Patents

Literature

122results about How to "Has not changed much" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

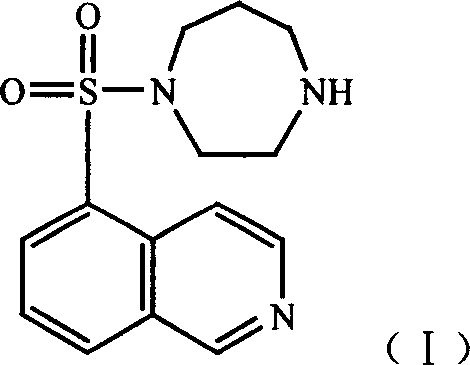

H.264/AVC frame inner prediction method based on edge characteristics

InactiveCN101494792AReduce complexityReduce the number of mode choicesTelevision systemsDigital video signal modificationPeak valueSignal-to-quantization-noise ratio

The invention discloses an H.264 / AVC intra-prediction method based on edge characteristics, which includes: performing data block prejudging before intra-prediction based on principal edge intensity (DES) and the like edge direction characteristics calculated by the edge histogram description describing the image marginal distribution, selecting the mode subclass corresponding to the characteristics to perform RDO calculation, thereby reducing the mode selection number of the intra-prediction; at the same time directly determining the Intra_8*8 chrominance prediction mode from the Intra_16*16 brightness prediction mode according to the correlativity of the chrominance prediction mode and the brightness prediction mode, to further reduce the complexity of the algorithm. The method has six steps, and is convenient and facilitating. Practice shows that the method can obviously improve the encoding speed, and can ensure that the bit-rate encoding (an increase of 3%) and peak signal-noise ratio (reduced about 0.02dB) have little change compared with the full search method. The method has very good practical value and application prospects.

