Patents

Literature

166results about How to "Accurate welding position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

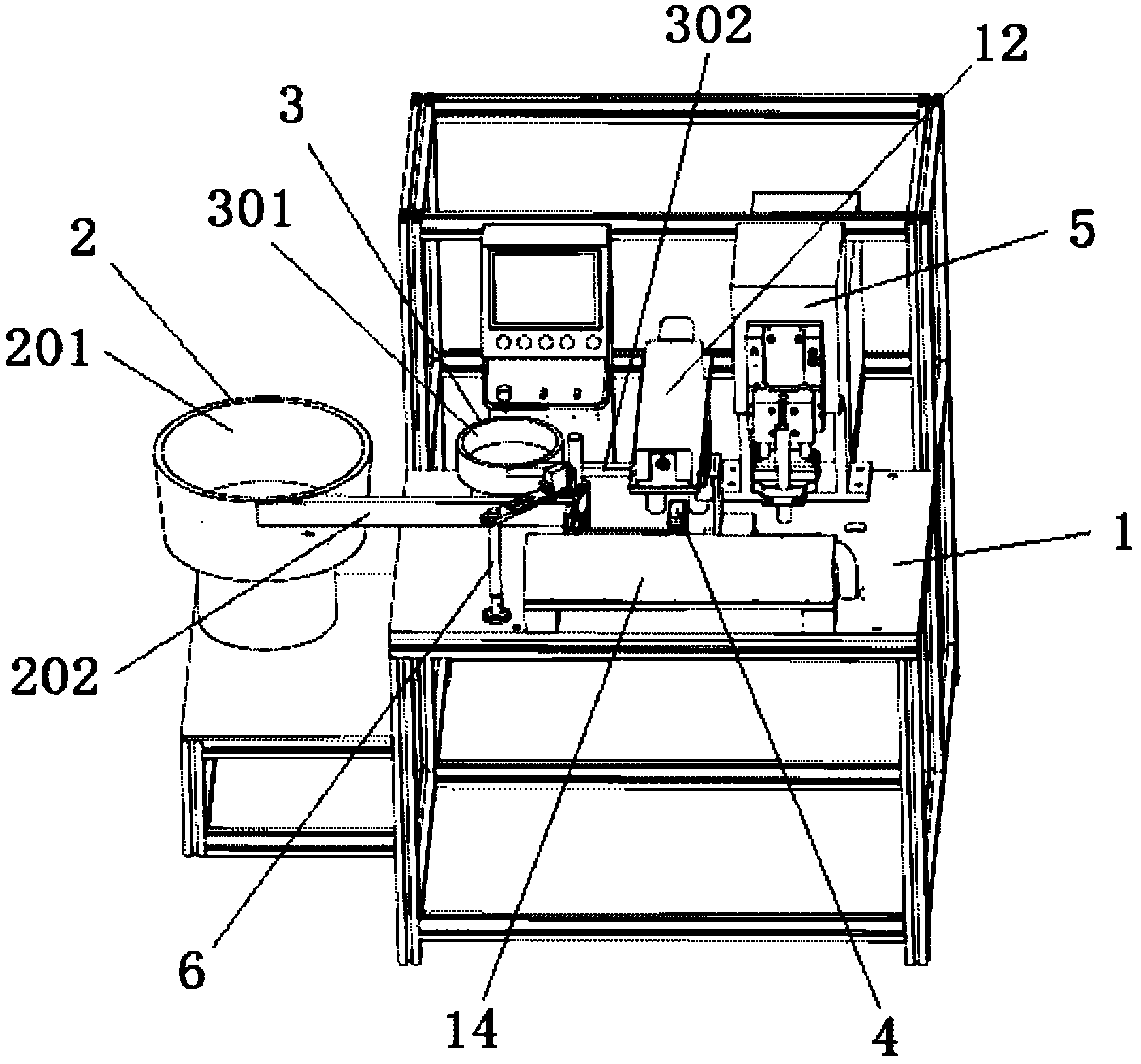

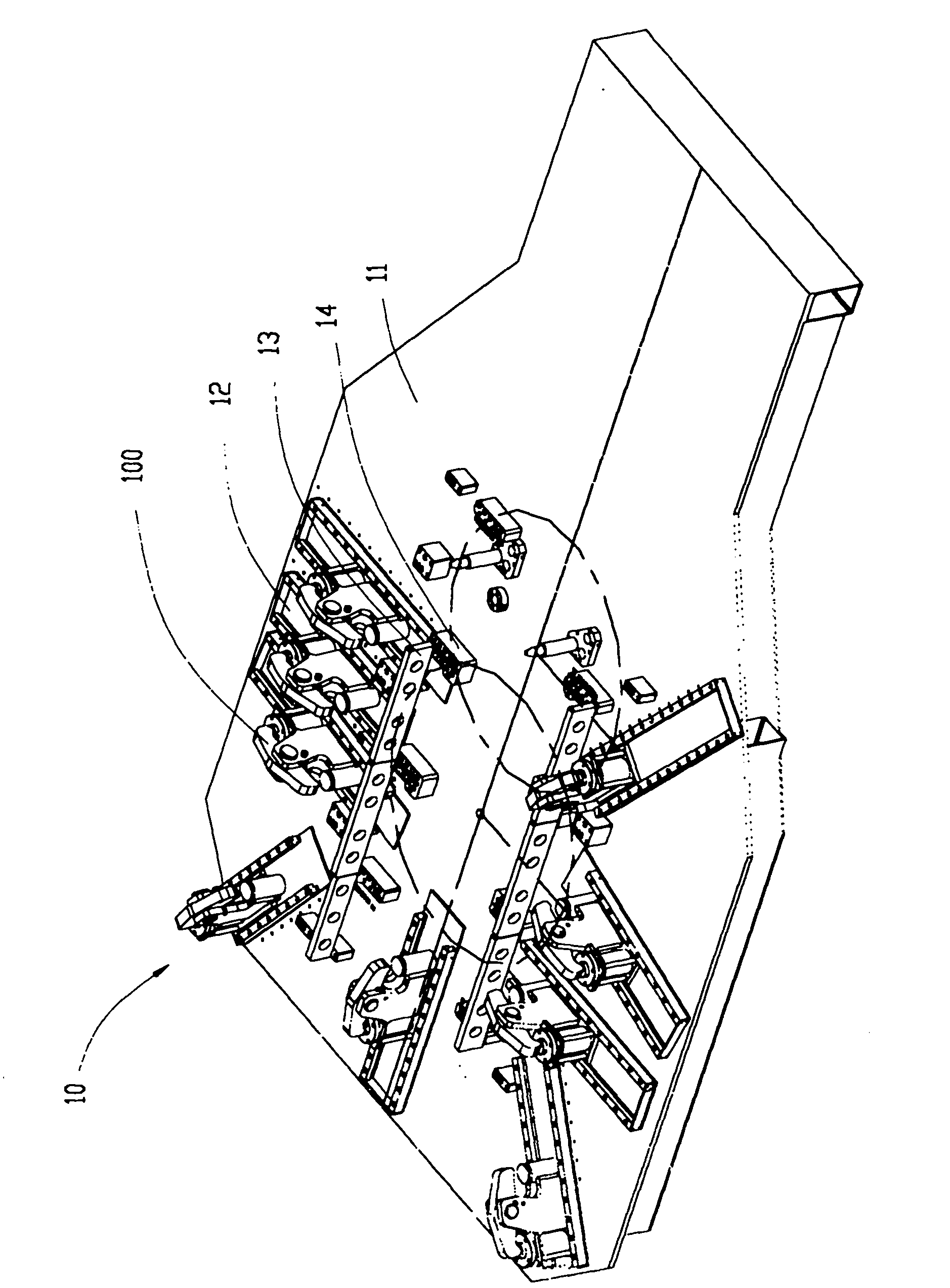

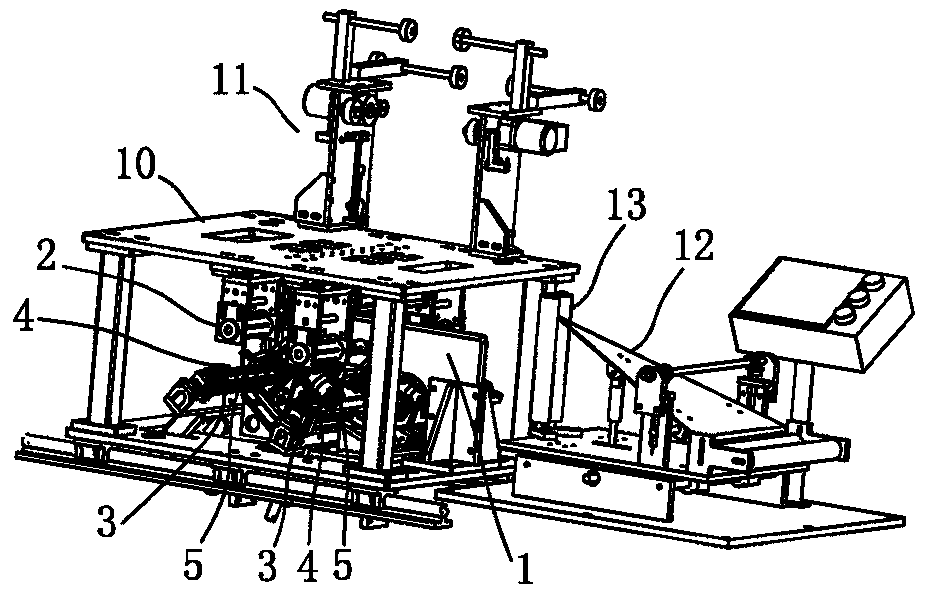

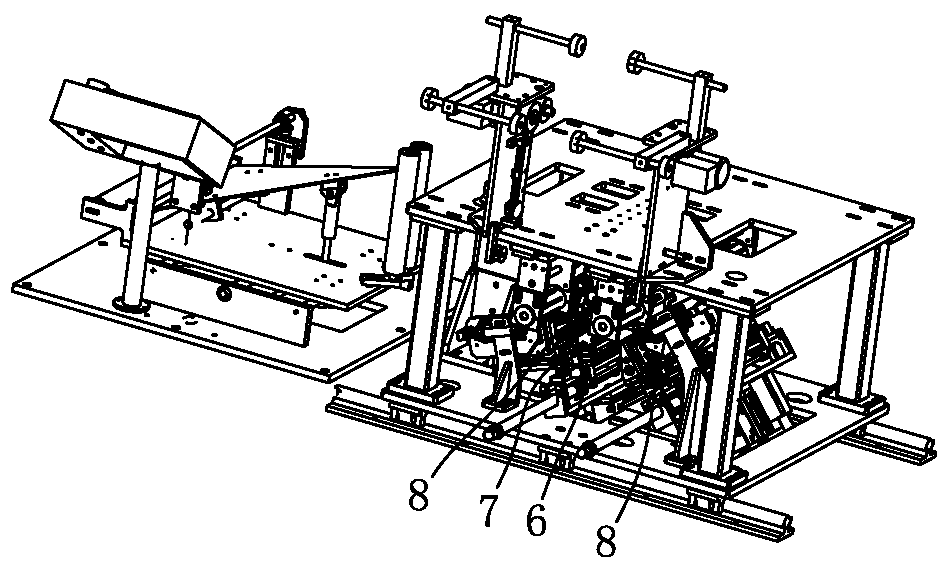

Static contact and silver point automatic welding device

ActiveCN102284813AHigh degree of automationNo manual operationWelding/cutting auxillary devicesAuxillary welding devicesSilverspotsSpot welding

The invention discloses a full-automatic welding device for a fixed contact and a silver point. The full-automatic welding device comprises a workbench and is characterized in that a fixed contact vibrating disc feeding device, a silver point vibrating disc feeding device, a transfer assembly table and an automatic spot-welding device are arranged on the workbench, wherein a fixed contact transfer device is arranged between the fixed contact vibrating disc feeding device and the transfer assembly table, an automatic spot-welding device is further arranged on an advancing route of the fixed contact transfer device, a sliver point transfer device is arranged between the silver point vibrating disc feeding device and the transfer assembly table and a fixed contact and silver point clamping and transferring device is arranged between the transfer assembly table and the automatic spot-welding device. The full-automatic welding device is high in degree of automation and can improve the production efficiency and the welding quality.

Owner:FORETECH ELEC APP JIANGSU CORP

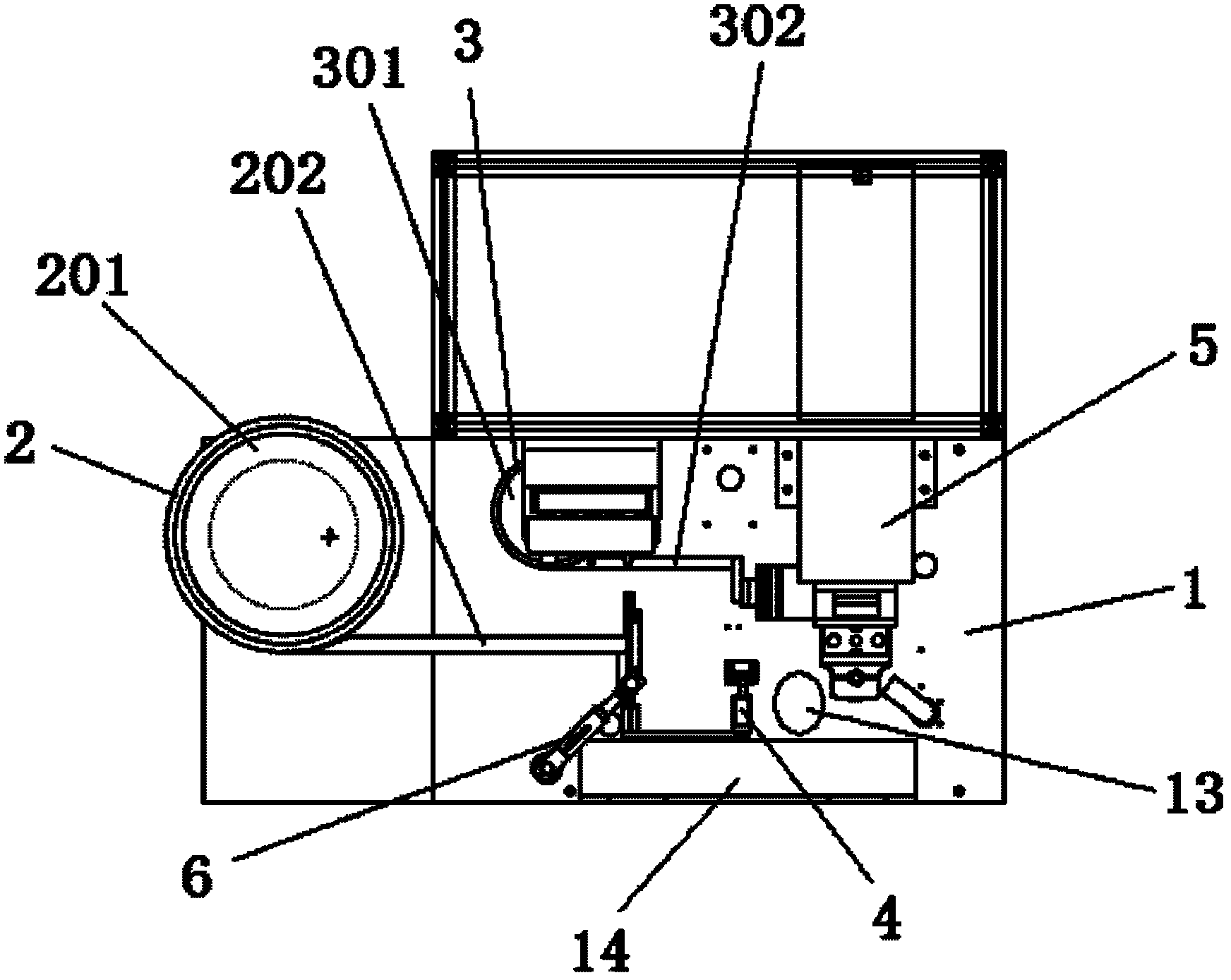

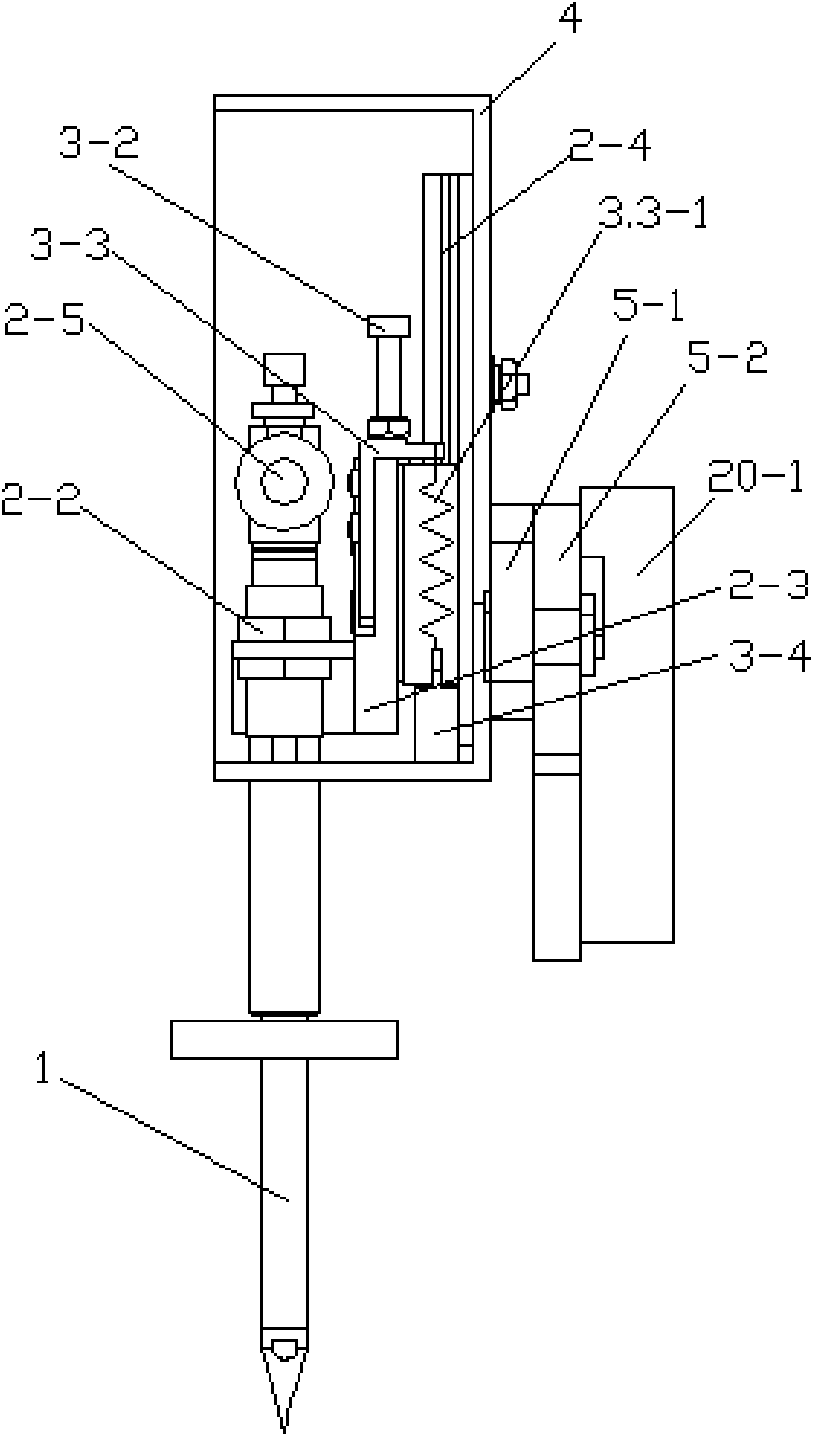

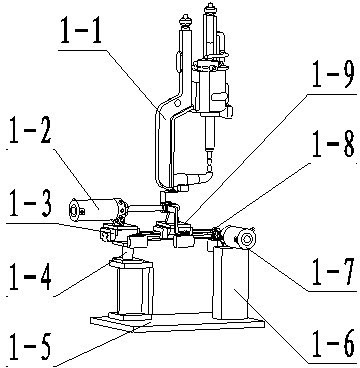

Tin soldering system of automatic tin soldering robot

ActiveCN102069254AGuaranteed accuracyReduce wearPrinted circuit assemblingWelding/soldering/cutting articlesEngineeringSlide plate

The invention discloses a tin soldering system of an automatic tin soldering robot, which comprises a soldering bit, a soldering bit moving mechanism and a tin wire accurate positioning mechanism, wherein the soldering bit moving mechanism comprises a moving device connected with the soldering bit; the moving device comprises a connecting block, an air cylinder, a sliding plate and a linear sliding rail; the upper end of the soldering bit and the cylinder body of the air cylinder are connected together by the connecting block, and the connecting block is also connected with the sliding plate; the sliding plate is in sliding connection with the linear sliding rail; a tin wire guide nozzle of the tin wire accurate positioning mechanism is connected with the connecting block through a connecting rod, the connecting block is connected with a connecting shaft, a deflection block is fixedly connected with the connecting shaft, the connecting shaft is connected with a pitching block in a rotating mode, the pitching block is connected with a clamping block, the clamping block is fixed on the upper end of the soldering bit, a horizontal adjustment screw is connected with the deflection block in a rotating mode, and the front end of the horizontal adjustment screw is connected with the pitching block in a sliding mode. The invention can reduce the abrasion of a mechanism which drives the soldering bit to move up and down, ensures the precision of the repeating motion of the soldering bit in tin soldering, and can enable transported tin wires accurately to be positioned to a tin soldering point of the soldering bit.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

