Electric coupler

A technology for electrical connectors and welding parts, applied in the direction of connection, fixed connection, welding/welding connection, etc., which can solve the problem of easy overflow of solder, affecting the coplanarity of the installation plane of the electrical connector, and the connection between the electrical connector and the circuit board is not tight And other problems, to achieve the effect of tight welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

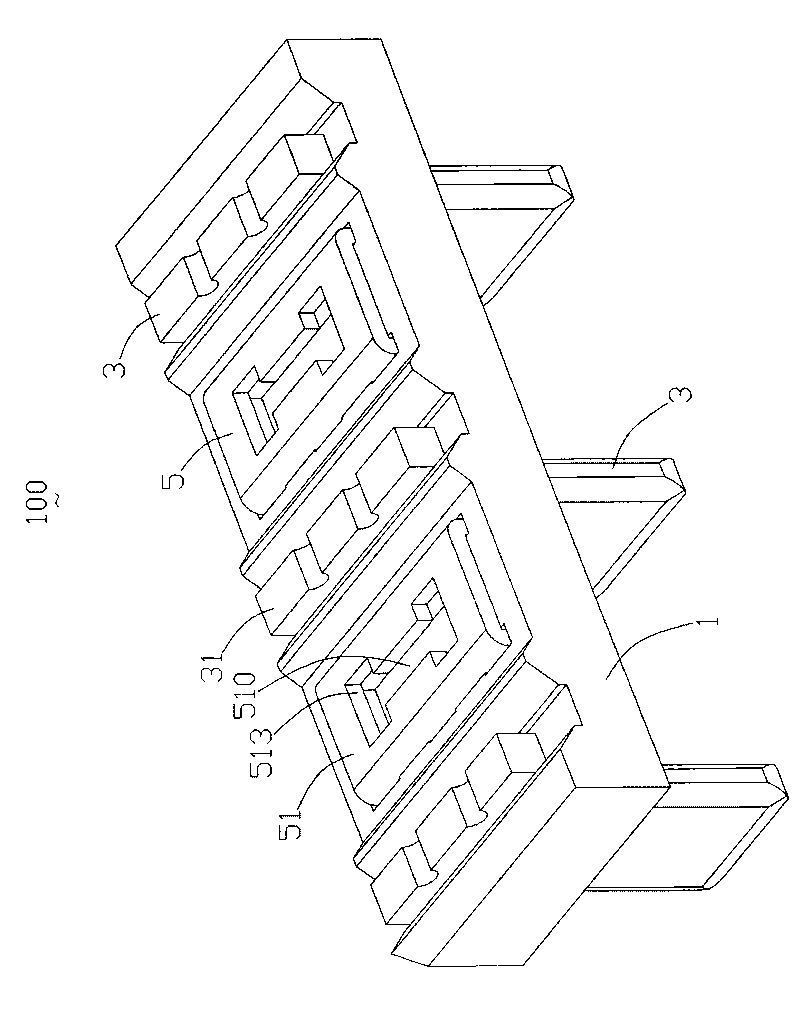

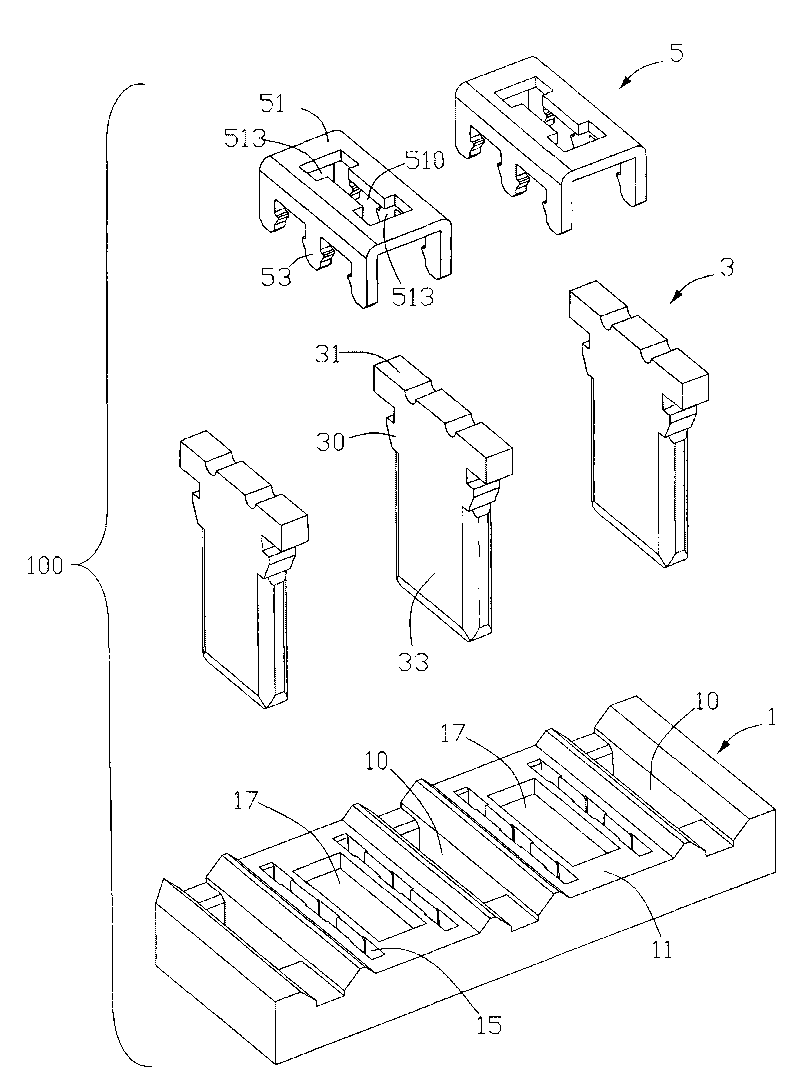

[0010] see Figure 1 to Figure 3 , which discloses an electrical connector 100 that can be mounted on an external circuit board (not shown) for electrical connection with a battery (not shown). The electrical connector includes an insulating body 