Stainless steel exhaust fume collecting hood welding, bonding and re-welding fixture

A welding fixture and fume collecting hood technology is applied in the field of tooling fixtures, which can solve the problems of increased fixture cost, welding deformation, low precision, etc., and achieve the effect of ensuring flatness and straightness, accurate relative position relationship, and accurate welding position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

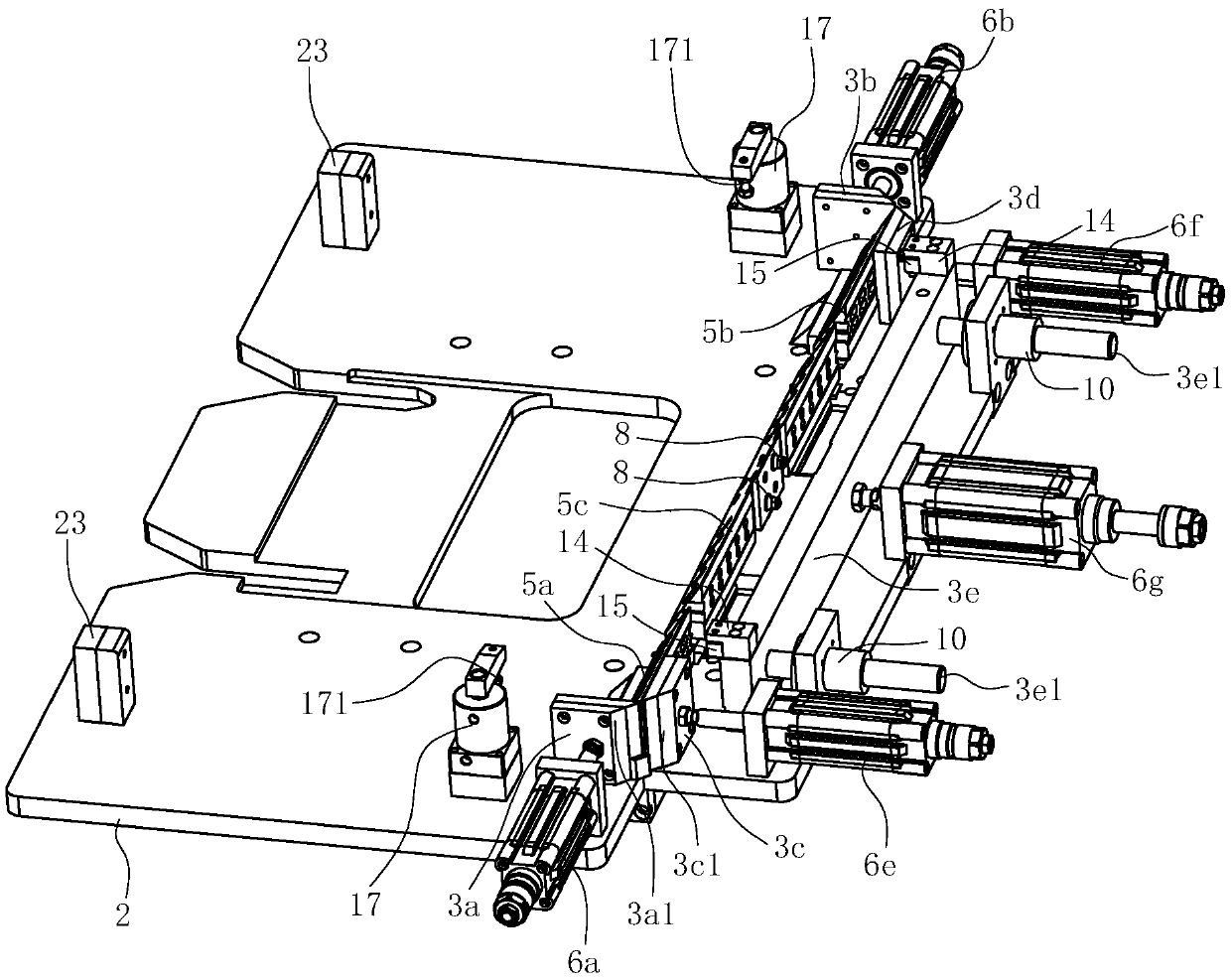

