Fuel filter filtering element, rotary mounting type fuel filter and plastic housing fuel filter

A technology of fuel filter and filter, which is applied in the direction of charging system, machine/engine, liquid fuel feeder, etc., and can solve problems such as engine stalling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

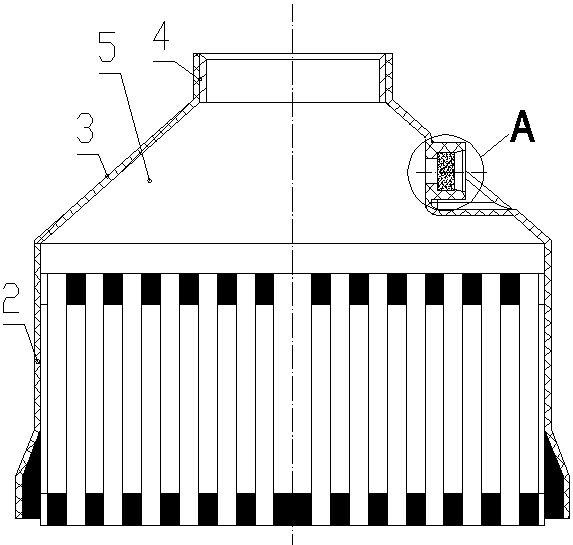

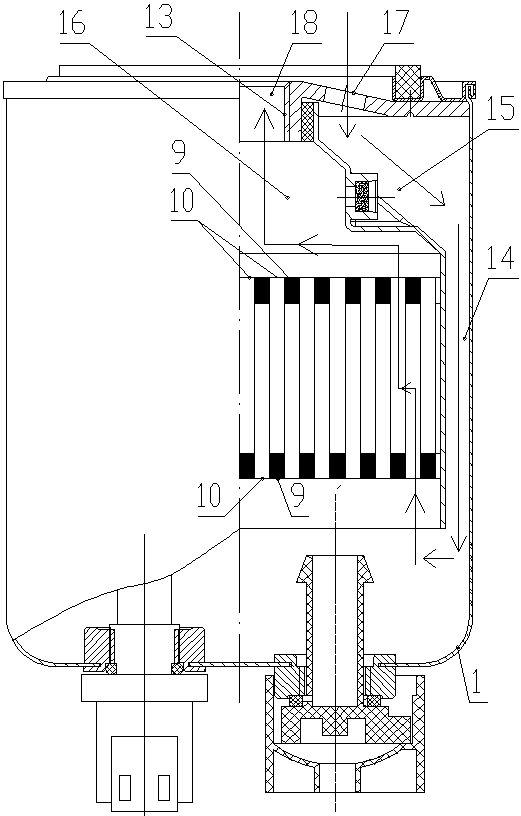

[0026] like figure 1 , figure 2 and Figure 5 As shown, the present invention provides a fuel filter element, including a filter element housing, one end of the filter element housing is an inlet end and the other end is an outlet end, and the inlet end and / or outlet end of the filter element housing are used for filtering The device housing 1 is connected;

[0027] Along the axial direction, the filter element housing includes a media support part 2, a cone-shaped part 3 with a trumpet-shaped cross section and an inlet and outlet part 4 connected in sequence; the diameter of the upper end of the cone-shaped part 3 is smaller than the diameter of its lower end;

[0028] The inner surface of the medium support part 2 is provided with a filter body in an interference-seal fit; the filter element housing at the conical part 3 and the filter body enclose a conical cavity 5;

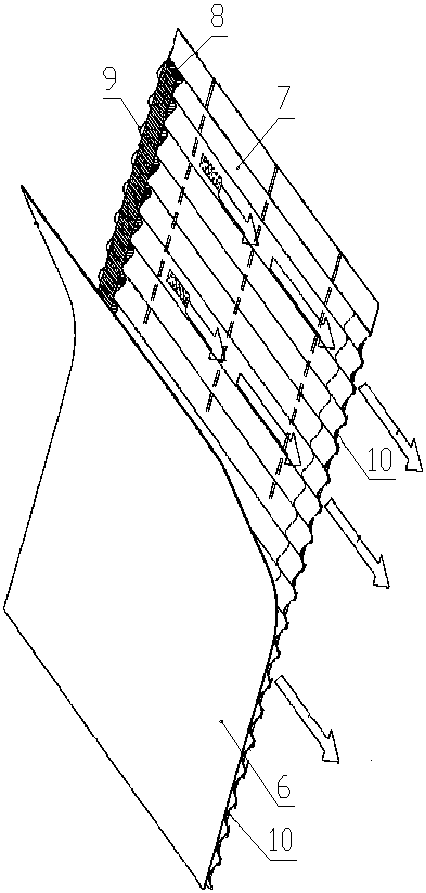

[0029] The filter body is densely wound by two layers of filter media, and is seamed at the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com