Patents

Literature

146results about How to "Guaranteed normal outflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

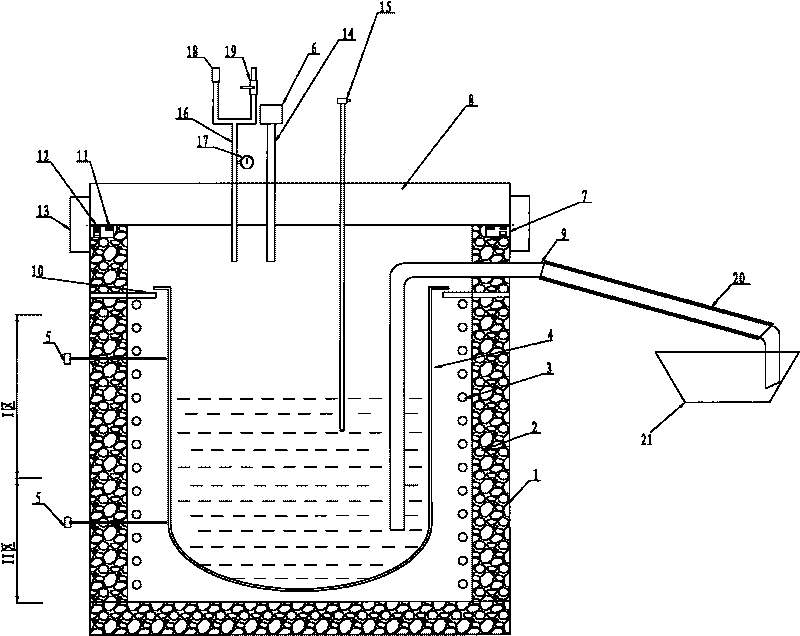

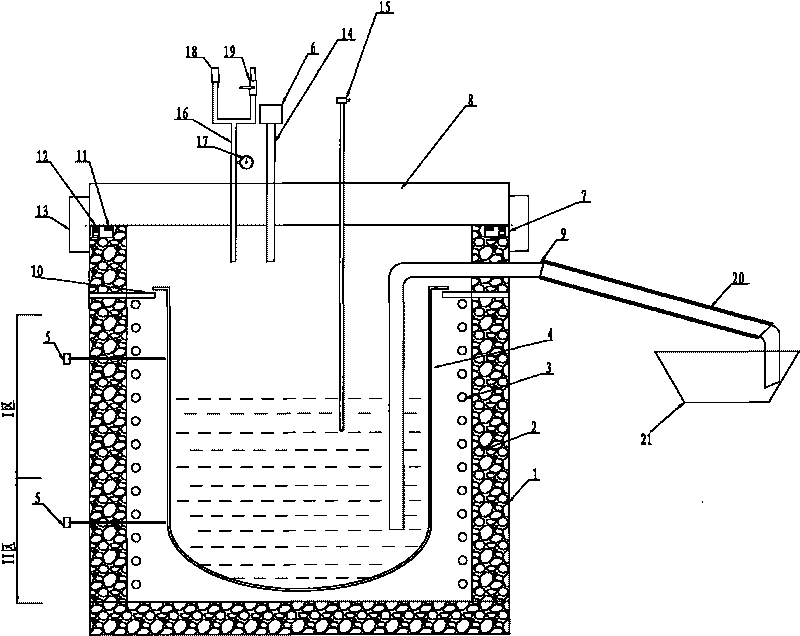

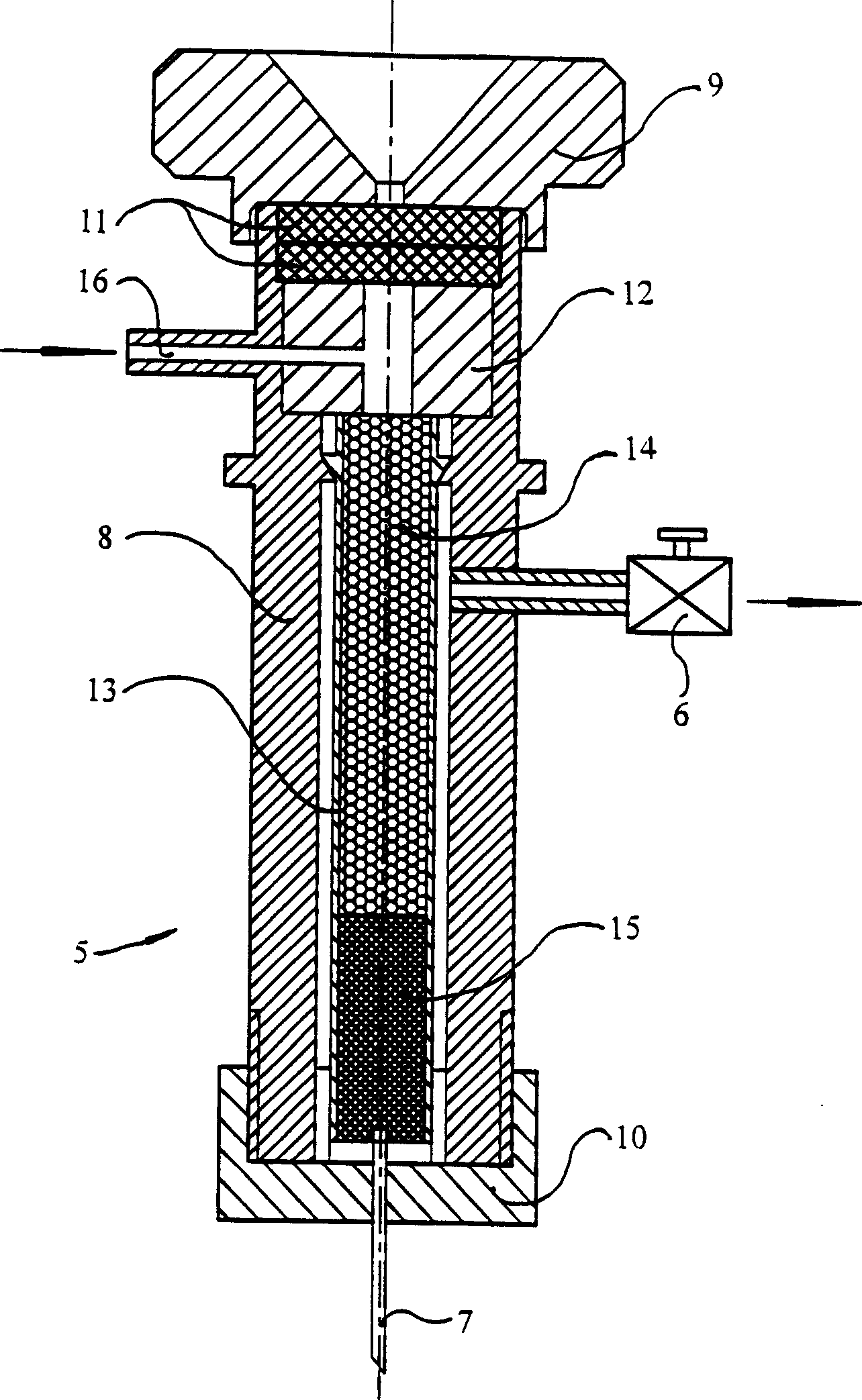

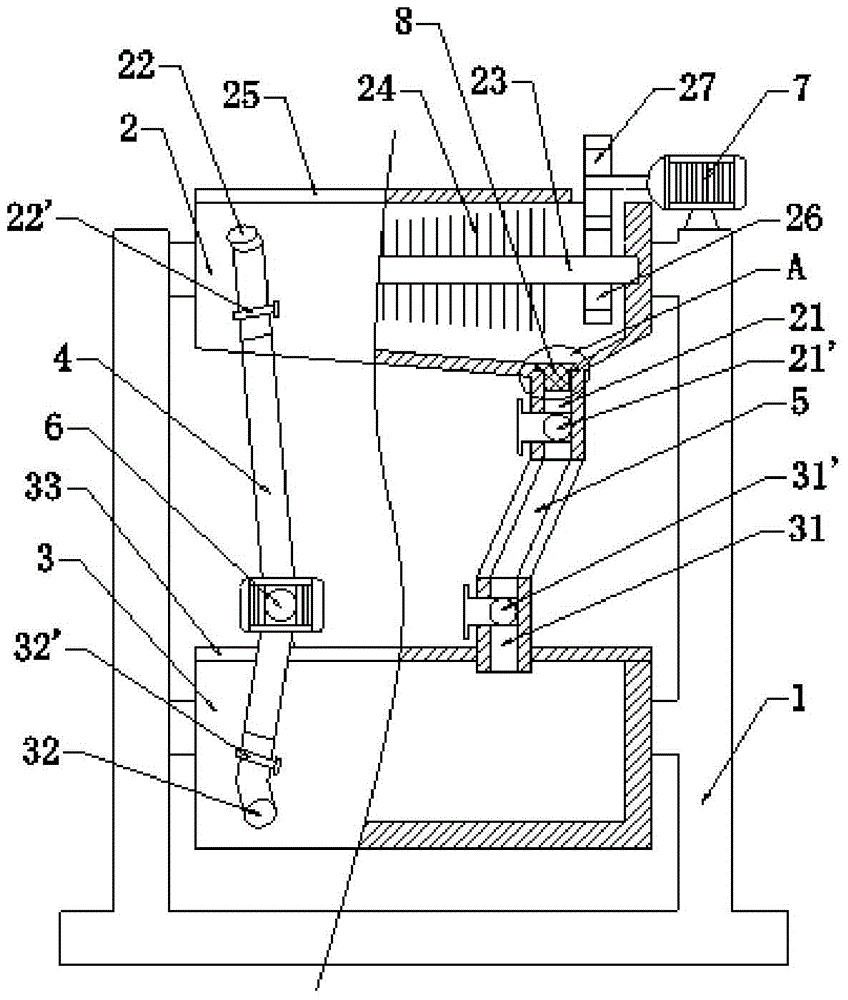

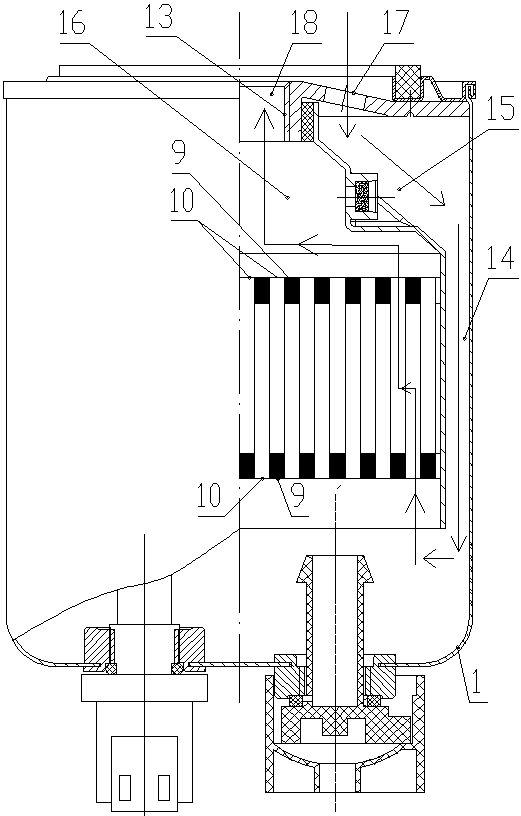

Pressure-flow-type magnesium alloy smelting heat insulating furnace

InactiveCN101706205AHighlight substantive featuresSignificant progressCrucible furnacesExhaust valveHearth

The invention relates to a pressure-flow-type magnesium alloy smelting heat insulating furnace which comprises a furnace body provided with a heat insulating layer, a crucible arranged inside a hearth, a heating element, a temperature measuring device and a furnace cover, wherein the furnace body comprises a furnace shell and a furnace liner; a water-cooling flange is arranged at a position where the upper part of the furnace body is matched with the furnace cover, and internally provided with high temperature resistant and fire-resistant filler material and a silicon rubber sealing ring; the water-cooling flange is internally filled with circulating cooling water; the furnace cover is locked with the furnace body by a compressing mechanism; a temperature thermocouple and a protection gas input pipeline extend into the furnace through inserting holes of the furnace cover, a pressure release pipe is arranged on the furnace cover, and the top of the pressure release pipe is provided with a safety valve and an exhaust valve; and a transfer pipette is introduced into the hearth through the furnace body. The furnace integrates the functions of smelting, heat insulating and melt transmission, accurately controls the flow rate of magnesium alloy melt, extracts the purer magnesium alloy melt at the middle part of the crucible, realizes continuous transmission with fixed flow rate, and prevents oxidation and combustion of the magnesium alloy. Furthermore, by combining corresponding foundry equipment, the magnesium alloy product with high quality can be prepared, and the equipment can be safe in use as well as simple and convenient for operation.

