Hydraulic turnover device of hot metal ladle

A technology of hydraulic flipping and molten iron tanks, which is applied to casting molten material containers, metal processing equipment, casting equipment, etc. It can solve the problems of high investment and maintenance costs, easy traffic accidents, and affecting ground traffic, etc., and achieves low operating costs. The effect of simple structure and low equipment power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

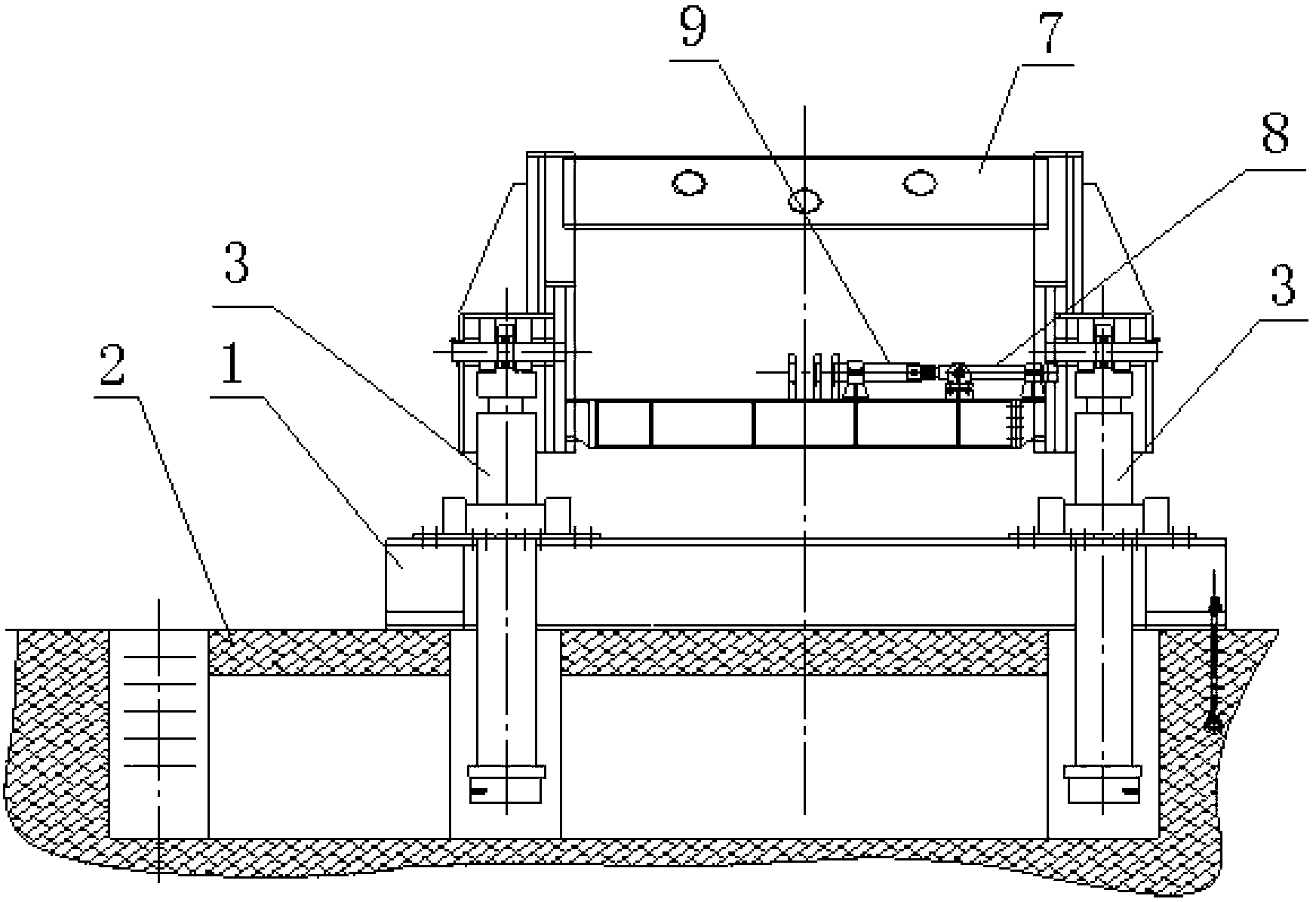

