Stress-Electrochemical Corrosion Test Apparatus

A corrosion test and stress corrosion technology, used in measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve the problem of easy overflow of the solution, reduce heat loss, and prevent corrosion. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

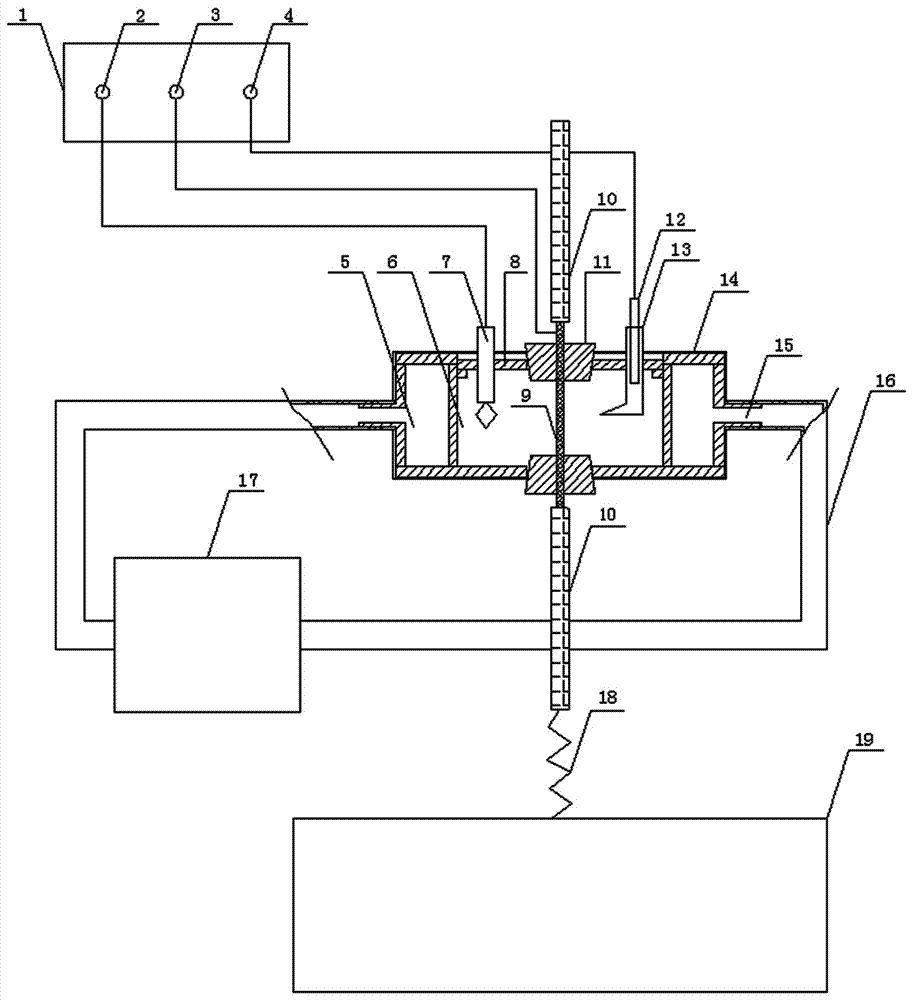

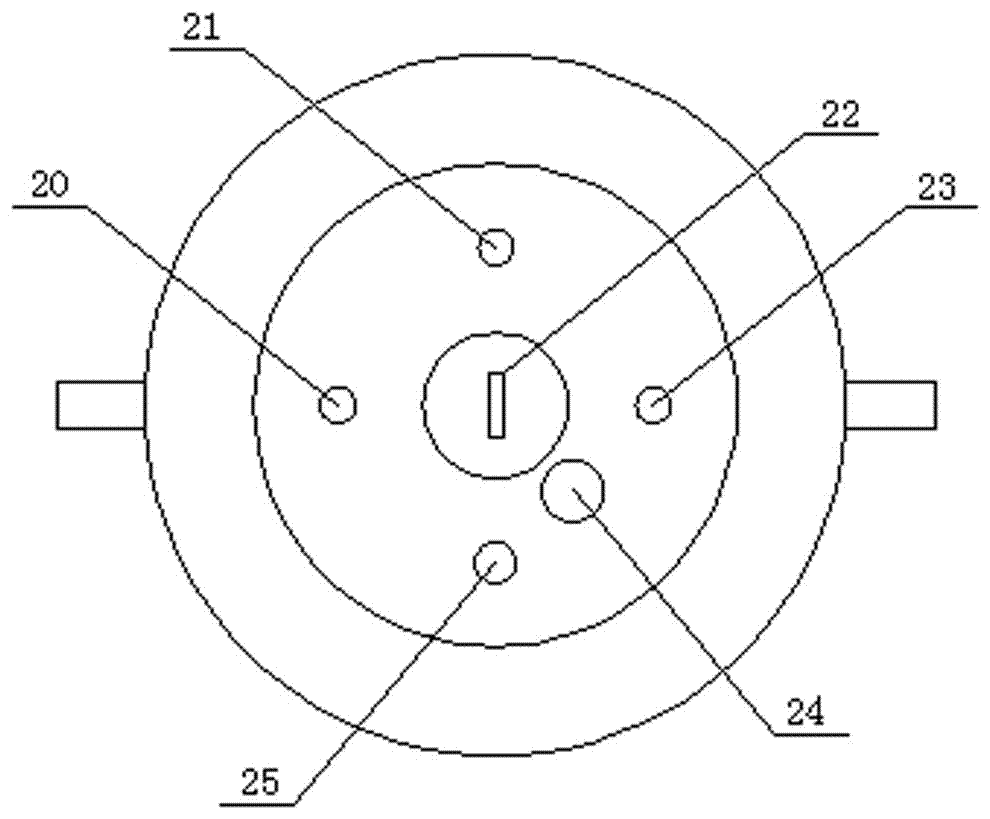

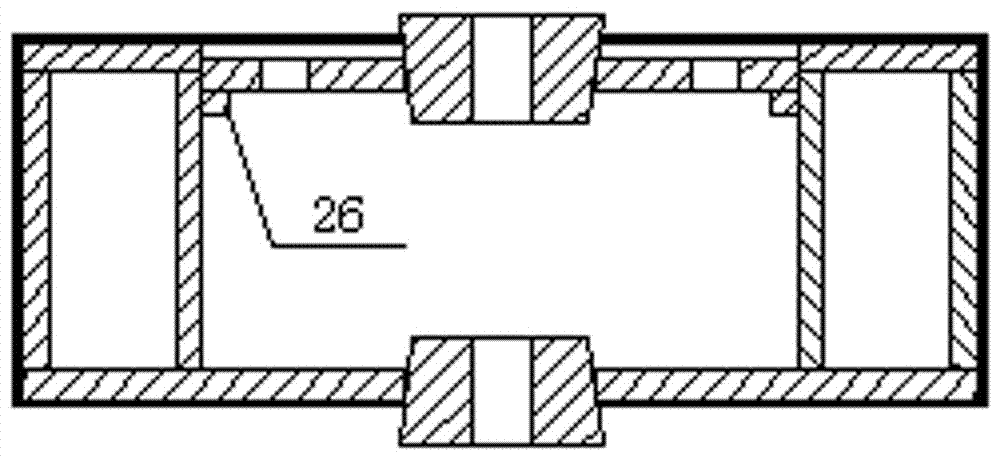

[0029] Such as Figure 1-3 As shown, it includes an electrochemical workstation 1, a stress corrosion stretching machine 19, a constant temperature water bath 17 and a stretching box. The stretching box is fixed on the stress corrosion stretching machine 19, and the water inlet and outlet 15 of the stretching box pass through the constant temperature water bath 17 The rubber tube 16 is connected, and the rubber tube is horizontally tied to the strut of the stretching machine. Two medium solutions of water and 95% ethanol are used in the constant temperature water bath 17; the stretching box has a double-chamber structure, and the outer chamber 5 carries the medium solution. The inner chamber 6 contains the test solution. The inner chamber has a thermometer and a nitrogen tube inserted in the test solution. The height of the inner chamber is lower than the outer chamber, and the top of the outer chamber is sealed. Multiple holes, including auxiliary electrode socket 20, thermome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com