Method for improving combined blown converter campaign length by metal furnace cinder composite mushroom

A mushroom head and metal technology, applied in the manufacture of converters, etc., can solve the problems of easy generation of pores, easy to fall off, poor combination with slag mushroom heads, etc., to achieve the effect of prolonging life and improving cooling energy

Active Publication Date: 2009-07-22

CENT IRON & STEEL RES INST

View PDF0 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The object of the present invention is to provide a method for increasing the service life of the double-blowing converter by using metal slag composite mushroom head, and a metal slag composite mushroom head is generated at the initial stage of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

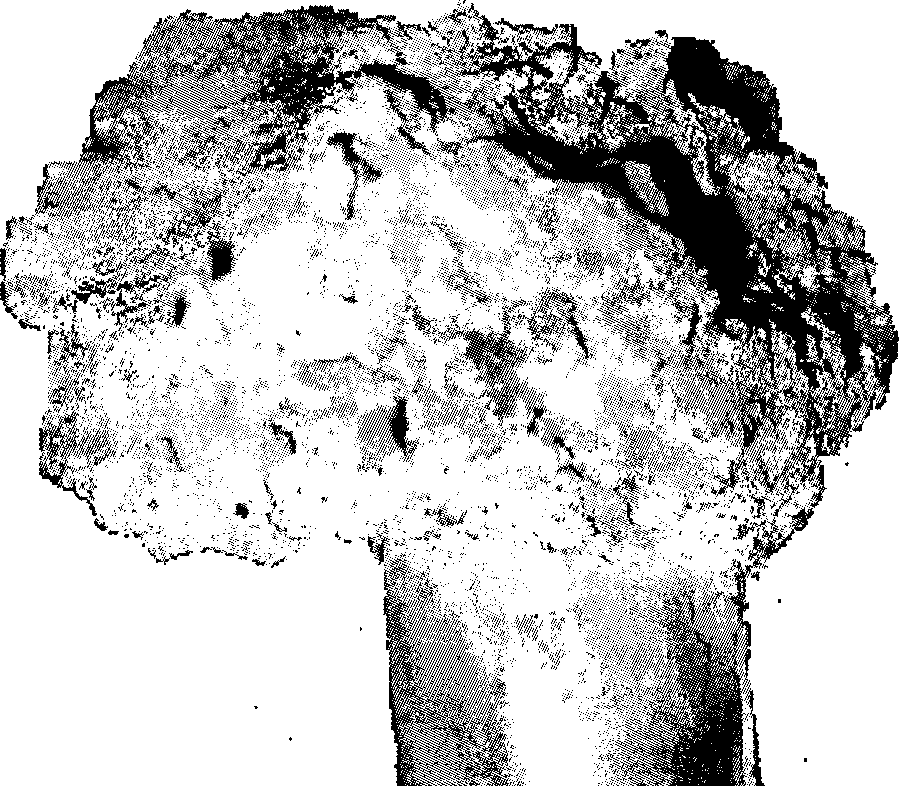

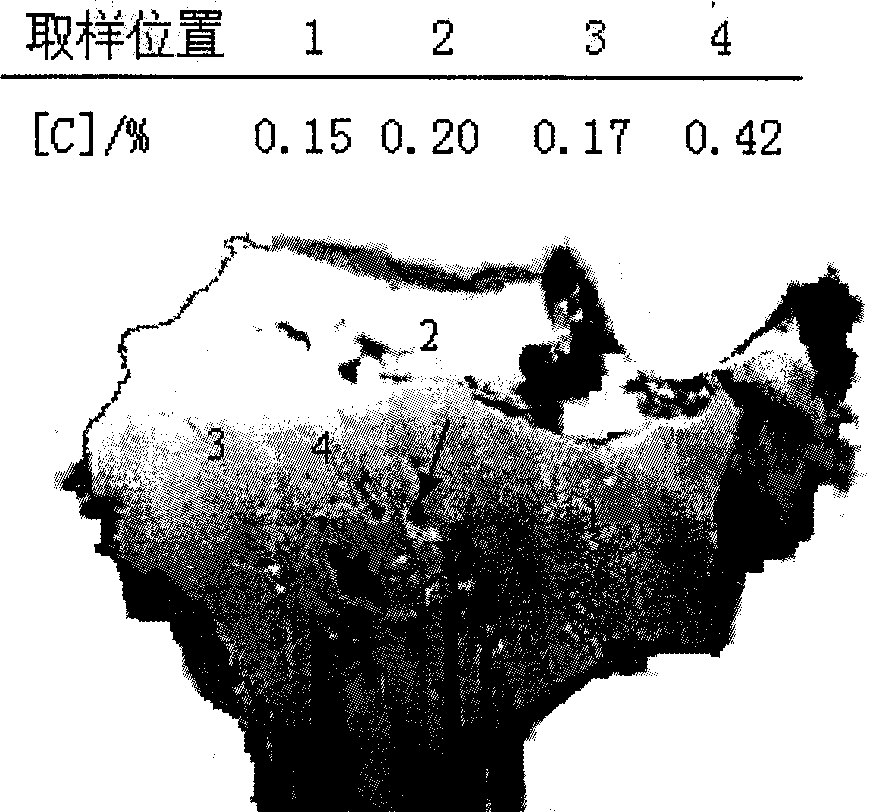

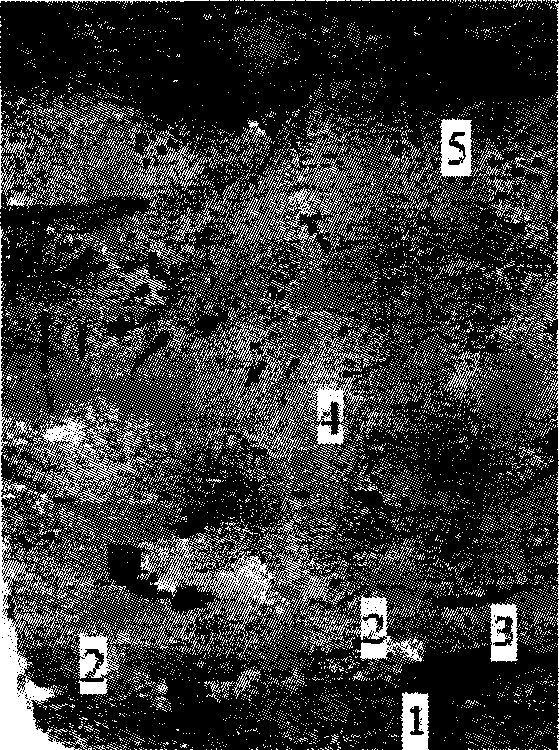

A method for prolonging the campaign life of a combined blown converter by adopting a metal slag syntactic mushroom head belongs to the technique field of oxygen converter steelmaking. A circular seam type bottom blowing air-supplying element is adopted to replace a capillary permeable brick, thus allowing airflow to concentrate and raising the cooling power on the tip of a nozzle. After well-developed metal mushroom head is formed at the initial campaign stage of smelting process, slag splashing process is carried out immediately to form a slag mushroom head on the surface of the metal mushroom head. After the initial formation of the metal slag syntactic mushroom head, attention is paid on detecting whether the air pressure, P-Q curve of the flow relation, and cold state measurement value have obvious discrepancy; if the