Digital laser dynamic caustics experiment method and system thereof

An experimental method and caustics technology, which can be applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of low success rate, difficult control of photographic effects, strict operation requirements, etc. The effect of high test success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

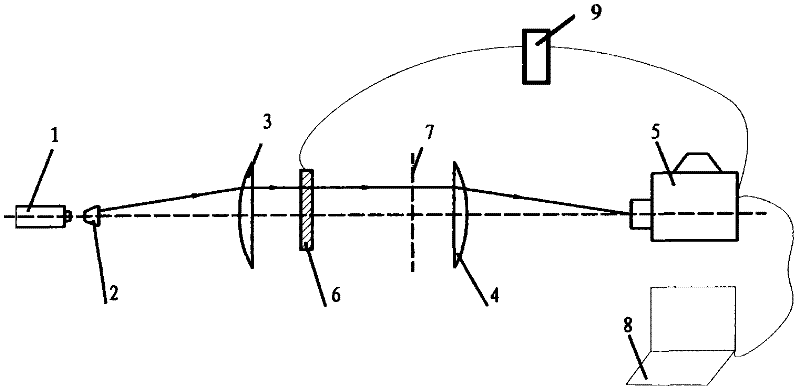

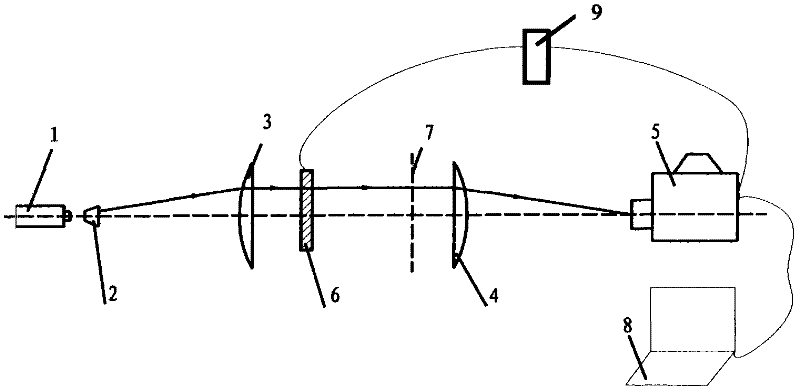

[0029] The central idea of the present invention is to obtain laser digital caustics photos and realize dynamic caustics experimental equipment and method by changing the photographic recording equipment, adopting a high-speed photographic system combined with a laser and a digital high-speed camera, and combining it with a caustics experimental system breakthrough.

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0031] Such as figure 1 As shown, in the digital laser dynamic caustics experimental method of the present invention, at first, the laser 1 is selected as the experimental light source, and after the laser 1 emits a stable and continuous laser, it becomes a surface beam diverging at a certain angle through the beam expander 2 , the light beam becomes parallel light after passing through the left field lens 3, and enters the test piece 6, and the light beam is converged by the right field lens 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com