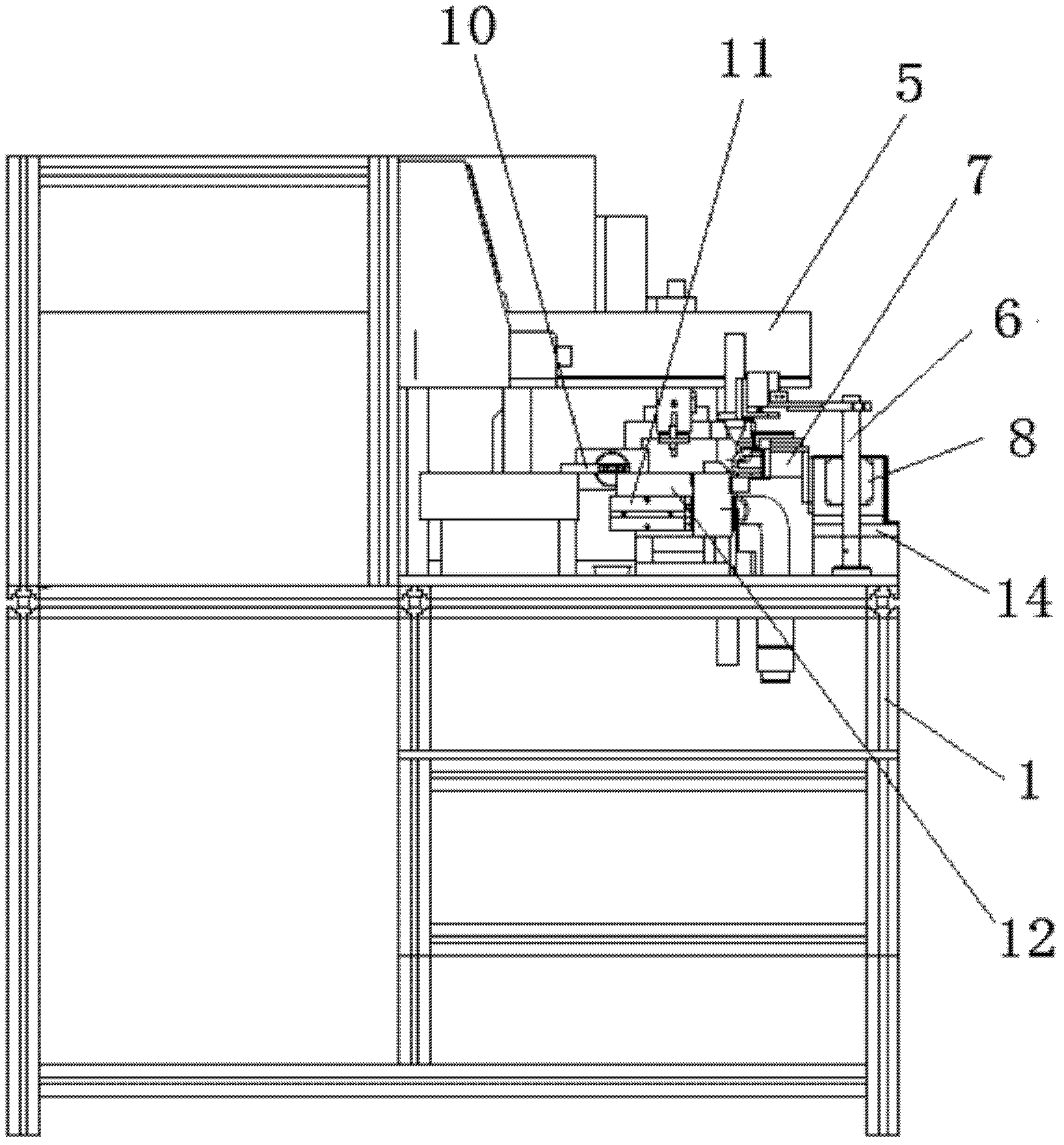

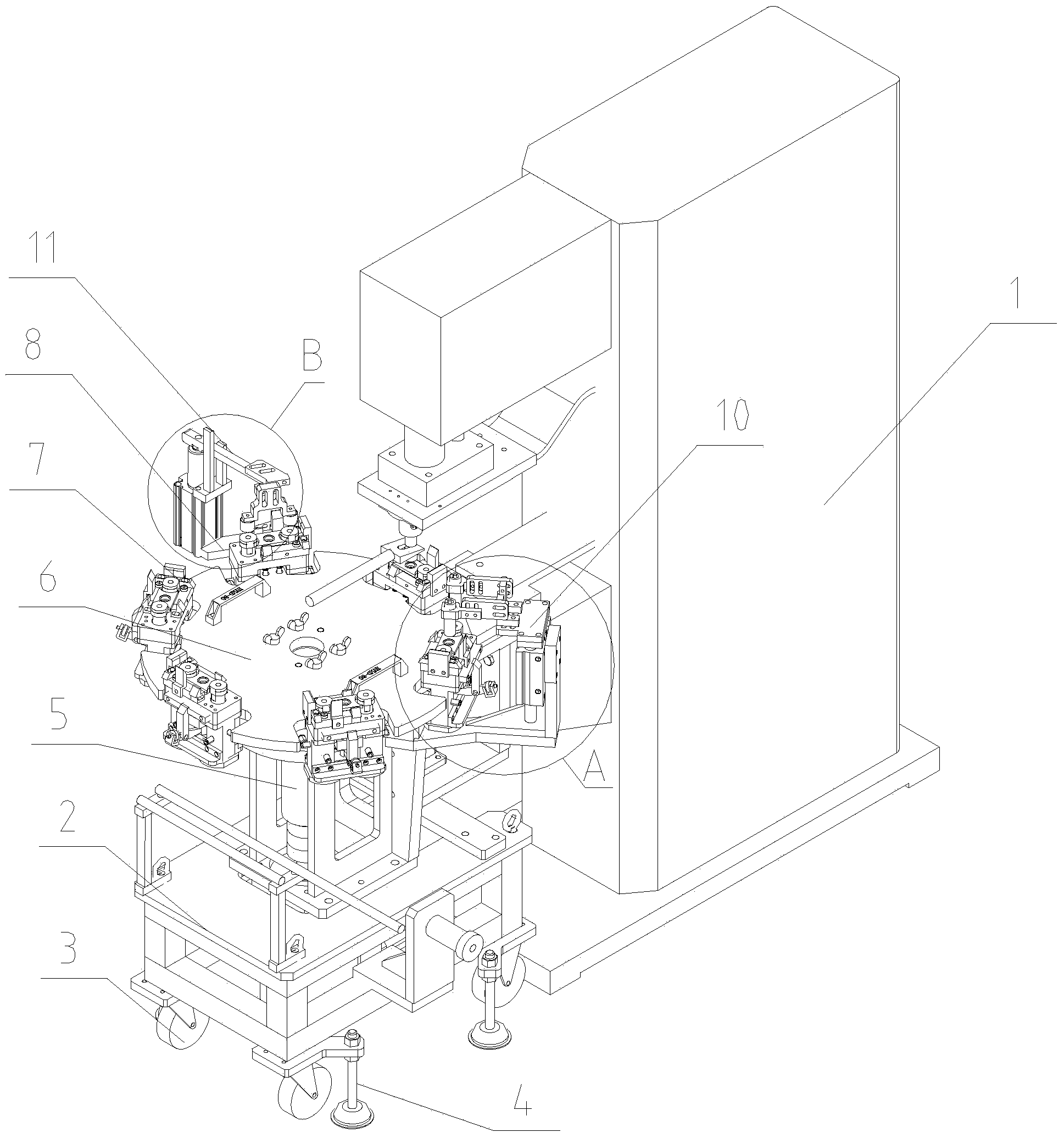

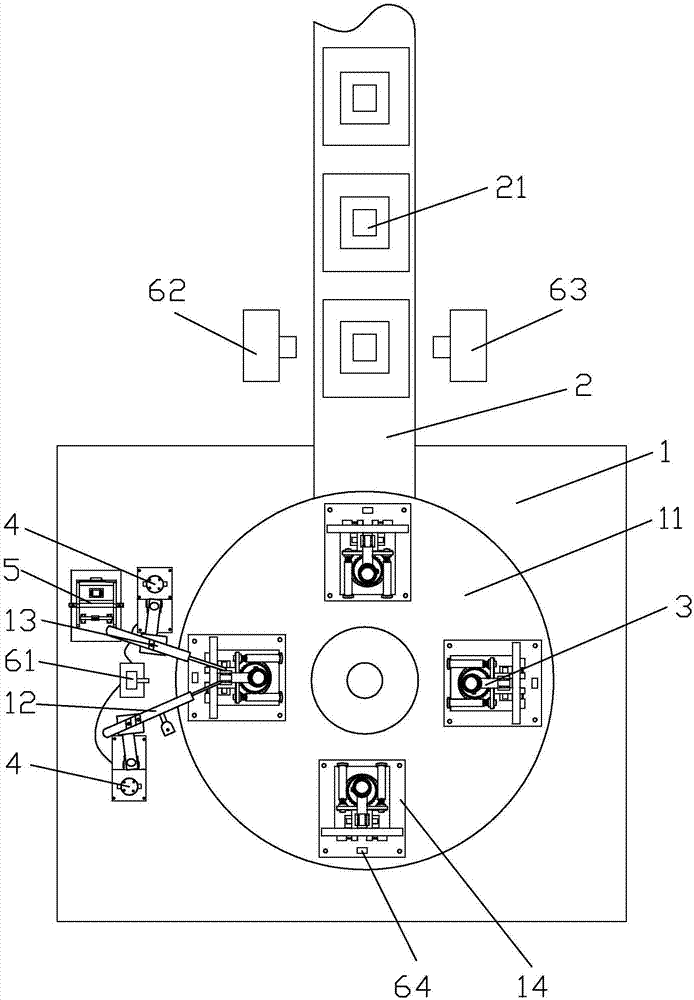

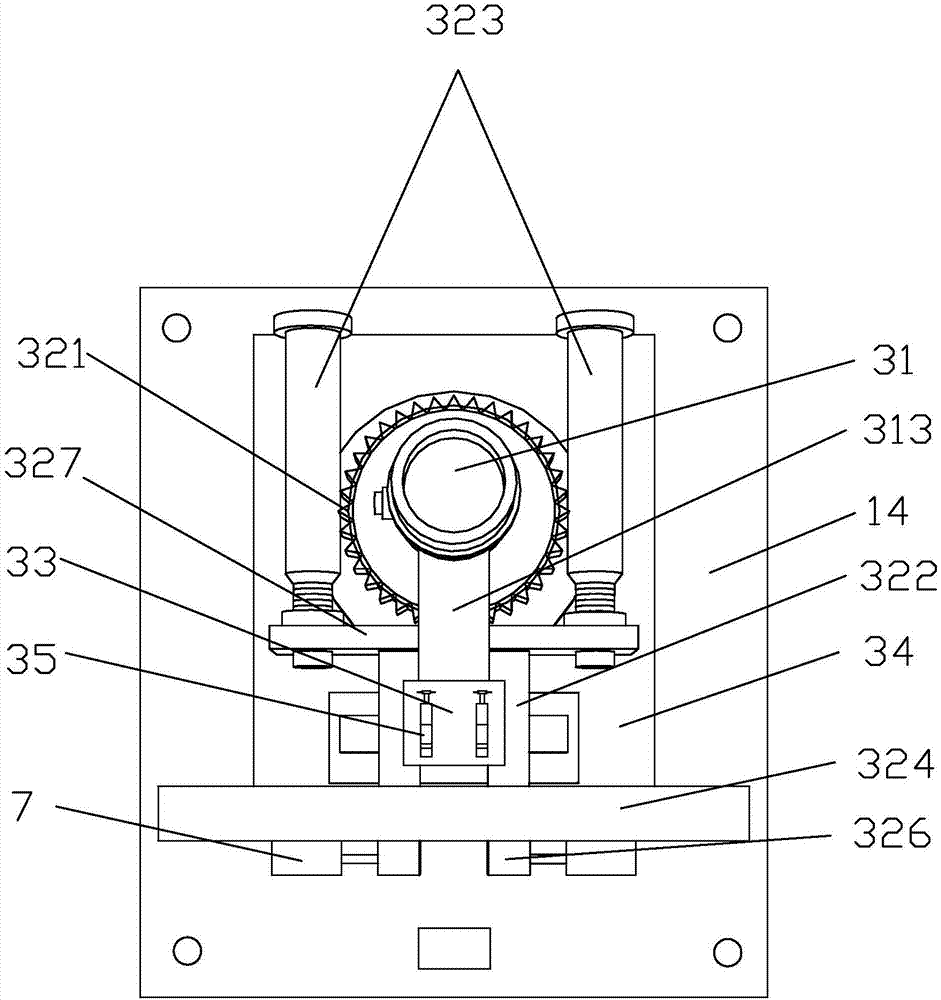

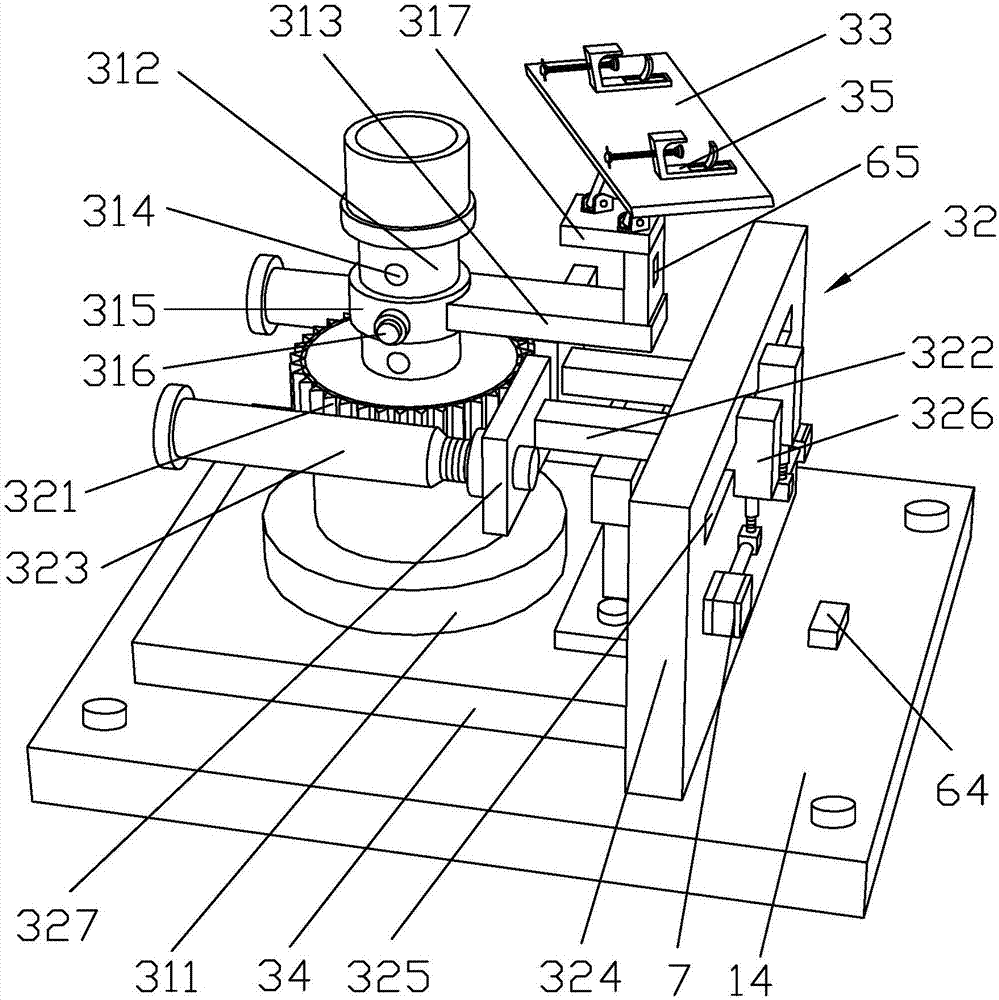

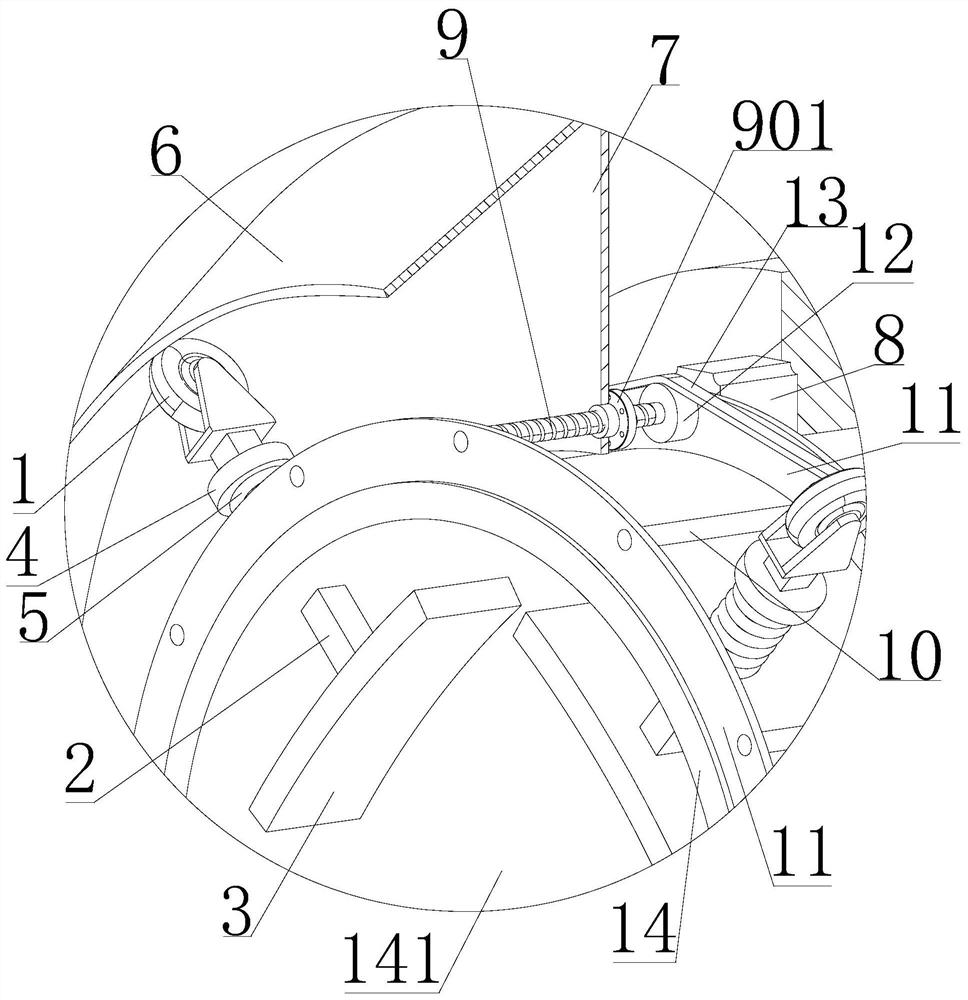

Automatic spot welding equipment

ActiveCN104227213AImprove efficiencyImprove securityResistance welding apparatusEngineeringSpot welding

The invention discloses automatic spot welding equipment with the advantages that the welding production efficiency is improved, and the work intensity is reduced. The automatic spot welding equipment comprises a welding machine body and an installing base, wherein a rotating device driven by a servo motor is vertically arranged on the installing base, an installing disc is detachably arranged at the upper part of the rotating device, at least four material support welding devices are uniformly distributed and arranged on the installing disc in the periphery direction, each material supporting welding device comprises a welding frame arranged on the installing disc, a lower electrode is arranged in the welding frame, a material jacking rod is movably arranged in the welding frame, the top of the material jacking rod is provided with a material jacking frame, the bottom of the material jacking rod is hinged to a crow bar, the middle part of the crow bar is hinged onto a bottom plate of the welding frame, the end part of the crow bar extends out of the welding frame, an inclined wedge block which is provided with the bottom surface downwards inclined in the rotating direction of a turntable and is used for downwards pressing a part, extending out of the welding frame, of the crow bar is arranged on the installing base, the top of the welding frame is provided with a corresponding lower electrode according to the position to be welded of the materials, and a detection device for detecting whether materials exist on the welding frame or not is arranged in a position, corresponding to the material support welding device in a former position of the welding station, on the installing base.

Owner:苏州金鸿顺汽车部件股份有限公司

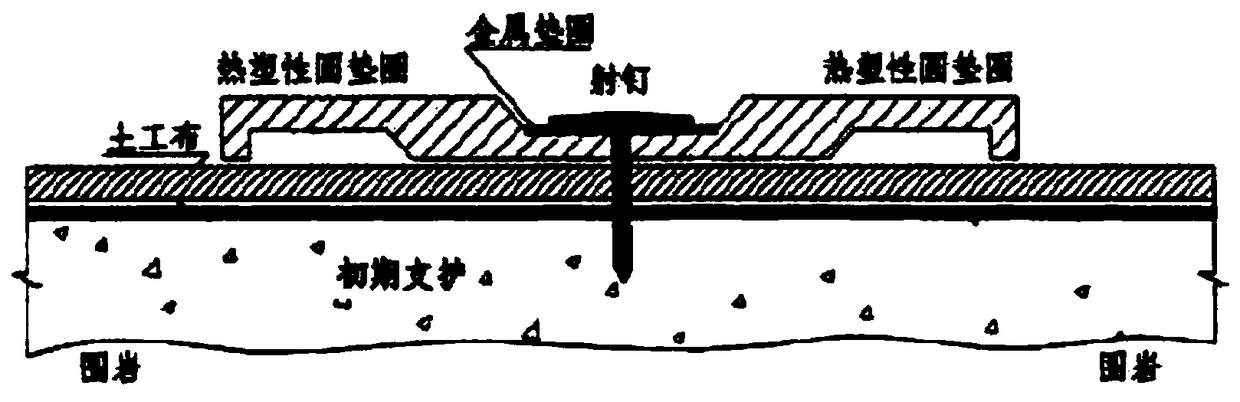

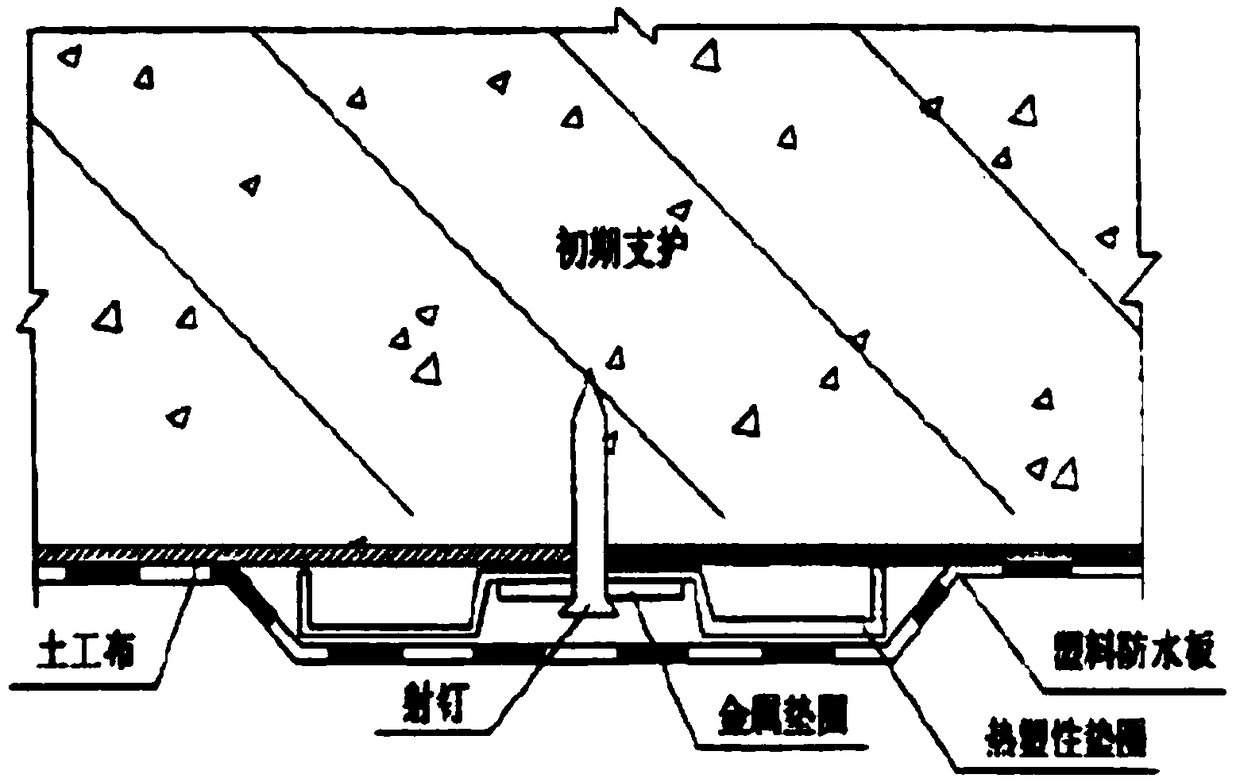

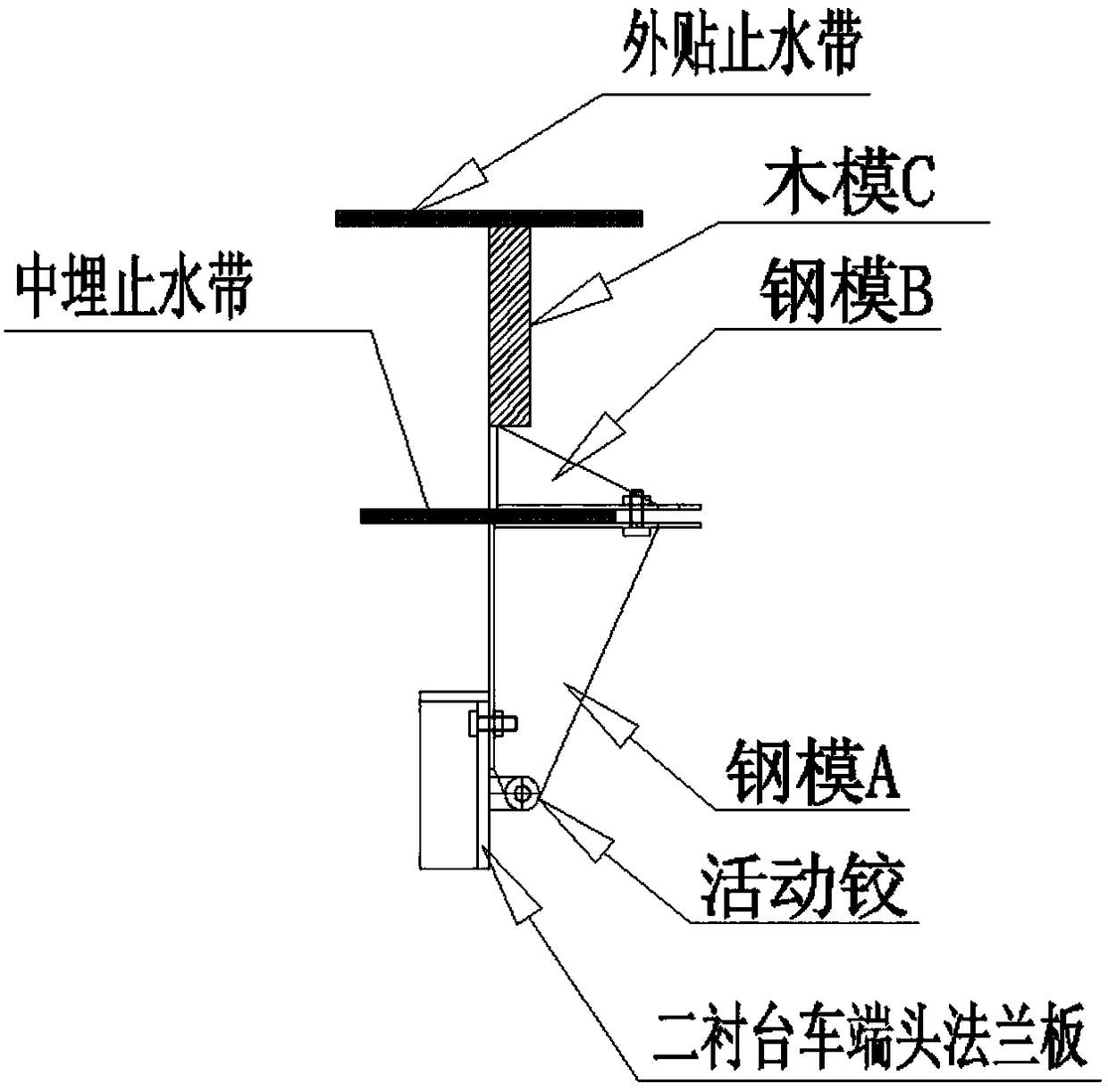

Karst rich water tunnel water-proof and drainage construction method

ActiveCN108222979AGuarantee welding qualityGuaranteed to stickUnderground chambersDrainageGeomorphologyKarst

The invention discloses a karst rich water tunnel water-proof and drainage construction method. By adopting the principle of "combination of prevention, drainage, interception and blockage, adaptationto local conditions and comprehensive treatment" and a water-proof method of combining water-proof with drainage is introduced to ensure the realization of project safety and quality objectives. Thekarst rich water tunnel water-proof and drainage construction method solves the problems that the difficulty of construction of a karst rich water tunnel such as an iron helmet mountain is high, the existing construction method cannot be applied well, and many potential safety hazards exist. The invention belongs to the technical field of tunnel construction.

Owner:CHINA RAILWAY ERJU 1ST ENG

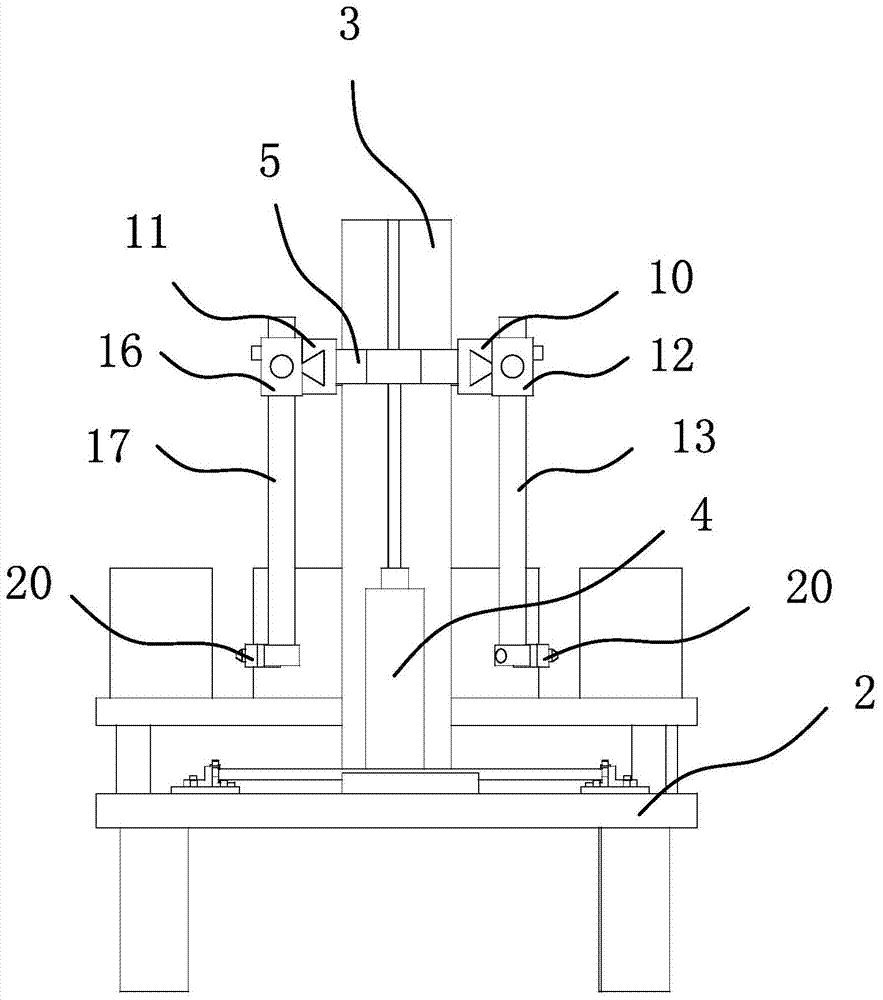

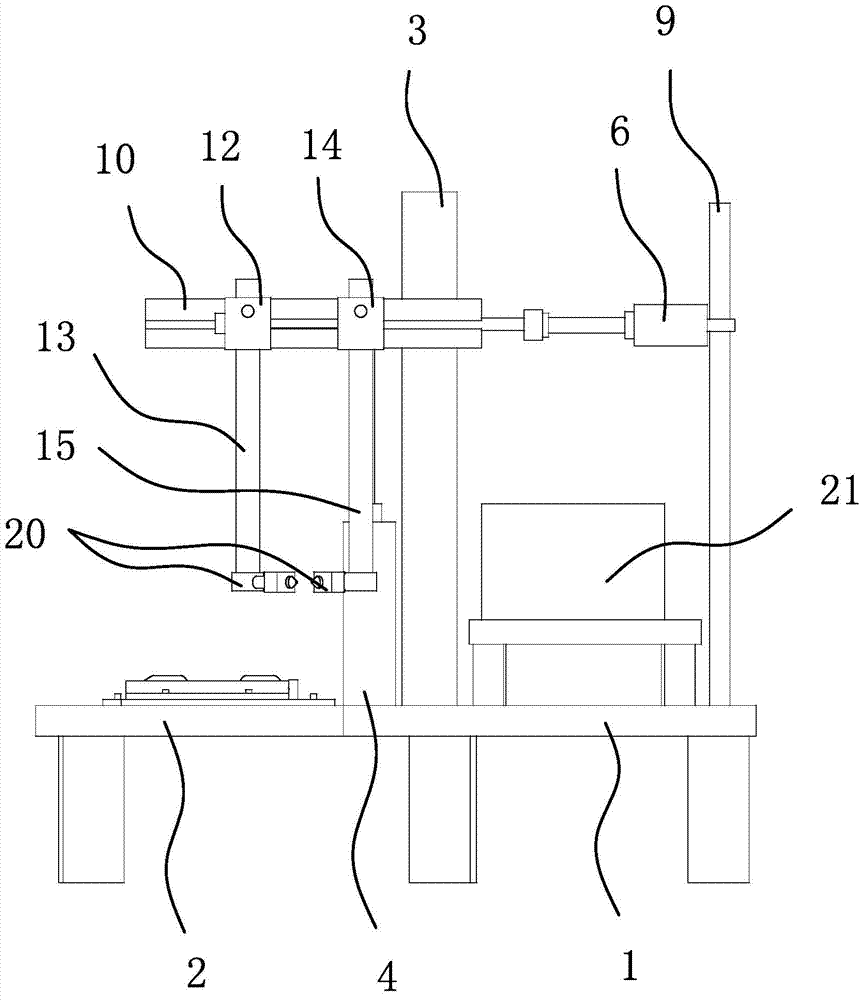

Pressing tool for assembling truck body

ActiveCN102744547AHigh strengthOpen smoothlyWelding/cutting auxillary devicesAuxillary welding devicesTruckPiston rod

The invention discloses a pressing tool for assembling a truck body. The pressing tool comprises an upright device, a pressing hook, a jack device and a workpiece locating device, wherein the upright device comprises uprights and bases, which are positioned on the two sides; the top ends of the uprights are provided with anti-rebound devices; guide devices and lug seats are arranged on the inner sides of the uprights; cylinders are arranged on the outer sides of the uprights; connecting devices matched with the guide devices are arranged on the inner sides of the guide devices; upper ends of the connecting devices are hinged with pressing hooks; pin holes and pin shafts I are arranged on the lug seats; the pin holes are matched with the pin shafts I; force amplifying levers, which rotate relative to the pin shafts I, are arranged on the pin shafts I; upper long circular holes and lower long circular holes are respectively formed in two ends of the force amplifying levers, wherein the upper long circular holes are hinged with connecting holes at lower ends of the connecting devices by pin shafts II; the lower long circular holes are hinged with connecting holes on end part joints of cylinder piston rods by pin shafts III; jack devices and workpiece locating devices are arranged on the inner sides of lower ends of the uprights; and the bases of the uprights, bottom surfaces of the jack devices and bottom surfaces of the workpiece locating devices are respectively connected with foundation embedded plates.