Owner:BEIHANG UNIV

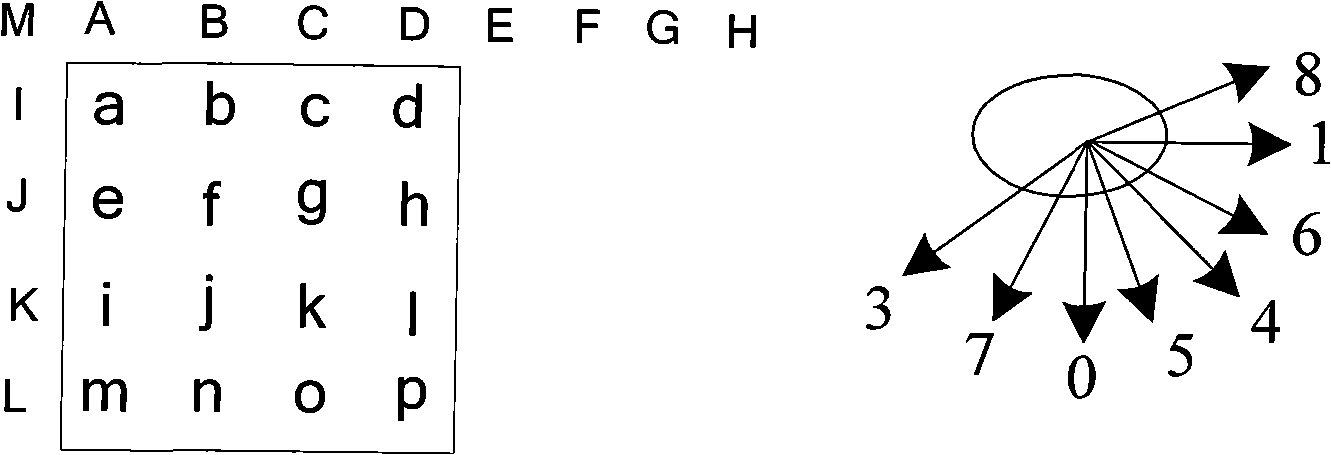

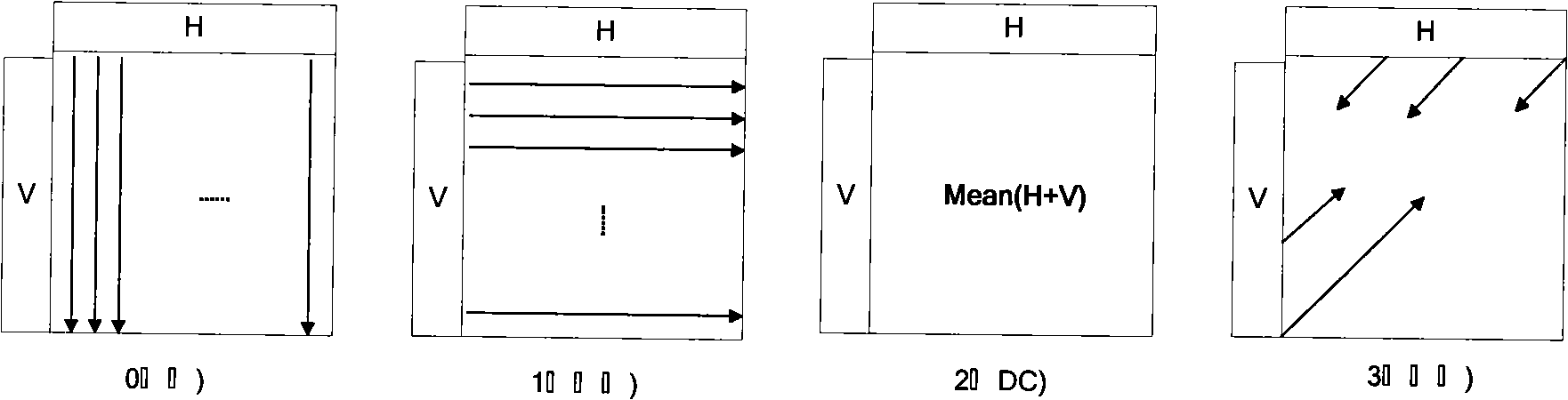

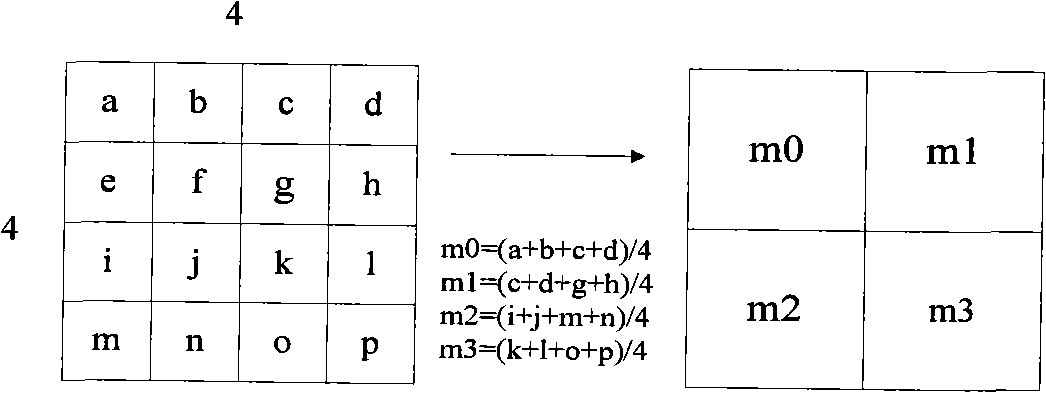

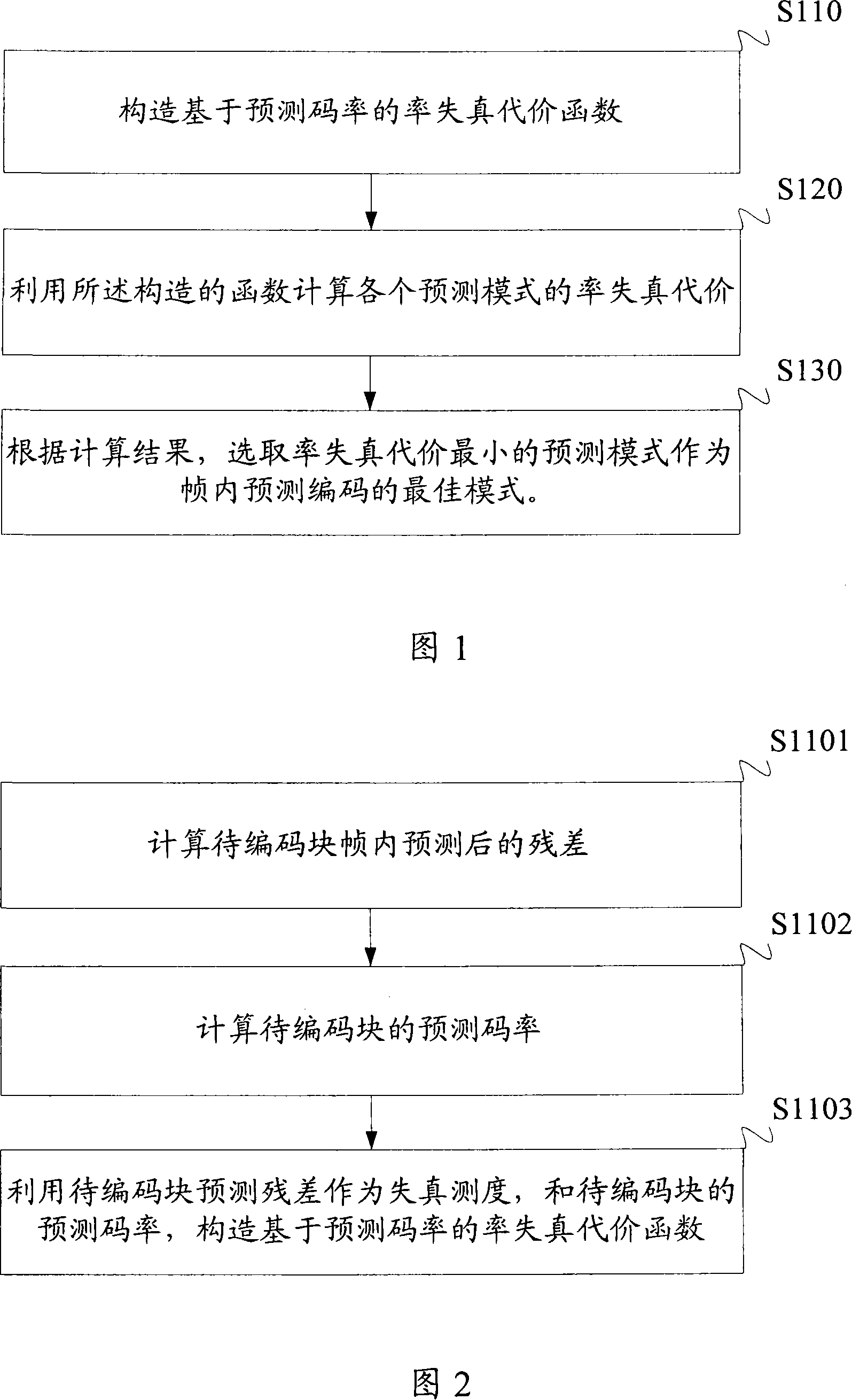

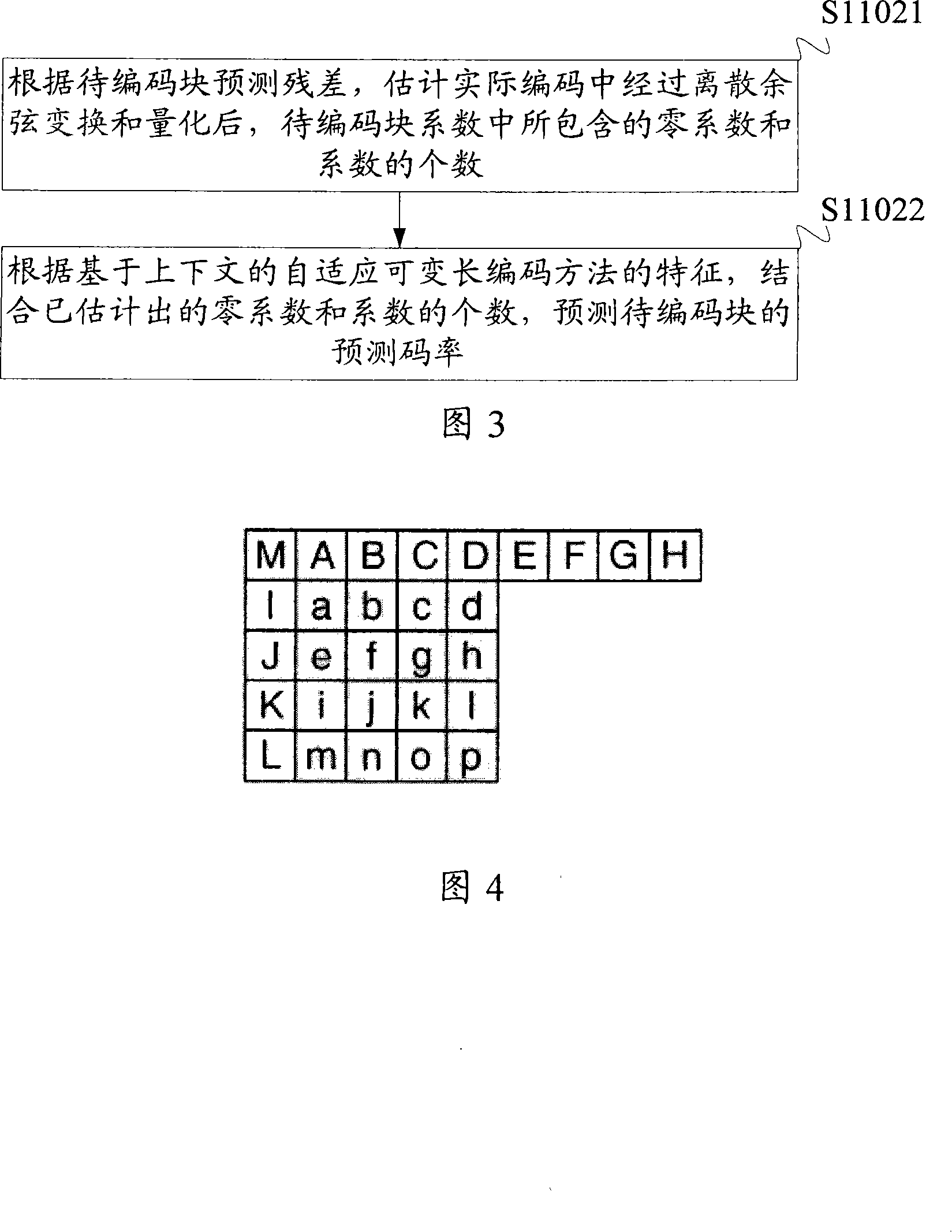

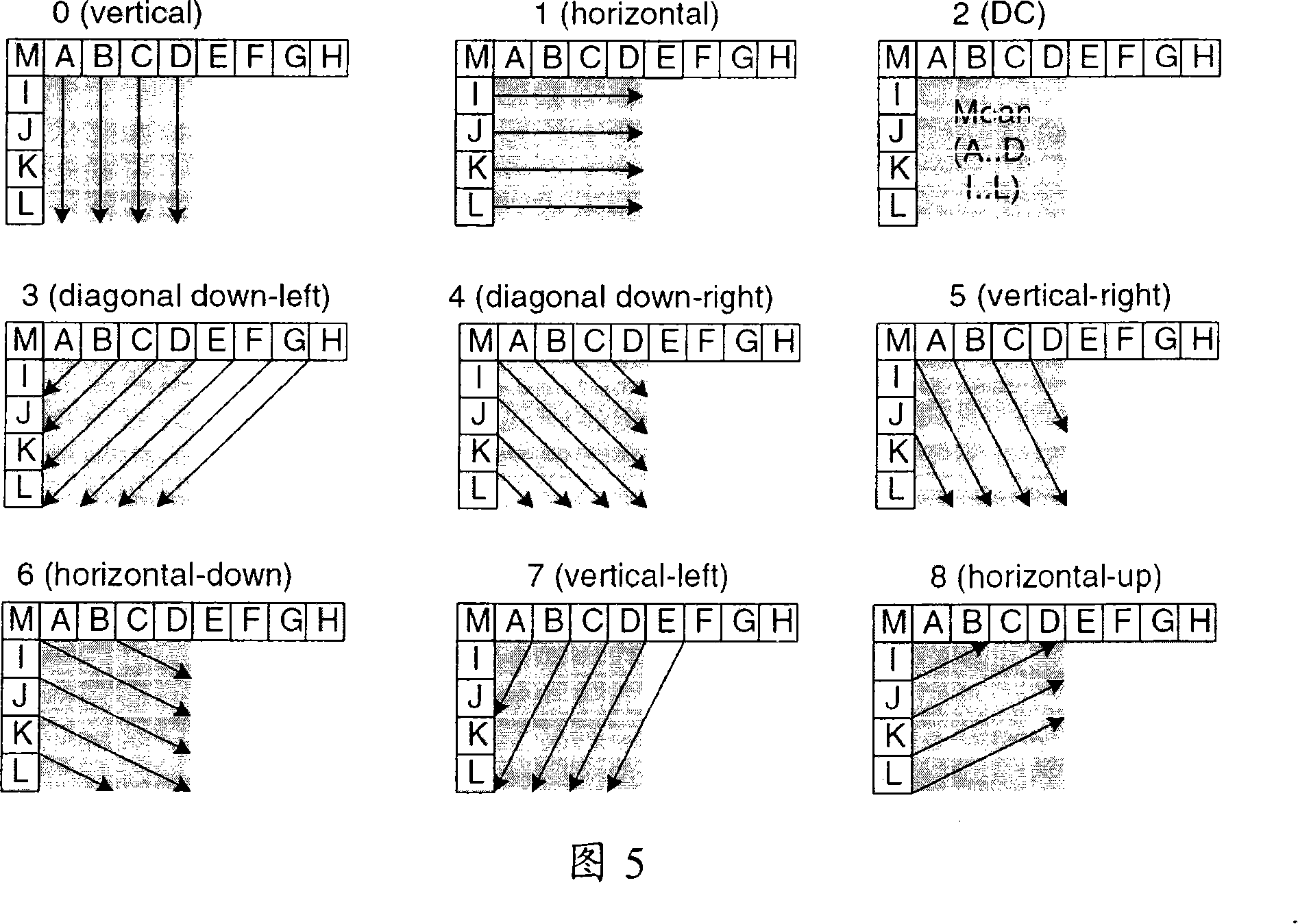

Intraframe prediction coding optimum mode selecting method and apparatus for video coding

InactiveCN101141649ASignificant changeSimple calculationPulse modulation television signal transmissionDigital video signal modificationComputer architectureModel selection

The present invention relates to a selecting method for the optimal mode of the intra prediction coding used for video frequency coding, which belongs to the video frequency coding and decoding field. The steps of the method are that a rate-distortion cost function is constructed on the basis of a prediction code rate; the rate-distortion cost of each prediction mode is calculated by the structured function, and the prediction mode with minimum rate-distortion cost is selected as the optimal mode of the intra prediction coding according to the calculating result. Proportionally, the present invention also provides a device for the selecting of intra prediction coding optimal mode of the video frequency coding. The present invention effectively avoids actually coding every blocks during