Patents

Literature

105results about How to "Accurate positional relationship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

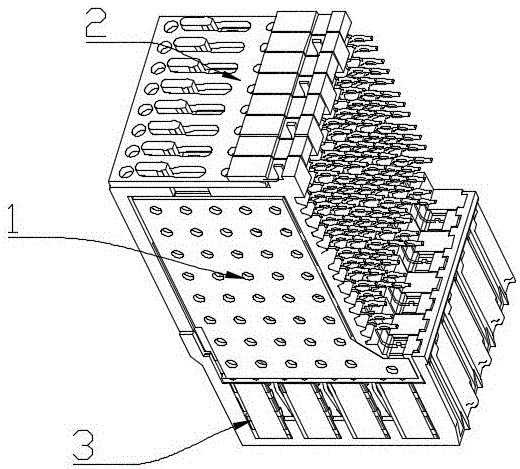

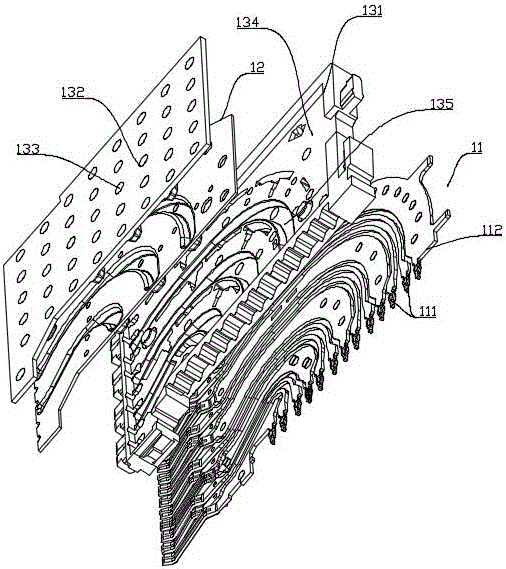

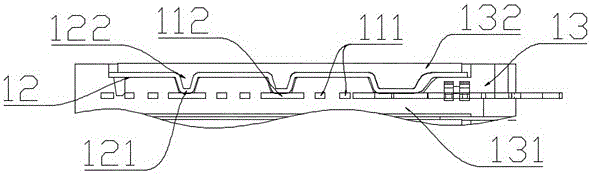

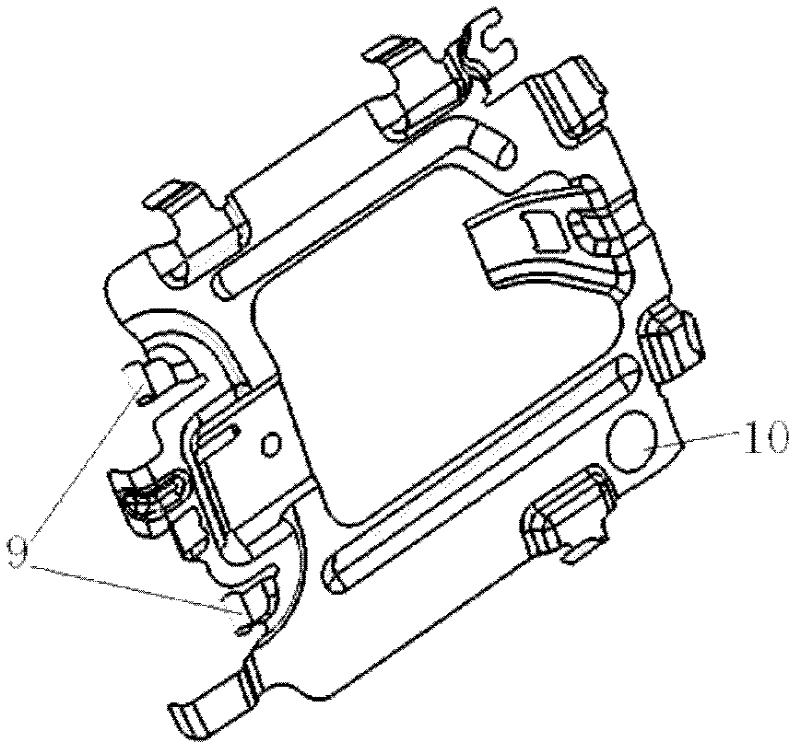

High-speed electric connector and signal module thereof, and molding method of signal module

ActiveCN106207569AImprove firmnessSolve easy deformationContact member assembly/disassemblyCoupling device detailsElectricityEngineering

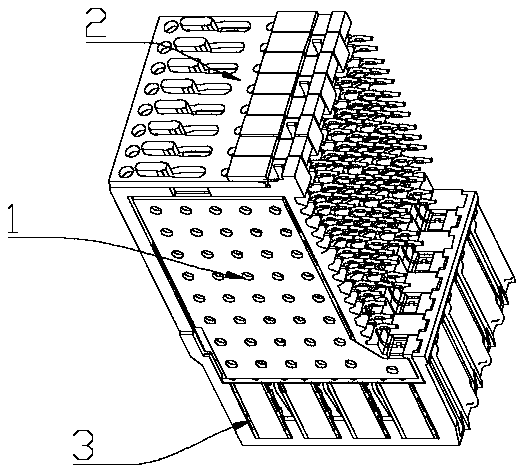

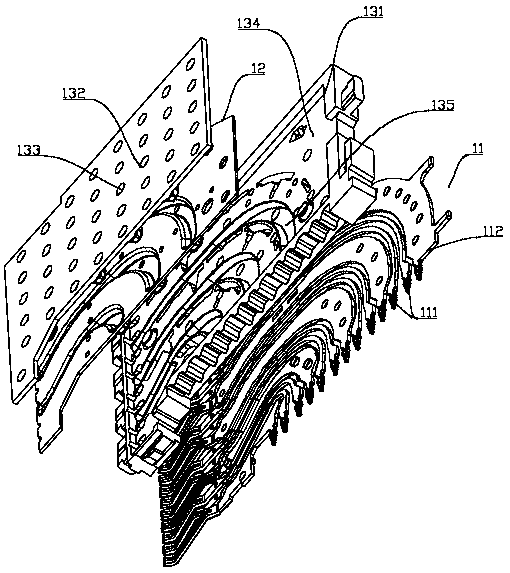

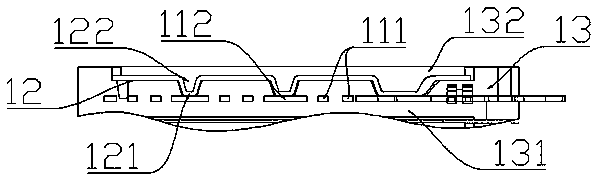

The invention relates to the field of connectors, in particular to a high-speed electric connector and a signal module thereof, and a molding method of the signal module. The high-speed electric connector comprises the signal module; the signal module comprises a contact part; a shield sheet is arranged on at least one side of the contact part; the signal module further comprises an insulator; and the insulator is molded on the contact part and the shield sheet in an injection molding manner to combine the contact part and the shield sheet. The insulator of the signal module of the electric connector is packaged on the contact part and the shield sheet in an injection molding manner, so that the firm degree of the signal module is strengthened and the problem that the signal module of an existing high-speed electric connector is easy to deform is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

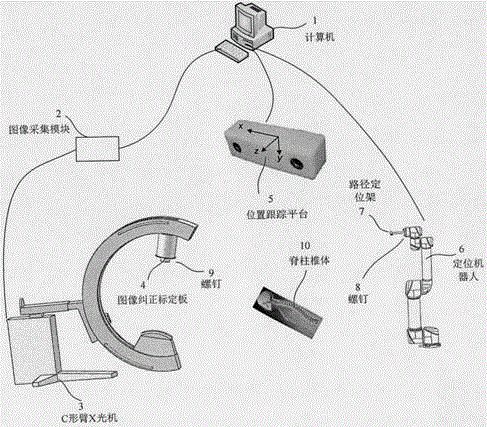

Spine pedicle screw implanting and locating device

InactiveCN106691600AImplanted accuratelyTrue location relationshipInternal osteosythesisSurgical navigation systemsAnatomical structuresImage correction

The invention relates to the field of medicine, in particular to a spine pedicle screw implanting and locating device. The spine pedicle screw implanting and locating device comprises hardware of a C-shaped arm, an image correction calibration plate, an image collection module, a locating robot, a path locating frame, a position tracking platform, a computer and the like, a spine pedicle screw implanting path planning module and a locating navigation module based on an X ray picture during an operation, wherein the spine pedicle screw implanting path planning module and the locating navigation module are stored in the computer. Through the spine pedicle screw implanting and locating device, according to the anatomical structure characteristics of a spine vertebral body, a coordinate system is established, an operation path planned in a 3D environment before the operation, an operation path planned in a 2D environment during the operation and an operation apparatus path during the operation are expressed, and by the use of the relationship of the three paths, a doctor is guided or a robot is controlled to complete precise operation path locating operation. The spine pedicle screw implanting and locating device can track the position relationships among all objects on a 2D image in real time, reflect the relationship between a tool and pedicle of vertebral arch actually, precisely and timely, eliminate errors of the traditional computer navigation system in an operation process, reduce the operation difficulty, and improve the operation efficacy.

Owner:苏州铸正机器人有限公司

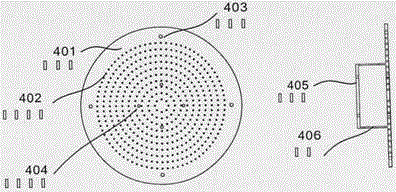

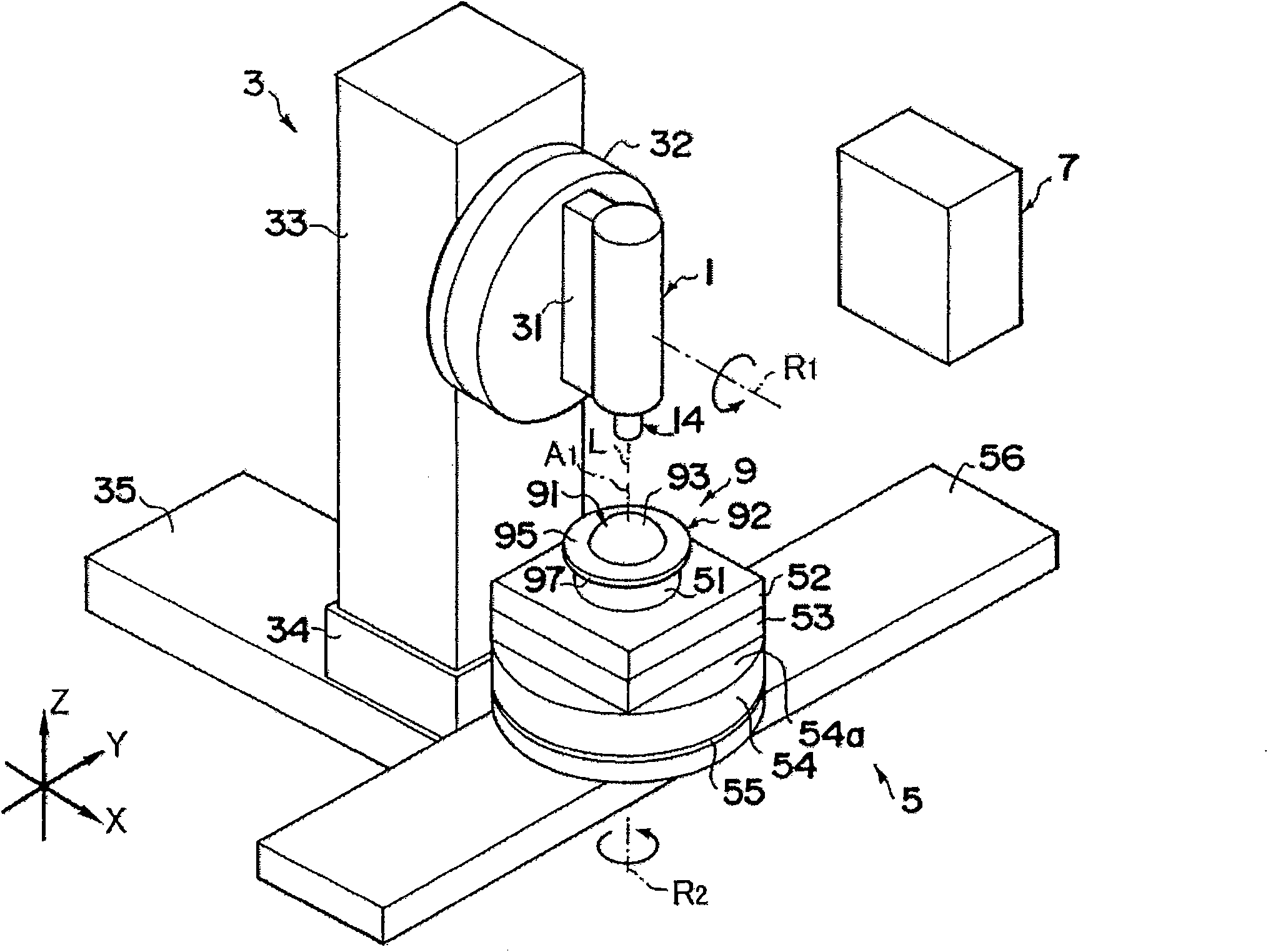

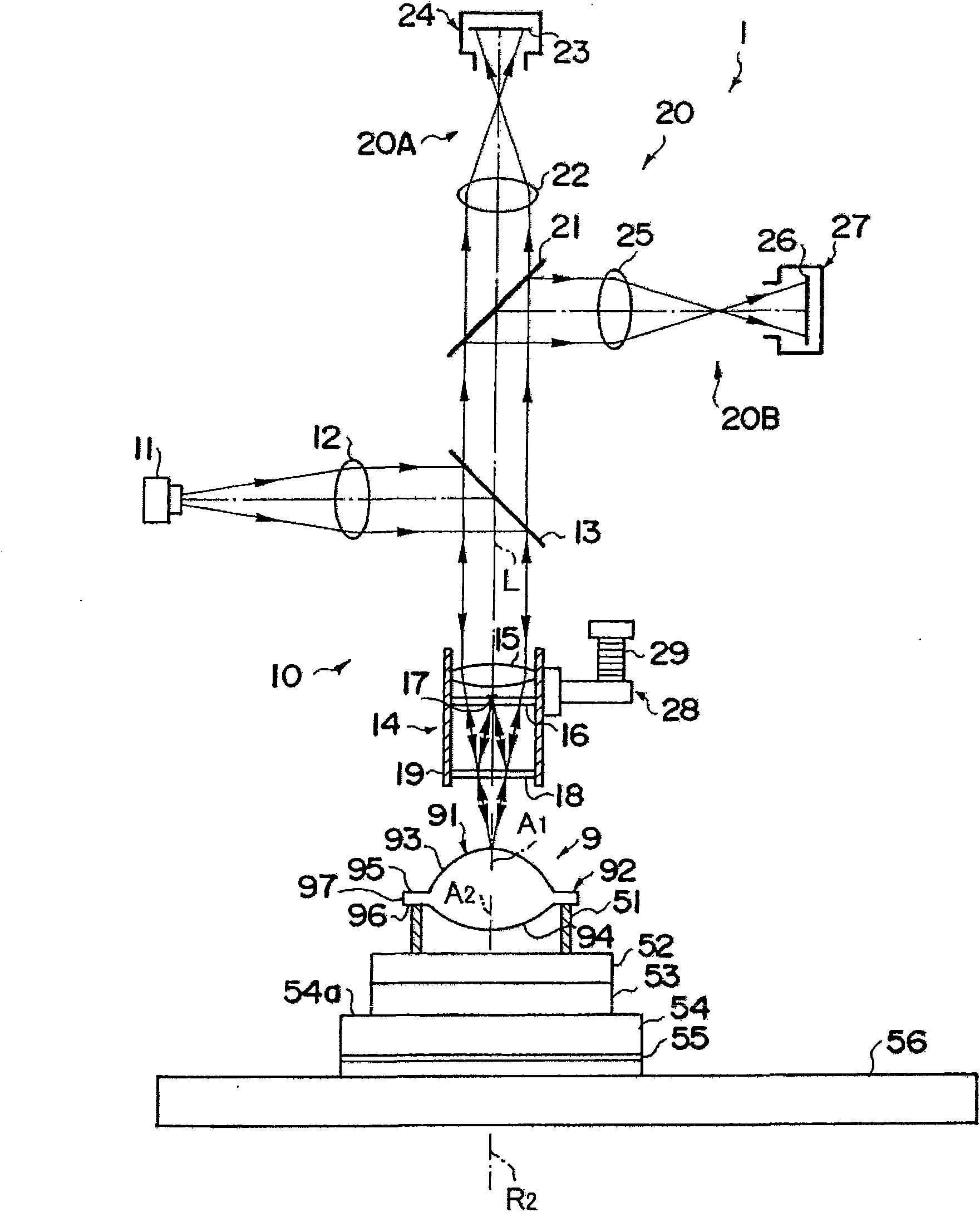

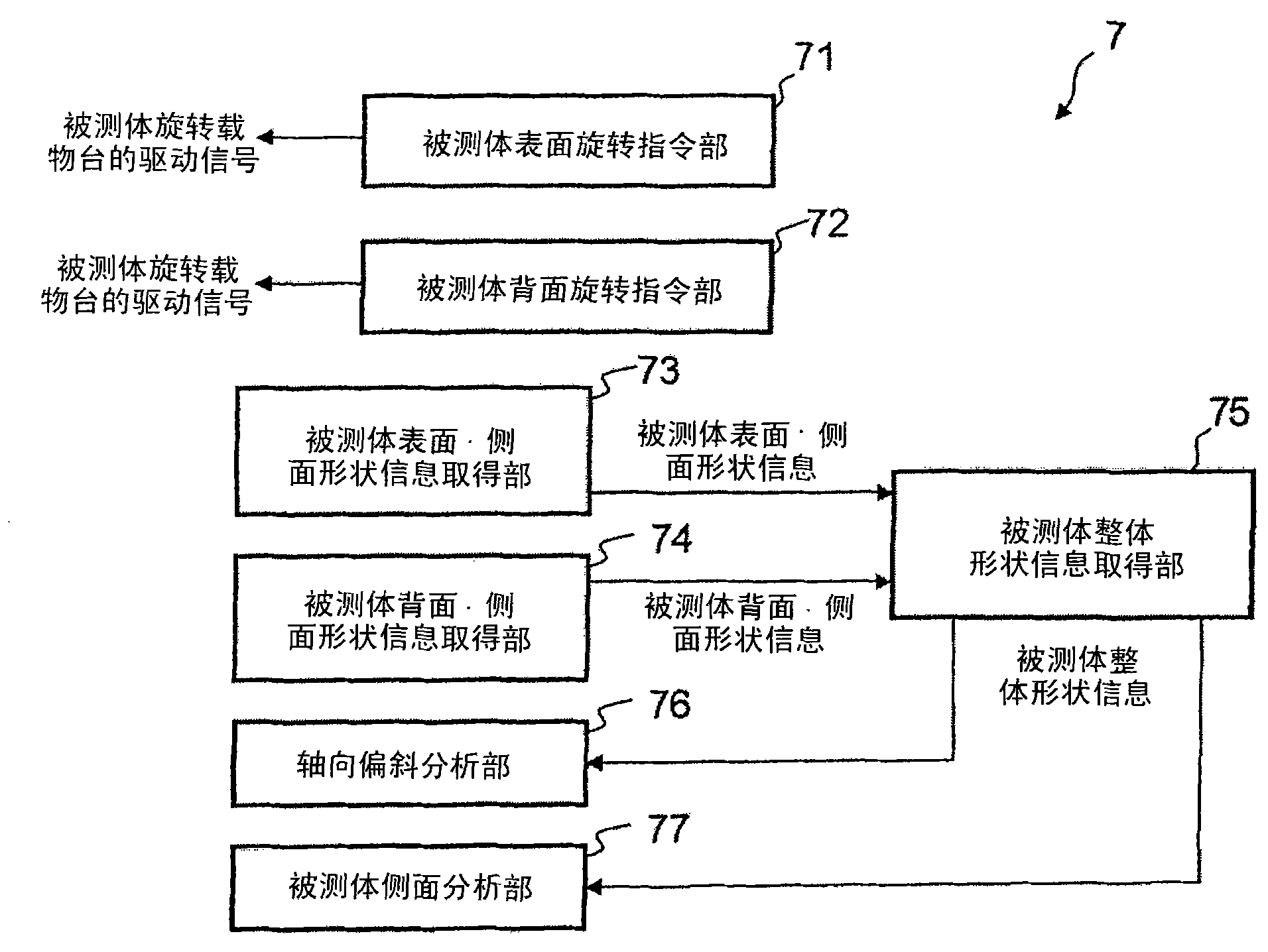

Three-dimensional shape measuring method and device

InactiveCN101915554AHigh precision measurementAccurate graspUsing optical meansOptical axis determinationEngineeringThree dimensional shape

A process of measuring a shape while changing the relative posture of an microscopic interferometer (1) to a sample lens (9) which is rotated about a rotation axis (R2) is divided into a process of measuring a top surface in a state where the sample lens (9) is supported from a back surface and a process of measuring a back surface in a state where the sample lens is supported from the top surface. By combining first shape information of a flange side surface (97) acquired by the process of measuring the top surface and second shape information of the flange side surface (97) acquired by the process of measuring the back surface, the relative positional relation between the sample top surface and the sample back surface is calculated.

Owner:FUJI PHOTO OPTICAL CO LTD

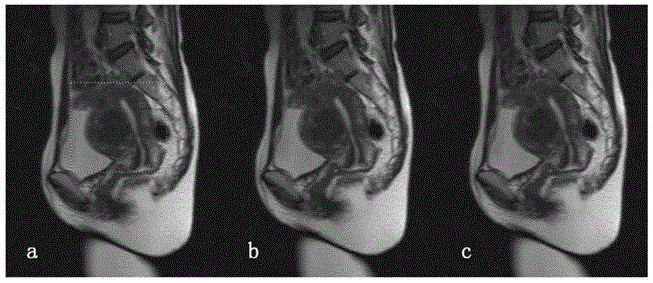

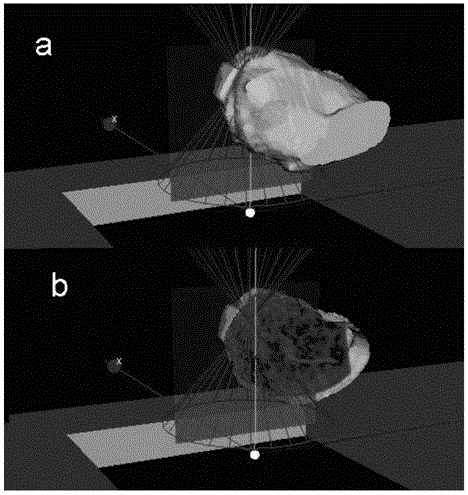

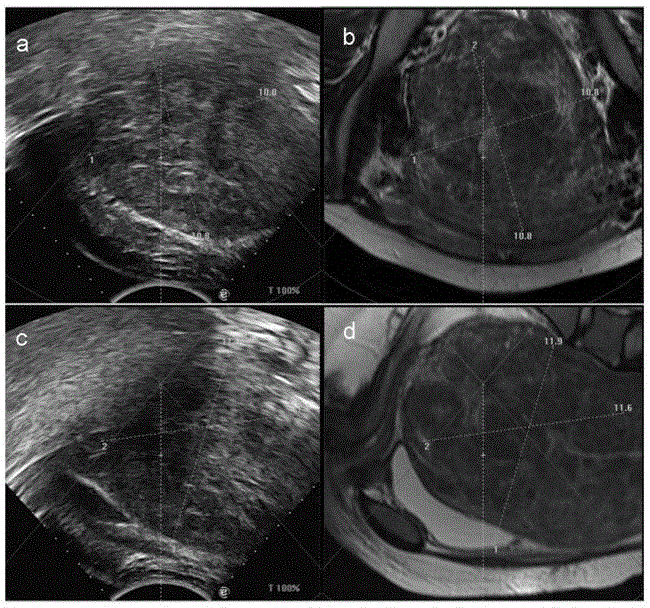

Construction method and device of three-dimensional model, image monitoring method and device

InactiveCN105078514APrecise registrationEnable mobilityImage analysisOrgan movement/changes detectionDimensional modelingComputer vision

Owner:CHONGQING HAIFU (HIFU) TECHNOLOGY CO LTD

LED (Light Emitting Diode) integrated structure, manufacturing method, lamp, display screen, backlight device, projecting device and injection mould of forming plastic part

InactiveCN101963295AReduce distanceRealize high-definition image displayPlanar light sourcesPoint-like light sourceLuminous fluxLight-emitting diode

The invention relates to an LED (Light Emitting Diode) integrated structure comprising a radiating base plate, an LED chip, a lens, a plastic piece of a positioning lens or a forming lens, a conducting wire and a layout circuit conducting layer, wherein two or more than two chip fixing lug bosses which are integrally formed with the radiating base plate are arranged on the radiating base plate, a first through hole of the positioning lens or the forming lens is arranged on the plastic piece of the positioning lens or the forming lens, the chip fixing lug bosses are arranged in the first through hole, the layout circuit conducting layer is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses, one end of the conducting wire is electrically connected with the LED chip, and the other end of the conducting wire is electrically connected with the layout circuit conducting layer which is extended between the inside wall of the first through hole and the outside walls of the chip fixing lug bosses. The LED integrated structure has the advantages of low thermal resistance of an intermediate link, good heat radiating performance, accurate position relation of the lens and the chip, high luminous flux, simple structure, simple assembly, good radiating effect and good optical effect.

Owner:杨东佐

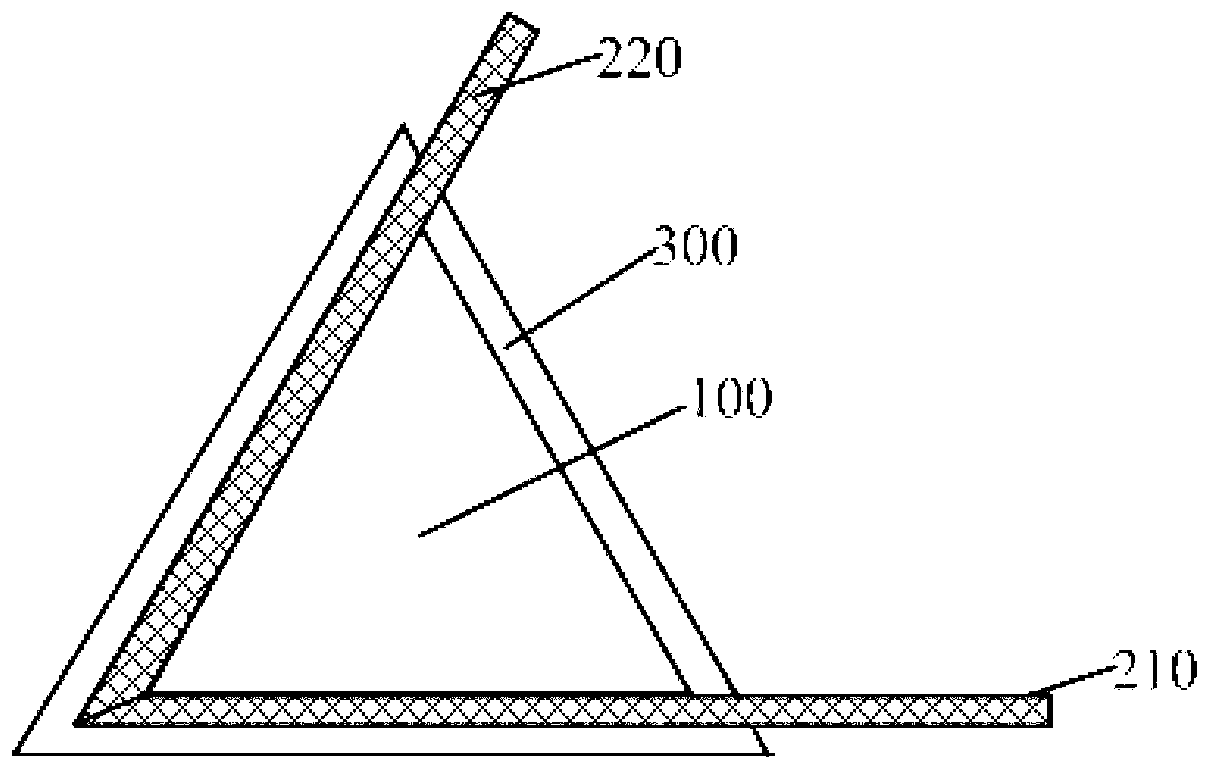

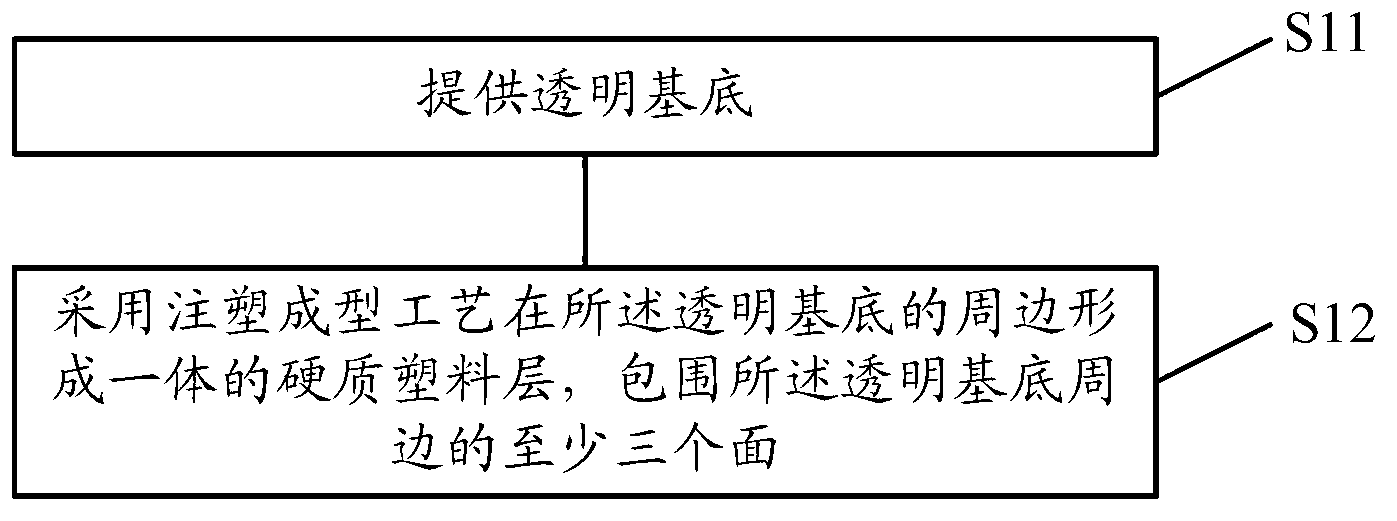

Car window assembly and binding method thereof

ActiveCN103057384AImprove adhesionImprove hemming efficiencyWindowsWindscreensEngineeringInjection moulding

Disclosed are a car window assembly and a binding method thereof. The car window assembly comprises a transparent base and an integrated hard plastic layer covering at least three peripheral sides of the transparent base. The binding method of the car window assembly includes: providing the transparent base; forming the integrated hard plastic layer on the periphery of the transparent base by injection molding to cover at least three peripheral sides of the transparent base. Bond between the plastic layer and glass in the car window assembly is higher, no dislocation occurs, binding efficiency is higher, and production cost is lowered.

