Patents

Literature

81results about How to "Weld tightly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

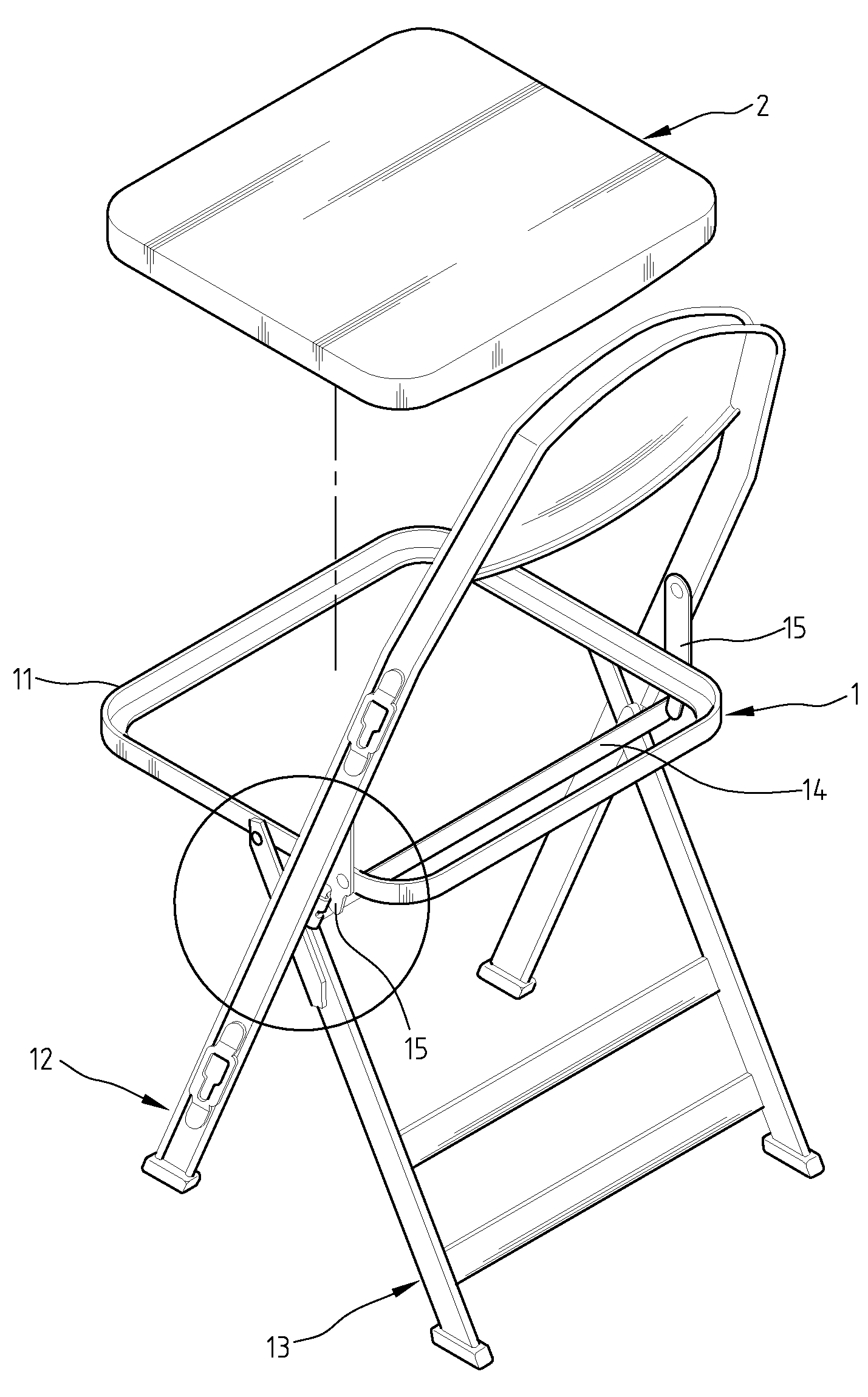

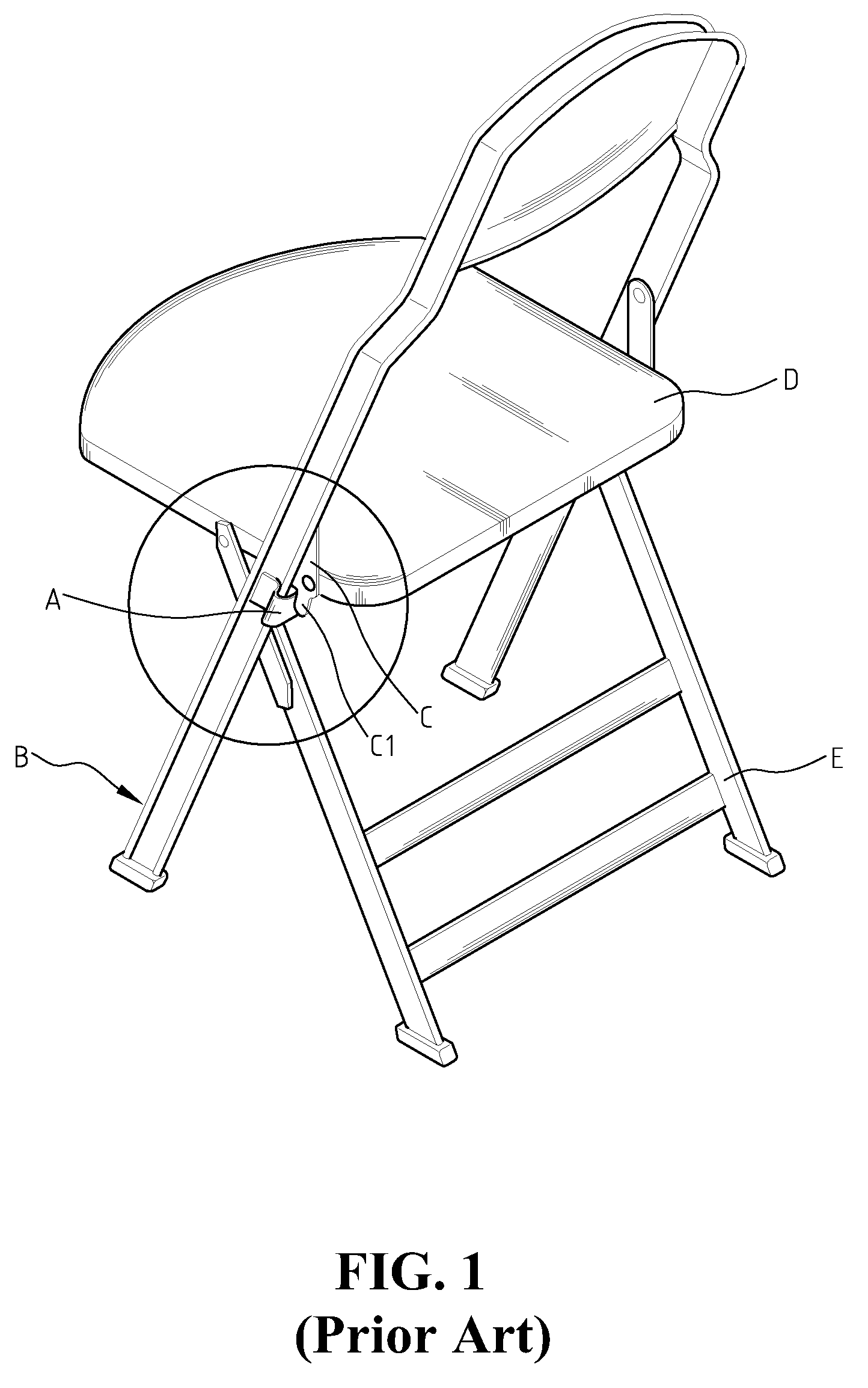

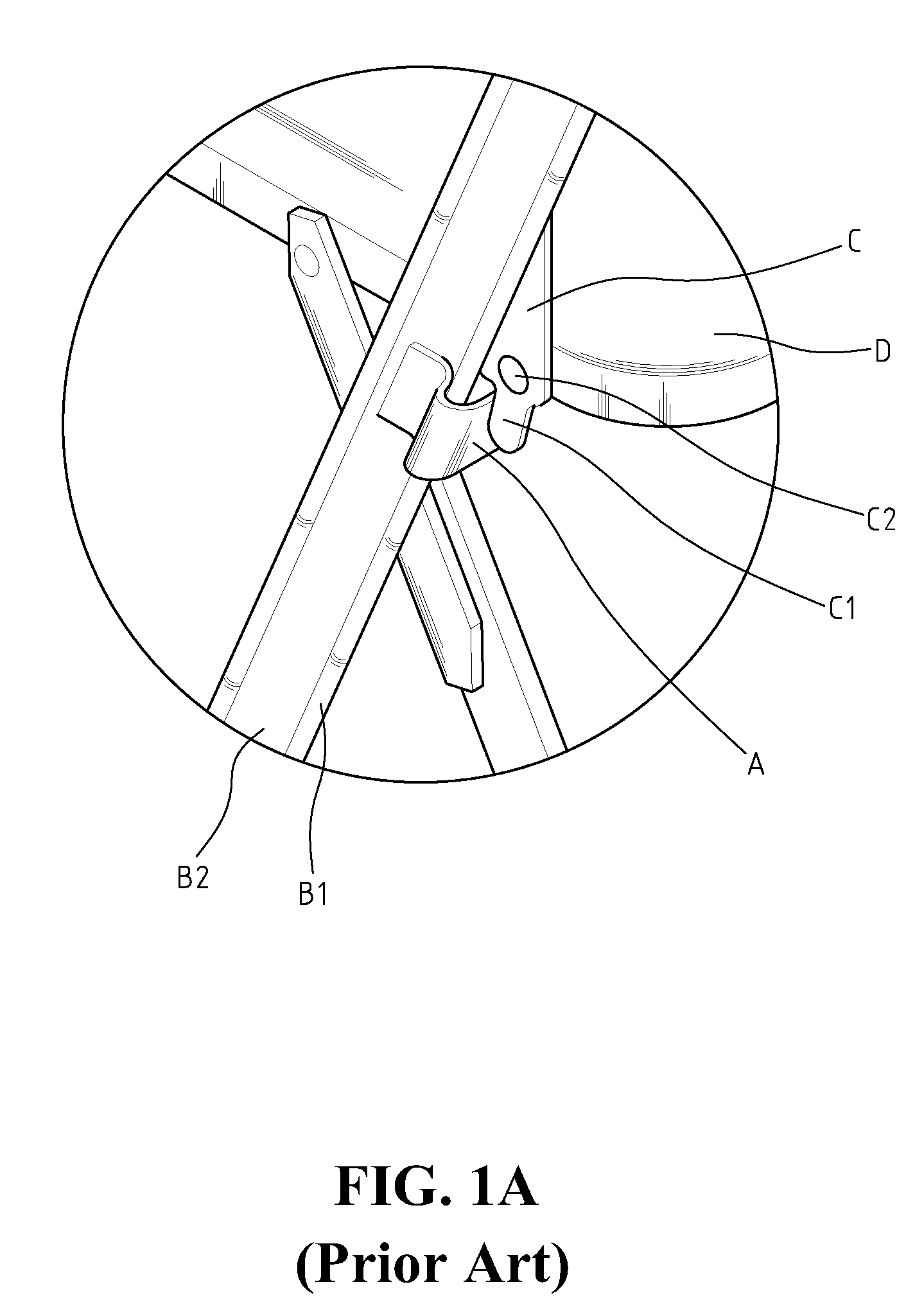

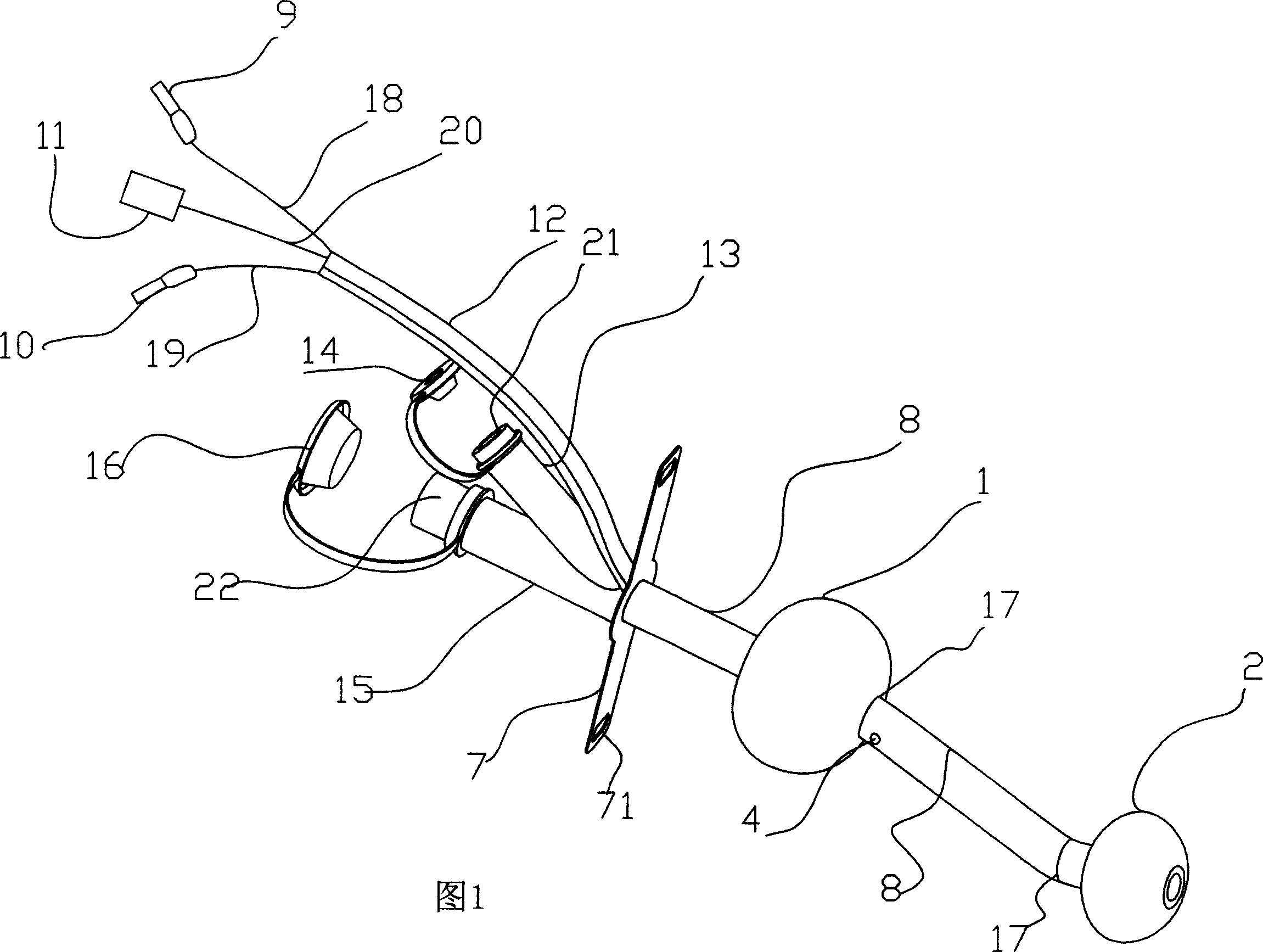

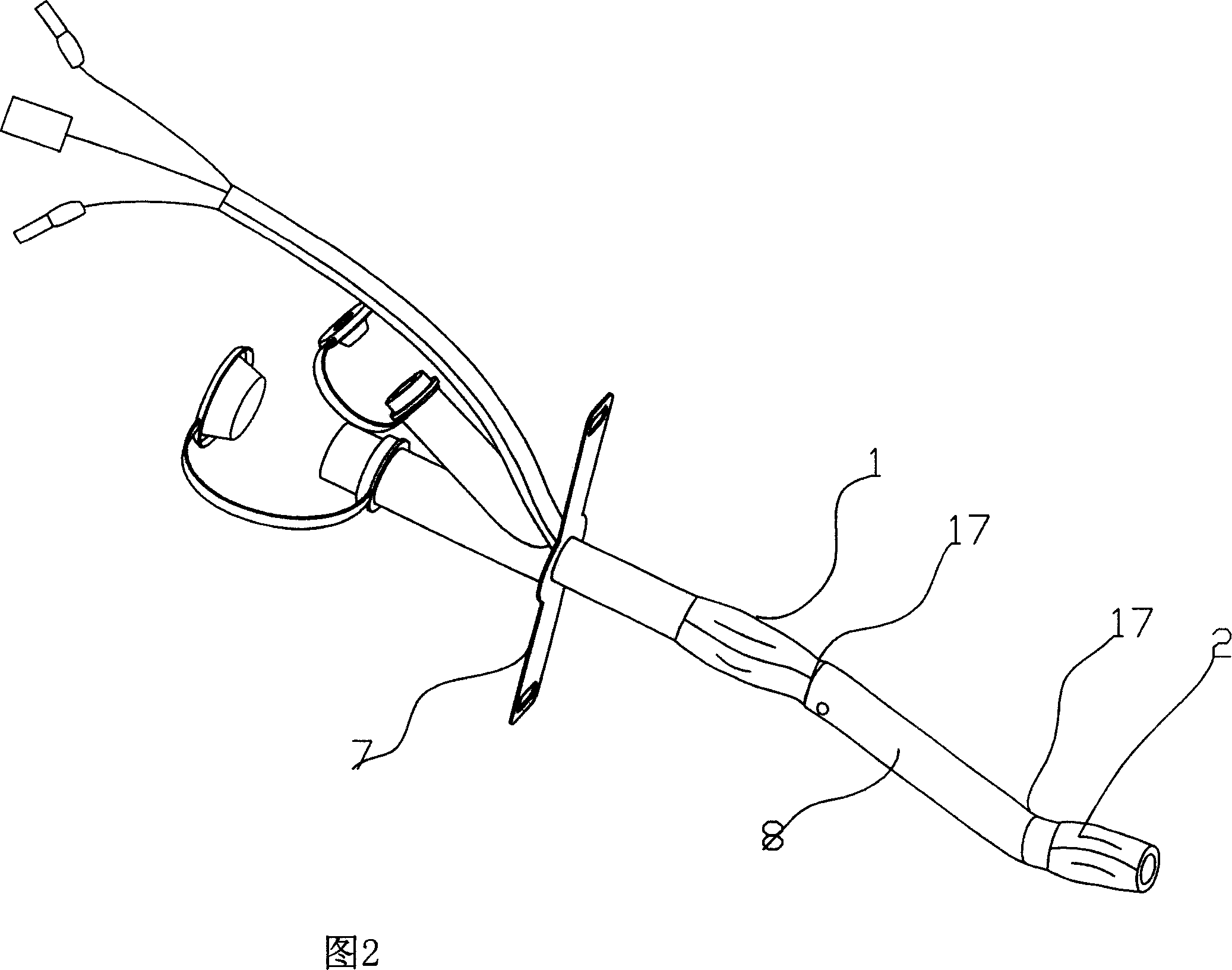

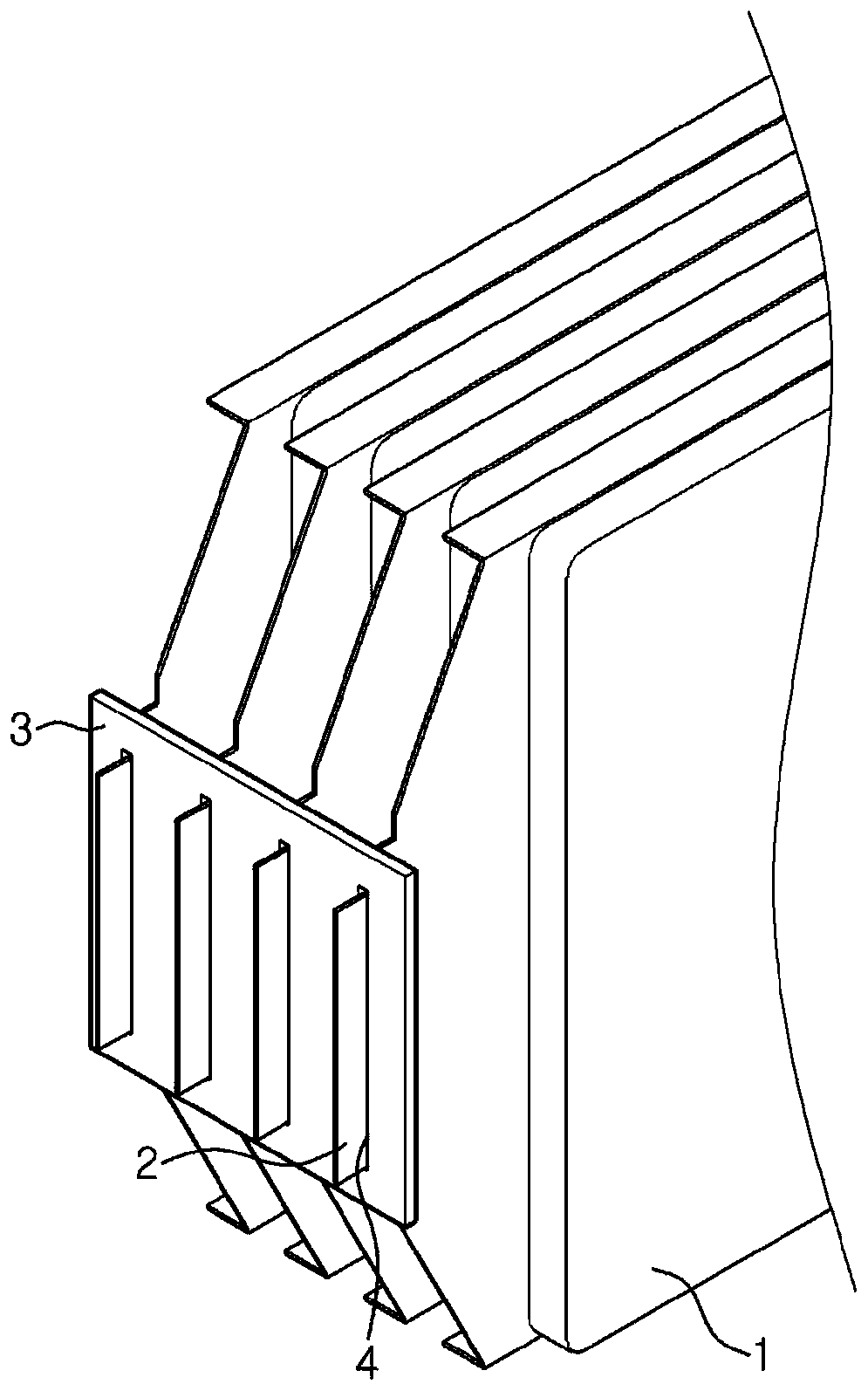

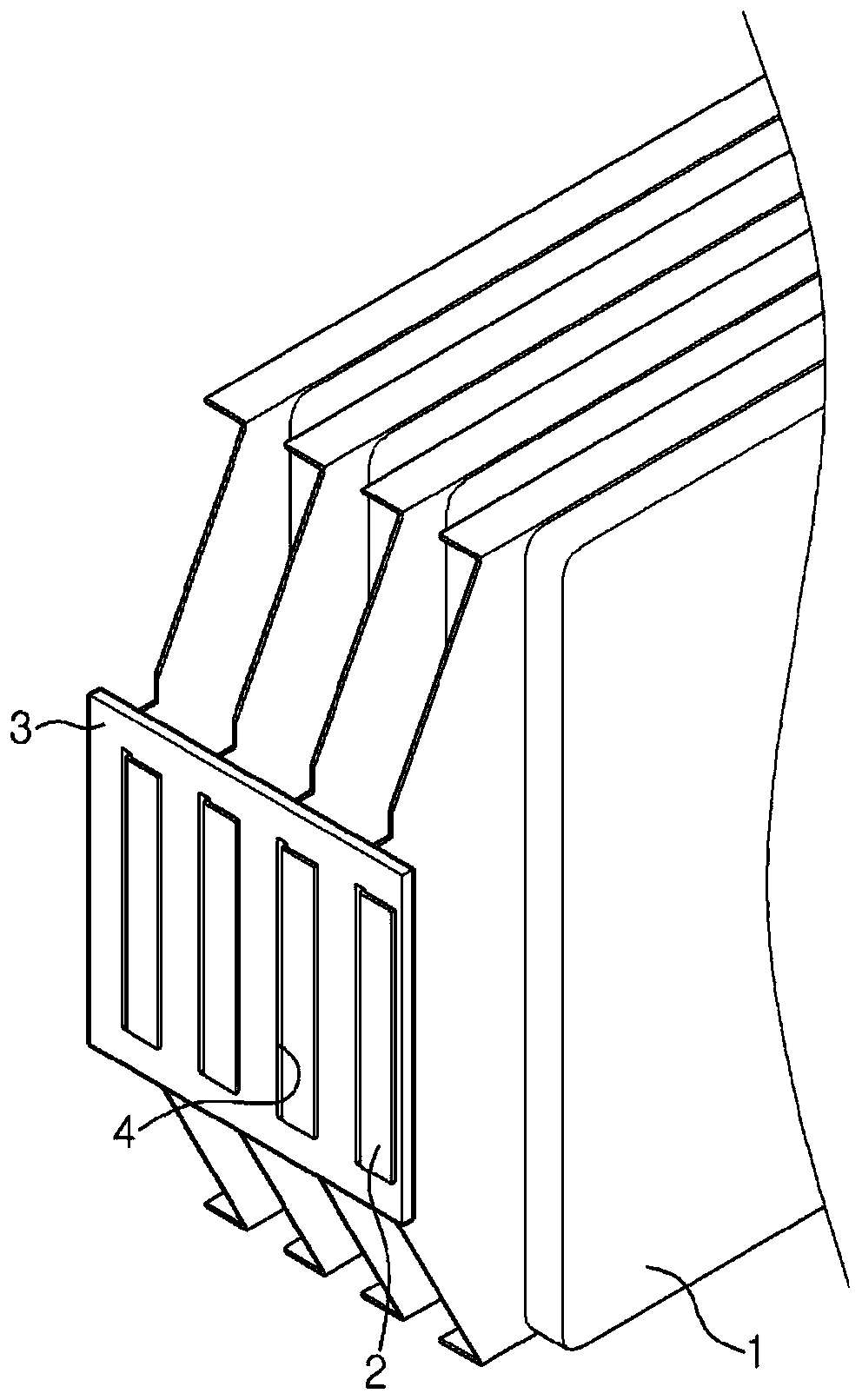

Structure for a seat supporting frame of a chair

ActiveUS7226123B1Easy to weldReduced lifespanFoldable chairDismountable chairsBraced frameEngineering

An improved structure for a seat supporting frame of a chair includes a seat, front legs and back legs mounted on the two sides, a horizontal support having flattened ends and forming a bent section. The bent section is welded with the inner side of the front leg. The two ends of the bent corners are formed with a curved section. The sides of the seat has vertical support pieces, one end of which is set on the side of the seating frame, and the other end is connected to the front leg. A stop abutment, mounted on the lower section of the vertical support piece, is firmly abutted to the inner side of the curved section of the horizontal support, so as to prevent it from sliding and fracture. The horizontal support, the front leg, the vertical support piece, and the stop abutment are held together tightly.