the rate-distortion optimizing process on the basis that the selected mode is closer to the optimal mode of the original rate-distortion optimization model selecting, and greatly improves the coding efficiency on the precondition of ensuring little change on the code rate and the PSNR of the coding and the full searching method.

Owner:PEKING UNIV +1

Fountain solution and preparation method thereof

InactiveCN101870213AEasy to keep hydrophilicAdequate dampening capacityPrinting pre-treatmentGermabenPropylene glycol

The invention discloses a fountain solution, which is characterized in that: the fountain solution comprises the following raw materials in percentage by weight: 1 to 15 percent of glycerin, 0.1 to 10 percent of ammonium citrate, 0.1 to 10 percent of malic acid, 0.1 to 5 percent of defoaming agent, 0.1 to 10 percent of wetting agent, 0.1 to 5 percent of bactericide, 1 to 15 percent of L-PCA-Na, 1 to 15 percent of propylene glycol and 1 to 15 percent of sorbierite; and the preparation method comprises the following steps: adding the ammonium citrate, the malic acid, the wetting agent, the L-PCA-Na in a weight percentage ratio, then adding 50 to 80 percent of water, uniformly mixing the materials and the water; and adding the propylene glycol, the sorbierite, the glycerin, the defoaming agent and the bactericide into the obtained mixture and then uniformly stirring the mixture so as to obtain the fountain solution. The fountain solution has the advantages of environmental protection, strong fountain capability, wet non-verbal-visual part, sufficient pH-value buffering, difficult ink emulsification, large electric conductivity, large surface-tension buffering range and easy operating control.

Owner:杜广清

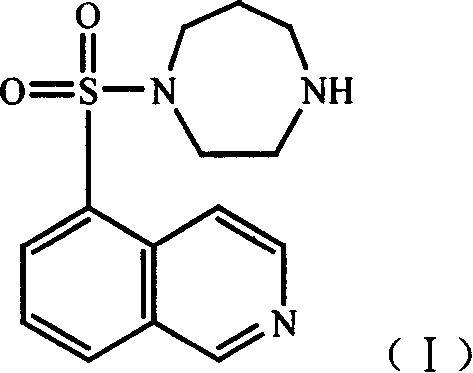

Hydrate of medicinal salt of Fasudil

InactiveCN101092413AImprove stabilityImprove solubilityOrganic active ingredientsOrganic chemistryHydrobromideDisease

This invention discloses hydrates of pharmaceutical salts of hexahydro-1-(5-sulfonylisoquinoline)-1H-1,4-diaza, i.e., fasudil, especially semi-hydrates of nitrate, sulfate, hydrobromide and mesylate of fasudil, their preparation method, and their application in drugs for preventing and / or treating cardio-cerebrovascular diseases. The hydrates of pharmaceutical salts of fasudil have such advantages as high stability and high solubility, and can be manufactured into various preparations with other active components and / or pharmaceutically acceptable carriers. The method has such advantages as simple process, high drug purity, high yield, and stable product quality, and is suitable for industrial production.

