Patents

Literature

374results about "Optical axis determination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

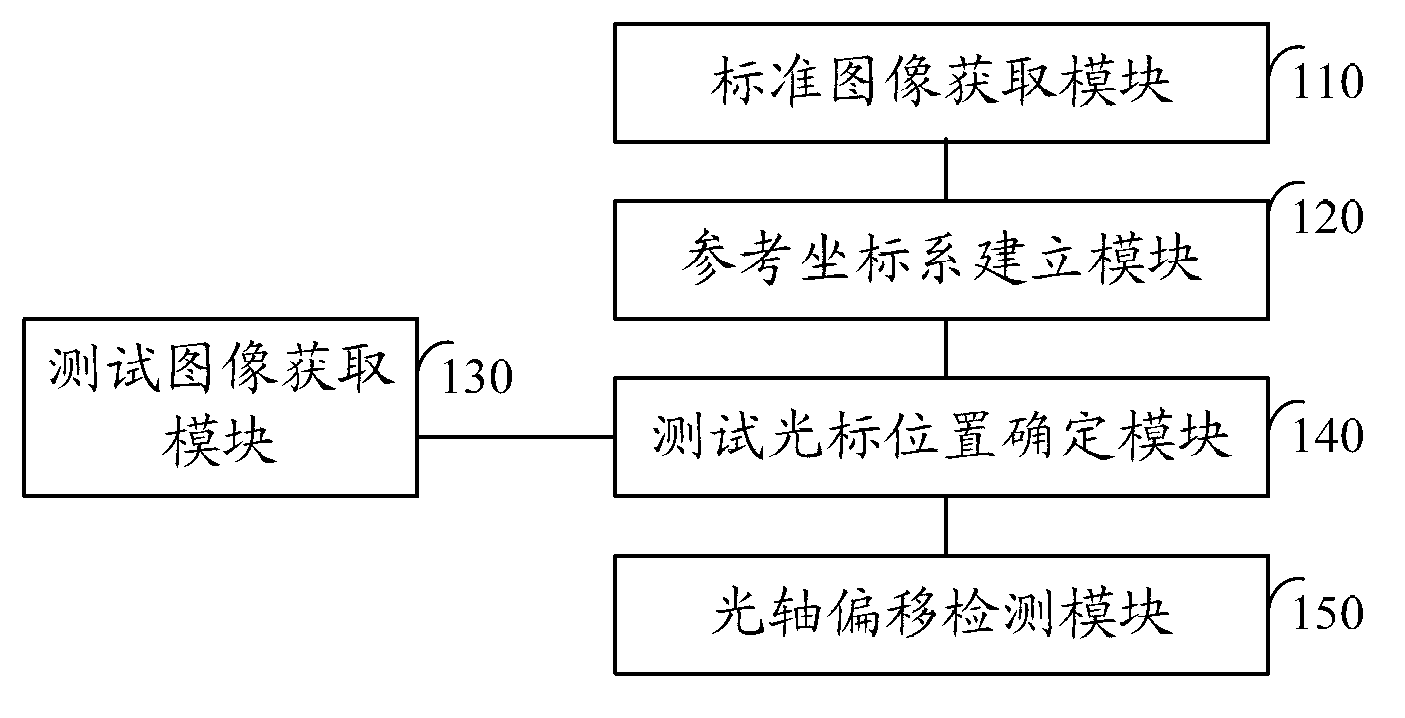

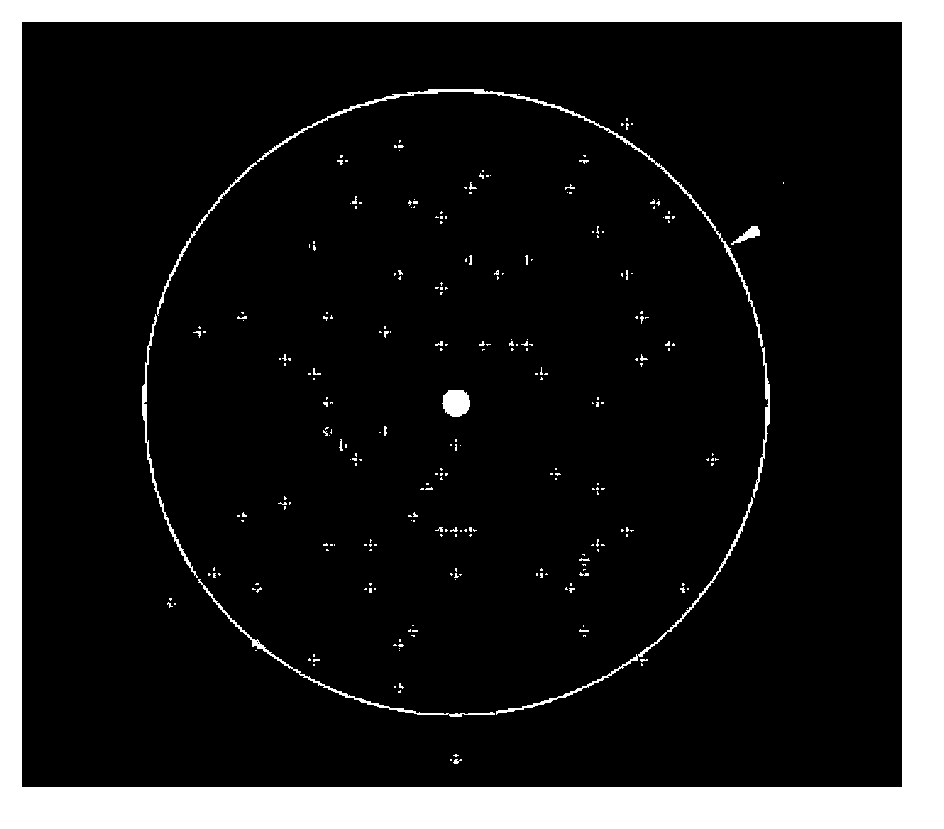

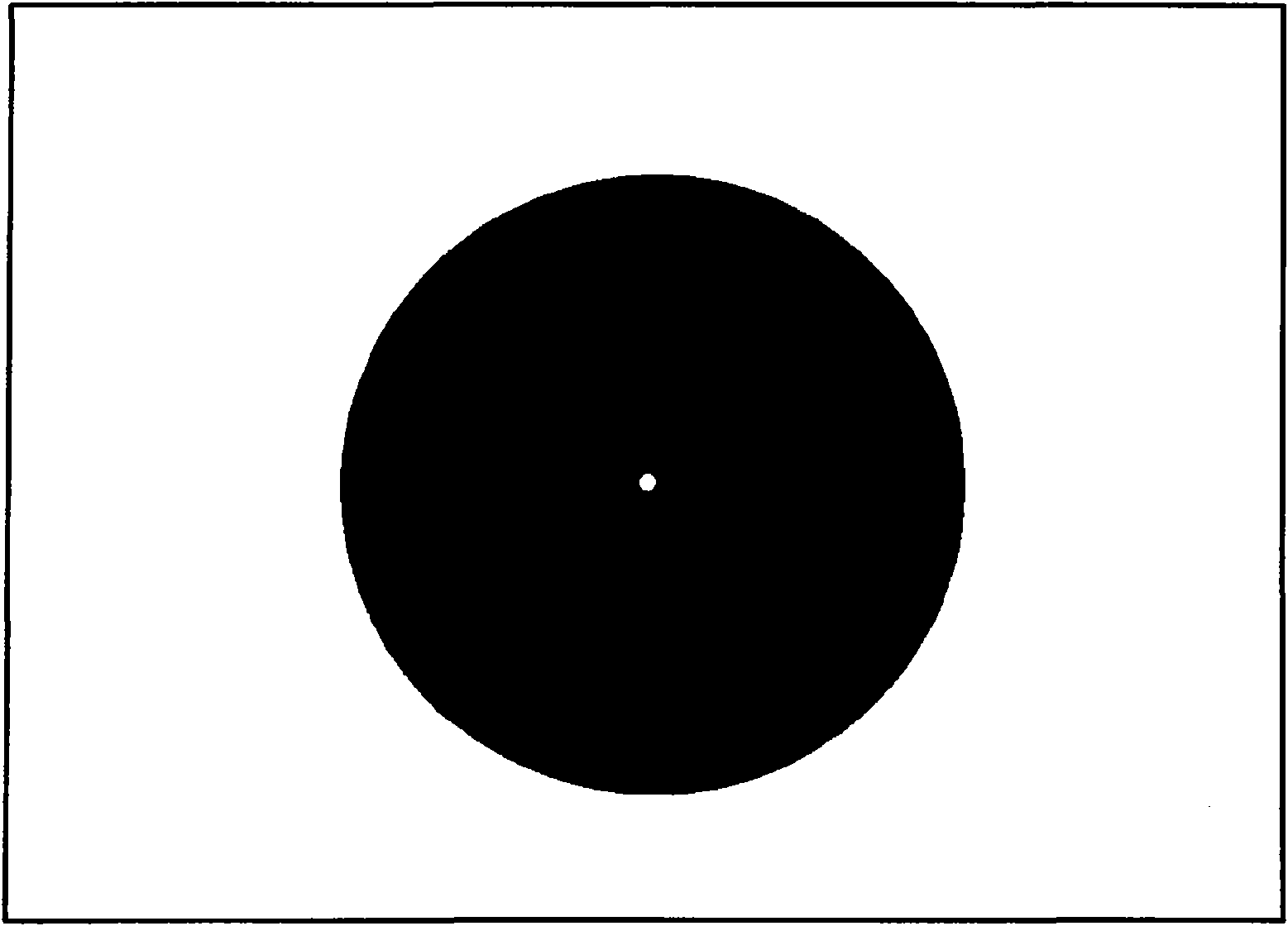

Device and method for detecting optical-axis offset of lens in equipment

ActiveCN103018015AEasy to detectUsing optical meansOptical axis determinationCamera lensOptical axis

The invention discloses a device and a method for detecting optical-axis offset of a lens in equipment. The device comprises a standard image acquiring module, a reference coordinate system setup module, a test image acquiring module, a test cursor position determining module and an optical-axis offset detecting module, wherein the standard image acquiring module is used for focusing a standard lens assembled in the equipment at a pickup position, picking up an image sample and acquiring a standard image of the image sample; the reference coordinate system setup module is used for taking the center of the standard image as coordinate origin and setting up a reference coordinate system; the test image acquiring module is used for focusing a to-be-detected lens assembled in the equipment at the pickup position, picking up the image sample and acquiring a test image of the image sample; the test cursor position determining module is used for taking the center of the test image as test cursor and determining the position of the test cursor in the reference coordinate system; and the optical-axis offset detecting module is used for determining optical-axis offset and / or optical-axis offset angle of the to-be-detected lens according the position. The device and the method for detecting optical-axis offset of the lens can solve the technical problem that the optical-axis offset of the lens in the equipment cannot be detected during assembly.