Owner:SPEC SEATS TECH

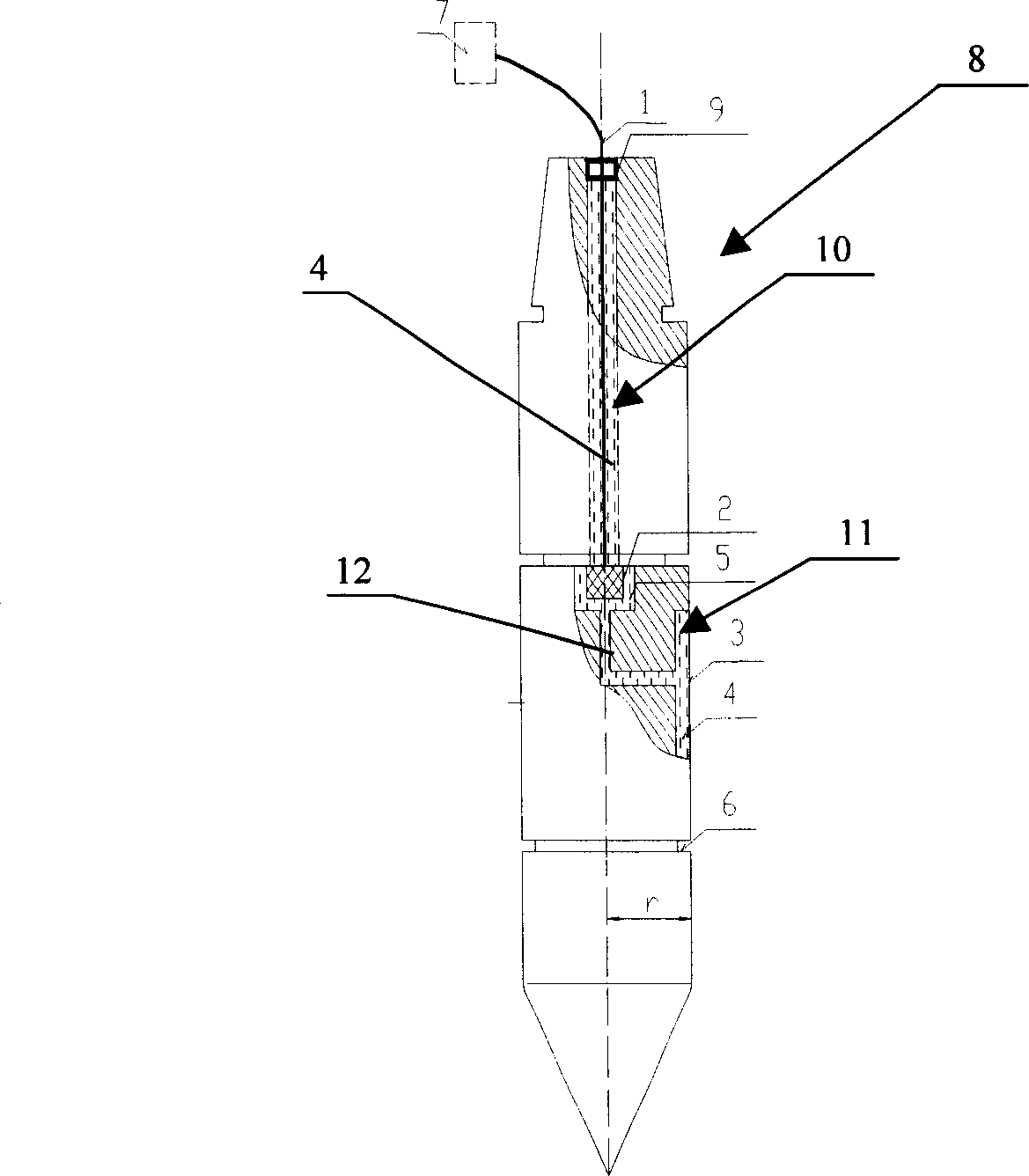

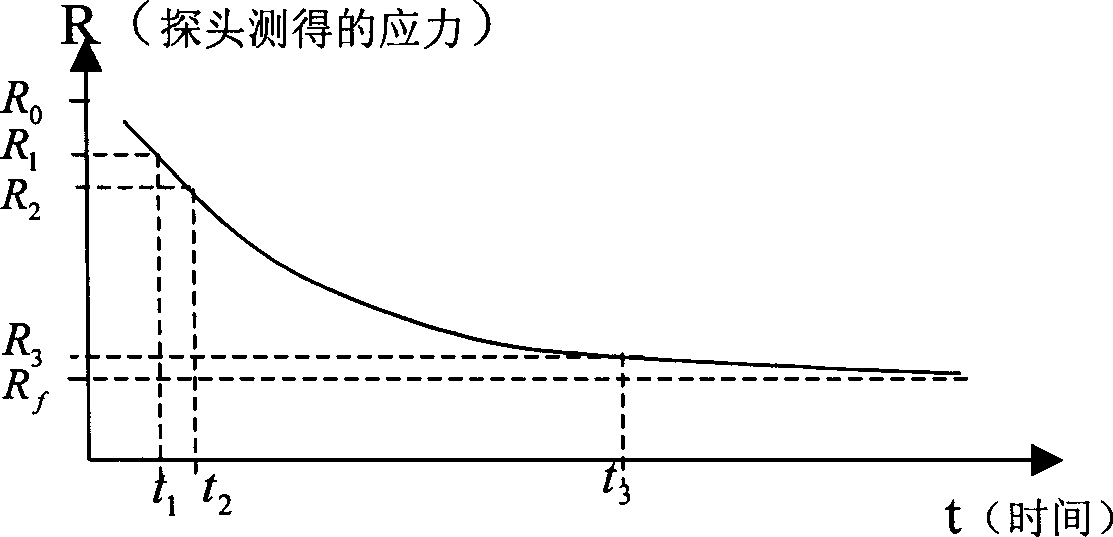

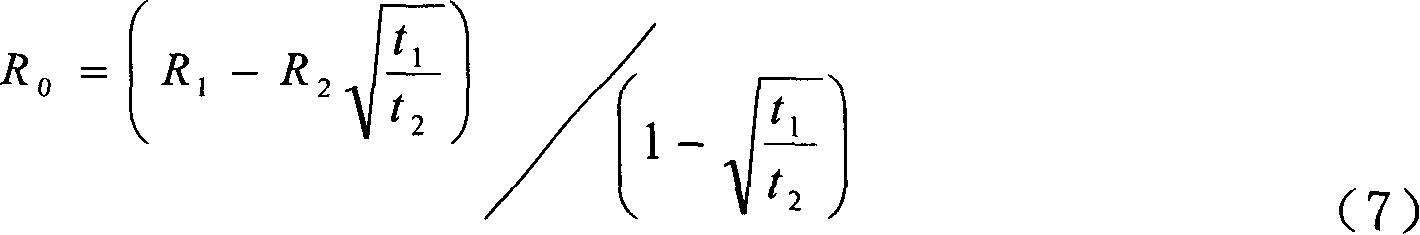

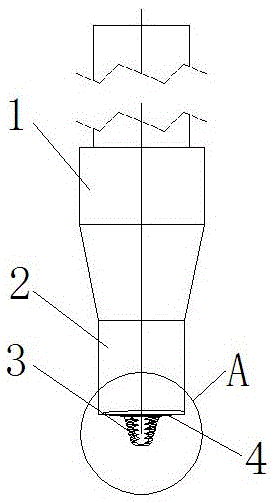

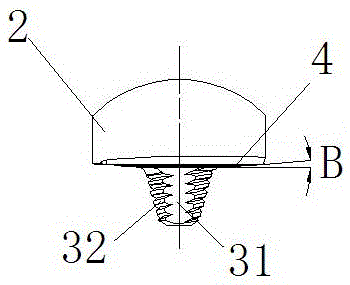

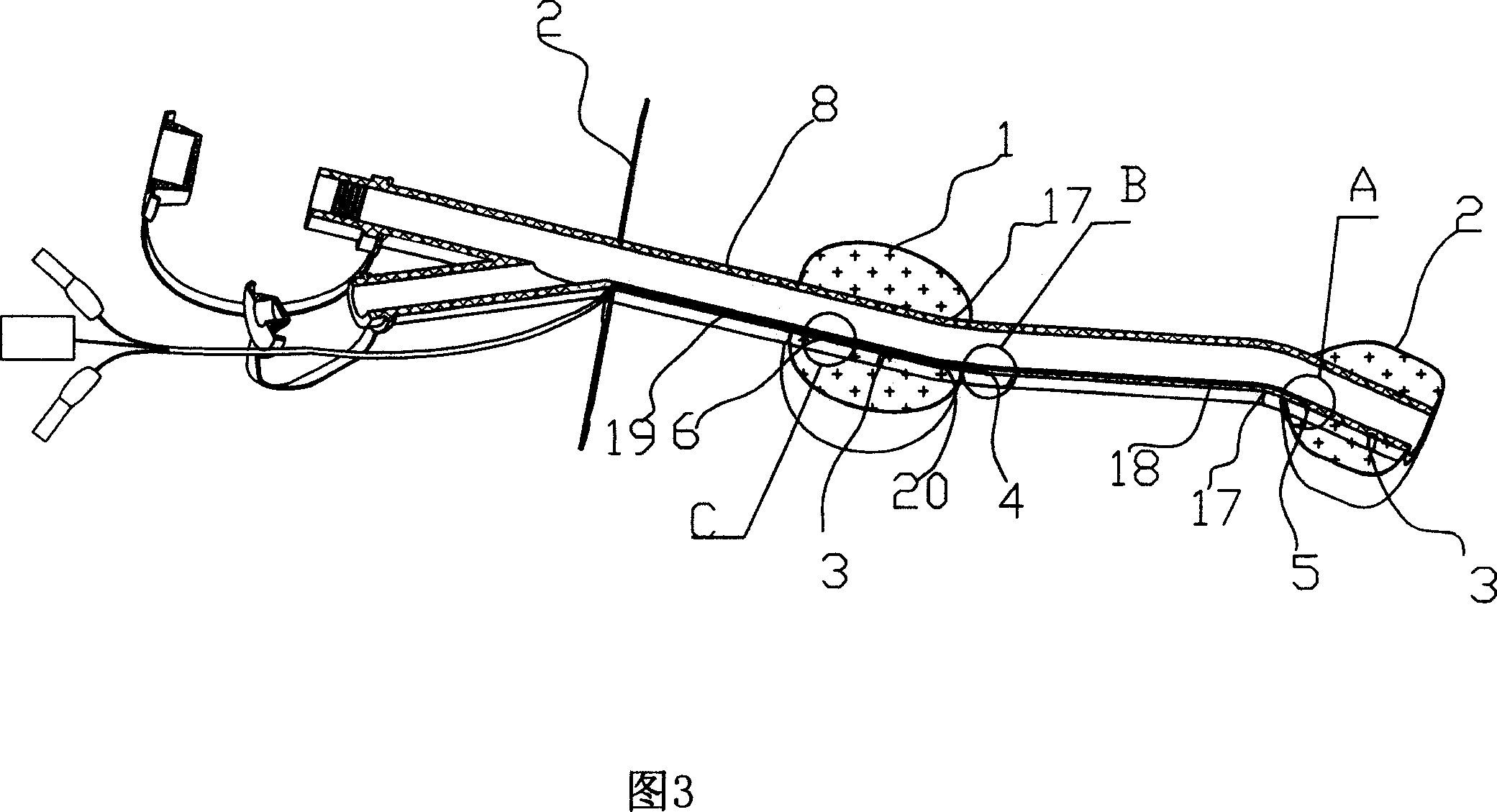

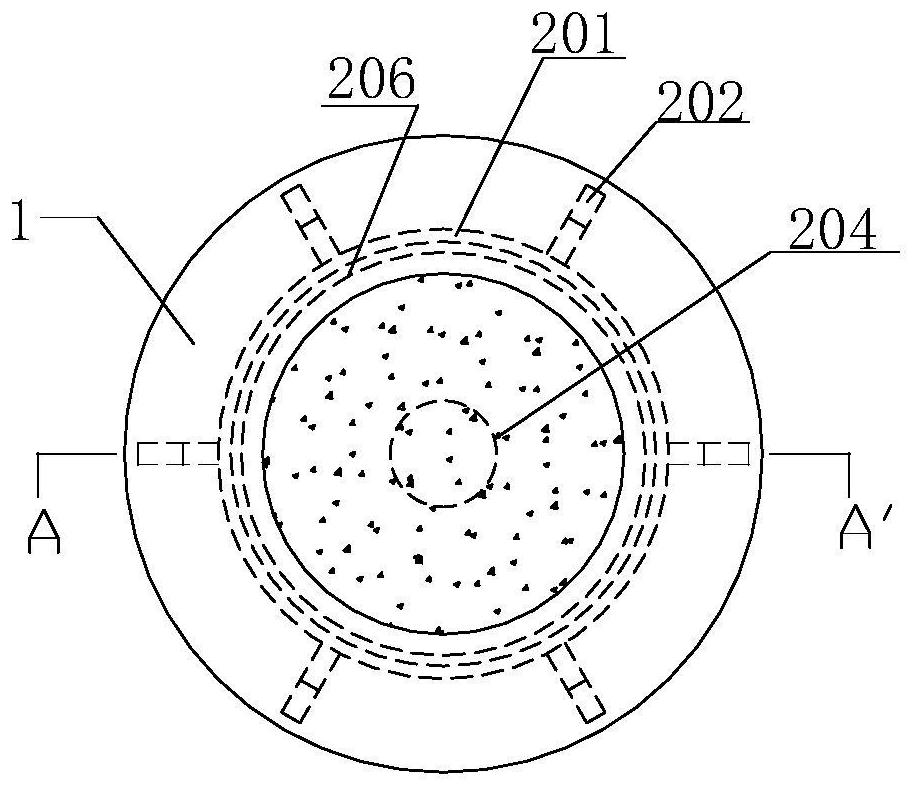

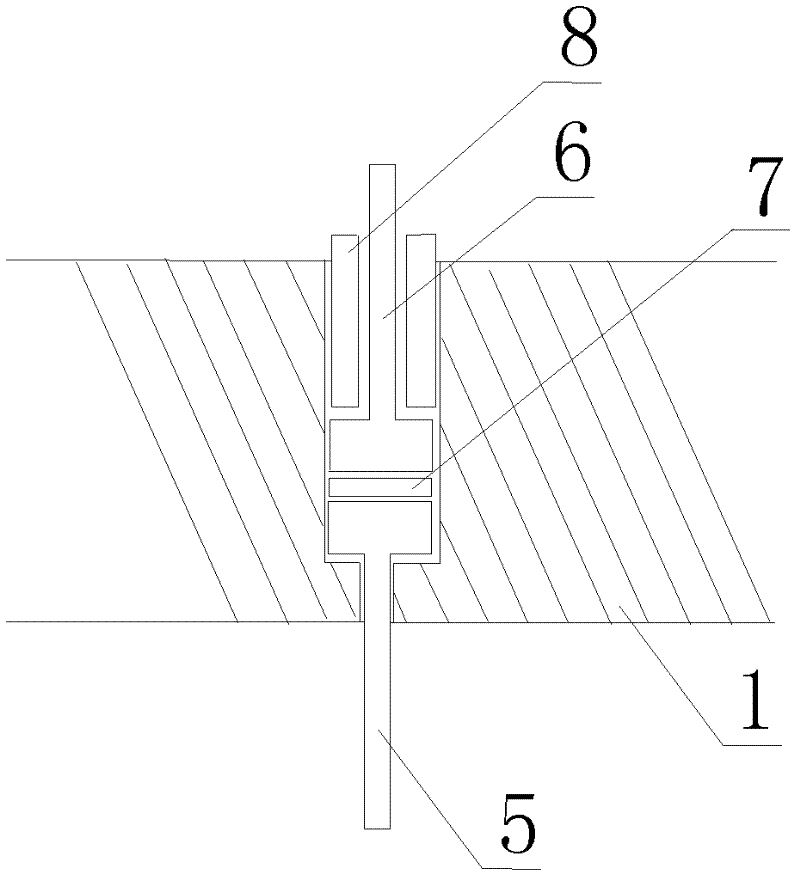

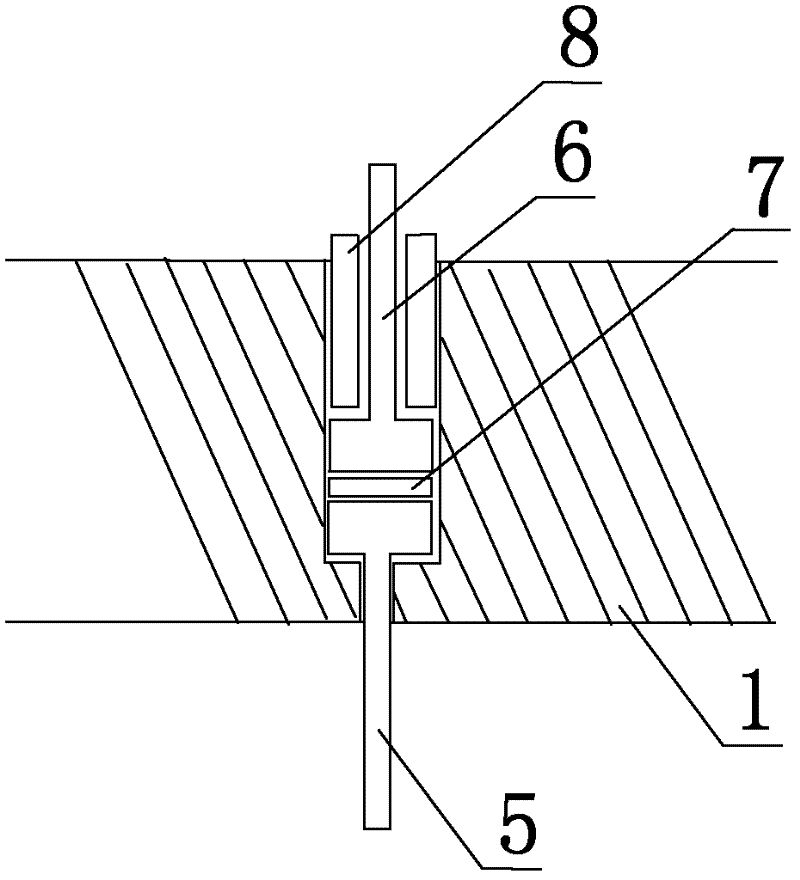

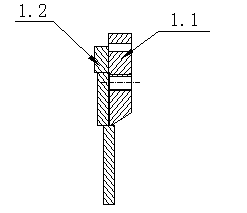

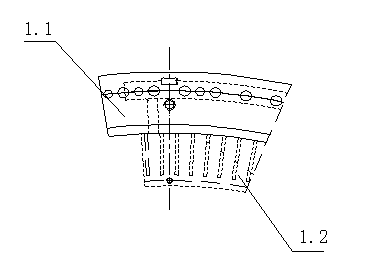

Probe for in-situ real time measuring saturated fine soil borizontal stress and measuring, calculating method

ActiveCN1793917ACompact structureWeld tightlyEarth material testingSpecial data processing applicationsHorizontal stressSoil science

A method for measuring horizontal stress of fine granulated saturation soil at original place in real time calculates out degree U of consolidation and horizontal consolidation coefficient C as well as static side pressure coefficient K by obtaining relation curve of horizontal pressure R at saturation soil layer deep position to time T and by applying three ¿C points calculation means to calculate horizontal stress R1 at initial time and horizontal stress at time of finalizing excess pore water pressure evanish . The probe for realizing said method is also disclosed.

Owner:铁道第三勘察设计院有限公司

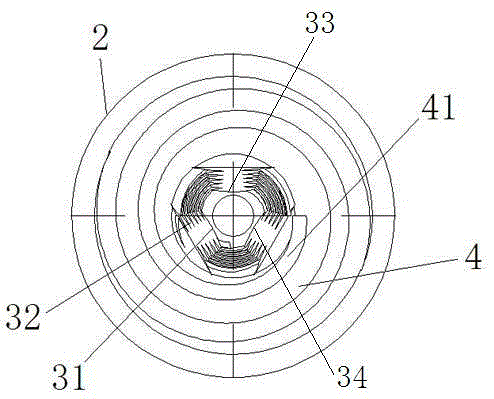

Stirring head for friction stir welding

InactiveCN105522275AEasy to controlSimplify the spindle structureNon-electric welding apparatusEngineeringFriction stir welding

The invention discloses a stirring head for friction stir welding, and belongs to the field of friction stir welding technical devices. The stirring head comprises a stirring head shaft shoulder; a stirring needle is positioned below the stirring head shaft shoulder; the bottom surface of the stirring head shaft shoulder is an inclined surface, and is a contact surface between the shaft shoulder and a welded workpiece; the direction of the inclined surface is as follows: when the stirring needle is downwards, the inclined surface is inclined from the center of the bottom surface to the outer and upper directions; and an included angle between the inclined surface and a vertical line of axis of the stirring head is 1-10 degrees. The stirring heads forms a compact welding line, improves the quality of the welding line, and guarantees high reliability and stability of the welding line.

Owner:河南正航主轴科技有限公司

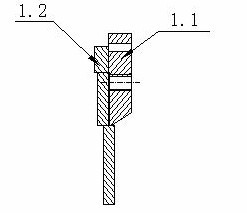

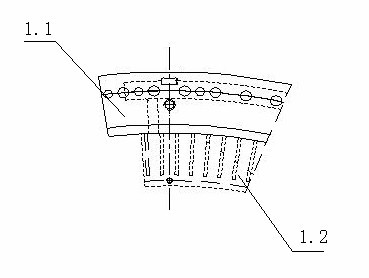

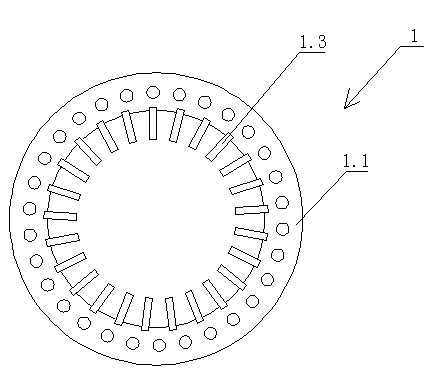

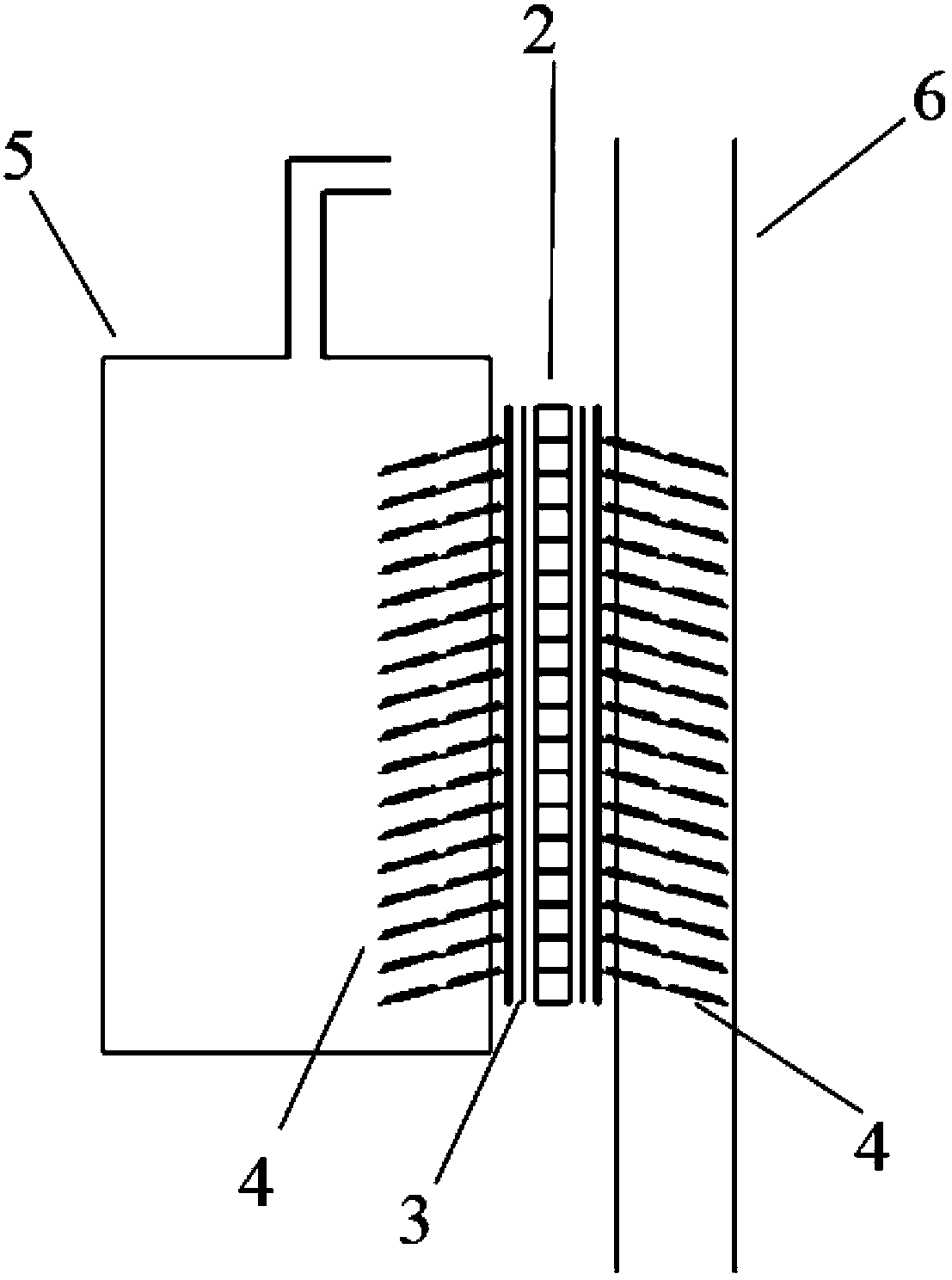

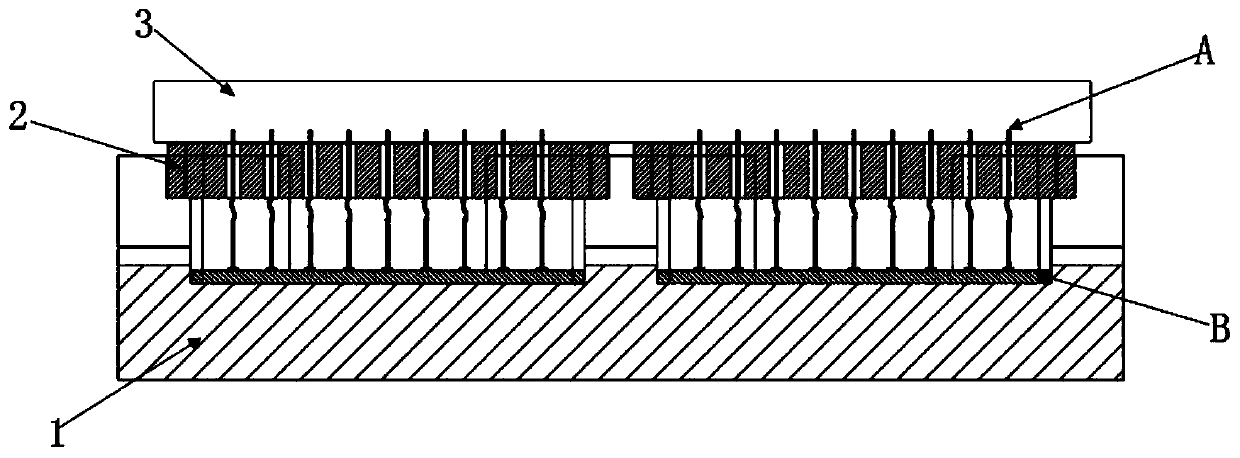

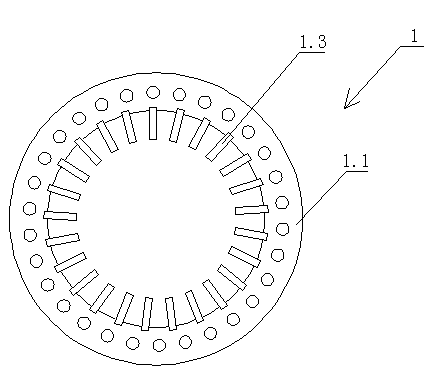

Assembly process for stator of 3MW permanent magnet synchronous wind-driven generator

InactiveCN102386726AQuality improvementImprove sealingManufacturing stator/rotor bodiesWind drivenEngineering

The invention relates to an assembly process for a stator of a 3MW permanent magnet synchronous wind-driven generator. The process comprises the following steps of: A, assembly of a stator tooth pressing plate; B, lamination of a stator core; C, assembly of a cooling system; D, assembly of the stator; and E, paint dipping and coating of the stator. By the assembly process for the stator of the 3MW permanent magnet synchronous wind-driven generator, the assembly is convenient; core lamination effects are good; radiation efficiency can be effectively improved; a cooling water pipe has good pressure resistant effects and high reliability; and a coil has high insulating and sealing properties.

