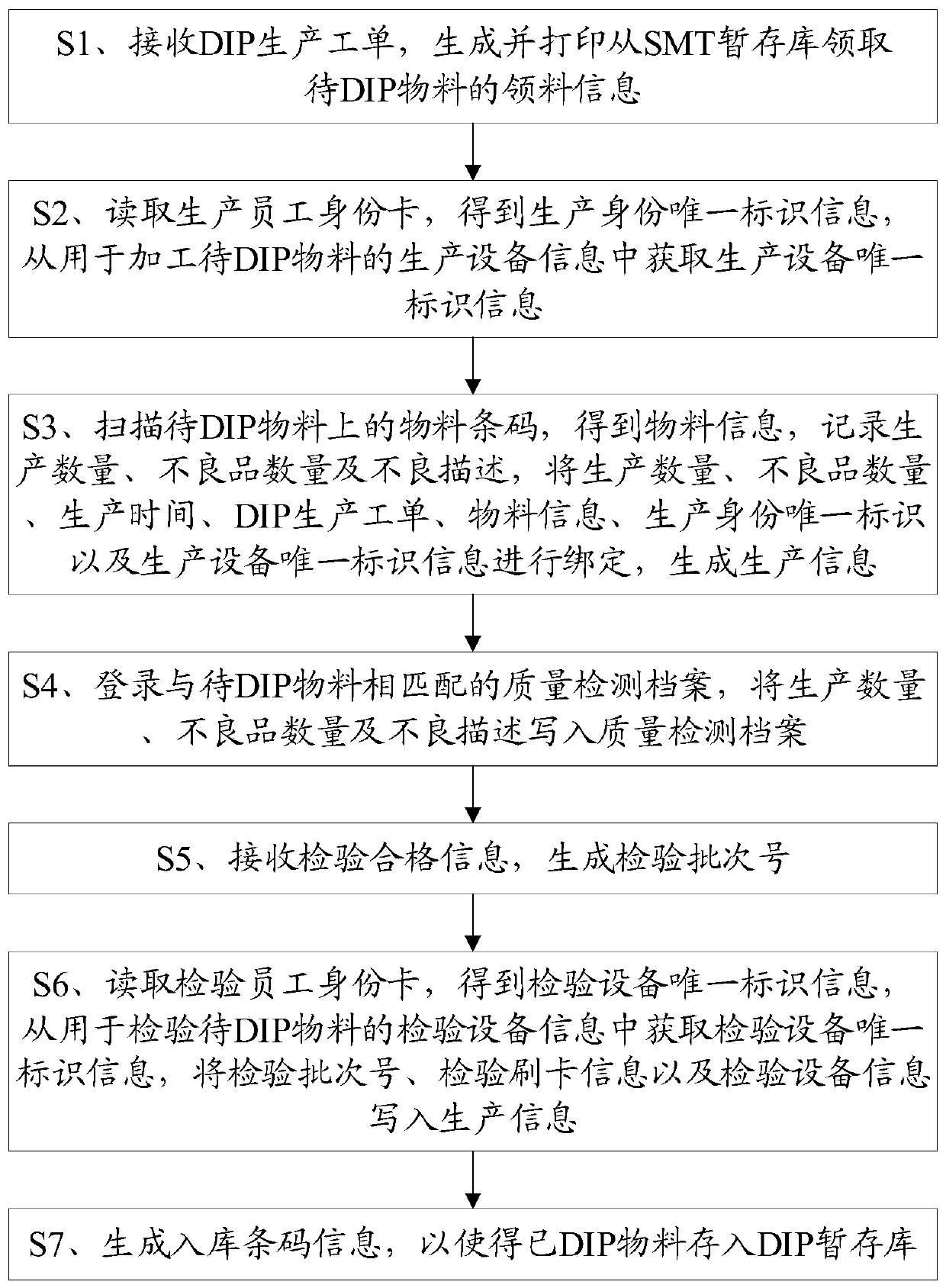

DIP production line management method and manufacturing end

InactiveCN109858928AFacilitate bad analysisImprove production yieldCo-operative working arrangementsCommerceBarcodeManufacturing engineering

The invention discloses a DIP production line management method and a manufacturing end, and the method comprises the steps: receiving a DIP production work order, and generating and printing materialreceiving information for receiving a to-be-DIP material from an SMT temporary storage library; reading a production employee identity card to obtain production identity unique identification information, and obtaining the production equipment unique identification information from the production equipment information used for processing the to-be-DIP material; scanning a material bar code on theto-be-detected DIP material to obtain material information, recording the production quantity and bad data, binding all the information to generate production information, and writing the productionquantity, the defective product quantity and bad description into a quality detection file; writing data related to inspection into production information; generating warehousing barcode information,so that the DIP materials are stored in a DIP temporary storage library; according to the invention, a complete product tracing system is formed, transparent management of production is ensured, subsequent adverse analysis is facilitated, and the production yield is improved.