Owner:苏州有色金属研究院有限公司

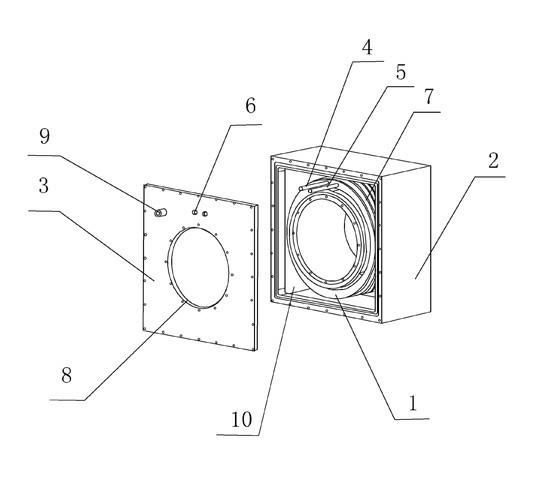

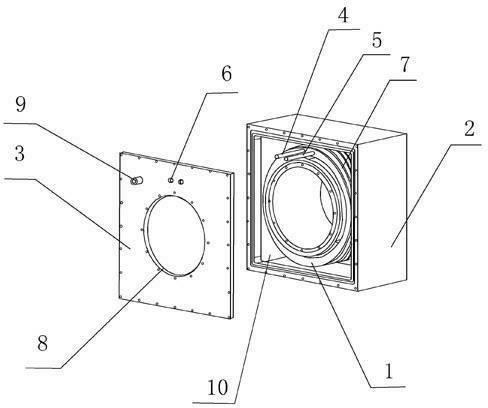

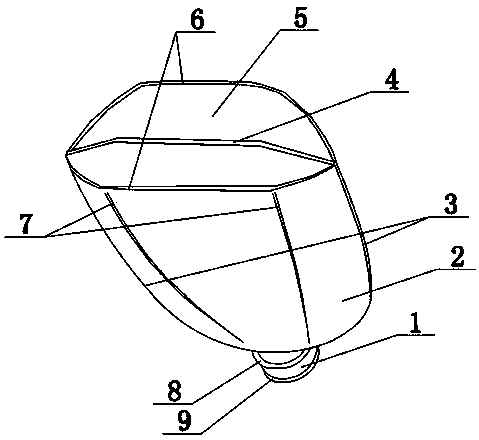

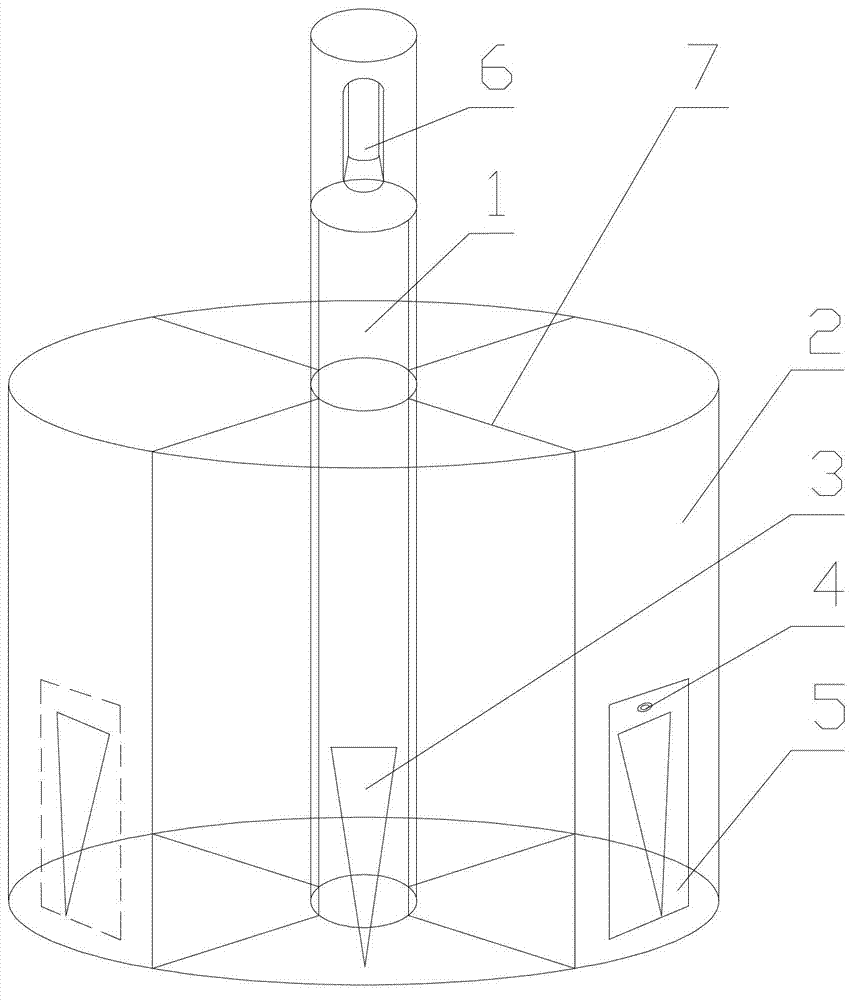

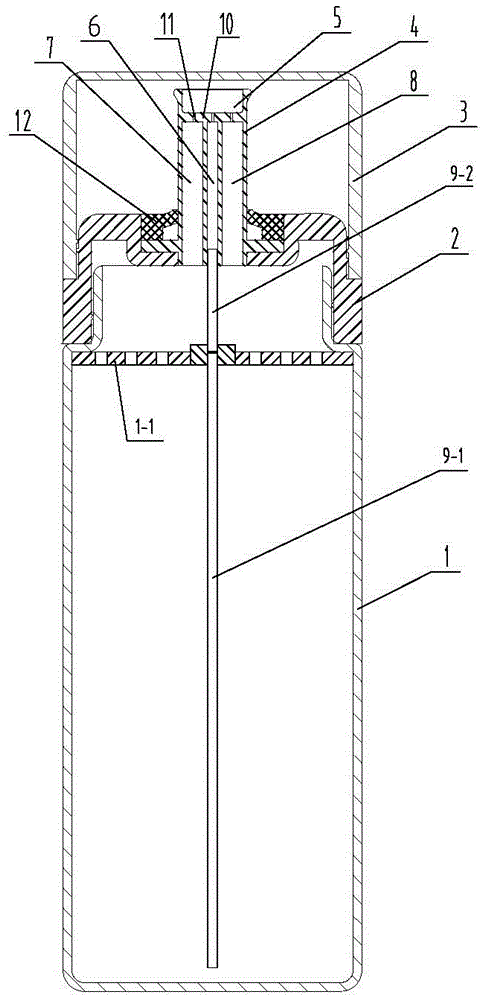

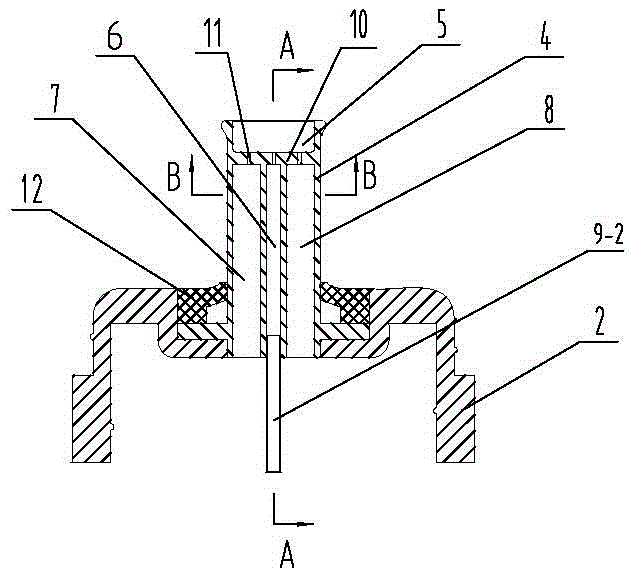

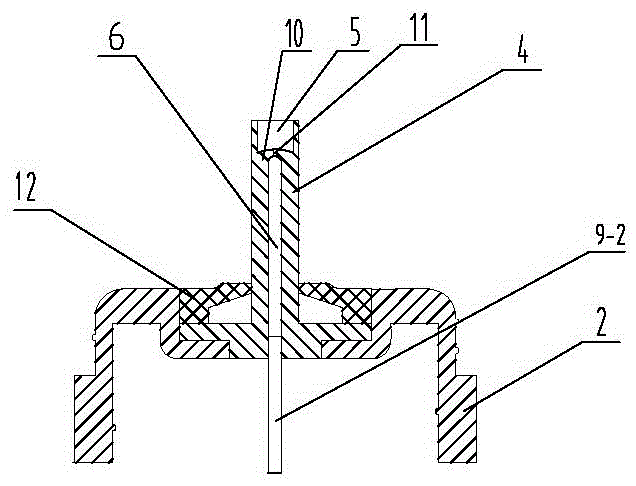

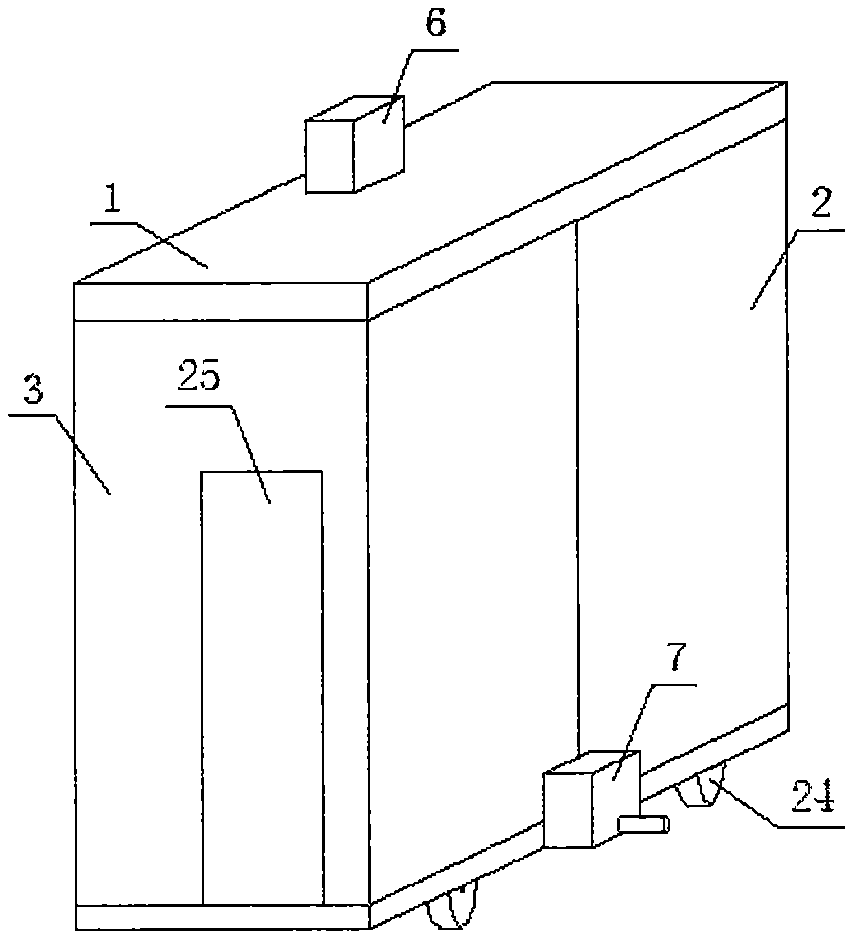

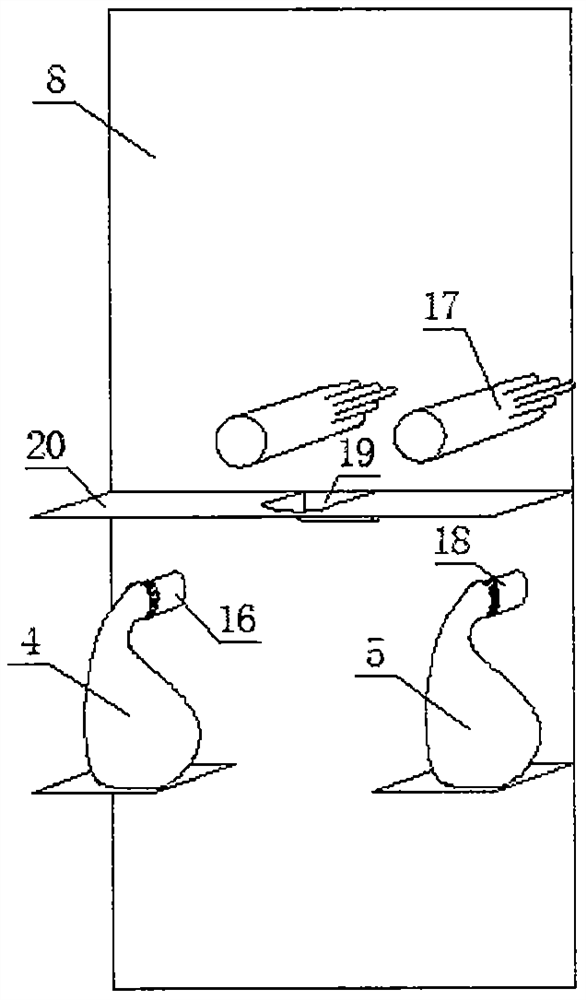

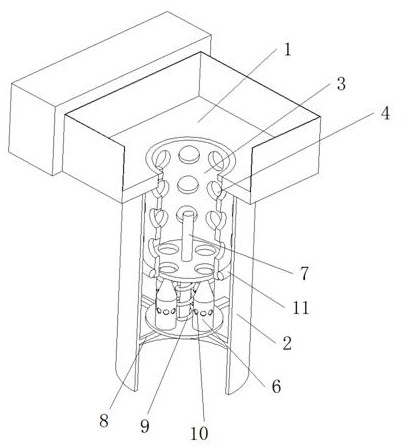

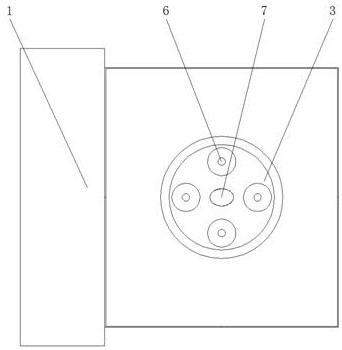

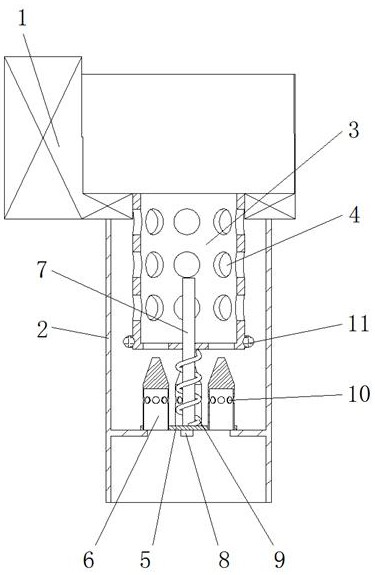

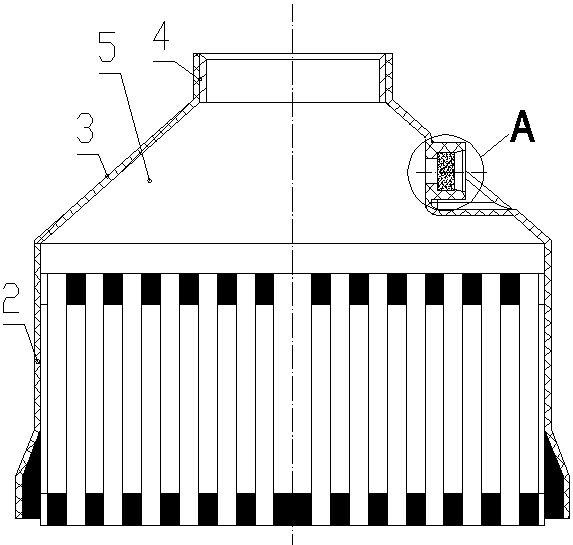

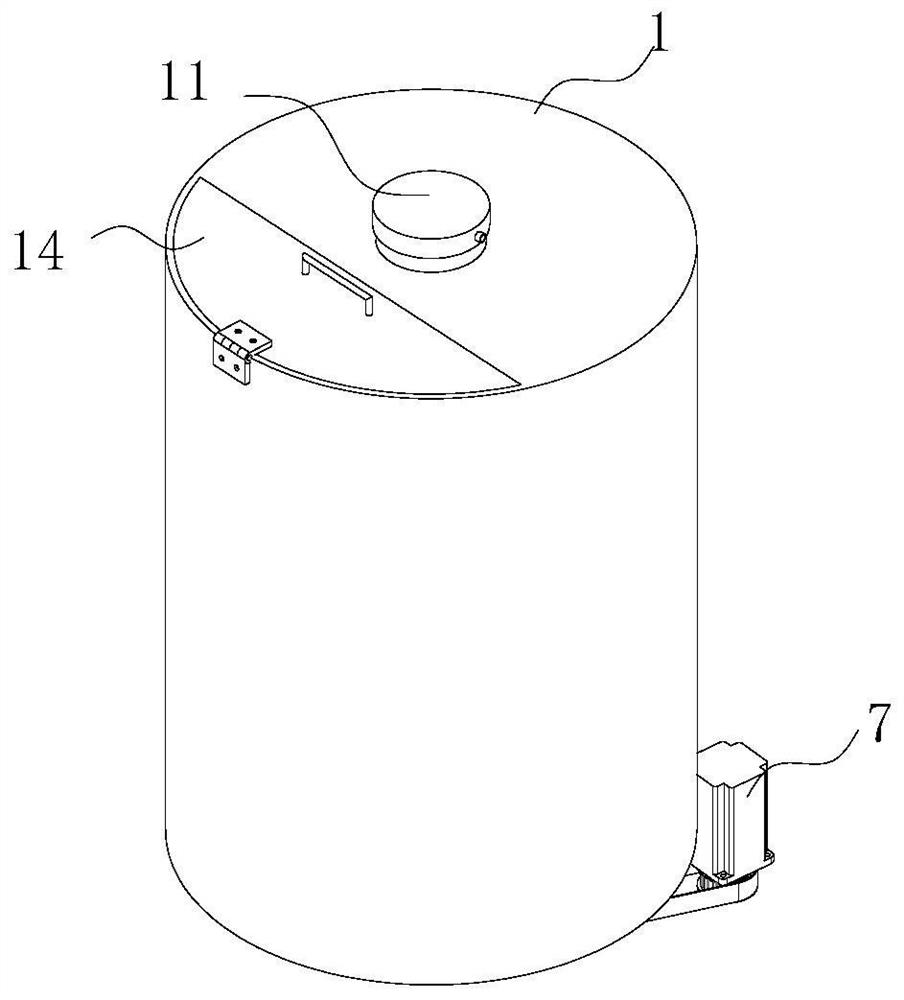

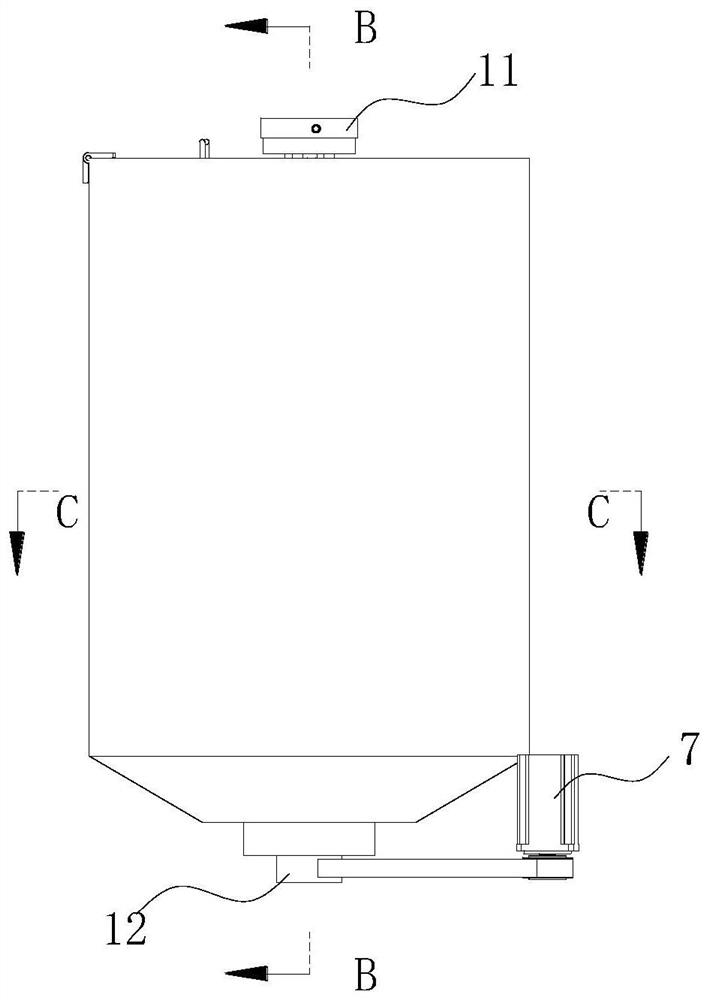

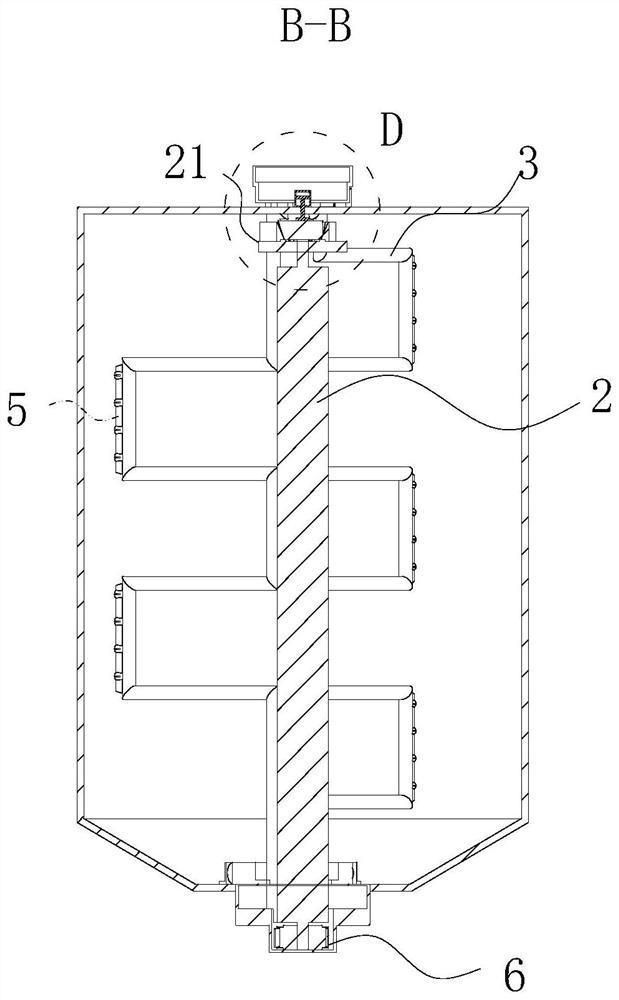

Nonmetal magnetism-free liquid nitrogen dewar

ActiveCN102661482AGuaranteed sealing performanceGuaranteed inflowContainer filling methodsNon-pressured vesselsVacuum pumpingInsulation layer

The invention discloses a nonmetal magnetism-free liquid nitrogen dewar which is composed of a vacuum cover and a dewar liner (1). The vacuum cover comprises an outer casing (2) and a cover plate (3), the dewar liner (1) is arranged inside the outer casing (2), at least one liquid inlet tube (4) or liquid outlet tube (5) is arranged on the dewar liner (1), at least one circular hole (6) is arranged on the cover plate (3), the circular hole (6) is matched with the liquid inlet tube (4) or the liquid outlet tube (5), a heat insulation layer (7) is arranged at the periphery of the dewar liner (1), a through hole (8) is arranged in the middle of the cover plate (3), the diameter of the through hole (8) is matched with the inner diameter of the dewar liner (1), and a vacuum pumping port (9) is further arranged on the cover plate (3). By means of the structure, the nonmetal magnetism-free liquid nitrogen dewar can be used for installing a high temperature superconducting radio frequency coil, simultaneously has the effects of containing liquid nitrogen and cooling the high temperature superconducting radio frequency coil.

Owner:TIME MEDICAL JIANGSU

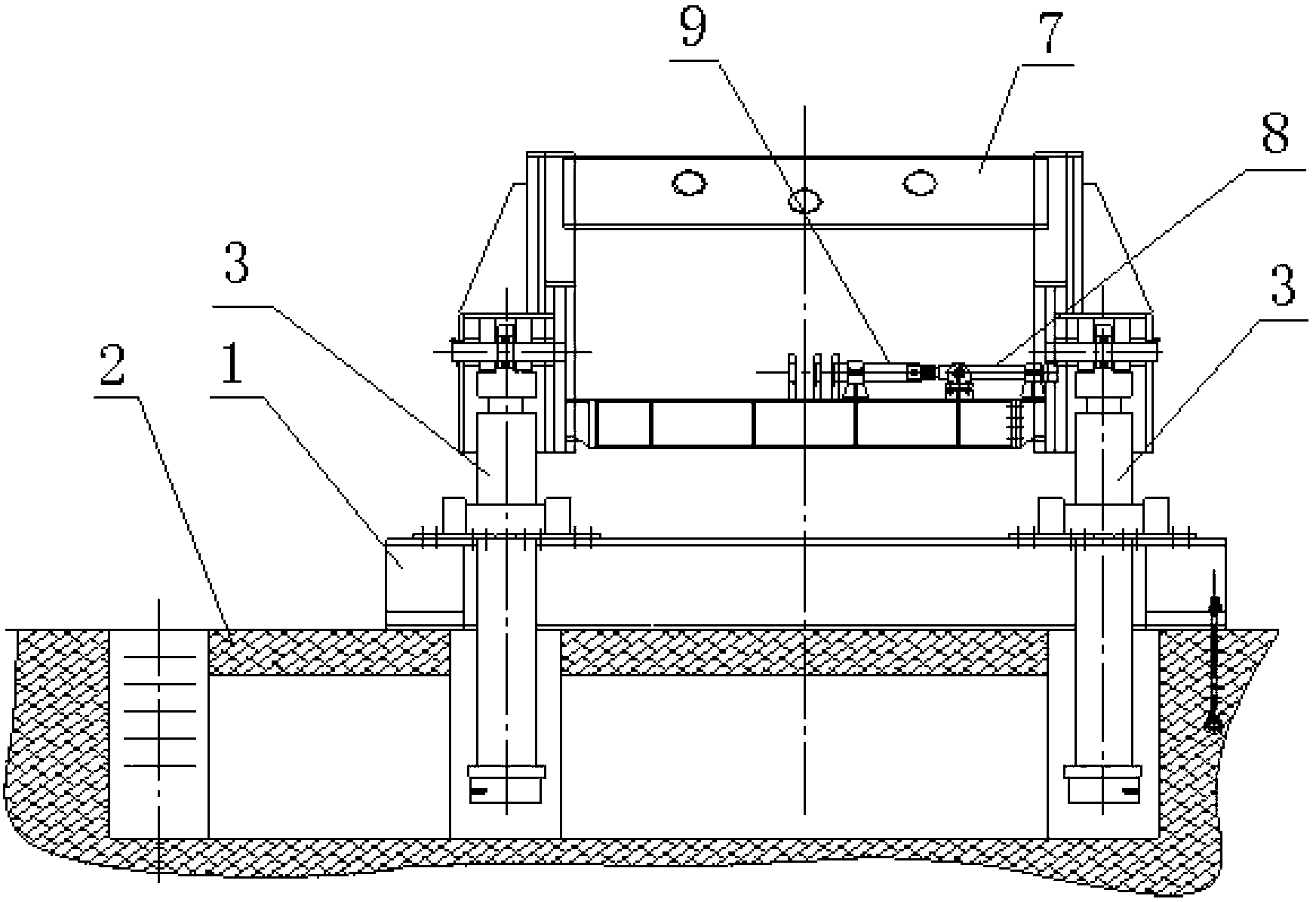

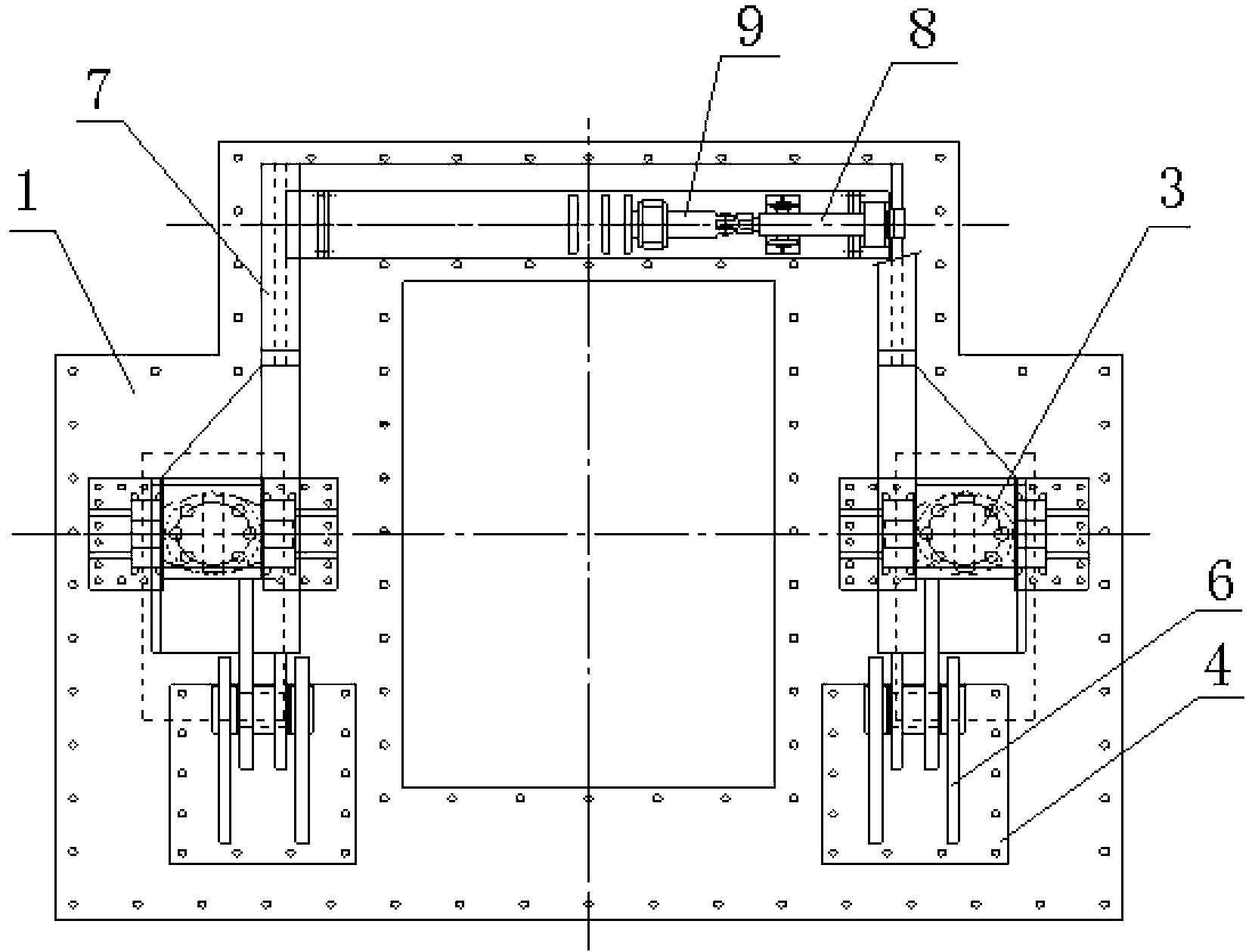

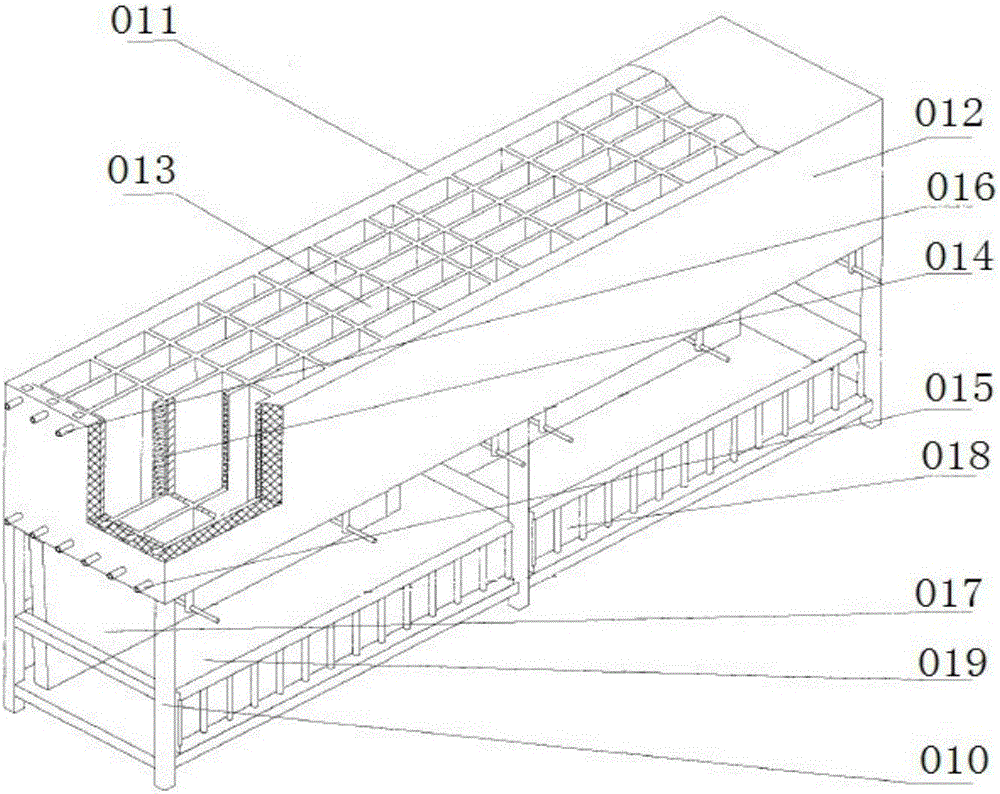

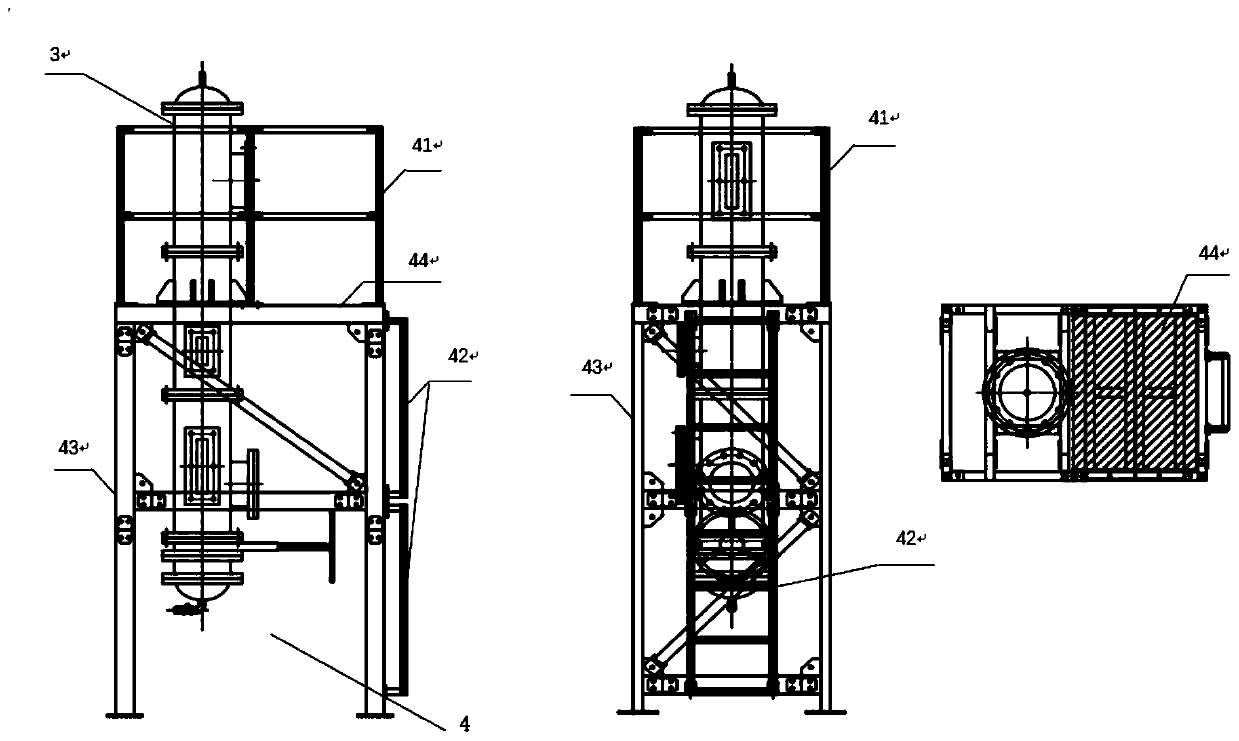

Hydraulic turnover device of hot metal ladle

The invention discloses a hydraulic turnover device of a hot metal ladle. A steel structure underframe of the hydraulic turnover device is fixed on a foundation, wherein two turnover hydraulic cylinders, two uprights and two buffer supports are symmetrically fixed on the two sides of the steel structure underframe; rotary supports are fixed at the top ends of the two uprights; a front cross beam of a movable bracket is symmetrically articulated with the two rotary supports; a rear cross beam base is arranged on the two buffer supports; piston rod ends of the two turnover hydraulic cylinders are symmetrically articulated with a left side plate and a right side plate of the movable bracket; and a locking oil cylinder and a locking pin shaft are mounted on a rear cross beam of the movable bracket. According to the hydraulic turnover device, a turnover acting force is totally borne by the steel structure underframe, and wholly transferred to the foundation by the steel structure underframe, so that a civil foundation is uniform in stressing and low in construction cost; particularly, most of cylinder body sections of the turnover hydraulic cylinders sink underground, so that the height of the gravity center of the turnover movable bracket is reduced greatly, and the height of the gravity center of the hot metal ladle during working is further reduced; and the two turnover hydraulic cylinders and the two bracing rotary supports are adopted, so that the turnover stability is improved greatly.