Owner:JIANGYIN BOFENG SPECIAL MOTOR

Means for taking-care of anus and intestine

InactiveCN1947668AAvoid harmUniform pressureBodily discharge devicesEnteral tube careIntestinal structure

Owner:高静静

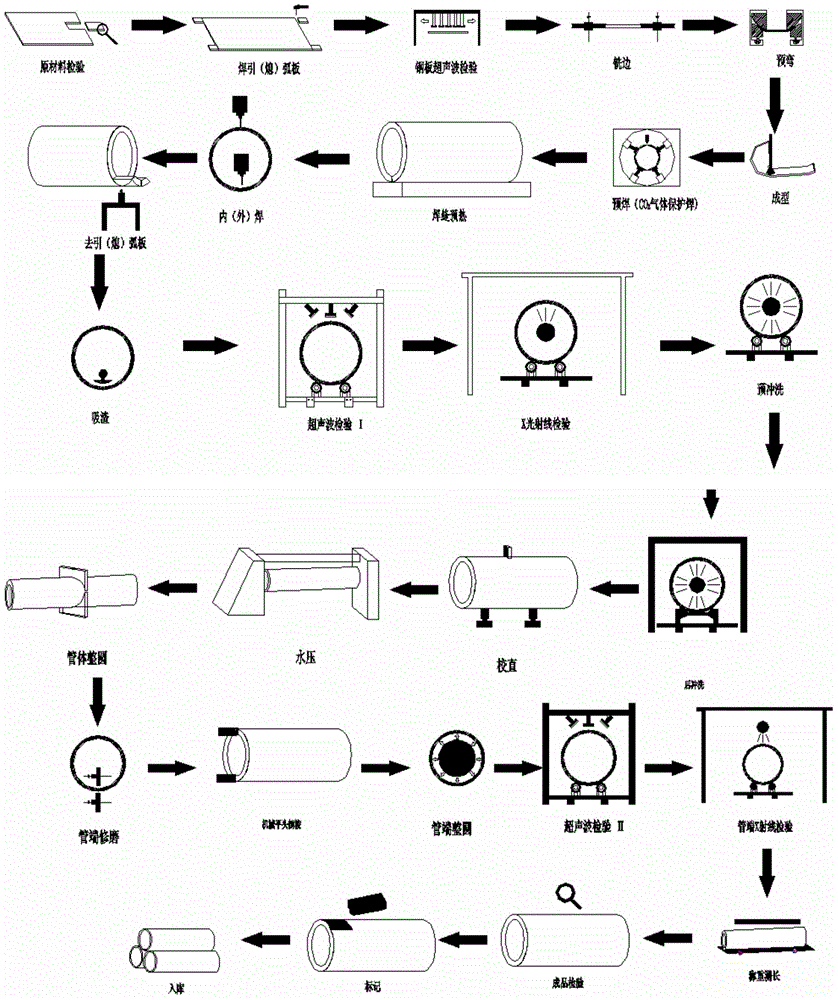

Steel tube manufacturing method

The invention discloses a steel tube manufacturing method. The steel tube manufacturing method comprises the steps of selection and inspection of raw materials, welding of arc striking and extinguishing plates, edge milling of a steel plate, prebending of the steel plate, forming of a JCO forming machine, internal and external welding, cut-off of the arc striking and extinguishing plates, weld flaw inspection, mechanical hole enlargement, rounding of the steel plate and other steps. According to the steel tube manufacturing method, novel Q345GJC-Z15 pipes are selected as the steel plate raw materials; the arc striking and extinguishing plates can ensure the welding quality; an obtained steel tube is firm and tight in welding, the influence of radial force on the service life of the steel tube can be reduced, and therefore the service life of the steel tube is prolonged; meanwhile, the bearing capacity of the steel tube is enhanced, and the use cost is lowered.

Owner:HUNAN SHENGLI XIANGGANG STEEL PIPE CO LTD

Method and equipment for improving latent heat utilization rate in seawater desalination

InactiveCN103449543AReduce volumeStrong pressure and shock resistanceThermo-electric condensationGeneral water supply conservationEngineeringLatent heat

The present invention relates to a method and equipment for improving latent heat utilization rate in seawater desalination and provides a method for improving latent heat utilization rate in seawater desalination. The method comprises the following steps: providing a thermoelectric device and electrifying the thermoelectric device. The invention further discloses equipment for improving latent heat utilization rate in seawater desalination.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

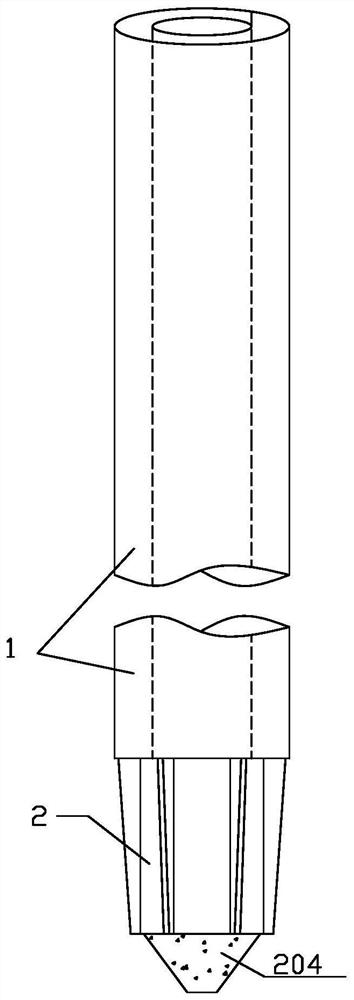

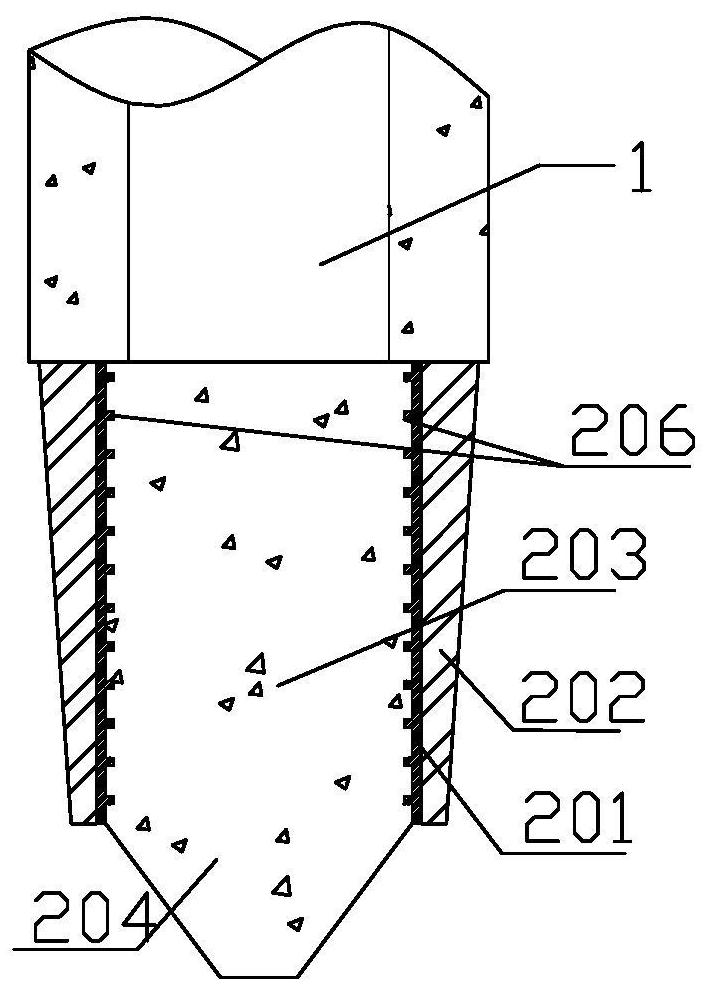

Rock-socketed hollow precast pile and rock-socketed construction method using precast pile

The invention provides a rock-socketed hollow precast pile and a rock-socketed construction method using the precast pile. The precast pile comprises a hollow pile body and a rock-socketed pile tip. The rock-socketed pile tip comprises a steel pipe pile joint section and a big-end-up circular-truncated-cone-shaped pile tip prefabricated by concrete, the steel pipe pile joint section comprises a thin-wall steel pipe, core filling concrete filled in the thin-wall steel pipe and a plurality of stiffening plates welded to the outer wall of the thin-wall steel pipe, and the core filling concrete and the circular-truncated-cone-shaped pile tip are integrally formed in a pouring mode. When rock-socketed construction is carried out, firstly, pile sinking equipment is adopted for sinking a precastpile till drilling footage is difficult, then, a rock core drilling machine is adopted for drilling or crushing plain concrete filling cores at the pile tip part and a hard soil layer and a rock stratum below the pile tip part from the hollow part of a pile body of the hollow precast pile to the designed pile bottom elevation, and a rock-socketed section pile hole is formed; and finally, the forcetransmission framework is put in, cementing materials are injected, and construction of the hollow precast rock-socketed pile is completed.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

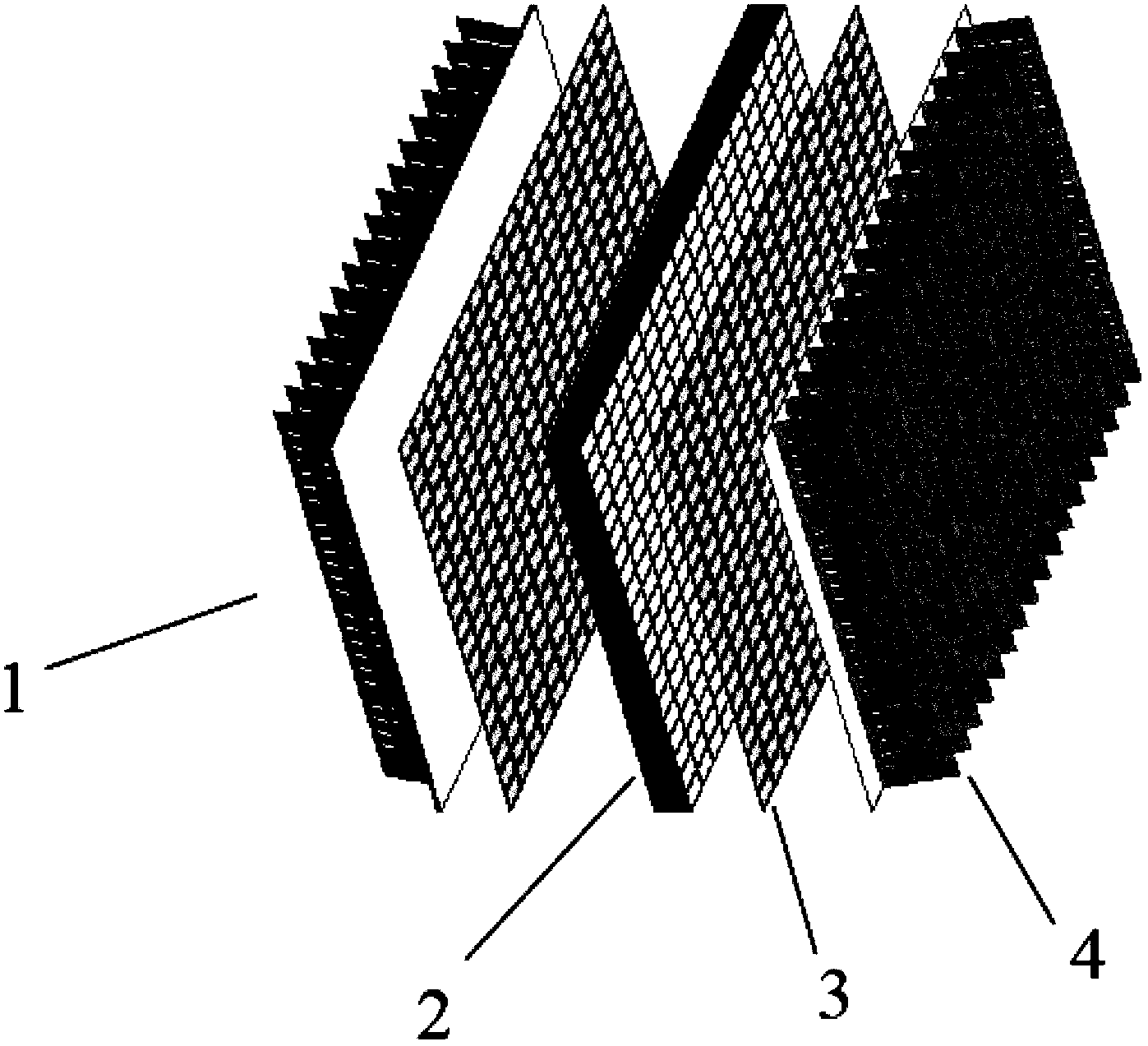

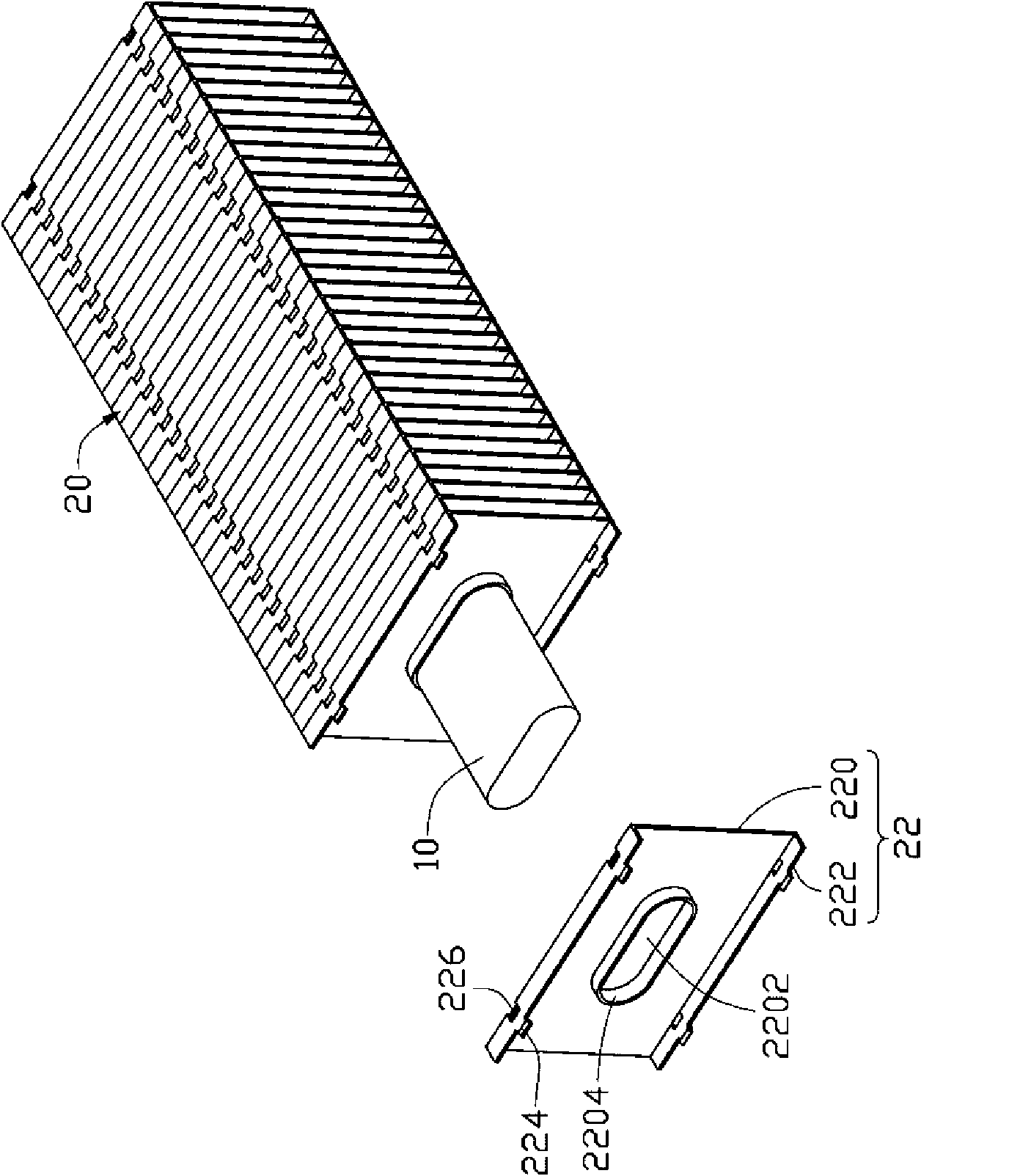

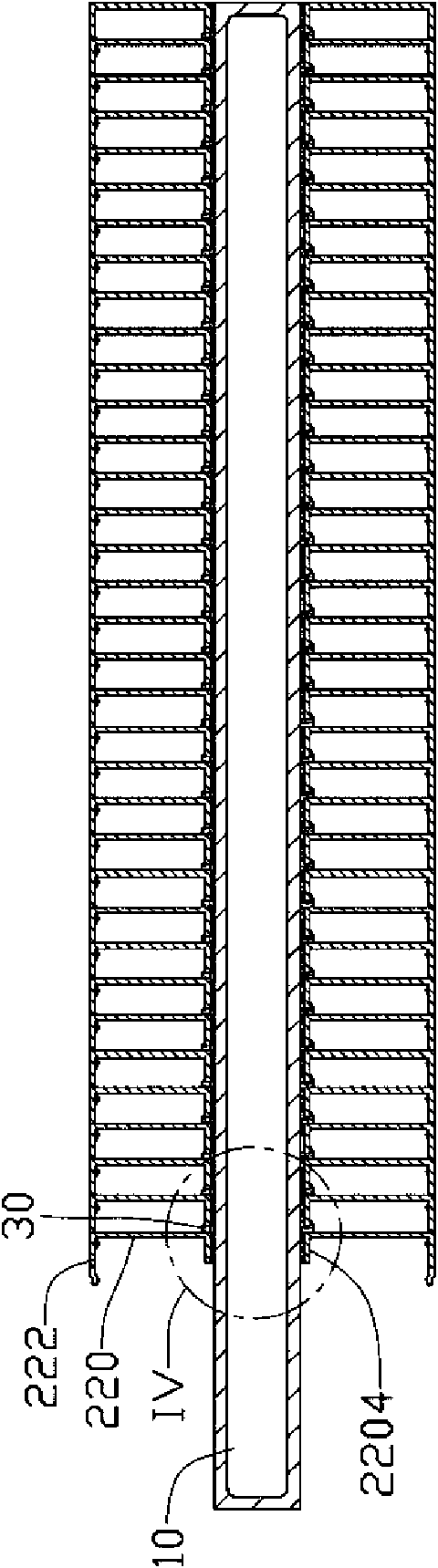

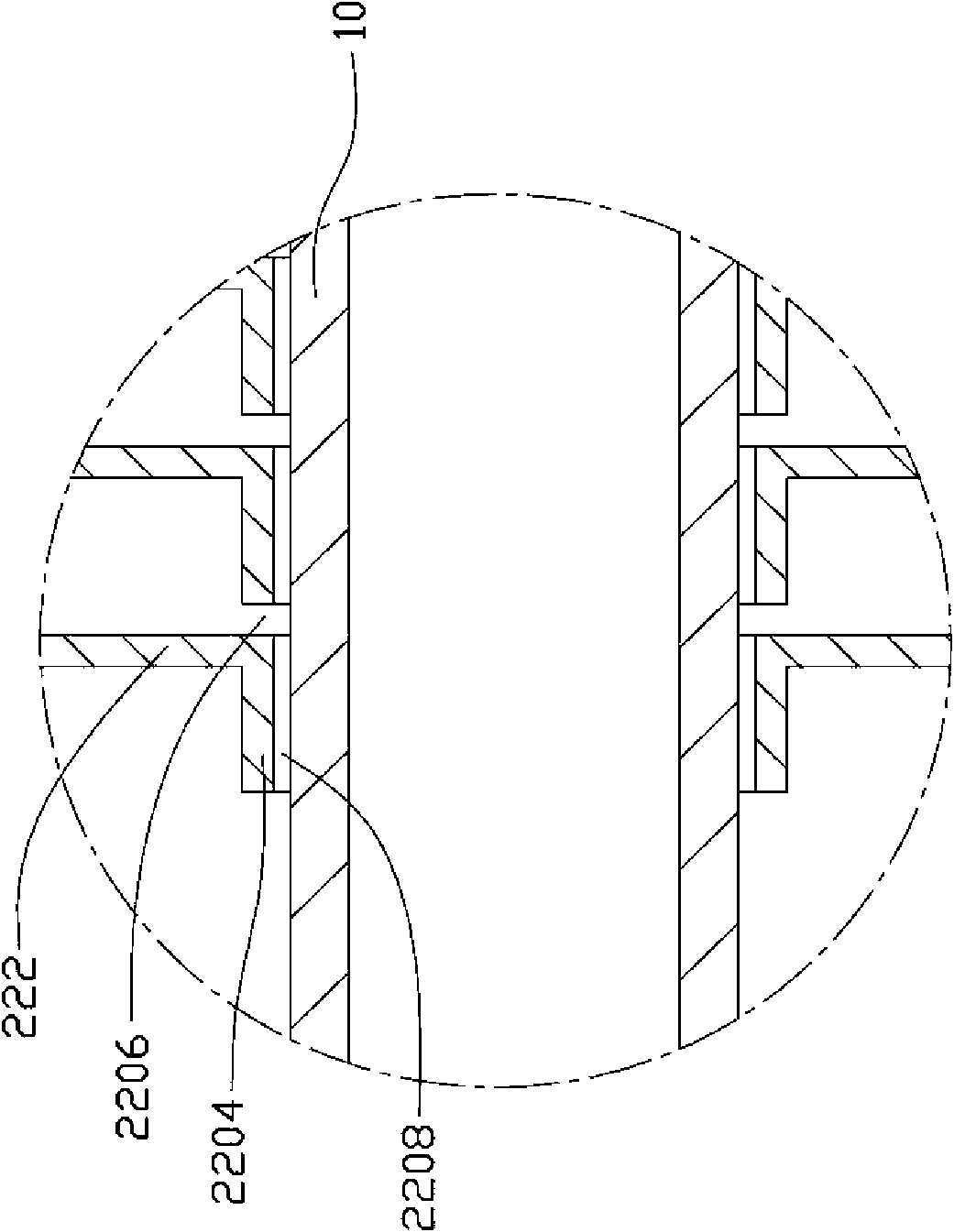

Radiating device

InactiveCN101641004AEfficient use ofWeld tightlySemiconductor/solid-state device detailsSolid-state devicesSolder pasteHeat pipe

The invention relates to a radiating device, comprising a heat pipe and a plurality of radiating fins, wherein each radiating fin comprises a main body and an edgefold formed by bending to one side from the end of the main body, and the edgefold abuts against the main body of the adjacent radiating fin; the main body of each radiating fin is provided with a through hole, and each main body extendsalong the circumference of the through hole to the direction of the main body of the adjacent radiating fin to form a ring edge; the ring edges form an accommodating channel which accommodates the heat pipe; the ring edge at least has a part whose height is smaller than the width of the edgefold so that a gap is formed between the part of the ring edge and the main body of the adjacent radiatingfin, and the gap is used for accommodating excessive solder paste filled between the heat pipe and the radiating fin; thus, when the heat pipe penetrates through the accommodating piece formed by thethrough holes, excessive solder paste can not be extruded out and can remain inside the gap, thus the solder paste can be effectively used.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

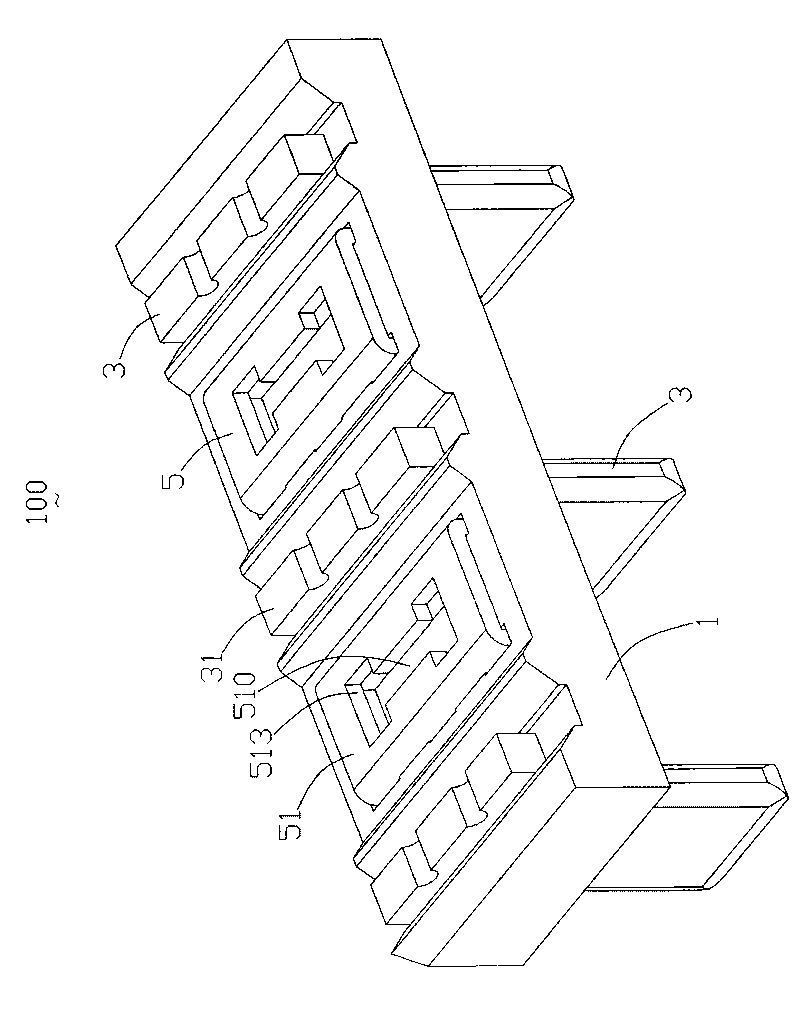

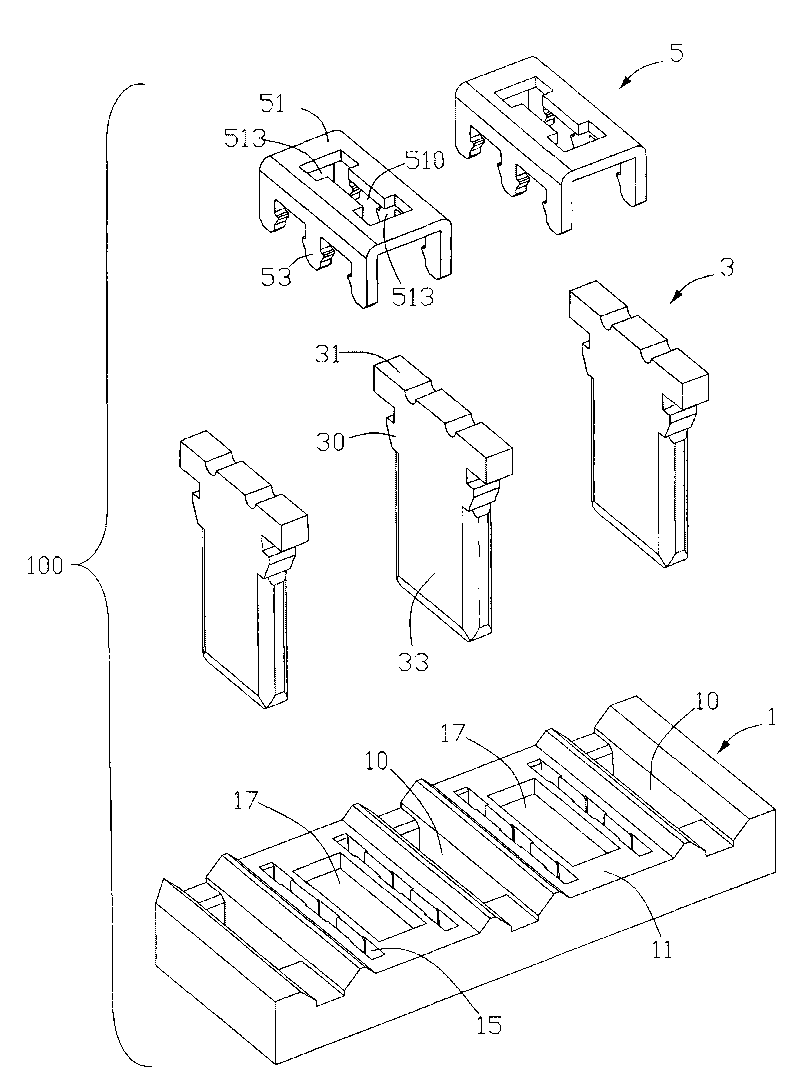

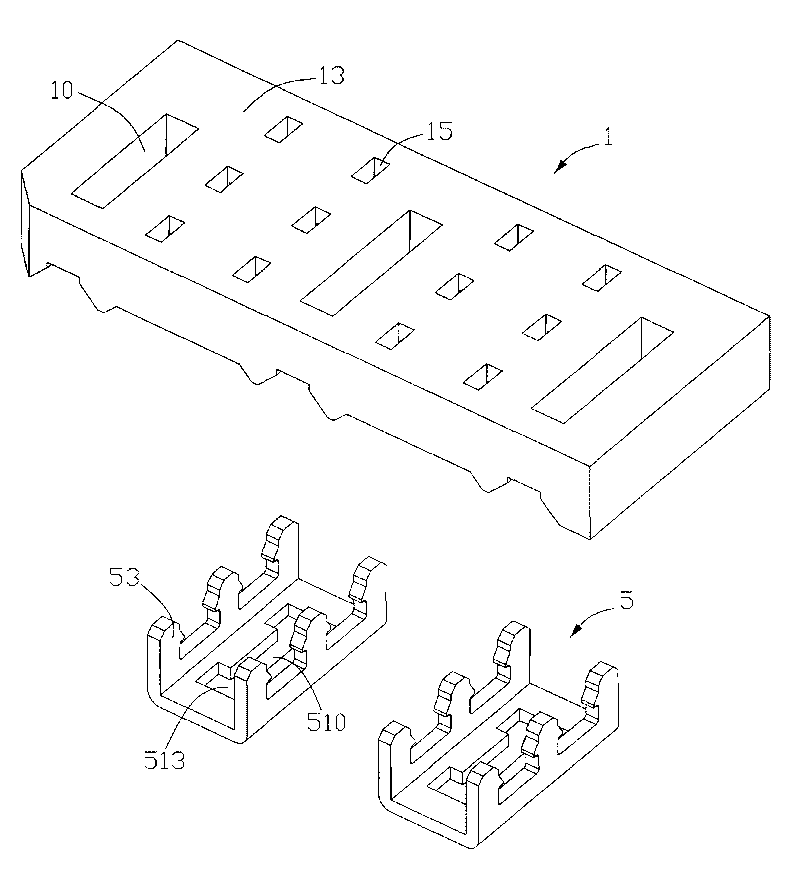

Electric coupler

InactiveCN101752705AWeld tightlySoldered/welded conductive connectionsFixed connectionsEngineeringSoldering