Owner:JIANGXI YINHE METER CO LTD

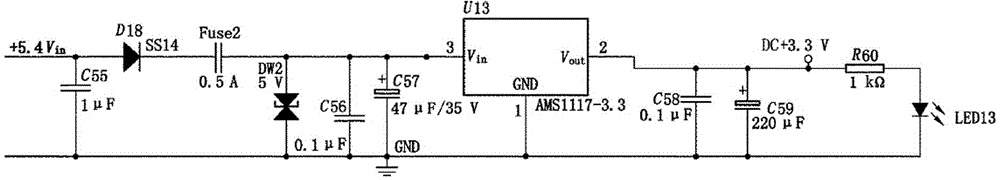

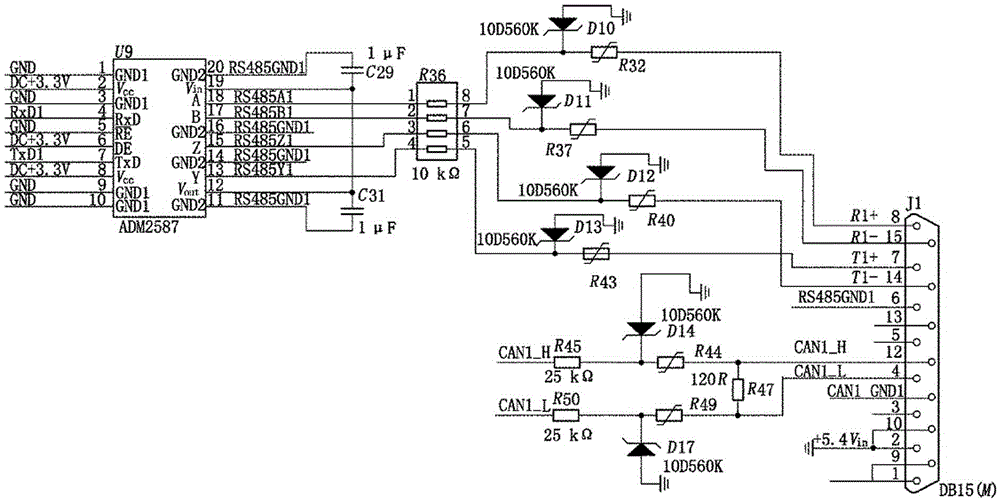

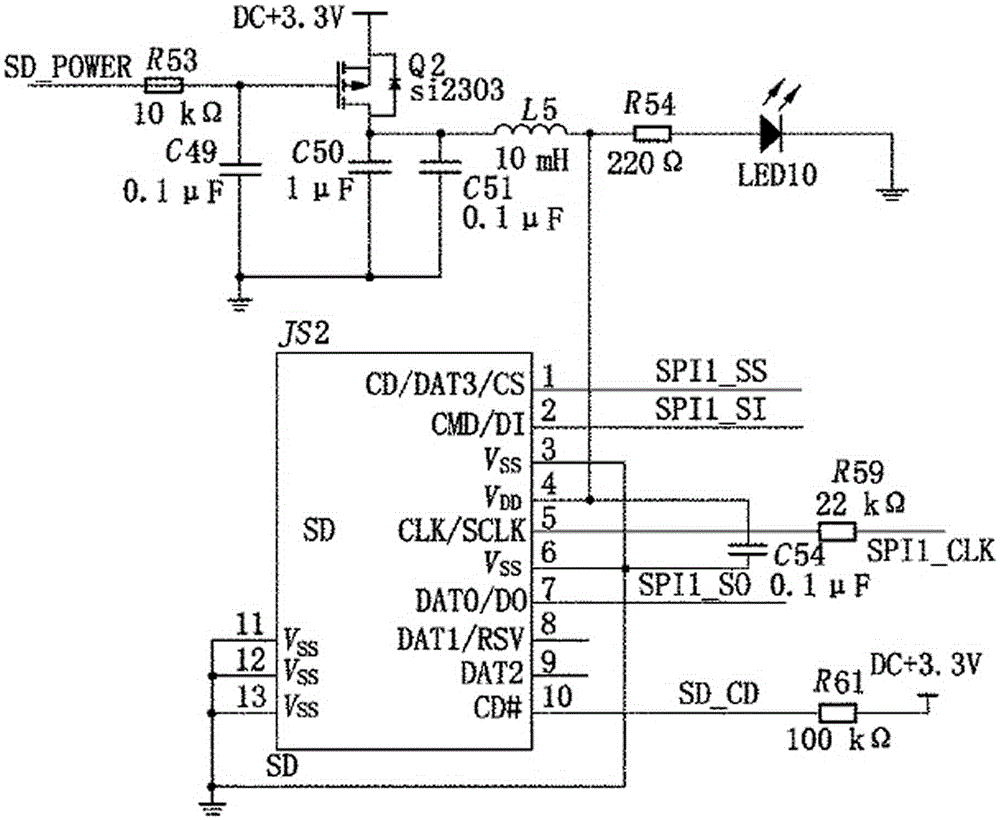

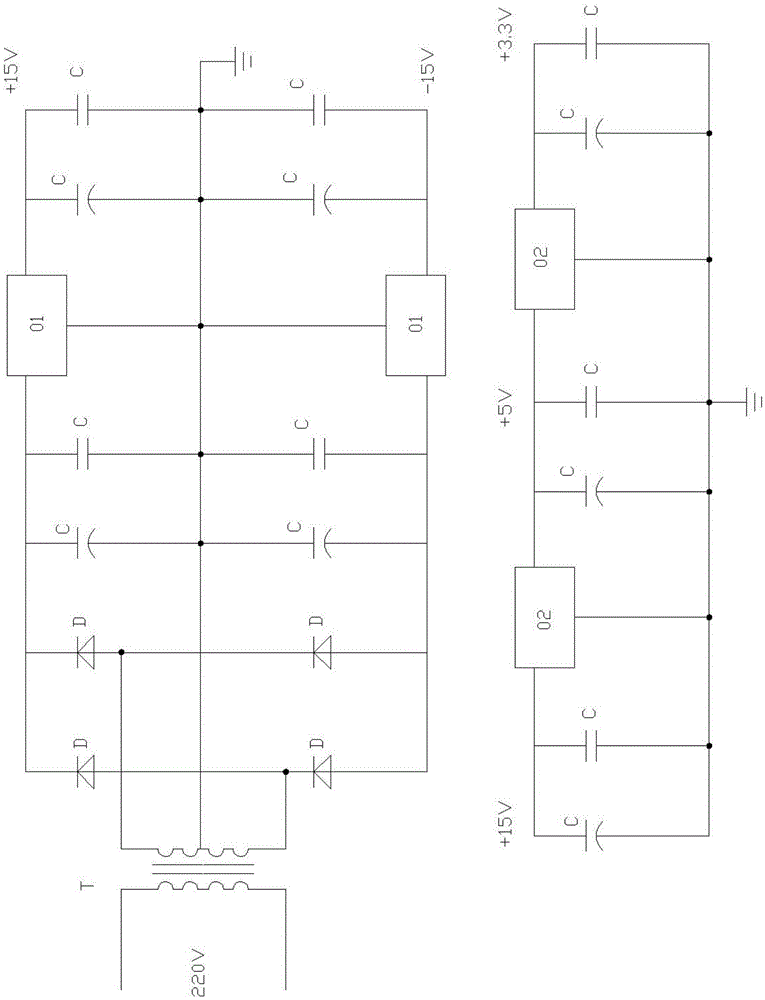

Steering data recording circuit

InactiveCN106707826AAchieve real-time recordingHigh feasibilityProgramme controlComputer controlPositive directionCurrent limiting

The invention relates to a steering data recording circuit, and a problem that steering control research lacks measured navigation data is solved, and a powerful mean is provided for deepening the ship control technology research. The steering data recording circuit comprises a microprocessor and peripheral circuits of the microprocessor. The structural points of the circuit are that the peripheral circuits comprise a crystal oscillator circuit, a power supply circuit, an RS485 serial circuit, and an SD card circuit; STM32F103RCT6 is employed by the microprocessor; positive low dropout voltage regulator AMS1171-3.3 is employed by the power supply circuit, 3.3V direct current is output, the precision is 1%; current limiting, overload and overheat protection circuits and a transient suppression diode D18SS14 are employed, the 3 pin of the AMS1171-3.3 is connected to the positive electrode end of a capacitor C57 and one end of C56, the 1 pin of the AMS1171-3.3 is connected to the ground, and the 2 pin of the AMS1171-3.3 is connected to one end of the capacitor C58 and the positive electrode end of a C59.