Owner:GOERTEK OPTICAL TECH CO LTD

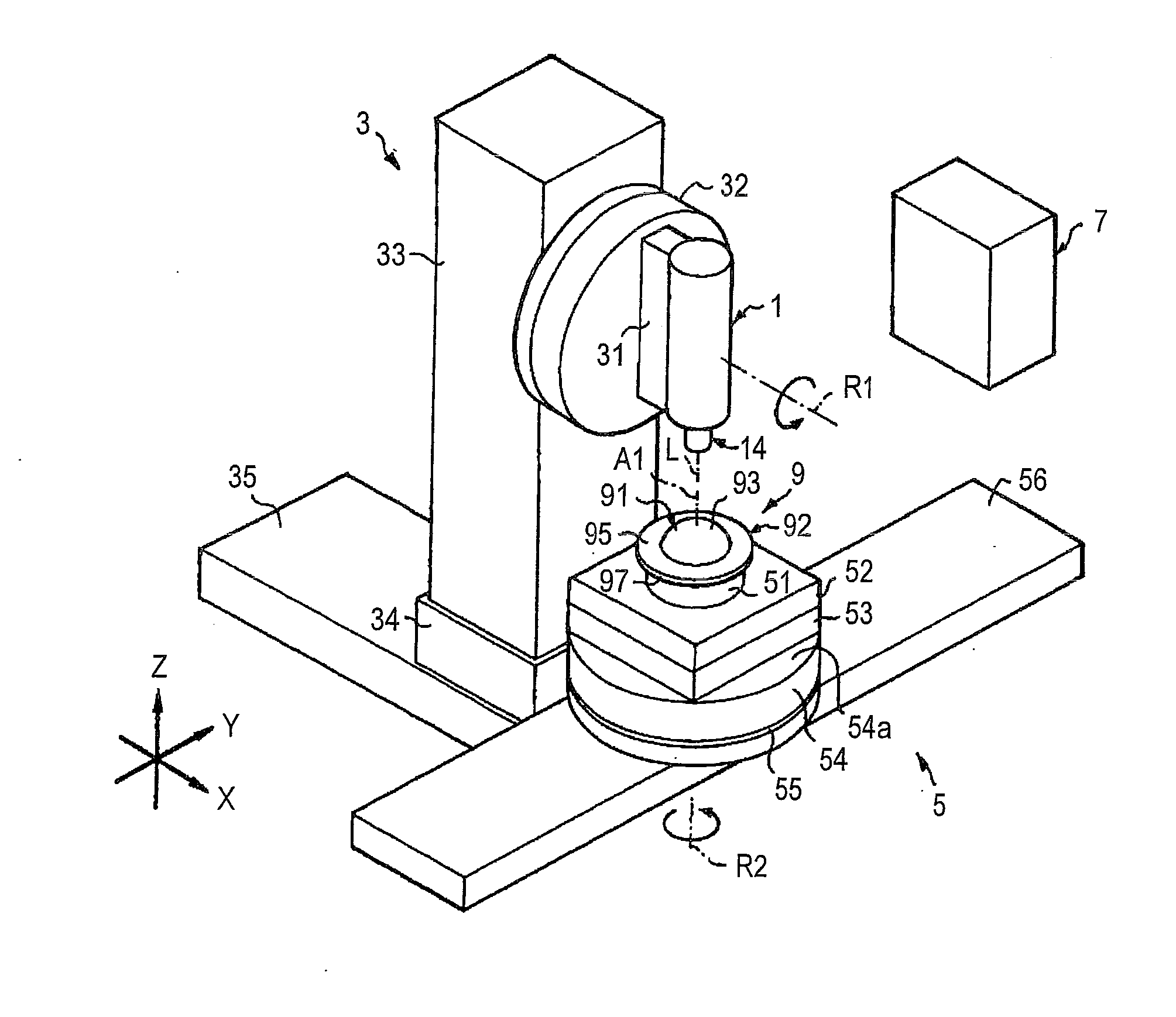

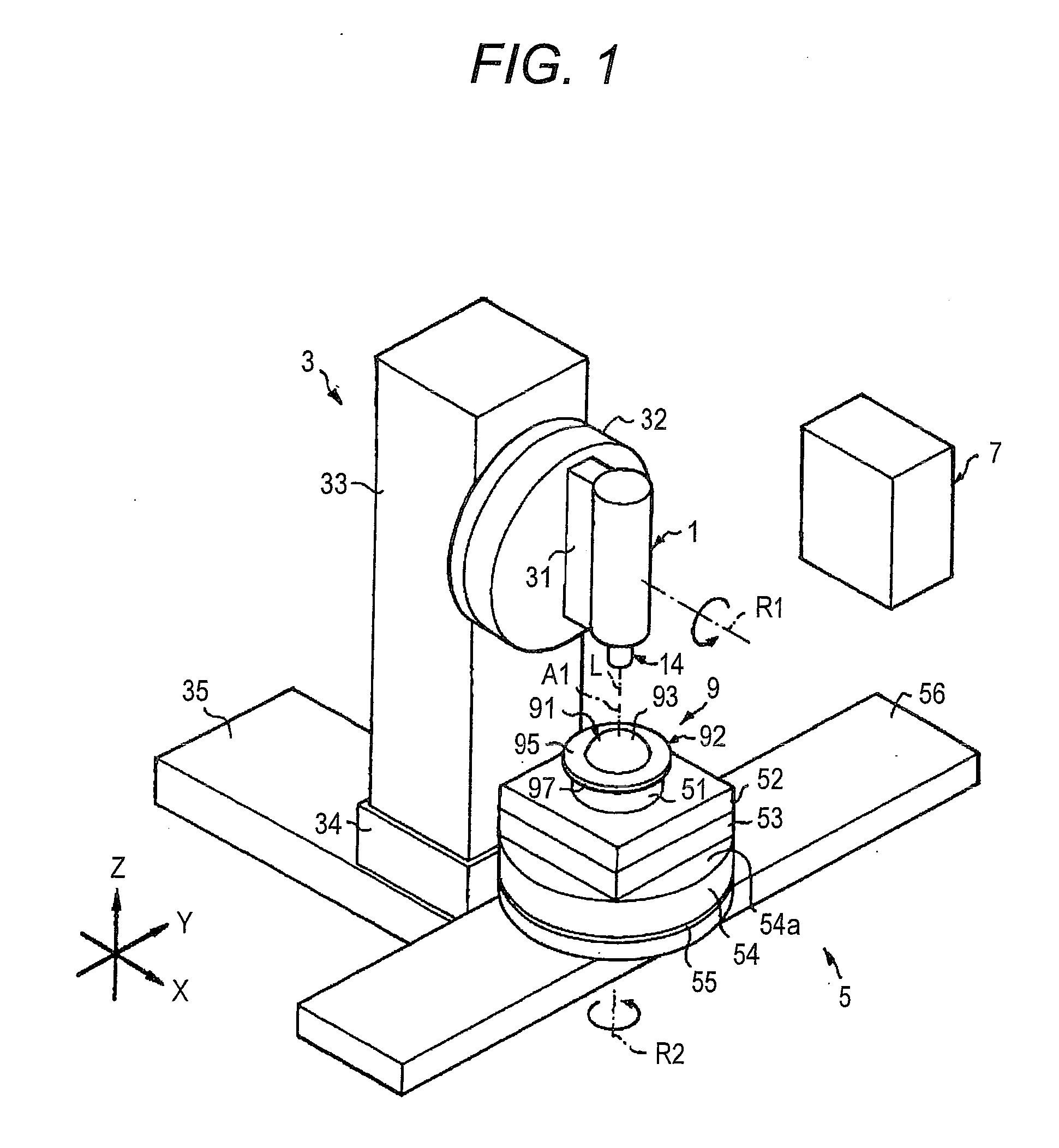

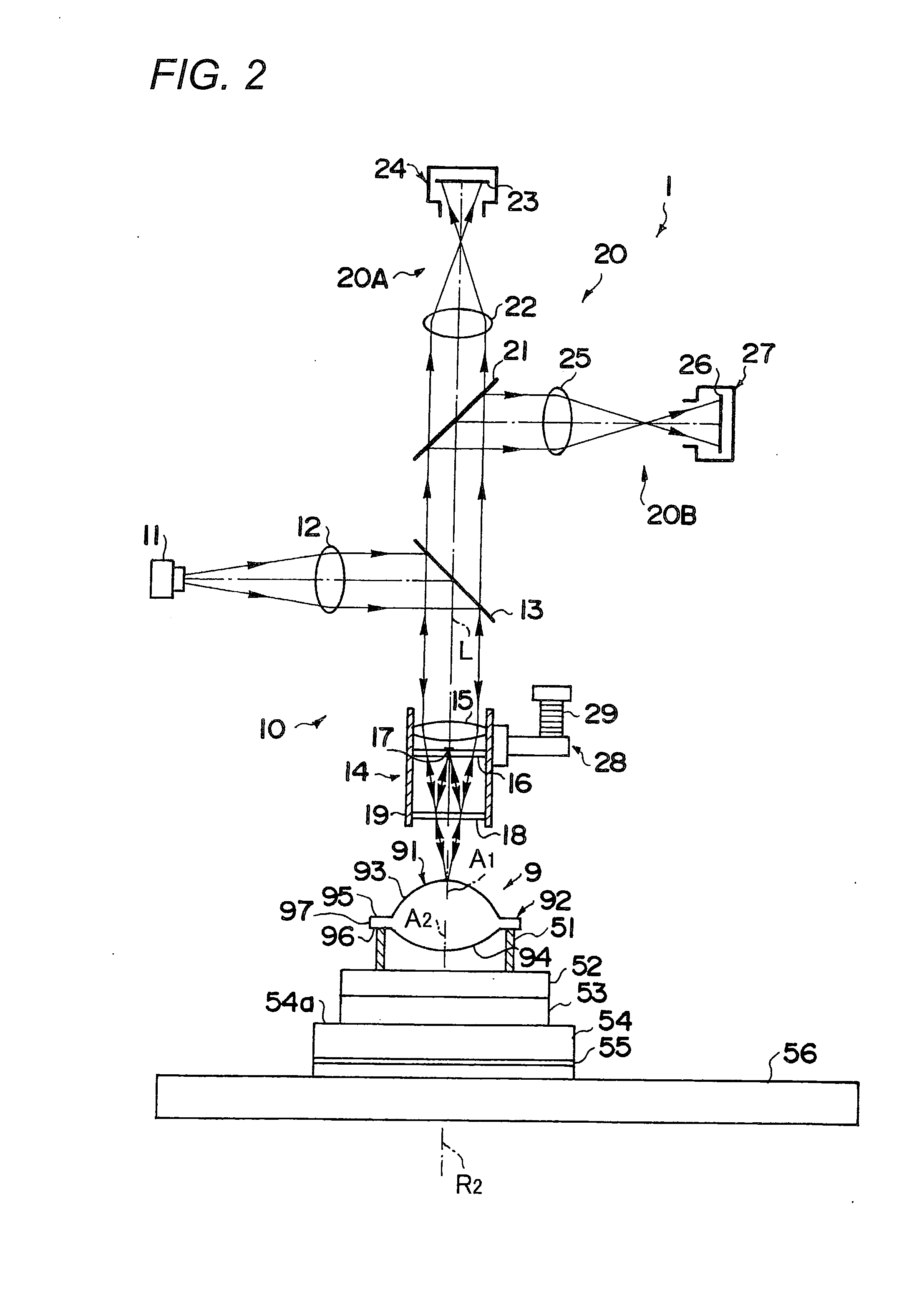

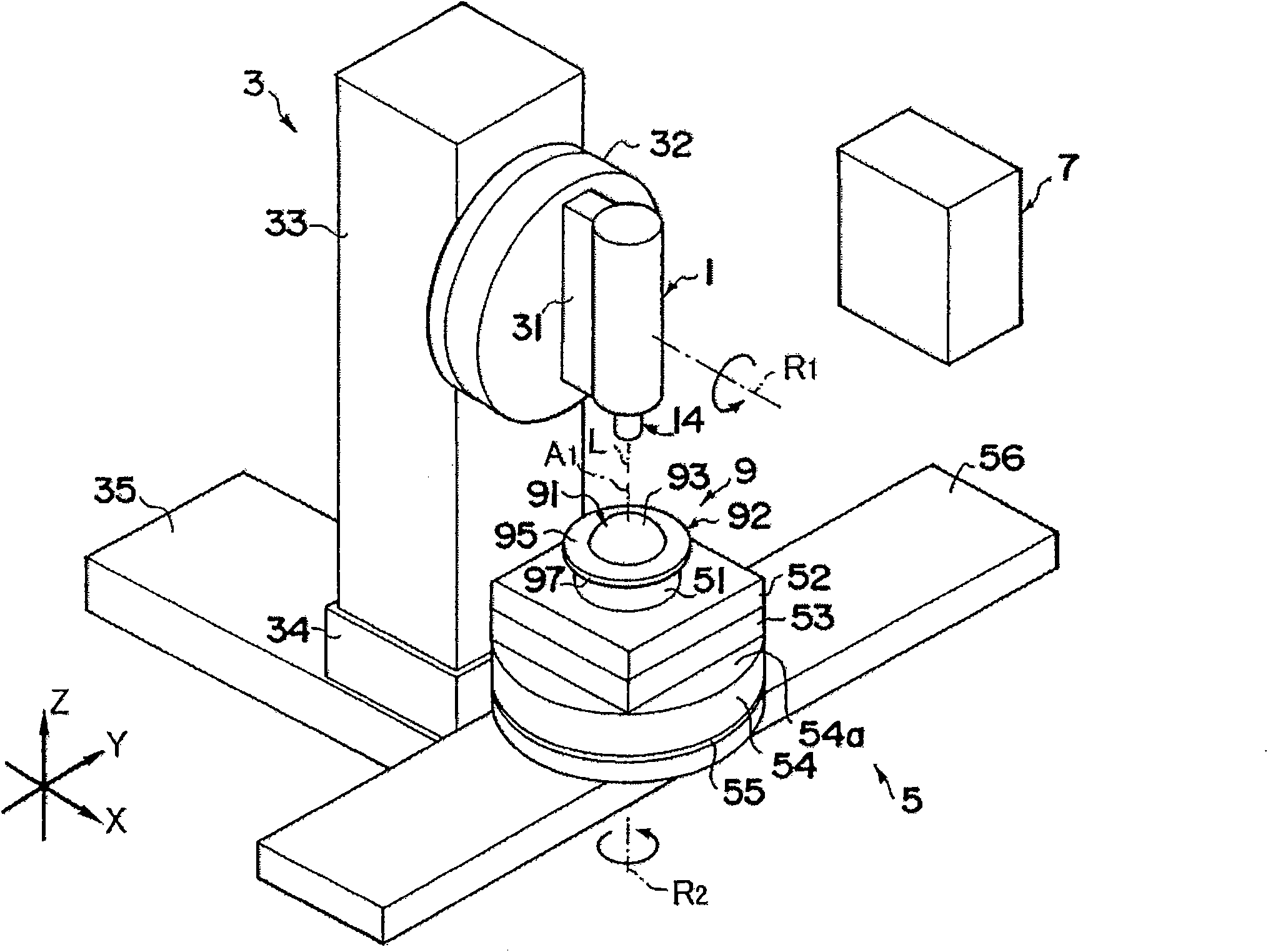

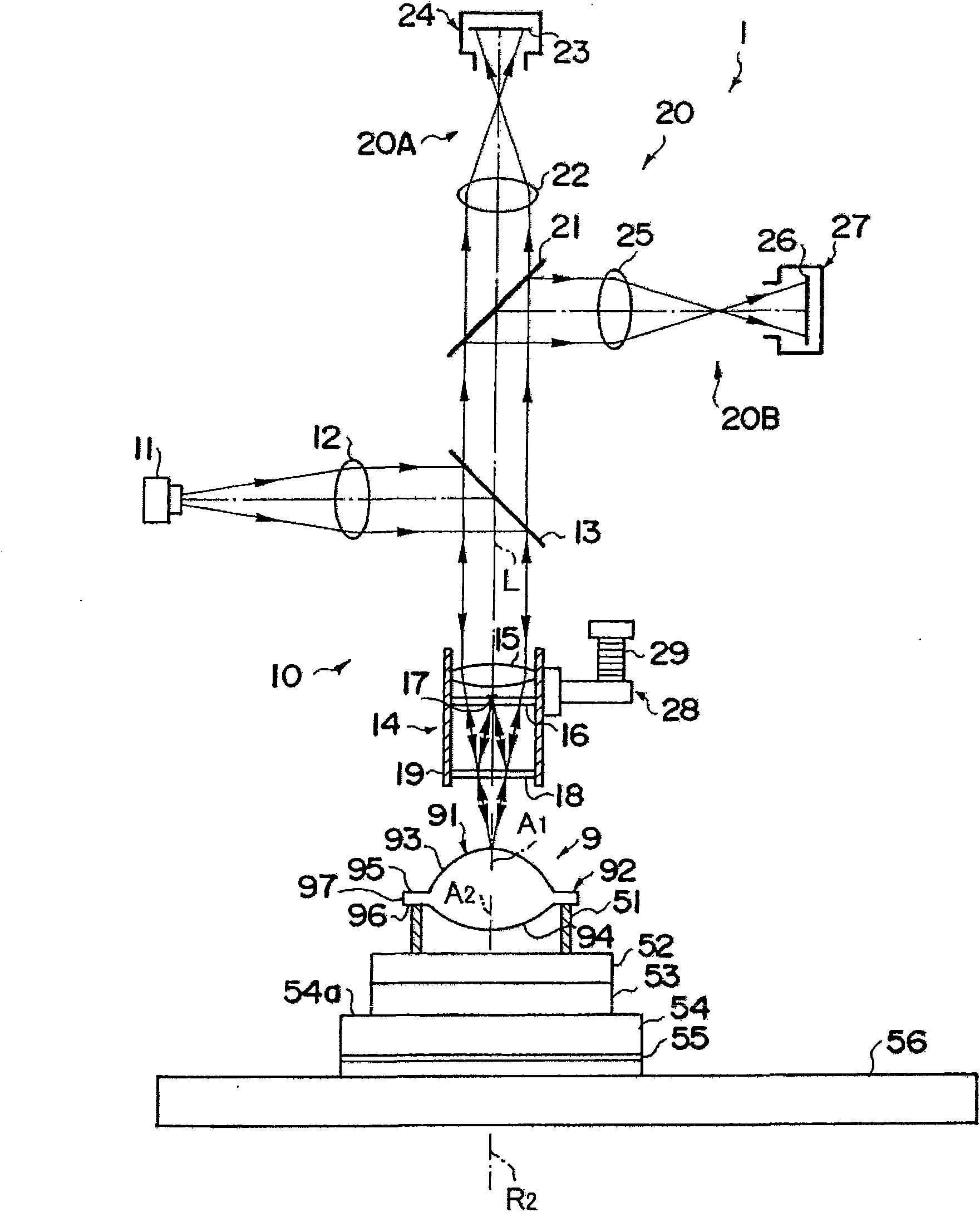

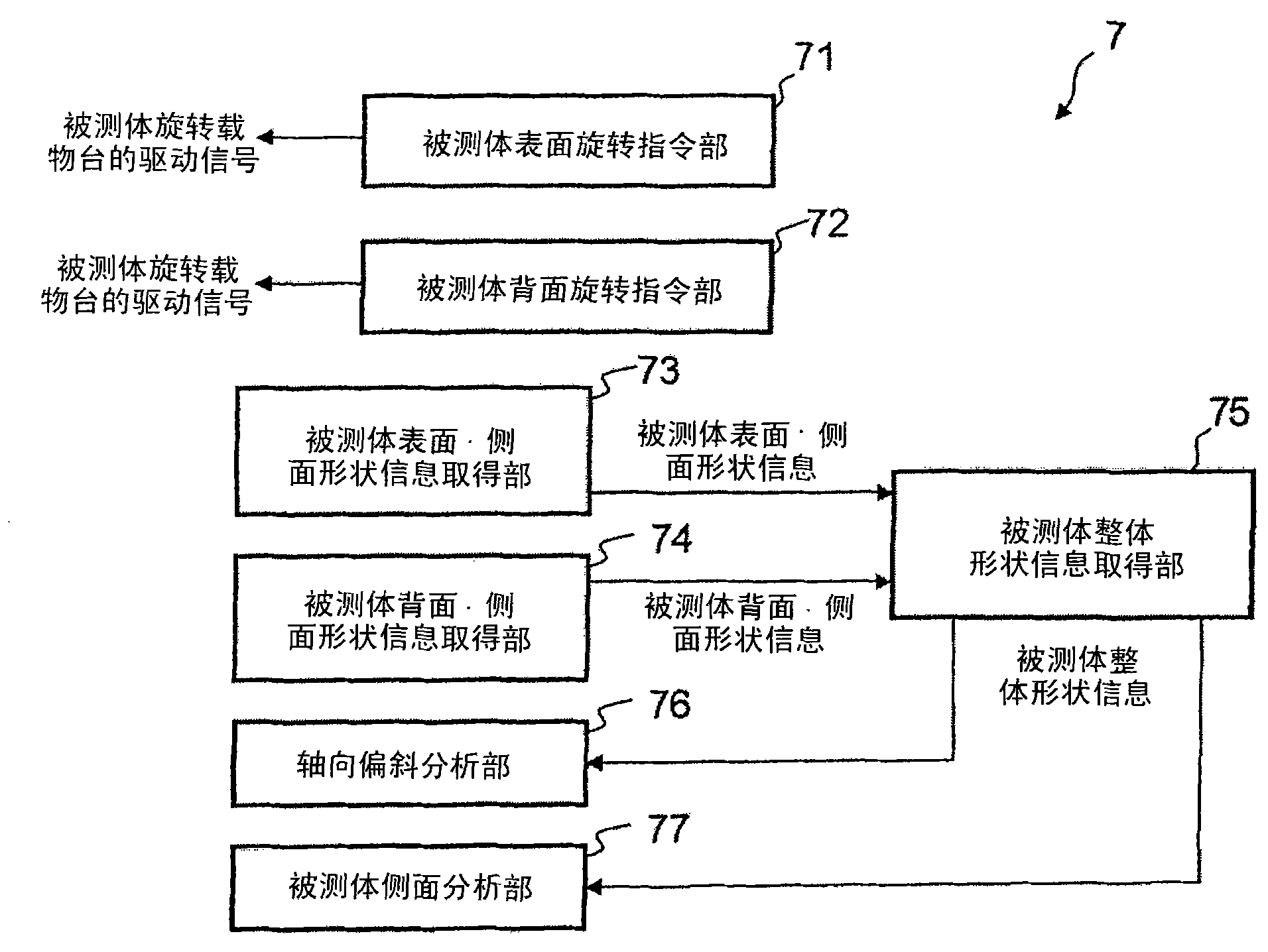

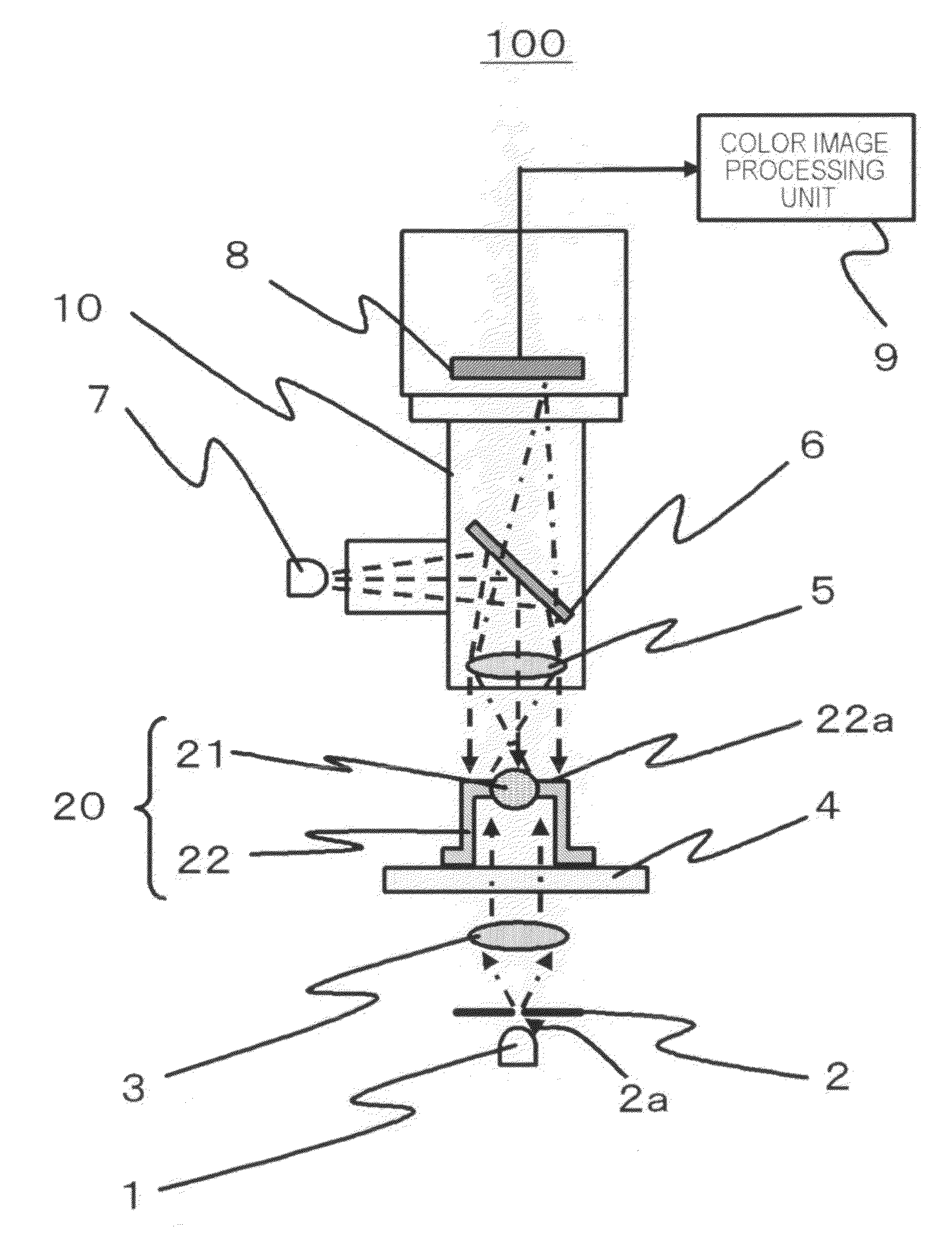

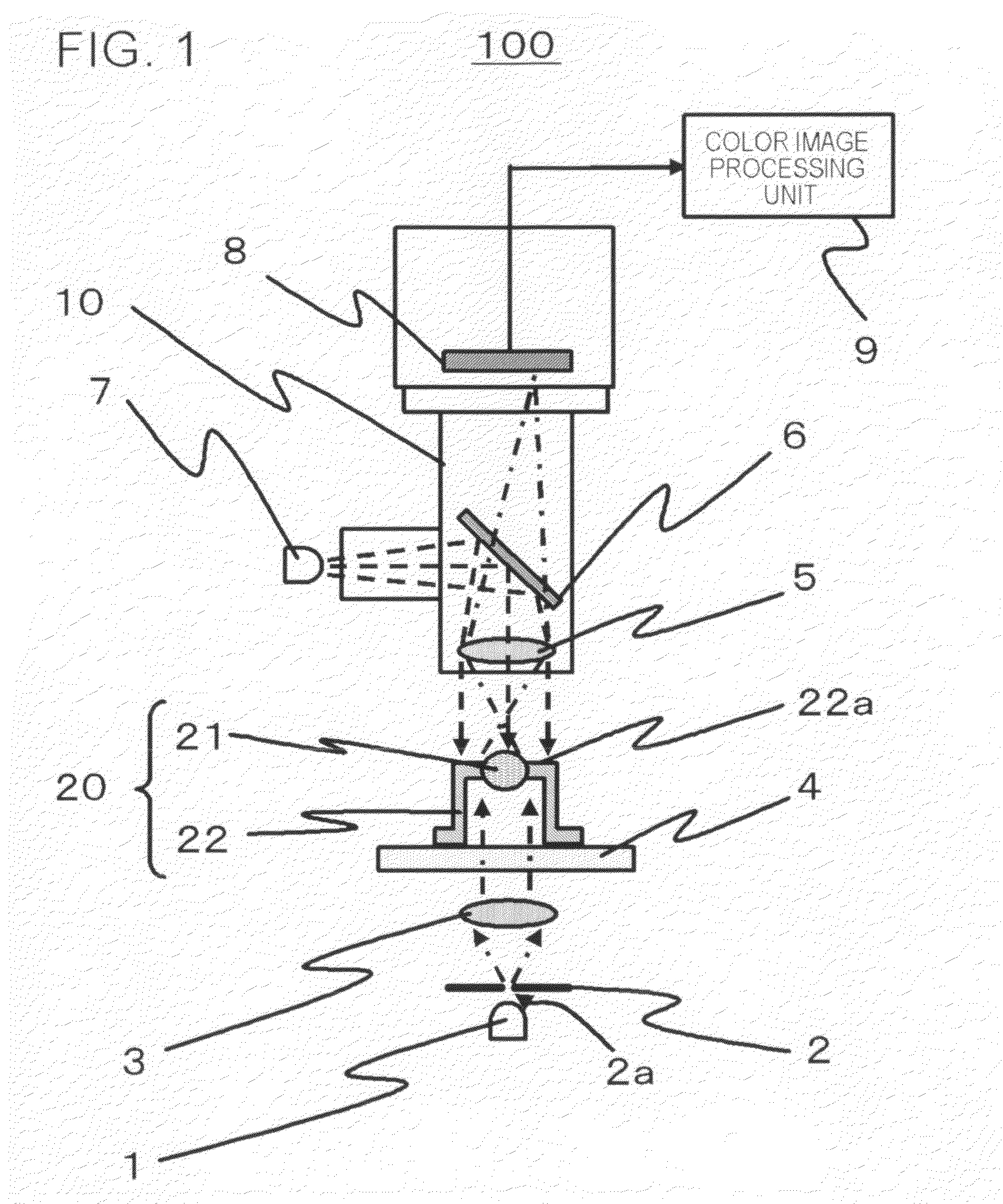

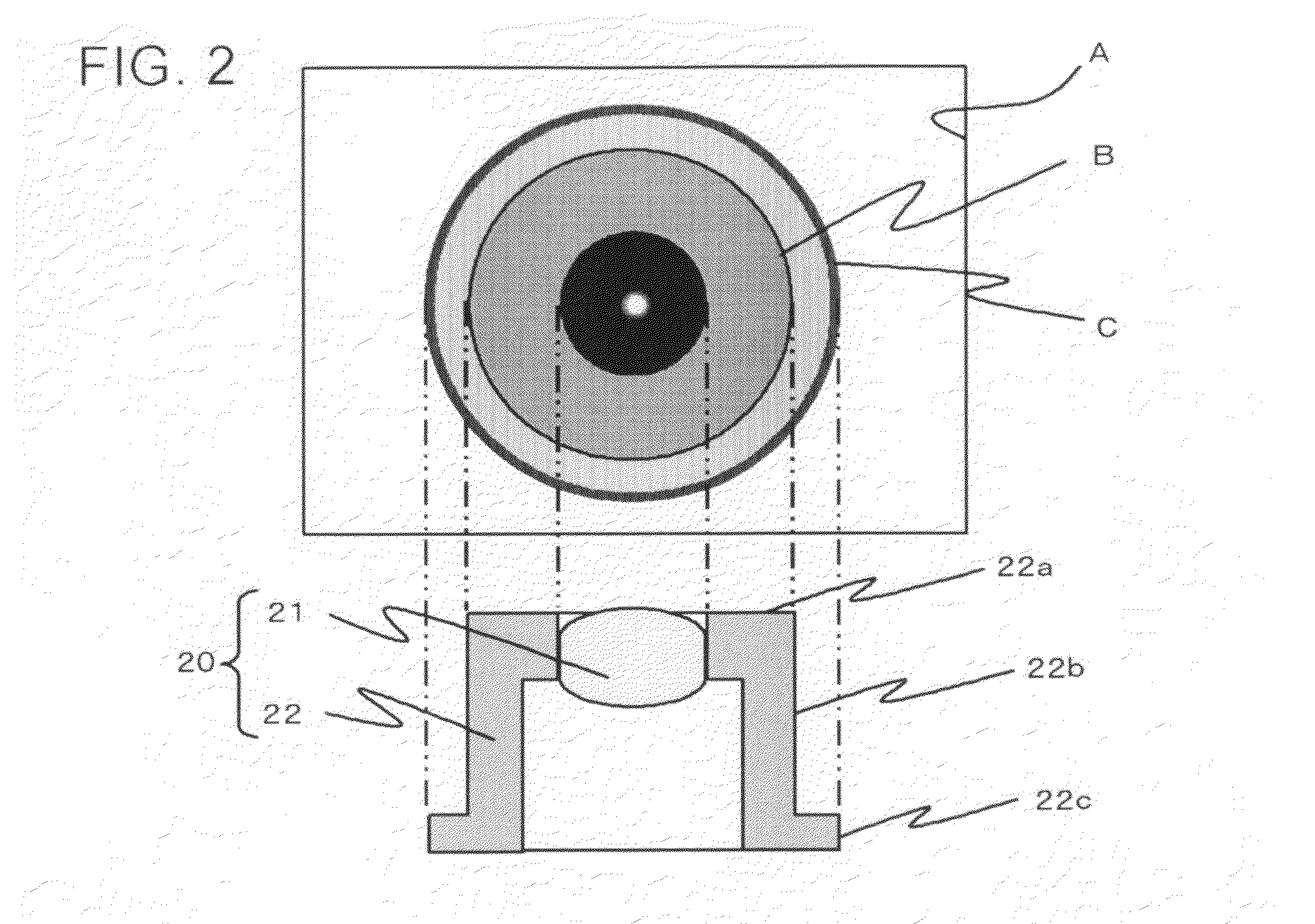

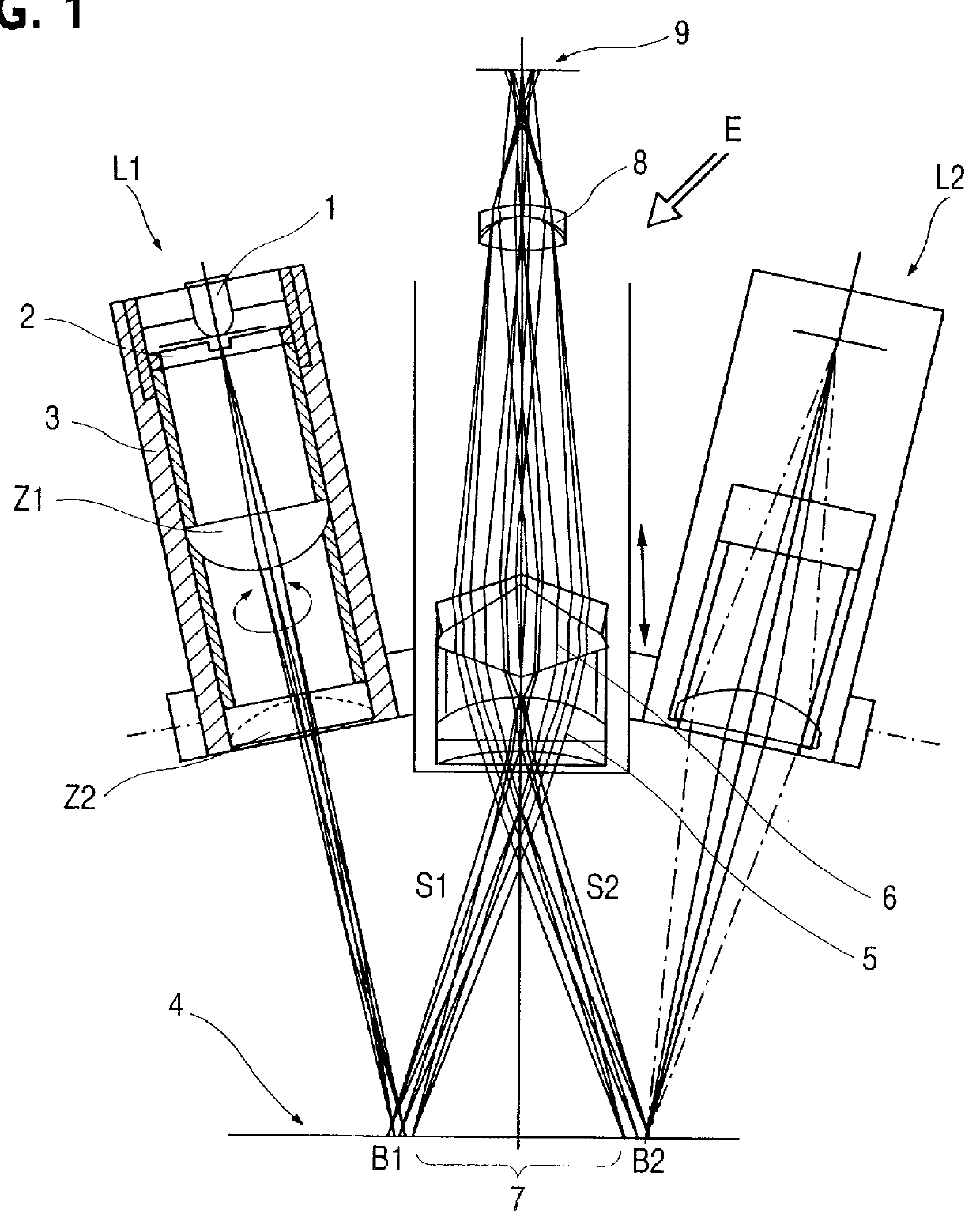

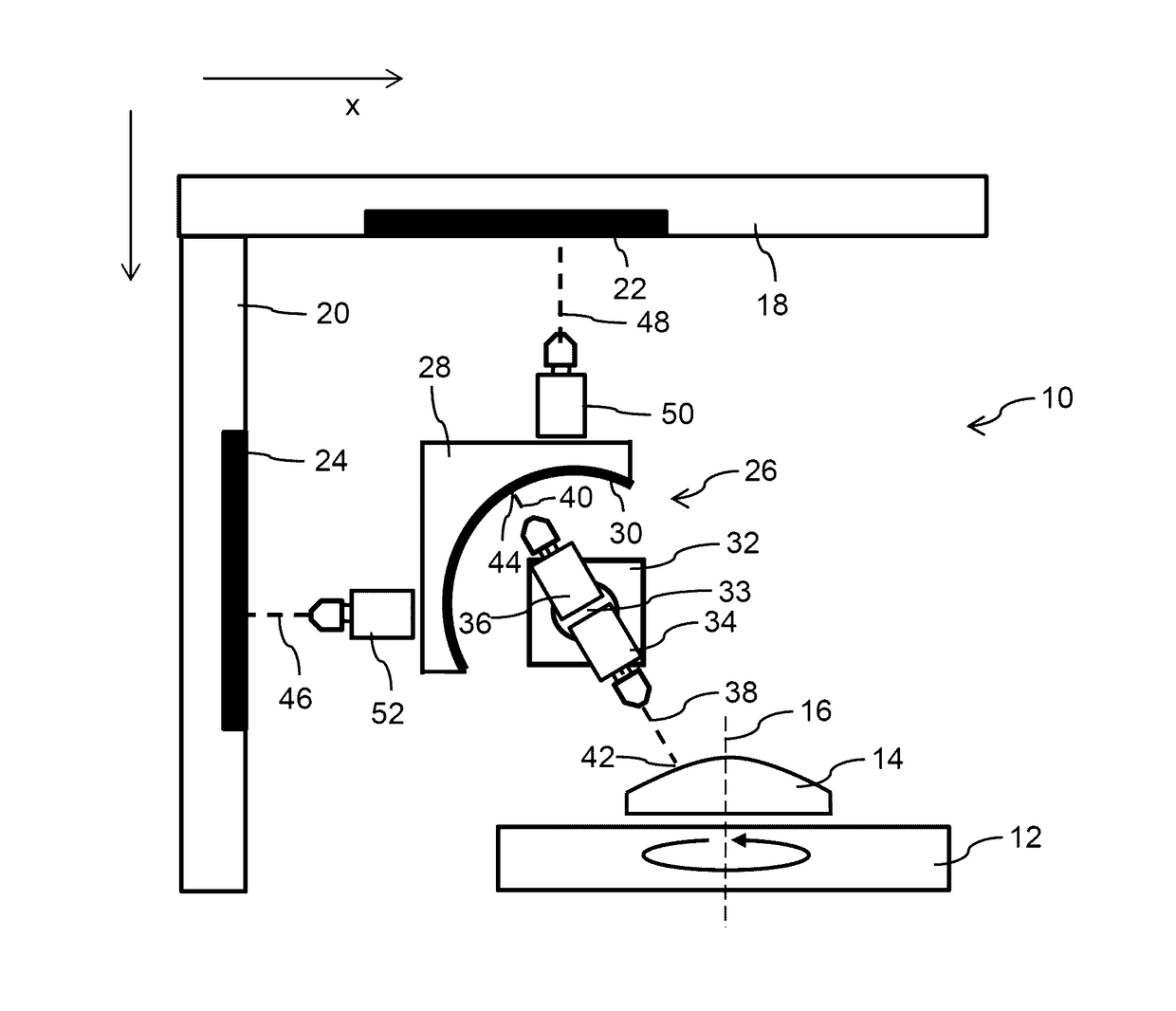

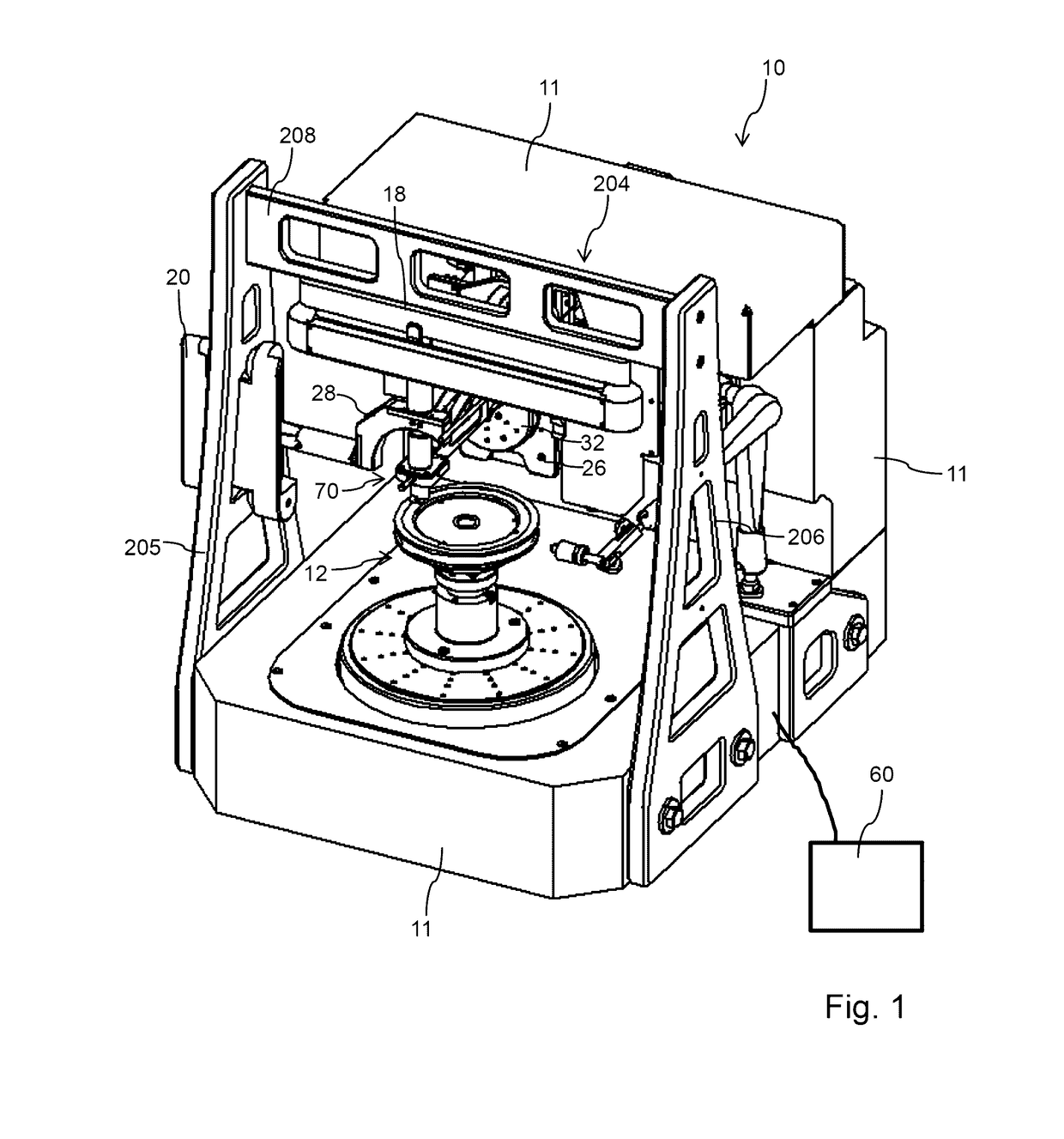

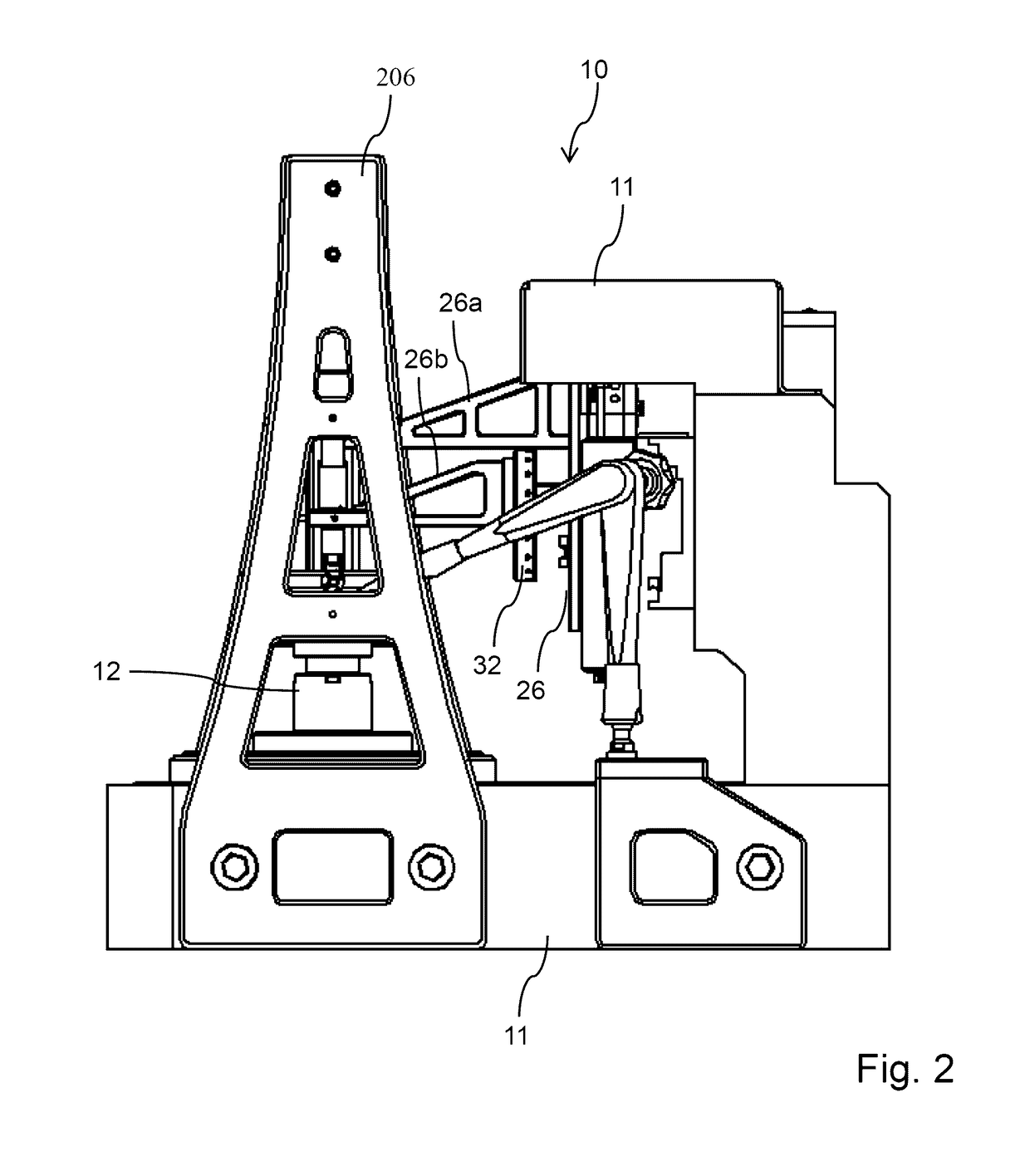

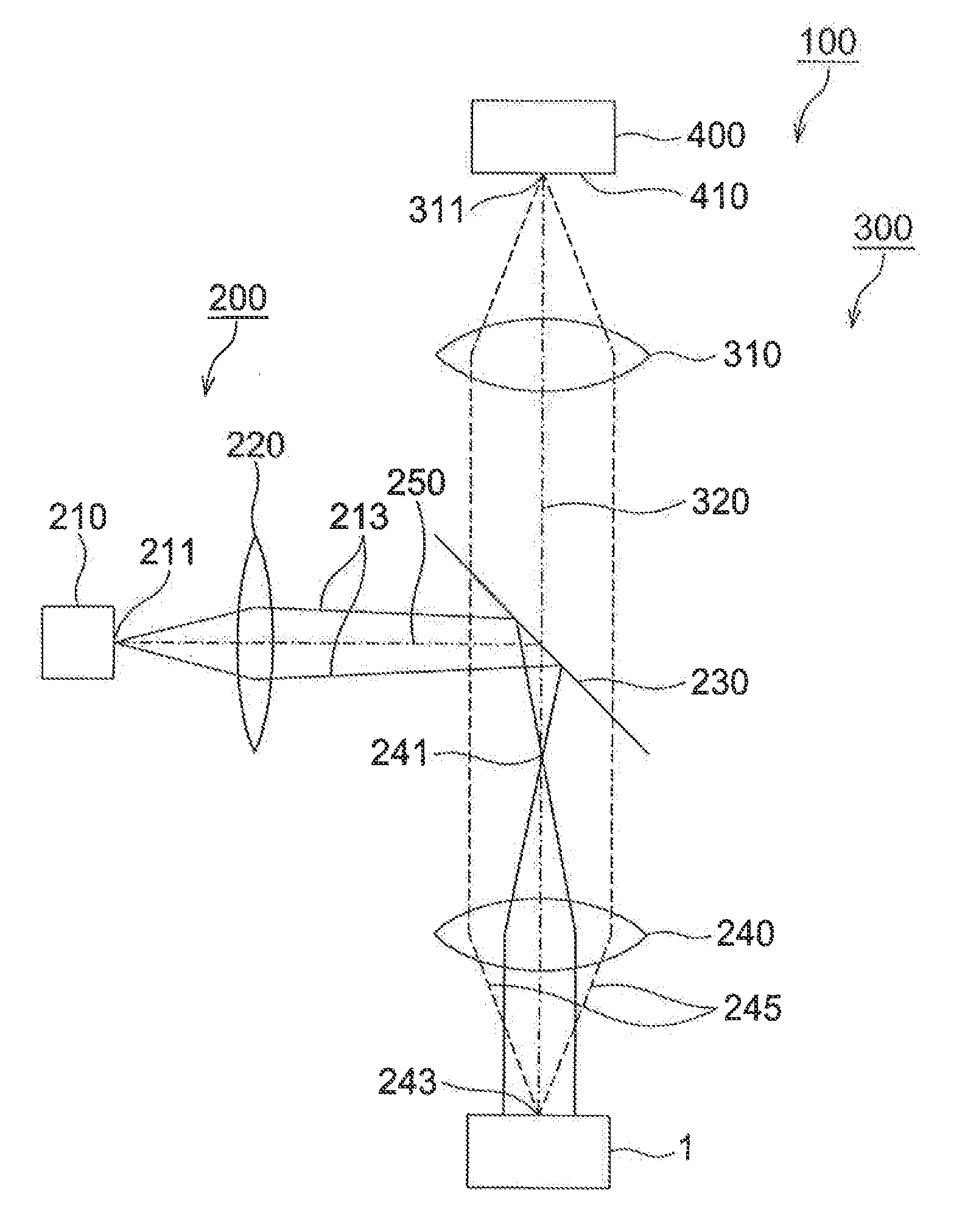

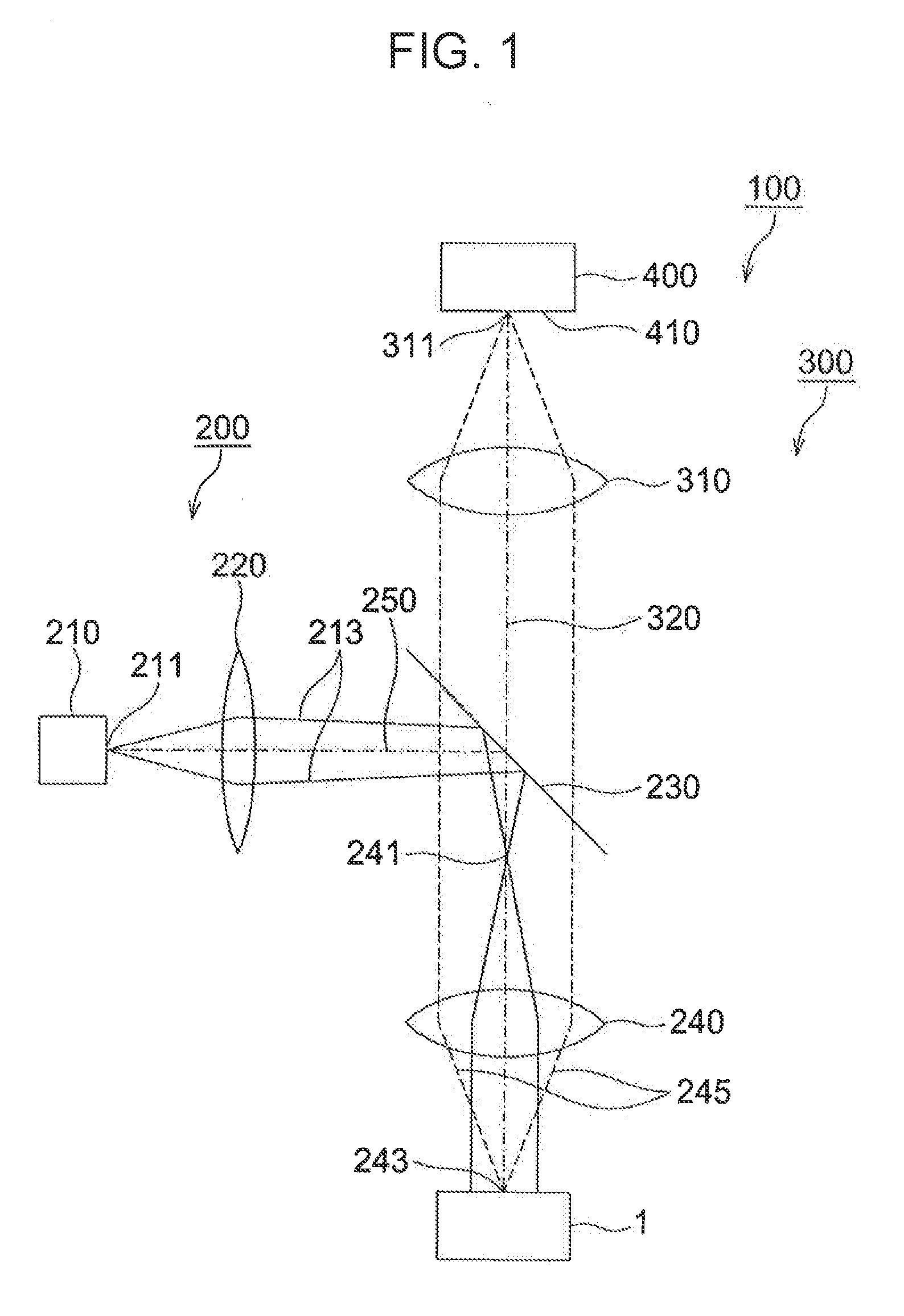

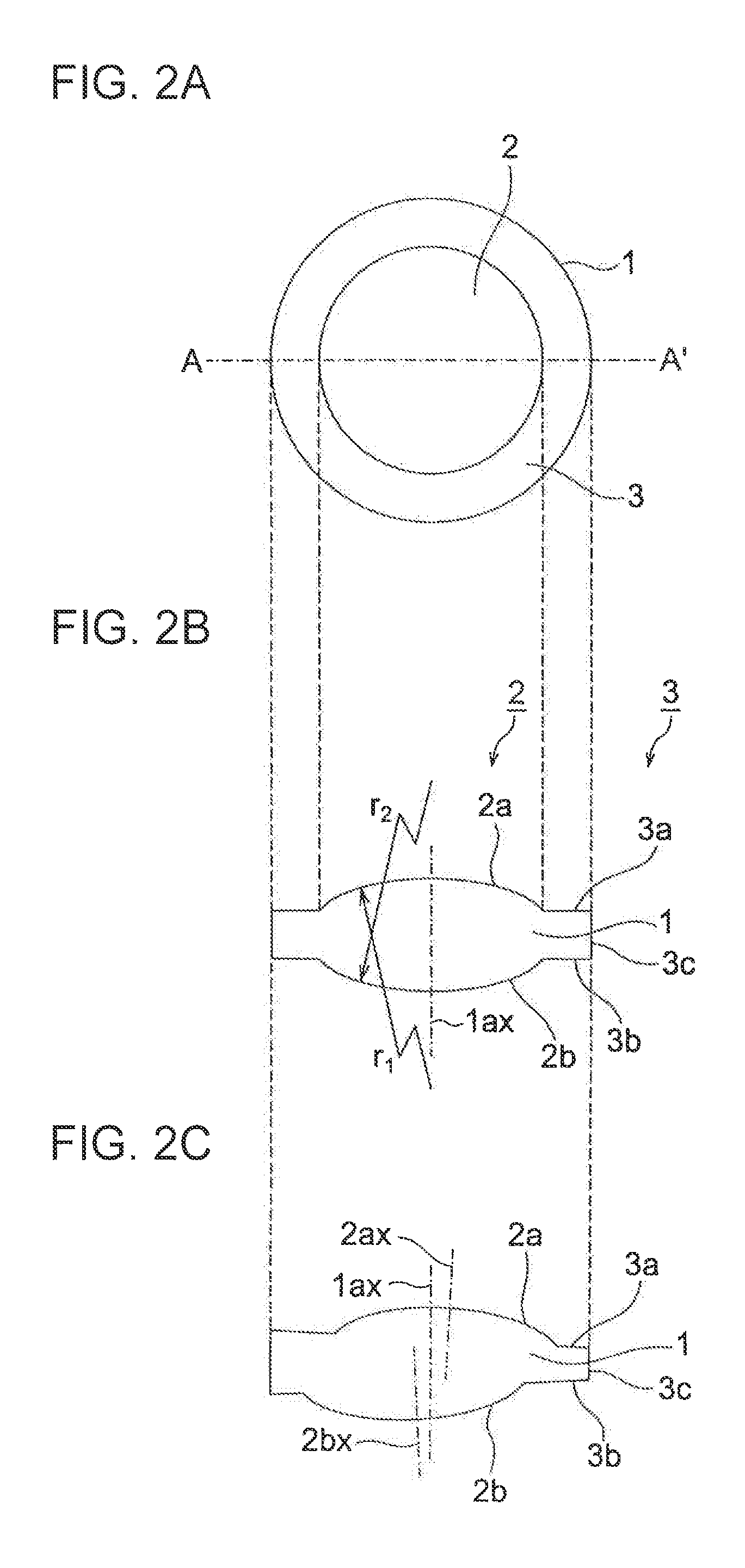

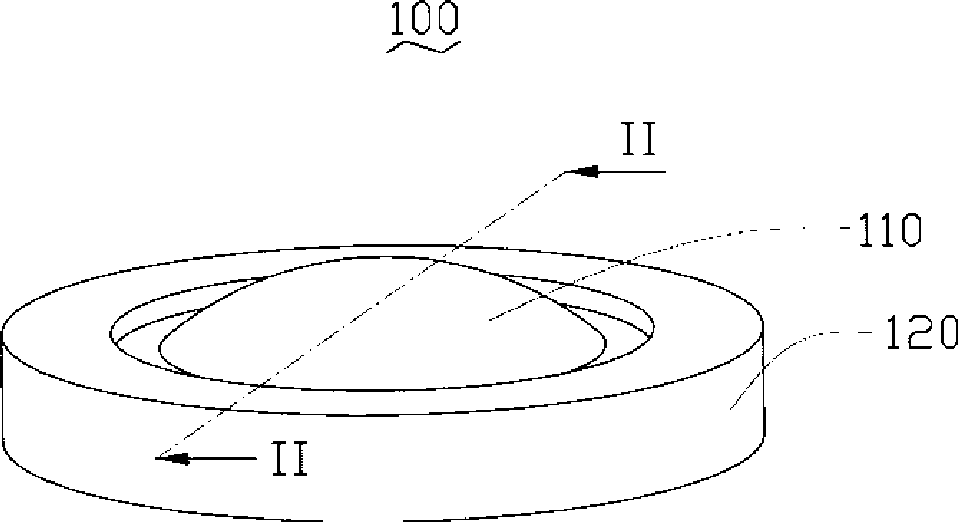

Three-dimensional shape measuring method and device

InactiveUS20100231923A1Precise positioningAccurate collectionUsing optical meansOptical axis determinationThree dimensional shapeFlange

A process of measuring a shape while changing the relative posture of an microscopic interferometer to a sample lens which is rotated about a rotation axis is divided into a process of measuring a top surface in a state where the sample lens is supported from a back surface and a process of measuring a back surface in a state where the sample lens is supported from the top surface. By combining first shape information of a flange side surface acquired by the process of measuring the top surface and second shape information of the flange side surface acquired by the process of measuring the back surface, the relative positional relation between the sample top surface and the sample back surface is calculated.

Owner:FUJI PHOTO OPTICAL CO LTD

Three-dimensional shape measuring method and device

InactiveCN101915554AHigh precision measurementAccurate graspUsing optical meansOptical axis determinationEngineeringThree dimensional shape

A process of measuring a shape while changing the relative posture of an microscopic interferometer (1) to a sample lens (9) which is rotated about a rotation axis (R2) is divided into a process of measuring a top surface in a state where the sample lens (9) is supported from a back surface and a process of measuring a back surface in a state where the sample lens is supported from the top surface. By combining first shape information of a flange side surface (97) acquired by the process of measuring the top surface and second shape information of the flange side surface (97) acquired by the process of measuring the back surface, the relative positional relation between the sample top surface and the sample back surface is calculated.