An electric coupler can be mounted on a circuit board and comprises an insulating body provided with a plurality of housing grooves, a plurality of terminals, part of which are housed in the housing grooves, and welding parts arranged in the insulating body. The welding parts comprise welded plates welded on the circuit board and grooves sunken on the welded plates. The welding parts at least comprise matching grooves conducted with the grooves. When the electric coupler is mounted on the circuit board, the residual soldering tin in the grooves can flow into the matching grooves, without overflowing from the grooves.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD +1

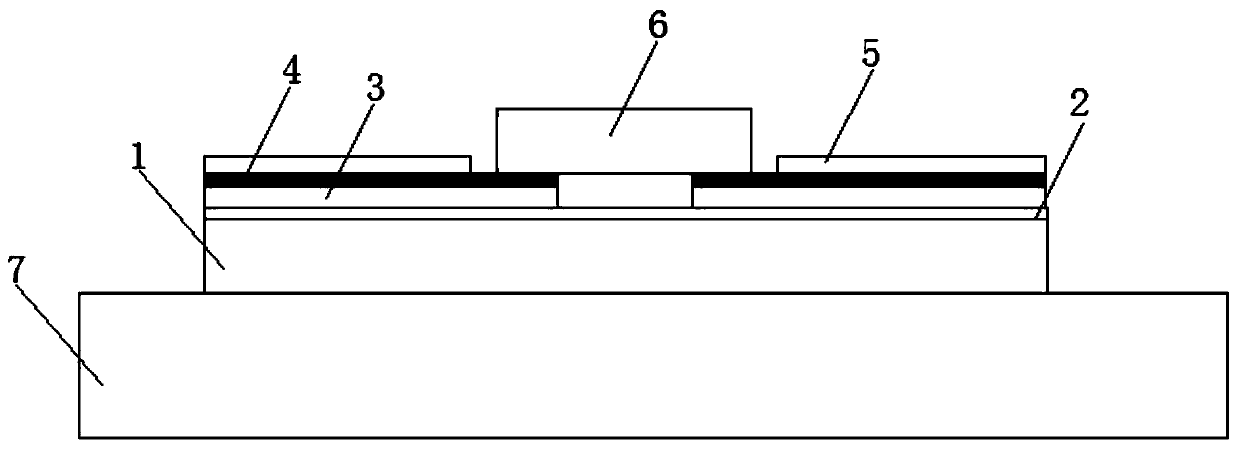

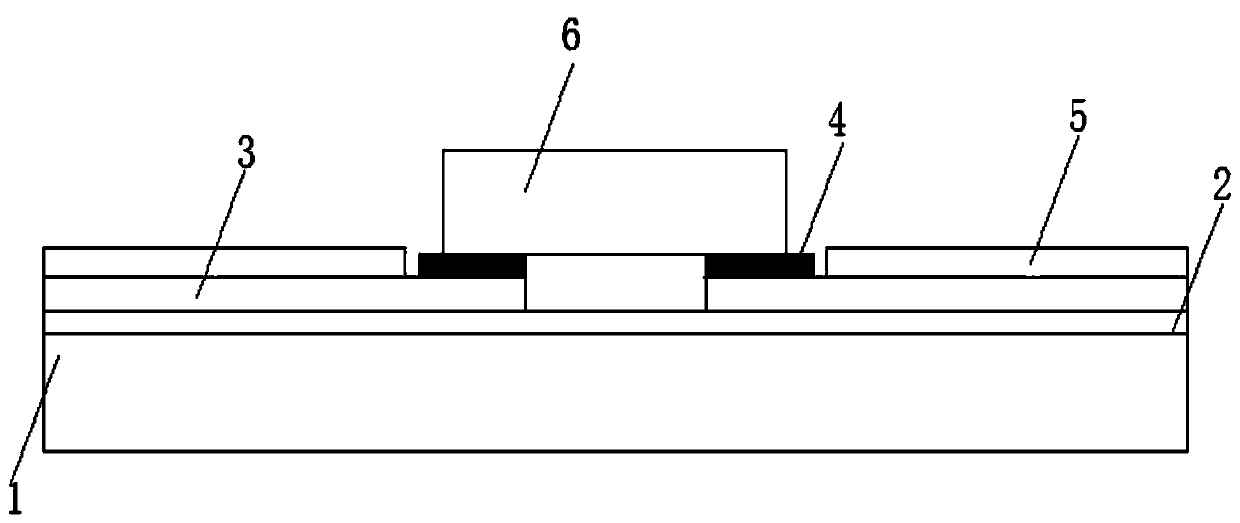

LED inverted substrate

PendingCN110459667AShort thermal pathWeld tightlySolid-state devicesSemiconductor devicesSolder pasteElectricity

The invention discloses an LED inverted substrate, which comprises an aluminum substrate and a copper conductive layer. The top of the aluminum substrate is horizontally connected with an insulating layer. The top of the insulating layer is horizontally connected with the copper conductive layer. A tin layer is arranged on the top of the copper conductive layer. A groove is arranged in the top middle of the copper conductive layer, and the upper part of the copper conductive layer is connected with a flip chip through the groove. The tin layer does not change color after oxidation, and does not affect the product performance. No solder paste is needed during die bonding on the tin layer. The tin layer has a great cost advantage over silver / gold. The thickness of the tin layer is controllable and usually within 8-25 microns. Compared with solder paste having a thickness of 100-130 microns, the tin layer has a shorter heat conduction path. The temperature of a heating block is 230 DEG C,which will not change the color of the ink and can make the flip chip conduct electricity evenly in use.

Owner:ANHUI COREACH TECH

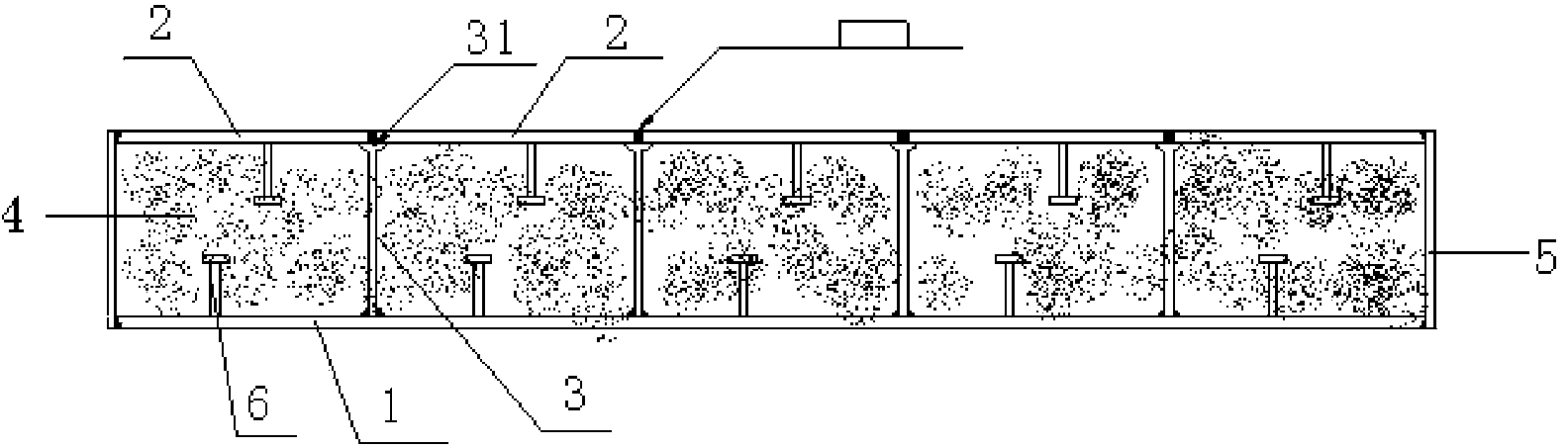

Filling and sealing system for double-chamber-bag powder cavity

PendingCN110949772AAvoid adsorptionWeld tightlyPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringWorkbench

The invention relates to a filling and sealing system for a double-chamber-bag powder cavity. The essential of the technical scheme is as follows: the filling and sealing system for the double-chamber-bag powder cavity comprises a workbench, a bag body conveying device arranged in the workbench in an embedding manner, as well as a powder filling device and a sealing device which are fixed to the workbench and sequentially arranged in a conveying direction for bag bodies, wherein the powder filling device comprises a powder storage bin fixedly installed above the bag body conveying device; a plurality of filling funnels are arranged at the bottom end of the powder storage bin; a first bag opening mechanism opening the double-chamber-bag powder cavity before powder filling, and a static electricity elimination mechanism used for neutralizing electric ions carried on medicine powder in a powder filling process are arranged below the filling funnels; and double chamber bags subjected to powder filling are conveyed to the sealing device through the bag body conveying device and subjected to hot-pressing sealing. The filling and sealing system for the double-chamber-bag powder cavity hasthe following advantages: the electric ions carried on the medicine powder can be neutralized during filling, the medicine powder is prevented from being adsorbed onto a notch in the top end of the medicine powder bags, and complete sealing performance of the sealed medicine powder bags is guaranteed.

Owner:北京锐业制药有限公司

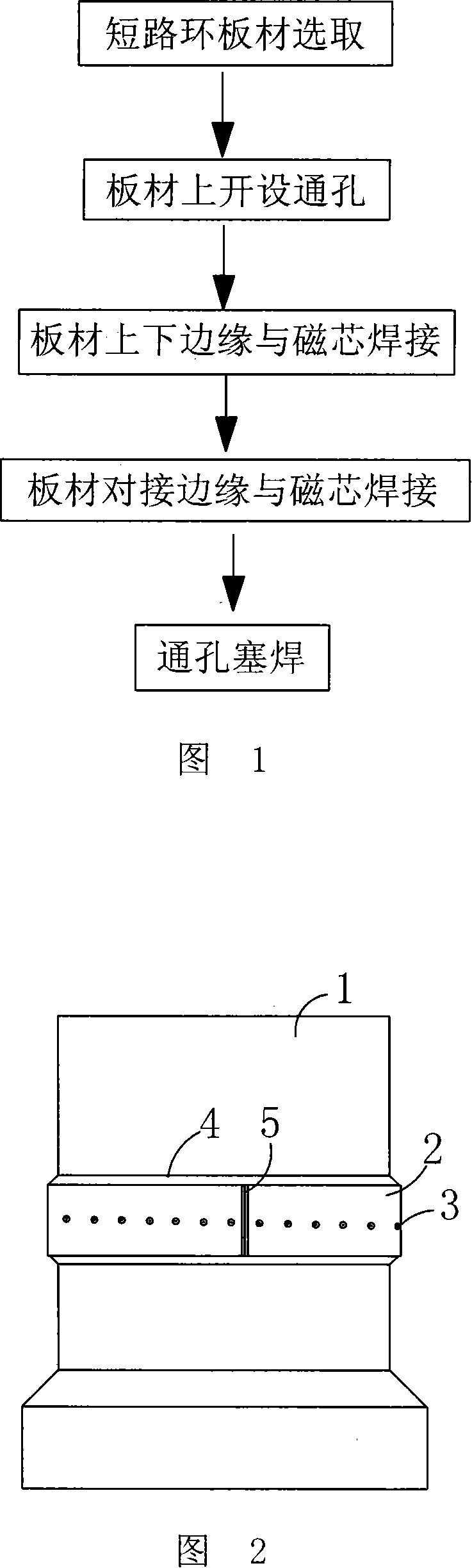

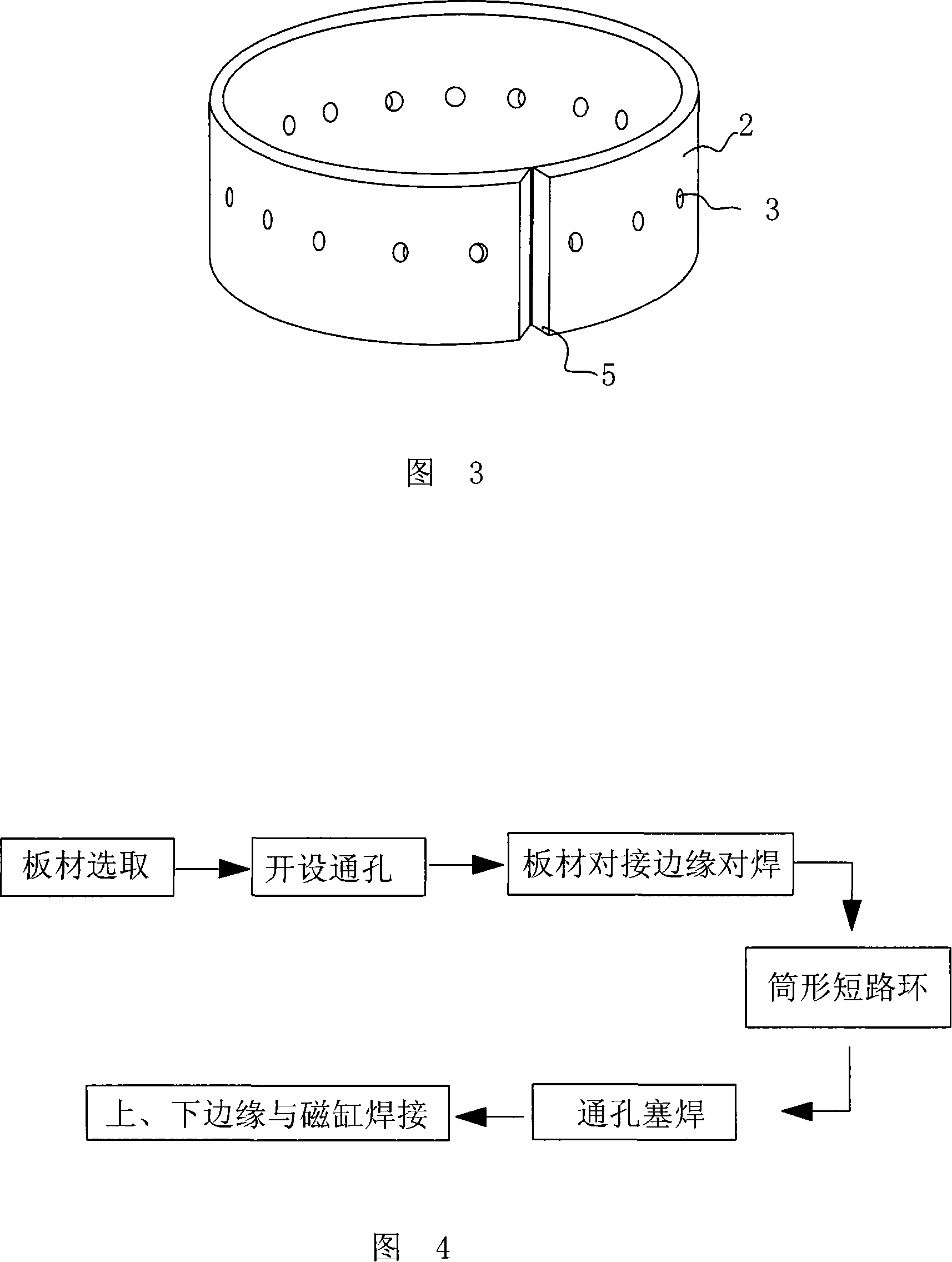

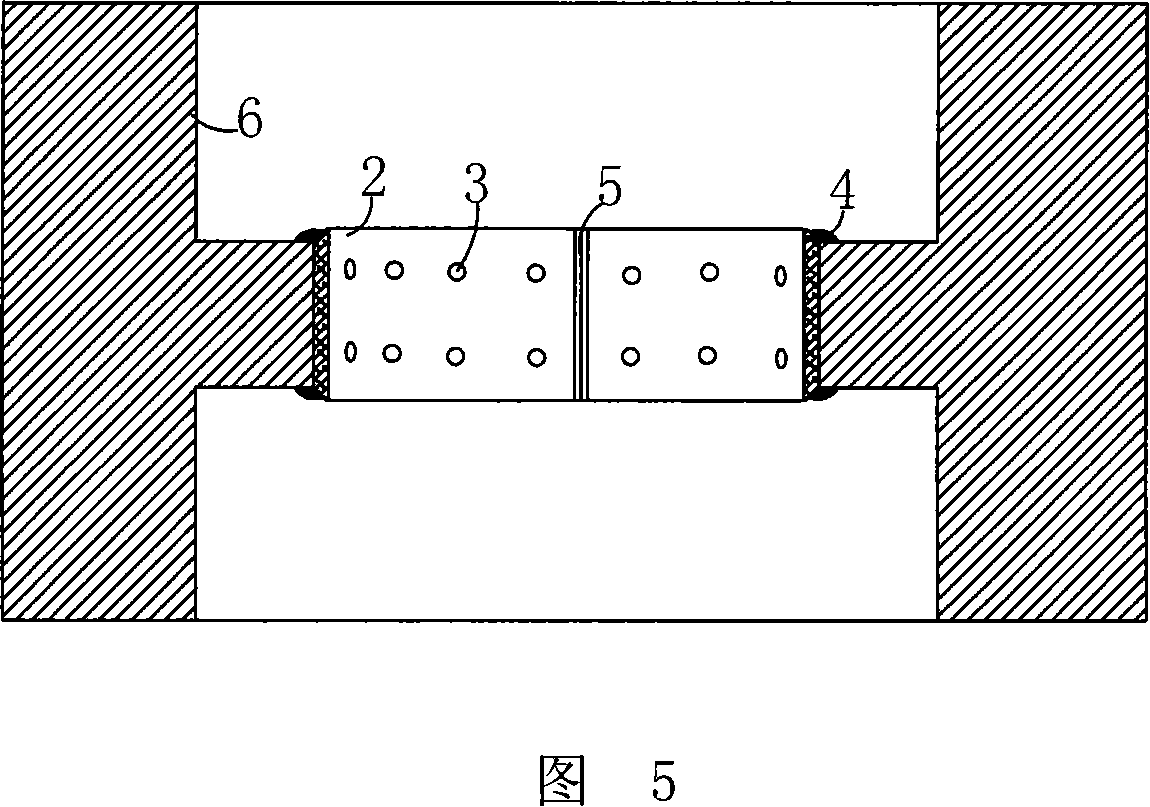

Welded fastening method of short-circuited conducting sleeve and adoptive short-circuited conducting sleeve thereof

ActiveCN101118198AWeld tightlyUniform solder jointsArc welding apparatusVibration testingSafety coefficientUltra high frequency

The present invention relates to a welding-fixing method of a short circuit ring and an adopted short circuit ring. A plank stuff is provided with a through hole, the plank stuff is curled to form a cylinder, and then gas shielded welding is used at the through hole position, the abutting edges after the plank stuff is curled, and the upper edge and the lower edge of the cylinder to weld the cylinder on a fixing surface. The short circuit ring is in the curled plank stuff shape, the plank stuff with the short circuit ring is provided with the through hole used for gas shielded welding. After the short circuit ring adopted by the short circuit ring welding fixing method is fixed, the welding spots are distributed reasonably, the service life is greatly prolonged, without easy loosening, and the manufacture cost is low in the severe and the ultra high frequency mechanical experiment environments; the structure of the short circuit ring adopted by the method is simple, the rationality of the welding fixing spots of the short circuit ring can be effectively ensured, the gap between the short circuit ring and the fixing surface is eliminated, a vibration test is not disturbed by the infirm fixing of the short circuit ring, the short circuit ring has firm structure, the service life of the short circuit ring is prolonged, and correspondingly, the service life and the safety coefficient of a vibrating platform are also improved.

Owner:SUZHOU DONGLING VIBRATION TEST INSTR

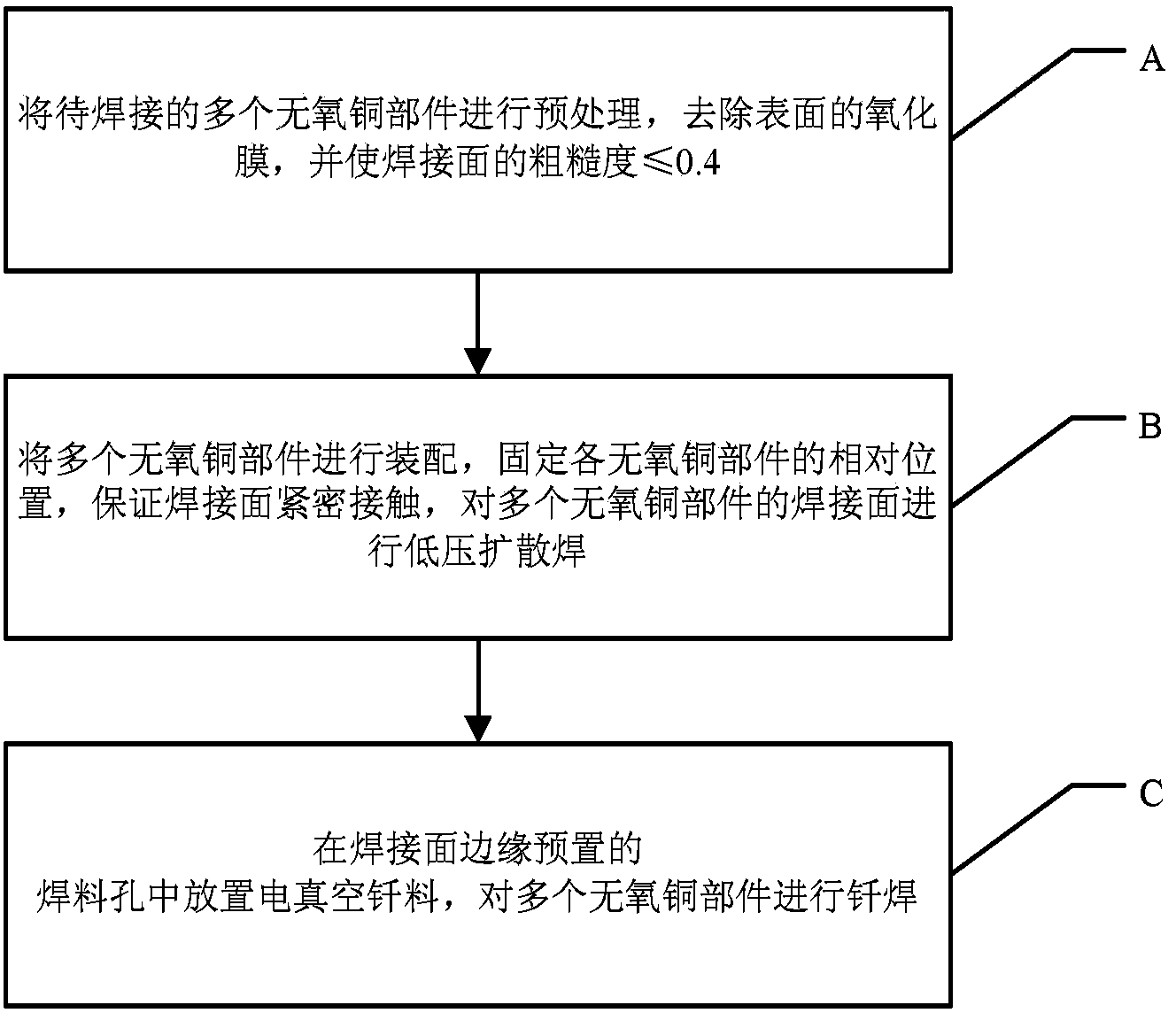

Oxygen-free copper composite welding method

ActiveCN103817451ATightly boundImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesOxideBase metal

The invention provides an oxygen-free copper composite welding method by combining low pressure diffusion welding with brazing compound welding. The oxygen-free copper composite welding method comprises the steps: step A, preprocessing multiple oxygen-free copper parts to be welded to remove the oxide film on the surfaces of the oxygen-free copper parts; step B, assembling the multiple oxygen-free copper parts, fixing the relative position of each oxygen-free copper part to ensure close contact of welding faces, and carrying out low pressure diffusion welding on the welding faces of the oxygen-free copper parts; step C, placing electric vacuum brazing filler metal in the welding holes preset in the edges of the welding faces and brazing the multiple oxygen-free copper parts. A composite welding head formed through the oxygen-free copper composite welding method is bonded tightly, the precision of welding is high, the vacuum leakproofness is good, and the joint tensile strength is 200-300 MPa, being close to or even higher than the oxygen-free copper base metal strength.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

