Circuit board one-time welding device

A technology for welding devices and circuit boards, which is applied in the direction of electric heating devices, auxiliary devices, tin feeding devices, etc., can solve problems such as wrong connection of lines, high welding costs, and connection of solder points to electricity, so as to achieve accurate raw material consumption, good welding effect, The effect of accurate welding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Below in conjunction with embodiment the present invention is further described:

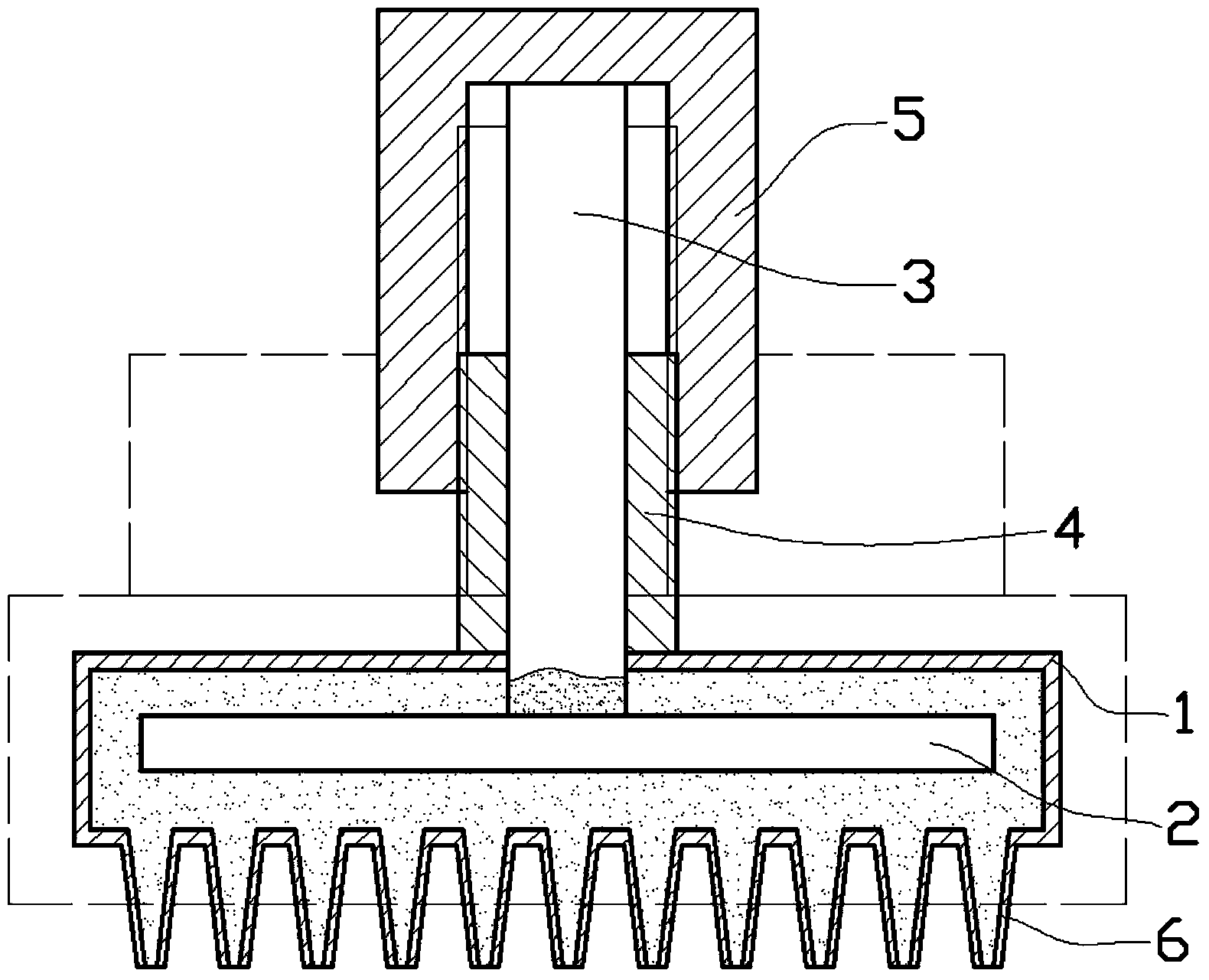

[0009] Such as figure 1 As shown in the embodiment, this circuit board one-time soldering device uses a solder cylinder 3 with a diameter greater than 6mm as a material, and includes a long tube-shaped heating chamber 1, and the heating chamber 1 is equipped with a strip-shaped heating plate 2 inside. The feed inlet of the solder cylinder 3 is facing the heating plate 2, and the feed inlet is communicated with the heating chamber 1 through the guide sleeve 4, and the axial direction in the middle of the guide sleeve 4 is processed with the solder cylinder 3. Corresponding to the through hole, the guide sleeve 4 is equipped with a carrying block 5 that pushes the solder cylinder 3 into the heating chamber 1 , and the wall of the heating chamber 1 is processed with tapered outlets 6 juxtaposed in the axial direction. The outside of the device is fixedly connected with the frame through the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com