Owner:由国峰

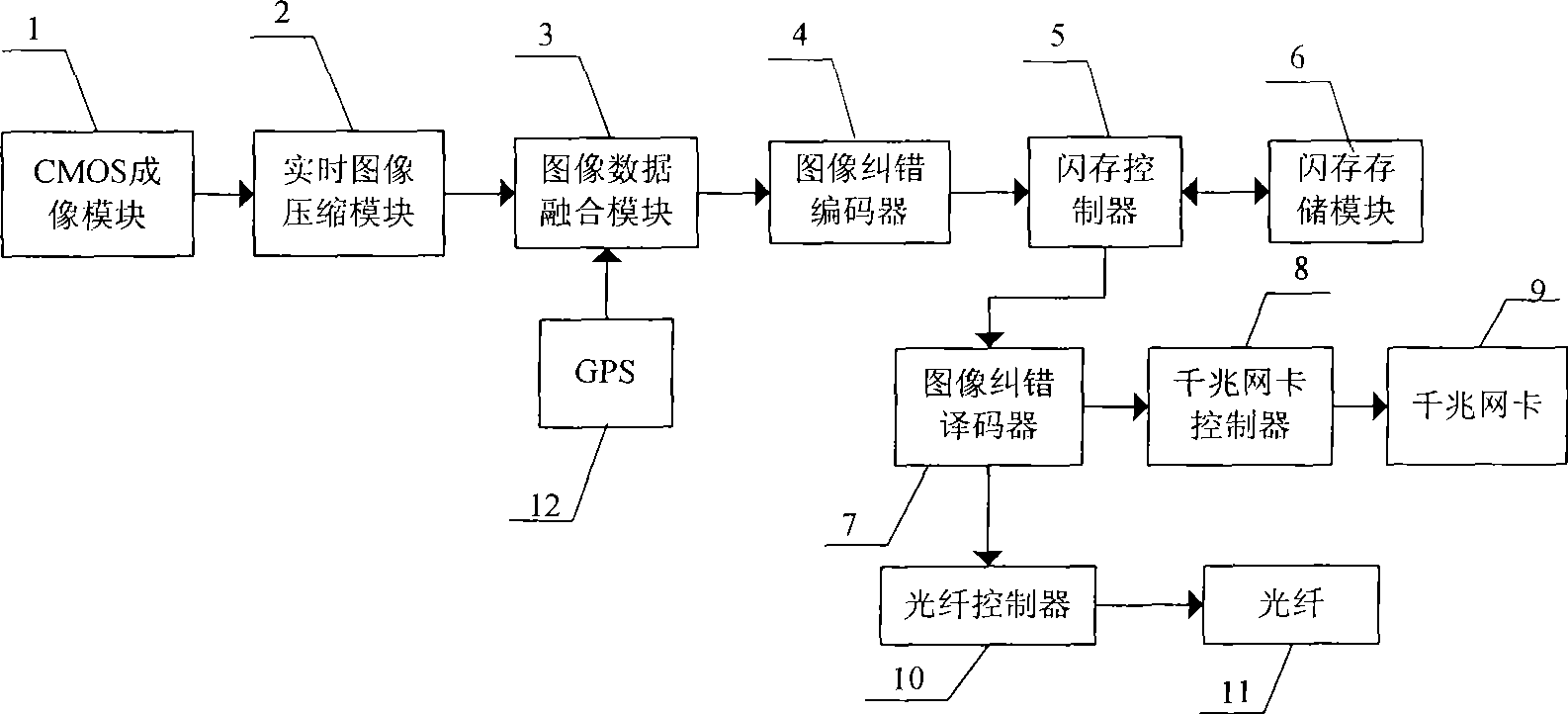

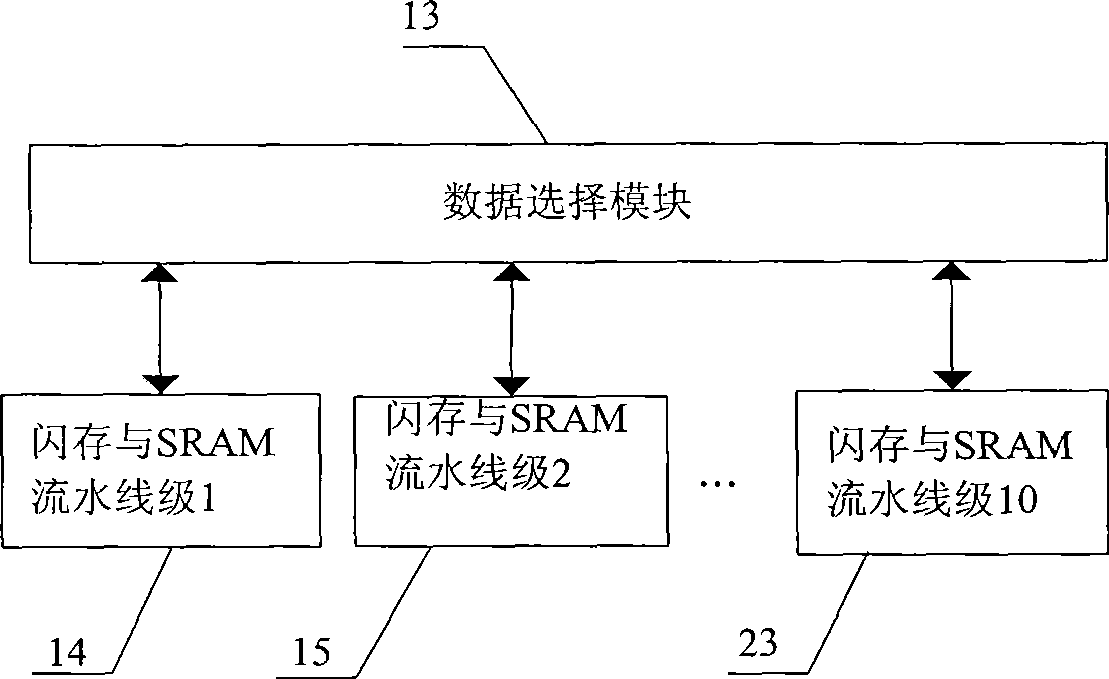

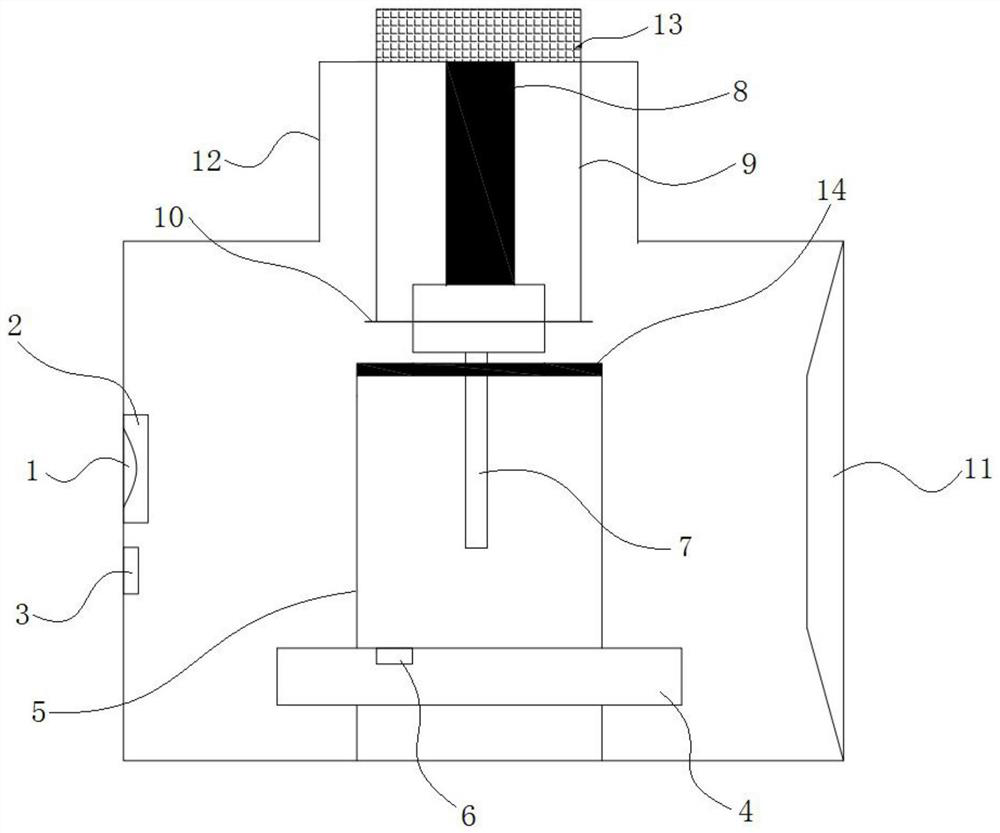

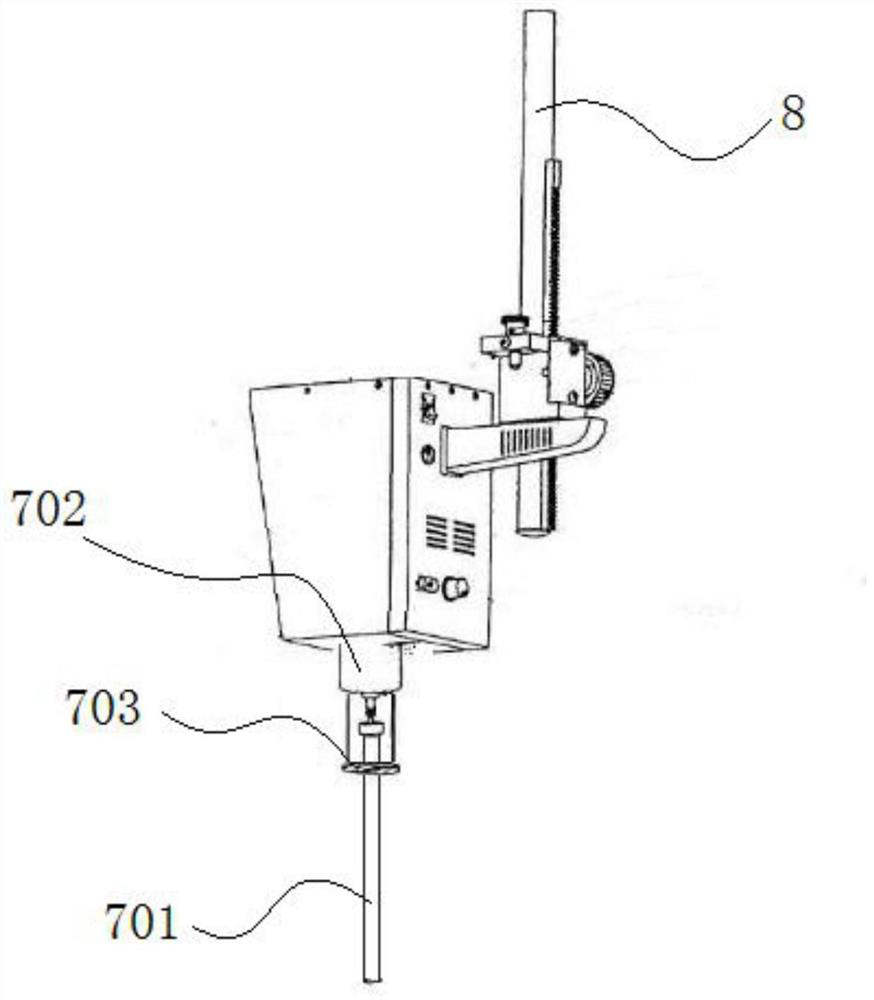

High-performance CMOS integrated digital camera

InactiveCN101510953AEasy to analyzeFacilitate communicationTelevision system detailsPicture taking arrangementsImage compressionFlash memory controller

The invention relates to a space camera, especially to a CMOS all-in-one digital camera with high performance, which comprises a CMOS imaging module, a flash memory memory module, an optical fiber and a kilo mega network card high speed data transmission, and also comprises a real-time image compression module, an image data fusion module, an image error correction encoder, a flash memory controller, an image error correction encoder, a kilo mega network controlling and an optical fiber controlling. The camera is convenient to analyze photoed image data by GPS high precision location / time, and saves storage space of the flash memory by compressing data, and guarantees the correctness of stored images by the image data error correction encoder, and improves anti-shocking ability of the system by using the flash memory as the storage media, and provides two data playback transmission modes of the kilo mega network card and the optical fiber in order for communicating between the device and the host computer. The space camera has the advantages of realizing continual high frame frequency image real-time recording and meanwhile realizing error correction encoding.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