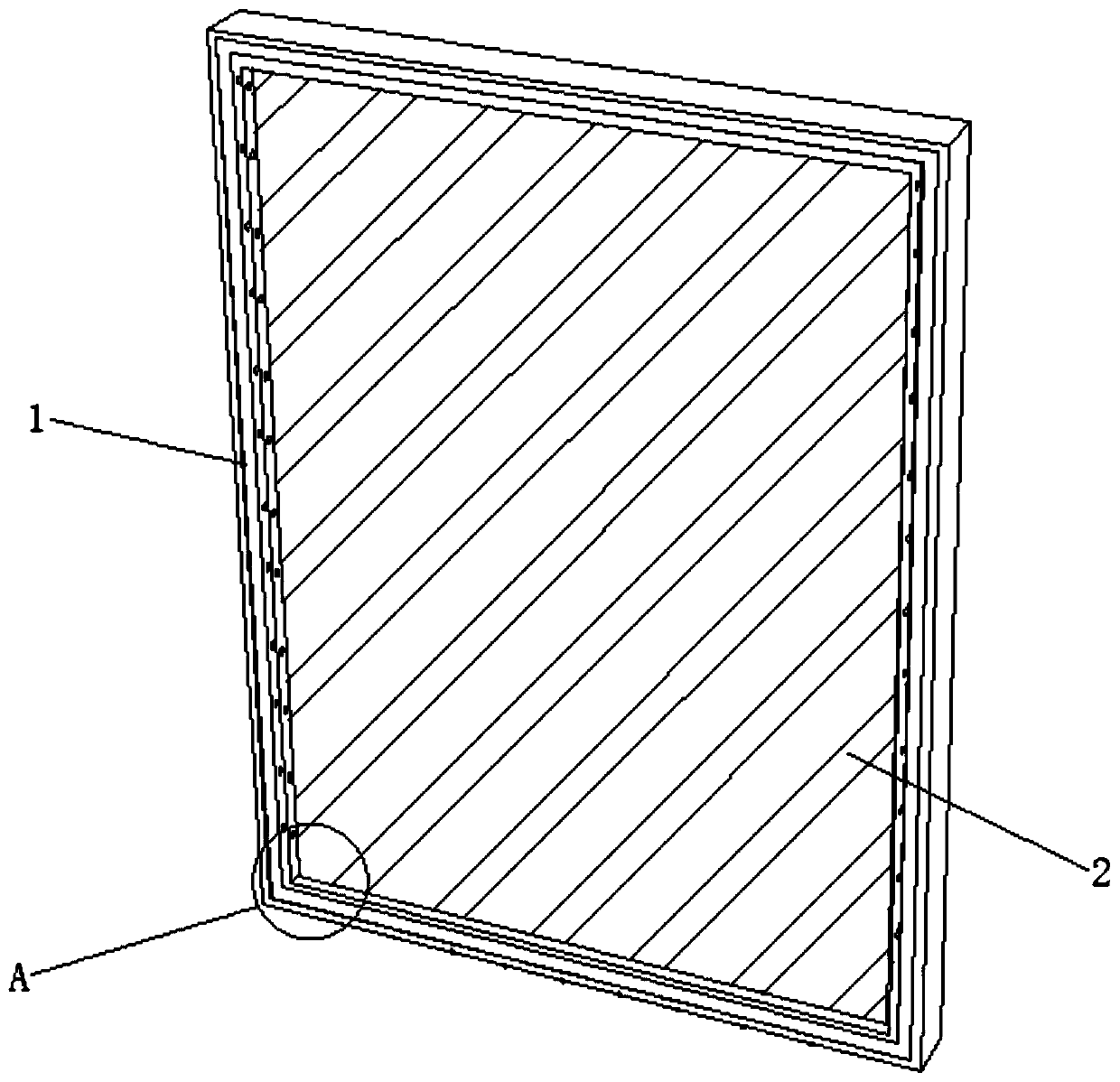

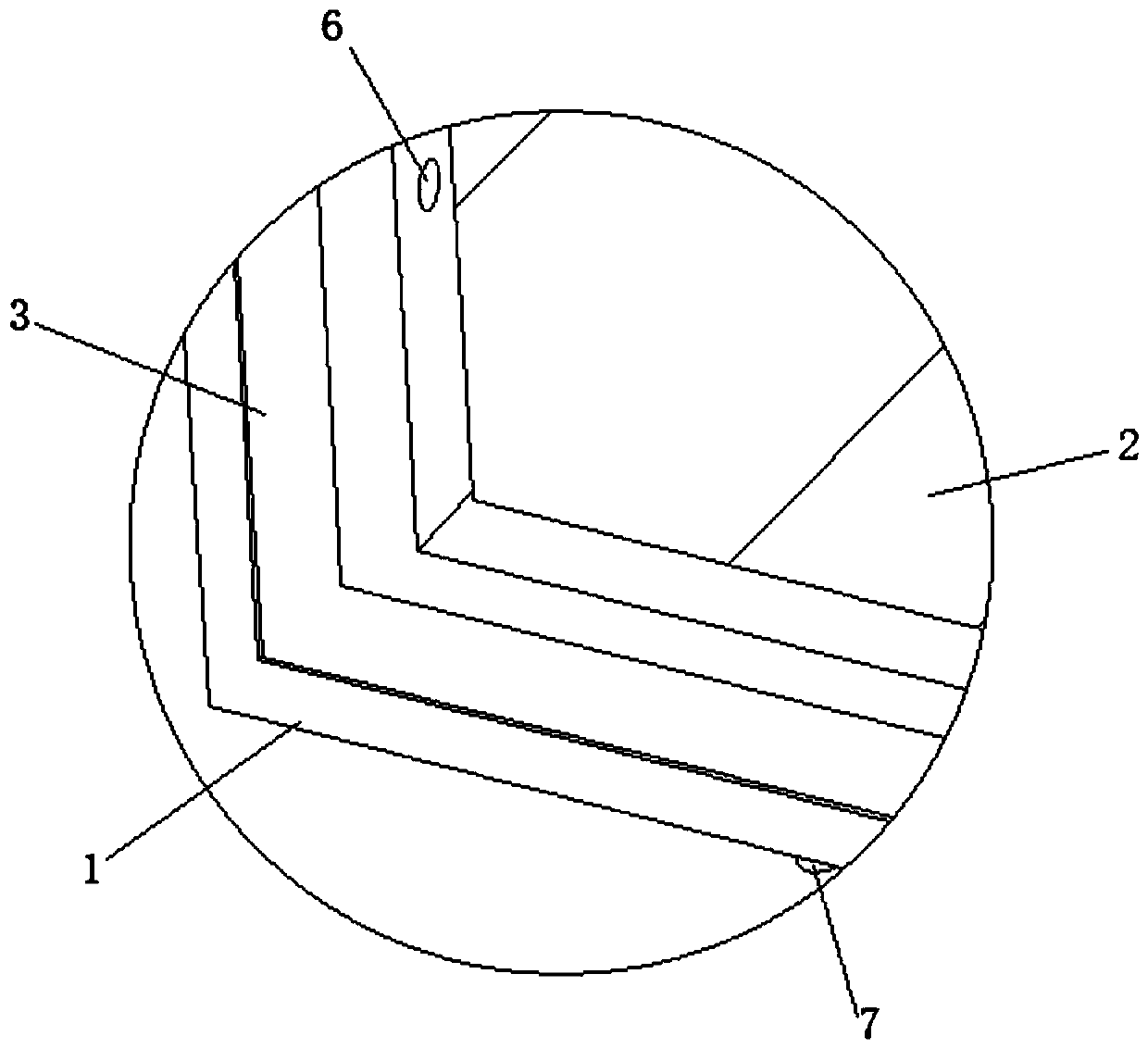

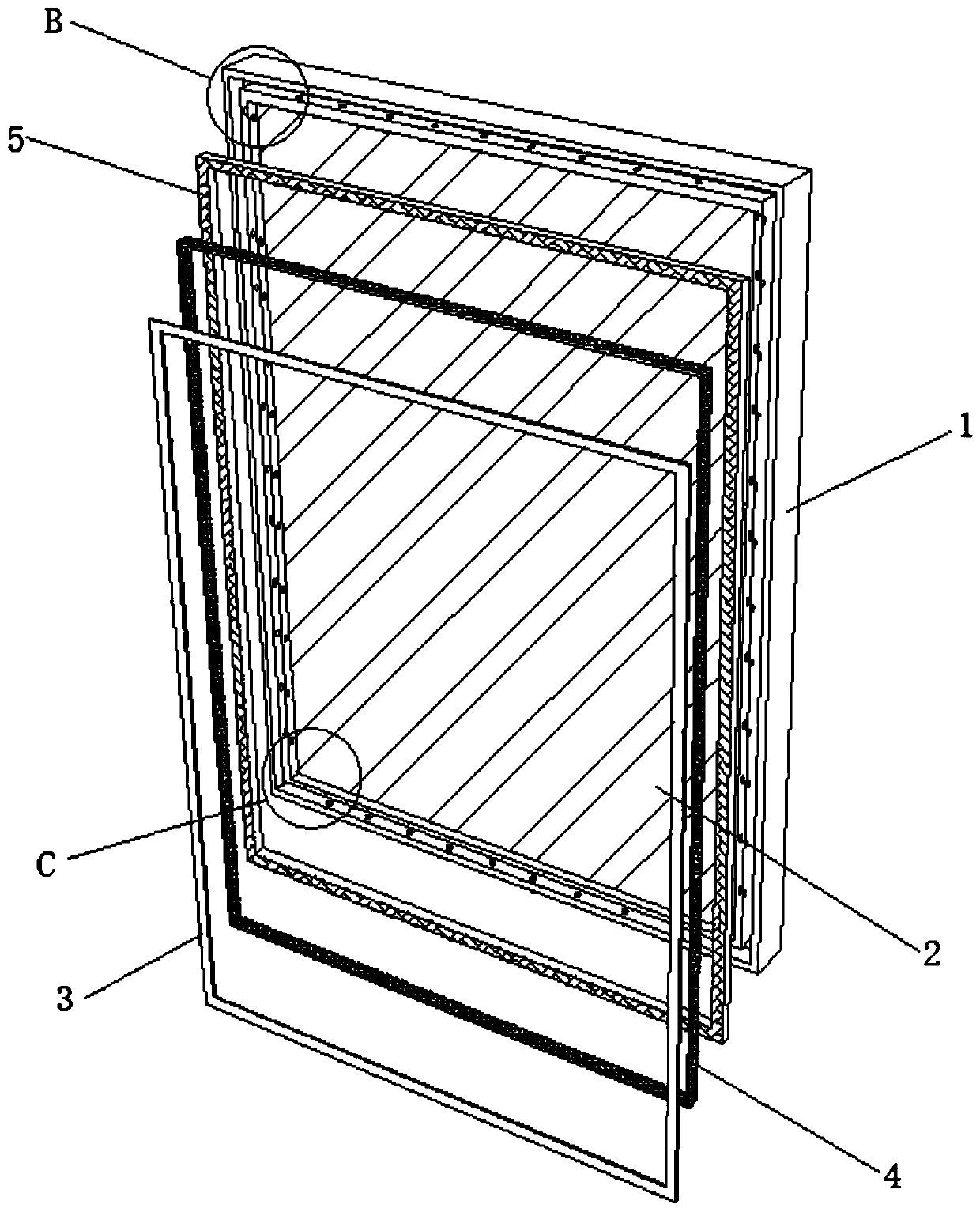

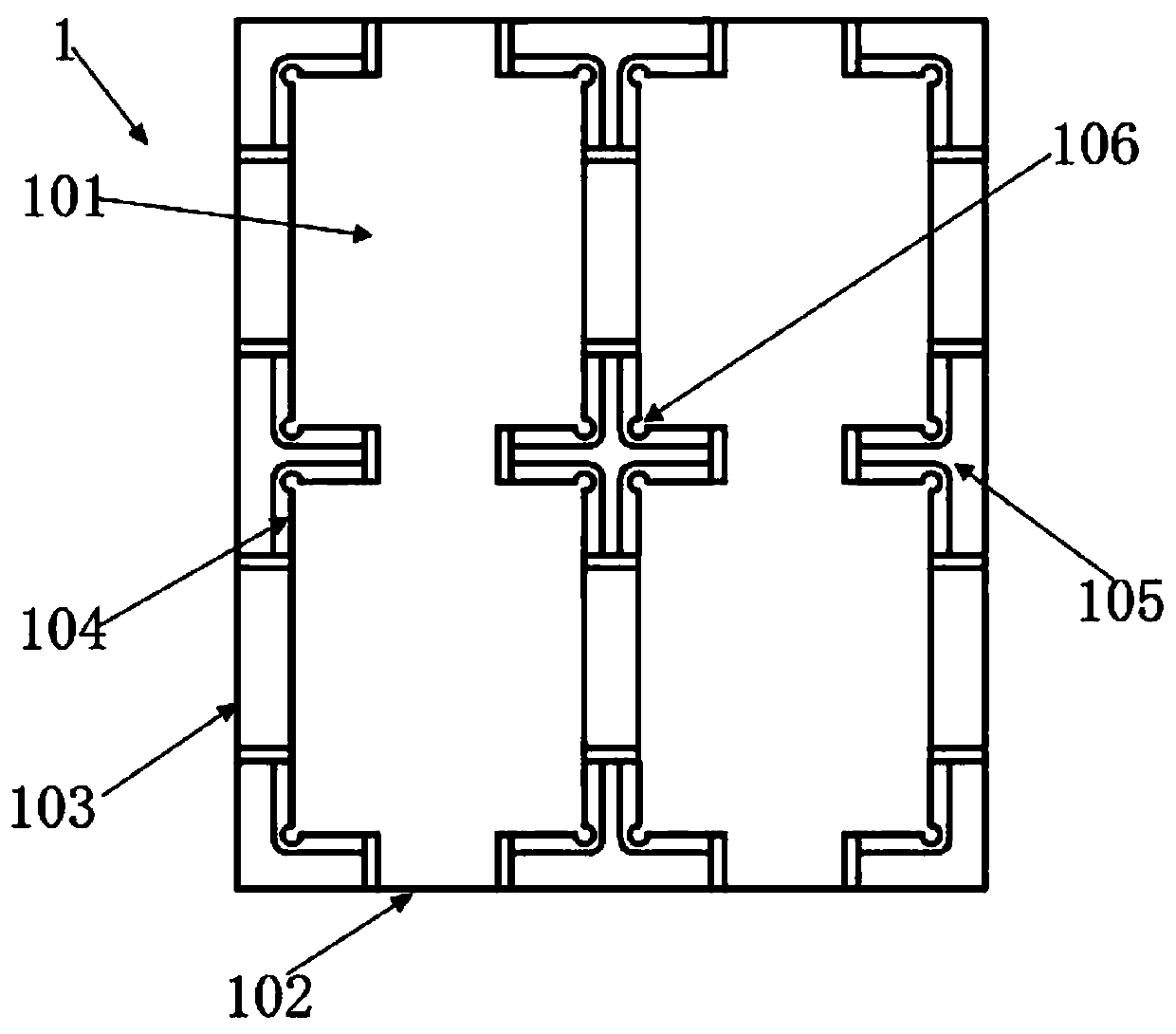

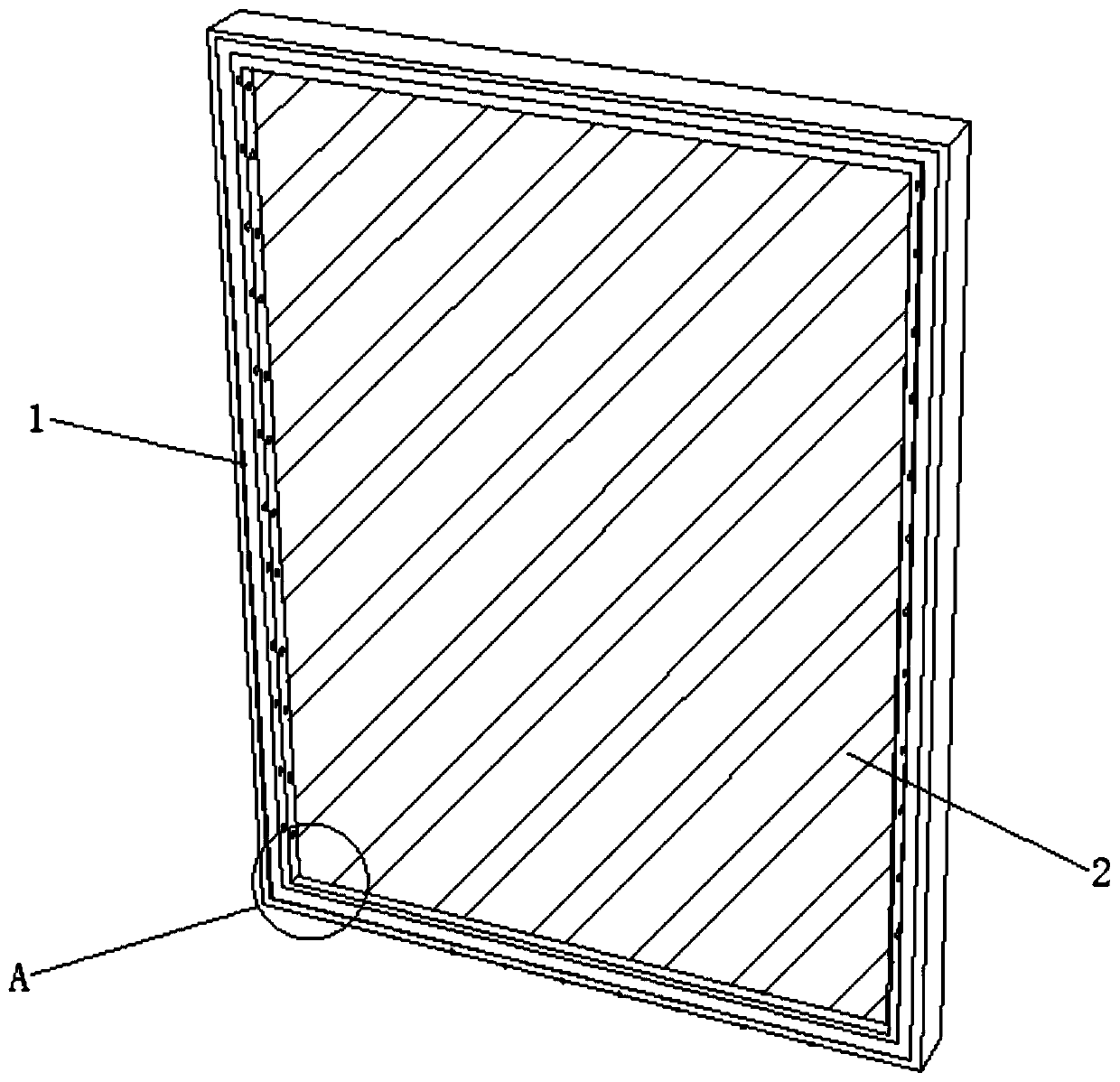

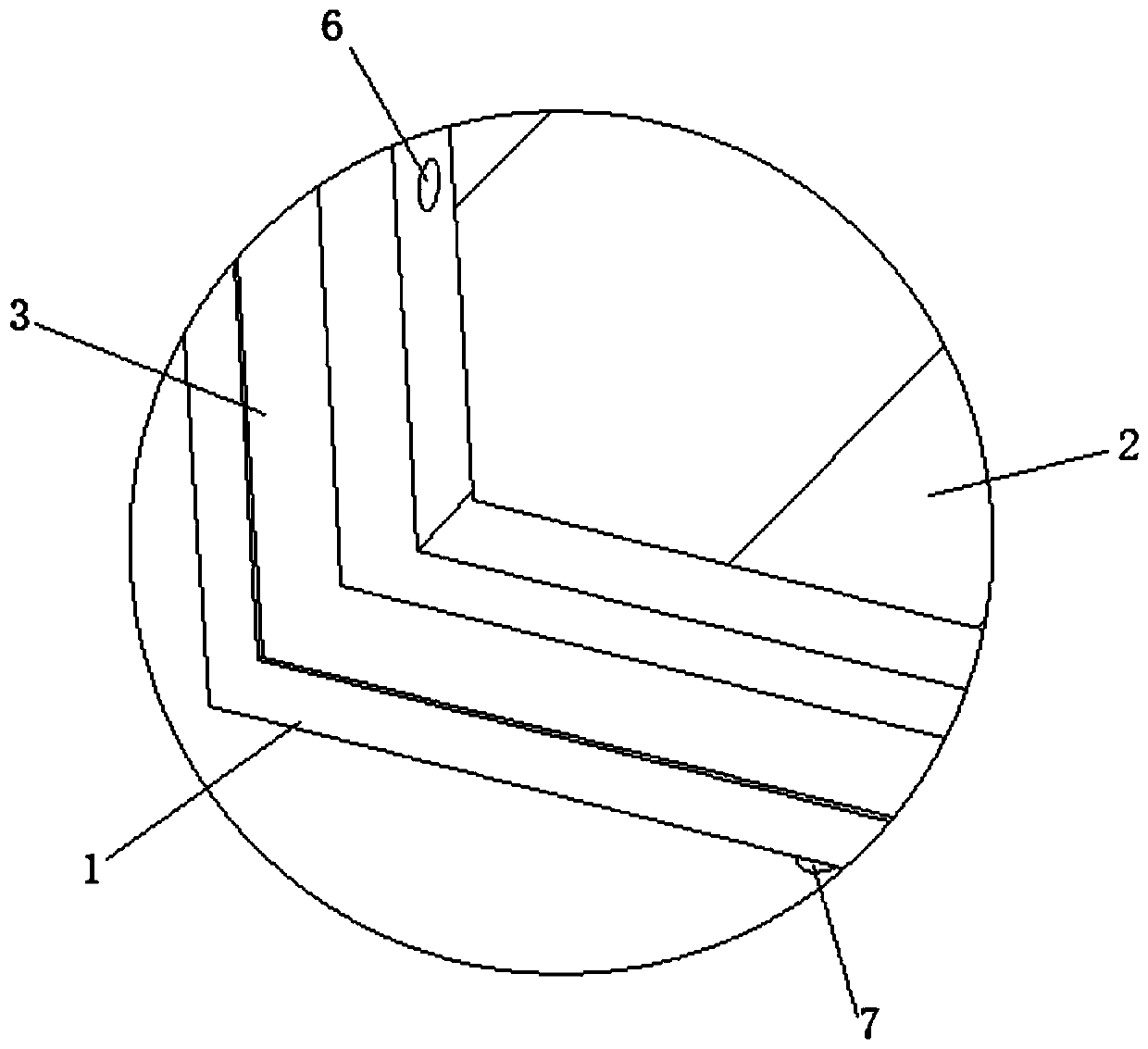

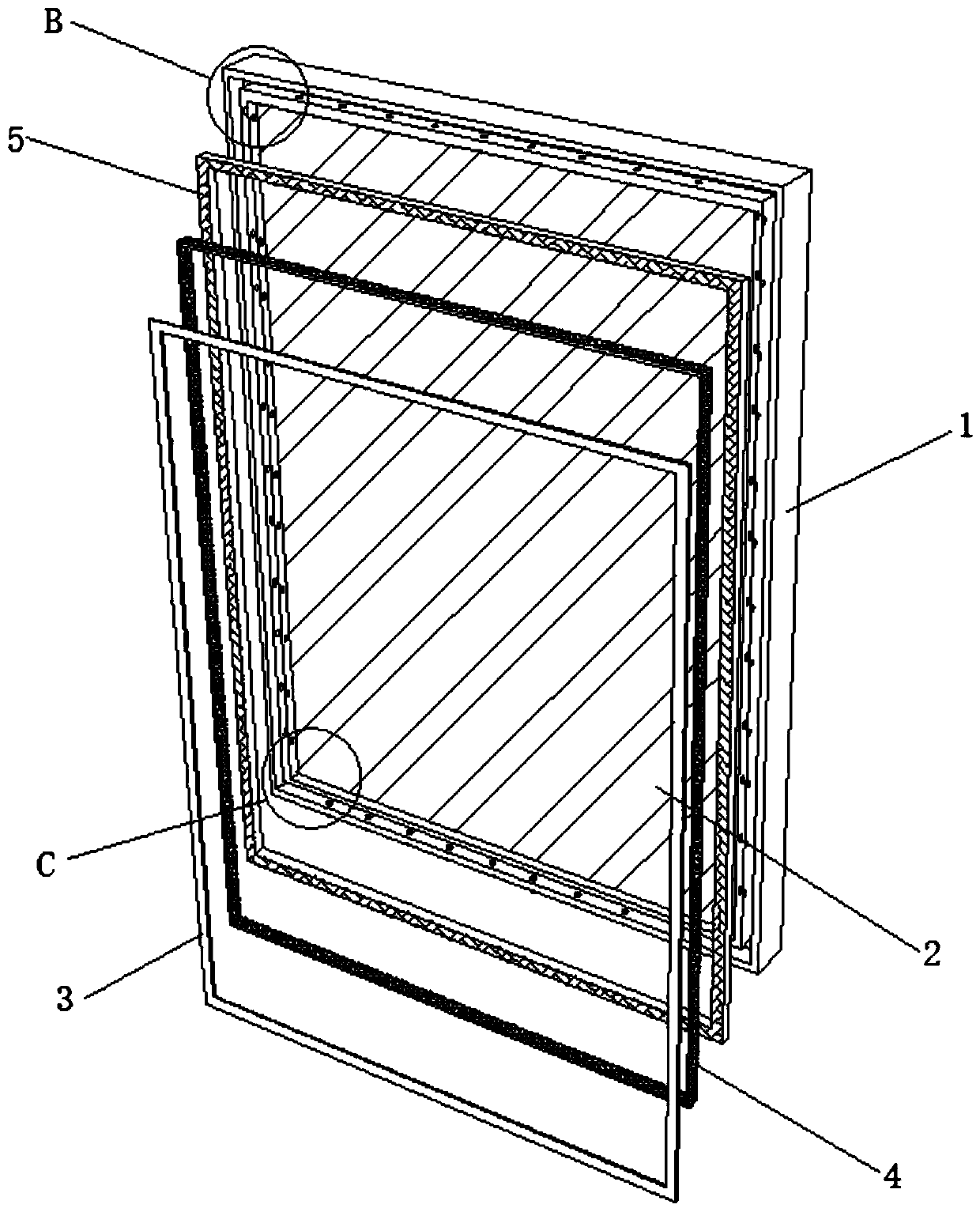

Aluminum alloy door and window achieving hidden type trace water drainage

ActiveCN110485857AGuaranteed flexibilityPrevent rustCondensed water drain-offCondensed water formation preventionWindow openingGlass sheet

The invention discloses an aluminum alloy door and window achieving hidden type trace water drainage and belongs to the field of aluminum alloy doors and windows. The aluminum alloy door and window achieving hidden type trace water drainage comprises an aluminum alloy door and window outer frame with a glass plate installed on the inner side. A hidden type water drainage groove is formed in the front end of the aluminum alloy door and window in a digging manner. A water absorbing frame is arranged in the hidden type water drainage groove. A sealing cover frame is connected to a groove openingof the hidden type water drainage groove. Multiple water guide holes are uniformly formed in the lower end of the aluminum alloy door and window outer frame in a digging manner. Embedded type water absorbing bars are fixedly connected into the water guide holes. Multiple side air drying holes are formed in the left inner side end and the right inner side end of the aluminum alloy door and window in a digging manner correspondingly. Upper air drying holes distributed uniformly are formed in the upper inner side end of the aluminum alloy door and window outer frame in a digging manner. Accordingto the aluminum alloy door and window, the multiple embedded type water absorbing bars are utilized for absorbing trace water spots on the surface of a sliding rail of the aluminum alloy door and window, the absorbed water is transferred and dried through the water absorbing frame, the surface of the sliding rail is effectively prevented from rusting, and flexibility of the door and window opening and closing is ensured.

Owner:江苏海鹰德拉图节能科技有限公司

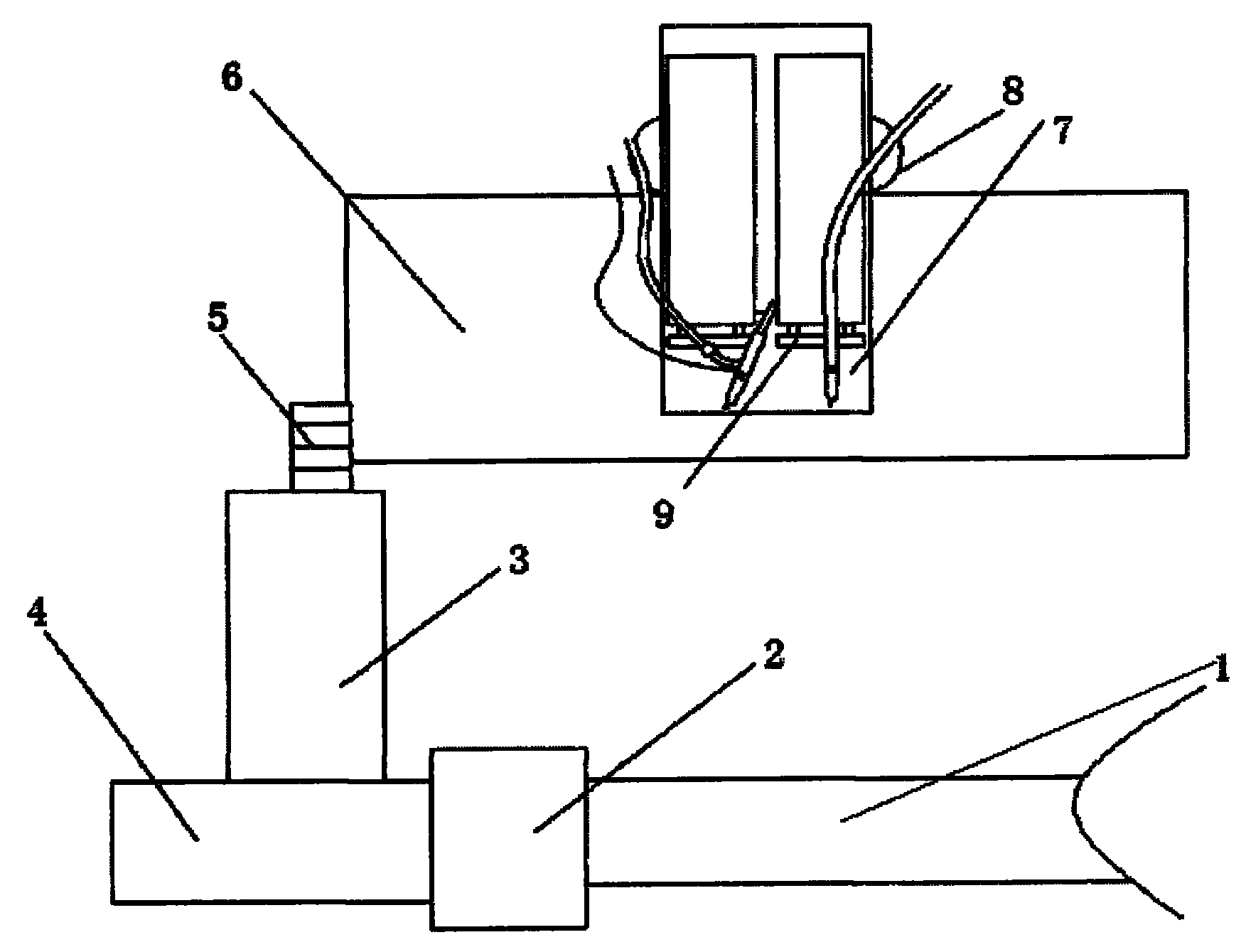

Full-automatic numerical control welding method and equipment

InactiveCN104325210AImprove stabilityImprove uniformitySupport devices with shieldingWelding/cutting auxillary devicesNumerical controlElectric machinery

The invention relates to the field of machinery, in particular to a full-automatic numerical control welding method and equipment. The equipment comprises a positioning device, wherein the positioning device comprises an X / Y / Z three-direction mobile device; the equipment comprises welding guns capable of moving along with the positioning device, and further comprises a grabbing device; one end of the grabbing device is provided with a clip, and the other end of the grabbing device is connected with a motor; and the grabbing device can rotate. Two welding guns are provided, and are respectively a carbon dioxide shielded welding gun and an argon arc welding gun. Compared with the prior art, the full-automatic numerical control welding equipment has the following beneficial effects: in the welding process, the stability and the uniformity of welding lines are excellent, and the welding is tight without leaking; after the carbon dioxide gas shielded welding and the argon arc welding are combined, the welding cost is reduced; and the welding time is largely decreased.