Owner:CRRC SHANDONG CO LTD

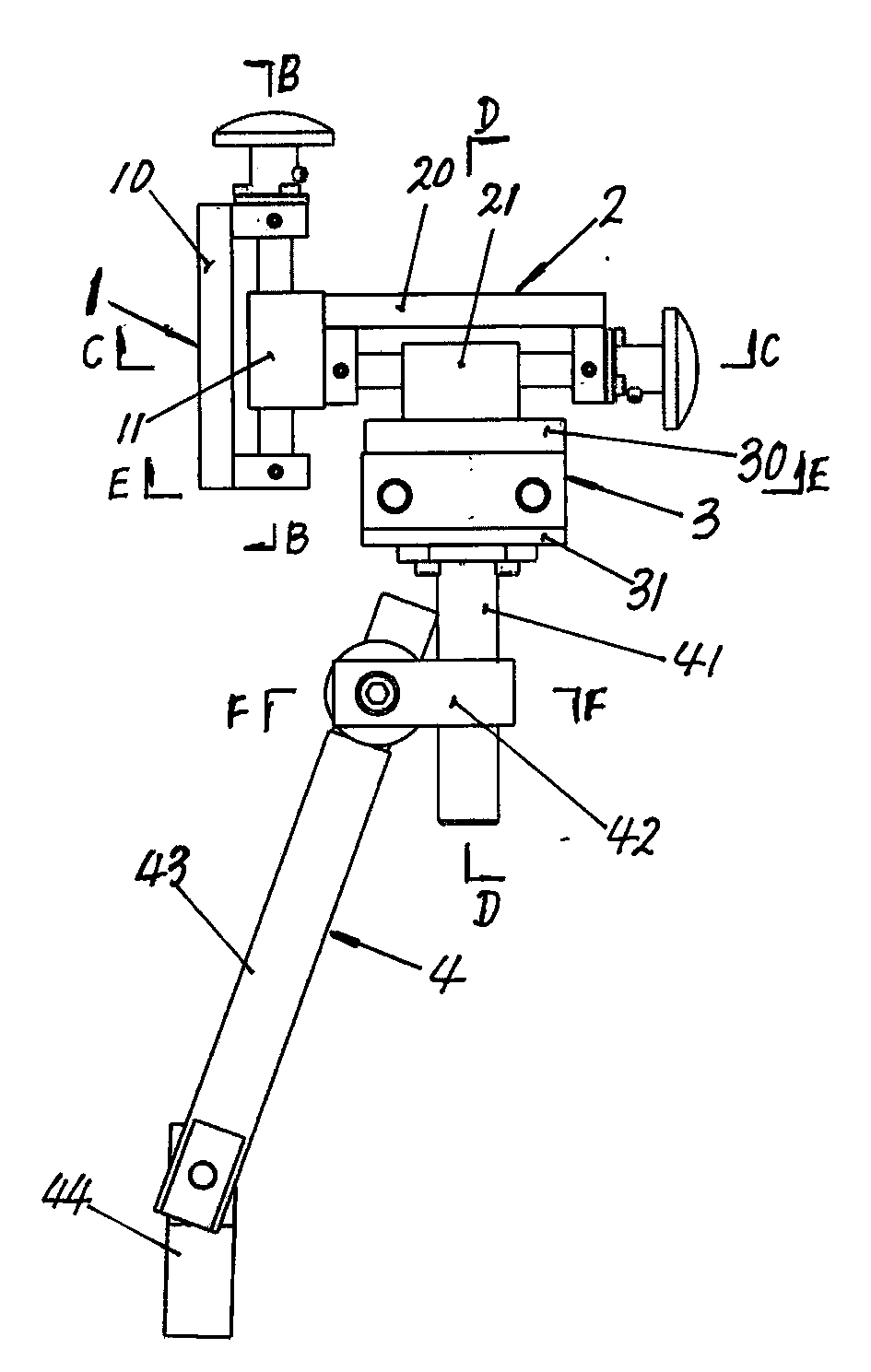

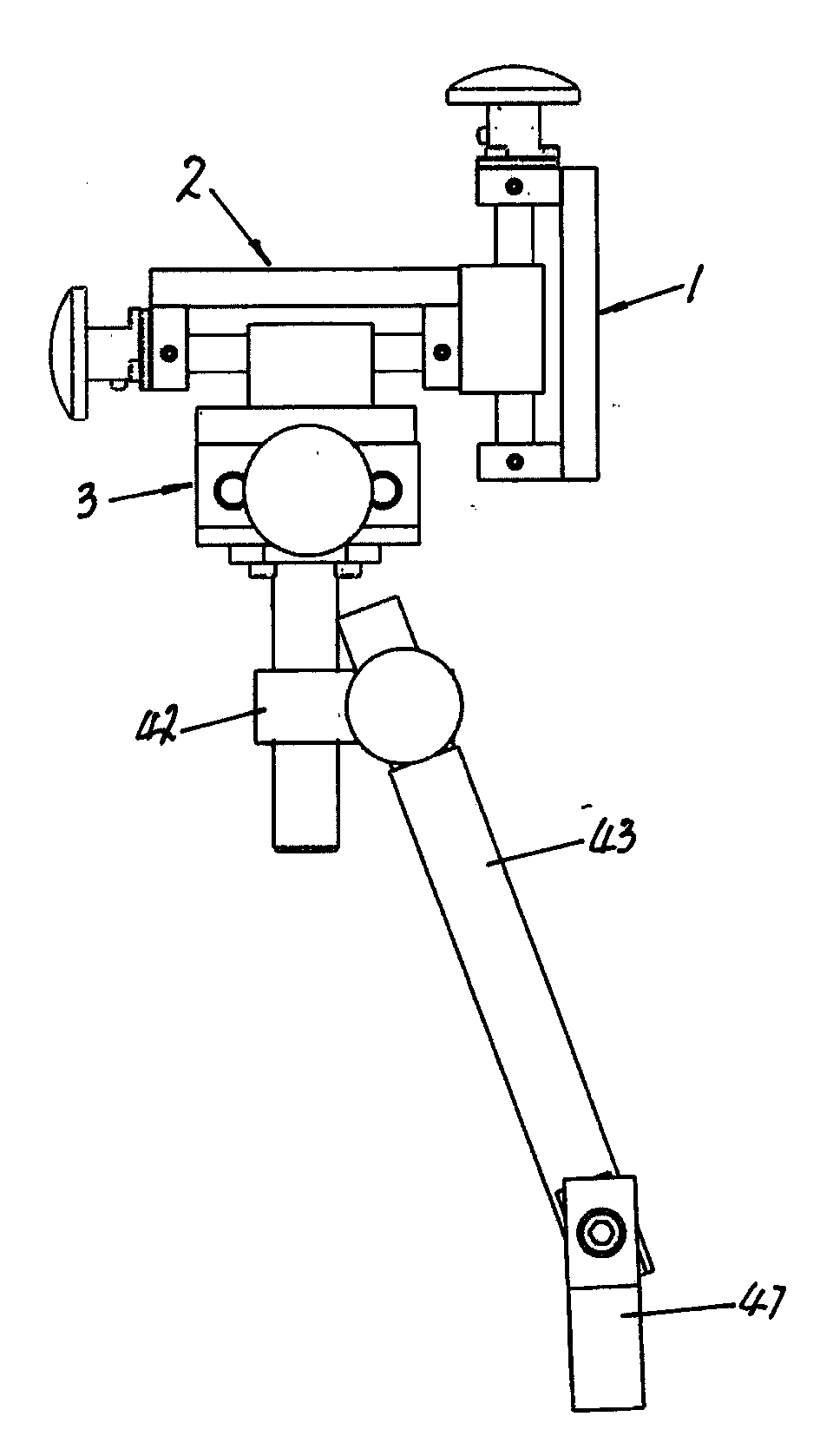

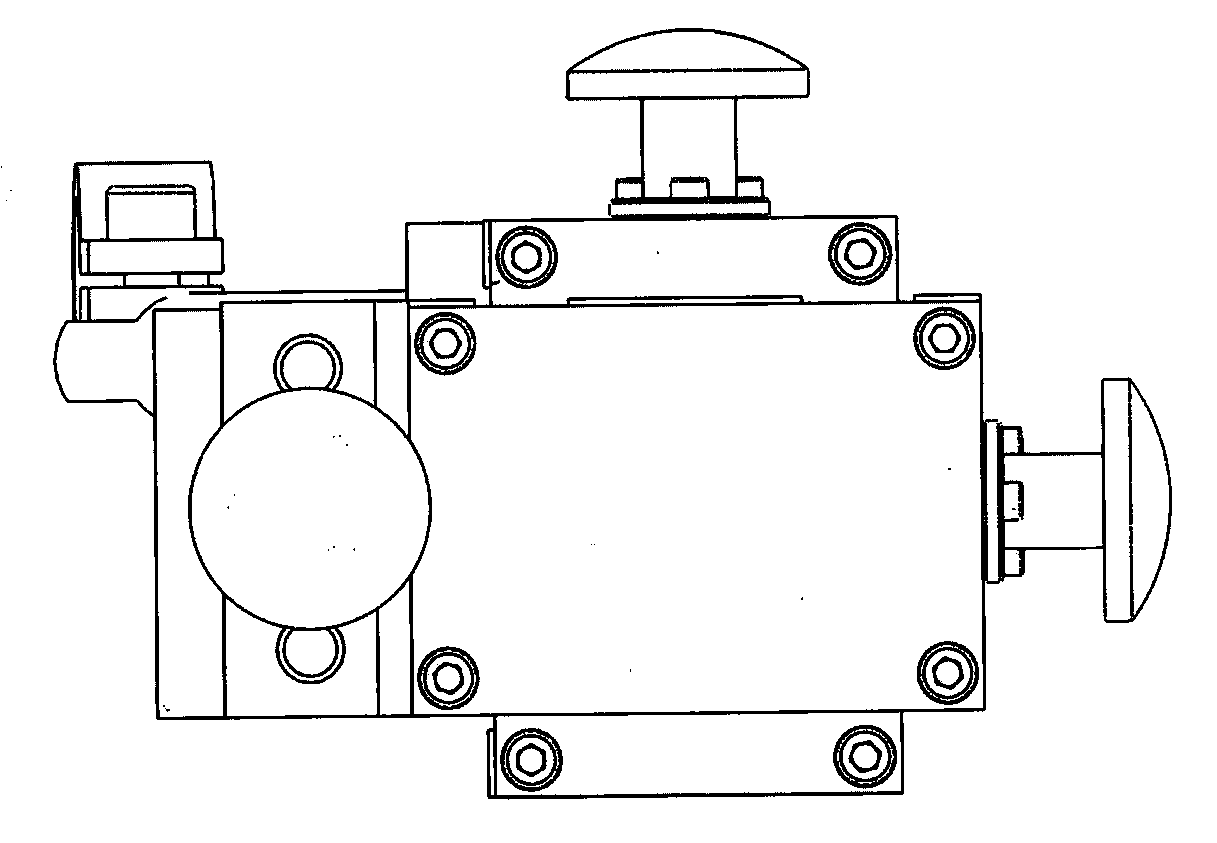

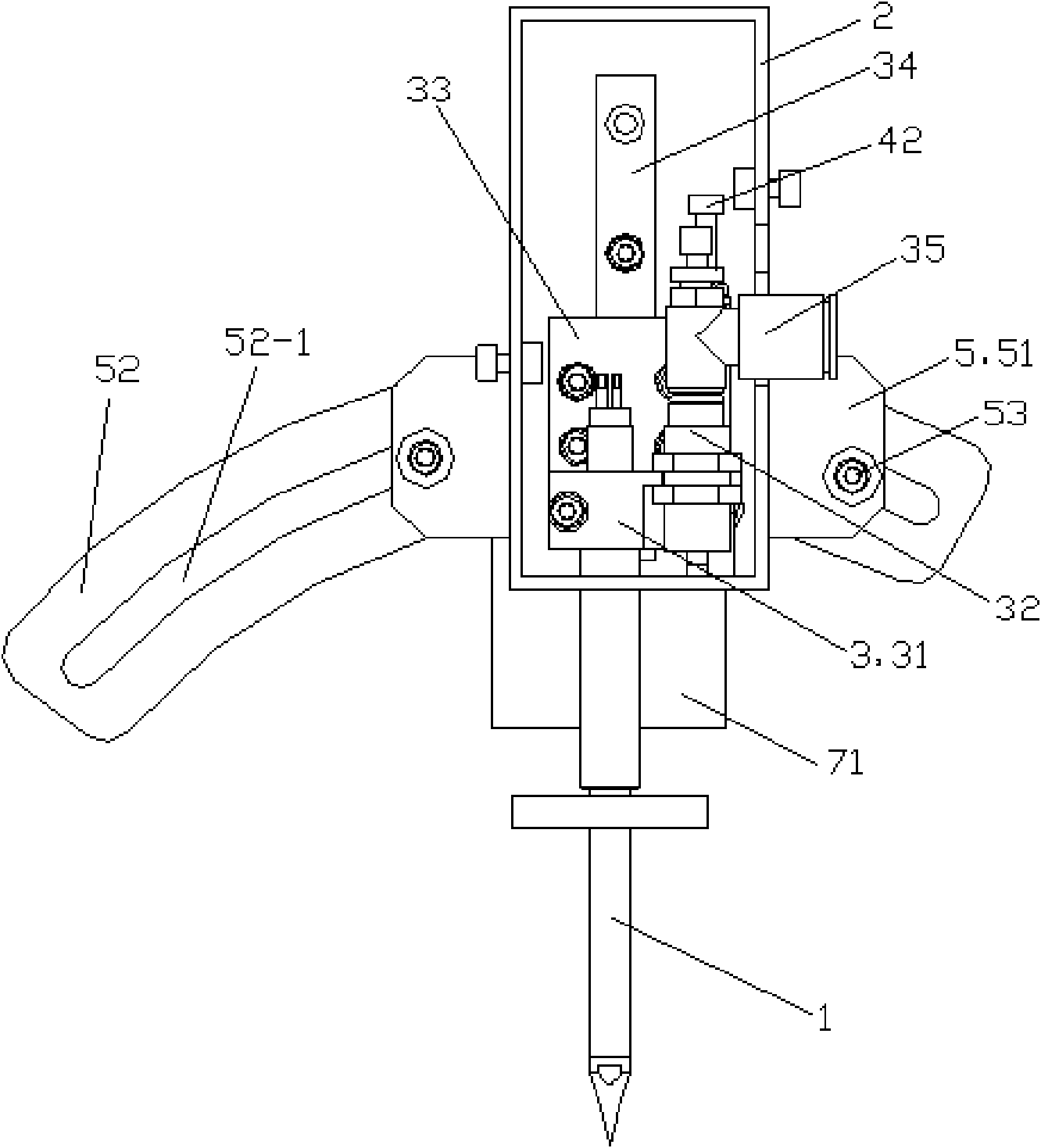

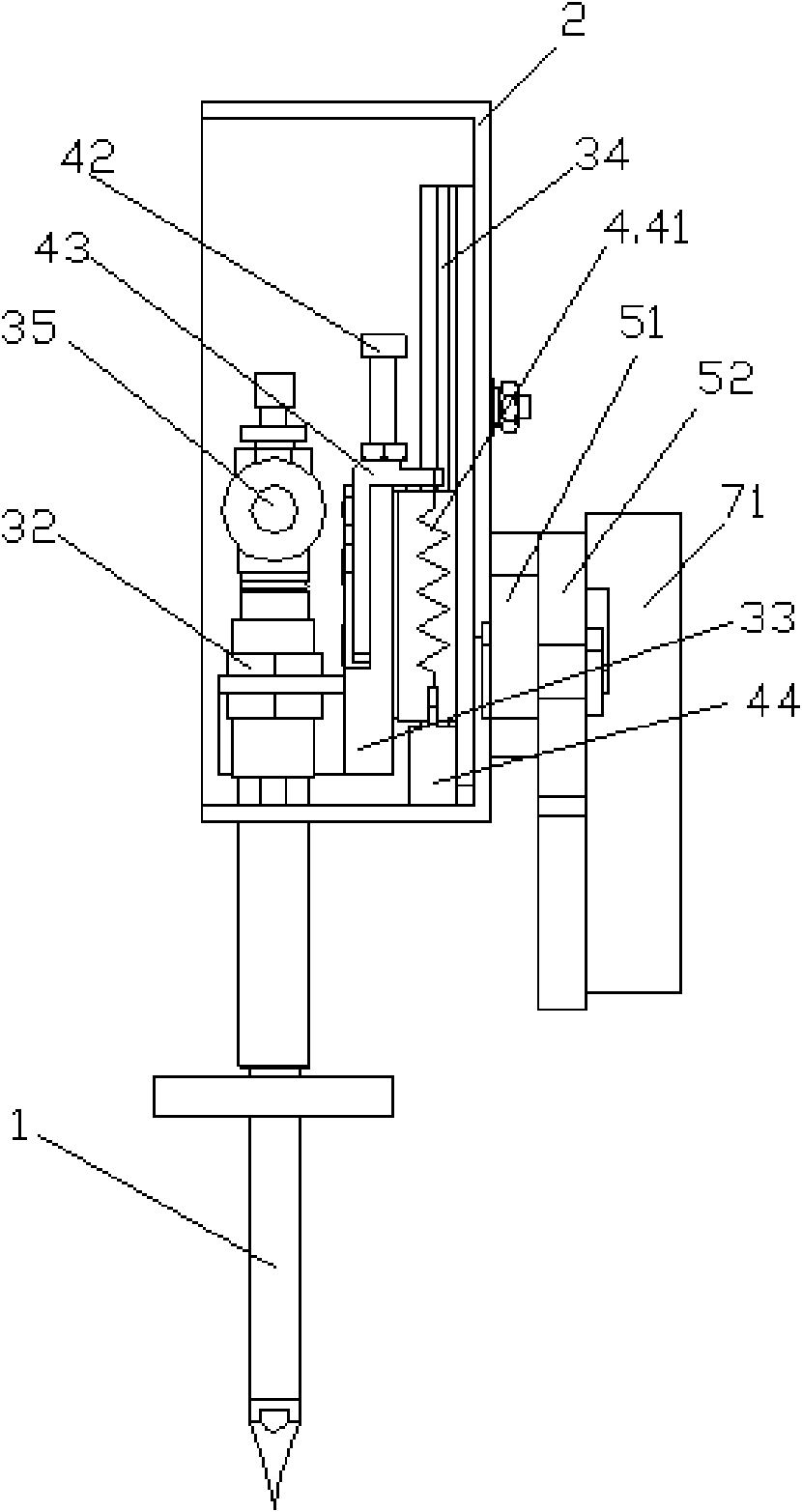

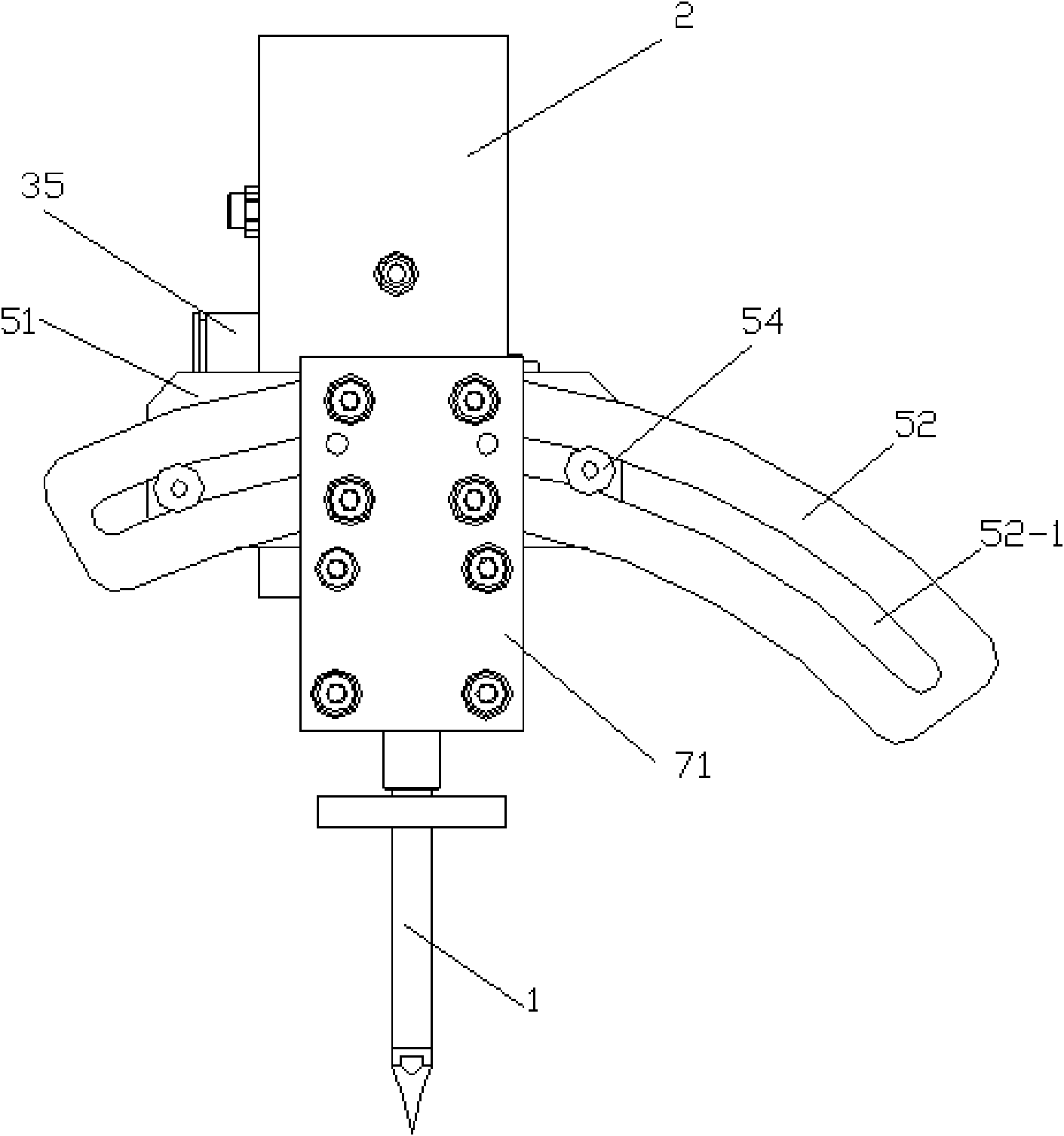

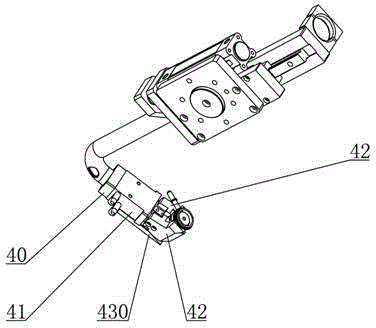

Three-dimensional adjustable fixing device of automatic welding gun

InactiveCN103418954AMake up for defects that cannot be fine-tunedIncrease flexibilityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a three-dimensional adjustable fixing device of an automatic welding gun, and is characterized by comprising an up-down movement device (1), a left-right movement device (2), a forward-backward movement device (3) and a rotary connecting rod device (4), wherein each of the movement devices comprises a C-shaped frame, a slider block, a slider block guide rod and a drive screw rod, the rotary connecting rod device (4) comprises an upper connecting rod (41), an upper clamp (42), a connecting rod (43) and a lower clamp (44). A welding gun fixed on the lower end of the connecting rod (43) is adjusted and driven to move to all directions through a hand wheel, and an angular position of a welding gun nozzle is adjusted through rotation of the connecting rod (43), the adjustment motion is stable, so that the welding gun can be fixed in a three-dimensional adjustable manner, the welding position is more accurate, and the welding quality is improved.

Owner:DANDONG TOP ELECTRONICS INSTR GRP

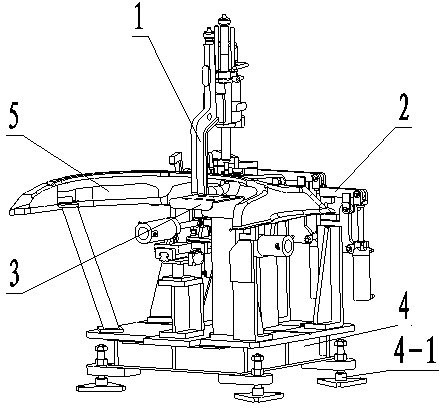

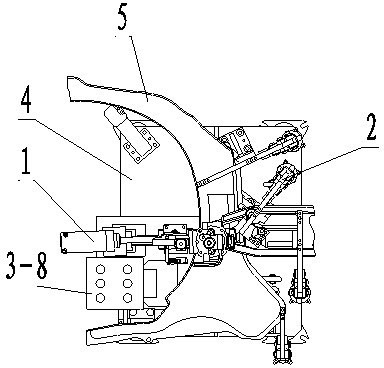

Automatic spot-welding equipment

ActiveCN102554529AShort time spentAvoid missing solderWelding/cutting auxillary devicesAuxillary welding devicesProgrammable logic controllerEngineering

Automatic spot-welding equipment is used for solving the problem of automated welding of sheet metal workpieces and comprises a welding execution mechanism, a workpiece positioning and clamping mechanism, a PLC (programmable logic controller) control system and a base. The welding execution mechanism comprises a welder, a translation cylinder, a rotary seat, a translation sliding rail, a sidesway cylinder and a bottom plate, wherein the translation cylinder is fixed onto the rotary seat through a translation cylinder support, the rotary seat is fixed onto the bottom plate and fixedly connected with one end of the translation sliding rail, the other end of the translation sliding rail is connected with a telescopic arm of the sidesway cylinder, the sidesway cylinder is fixed onto the bottom plate through a sidesway cylinder support, the bottom plate is fixedly mounted on a base, the welder is fixed onto a welder support fixedly connected with the telescopic arm of the translation cylinder, and the bottom of the welder support is provided with a sliding groove matched with the translation sliding rail. By the aid of the automatic spot-welding equipment, the labor intensity of operators can be greatly reduced, and working efficiency and workpiece welding quality can be remarkably improved.

Owner:长城汽车股份有限公司平湖分公司

Turntable type flame welding machine

ActiveCN107378183AAvoid going off courseGuaranteed accuracyGas flame welding apparatusContinuous/uninterruptedInductor

The invention mainly discloses a turntable type flame welding machine. The technical scheme of the turntable type flame welding machine is characterized by comprising a workbench and a conveying rail, wherein a rotary table, a welding gun, a wire feeding gun and an induction device are arranged on the workbench; the rotary table is driven to rotate by a first driver, machining stations are distributed on the rotary table in the circumferential direction, and the machining stations are provided with machining clamps and induction switches; the machining clamps comprise rotating devices, locking devices and supporting plates, the rotating devices are driven by a second driver, and the supporting plates are used for fixing welding workpieces through fixing clamps; the welding gun and the wire feeding gun are connected with angle adjusting mechanisms respectively, and the wire feeding gun is further connected with a wire feeding device; and the induction device is connected with the first driver and the second driver, and the induction device comprises a first inductor and a second inductor. The turntable type flame welding machine is stable in work, accurate in positioning, capable of effectively improving the welding quality and ensuring the uniformity of welding joints, high in automation degree, capable of working continuously and reducing the labor intensity of workers, and capable of automatically welding large-batch products.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

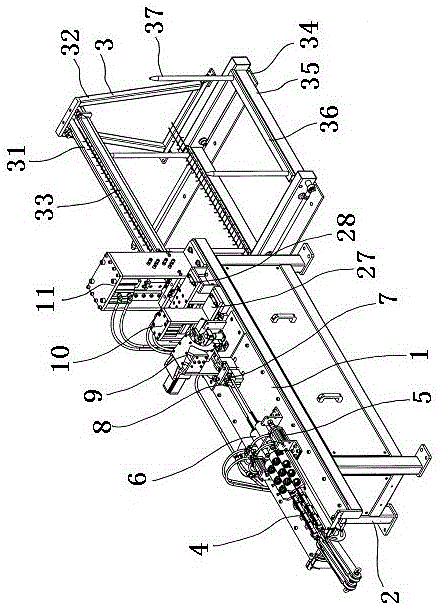

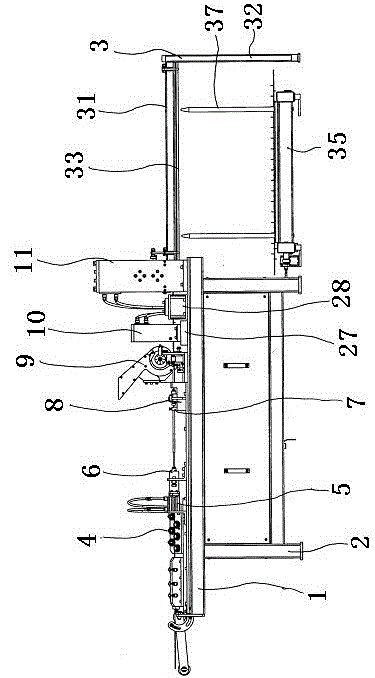

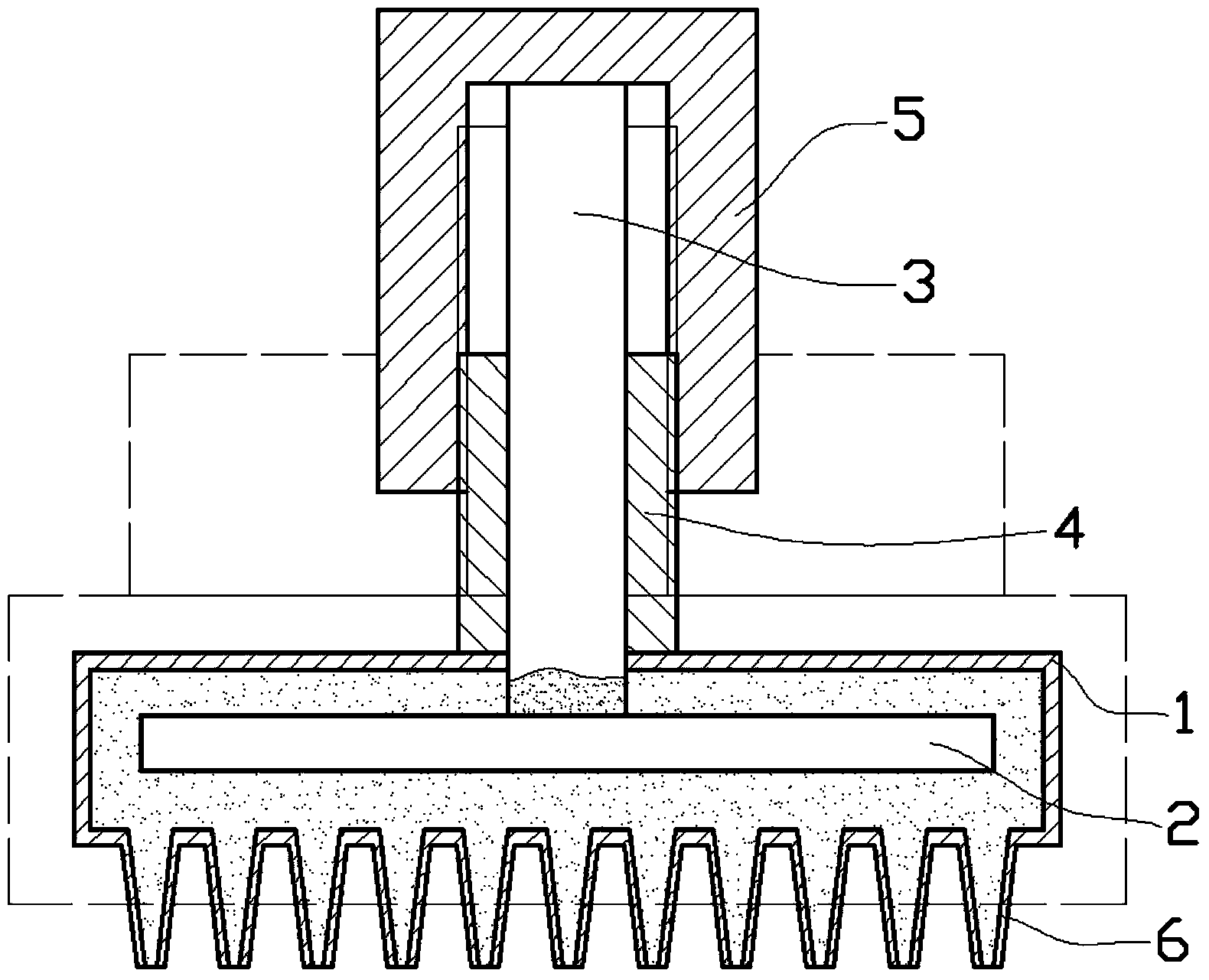

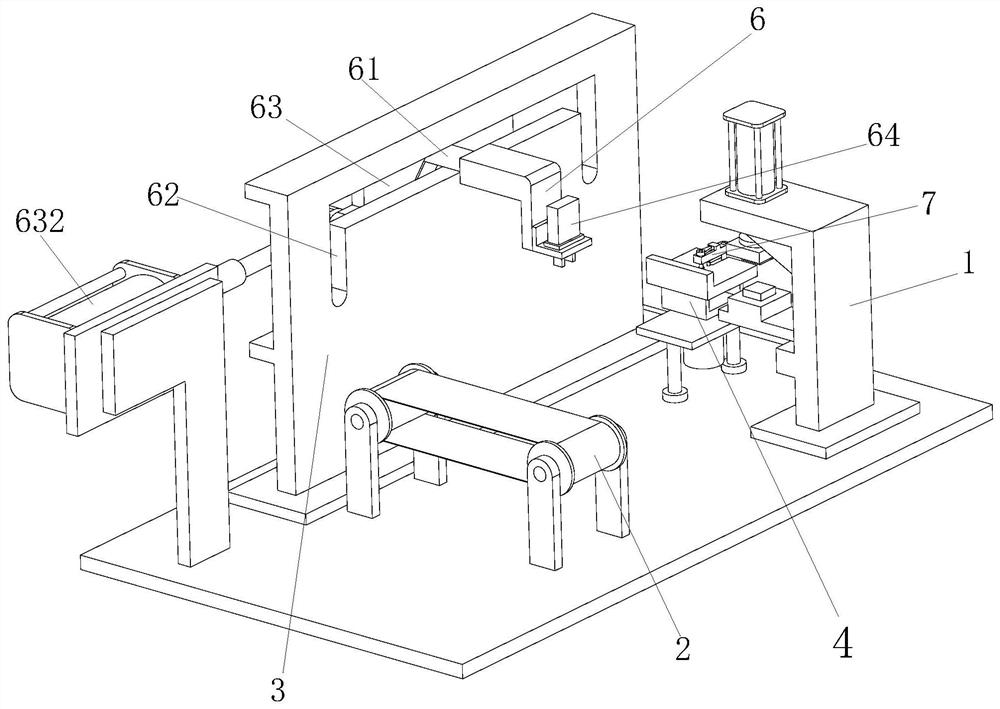

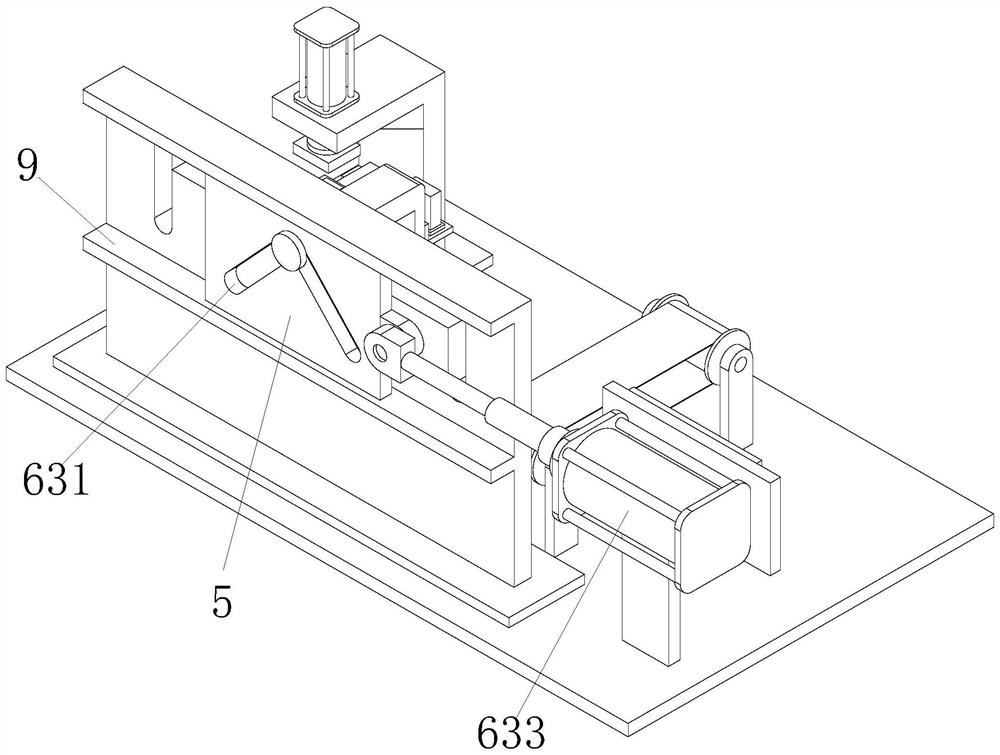

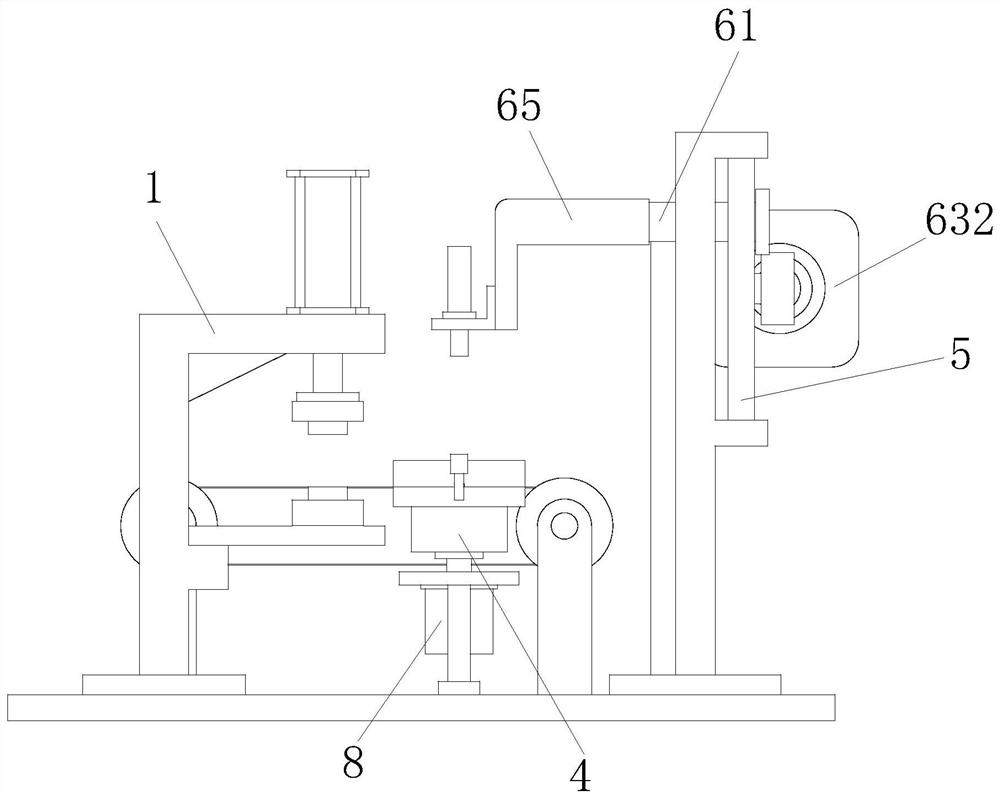

Dust removal mesh welding device and dust removal mesh welding method

ActiveCN105945582ANo inclination etc.Accurate welding positionOther manufacturing equipments/toolsContact positionWelding

The invention belongs to the technical field of welding machines and dust removal mesh welding methods and discloses a dust removal mesh welding device and a dust removal mesh welding method. The dust removal mesh welding device is mainly characterized by comprising a straightening mechanism, a wire pushing sleeve, a threading rack, a welding mechanism and a transverse wire bending mechanism, which are arranged on an operation platform, wherein a lateral wire baffle is arranged on one side of a wire holding disc; a lower wire baffle is movably fixed below the lateral wire baffle through a fixing pin; a propping spring is arranged between the lower wire baffle and the lateral wire baffle; two lower welding heads are arranged on the operation platform and located on two sides below the wire holding disc; a swinging passage for allowing the lower wire baffle to swing in is formed between the two welding heads; two down-pressing air cylinders with down-pressing plates are arranged on the operation platform and located on the outer sides of two welding head seats; the opposite side surfaces of the two down-pressing plates cling to the side surfaces of the wire holding disc; and an upper welding head is located below the down-pressing plates. According to the invention, transverse wires are pressed down by the down-pressing plates, the contact and welding positions of longitudinal wires and the transverse wires are close to the outer sides of wire holding grooves, the contact positions of the longitudinal wires and the transverse wires are accurate, and the welding quality is high.

