Infrared-visible light dual-band photoelectric detection system and axis angle error measuring method

A photoelectric detection and dual-band technology, applied in the optical field, can solve problems such as unusable, susceptible to environmental interference, performance discount, etc., and achieve the effect of reducing mass and volume, high-resolution imaging, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

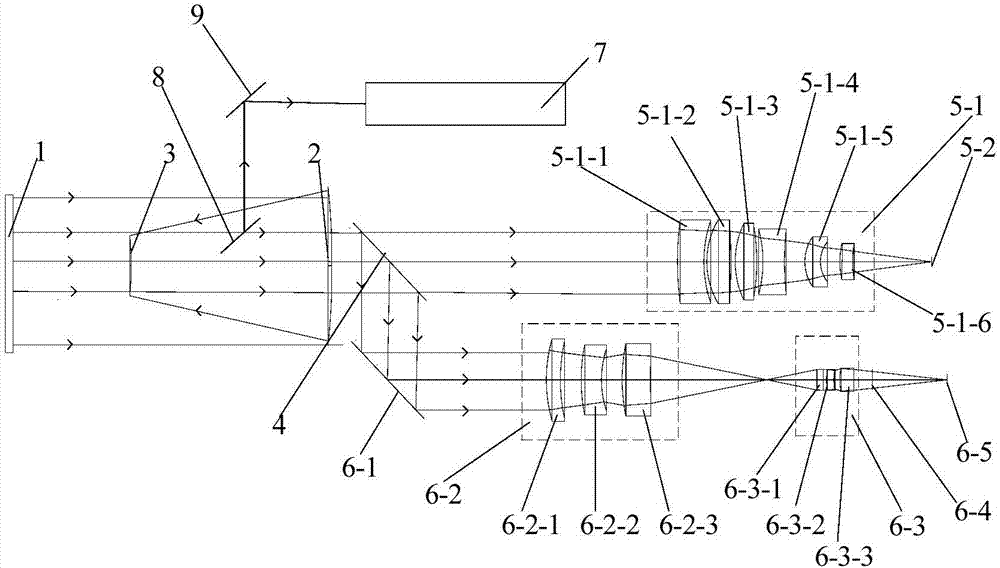

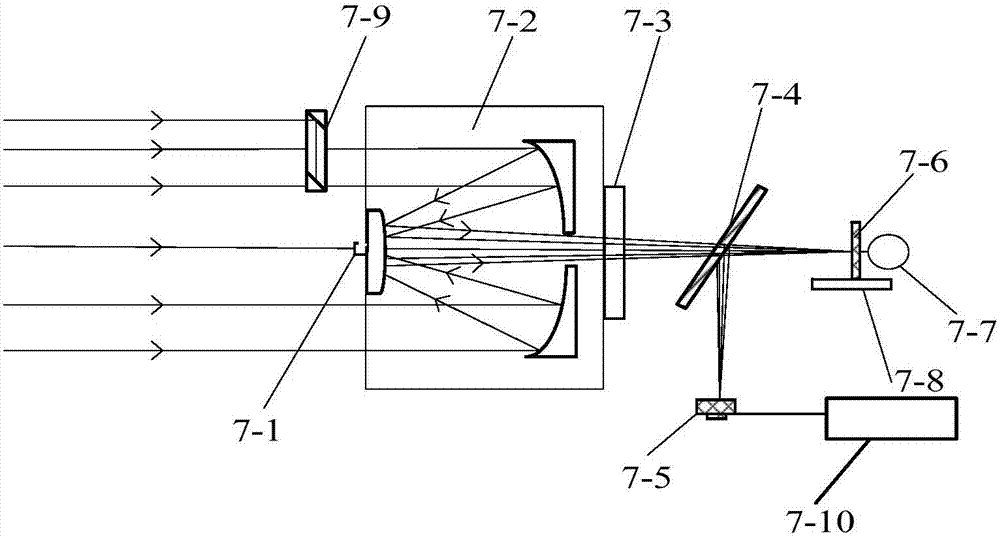

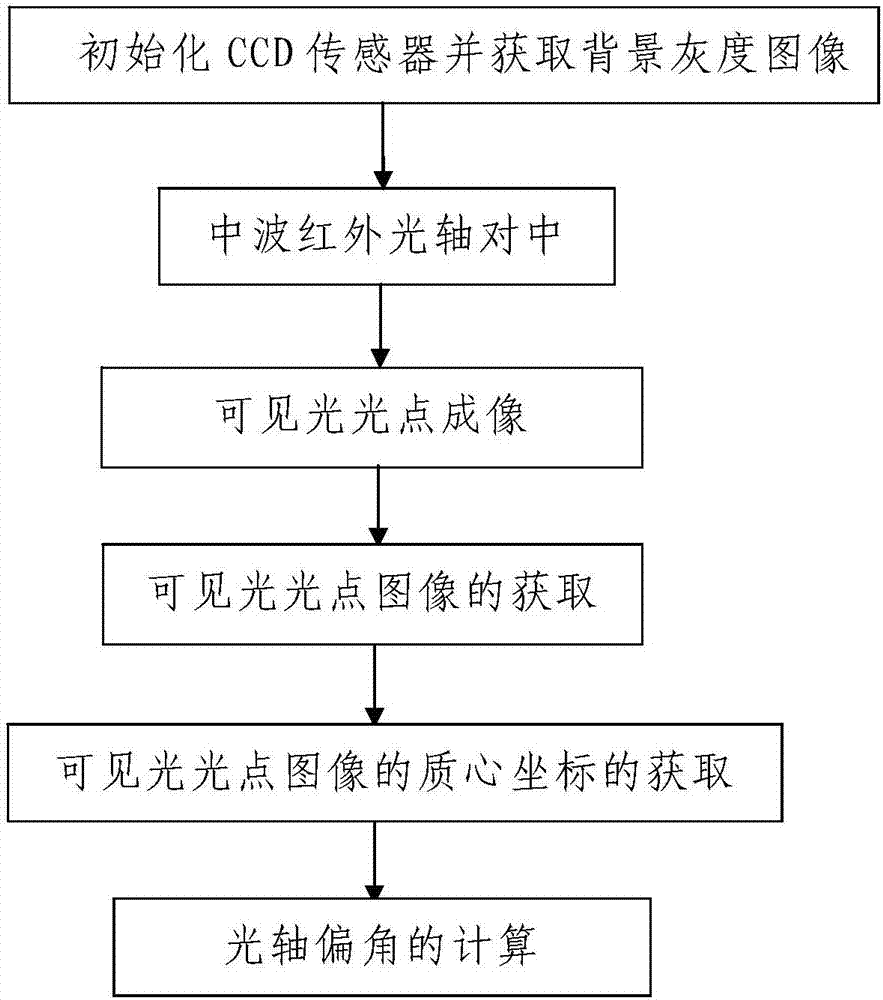

[0050] Such as figure 1 with figure 2 An infrared-visible dual-band photoelectric detection system is shown, including a reflection system arranged on the reflected light path of the measured object 1, a beam splitter 4 for splitting mid-wave infrared waves and visible light waves, and a beam splitter 4 for transmission The visible light imaging unit on the optical path, the mid-wave infrared light imaging unit on the reflection light path of the beam splitter 4, and the optical axis deflection angle measurement unit on the reflection light path of the reflection system, the object 1 can be reflected at the same time Wave infrared light and visible light.

[0051] In specific implementation, the reflection system reflects the visible light and mid-wave infrared light reflected by the test object 1 in parallel beams to the beam splitter 4, and the beam splitter 4 transmits the visible light to the visible light imaging unit and reflects the mid-wave infrared light to the middle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com