Owner:QINGDAO GOLDEN PHOENIX HVAC EQUIP

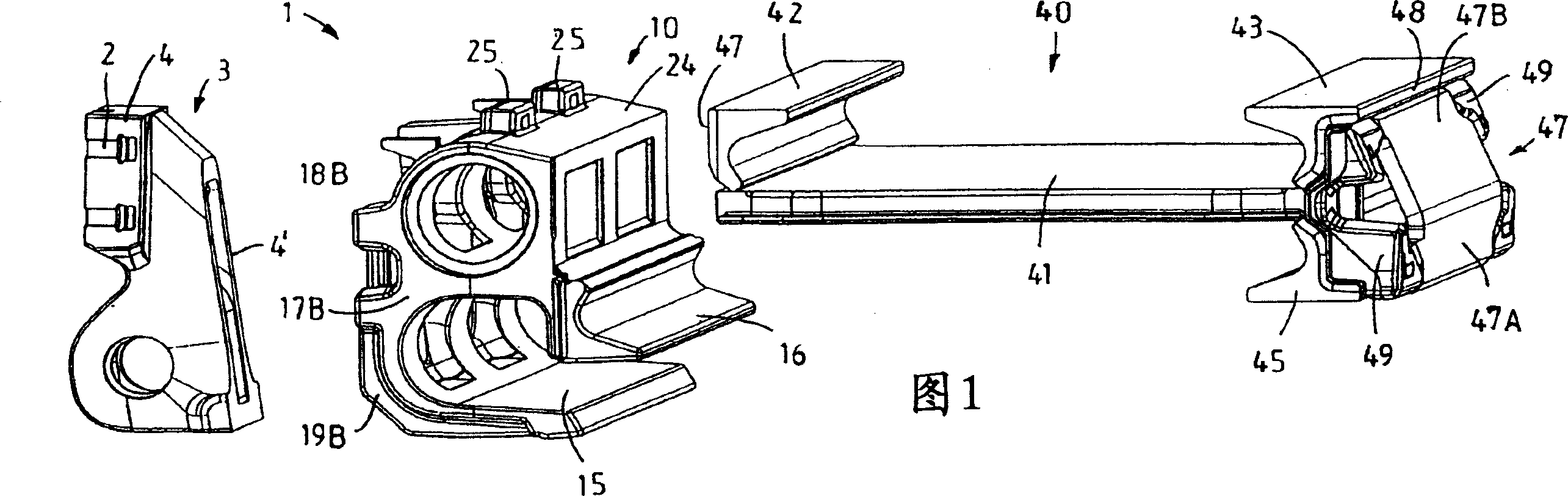

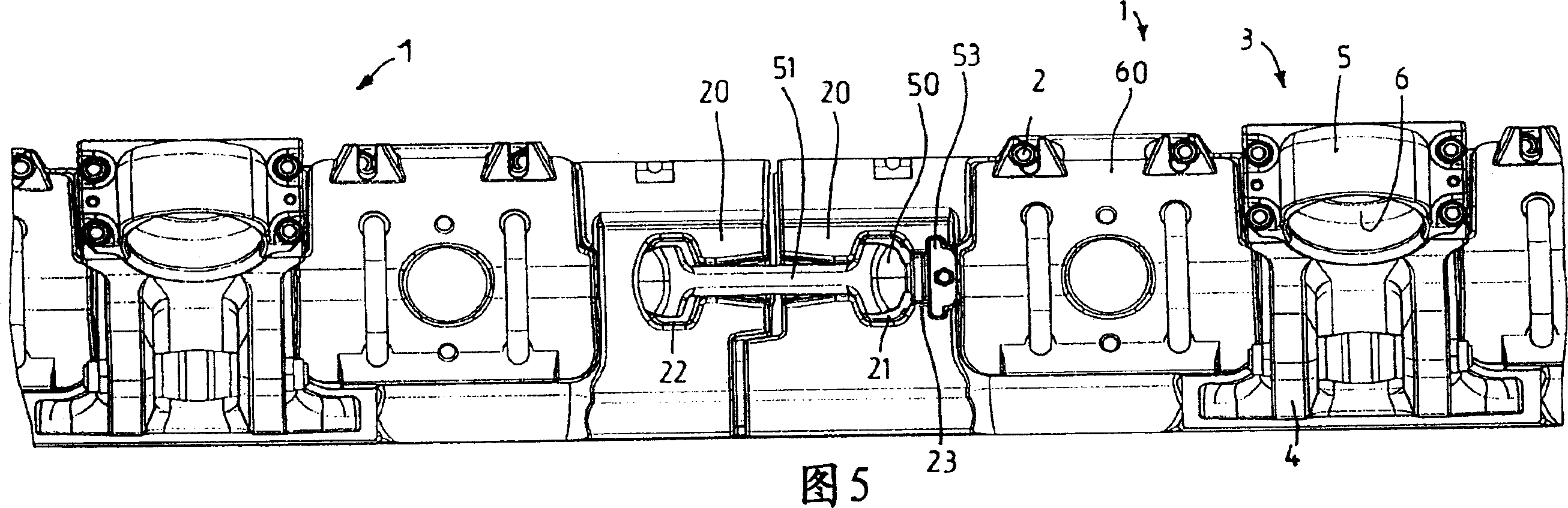

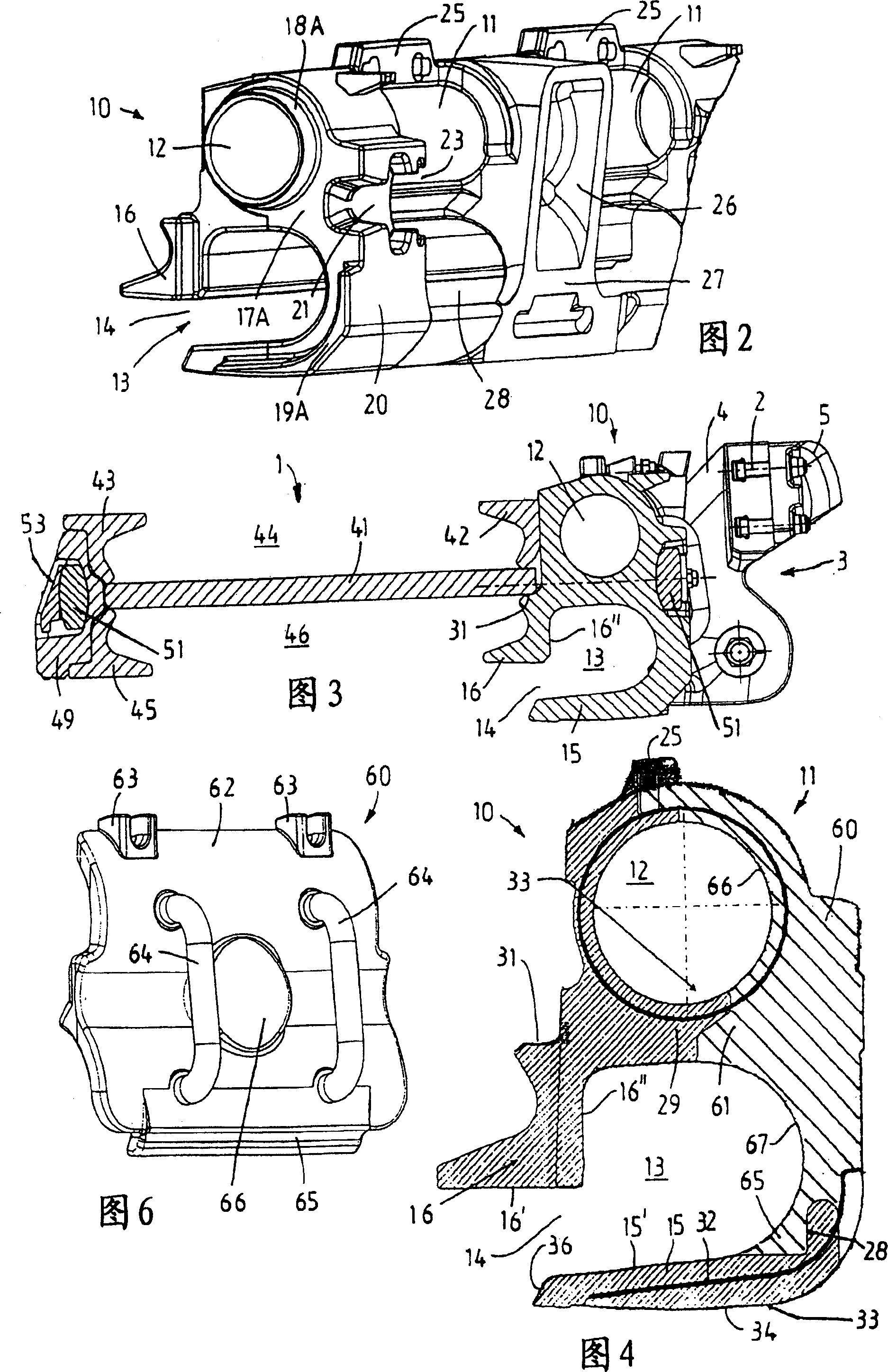

Guiding device for guiding a chain-drawn sword plane

InactiveCN1948710ALess soldering stepsEasy to wearSlitting machinesEngineeringMechanical engineering

The present invention relates to a guiding device (1) for guiding a chain-drawn sword plane which comprises a guiding element (10) consisting of a conveying shute (44) defined by the side section bar (42, 43) on the conveyor and a reversion groove (46) defined by the channel bar (16, 45) disposed at the filling side. The guiding device has an upper chain channel (12) and a lower chain channel (13) disposed with a guiding opening (14) for the planer prop. Each accommodating groove is constituted to be used to connect the clamping held for the clamping handle on the guiding element in order to connect the abutting the guiding device for guiding a chain-drawn sword plane. According to the invention, the guiding element is composed of the length extending cast for the guiding device for guiding a chain-drawn sword plane. On the cast the channel bar (16) at the filling side for each accommodating groove and / or the reversion groove and or the guiding part (16'', 15) for guiding a chain-drawn sword plane are casted as a whole.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

Modular efficient wire welding device

Owner:CHANGZHOU SINAJET SCI & TECH

Pin welding fixture and pin fixing method

InactiveCN109732173ASolve the phenomenon of easy fallingPrevent easy looseningSoldering auxillary devicesEngineeringCopper

The invention relates to a pin welding fixture and a pin fixing method. A groove is formed in an upper end of a base portion; a gland portion is arranged on the upper portion of the base portion in afitted mode; a plurality of positioning holes penetrating up and down are formed on the gland portion; the positioning holes after the gland portion is fitted with the base portion cover over the groove; the gland portion is provided with an elastic body; the elastic body is used for fixing a pin according to the layout of the positioning holes; the elastic body carried with the fixed pin extendsinto the groove to make contact with a ceramic copper clad plate placed in the groove for welding, and the ceramic copper clad plate to be welded is pre-placed in a groove of a bottom plate body of the base portion; the ceramic copper clad plate is positioned through an inner positioning angle; the gland portion is placed upside down on the elastic body; the pin sequentially penetrates through thepositioning holes of the gland portion, so that the end of the pin is inserted into the elastic body; and the pin that is carried and fixed by the elastic body extends into the groove to contact theceramic copper clad plate placed in the groove, and the gland portion is fixed on the base portion by an external positioning angle. By means of the pin welding fixture and the pin fixing method, thewelding effect is good, and the welding is firm.

Owner:YANTAI TAIXIN ELECTRONICS TECH CO LTD

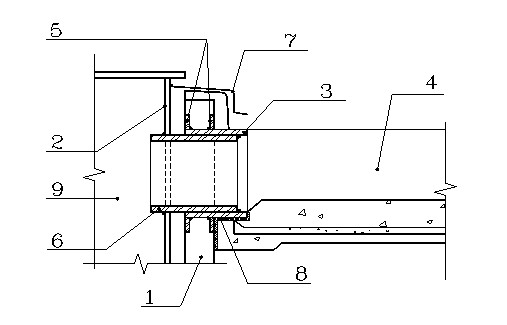

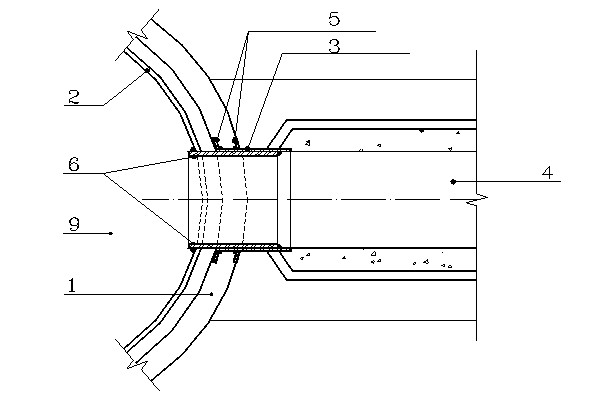

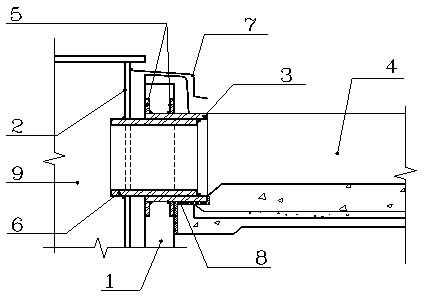

Trench and sewage tank anticorrosion connecting structure

InactiveCN102486033AWeld tightlyPrevent leakageGeneral water supply conservationBranching pipesSteel platesCorrosion

The invention relates to a trench and sewage tank connecting structure, in particular to a trench and sewage tank anticorrosion connecting structure which is suitable for aluminum oxide plants and can resist alkali corrosion. The trench and sewage tank anticorrosion connecting structure comprises a sewage tank pit and an alkali-resisting trench. A steel plate rectangular connecting pipe is arranged at a position at which the sewage tank pit is connected with the alkali-resisting trench. A steel plate casing is sheathed outside the steel plate rectangular connecting pipe. The steel plate casing is fixed in the sewage tank pit through flat steel. A sewage tank is arranged in the sewage tank pit. The steel plate rectangular connecting pipe is inserted into the wall of the sewage tank. A steel plate flashing sheet is arranged above the steel plate casing. Alkali-resisting cement is used for the plugging between the steel plate casing and the alkali-resisting trench and between the alkali-resisting trench and the sewage tank pit. The trench and sewage tank anticorrosion connecting structure has the advantages that the tightness is good, the structure is rainproof, the service life is long, and not only can the problem of settlement between two structures be effectively solved, but also the leakage of alkali liquid is effectively prevented and the durability is good.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

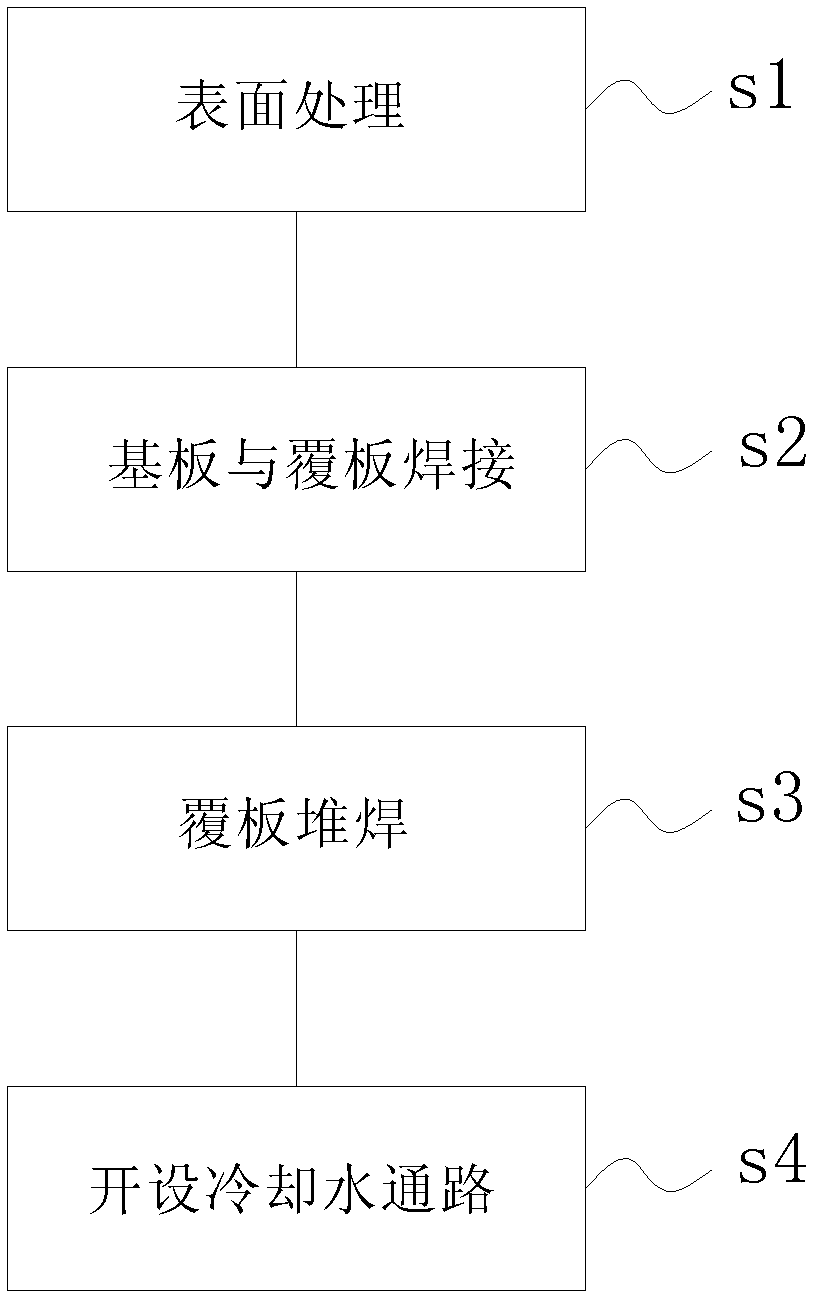

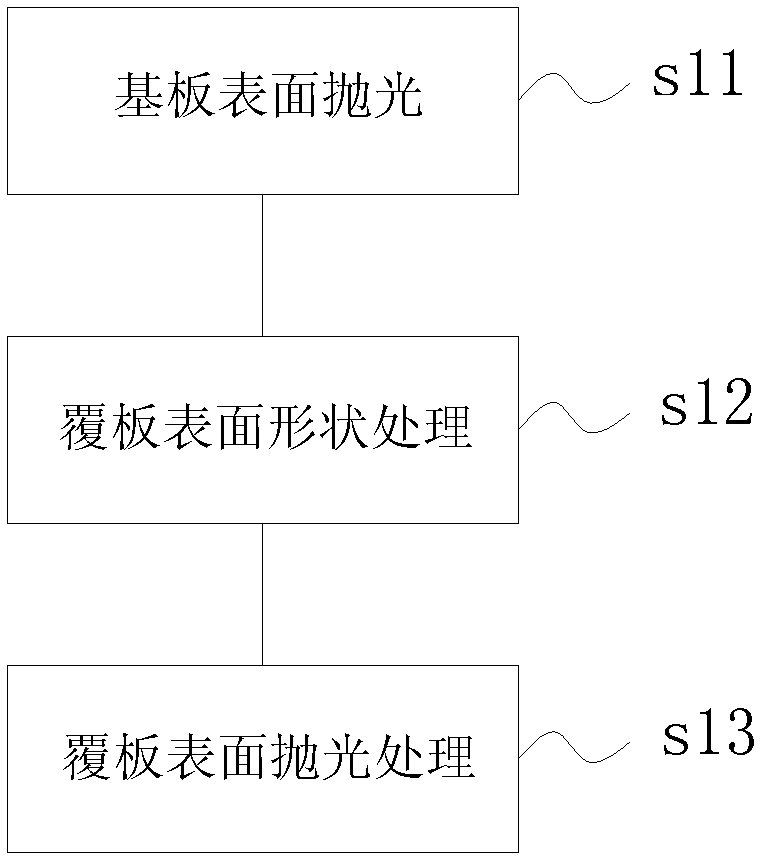

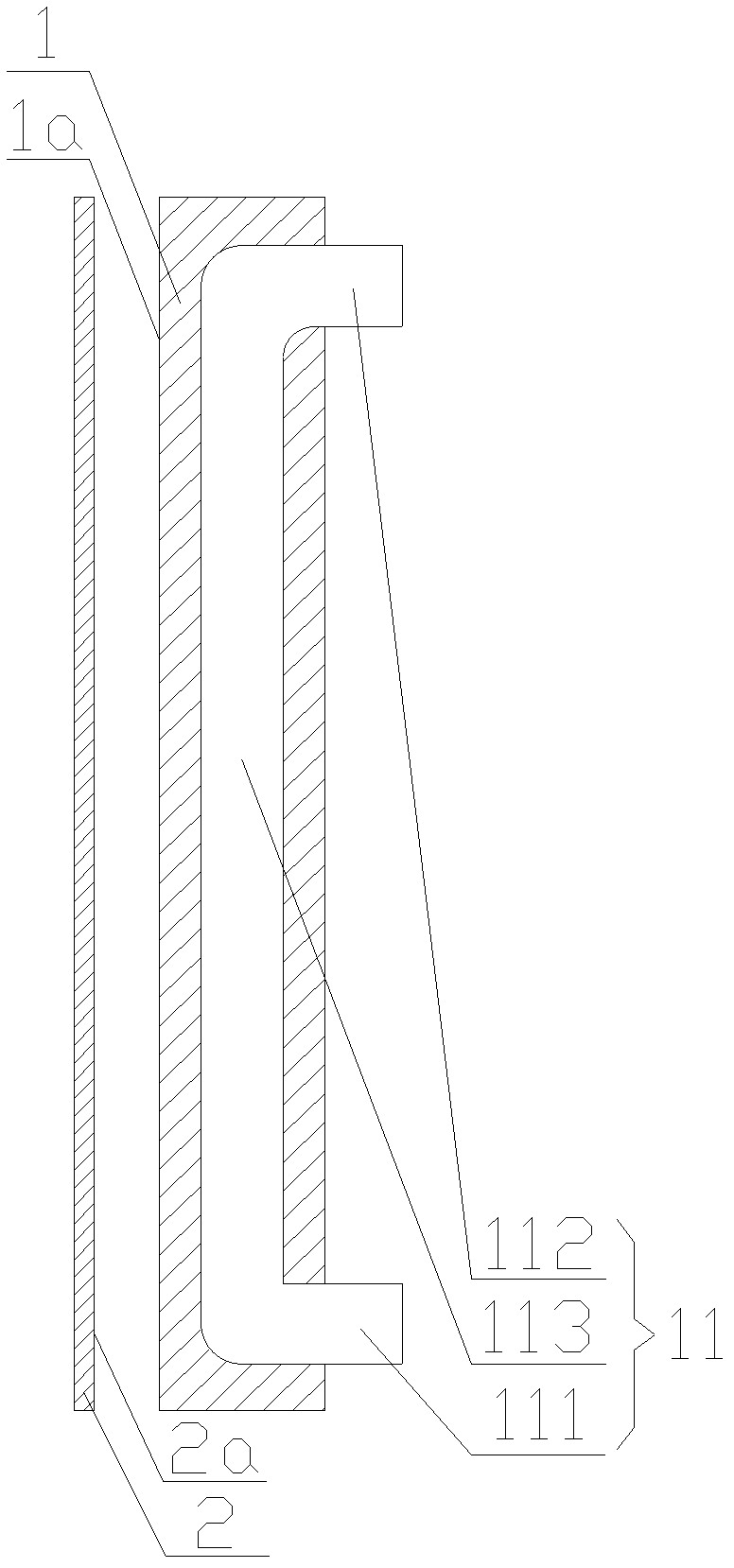

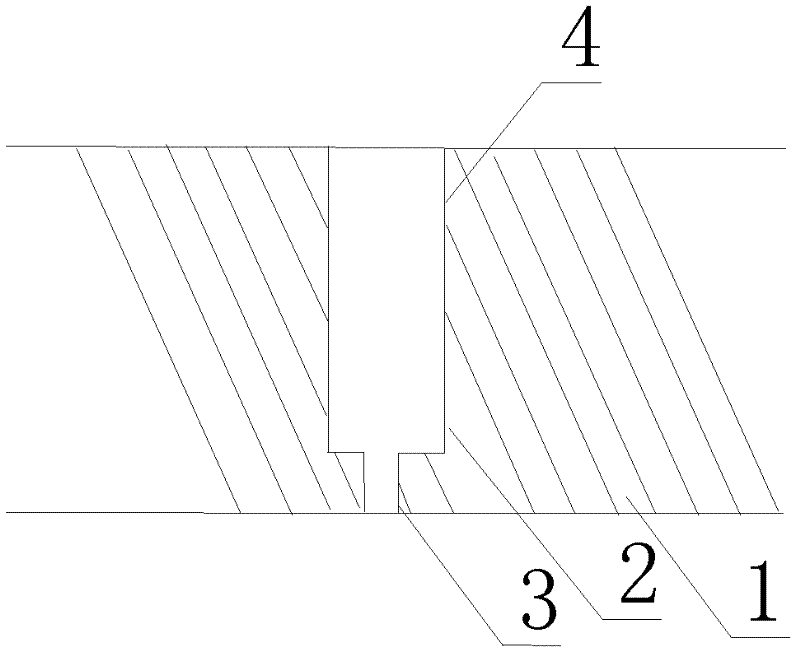

Method for manufacturing cooling element and cooling element

The invention discloses a method for manufacturing a cooling element. A copper substrate is welded with a stainless steel shroud plate by an explosive welding method, so that the cleaning degree of the welding surface on a welding piece can be improved; and the heating time of the welding piece during welding is short, so that the degree of heated oxidation of the welding surface is reduced, and the reliability of welding is improved. The invention also provides the cooling element manufactured by the method. Due to the adoption of the explosive welding method, the degree of oxidation of the surface of the welding piece is reduced, and the generation of oxides on the copper substrate is avoided, so that the welding quality of the cooling element is improved, and the operating reliability of the cooling element is improved. In addition, the cooling element is welded with the stainless steel shroud plate and an overlaying layer, and the stainless steel shroud plate and the overlaying layer can prevent a metallurgical furnace from damaging the copper substrate directly, so that the damage resistance of the cooling element is improved.