Owner:SAINT-GOBAIN GLASS FRANCE

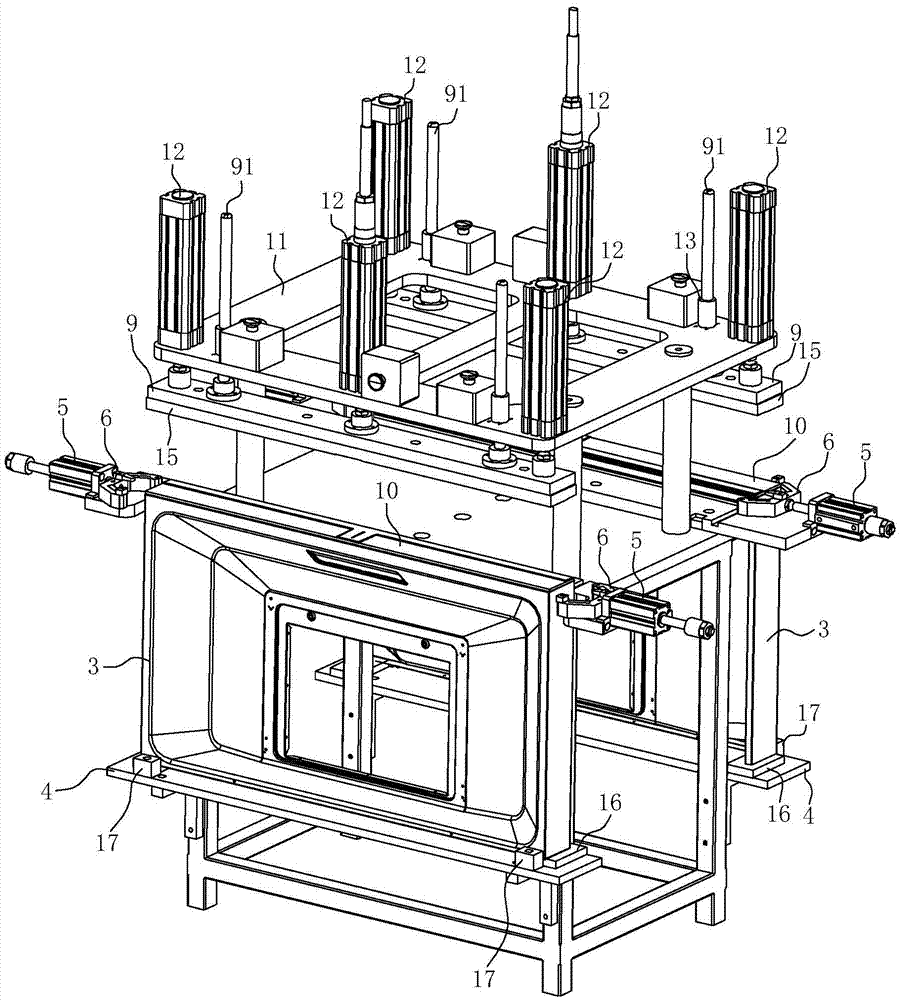

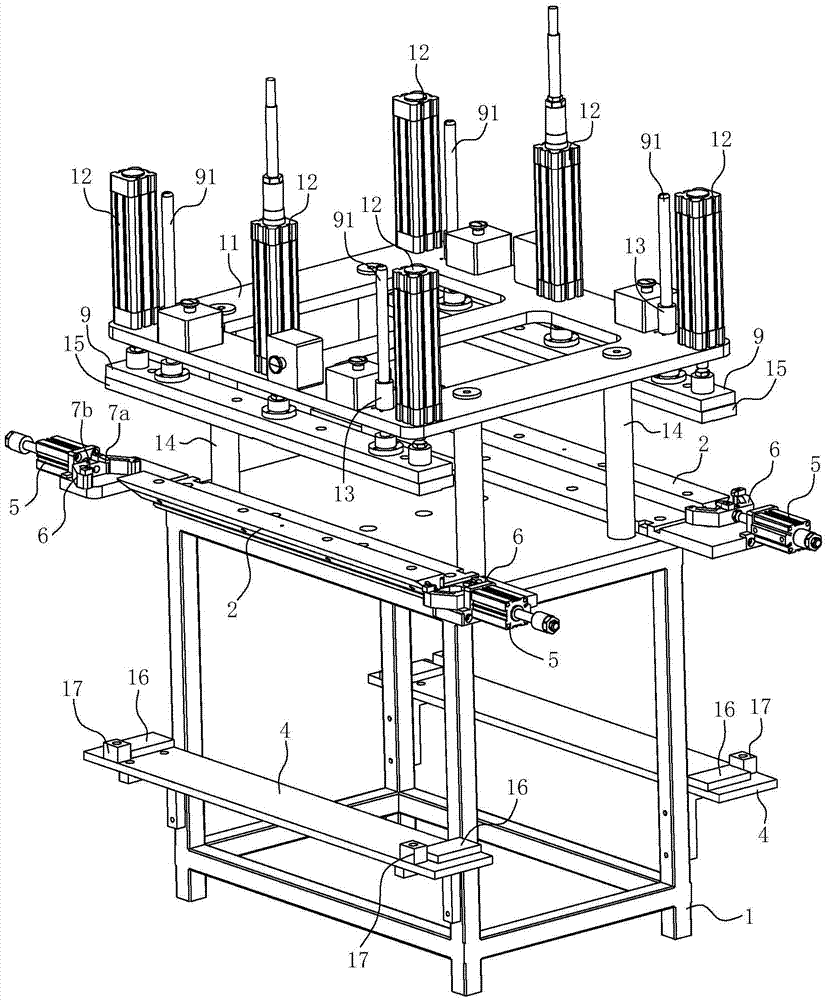

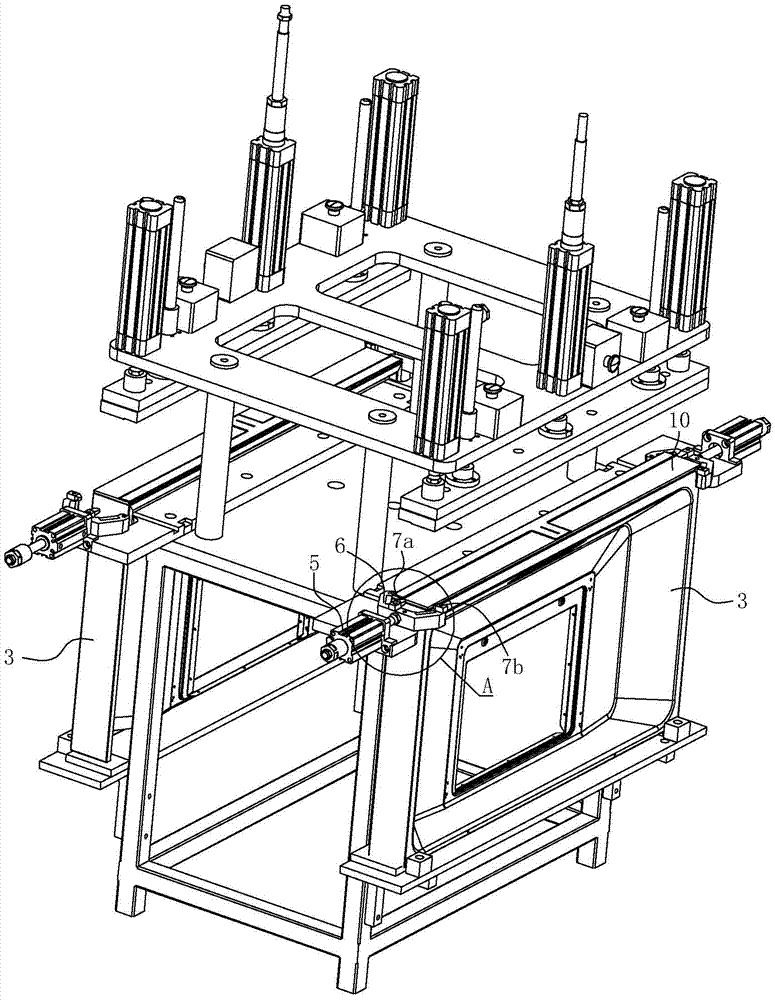

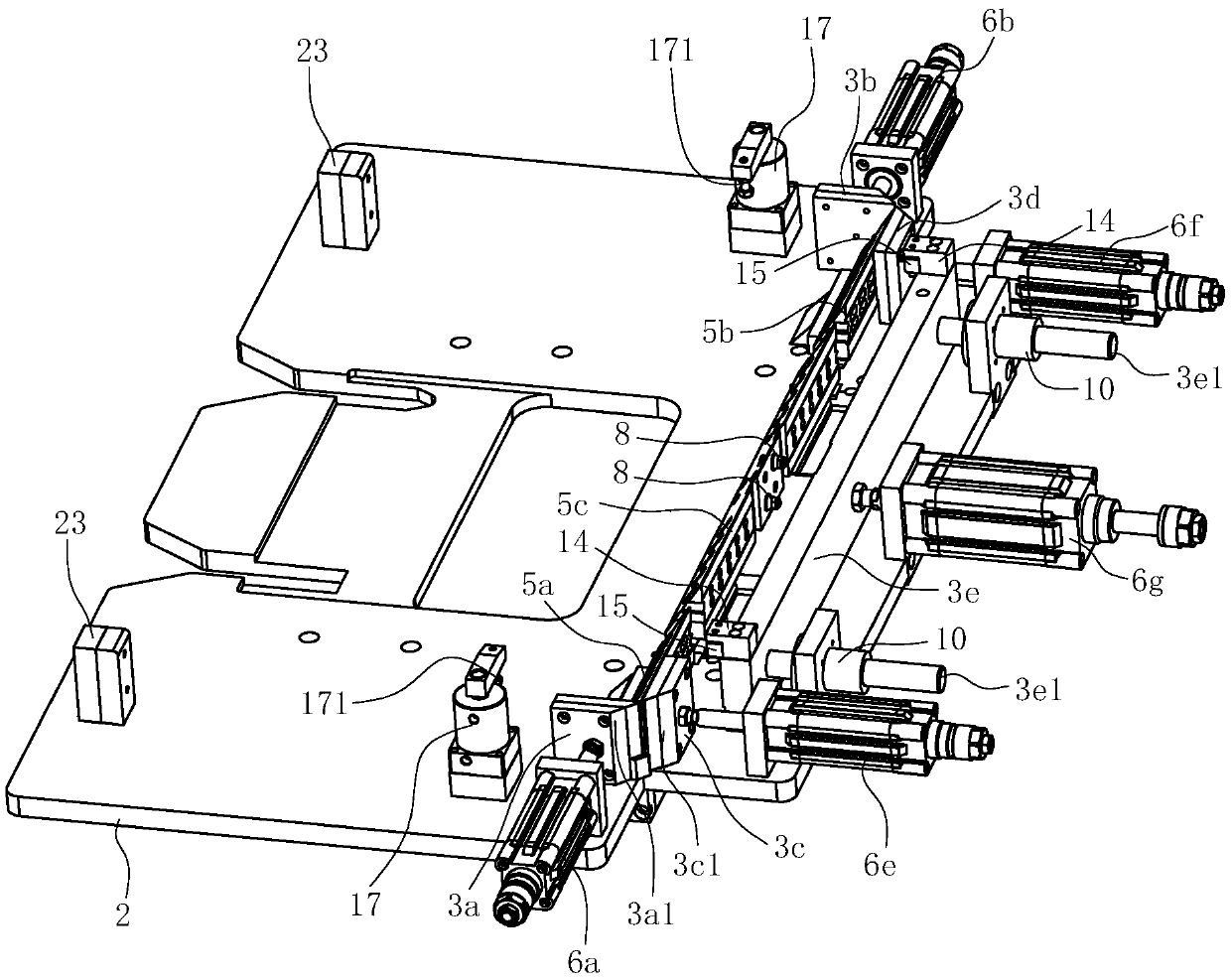

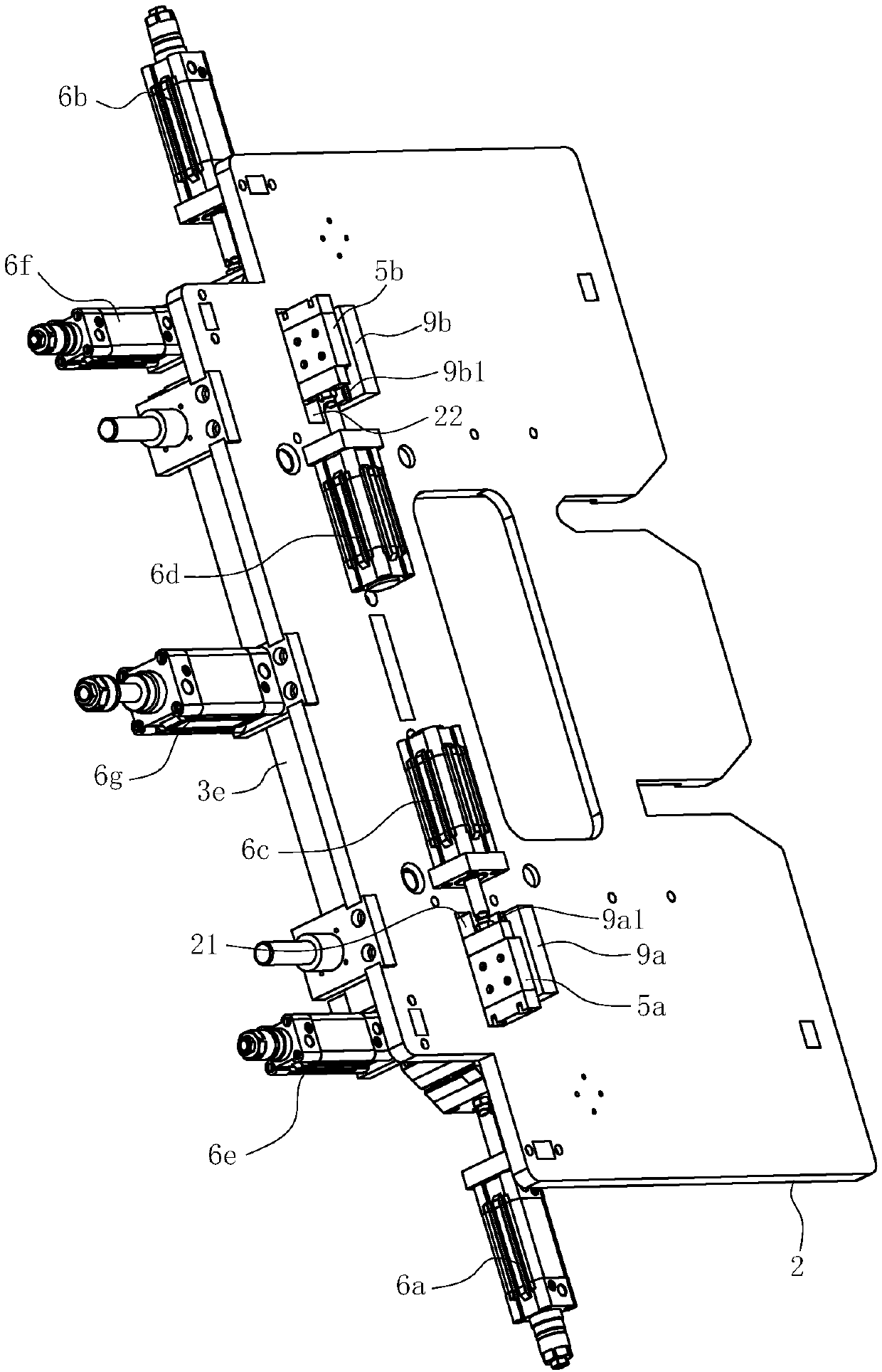

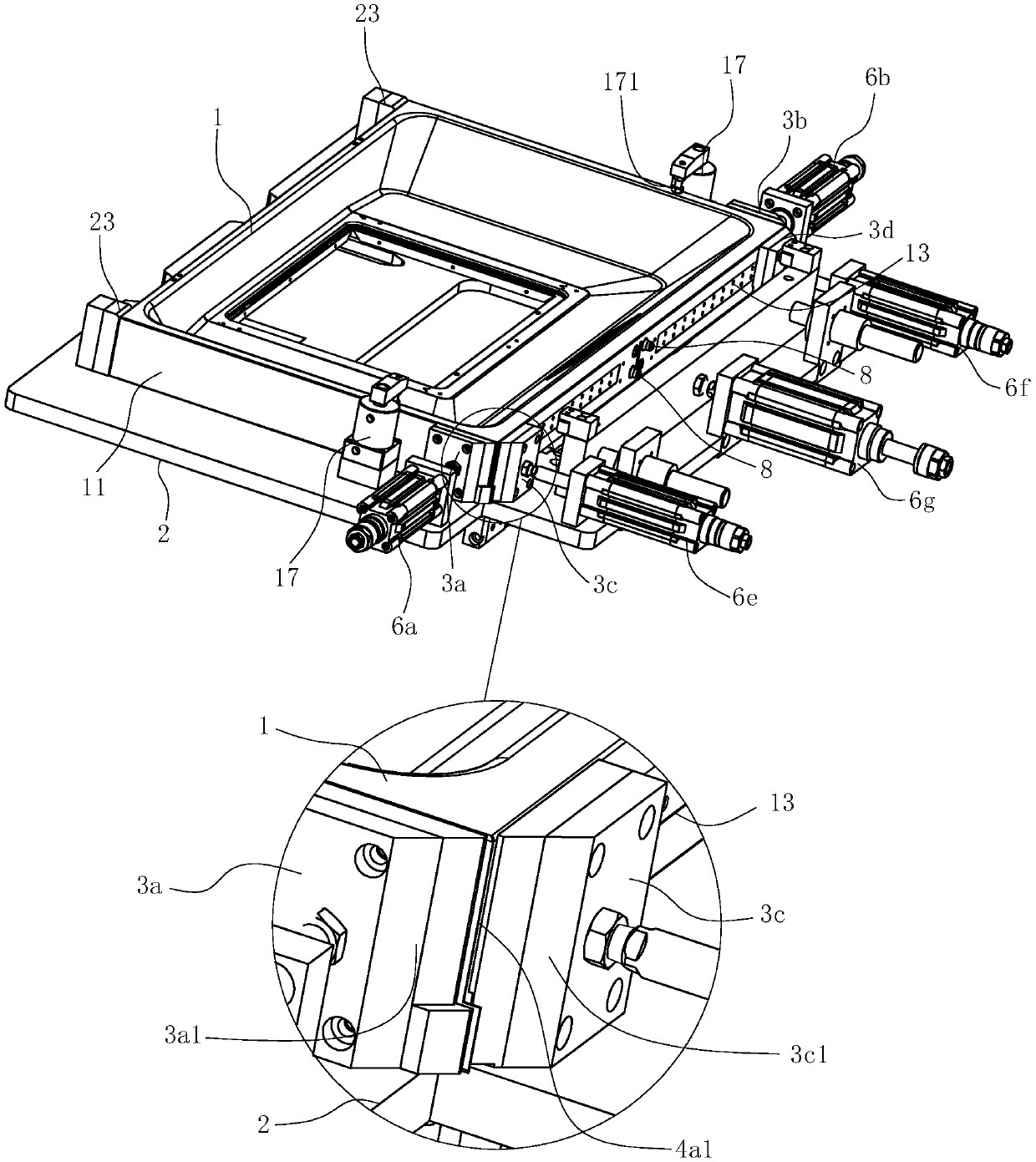

Adhering tool for adhering glass panel to exhaust fume collecting hood

The invention relates to an adhering tool for adhering a glass panel to an exhaust fume collecting hood. The adhering tool comprises a support, and an adhering structure is at least arranged on one side of the support. The adhering tool is characterized in that the adhering structure comprises an upper bearing board, a lower bearing board, two positioning air cylinders, an upper installation board and compression blocks, wherein locating detents are installed on piston rods of the positioning air cylinders and provided with horizontal arms and inclined arms; first positioning blocks are fixed to the horizontal arms; second positioning blocks are fixed to the ends of the inclined arms on at least one side; the upper installation board is fixed above the support; the upper installation board and a top board of the support are spaced vertically; the compression blocks are located over the upper bearing board and driven by a compression air cylinder to vertically and perpendicularly move; the compression blocks press downwards to compress the glass panel to the front end face of the exhaust fume collecting hood for pressure maintaining. The adhering tool has the advantages that structural design is reasonable, the glass panel adheres to the exhaust fume collecting hood accurately and firmly, the binding efficiency and precision are high, a few procedures are needed, and operation is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

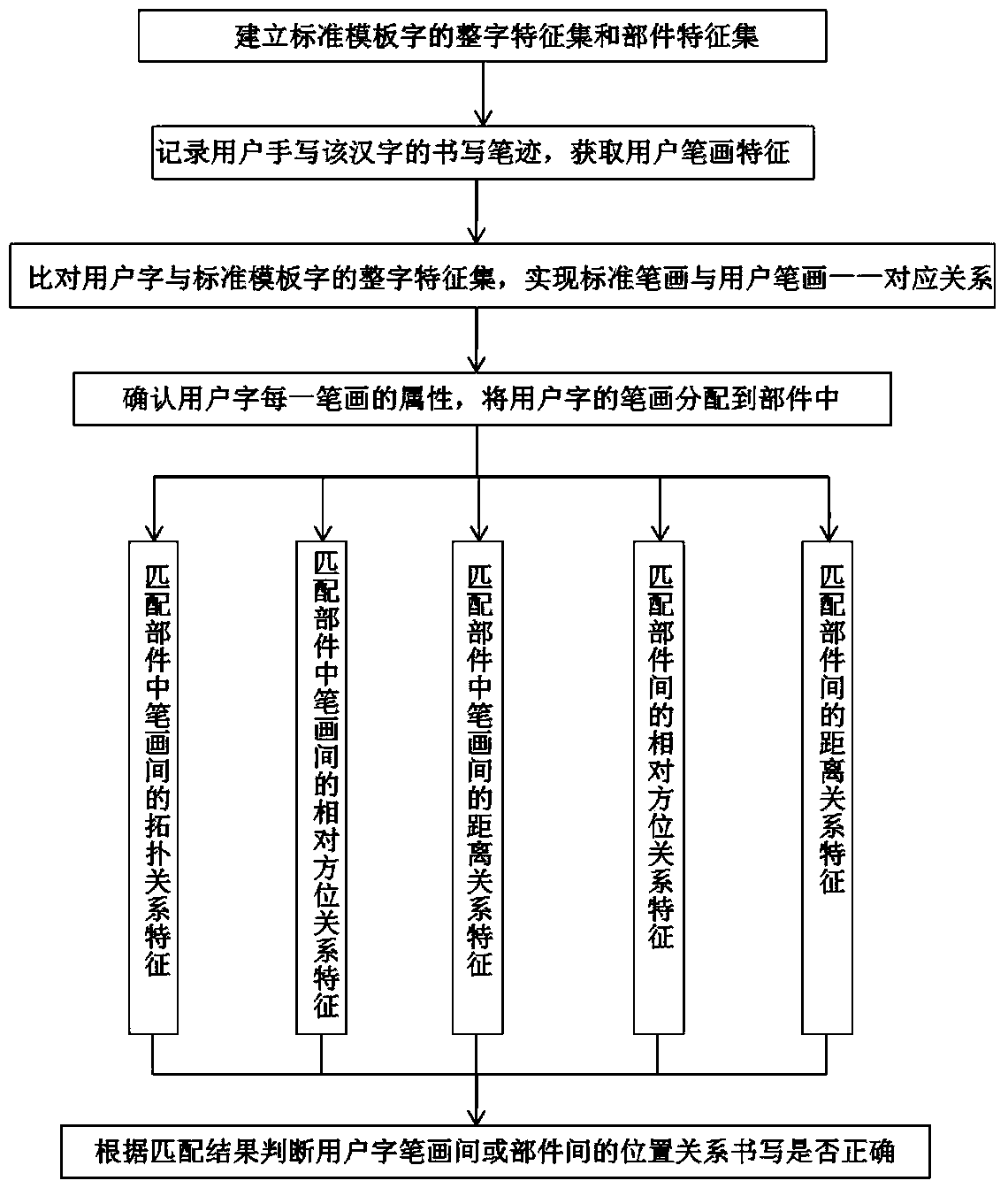

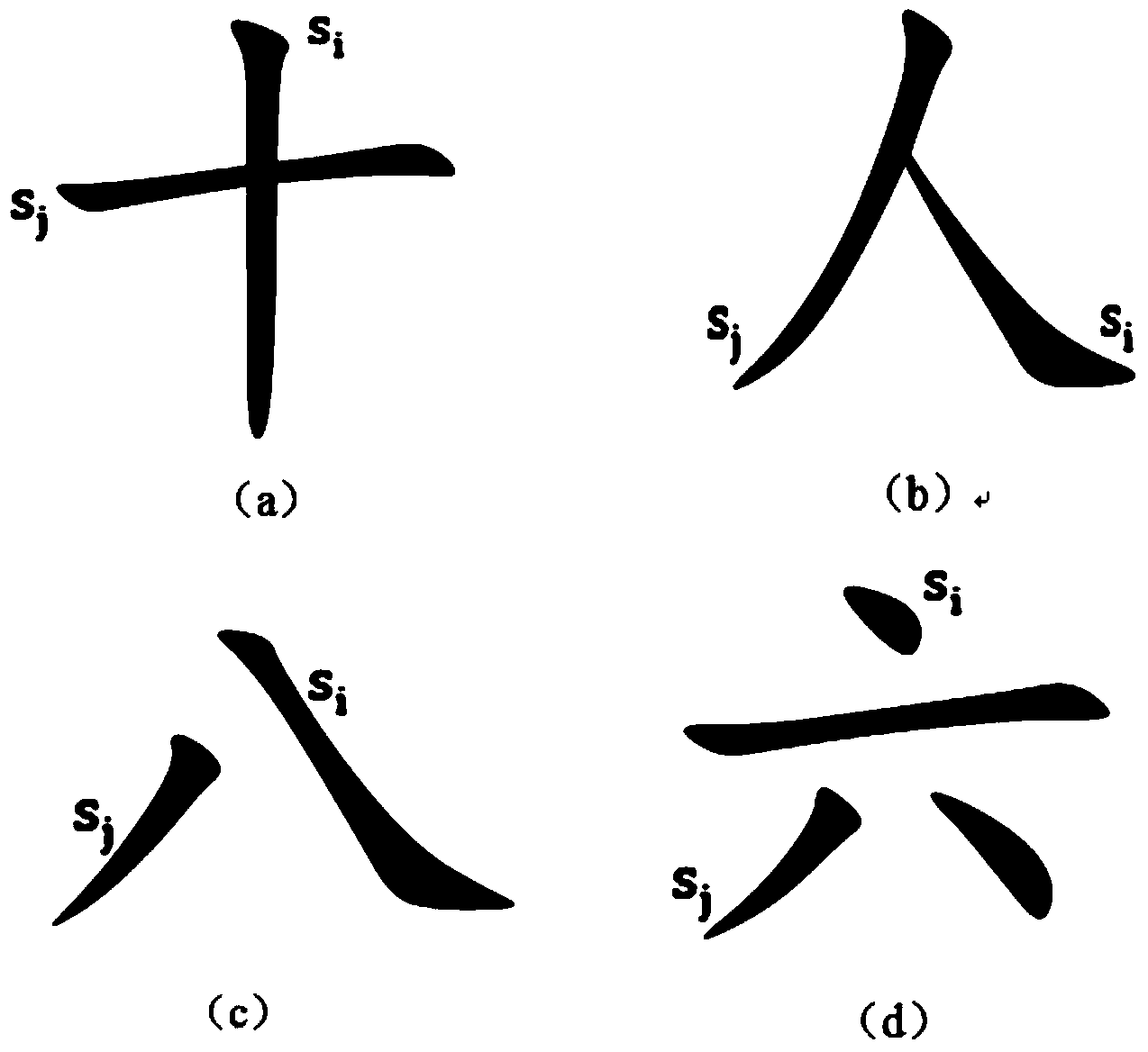

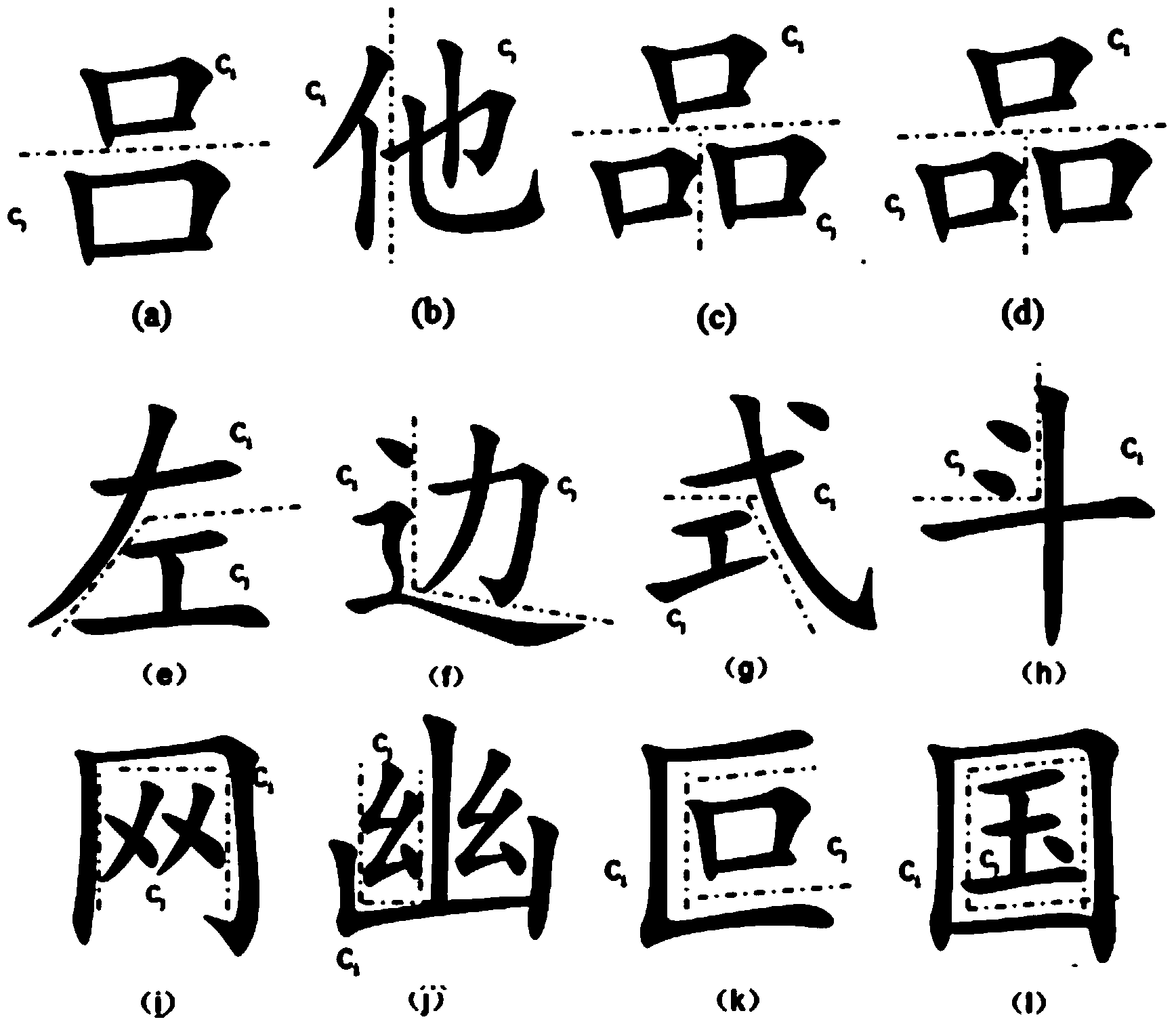

Method for judging correctness of position relation of strokes of handwritten Chinese character based on template matching

