Device for guiding metal strip on gas cushion

A technology of metal strips and strips, applied in the direction of winding strips, transportation and packaging, loading/unloading, etc., can solve problems such as uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

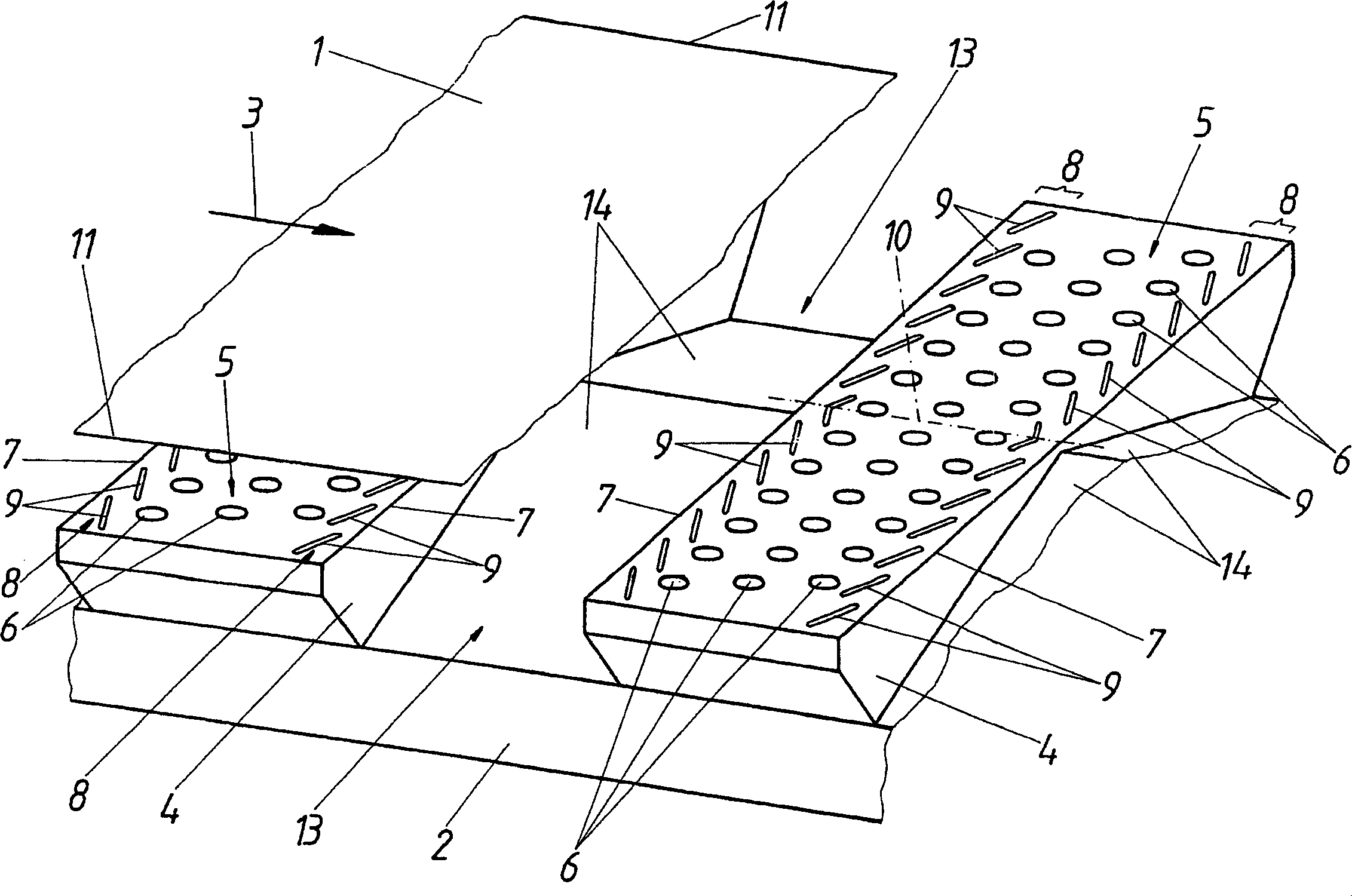

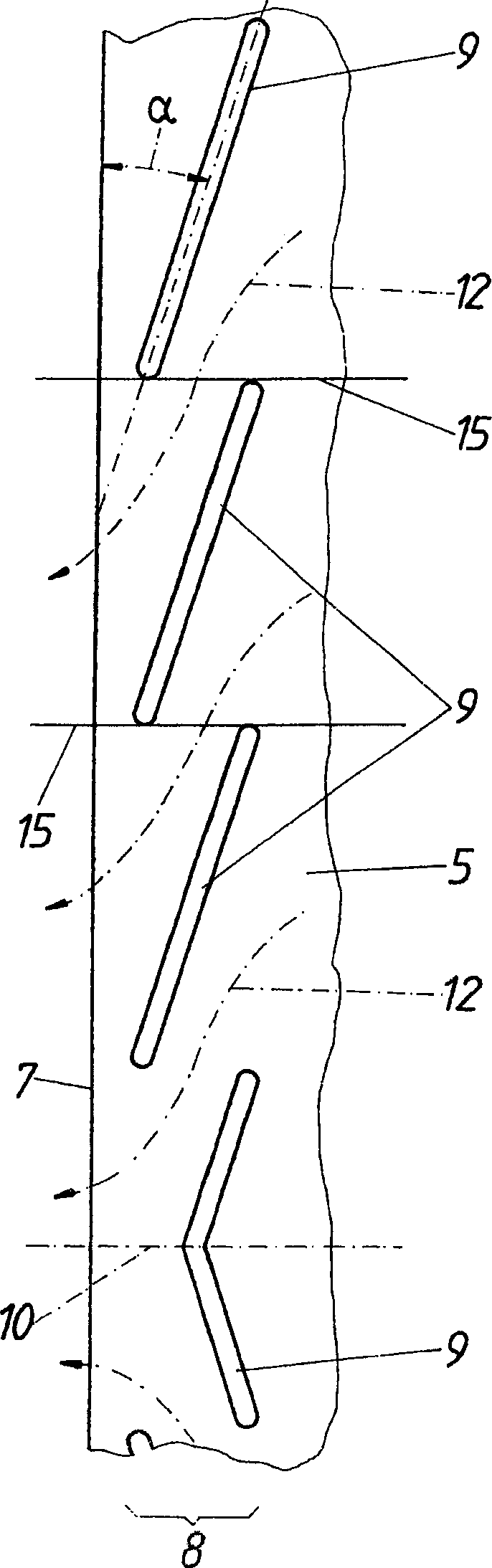

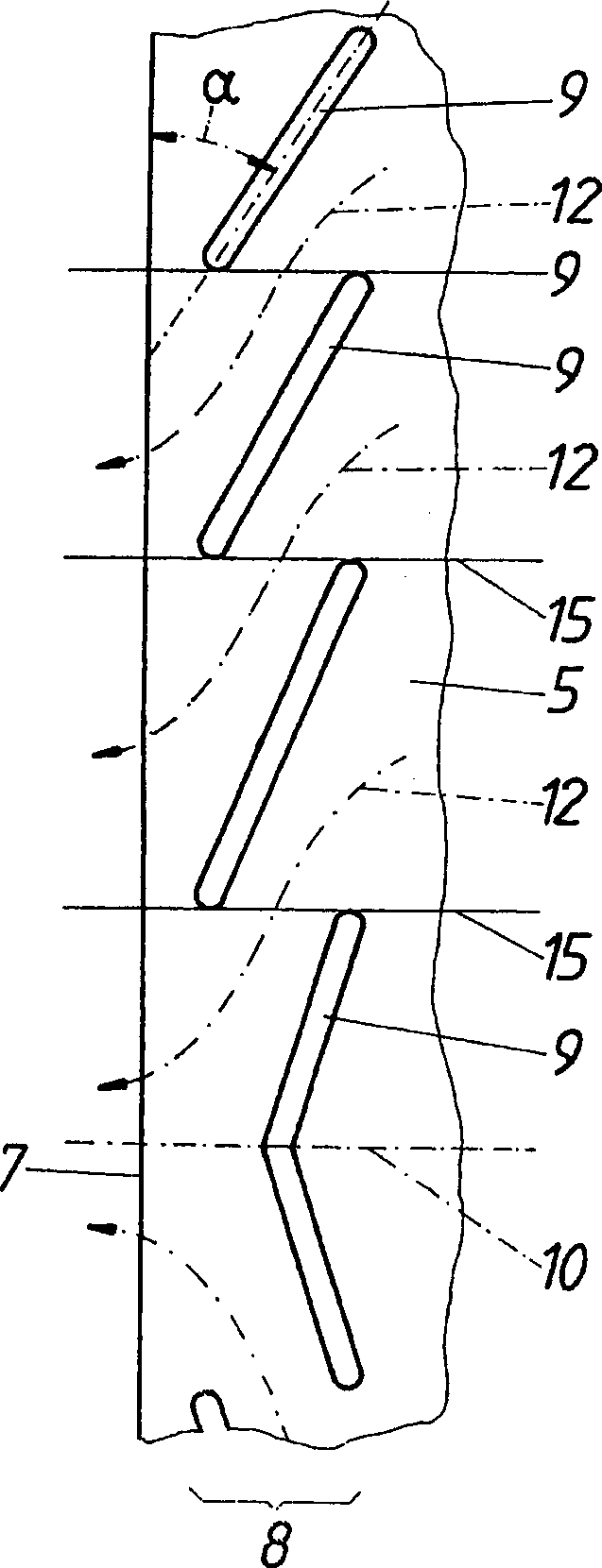

[0012] according to figure 1 , the device for guiding the metal strip 1 comprises a frame 2 which carries blowing boxes 4 which are positioned successively in the longitudinal direction 3 of the strip and form a nozzle area 5 . Said nozzle area extends transversely to the strip longitudinal direction 3 and is provided with hole-shaped nozzles 6 distributed over the surface area of the nozzle area through which gas, such as air, is blown towards the metal strip to form an air cushion. Along the edge 7 of the nozzle region 5 running transversely to the longitudinal direction 3 of the strip are arranged slot-shaped nozzles 8 which consist of nozzle slots 9 . Said nozzle slots 9 arranged in a row parallel to the edge are inclined inwardly relative to the edge 7 (starting from the center of the respective edge 10 ), so that the nozzle slots 9 opposite each other with respect to the nozzle area 5 make the nozzle area 5 narrows relative to the longitudinal edge 11 of the metal str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com