Owner:FUJI PHOTO OPTICAL CO LTD

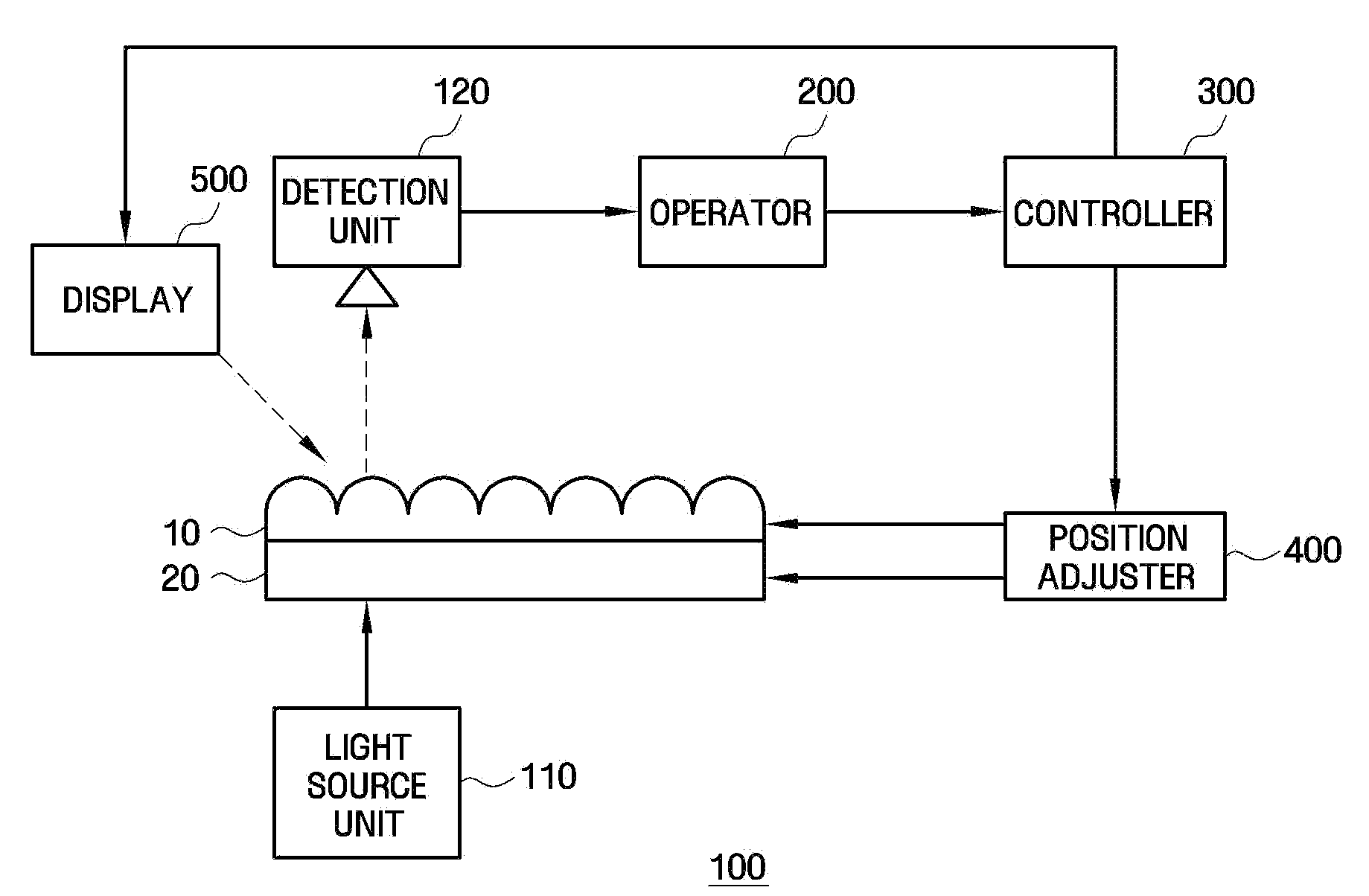

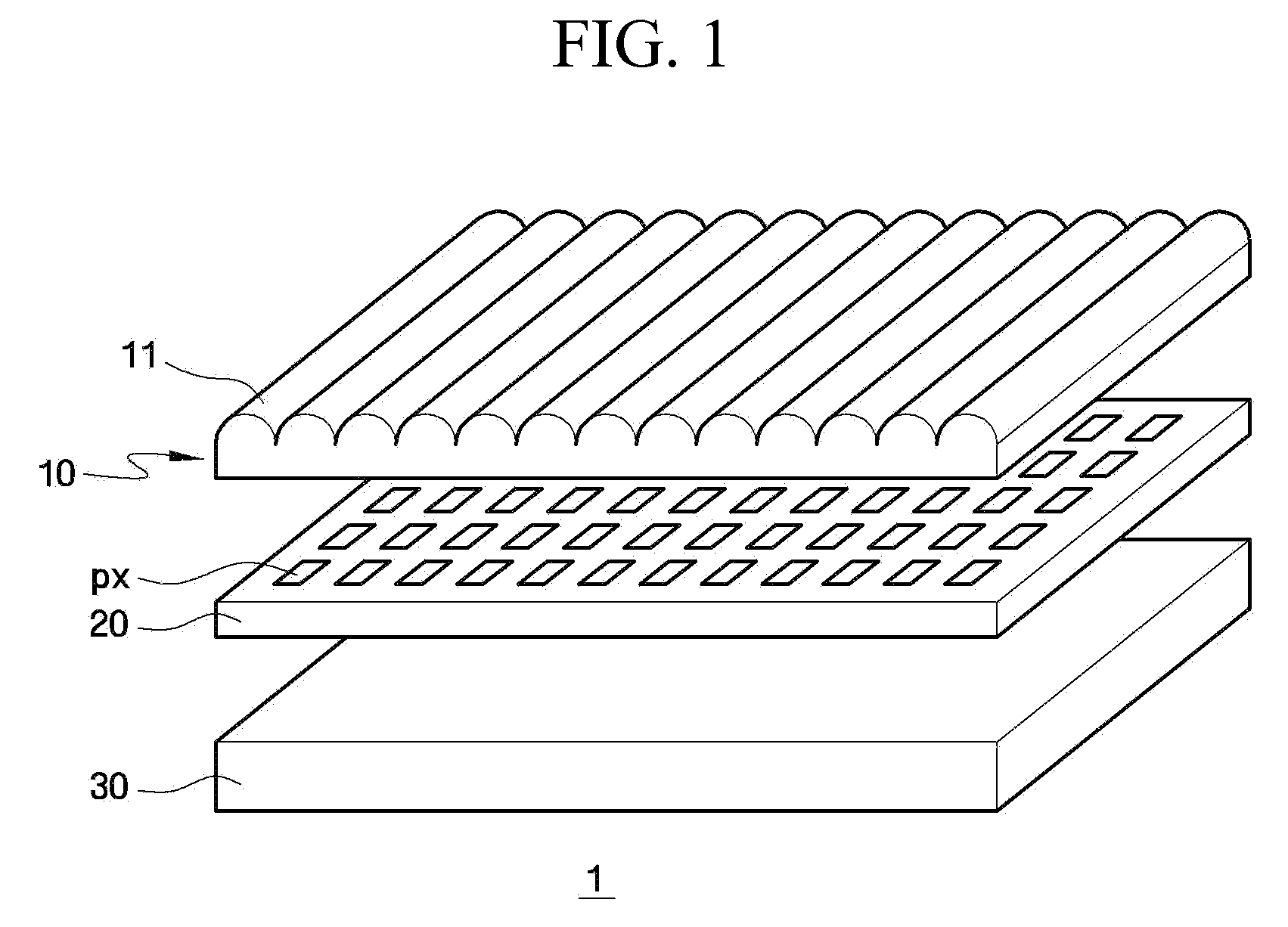

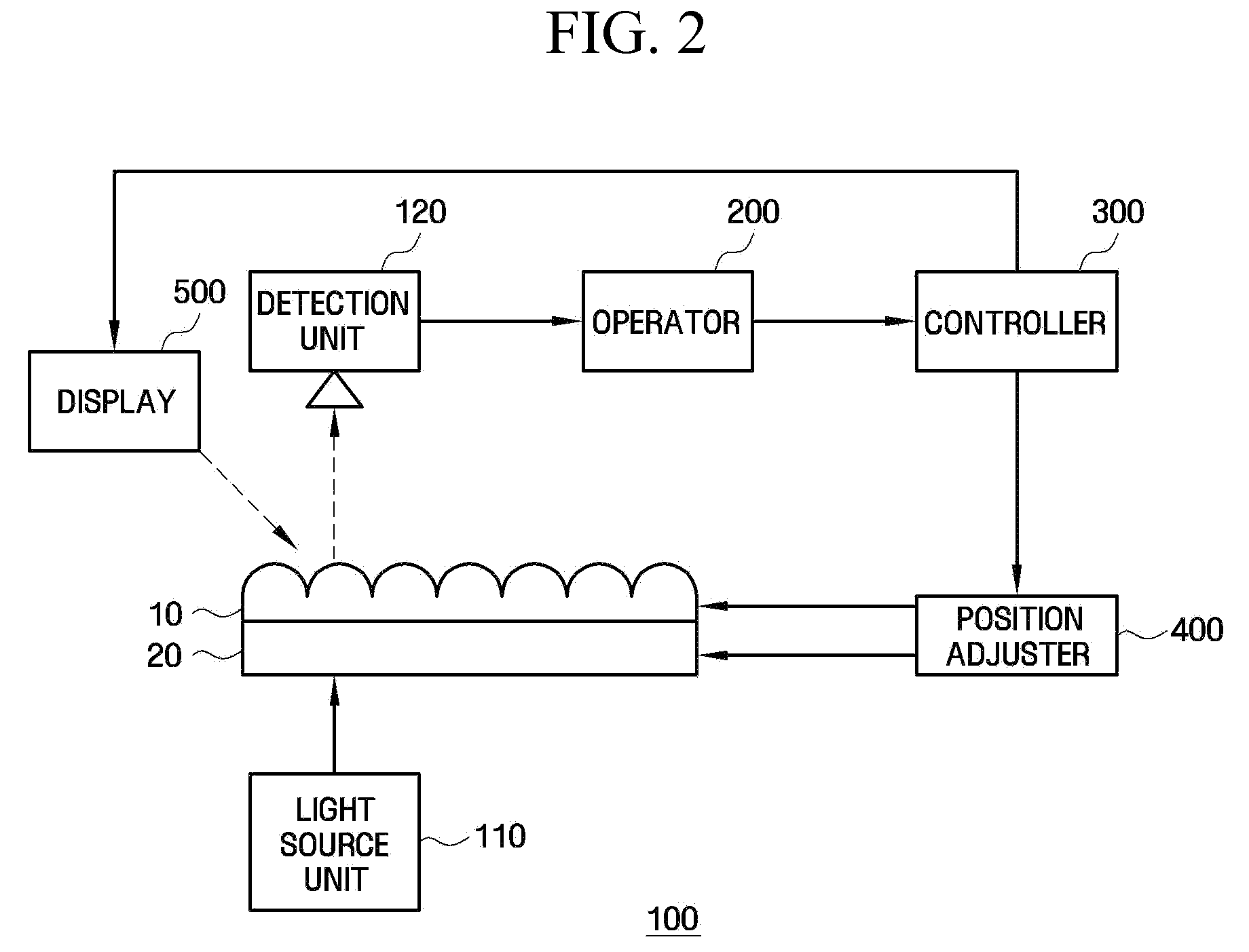

Method and apparatus for manufacturing display device

ActiveUS20100026993A1Precise alignmentAccurate attachmentUsing optical meansOptical axis determinationDisplay deviceLenticular lens

Provided are a method and apparatus for manufacturing a display device, which can ensure precise alignment and attachment of a lenticular sheet onto a display panel. The method includes sequentially stacking a display panel and a lenticular sheet on a stage, irradiating light that is incident in parallel toward the display panel and the lenticular sheet from below the display panel, detecting the light that has passed through the display panel and the lenticular sheet, and determining an axial direction of a columnar lens formed on the lenticular sheet.

Owner:SAMSUNG DISPLAY CO LTD

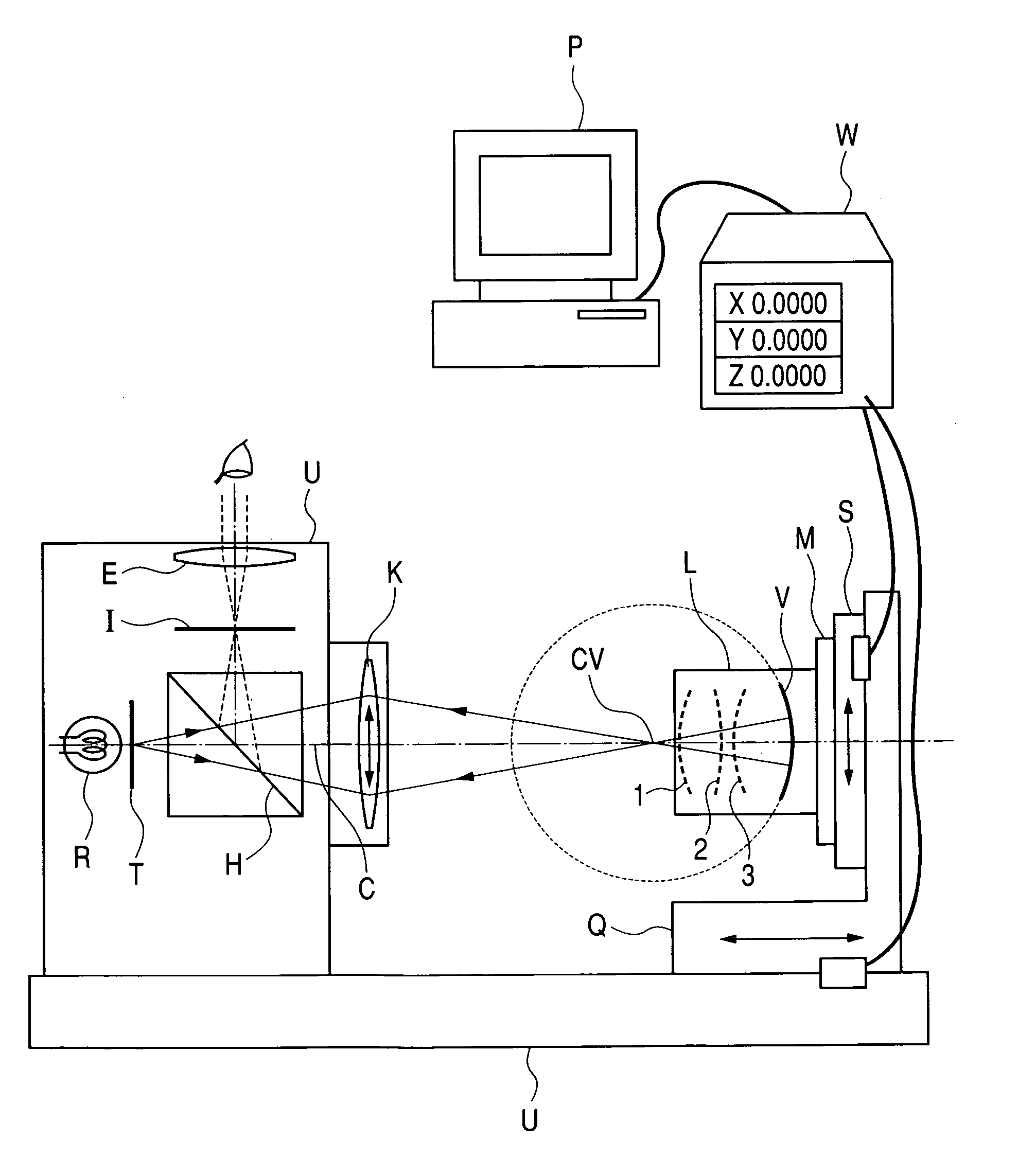

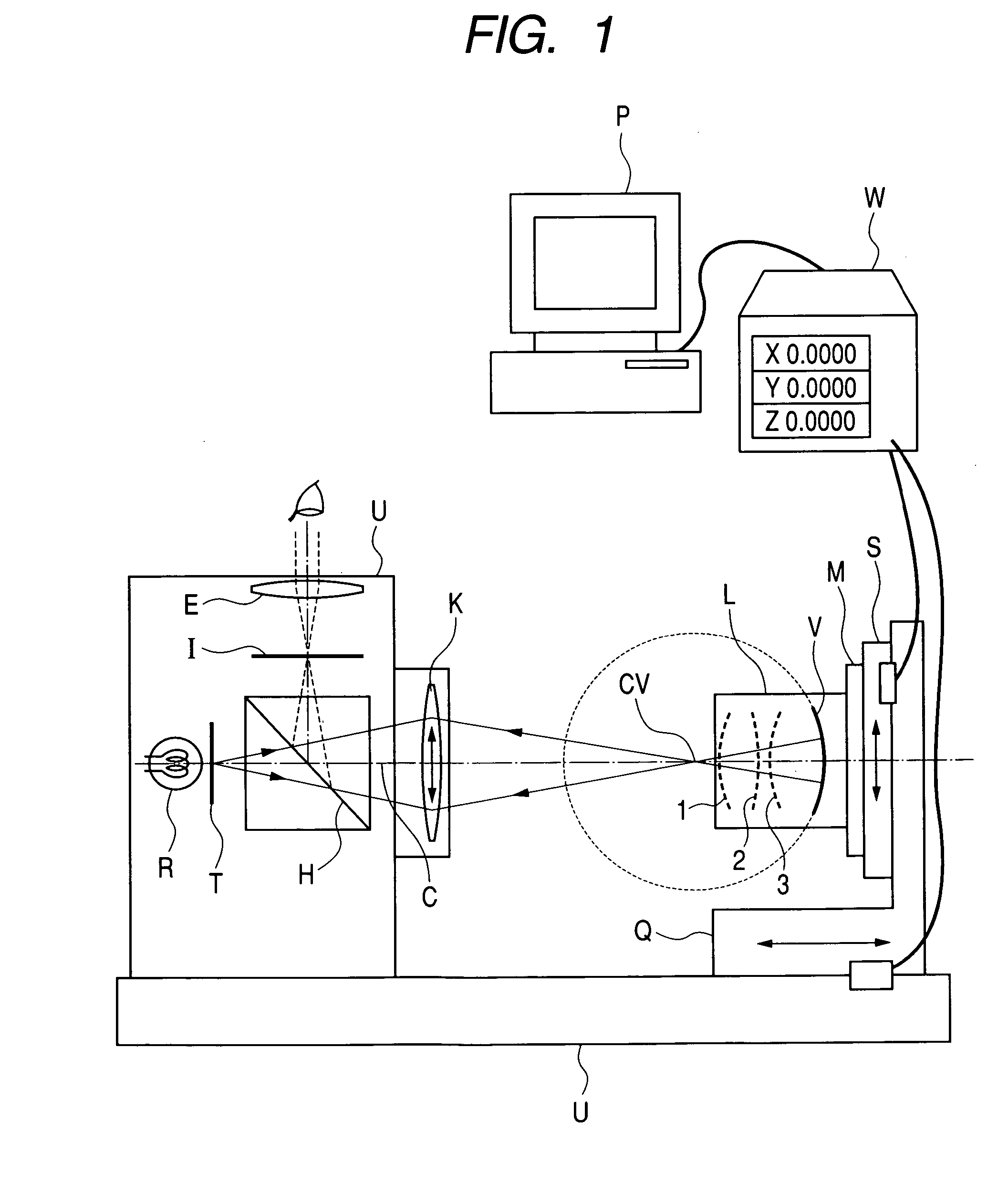

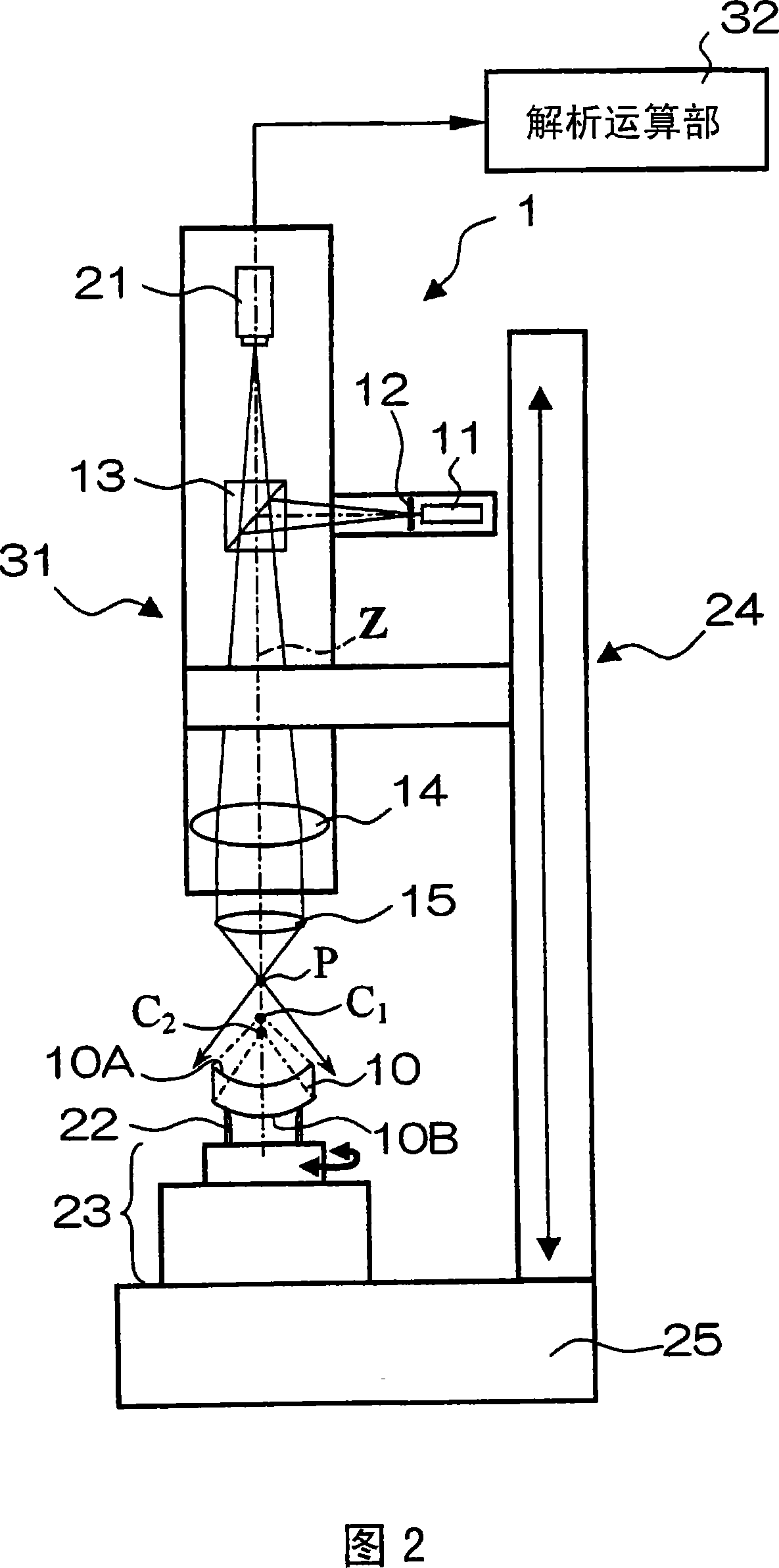

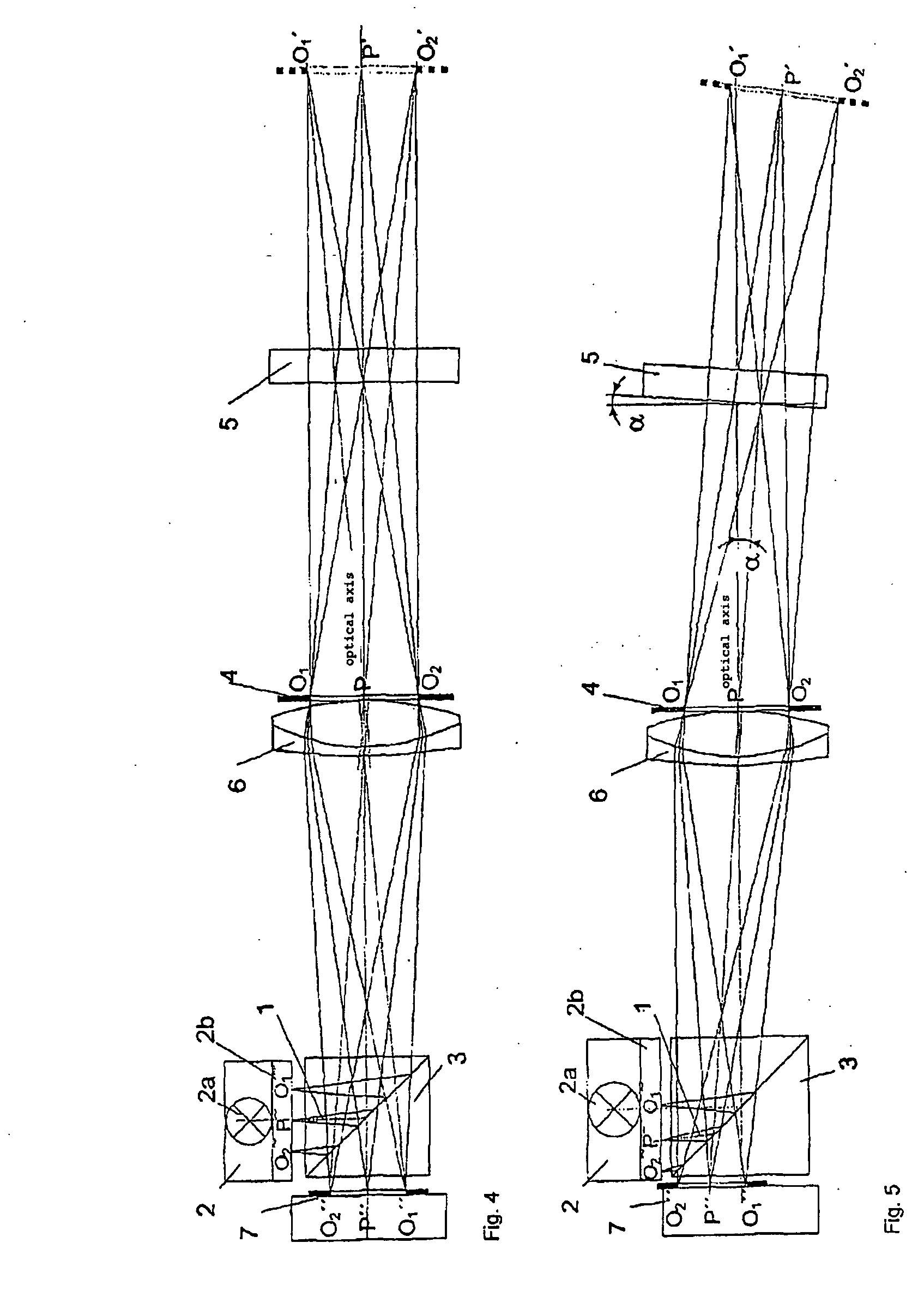

Eccentricity measuring method and eccentricity measuring apparatus

InactiveUS20050128468A1Accurate quantityReduce measurementUsing optical meansOptical axis determinationMeasurement deviceEntire lens

A surface to be tested and an optical system for projecting an index to an apparent spherical center position of the surface to be tested are moved relative to each other and an eccentric quantity of the surface to be tested is calculated from an movement quantity. A focal distance of an optical system is changed according to an apparent radius of curvature of each surface to be tested, which is calculated in advance. A reflection image on a surface to be tested, which is to be measured, is determined from the apparent radius of curvature of each surface to be tested, which is calculated in advance. Thus, an eccentric quantity of the entire lens system is accurately measured.

Owner:CANON KK

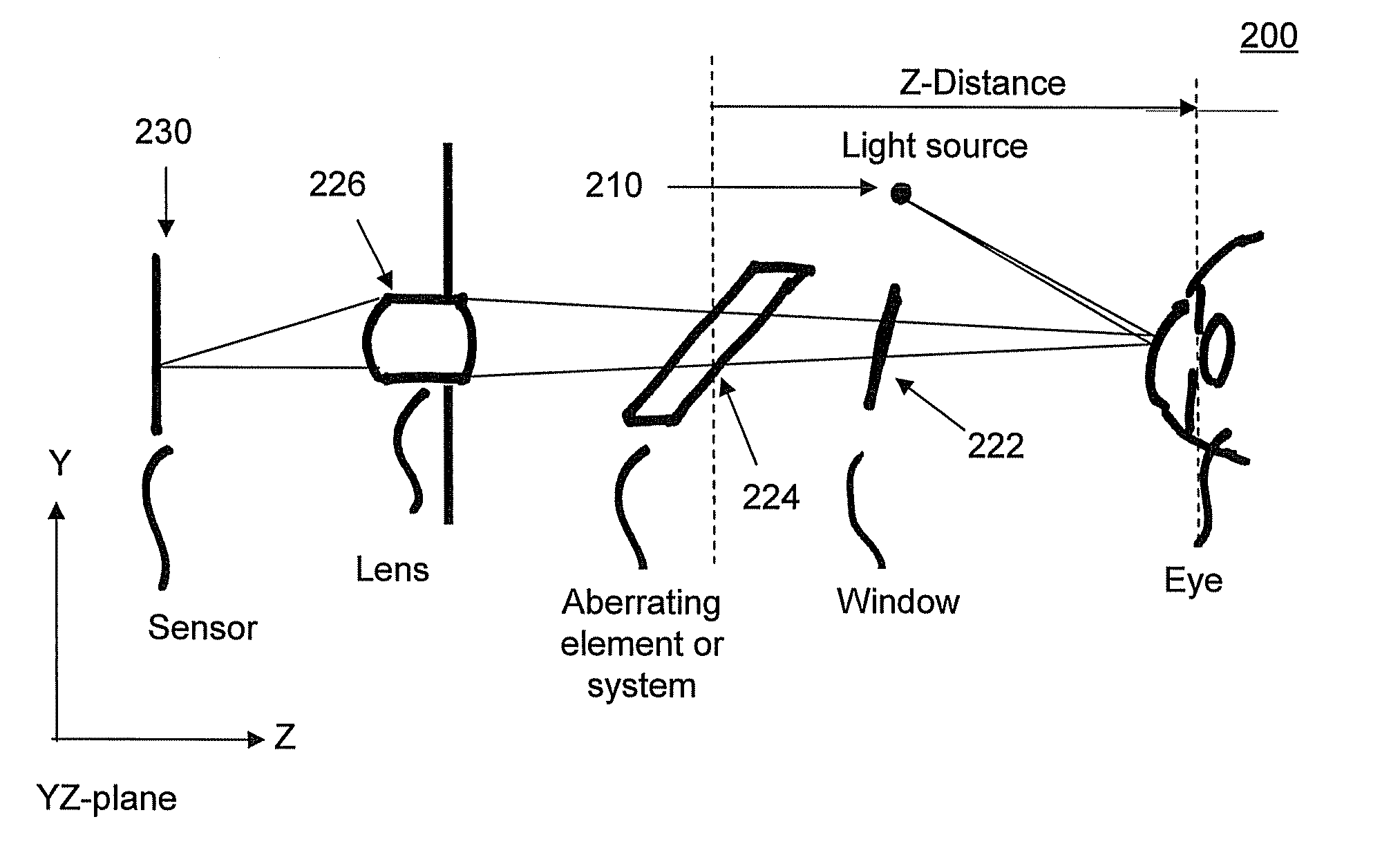

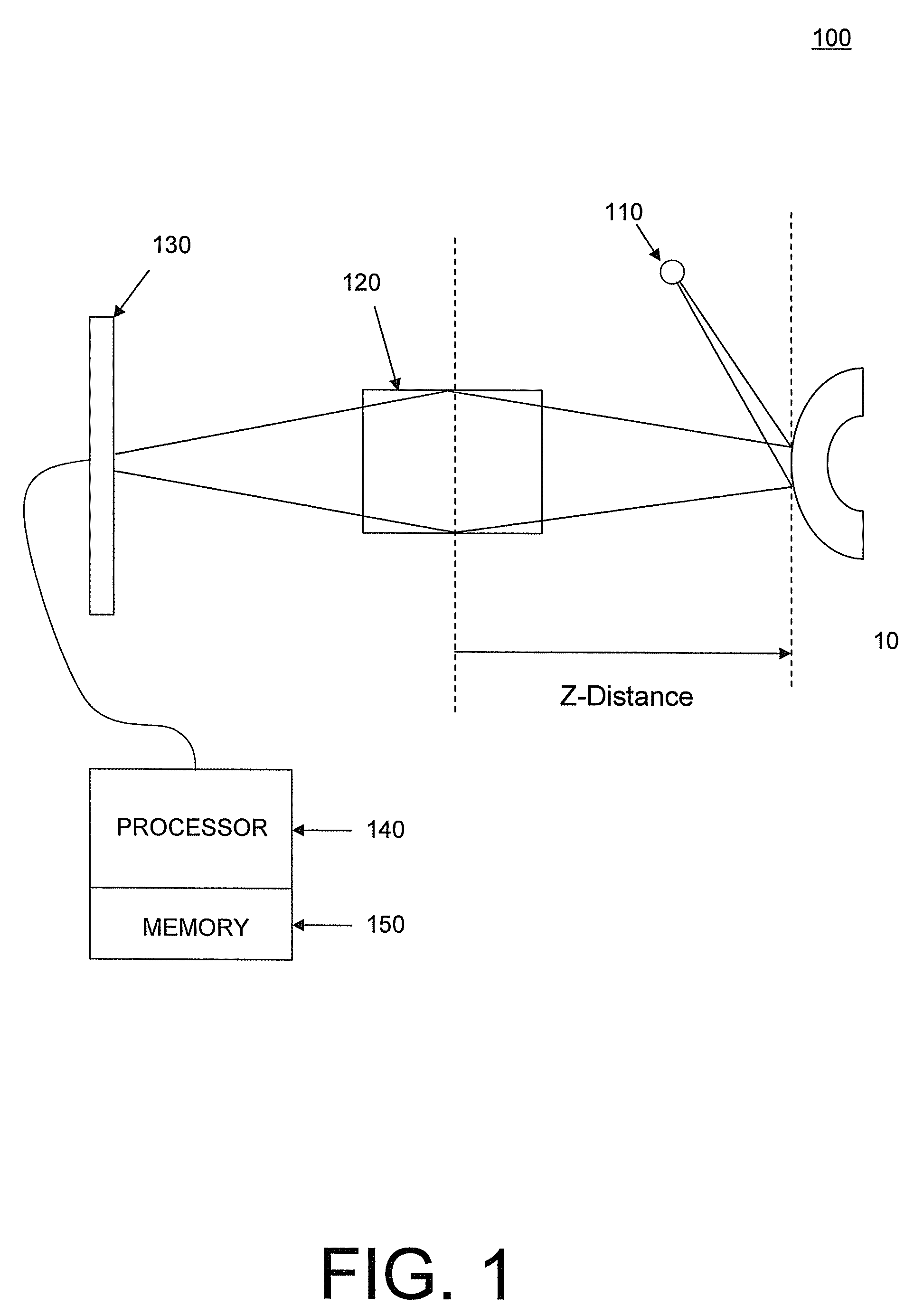

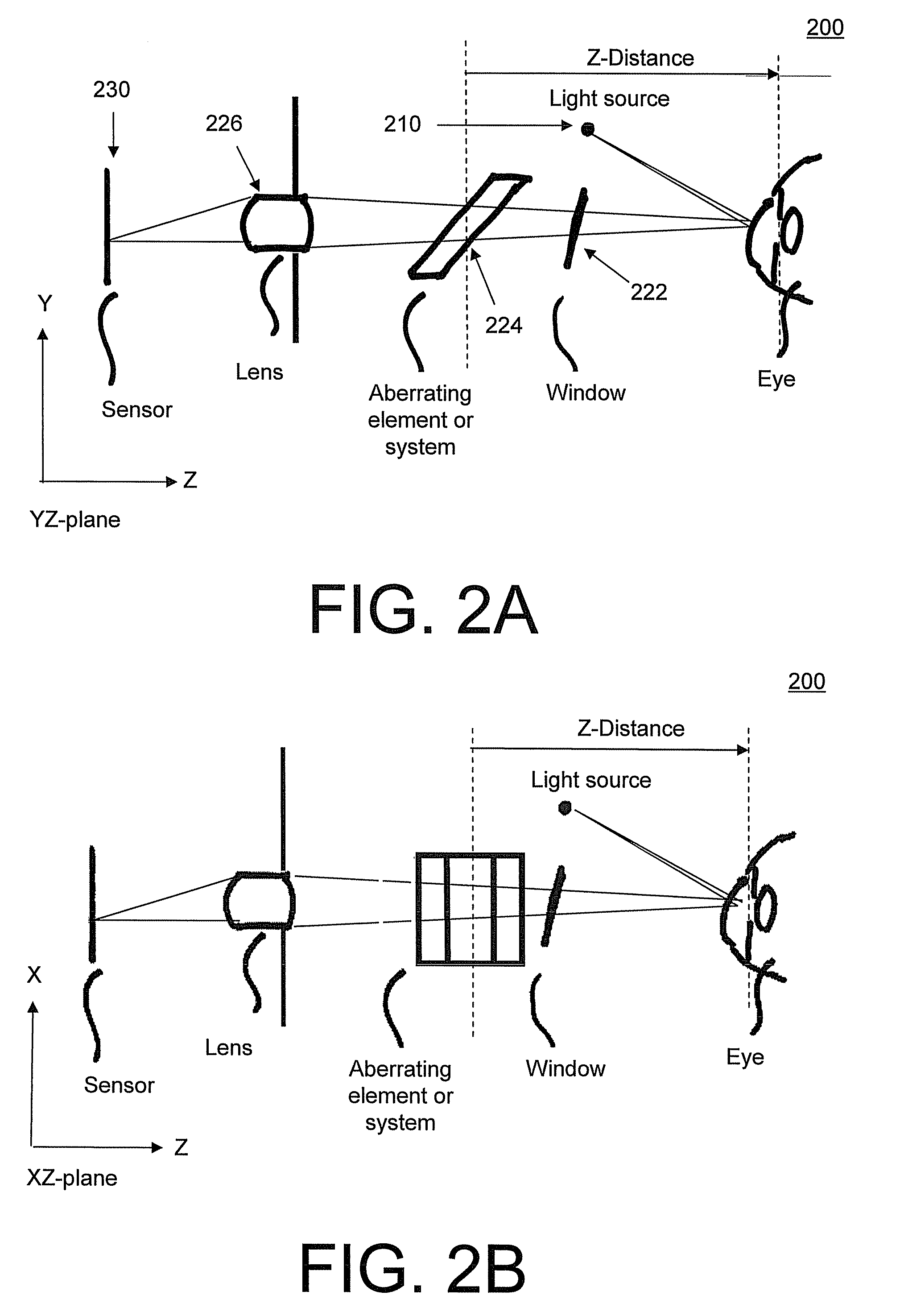

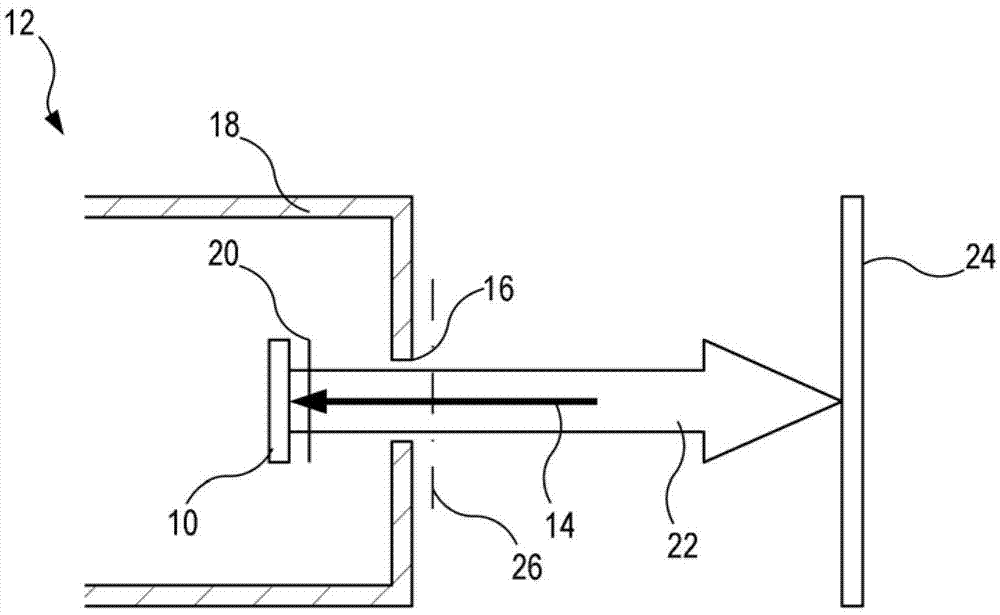

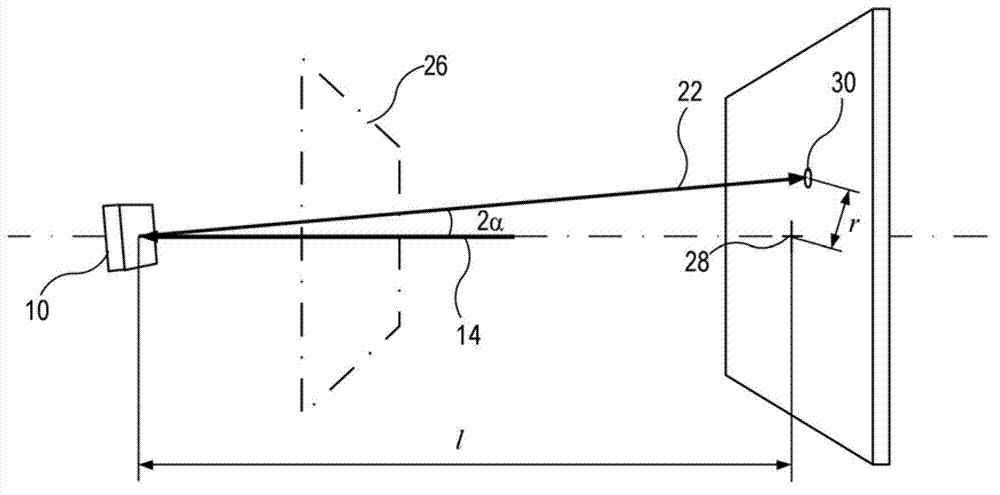

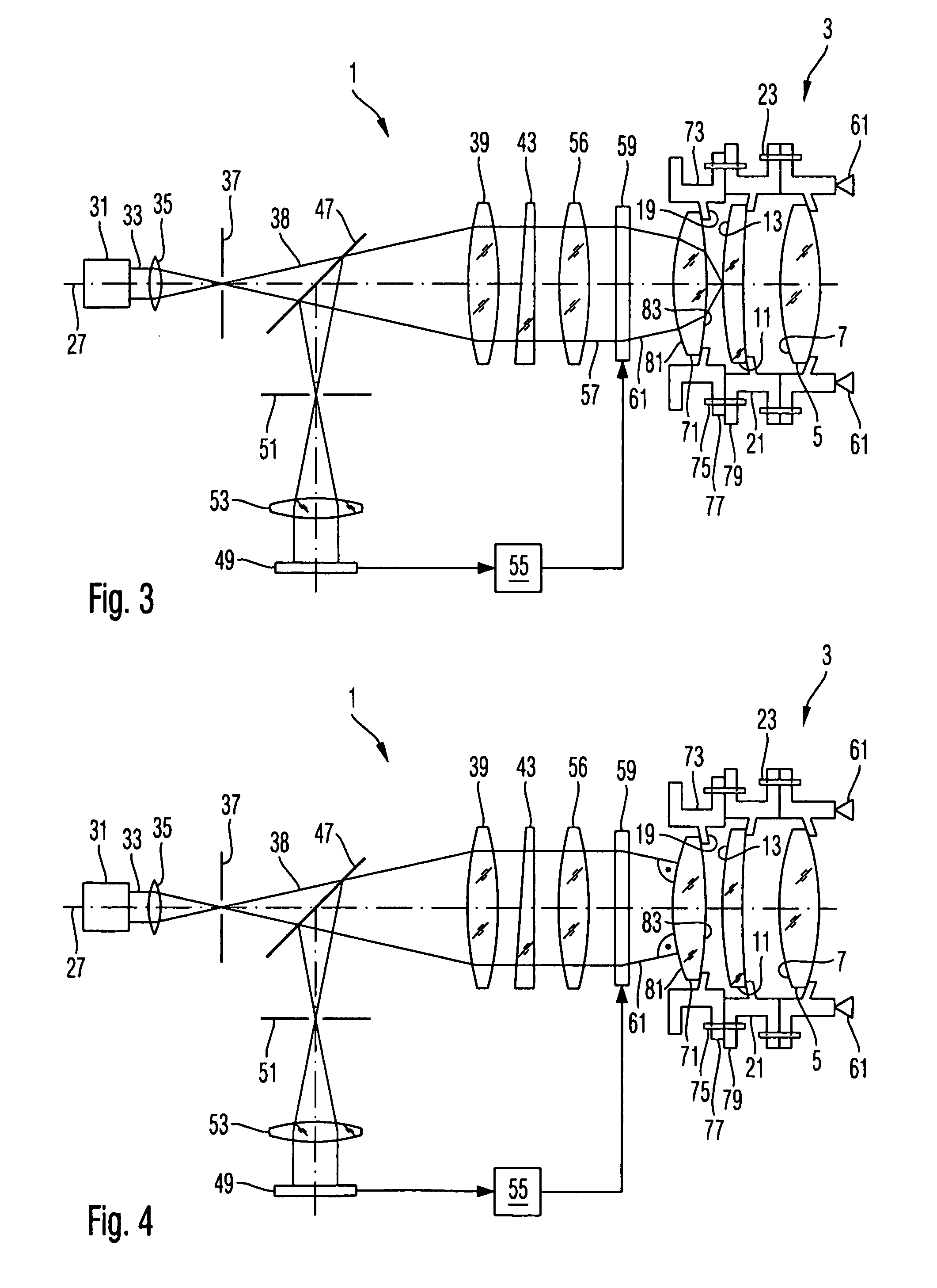

Method and apparatus for obtaining the distance from an optical measurement instrument to an object under test

