Fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring system and method

A fractional Fourier and fractional Fourier technology, which is applied in the field of fractional Fourier holographic femtosecond laser three-dimensional parallel processing and monitoring systems, can solve the problems of shortening processing time and low efficiency, and improve the utilization rate of laser energy. , The application is flexible and variable, and the effect of reducing processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

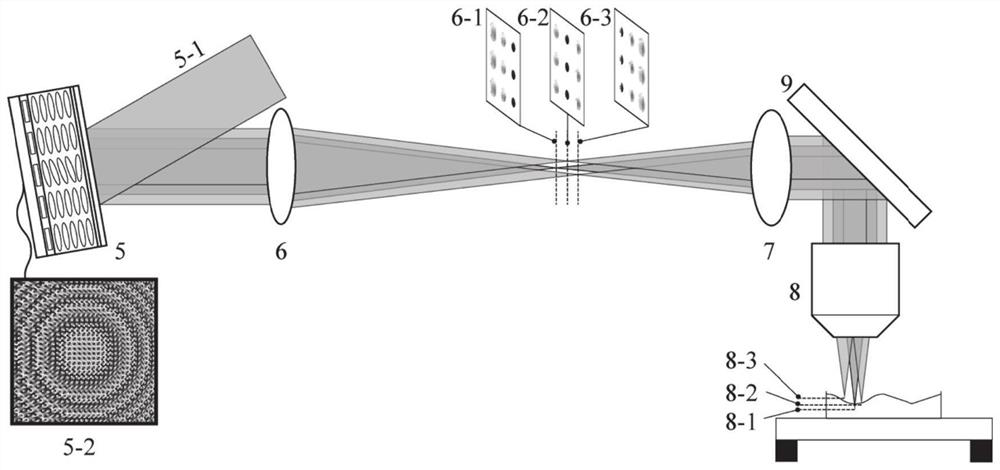

[0059]As introduced in the background art, the existing laser processing technology has processing dimensions and efficiency limitations, which have become an obstacle to the development and industrial application of laser micro-nano manufacturing technology. In order to solve the above technical problems and break through the limitations of laser multi-dimensional processing and efficiency, Embodiment 1 of the present disclosure proposes a fractional Fourier holographic femtosecond laser three-dimensional parallel processing system, such asfigure 1 withfigure 2 Shown.

[0060]The system described in this embodiment can use a programmable liquid crystal spatial light modulator (LOC-SLM) to modulate the femtosecond laser beam without changing the focal length of the lens to control the focus position of the beam to obtain a three-dimensional, arbitrarily distributed focused spot array. It is a precise and efficient multi-dimensional laser processing method that can realize the three-dim...