Owner:BAOJI XY EQUIP MFG

Non-pump constant flow low pressure drip irrigation device

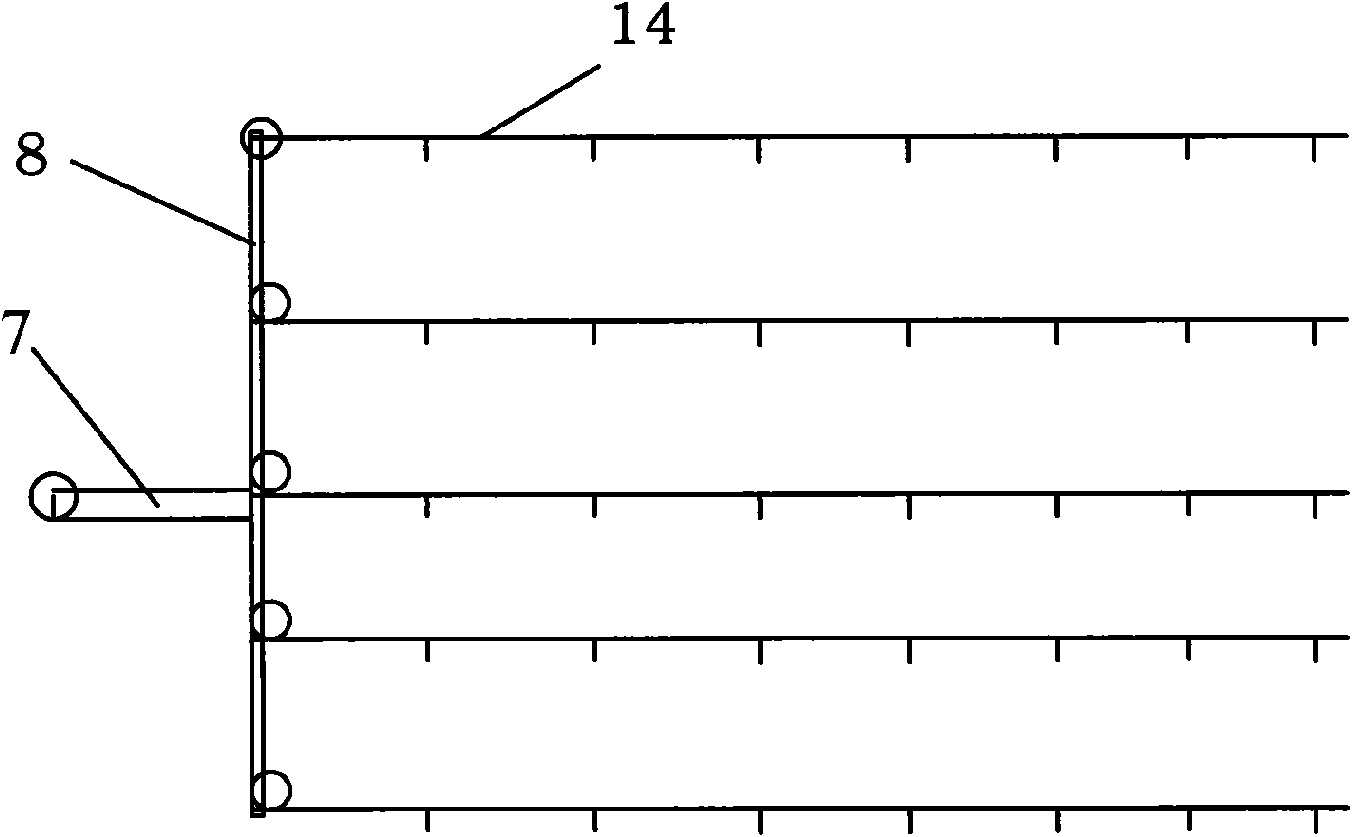

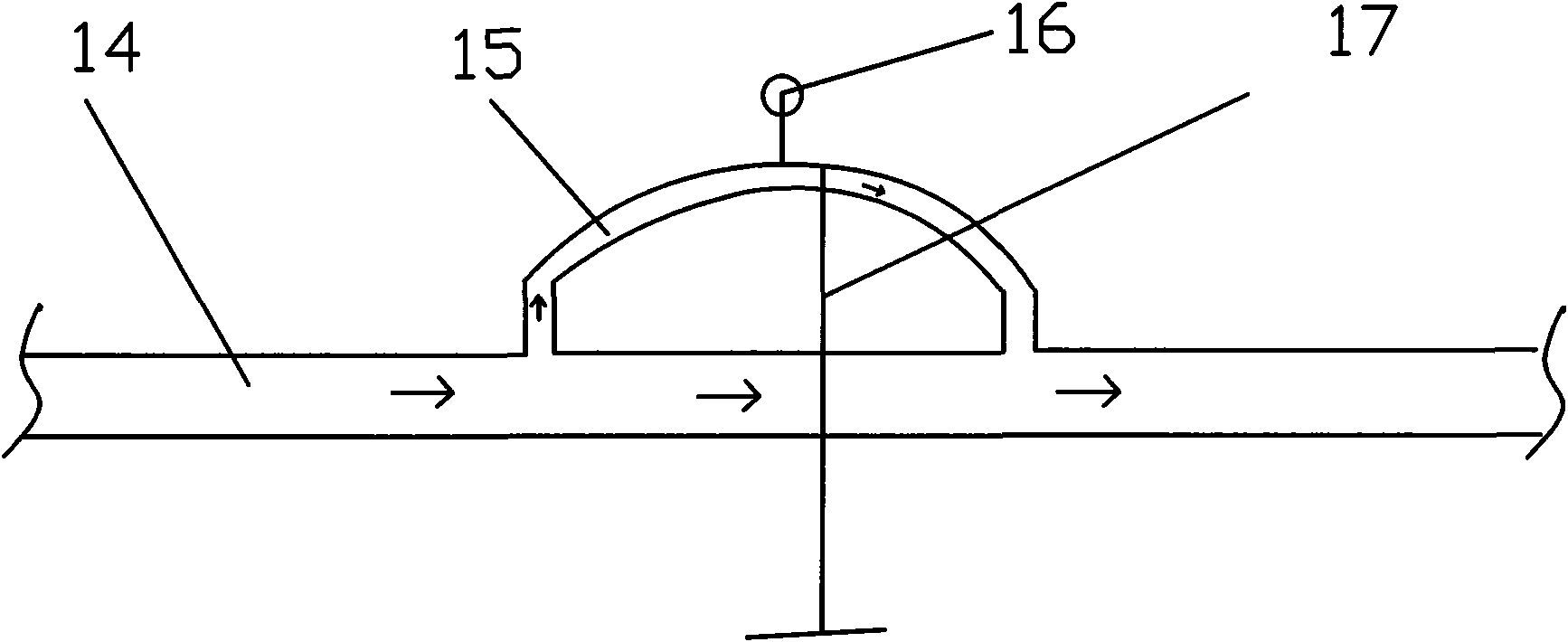

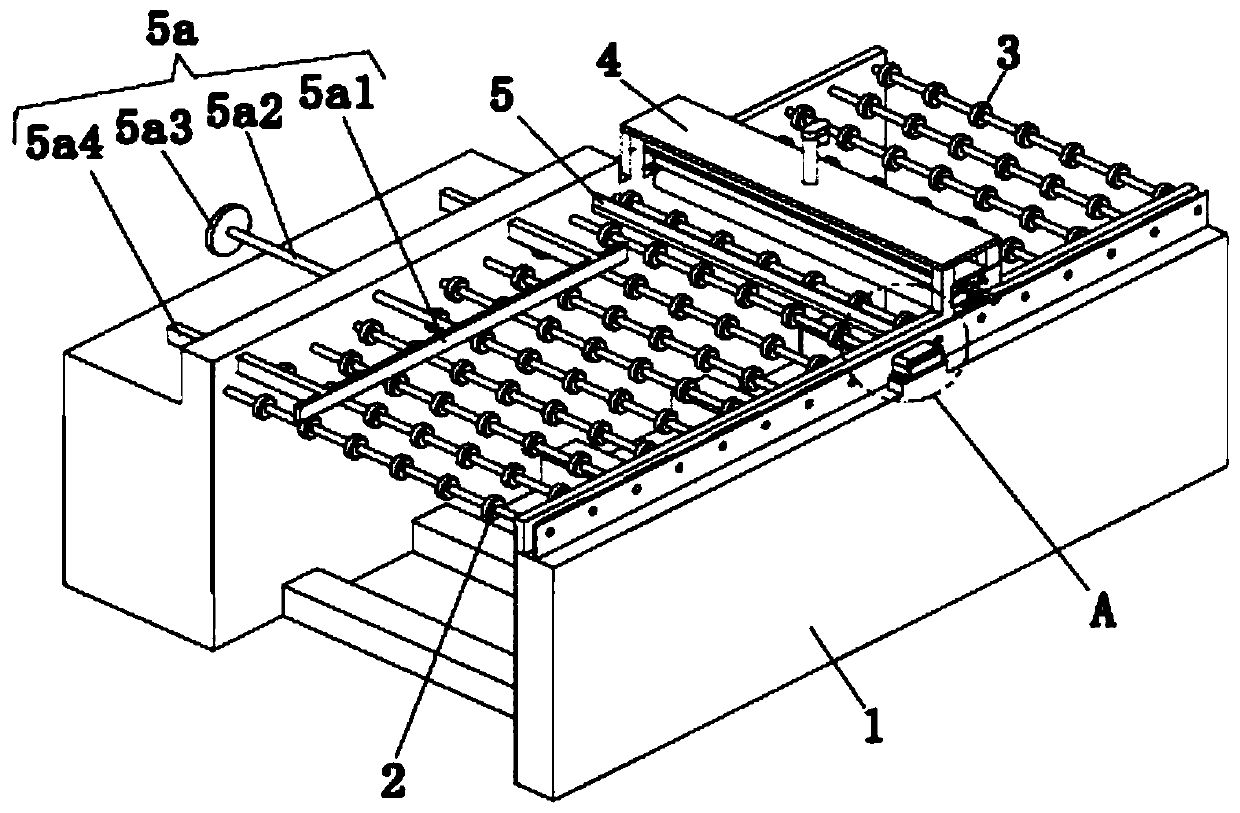

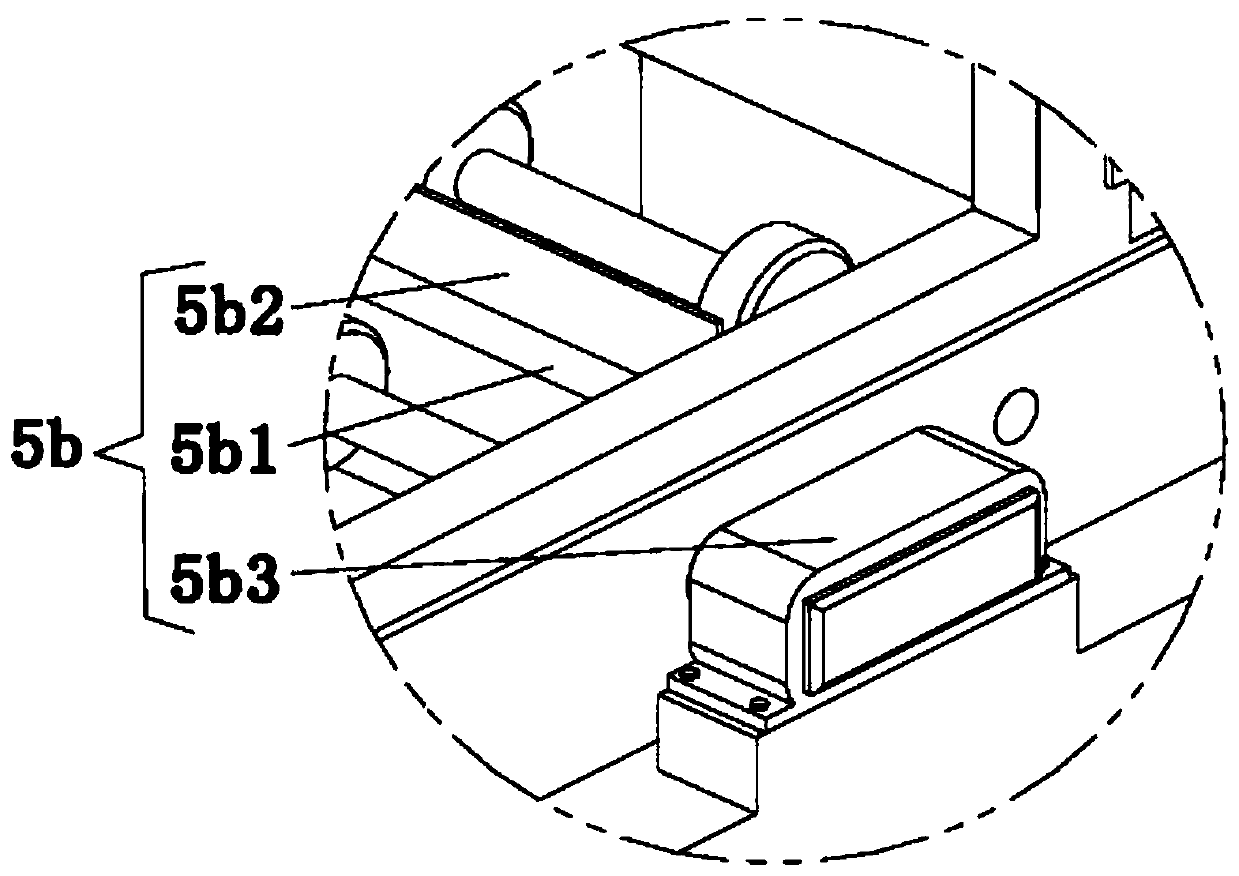

InactiveCN101584294ALow costImproves irrigation uniformityWatering devicesCultivating equipmentsWater tanksContinuous irrigation

The invention discloses a non-pump constant flow low pressure drip irrigation device, comprising a main tube, a branch tube, a hair canal, a bypass closed hose, a micro path emitter, a support, a water tank, a main tube water pressure regulating mechanism and a branch tube water pressure regulating mechanism. Compared with the prior art, the invention has the advantages of stable pressure, energy saving, water saving, low costs, high irrigation evenness. The power for continuous irrigation is provide by a gravity flow generated from the water head of the water tank on high without a water pump. The main tube water pressure regulating mechanism regulates the water flow at the mouth of the main tube and the branch tube water pressure regulating mechanism ensures the work pressure at the inlet end of the hair canal to be constant, thus reducing the head loss. The bypass closed hose and an adjustable support arranged at the micro path emitter guarantee the outflow rate of each emitter along the hair canal to be equal. Therefore, the device has a good irrigation effect and is suitable for using in wide countryside.

Owner:HOHAI UNIV

Paper board gluing control method

ActiveCN111013921AAvoid wastingReduce usageLiquid surface applicatorsCoatingsPaperboardAdhesive glue

Owner:重庆市金星纸制品有限责任公司

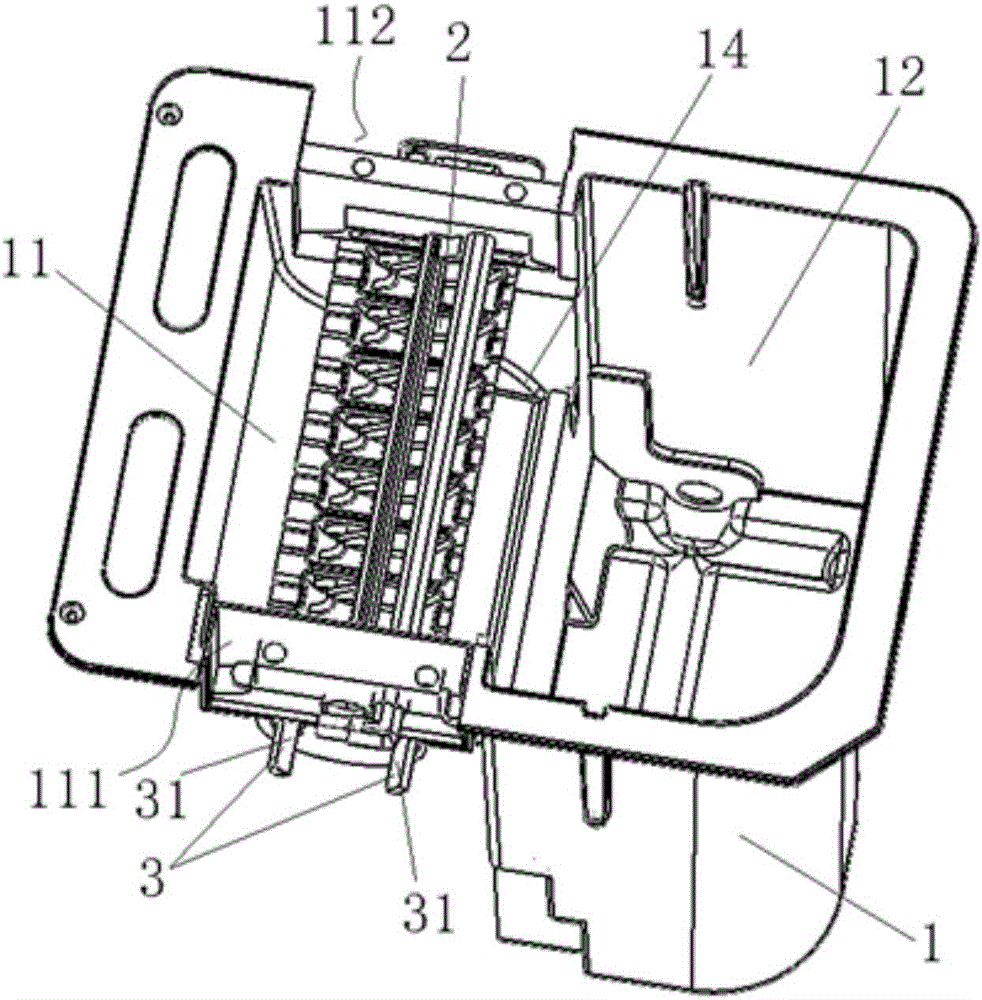

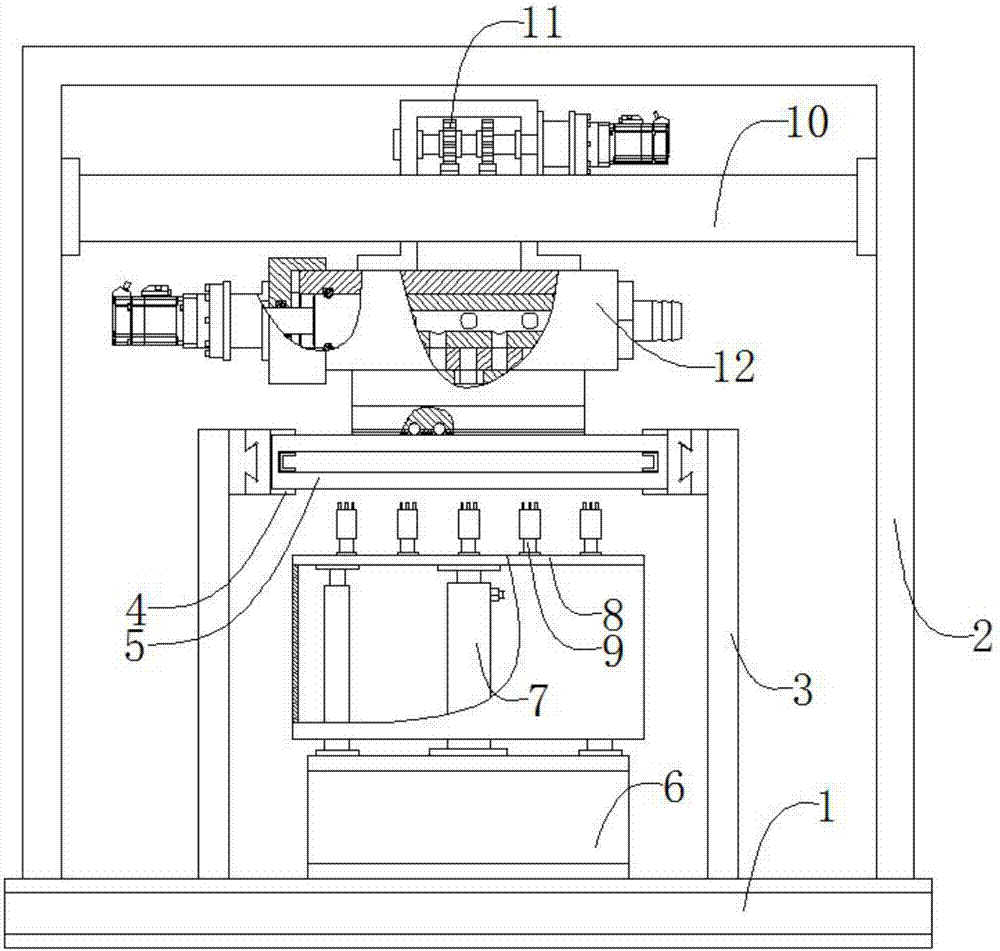

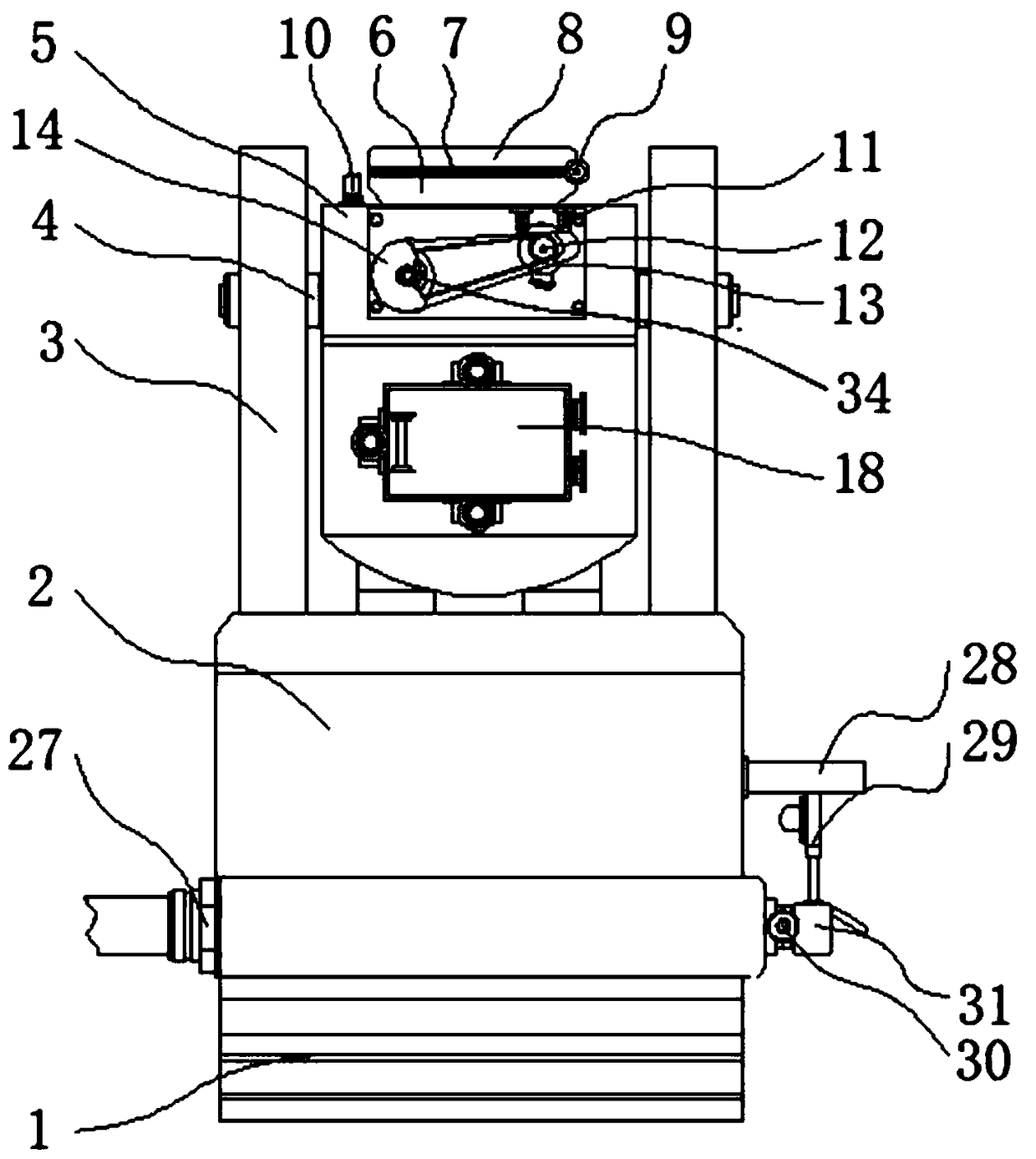

Medical dispensing machine

InactiveCN105496779AImprove work efficiencyGuaranteed accuracyPharmaceutical containersMedical packagingFixed frameBiomedical engineering

Provided is a medical dispensing machine. The medical dispensing machine is characterized in that the medical dispensing machine comprises a fixing frame, a driving mechanism, a sliding block, a guide rail, a syringe, a medicine pumping pipeline and a medicine discharging pipeline; the syringe is composed of a push rod and a needle cylinder which is fixed and supported on the fixing frame, and the push rod is fixedly connected with the sliding block; the sliding block can be driven by the driving mechanism to do rectilinear motion in the length direction of the syringe, the sliding block is located on the guide rail, and the guide rail is fixed relative to the fixing frame; a liquid outlet is formed in the head part of the needle cylinder, one end of the medicine pumping pipeline is connected with the liquid outlet, the other end of the medicine pumping pipeline is connected with a medicine bottle, the medicine pumping pipeline is internally provided with a first one-way valve, and the conducting direction of the first one-way valve is from the medicine bottle to the needle cylinder; one end of the medicine discharging pipe is connected with the liquid outlet, the other end of the medicine discharging pipe is connected with a liquid collector, the medicine discharging pipe is provided with a second one-way valve, and the conducting direction of the second one-way valve is from the needle cylinder to the liquid collector. The medical dispensing machine has higher accuracy, and the safety, simplicity and reliability of medicine pumping work of medial staff are improved.

Owner:SOOCHOW UNIV AFFILIATED CHILDRENS HOSPITAL +1

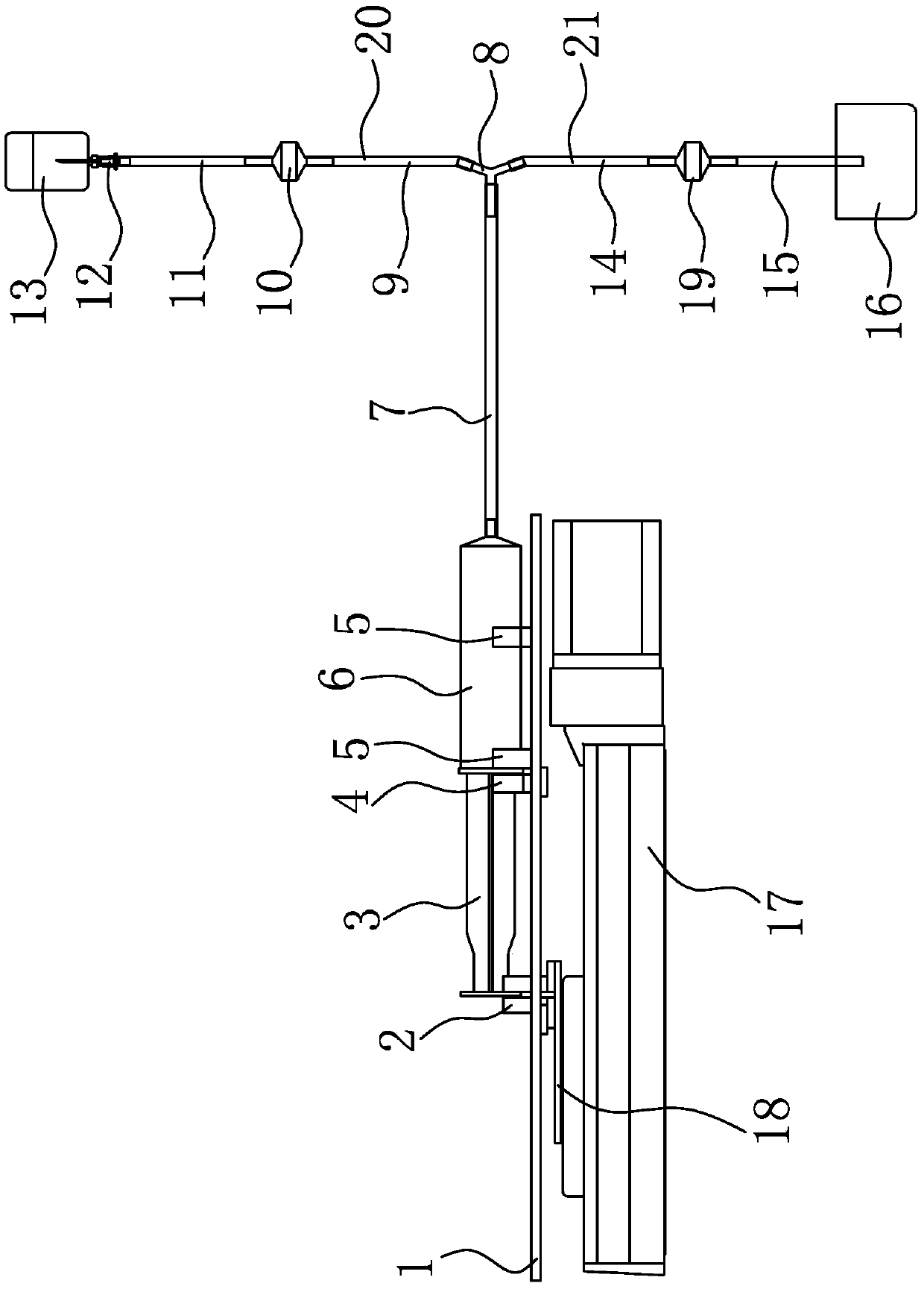

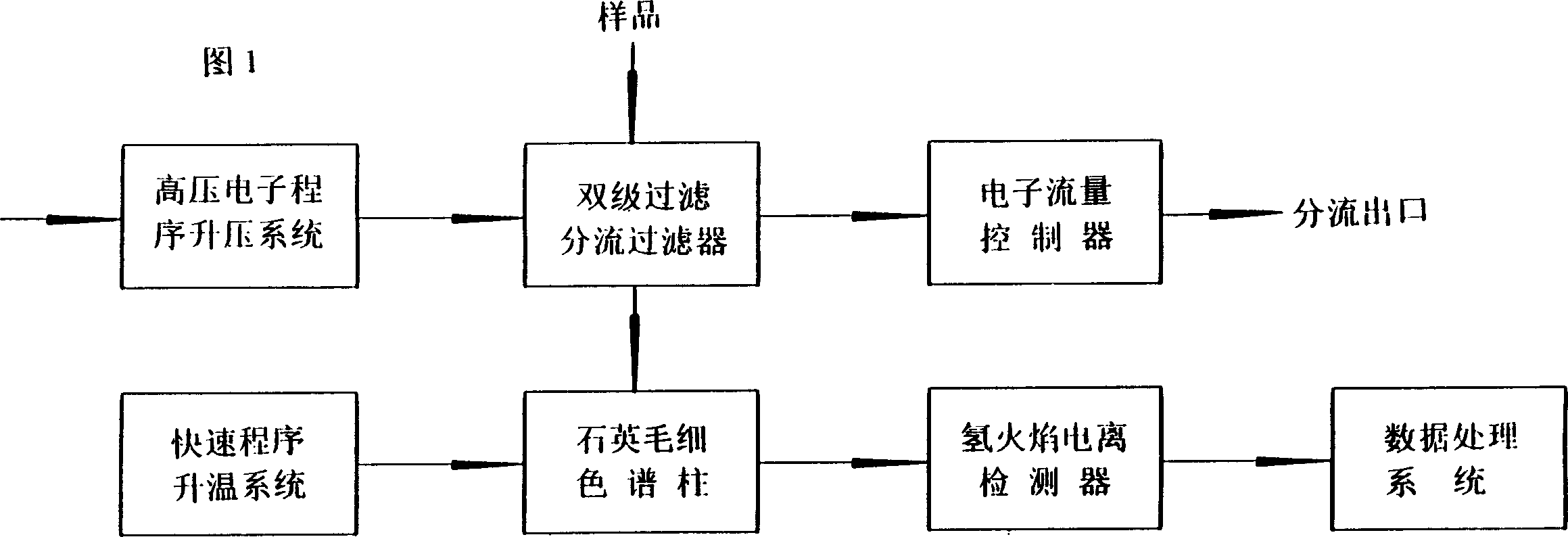

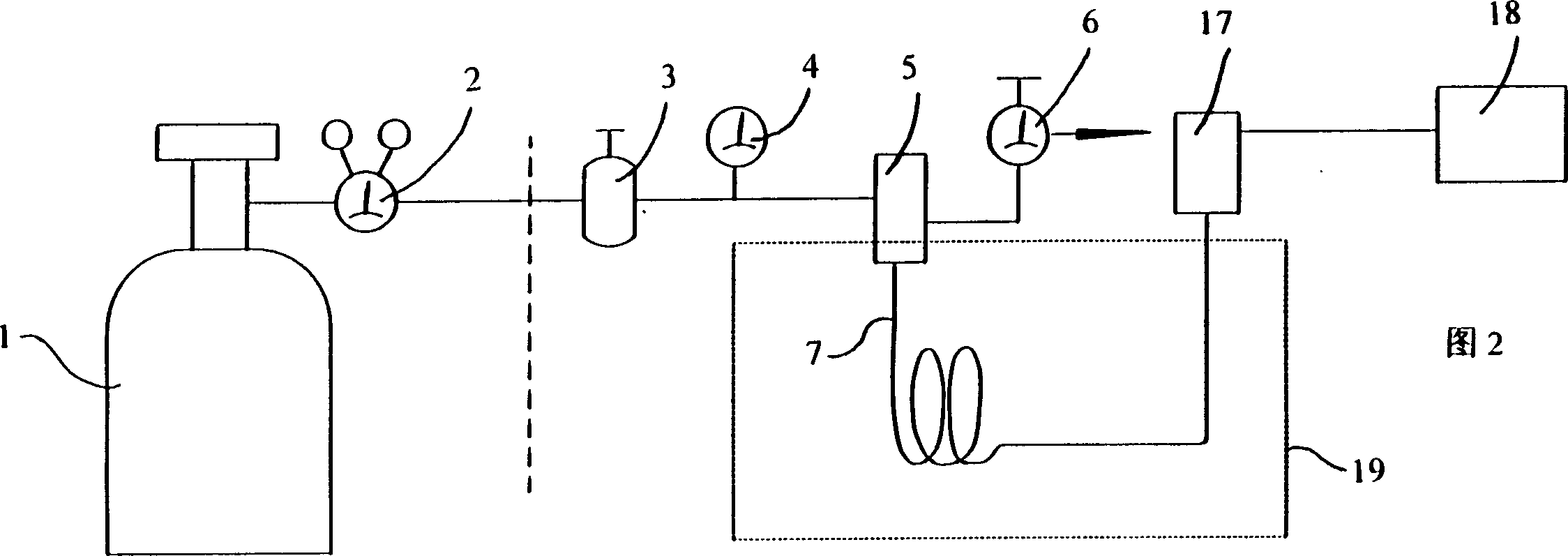

Quick petroleum hydrocarbon distribution analysis instrument

InactiveCN1450349AFast analysisGuaranteed normal outflowComponent separationChemical industrySoftware system

The invention is a quick distribution analyzer of petroleum hydrocarbon, including high-voltage electronic program step-up system with the pressure 0.2-1.0 MPa and the pressure programmed speed, 0.01-0.1 MPa / m, double-level filtering and diffluent sample-entering device, quartz capillary chromatogram column with the mixed stationary phase of SE-54 OV-1 in the inner wall, the proportion 1:(1-4) according to the weight shares, quick temperature programmed system with the temperature-increasing speed 20-60 deg.C / m, detector and the data processing system with the distribution of petroleum hydrocarbon and boiling-range distribution software system. The analyzer has quick speed and high resolution, and can be widely used in the fields such as oil, petrifaction, environmental protection and chemical industry.