Owner:河北骄阳焊工有限公司

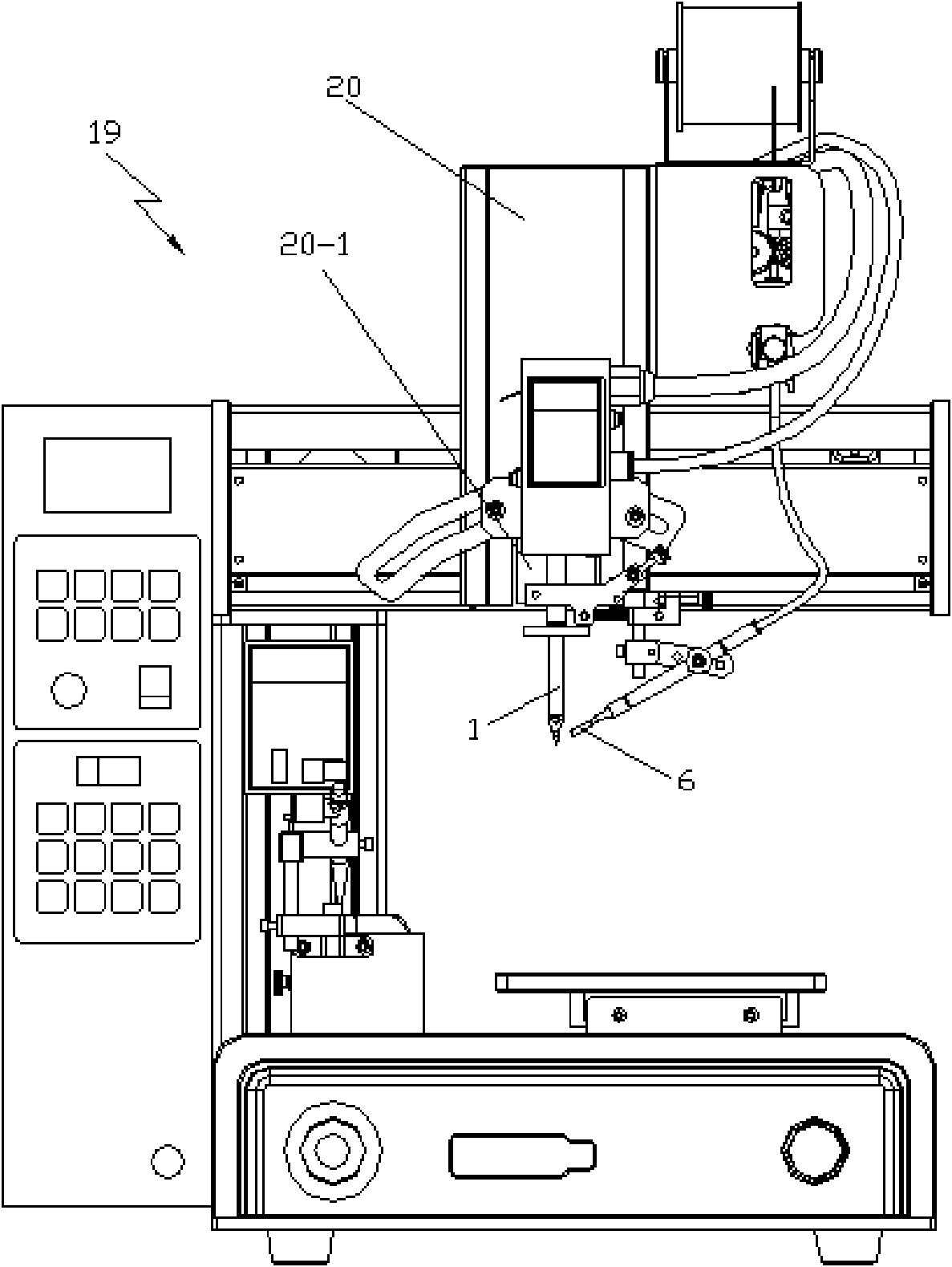

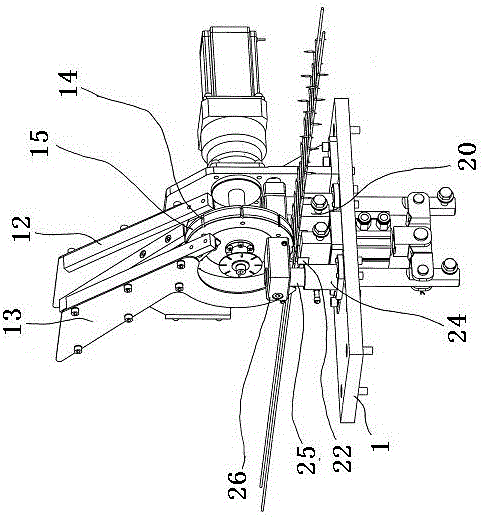

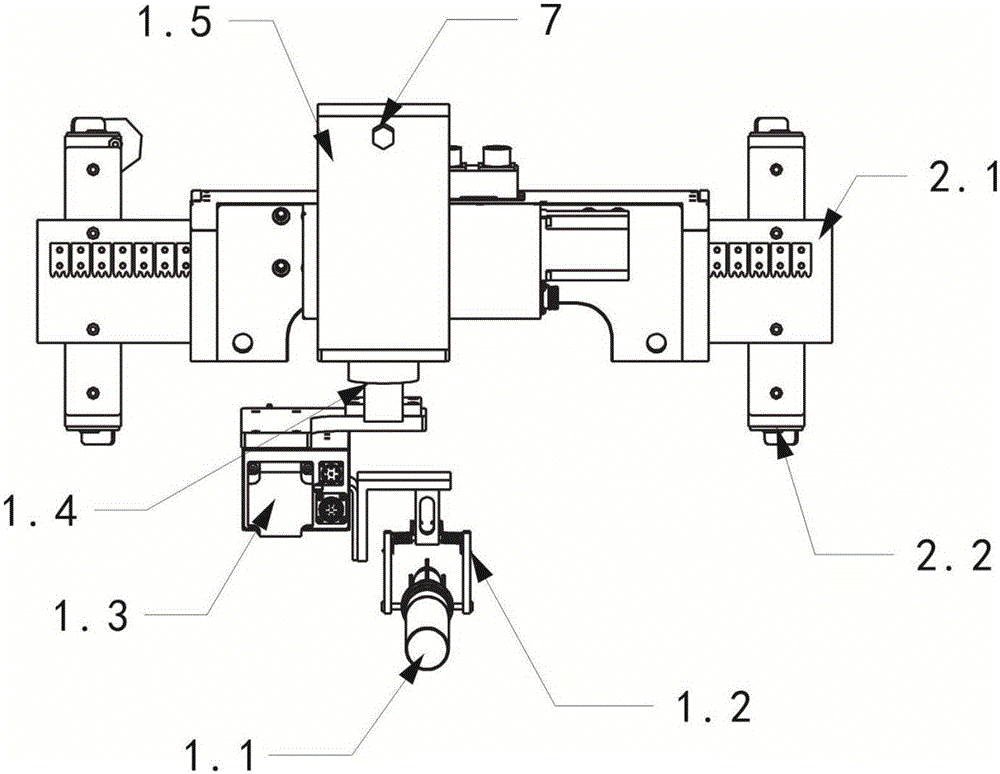

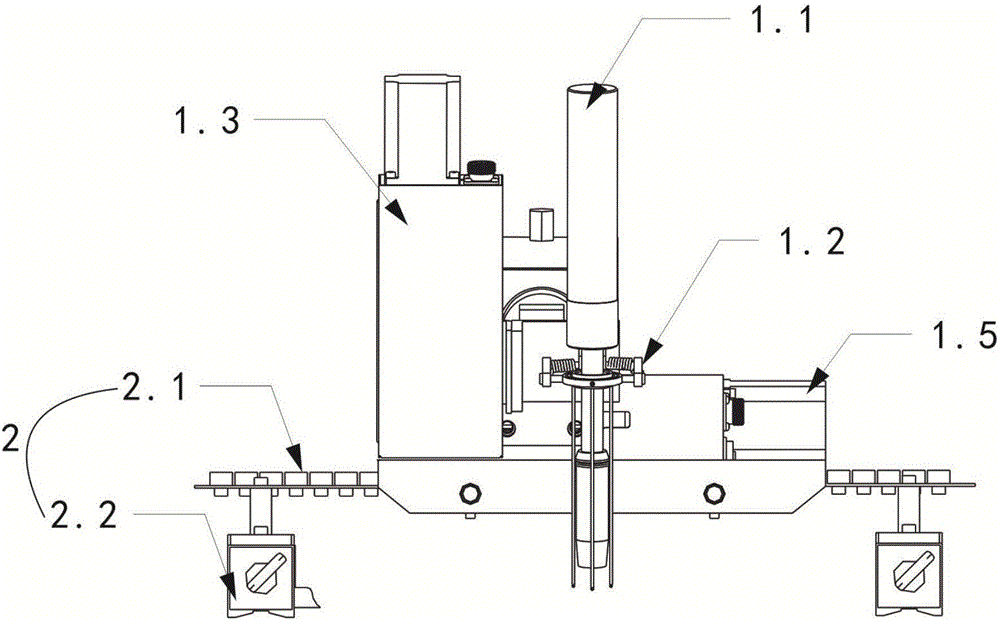

Flexible guide rail welding robot

ActiveCN106624523AReduce labor costsImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesSteel ballEngineering

The invention discloses a flexible guide rail welding robot which comprises a welding main body (1) for controlling welding operation and a rail device (2) adsorbed on the surface of a welding workpiece, wherein the welding main body (1) slides on the rail device (2); the rail device (2) comprises a flexible guide rail (2.1) and magnetic seats (2.2) uniformly distributed at the bottom of the flexible guide rail (2.1); and the magnetic seats (2.2) are adsorbed on the surface of the welding workpiece. The robot disclosed by the invention can automatically perform welding work on large-sized arc surface equipment such as a steel ball tank, a storage tank and a ship body, so that the labor cost is reduced, and the welding precision is improved.

Owner:CHENGDU NANFANG ELECTRONICS METER CO LTD

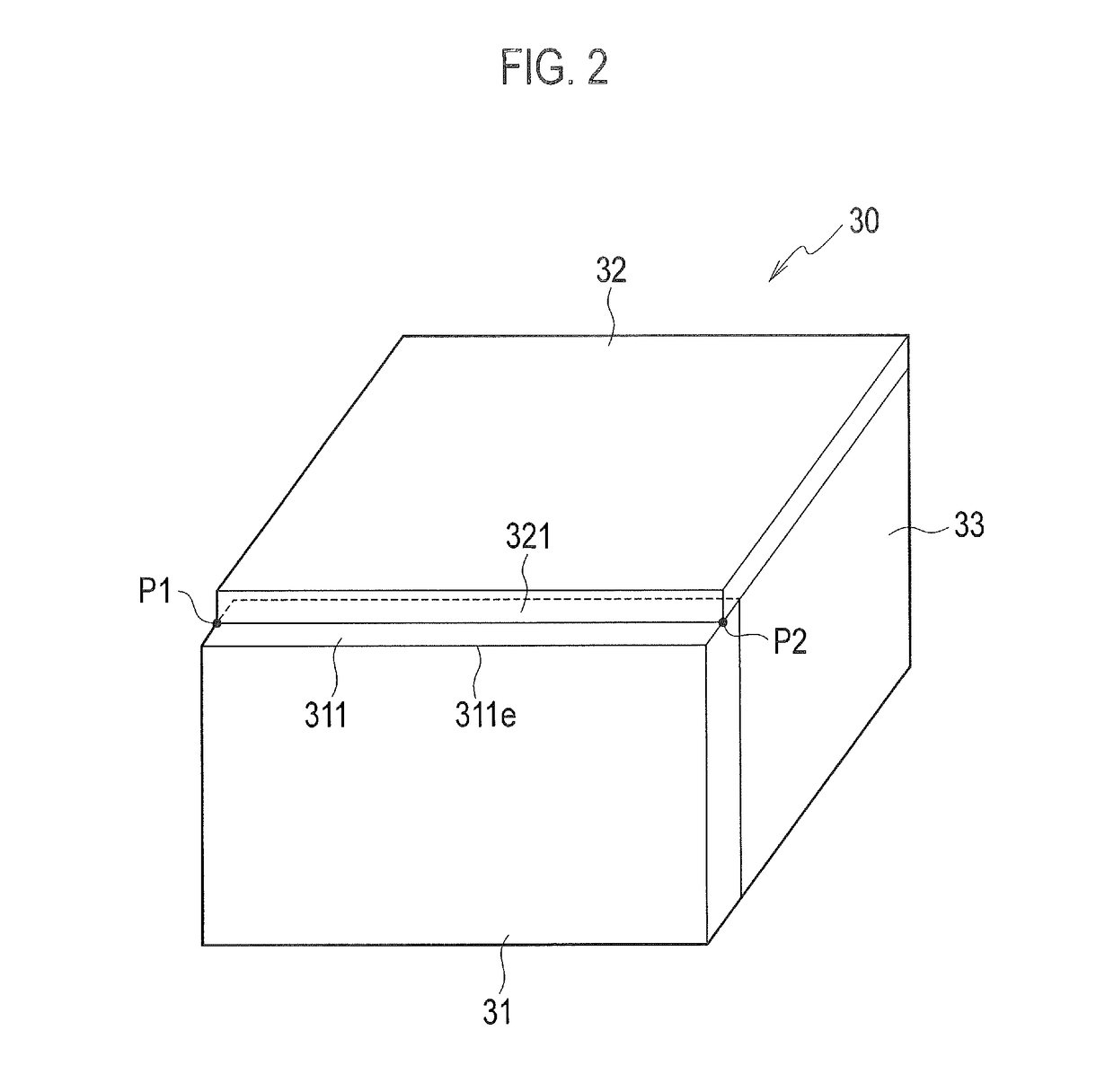

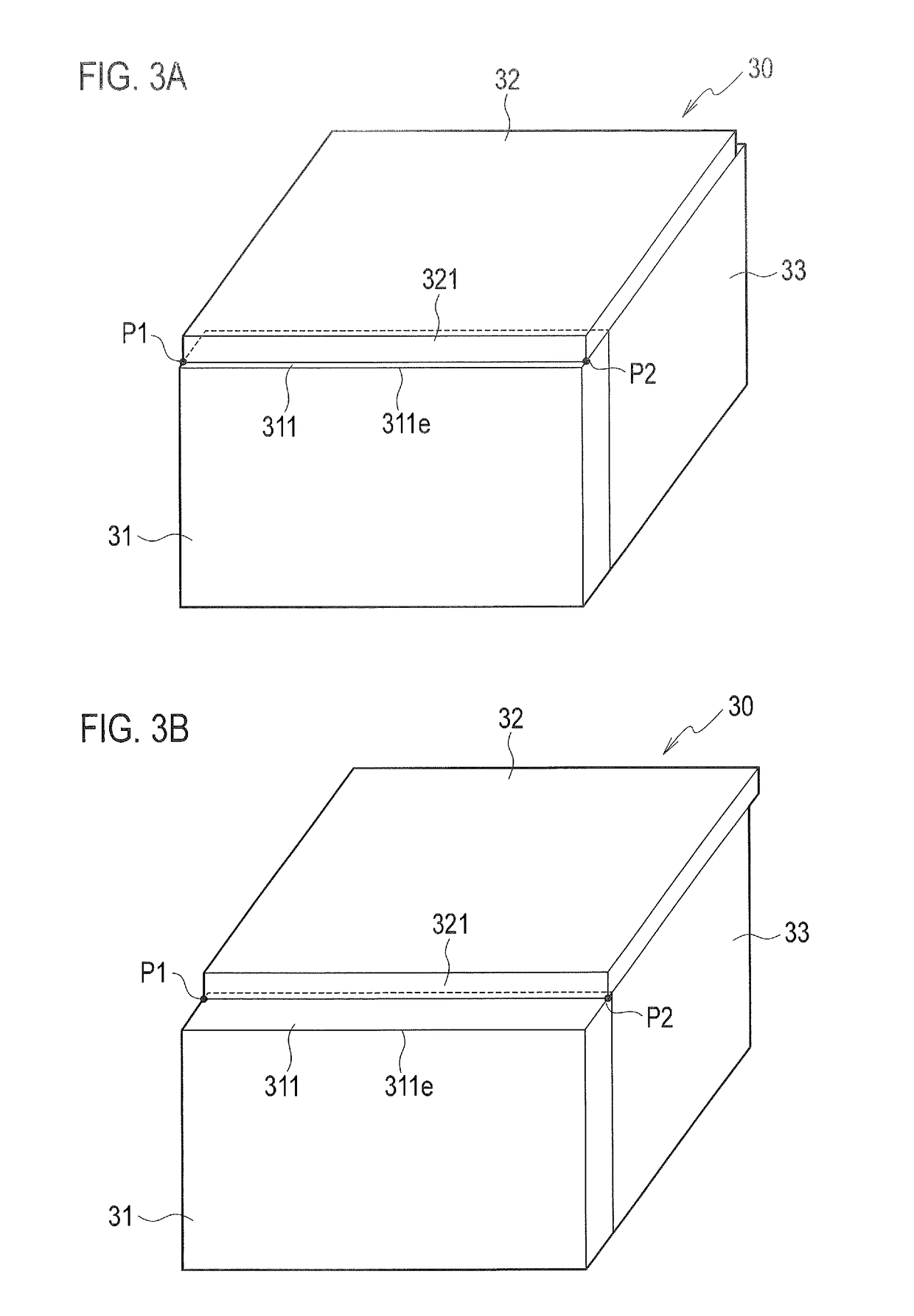

Connection structure of lugs and cover plate of battery

InactiveCN101651187AGuaranteed connection locationAccurate welding positionCell component detailsInsulation layerInternal resistance

The invention discloses a connection structure of lugs and a cover plate of a battery, which comprises the lugs and the cover plate, wherein the lugs are led out from the end of a battery coil core and are also provided with a lug lead-out device arranged at the end of the coil core; the lug lead-out device is provided with an insulation layer contacting the end of the coil core and a conductive layer far away from the end of the coil core; the lugs are electrically connected with the conductive layer; and the conductive layer is electrically connected with the cover plate. The connection structure also comprises a connecting piece and a second gasket stacked between the conductive layer of the lug lead-out device and the cover plate; and the connecting piece tightly compresses the lugs between the second gasket and the conductive layer of the lug lead-out device. The lugs are connected to the lug lead-out device and are mechanically compressed through the second gasket so as to ensurereliable connection of the lugs and the cover plate, reduce the inner resistance of the battery and ensure firm fixation of the coil core. The connection structure is simple in assembly process, is suitable for line production and is suitable for assembling the batteries of hybrid electric automobiles with multiple lugs and large volume and pure electric automobiles or is used for assembling large storage batteries.

Owner:SHENZHEN BAK BATTERY CO LTD

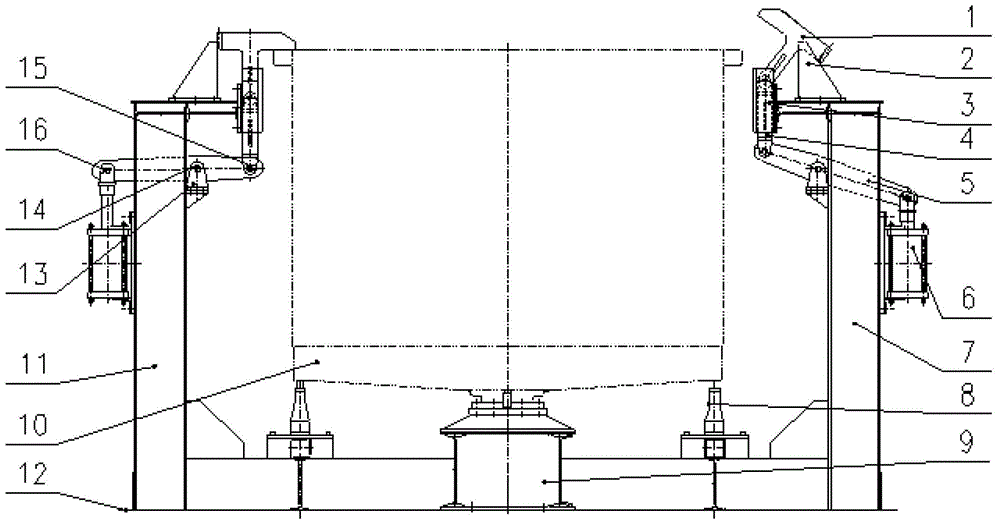

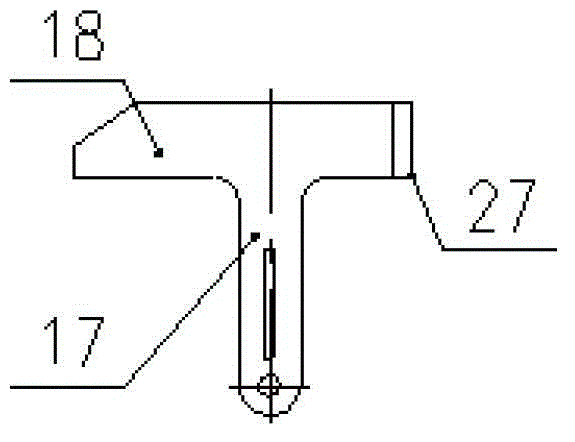

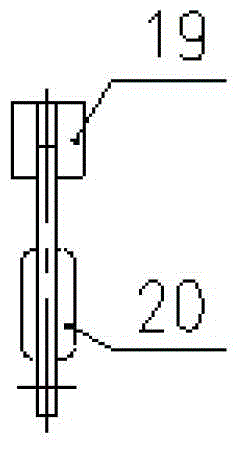

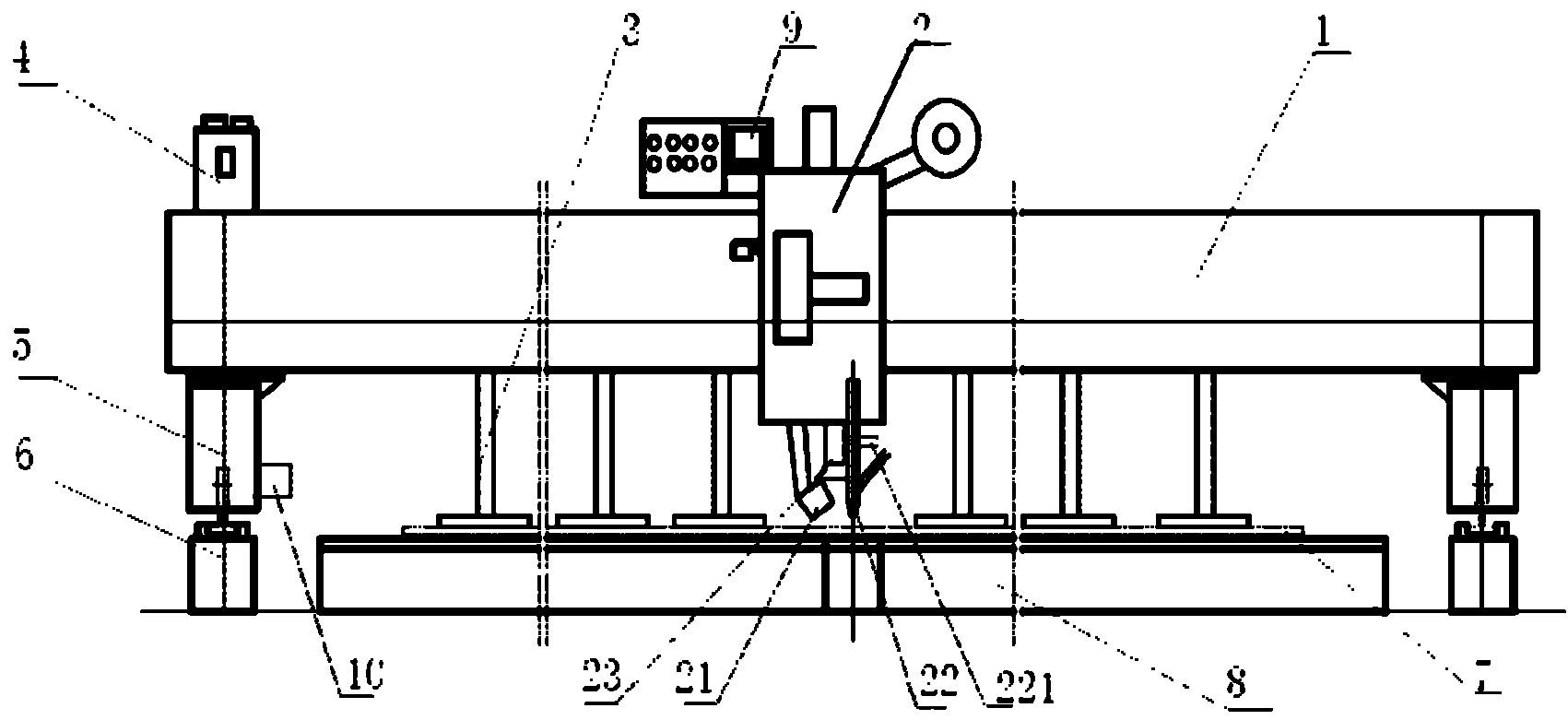

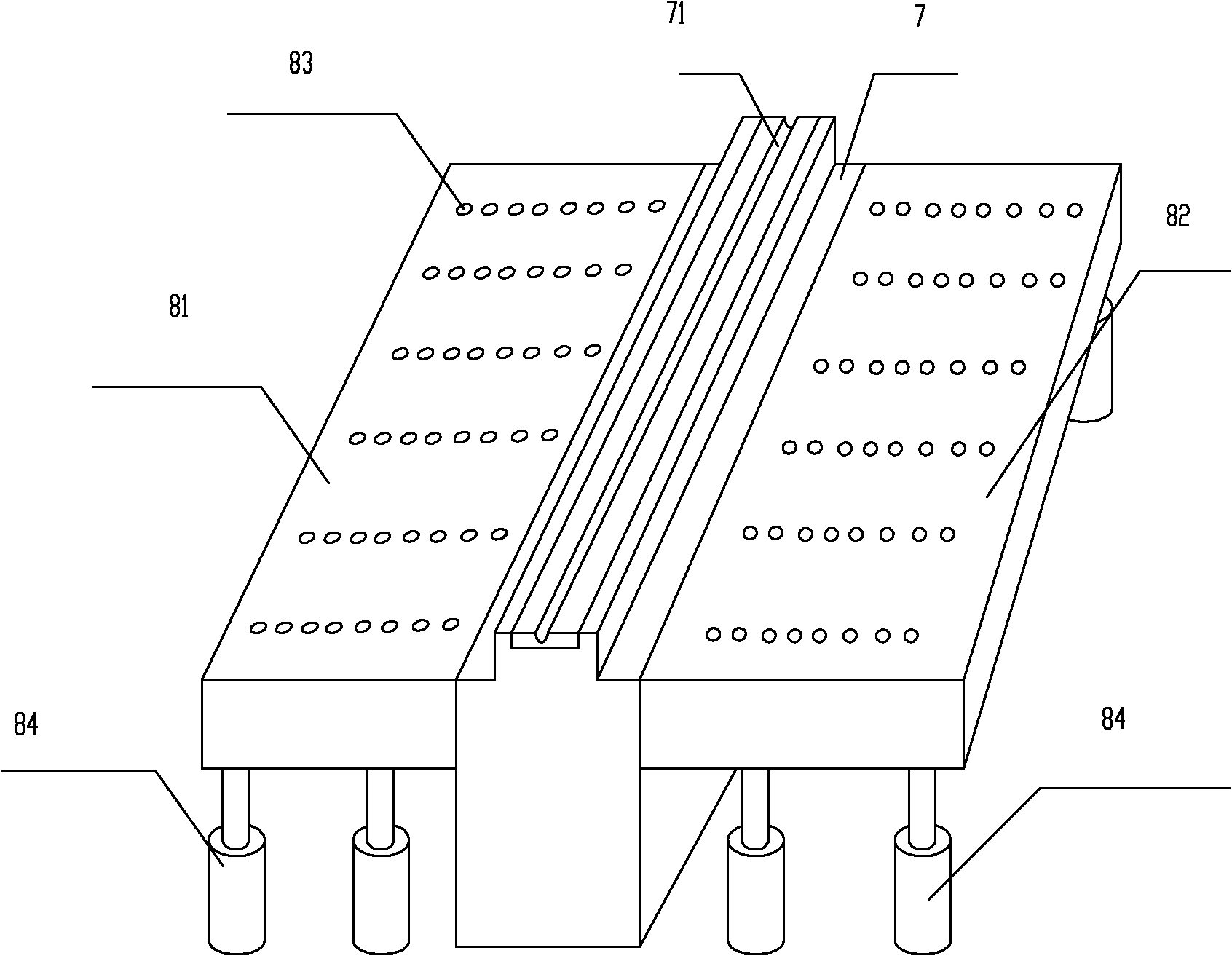

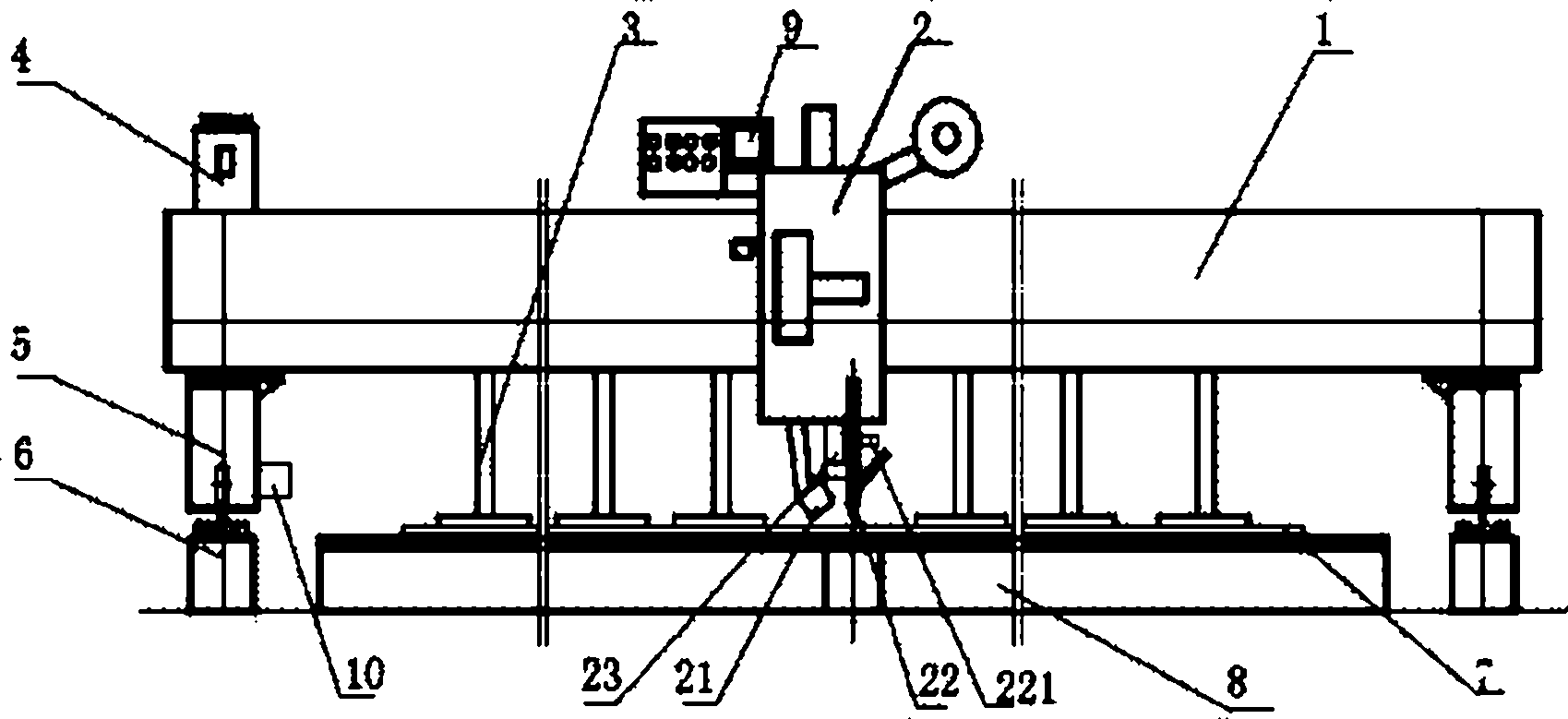

Novel automatic gantry welding machine

InactiveCN102528247AImprove welding efficiencyReduce manufacturing costWelding accessoriesControl engineering

The invention relates to a novel automatic gantry welding machine which comprises a gantry and a welding head; a welding wire conveying device, a welding gun, a hydraulic compressing device, a hydraulic station, a travelling mechanism and a rail component are mounted on the welding head; the novel automatic gantry welding machine further comprises an installation debugging and working platform system; the installation debugging and working platform system comprises a left working platform and a right working platform; a fixed welding support beam is arranged between the left working platform and the right working platform; and hydraulic lifting devices are arranged at the lower parts of the left working platform and the right working platform respectively. The novel automatic gantry welding machine is good in operability, is automatic and integrated, and can operate continuously.

