Automatic polishing cutter assembly device

A technology of automatic assembly device and assembly device, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency of light-receiving knives, and achieve the effects of tight connection, improved strength, and precise welding position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

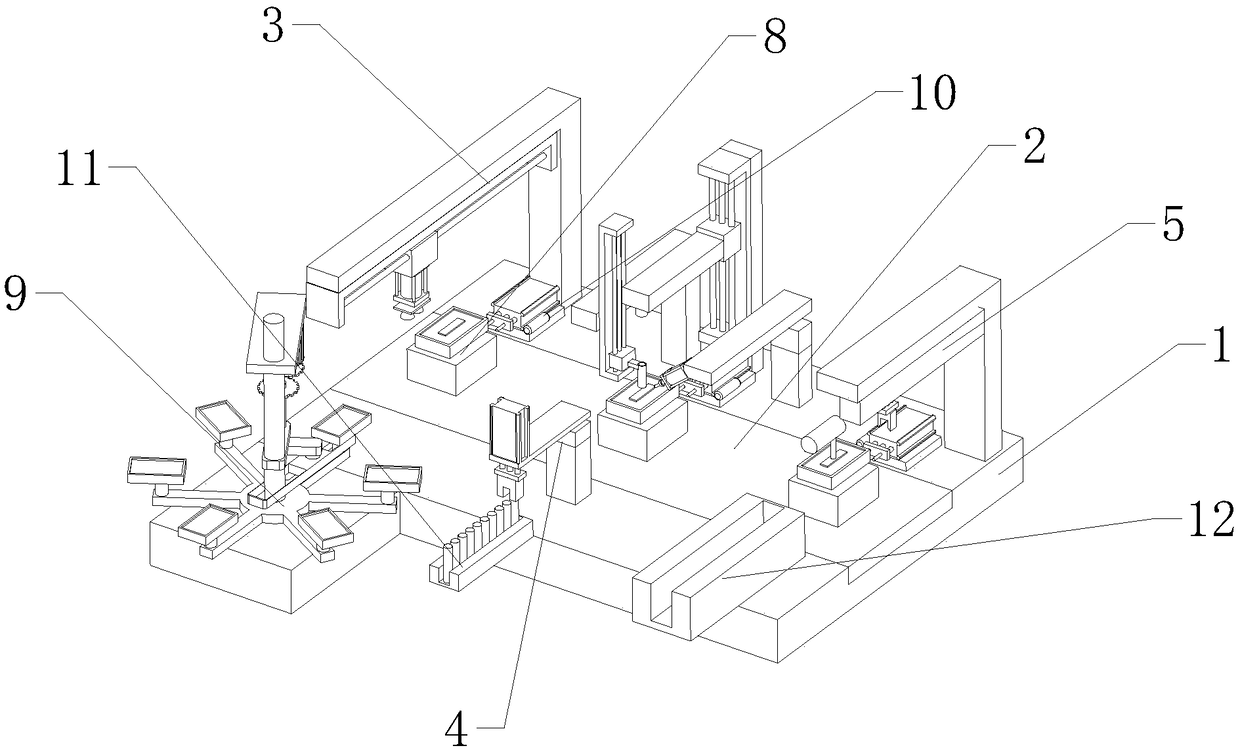

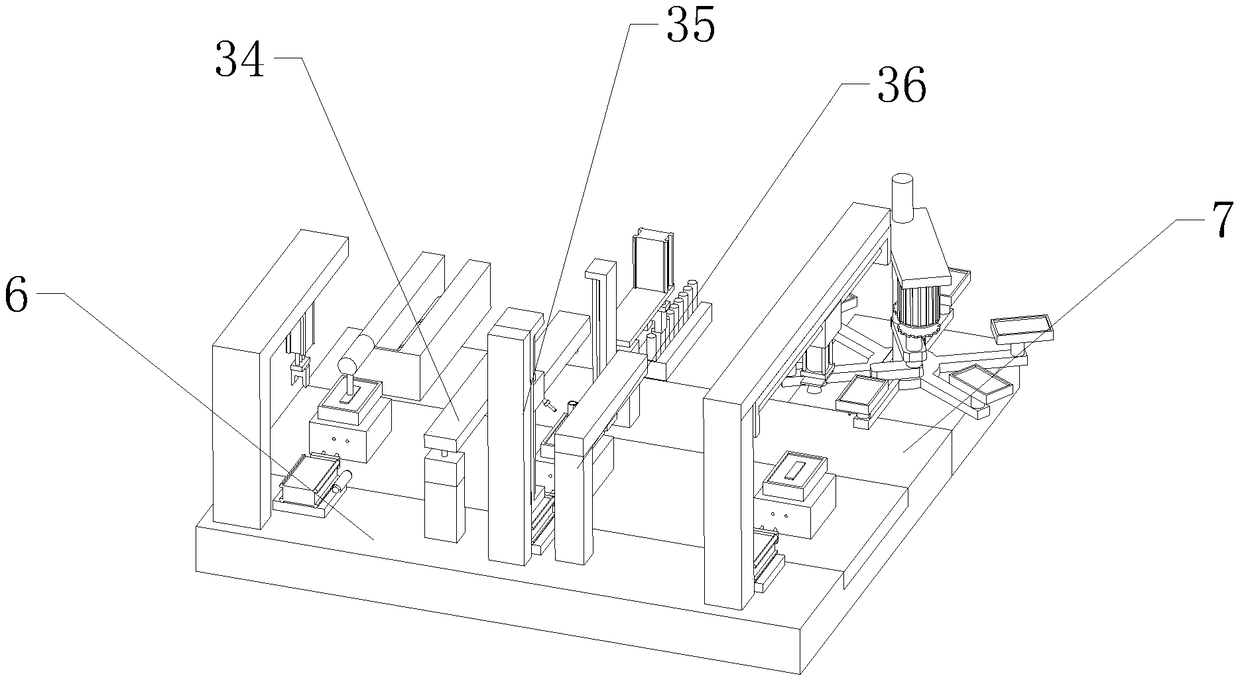

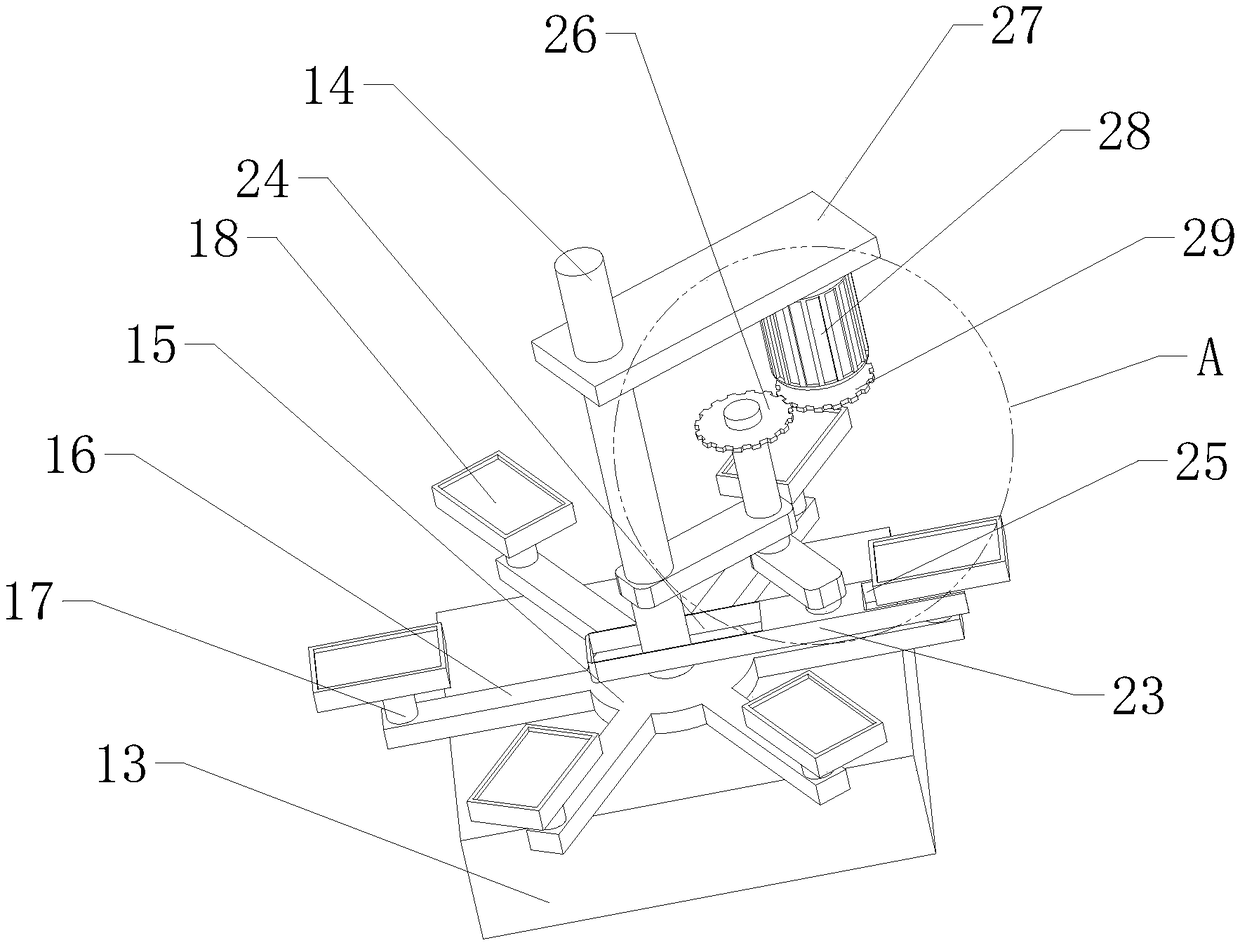

[0028] refer to Figure 1 to Figure 10 The shown automatic assembly device for finishing knives includes a workbench 1, a conveyor belt 2, a knife body assembly device, a connecting rod assembly device, and a handle assembly device 5. The conveyor belt 2 is arranged in the middle of the workbench 1, and the workbench 1 It includes a left guide platform 6 and a right guide platform 7 arranged on both sides of the conveyor belt 2, and a plurality of jig devices 8 are evenly distributed on the conveyor belt 2. The cutter body assembly device includes a cutter body feeding device 9 and a cutter body Material conveying device 3, described cutter body feeding device 9 is arranged on the side of right guide platform 7, and cutter body conveying device 3, connecting rod assembly device and handle assembly device 5 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com