Owner:中国石油天然气总公司石油勘探开发科学研究院

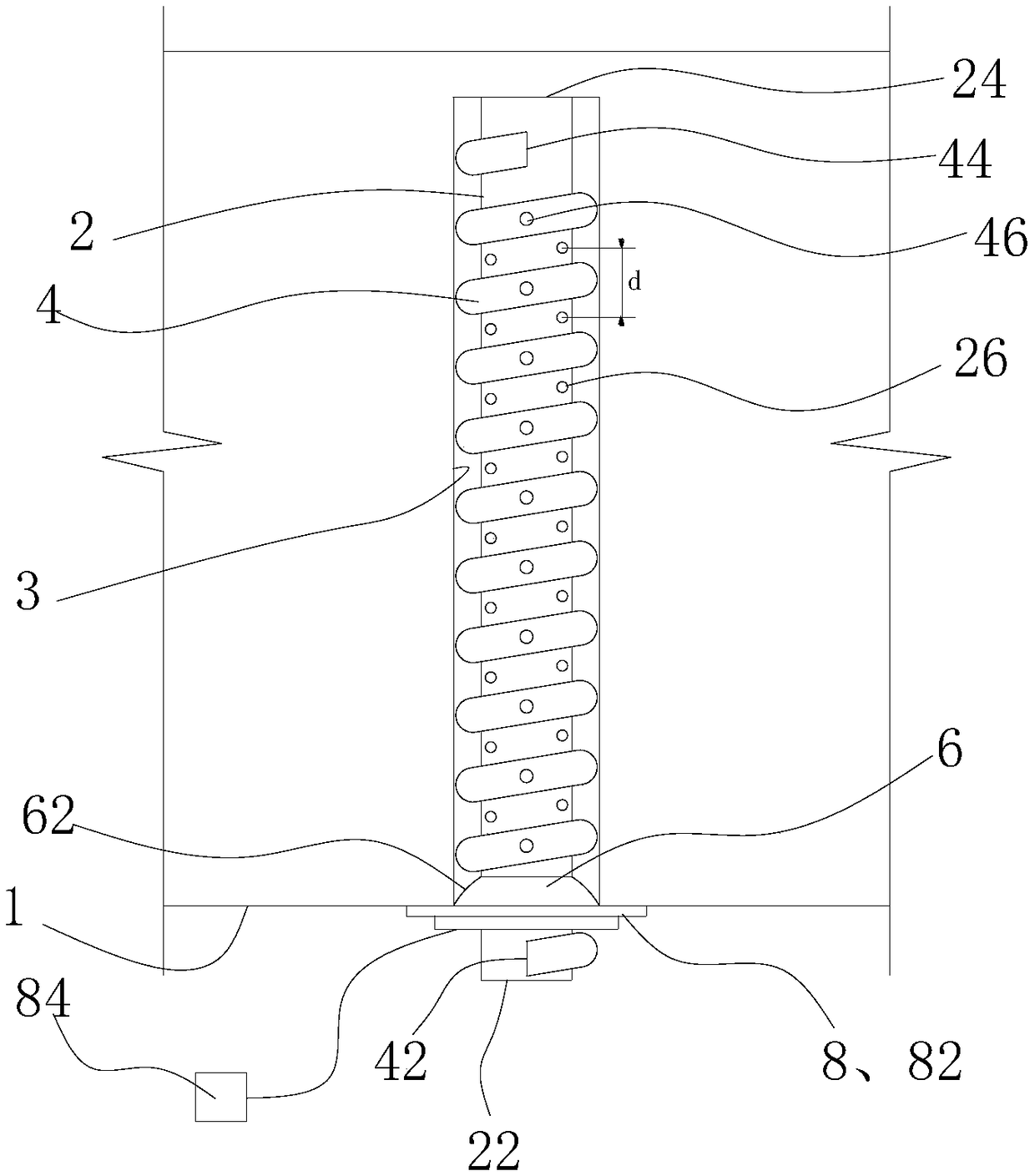

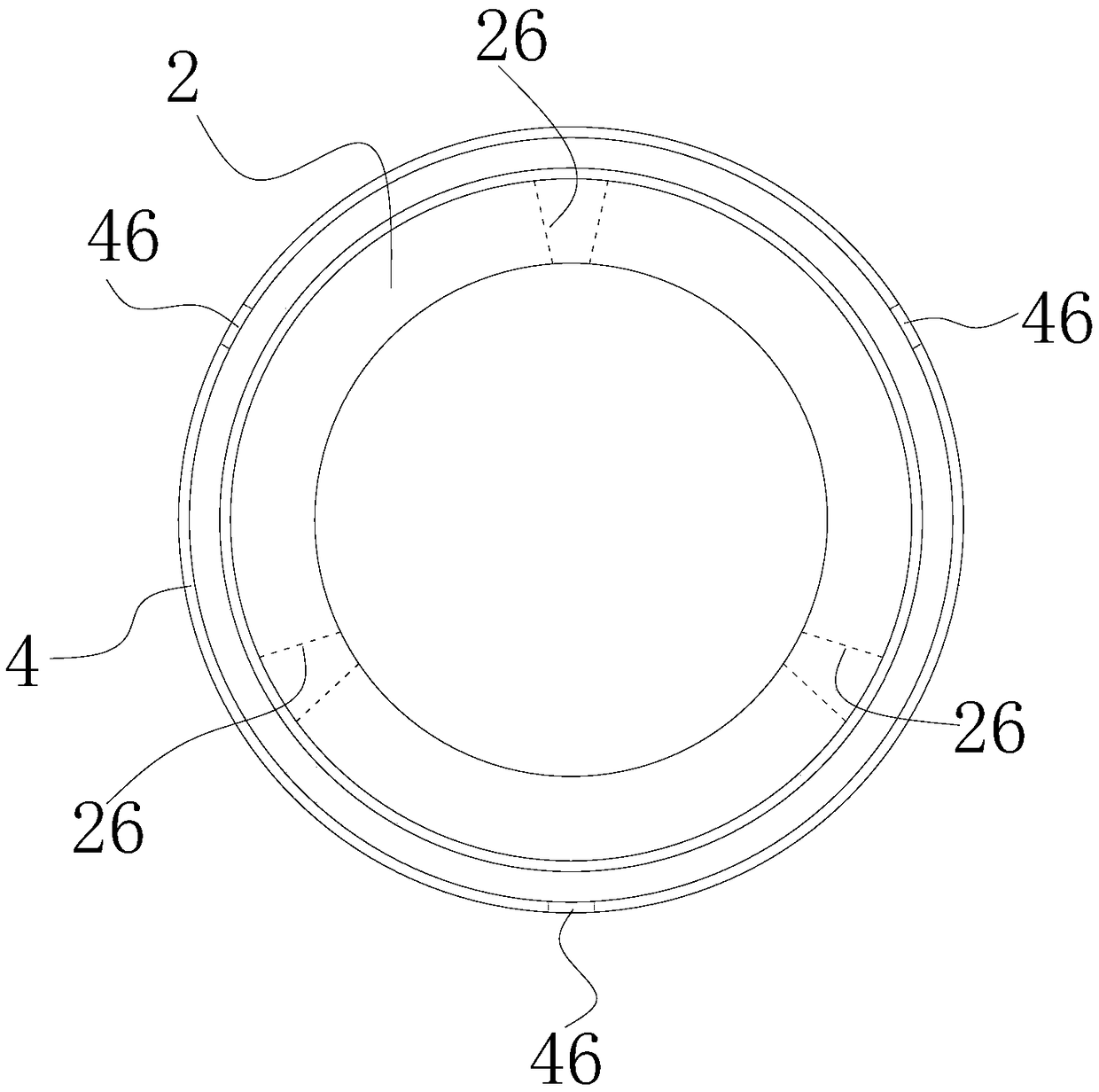

Grouting pipe with improved grouting effect and grouting process

ActiveCN109026023APrevent slurry lossGuaranteed grouting effectUnderground chambersTunnel liningEngineeringCement accelerator

The invention discloses a grouting pipe with an improved grouting effect. The grouting pipe comprises a hollow tubular body, a plurality of first spouting ports disposed on the side portion of the body and capable of spouting slurry outwards, and a branch pipe spirally surrounding the outer side of the body and provided with a plurality of second spouting ports capable of spouting the slurry outwards. Therefore, the grouting pipe has two passages including the body and the branch pipe through which mortar and a cement accelerator can be poured simultaneously and respectively. The combination of the body and the branch pipe has a better rock formation reinforcement effect, especially for water-rich rock formations. A tunnel grouting process, by using the grouting pipe of the present invention, can easily and simultaneously pour the mortar and the cement accelerator, is simple in process and has a better rock formation reinforcement effect.

Owner:江苏华设远州交通科技有限公司 +1

Device and method for making fancy ice

InactiveCN105042974AGuaranteed normal outflowEasy to dial outLighting and heating apparatusIce productionMarine engineeringEvaporation

The invention provides a device and method for making fancy ice. The device comprises an ice making box and evaporation pipes. The ice making box comprises an ice making inner cavity. The evaporation pipes are located at the bottom of the ice making box and used for cooling water in the ice making inner cavity into ice. The device further comprises a diversion structure arranged on the ice making box and used for leading water exceeding the maximum water capacity of the ice making inner cavity out of the ice making box. According to the device for making the fancy ice, when a small amount of water is supplied into the ice making box and kept still, the small amount of water can be completely cooled into white ice through the evaporation pipes; when water continues to be supplied to the surface of the white ice and flows on the surface of the white ice, the diversion structure can lead the water exceeding the maximum water capacity of the ice making inner cavity out of the ice making box, the evaporation pipes cool the water on the surface of the white ice into a layer of transparent ice, and therefore the white ice and the fancy ice with the transparent ice layer arrayed in an overlapped manner can be made.

Owner:NINGBO TEXA ELECTRIC MFG

Drinking water device free of secondary pollution

ActiveCN103462503AGuaranteed normal outflowAvoid secondary pollutionClosuresClosure using stoppersWater drinkingWater pipe

The invention relates to a drinking water device free of secondary pollution and belongs to the technical field of drinking water devices. The drinking water device is characterized by comprising a foldable bucket and a water dispenser. The foldable bucket comprises a bucket neck, a bucket body and a bucket bottom which are formed by food grade plastics by integrated blow molding. The water dispenser comprises a supporting basin, a water guide pillar, a water pipe and a machine body which are formed by food grade plastics by integrated injection molding. The supporting basin is used for supporting the foldable bucket, the water pipe is arranged in the machine body, and one end of the water pipe is communicated with the water guide pillar. The drinking water device free of secondary pollution is simple in structure and convenient to use. When the drinking water device is in use, the foldable bucket is installed on the water dispenser; when a faucet is opened, the foldable bucket can be automatically folded under combined effect of gravity of drinking water and atmospheric pressure, all pipes from the foldable bucket to the faucet are sealed completely, the drinking water can flow out of the faucet in an all sealed state, and the secondary pollution can be effectively avoided.

Owner:CHUNAN QIANDAOHU RENREN ENTERPRISE CO LTD

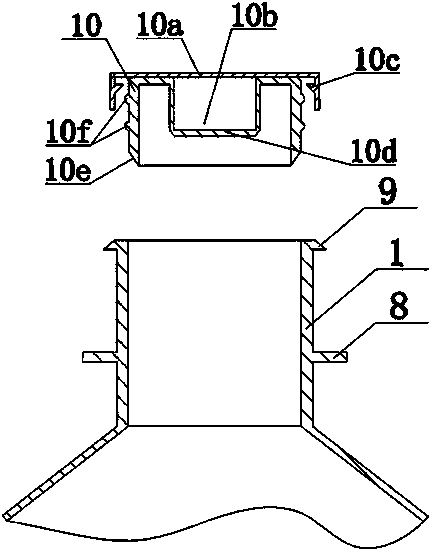

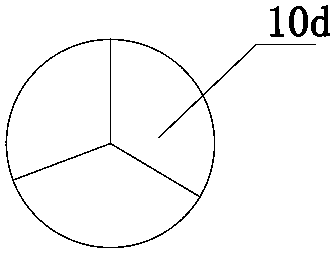

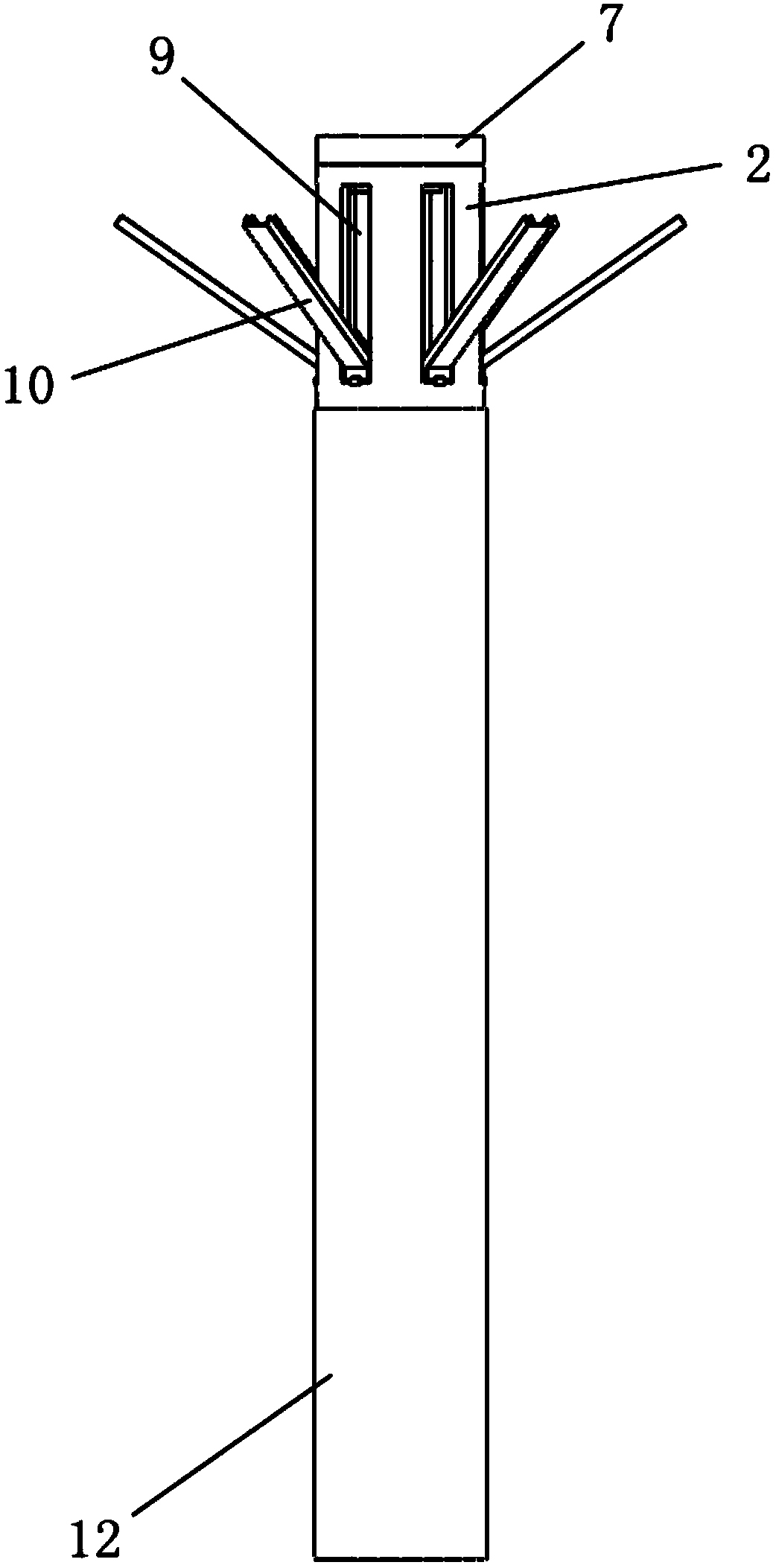

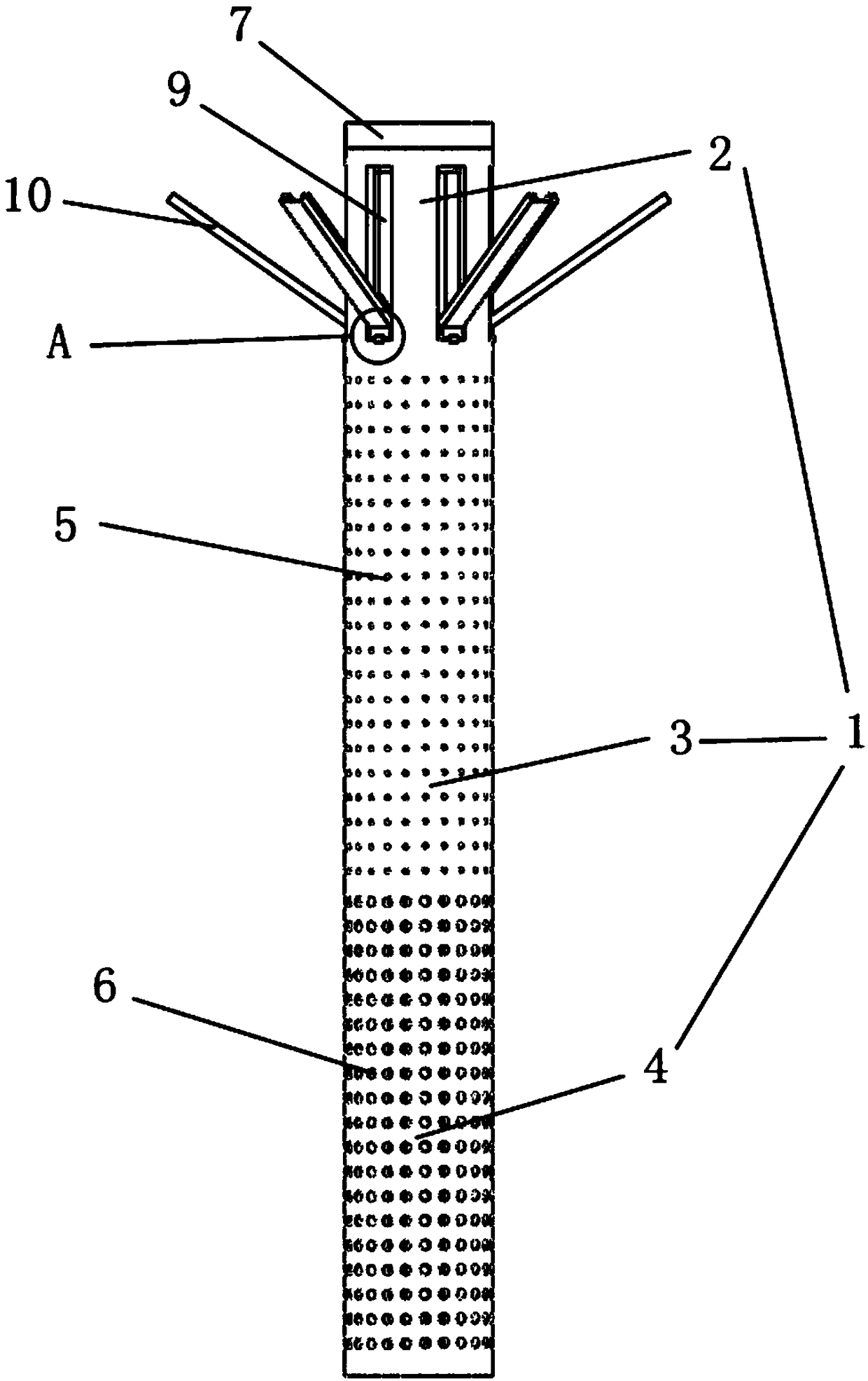

Sustained-release soil heavy metal repair pile foundation

InactiveCN108580540ASimple structureReduce consumptionContaminated soil reclamationContaminated soilsStructural engineering

The invention discloses a sustained-release soil heavy metal repair pile foundation comprising a pile foundation body, a sealing cover and filtering cloths. The pile foundation body is of a structurewith the sealed bottom and the hollow interior. The pile foundation body is internally provided with a heavy metal decomposer. The pile foundation body comprises an external pile foundation main body,a shallow pile foundation main body and a deep pile foundation main body which are arranged from top to bottom. Filtering holes are formed in the outer surfaces of both the shallow pile foundation main body and the deep pile foundation main body correspondingly. The sealing cover is located at the top end of the pile foundation body and matched with the external pile foundation main body. The filtering cloths are located on the outer surfaces of both the shallow pile foundation main body and the deep pile foundation main body. According to the sustained-release soil heavy metal repair pile foundation, heavy metal contaminated soil can be repaired continuously, and due to the simple structure, the sustained-release soil heavy metal repair pile foundation can be used for repair of the heavymetal contaminated soil on a large scale.