Owner:宜兴市九洲封头锻造有限公司

Secondary battery

ActiveCN101604737AGuaranteed connection locationAccurate welding positionWound/folded electrode electrodesCell lids/coversInternal resistancePure electric vehicle

The invention discloses a secondary battery comprising a winding core and a cover plate, wherein the end part of the winding core extends with a pole lug and is also provided with a pole lug leading device placed on the end part of the winding core, the pole lug leading device is provided with an insulating layer contacted with the end part of the winding core and a conducting layer far away from the end part of the winding core, the pole lug is electrically connected with the conducting layer, and the conducting layer is electrically connected with the cover plate. The secondary battery also comprises a connecting piece and a second spacer arranged between the conducting layer of the pole lug leading device and the cover plate in an overlapping way, and the pole lug is tightly pressed between the second spacer and the conducting layer of the pole lug leading device by the connecting piece. The secondary battery is provided with the pole lug leading device, and the pole lug is welded on the pole lug leading device and is mechanically contacted with and tightly pressed on the pole lug leading device through the second spacer, thereby the invention ensures the pole lug of an electric core to be reliably connected with a pole column, reduces the internal resistance of a battery, ensures the firm fixing of the winding core, has simple assembly technology, is adapted to line production and suitable for batteries of a hybrid electric vehicle with multiple pole lugs and a large volume and a pure electric vehicle and can also be suitable for large-sized energy storage batteries.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

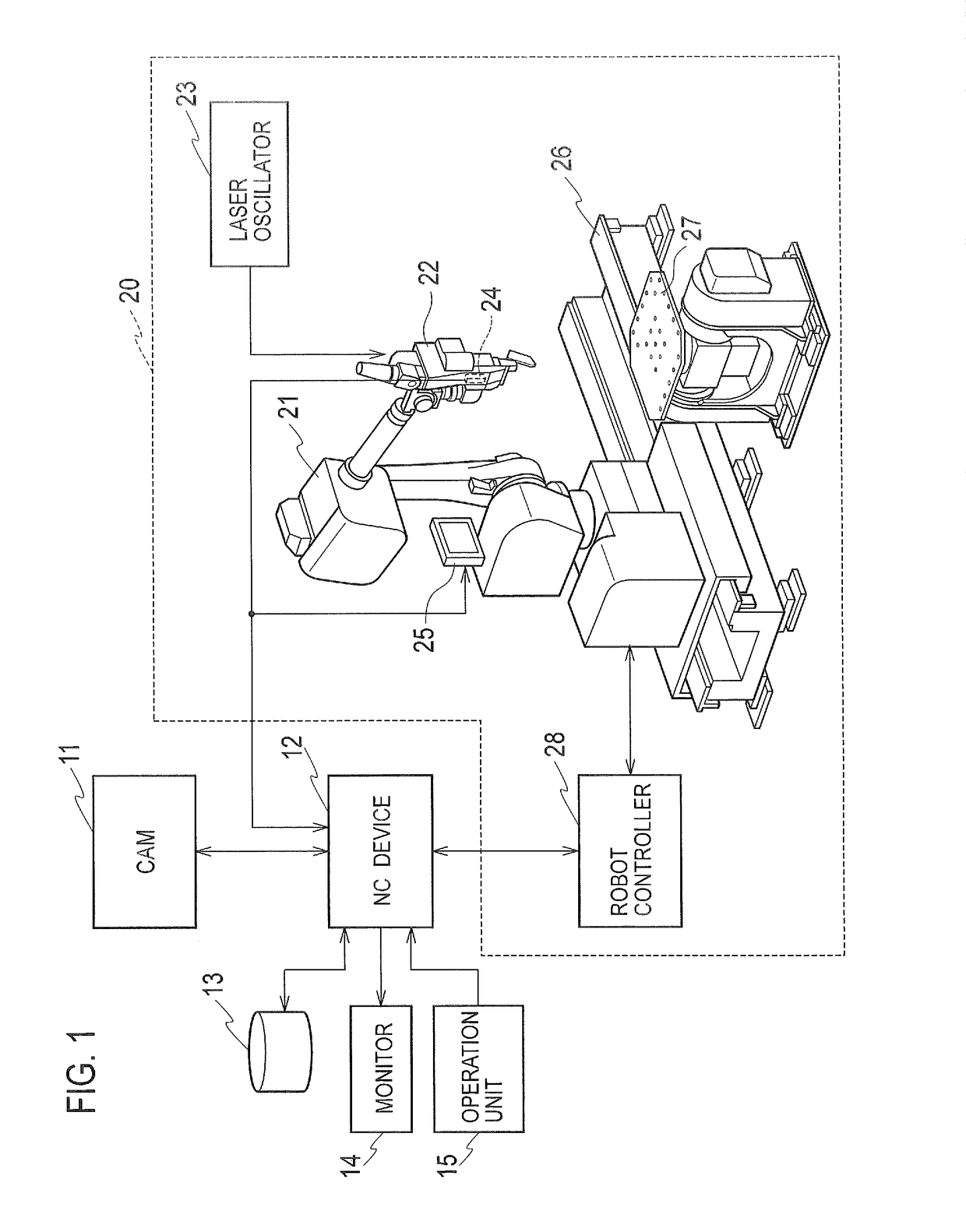

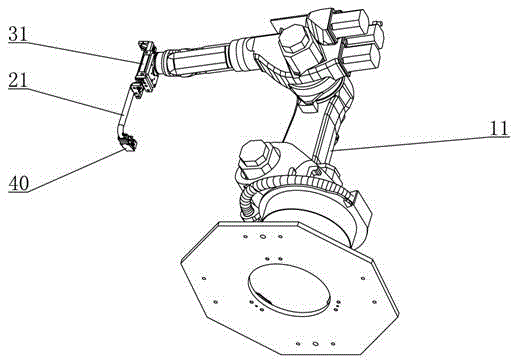

Welding machine and control method therefor

ActiveUS10191470B2Accurate correctionAccurate welding positionProgramme controlProgramme-controlled manipulatorPattern matchingEdge extraction

An edge extraction unit extracts an edge image from a photographed image obtained by photographing a product with a camera. A constant edge acquisition unit acquires, as a constant edge image, an edge image in a constant surface where a positional deviation does not occur with respect to a welding point set by a processing program, the acquired image belonging to the extracted edge image. A correction amount acquisition unit performs pattern-matching between a master constant edge image and a workpiece edge image, which are acquired by the constant edge acquisition unit, and acquires a deviation amount between both thereof as a correction amount with respect to the welding point. A processing program correction unit corrects the welding point by the correction amount, and generates a corrected processing program for welding the workpiece. A welding robot welds the workpiece based on the corrected processing program.

Owner:AMADA HLDG CO LTD

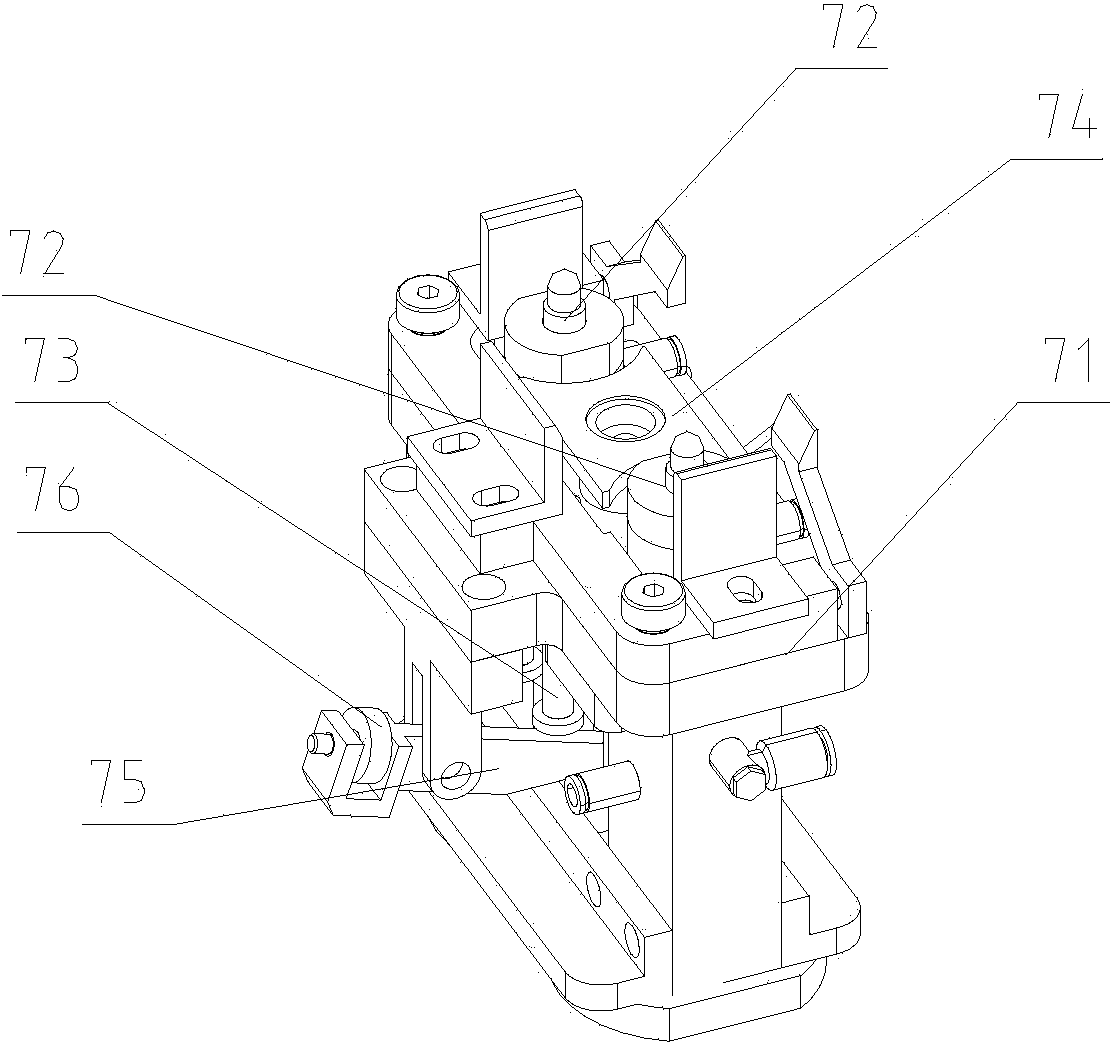

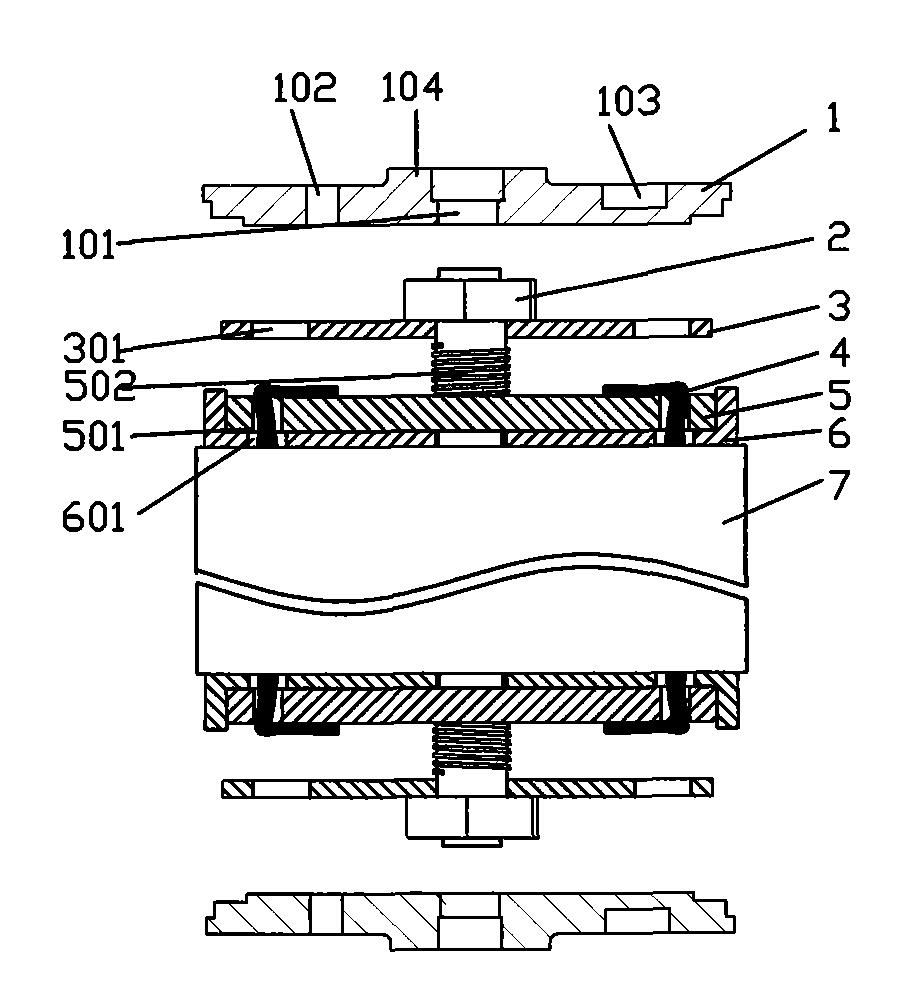

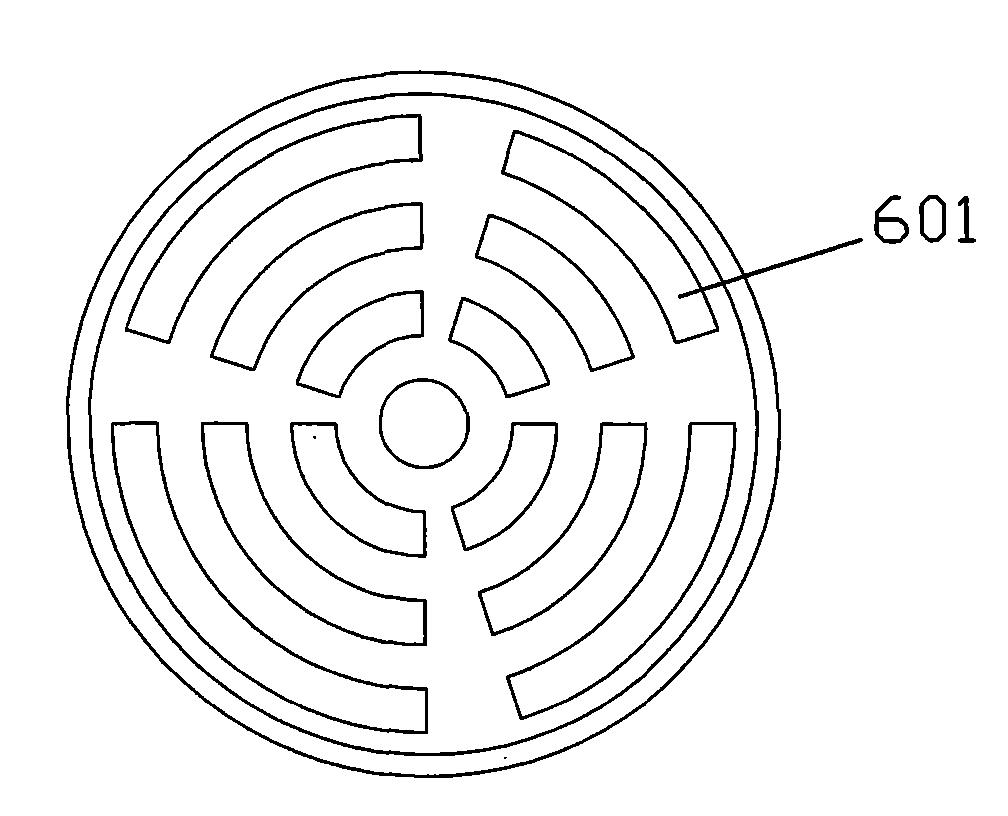

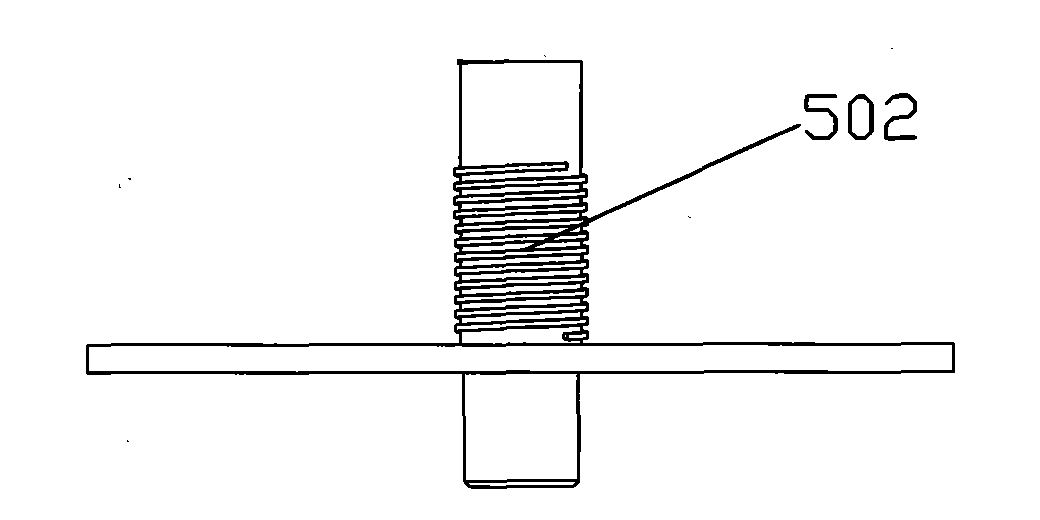

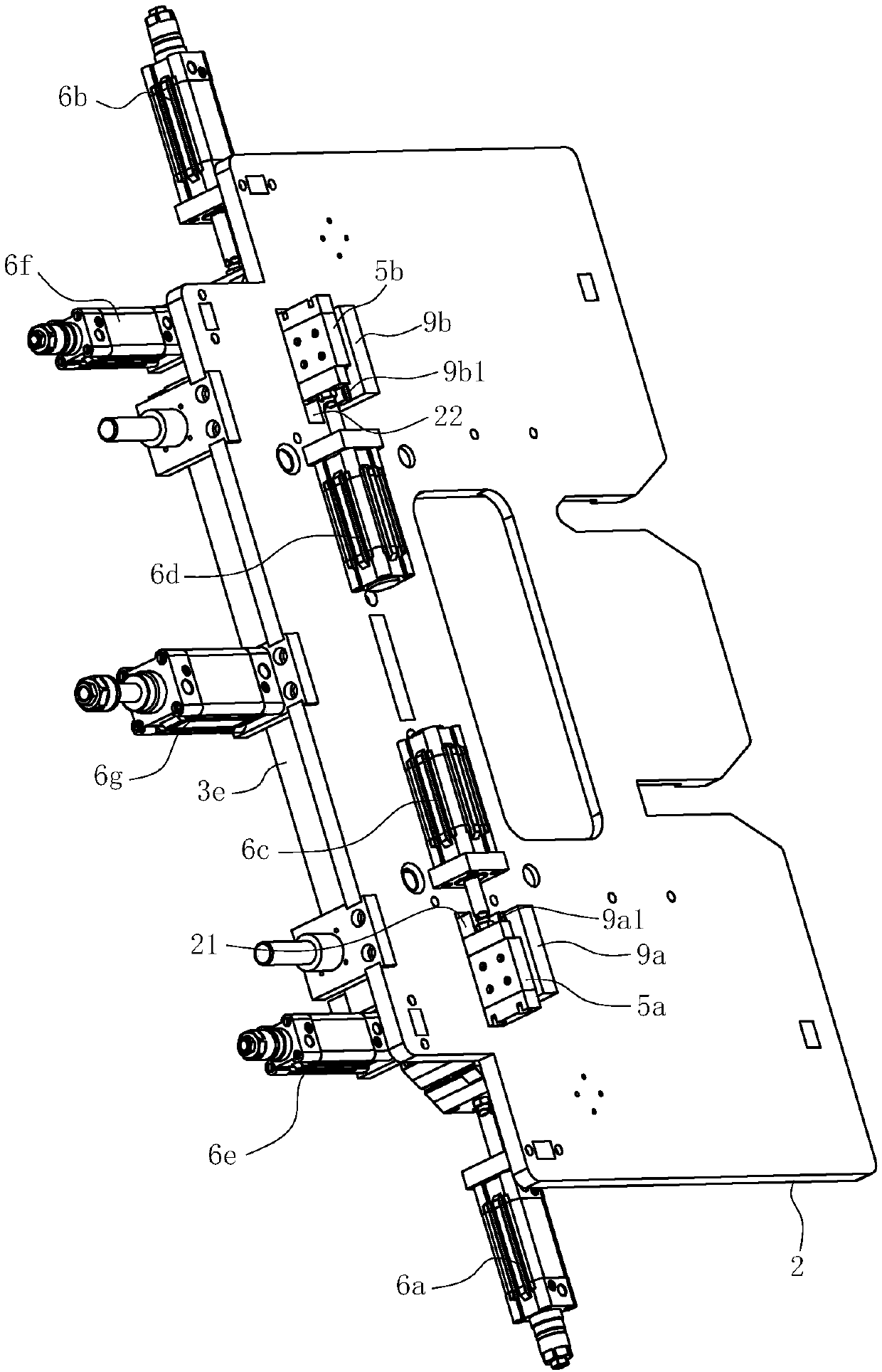

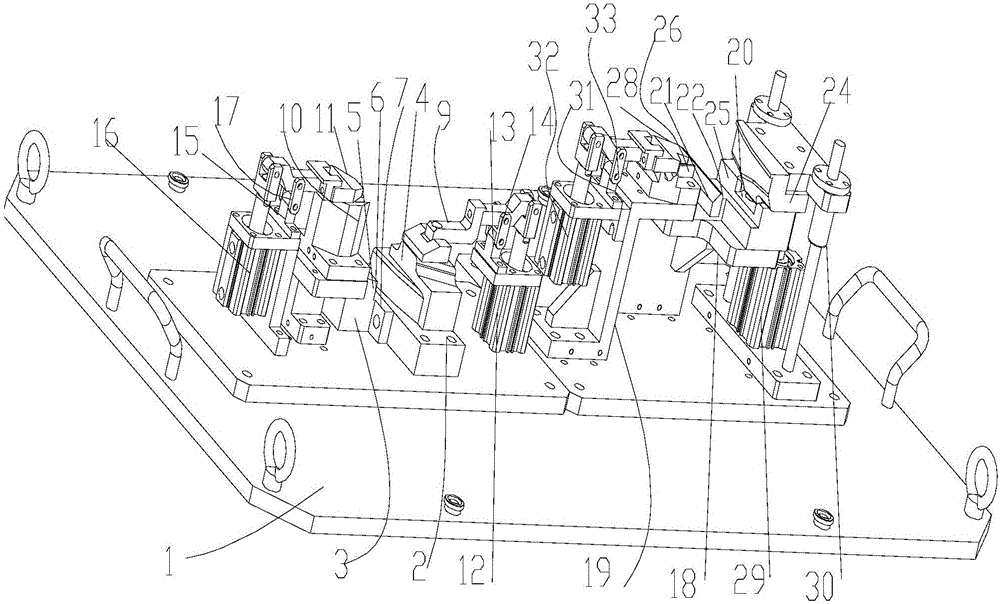

Hold-down device and welding equipment with hold-down device

InactiveCN102284818APrevent movementAccurate welding positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

A welding device includes a base plate and a pressing device fixed on the base plate. The pressing device includes a bracket, and a pressing plate fixed on the bracket is rotatable. The pressing device also includes a power mechanism for pushing the pressing plate to rotate, a supporting mechanism for supporting the welding workpiece, and a rotating part for connecting the bracket and the pressing plate in rotation. The power mechanism is fixed on the bracket, and the power mechanism includes a power part, a guide post, and a guide sleeve. The guide sleeve is provided with a first through hole, and the guide column can slide in the guide sleeve through the first through hole. One end of the guide post abuts against one end of the pressure plate, and the other end of the guide post abuts against one end of the power part. The power mechanism pushes the guide column to move up and down, the guide column presses the pressure plate to rotate around the rotating part, and the other end of the pressure plate presses the welding workpiece between the other end of the pressure plate and the supporting mechanism. The above-mentioned welding equipment compresses the welding workpiece through the pressing device, so as to prevent the welding workpiece from moving during the welding process and ensure the accuracy of the welding position.