Embodiment 2

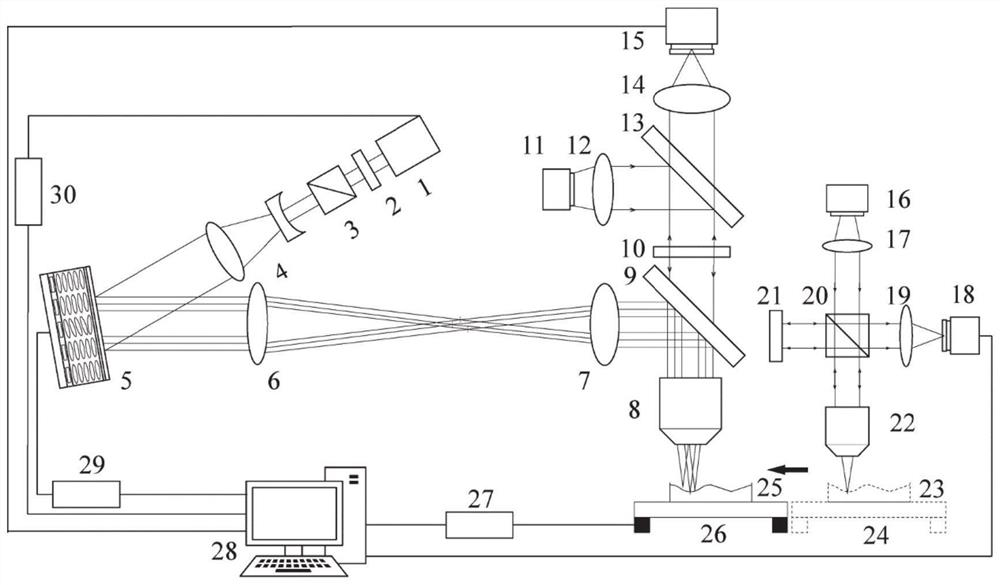

[0072]Embodiment 2 of the present disclosure provides a fractional Fourier holographic femtosecond laser three-dimensional parallel processing monitoring system, such asimage 3 ,Figure 4 withFigure 5 As shown, it includes the parallel processing system described in Embodiment 1 of the present disclosure and the LED white light source 11, the first collimator 12, the second beam splitter 13, the infrared filter 10, the second lens 14, and the first CCD camera 15. ;

[0073]The light beam emitted by the LED white light source 11 sequentially passes through the first collimator 12, the second beam splitter 13, the infrared filter 10 and the first focusing objective lens 8 to reach the surface of the workpiece;

[0074]The reflected light reaches the first CCD camera 15 after passing through the first focusing objective lens 8, the infrared filter 10, the second beam splitter 13, and the second lens 14, and real-time monitoring of workpiece processing is carried out according to the image rec...

Embodiment 3

[0082]The present disclosure Example 3 provides a three-dimensional parallel processing method of fractal Fourier holographic femtosecond laser, using the monitoring system described in Example 2, including the following steps:

[0083]S1: Optical Interferometry Measuring the surface profile of the workpiece, transmitting the camera to the camera to obtain a surface three-dimensional shape by image processing;

[0084]S2: Combined with the three-dimensional shape of the workpiece surface and the distribution, size, shape, etc. of the target microstructure, and the control center converts the surface profile of the workpiece to the point array information;

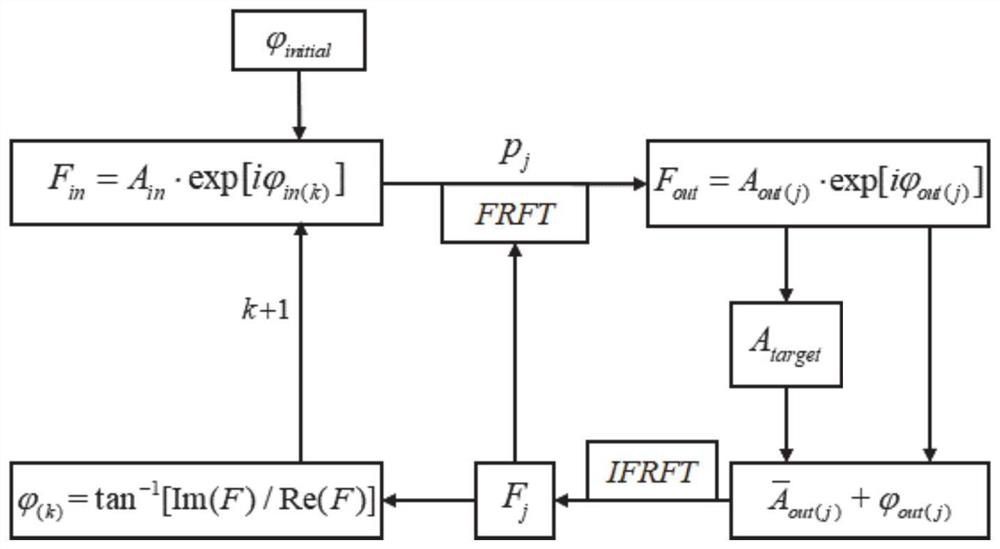

[0085]S3: According to different depth information, design target patterns and corresponding coordinate files; the same position in the three-dimensional distribution focus array corresponds to the same range, and calculates three-dimensional division of Fourier hologram through iterative fractional Fourier transform algorithm. ;

[0086]S4:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com