1 with a plurality of receiving grooves 10 , terminals 3 partially accommodated in the receiving grooves 10 , and a plurality of soldering parts 5 .

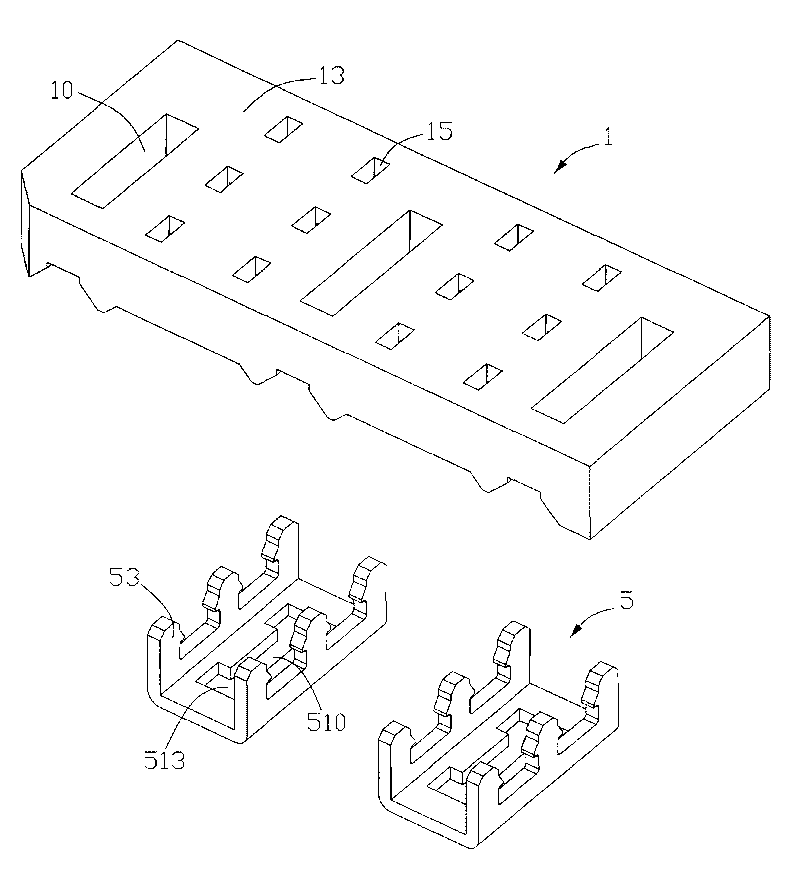

[0011] The insulating body 1 includes an upper surface 11 , a lower surface 11 opposite to the upper surface 11 , and several sets of slots 15 penetrating through the upper and lower surfaces 11 , 13 . The upper surface 11 of the insulating body 1 is recessed with an opening groove 17 , and the opening groove 17 is a single-sided opening groove 17 .

[0012] The welding part 5 includes a welding plate 51 and a clamping arm 53 protruding from the welding plate 51 . The locking arms 53 are received in the corresponding slots 15 . The welding plate 51 is provided with a groove 510 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com