Owner:SHANDONG XUANZHU PHARMA TECH CO LTD

Low-viscosity skin lotion and preparation method thereof

ActiveCN101433500ANo oil-water separationSignificant changeCosmetic preparationsToilet preparationsPreservativeCentrifugation

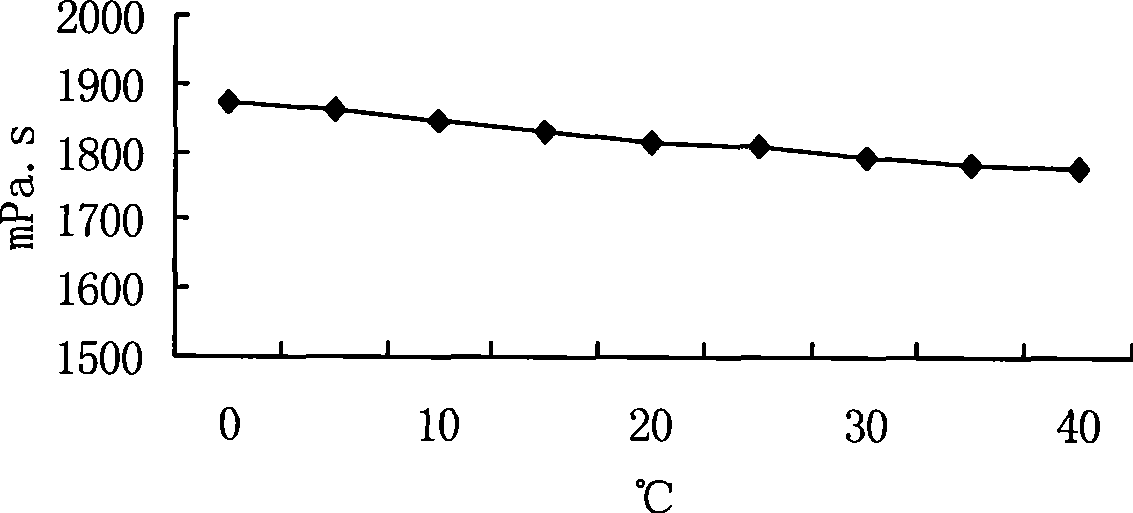

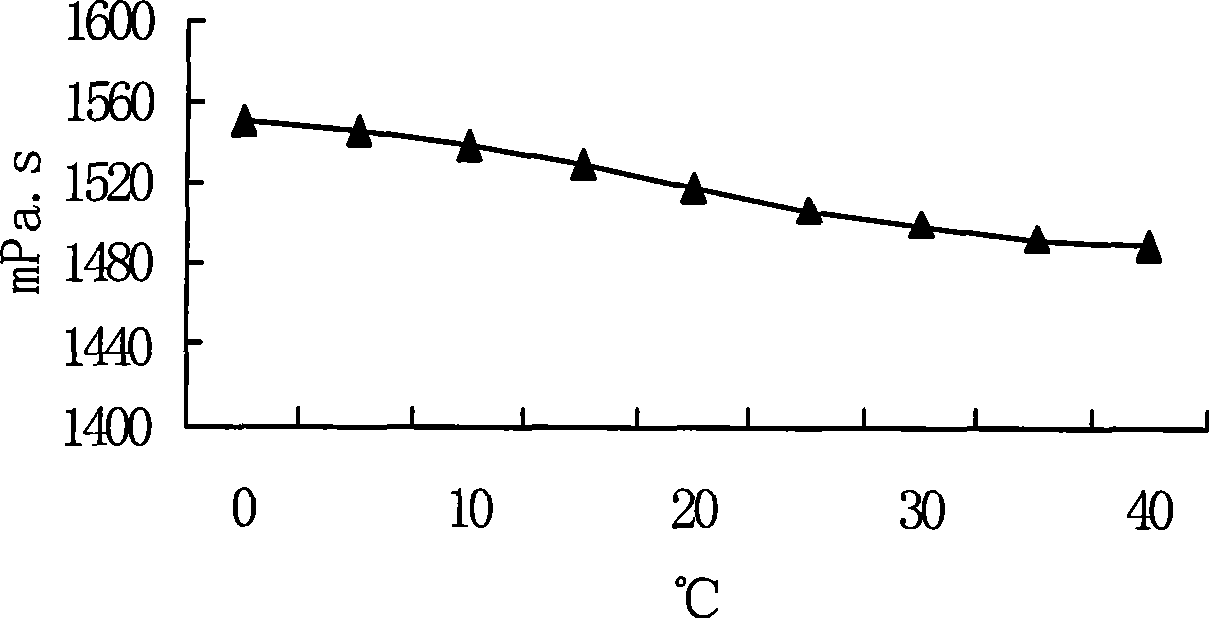

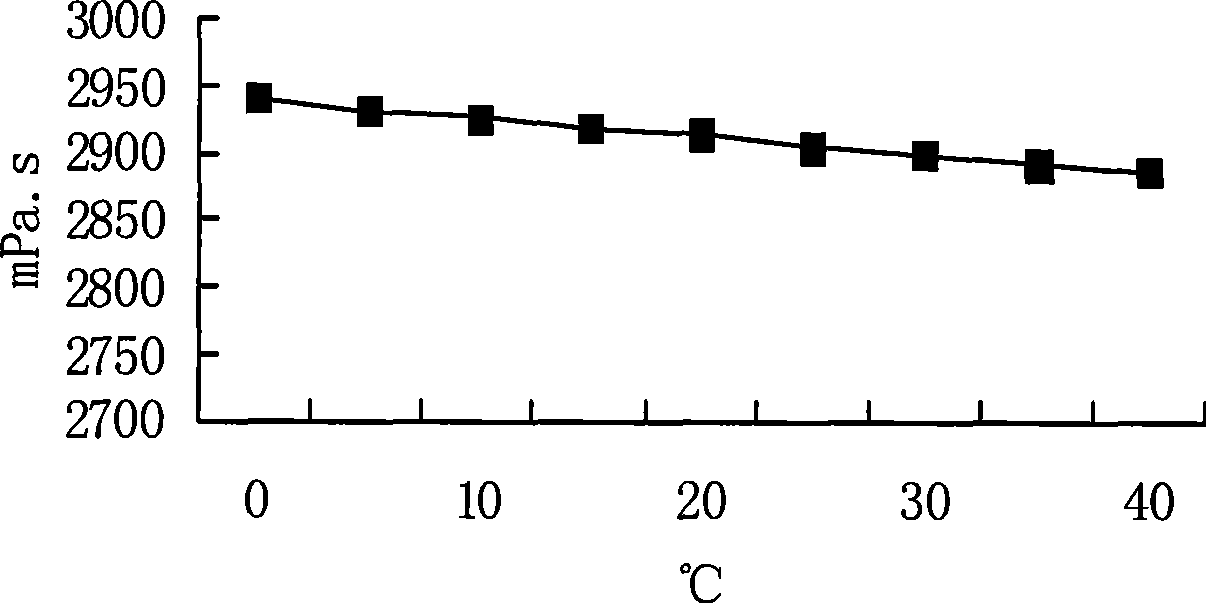

The invention discloses low-viscosity skin-care emulsion and a preparation method thereof. The preparation method comprises the following steps: firstly, weighing the following components by weight percentage according to a formulation: 1.0 to 3.0 percent of main emulsifying agent, 1.0 to 3.0 percent of auxiliary emulsifying agent, 0.4 to 0.8 percent of stabilizing agent, 17.0 to 27.0 percent of emollient, 0.6 to 1.6 percent of preservative, and the balance being additive and deionized water; and then adding an oil-soluble component into an oil-phase pot, adding a water-soluble component into a water-phase pot, heating the pots respectively, extracting raw materials in the oil-phase pot and the water-phase pot into an emulsifying pot to homogenate the mixture, later cooling the mixture, adding residual components into the mixture, and discharging the skin-care emulsion. The viscosity of the low-viscosity skin-care emulsion prepared by the method is between 1,500 mpa.s and 3,000 mpa.s, emulsion centrifugation does not cause oil-water separation phenomenon, the viscosity of the emulsion is affected by temperature little, and at the same time, the production method for the emulsion has the advantage of simple process and can produce the emulsion by using the prior producing technique and equipment.