Owner:湖南本农环境科技有限公司

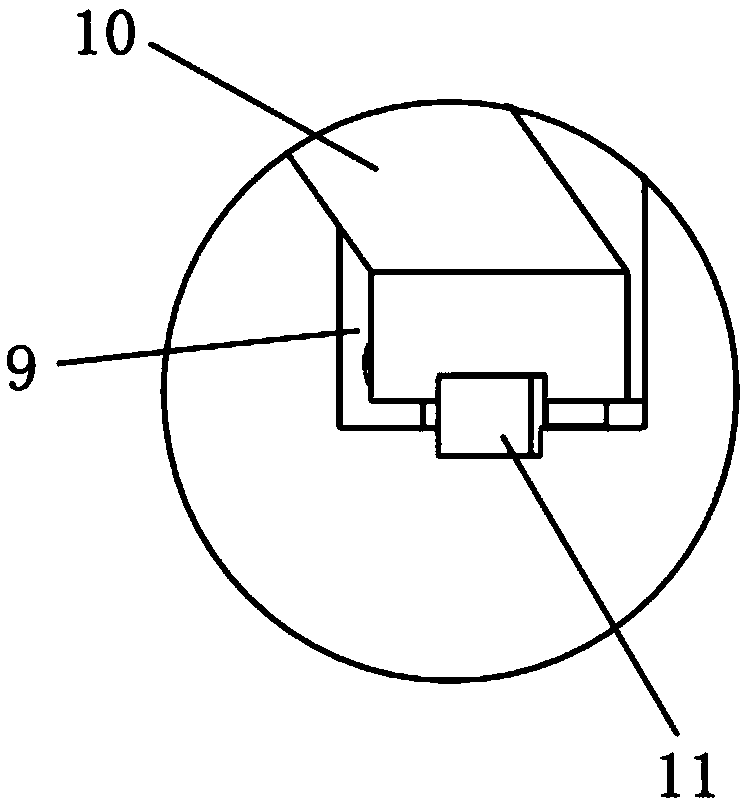

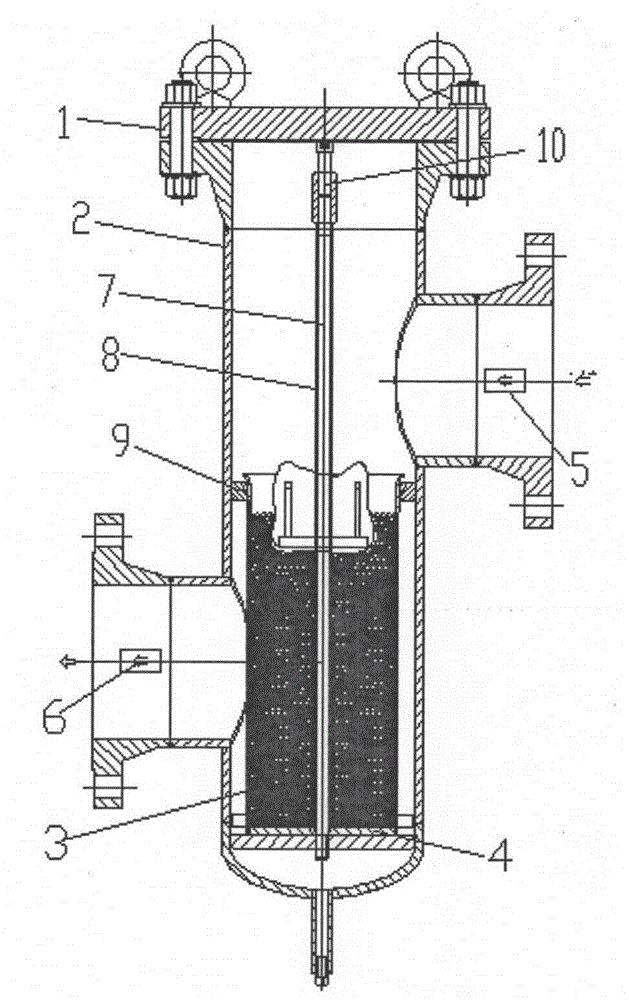

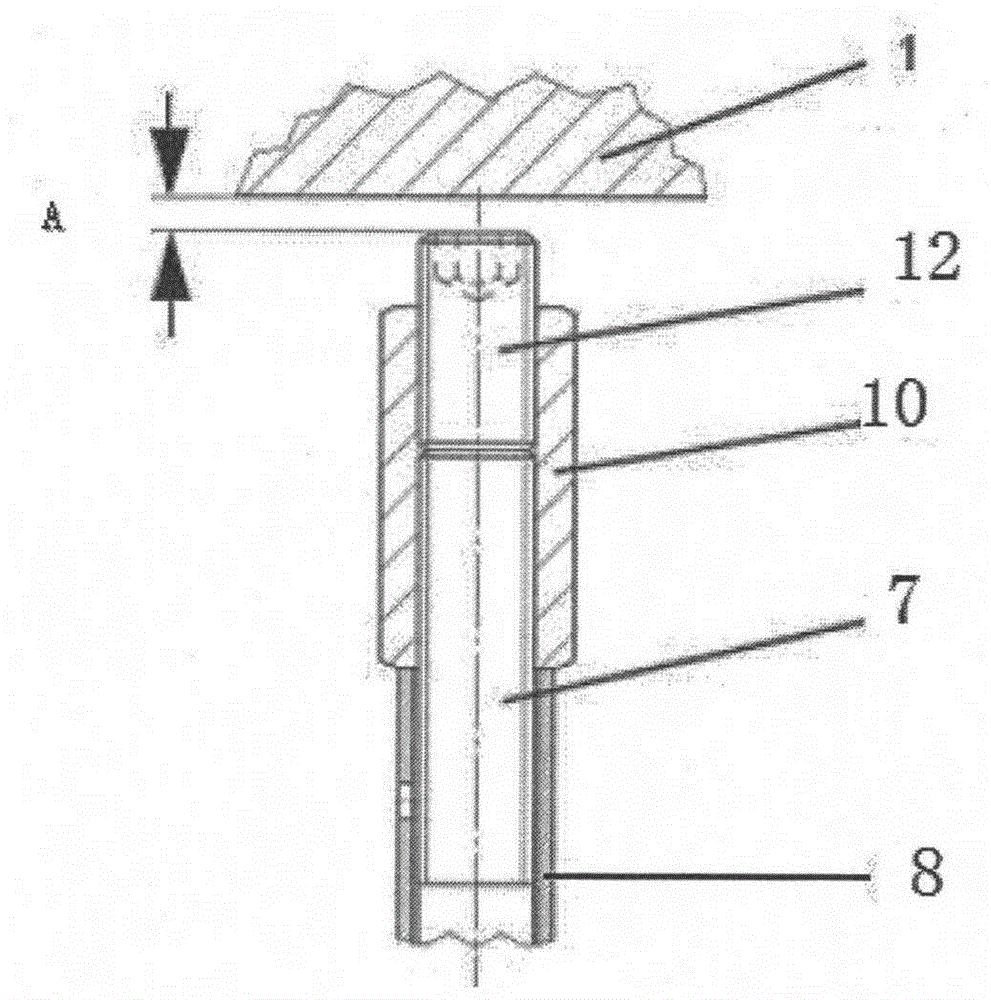

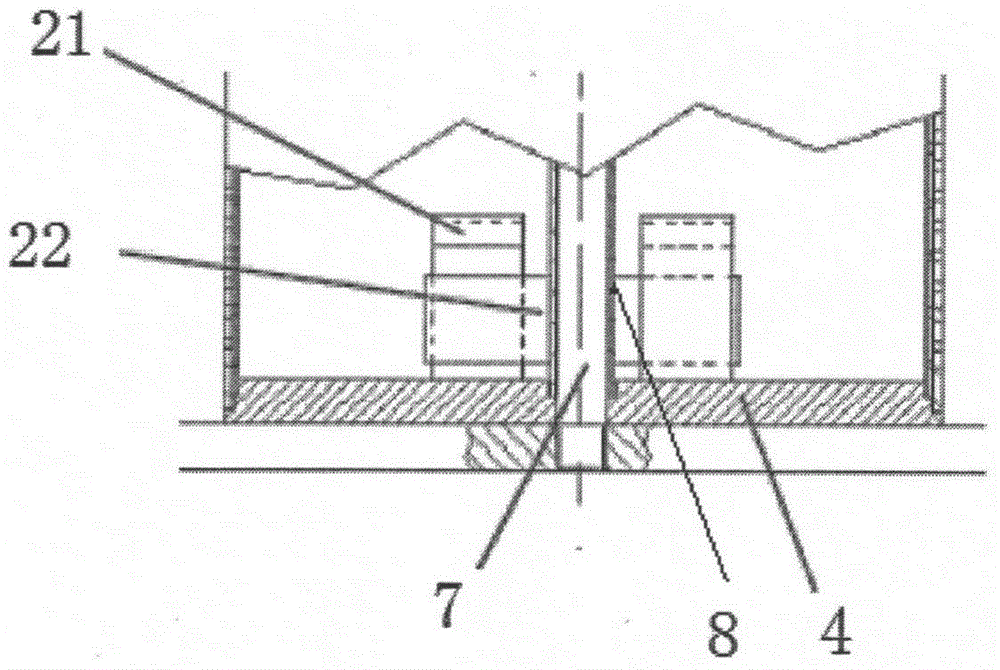

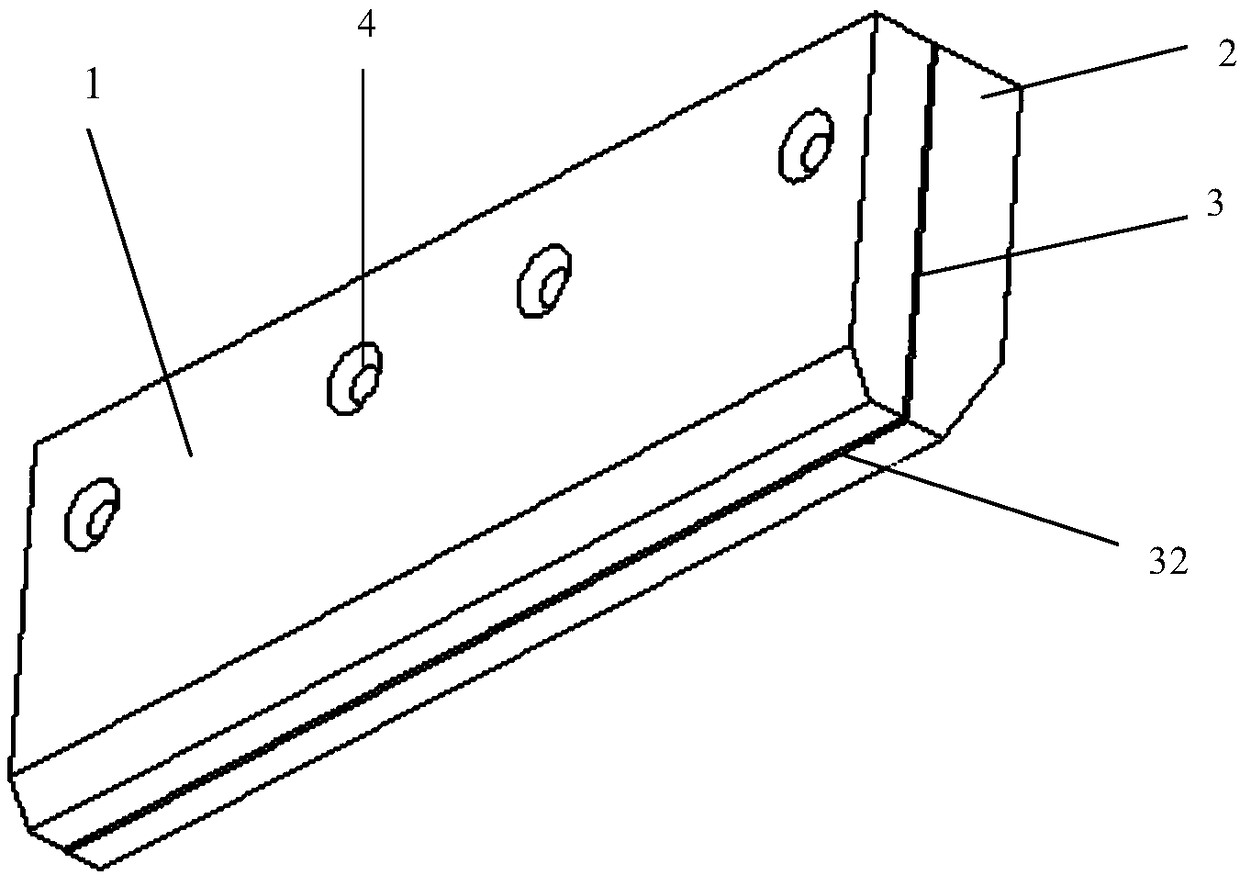

Natural gas filtering device and using and disassembling method thereof

InactiveCN104436919AEasy to fixEasy to assemble and disassembleDispersed particle filtrationGaseous fuelsEngineeringNatural gas

The invention provides a natural gas filtering device and a using and disassembling method of the natural gas filtering device. The natural gas filtering device comprises a filter barrel body, wherein a filter core is fixed in the filter barrel body by a filter core fixing device, the filter core comprises a filter core bottom plate and a filter core body arranged at the upper side of the filter core bottom plate, the filter core fixing device comprises a fixed screw rod and an anchorage pipe sheathed outside the fixed screw rod, the lower end of the fixed screw rod is fixedly connected with a supporting plate fixed in the filter barrel body, the upper end of the fixed screw rod is connected with a locking nut, the locking nut is pressed at the upper end of the anchorage pipe, the lower end of the anchorage pipe is pressed on the filter core bottom plate, and the filter core bottom plate is pressed on the supporting plate by the locking nut through the anchorage pipe and the fixed screw rod. The natural gas filtering device has a compact structure and good sealing property, and the filter core can be disassembled conveniently and can be fixed easily.

Owner:SHANGHAI POWER EQUIP RES INST

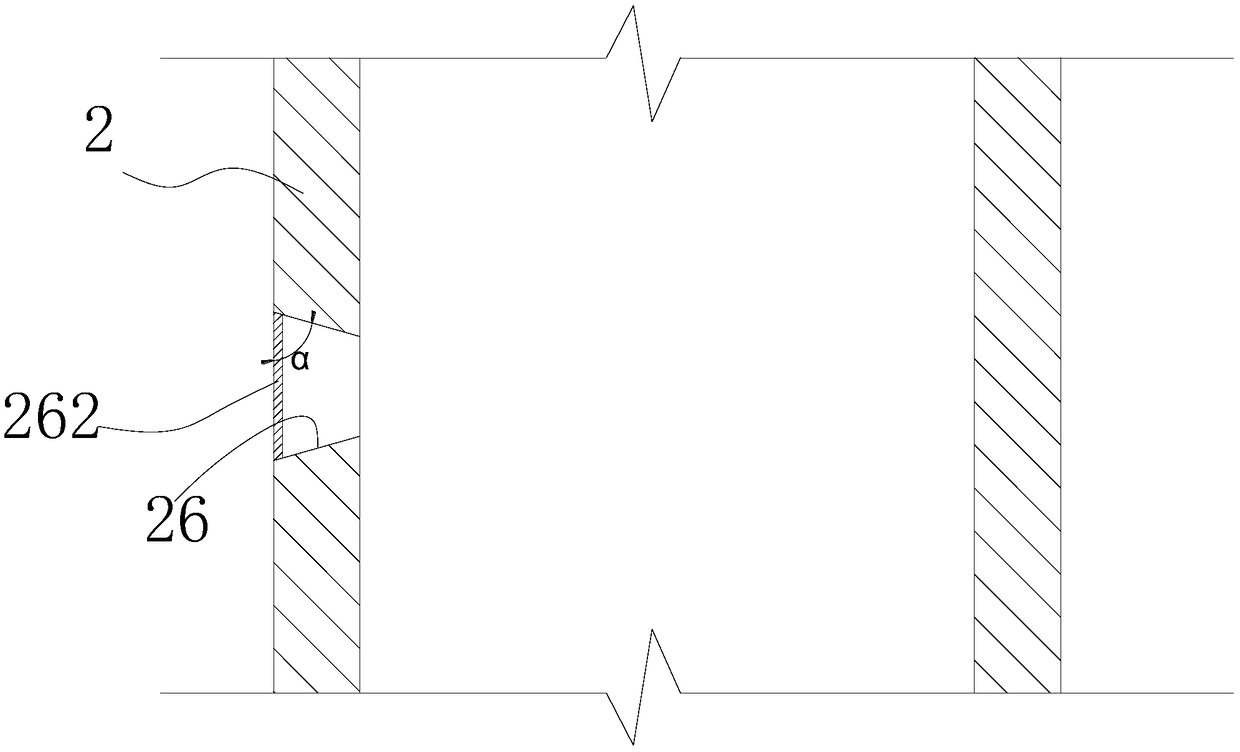

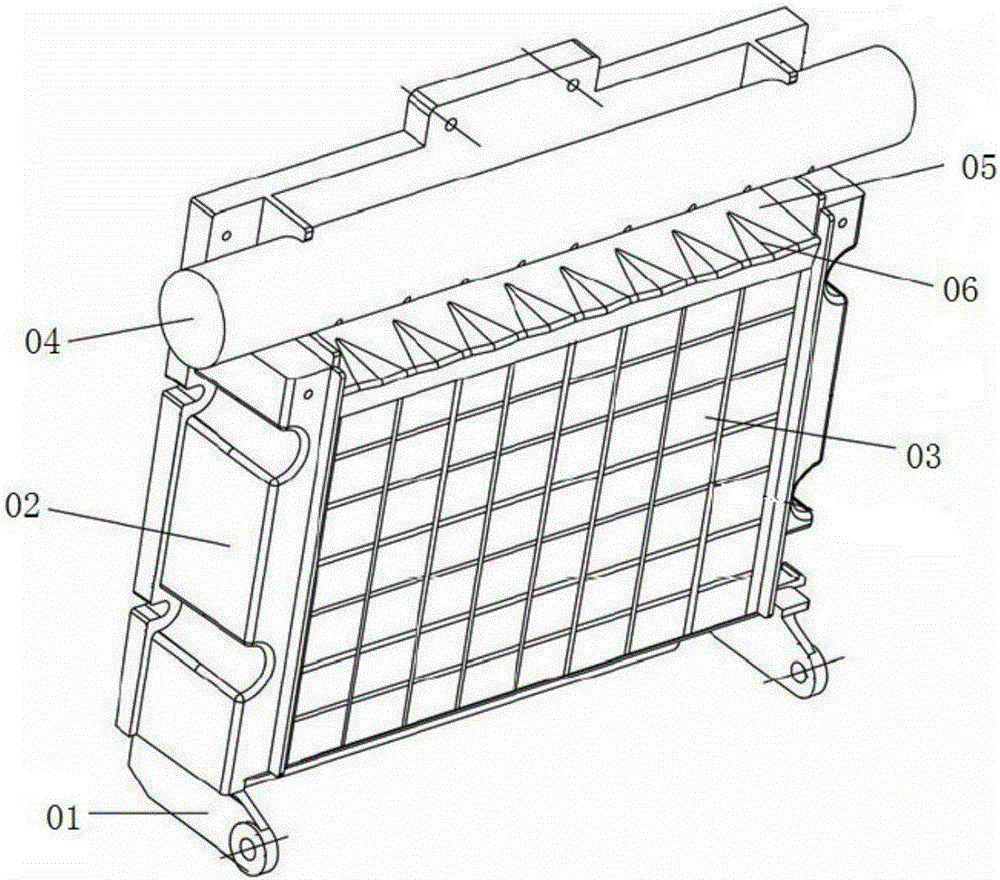

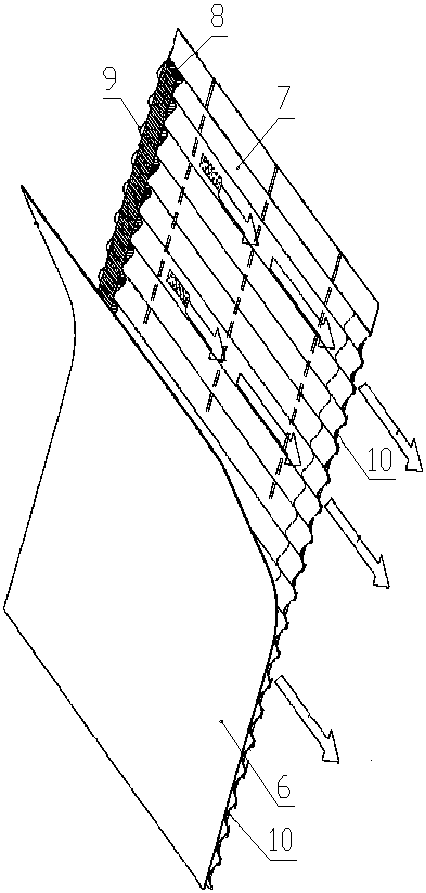

Device for guiding metal strip on gas cushion

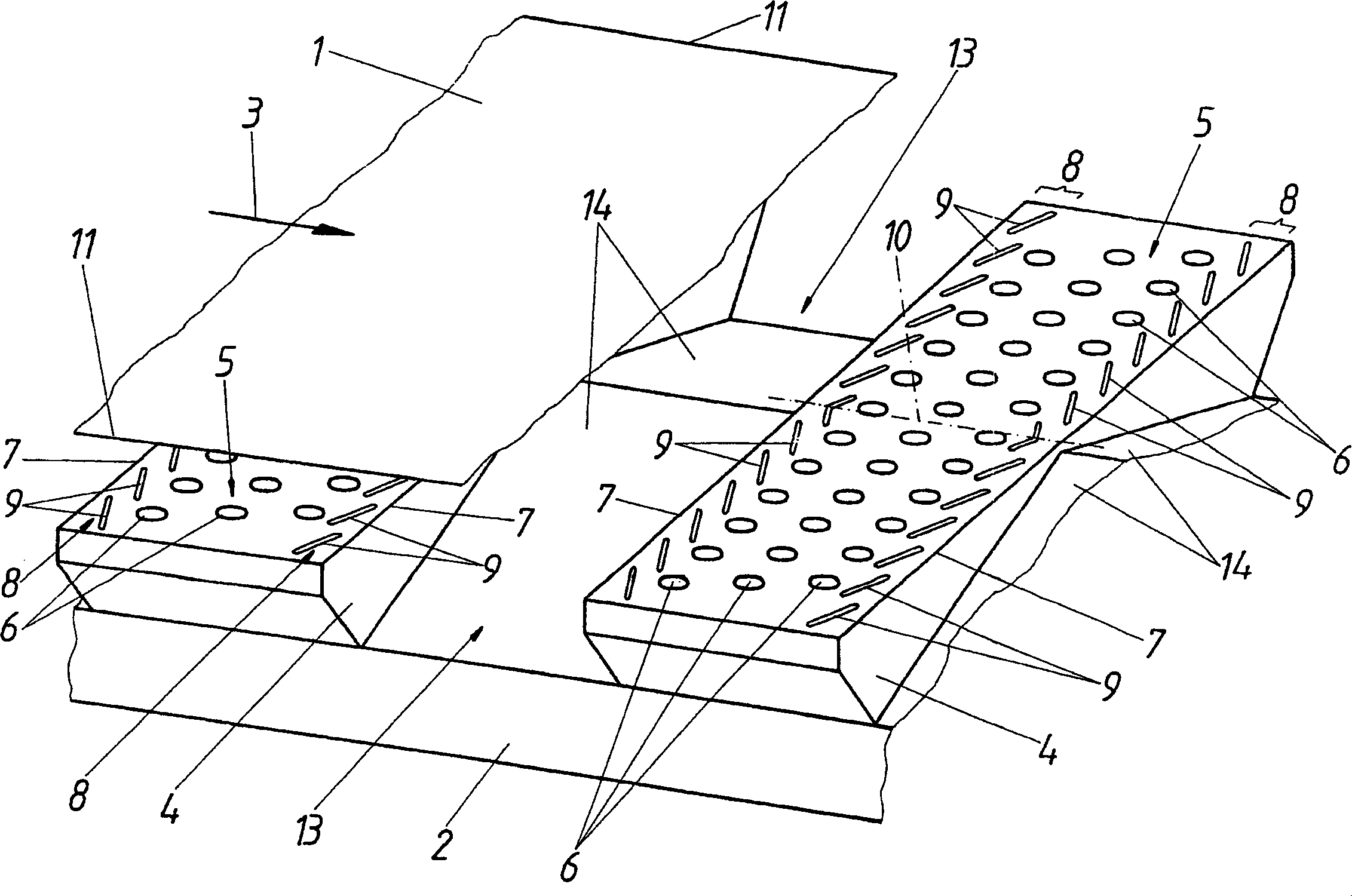

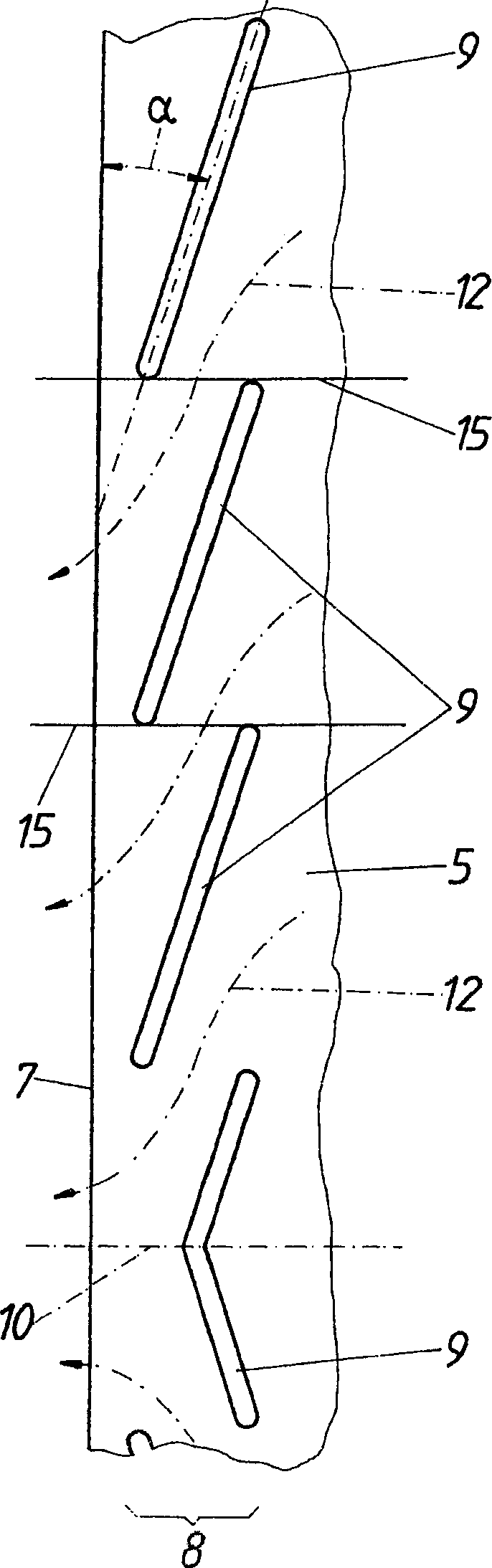

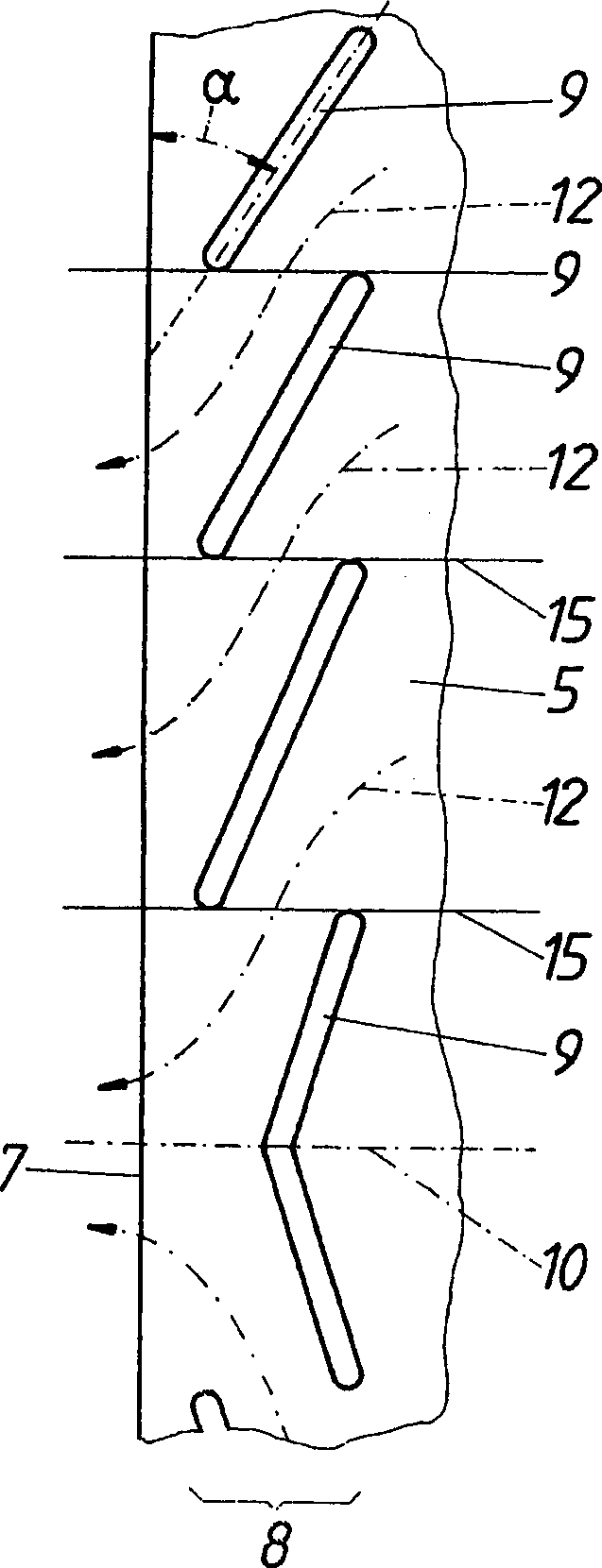

InactiveCN1427795AReduce flow rateGuaranteed normal outflowConveyorsDrying machines with progressive movementsMetal stripsEngineering

A device for guiding a metal strip (1) on a gas cushion with blast boxes (4), arranged in a row at a separation from each other, in the longitudinal direction (3) of the strip. The nozzle fields (5) of the above, which extend across the longitudinal strip direction (3), comprise hole jets (6) arranged over the field surface and slit jets (8) arranged along the edges (7) running transverse to the longitudinal strip direction (3). According to the invention, in order to achieve advantageous construction conditions, the slit jets (8) along the edges (7) comprise several jet slits (9) arranged in a series of rows, one behind the other, parallel to the edge, which, starting from the mid-point (10) of an edge, are directed inwards, relative to the edge (7).

Owner:彼得・埃布纳

Contact type printed circuit board (PCB) cleaning device

PendingCN107442491AReduce frictionEasy to moveCleaning using liquidsElectronic waste recyclingPrinted circuit boardMechanical engineering

The invention discloses a contact type printed circuit board (PCB) cleaning device. The cleaning device comprises a base, a portal, two vertical frames, inserting strips, a connecting plate, a heightening pad, an air cylinder, a supporting plate, two or more elastic supporting mechanisms, a transverse beam, a feeding mechanism and a liquid spraying mechanism, wherein the two vertical frames are symmetrically distributed along the base; and the elastic supporting mechanisms are uniformly distributed along the supporting plate. The air cylinder performs jacking so as to push and jack up the supporting plate, the elastic supporting mechanisms perform multi-point elastic supporting on a PCB, then the PCB makes contact with the liquid spraying mechanism, and a rubber pad arranged on the liquid spraying mechanism is deformed to seal an area which the rubber pad directly faces, so that the effect that cleaning liquid flows out through PCB holes is guaranteed; the liquid spraying mechanism works to uniformly spray out the cleaning liquid; and meanwhile the feeding mechanism drives the liquid spraying mechanism to perform longitudinal scanning type movement so as to clean all areas of the PCB. The contact type PCB cleaning device is simple in structure, cleaning is uniform without dean zones, and furthermore by means of contact type sealing cleaning, the cleaning liquid completely flows out through the PCB holes, so that the PCB holes are deeply cleaned and the cleaning effect is improved.