discrepancy is larger, the technology is appropriately adjusted to ensure the ventilation property. In the following campaign period, the mushroom head is protected; the mushroom head and hearth height are often detected; the deviation between cold state P-Q curve and the hot sate P-Q curve is detected, thus ensuring that the mushroom head can protect the bottom blowing element effectively in the whole campaign period and having good ventilation property. The method has the advantages of allowing the furnace campaign of the combined blown converter to achieve over 10000 and can reach to 30000 for maximum.

Description

technical field [0001] The patent of the invention belongs to the technical field of oxygen converter steelmaking, and in particular provides a method for increasing the service life of reblowing converters by using metal slag composite mushroom heads to protect bottom blowing gas supply components by generating a metal slag composite mushroom head at the initial stage of furnace service , so that the life of the bottom blowing gas supply element is synchronized with the life of the converter lining after slag splashing. Background technique [0002] Converter compound blowing is an advanced steelmaking process. Its technical principle is to install several bottom-blown gas supply elements at the bottom of the top-blown oxygen converter, blow inert gas into the furnace to stir the molten pool, and promote the slag-steel reaction balance. Adopting the combined blowing converter steelmaking process can change the technical problem that the melt pool reaction deviates from the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C5/30C21C5/48

Inventor 刘浏佟溥翘郑丛杰杨利彬李春龙王毅赵进宣陈峰吴伟

Owner CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com