Owner:TANGSHAN KAIYUAN ROBOT SYST

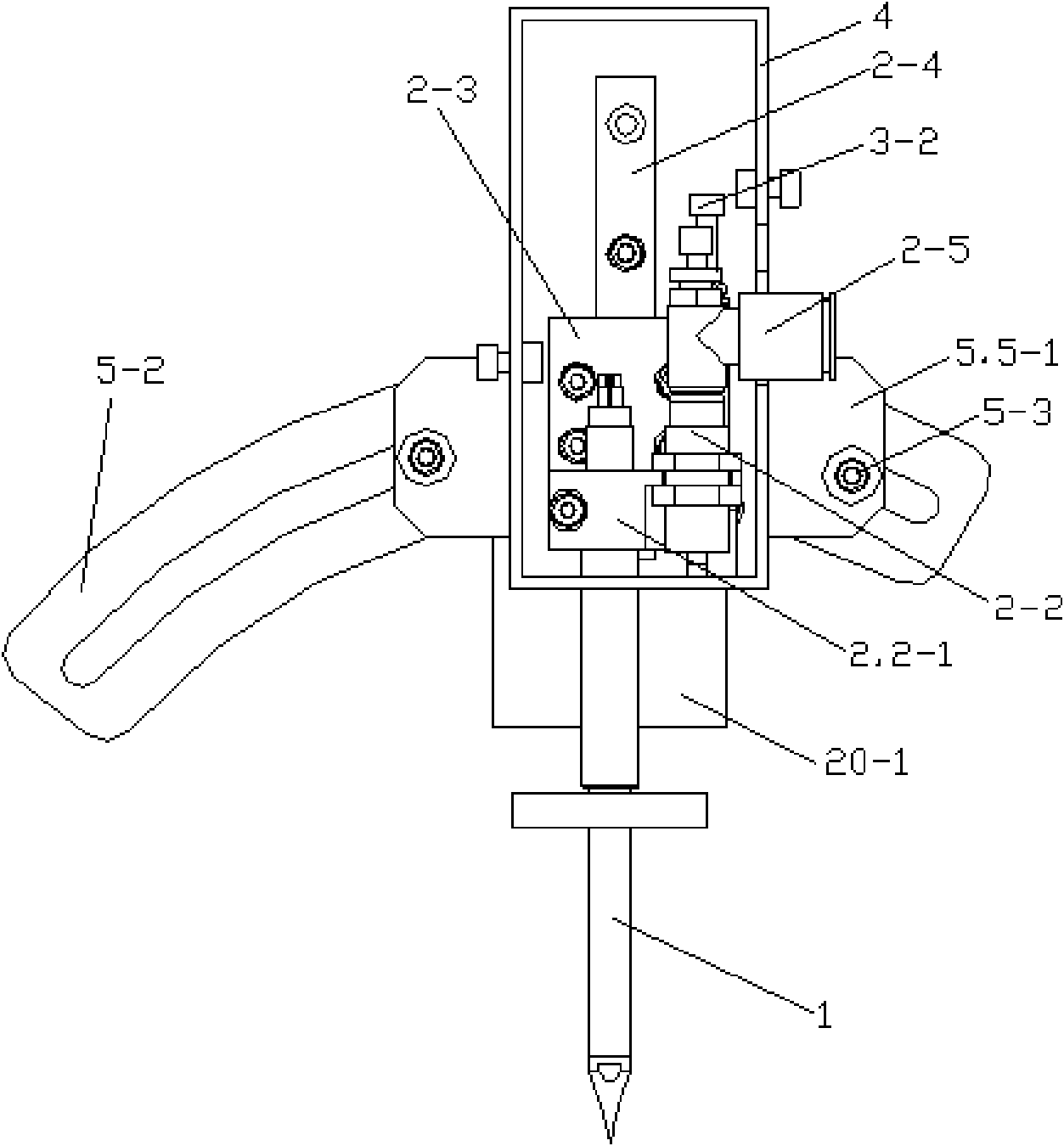

Soldering bit mechanism of automatic soldering robot

ActiveCN102069259AGuaranteed accuracyReduce wearSoldering ironSoldering auxillary devicesSlide plateSoldering iron

The invention discloses a soldering bit mechanism of an automatic soldering robot. The soldering bit mechanism comprises a soldering bit and is fixed on a Z-axis module of the automatic soldering robot, wherein the Z-axis module is used for controlling upward and downward movements; and the soldering bit is connected with a box body. The soldering bit mechanism also comprises a soldering bit moving mechanism for controlling the soldering bit, wherein the soldering bit moving mechanism comprises a shifting device which is connected with the soldering bit and arranged in the box body; the shifting device comprises a connection block, a cylinder, a sliding plate and a linear slide rail; the connection block connects the upper end of the soldering bit with the body of the cylinder and is also connected with the sliding plate; and the sliding plate is connected with the linear slide rail in a sliding manner. The soldering bit mechanism has the following beneficial effects: the shifting device of the soldering bit moving mechanism disclosed by the invention adopts the cylinder connected with the soldering bit as the power for driving the soldering bit to move up and down frequently and the soldering bit is driven to quickly and stably move through stretching / withdrawing of the body of the cylinder until a soldering work point is finished, thus avoiding the problem that the Z-axis module moved up and down frequently in the work process before and reducing the abrasion of the Z-axis module.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

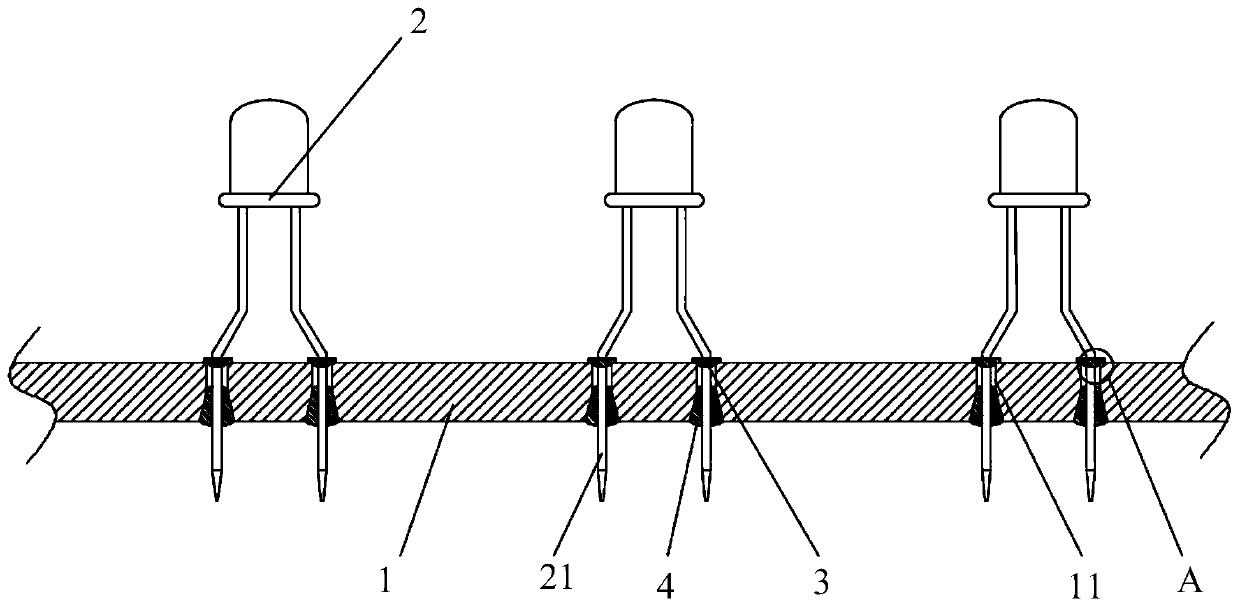

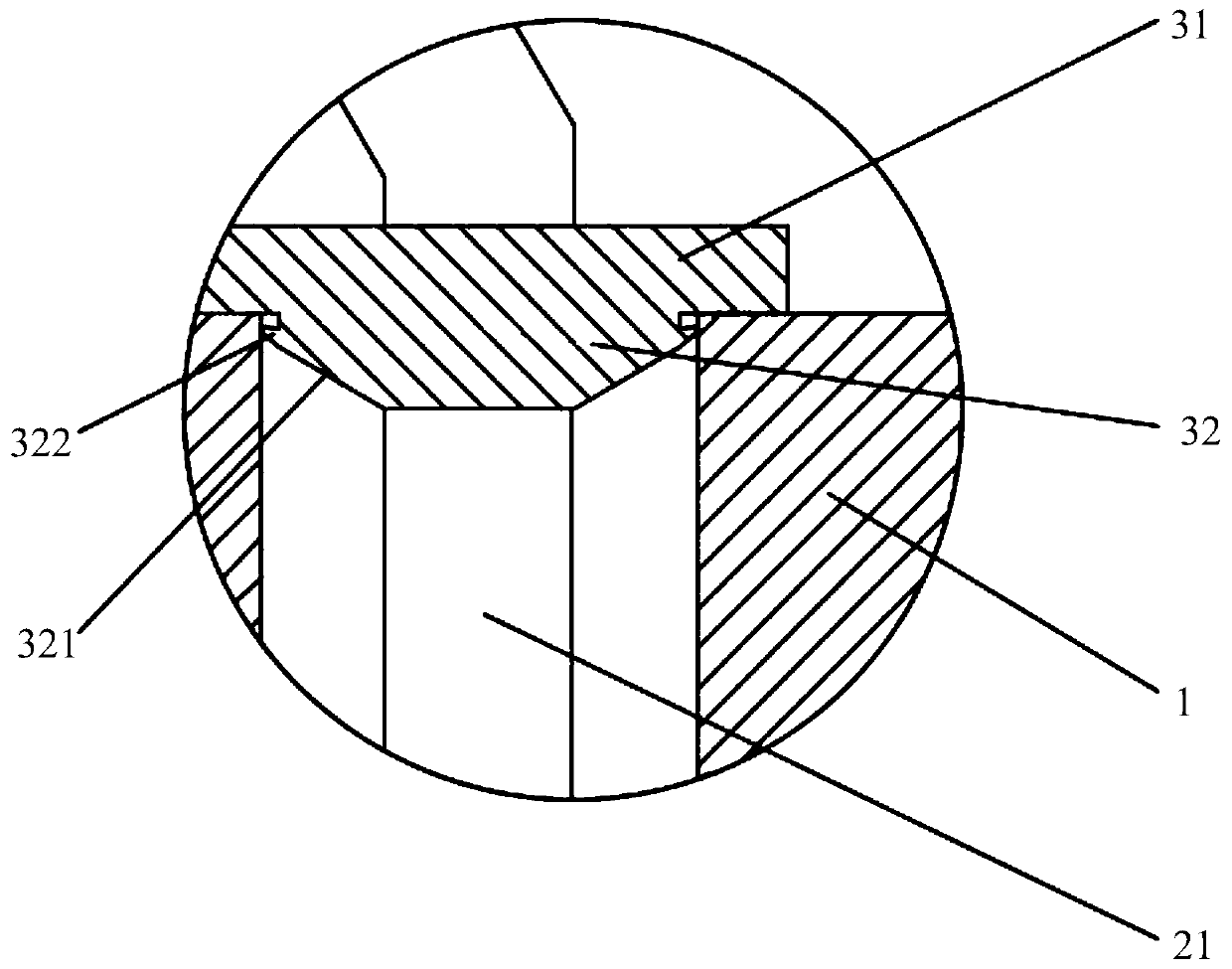

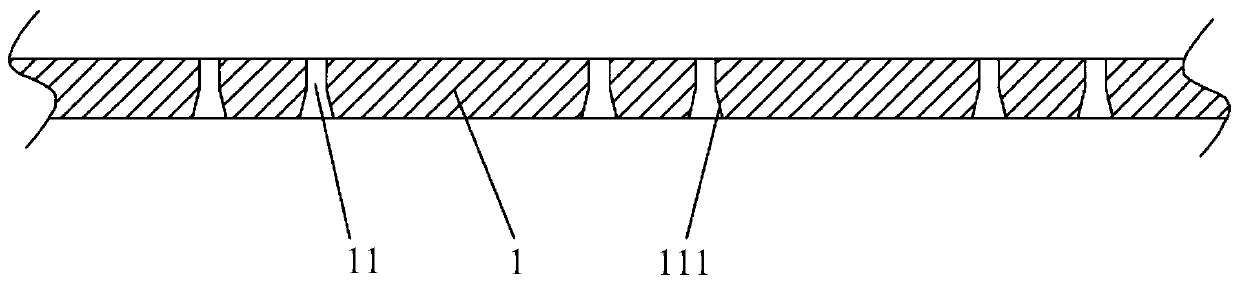

Positional precision auxiliary device for soldering diode pins

ActiveCN109951967APrevent overflowAvoid mutual short circuitPrinted circuit assemblingDiodeEngineering

The invention discloses a positional precision auxiliary device for soldering diode pins. The device comprises a circuit board and a stopping ring, wherein pin jacks are formed on the circuit board; pins of the diode are placed in the pin jacks; the inner wall of the solder-coated end of each pin jack is provided with a first tapered edge inclined from the inside to the outside away from the center of the jack; a stopping portion sleeves the pin and is fastened to the end of the pin jack away from the first tapered side. In the invention, the stopping ring and the first tapered side of the circuit board are arranged to make the pins are stable in positions and good in soldering effect, and the solder is less likely to leak, and does not affect other lines.

Owner:HEBEI UNIV OF ENG

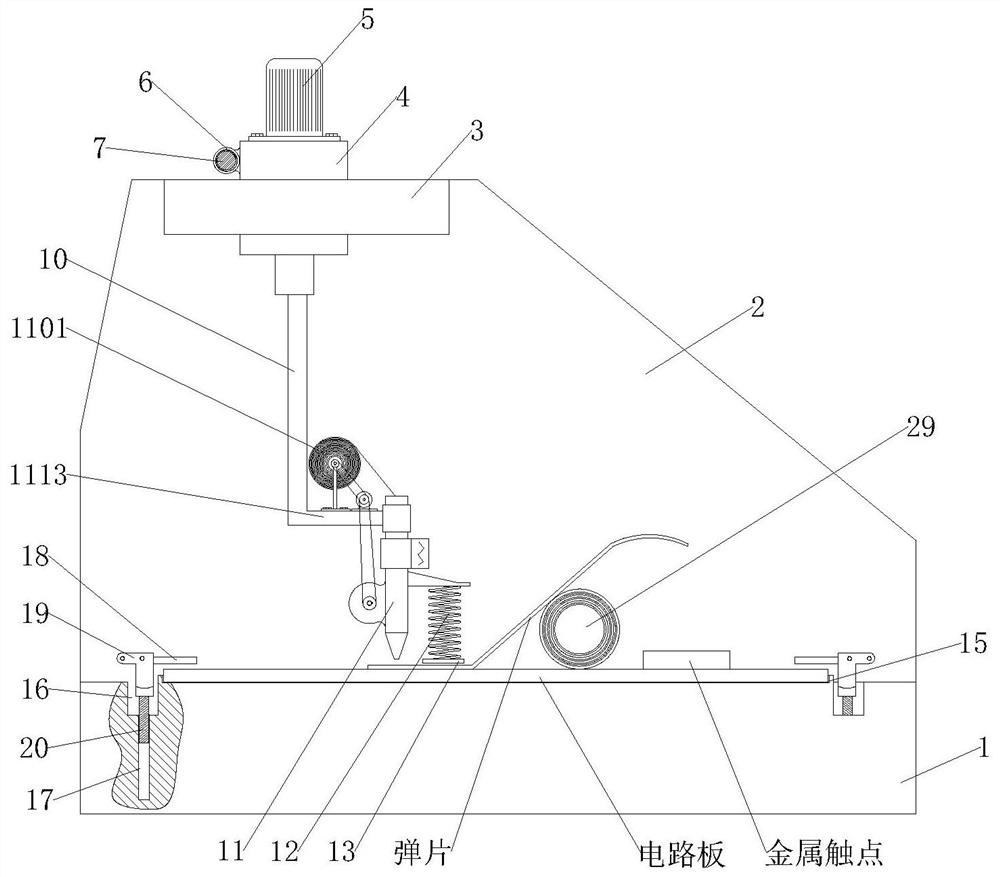

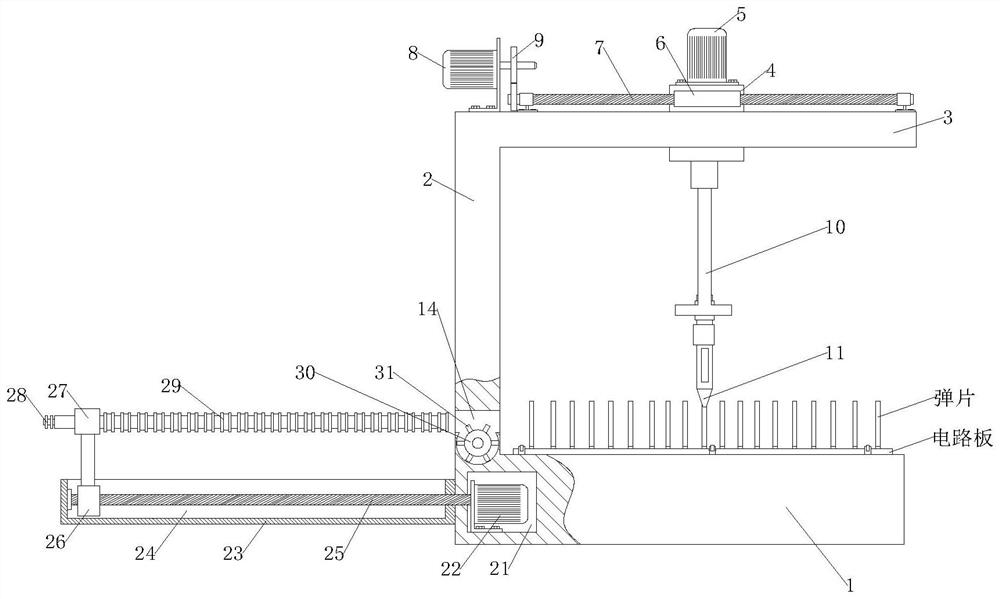

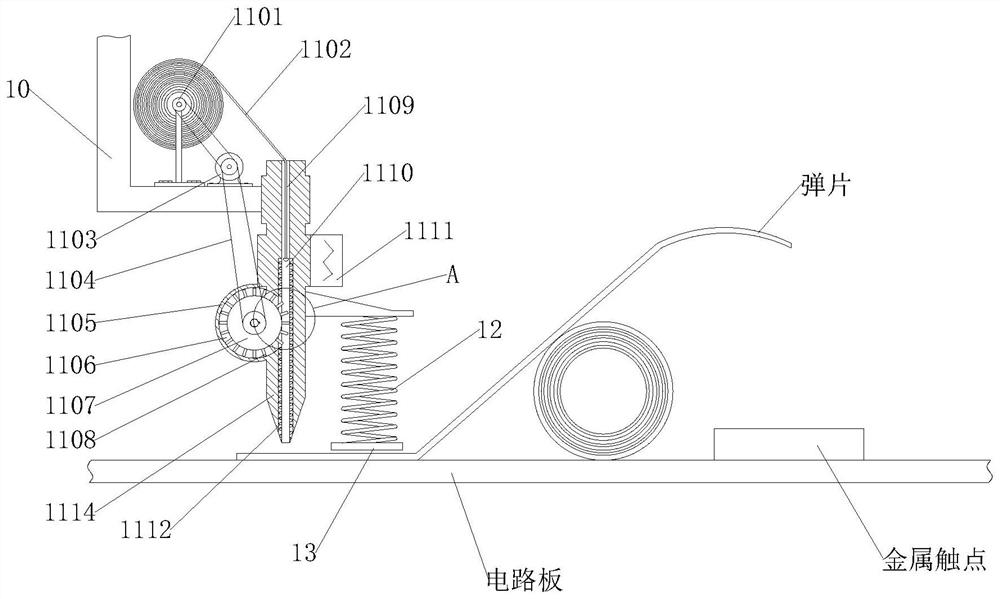

Elastic piece welding machine

ActiveCN111687512AImprove position securityImprove firm performanceWelding/soldering/cutting articlesMetal working apparatusEngineeringWire wrap

The invention provides an elastic piece welding machine and relates to the technical field of welding processing. The elastic piece welding machine comprises a bottom supporting plate, wherein a sidesupporting rib plate vertically fixed to the top end of the bottom supporting plate is arranged at the top end of the bottom supporting plate, a horizontally fixed top supporting rib plate is arrangedat the top end of the side supporting rib plate, a penetrated slide hole formed in the top end of the top supporting rib plate, and a slide block is mounted in a slide fit manner in the slide hole ofthe top supporting rib plate. An electric motor drives an impeller and a bonding wire reel to rotate synchronously and intermittently at equal intervals. Matched with intermittent movement of the slide block, a welding pen stays intermittently above each elastic piece. As the impeller and the bonding wire reel rotate intermittently, a liquid smelted by a bonding wire is put onto a welding piece of a circuit board in the process that the welding gun stays above each elastic piece so as to weld and fix the welding piece to the circuit board, so that the elastic piece welding efficiency is improved.

Owner:深圳市丰源升科技有限公司

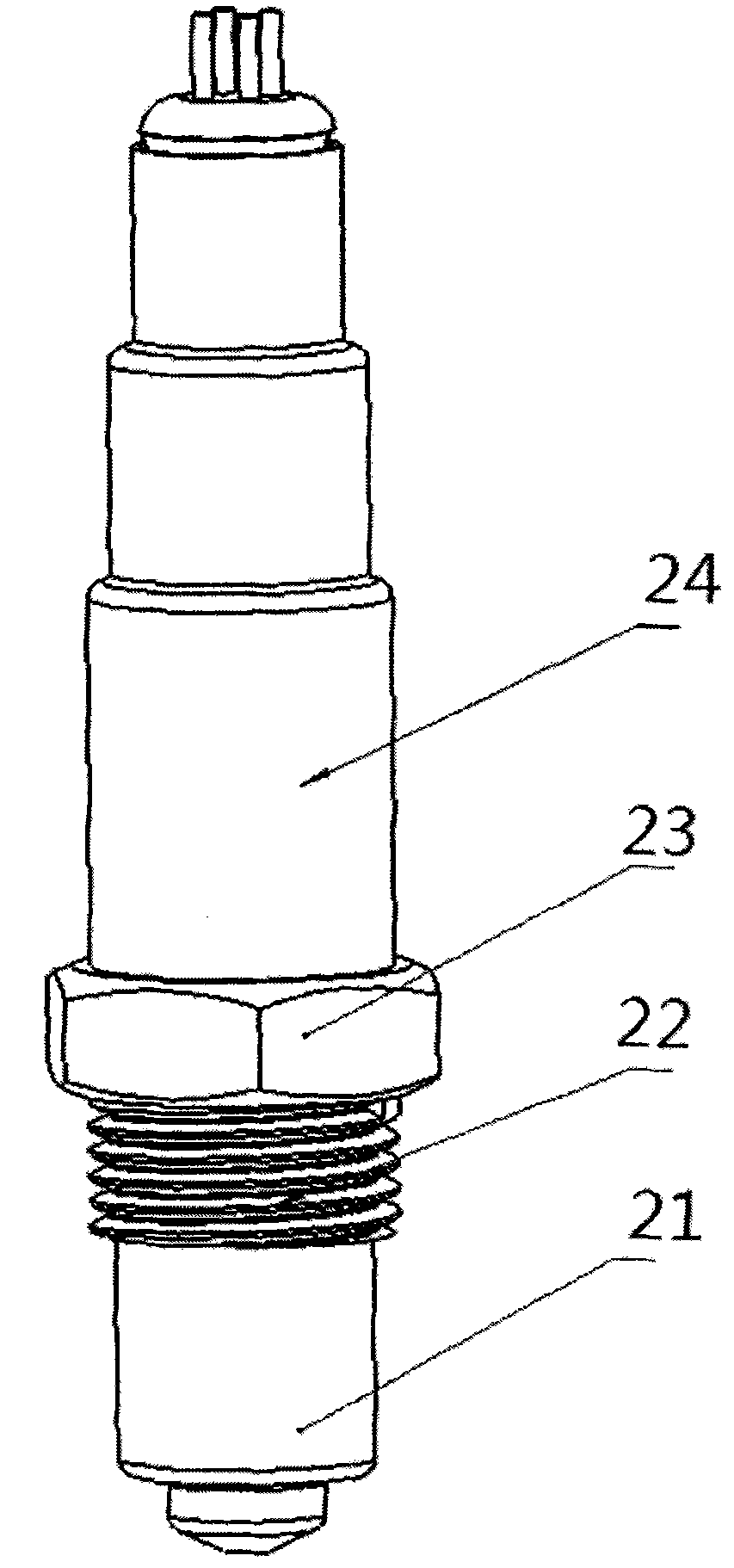

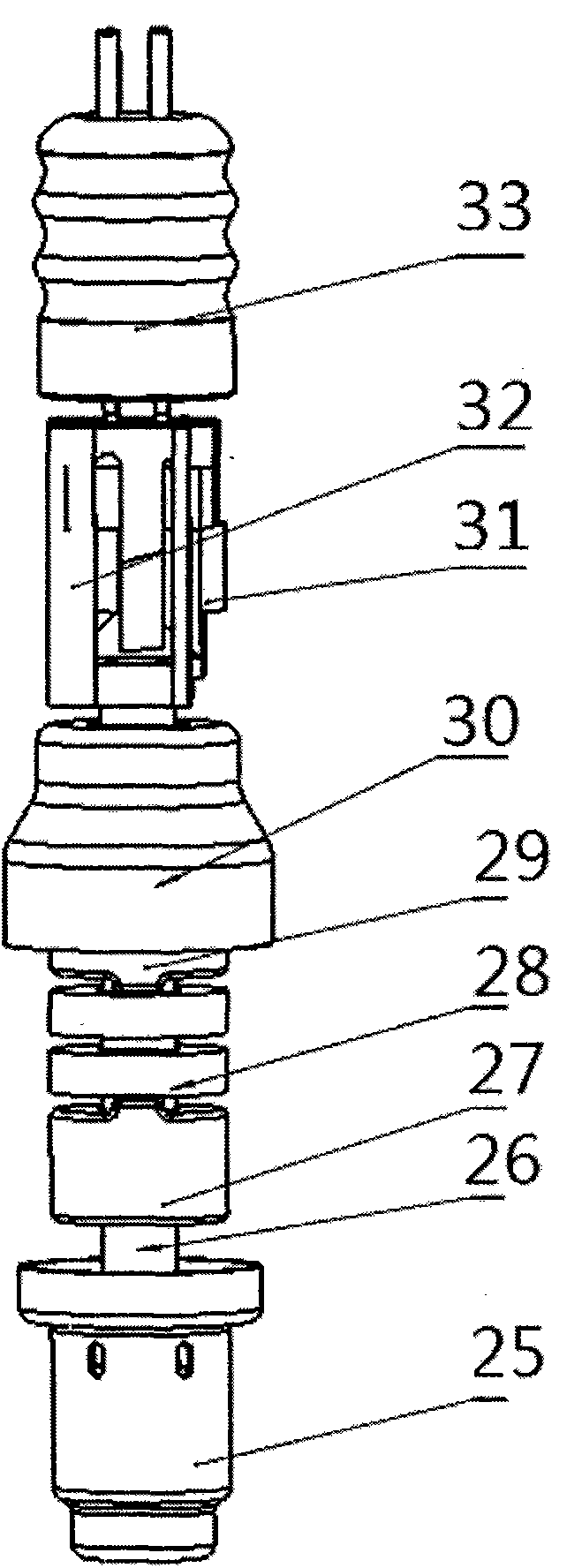

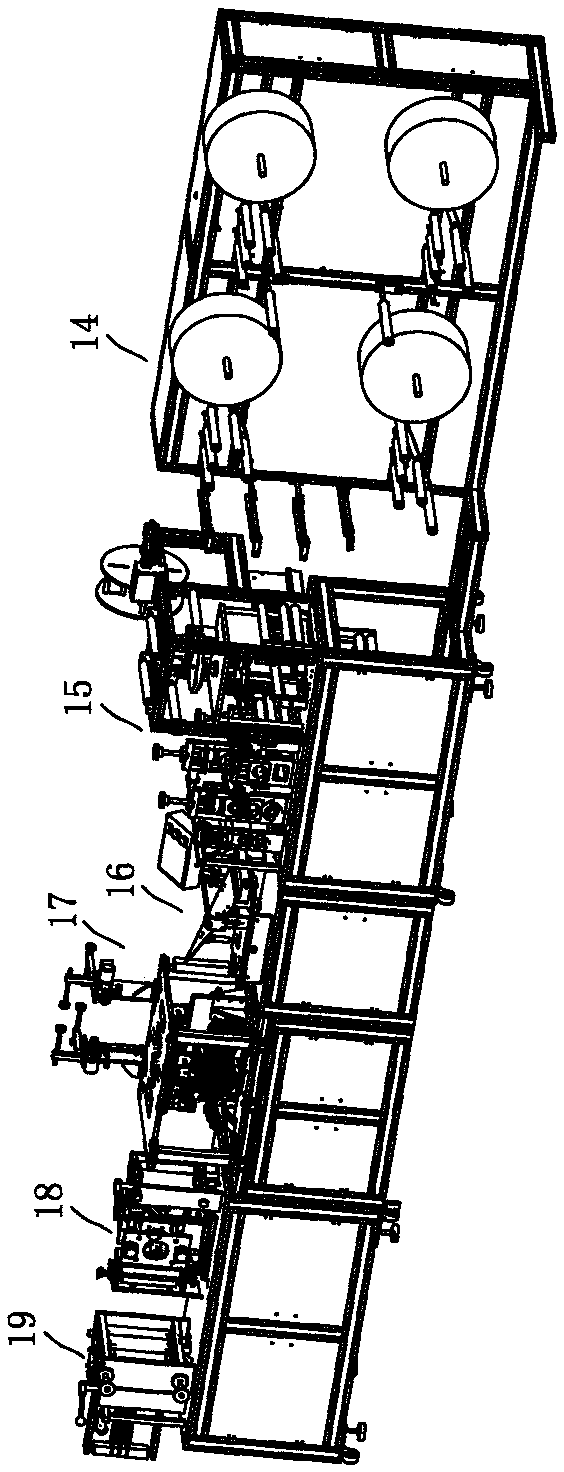

Automatic production line device for packaging oxygen sensor

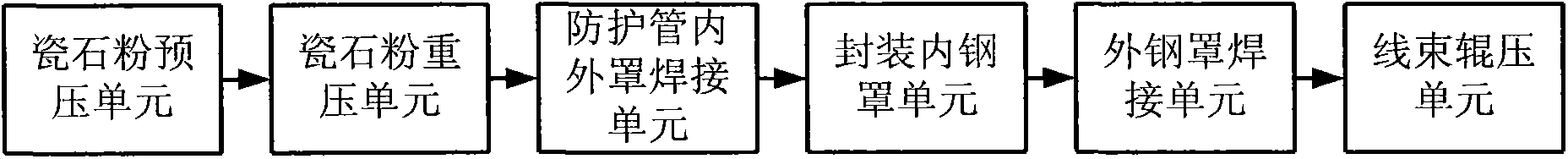

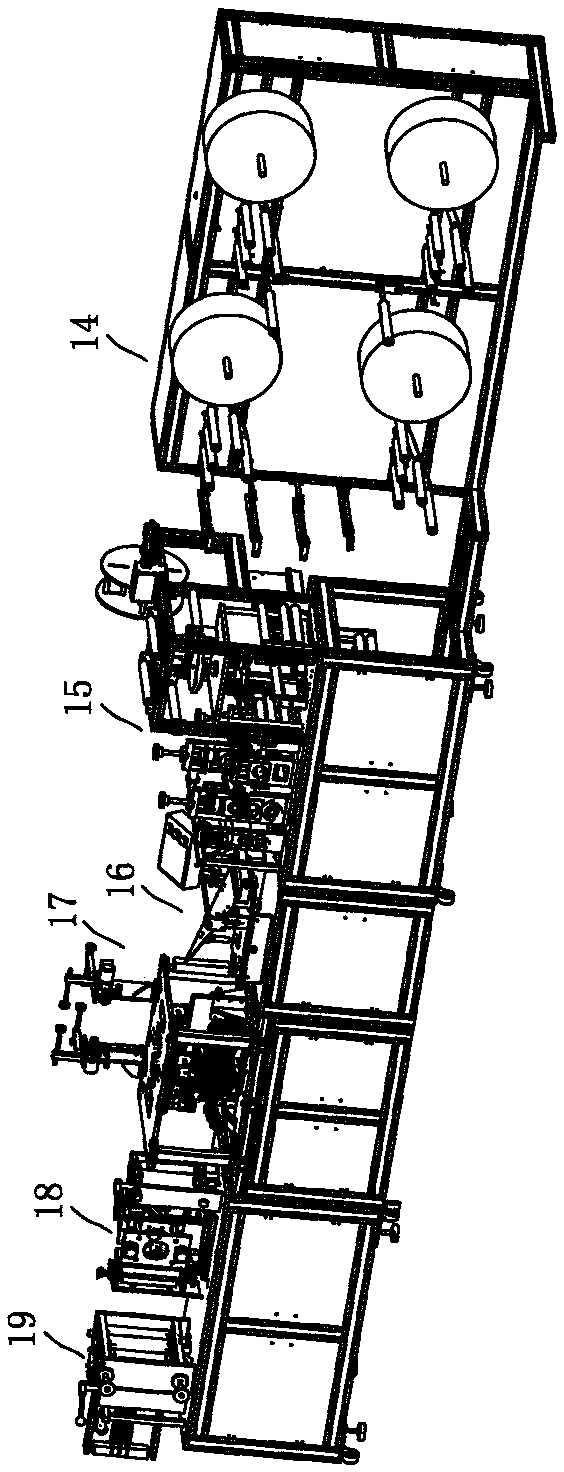

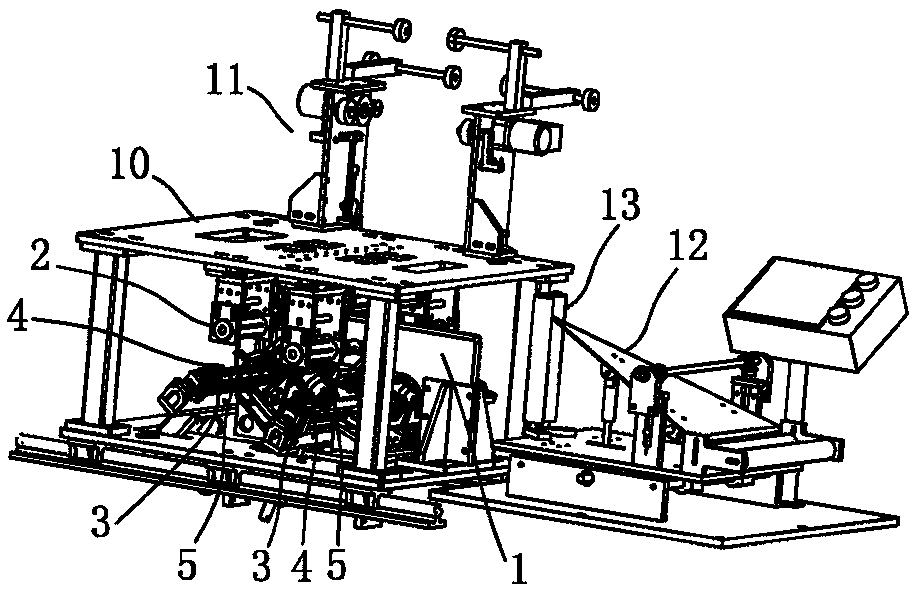

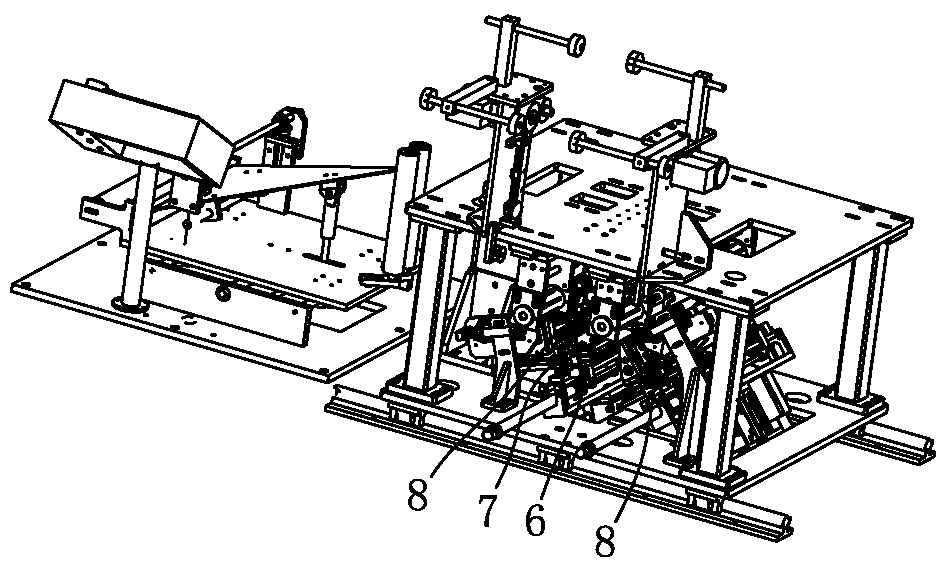

ActiveCN103949891ARealize the assemblyIn line with the status quo of production technologyOther manufacturing equipments/toolsProduction lineOxygen sensor

The invention provides an automatic production line device for packaging an oxygen sensor. The automatic production line device comprises a China stone powder pre-pressing unit, a China stone powder repressing unit, a protective inner and outer cover welding unit, an inner steel cover packaging unit, an outer steel cover welding unit and a wire harness rolling unit, wherein the structures of the protective inner and outer cover welding unit and outer steel cover welding unit are the same, a laser beam is used for welding a protective pipe inner cover, a protective pipe outer cover and an outer steel cover with a hexagonal base together so as to protect an interior sensor chip. According to the automatic production line device, the units are sequentially connected according to the assembling technology of the oxygen sensor, and semi-automatic and full-automatic assembling of the oxygen sensor product is realized, so that the product quality can be stabilized and improved, the working conditions are improved, the occupied area for production is reduced, the production cost is reduced, and the production cycle is shortened.