Owner:SUZHOU WUTONG ELECTRONICS CO LTD

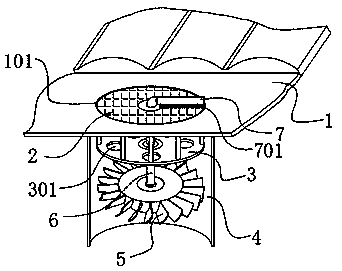

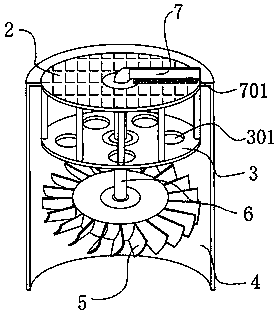

Sloping roof building rainwater drainage device

InactiveCN110331824AAvoid affecting normal drainageGuaranteed normal outflowRoof drainageAgricultural engineeringSiphon

The invention discloses a sloping roof building rainwater drainage device. The device comprises a sloping roof. A drainage groove is formed in the bottom end of the sloping roof in a penetrating mode.A grating plate is movably mounted in the drainage groove. A siphon plate is fixedly mounted at the lower end of the grating plate through connecting rods and mounted at the upper end of a drainage pipe. A turbine is rotationally arranged in the drainage pipe. The upper end of the turbine is fixedly connected with a rotary shaft. The rotary shaft movably penetrates through the middle of the siphon plate through a bearing, and in addition, the top end of the rotary shaft movably penetrates through the grating plate. The top end of the rotary shaft is located outside the grating plate and transversely and fixedly connected with a scraping plate. A bristlebrush is arranged at the bottom end of the scraping plate and makes movable contact with the top surface of the grating plate. When a water inlet of the drainage pipe is blocked, only a worker dredging method is available in the prior art. Through the rainwater drainage device provided by the invention, the turbine can be driven to rotate under the effect of rainwater flow, accordingly, the scraping plate provided with the bristlebrush is made to rotate repeatedly on the top surface of the grating plate, and tree leaves are scrapedoff the surface of the drainage pipe.

Owner:SINO RISING SUN CONSTR GRP

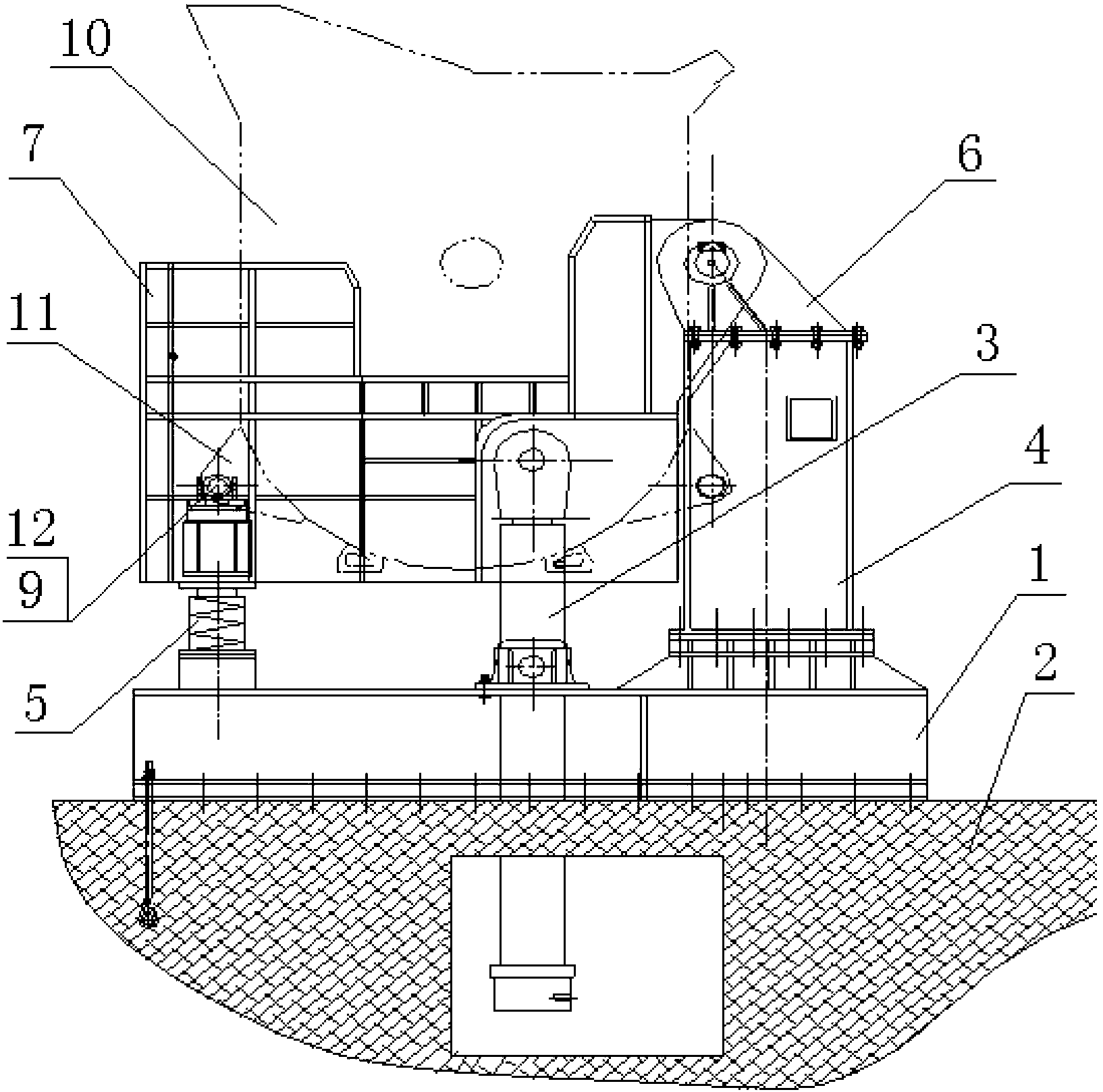

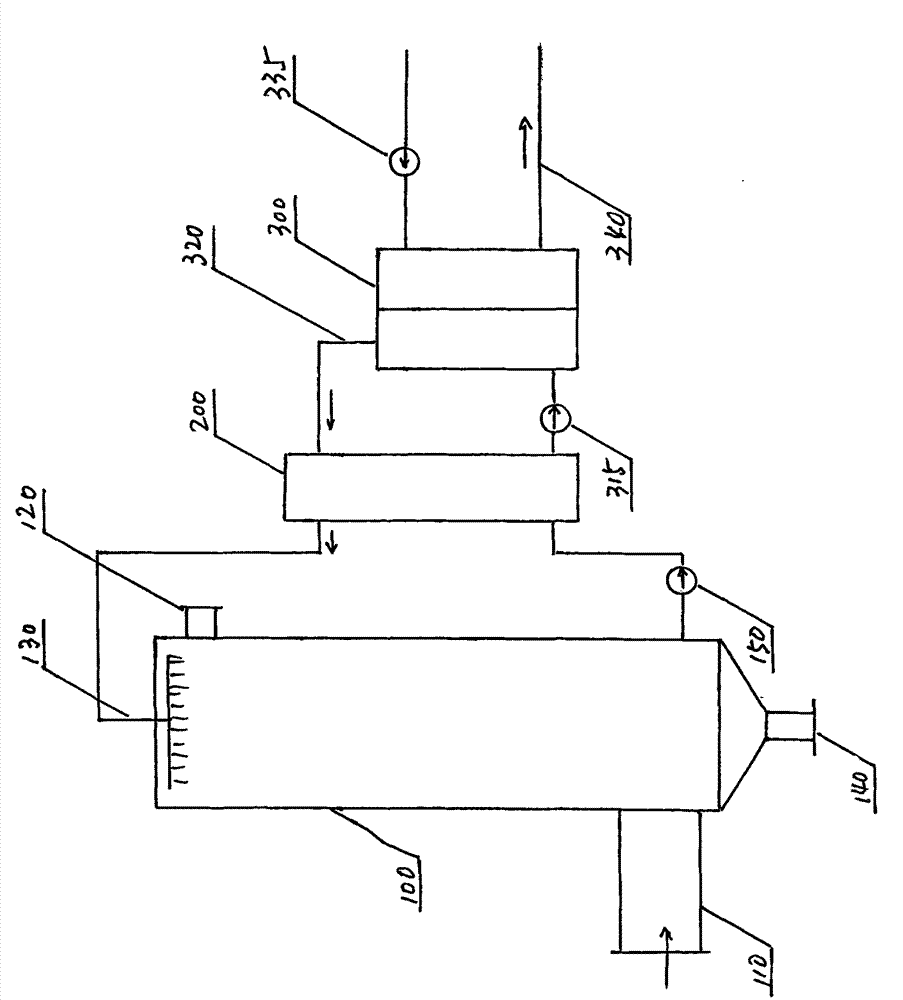

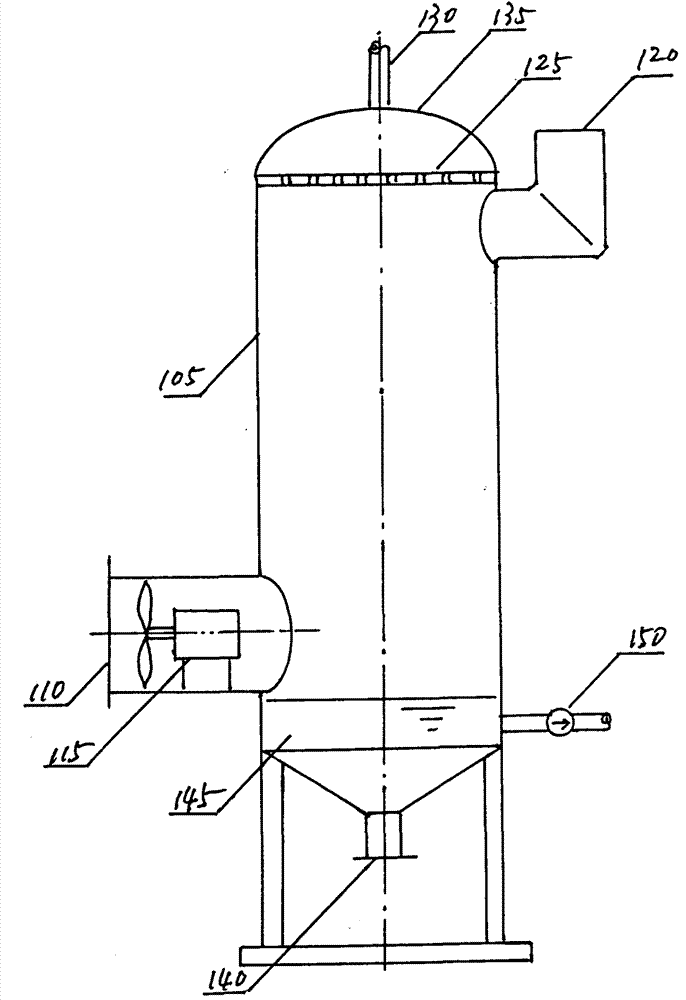

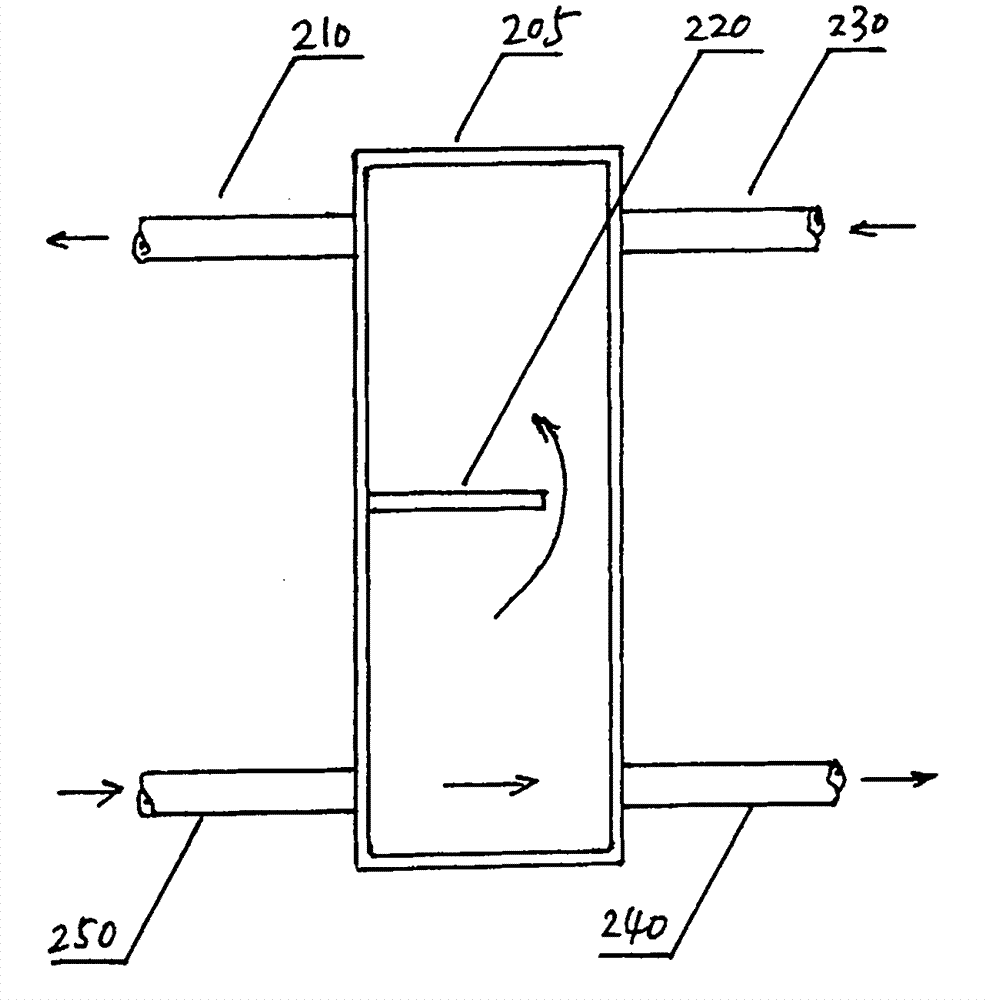

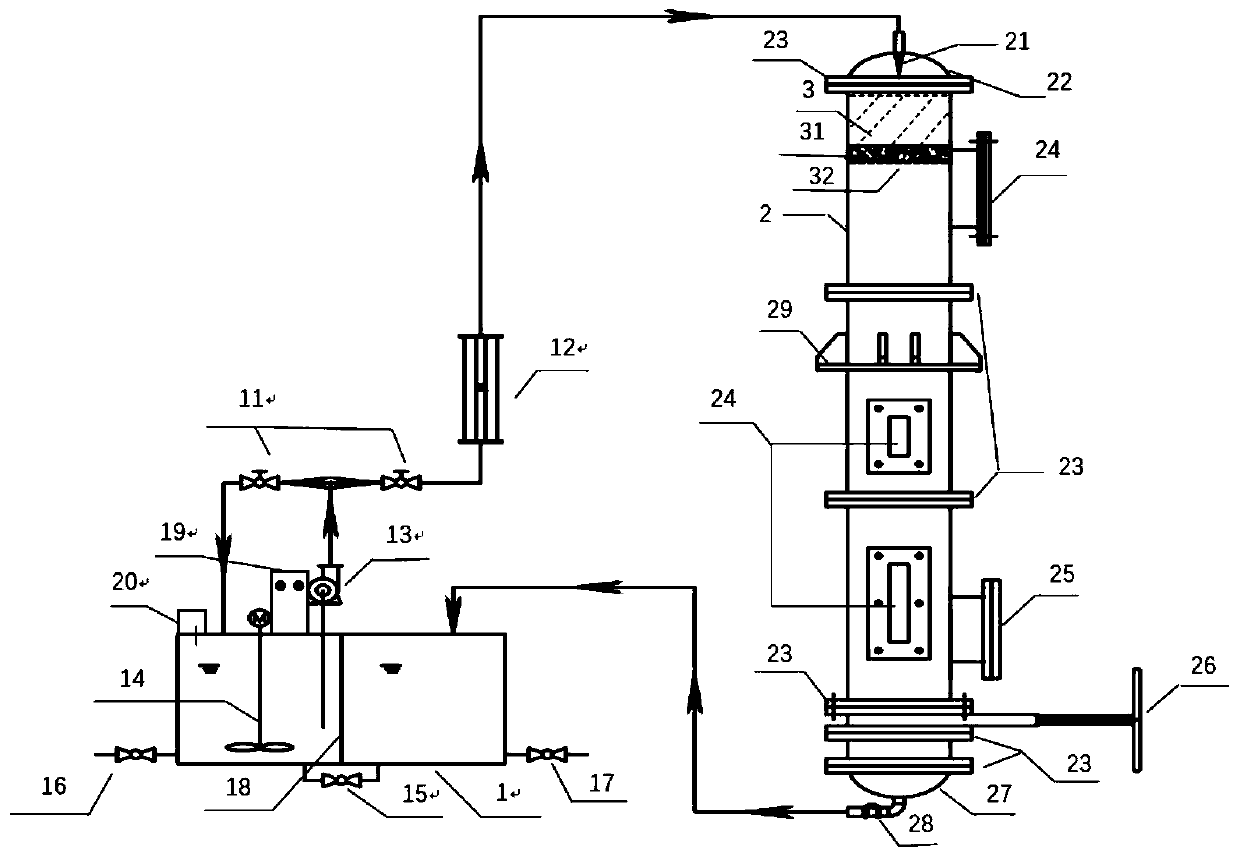

Blast furnace slag water quenching steam waste heat recovery device

ActiveCN104745751AIncrease flow resistanceGuaranteed normal outflowIncreasing energy efficiencyWaste heat treatmentWater vaporSlag

The invention provides a blast furnace slag water quenching steam waste heat recovery device. The device is composed of a spray-type heat exchanger and a runner type heat exchanger; in the spray-type heat exchanger, the water steam generated by blast furnace slag water quenching comes into contact with spraying water to exchange heat; in the runner type heat exchanger, heating circulating water exchanges heat with intermediary water, and then supplies heat to users by use of pipelines. The blast furnace slag water quenching steam waste heat recovery device is characterized by further comprising a mixed heat exchanger. Only one water baffle plate is arranged inside the mixed heat exchanger, and the other part inside the mixed heat exchanger is a cavity; the entering spraying water and the intermediary water are mixed together in addition to heat exchange; the water baffle plate functions in improving the flowing resistance, so that water flowing out of an intermediary water outlet can be completely the spraying water entering from a spraying water inlet and at a relatively high temperature; besides, the left spraying water at the relatively high temperature flows through the water baffle plate and flows out of a spraying water outlet together with the intermediary water entering via an intermediary water inlet.

Owner:HIT HARBIN INST OF TECH KINT TECH

Variable flow leaching integration device

PendingCN110361504AReasonable designSimple disassembly and assembly of equipmentConstruction waste recoverySolid waste disposalStormwaterCorrosion

The invention discloses a variable flow leaching integration device. The device comprises a fluid preparation and collection area, a leaching column, a water distribution groove and a support. The device has advantages that integration of fluid preparation, fluid inlet and collection is realized; a fluid preparation area has a stirring function; when simulated acid rain is configured, manpower andmixing unevenness can be alleviated; an online PH monitor is installed in the fluid preparation area so as to conveniently and rapidly observe a specific condition of simulated acid rain configuration; a fluid inlet flow can be adjusted, an influence of different rainfall intensities on dissolution of pollutants in different regions can be simulated; a height is changeable, the influence of different high slag heap rainwater infiltration time on the dissolution of the pollutants is studied, and the device is closer to an reality than a laboratory device; an insertion plate valve is arranged to facilitate loading and unloading of slag during engineering, and the slag can be effectively stored when a leaching solution flows out; and a material is resistant to acid and corrosion, use of a certain solid is not limited, and leaching experiments of general industrial solid wastes, hazardous wastes, urban construction wastes, soil and the like can be researched.

Owner:云南省环境科学研究院(中国昆明高原湖泊国际研究中心)

Seasoning box

The invention discloses a seasoning box, which comprises a box body and a rotating shaft, wherein the box body is a cylindrical box body which can rotate along the rotating shaft, the box body is uniformly divided by baffle plates into a plurality of fan-shaped drawers, the outer side of each fan-shaped drawer is provided with an inverted triangular opening, and the outer side of the opening is also provided with a rectangular discharging plate. A plurality of drawers are integrated, and seasoning can flow out freely by pulling the discharging plate, so that flexibility in application can be realized; and meanwhile, through the inverted triangular opening, the effluent rate of the seasoning is gradually increased.

Owner:蔡宇飞

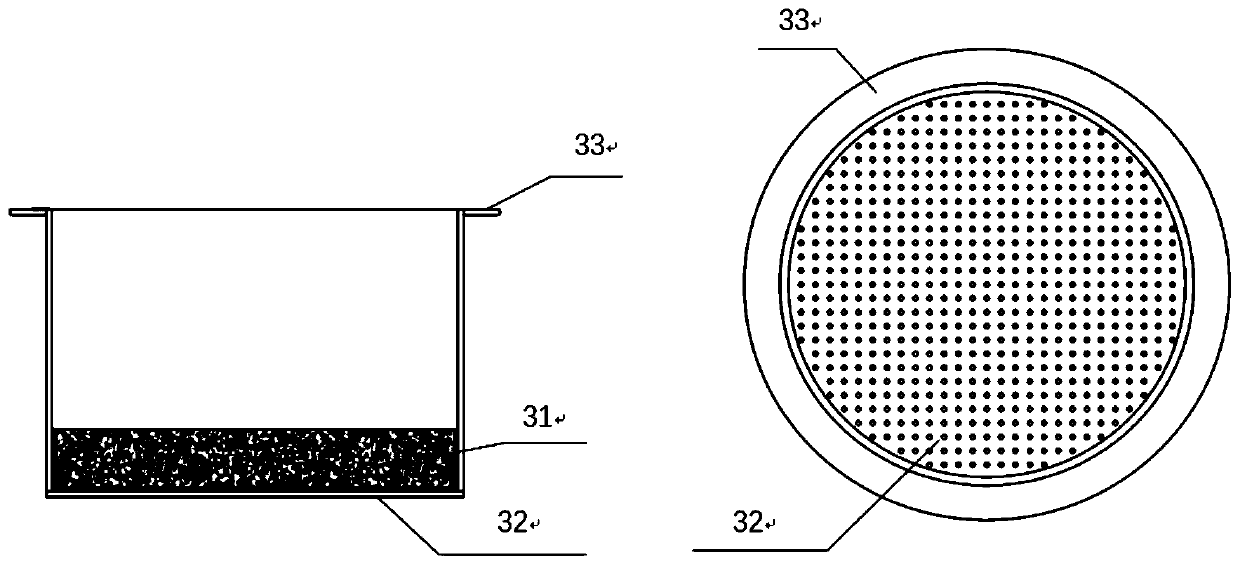

Part cleaning tank

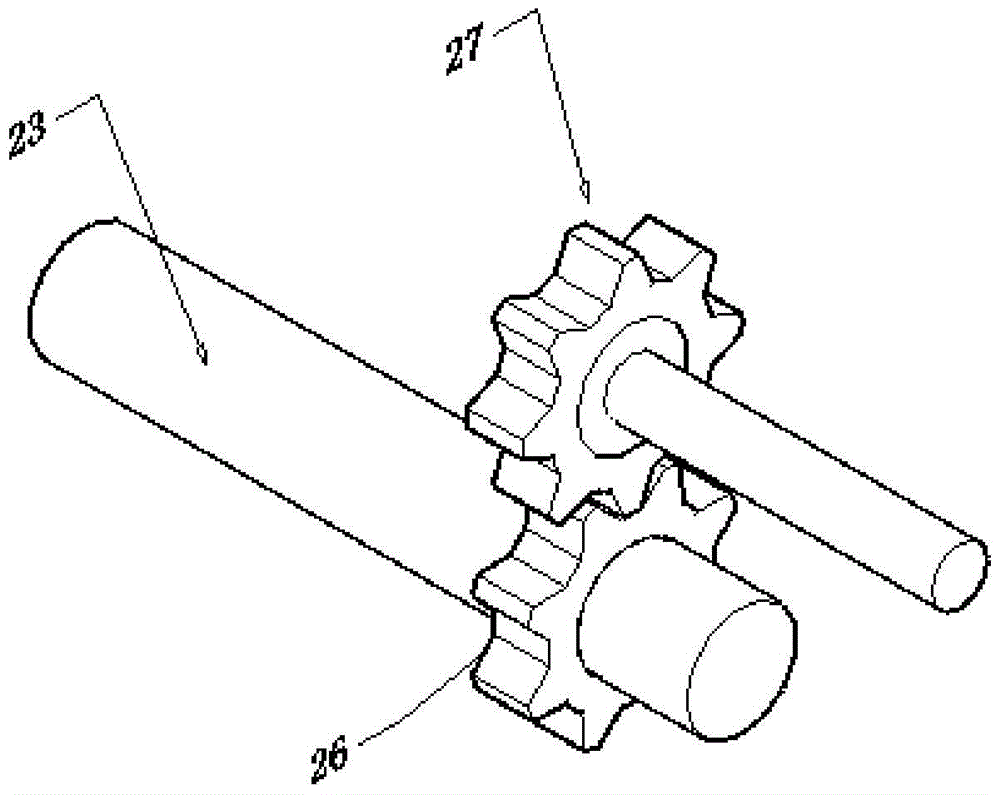

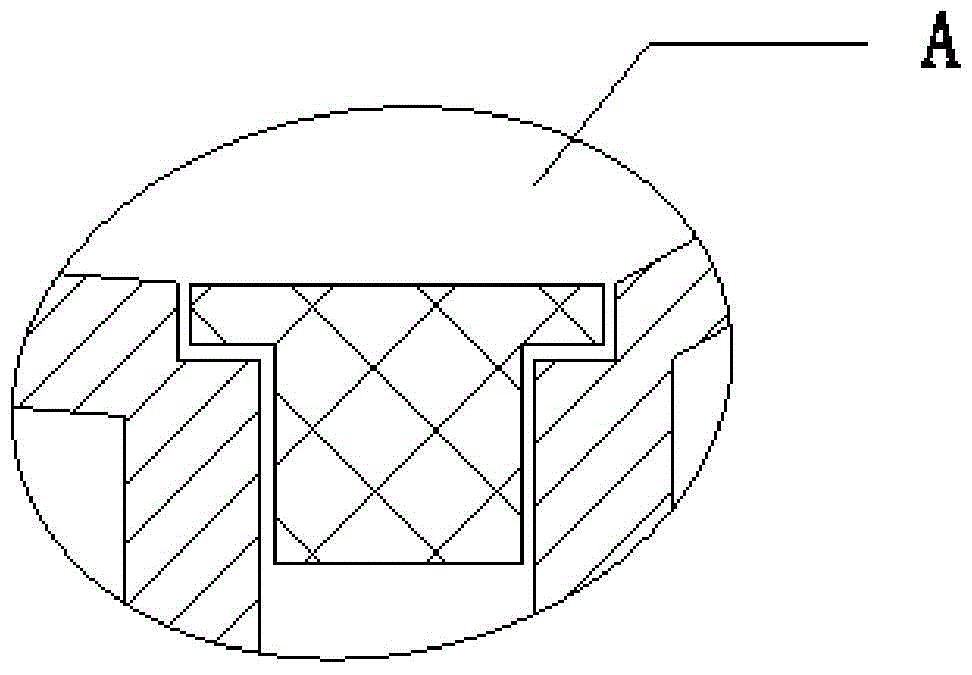

InactiveCN105750259AAvoid accumulationExtended service lifeAnti-corrosive paintsCleaning using toolsOil canDrive wheel

The invention discloses a part cleaning tank. The part cleaning tank comprises a cleaning cylinder and an oil storage cylinder located on a support, wherein an oil outlet in the bottom of the cleaning cylinder is directly connected with an oil inlet in the upper portion of the oil storage cylinder through an oil drainage pipe, an oil outlet in the bottom of the oil storage cylinder is connected with an oil inlet in the upper portion of the cleaning tank through an oil inlet pipe, and an oil well pump is arranged in the middle of an oil inlet pipeline to be used for pumping oil in the oil storage cylinder into the cleaning tank; a long shaft is arranged in the cleaning cylinder and penetrates through the cleaning cylinder, the two ends of the long shaft are inserted into the left side and right side of the inner wall of the cleaning cylinder, a gear is fixedly arranged at the right end of the long shaft, a driving wheel driven by a motor is arranged above the gear, the driving wheel is meshed with the gear to drive the long shaft to rotate, the motor is located outside the cleaning tank, and a layer of bristles adhere to the outer surface of the long shaft. The part cleaning tank is suitable for automatic cleaning of a small batch of parts, cleaning efficiency is high, hands do not get dirty easily, cleaning oil can be recycled, occupied space is small, and service life is long.