Owner:广东名臣日化有限公司

Machining method for preparing Al/Mg/Al alloy composite board by rolling

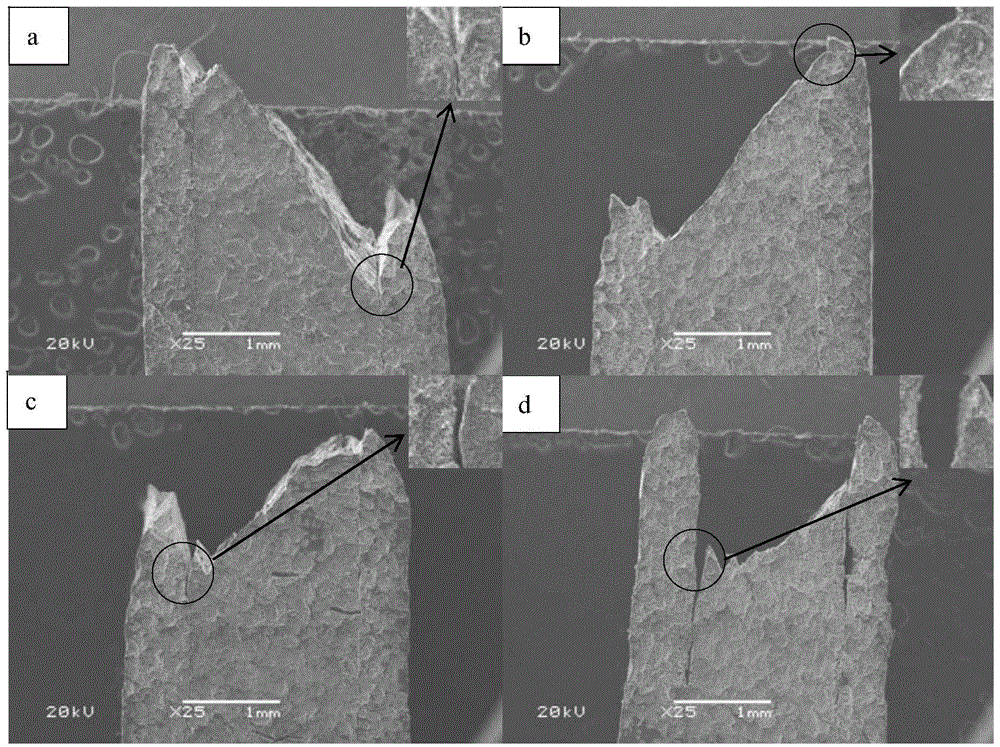

InactiveCN104907334ANo peeling phenomenonSignificant changeTemperature control deviceMetal rolling arrangementsSurface cleaningAlloy composite

The invention provides a machining method for preparing an Al / Mg / Al alloy composite board by rolling. The method comprises: (1) a composite rolling process of cutting a Mg alloy board and aluminum boards, which are to be compositely rolled, into shapes with equal sizes, and performing surface cleaning and polishing treatment, sandwiching and fixing the Mg alloy board between the two aluminum boards and performing single-pass composite rolling on the fixed boards, wherein the rolling reduction ratio is 30 to 60 percent, the rolling temperature is 300 to 450 DEG C, and time for heat preservation before rolling is 5 to 15min; (2) a composite board annealing process of placing the rolled Al / Mg / Al alloy composite board into a heating furnace, heating the Al / Mg / Al alloy composite board to 150 to 230 DEG C, preserving heat for 1 to 12 hours, and taking out the Al / Mg / Al alloy composite board for air cooling. According to the method, a unique annealing process is adopted, and at proper annealing temperature, the interface bonding force of two alloys can be strengthened and the formation of a fragile phase is avoided, so that the phenomenon of stripping of the composite board in a serving process is avoided.