Owner:WENZHOU UNIVERSITY

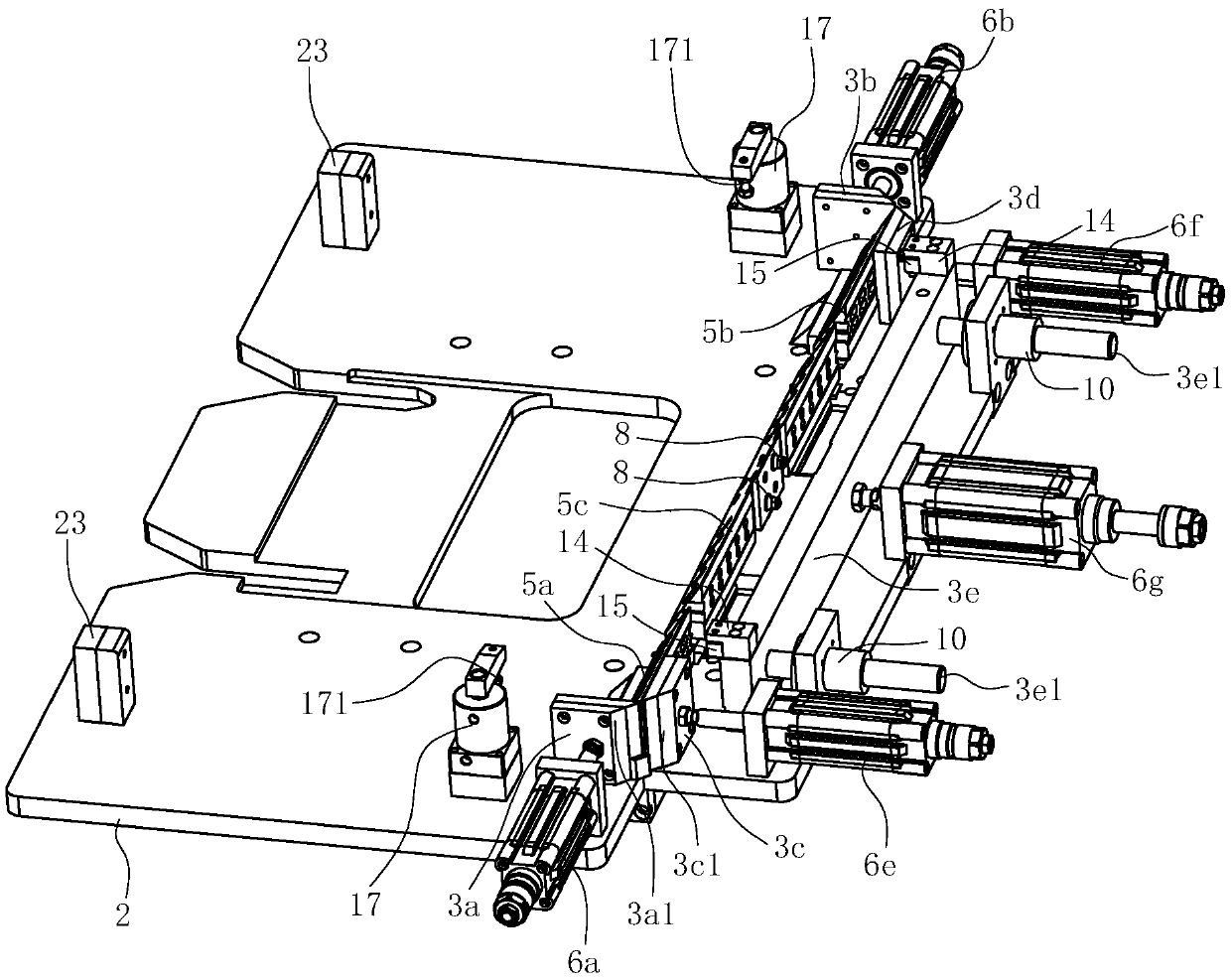

Automatic machine for head-hanging foldable mask

PendingCN108338434AAccurate welding positionRealize fully automatic productionProtective garmentRespiratorUltrasonic welding

The invention relates to the technical field of mask machines, in particular to an automatic machine for a head-hanging foldable mask. The automatic machine comprises an ear band welding device, an upper fixing plate is fixed to a working table, and a center insertion plate is longitudinally installed on the working table; ultrasonic welding heads are symmetrically fixed to the bottom face of theupper fixing plate, and are separately perpendicular to the center insertion plate; sliding clamp rails are correspondingly arranged below the ultrasonic welding heads, sliding clamps slide on the sliding clamp rails, and the center lines of the sliding clamp rails are perpendicular to the center insertion plate; a rotating clamp driving base is arranged below the center insertion plate, the center line of the rotating clamp driving base is perpendicular to the center insertion plate, and rotating clamps are symmetrically arranged on the rotating clamp driving base, can move in three directions and rotate automatically, and are movably located below the ultrasonic welding heads. Through the ear band welding device, ear bands are welded to the mask, in this way, full-automatic production isrealized, and production efficiency is greatly improved; the welding positions of the ear bands are accurate, so that package materials are saved.

Owner:东莞快裕达自动化设备有限公司

Circuit board one-time welding device

InactiveCN103962677AAccurate welding positionThe amount of raw materials is accurateHeating appliancesWelding/cutting media/materialsCavity wallSoldering

The invention provides a circuit board one-time welding device. The circuit board one-time welding device comprises a long barrel-shaped heating cavity, wherein a long strip-shaped heating plate is assembled inside the heating cavity, a feeding port of a soldering tin cylinder right faces the heating plate and is communicated with the heating cavity through a guide sleeve, a through hole corresponding to the soldering tin cylinder is machined in the middle of the guide sleeve in the axial direction, an advancing block used for pushing the soldering tin cylinder into the heating cavity is assembled on the guide sleeve, and conical outlets arranged side by side axially are machined in the cavity wall of the heating cavity. The circuit board one-time welding device is used for carrying out welding operation on a circuit board. According to the welding method, soldering tin is extruded from the conical outlets designed in advance, the welding position is more accurate, raw materials are extruded through the advancing block, the use amount of the raw materials is more accurate, and the welding effect is better.

Owner:珠海三颖有限公司

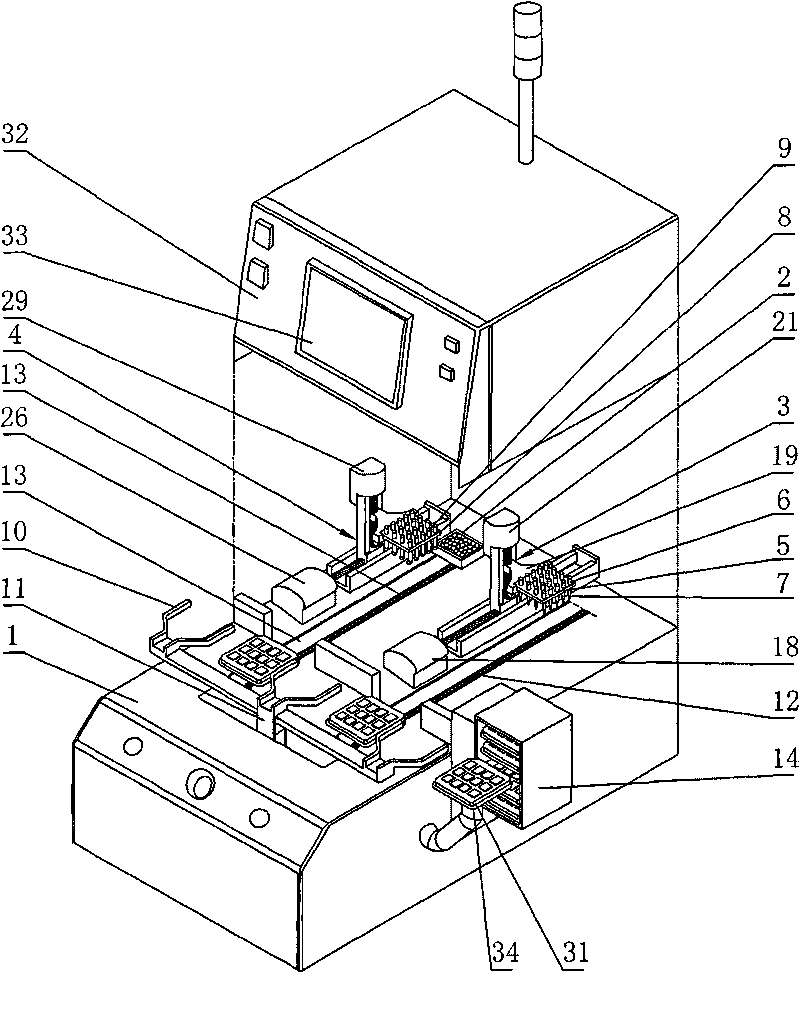

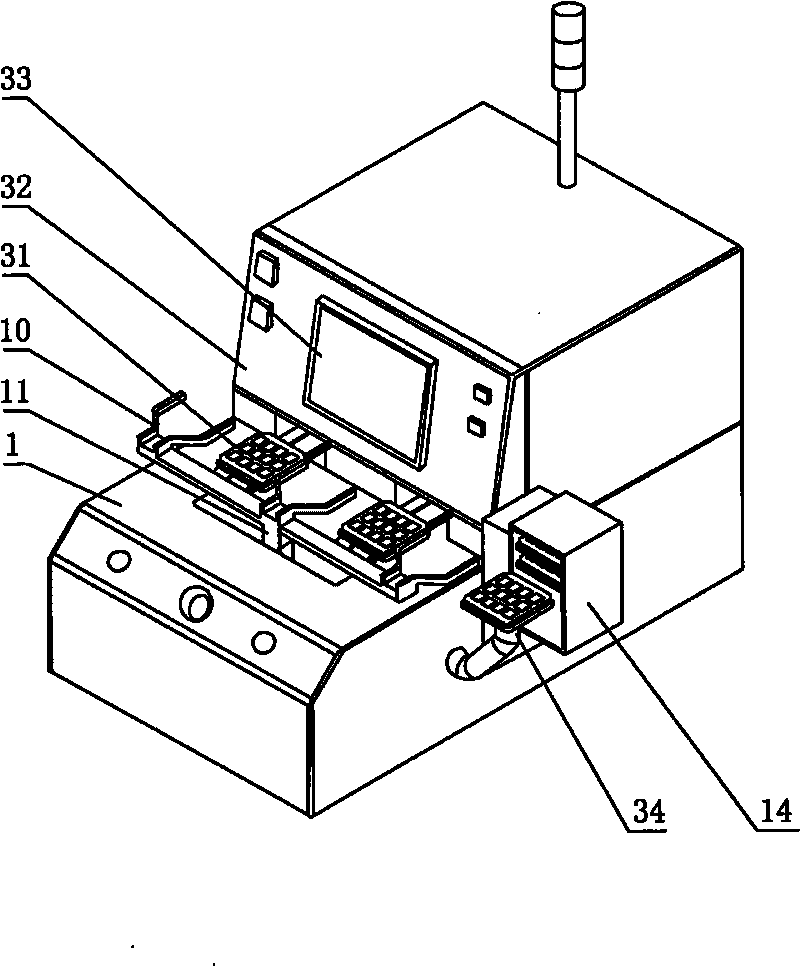

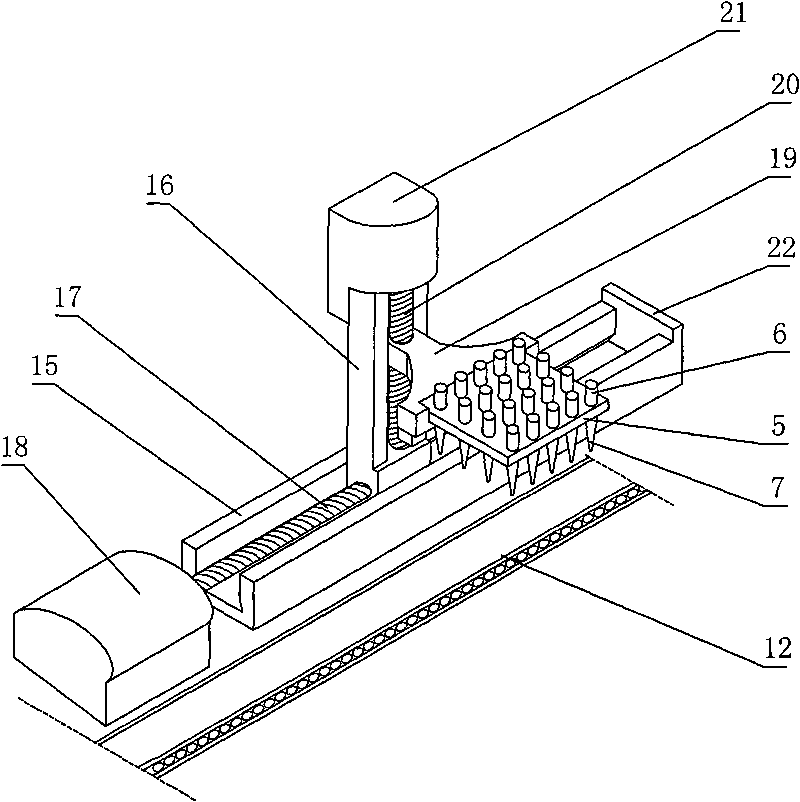

Full-automatic ball attachment machine

ActiveCN101698260AWon't wasteHigh positioning accuracyPrinted circuit assemblingSolder feeding devicesSolder ballEngineering

The invention discloses a full-automatic ball attachment machine, which comprises a workbench, a conveying chain arranged on the workbench, a solder ball storage disk, a flux paste dropwise-adding device which adds flux paste dropwise on substrates to be machined, and a solder ball placement device which places solder balls on the substrates to be machined. In the full-automatic ball attachment machine, the flux paste is directly injected into mounting holes of the substrates to be machined through a plurality of flux paste injection tubes on a dispensing mould, and the solder balls are placed into the mounting holes of the substrates to be machined through a plurality of vacuum ball absorption tubes on a ball attachment mould, so a plurality of substrates to be machined can be dispensed and placed once, positioning accuracy is high, raw materials are saved and production cost is reduced; and a whole power source is controlled by a PLC controller, thus the degree of automation is higher and operations are more convenient.

Owner:CHONGQING QUNWIN ELECTRONICS MATERIAL CO LTD

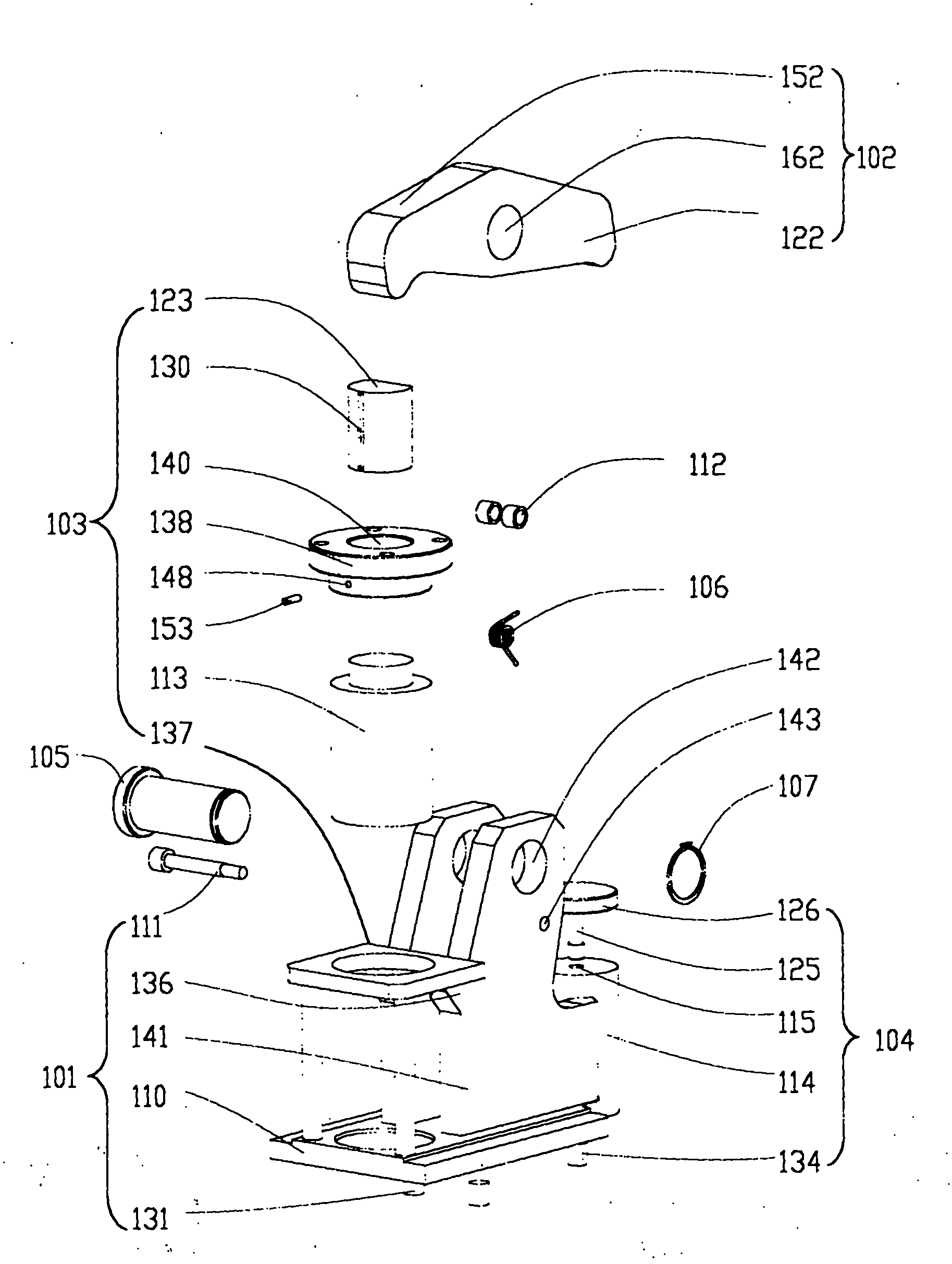

Device capable of performing pressure welding on copper bar for new energy automobile

InactiveCN112338345APrevent looseningAccurate welding positionNon-electric welding apparatusHydraulic cylinderNew energy

The invention relates to a device capable of performing pressure welding on a copper bar for a new energy automobile. The device comprises a welding machine, a conveying line is arranged on the side edge of the welding machine, a mounting table is arranged between the welding machine and the conveying line, a turntable for driving the copper bar to enter the welding machine for welding is arrangedbetween the mounting table and the welding machine, the turntable is connected with a motor, and a moving table is mounted on the mounting table in a sliding manner; and a grabbing device used for conveying the copper bar on the conveying line to the turntable is arranged on the moving table, and a pressing mechanism used for pressing the copper bar to prevent the copper bar from scattering is arranged on the turntable. The moving table is driven by a hydraulic cylinder to slide, so that a V-shaped groove drives a mounting rod to slide in the U-shaped groove, the copper bar is conveyed to theturntable from the conveying line, then the turntable is rotated by the motor, the copper bar is subjected to pressure welding through the welding machine, manual operation is not needed, and the automation degree is high; and a pressing rod is driven by a spring to press the copper bar, the copper bar is prevented from loosening in the rotating process, and it is guaranteed that the welding position of the copper bar is accurate.

Owner:WUHU HENGKUN AUTO PARTS

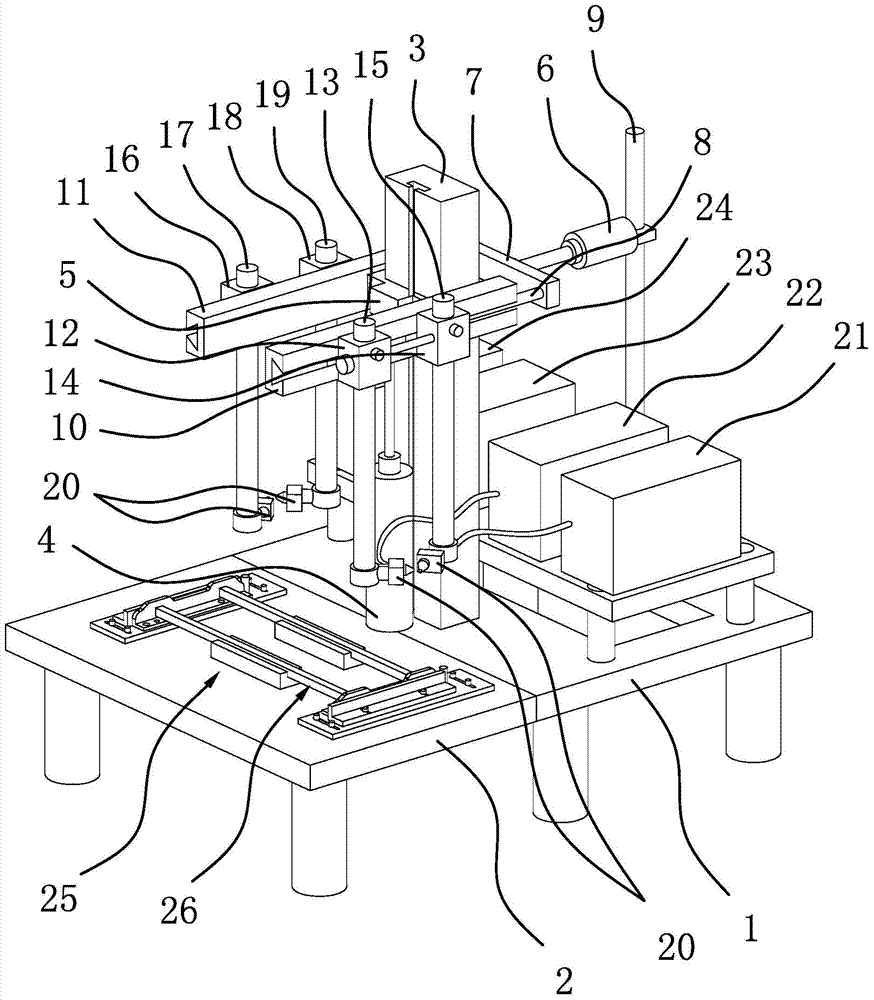

Automatic welding machine with PLC

ActiveCN104708168AAccurate welding positionImprove welding qualityElectrode holder supportersEngineeringWelding

The invention provides an automatic welding machine with a PLC, and belongs to the technical field of machinery. The automatic welding machine solves the problem that in the prior art, the efficiency is low as a rocking chair iron support adopts manual welding. According to the automatic welding machine with the PLC, the rocking chair iron support comprises a first steel ribbon and a second steel ribbon arranged in parallel and a first installing seat and a second installing seat arranged in parallel; the welding machine comprises a rack, a working platform is arranged on the rack, a vertical column is vertically fixed to the working platform, a lifting and dropping block is arranged on the vertical column, and the lifting and dropping block is connected with a first driving mechanism; the working platform is further provided with a positioning device capable of fixing the first steel ribbon, the second steel ribbon, the first installing seat and the second installing seat, and the positioning device comprises a first positioning block and a second positioning block which can circumferentially position the first steel ribbon and the second steel ribbon and further comprises a first positioning ribbon and a second positioning ribbon which can axially position the first steel ribbon and the second steel ribbon. According to the automatic welding machine with the PLC, the automatic welding of the rocking chair iron support can be achieved, and the welding efficiency is high.

Owner:ZHEJIANG FEILI TECH CO LTD

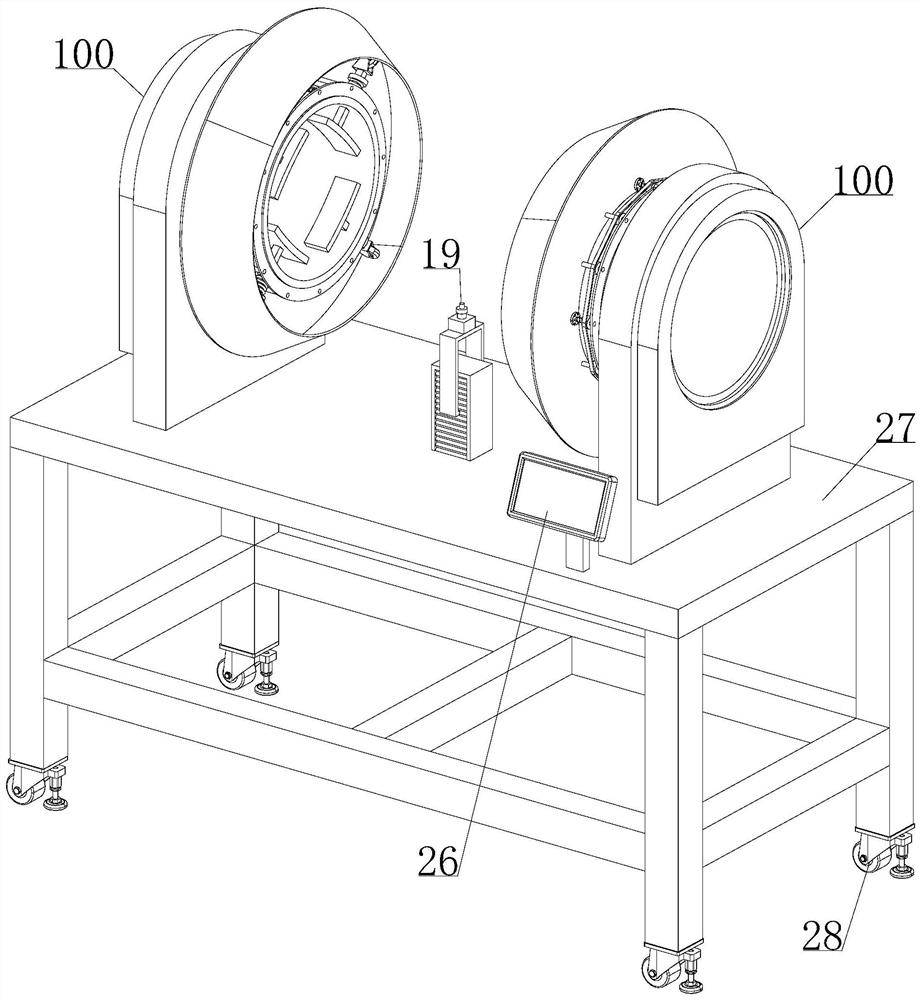

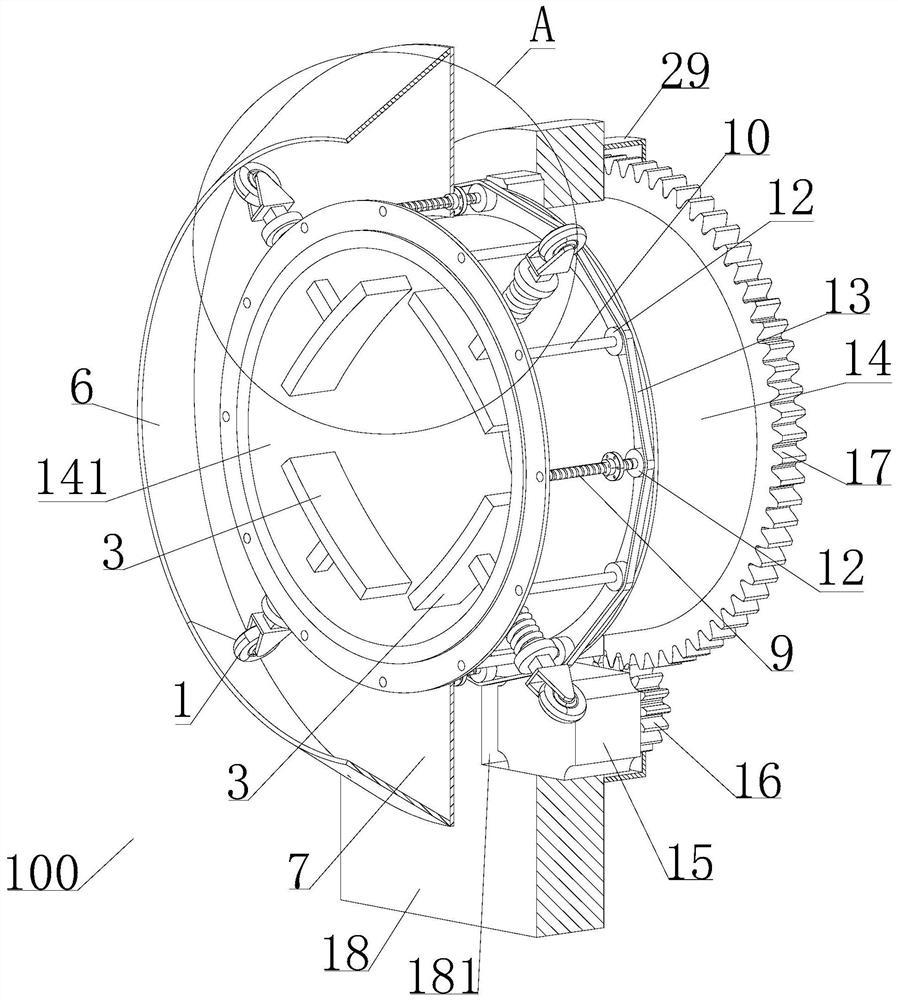

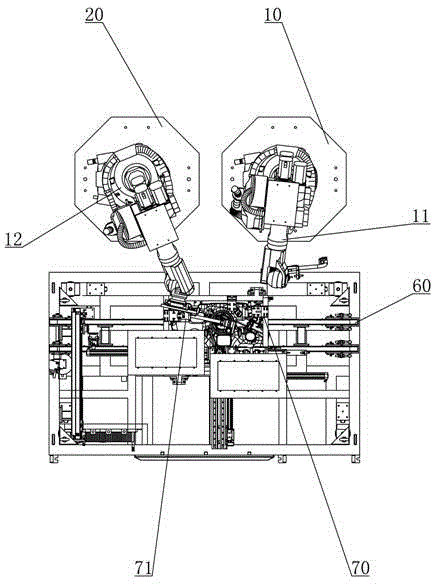

Automatic welding equipment

InactiveCN112296556AHigh degree of automationImprove welding precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses automatic welding equipment. The automatic welding equipment comprises clamp rotation mechanisms, a welding head, a control panel and a machine frame, wherein two groups of clamp rotation mechanisms are arranged abreast in the horizontal direction; each group of clamp rotation mechanisms comprises a clamping assembly, a push plate, a connecting plate, a rotary drum, a mounting table, a movable driving mechanism for driving the connecting plate to be moved in the horizontal direction and a rotation driving mechanism for driving the rotary drum to be rotated, wherein a lifting mechanism for driving the welding head to be lifted is arranged on the machine frame; a central shaft of the corresponding rotary drum is horizontally arranged; a clamp channel is coaxially arranged on the corresponding rotary drum; the rotary drum is rotatably arranged on the corresponding mounting table; the rotation driving mechanism is arranged on the corresponding mounting table; and the control panel is separately connected with the corresponding welding head, the corresponding movable driving mechanism, the corresponding rotation driving mechanism and the corresponding lifting mechanism. According to the automatic welding equipment disclosed by the invention, metal tube can be stably clamped and can be driven to be rotated, and in a rotation process of the metal tubes, the twometal tubes can be automatically welded through the welding head, and thus, the automation degree is high, the welding accuracy is high, and the welding quality is high.