Owner:DONGGUAN QINGMAITIAN DIGITAL TECH

Glass cover and glass easy for water drinking in recumbency

ActiveCN106037389AGuaranteed normal outflowAvoid the disadvantages of being chokedDrinking vesselsGlass coverWater flow

The invention discloses a glass cover and a glass easy for water drinking in recumbency, and belongs to the field of water drinking glasses. The glass cover includes a cover body and is characterized in that the cover body is connected to a water nozzle which is provided with a first through cavity and a second through cavity therein. The cover body is provided with a water passage hole. The first through cavity on the water nozzle communicates with the water through hole on the cover body so as to form a water passage. The second through cavity on the water nozzle is inserted by a through pipe so as to form an air passage. The cover body or the water nozzle is provided with a switch apparatus which can control the on and off of the water passage and the air passage. When a user drinks water, a glass body is tilted, the user turns on the switch apparatus, and the water flow takes up part of the space of the water passage, and ambient air enters the glass body from the space left by the water passage, so that the air pressure in and out of the glass body is kept at balance so as to guarantee the water inside to flow naturally, and the user can directly enjoy the water and avoid suction. Especially for weak patients who have to lie in bed, the glass lid and the glass are very easy to use, conductive to rehabilitation, and also prevent users from being choked caused by suction of the water which is often the case of prior art.

Owner:淄博领智智能科技有限公司

Copper indium gallium selenide (CIGS) thin-film solar cell window layer and preparation method thereof

ActiveCN106684184AEasy to operateConducive to productionFinal product manufacturePhotovoltaic energy generationCopper indium gallium selenide solar cellsCopper indium diselenide

The invention discloses a copper indium gallium selenide (CIGS) thin-film solar cell window layer which is composed of a lower film layer and an upper film layer from bottom to top. The lower film layer is a doped ZnO film layer, the upper film layer is an ITO film layer or a doped ZnO film layer, and when the lower and upper film layers are both doped ZnO film layers, the lower and upper film layers are different doped ZnO film layers. The invention also discloses a preparation method thereof. Two different films can be deposited with a common DC power supply without additional equipment, the operation is convenient, and production is facilitated. When the lower film layer is deposited, a different doped ZnO target material can be selected to obtain the lower film layer satisfying the production requirement by adjusting the deposition temperature, atmosphere, air pressure, power and so forth, the obtained lower film layer is combined with the continuously produced upper film layer to match with the entire battery, the production efficiency is improved in the process, the production cost is reduced, and the film quality is easy to control.

Owner:浙江尚越新能源开发有限公司

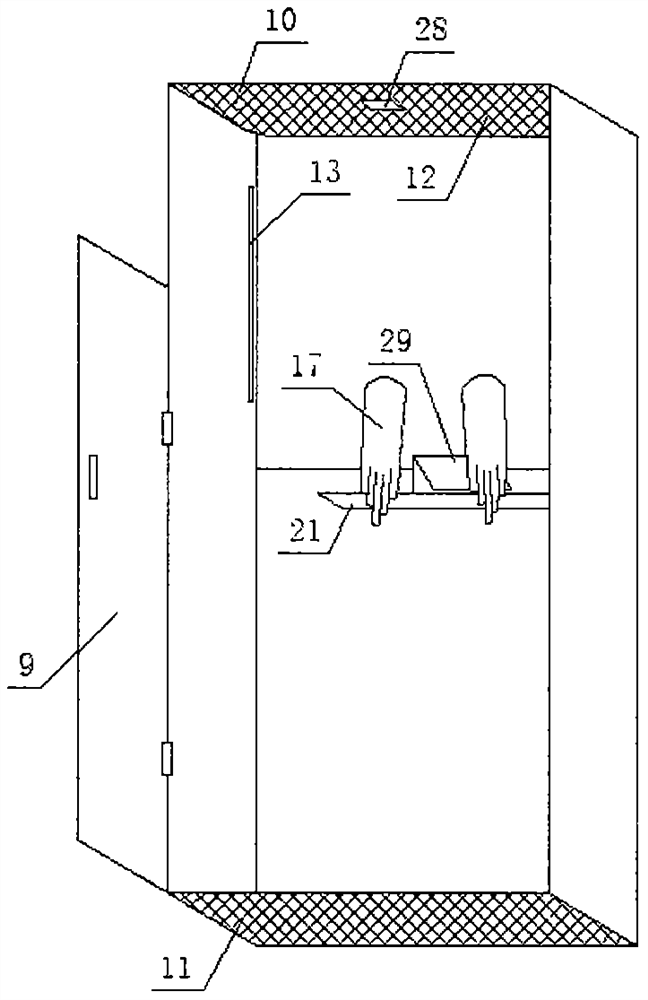

Throat swab sampling safety protection operation apparatus

PendingCN112137655AEasy to operateSimple structureSurgeryVaccination/ovulation diagnosticsThroat swab sampleThroat swab

The invention discloses a throat swab sampling safety protection operation apparatus, and relates to the technical field of medical protection equipment. According to the throat swab sampling safety protection operation apparatus, the risk that medical staff and normal collected people are infected during current throat swab collection is solved. The throat swab sampling safety protection operation apparatus is provided with a negative pressure system, a collection chamber, an isolation chamber, a waste collection bag and a throat swab culture tube collection bag, wherein a transparent isolation plate is sequentially provided with a waste collection bag fixing sleeve pipe, two sealing arm gloves and a throat swab culture tube collection bag fixing sleeve pipe. The throat swab sampling safety protection operation apparatus is simple in structure and easy to operate, and the hidden danger that medical staff and other sampled personnel are infected is completely eliminated.

Owner:关丙喜

Domestic sewage filtering device

InactiveCN113384937AGuaranteed normal outflowTo achieve the goal of self-clearingStationary filtering element filtersWater flowSewage

The invention relates to the technical field of advanced environmental protection industry, and discloses a domestic sewage filtering device which comprises a filter tank, a sewer pipe communicated with an inner cavity of the filter tank is fixedly mounted at the bottom of the filter tank, a limiting block is fixedly connected to the inner wall of the sewer pipe, a fixing frame is placed in the inner cavity of the sewer pipe and located above the limiting block, a top head is fixedly mounted on the surface of the fixing frame, a reset spring is fixedly mounted in the middle of the fixing frame, and a filter screen is fixedly mounted at the other end of the reset spring. The top head is arranged at the bottom of the filter screen, and meanwhile, the filter screen is jacked up through the reset spring, so that when the filter holes are blocked, the gravity is increased due to the increase of a medium in the filter screen, the reset spring is compressed, the blocked filter holes are jacked up through the top head, and blockage cleaning is realized at the blocked positions of the filter holes at the bottom of the filter screen; water flow in the inner cavity of the filter screen can flow out through the filter holes in the bottom of the filter screen, and finally the purpose of automatic blockage clearing is achieved.

Owner:深圳市弘欣德网络科技有限公司

High-coverage adjustable limestone feeding device for sewage treatment device

InactiveCN109248573AImprove rigidityLess likely to break and collapseTransportation and packagingMixer accessoriesEngineeringSewage treatment

The invention relates to a high-coverage-rate adjustable limestone feeding device for a sewage treatment device. The high-coverage adjustable limestone feeding device comprises a device body and an air blower connection pipeline, wherein the lower end of the device body is connected with a base; fixing columns are arranged on both sides of the upper end of the device body; the air blower connection pipeline is fixed to the left side of the lower end of the device; the right side of the air blower connection pipeline is provided with a connection pipeline; limiting blocks pass through the middle parts of the inner sides of the fixing columns; a storage tank is embedded into the right ends of the limiting blocks. By adopting the high-coverage adjustable limestone feeding device, the device body and the fixing columns are welded integrally, placed in a horizontal-vertical state, and made of a stainless steel material, so that the limestone feeding device has high rigidity, and is not prone to fracturing and collapsing in a using process. Meanwhile, the whole device is placed in the horizontal-vertical state, so that the whole device can run normally in the running process.