InactiveCN104182766ARealize judgmentStrong timelinessCharacter and pattern recognitionTemplate matchingFeature set

The invention discloses a method for judging the correctness of the position relation of strokes of a handwritten Chinese character based on template matching. The method comprises the specific steps of building a whole character feature set and a part feature set of a standard Chinese character; recording handwriting of the Chinese character handwritten by a user to obtain stroke features of the Chinese character; carrying out matching comparison on whole character features of the user Chinese character and whole character features of the standard Chinese character, building the one-to-one correspondence relation between the strokes of the user Chinese character and strokes of the standard Chinese character, confirming the attribute of each stroke of the user Chinese character, and distributing the strokes of the user Chinese character into parts to which the strokes belong; carrying out matching comparison on part features of the user Chinese character and part features of the standard Chinese character, judging whether the relative azimuth relation and the distance relation between the strokes in the parts of the user Chinese character are correct, and judging whether the relative azimuth relation and the distance relation between the parts of the user Chinese character are correct. The method can be used for judging whether the position relation between the strokes of the Chinese character handwritten by the user is correct and whether the position relation between the parts of the Chinese character handwritten by the user is correct and has important value in applications of judging the writing quality of the handwritten Chinese character and the like.

Owner:NANJING NORMAL UNIVERSITY

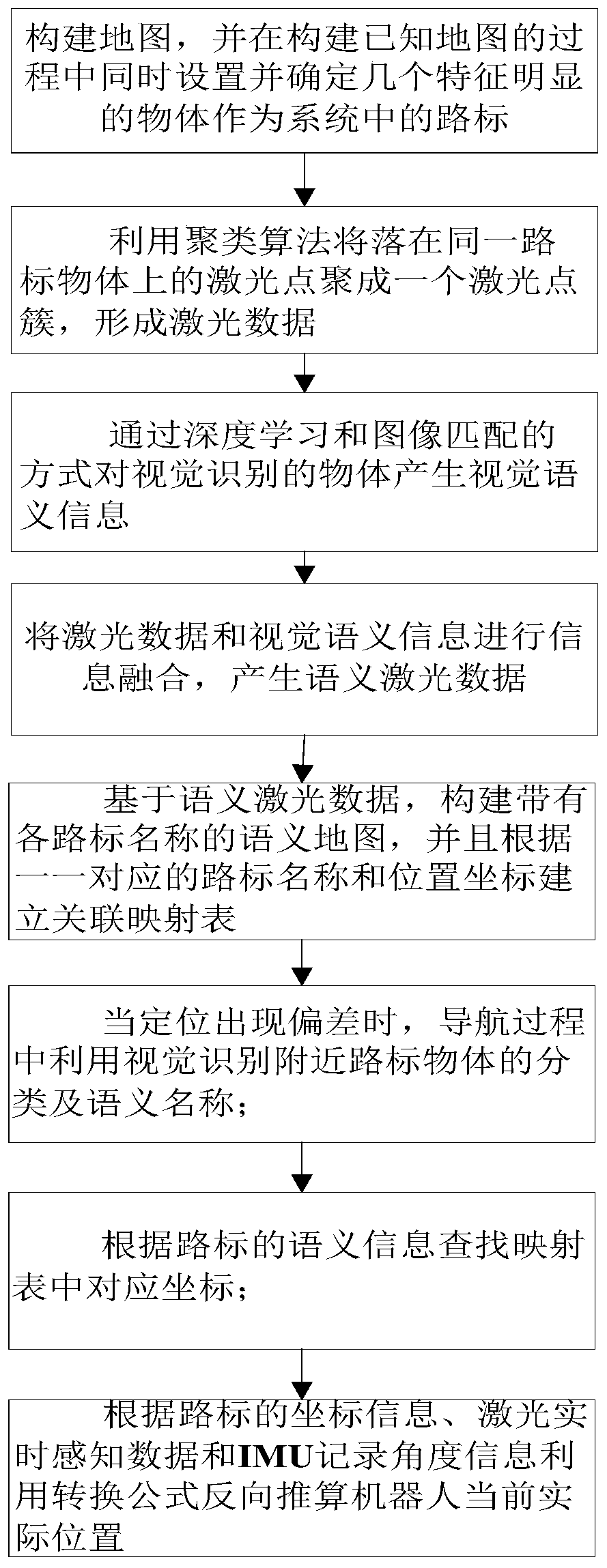

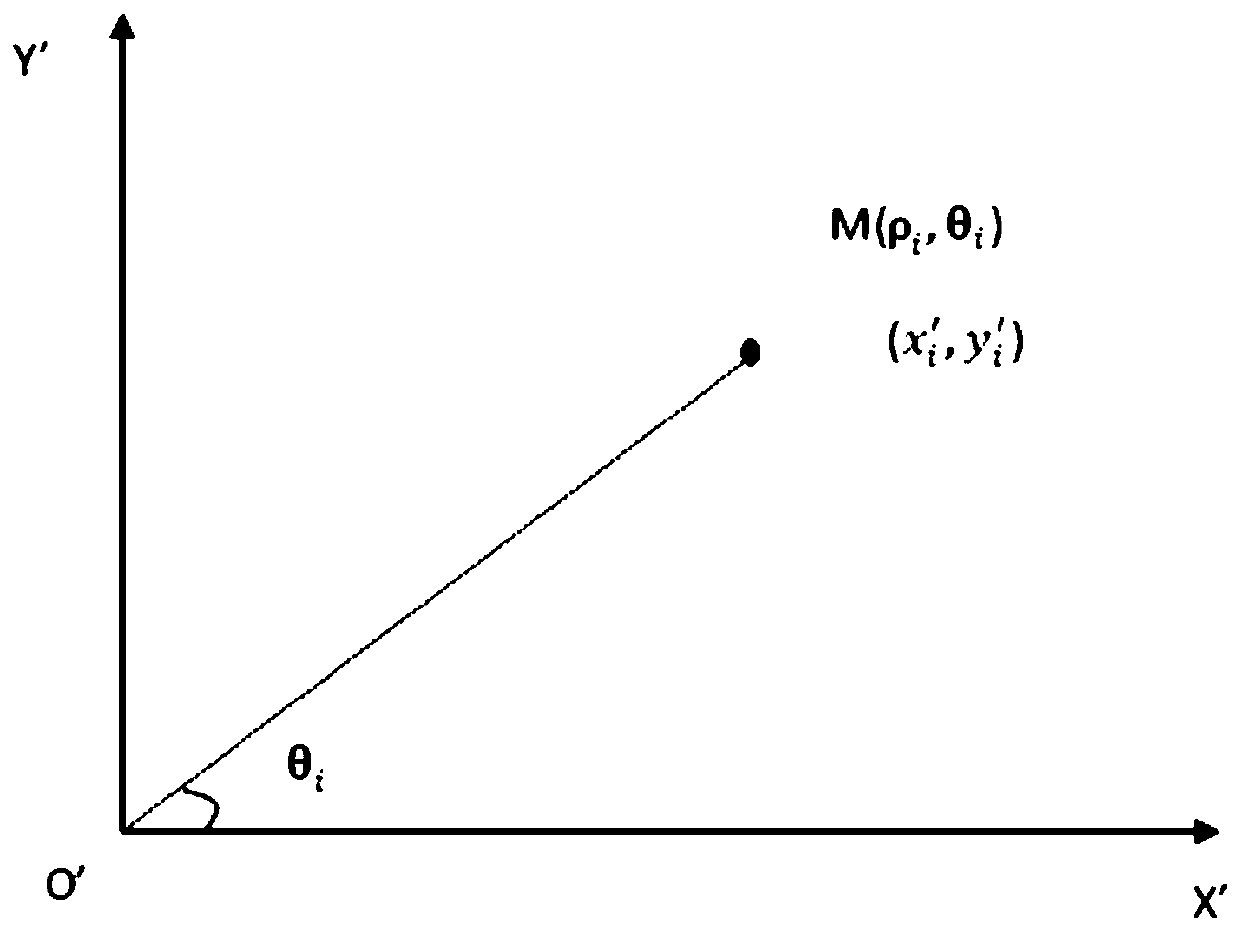

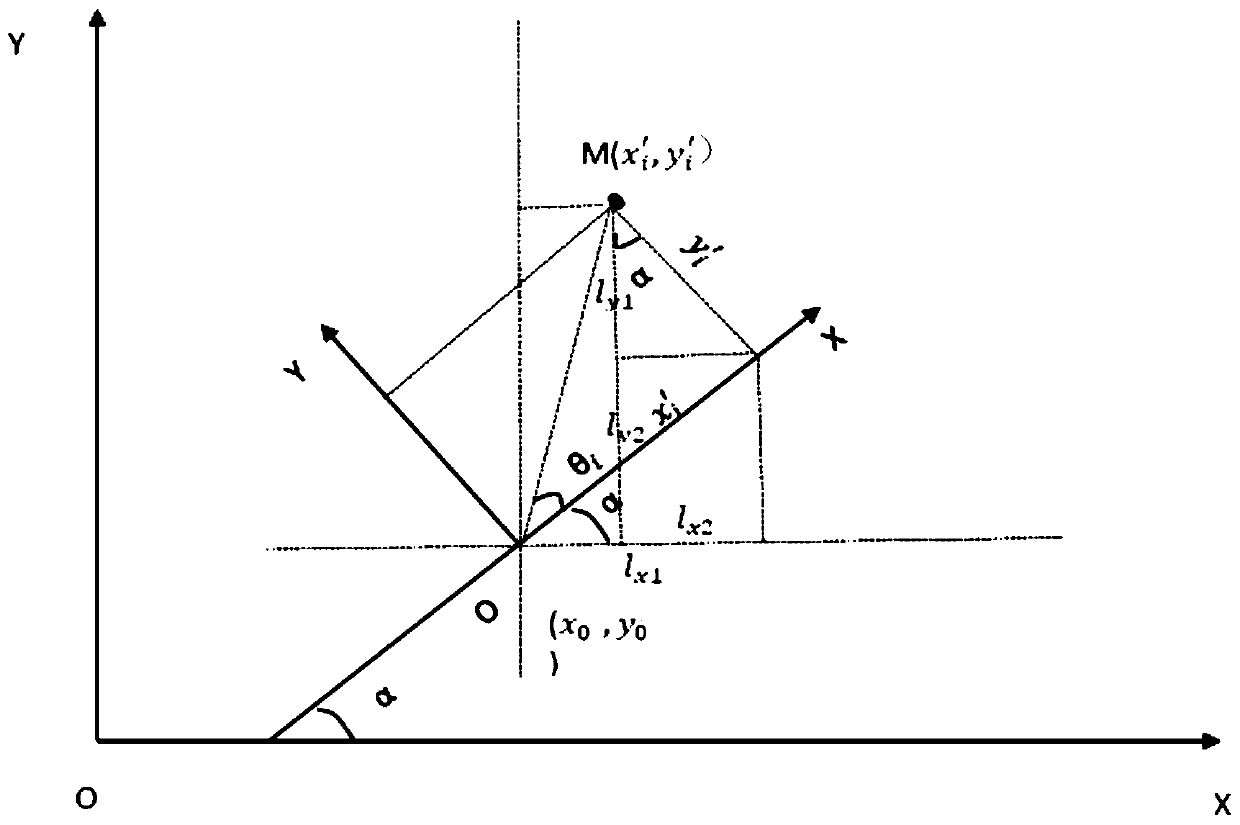

Robot relocation method based on landmark information and multi-sensor data fusion

InactiveCN110147095AAccurate positional relationshipPrecise pose correction effectPosition/course control in two dimensionsVehiclesPattern recognitionVisual recognition

The invention provides a robot relocation method based on landmark information and multi-sensor data fusion for the problem of positioning error in synchronous instant mapping and positioning, and aims to achieve the purposes of overcoming shortcomings and defects of positioning technique of existing robots in a complex environment. The objective of the invention is to incorporate visually recognized landmark information into laser-perceived data, and correspond the landmark marked with a semantic label to an accurate position information on the map, and then reversely calculate the true position of the robot on the map, thereby correcting the positioning error of the robot, improving positioning accuracy and repositioning ability of the robot in the autonomous navigation process, and enhancing position self-correcting level of the robot.

Owner:GUANGDONG UNIV OF TECH

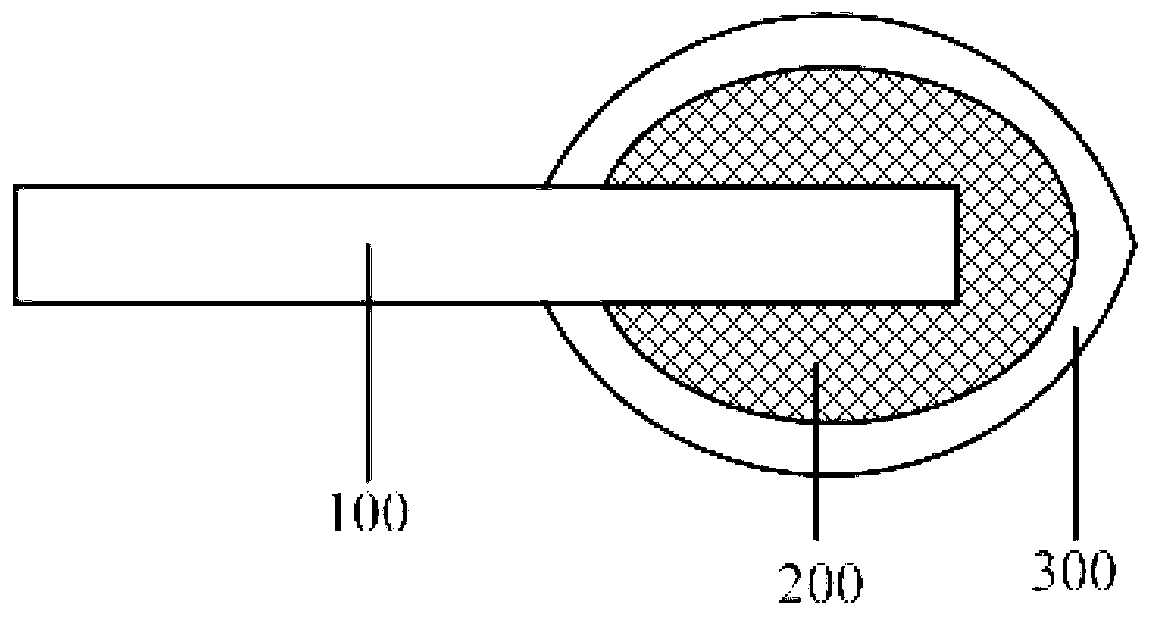

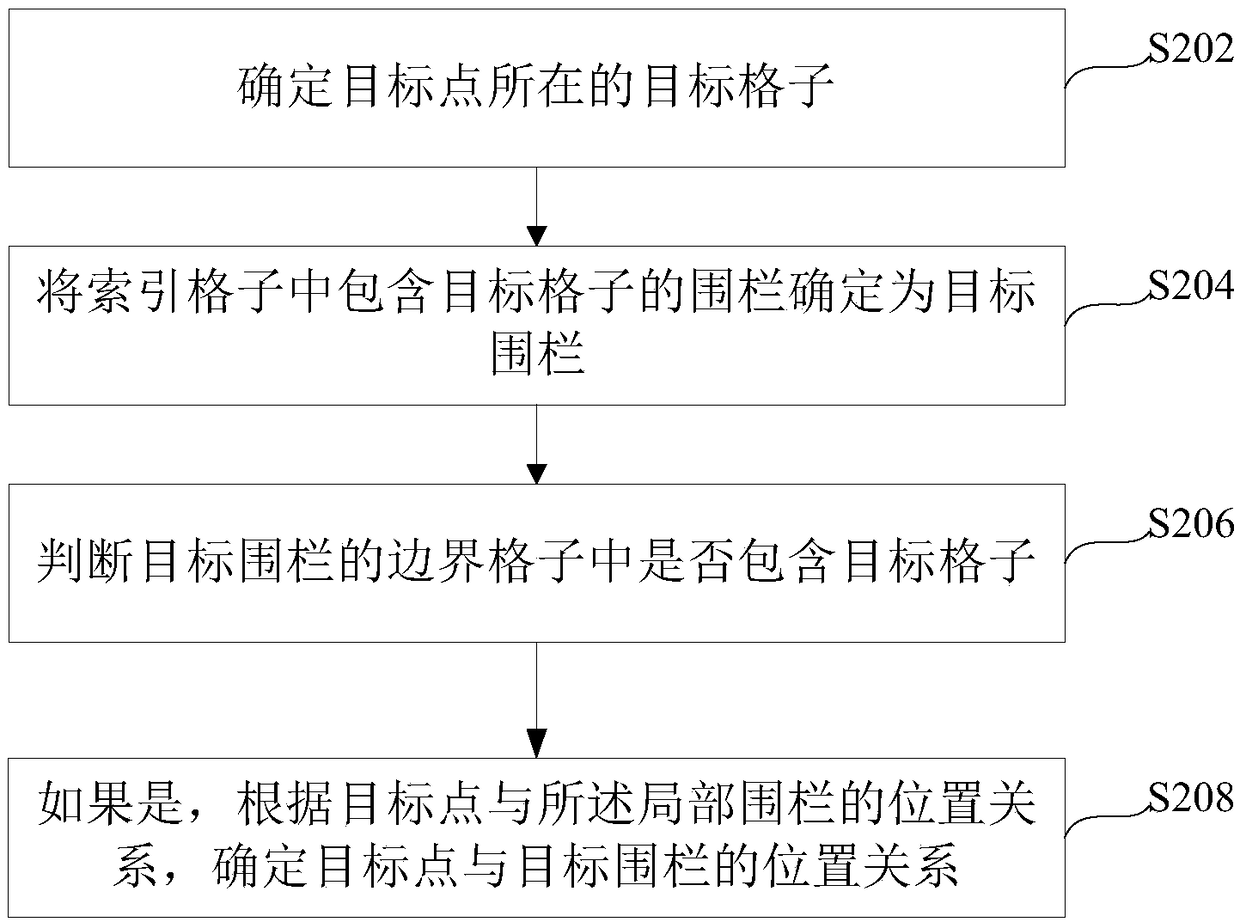

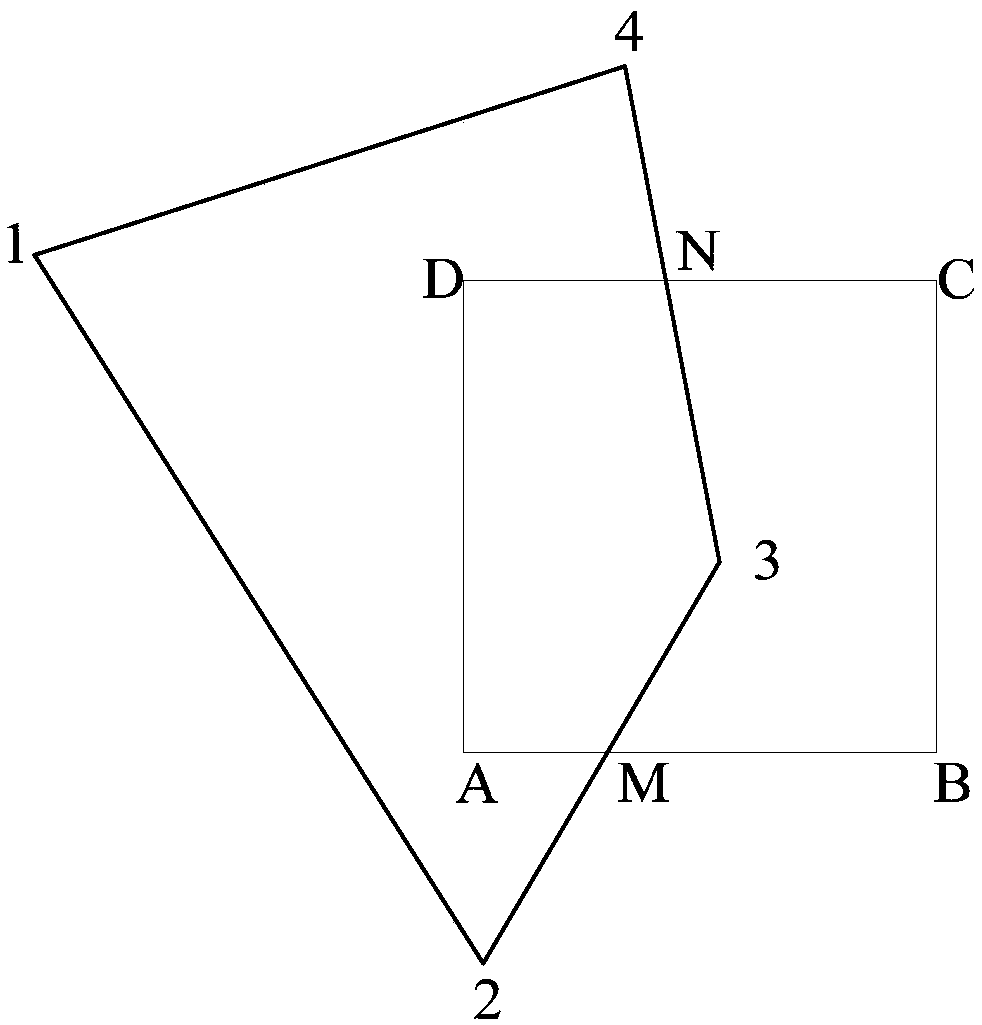

Method and device for determining relationship between point and fence and electronic device

ActiveCN108846882AAccurately determineImprove determination efficiencyDrawing from basic elementsGeographical information databasesAlgorithmElectrical and Electronics engineering

The present invention provides a method and a device for determining a relationship between a point and a fence and an electronic device, and relates to the technical field of data processing. The method includes the following steps: determining a target grid where a target point is located; determining a fence containing the target grid in an index grid as a target fence, wherein a fence object of the target fence includes a local fence which is an intersection area of a boundary grid of the target fence and the target fence; judging whether the target grid is included in the boundary grid ofthe target fence; and if the target grid is included in the boundary grid of the target fence, according to the positional relationship between the target point and the local fence, determining the positional relationship between the target point and the target fence. The method can improve the determination efficiency of the positional relationship between the point and the fence, and can also identify more accurately the relationship between the point and the fence.

Owner:BEIJING DIDI INFINITY TECH & DEV

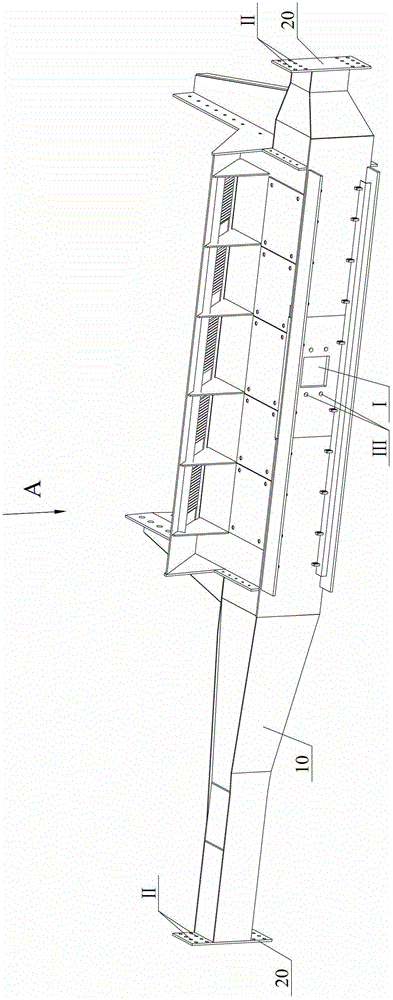

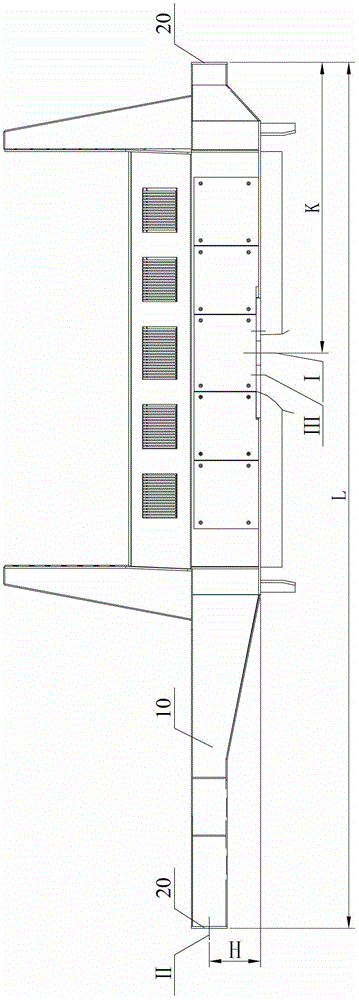

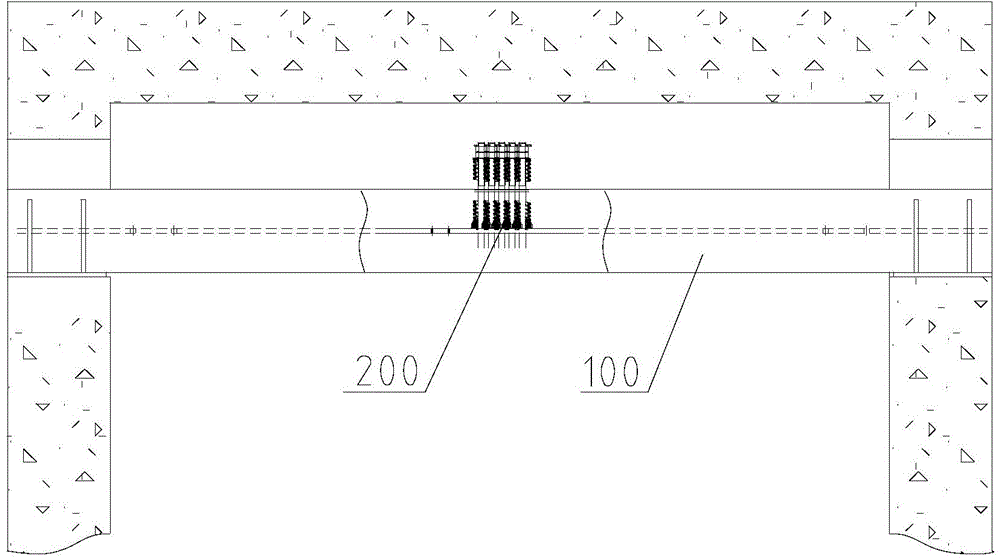

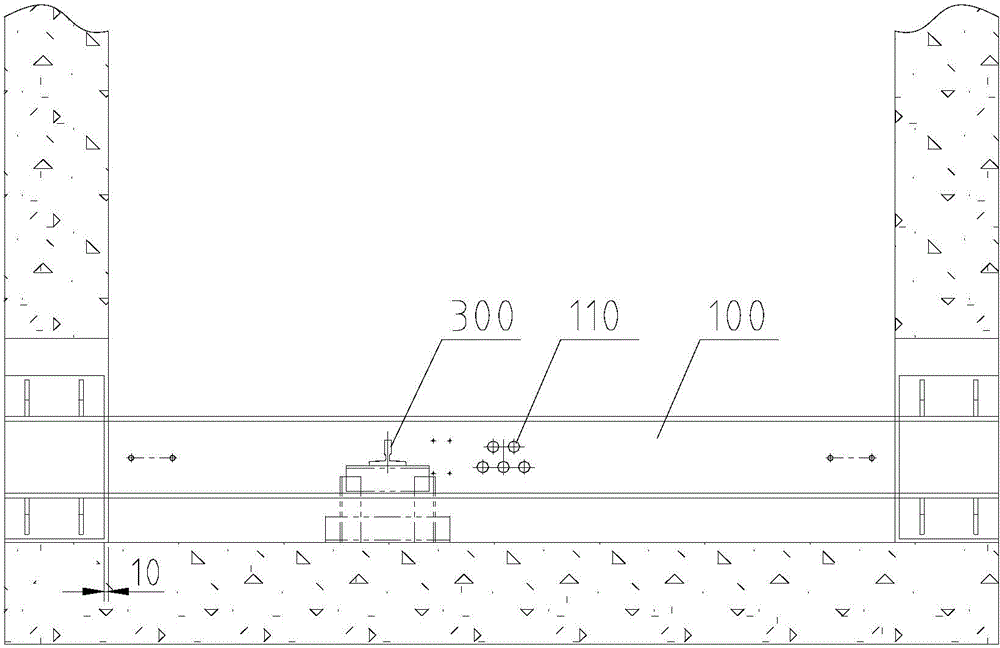

Processing technology and exclusive welding tool for annular cooler special-shaped beam

ActiveCN103143874AAvoid unqualifiedAvoid unqualified defectsWelding/cutting auxillary devicesAuxillary welding devicesShaped beamEngineering

The invention discloses an exclusive welding tool for an annular cooler special-shaped beam. A beam body bearing thereof is used to bear and position the beam body of the special-shaped beam; an upper surface thereof is provided with a first position limitation part adapted with an adapter positioning hole in the bottom of the beam body; two flange end plate bearings thereof are respectively used to bear the inside and outside flange end plates of the special-shaped beam; the opposing side surfaces of the two flange end plate bearings are respectively provided with a second position limitation part adapted with the flange hole group of the corresponding flange end plate; the height from the upper surface of the beam body bearing to the second position limitation part is consistent with the height from the bottom surface of the beam body to the flange hole group on the corresponding flange end plate; and the lengths from the first position limitation part on the beam body bearing to the opposing side surfaces of the two flange end plate bearings are respectively consistent with the lengths from the adapter positioning hole in the bottom of the beam body to the flange surfaces of the inside and outside flange end plates. The exclusive welding tool greatly improves operating efficiency while ensuring processing accuracy for the special-shaped beam. Based on the exclusive welding tool, the invention also provides a processing technology for an annular cooler special-shaped beam.