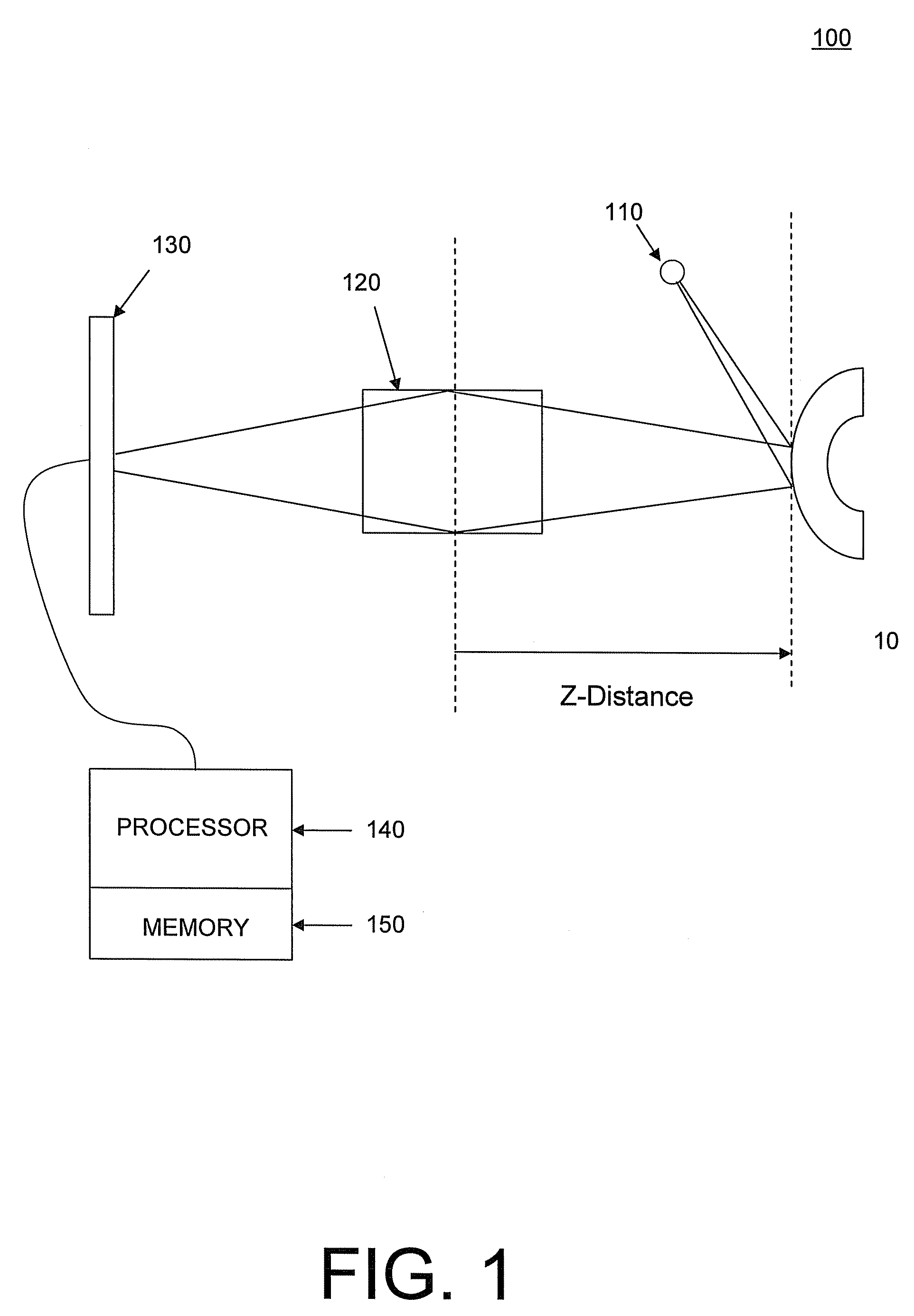

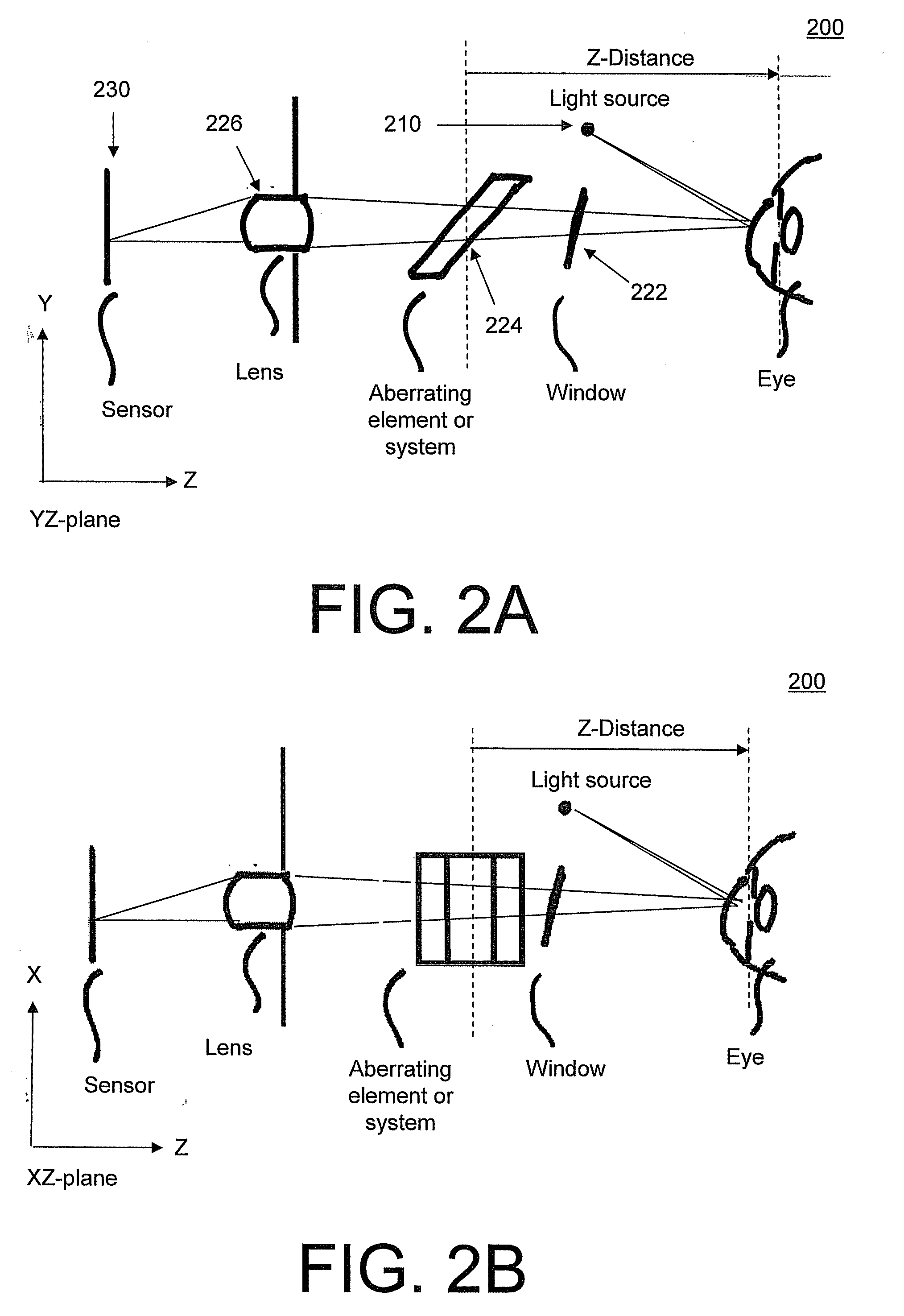

ActiveUS20080291396A1Accurately determineAccurately measuring and computingEye diagnosticsUsing optical meansOptical measurementsLighting system

Systems and methods for measuring a distance from a reference plane of an optical measurement instrument to a reference plane of an optical device under test are disclose. In one embodiment a system for measuring this distance includes an illumination system, an optical system, and optical sensor and a processor. The illumination system is configured or adapted to illuminate the object under test. The optical system is configured or adapted to receive light from the object under test and to produce an aberrated image. The optical sensor is configured or adapted to receive and sense the aberrated image. The processor determines the distance from the reference plane of the optical measurement instrument to the reference plane of the optical device based on an aspect of the aberrated image sensed by the optical sensor.

Owner:AMO DEVMENT

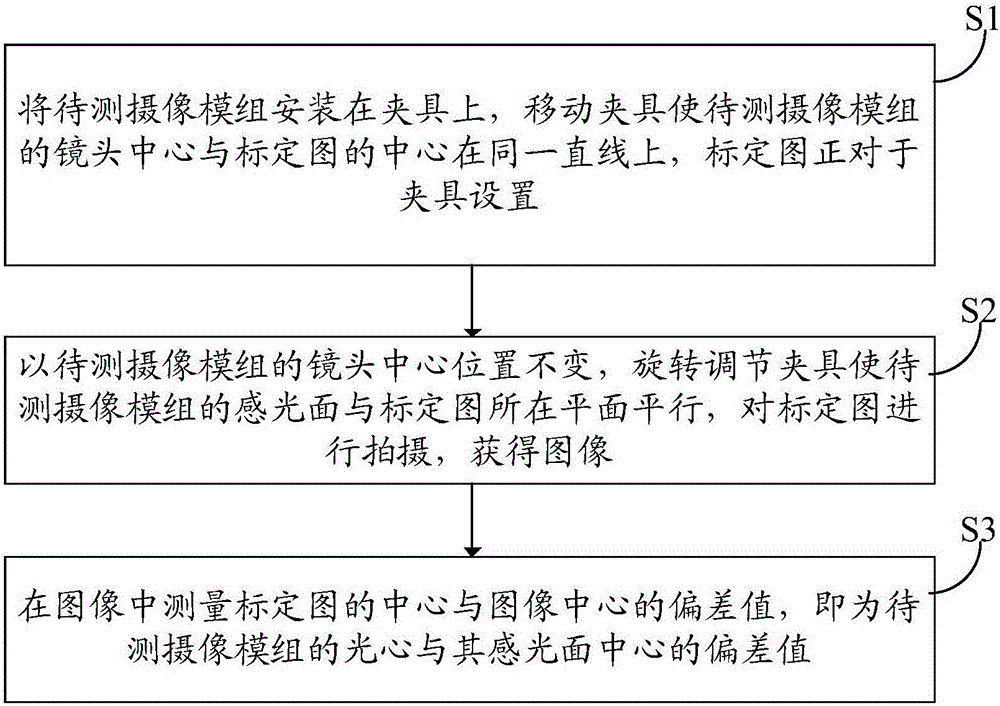

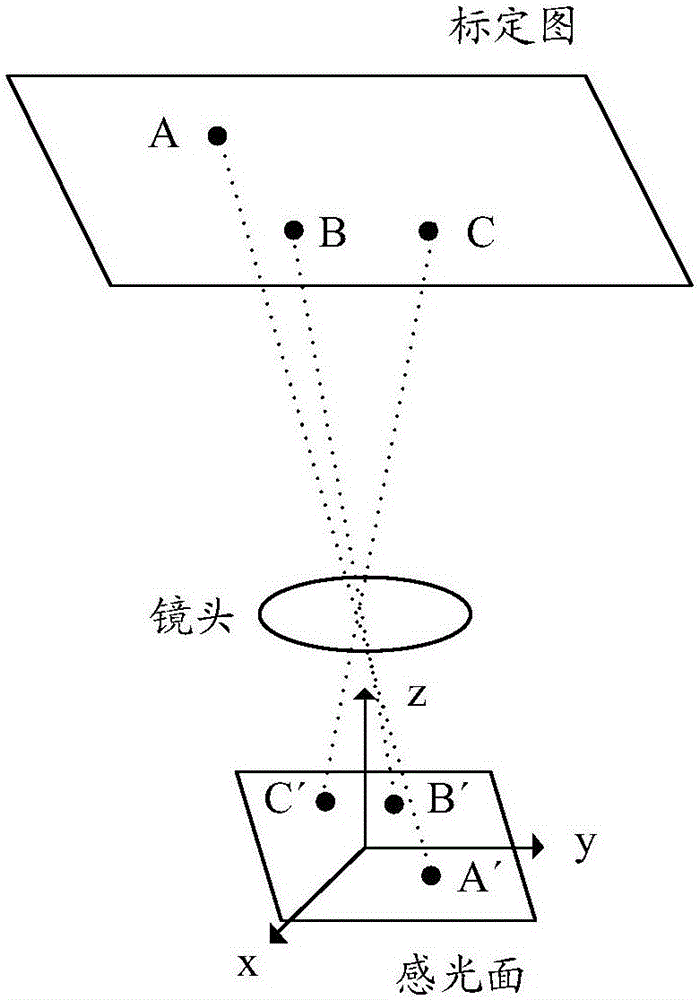

Camera module optical center position measuring method and system

ActiveCN106644410ARealize measurementOptical axis determinationLens position determinationCamera lensCamera module

The invention discloses a camera module optical center position measuring method and system; the method comprises the following steps: mounting a tested camera module on a clamp, moving the clamp so as to enable the lens center of the tested camera module to be on a same line with a labeled graph center, wherein the clamp can be translated and rotated, and the labeled graph is right opposite to the clamp; keeping the lens center position of the tested camera module to be unchanged, rotating and adjusting the clamp so as to enable a light-sensitive surface of the tested camera module to be parallel to a plane on which the labeled graph is located, shooting the labeled graph and obtaining an image; measuring the deviation value between the labeled graph center and the image center in the image, i.e., the deviation value between the optical center of the tested camera module and the light-sensitive surface center. The camera module optical center position measuring method and system can measure the optical center position of the tested camera module; the method is more stable and faster in testing when compared with a conventional method.

Owner:TRULY OPTO ELECTRONICS

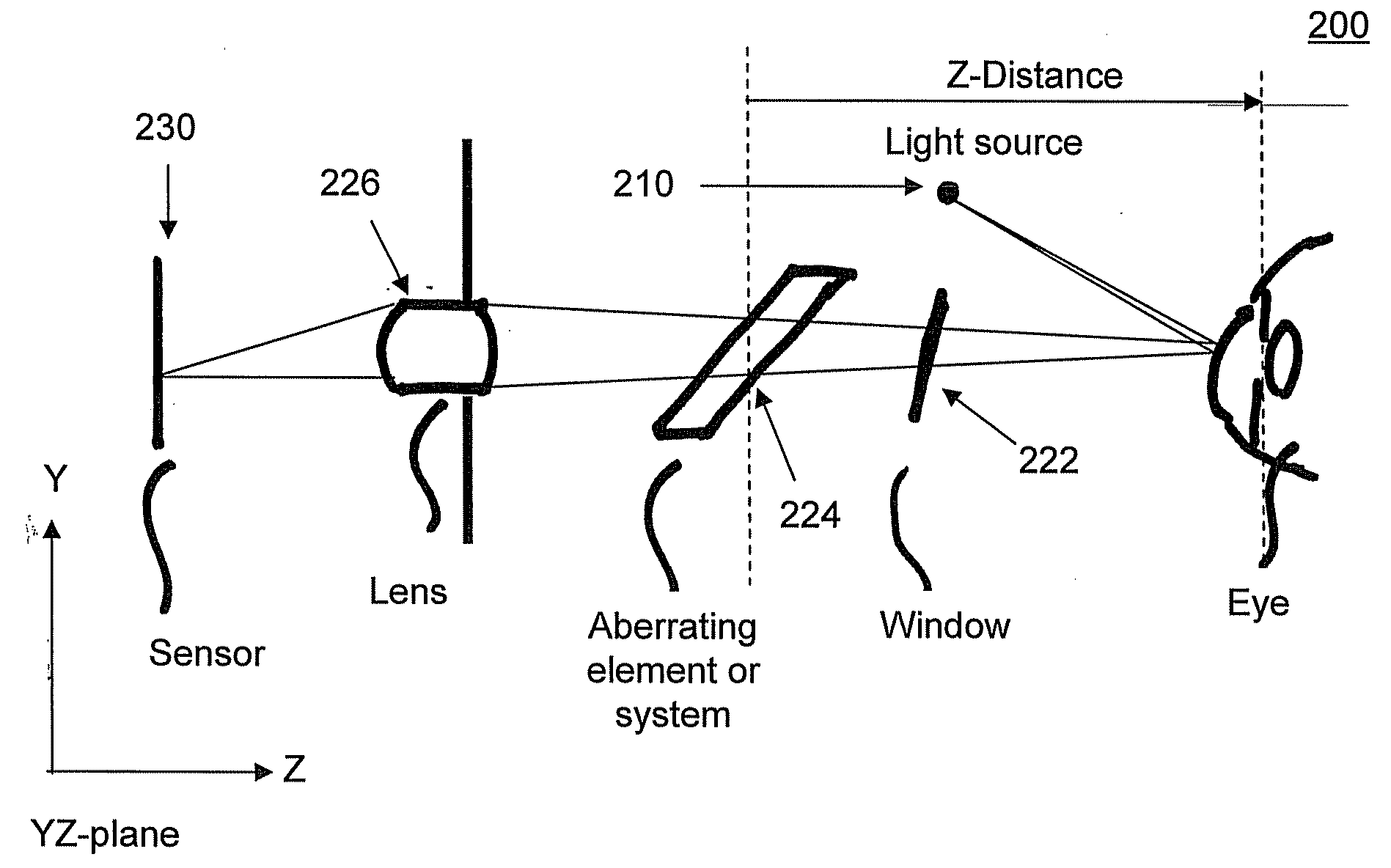

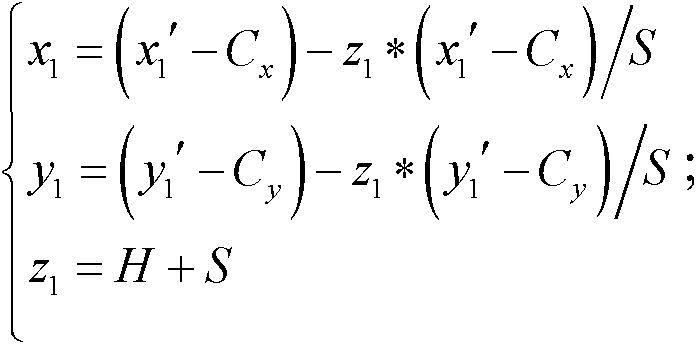

Method and apparatus for obtaining the distance from an optical measurement instrument to an object under test

ActiveUS7887184B2Accurately determineAccurately measuring and computingEye diagnosticsUsing optical meansOptical measurementsInstrumentation

Systems and methods for measuring a distance from a reference plane of an optical measurement instrument to a reference plane of an optical device under test are disclose. In one embodiment a system for measuring this distance includes an illumination system, an optical system, and optical sensor and a processor. The illumination system is configured or adapted to illuminate the object under test. The optical system is configured or adapted to receive light from the object under test and to produce an aberrated image. The optical sensor is configured or adapted to receive and sense the aberrated image. The processor determines the distance from the reference plane of the optical measurement instrument to the reference plane of the optical device based on an aspect of the aberrated image sensed by the optical sensor.

Owner:AMO DEVMENT

Lens shift measuring apparatus, lens shift measuring method, and optical module manufacturing method

InactiveUS20110075887A1Short timeSimple configurationLamination ancillary operationsLaminationOptical ModuleFacula

Owner:RENESAS ELECTRONICS CORP

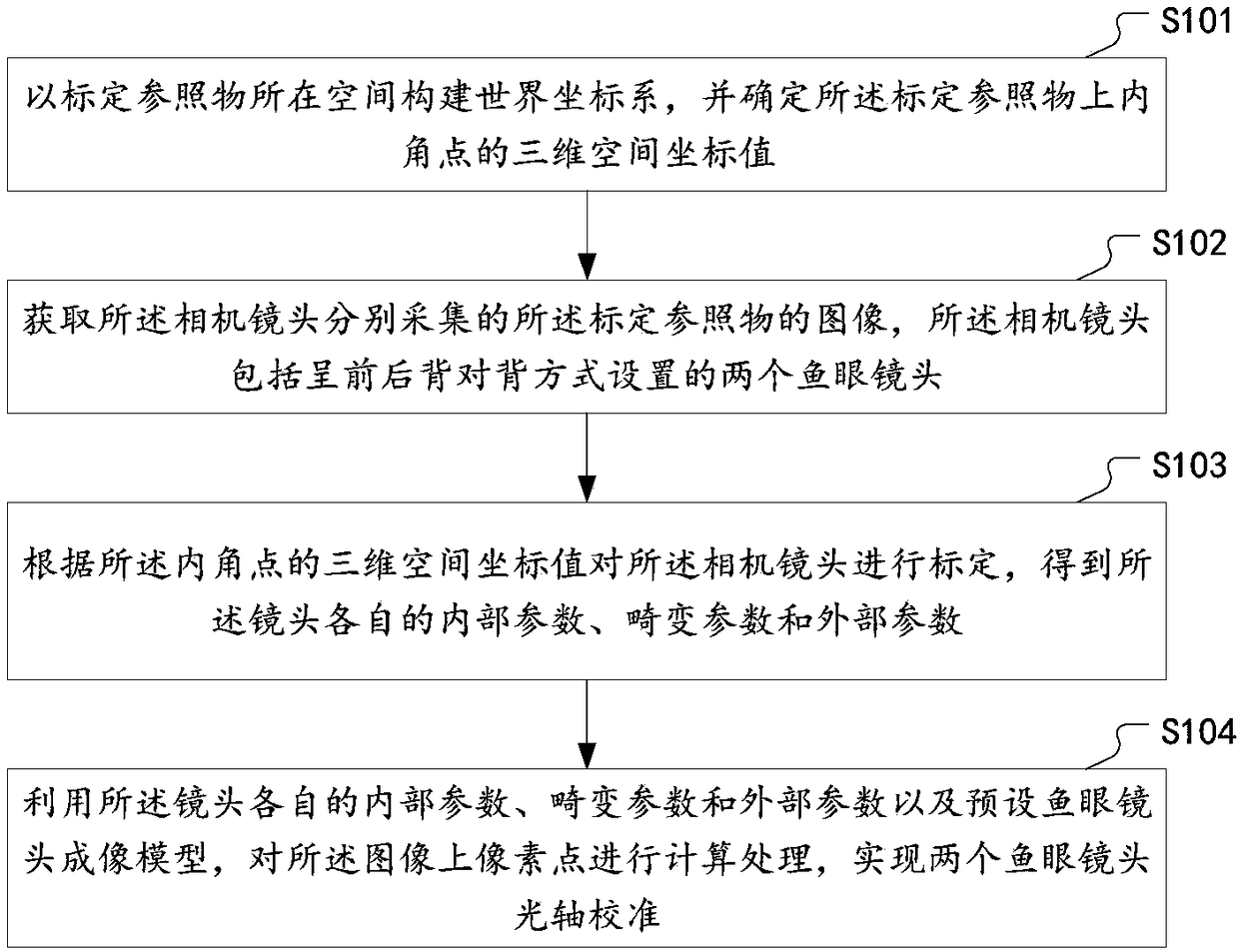

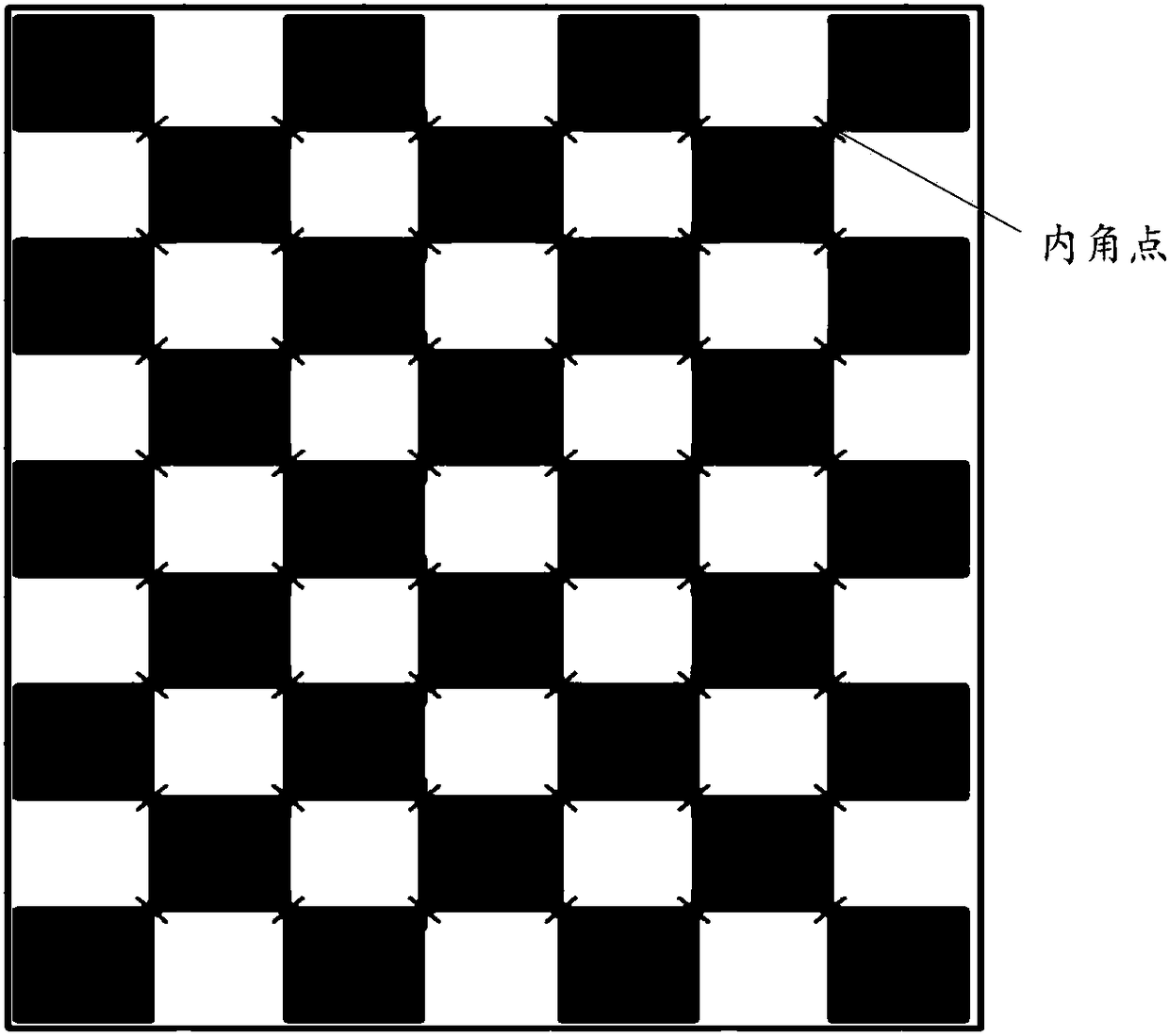

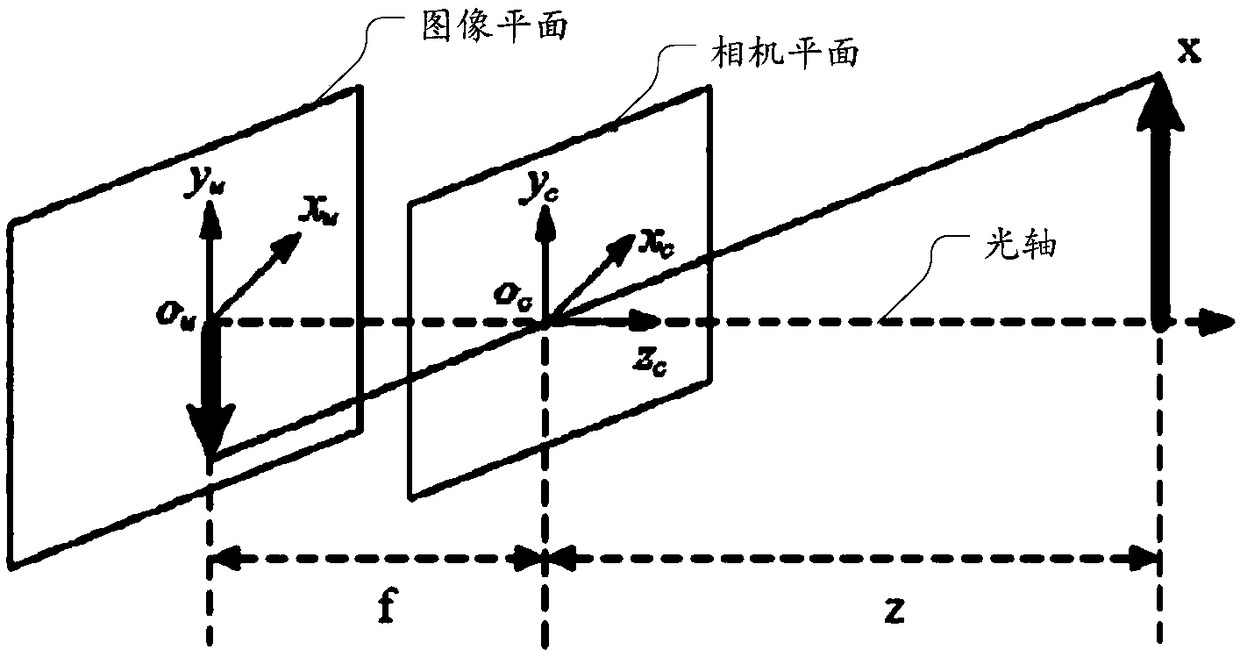

Camera lens optical axis calibration method and apparatus

ActiveCN108257183AGood effectImprove user experienceImage analysisOptical axis determinationCamera lensFisheye lens

The invention discloses a camera lens optical axis calibration method and apparatus. The method comprises the steps of building a world coordinate system by spaces where calibration reference objectsare located, and determining three-dimensional space coordinate values of internal corner points on the calibration reference objects; obtaining images of the calibration reference objects, collectedby camera lenses; according to the three-dimensional space coordinate values of the internal corner points, calibrating the camera lenses to obtain internal parameters, distortion parameters and external parameters of the lenses; and by utilizing the internal parameters, the distortion parameters and the external parameters of the lenses and a preset fisheye lens imaging model, performing calculation processing on pixel points on the images to realize optical axis calibration of two fisheye lenses. The corresponding camera lens optical axis calibration apparatus comprises a reference object determination unit, an image obtaining unit, a parameter calculation unit and an optical axis calibration unit. According to the technical scheme, the problem of subsequent image splicing dislocation caused by inaccurate back-to-back state of the front and back fisheye lenses of a camera is solved; the panoramic image effect is improved; and the usage experience of a user is improved.

Owner:GOERTEK OPTICAL TECH CO LTD

Method for determining the tilt of an image sensor

The invention relates to a method for determining the tilt of an image sensor. Specifically, the present invention relates to a method for determining a tilt of an image sensor surface plane in a camera in relation to a lens reference plane of the camera. The method comprises sending light onto the image sensor, receiving light reflected from the image sensor, identifying an interference pattern in the reflected light, identifying a feature of said interference pattern, and determining the tilt of the image sensor surface plane based on a position of the feature identified in said interference pattern.