Owner:FOSHAN UNIVERSITY

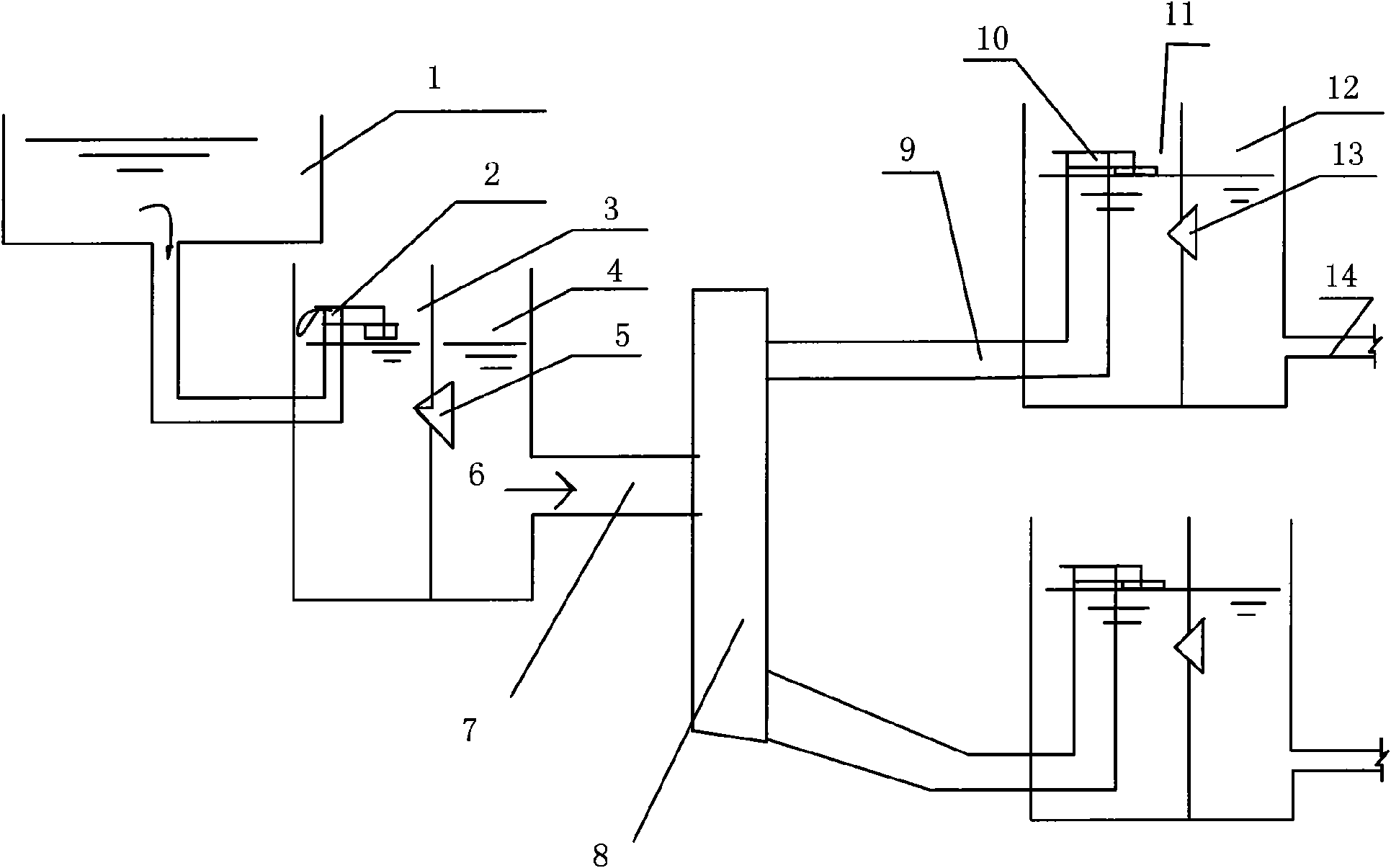

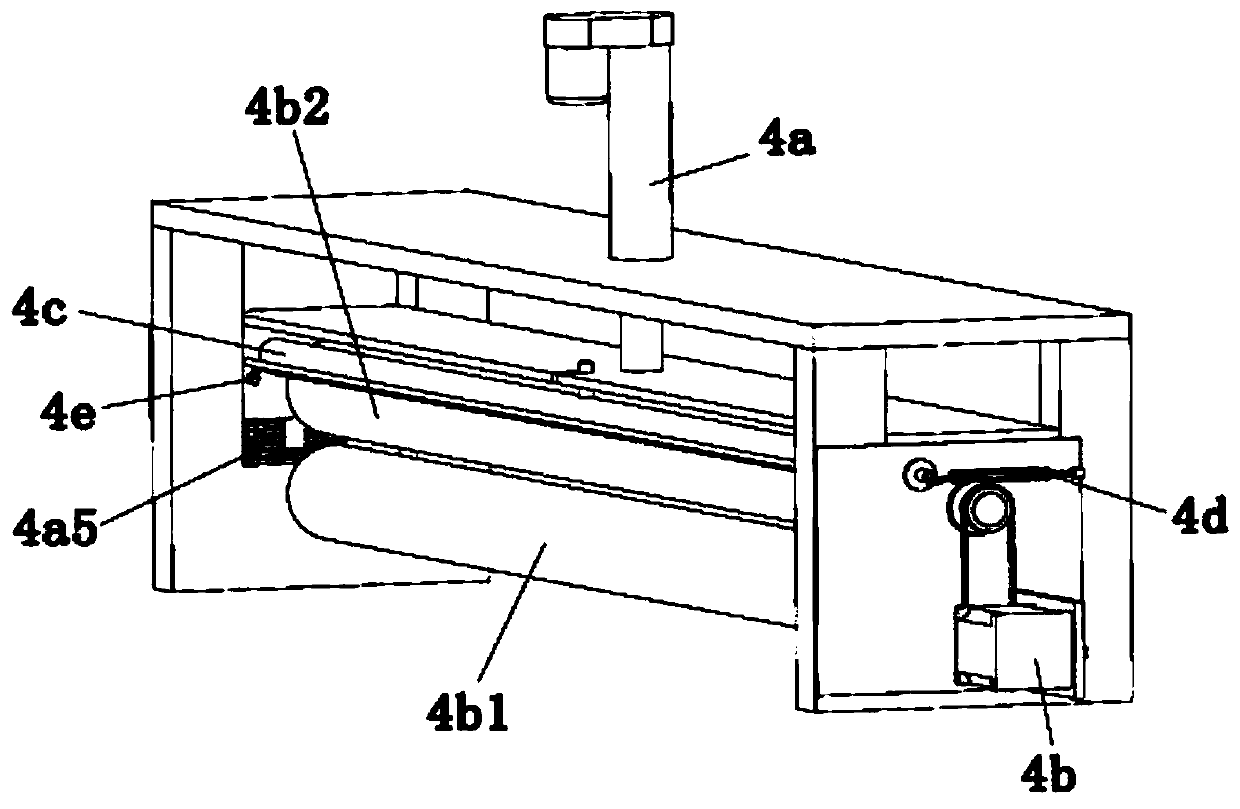

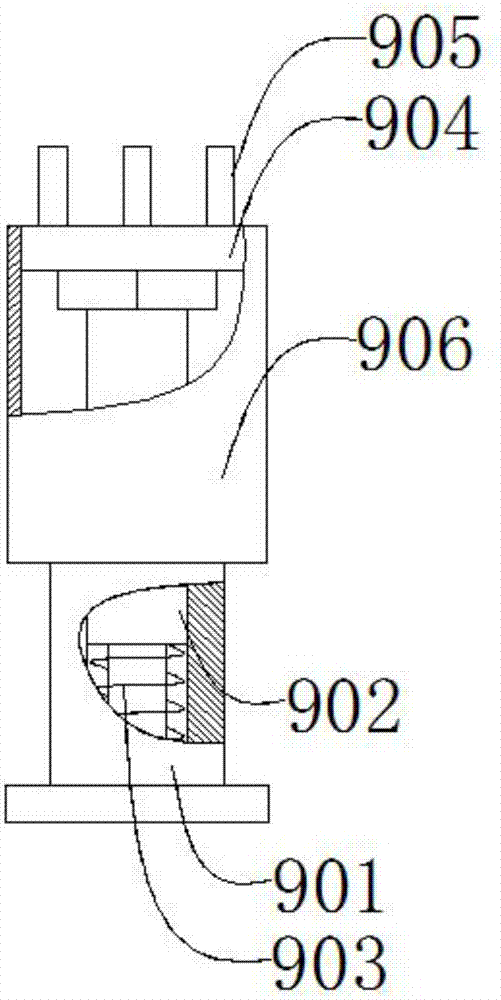

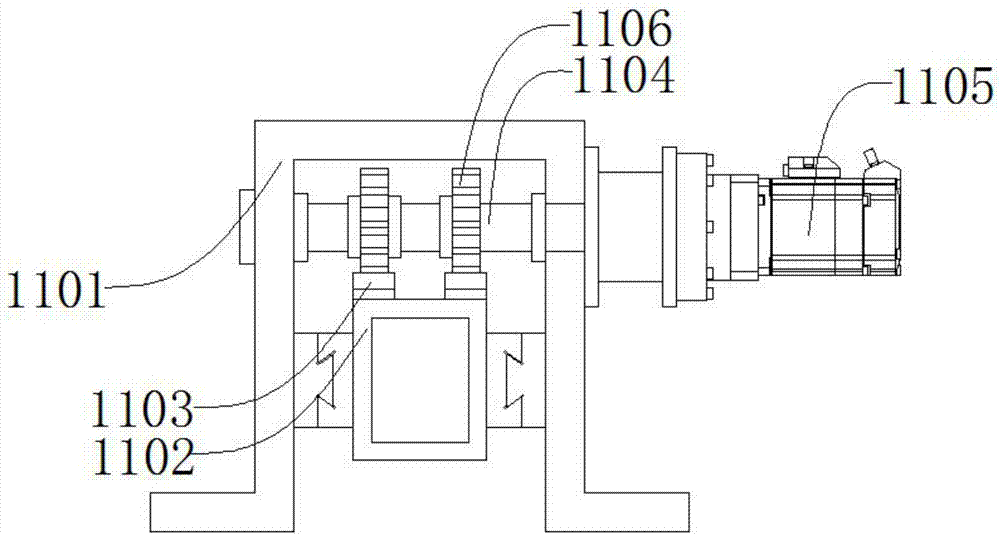

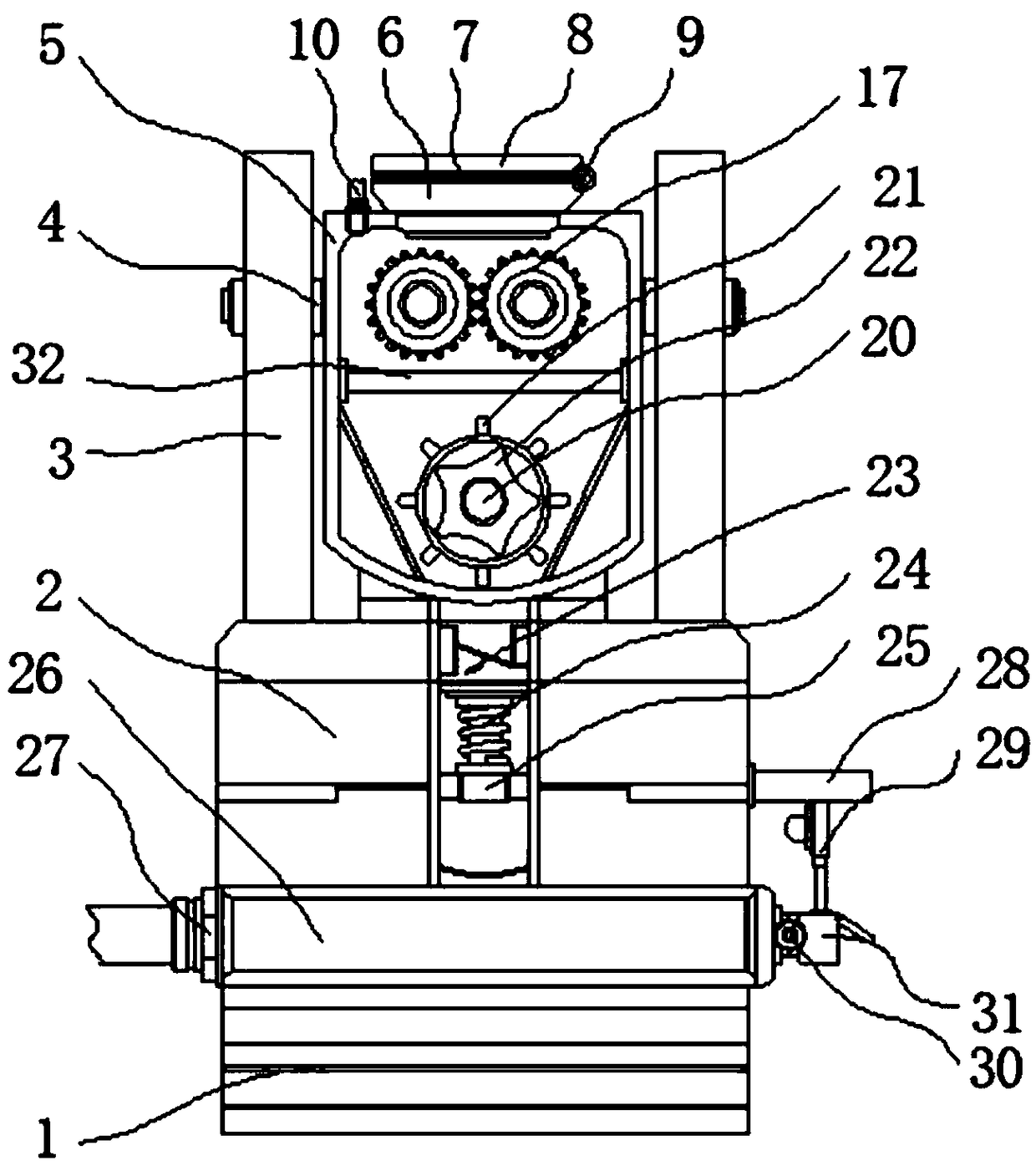

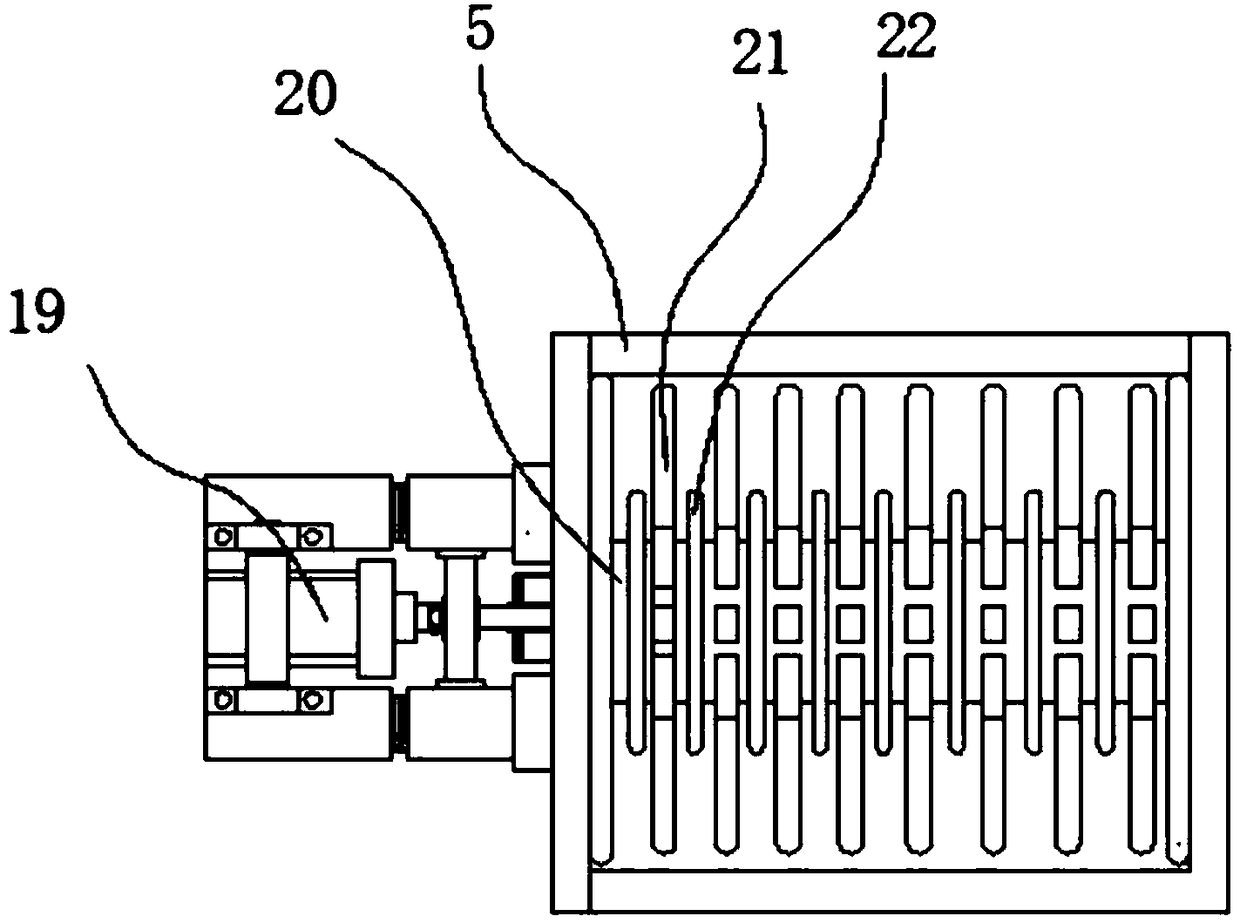

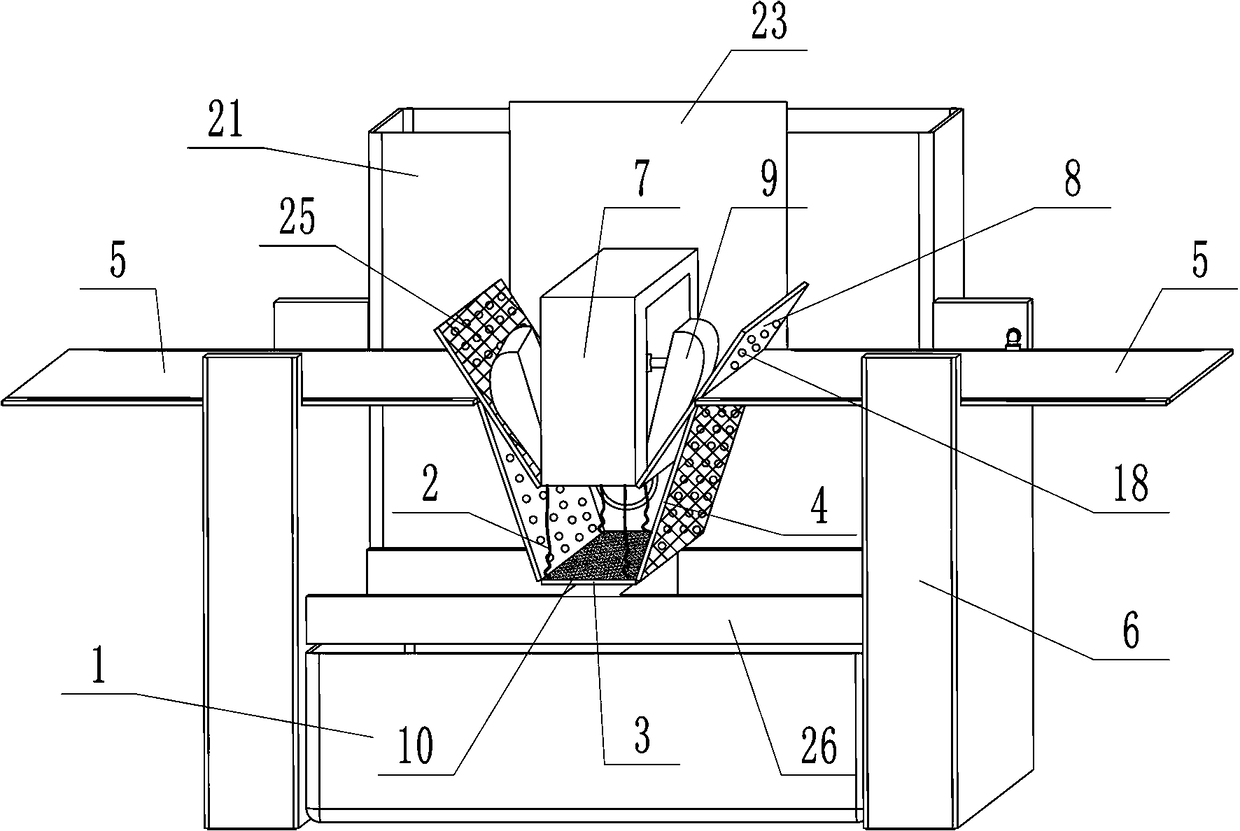

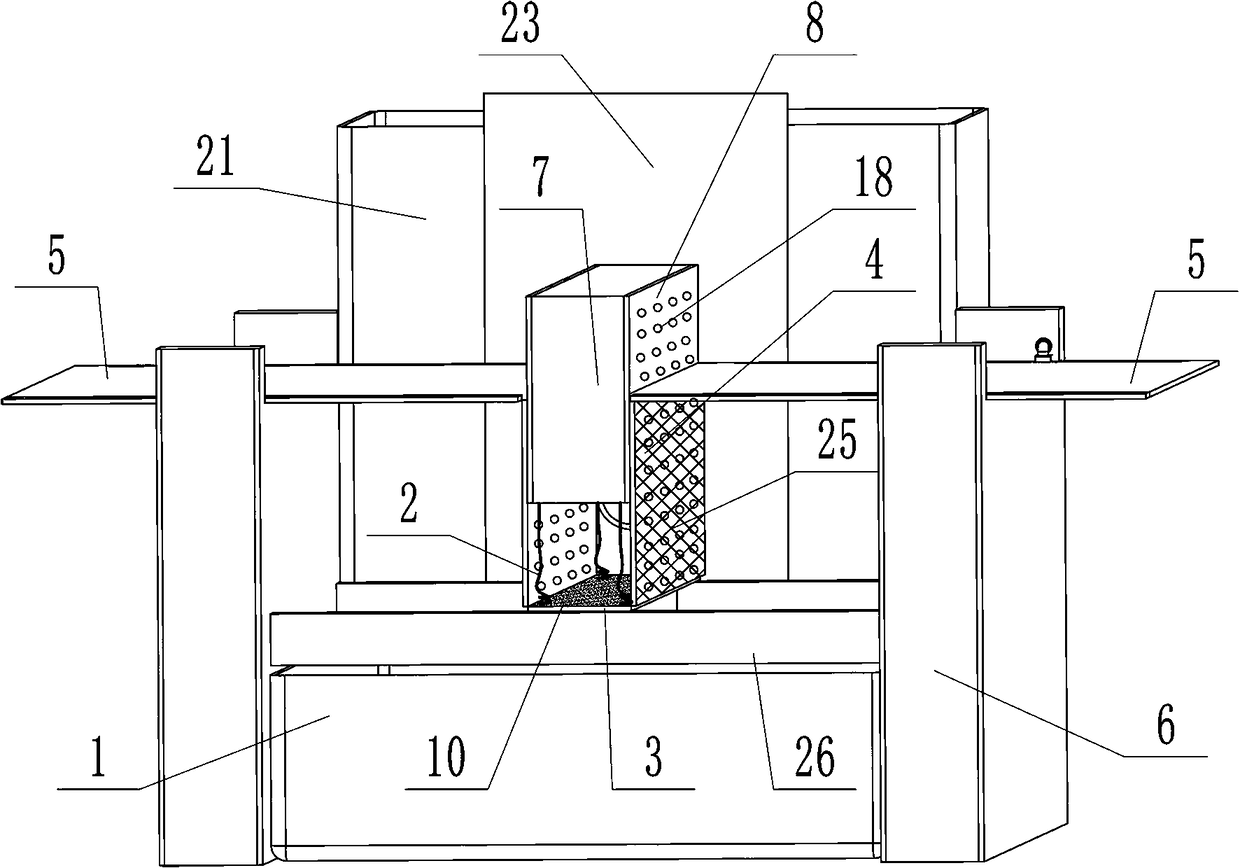

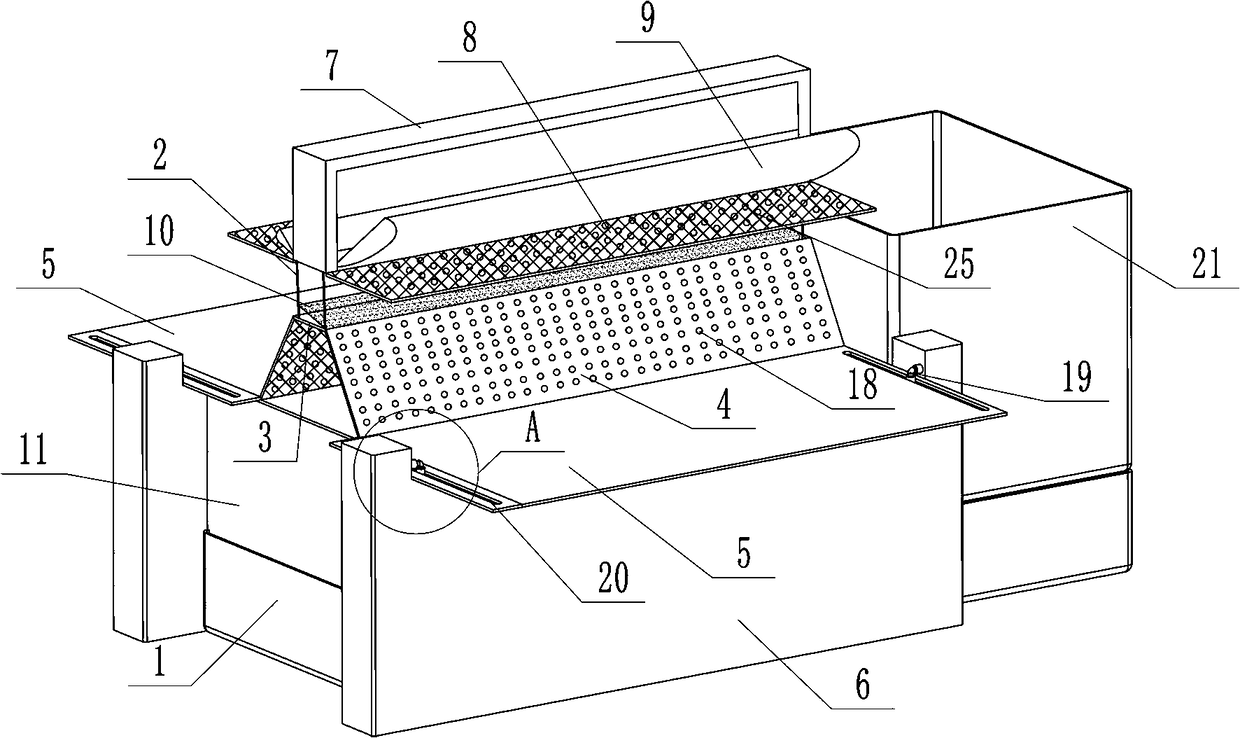

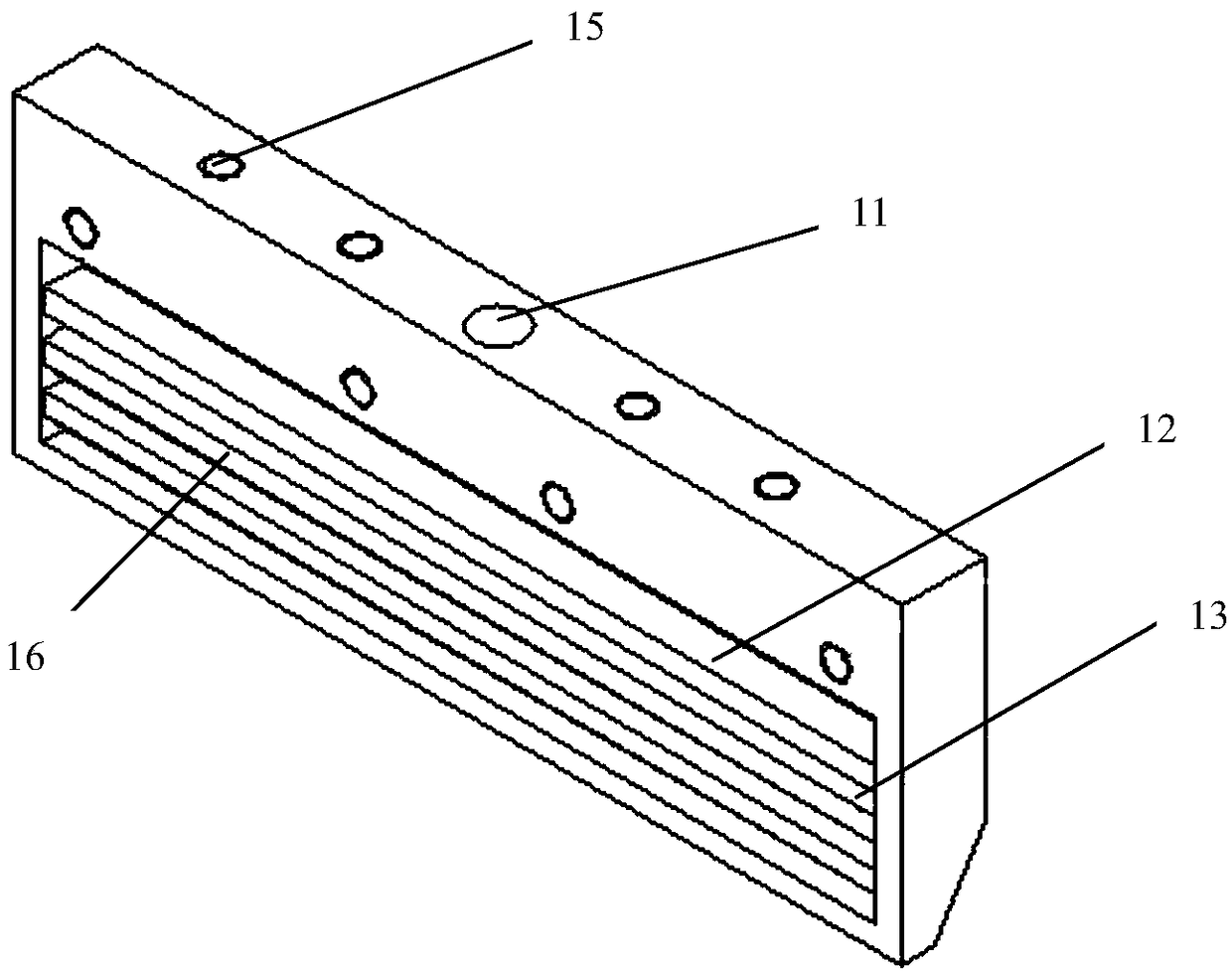

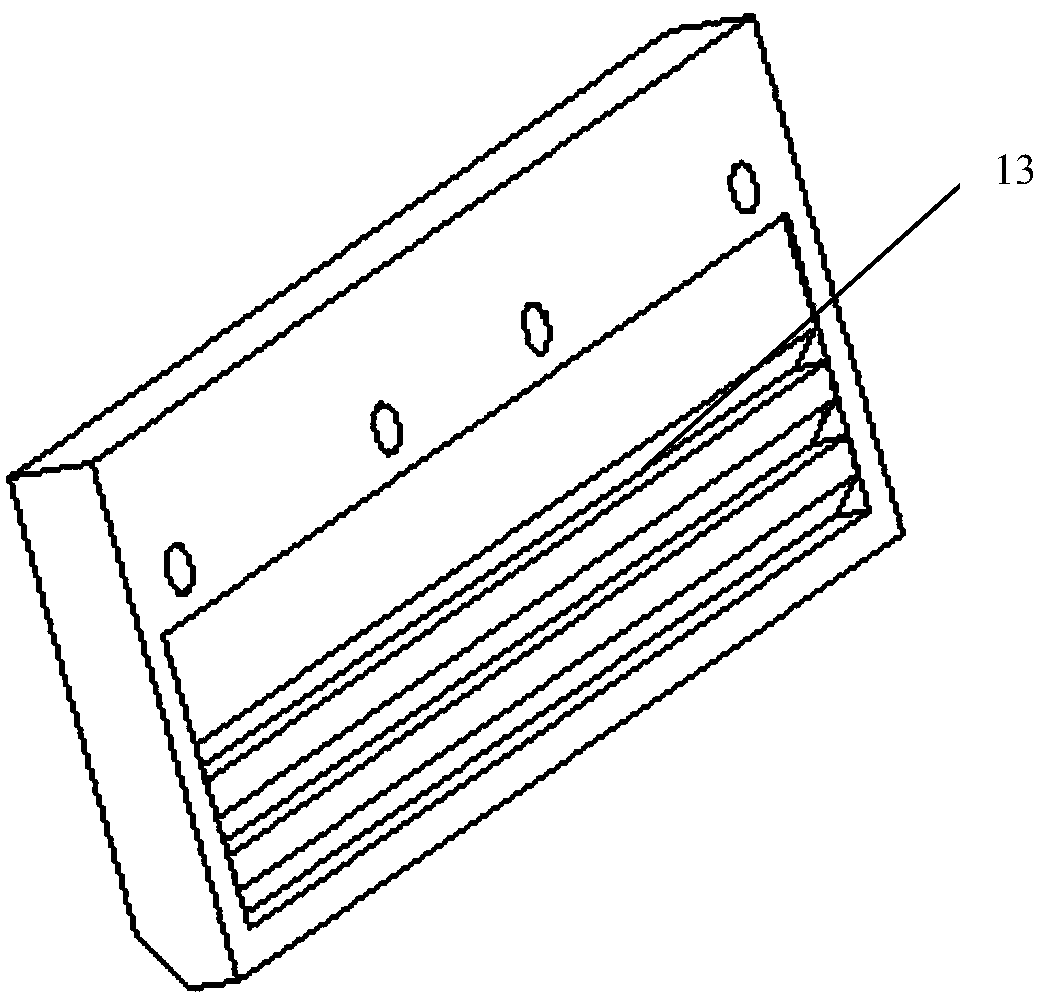

City sludge solid impurity separation mechanism

ActiveCN108609818AEasy to separateGuaranteed normal outflowSludge treatment by de-watering/drying/thickeningSludgeSlide plate

The invention relates to a city sludge solid impurity separation mechanism which comprises a sludge filtering mechanism and a sludge extrusion mechanism, wherein the sludge filtering mechanism is usedfor containing sludge; the sludge extrusion mechanism is used for extruding the sludge filtering mechanism; the sludge filtering mechanism is connected with the sludge extruding mechanism through a steel wire rope; a plurality of filtering holes are formed in the sludge filtering mechanism; the sludge extruding mechanism is used for extruding and filtering sludge after being pressed down; the sludge extruding mechanism is lifted up to drive the sludge filtering mechanism to turn over through the steel wire rope to automatically pour out compacted impurities. As further improvement of the mechanism, the sludge filtering mechanism comprises a central plate, two side filtering plates which are rotationally arranged on two sides of the central plate, and two sliding plates which are respectively rotationally connected with the two side filtering plates; the two sliding plates are respectively arranged on two support bases in a sliding manner; the two side filtering plates, the two slidingplates and the two support bases are respectively and symmetrically arranged about the central plate.

Owner:江苏晟通固废环保处置有限公司

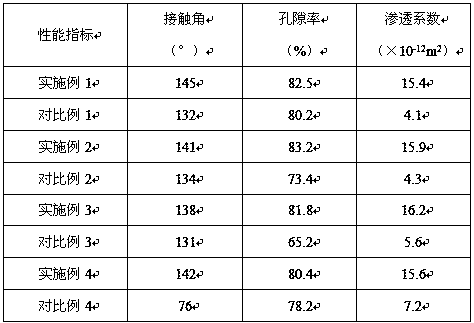

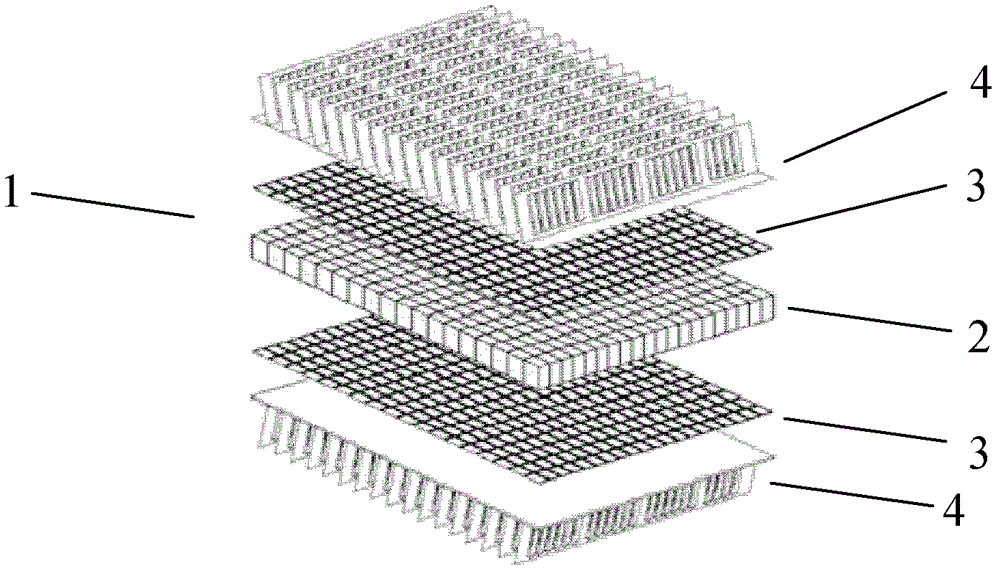

A method for promoting liquid-phase water discharge from a gas diffusion layer of a fuel cell

InactiveCN109103463AEnsure gas-liquid balanceGuaranteed normal outflowCell electrodesFuel cellsFiberFuel cells

A method for promoting liquid-phase water discharge from a gas diffusion layer of a fuel cell is provided. The method comprises following steps: at first, an organic material is put in a flow guidinggroove of an electrode plate, a hollow tubular array is grown on the surface of the organic material, and then carbon fibers are arranged between the array layers for filling and hydrophobic treatmentis performed to form a structure in which the hydrophobic hollow tubular array is directly connected with a metal electrode plate flow guide groove, so that the liquid phase water in the gas diffusion layer of the fuel cell can be discharged in a timely manner. The method provided by the invention provides a good liquid flow channel for the gas diffusion layer, thereby effectively suppressing water flooding inside the gas diffusion layer, simultaneously separating gas from liquid in the gas diffusion layer, ensuring the concentration of fuel gas, and ensuring the durability of the gas diffusion layer and even the whole fuel cell.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

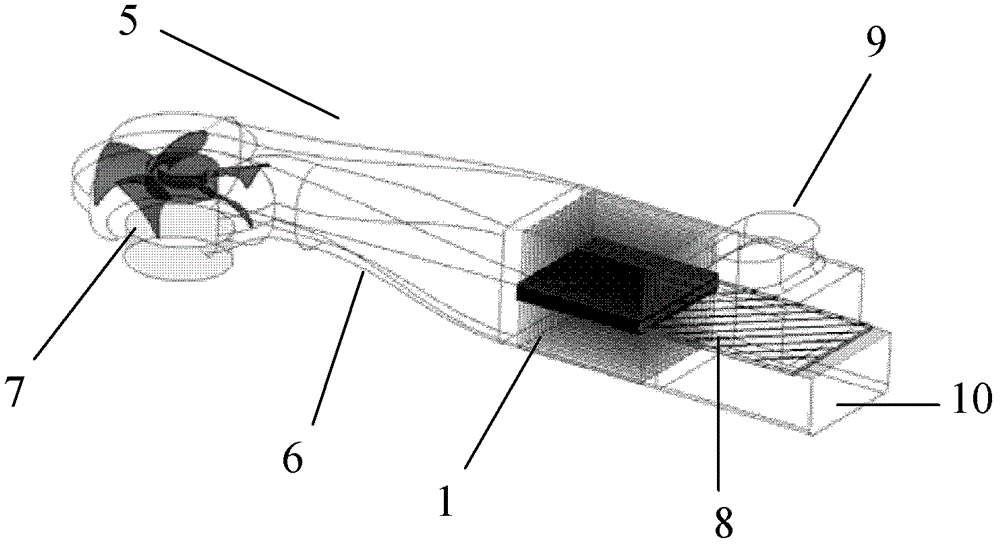

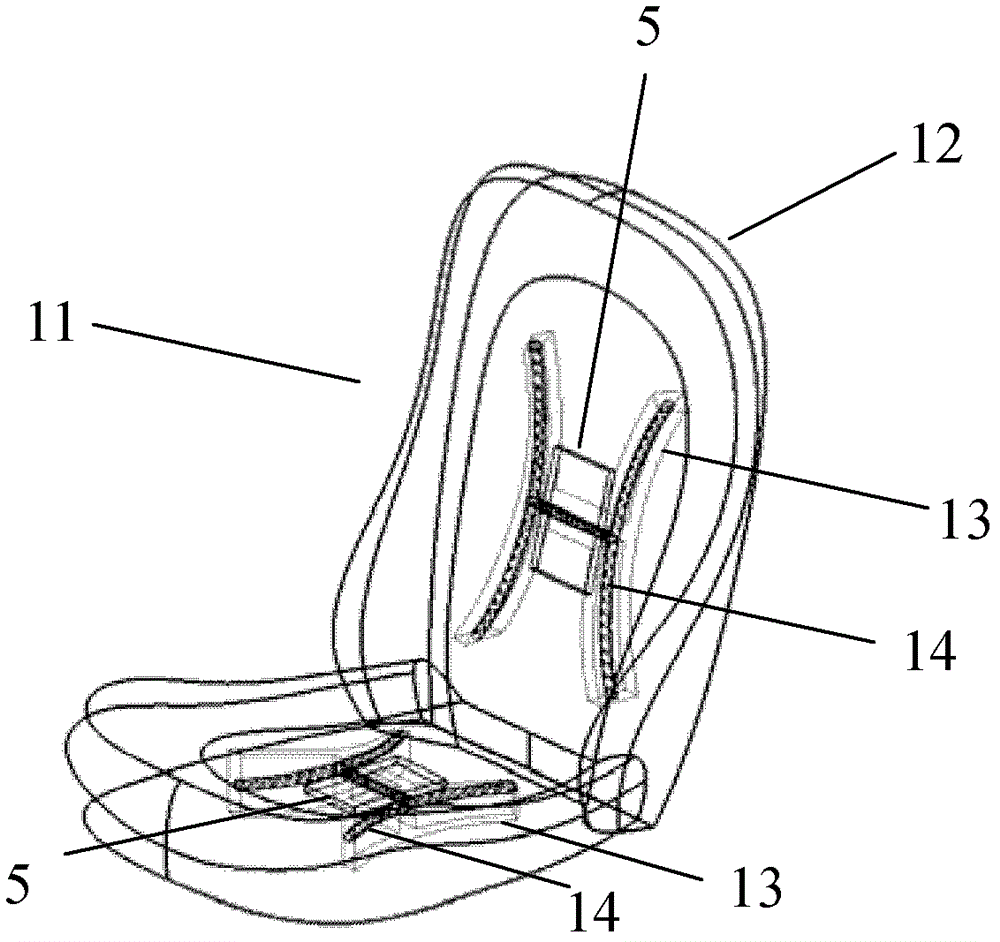

Thermoelectric air conditioning unit and car air conditioning seat with the same

ActiveCN103057449AOvercome fragileWeld tightlySeat heating/ventillating devicesBusiness efficiencyAutomobile air conditioning

The invention aims to provide a thermoelectric air conditioning unit and a car air conditioning seat with the same. The car air conditioning seat with the thermoelectric air conditioning unit is suitable for a car and energy efficiency ratio is improved. The thermoelectric air conditioning unit comprises thermoelectric devices, copper-clad films and cooling fins. The copper-clad films are arranged on the upper and lower sides of the thermoelectric devices, and the cooling fins are arranged on the sides of the copper-clad films in a laminating mode, opposite to the thermoelectric devices.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Fuel filter filtering element, rotary mounting type fuel filter and plastic housing fuel filter

PendingCN108457783AReduced service lifeEasy to manufactureMachines/enginesLiquid fuel feedersFlameoutFilter media

The invention discloses a fuel filter filtering element which comprises a filtering element shell which comprises a medium supporting part, a taper part and an in-out opening part which are connectedin sequence, and the cross section of the taper part is in a horn shape; a filtering body is arranged on the inner surface of the medium supporting part in an interference sealing fit manner, the filtering body is formed by tightly winding two layers of filtering media, the structures of the two layers of filtering media are the same, and the two layers of filtering media comprise flat-plate filter paper and corrugation filter paper; one end of the corrugation filter paper in the width direction and is flush with the flat-plate filter paper, an interval is reserved between the other end of thecorrugation filter paper and the end of the flat-plate filter paper, and a glue solution pasting layer is arranged at the interval; the closed end of the first layer of filtering medium is flush withthe opening end of the second layer of filtering medium; and an anti-flameout structure is arranged on the position, where the taper part is located, of the filtering element shell. By means of the fuel filter filtering element, engine flameout can be prevented, and the service life of the fuel filter filtering element is prolonged.

Owner:PINGYUAN FILTER

Multi-level expansion cavity sprayer

PendingCN108212567AGuaranteed normal outflowSolve mucous membrane problemsSpray nozzlesCleaning using gasesRight triangleAirflow

The invention relates to a cleaning device, and aims at providing a multi-level expansion cavity sprayer. The sprayer can spray high-frequency turbulent flow, the situation that airflow impacts on a photovoltaic panel, and an adhering film is formed is avoided, and the beneficial effects of high efficiency and thorough dust removal are achieved. According to the technical scheme, the multi-level expansion cavity sprayer comprises front shells, a rear shell and n-shaped gaskets located between the front shells and the rear shell; the front shells, the rear shell and the gaskets are fixedly connected through connecting pieces; the face, facing the corresponding gasket, of each front shell is provided with a rectangular groove so that a rectangular air storage cavity temporally storing airflow can be formed, wherein an air inlet hole penetrating the wall part of the front shell for high-pressure gas input is formed above the rectangular groove; a plurality of right-angle triangular grooves are manufactured in the part, below the corresponding rectangular groove, of each front shell, and horizontally-arranged and mutually-parallel trapezoid columns arranged at the interval of a certaindistance in pairs are formed between every two right-angle triangular grooves and between the right-angle triangular grooves and the rectangular groove; and the rear shell is symmetrically provided with trapezoid columns, wherein the number of the trapezoid columns is the same with the number of the front shells, and the trapezoid columns correspond to the front shells in position.

Owner:ZHEJIANG SCI-TECH UNIV

Epoxy resin chemical coating production method

ActiveCN112403298AEasy to cleanAvoid cleaning effectsTransportation and packagingMixing methodsPolymer scienceEpichlorohydrin

The invention discloses an epoxy resin chemical coating production method in the field of chemical engineering. The production method comprises the following steps of S1, taking bisphenol A, epoxy chloropropane and alkali liquor, S2, adding the raw materials in the step S1 into an emulsifying machine for heating and stirring, and S3, putting the coating obtained in the step S2 into a barrel for later use. Through the S1, S2 and S3, the heating area is enlarged, the stirring efficiency is improved, and the problem that the barrel body is difficult to clean is solved.

Owner:惠州市飞世尔实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com