An SMT production line management method and a manufacturing end

A management method and production line technology, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve problems such as limited data, and achieve the effect of improving production yield and facilitating defect analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

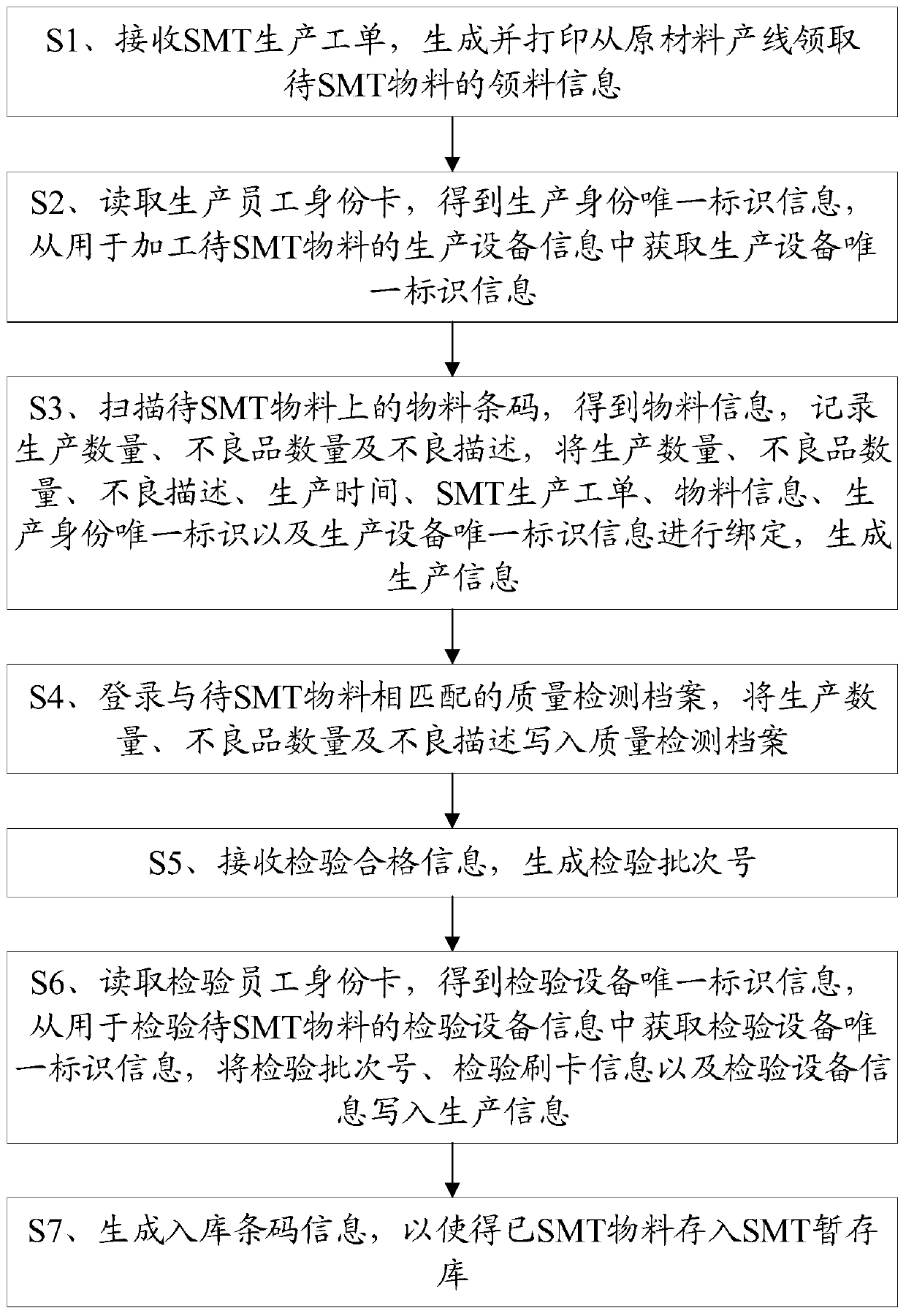

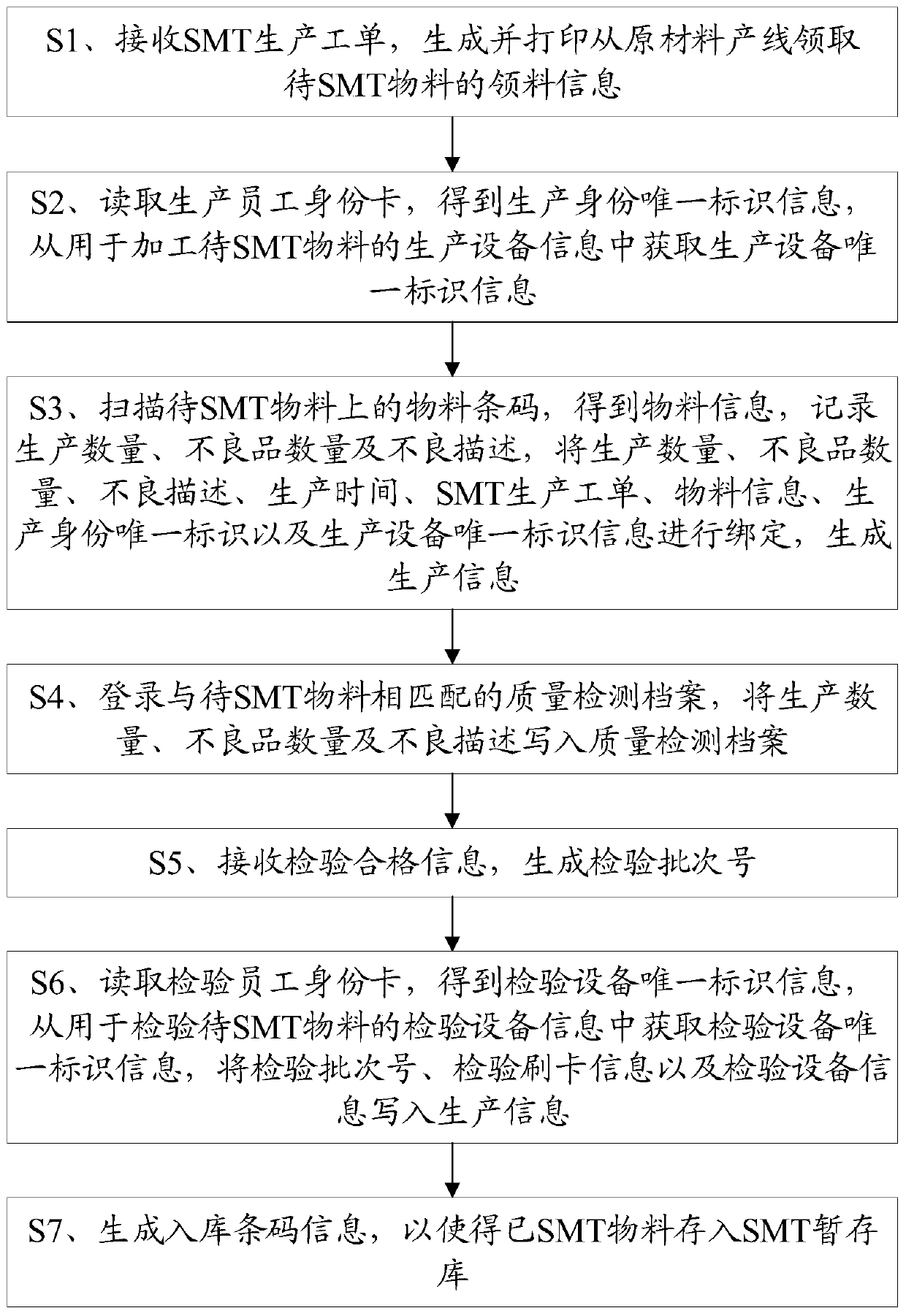

[0125] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0126] A method for managing an SMT production line, comprising the steps of:

[0127] S1. Receive the SMT production work order, generate and print the picking information for receiving the materials to be SMT from the raw material production line;

[0128] S2. Read the identity card of the production employee to obtain the unique identification information of the production identity, and obtain the unique identification information of the production equipment from the information of the production equipment used to process the SMT material;

[0129] S3. Scan the material barcode on the material to be SMT to obtain material information, record the production quantity, defective product quantity and defective description, and record the production quantity, defective product quantity, defective description, production time, SMT production work order, material information, and production identity Th...

Embodiment 2

[0144] Please refer to figure 1 , the second embodiment of the present invention is:

[0145] A kind of SMT production line management method, on the basis of above-mentioned embodiment 1, step S34 also comprises:

[0146] Remove the chip PCB information from the PCB information on the upper board to obtain the bad PCB information, record the number of bad PCB information, and get the number of bad products;

[0147] Step S36 also includes:

[0148] Remove the reflow soldering PCB information from the chip PCB information to get the bad PCB information, record the number of bad PCB information, and get the number of bad products;

[0149] Step S38 also includes:

[0150] Remove the lower board PCB information from the reflow soldering PCB information to obtain the reflow soldering defective PCB information, record the number of reflow soldering defective PCB information, and obtain the number of reflow soldering defective products;

[0151] Also include after step S38:

...

Embodiment 3

[0153] Please refer to figure 1 , Embodiment three of the present invention is:

[0154] A kind of SMT production line management method, on the basis of above-mentioned embodiment 1, step S33 also comprises:

[0155] Count from the first piece of pasted PCB detected, get the paste detection sequence, obtain the bad position information of the inconsistent pasted PCB on the paste detection sequence, and find the position information and bad position information from the upper board sequence The same board PCB information is marked as bad paste PCB information, and the bad paste PCB information is added to obtain the number of bad paste products, and the board sequence is the board PCB information arranged in order according to the board loading time;

[0156] Step S35 also includes:

[0157] Count from the first piece of PCB that has been inspected to get the placement inspection sequence, obtain the bad position information of the inconsistent mounted PCB on the placement i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com