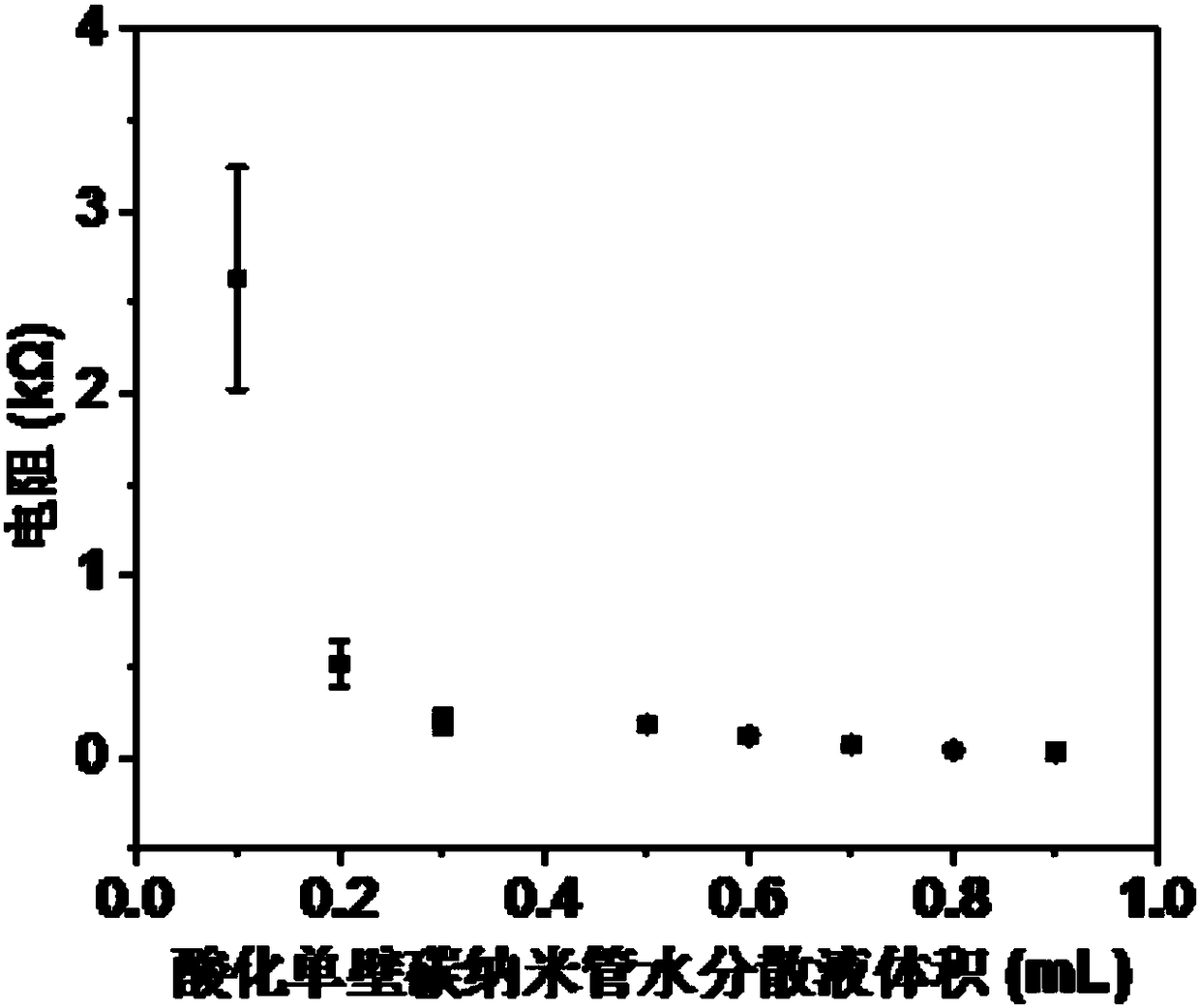

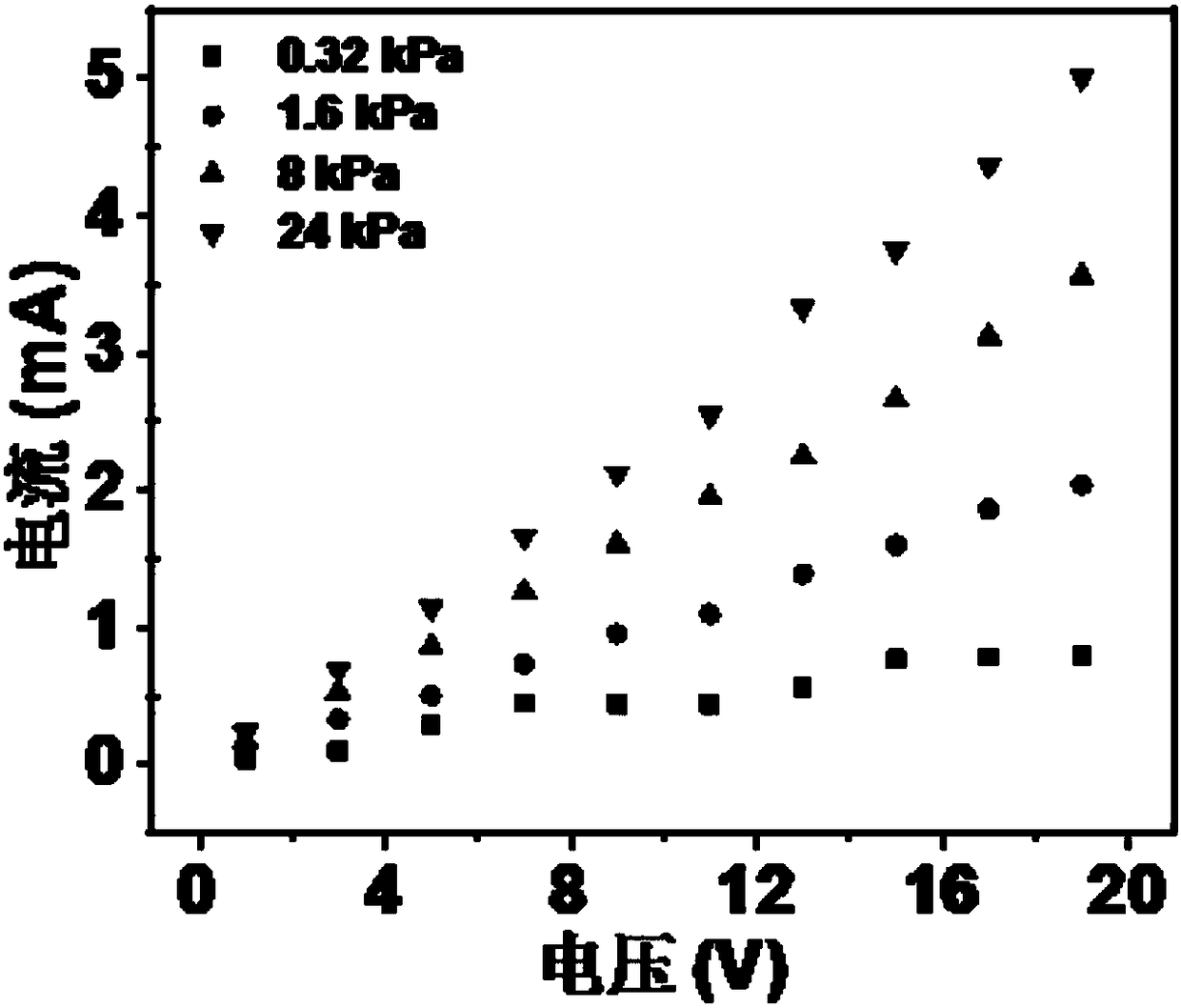

Nanofluid stability monitoring system and method

PendingCN111829924ARealize real-time observationAchieve real-time recordingNanoparticle analysisFlow propertiesAbsorbanceChemistry

The invention provides a nanofluid stability monitoring system and method. The system comprises a sample containing system, an absorbance testing system, a viscosity testing system, a surface tensiontesting system and a data acquisition system which are arranged in an inner cavity of a device housing. The sample containing system comprises a visual sample chamber placed on the rotating platform.A to-be-monitored nanofluid is contained in the visual sample chamber. The monitoring method of the monitoring system comprises the steps of transmitted light intensity collection, surface tension data collection, viscosity data collection, photographing recording and the like. The device not only can realize real-time observation of the stability of the nanofluid, but also can realize real-time recording of physical parameters of a system, more comprehensively represents the stability change of the nanofluid, is beneficial to scientific and accurate analysis of the stability of the nanofluidat the same time, and realizes a good synergistic effect of various stability representation methods.

Owner:CHONGQING UNIV

Method for recording walking step number on the basis of conducting leather

InactiveCN108398140AAchieve real-time recordingReasonably plan exerciseDistance measurementStep numberEngineering

The invention discloses a method for recording a walking step number on the basis of conducting leather, and is used for monitoring the walking step number of a person who wears leather shoes. The method comprises the following steps: arranging the conducting leather on the sole of each leather shoe; when pressure is continuously applied and released from the conducting leather, recording the walking step number by a current signal period generated by the three-dimensional multilevel structure deformation of the conducting leather. The method has the advantages of simpleness, low cost and easiness in popularization and use. In addition, the leather material is popularized and has a mature production technology, and the leather material is used as a platform to record the walking step number, and the walking step number can be recoded in real time so as to be favorable for a user to reasonably plan exercise training according to the walking step number.

