Nanofluid stability monitoring system and method

A nanofluidic and monitoring system technology, applied in flow characteristics, nanoparticle analysis, color/spectral characteristics measurement, etc., can solve the problems of nanofluidic device and single angle, unable to detect the same sample synchronously, unable to guarantee the accuracy of test data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

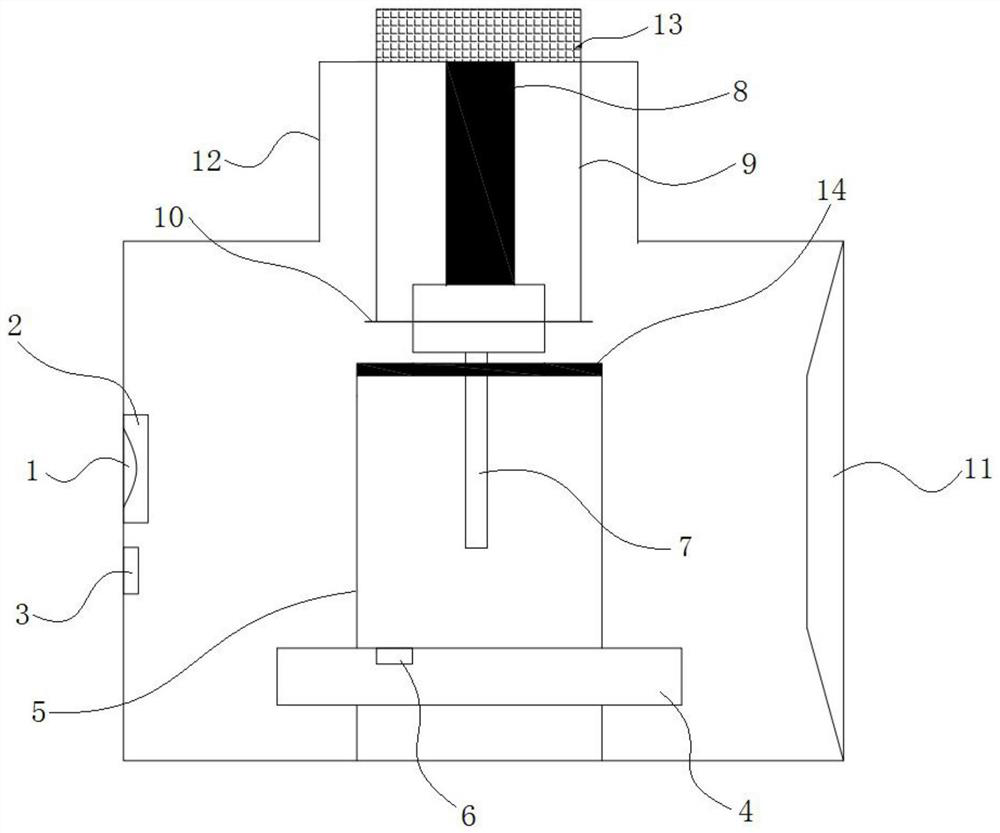

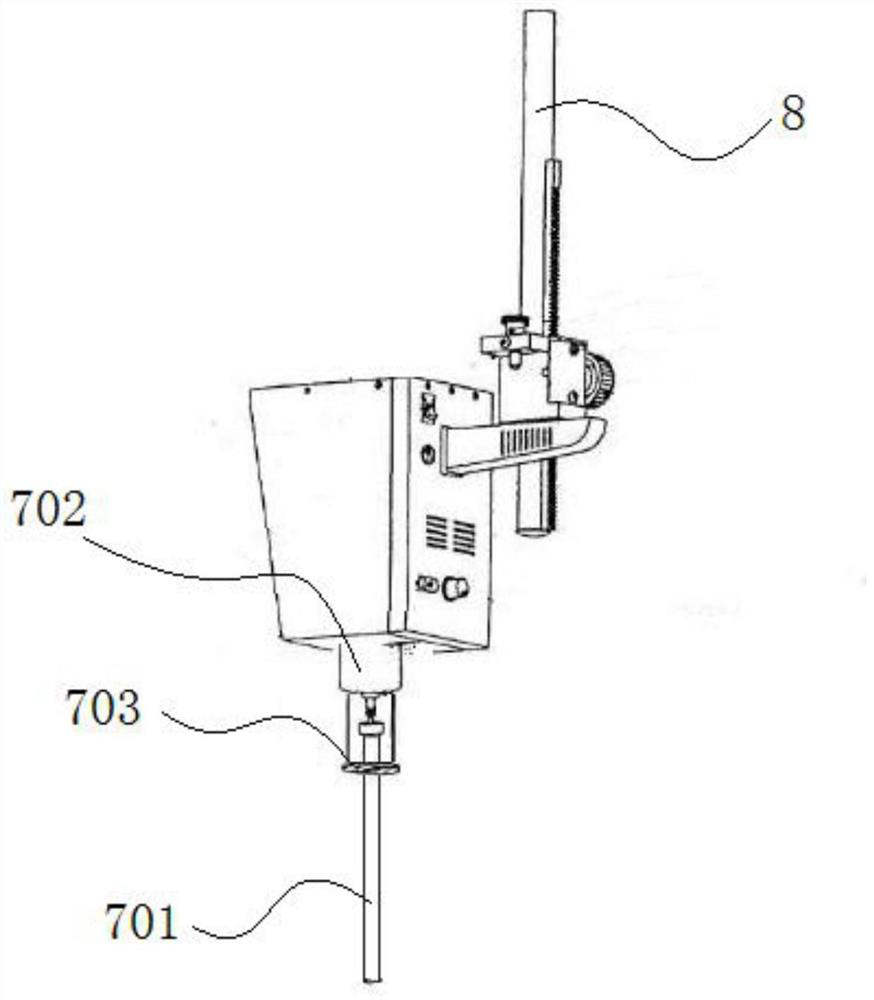

[0038] see figure 1 , the present embodiment discloses a nanofluid stability monitoring system, including a sample holding system, an absorbance testing system, a viscosity testing system, a surface tension testing system and a data acquisition system arranged in the inner cavity of the device housing 12 .