Owner:YANGGU XIANGGUANG COPPER

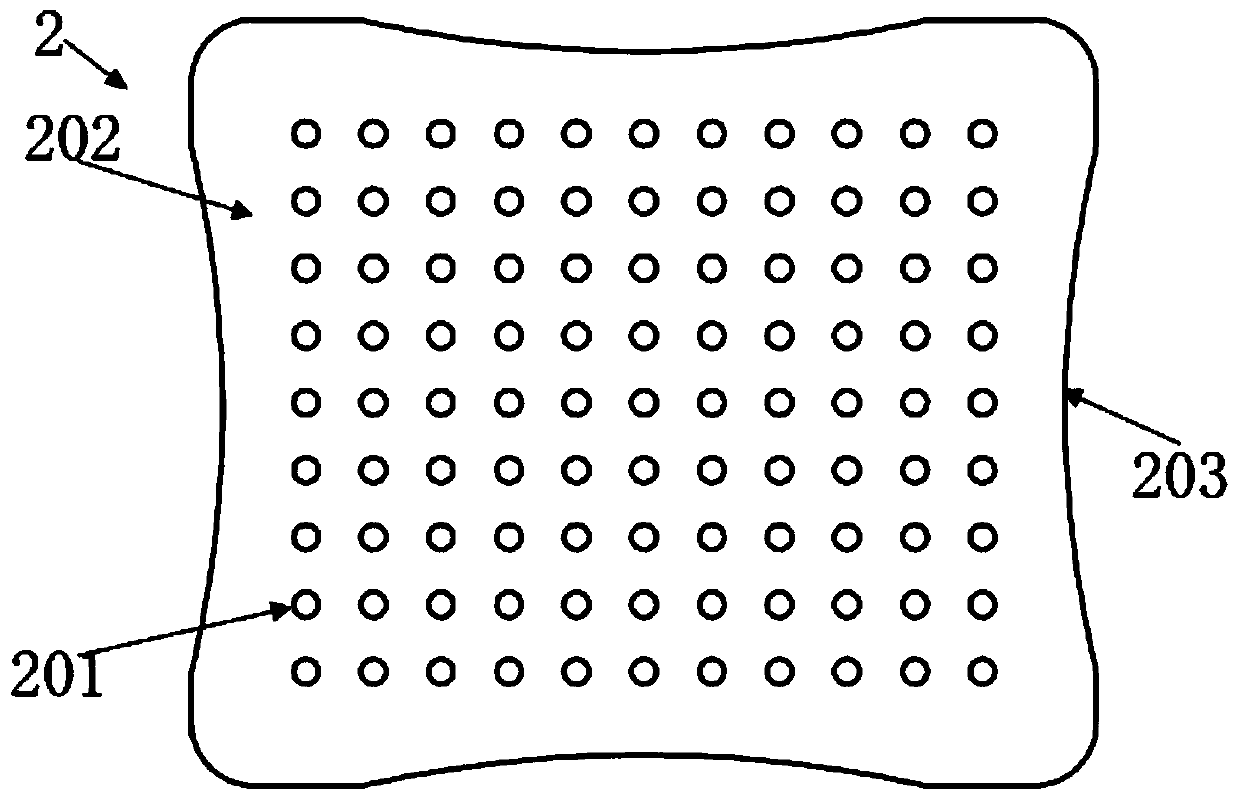

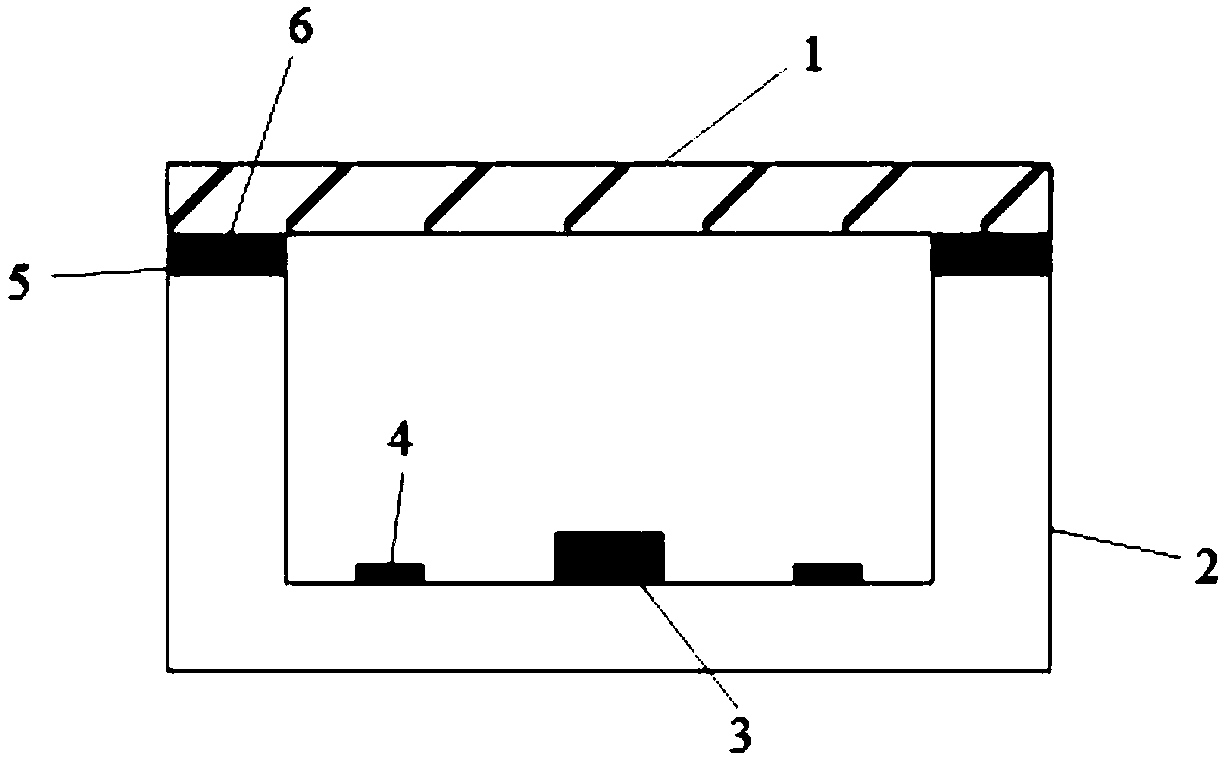

One-hole welding mold and welding process for electronic components

InactiveCN102259247AWill not polluteNo pollution in the processWelding/cutting auxillary devicesSolid-state devicesSemiconductor chipEngineering

A one-hole welding mold for electronic components and a welding process, comprising a welding mold body (1), a plurality of positioning welding molds (2) for placing electronic components on the welding mold body (1), the positioning welding The die (2) consists of a small hole (3) and a countersunk hole (4), the small hole (3) and the countersunk hole (4) pass through, and the centers coincide; the small hole (3) is used to place the lead end of the lower lead (5). , the aperture of the small hole (3) is matched with the lead end of the lower lead (5); the countersunk hole (4) is used to place the head of the lower lead (5), the chip (7) and the upper lead (6), The hole diameter of (4) is matched with the head of the lower lead (5). In the present invention, the upper and lower leads and the semiconductor chip are welded in the same hole, and the welding precision is high, and there is no need to worry about welding dislocation and virtual welding, and the product quality and yield are greatly improved.

Owner:许行彪

Assembly process for stator of 3MW permanent magnet synchronous wind-driven generator

InactiveCN102386726BQuality improvementImprove sealingManufacturing stator/rotor bodiesWind drivenPermanent magnet synchronous motor

The invention relates to an assembly process for a stator of a 3MW permanent magnet synchronous wind-driven generator. The process comprises the following steps of: A, assembly of a stator tooth pressing plate; B, lamination of a stator core; C, assembly of a cooling system; D, assembly of the stator; and E, paint dipping and coating of the stator. By the assembly process for the stator of the 3MW permanent magnet synchronous wind-driven generator, the assembly is convenient; core lamination effects are good; radiation efficiency can be effectively improved; a cooling water pipe has good pressure resistant effects and high reliability; and a coil has high insulating and sealing properties.

Owner:JIANGYIN BOFENG SPECIAL MOTOR

An aluminum alloy door and window with concealed micro drainage

ActiveCN110485857BGuaranteed flexibilityPrevent rustCondensed water drain-offCondensed water formation preventionWindow openingWater spot

The invention discloses an aluminum alloy door and window achieving hidden type trace water drainage and belongs to the field of aluminum alloy doors and windows. The aluminum alloy door and window achieving hidden type trace water drainage comprises an aluminum alloy door and window outer frame with a glass plate installed on the inner side. A hidden type water drainage groove is formed in the front end of the aluminum alloy door and window in a digging manner. A water absorbing frame is arranged in the hidden type water drainage groove. A sealing cover frame is connected to a groove openingof the hidden type water drainage groove. Multiple water guide holes are uniformly formed in the lower end of the aluminum alloy door and window outer frame in a digging manner. Embedded type water absorbing bars are fixedly connected into the water guide holes. Multiple side air drying holes are formed in the left inner side end and the right inner side end of the aluminum alloy door and window in a digging manner correspondingly. Upper air drying holes distributed uniformly are formed in the upper inner side end of the aluminum alloy door and window outer frame in a digging manner. Accordingto the aluminum alloy door and window, the multiple embedded type water absorbing bars are utilized for absorbing trace water spots on the surface of a sliding rail of the aluminum alloy door and window, the absorbed water is transferred and dried through the water absorbing frame, the surface of the sliding rail is effectively prevented from rusting, and flexibility of the door and window opening and closing is ensured.

Owner:江苏海鹰德拉图节能科技有限公司

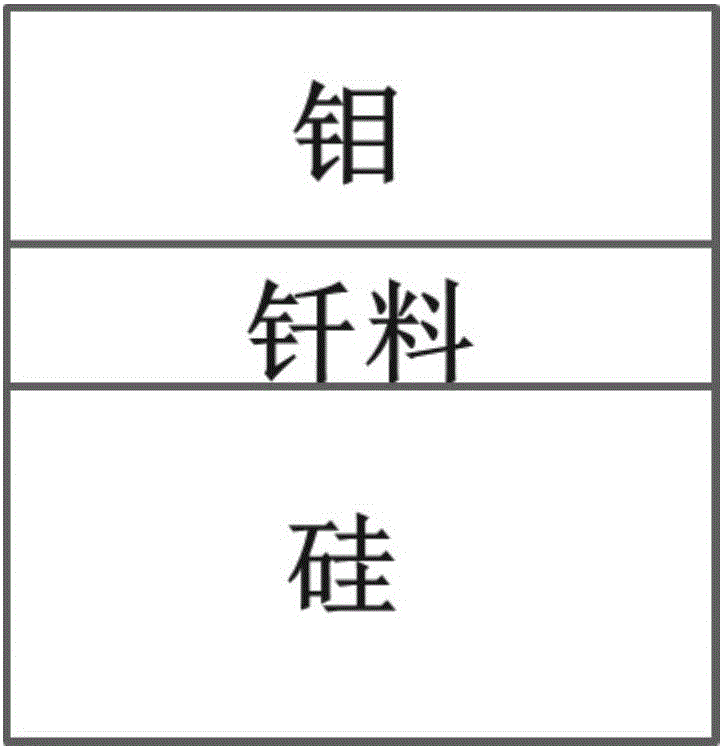

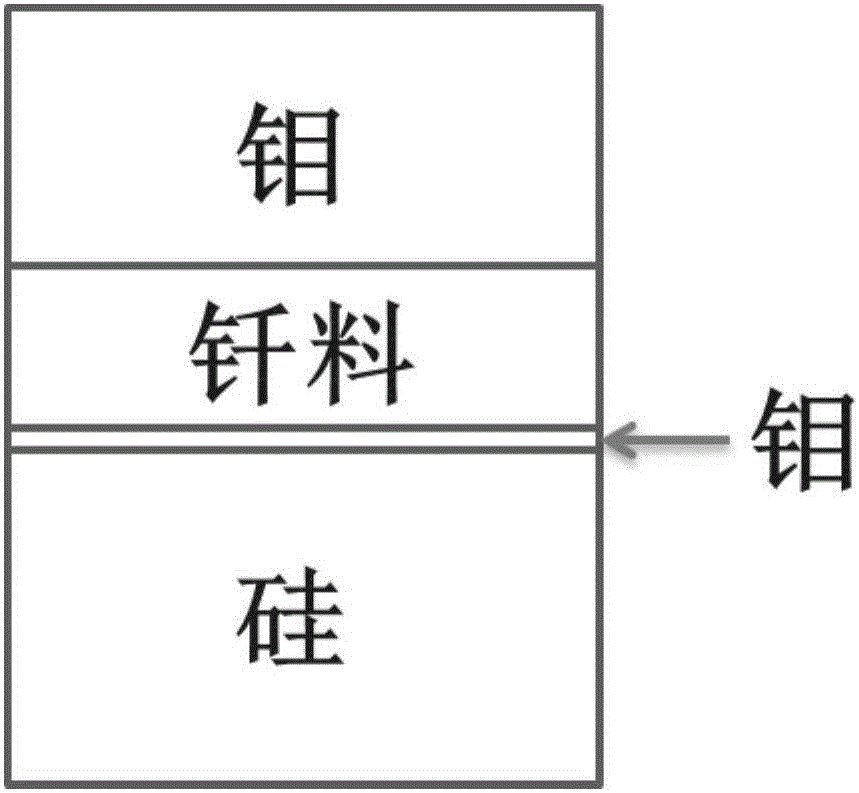

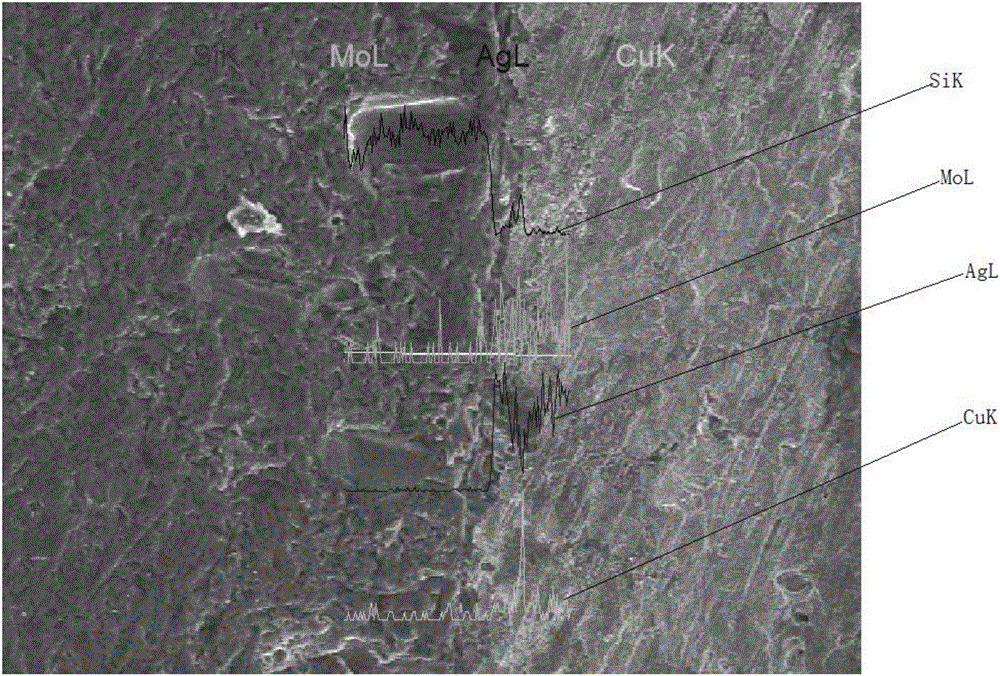

Molybdenum and silicon substrate welding method in field emission device

ActiveCN105870028AAvoid pollutionWeld tightlySolid-state devicesSoldering apparatusField emission deviceWeld strength

The invention provides a molybdenum and silicon substrate welding method in a field emission device. The method comprises the steps of evaporating a molybdenum thin film on a silicon substrate, and then welding the silicon substrate on which the molybdenum thin film is evaporated and a molybdenum plate, i.e., plating a molybdenum protecting layer on the silicon substrate to play a brazing filler metal barrier role. Silicon and the molybdenum plate are closely connected and cannot be broken, so the welding strength is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Light-emitting diode

ActiveCN108417690AEnsure reliabilityWeld tightlySemiconductor/solid-state device detailsSolid-state devicesGlass coverProcess complexity

The invention discloses a light-emitting diode. The light-emitting diode comprises a glass cover plate, a ceramic substrate, a light-emitting diode chip and a circuit structure layer. The ceramic substrate is provided with a groove. The shape of the glass cover plate is matched with the shape of the groove, and the glass cover plate covers the groove. The contact surface of the ceramic substrate and the glass cover plate is provided with a glaze layer. The contact surface of the glass cover plate and the groove is provided with a glass paste layer. The glass paste layer is used for welding theglass cover plate and the ceramic substrate together in a fusion way. The light-emitting diode chip is arranged in the groove, and the light-emitting diode chip is connected with the circuit structure layer. According to the light-emitting diode, the smooth glaze layer is manufactured on the surface of the ceramic substrate, and low temperature compact fusion welding of the glass cover plate andthe ceramic substrate is realized by using the glass paste so that the process complexity can be reduced, and the packaging air tightness and the reliability of the light-emitting diode can be enhanced.

Owner:SHANGHAI UNIV

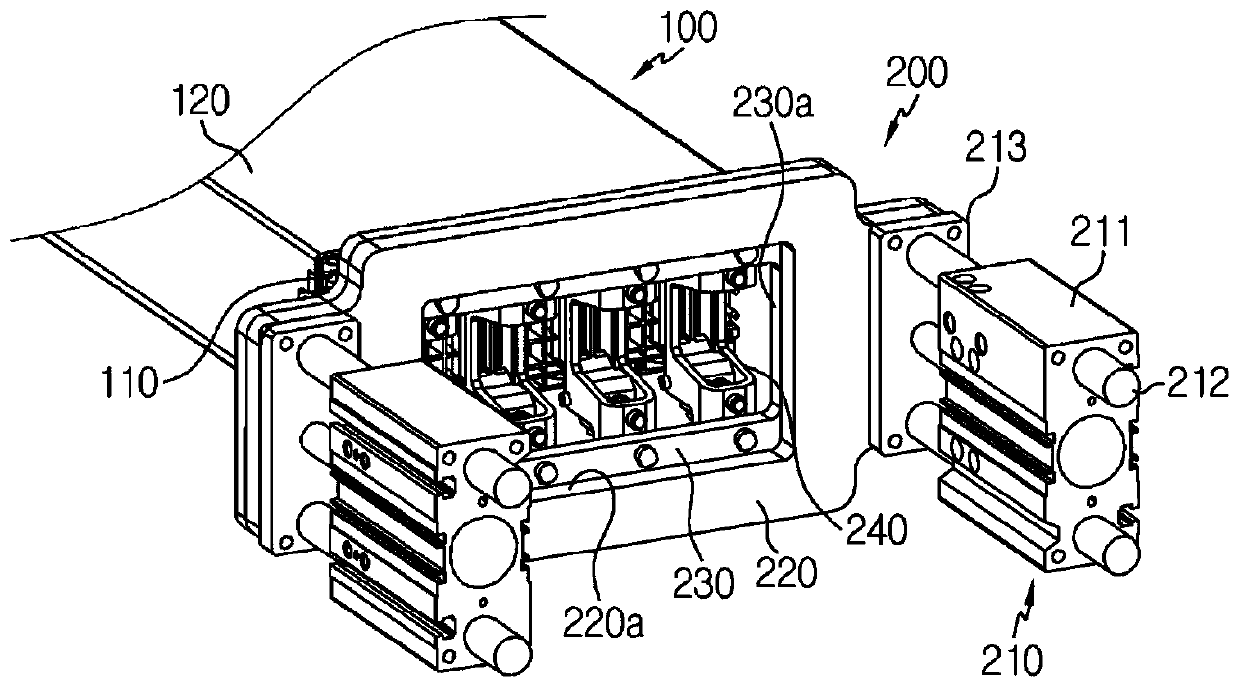

Auto-pressing jig apparatus for pressing electrode lead to busbar

ActiveCN111448685AWeld tightlyAttached tightlyCurrent conducting connectionsFinal product manufactureElectrical batteryBusbar

An auto-pressing jig apparatus according to an embodiment of the present invention is a pressing jig apparatus configured to press a busbar, which is provided in a battery module, and a lead assemblyto each other, the auto-pressing jig apparatus comprises a plurality of pressing units which press each of a plurality of busbars provided in the battery module simultaneously, and press an end portion of the lead assembly from an upper portion of the busbars such that the lead assembly does not protrude to a surface of the busbars; a support plate which is connected to an end portion at one sideof the pressing units to support the plurality of pressing units; and a distance adjustment unit which is connected to the support plate to enable the support plate to flow, such that the plurality ofpressing units move away from or close to the battery module.