Owner:HUNAN ZHONGZHI CHANGTIAN HEAVY IND TECH

Vegetable dehydrator with elastic dialing mechanism

InactiveCN101744352AImprove operational reliabilitySmooth left and right alternate positionsFood treatmentEngineeringSprocket

The invention provides a vegetable dehydrator with an elastic dialing mechanism, comprising a tank body, transmission devices, conveying devices, radiation devices and guide rails, wherein a set of conveying device driven by the transmission devices is arranged in each layer of drying tank, each conveying chain plate is supported on each guide rail to form a groove-shaped material channel, each radiation device is arranged above each channel, material guiding grooves are arranged below the tail ends of the channels, the top of the tank body is provided with a material inlet, and the bottom of the tank body is provided with a material outlet. The vegetable dehydrator is characterized in that the conveying device in each layer is provided with an elastic dialing mechanism between two movable conveying chain wheels, both ends of a pin shaft provided with a rolling body are fixed on a U-shaped frame, one end of a telescopic rod, having a large diameter, is fixed at the outer side of the bottom of the U-shaped part, the small end of the telescopic rod, which is sleeved with a spring at the outside, is inserted in a small hole in the outer vertical wall of a support and is fixed through nuts, a spacing plate is clamped between the two nuts through the other nut, and one side face of the spacing plate is attached with the plane on the groove bottom of the support. The vegetable dehydrator can ensure the alternative conversion of each conveying chain plate and reliably turn over blanks.

Owner:SHANDONG UNIV OF TECH

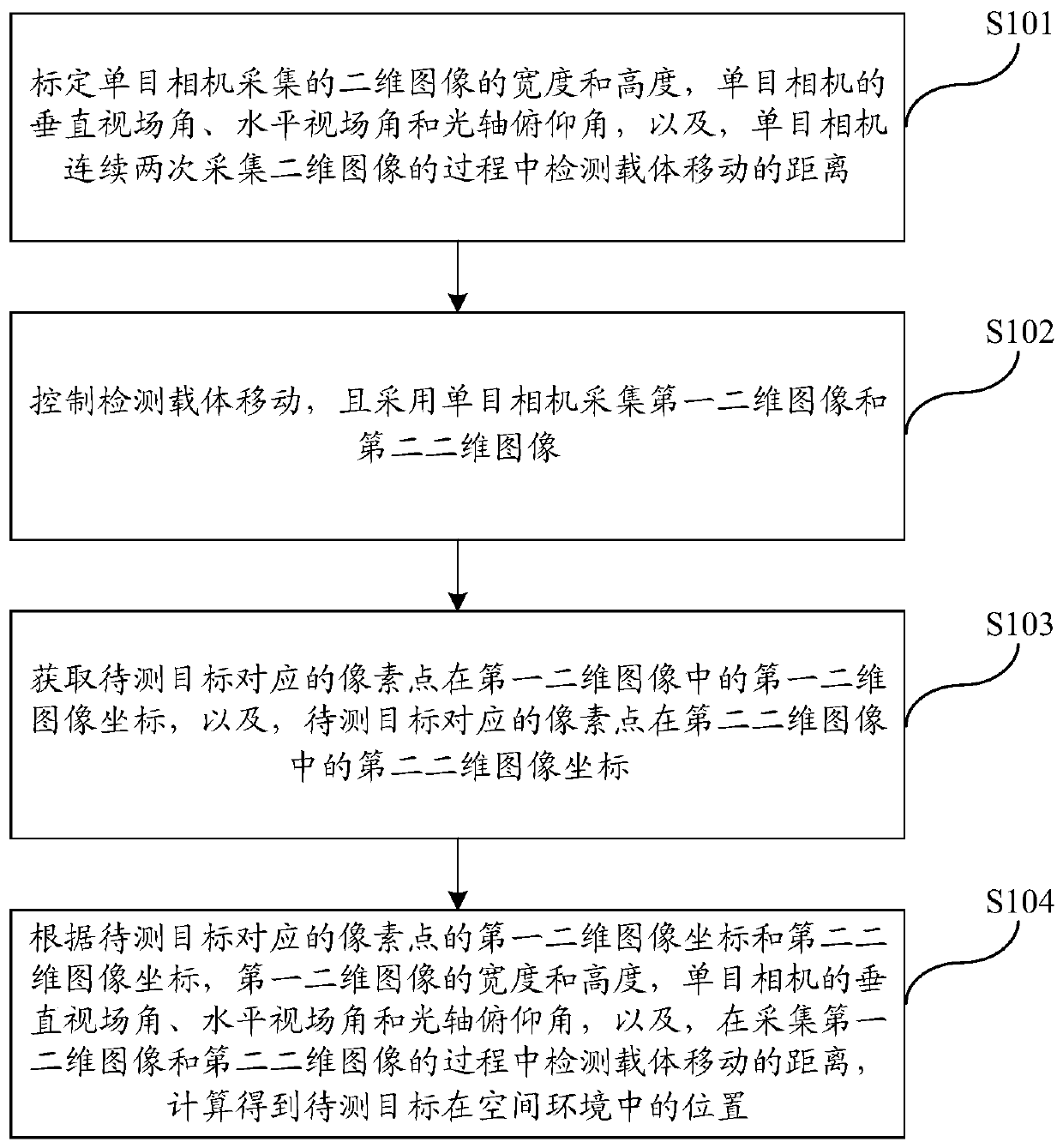

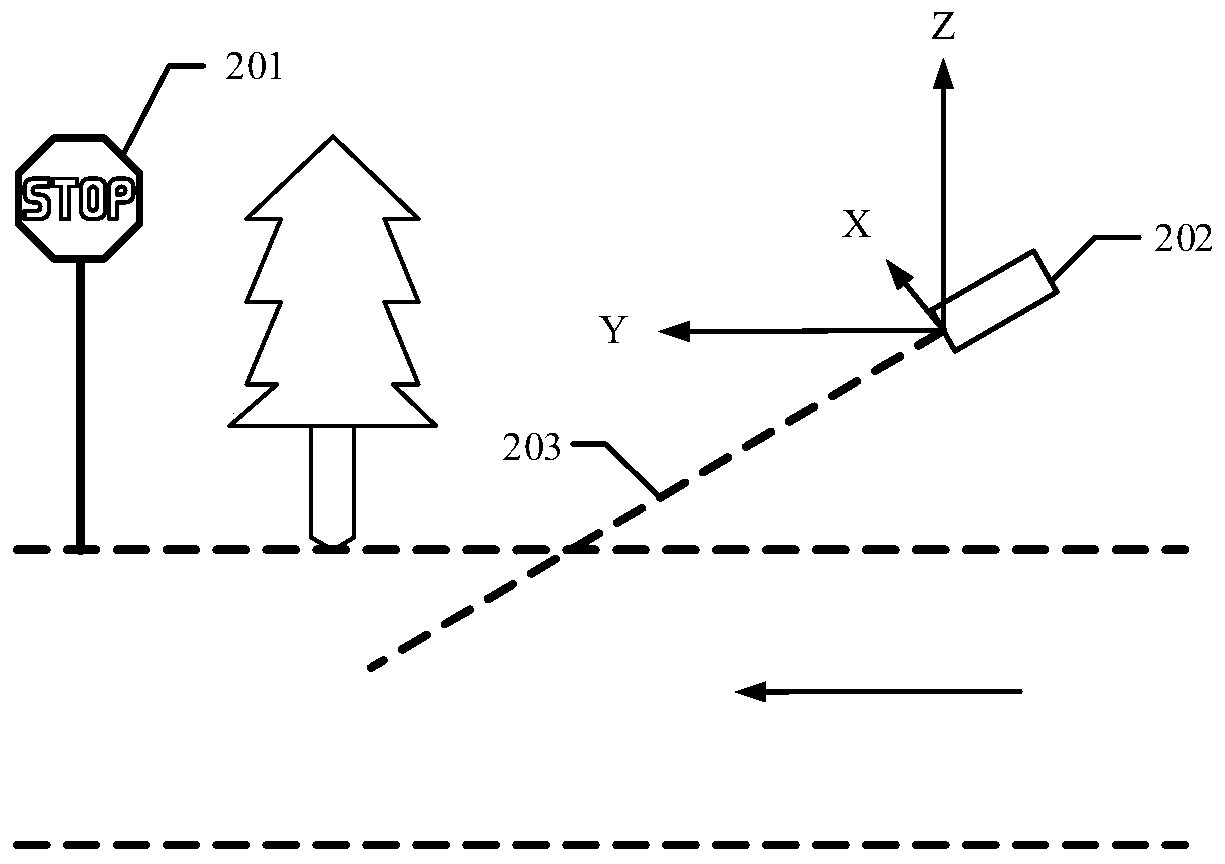

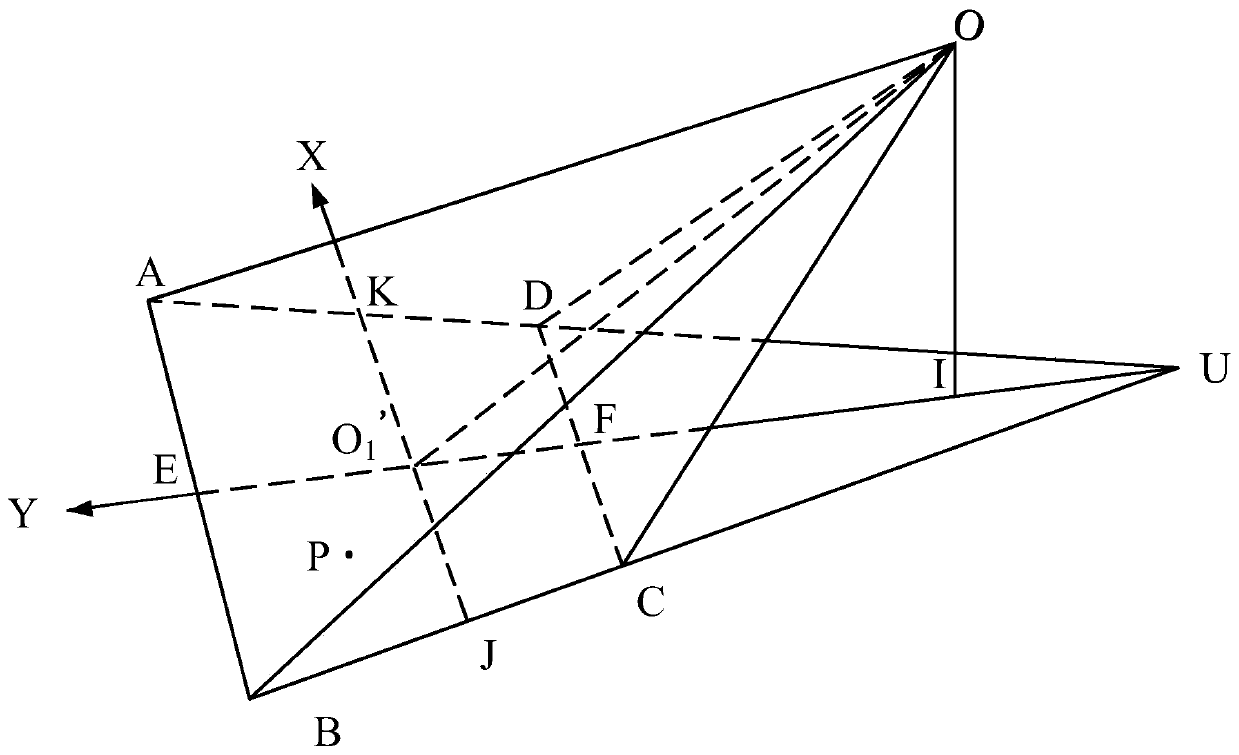

Photogrammetry method and system based on monocular camera

ActiveCN109764858AAccurate positional relationshipPhotogrammetry/videogrammetrySpace environmentOptical axis

The invention discloses a photogrammetry method and system based on a monocular camera. The photogrammetry method comprises the steps that the width and height of two-dimensional images acquired by the monocular camera, the vertical field of view angle, the horizontal field of view angle and the optical axis pitch angle of the monocular camera as well as the moving distance of a detection carrierin the process that the monocular camera acquires the two-dimensional image for two consecutive times are calibrated; the detection carrier is controlled to move, and the first two-dimensional image and the second two-dimensional image acquired by the monocular camera are adopted; first two-dimensional image coordinates of pixel points corresponding to a target to be measured in the first two-dimensional image and second two-dimensional image coordinates of pixel points corresponding to the target to be measured in the second two-dimensional image are acquired; and calculating is carried out to obtain the position of the target to be measured in the space environment. According to the photogrammetry method and system, the spatial position of any target in the monocular camera visual fieldcan be accurately obtained without specifying a reference object, and the application scene is wide.

Owner:ROADMAINT CO LTD +1

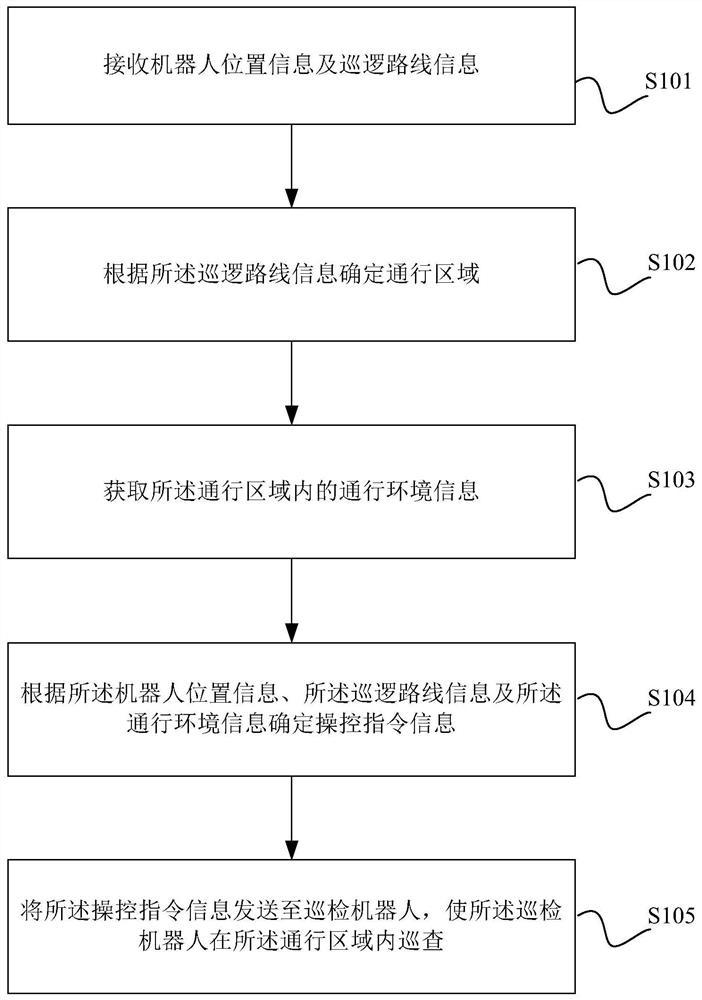

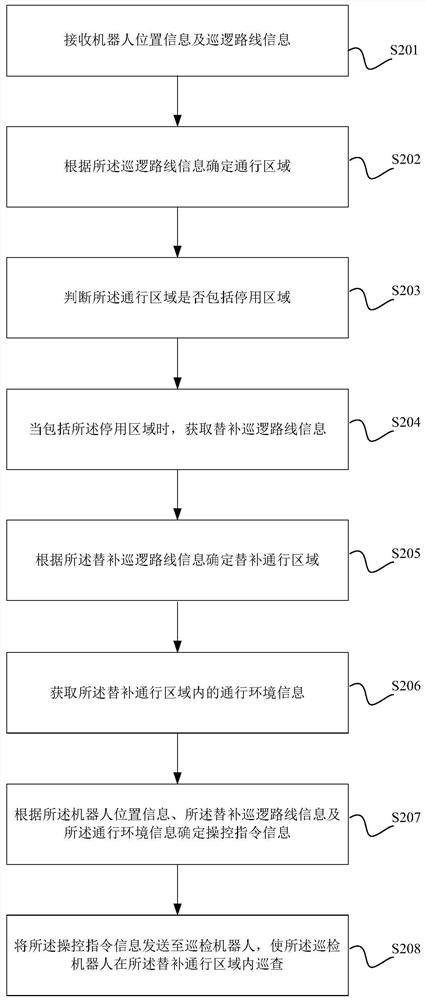

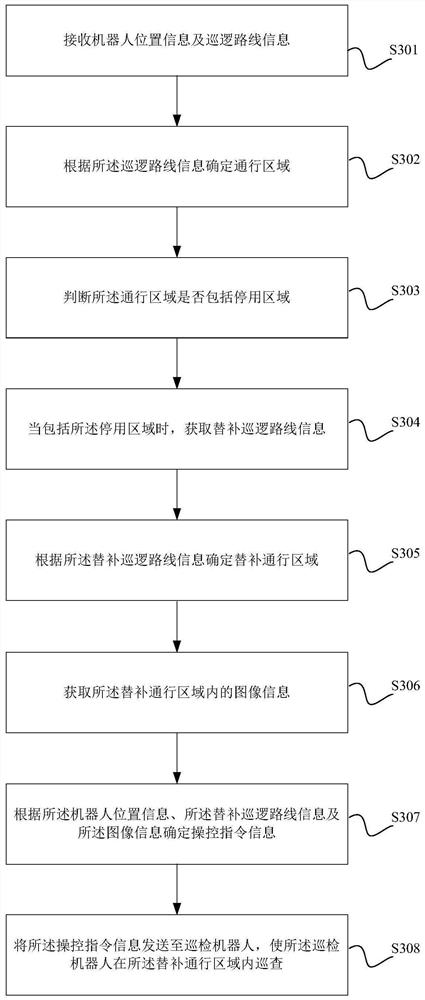

Control method and device of inspection robot and robot inspection system

InactiveCN111830987AImproved ability to avoid pedestrian roadblocksAvoid Dangerous Scenarios of Impromptu JudgmentPosition/course control in two dimensionsVehiclesRobot positionEngineering

The invention discloses a control method of an inspection robot. The control method comprises the following steps of receiving robot position information and inspection route information; determininga passing area according to the patrol route information; acquiring passage environment information in the passage area; determining control instruction information according to the robot position information, the patrol route information and the traffic environment information; and sending the control instruction information to an inspection robot so that the inspection robot inspects in the passing area. Due to the fact that the roadblock, the pedestrian and other information in the passing area are determined in advance, the dangerous scene that the roadblock and the pedestrian appear in the visual field of the inspection robot and then the inspection robot makes temporary judgment is avoided, and sufficient processing time is provided for the system to be used for adjusting the advancing route of the inspection robot. The invention further provides a control device and equipment of the inspection robot, a computer readable storage medium and a robot inspection system.

