Method for measuring eccentricity quantity

A measurement method and technology of eccentricity, applied in the direction of measuring devices, optical axis determination, optical instrument testing, etc., can solve problems such as difficult circle radius and difficult pinhole image, and achieve high-precision eccentricity measurement and simple eccentricity Measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

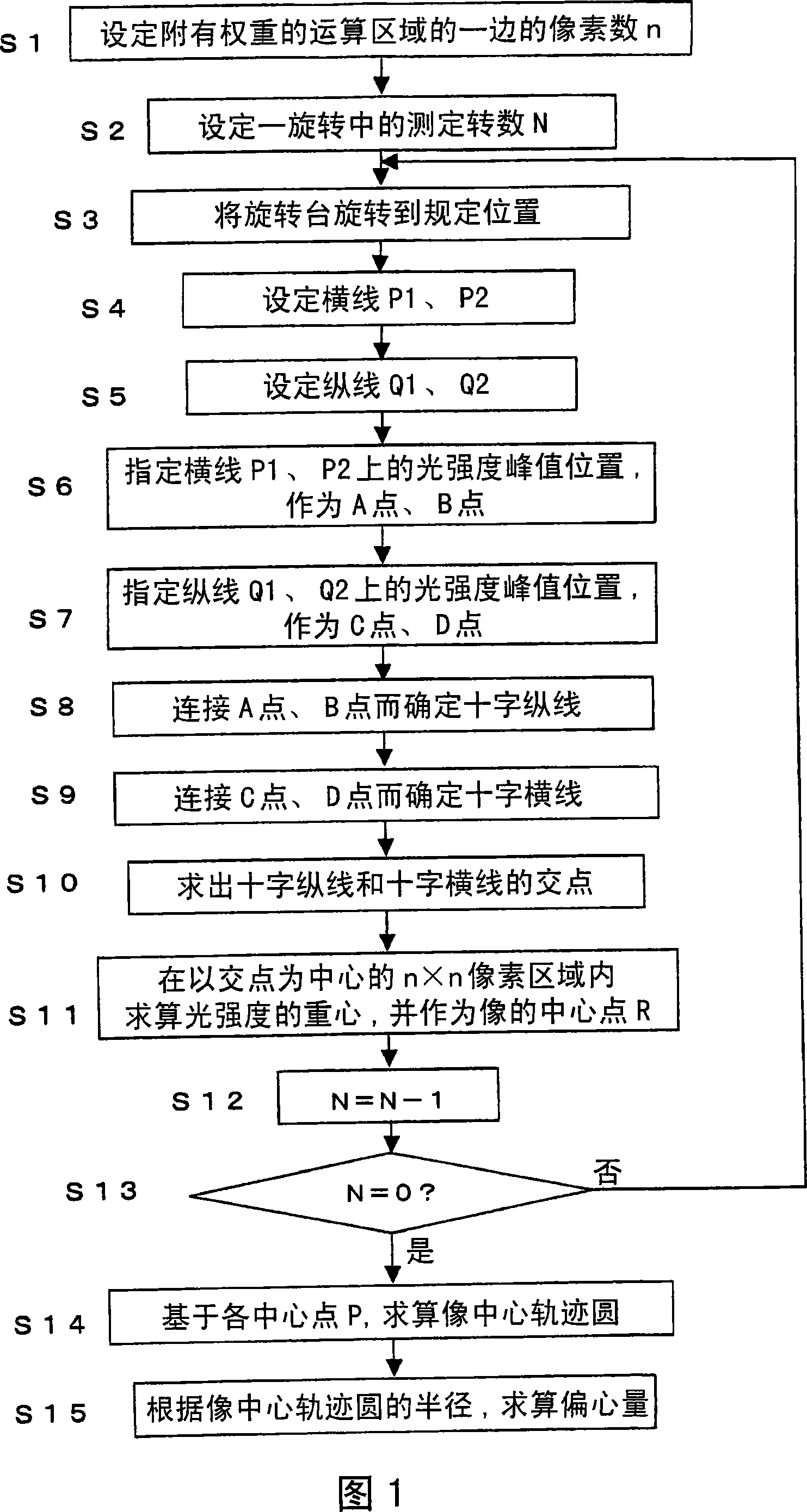

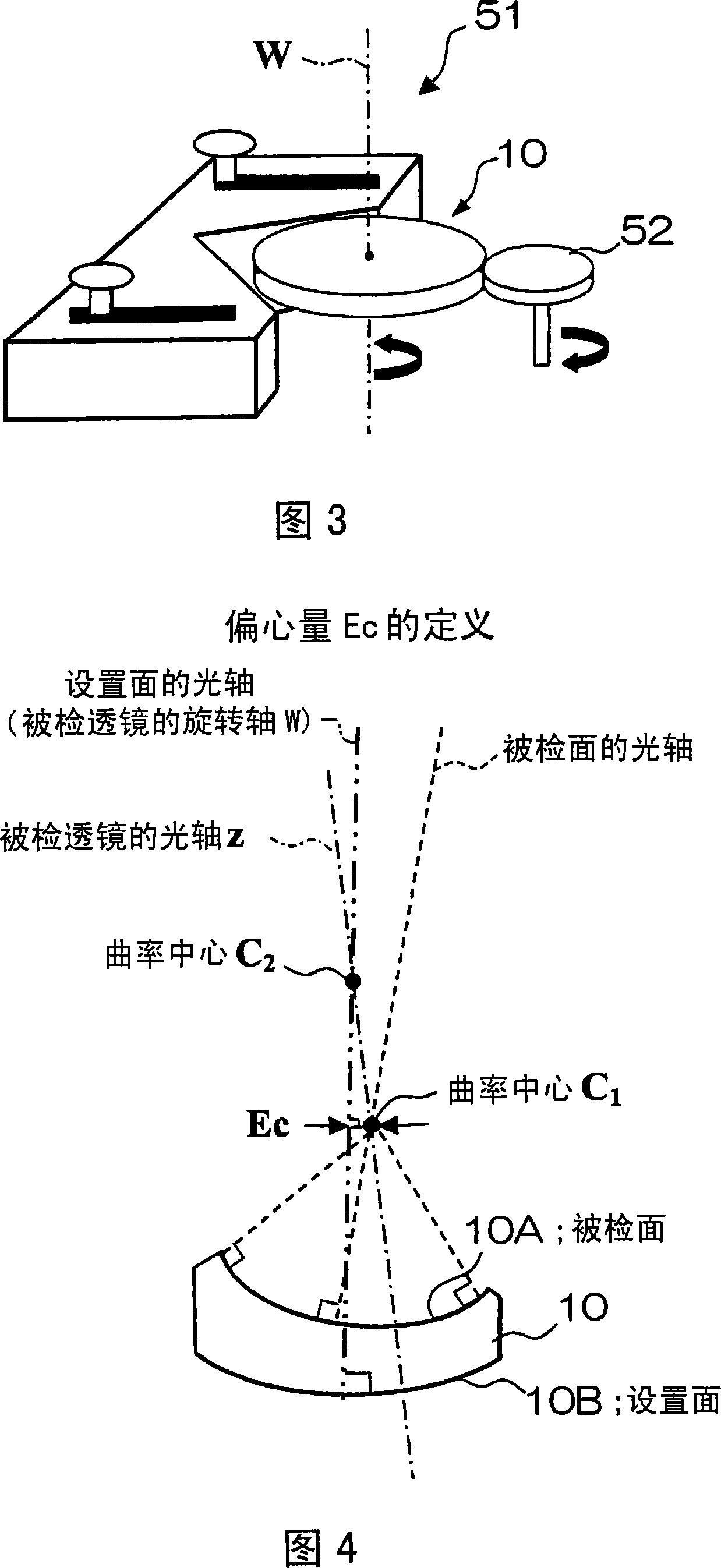

[0039] Hereinafter, embodiments according to the present invention will be described in detail with reference to the drawings.