Owner:HARBIN ENG UNIV

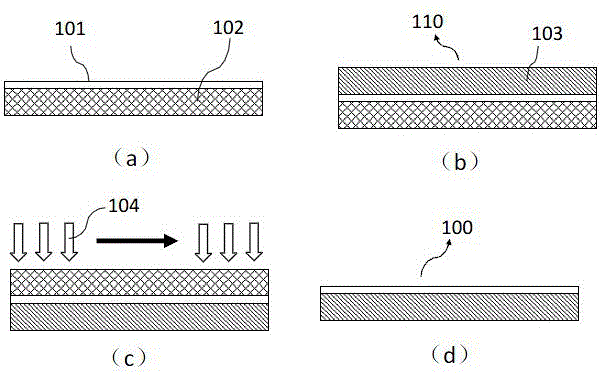

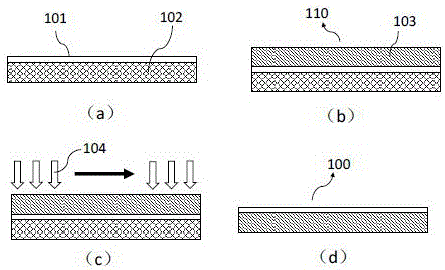

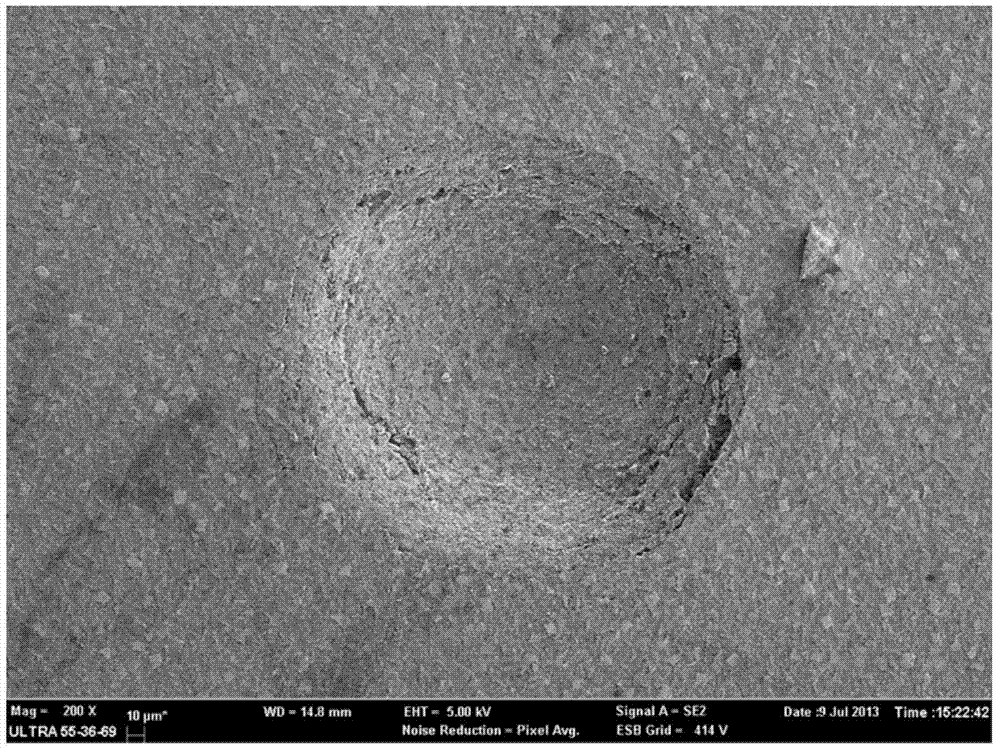

Method based on femtosecond laser technology for peeling GaN film and sapphire substrate

InactiveCN105006446AHigh precisionImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingLaser technologyFemto second laser

The invention discloses a method based on a femtosecond laser technology for peeling a GaN thin film and a sapphire substrate, and the method belongs to the field of LED and power device chips. The method comprises the steps of: (1) growing the GaN thin film on the sapphire substrate by adopting chemical vapor deposition; (2) bonding a target substrate on the GaN thin film to obtain a sapphire / GaN / target substrate; (3) carrying out scanning radiation on the upper surface of the sapphire substrate by adopting femtosecond laser from the edge of the sapphire / GaN / target substrate; (4) and heating the sapphire / GaN / target substrate to not lower than 30 DEG C and removing the sapphire substrate to obtain a bilayer structure of the GaN / target substrate. The method provided by the invention has the advantages that: the method is a cold processing method, the temperature in the GaN thin film before and after femtosecond laser radiation is even and has no obvious change, the thermal stress influence on the GaN thin film is effectively reduced, and the laser peeling quality is improved; and the method increases the efficiency and yield of peeling the sapphire substrate, and overcomes the defect that the GaN thin film is liable to damage.