Owner:JINAN INSPUR HIGH TECH TECH DEV CO LTD

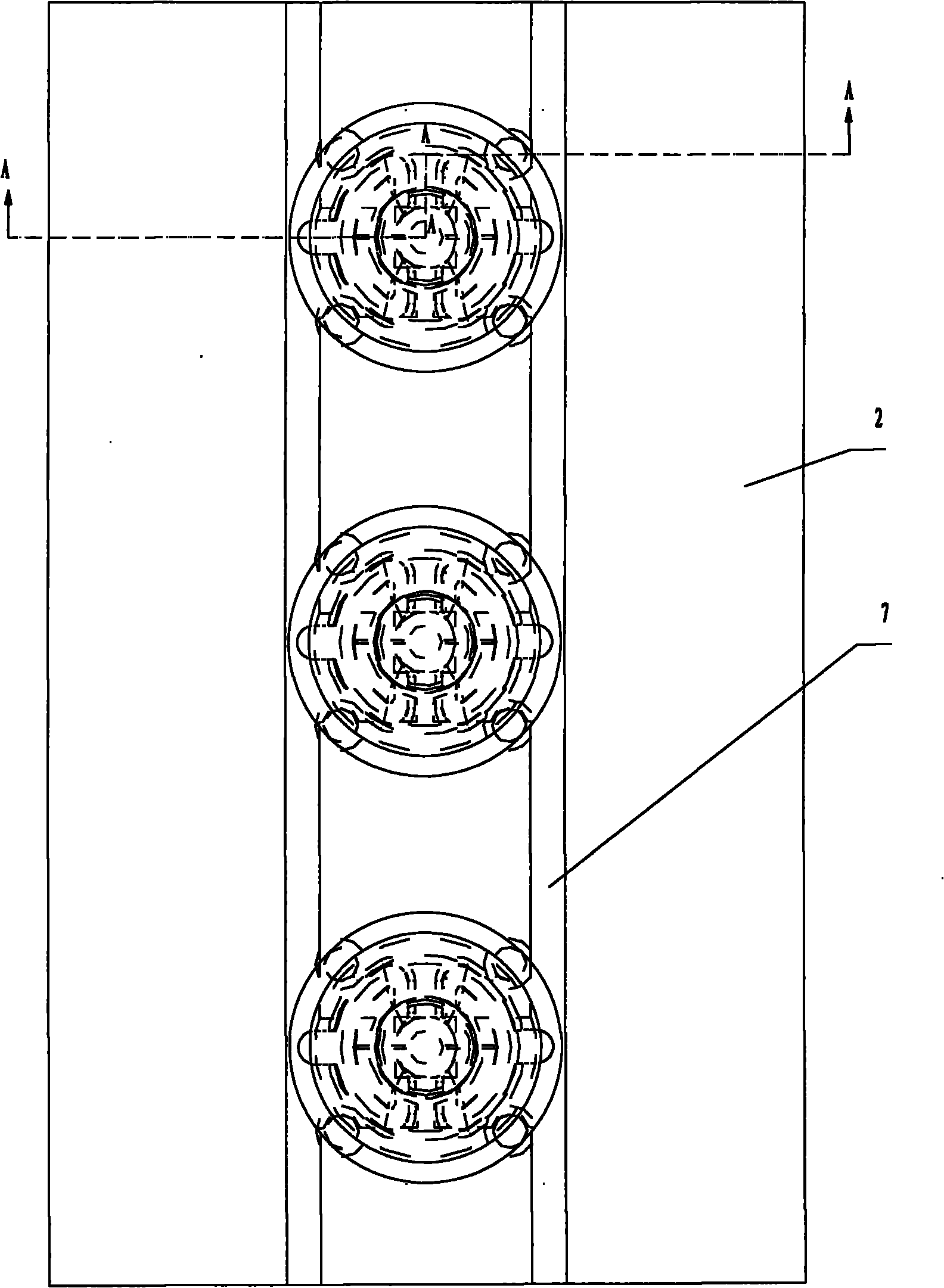

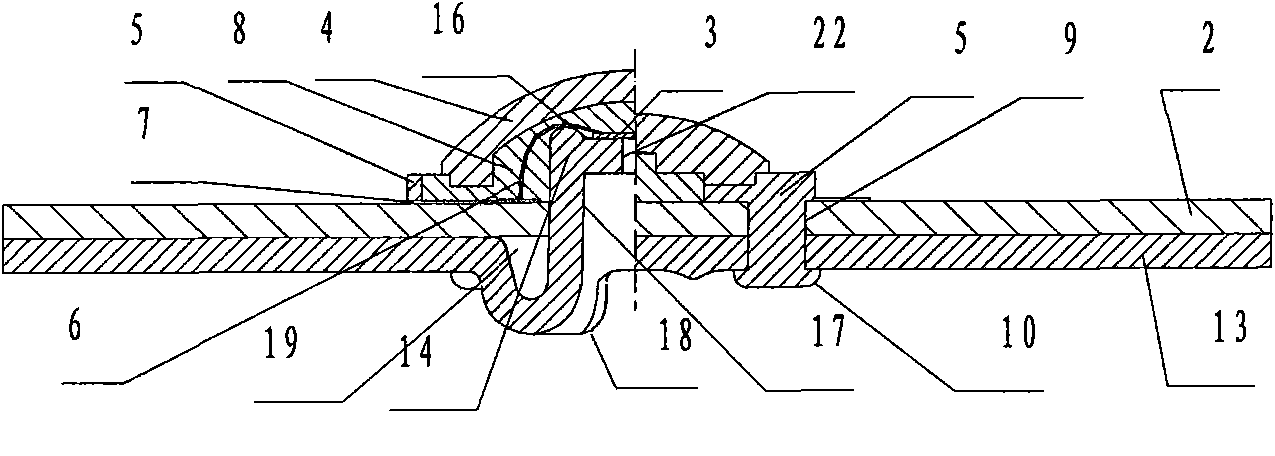

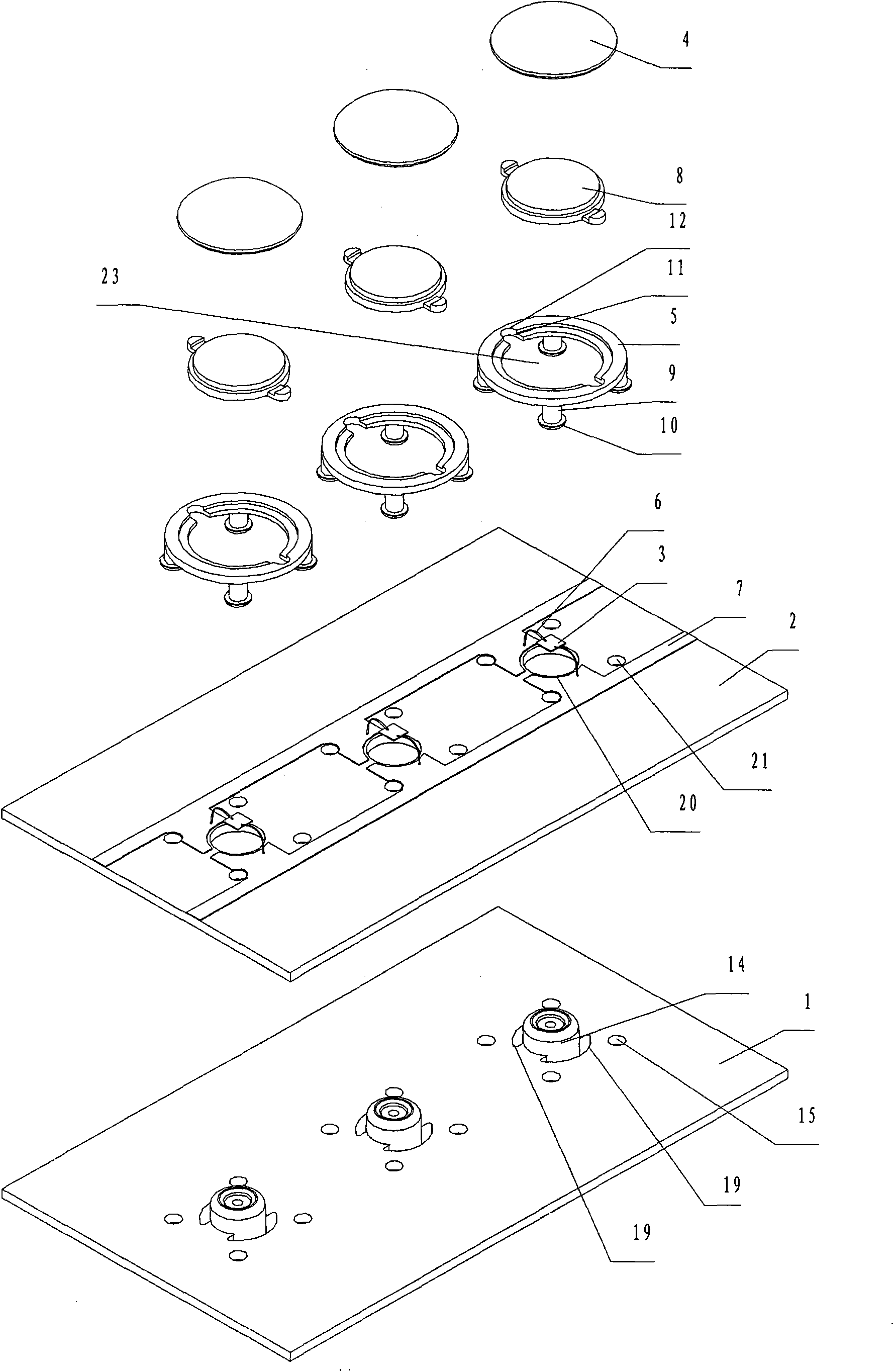

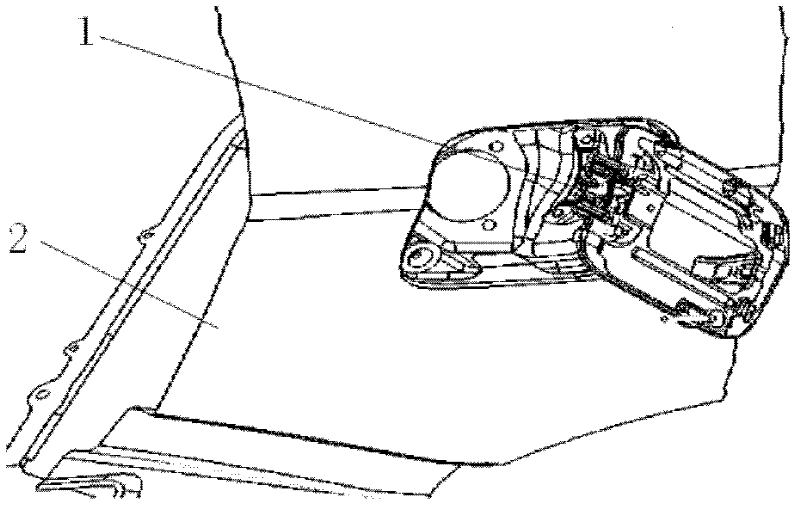

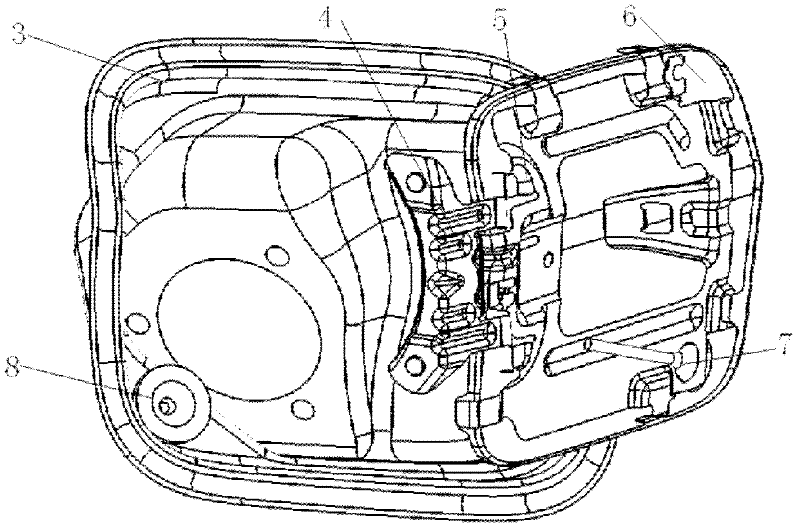

Automobile oil filler cap assembly

ActiveCN102358173ANo vertical vibrationGuaranteed aestheticsFuel supplyVertical vibrationRoad surface

The invention discloses an automobile oil filler cap assembly, which comprises an oil filler box, an oil filler outer cap and a positioning mechanism, wherein an inner board of the oil filler outer cap is hinged with the oil filler box; and the positioning mechanism is used for positioning the oil filler outer cap and the oil filler box in a closed state in a matched manner. By adoption of the technical scheme, when the oil filler cap assembly is closed, a positioning pin is inserted into a positioning hole in a positioning pin seat to ensure an accurate position relation between the oil filler outer cap and the oil filler box and accurate locking of a locking buckle, so that the difficulty in closing caused by deformation can be avoided, the section of the oil filler cap is matched with the whole shape of an automobile body, so the appearance of the whole automobile is attractive; furthermore, when the automobile runs on a bumpy road, the positioning mechanism can avoid vertical vibration of the oil filler cap.

Owner:CHERY AUTOMOBILE CO LTD

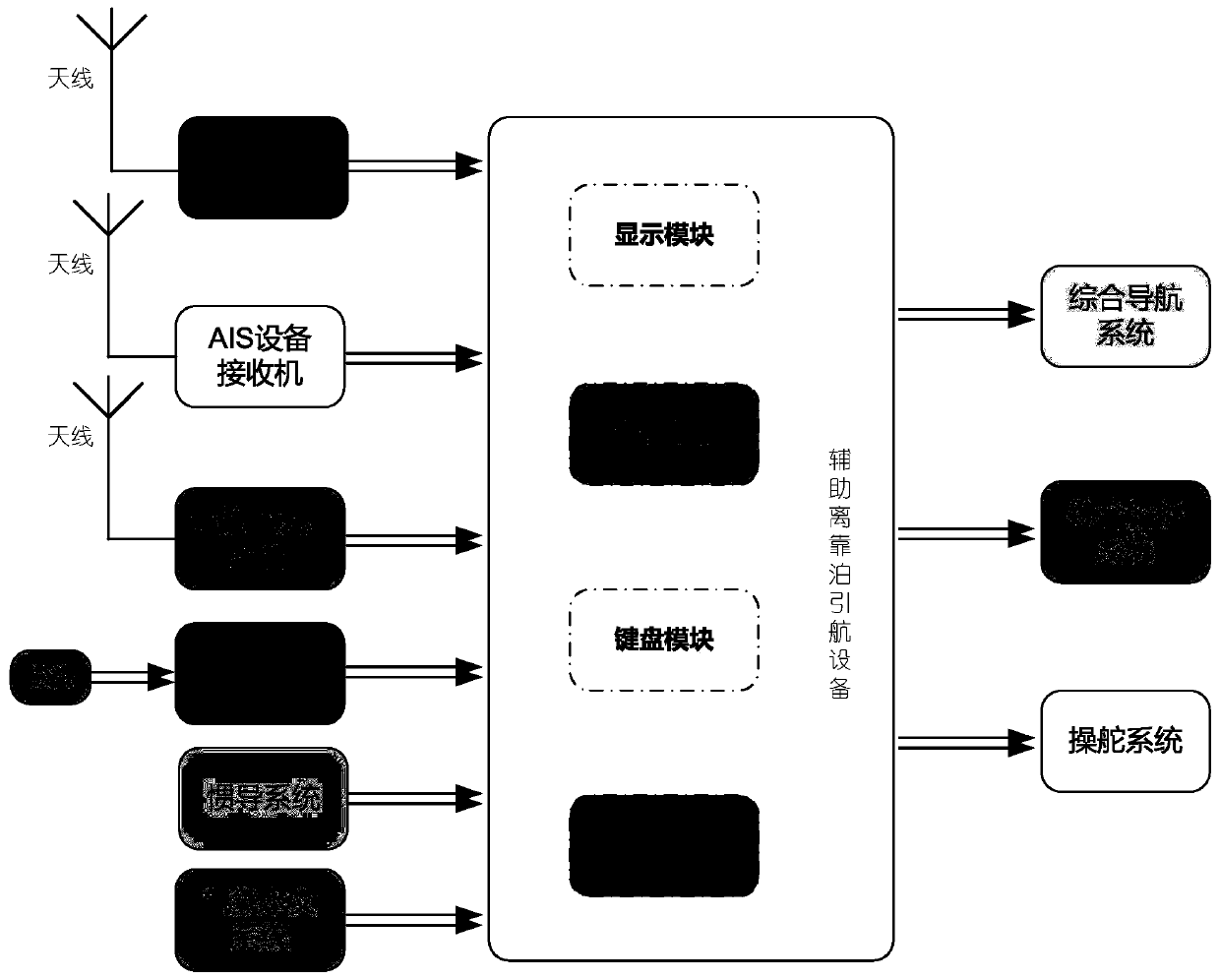

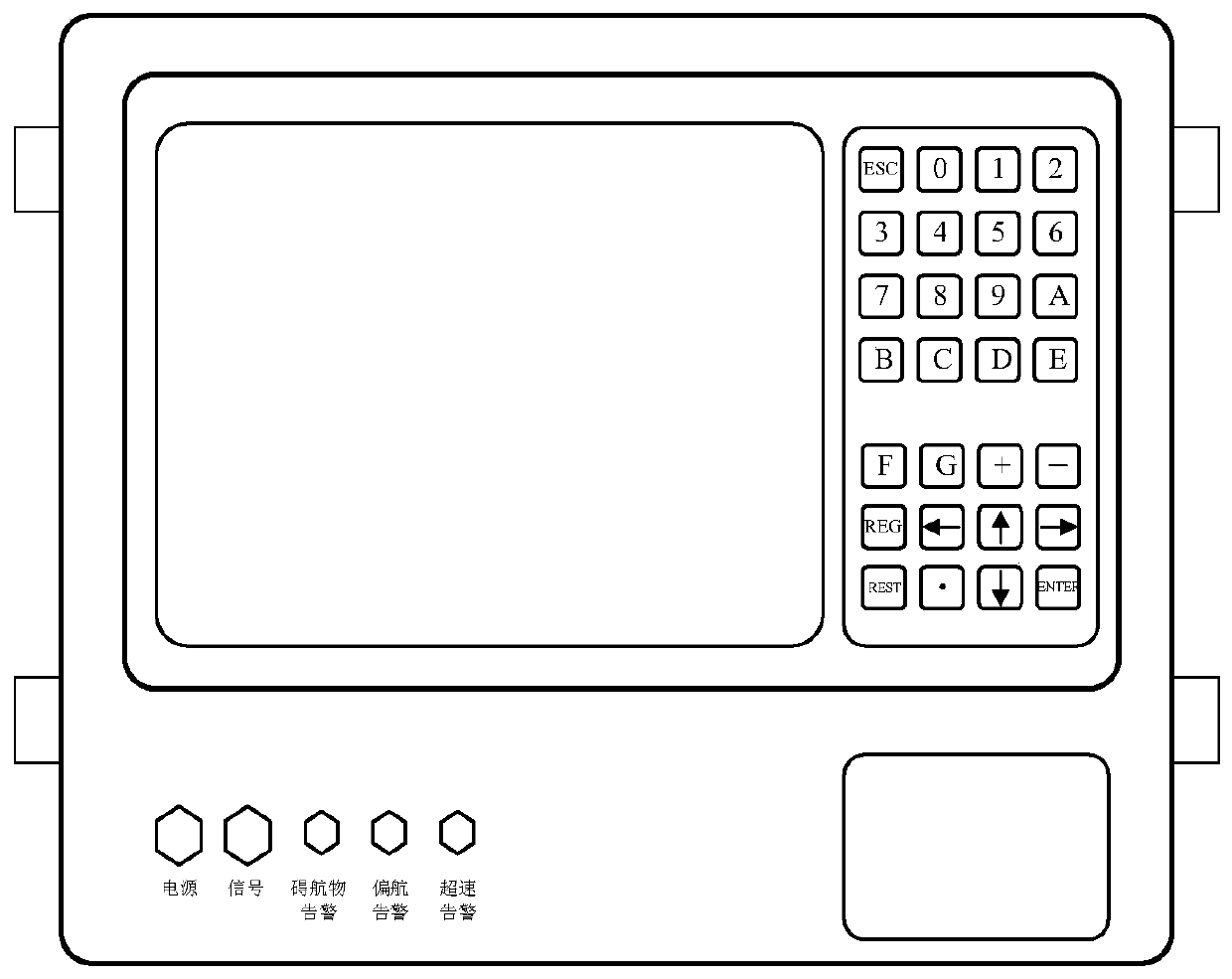

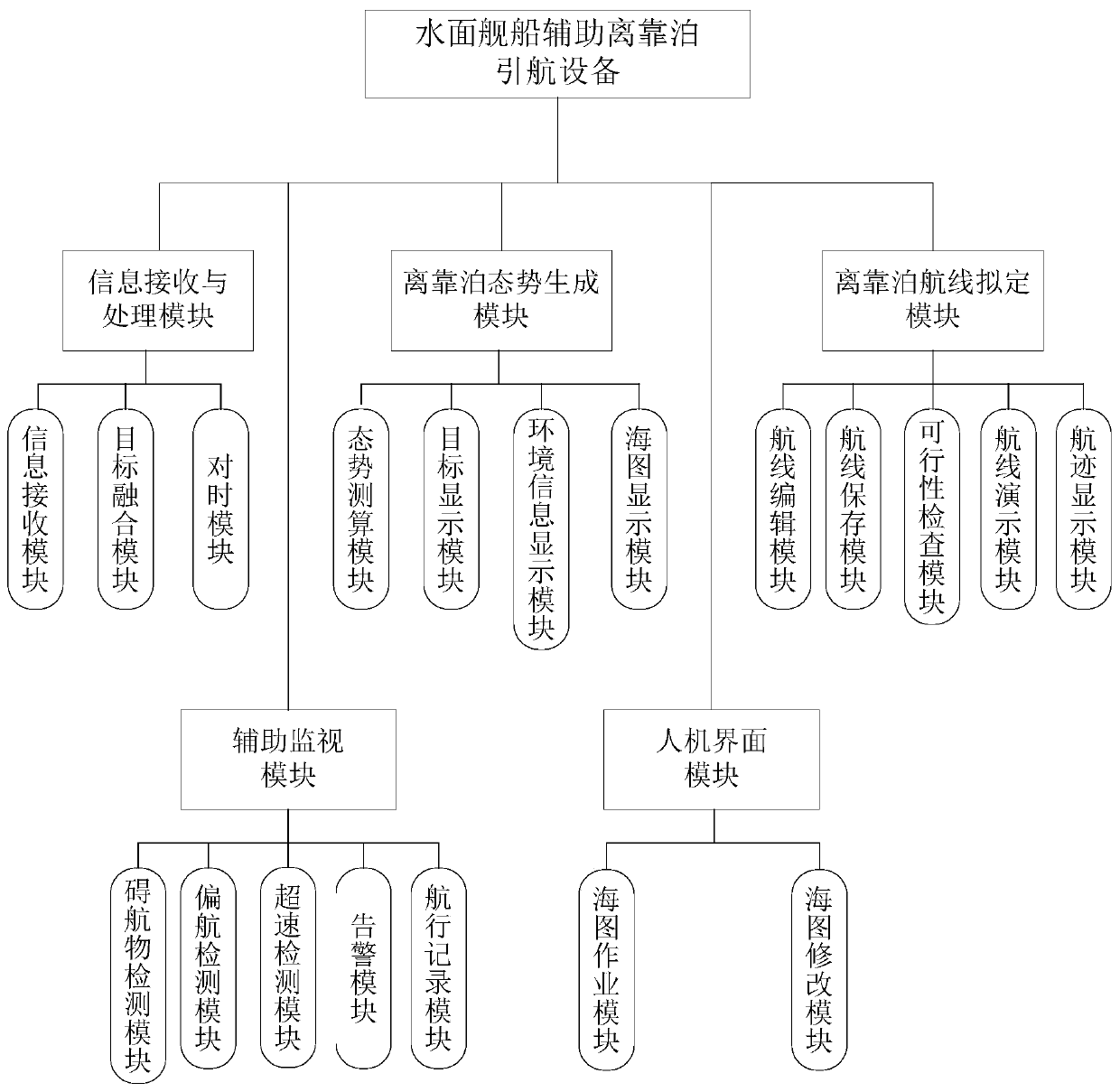

Novel surface vessel auxiliary unberthing/berthing pilot equipment and method

PendingCN110133659AImprove automationImprove securityNavigational calculation instrumentsNavigation by speed/acceleration measurementsHuman–machine interfaceMultiple sensor

The invention discloses a novel surface vessel auxiliary unberthing / berthing pilot equipment and method. The pilot equipment is connected with a Beidou positioning system, a navigation radar, an AIS system, an inertial navigation system, laser ranging equipment and a meteorological and hydrological system through a vessel-borne network; a hardware part of the pilot equipment comprises a display module, a host module and a keyboard module; and the following software modules are arranged inside the host module: an information receiving and processing module, an unberthing / berthing situation generating module, an unberthing / berthing route planning module, an auxiliary monitoring module and a man-machine interface module. According to the pilot equipment, information of multiple sensors and apositioning terminal is integrated, and information about the vessel accurate positioning, speed, vessel-to-shore relative state, sea surface target motion state and sea area hydrometeorology is utilized in combination with an electronic sea chart information system in order to provide comprehensive unberthing / berthing situation information and reference unberthing / berthing route information and provide auxiliary decision-making information support for vessel unberthing / berthing operation, thereby improving the unberthing / berthing efficiency.

Owner:CHINA SHIP DEV & DESIGN CENT

Split lens and camera module

The invention relates to a split lens, which comprises an independent object side group forming a free end of the split lens, at least one independent image side group and a diaphragm, wherein the independent image side groups and the independent object side group are sequentially arranged and fixedly connected; and a fit clearance is formed between the object side group and the image side groups. According to the split lens, alignment is freer and more flexible, assembly is convenient and fast and the coordinating precision is high.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Depth image generating method and apparatus, and electronic device

The embodiment of the invention provides a depth image generating method and apparatus, and an electronic device. The method comprises: a first color image and a first depth image that include same scenery are obtained; according to similarity between reference pixel points and non-reference pixel points respectively included in a plurality of first preset regions in the first color image, the pixel points included by the plurality of first preset regions are classified; according to pixel points being located in the same first preset regions and having the same types, corresponding target pixel points of the reference pixel points included by the plurality of first preset regions in the first depth image are determined; the depth values of the target pixel points are determined as depth coefficients of to-be-generated pixel points in a second depth image; and a second depth image is generated by combining the depth coefficients. Therefore, the target pixel points are determined basedon the pixel point types and thus the depth values of the to-be-generated pixel points are calculated accurately, so that the accuracy of the generated depth image is improved and an object distortionphenomenon occurring in the virtual viewpoint image is avoided.

Owner:QINGDAO RES INST OF BEIHANG UNIV

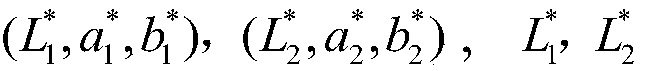

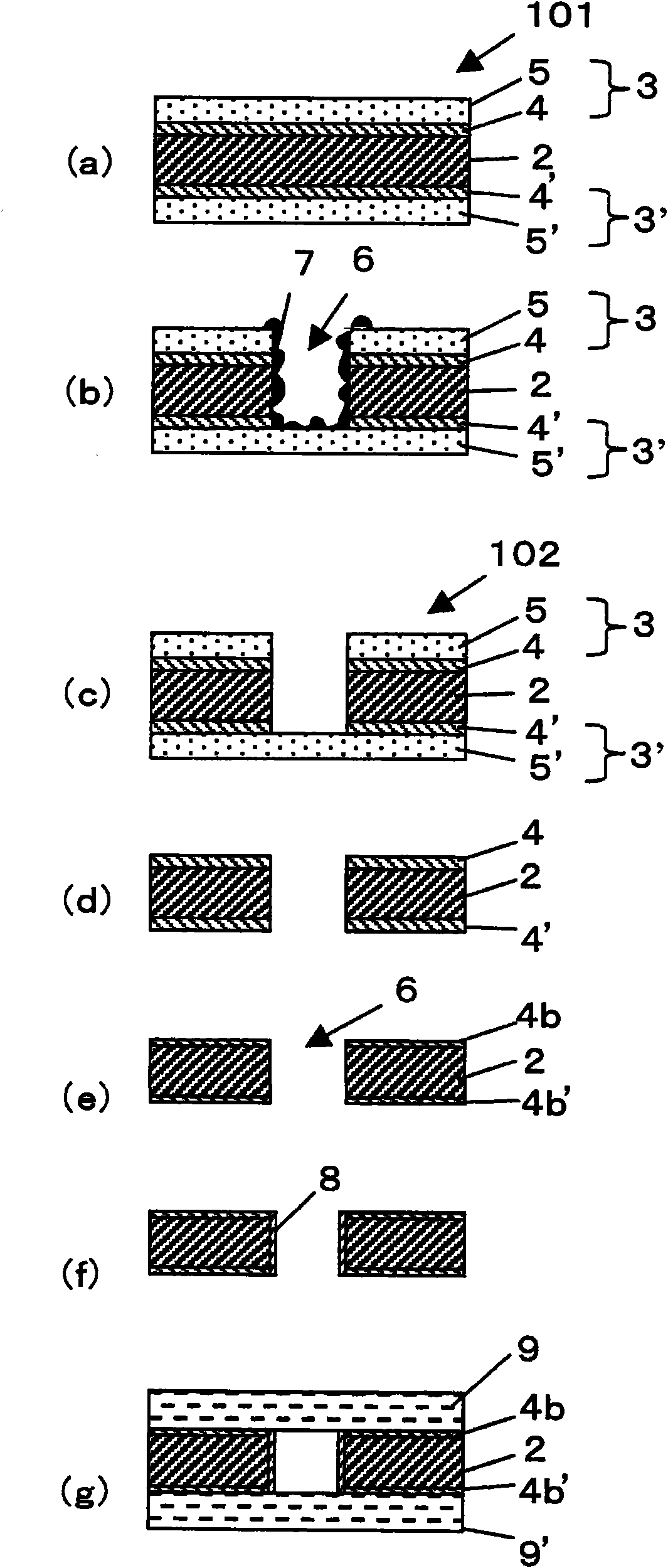

Method for manufacturing printed wiring board

InactiveCN101897246AGood dimensional stabilityAvoid stretchingInsulating layers/substrates workingCircuit precursor manufactureProduction rateEngineering

Provided is a method for manufacturing with high productivity a printed wiring board having high dimensional stability. The manufacturing method is provided with a step of preparing a metallic laminated body wherein a metal layer having an inner metal layer section and a protection layer section is laminated on at least one side of an insulating resin layer, with the inner metal layer section on the side of the insulating resin layer; a step of forming a via hole on the metal layer and the insulating resin layer; a step of performing blast processing after forming the via hole; and a step of removing the protection layer section after performing blast processing.