Owner:NANJING UNIV OF TECH

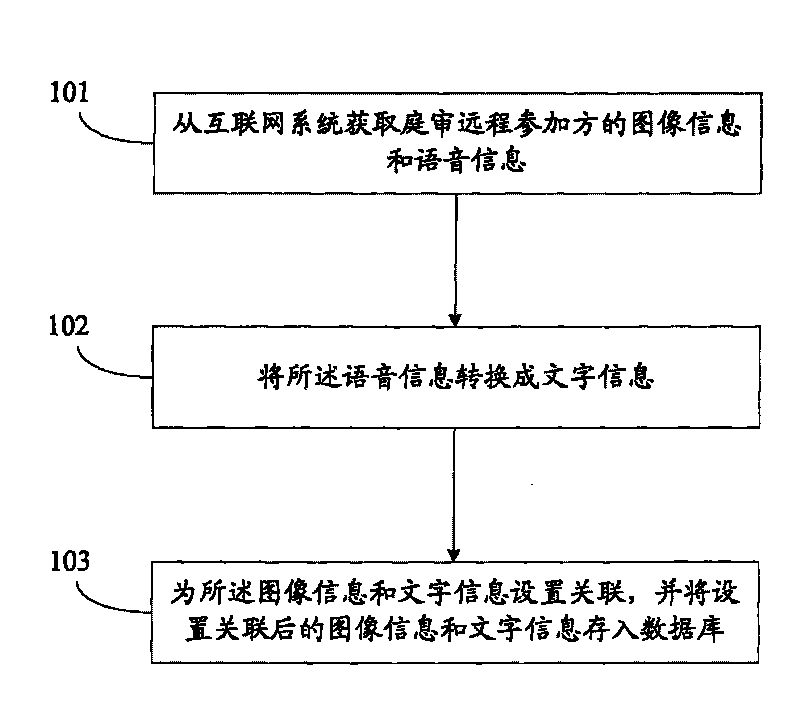

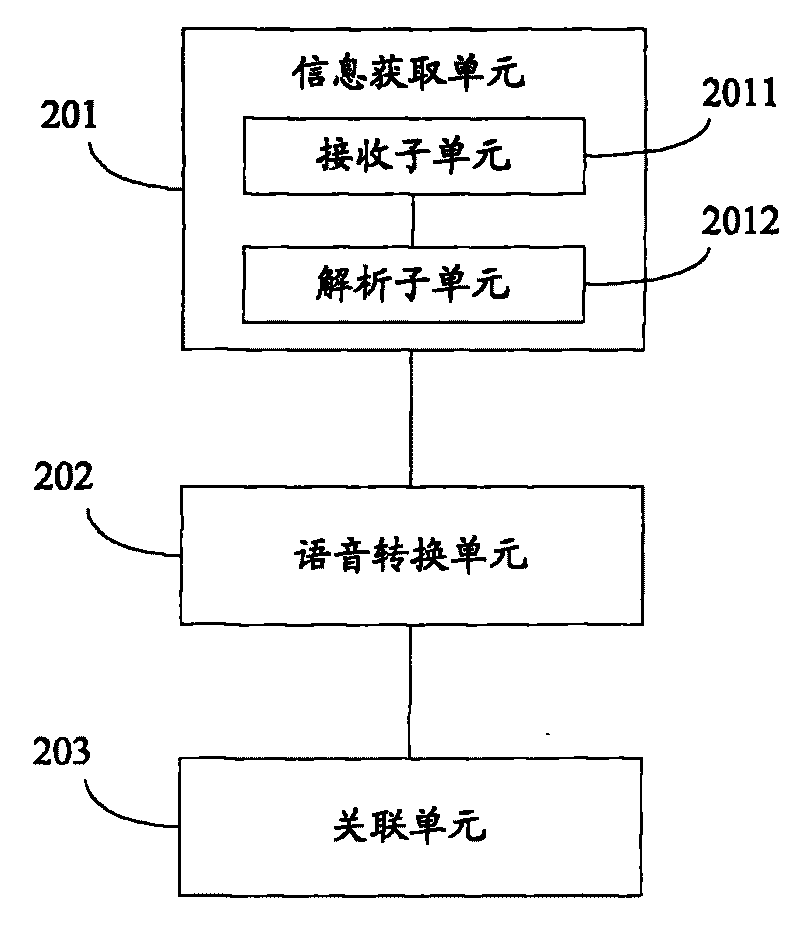

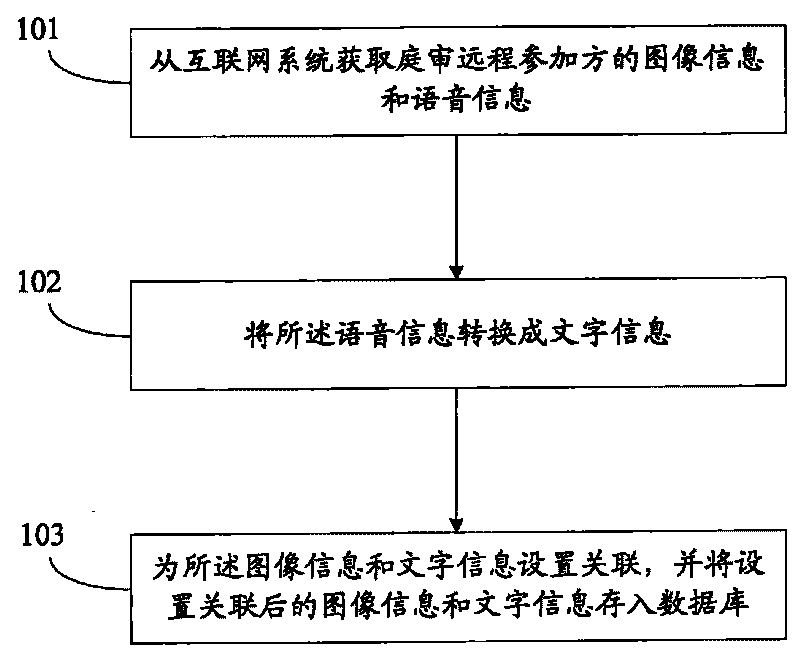

Method for recording remote court trial data in real time and device thereof

InactiveCN101763881AAchieve real-time recordingElectronic editing digitised analogue information signalsCarrier indexing/addressing/timing/synchronisingThe InternetSpeech sound

The invention discloses a method for recording remote court trial data in real time and a device thereof. The method comprises the following steps: acquiring image and voice information of remote party relative to court trail from the internet system; converting the image and voice information into word information; and setting association for the image and voice information, and storing the associative image and voice information to a database. The invention acquires image and voice information of remote party relative to court trail from the internet system, sets association for the image and voice information, and stores the associative image and voice information to a database, thus realizing the remote court trial process.