Owner:AXIS

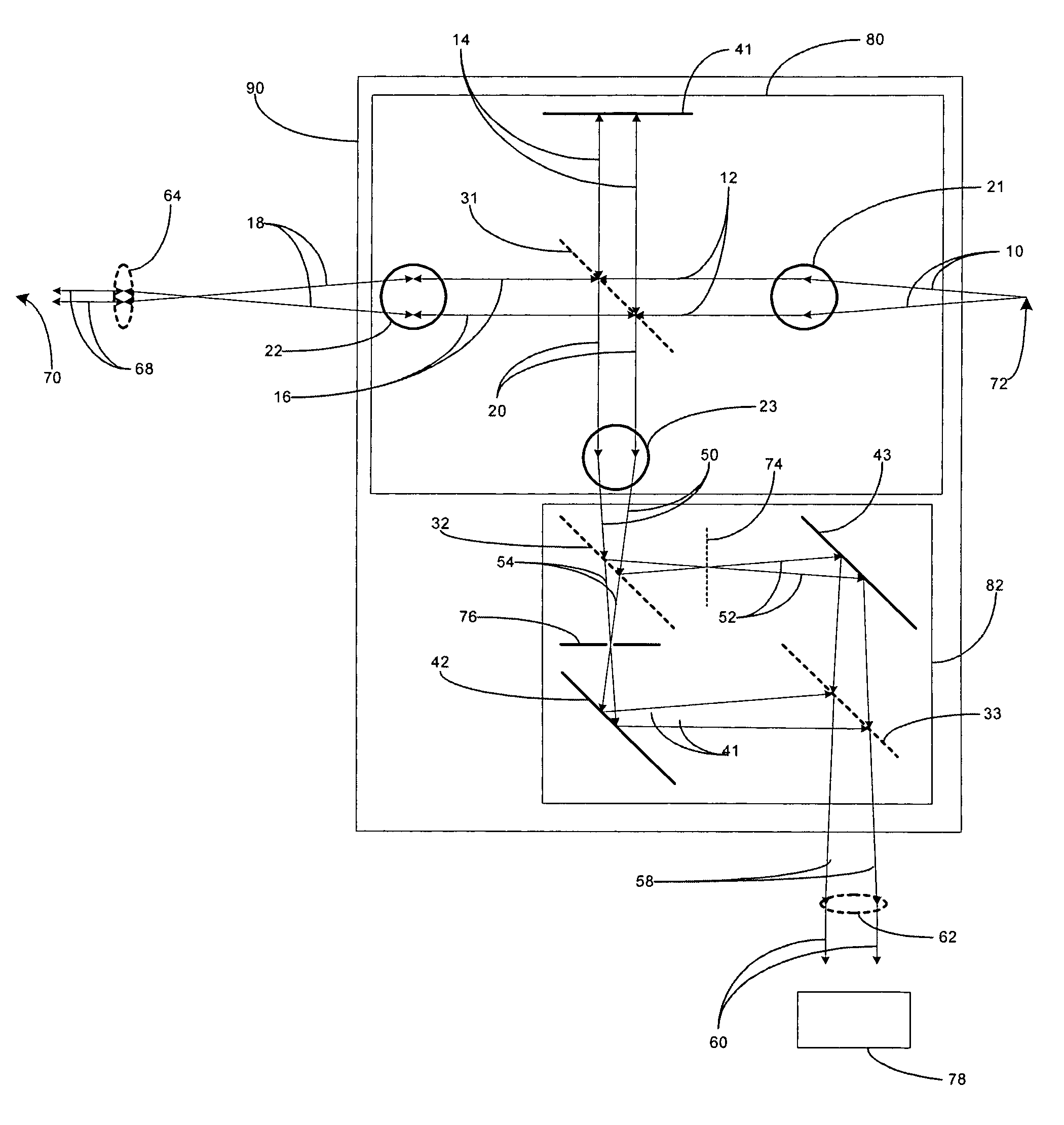

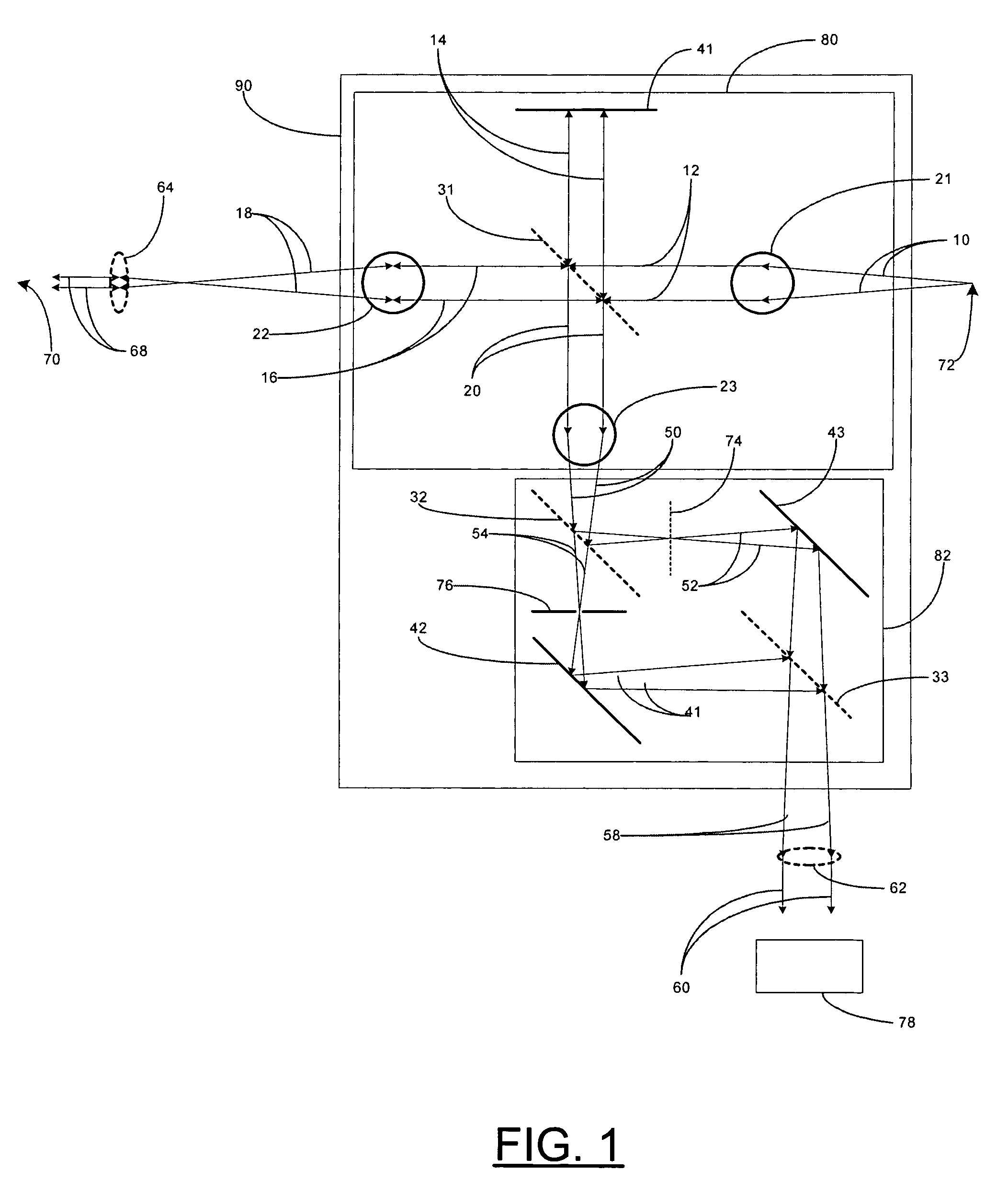

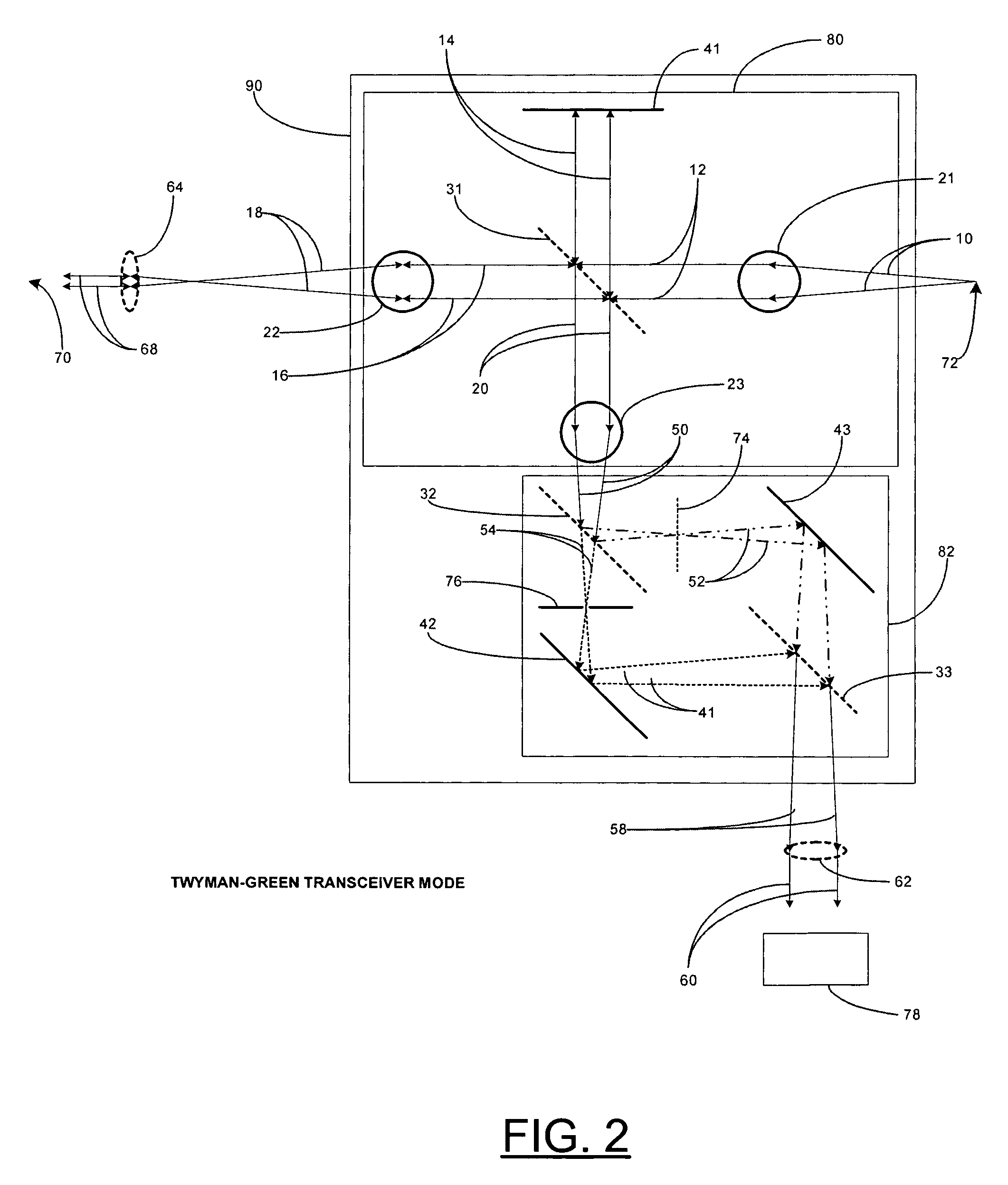

Optical MEMS wavefront diagnostic transceivers and receiver

A combination interferometer (ifo) inspection device is provided which includes a Twyman-Green (T-G) ifo optically coupled to a Mach-Zehnder (M-Z) ifo. MEMS and MOEMS versions permit substantial reduction in size and weight to permit permanently embedding an inspection device into an optical system which permits remote and automated inspection and / or adjustment of the optical system. The inspection device permits use of different coherence length light sources and receipt of an output signal from an optical system. The addition of the T-G ifo to the M-Z ifo aids pinhole alignment and general alignment to the optical system under test, as well as inspection with long coherence sources, while the addition of the M-Z ifo permits measurement with long or short coherence sources, allows measurement of the output beam, and permits the system to operate in a receive-only mode with an external source. The inspection device provides versatile functionality and redundancy for using a single inspection device in a variety of situations and manners in the same application.

Owner:THE BOEING CO

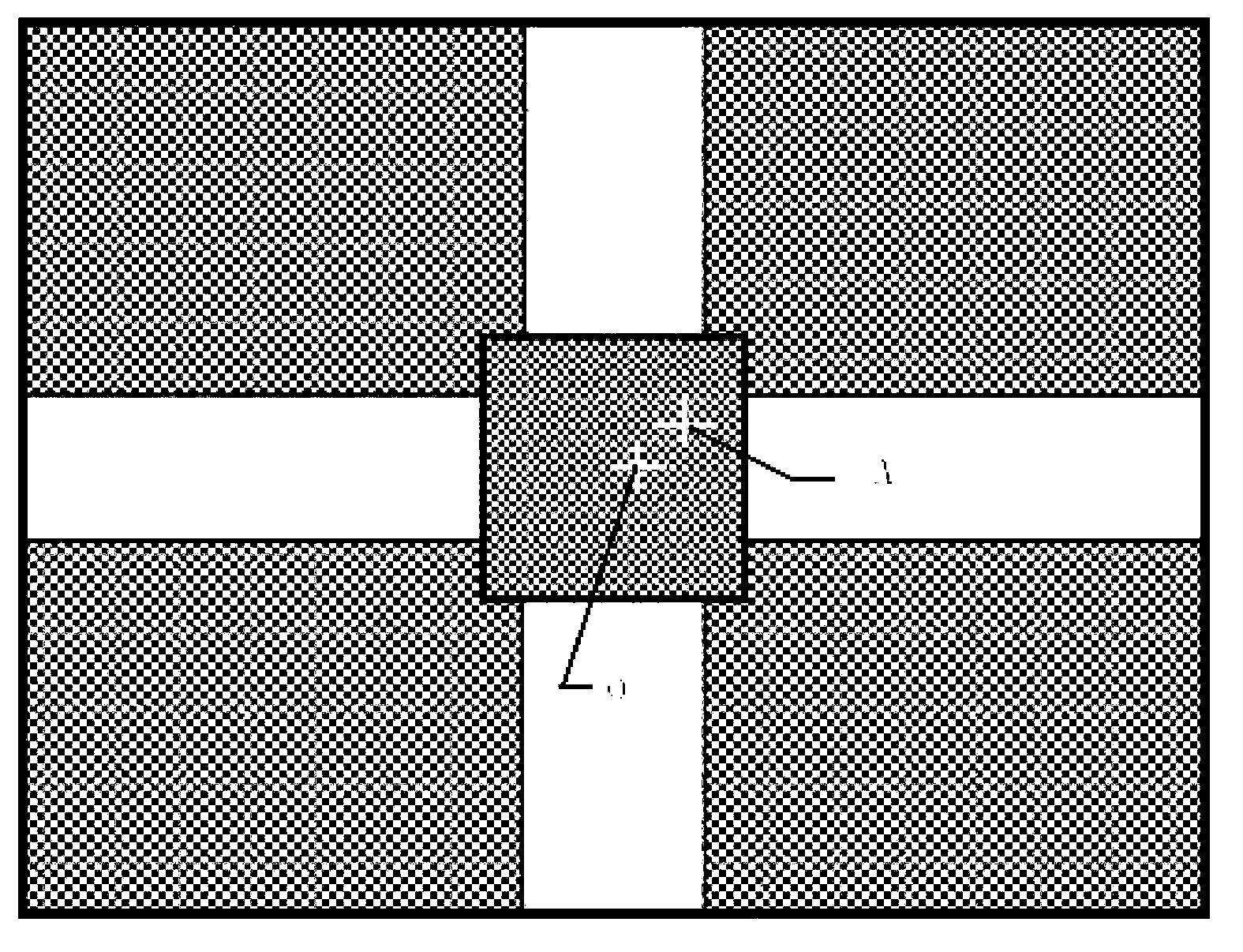

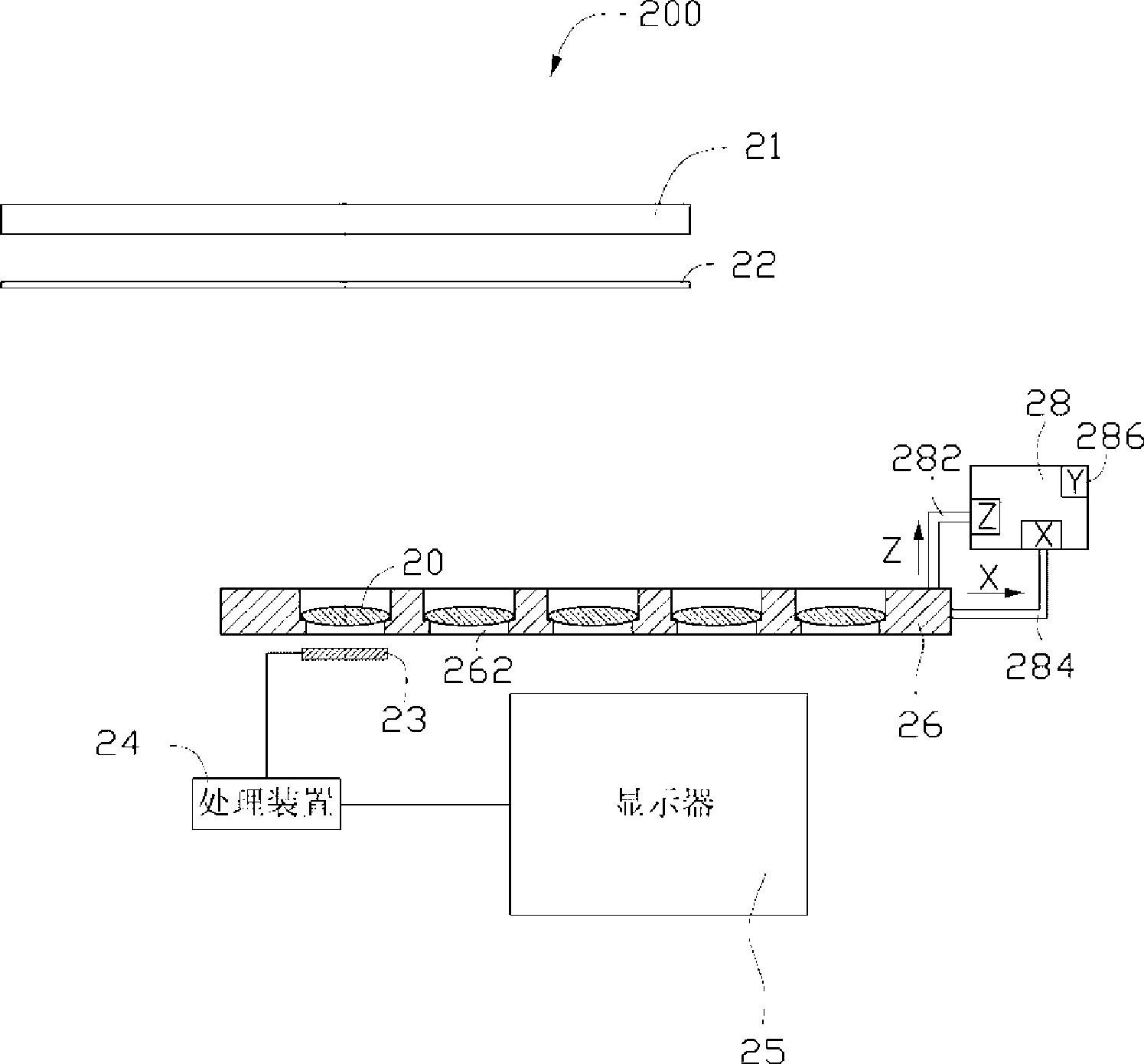

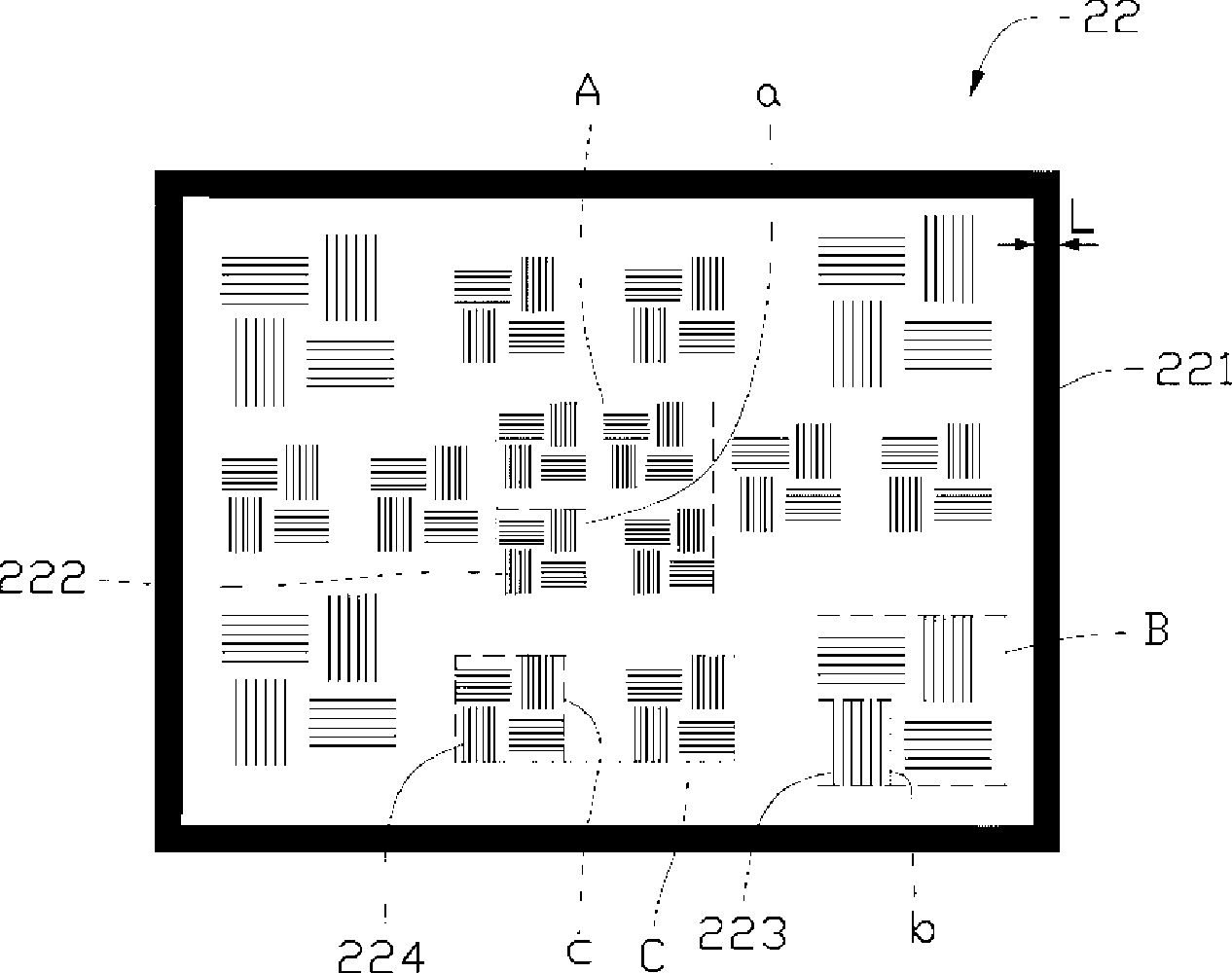

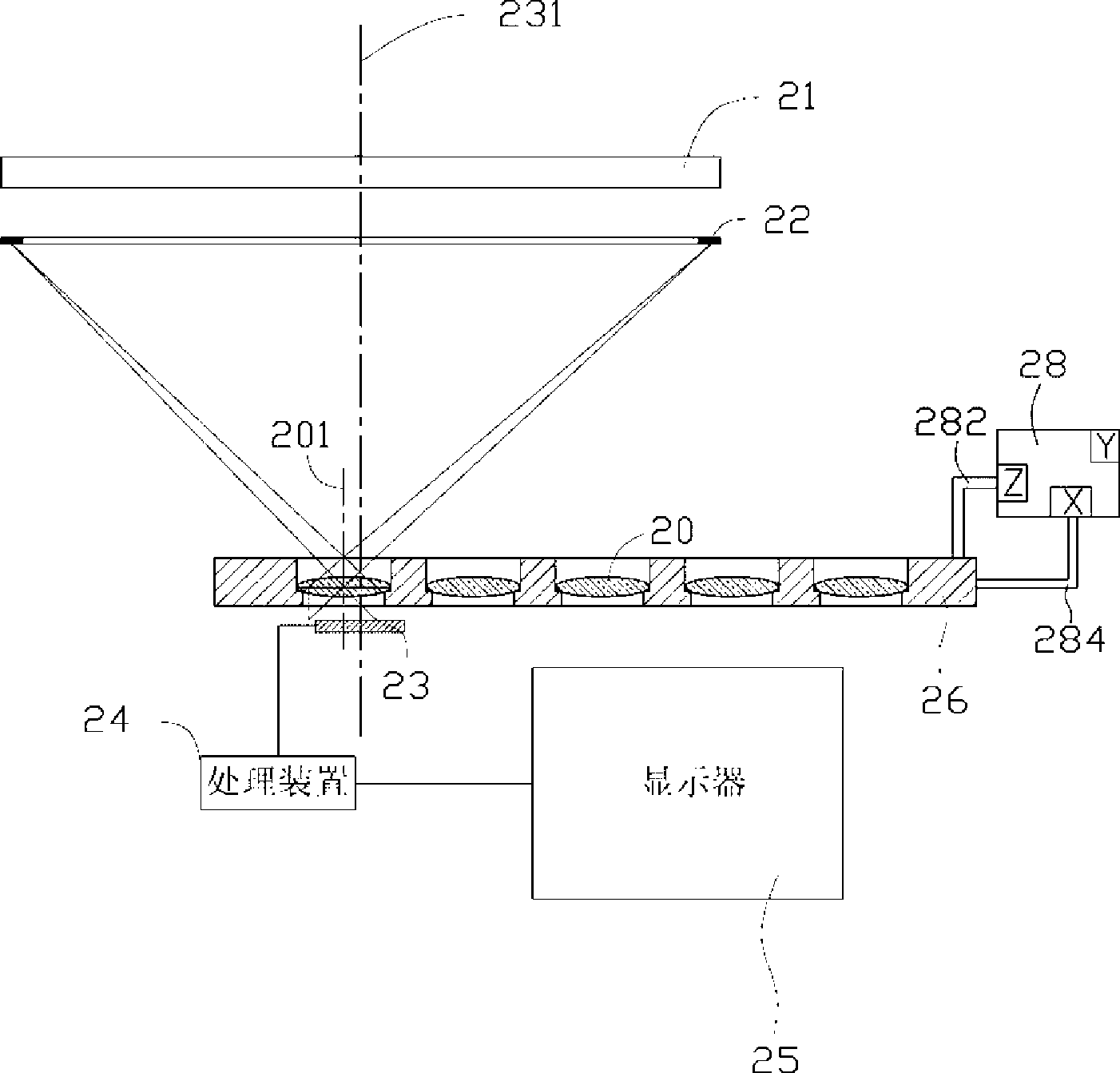

Wire pair testing drawing board, lens optical parsing and measuring system and measuring method thereof

InactiveCN101458441AOptical resolving power measurement value is accurateOptical axis determinationLens position determinationDisplay deviceEngineering

The invention provides a test line pair drawing board which is provided with a bold frame-shaped pattern and a plurality of test line pair figures, wherein, the bold frame-shaped pattern is centrally symmetrical about the entire test line pair drawing board, and the test line pair figures are positioned within the bold frame-shaped pattern. The invention also provides a lens optical analysis and measurement system including the test line pair drawing board, a light source, an image sensor, a processing device and a display device, wherein, a lens is corresponding the test line pair drawing board to be measured; the light source is used for emitting light to irradiate the test line pair drawing board; the image sensor is used for receiving an optical signal that the light reflected by the test line pair drawing board penetrates through the lens to be measured and for converting the optical signal into an electric signal; the processing device is used for receiving the electric signal from the image sensor and converting the electric signal into a digital signal to calculate and output brightness distribution data and optical analysis modulation and conversion function values; and the display device is used for receiving and displaying the output brightness distribution data and optical analysis modulation and conversion function values. The invention also provides an optical analysis measurement method for the lens.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

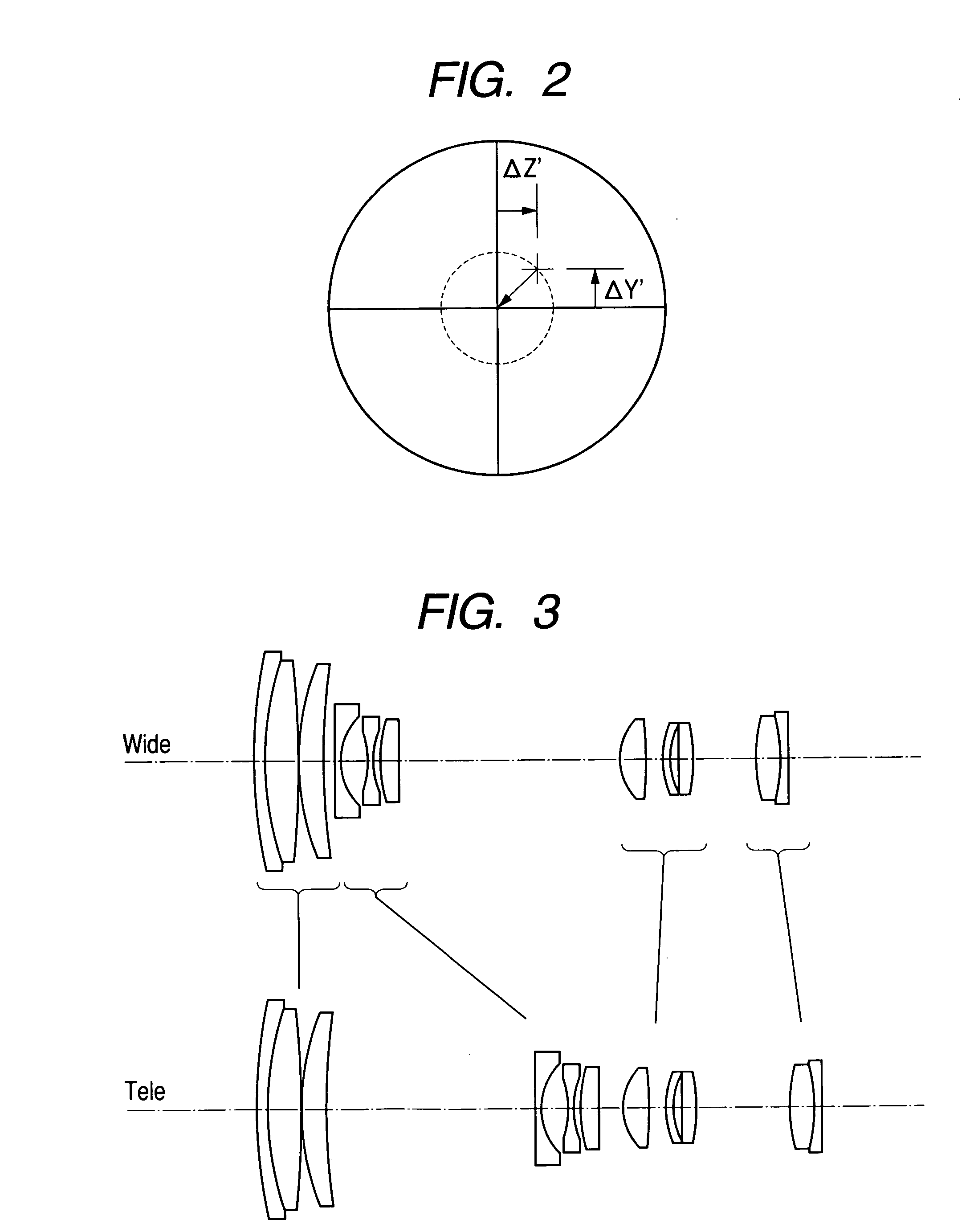

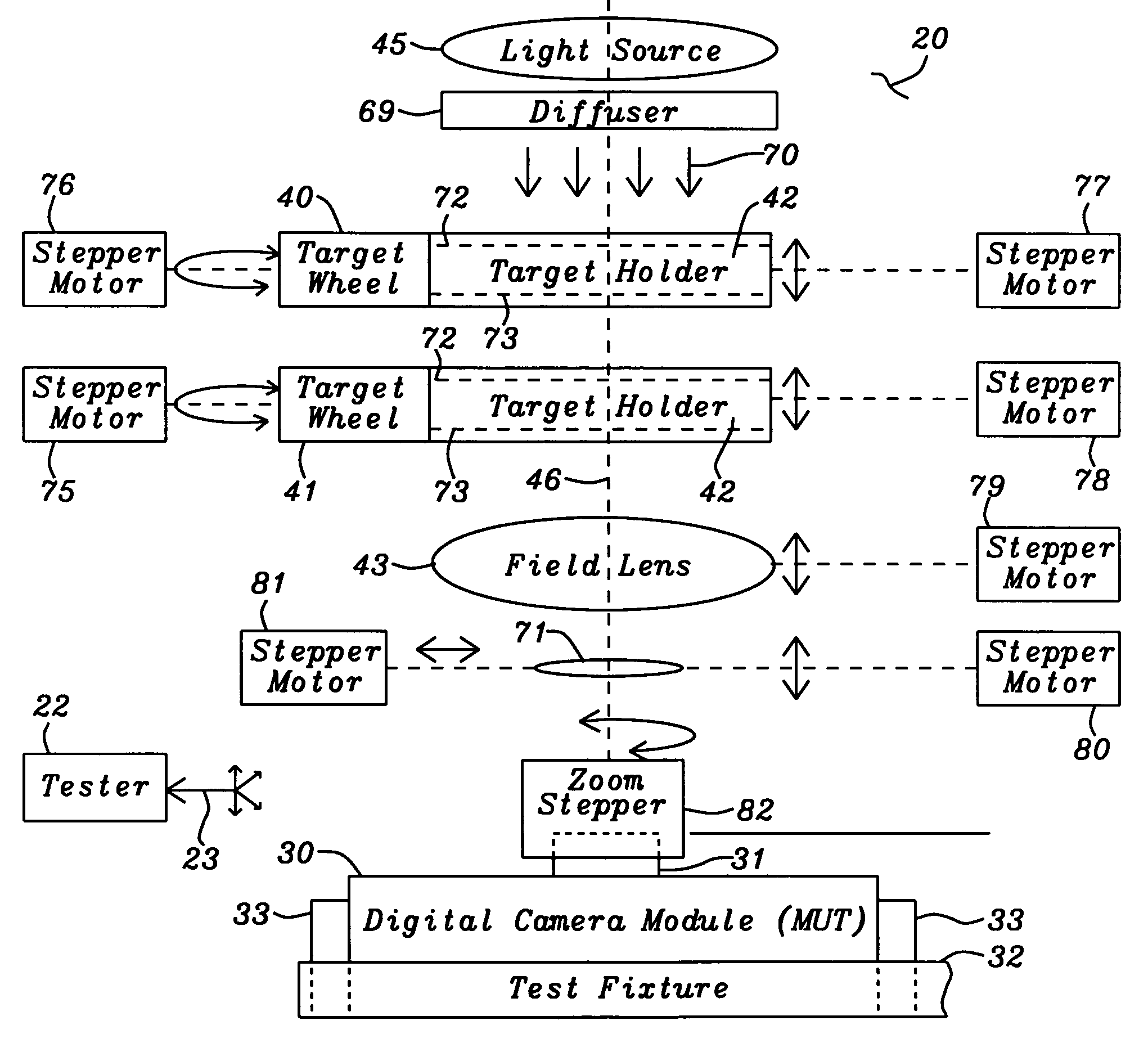

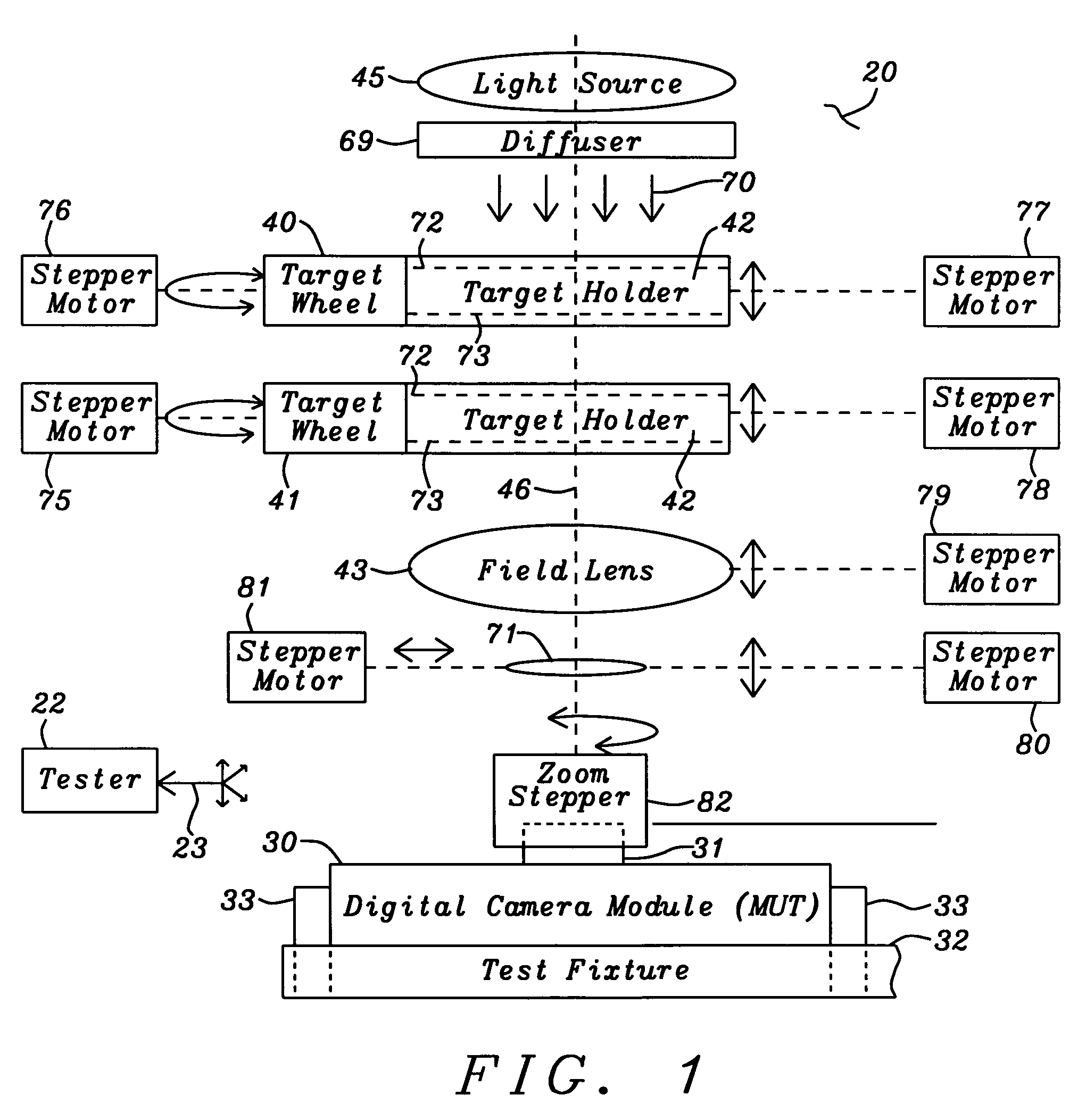

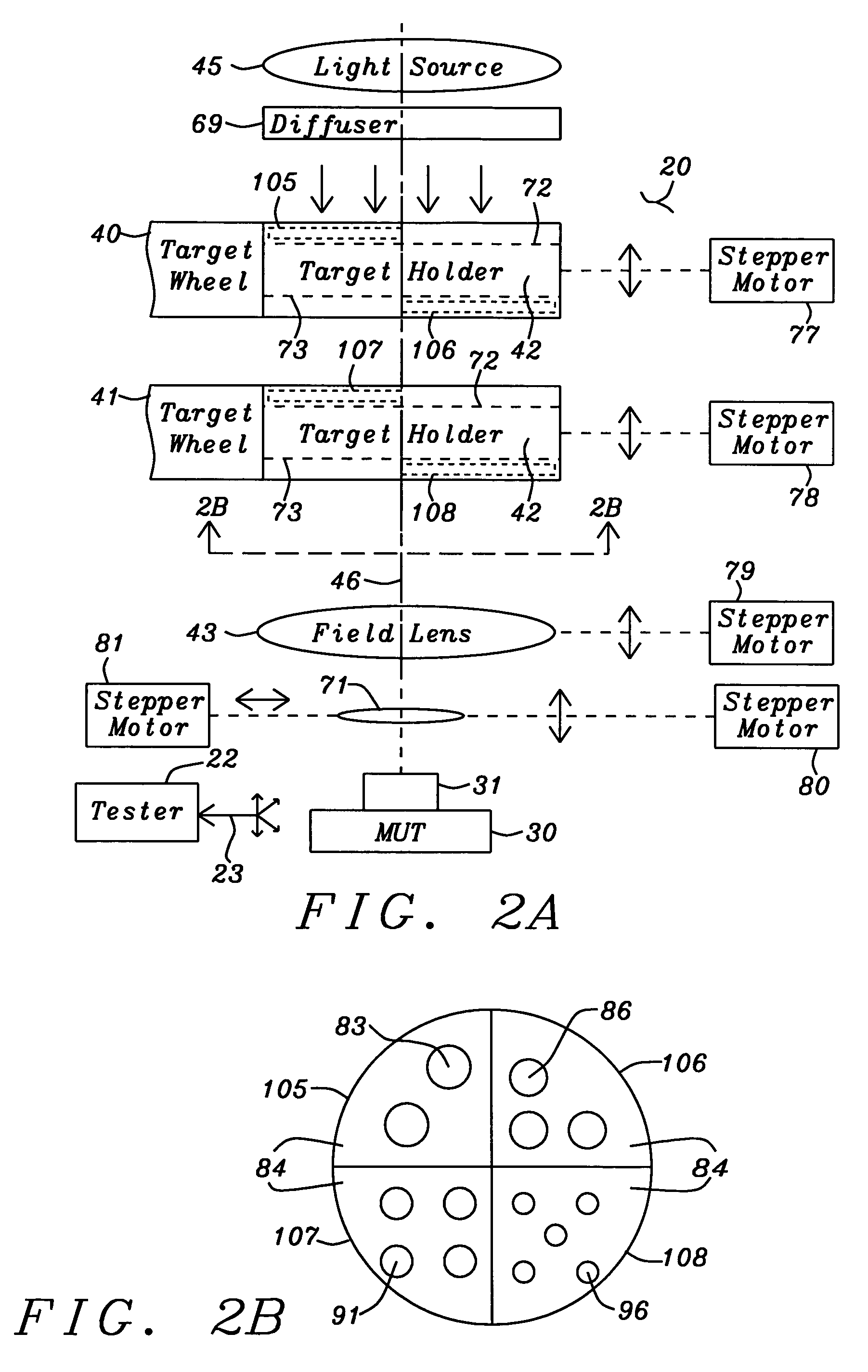

Testing of miniaturized digital camera modules with electrical and/or optical zoom functions

InactiveUS7403229B2Shorten test timeTelevision system detailsColor television detailsCamera lensTarget capture

Owner:RPX CORP

Process and device for measuring the optical properties of spectacle lenses by means of an optical detector of engravings in the spectacle lenses

InactiveUS6088089AMeasure quickly and accuratelyQuickly and accurately approachedOptical surface grinding machinesUsing optical meansEngravingOptical property

PCT No. PCT / DE97 / 01347 Sec. 371 Date Feb. 12, 1998 Sec. 102(e) Date Feb. 12, 1998 PCT Filed Jun. 27, 1996 PCT Pub. No. WO98 / 00693 PCT Pub. Date Jan. 8, 1998An apparatus for detecting parameters of an ophthalmic lens including a vertex refractometer having a lens support for the ophthalmic lens and a detection device for optical detection of at least one engraved marking on at least one predetermined surface area of the ophthalmic lens. The vertex refractometer has a measurement beam path which passes through the ophthalmic lens when the ophthalmic lens is lying on the lens support and the detection device has at least one light source, an imaging optical system for directing light from the at least one light source onto the at least one predetermined surface area of the ophthalmic lens with at least one engraved marking, and an optical receiver system having a light sensor which is connected to an evaluation and representation unit. The optical receiver system images light beams from the imaging optical system which are reflected from the at least one predetermined surface area of the ophthalmic lens. The vertex refractometer and the detection device are disposed so that a spacing between an axis of the measurement beam path of the vertex refractometer and an axis of the optical receiving system of the detection device is selected so that with the ophthalmic lens being positioned relative to the measuring beam path passing through the ophthalmic lens, the at least one predetermined surface area with the at least one engraved marking of the ophthalmic lens is illuminated by the at least one light source.