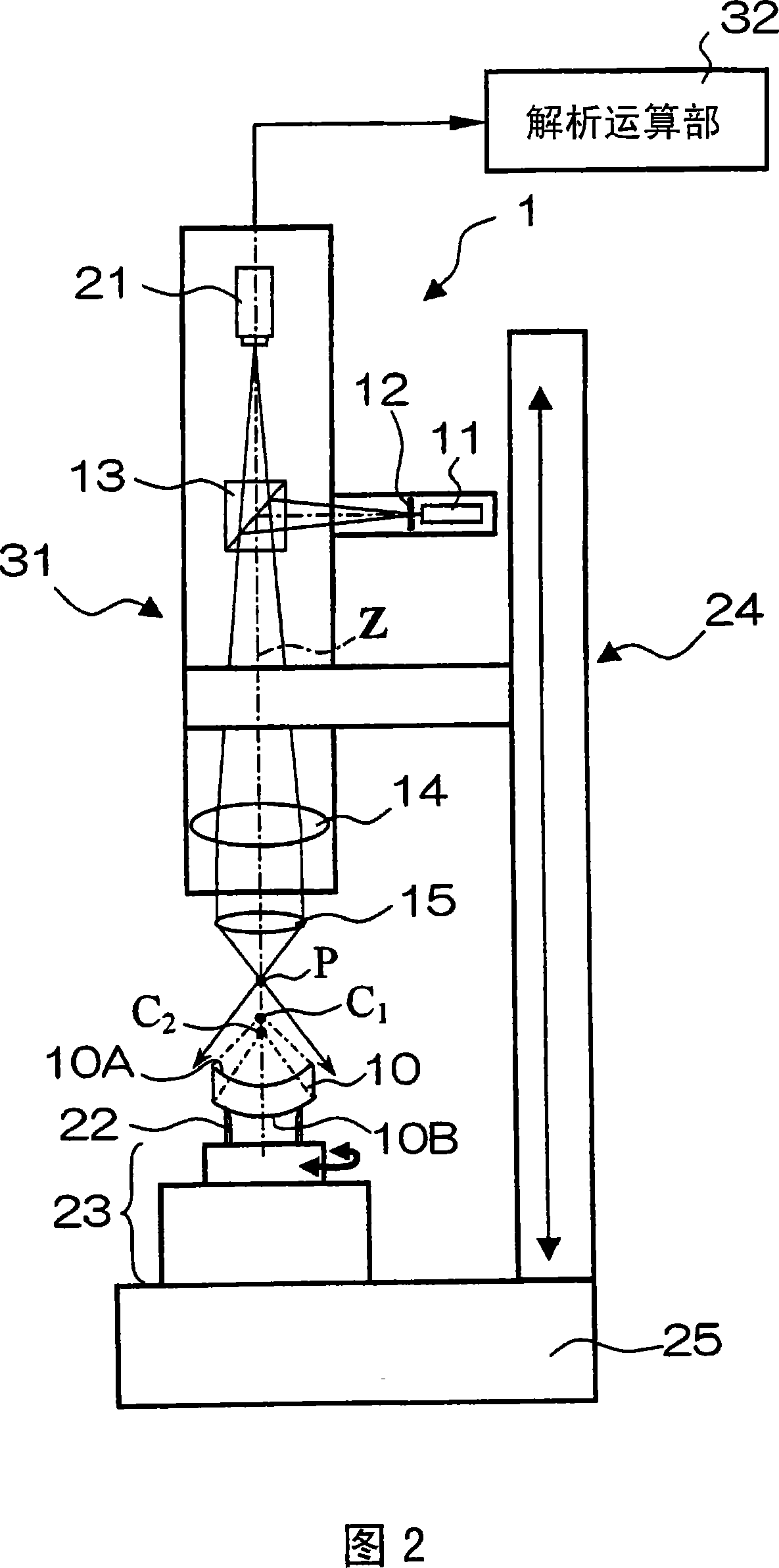

[0040] First, based on FIG. 2 , a schematic configuration of a reflection-type eccentricity measurement device for implementing the eccentricity measurement method according to an embodiment of the present invention will be described.

[0041] This eccentricity measurement device 1 is a device for measuring the eccentricity of the lens 10 to be inspected, and has: a light source 11 that irradiates light to an upper surface 10A and a lower surface 10B that become the inspection surface; a reticule plate 12, It transmits the light beam from the light source 11 and has a cross-shaped slit; and an optical system 31 for measurement. The measuring optical system 31 is provided with: a beam splitter 13 for reflecting the light from the index plate 12 approximately at a right angle; a collimator lens 14 for making the incident light beam into a parallel beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com