Owner:NEWAUTO SILICON VALLEY VIDEO TECH

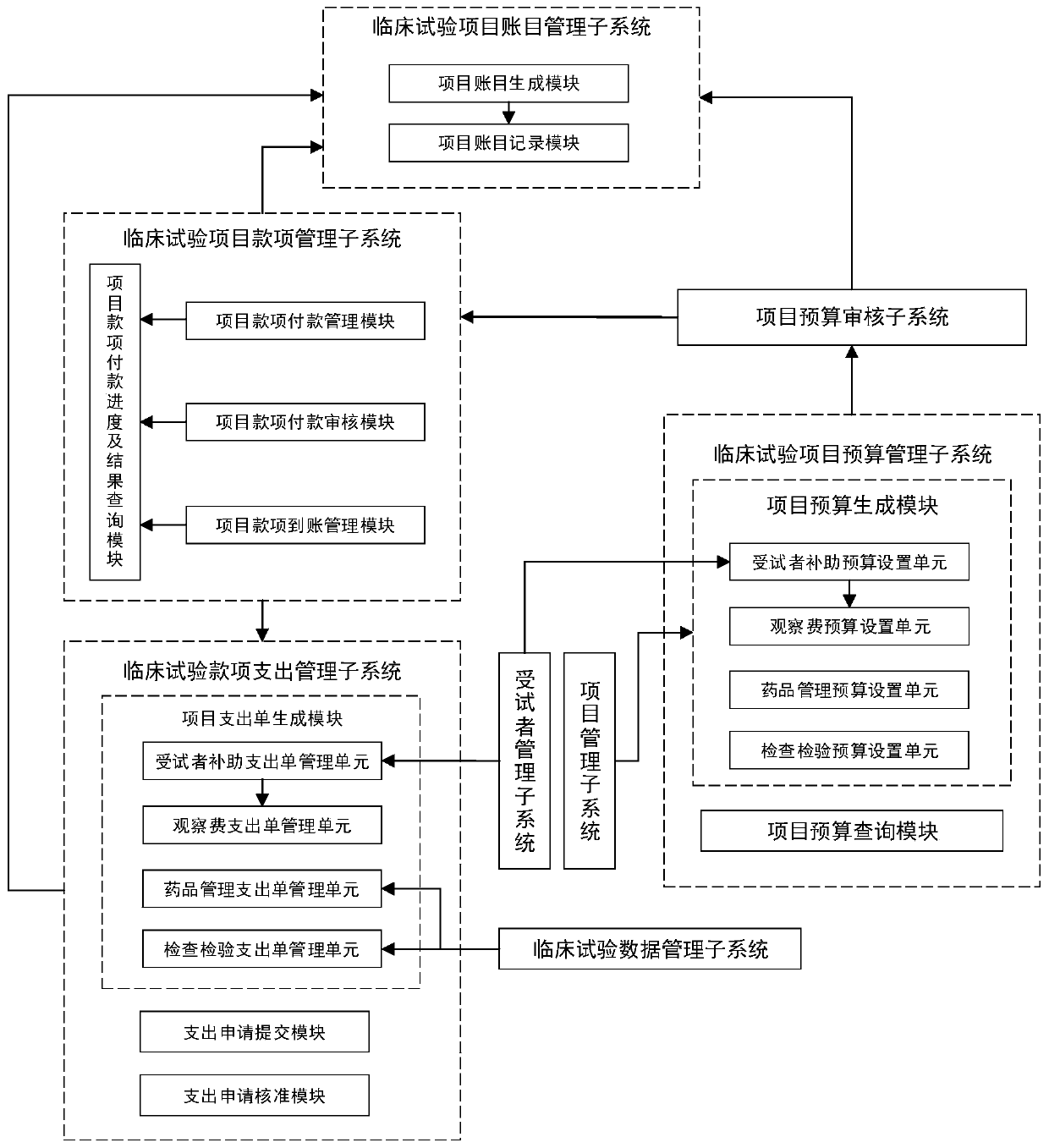

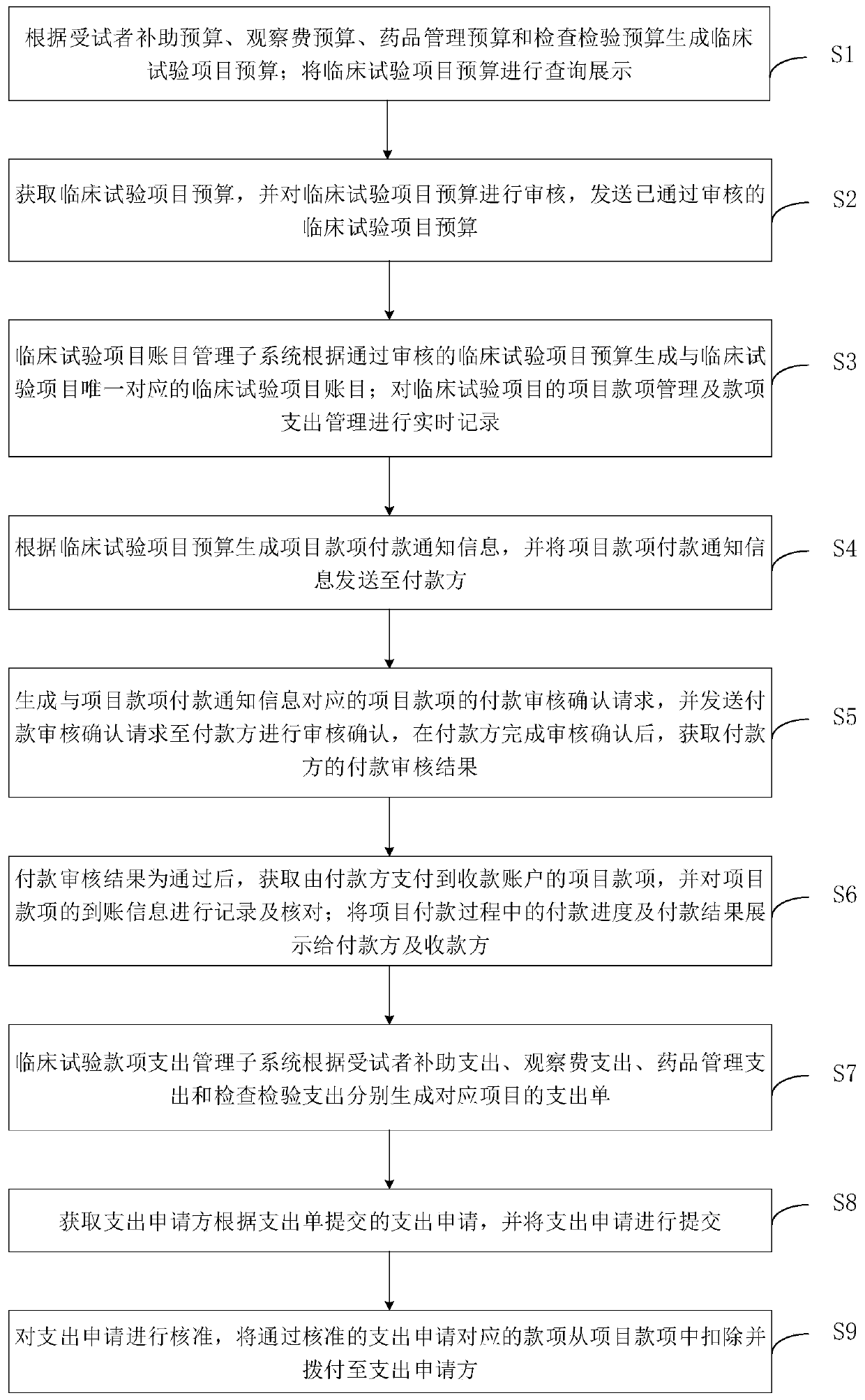

A clinical test financial management system and management method

InactiveCN109697598AReduce financial management costsFinancial Management Cost GuaranteeFinanceOffice automationInformatizationMedicine

The invention provides a clinical test financial management system and management method. The system relates to the technical field of clinical test process data management, and comprises a clinical test project budget management subsystem, a project budget auditing subsystem, a clinical test project account management subsystem, a clinical test project fund management subsystem and a clinical test fund expenditure management subsystem. According to the technical scheme, clinical test project budget management is adopted; the invention discloses a technology combining clinical test project account management and clinical test project fund management. the online management of the financial data in the clinical test process is realized; according to the invention, the method achieves the real-time recording, avoids the adoption of a traditional paper examination and approval process, reduces the financial management cost of a clinical test, improves the financial process examination andapproval efficiency of the clinical test, and alleviates the technical problems of low financial data management informatization degree and poor management efficiency in the clinical test process in the prior art.