Owner:G RODENSTOCK INSTR

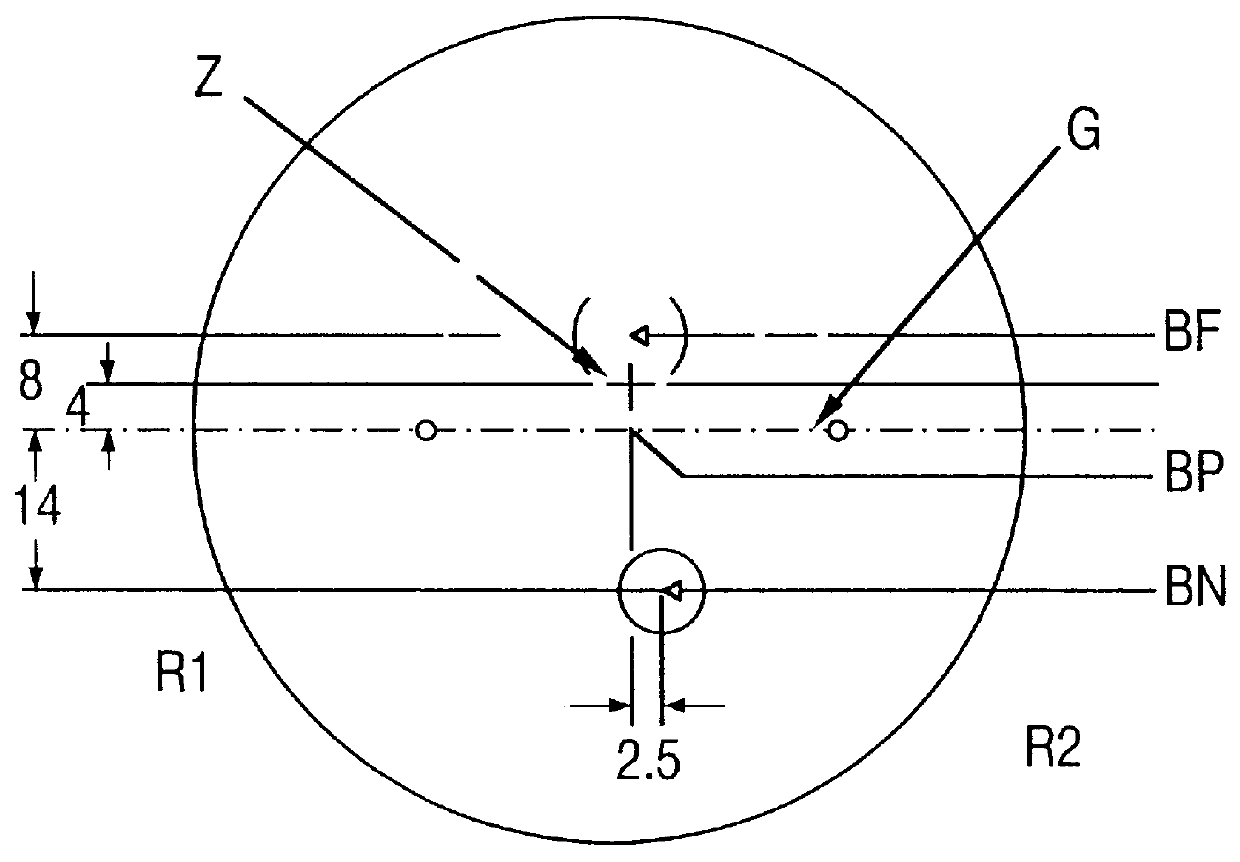

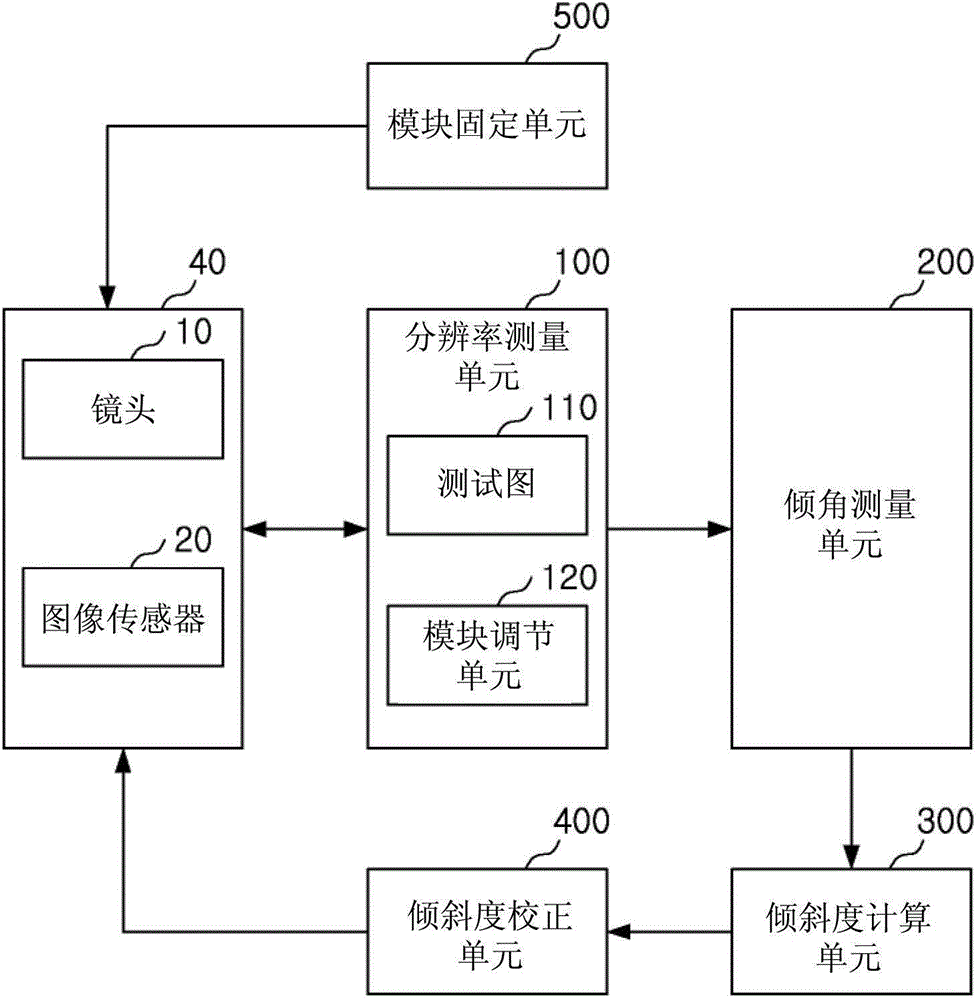

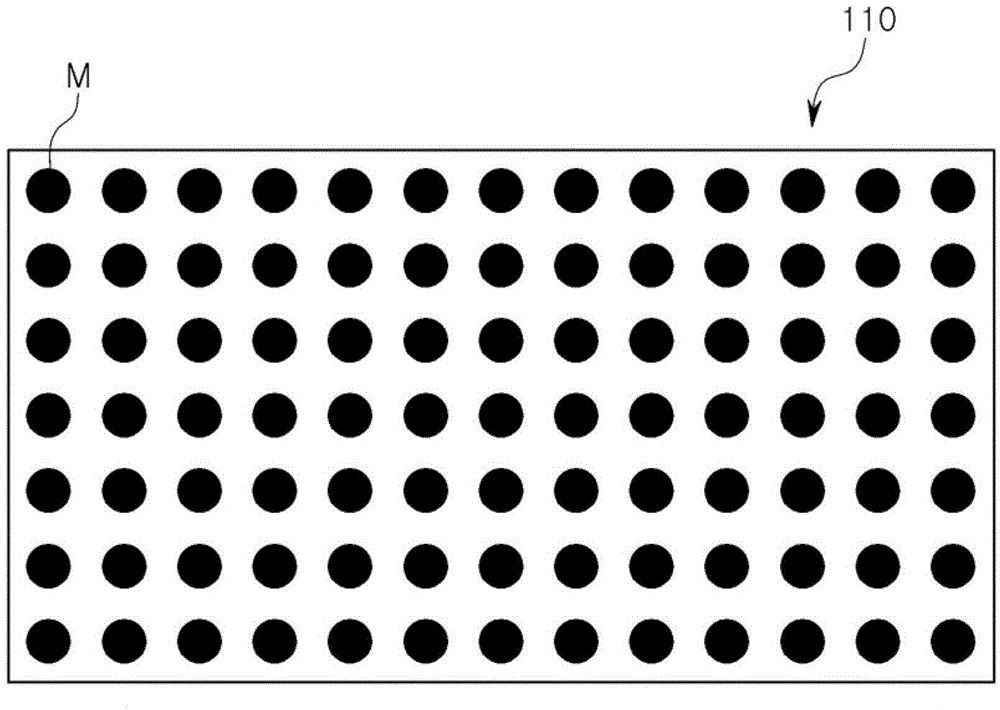

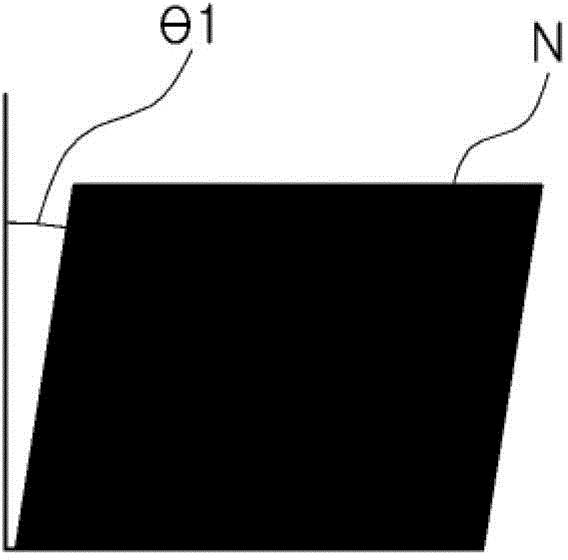

System and method of measuring and correcting tilt angle of lens

InactiveCN106162159AImprove productivityImprove accuracyUsing optical meansTelevision systemsOphthalmologyImage resolution

A system and a method of measuring and correcting an angle of tilt of a lens are provided. A resolution of the lens is measured using a test chart, and it is selected whether or not a tilt of the lens is corrected depending on whether or not the measured resolution of the lens is equal to or greater than a preset value. Whereby, productivity of a camera module may be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Device And Method For Geometrically Measuring An Object

ActiveUS20170082521A1Reduce demandAccurate measurementUsing optical meansOptical axis determinationSupporting systemRelative motion

A device and method for geometrically measuring an object, with a base and a support system arranged thereon for the object, at least one reference object which can be fixed relative to the base, at least one distance measuring system, by means of which a distance between the reference object and the surface of the object facing the reference object can be determined, and an object holder having a top side and an underside, to which the object can be attached, wherein the object holder can be selectively arranged in a first orientation and a second orientation on the support system, wherein the distance measuring system and the object holder are movable relative to each other in order to scan the surface of the object, and the object holder has on the top side thereof and on the underside thereof respective reference structures corresponding to the relative motion of the object holder and to the distance measuring system.

Owner:TAYLOR-HOBSON

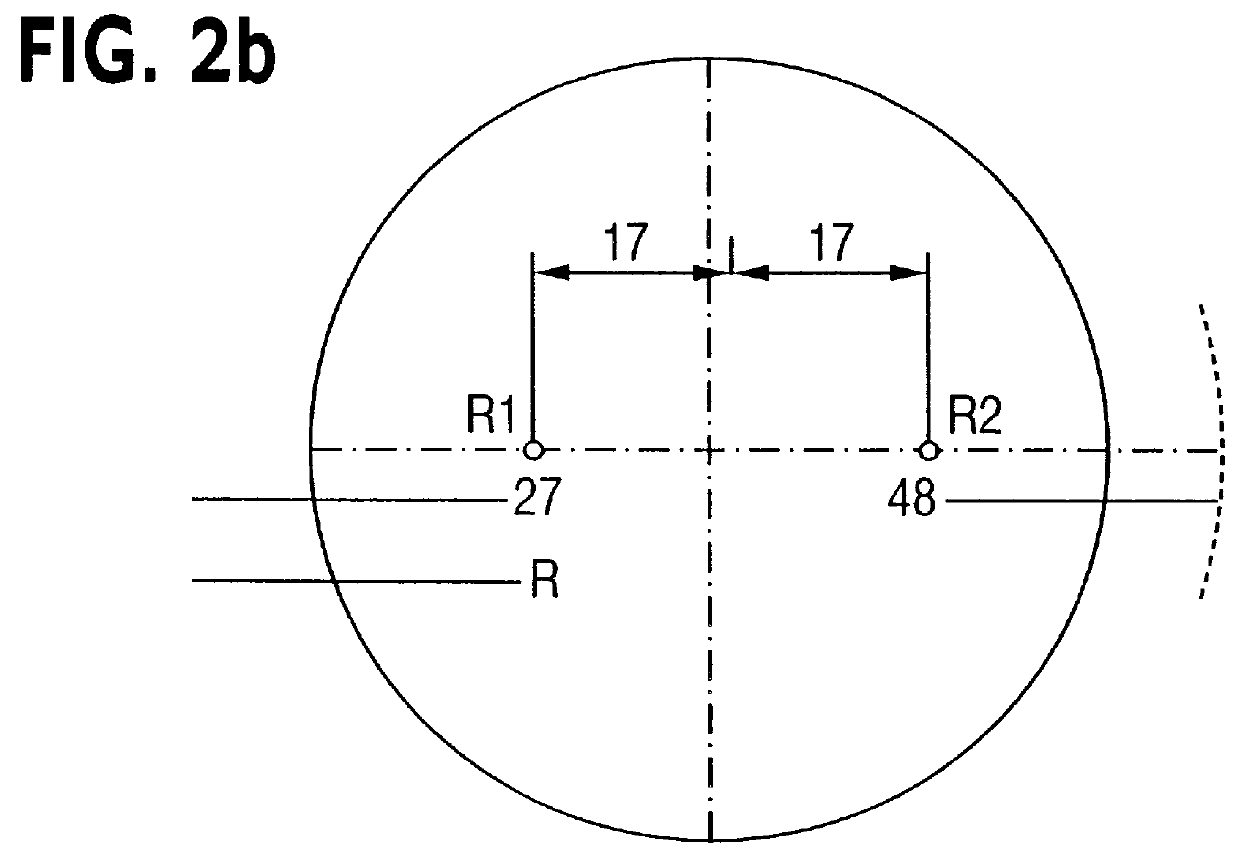

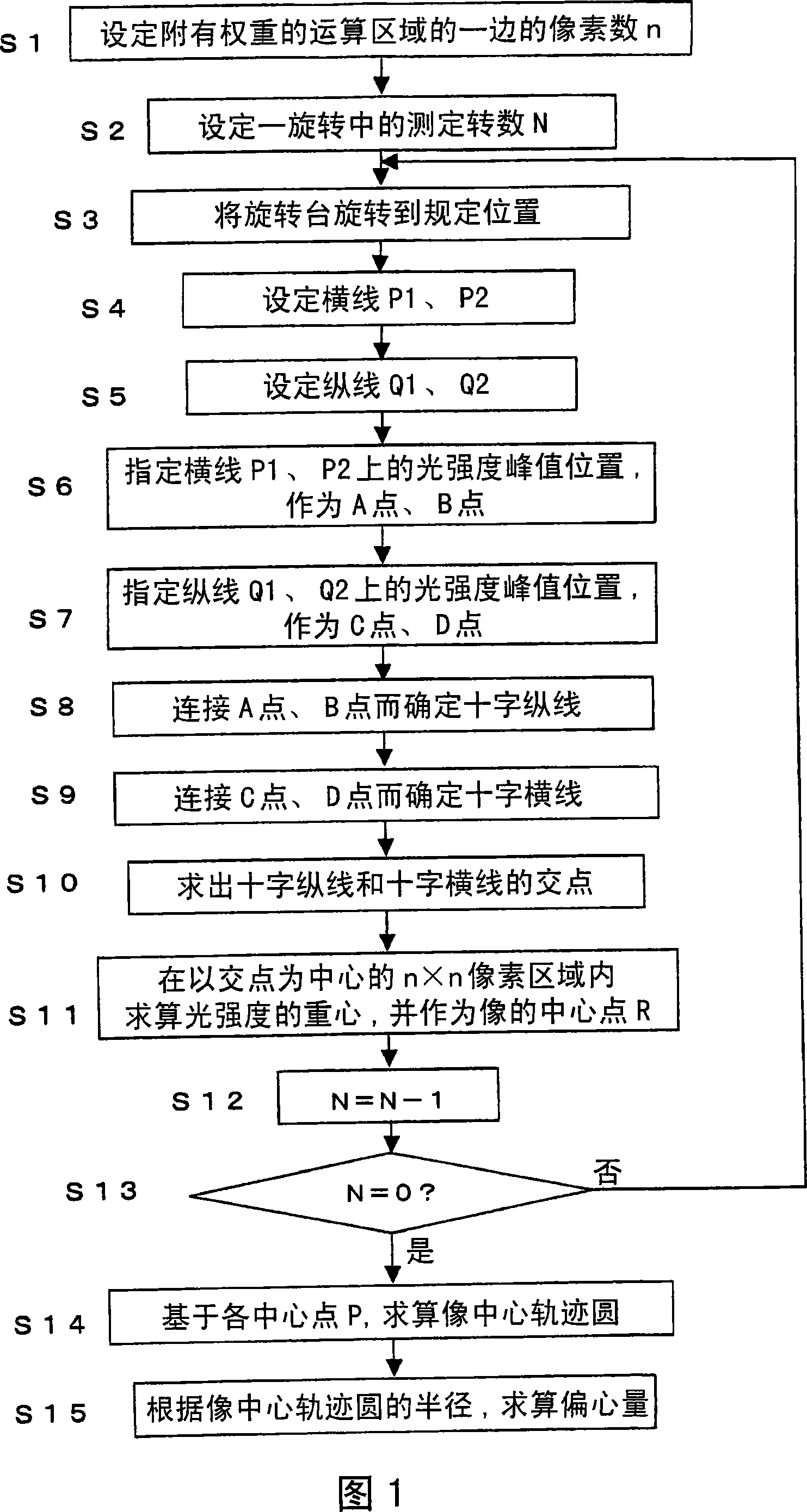

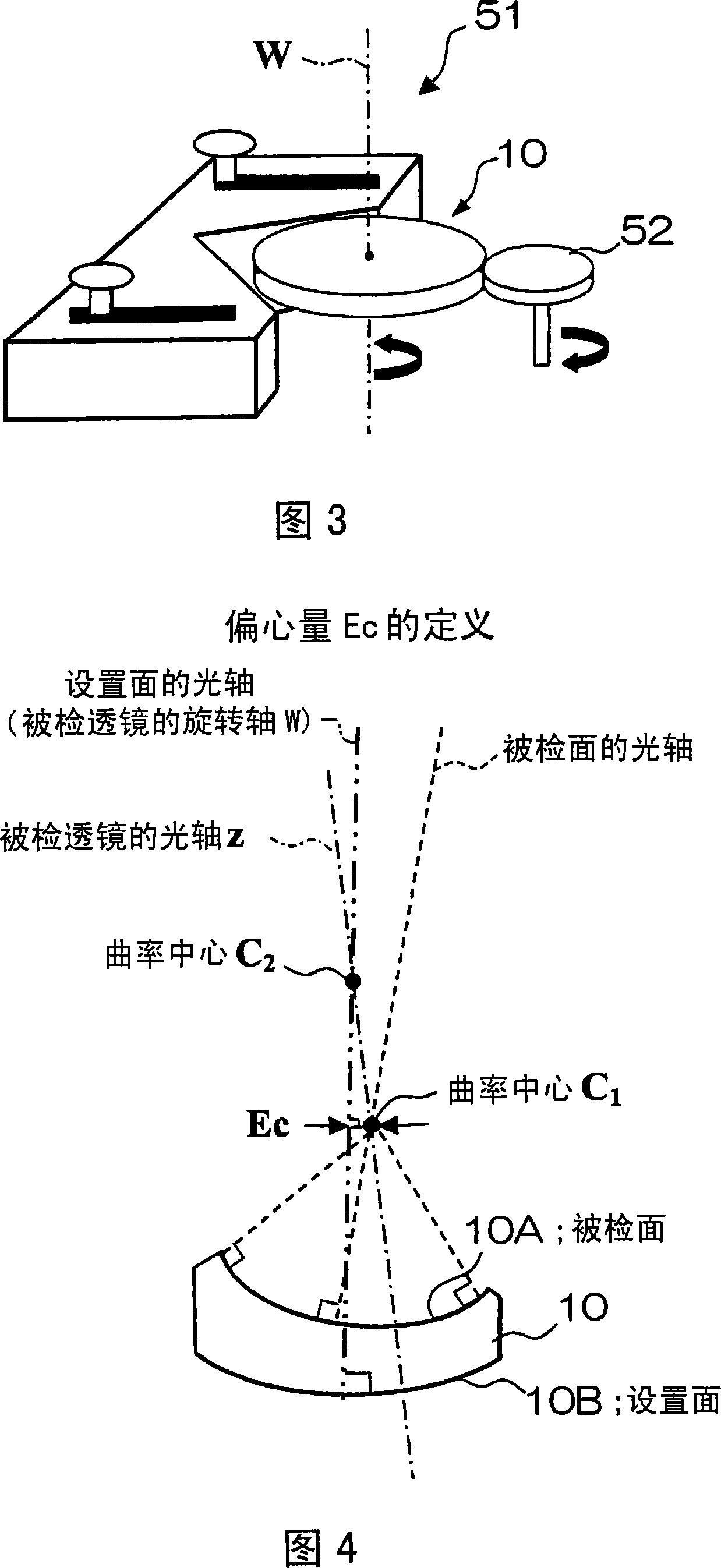

Method for measuring eccentricity quantity

InactiveCN101086445ASimple and high-precision measurement of eccentricityHigh measurement accuracyUsing optical meansOptical axis determinationAutocollimationClassical mechanics

The invention discloses a measuring method of eccentricity. A detected lens (S3) is set at a preset rotating angle, and transversal line (P1,P2)(S4) crosses with image ordinate of reticule, and ordinate (Q1,Q2)(S5) crosses with image transversal line of reticule, and the peak position A, B of light intensity on the transversal line (P1,P2) and the peak position C, D of light intensity on the ordinate (Q1,Q2) is specified. The cross ordinate for connecting A and B is determined and the cross transversal line (S8,S9) for connecting C and D is also determined. Then, the crossing point of the cross ordinate and cross transversal line is specified to be as center R(S11) of reticule image. Each center R is based on multi rotating positions, the image center tracking circle (S14) is calculated and the radius of the image center tracking circle is used as eccentricity Ec(S15) of the detected surface. Therefore, in the measuring method of eccentricity using autocollimation method, the measurement precision is greatly raised in simple structure.

Owner:FUJI PHOTO OPTICAL CO LTD

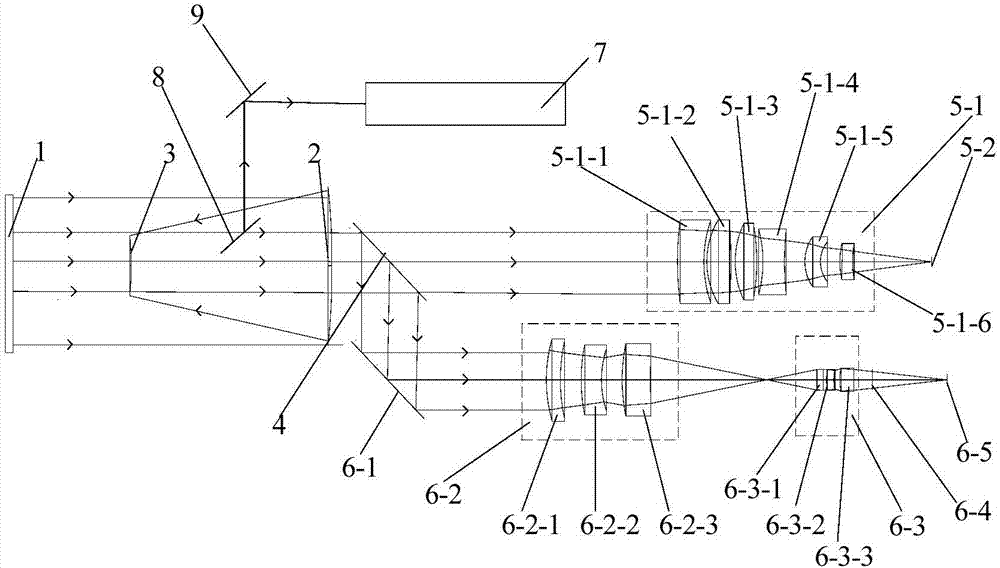

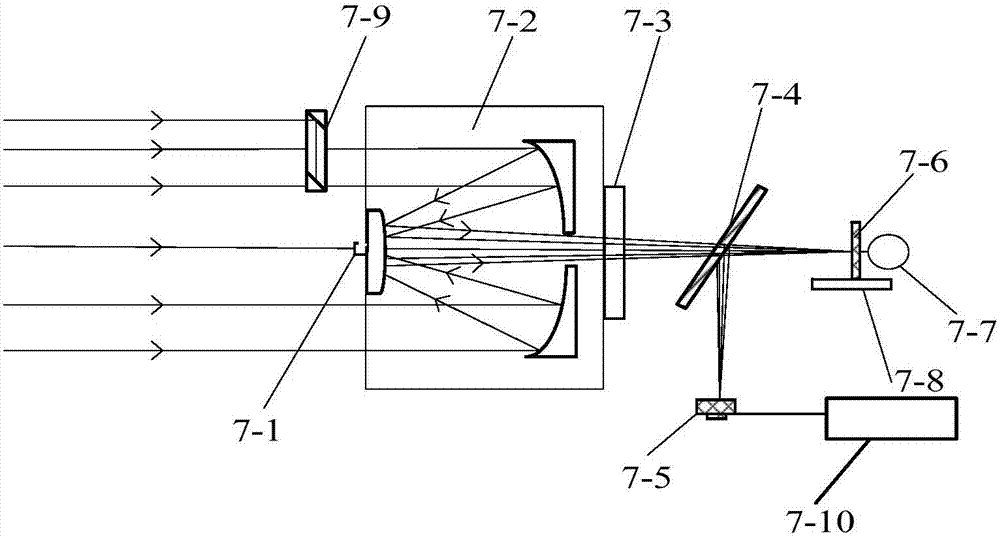

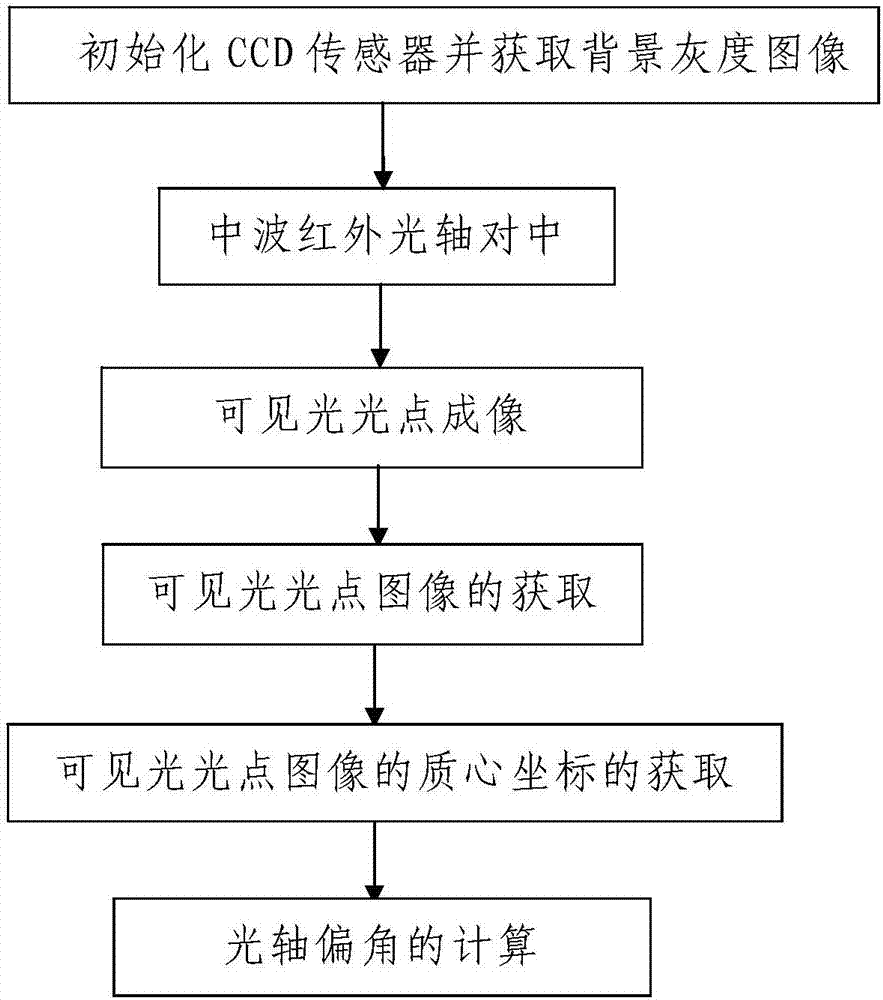

Infrared-visible light dual-band photoelectric detection system and axis angle error measuring method

InactiveCN107991686AAccurately identify the targetHigh resolutionTelevision system detailsColor television detailsBeam splitterImaging quality

The invention discloses an infrared-visible light dual-band photoelectric detection system and an axis angle error measuring method. The Infrared-visible light dual-band photoelectric detection systemand axis angle error measuring method comprises a reflecting system, a beam splitter, a visible light imaging unit on a reflecting path of the beam splitter, a medium-wave infrared imaging unit on atransmitting path, and an axis angle error measuring unit. The axis angle error measuring method comprises: I, initializing a CCD (charge coupled device) sensor, and acquiring a background gray image;II, centering a medium-wave infrared axis; III, performing visible light spot imaging; IV, acquiring a visible light spot image; V, acquiring coordinates of a center of mass of the visible light spotimage; VI, calculating axis angle error. The infrared-visible light dual-band photoelectric detection system and the axis angle error measuring method have the advantages that the advantages of a visible light band optical system and those of a medium-wave infrared band optical system are combined, observing efficiency and inspecting efficiency are improved, remote high-definition all-weather imaging is achieved, imaging quality is effectively improved, the axis angle error measuring unit can measure angle errors for visible light axis and medium-wave infrared axis, and stability of the photoelectric detection system can be measured.