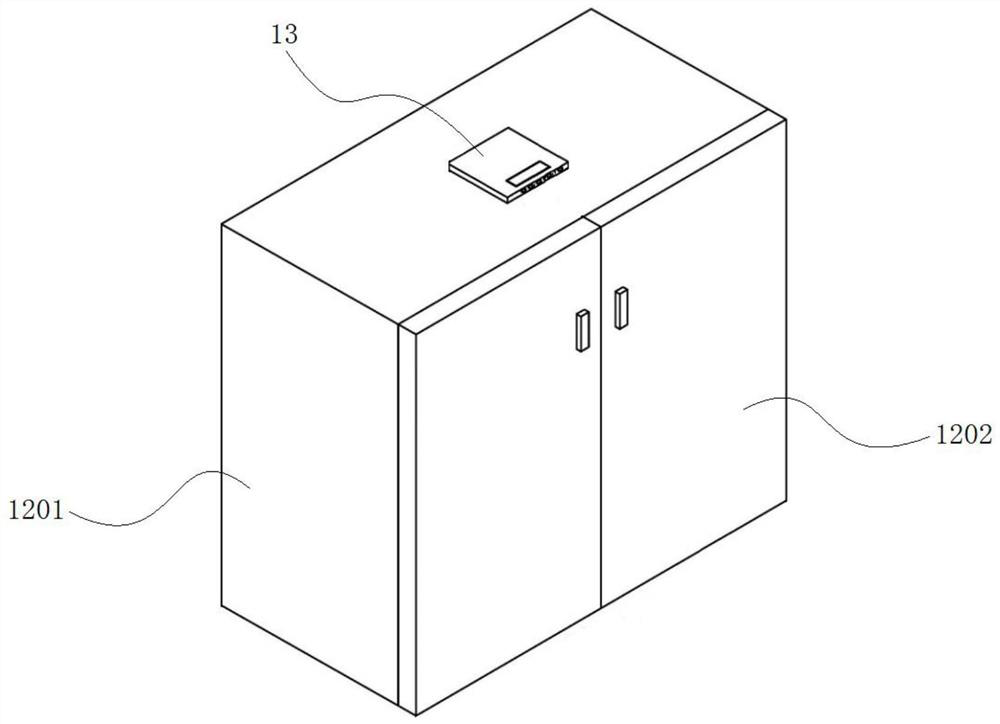

[0039] see figure 2 , the device casing 12 includes a cabinet body 1201 with one side open. The open side of the cabinet body 1201 is rotatably connected with a cabinet door 1202 . Asbestos is arranged on the outer wall of the device casing 12 . The device casing 12 adopts a double-layer structure of asbestos and metal, which not only ensures the characteristics of heat insulation and leakage prevention, but also ensures the firmness and stability of the device as a whole.

[0040] The sample holding system includes a visualized sample chamber 5 placed on a rotating platform 4 . The visualized sample chamber 5 is a transparent barrel. The upper opening of the staving...

Embodiment 2

[0047] This embodiment provides a monitoring method using the monitoring system described in Embodiment 1 for the problems that the time-varying mechanism of nanofluid stability is unclear and the stability is difficult to predict, including the following steps:

[0048] 1) Pour the prepared nanofluid into the visualized sample chamber 5 .

[0049] 2) Turn on the temperature detector 6 through the data acquisition controller 13 to keep detecting the temperature of the nanofluid in the visualized sample chamber 5 .

[0050] 3) Turn on the light source 1 and the observation camera 3 through the data acquisition controller 13 to maintain real-time detection of the nanofluid system in the visualized sample chamber 5 . After the sample chamber was left to stand for 3 minutes, the observation camera 3 was set to take pictures of the nanofluid three times.

[0051] 4) Turn on the monochromator 2 and the detector 11, set the wavelength of the ultraviolet light transmitted by the mono...

Embodiment 3

[0063] This embodiment provides a monitoring method using the monitoring system described in Embodiment 1, comprising the following steps:

[0064] 1) Pour the prepared nanofluid into the visualized sample chamber 5 .

[0065] 2) Turn on the temperature detector 6 through the data acquisition controller 13 to keep detecting the temperature of the nanofluid in the visualized sample chamber 5 .

[0066] 3) Turn on the light source 1 and the observation camera 3 through the data acquisition controller 13 to maintain real-time detection of the nanofluid system in the visualized sample chamber 5 . After the sample chamber was left to stand for 3 minutes, the observation camera 3 was set to take pictures of the nanofluid three times.

[0067] 4) Turn on the monochromator 2 and the detector 11, set the wavelength of the ultraviolet light transmitted by the monochromator and the incident light intensity, so that the ultraviolet light is projected on the detector 11 through the visual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com