Owner:TIANJIN ABSOLUTE SCI & TECH CO LTD

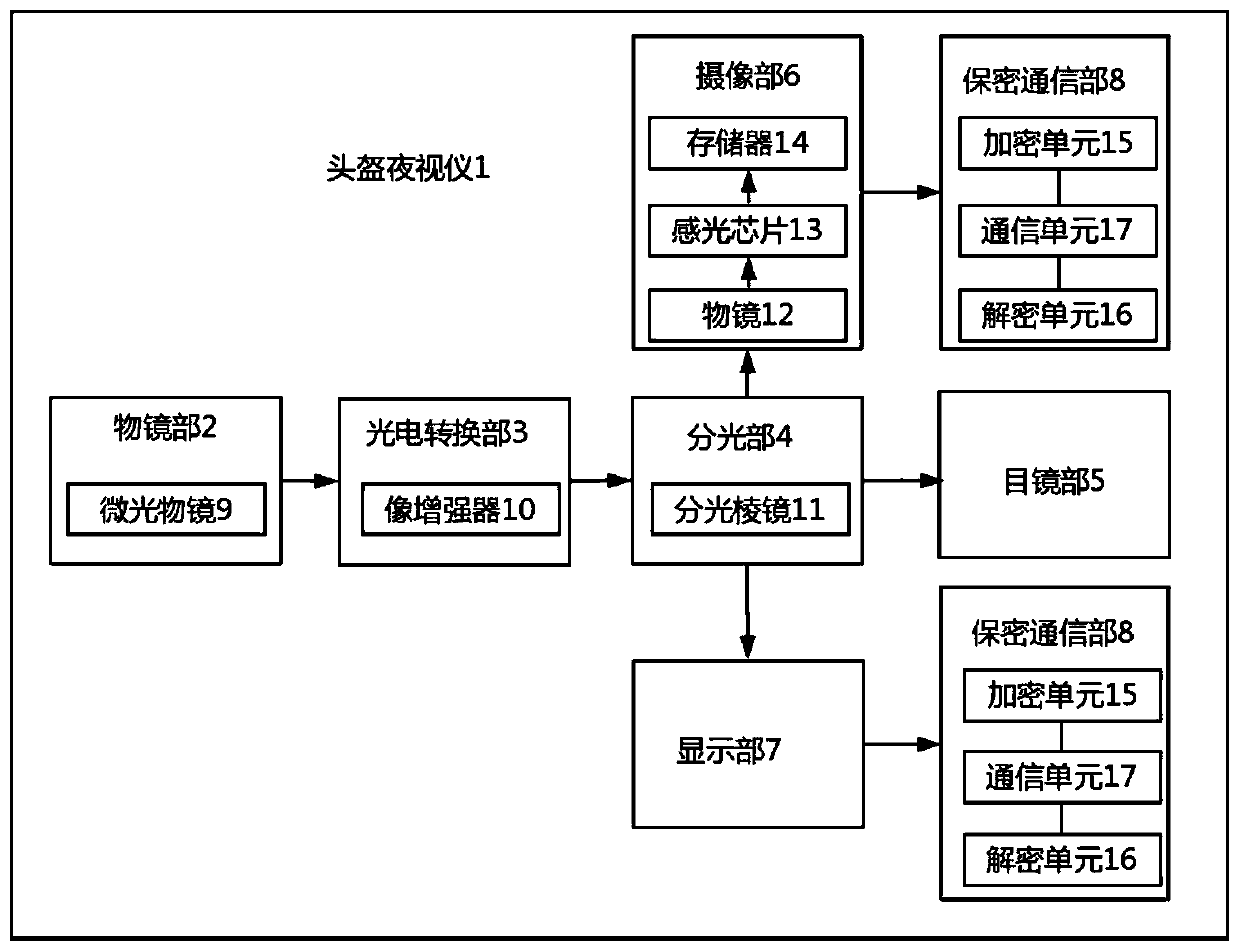

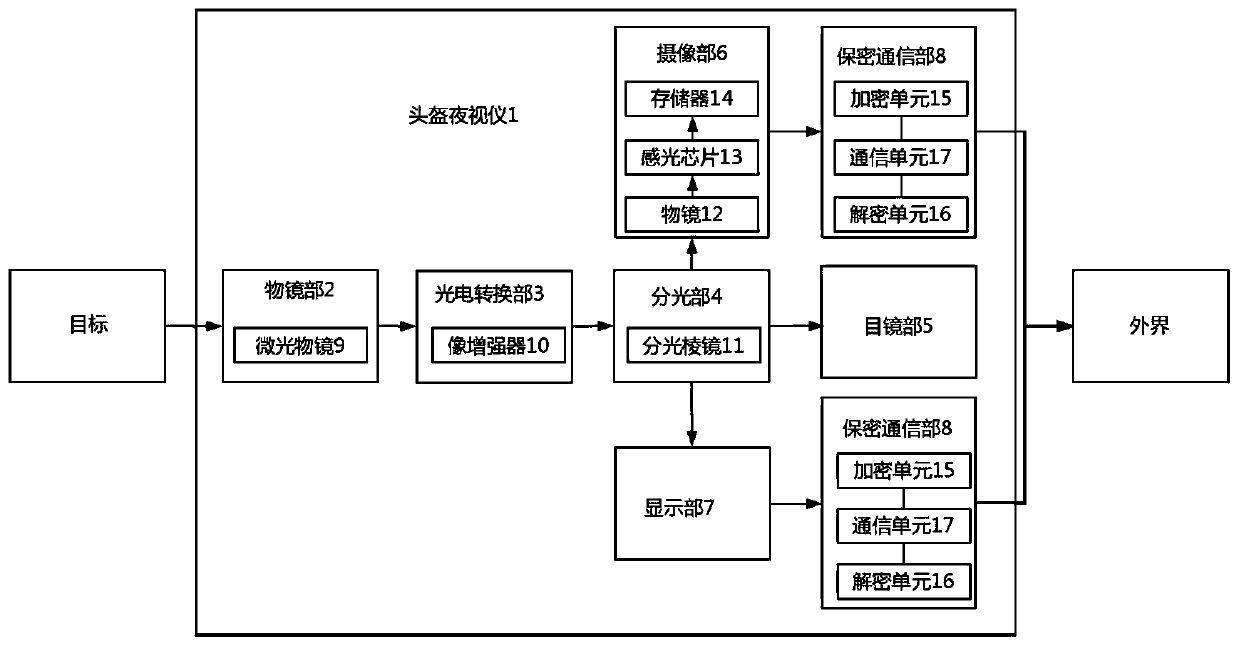

Helmet night vision device with secret communication function

InactiveCN110794570AAchieve real-time recordingEnhanced interactionAnalogue secracy/subscription systemsTelescopesEyepieceEngineering

A helmet night vision device with a secret communication function comprises an objective lens part, a photoelectric conversion part, a light splitting part, an eyepiece part, a camera shooting part, adisplay part and a secret communication part. According to the helmet night vision device with the secret communication function, real-time recording of an observation target by the helmet night vision device, secret transmission with the outside and real-time acquisition of an instruction signal are achieved, and interaction between the helmet night vision device and the outside is enhanced.

Owner:TOEC TECH

Electronic intelligent electric energy meter

InactiveCN105548685AAchieve real-time recordingRealize remote communicationElectrical measurementsEngineeringElectric parameter

The invention discloses an electronic intelligent electric energy meter which comprises a front-end circuit conditioning module, an electric energy metering chip, an LED indication module, a micro control module, a display module, a communication module, a keyboard control module, a clock module, a memory and a power supply module, wherein the front-end circuit conditioning module is connected with the electric energy metering chip, the LED indication module is connected with the electric energy metering chip, the micro control unit is connected with the electric energy metering chip, and the display module, the communication module, the keyboard control module, the clock module and the memory are connected with the micro control module. The electric energy meter of the invention can be used to measure, display, collect and process electric parameters as the electric energy.

Owner:彭江莲

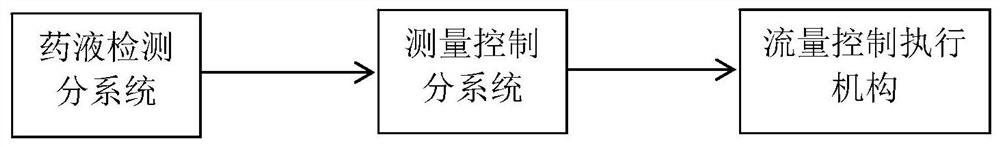

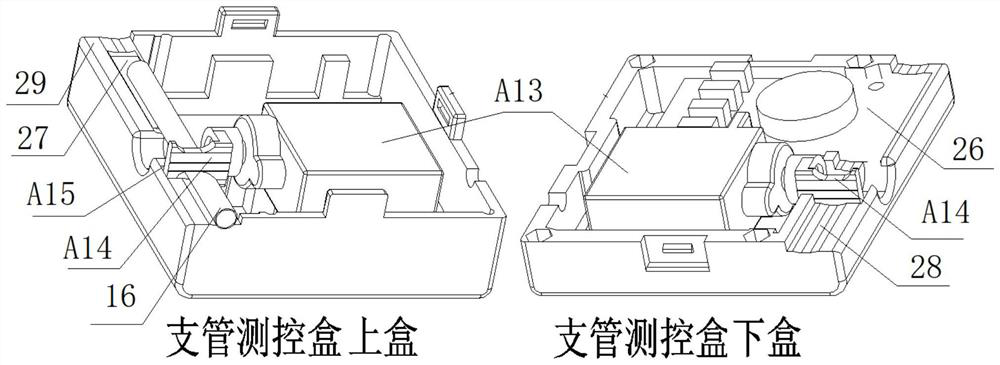

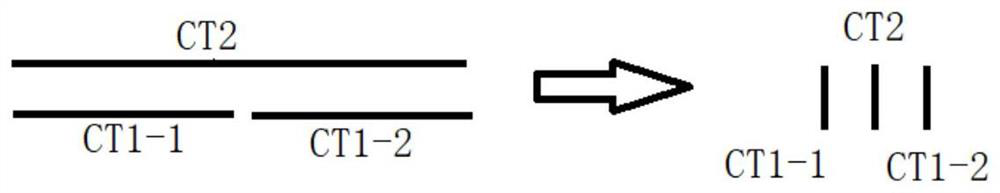

Infusion monitoring control system and device

ActiveCN111632227AReduce human workloadRelieve pressureFlow monitorsFlow controlControl systemEmergency medicine

The invention provides an infusion monitoring control system and device. The system and device not only can monitor and control an infusion process, but also can simultaneously monitor and control aninfusion system with multiple bottles (bags) of infusion and meet requirements of infusion in multiple combination modes (such as timing switching, quantitative switching and empty bottle switching),realizes automatic and accurate infusion to a certain extent, and reduces working pressure of medical personnel. The infusion monitoring control system comprises: a liquid medicine detection subsystem, a measurement control subsystem and a flow control executing mechanism; wherein the liquid medicine detection subsystem monitors presence or absence of liquid medicine in an infusion tube in real time through a capacitive liquid medicine sensor, and monitors a dropping speed and a dropping number of the liquid medicine drops in a dropping funnel in real time through a photoelectric liquid medicine sensor; and the flow control actuator is used for opening or closing an infusion pipeline under control of the measurement control subsystem.

Owner:罗云汉 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com