Owner:UBE IND LTD

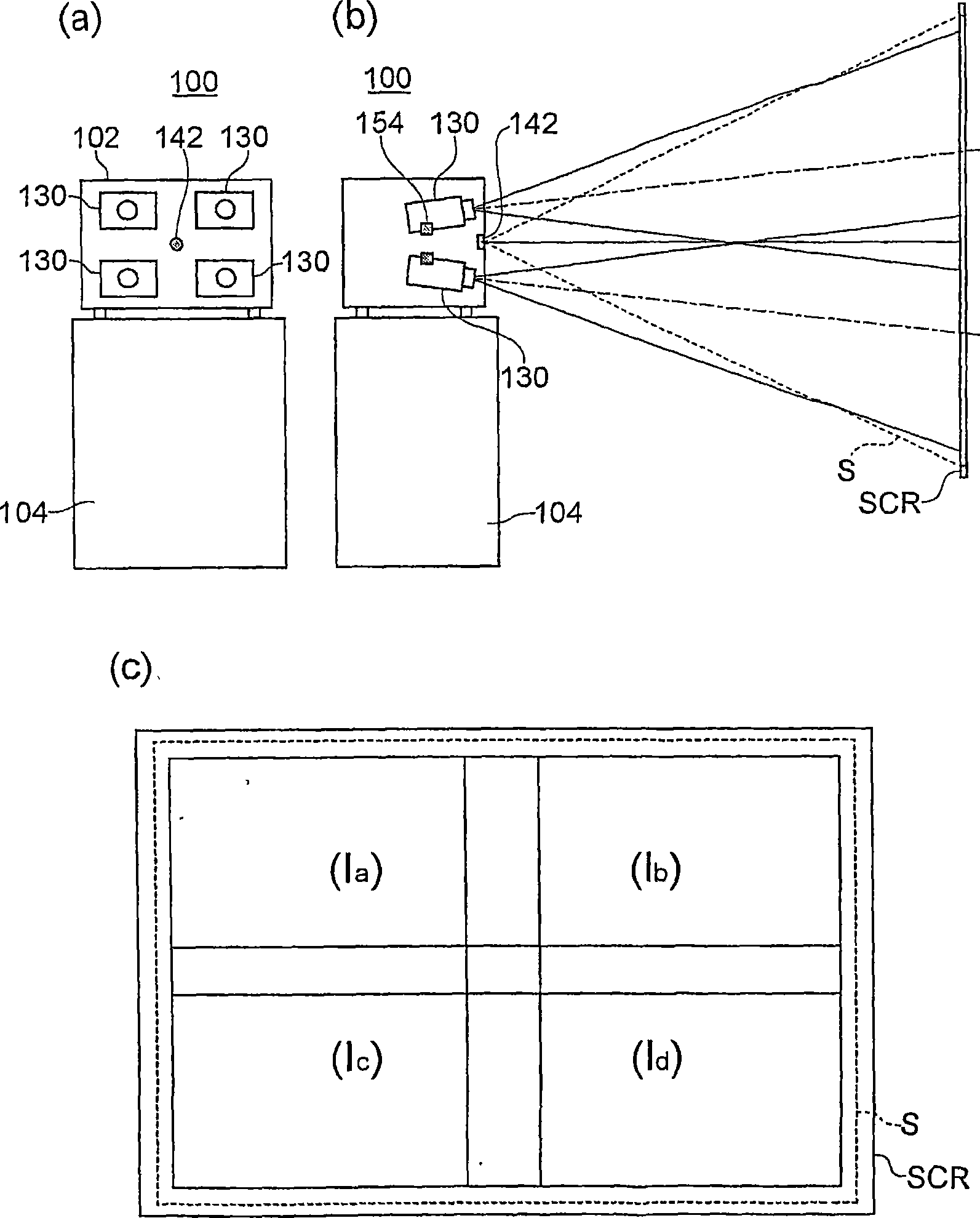

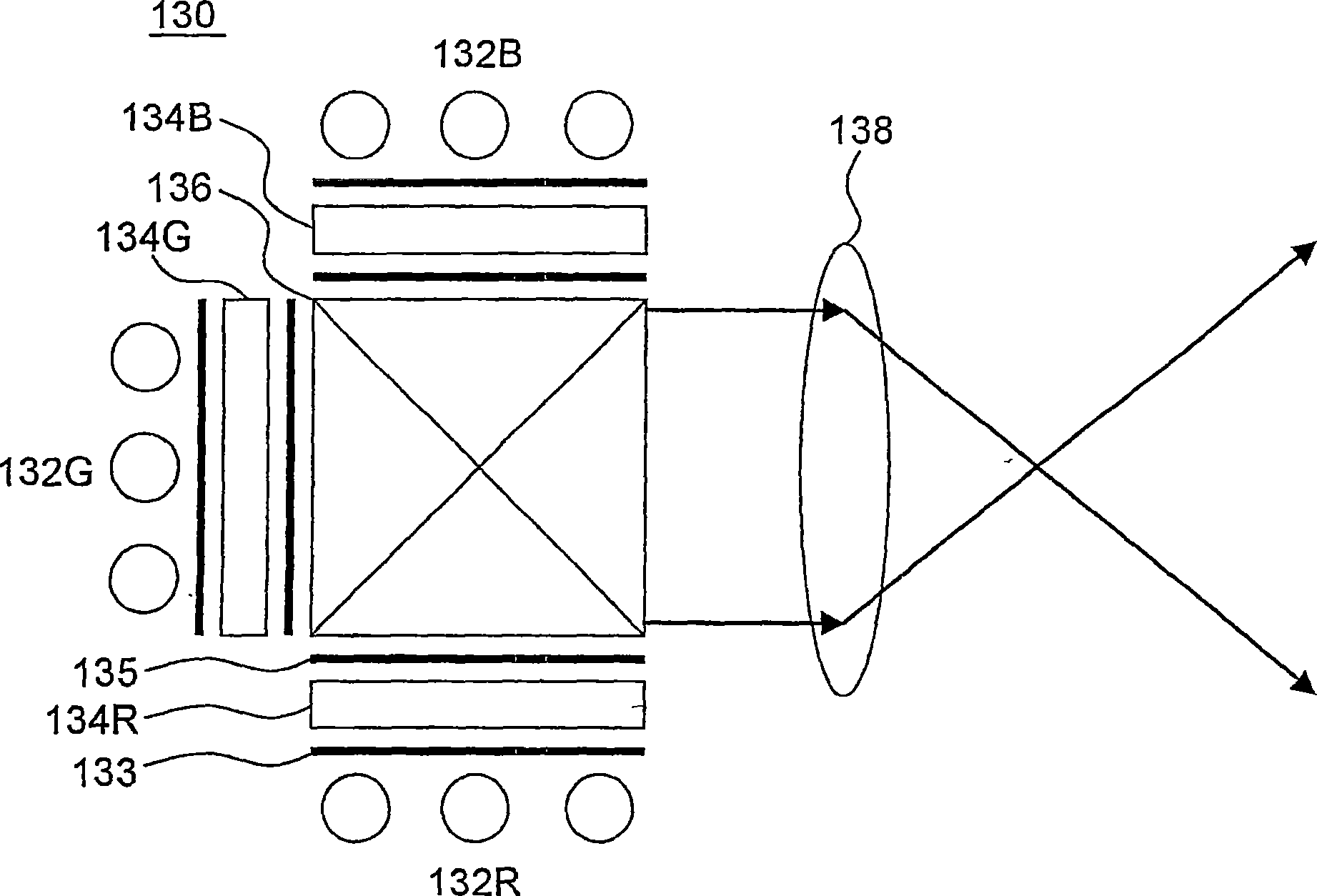

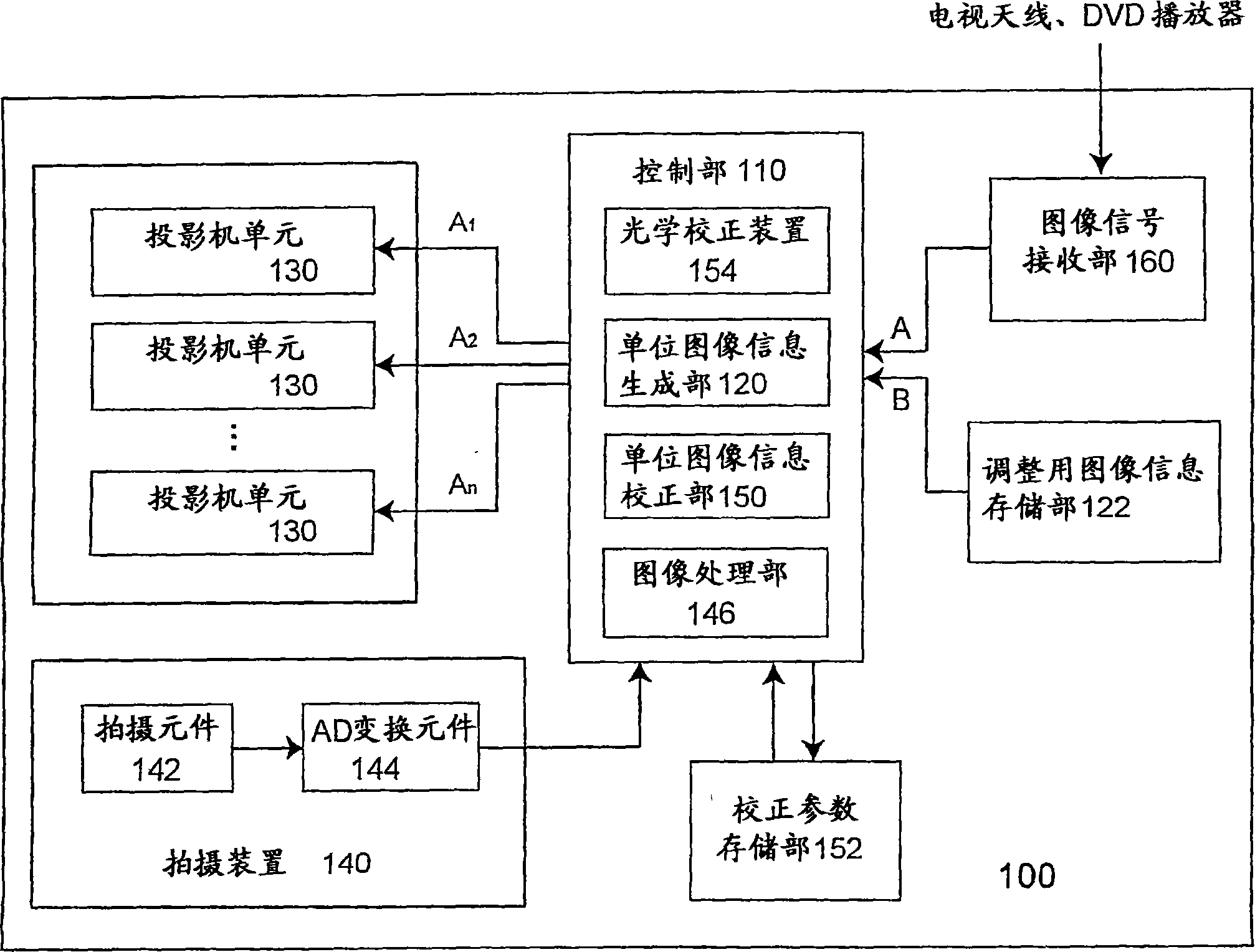

Front projection type multi-projection display

InactiveCN1906933AEasy to adjustShorten adjustment timeTelevision system detailsProjectorsProjection imageDisplay device

A front projection type multi-projection display includes a plurality of projector units to modulate and project light from a light source based on image information, an image-capturing device disposed in a housing to capture predetermined regions of the projection images projected onto the screen, a unit image information generating unit to generate image information to be input to each of the plurality of projector units, and a unit image information correcting unit to correct the unit image information based on a result captured by the image-capturing device. Therefore, it is possible to perform the adjustment process and to further reduce the adjustment time.

Owner:SEIKO EPSON CORP

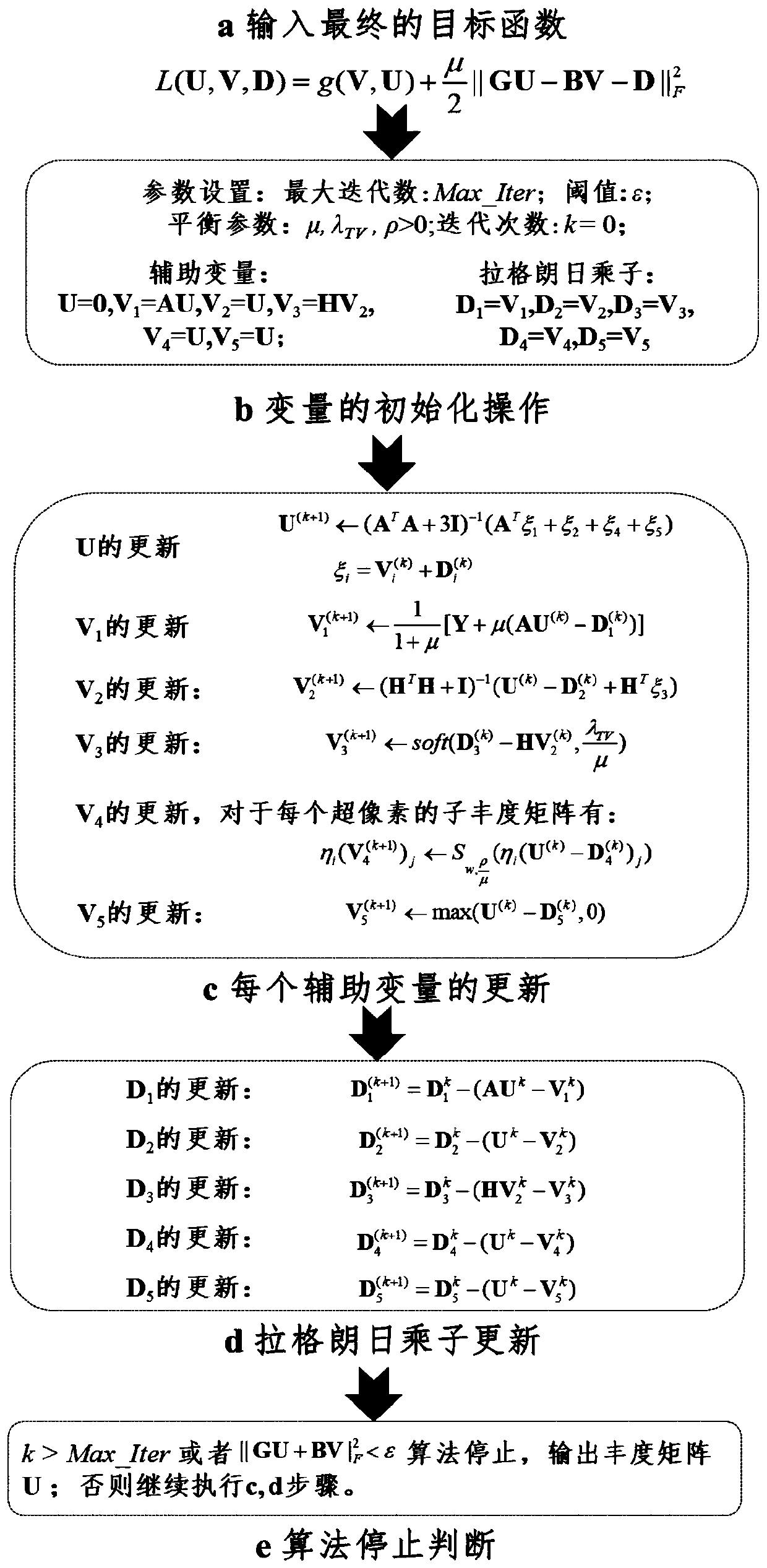

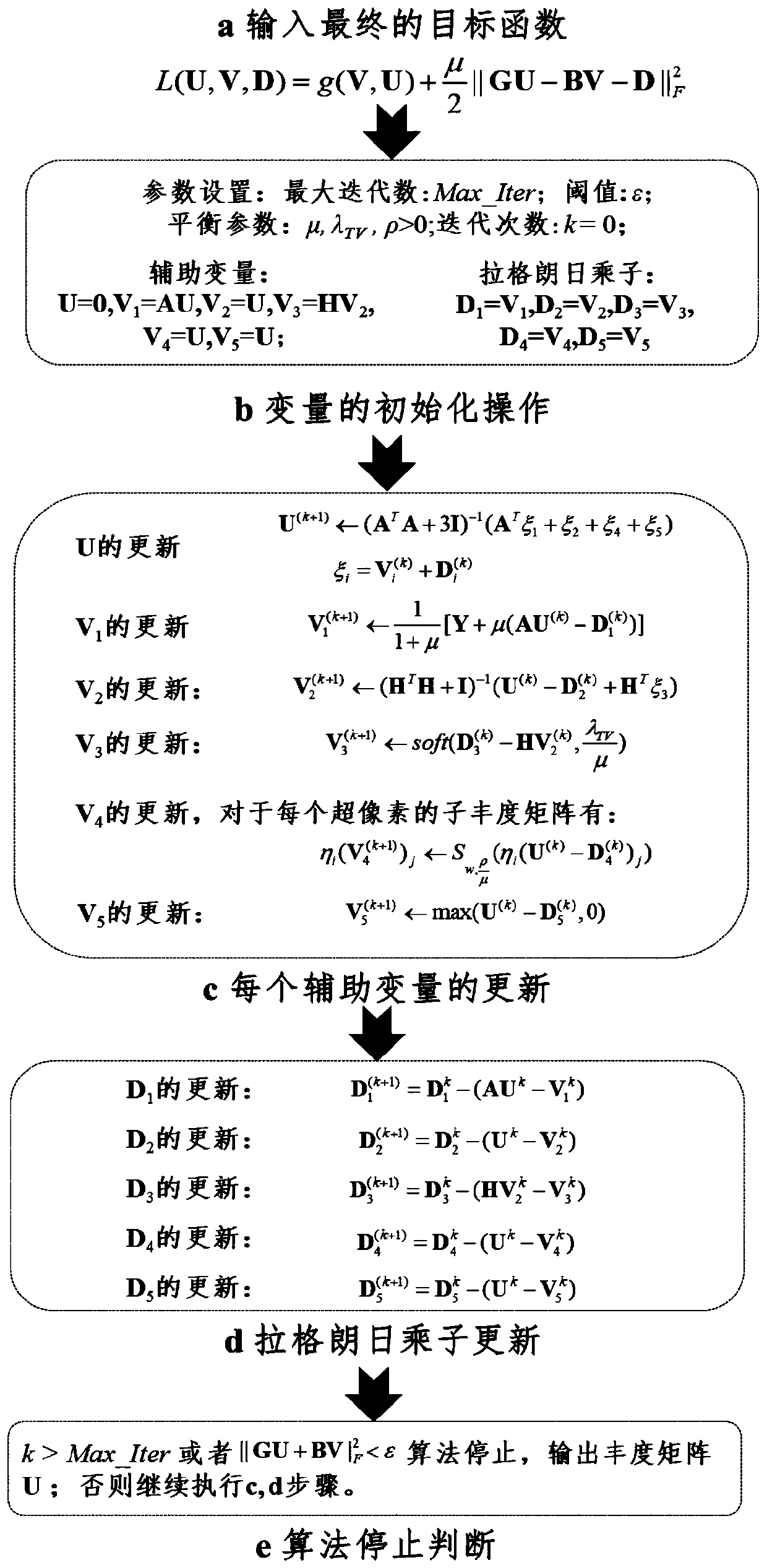

Space-spectrum fused hyperspectral image mixed pixel low-rank sparse decomposition method

PendingCN111161199AAccurate positional relationshipEffective local detail featuresImage enhancementImage analysisConstrained optimization problemAlgorithm

The invention discloses a space-spectrum fused hyperspectral image mixed pixel low-rank sparse decomposition method, which comprises the following steps of: normalizing hyperspectral image data, and generating superpixels by adopting a linear iterative clustering method; searching an abundance matrix of a local block of the superpixel, constructing a low-rank constraint expression item, adding a total variation space regular item, and adding a data fidelity item to obtain a target function; introducing a plurality of auxiliary variables to construct a split target function, and converting a constrained optimization problem into an unconstrained optimization problem by adopting augmented Lagrange; and solving the target function by adopting an alternating iterative algorithm to obtain an abundance graph of evaluation confirmation. By adopting the method, the obtained spatial information is more accurate than the simple position relationship among the pixels, the local detail features ofthe abundance matrix are extracted, and the smoothness of the abundance matrix is promoted, so that the whole abundance graph has global features, the target function is split, meanwhile, the algorithm is quickly converged, and a more accurate target solution is obtained.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

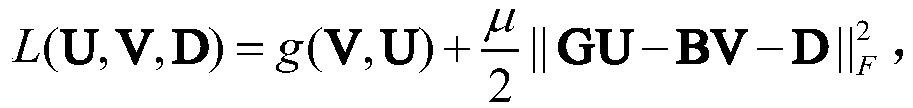

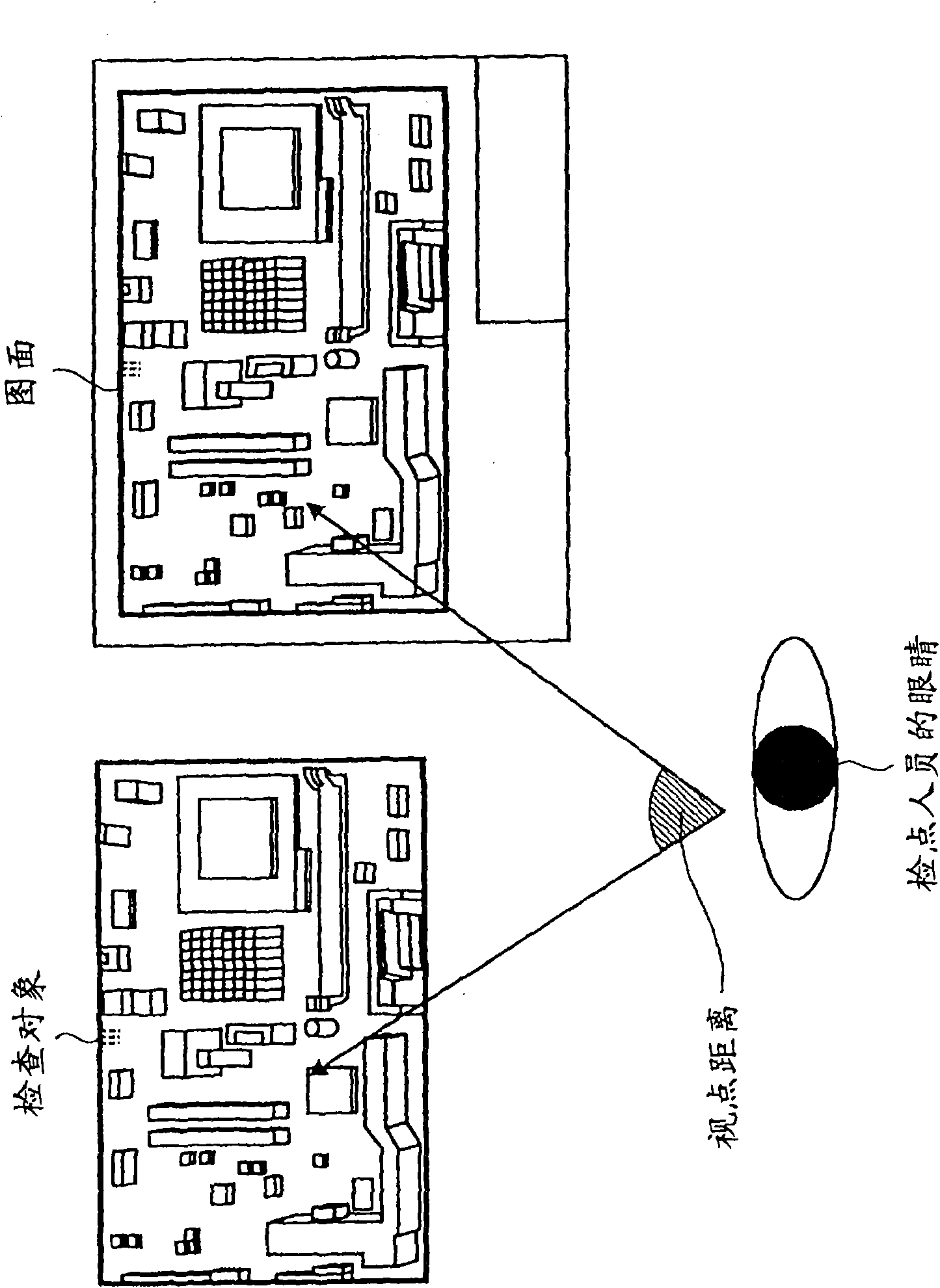

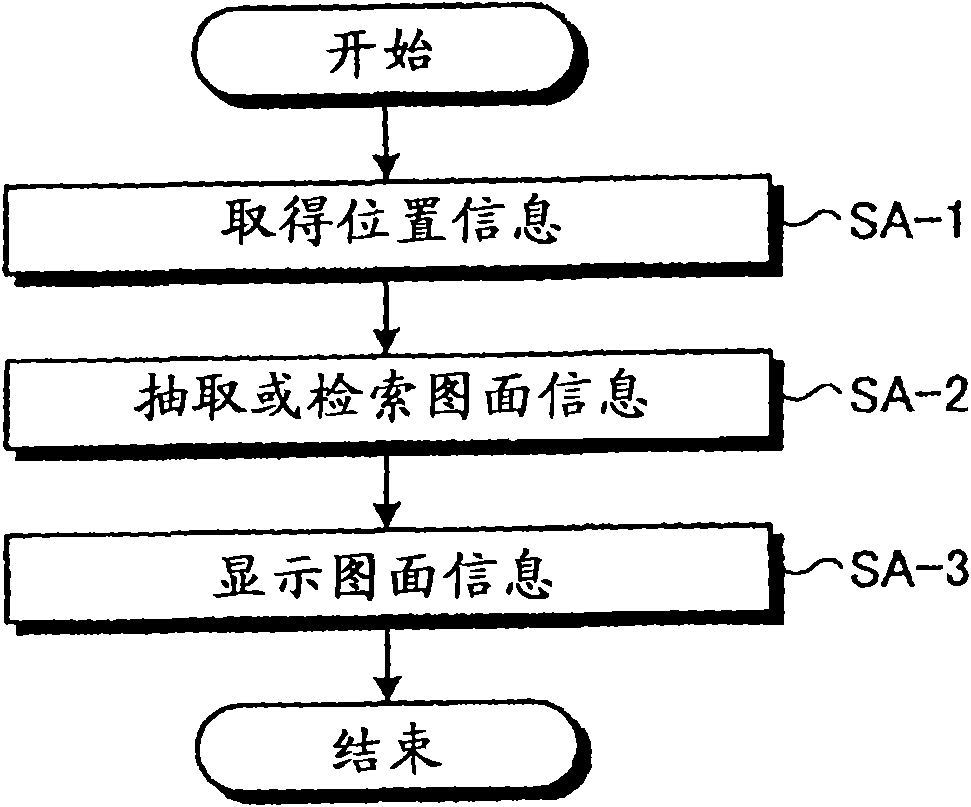

Drawing information management device and comparison checking method thereof

InactiveCN101581581AReduce visual burdenWon't missOptically investigating flaws/contaminationPicture interpretationComputer terminalLarge size

The present invention provides a drawing information management device and a comparison checking method thereof. The point checking personnel does not require adjusting a portable terminal, etc. to the appropriate position and orientation. Even the large-size checking object can be executed with comparison checking. The comparison checking can be executed efficiently with a view distance that can reduce the view burden of the point checking personnel. In the comparison checking method of the invention, the drawing information of the checking object is stored in a storing part. A first image which is obtained with an image shooting part and comprises at least one part of the checking object is compared with a second image that comprises at least one part of the checking object and the portable terminal thereby obtaining the position information of the portable terminal on the checking object. The drawing information of a preset area is drawn from the drawing information stored in the storing part according to the obtained position information, and is transmitted to the portable terminal so that the display part of the portable terminal displays the drawing information of the preset area.

Owner:PFU LTD

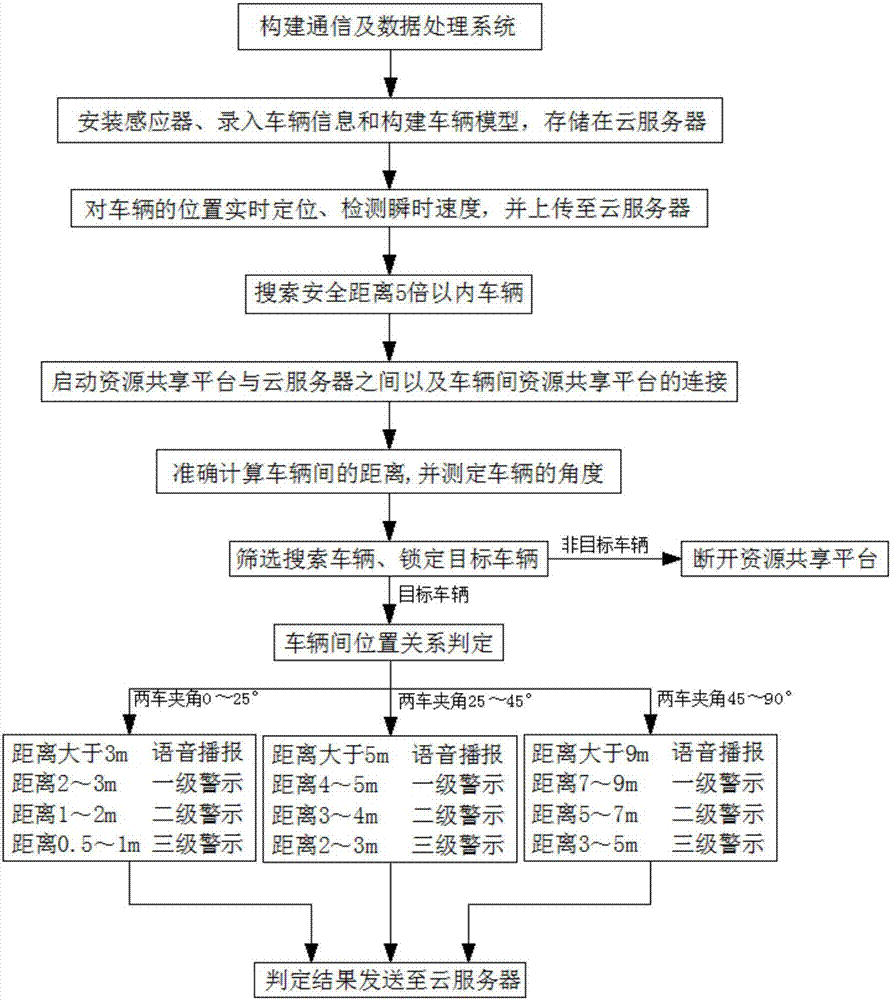

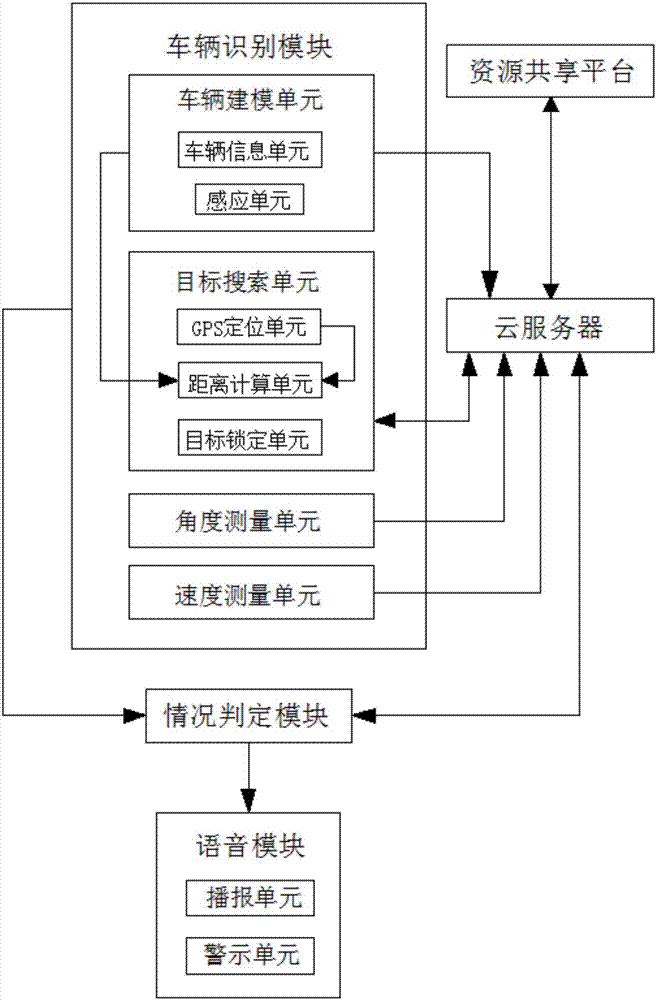

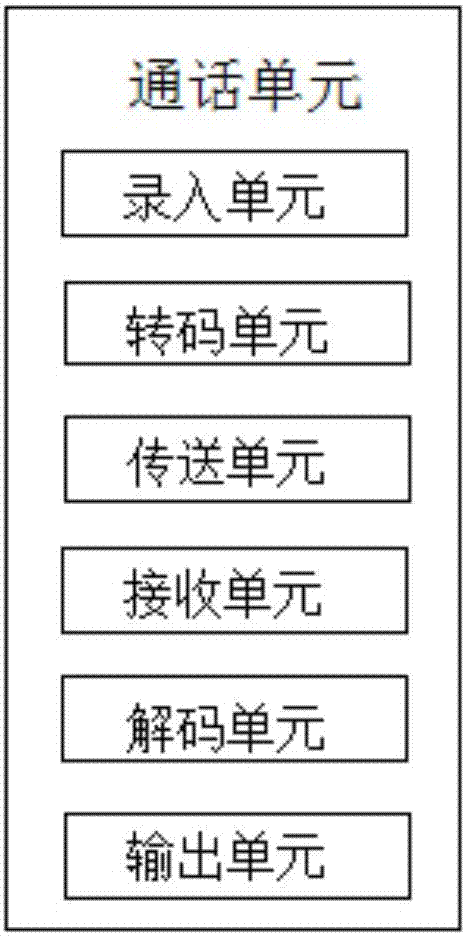

Inter-vehicle communication and data processing method

InactiveCN107516436AAccurate positional relationshipAccurate guidanceAnti-collision systemsData processing systemTraffic accident

The invention belongs to the technical field of communication, particularly to an inter-vehicle communication and data processing method. The inter-vehicle communication and data processing method solves the problems of poor information timeliness and low inter-vehicle distance accuracy in the prior art. The inter-vehicle communication and data processing method comprises the following steps of S1, structuring an inter-vehicle communication and data processing system; S2, mounting sensors, recording vehicle information and structuring vehicle models; S3, searching for and locking target vehicles; S4, determining inter-vehicle position relations, and broadcasting voice or issuing alarm. The inter-vehicle communication and data processing method is high in timeliness and capable of effectively reducing inter-vehicle traffic accidents and improving inter-vehicle rescue efficiency.