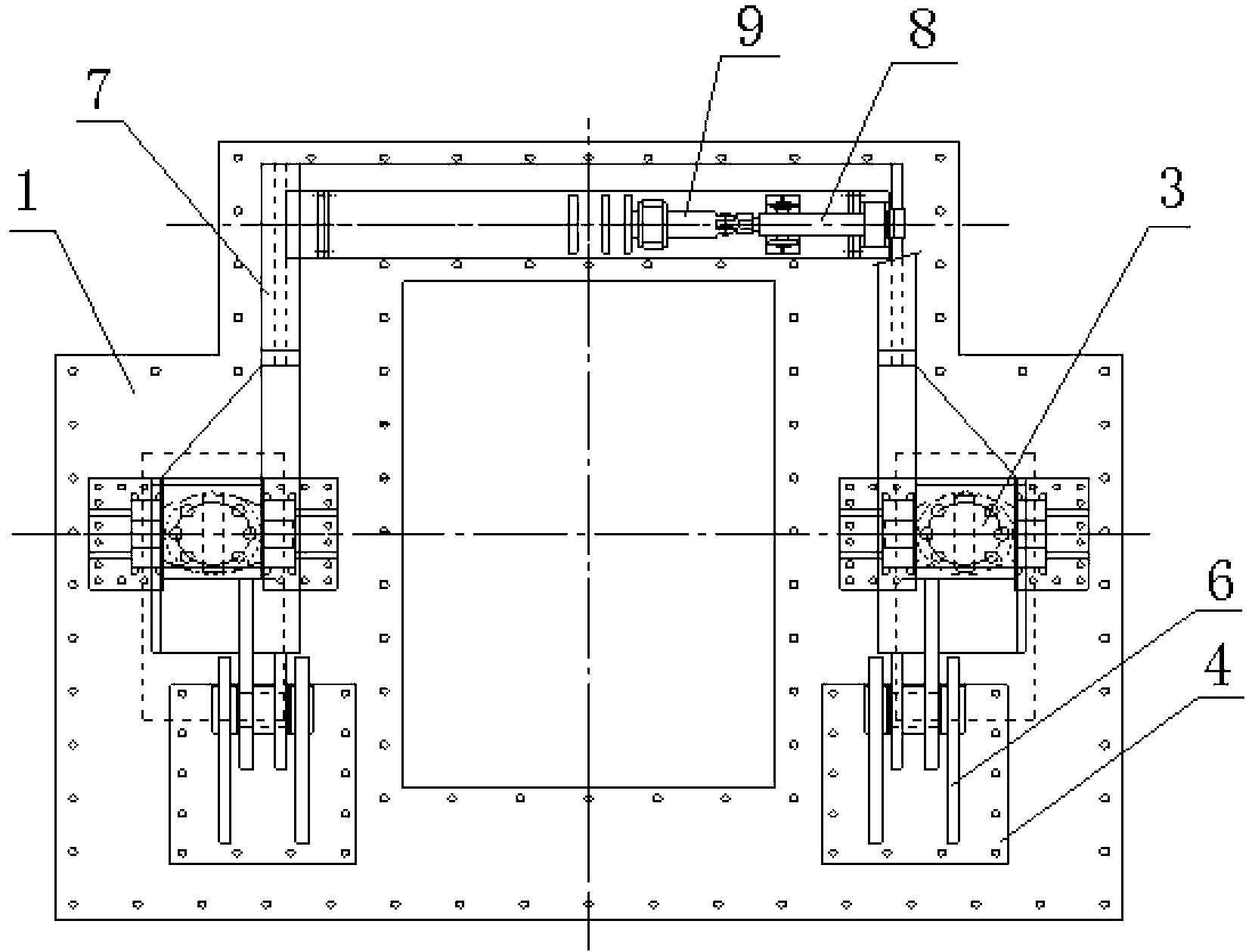

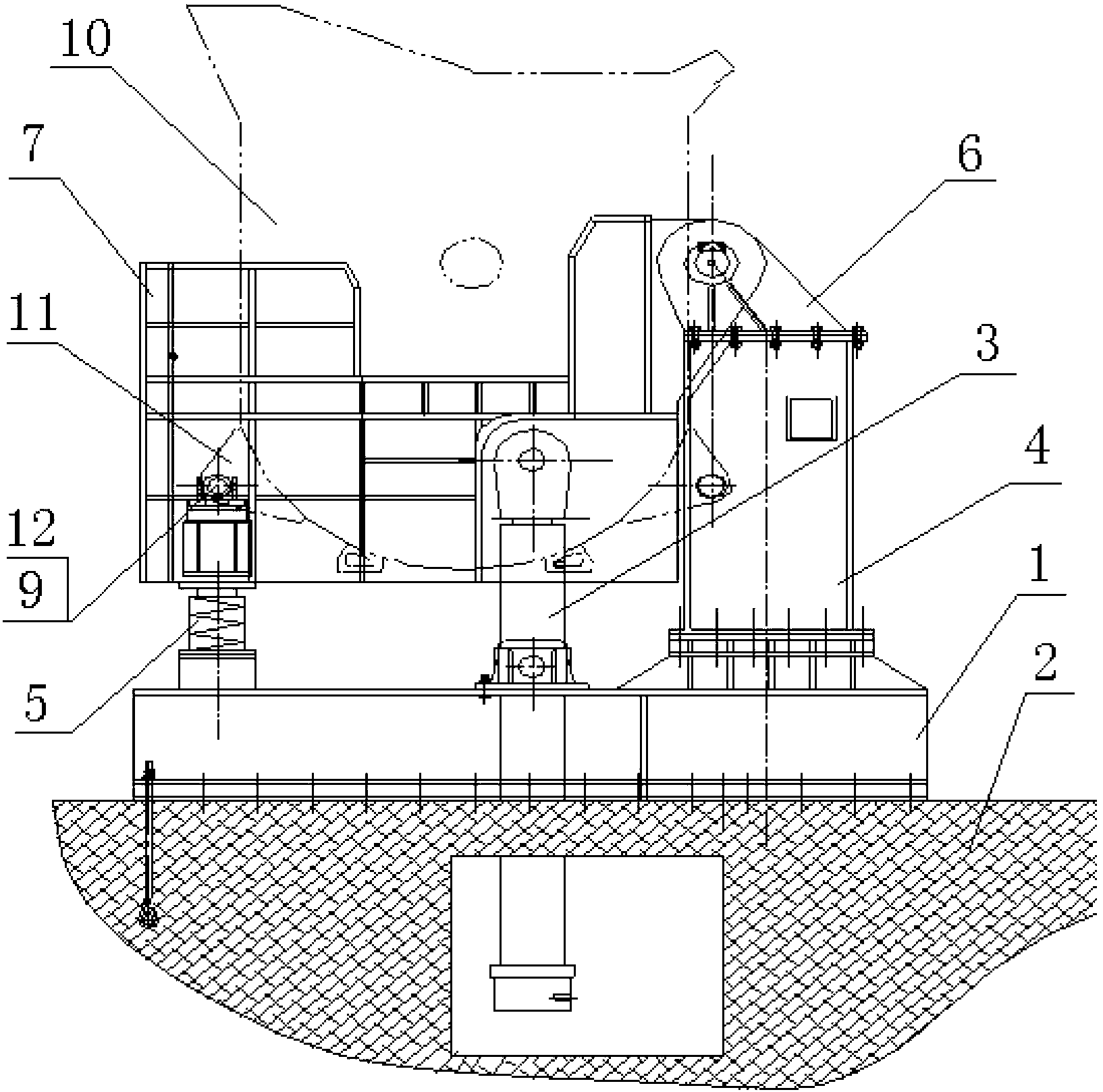

[0017] Combine below figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0018] A hydraulic turning device for a molten iron tank, which has a steel structure chassis 1 fixed on a foundation 2; two turning hydraulic cylinders 3 and two columns 4 are symmetrically fixed on both sides of the steel structure chassis 1 and two buffer bearings 5, and two overturning hydraulic cylinders 3 are respectively located between the two columns 4 and the two buffer bearings 5; The front crossbeam is symmetrically hinged on the two rotating supports 6, and the rear crossbeam is seated on the two buffer supports 5; the piston rod ends of the two overturning hydraulic cylinders 3 are symmetrically hinged on the left and right side plates of the movable support 7; A locking oil cylinder 8 and a locking pin 9 are installed on the rear beam of the movable support 7, and one end of the locking pin 9 is hinged with the piston rod end of the locking oil cylinder 8, and the locki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com