Tooling device for welding circuit board and keyboard plate

A key board and circuit board technology, which is applied in the direction of assembling printed circuits with electrical components, and can solve problems such as circuit boards with complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

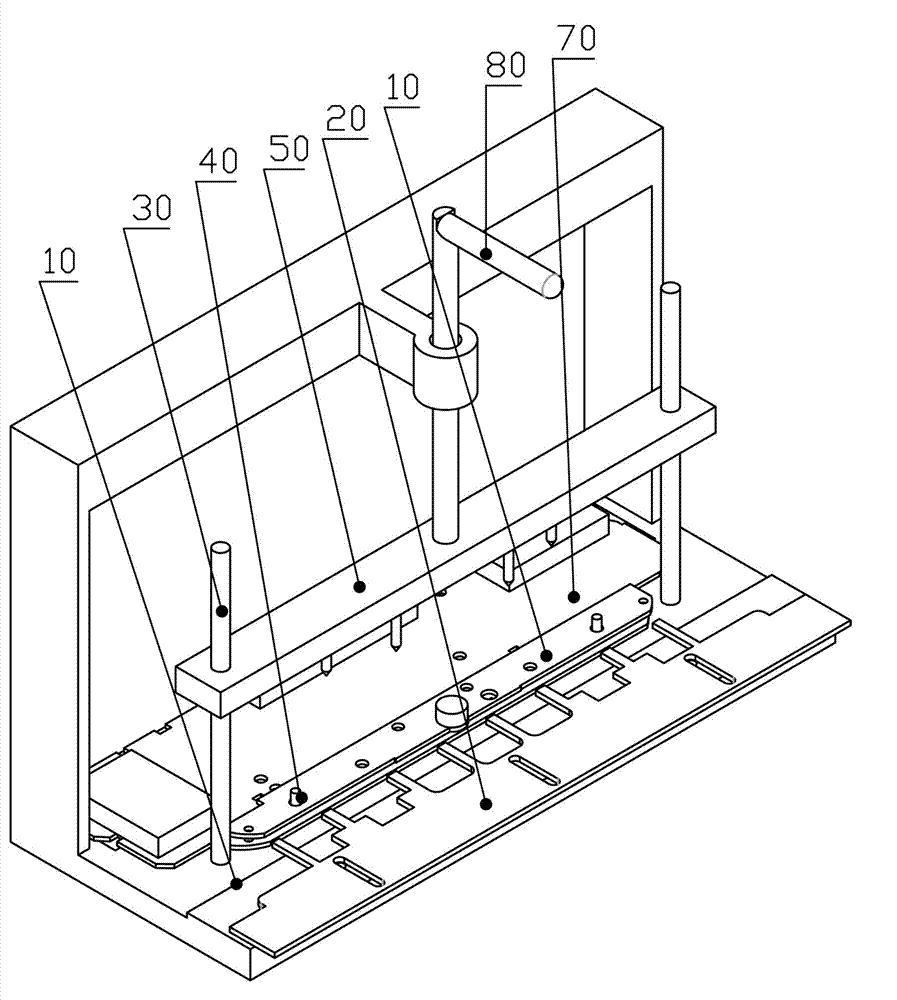

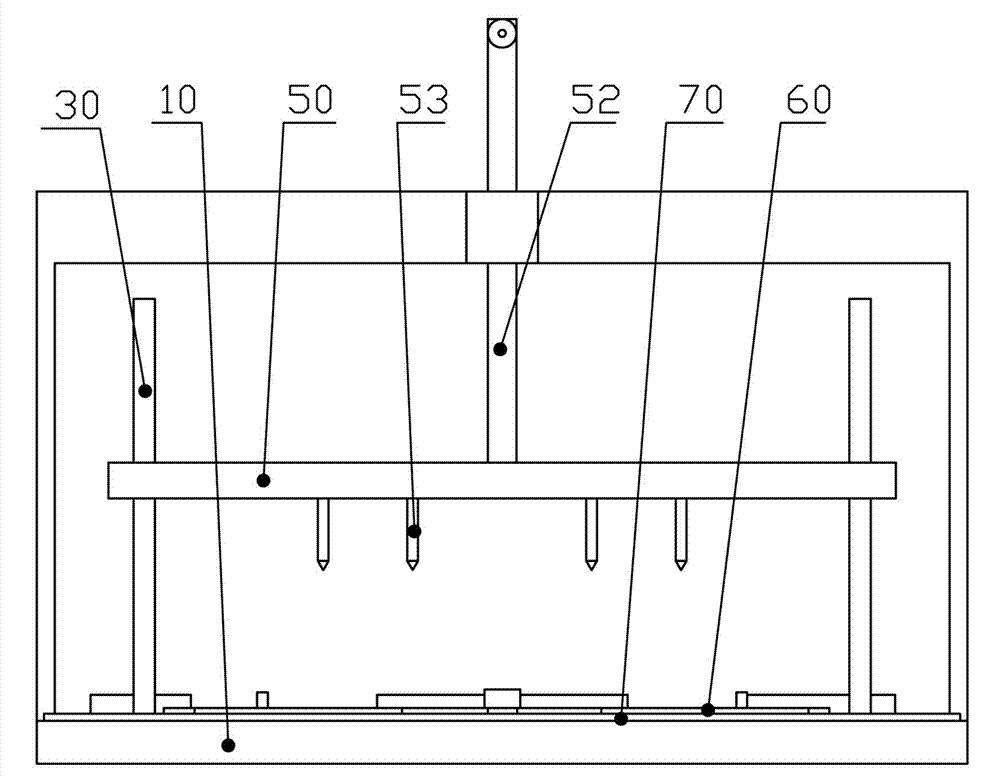

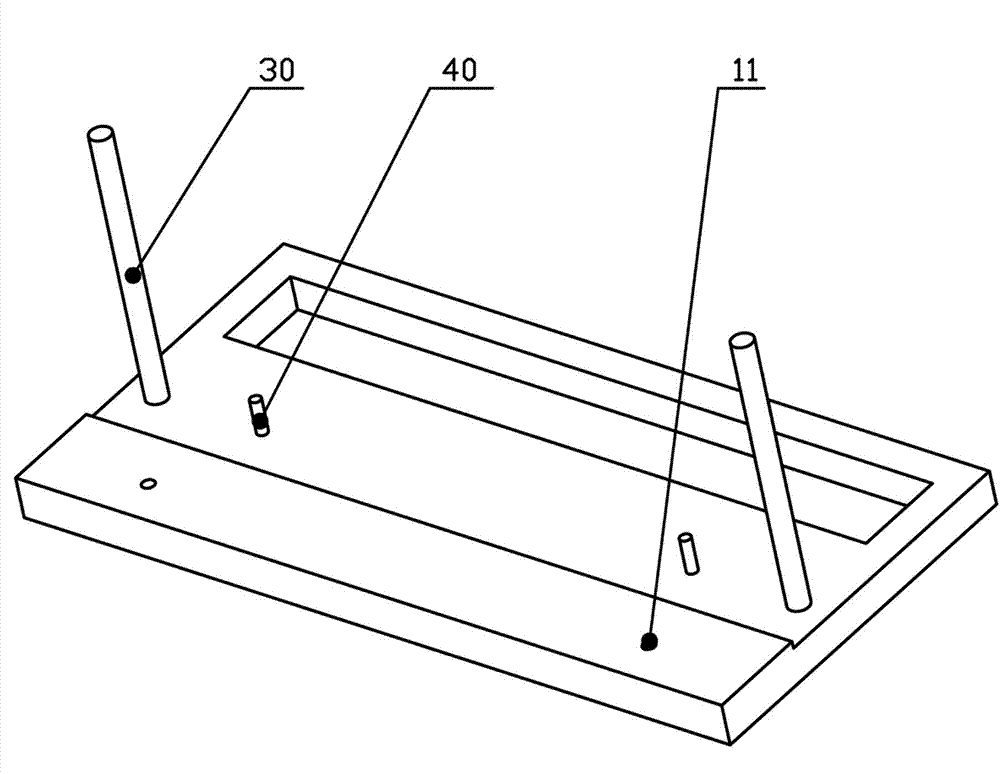

[0037] The specific implementation of the tooling device for welding circuit boards and keypads of the present invention will be further described below in conjunction with the accompanying drawings.

[0038] Such as Figure 1-Figure 2As shown, the tooling device for welding circuit boards and keypads according to the present invention includes a base 10, a positioning plate 20, a guide post 30, a positioning post 40, and a movable pressing device 50. First, the positioning plate 20 is slid to the outermost side. Next, the circuit board 70 is fixed on the upper plane of the base 10 through the positioning column 40, the pins are inserted into the pin holes 63 and then the pins are welded together with the upper plane 71 of the circuit board, and the positioning board 20 is fixed after a while. Slide to the innermost side and place the keypad 60 and the lower plane 61 of the keypad is fully attached to the upper plane 24 of the positioning plate 20, then pull the handle 80 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com