Owner:GUANGDONG INST OF SCI & TECH

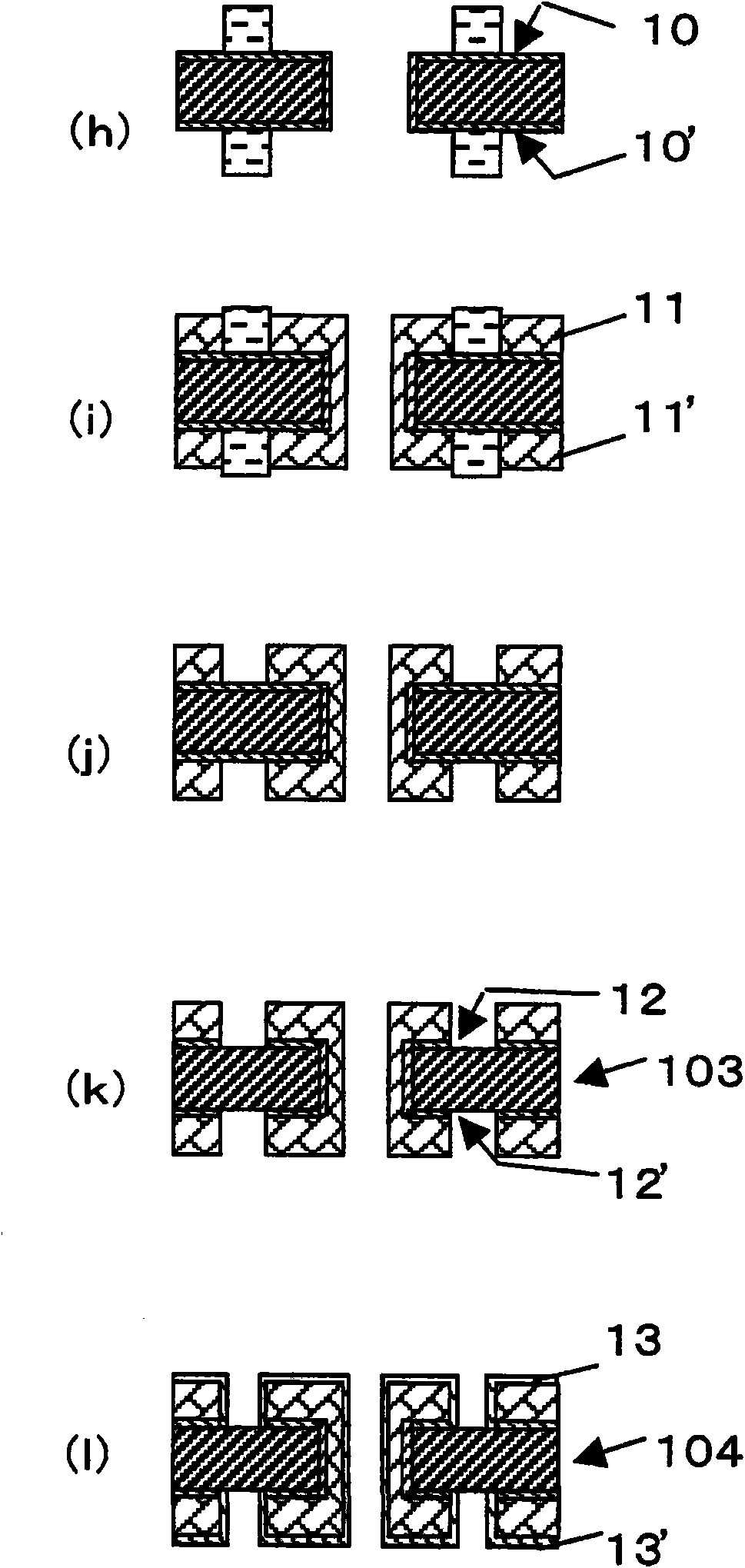

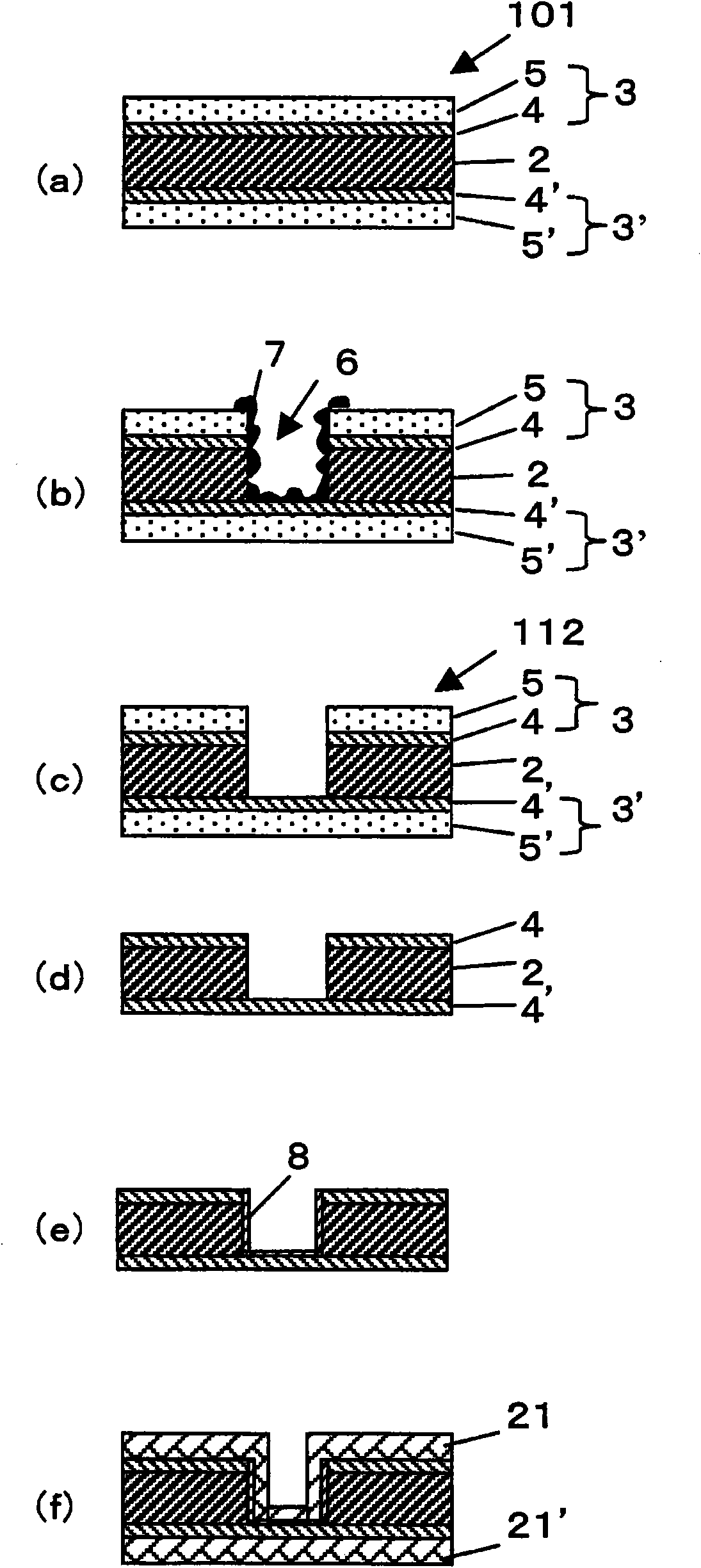

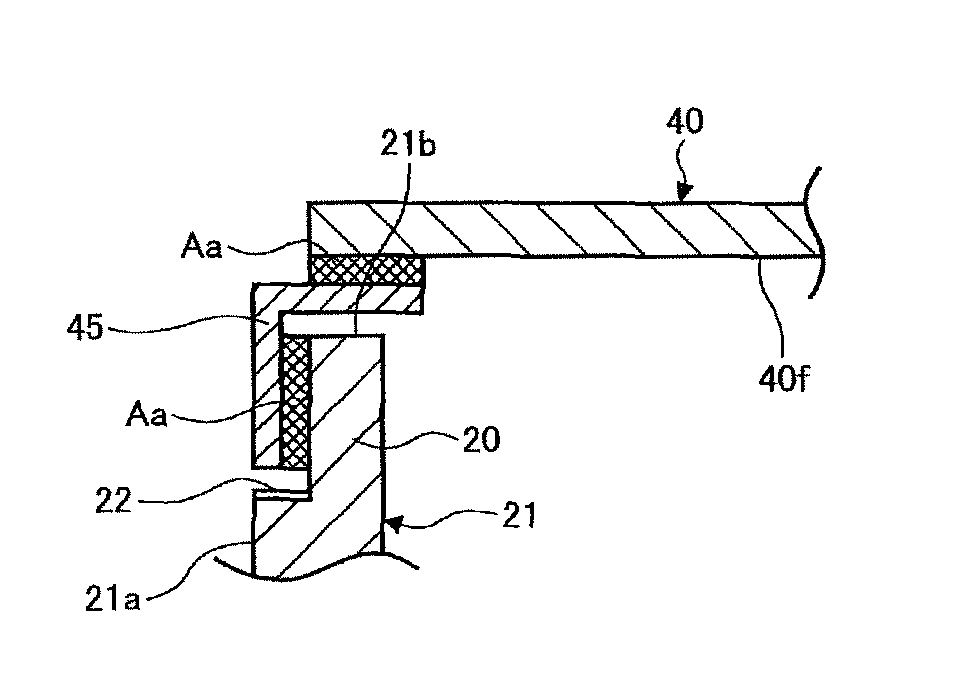

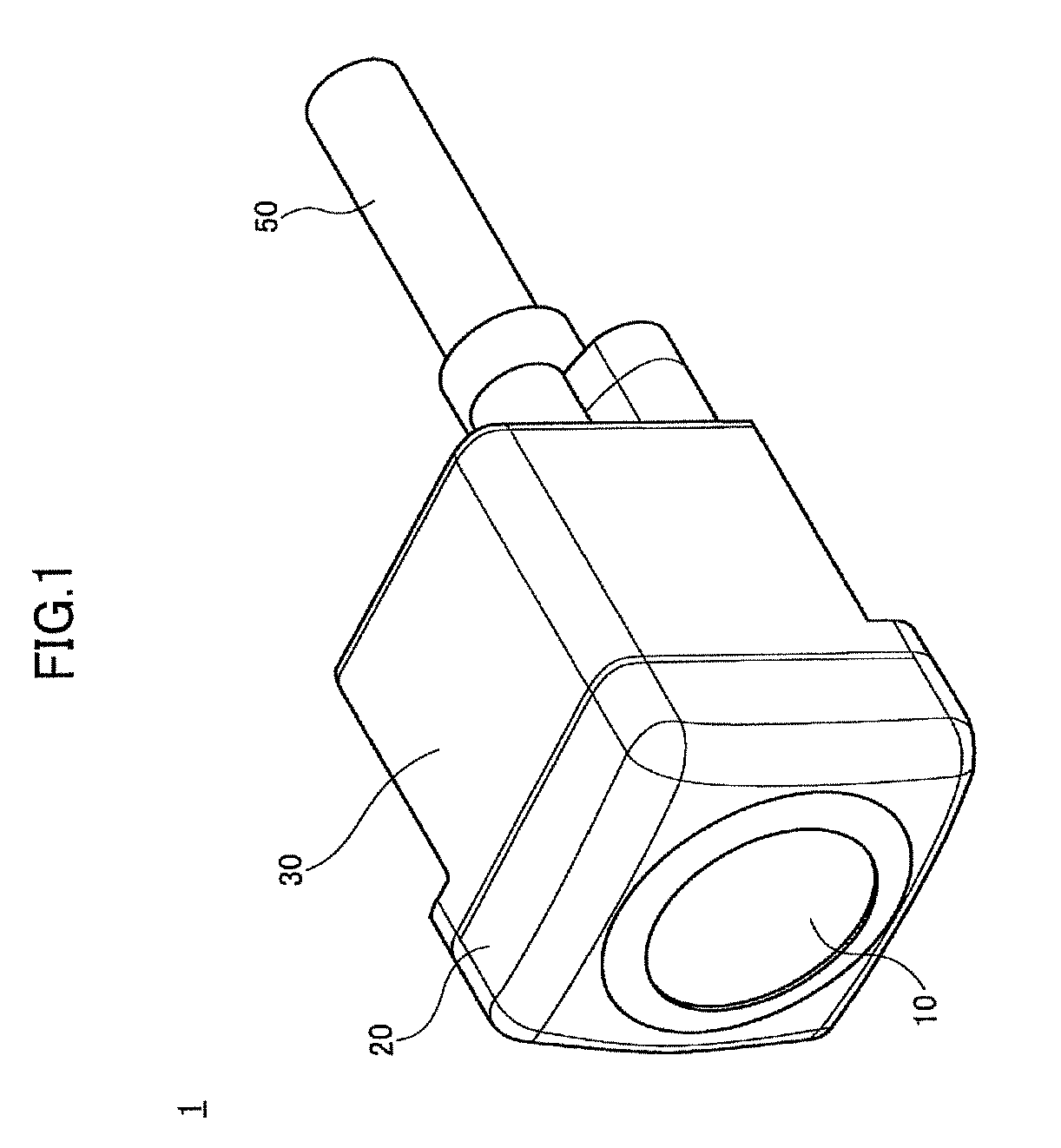

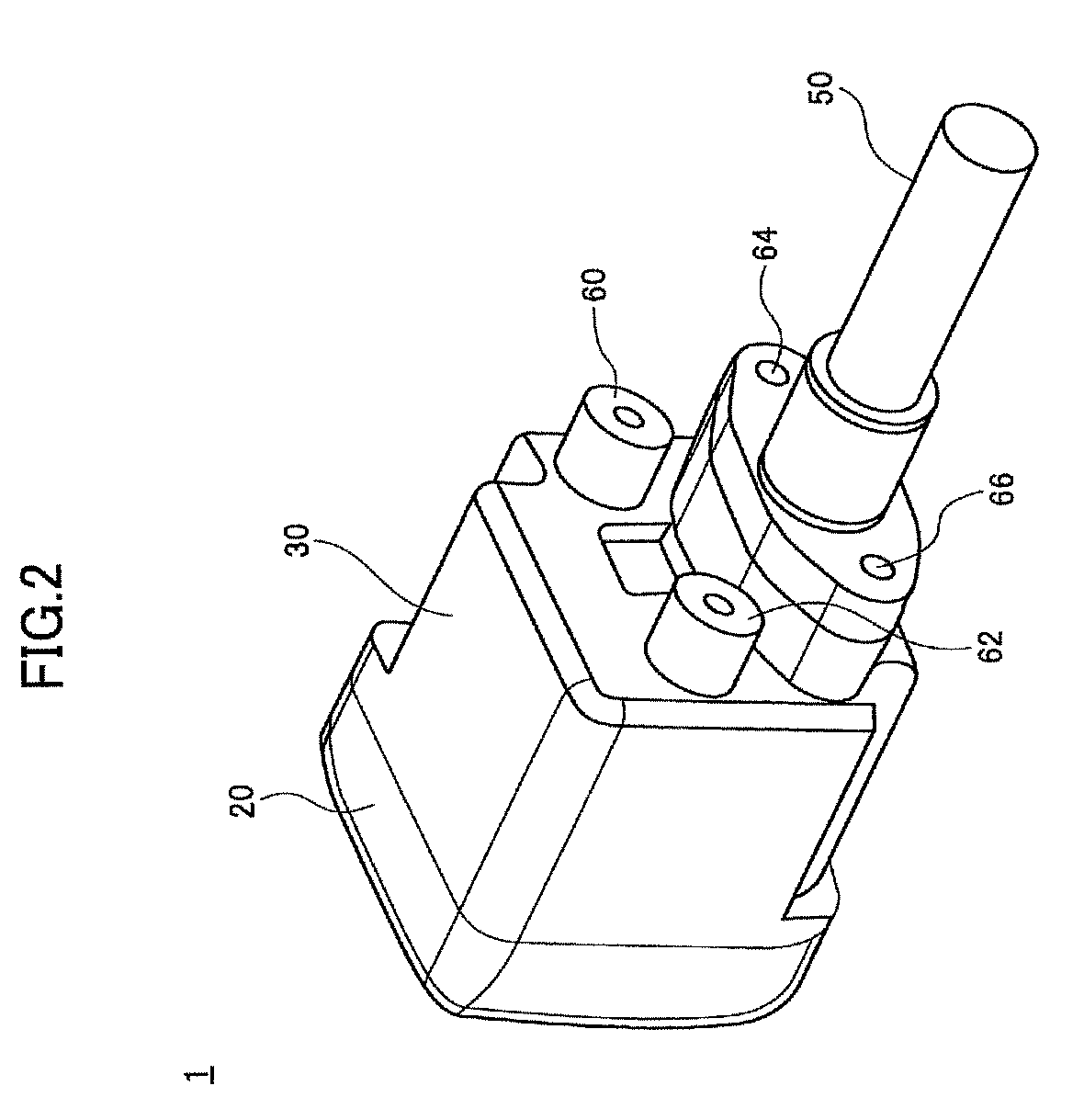

Image pickup apparatus, on-vehicle image pickup apparatus, method and apparatus for manufacturing image pickup apparatus

ActiveUS8427540B2Accurate positional relationshipManufacturing such an image pickup apparatus more efficientlyTelevision system detailsColor television detailsUV curingAdhesive

A disclosed image pickup apparatus includes a first member holding a lens, and a second member holding an image pickup element converting an image formed via the lens into an electric signal, the second member having an approximately rectangular shape and two approximately arc-shaped location cutout portions at respective diagonal corners of the approximately rectangular shape. In the image pickup apparatus, the first and the second members are bonded via an indirect bonding structure portion where the first and second members are bonded via a fixing member with an ultraviolet curable adhesive and a filler bonding structure portion where the first and second members are bonded by supplying a thermosetting adhesive therebetween.

Owner:RICOH KK

Stainless steel exhaust fume collecting hood welding, bonding and re-welding fixture

InactiveCN110653540AGuaranteed flatnessGuaranteed straightnessDomestic stoves or rangesLighting and heating apparatusExhaust fumesStructural engineering

The invention relates to a stainless steel exhaust fume collecting hood welding, bonding and re-welding fixture which is characterized by comprising a platform, a left-side external pressing block, aright-side external pressing block, a left front external pressing block, a right front external pressing block, a left internal pressing block, a right internal pressing block, a middle internal pressing block and a middle external pressing block. The platform is used for placing a stainless steel exhaust fume collecting hood; the stainless steel exhaust fume collecting hood is provided with a left folding edge, a right folding edge and a front folding edge; a positioning structure is arranged on the platform; the left-side external pressing block is driven by a left outboard drive structure;the right-side external pressing block is driven by a right outboard drive structure; the left front external pressing block is driven by a left front drive structure; the right front external pressing block is driven by a right front drive structure; the left internal pressing block is constrained on the platform, can slide move and right, and is driven by a left inner-side drive structure; theright internal pressing block is constrained on the platform, can slide move and right, and is driven by a right inner-side drive structure; the middle internal pressing block is fixed onto the platform; a locating pin is fixed onto the middle internal pressing block; and the middle external pressing block is arranged in the middle of the front part of the platform and is driven by a middle drivestructure. According to the fixture, the process of welding, bonding and re-welding is completed, so that the fixture cost is reduced, meanwhile, the process is simplified, and the time and the cost are reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

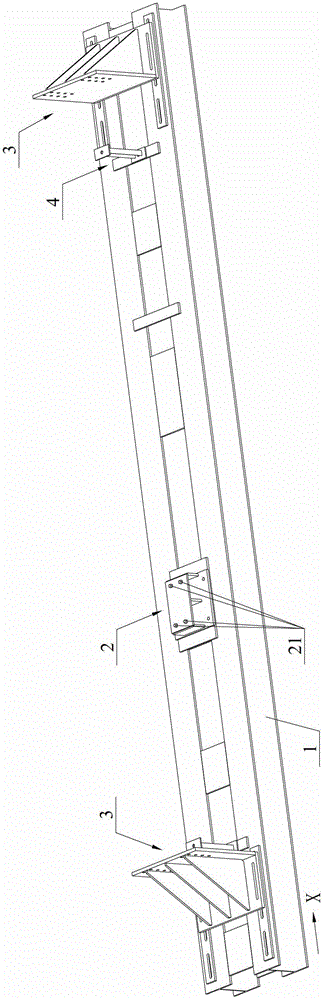

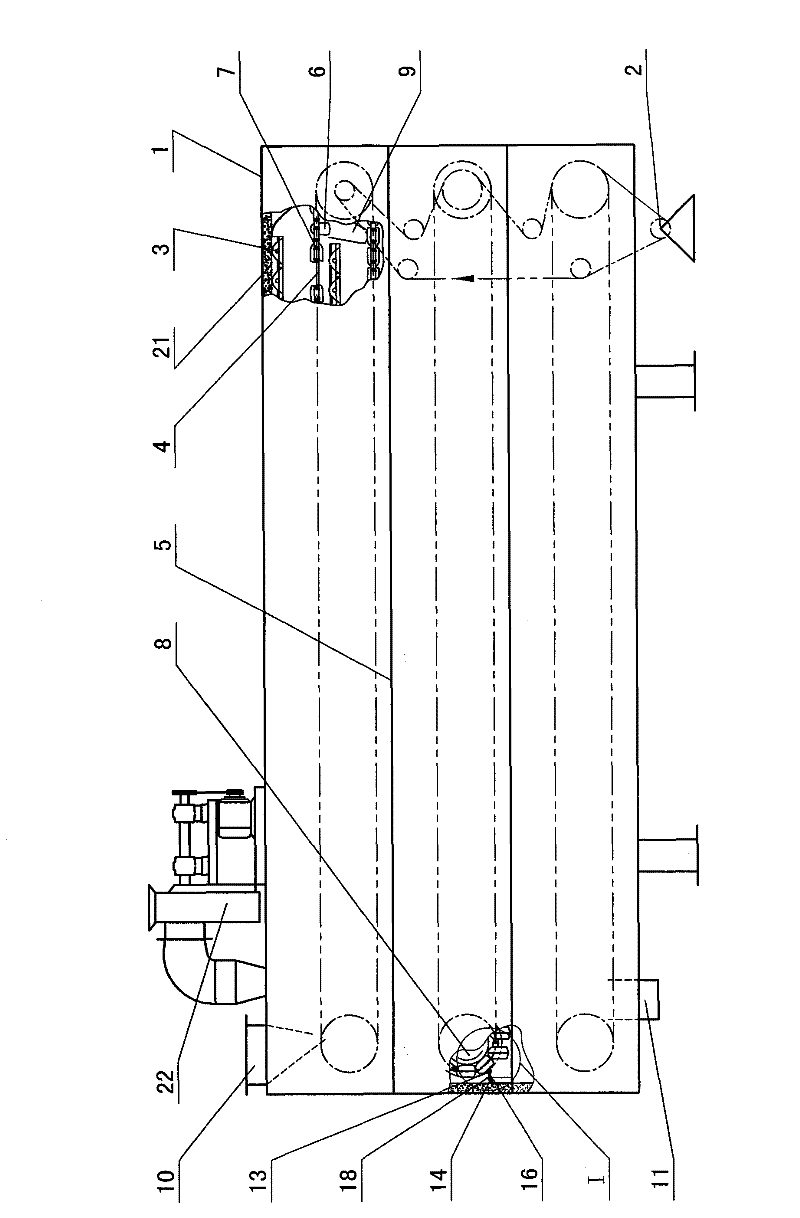

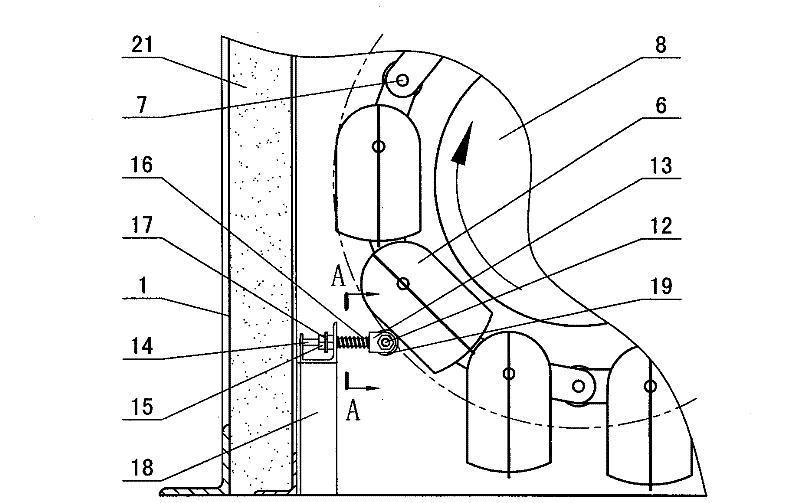

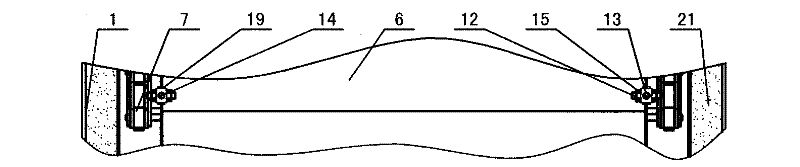

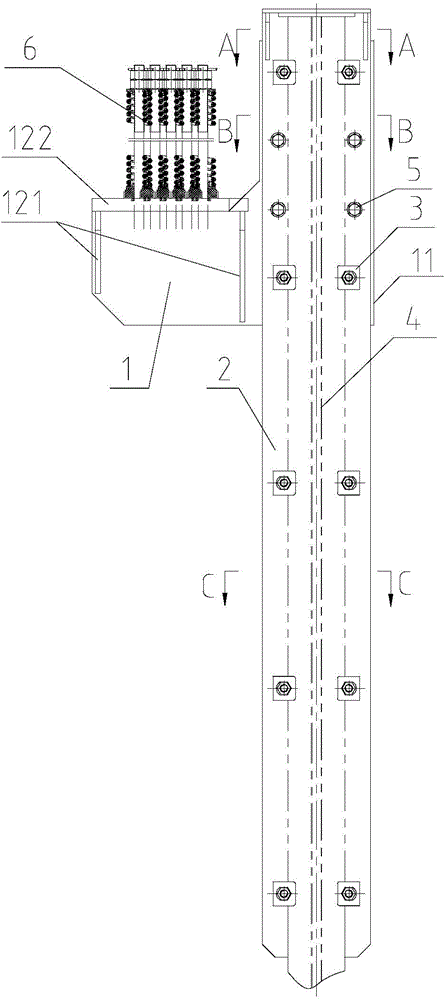

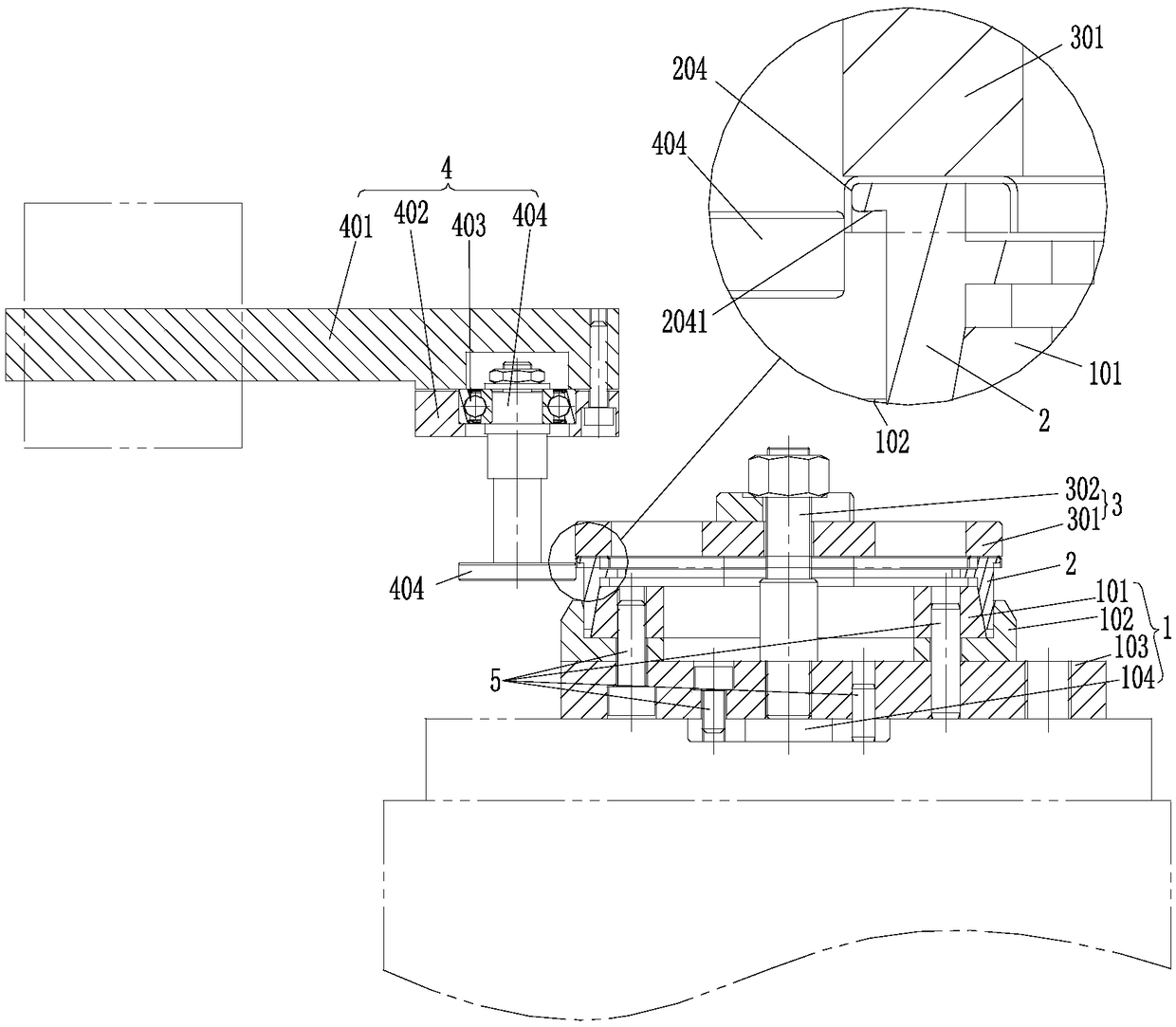

Elevator lift car rope end installing structure

The invention discloses an elevator lift car rope end installing structure, which comprises a lift car guide rail (4), a guide rail vertical plate (2) and a rope end plate (1), wherein the rope end plate (1) is used for connecting a lift car rope end, and is provided with a connecting part (11) used for connecting the guide rail vertical plate (2) and a support part (12) connected with the lift car rope end, the connecting part (11), the guide rail vertical plate (2) and the lift car guide rail (4) are fixed together through a fastening element (5), and the support part (12) is positioned at the outer side of the guide rail vertical plate (2). The elevator lift car rope end installing structure has the advantages that the rope end plate and the guide rail vertical plate are fixed together, the structure is simple, the installation is convenient, the installation of a load bearing beam is omitted, the building cost is reduced, and in addition, during the installation of the rope end plate, the relative position relationship between the rope end and the lift car guide rail is more precise.