Owner:LG ENERGY SOLUTION LTD

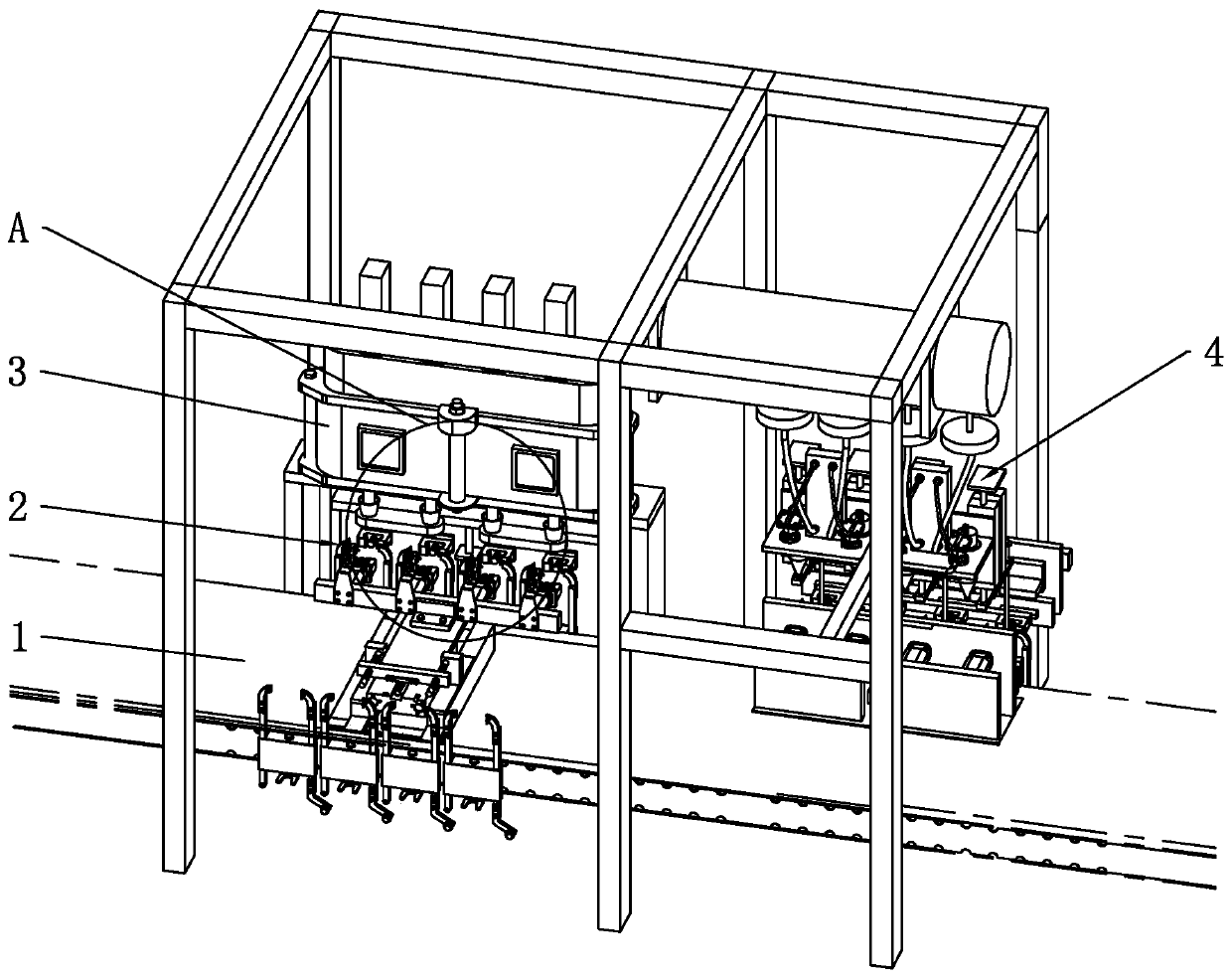

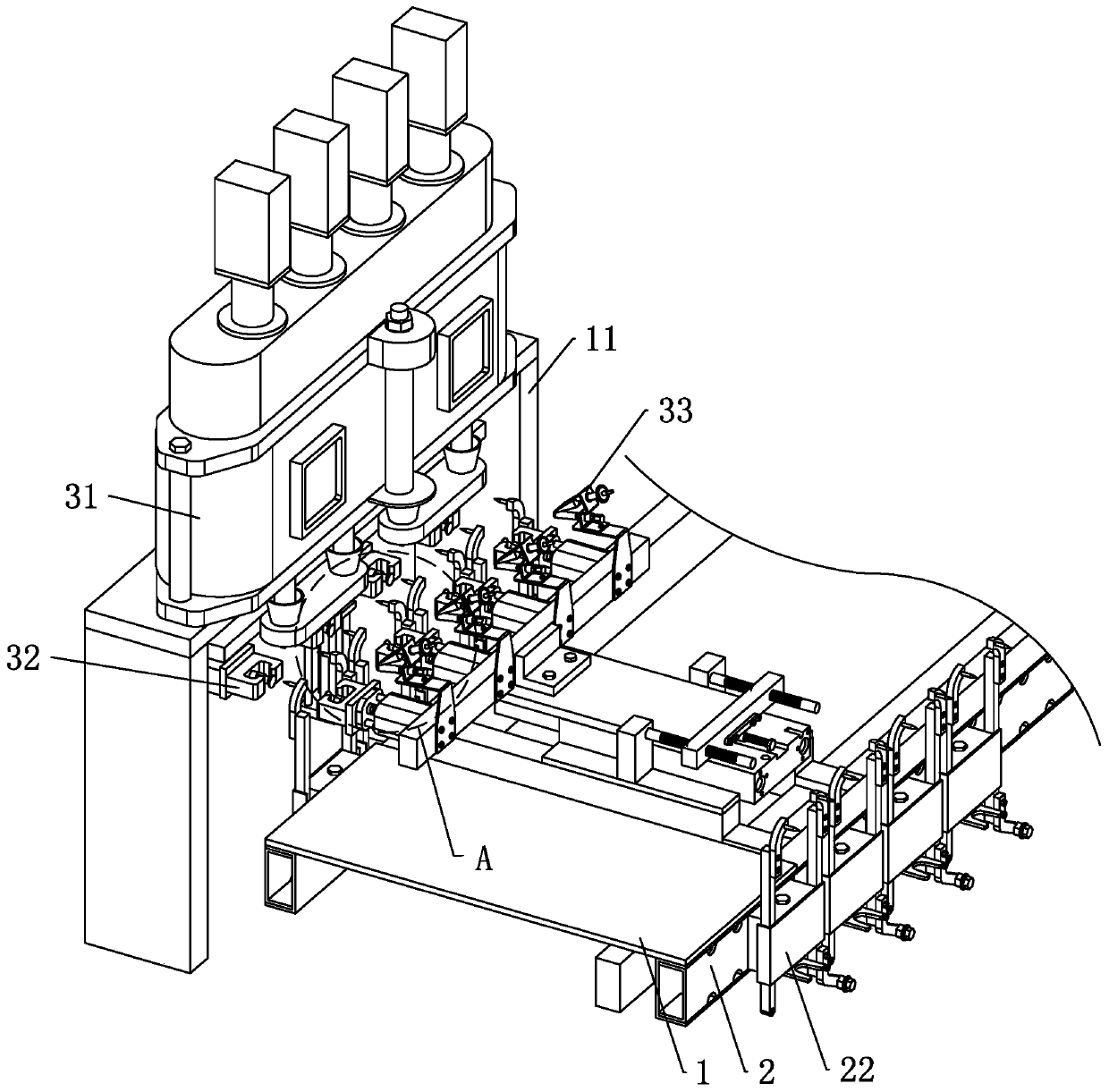

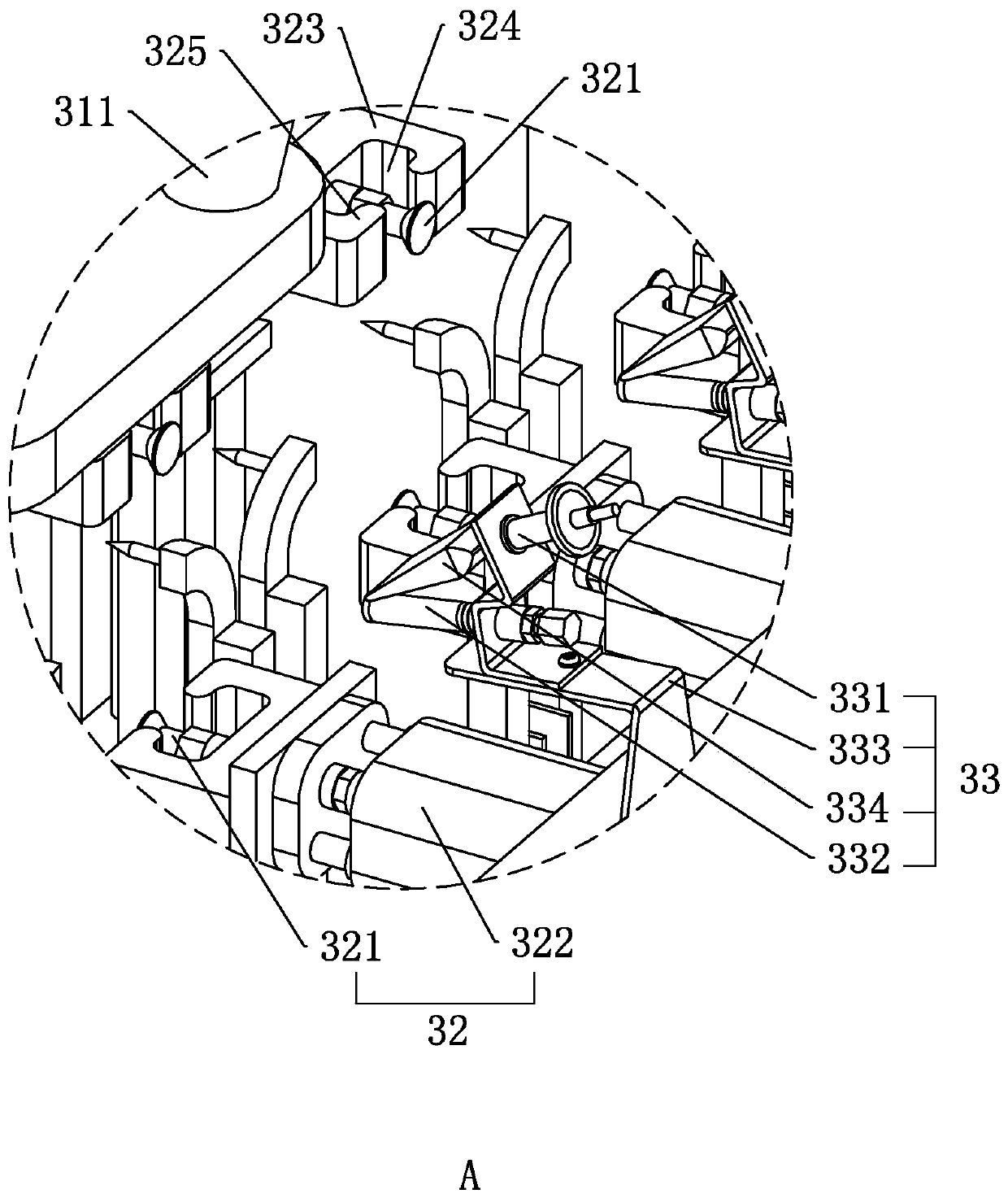

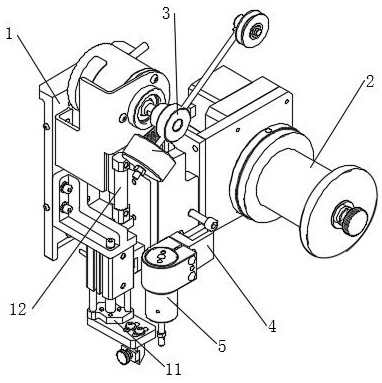

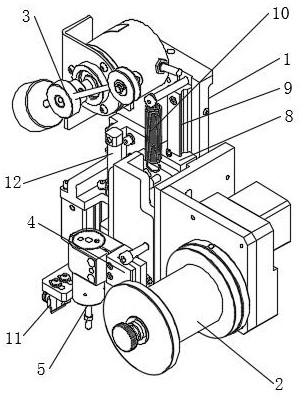

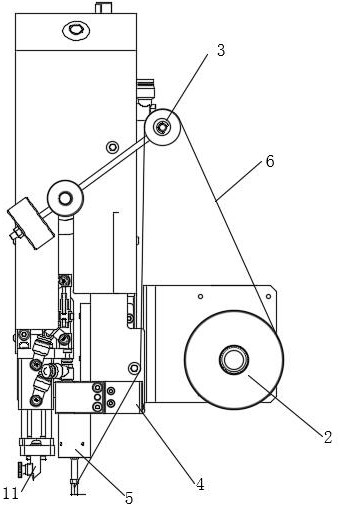

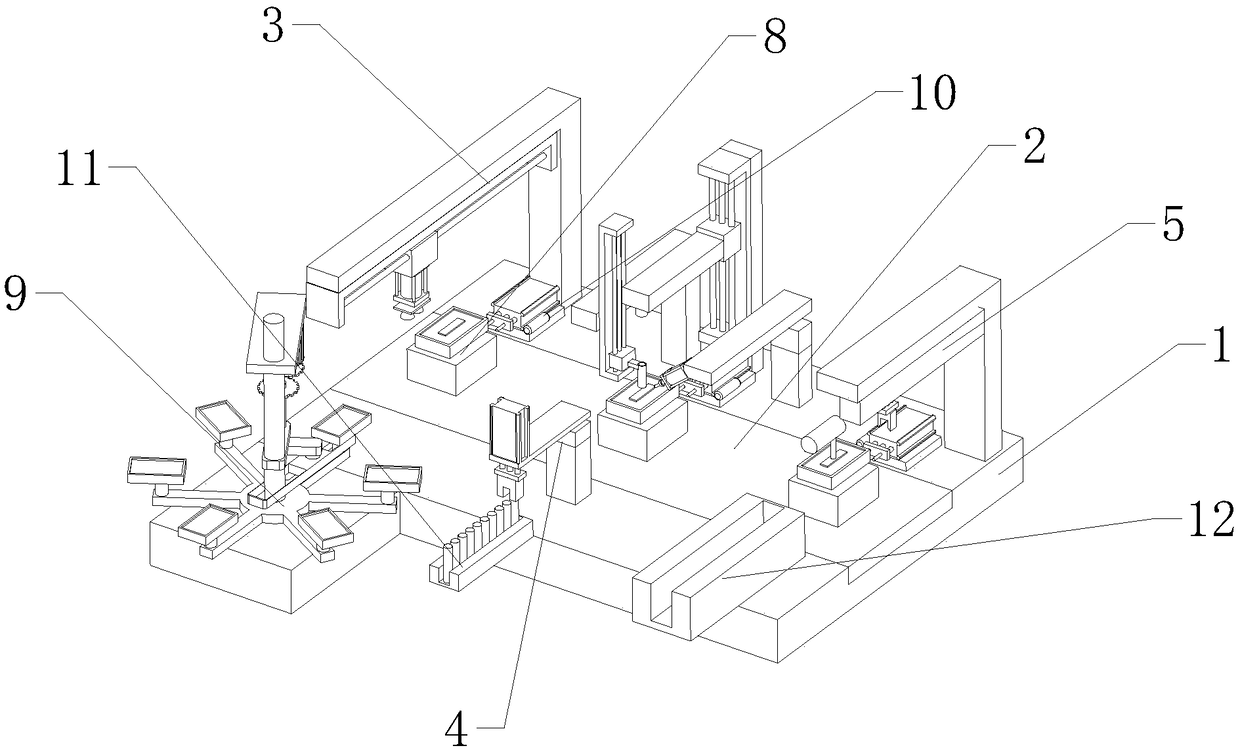

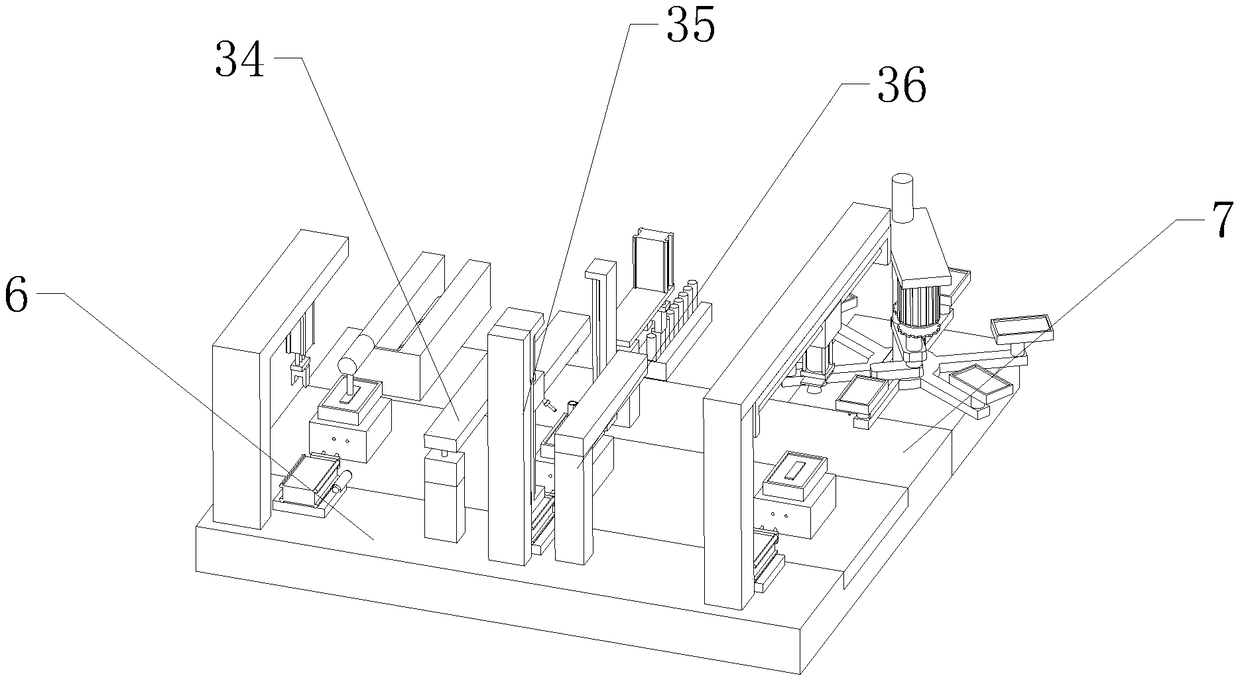

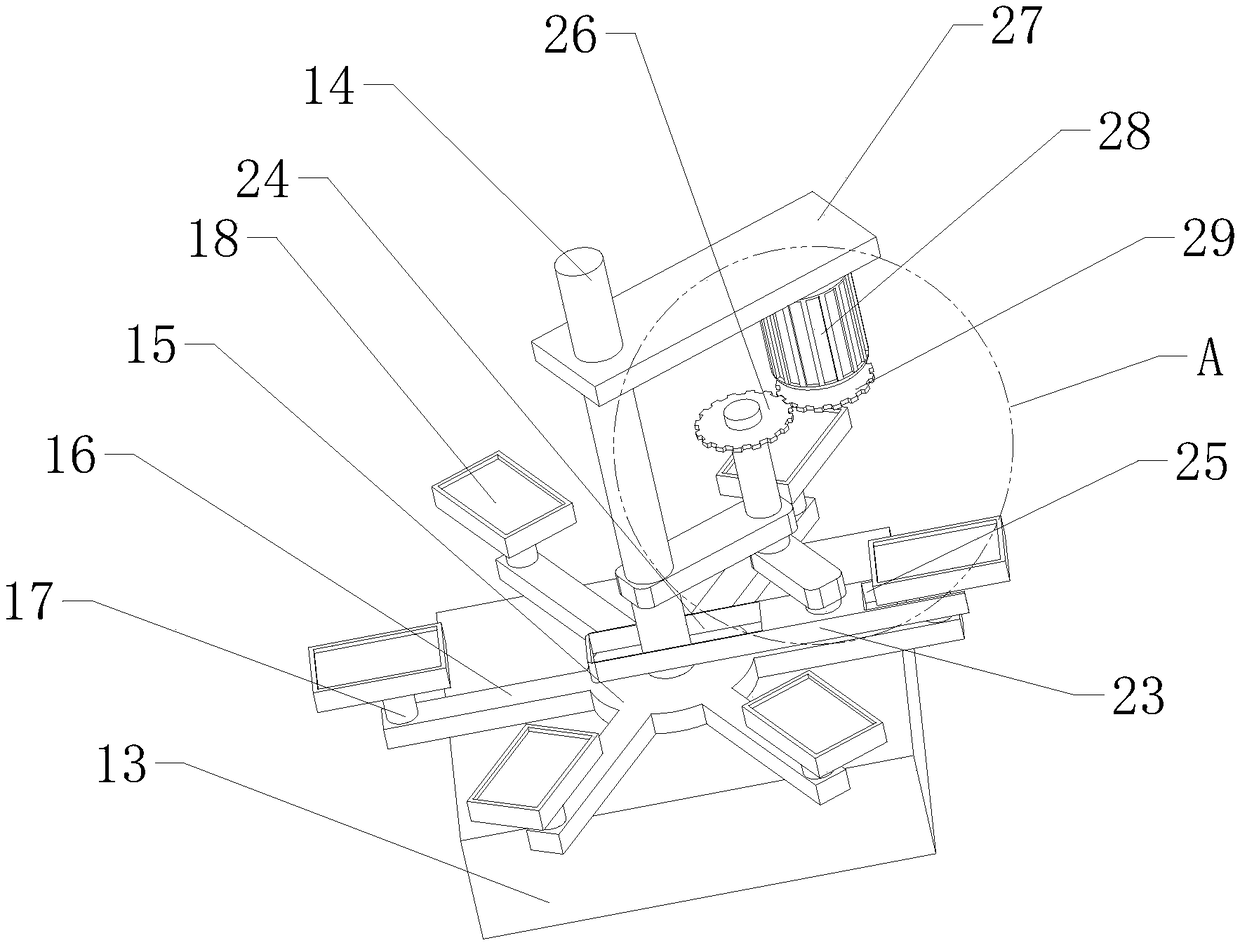

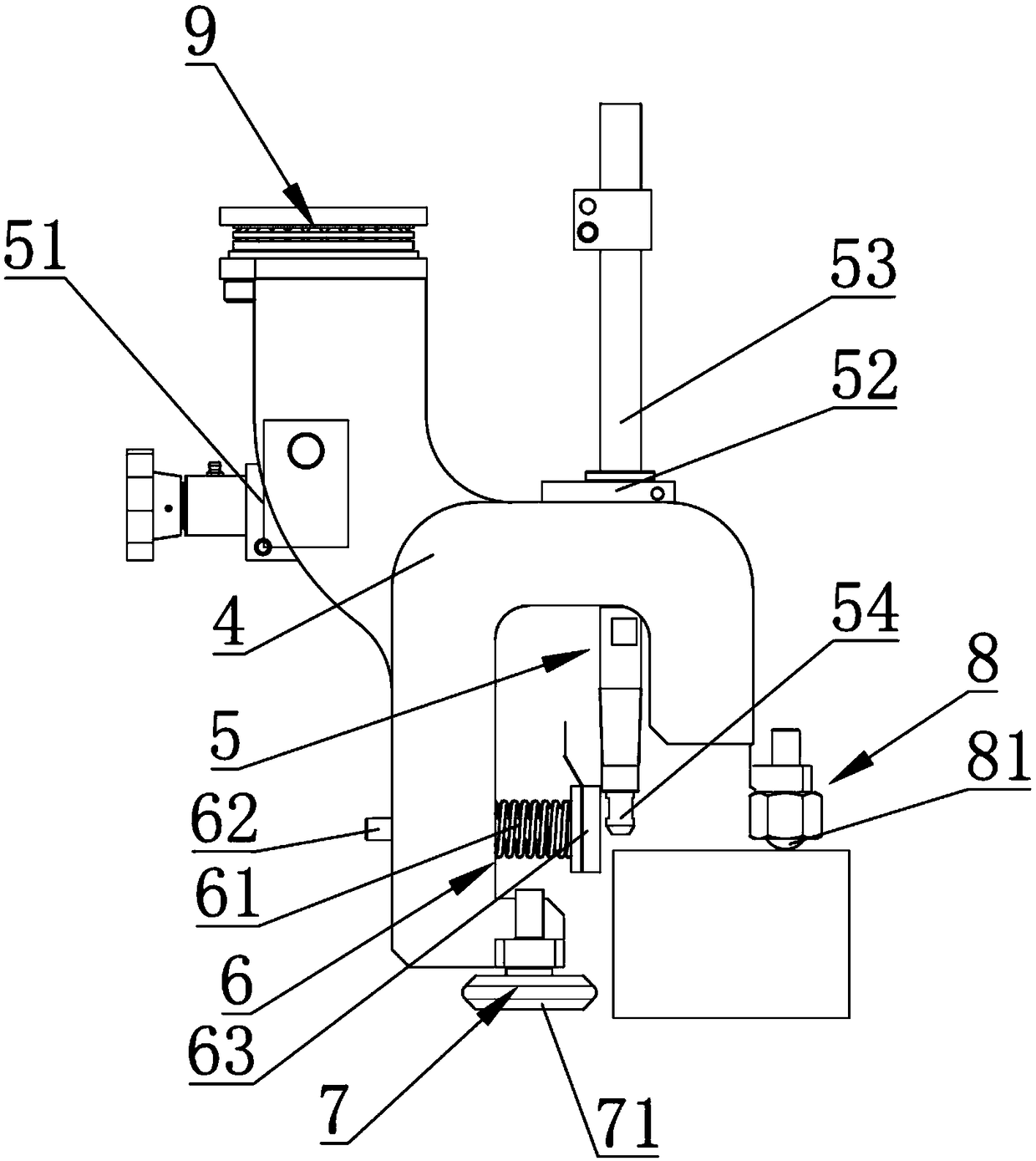

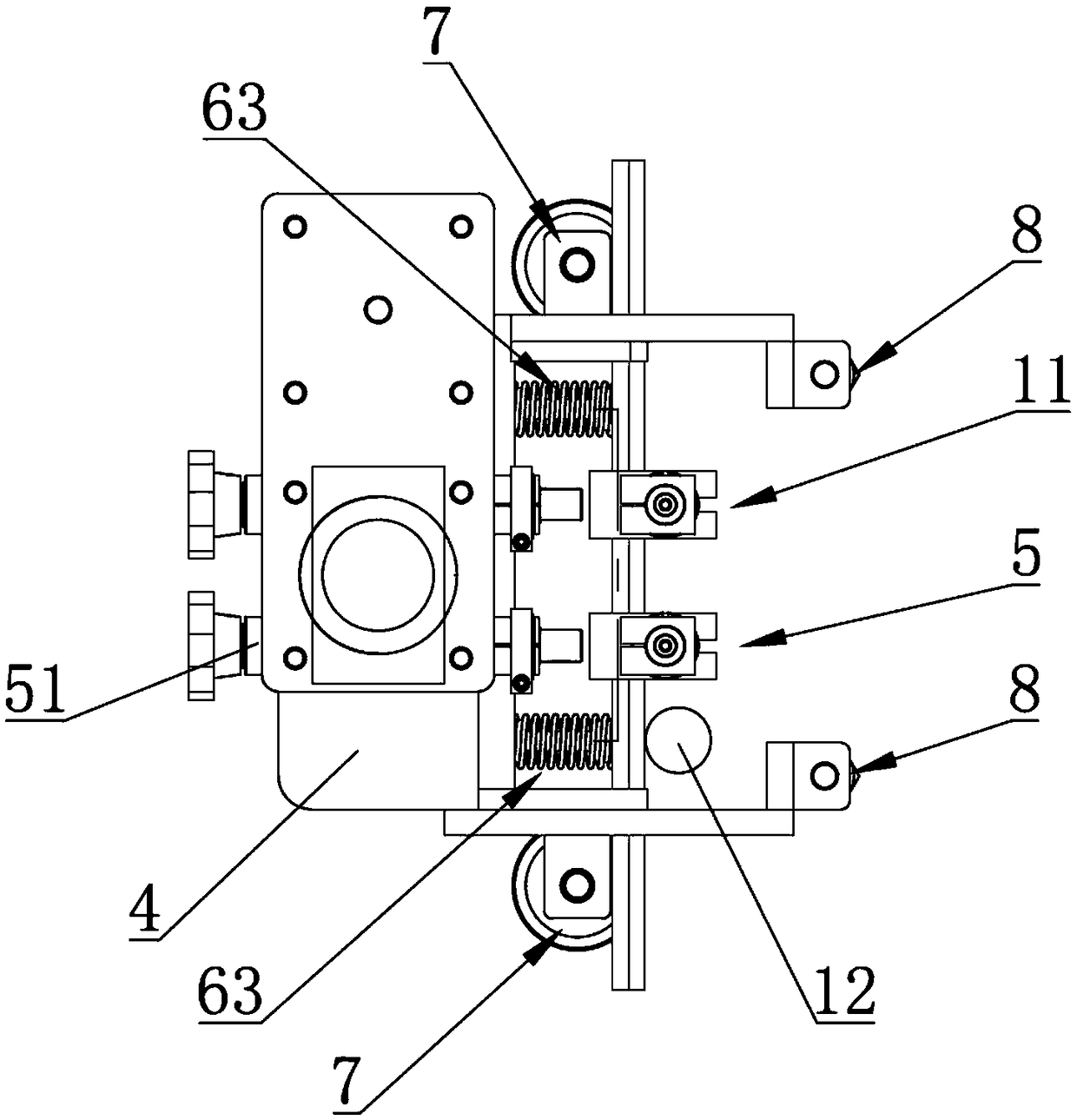

Automatic polishing cutter assembly device

ActiveCN108971972AThe connecting rod is welded tightlyWeld tightlyAssembly machinesEngineeringMechanical engineering

The invention relates to the field of automatic assembly devices, in particular to an automatic polishing cutter assembly device. The automatic polishing cutter assembly device comprises a workbench,a conveying belt, a cutter body assembling device, a connecting rod assembling device and a handle assembling device; the conveying belt is arranged in the middle position of the workbench; the workbench comprises a left guide table and a right guide table which are arranged on the two sides of the conveying belt; a plurality of jig devices are uniformly distributed on the conveying belt; the cutter body assembling device comprises a cutter body charging device and a cutter body conveying device; the cutter body charging device is arranged at the side part of the right guide table; the cutterbody conveying device, the connecting rod assembling device and the handle assembling device are sequentially arranged on the left guide table; locating devices are arranged at the side parts of the jig devices; and a connecting rod conveying rail and a handle conveying rail are arranged on the side parts of the connecting rod assembling device and the handle assembling device respectively. The assembly efficiency of a polishing cutter is improved greatly.

Owner:北京中兴卓越科技有限公司

Steel tube bundle composite structure of upset head webs

The invention discloses a steel tube bundle composite structure of upset head webs. The steel tube bundle composite structure comprises a steel tube bundle assembly. The steel tube bundle assembly comprises a plurality of steel tube units which are sequentially connected with one another, each steel tube unit is provided with a cavity, and concrete is poured in each cavity; a continuous flange and spliced flanges which are parallel to one another are separated from one another by the upset head webs to form the steel tube units, the end, which is not provided with an upset head, of each upset head web is perpendicularly welded on the continuous flange, and the upset heads of the upset head webs are welded on weld joints among the adjacent spliced flanges; the front-end steel tube unit and the rear-end steel tube unit are respectively closed and welded by steel plates; partition plates among the adjacent steel tube units are formed by the upset head webs. The steel tube bundle composite structure has the advantages that the performance of steel can be sufficiently played by the upset head webs as compared with an existing web with a bent end, and accordingly steel can be saved; the upset heads are closely laid on flange plates, so that the steel tube bundle composite structure is favorable for guaranteeing full and flat weld joints, and the quality of the weld joints can be improved.

Owner:HANGXIAO STEEL STRUCTURE

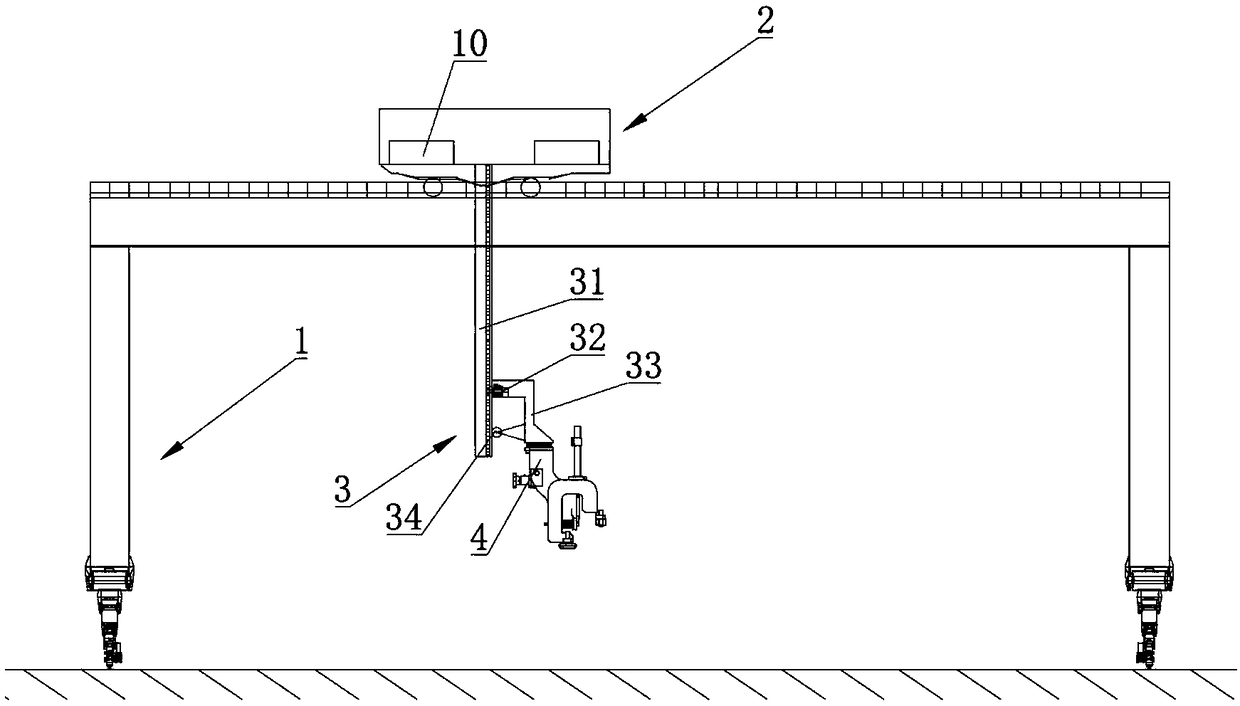

Box beam welding equipment and welding method

InactiveCN108817764AQuality improvementReduce harmWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPressure measurement

The invention relates to the technical field of welding and particularly relates to box beam welding equipment. The box beam welding equipment comprises an X-axis moving device, a Y-axis moving device, a Z-axis moving device, a mounting frame and a welding device, wherein the X-axis moving device, the Y-axis moving device, the Z-axis moving device, the mounting frame and the welding device are connected sequentially; the welding device is installed at the mounting frame; a baffle component is installed at the mounting frame; the welding device is arranged at one side of the baffle component; afirst pressure measuring component and a second pressure measuring component are installed at the mounting frame; the Y-axis moving device is provided with a welding wire conveying device; the box beam welding equipment further comprises a control device; the control device is correspondingly electrically connected with the X-axis moving device, the Y-axis moving device, the Z-axis moving device,the welding device and the welding wire conveying device; and the first pressure measuring component is electrically connected with the second pressure measuring component. Besides, the invention further provides a box beam welding method, the welding efficiency and quality is improved, and injuries of a welding worker are reduced.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com