Owner:深圳市励东科技发展有限公司

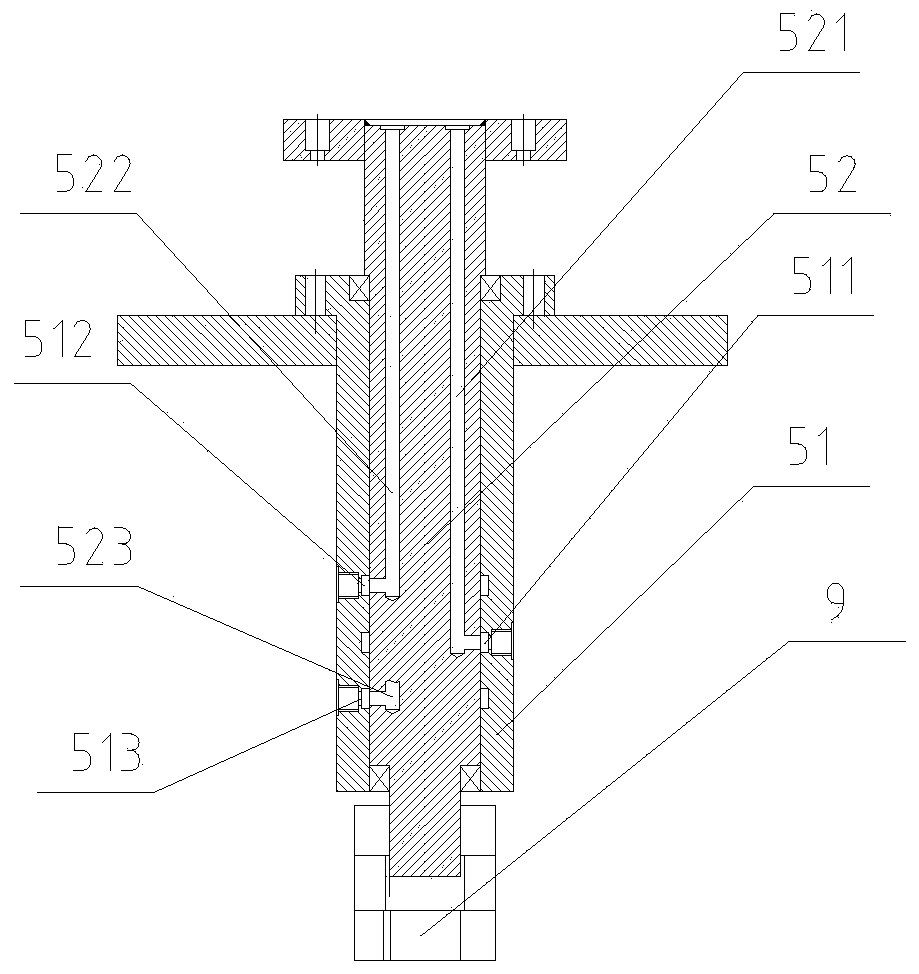

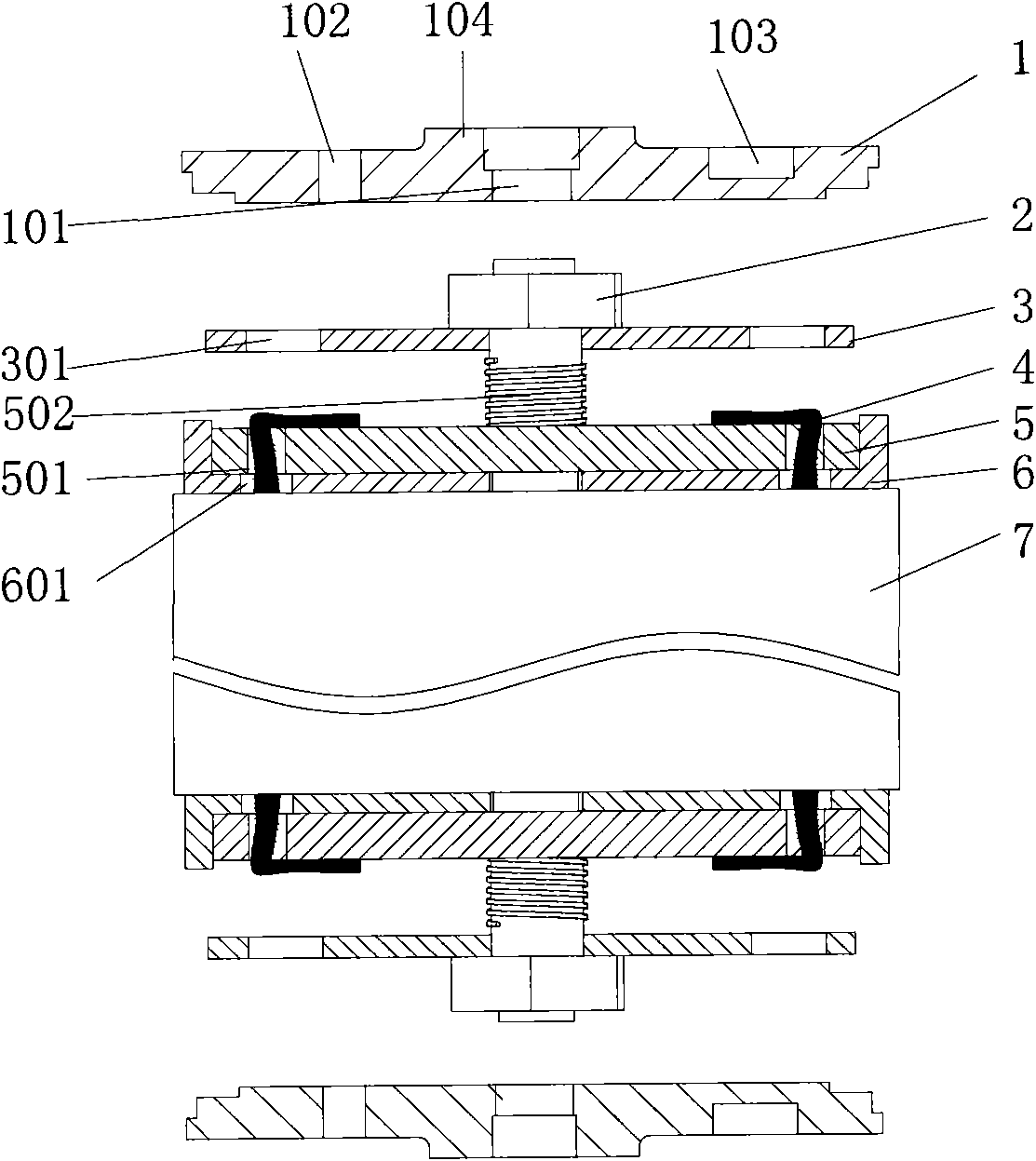

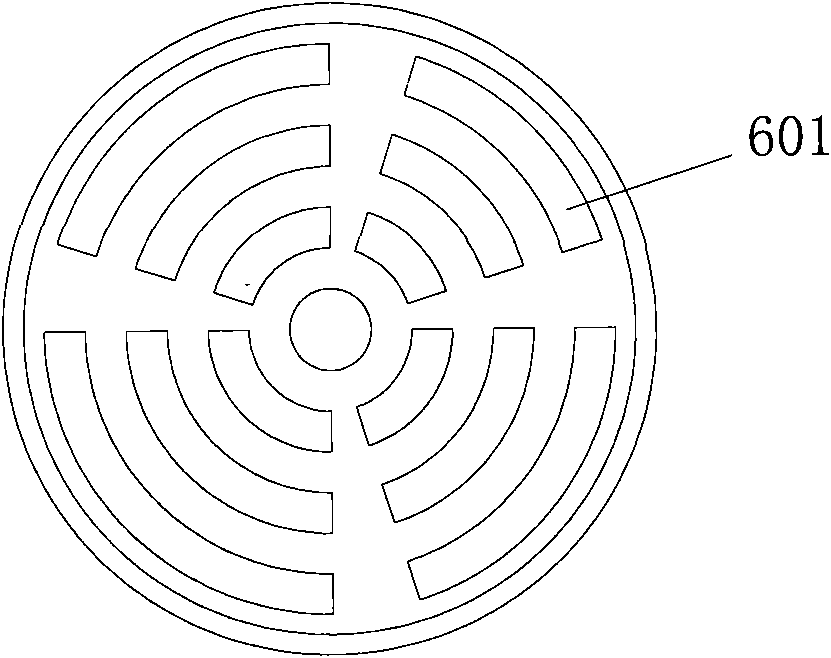

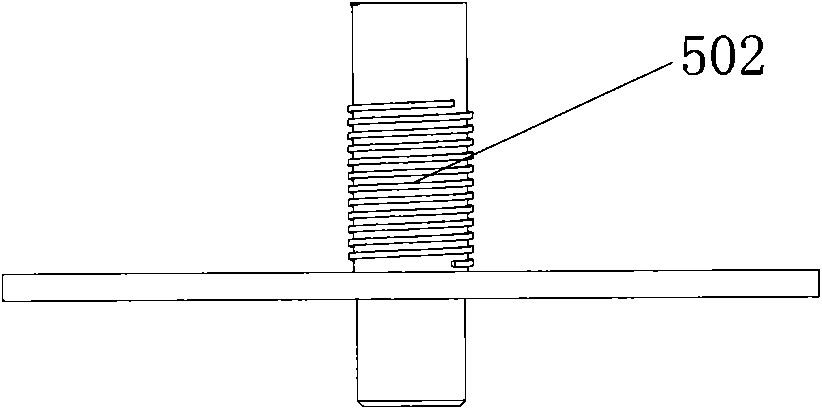

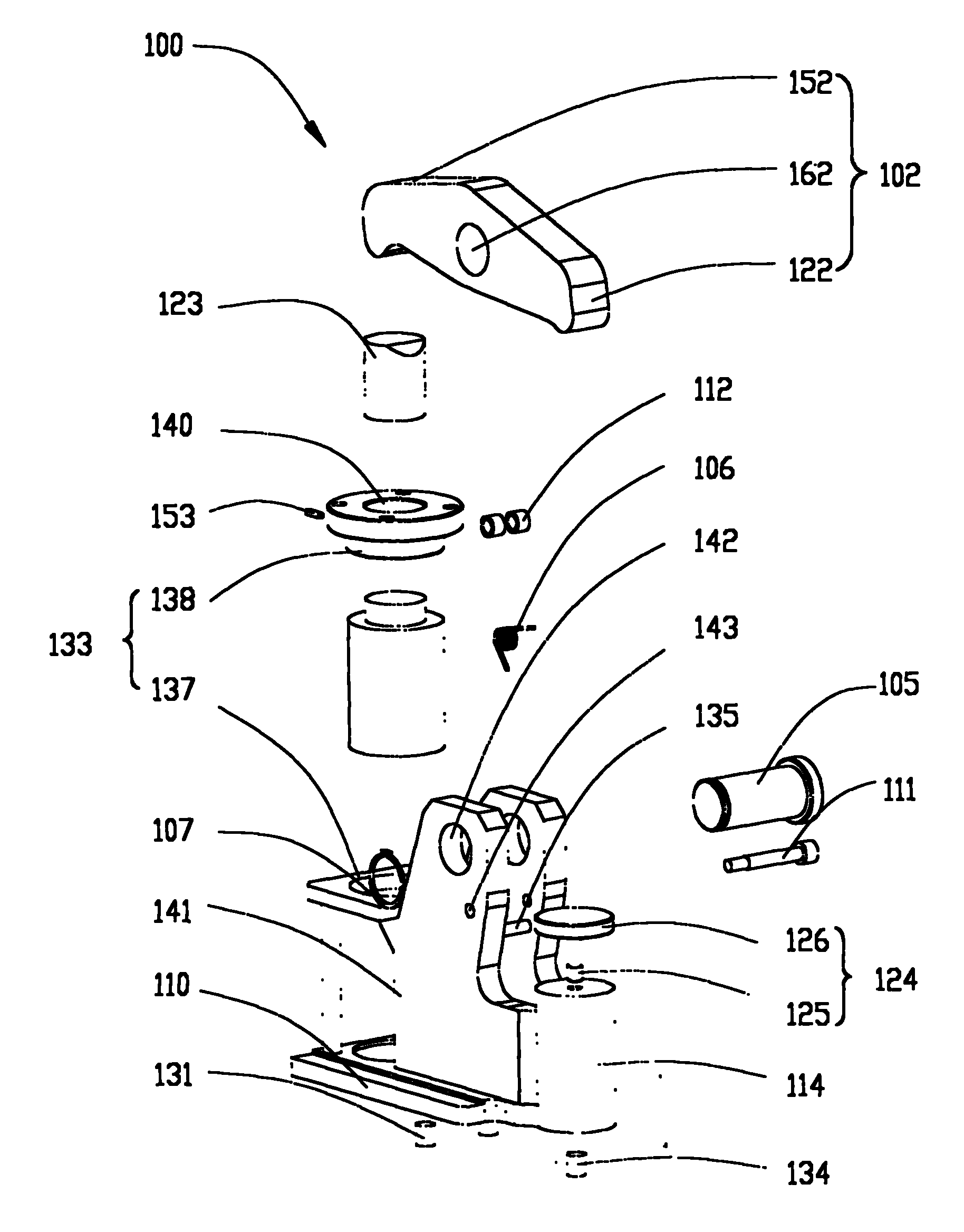

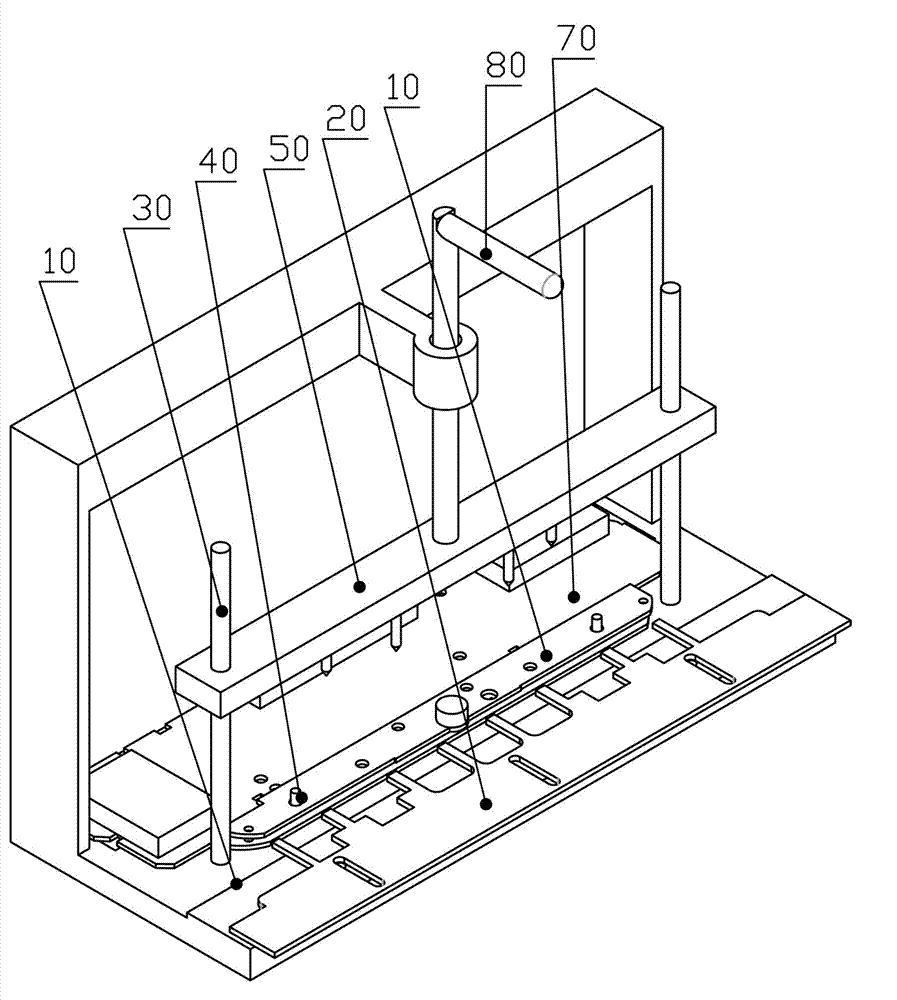

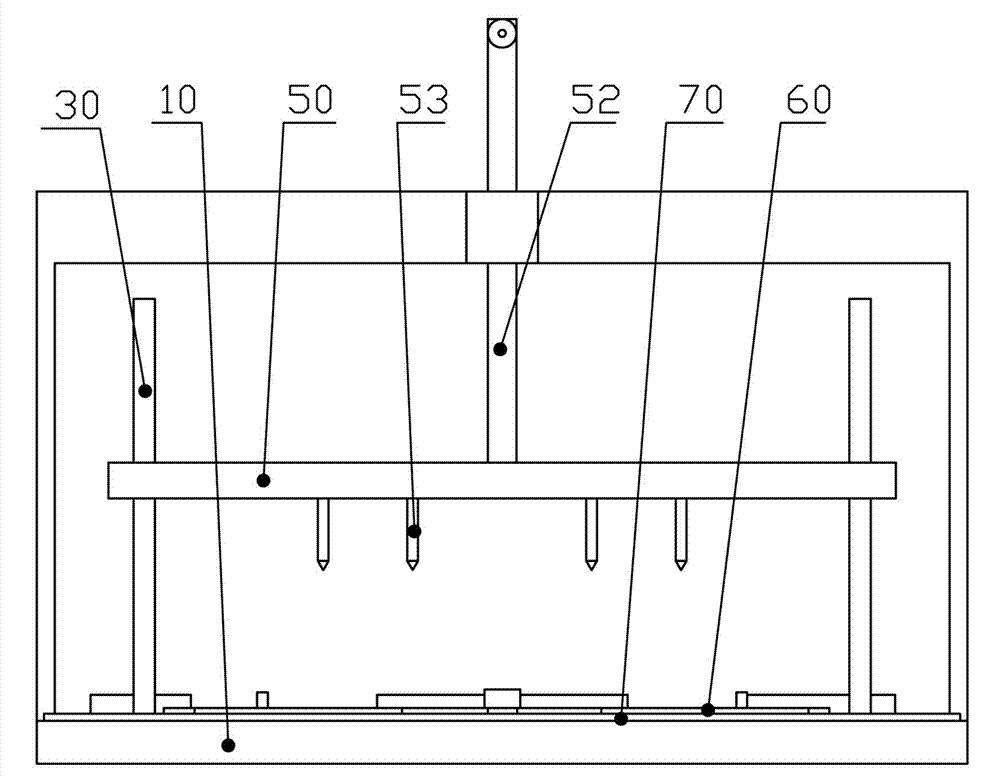

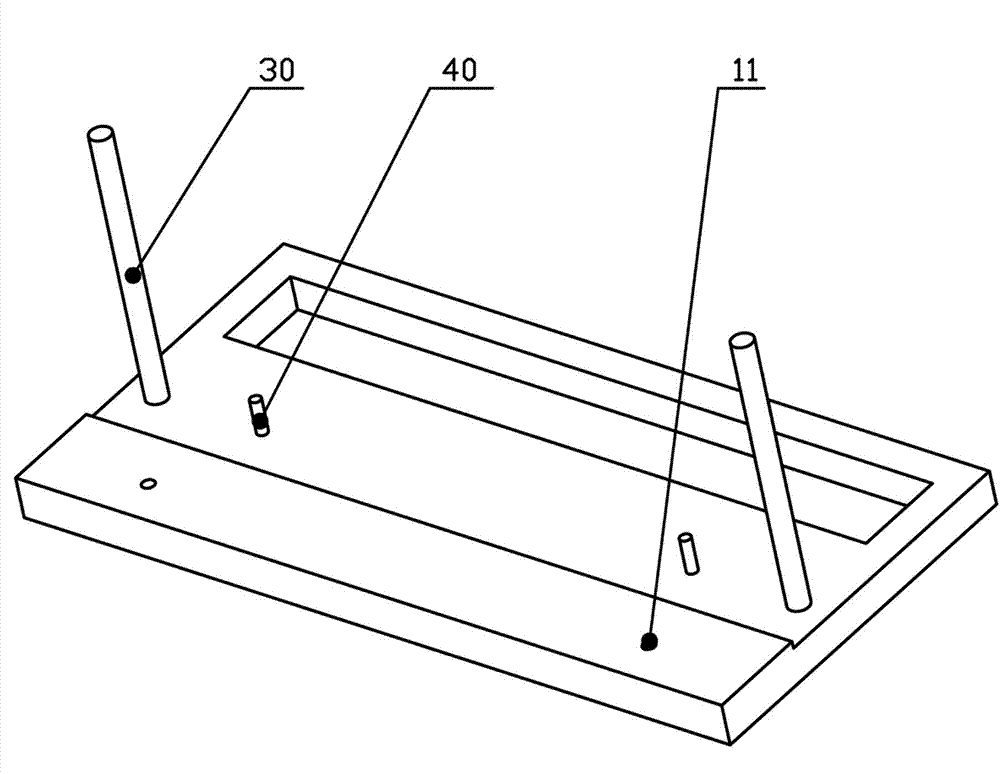

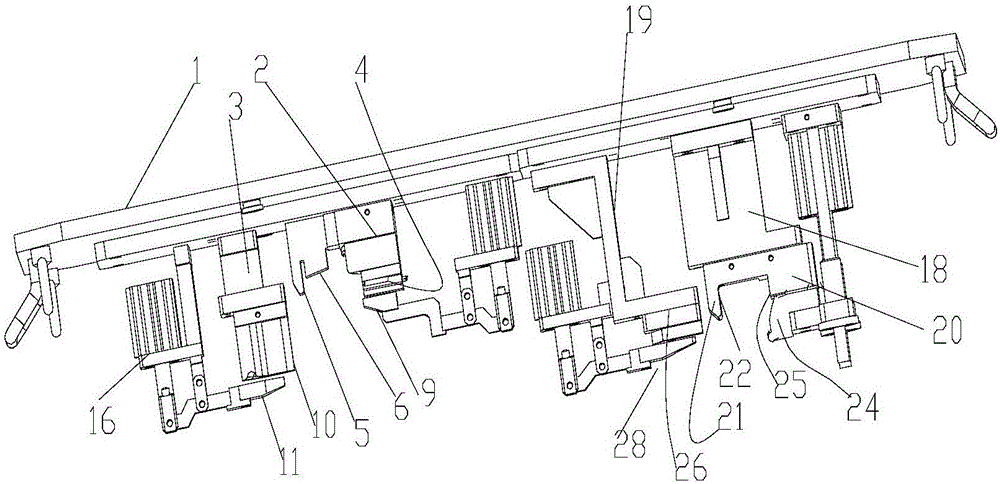

Tooling device for welding circuit board and keyboard plate

The invention relates to the welding field of circuit boards, in particular to a tooling device for welding a circuit board and a keyboard plate. The tooling device comprises a pedestal (10), a positioning plate (20), a guide column (30), a positioning column (49) and a movable compressing device (50); and moreover, a keyboard plate (60) and a main circuit board (20) are separated by the positioning plate (29) when the tooling device runs, and the keyboard plate (60) is compressed by the movable compressing device (50); the keyboard plate (60) and the main circuit board (70) are integrally connected through inserting pins; and then a handle (80) can be pulled to enable the movable compressing device (50) to move upwards, therefore, the positioning plate (20) can slide to the outermost side, and finally, a component produced by jointly welding the main circuit board (70) and the keyboard plate (60) can be taken out. With the adoption of the tooling device, the inserting pins is enabled not to be inclined when being assembled, the correct welding position can be guaranteed, the welding quality is stable, and the circuit board is conveniently taken in and out.

Owner:兴科迪科技(泰州)有限公司

Manufacturing process of head-hanging folding face mask

PendingCN108634440AAccurate welding positionRealize fully automatic productionProtective garmentUltrasonic weldingEngineering

The invention relates to the technical field of face masks, and in particular relates to a manufacturing process of a head-hanging folding face mask. According to the manufacturing process, a cloth material of the face mask is horizontally fed, the cloth material is cut to form a face mask main body, the shape that a front face mask body and a rear face mask body are sequentially connected is formed, the face mask main body is folded along the discharging direction, two ear belt heads of the same ear belt are oppositely folded from two sides of the face mask main body, the ear belt heads are welded to the face mask main body through an ultrasonic welding head, and independent individual face masks are formed through cutting. By rotatably welding the ear belts to the face mask main body below the face mask main body in the vertical state, the full-automatic manufacturing is realized, the manufacturing efficiency is greatly improved, meanwhile, the welding positions of the ear belts areaccurate, and packaging materials can be saved.

Owner:东莞快裕达自动化设备有限公司

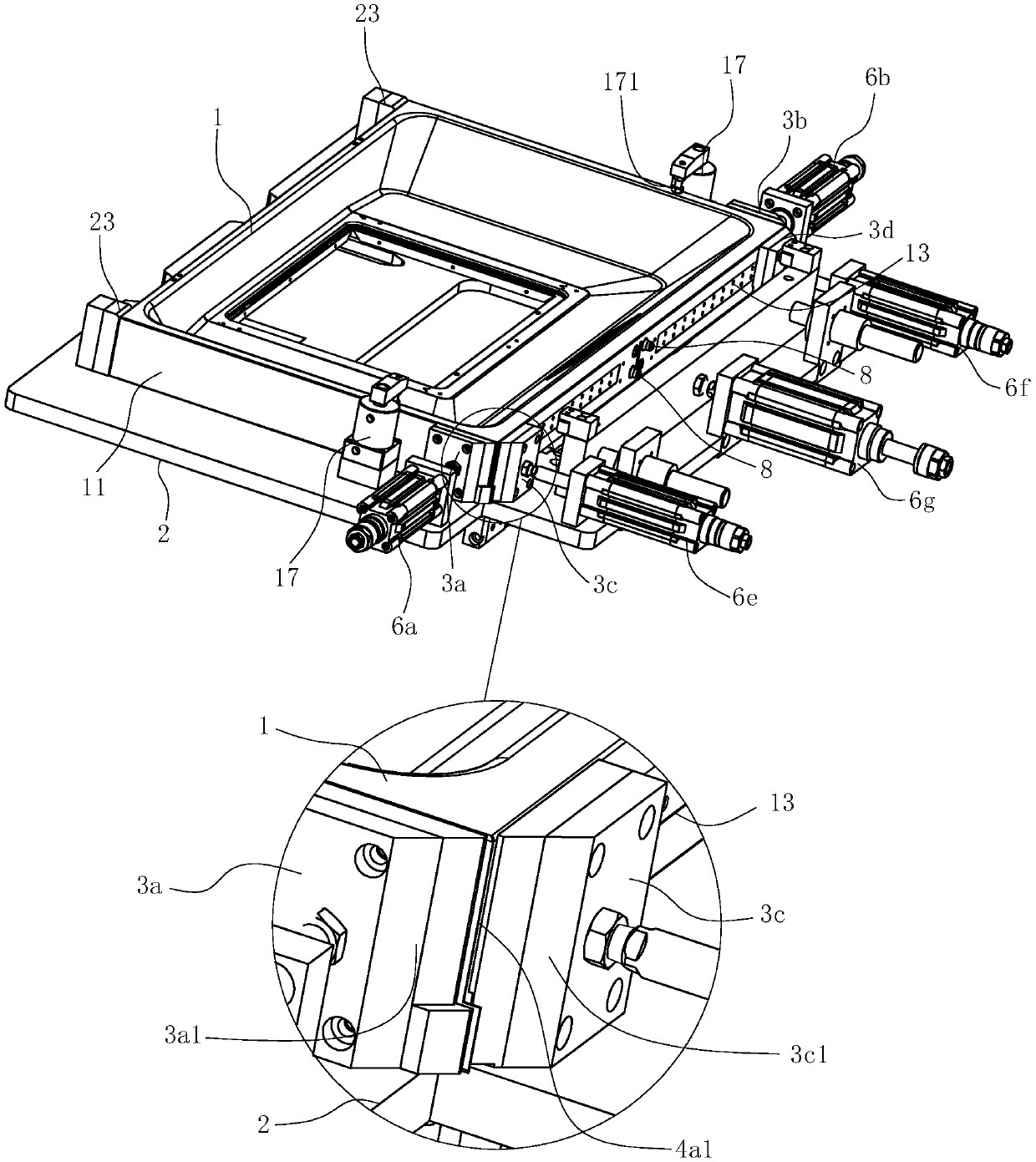

Stainless steel exhaust fume collecting hood welding, bonding and re-welding fixture

InactiveCN110653540AGuaranteed flatnessGuaranteed straightnessDomestic stoves or rangesLighting and heating apparatusExhaust fumesStructural engineering

The invention relates to a stainless steel exhaust fume collecting hood welding, bonding and re-welding fixture which is characterized by comprising a platform, a left-side external pressing block, aright-side external pressing block, a left front external pressing block, a right front external pressing block, a left internal pressing block, a right internal pressing block, a middle internal pressing block and a middle external pressing block. The platform is used for placing a stainless steel exhaust fume collecting hood; the stainless steel exhaust fume collecting hood is provided with a left folding edge, a right folding edge and a front folding edge; a positioning structure is arranged on the platform; the left-side external pressing block is driven by a left outboard drive structure;the right-side external pressing block is driven by a right outboard drive structure; the left front external pressing block is driven by a left front drive structure; the right front external pressing block is driven by a right front drive structure; the left internal pressing block is constrained on the platform, can slide move and right, and is driven by a left inner-side drive structure; theright internal pressing block is constrained on the platform, can slide move and right, and is driven by a right inner-side drive structure; the middle internal pressing block is fixed onto the platform; a locating pin is fixed onto the middle internal pressing block; and the middle external pressing block is arranged in the middle of the front part of the platform and is driven by a middle drivestructure. According to the fixture, the process of welding, bonding and re-welding is completed, so that the fixture cost is reduced, meanwhile, the process is simplified, and the time and the cost are reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Automatic welding equipment of plastic case

The invention discloses automatic welding equipment of a plastic case. The automatic welding equipment comprises a control system, a welding device and a conveyer device and a fixation device which are arranged below the welding device. The welding device, the conveyer device and the fixation device are all electrically connected with the control system. The welding device comprises a weldment clamping mechanism and a hot mould mechanism. The weldment clamping mechanism contains a first six-axis manipulator and an L-shaped first linking arm connected with the first six-axis manipulator. The other end of the first linking arm is connected with a clamping jaw. The hot mould mechanism contains a second six-axis manipulator and an L-shaped second linking arm connected with the second six-axis manipulator. The other end of the second linking arm is connected with a heating module. By the welding equipment, weldments can efficiently be welded from an inner side of an enclosed case towards an inner wall of the enclosed case, and welding quality is raised greatly.

Owner:深圳市远望工业自动化设备有限公司

Device for assembling automobile hook assembly

ActiveCN106736175AAccurate welding positionEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a device for assembling an automobile hook assembly. The device comprises a positioning base. The positioning base is provided with a first mounting assembly. The first mounting assembly comprises a first limiting base and a second limiting base arranged on the positioning base. The first limiting base is provided with a first clamping groove used for fixing a hook base and a limiting block located between the first limiting base and the second limiting base. The limiting block is provided with a first datum face and a second datum face used for limiting the position of the hook base. A first clamping arm opened at the first clamping groove in an overturned mode is arranged beside the first limiting base. The second limiting base is provided with a second clamping groove used for fixing a plurality of hooks. A second clamping arm opened at the second clamping groove in an overturned mode is arranged beside the second limiting base. By the adoption of the device, the hook base to be welded and the multiple hooks are quickly positioned and clamped, the hooks at the two sides of the hook base can be welded through the device, and thus the machining precision and working efficiency are improved.

Owner:景和智能制造(广东)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com