Owner:三六零安全科技股份有限公司

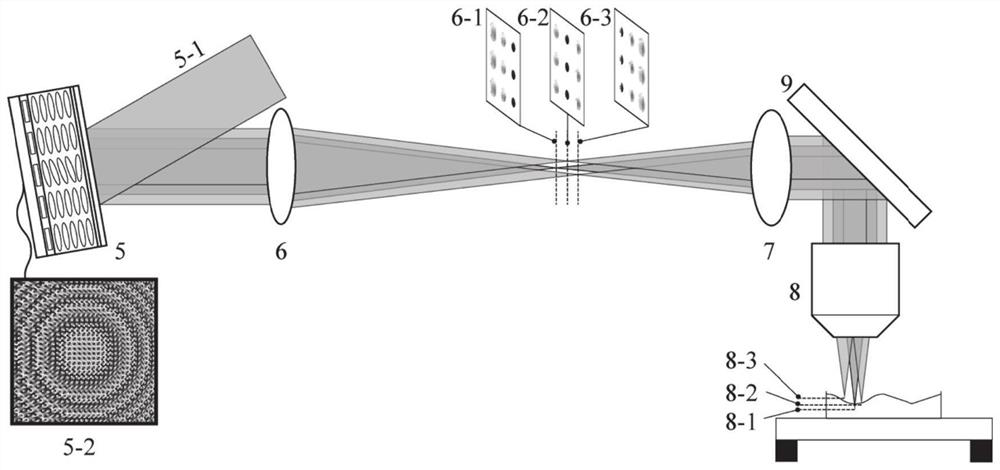

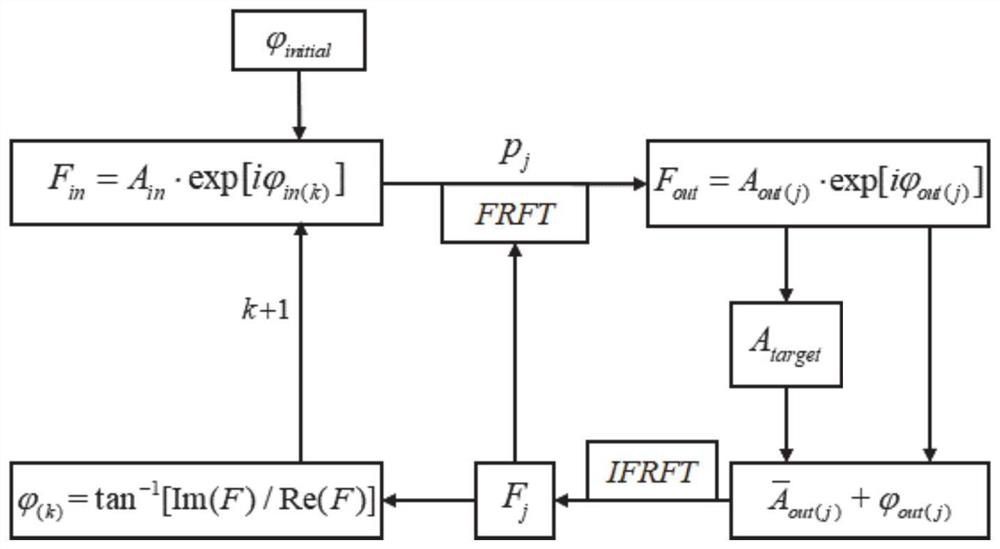

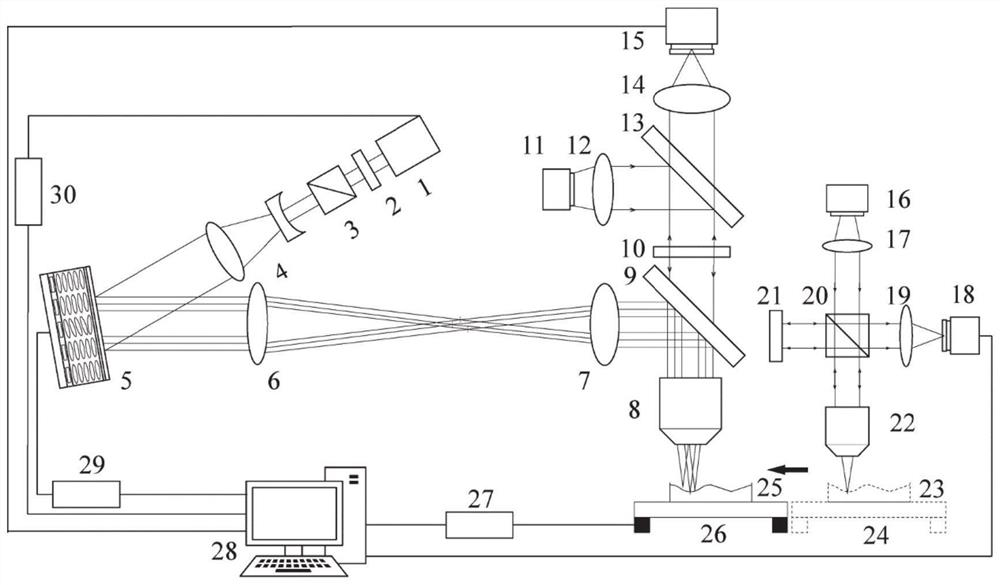

Fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring system and method

PendingCN112388159ARealize 3D parallel processingFine microstructureLaser beam welding apparatusSpatial light modulatorBeam splitter

The invention provides a fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring system and a fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring method. The system comprises a spatial light modulator, a Fourier lens, a first lens, a first spectroscope and a first focusing objective lens; the spatial light modulator is configured to receive a femtosecond laser beam and a fractional Fourier hologram and emit a plurality of paths of modulated light beams to a plurality of focusing planes; and after the light beams passing through the focusing plane sequentially pass through the first lens, the first spectroscope and the first focusing objective lens, a light spot array is focused at a plurality ofdifferent depths of a specific machining position. The system and method provided by the invention solve the problems about multi-dimensional scale machining and low efficiency, overcome the machining difficulty of a microstructure in a complex shape, effectively improve the machining quality and the machining efficiency of a microstructure in a three-dimensional distribution, improve the machining efficiency to one order of magnitude or above, remarkably shorten the machining time, and greatly improve the inter-structure position precision of three-dimensional distribution.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

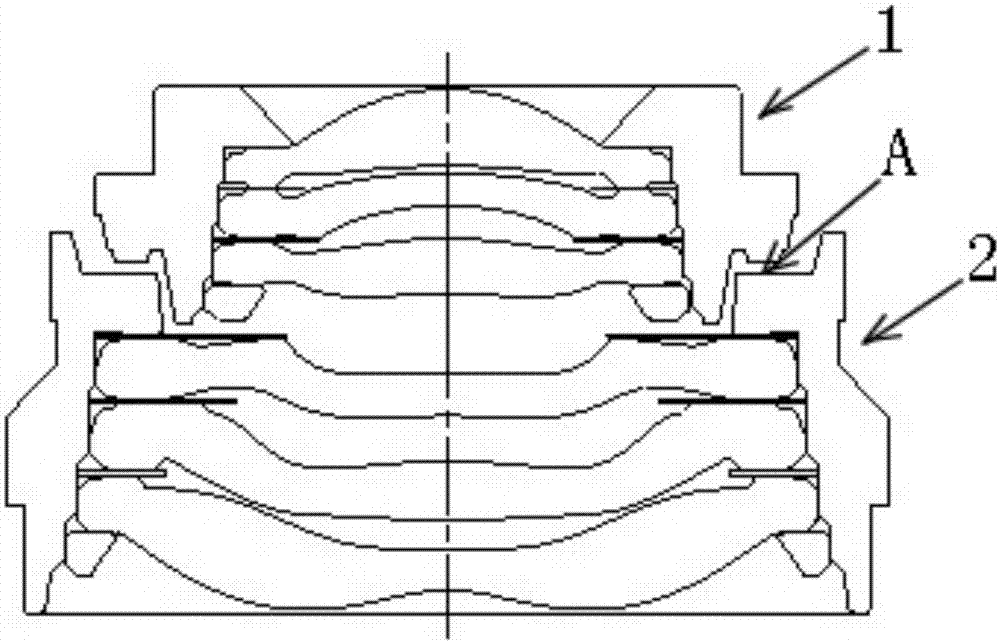

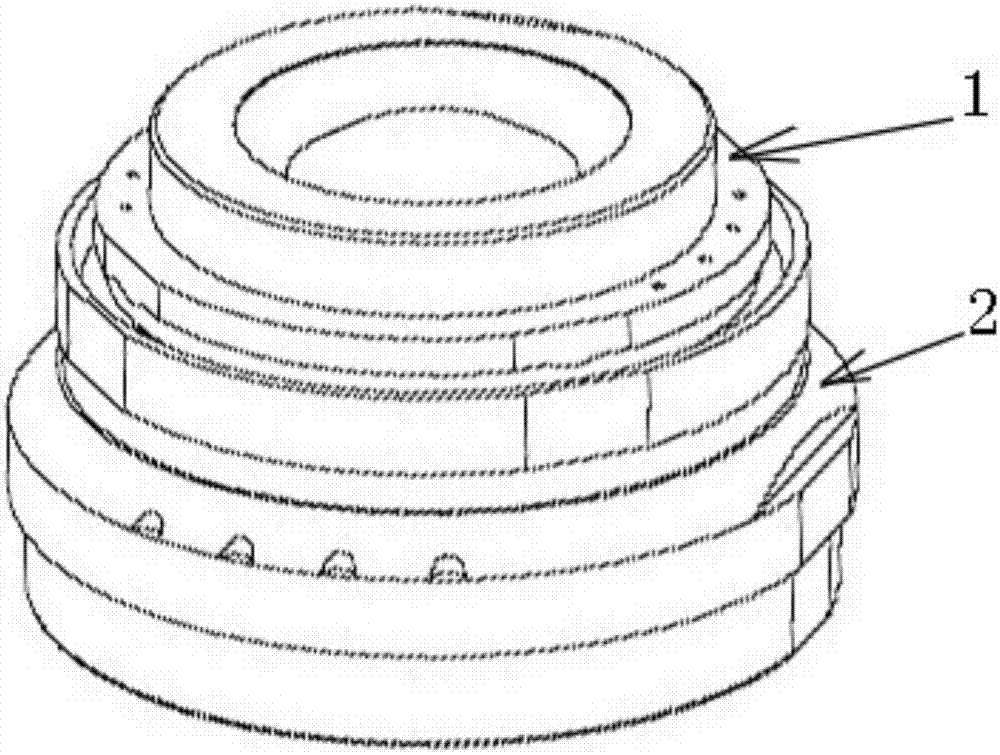

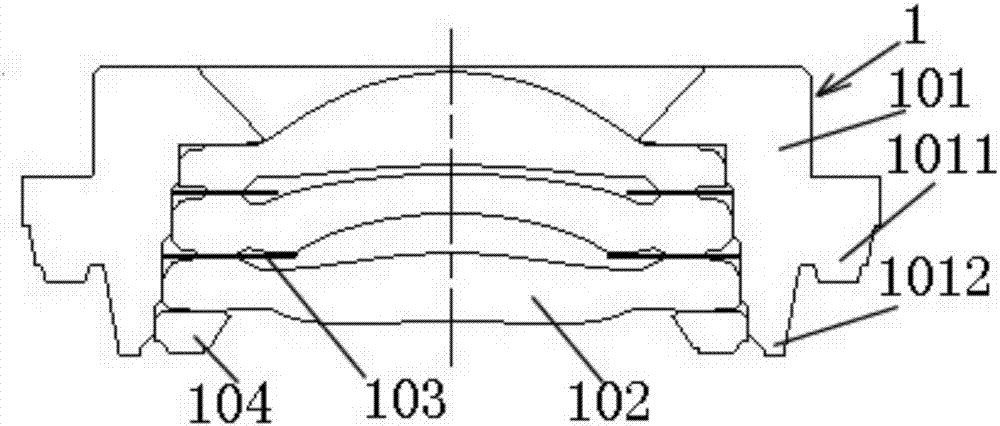

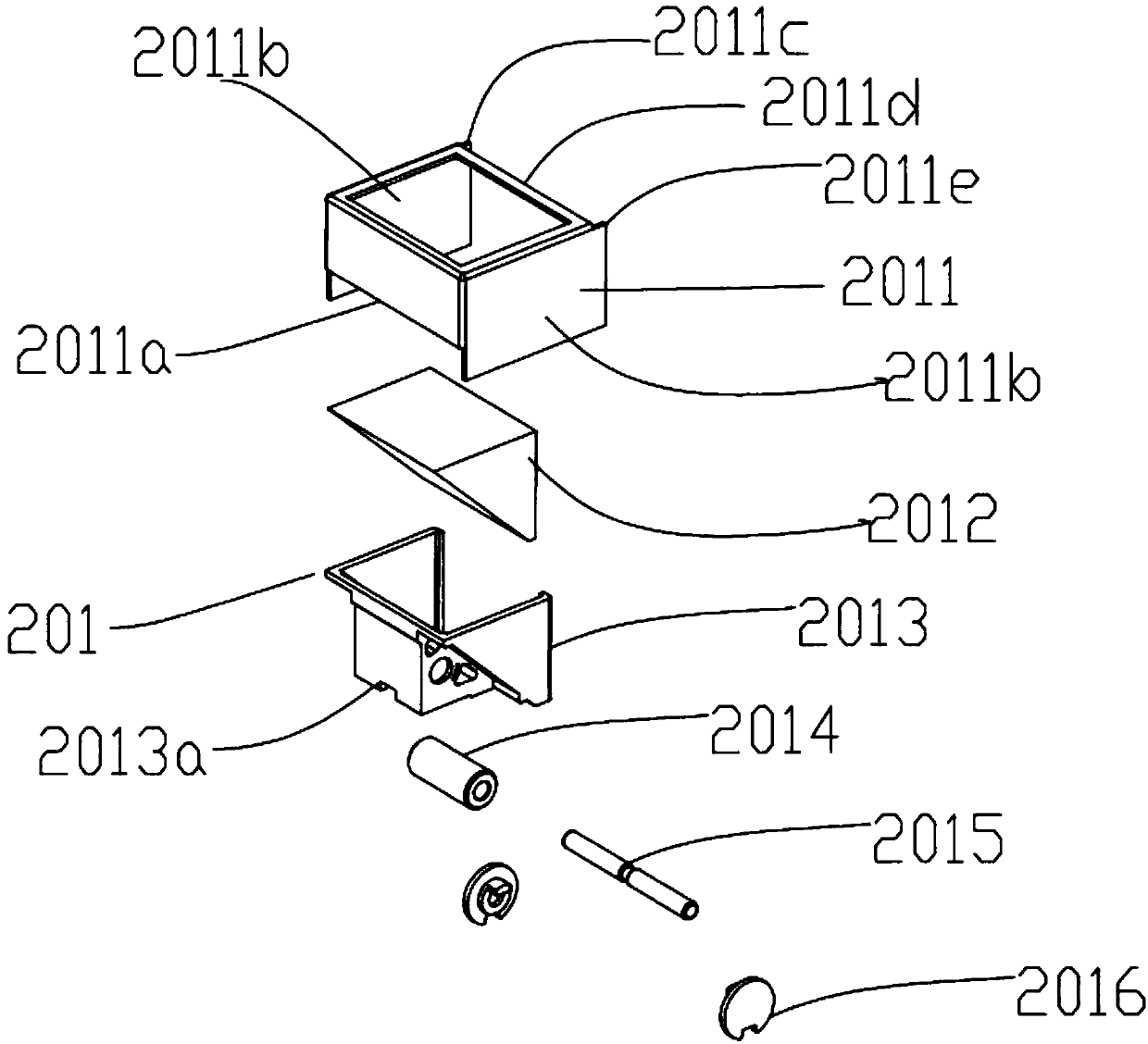

High-speed electrical connector, its signal module, and the forming method of the signal module

ActiveCN106207569BImprove stabilitySolve the deformationContact member assembly/disassemblyCoupling device detailsElectricityComputer module

The invention relates to the field of connectors, in particular to a high-speed electrical connector, a signal module thereof and a forming method of the signal module. The high-speed electrical connector includes a signal module, the signal module includes a contact piece, at least one side of the contact piece is provided with a shielding sheet, and the signal module also includes an insulator, and the insulator is molded on the contact piece and the shielding sheet to connect the contact piece and the shielding sheet pieces together. The insulator of the signal module of the electrical connector of the present invention is encapsulated on the contact piece and the shielding piece by injection molding, which enhances the firmness of the signal module and solves the problem that the signal module of the current high-speed electrical connector is easily deformed.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Machining equipment and machining method for annular groove in outer side of annular part

The invention discloses machining equipment and a machining method for an annular groove in the outer side of an annular part. The machining equipment for the annular groove in the outer side of the annular part comprises a bottom support assembly used for supporting and locating from the bottom, a shape supporting assembly fixed to the bottom support assembly and used for being supported and sleeved in a groove of a part to be machined from the bottom and forming a formed surface of the annular groove in the outer side of the part to be machined, a compression assembly located above the shapesupporting assembly and used for compressing a groove bottom plate part of the part to be machined onto the shape supporting assembly, and a spinning rolling wheel device located at the periphery ofthe shape supporting assembly and used for rolling a vertical groove wall at the outer side of the part to be machined on the shape supporting assembly in a manner of rolling to form the annular groove in the outer side, wherein the shape supporting assembly is provided with a demolding movable block used for carrying out rolling forming on the annular groove in the outer side of the part to be machined and then demolding in the radial direction of the part to be machined. The machining equipment for the annular groove in the outer side of the annular part is simple in structure, and blockingduring demolding for the part is eliminated, so that the machined part can be taken out without damage. The machining equipment and the machining method for the annular groove in the outer side of theannular part are applicable to machining and demolding for annular grooves in the outer sides of various annular parts.

Owner:CHINA HANGFA SOUTH IND CO LTD

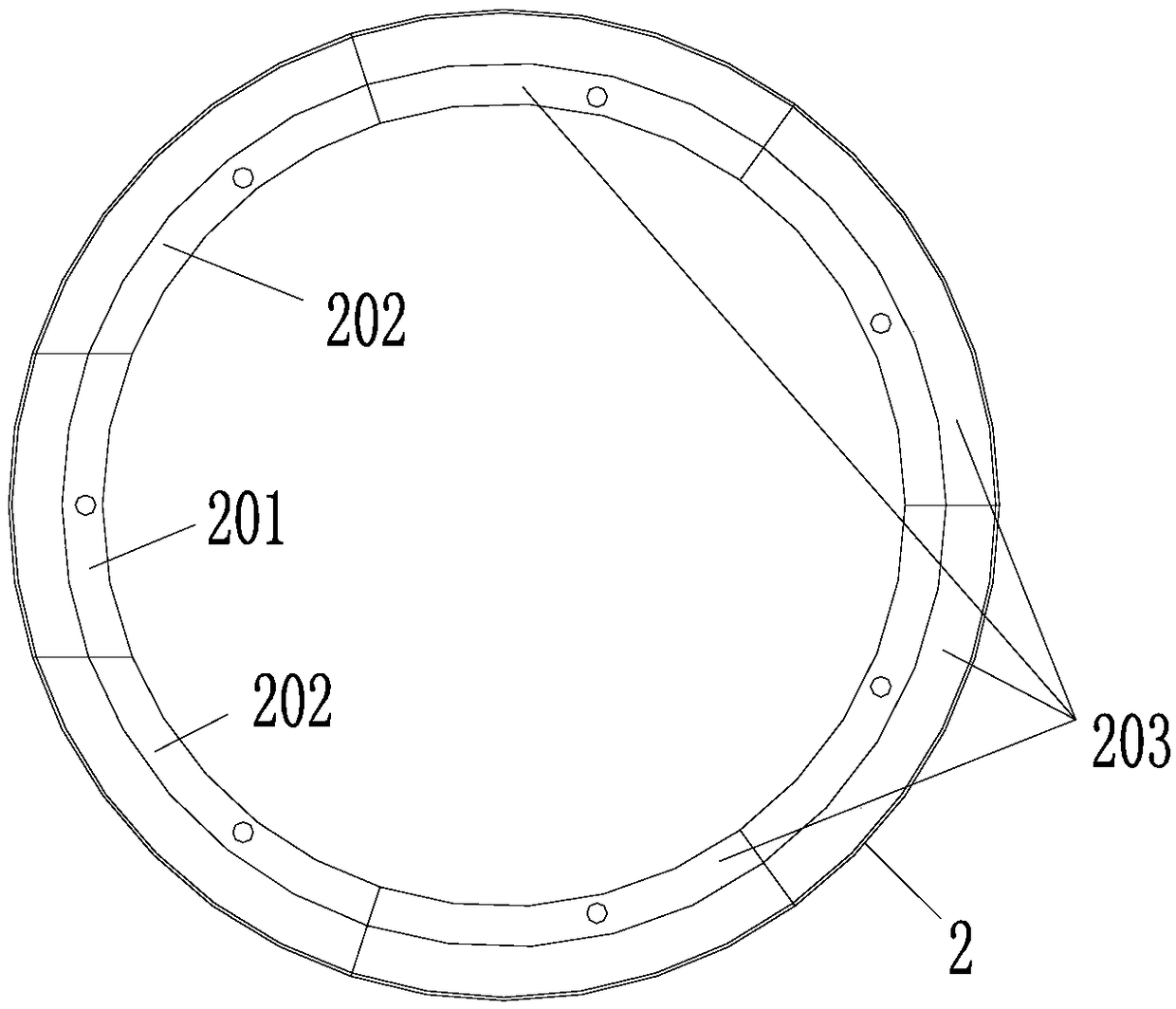

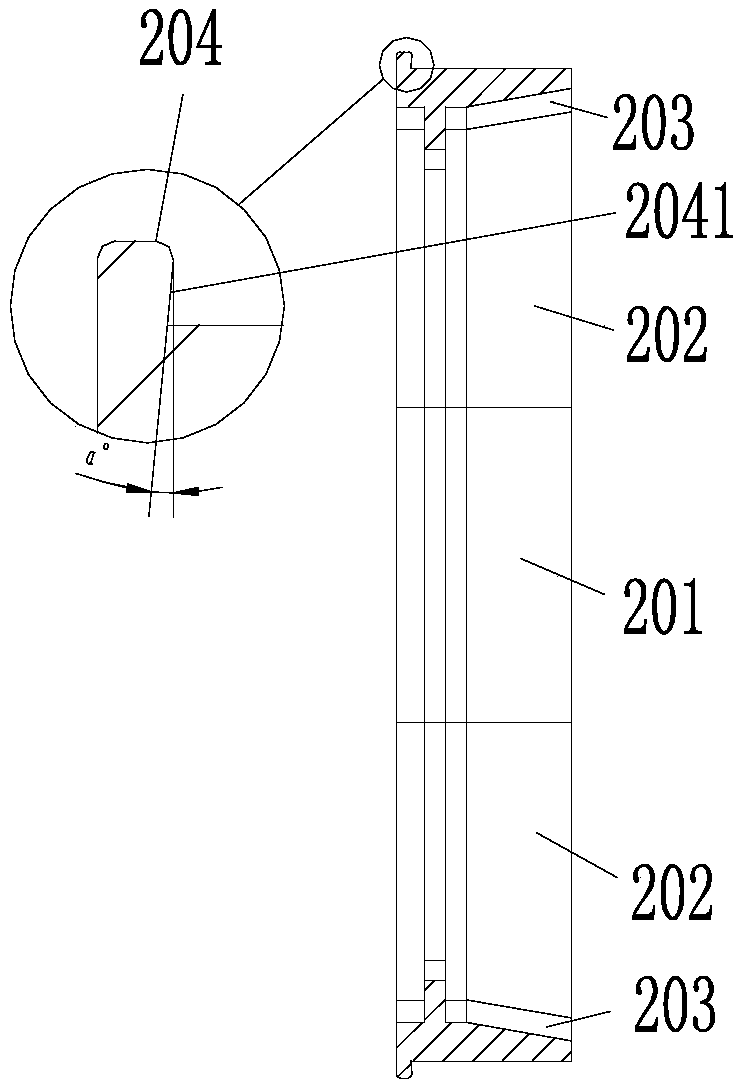

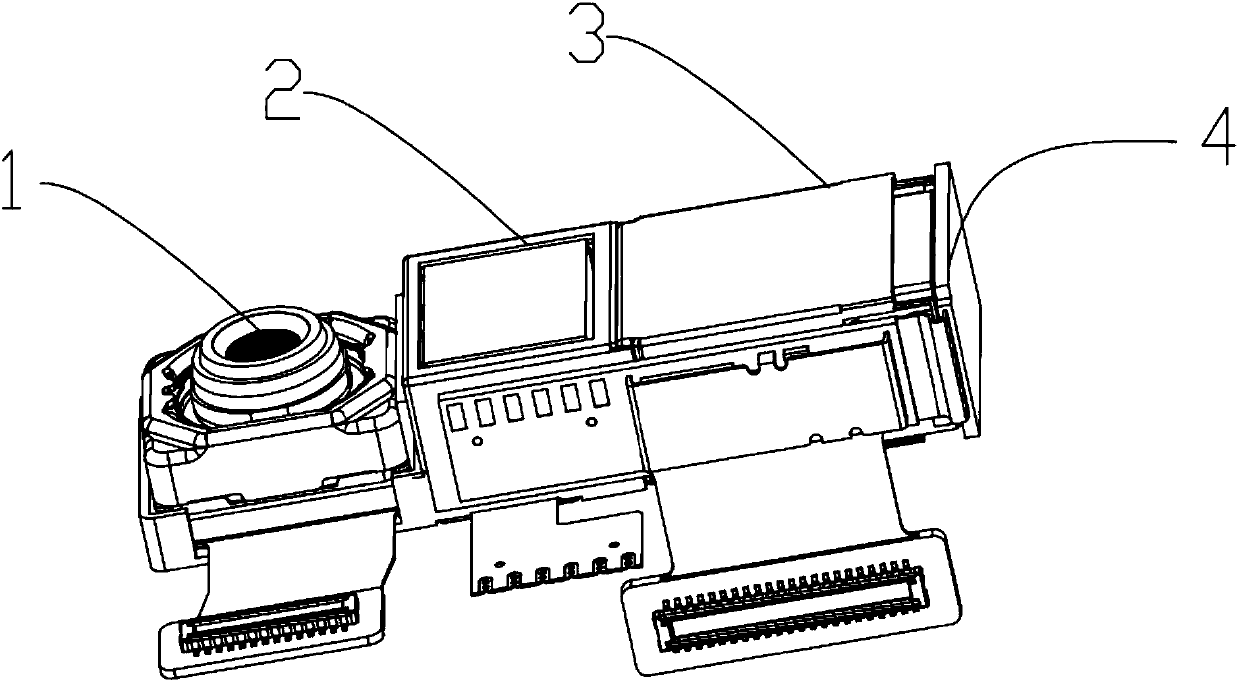

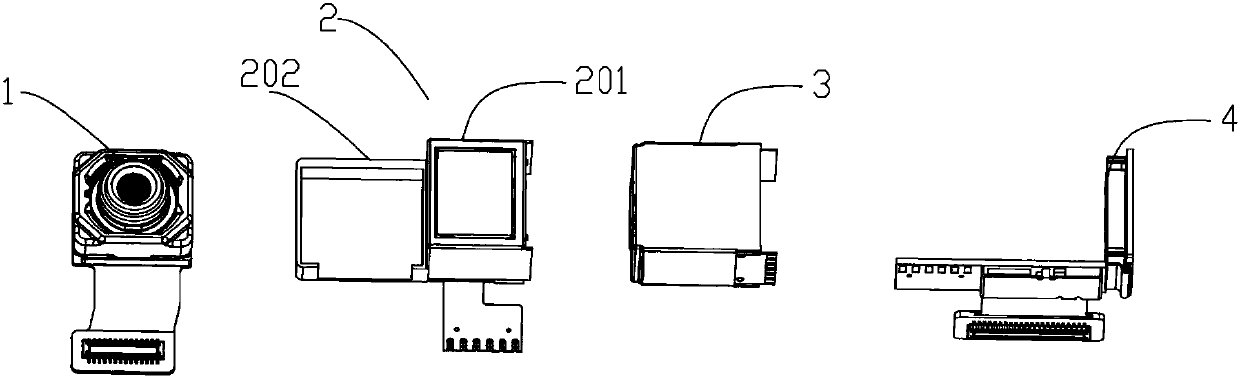

Double-shooting zooming module

PendingCN107783246AGuaranteed image qualityImprove rigidityMountingsFocusing aidsMating connectionOptical axis

The invention relates to a double-shooting zooming module. The double-shooting zooming module comprises a first shooting module, a prism module, a second shooting module and a circuit board. The double-shooting zooming module is characterized in that the first shooting module and the prism module are arranged in a co-plane mode, and the prism module and an optical axis of the second shooting module are coaxially arranged. According to the double-shooting zooming module, a prism base is provided with an intermediate reinforcing plate to reinforce the prism base, the prism base is further provided with a positioning projection, the second shooting module is provided with a positioning hole, the positioning projection and the projection hole are in matching connection to guarantee that the mutual position relationship is correct, and imaging quality is improved. The double-shooting zooming module is advantaged in that the split structure is employed, different components are divided intodifferent units, the different parts are then assembled into one body, so the parts can be flexibly changed, and cost and maintenance expenditure are saved.

Owner:NINGBO SUNNY OPOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com