Mixed gas supply type visual natural gas hydrate experiment system

An experimental system, hydrate technology, applied in the field of mixed gas supply visual natural gas hydrate experimental system, can solve the problems of low level of automation and digitalization, single input gas composition, lack of visualization, etc., to achieve easy sampling and easy operation , digitalization and high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The structure and function implementation plan of each unit of the system

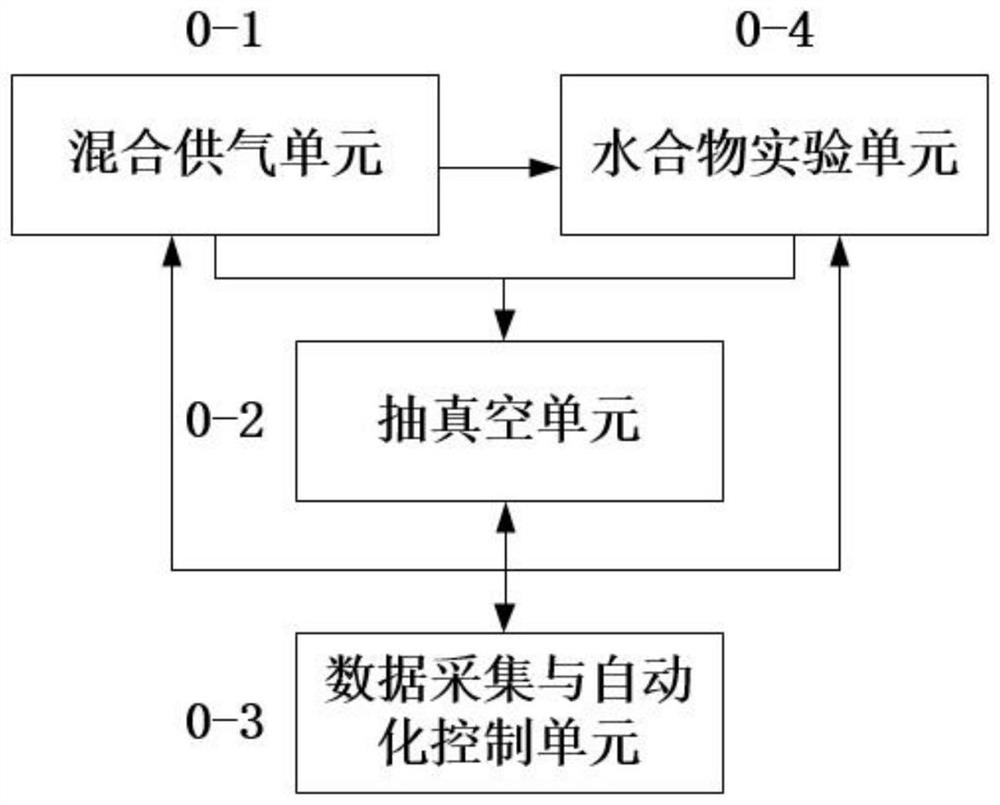

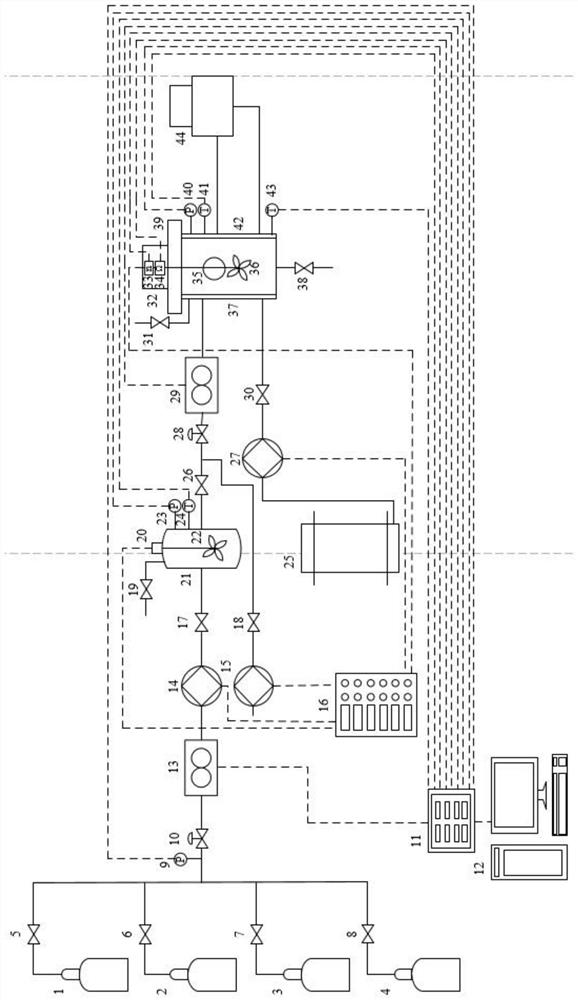

[0026] Such as figure 1 and figure 2 As shown, a mixed gas supply visual natural gas hydrate experimental system of the present invention can be divided into mixed gas supply unit 0-1, vacuum unit 0-2, data acquisition and automatic control unit 0-3, and hydrate experimental unit 0-4. The mixed gas supply unit 0-1 is connected with the hydrate experimental unit 0-4, and the high-pressure mixed gas is transmitted in one direction; the mixed gas supply unit 0-1, the hydrate experimental unit 0-4 are connected with the vacuum unit 0-2, and the one-way Air extraction; mixed gas supply unit 0-1, hydrate experiment unit 0-4, vacuum unit 0-2 are connected with data acquisition and automatic control unit 0-3, bidirectional transmission of electrical signals, instrument parameter acquisition and equipment control.

[0027] Mixed gas supply unit 0-1 includes methane gas cylinder 1, first...

Embodiment 2

[0031] Example 2: Basic Experimental Scheme for Methane Mixed Gas Hydrate Formation-Decomposition

[0032]Step 1: Operation of pipeline vacuum equipment before the experiment: Check the system connection and confirm whether all pipeline valves are closed when the equipment is not running. After confirmation, open the vacuum valve 18, the second intake valve 26, and the second pressure regulating valve 28, and simultaneously close the first intake valve 17, the first vent valve 19, the liquid inlet valve 30, the second vent valve 31, Drain valve 38 and reactor top cover 39. Then start the vacuum pump 15 through the control cabinet 16, observe the readings of the second pressure sensor 23 and the third pressure sensor 40, until the rated suction pressure of the vacuum pump 15 is reached and no white mist appears at the air outlet of the vacuum pump 15, then close the vacuum pump 15 and the vacuum valve 18. If the rated extraction pressure of the vacuum pump 15 cannot be reached...

Embodiment 3

[0053] Embodiment 3: High-pressure reactor vacuumizes operation separately

[0054] If the experiment needs to continue to use the remaining mixed gas from the previous experiment, the high pressure reactor 37 should be vacuumed separately. First check whether the second air intake valve 26, the second vent valve 31, the liquid discharge valve 38 and the top cover 39 of the reaction kettle are tightly closed, and after confirming that they are correct, open the vacuum valve 18 and the second pressure reducing valve 28, and start the vacuum pump 15 to start vacuuming Until the rated extraction pressure of the vacuum pump 15 is reached and white mist does not appear at the outlet of the vacuum pump 15, the vacuum pump 15, the vacuum valve 18 and the second pressure regulating valve 28 are closed, and the vacuuming operation of the high-pressure reactor is completed alone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com