Owner:XIAN TECHNOLOGICAL UNIV

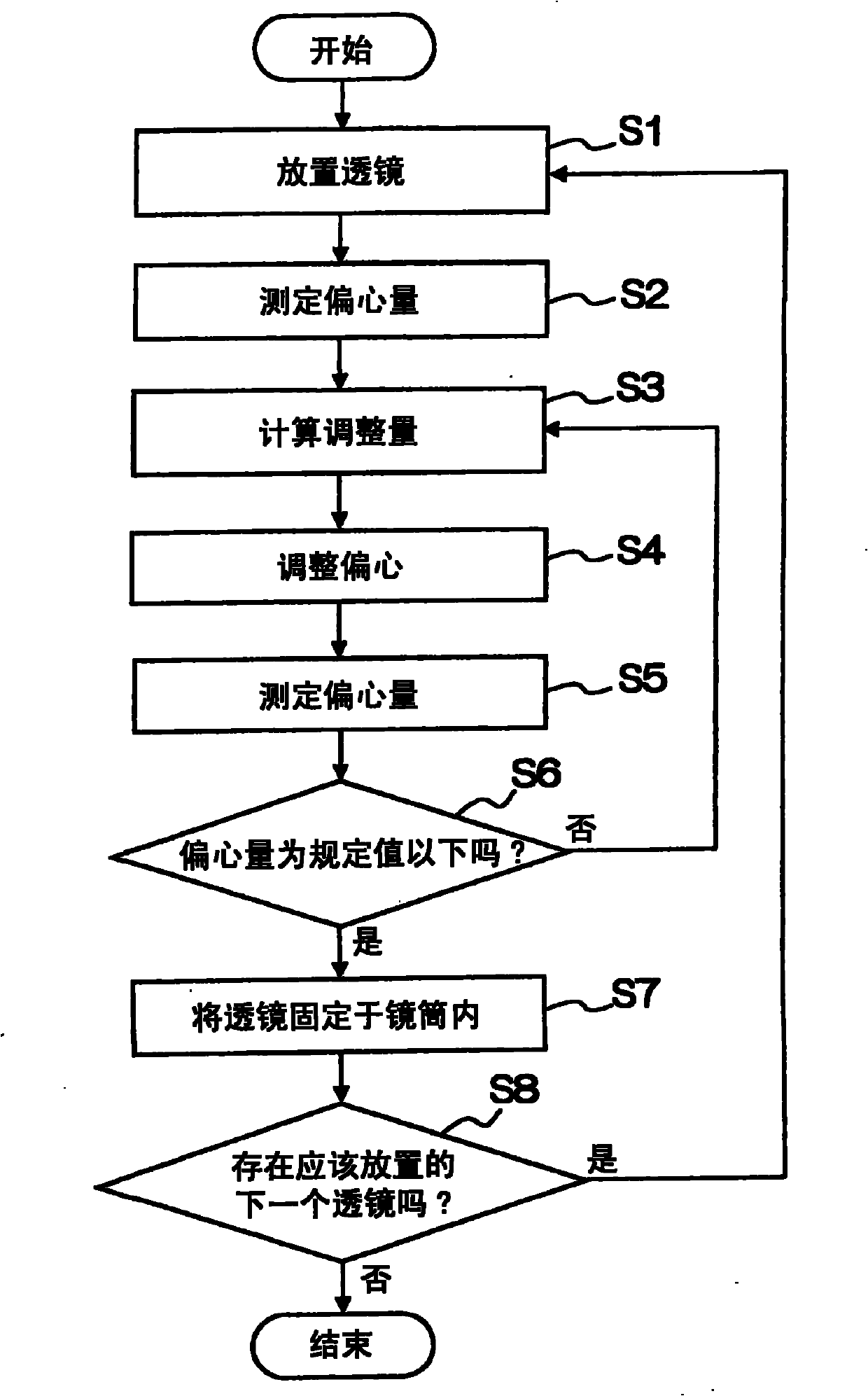

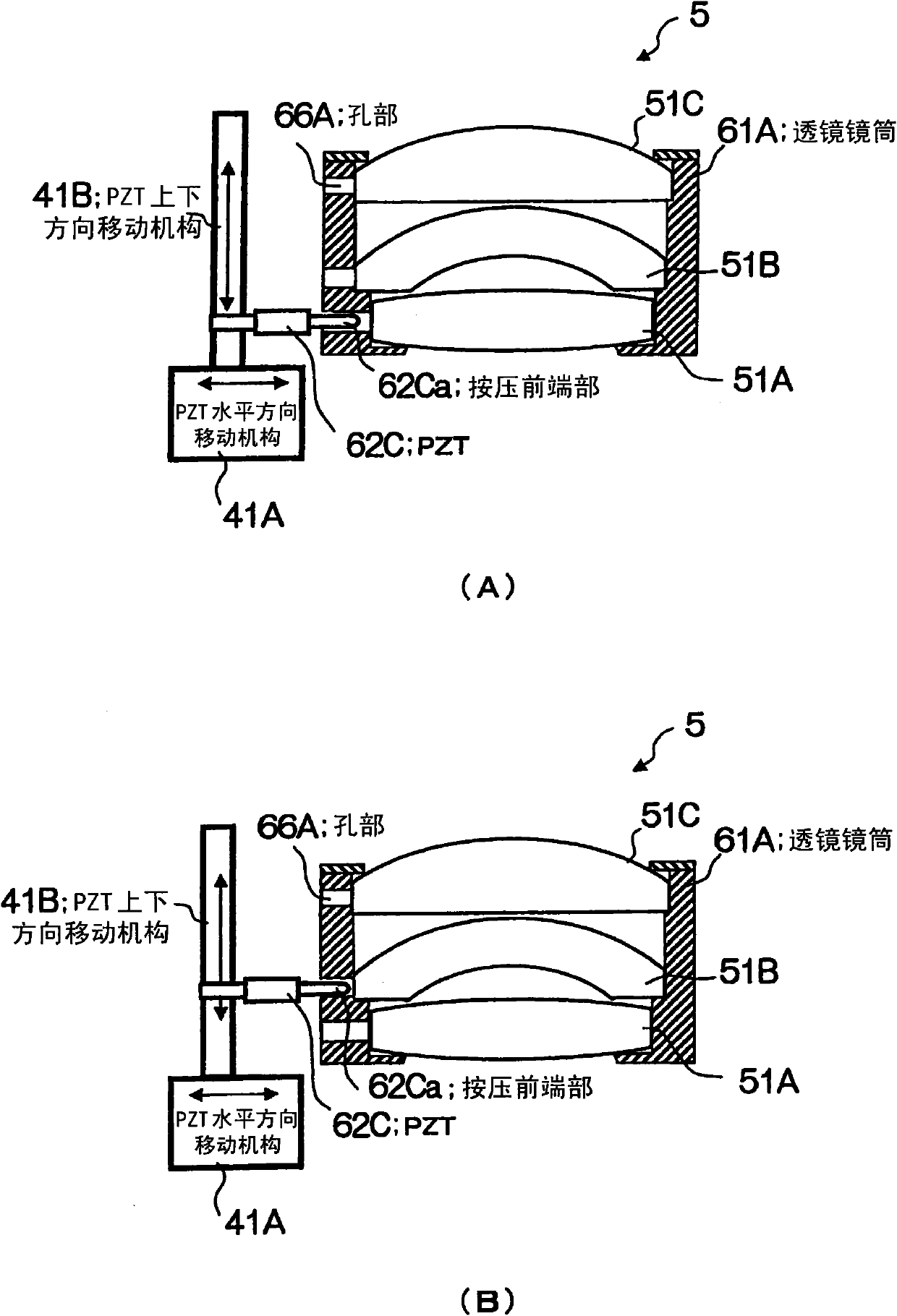

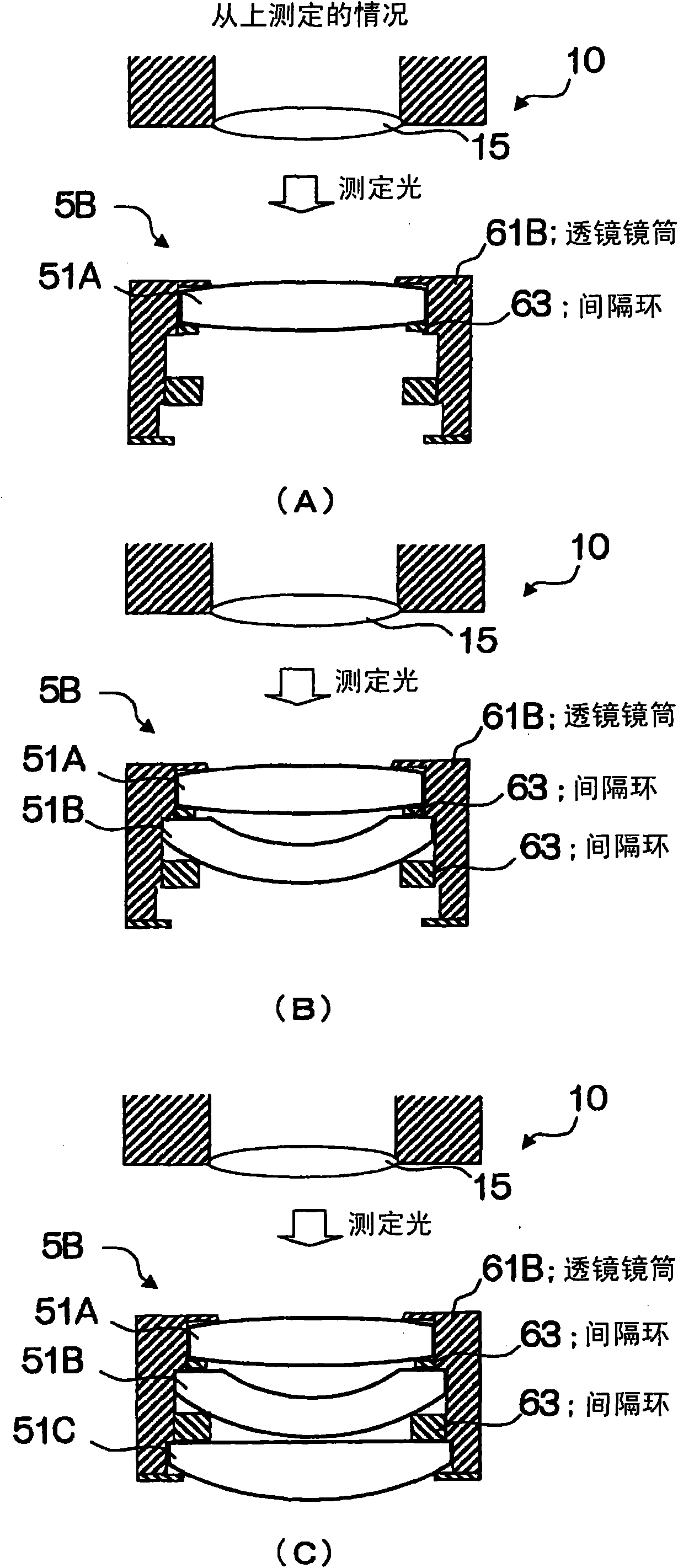

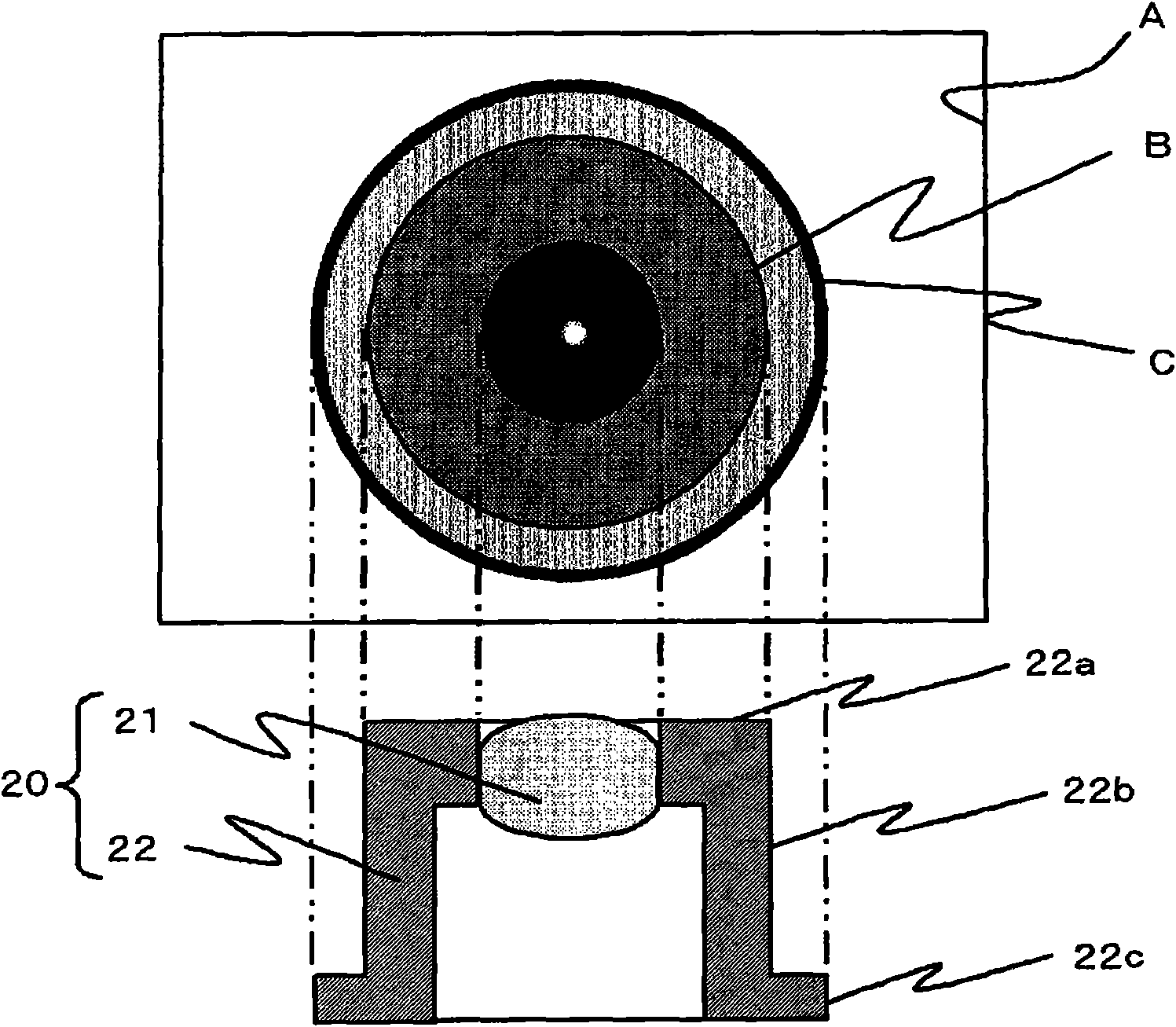

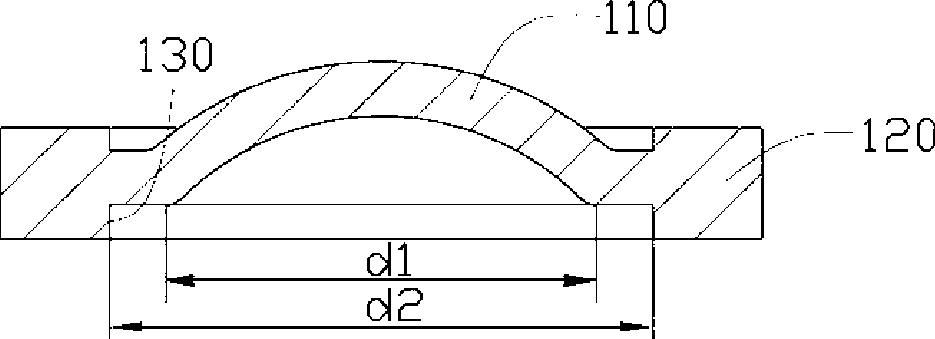

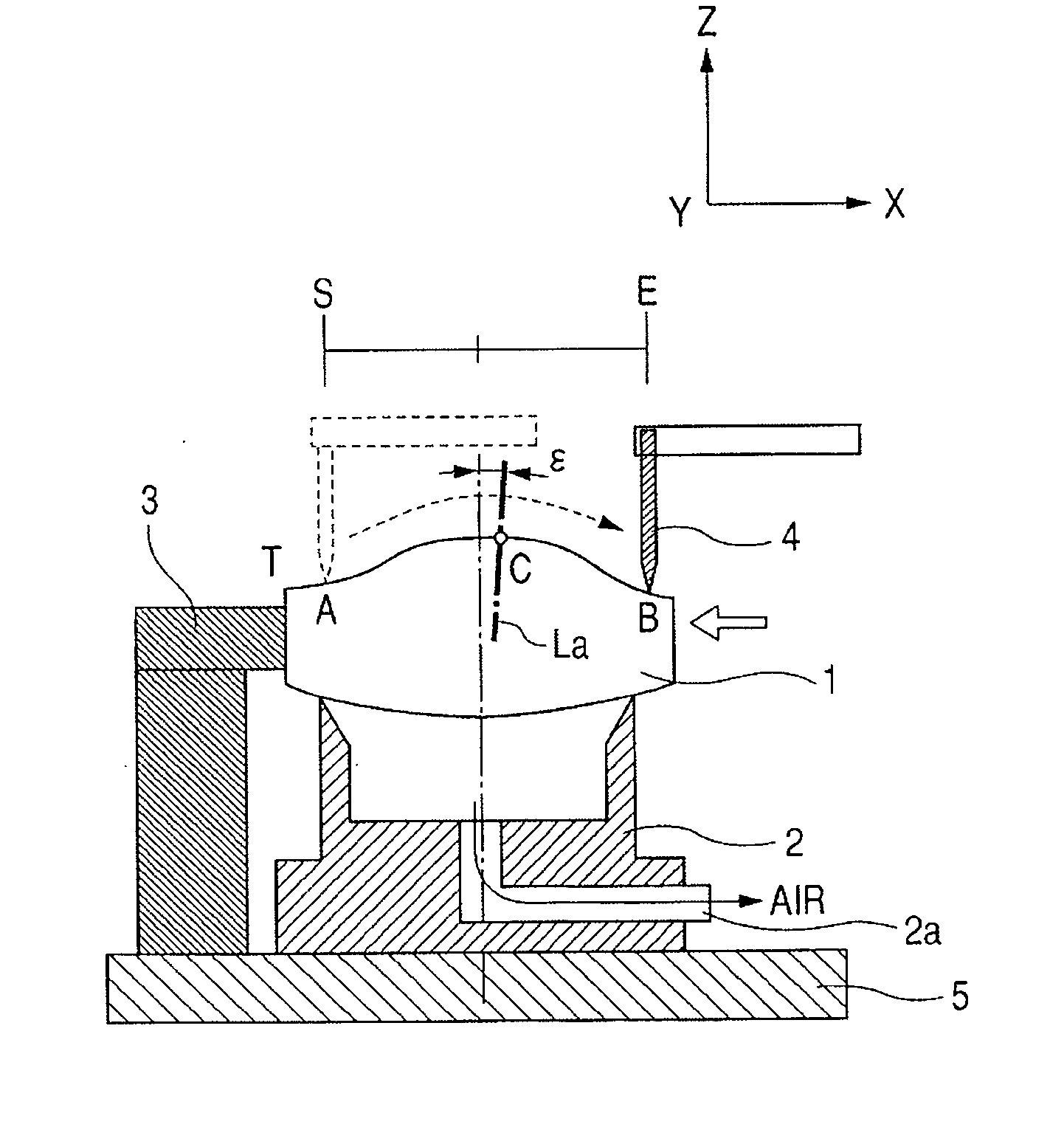

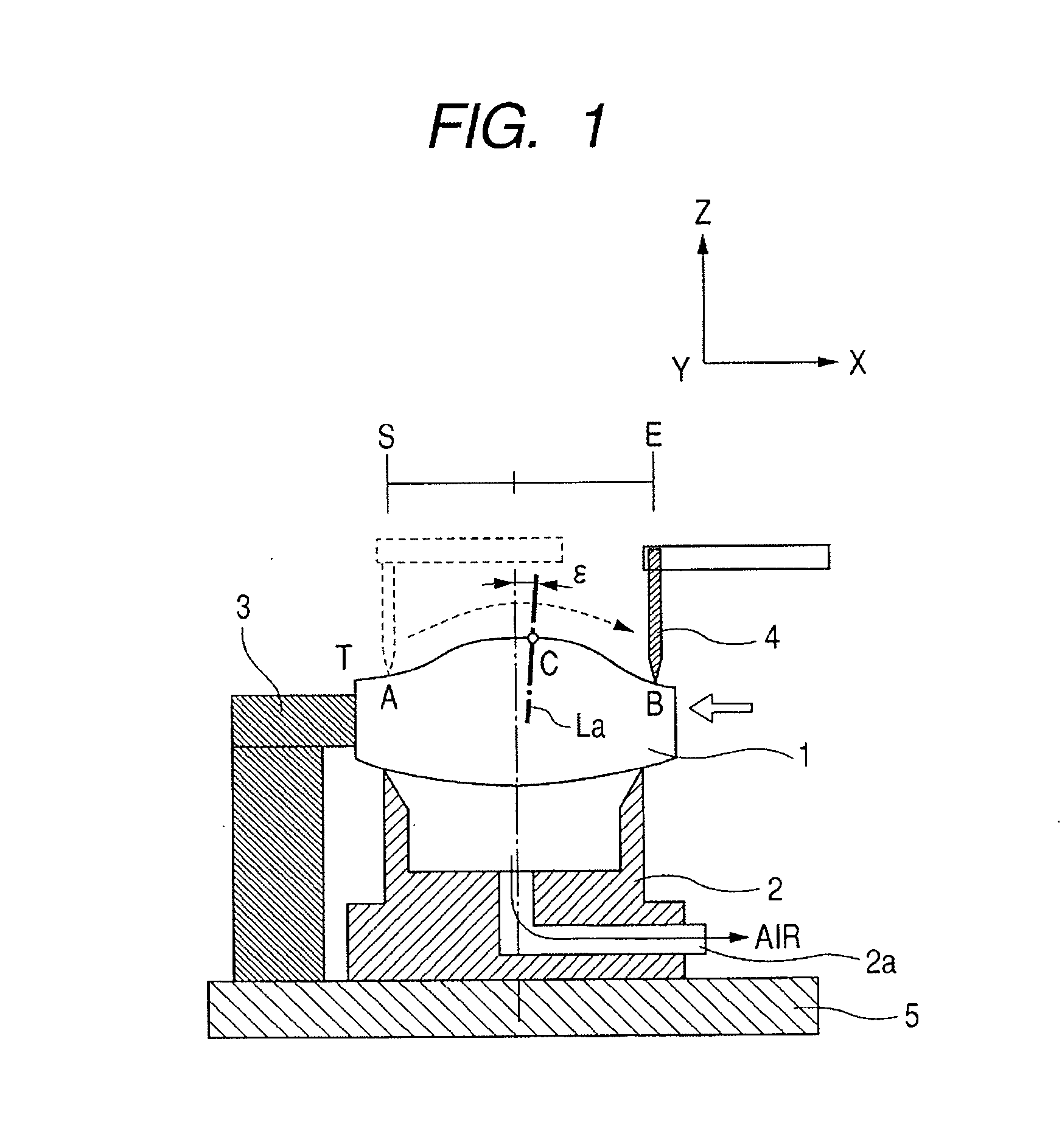

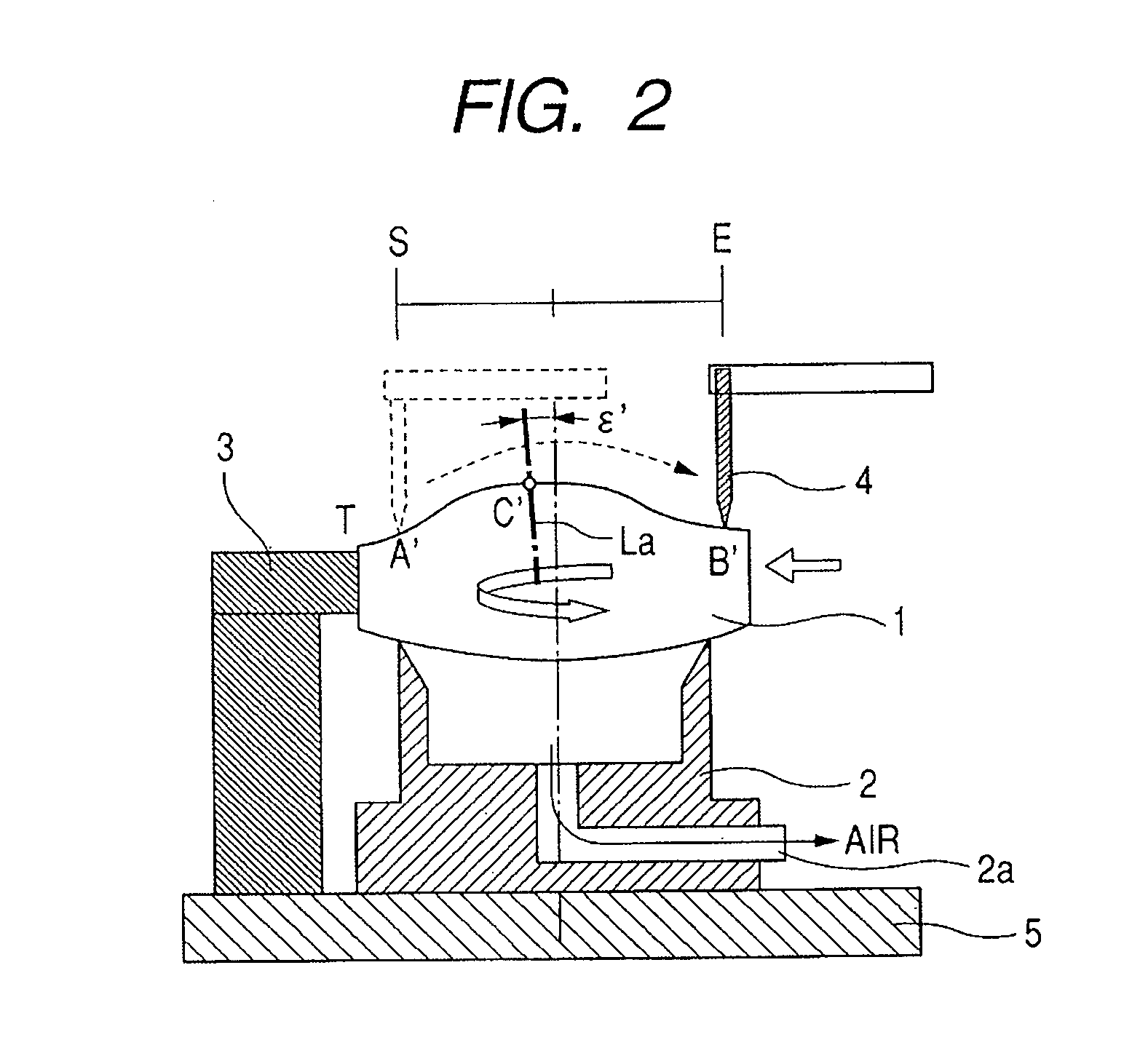

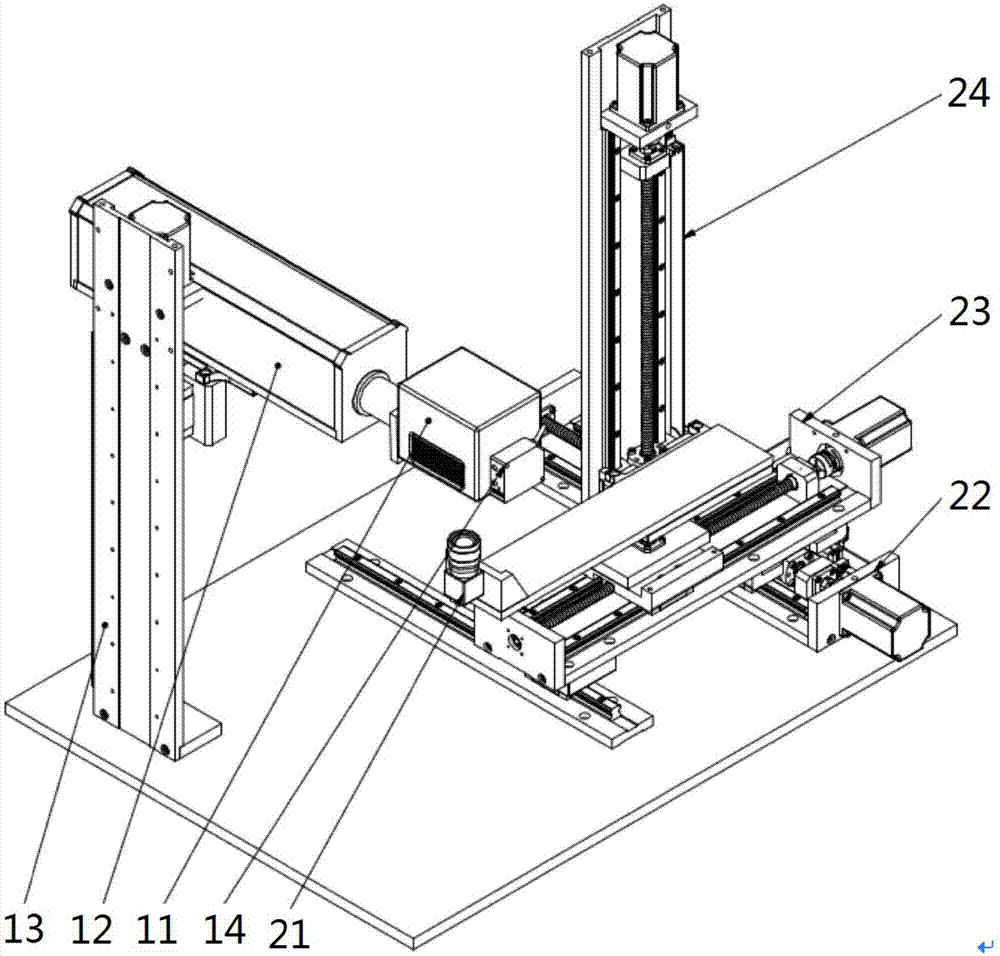

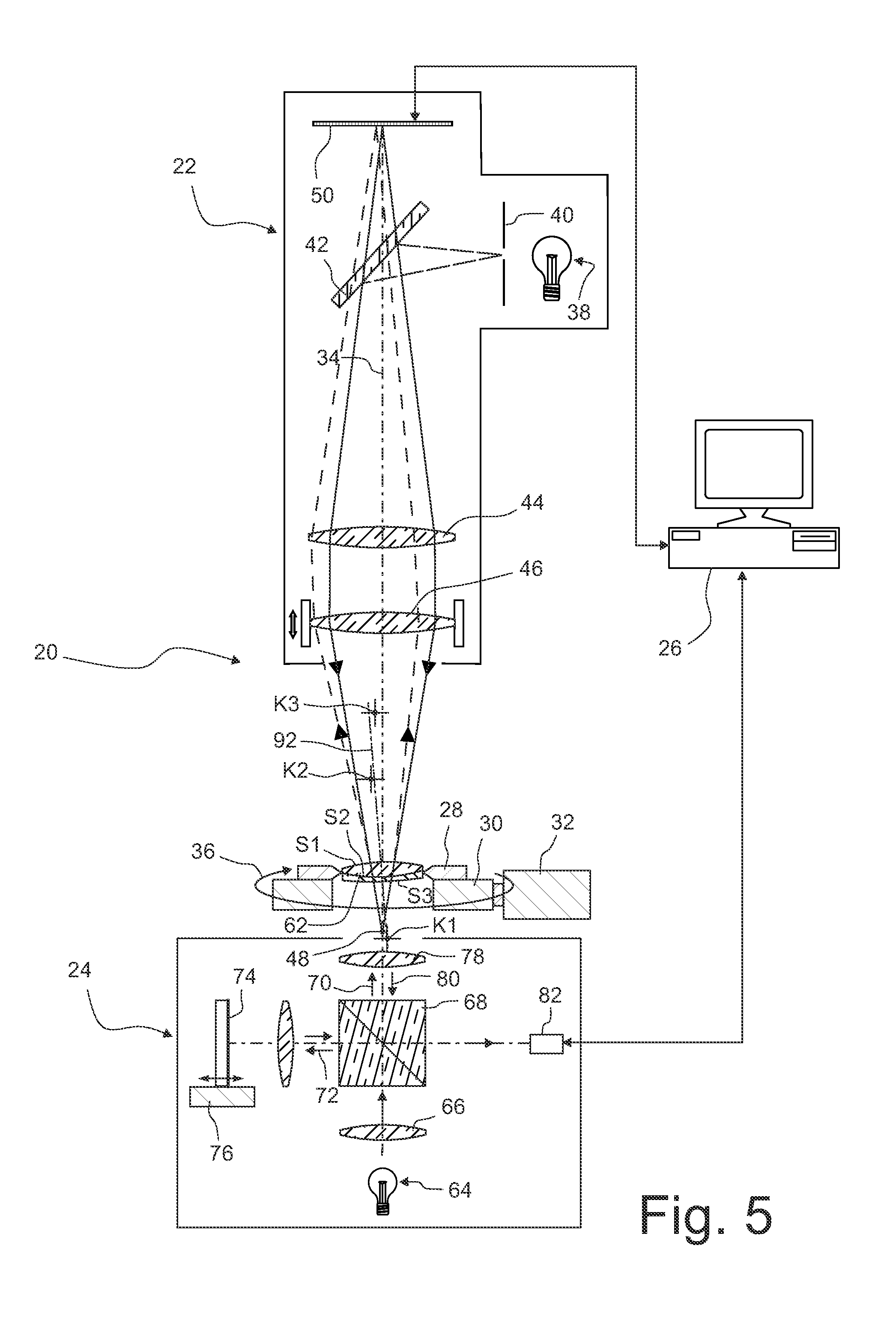

Eccentricity adjusting and assembling method, and eccentricity adjusting and assembling device of optical element

The invention provides an eccentric adjusting and assembling method and adjusting and assembling device of optical element. The method includes: only mounting a first lens located most against the incident side of the measuring light S1; secondly, measuring the eccentric amount of the first lens S2, and calculating the position adjusting amount of the first lens based on the measured value S3; subsequently adjusting the eccentric amount of the first lens to make the eccentric amount close to 0 S5, measuring the eccentric amount of the first lens again S5, to judge whether it is below the critical value S6; returning to step 3 if it is larger than the critical value, adhering the first lens to the inside of the lens barrel 61 if it is below the critical value S7; and then judging whether a next lens needed to mount exists S8, if so, repeating the steps 1 to 7 to the lens. Therefore, when the optical element group to be detected is a coaxial group configured with a plurality of optical elements, as an integral system, the eccentric adjusting and assembling method and adjusting and assembling device of optical element can be effectively performed at high accuracy.

Owner:FUJIFILM CORP

Method and measuring device for contactless measurement of angles or angle changes on objects

The invention relates to a method for the contactless measurement of angles or angle modifications, distances or lateral displacements in objects. According to said method, an aperture is transilluminated by means of a ray bundle and after being reflected by a distant reflective element, which generates or is subjected to the angles, angle modifications or lateral displacements that are to be measured, is projected onto a detector surface by an optical system. The image of the aperture on the detector surface is captured, the position of the aperture image is determined in relation to a reference point on the detector surface and the measured value of the angle modification or lateral displacement is calculated using the distance of the centre of the image from the reference point. The invention also relates to an angle or height measuring device.

Owner:HOFBAUER ENGELBERT

Lens shift measuring apparatus, lens shift measuring method, and optical module manufacturing method

Owner:RENESAS ELECTRONICS CORP

Eccentricity measuring method

In an eccentricity measuring method according to the present invention, a first position of a light source image formed by reflection at one optical surface is measured (S2), a predetermined second position related to another optical surface is measured (S3), and a relative eccentricity between both optical surfaces is calculated based on the first and second positions (S5). Therefore, the eccentricity measuring method enables measurement of eccentricity by a same measurement optical system regardless of a radius of curvature of an optical surface of an optical element.

Owner:KONICA MINOLTA INC

System and method for detecting eccentricity of glasses lens

InactiveCN101373167ANo tiltThe test result is accurateOptical axis determinationLens position determinationEngineeringLens plate

An eyeglass eccentricity detecting system is used for conducting eccentricity detection on an eyeglass to be detected. The eyeglass comprises a main body and a peripheral part surrounding the main body; the peripheral part of the eyeglass is provided with an inner side wall. The eccentricity detecting system comprises a detecting device, a load bearing device and an eyeglass support bearing device, wherein the detecting device is used for conducting eccentricity detection on a rotating eyeglass to be detected; the load bearing device is used for bearing the eyeglass; the eyeglass support bearing device is positioned in the load bearing device, and comprises at least three spheres and an elastic element, wherein the three spheres are propped against the inner side wall of the peripheral part of the eyeglass; the eyeglass is propped by the spheres of the eyeglass support bearing device to prevent inclination during the rotation of the eyeglass; and the eyeglass support bearing device drives the eyeglass to rotate around the central axis of the main body.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Method of measuring decentering of lens

Disclosed is a measuring method which can measure the decentering of an axis by the measurement of a two-dimensional curved surface profile. This method has a first step of measuring a profile of a examined surface by a probe from a first reference position which is a position separate by a predetermined amount from a predetermined position on the examined surface of a subject lens, a second step of measuring the profile of the examined surface by scanning the examined surface by the probe from the second reference position which is a position separate by a predetermined amount from said predetermined position in a route opposite to the scanning direction of said first step after a rotation of the subject lens; and the step of obtaining the decentering amount of the examined surface by the use of the measurement results obtained at the first and second steps.

Owner:CANON KK

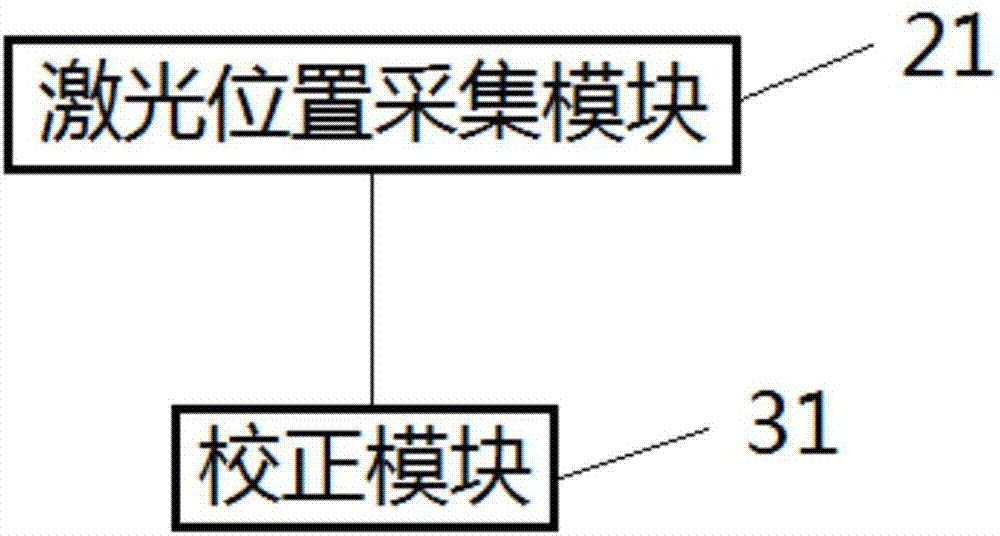

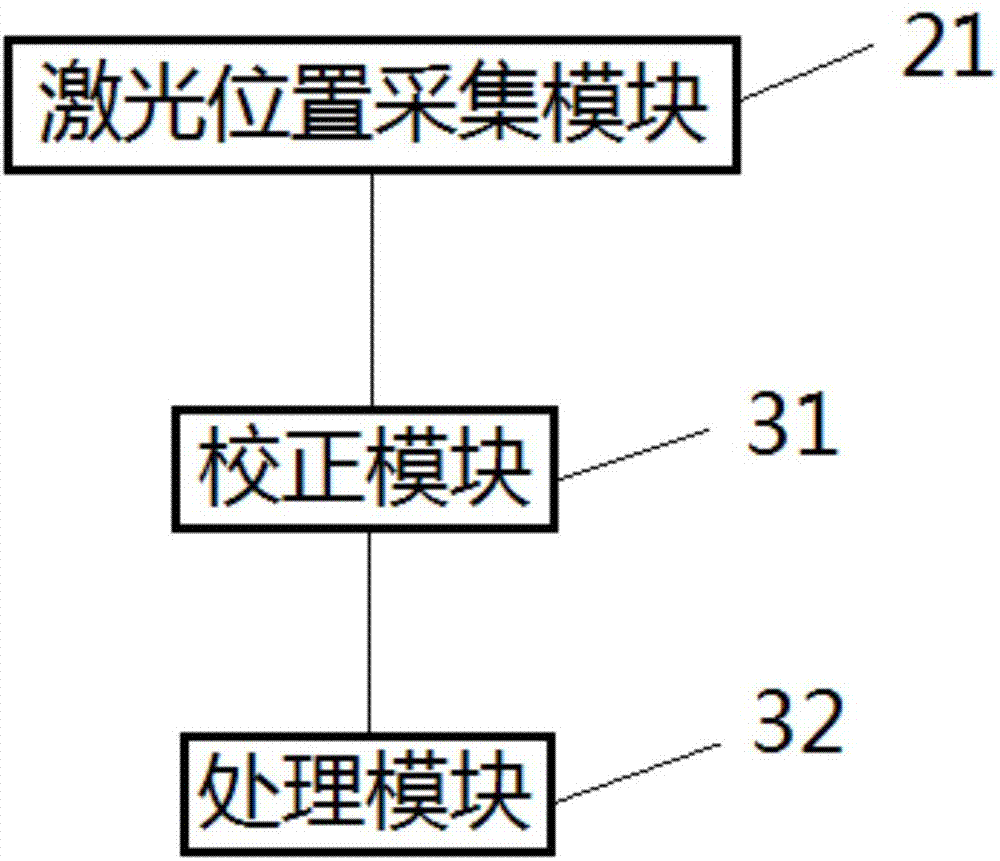

Laser mirror calibration system and laser mirror calibration method

InactiveCN107367376AHigh precisionImprove detection accuracyOptical axis determinationLens position determinationElectricityOptoelectronics

The invention provides a laser mirror calibration system and a laser mirror calibration method and relates to the technical field of laser mirrors. The laser mirror calibration system comprises a laser detection unit and a calibration unit which are electrically connected; the laser detection unit comprises a mirror control mechanism and a laser collecting mechanism; the mirror control mechanism comprises a laser support used for fixing the mirrors and lasers; the laser collecting mechanism comprises a displacement assembly and a laser location collecting module which are connected; the calibration unit comprises a calibration module which is electrically connected with the laser location collecting module and used for generating calibrated-location information according to the laser location information collected through the laser location collecting module. By the arrangement, the laser location collecting module can automatically sense laser optical pathment emitted by the lasers, location information of laser spots can be automatically detected, and location calibration can be automatically performed according to detection results.