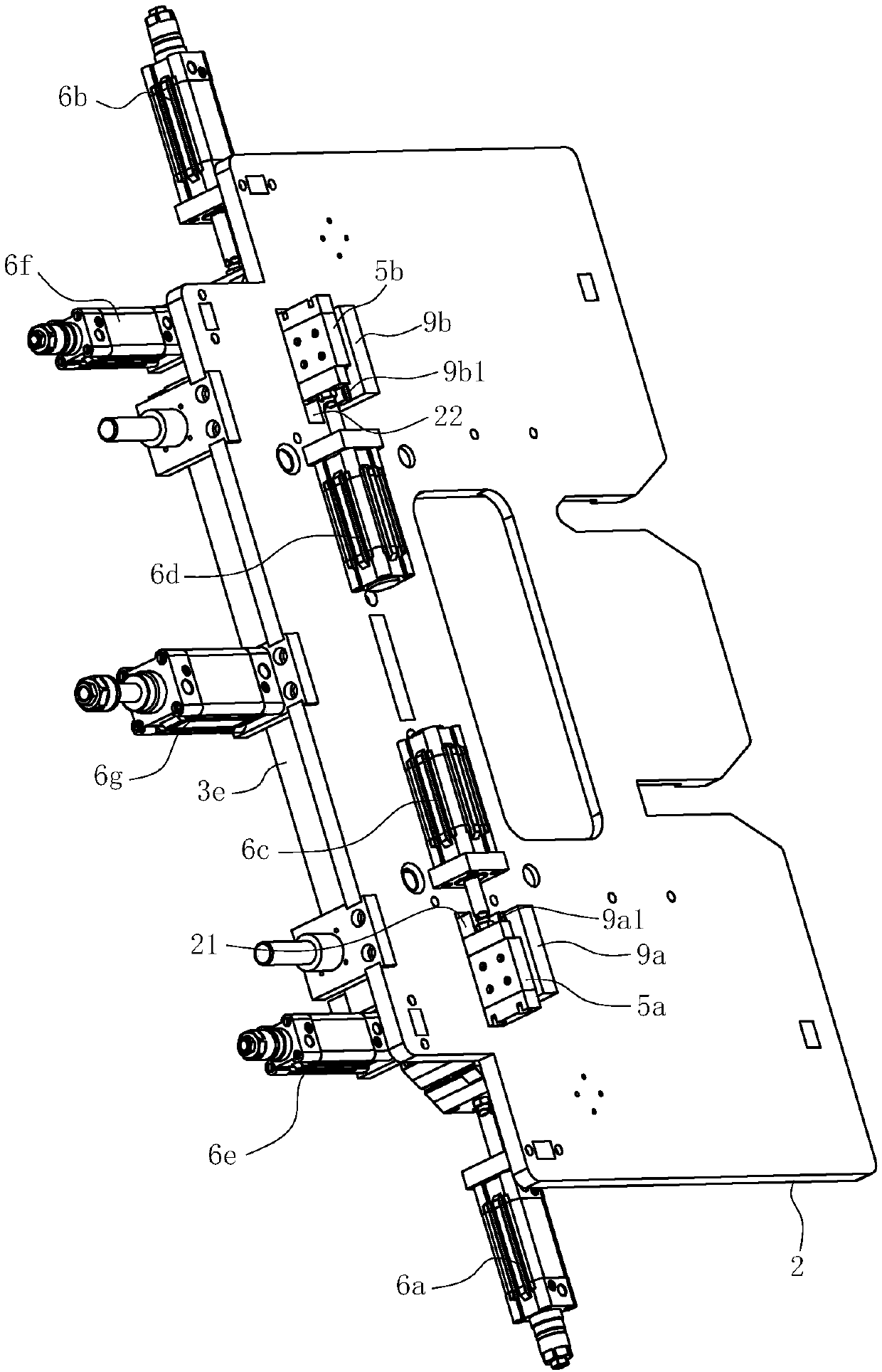

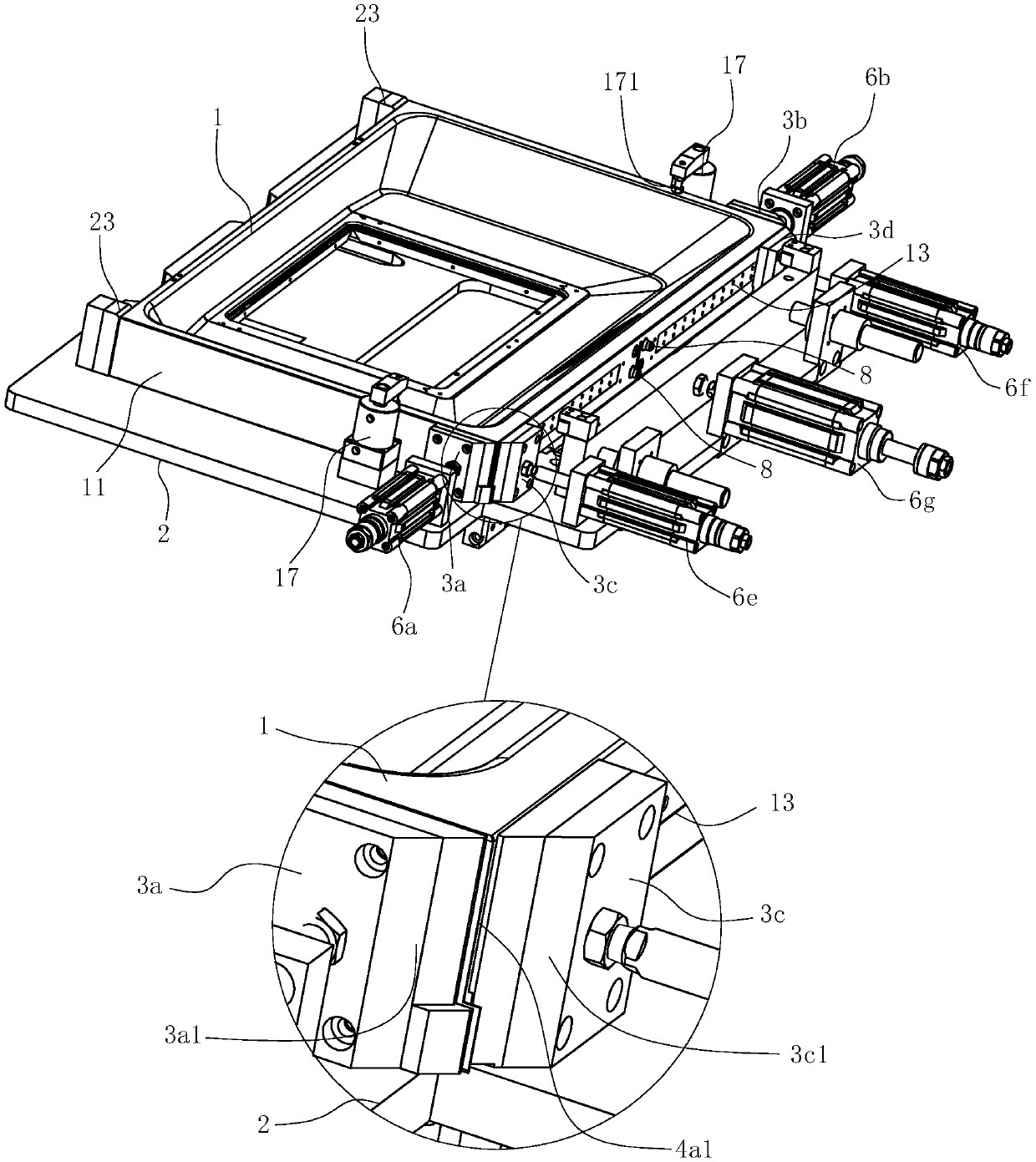

[0029] Such as Figure 1-9 Shown is a preferred embodiment of the present invention.

[0030] A stainless steel fume collecting hood welding bonding re-welding fixture, the fixture can weld the corresponding position of the stainless steel fume collecting hood, and at the same time bond the glass panel 7 bonded with the decorative strip 71 to the front fold of the stainless steel fume collecting hood 1 The side 13 drives the outer end surface, and the position of the decorative strip 71 and the corresponding side of the stainless steel fume collecting hood 1 is welded. Specifically include

[0031] A platform 2 for placing the stainless steel fume collecting hood 1. The stainless steel fume collecting hood 1 has a left fold 11, a right fold 12 and a front fold 13. The platform 2 is provided with a positioning structure for positioning the stai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com