Owner:ZHENJIANG JINHAICHUANG TECH

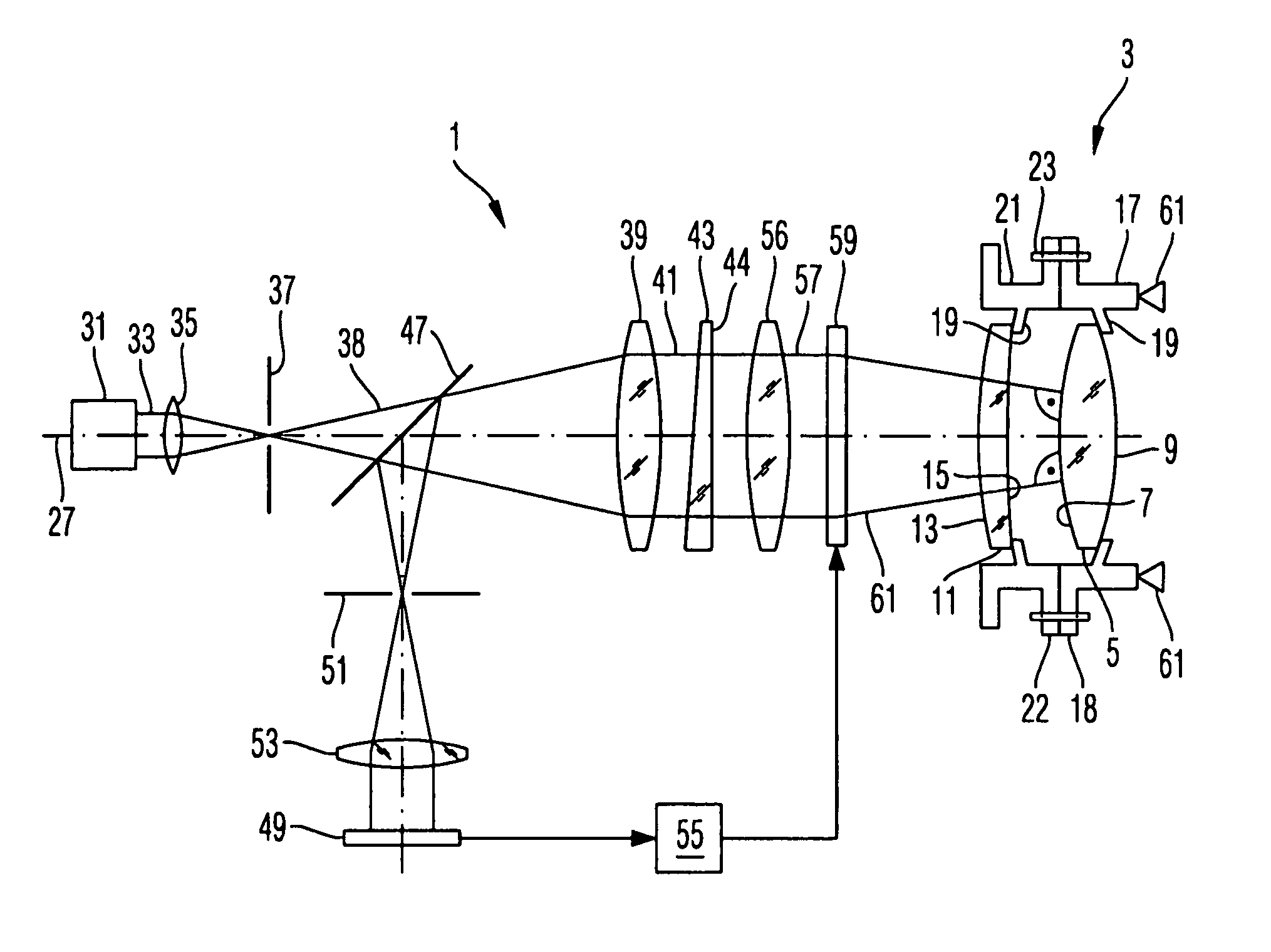

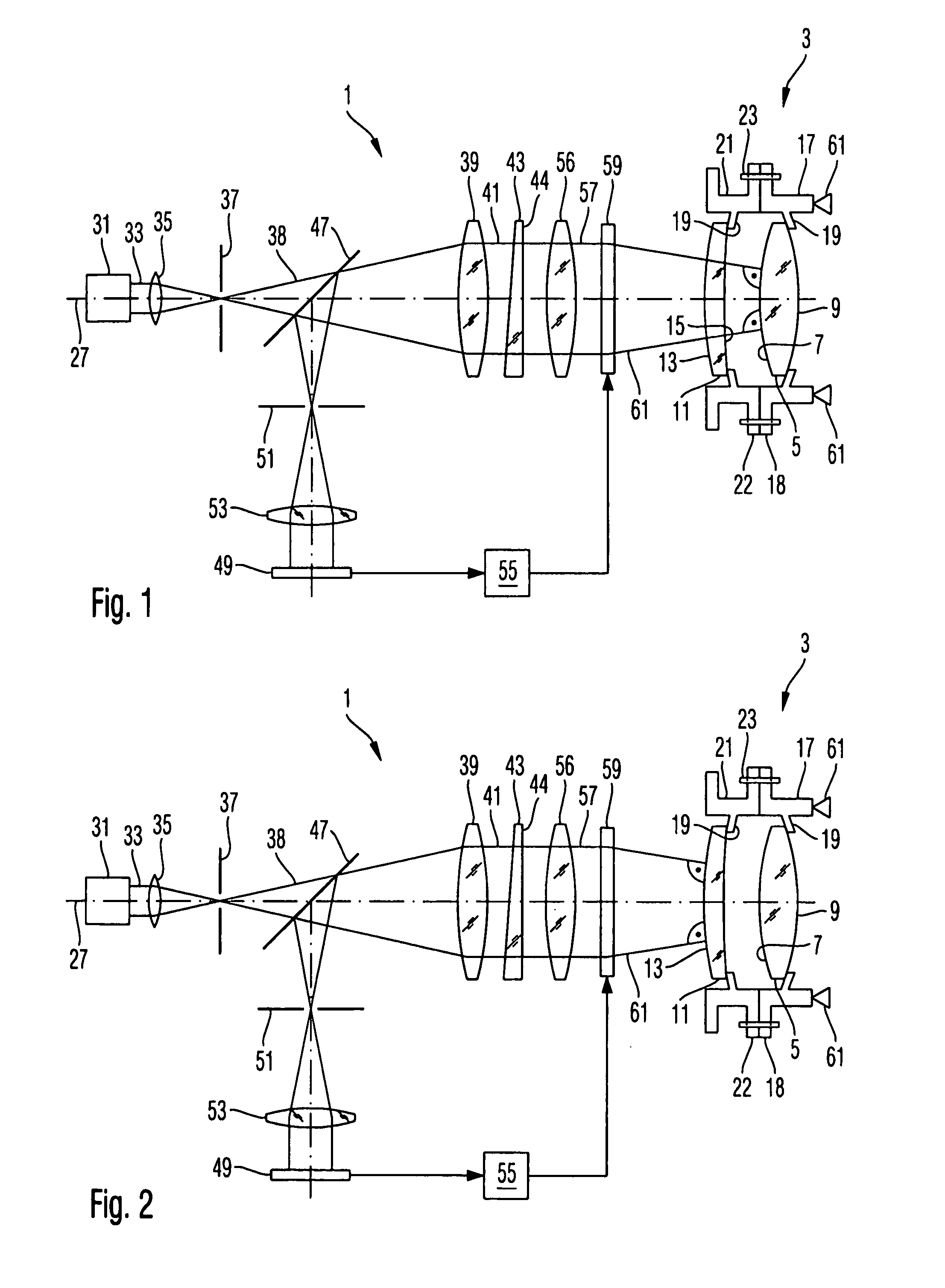

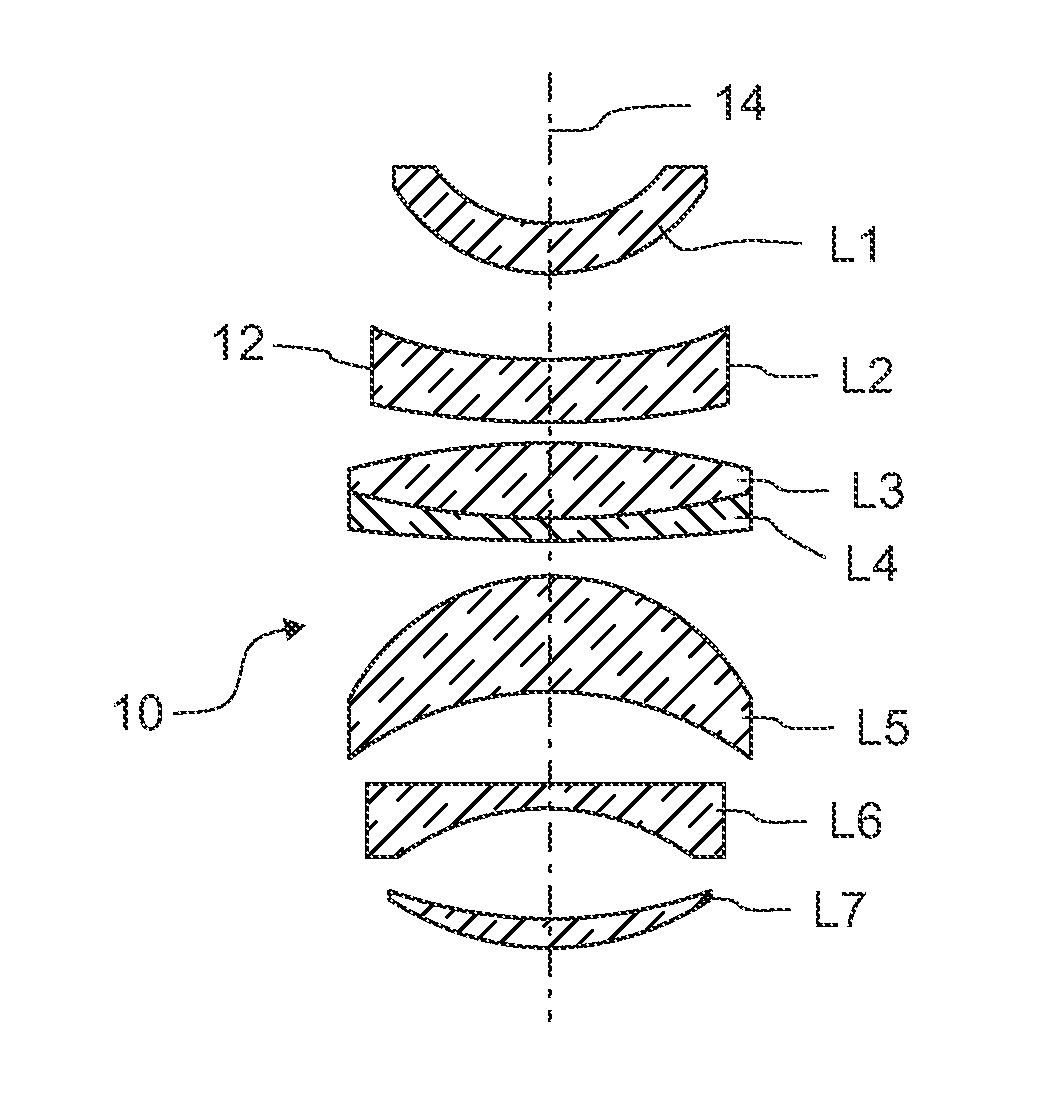

Method of aligning an optical system

ActiveUS20090231593A1Easy alignmentPhotomechanical apparatusUsing optical meansLight beamStructure based

A method of manufacturing an optical system having plural optical elements mounted relative to each other on a mounting structure of the optical system comprises disposing the optical system in a beam path of an interferometer apparatus having an interferometer optics and a selectable hologram for shaping a beam of measuring light to be incident on surfaces of the optical elements of the optical system; selecting a first hologram of the interferometer apparatus and recording at least one first interference pattern generated by measuring light reflected from a surface of a first optical element; selecting a second hologram of the interferometer apparatus, wherein the second hologram is different from the first hologram, and recording at least one second interference pattern generated by measuring light reflected from a surface of a second optical element, which is different from the first optical element; and adjusting a position of the first optical element relative to the second optical element on the mounting structure based upon the first interference pattern and the second interference pattern.

Owner:CARL ZEISS SMT GMBH

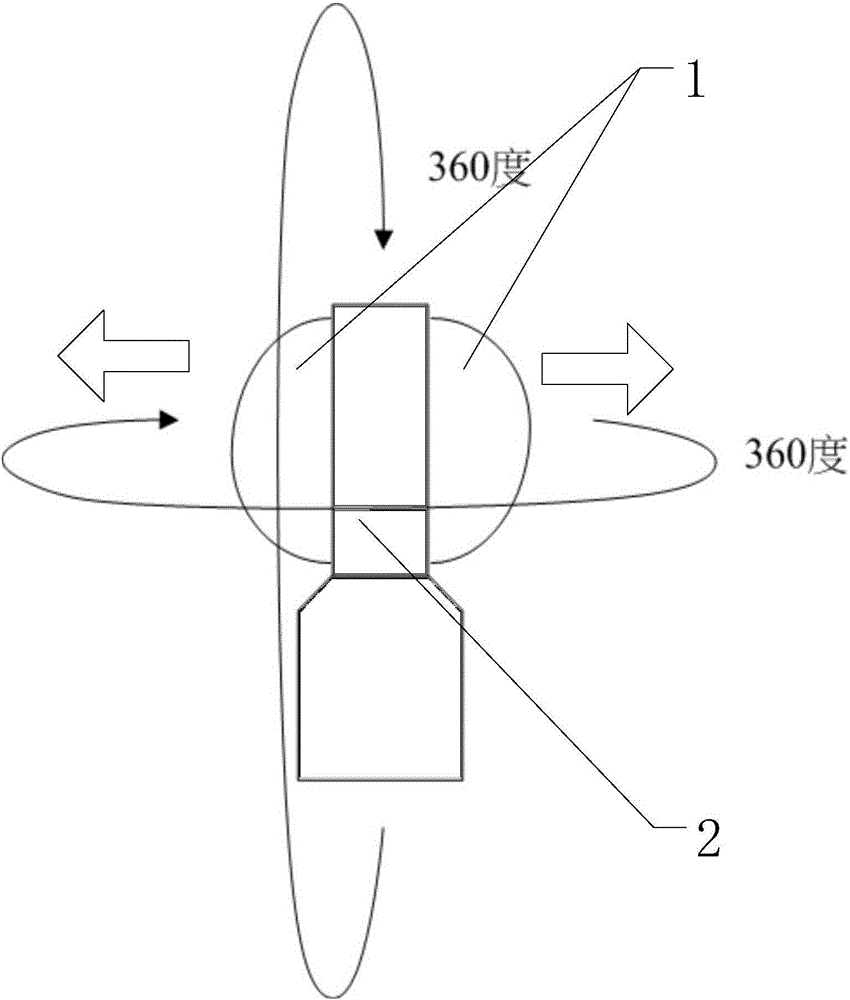

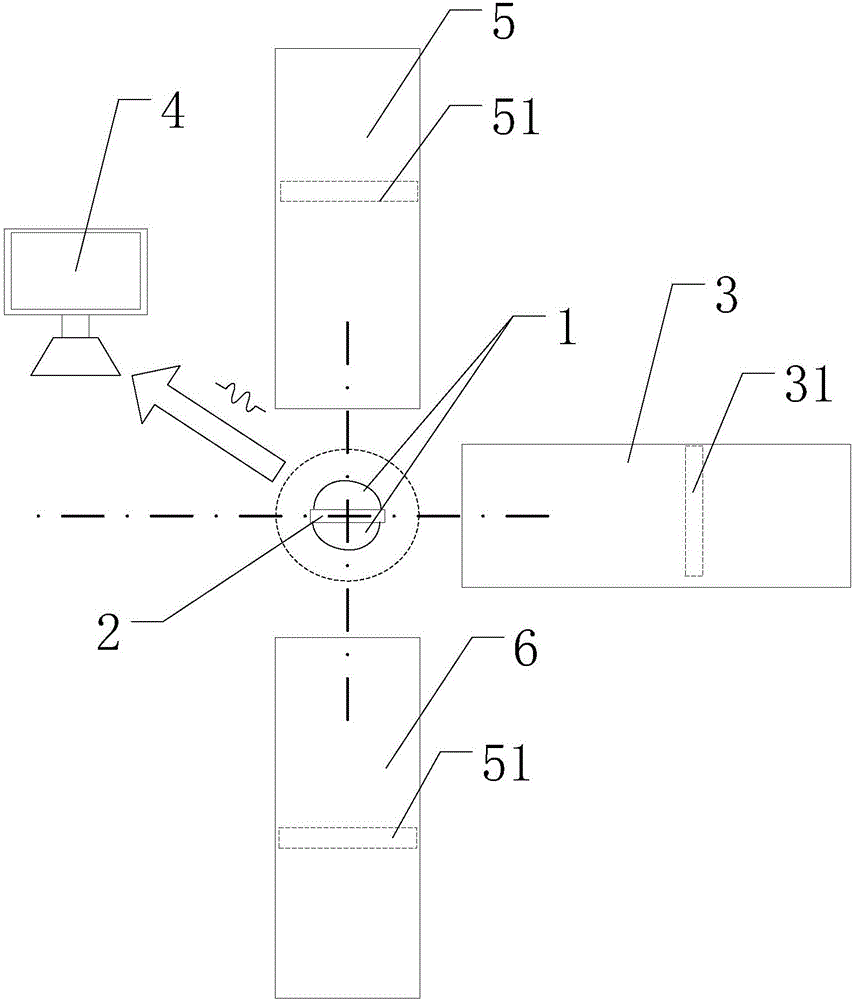

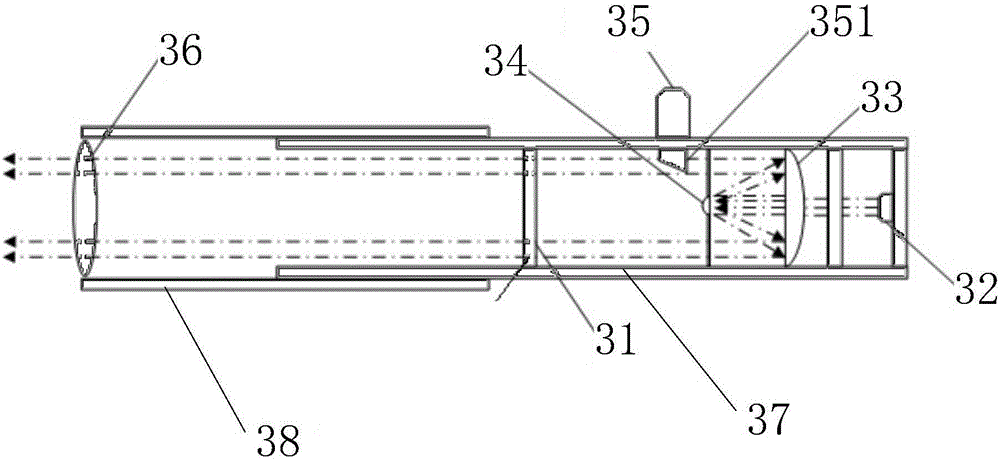

Dual-lens positioning detection system and dual-lens positioning detection method

PendingCN106596077ARealize detectionOptical axis determinationLens position determinationCamera lensOptical axis

The invention discloses a dual-lens positioning detection system and a double-lens positioning detection method. The detection system comprises a first collimator and a display device. The first collimator is internally provided with a first transmission test target. The first collimator is perpendicular to the optical axis of a dual-lens and is aligned at the middle position of two lenses of the dual-lens. In detection, the two lenses collect first transmission test target images in the first collimator and send the images to the display device. The display device receives the images from the two lenses and carries out parallel displaying of the images from the two lenses at the same time. The first collimator is arranged to be aligned at the middle position of the two lenses of the dual-lens and perpendicular to the optical axis of the dual-lens, the two lenses are used to collect the first transmission test target images in the first collimator and send the images to the display device for parallel displaying, through observing whether the two images are aligned to each other, whether the two lenses are in a same horizontal position is judged, and the detection of the optical axis dislocation of the dual-lens is realized.

Owner:GOERTEK OPTICAL TECH CO LTD

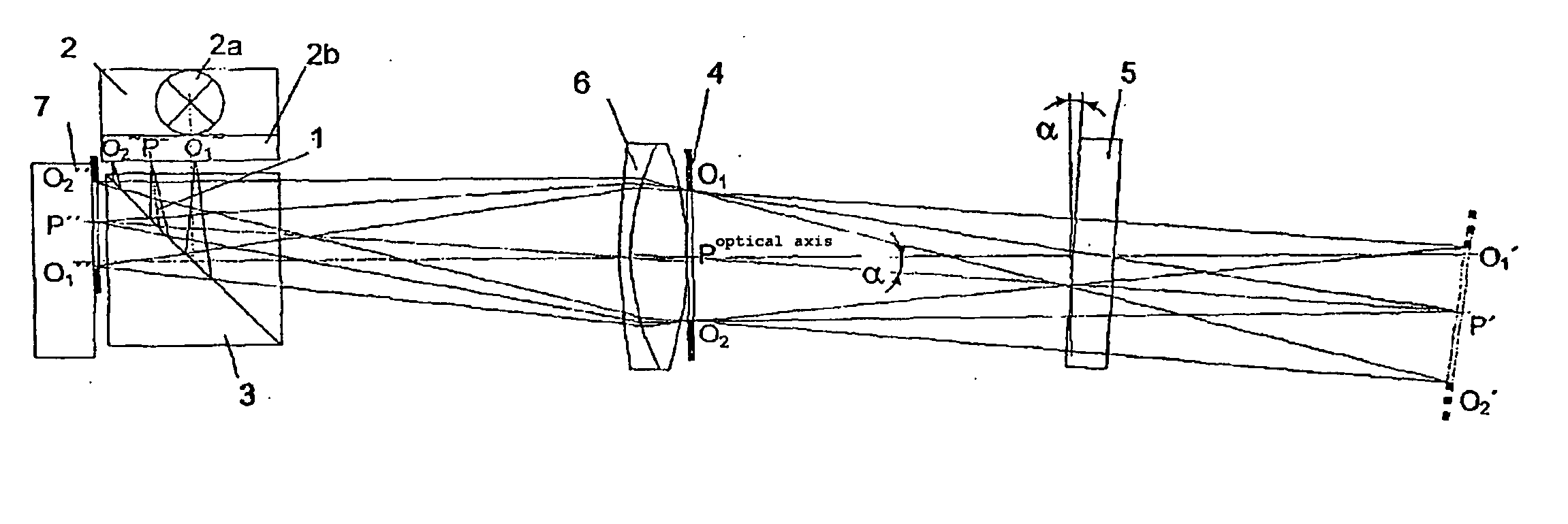

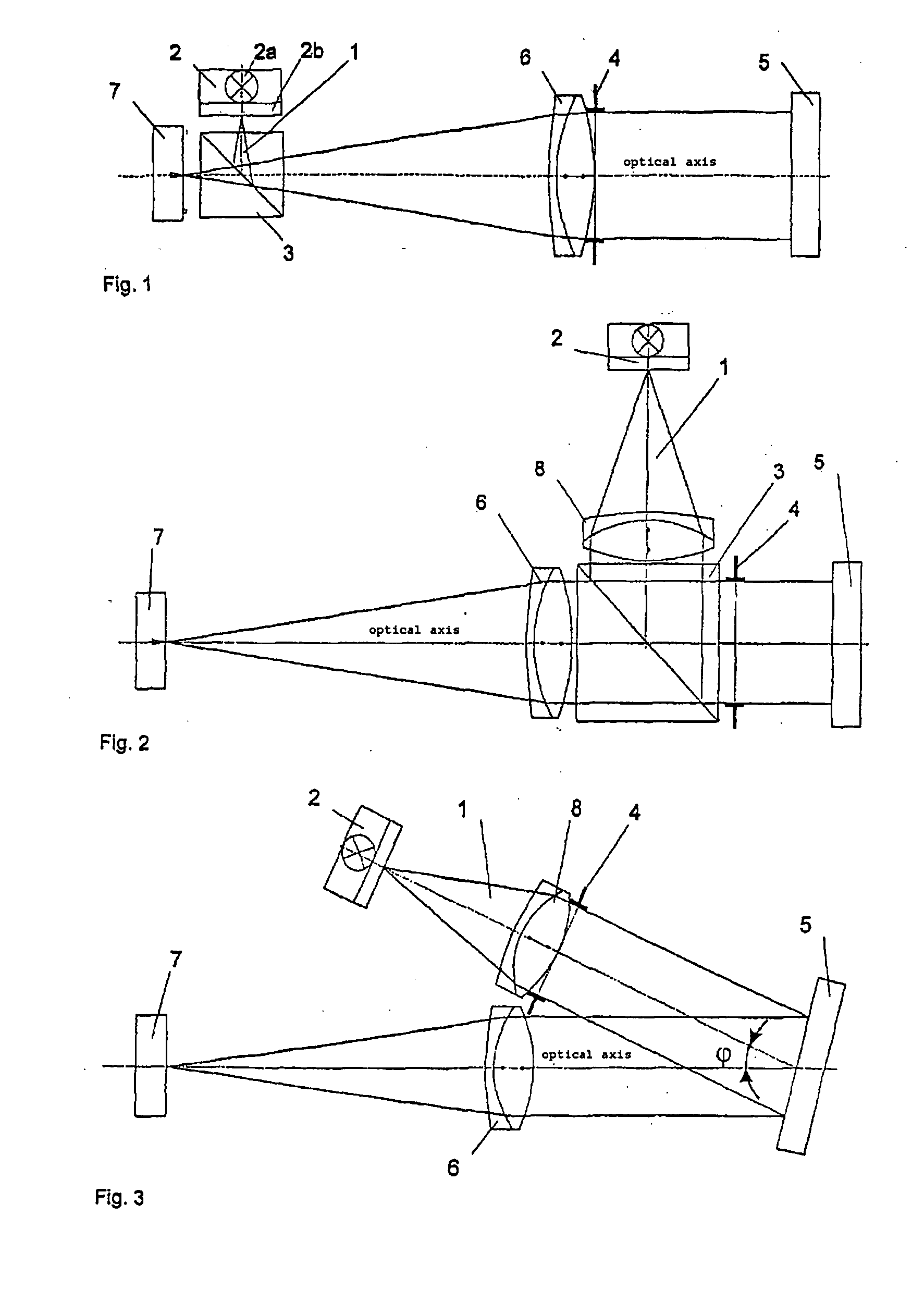

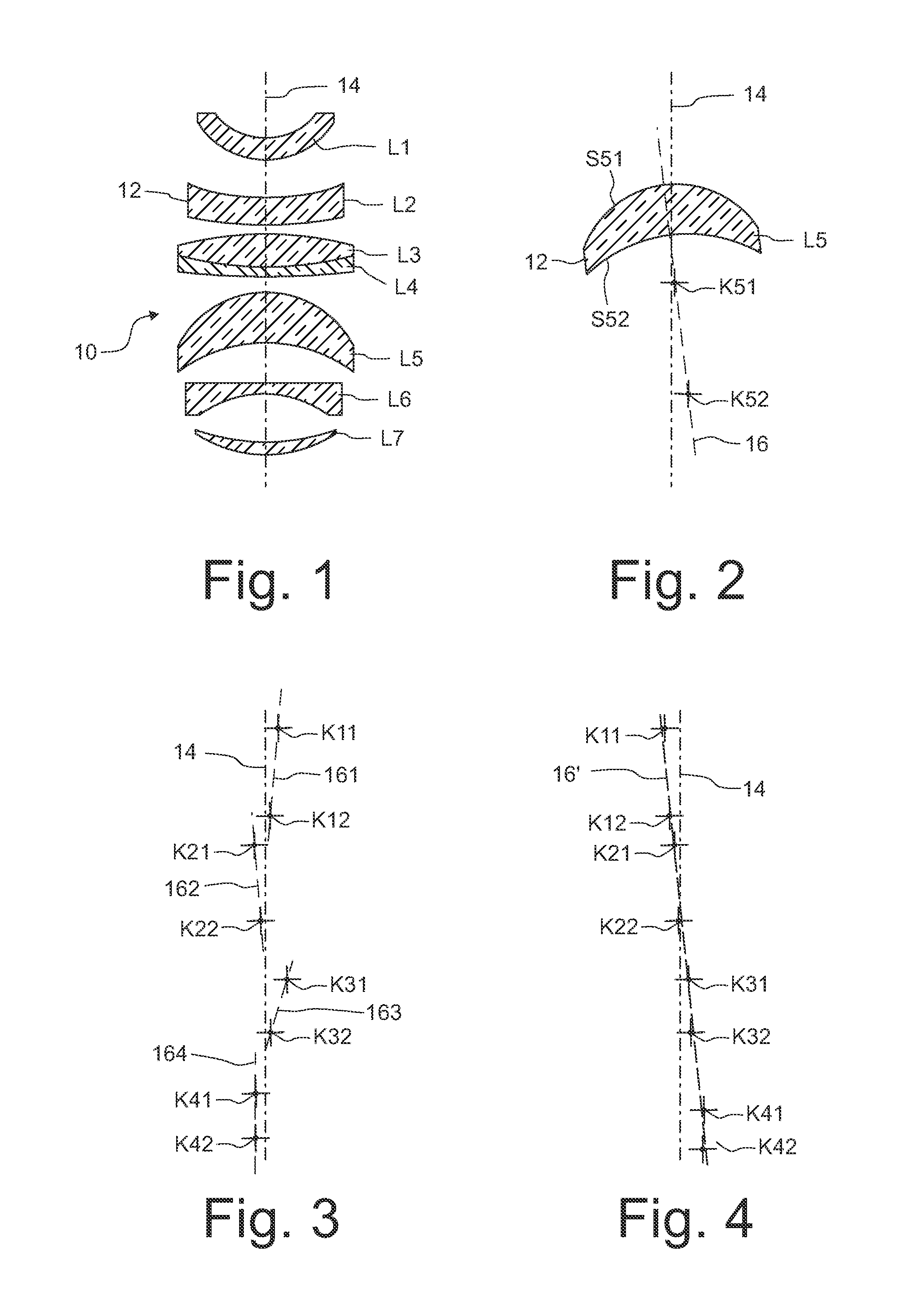

Measurement of the Positions of Centres of Curvature of Optical Surfaces of a Multi-Lens Optical System

ActiveUS20120133924A1Compact structureHigh measurement accuracyMaterial analysis by optical meansUsing optical meansOptical surfaceAccuracy and precision

A method measures the positions of centres of curvature of optical surfaces of a multi-lens optical system. The spacings between the surfaces are measured along a reference axis using an interferometer. Subsequently the centres of curvature of the surfaces are measured using an optical angle-measuring device. In the course of the measurement of the position of the centre of curvature of a surface situated within the optical system, the measured positions of the centres of curvature of the surfaces situated between this surface and the angle-measuring device and the previously measured spacings between the surfaces are taken into consideration computationally. In this way, a particularly high accuracy of measurement is achieved, because desired spacings do not have to be fallen back upon.

Owner:TRIOPTICS GMBH

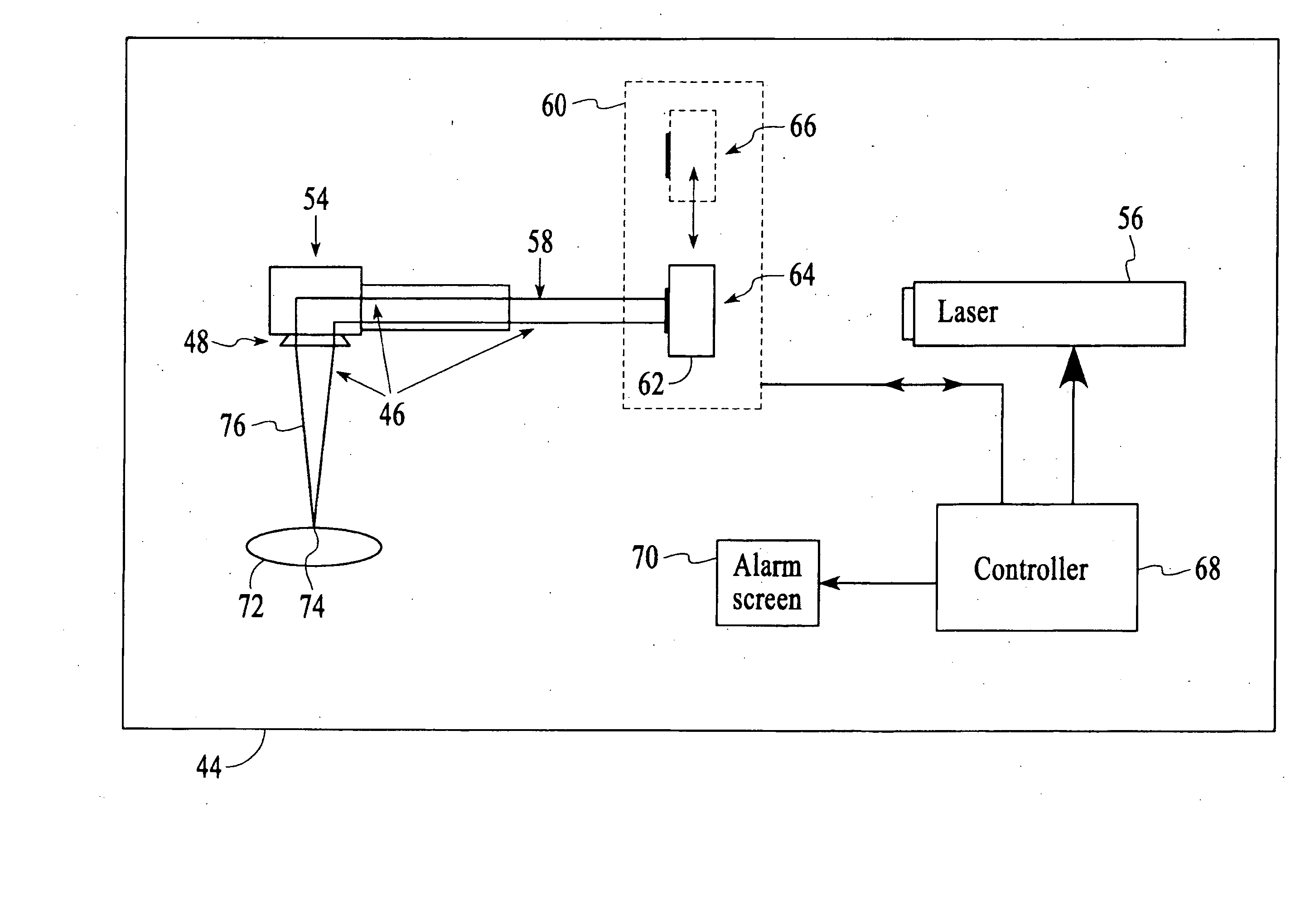

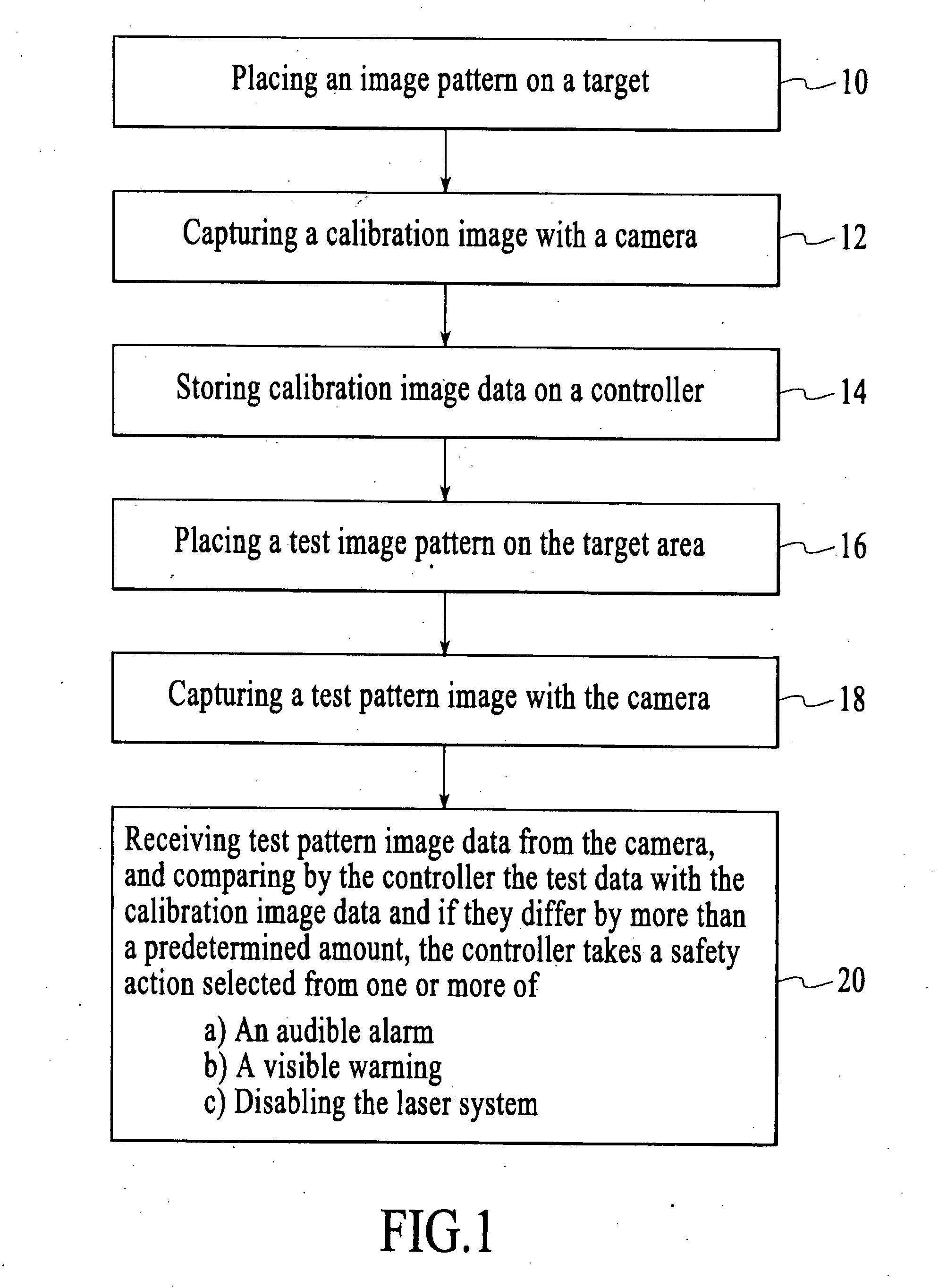

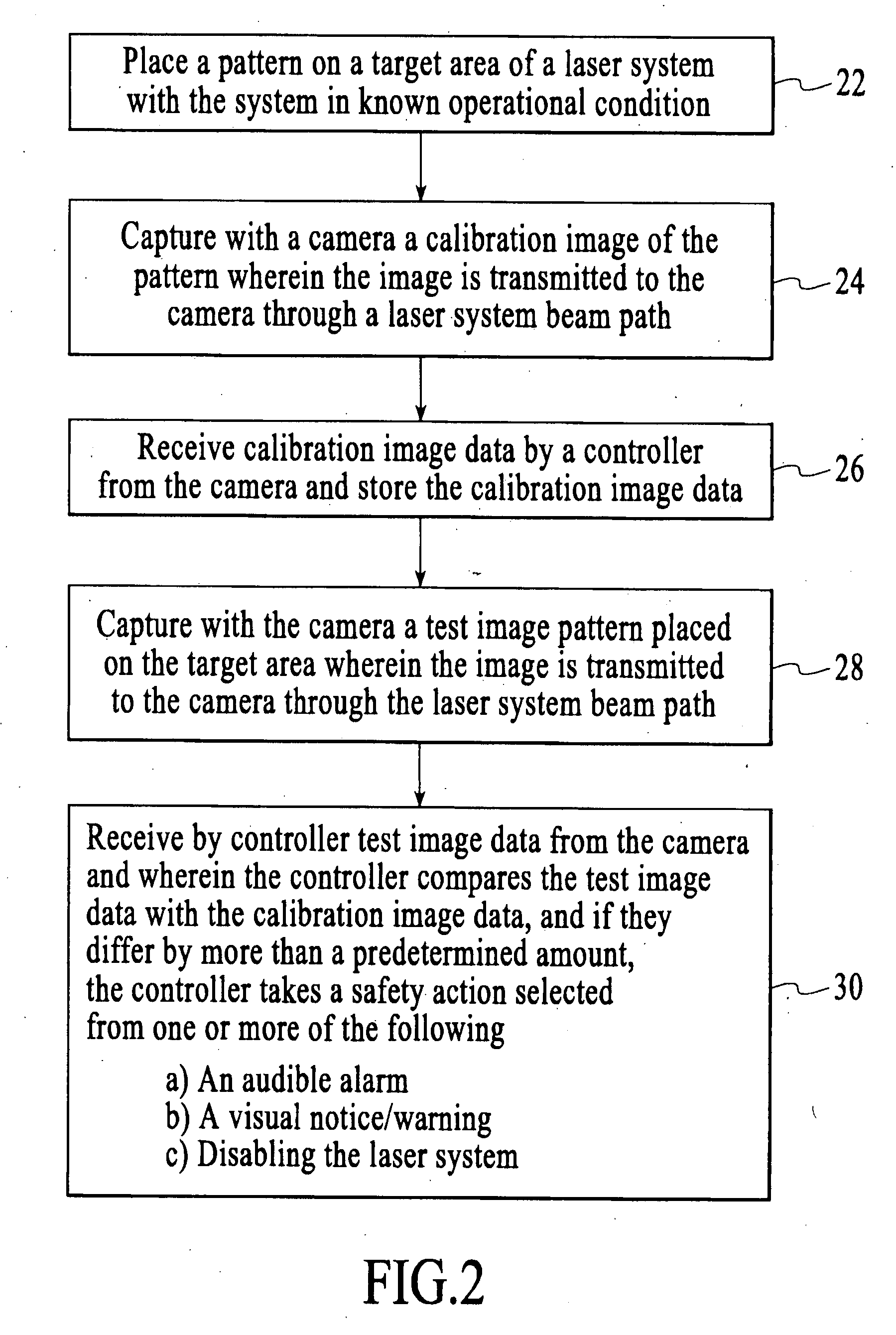

Laser safety system

ActiveUS20080044178A1Improve securityReduce riskCharacter and pattern recognitionSurgical instrument detailsLaser beamsImage capture

A laser safety system providing a system for checking the presence, focus and integrity of a laser beam focusing lens is disclosed. The laser safety system checks the focusing lens properties by capturing an image of a target by viewing the target through the focusing lens from along the laser beam path. An initial, known good, image is compared to an image captured immediately before enablement of the laser beam source to determine if the focusing lens is present, focused and is not damaged. The system may also utilize a mask projected onto the target as well as a low-power visible light laser directed along the path of the processing laser to determine the focusing lens properties. The system can also provide target recognition.

Owner:TELESIS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com