Owner:WUHAN UNIV +1

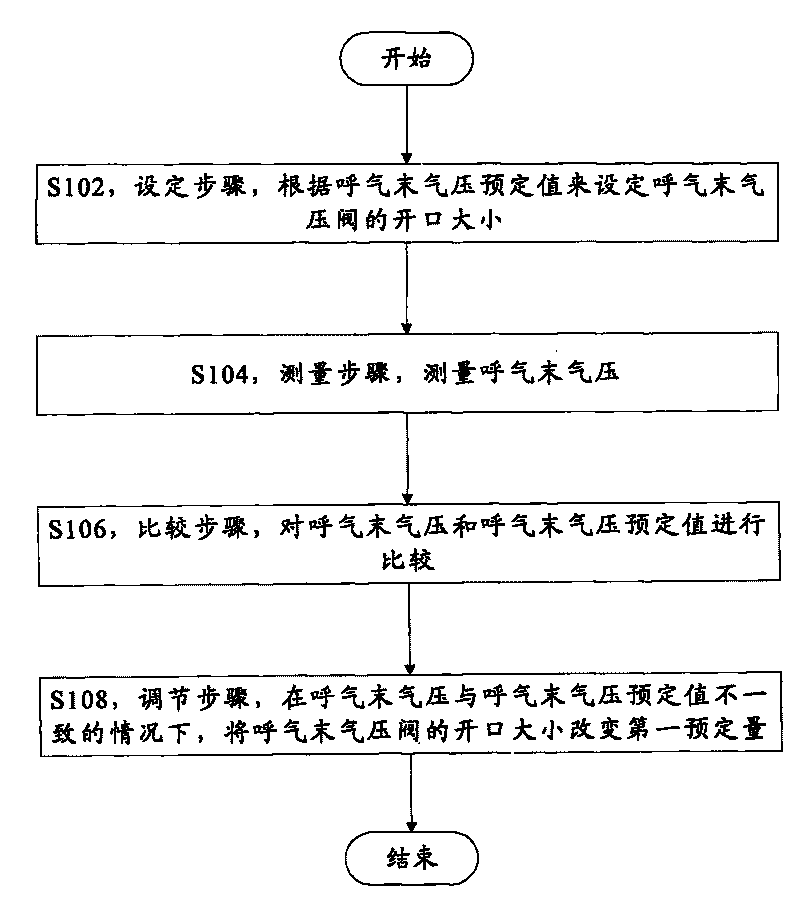

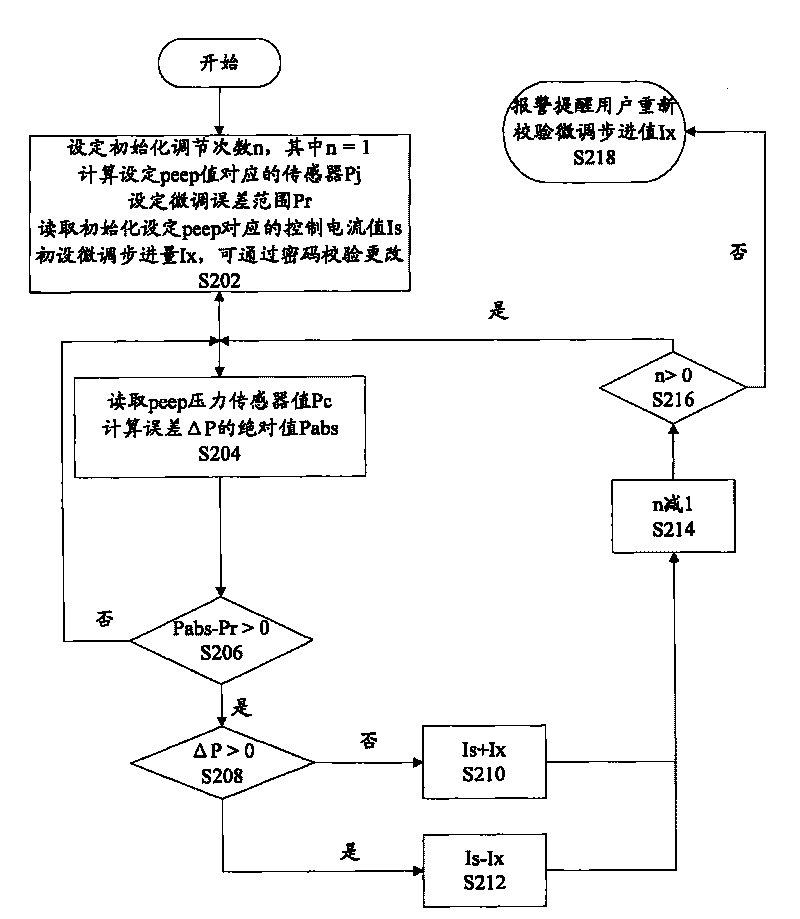

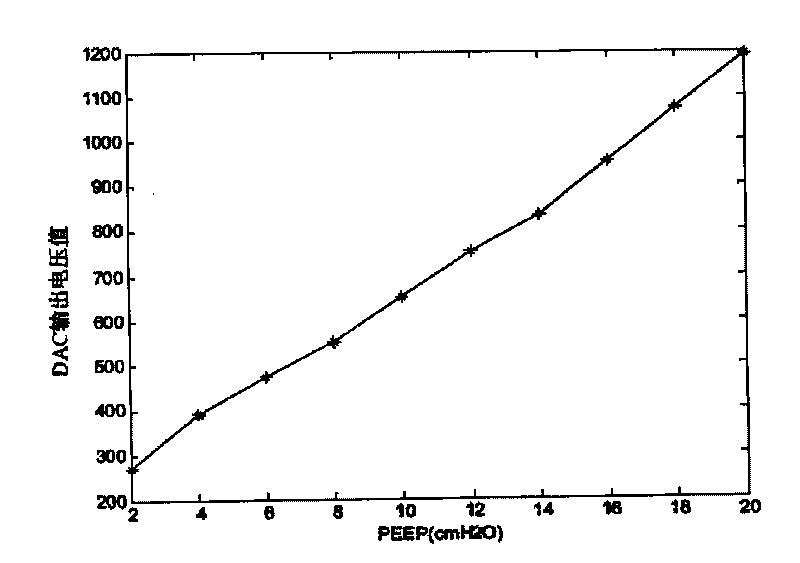

Method for controlling end-expiratory pressure and ventilator using same

Owner:BEIJING AEONMED

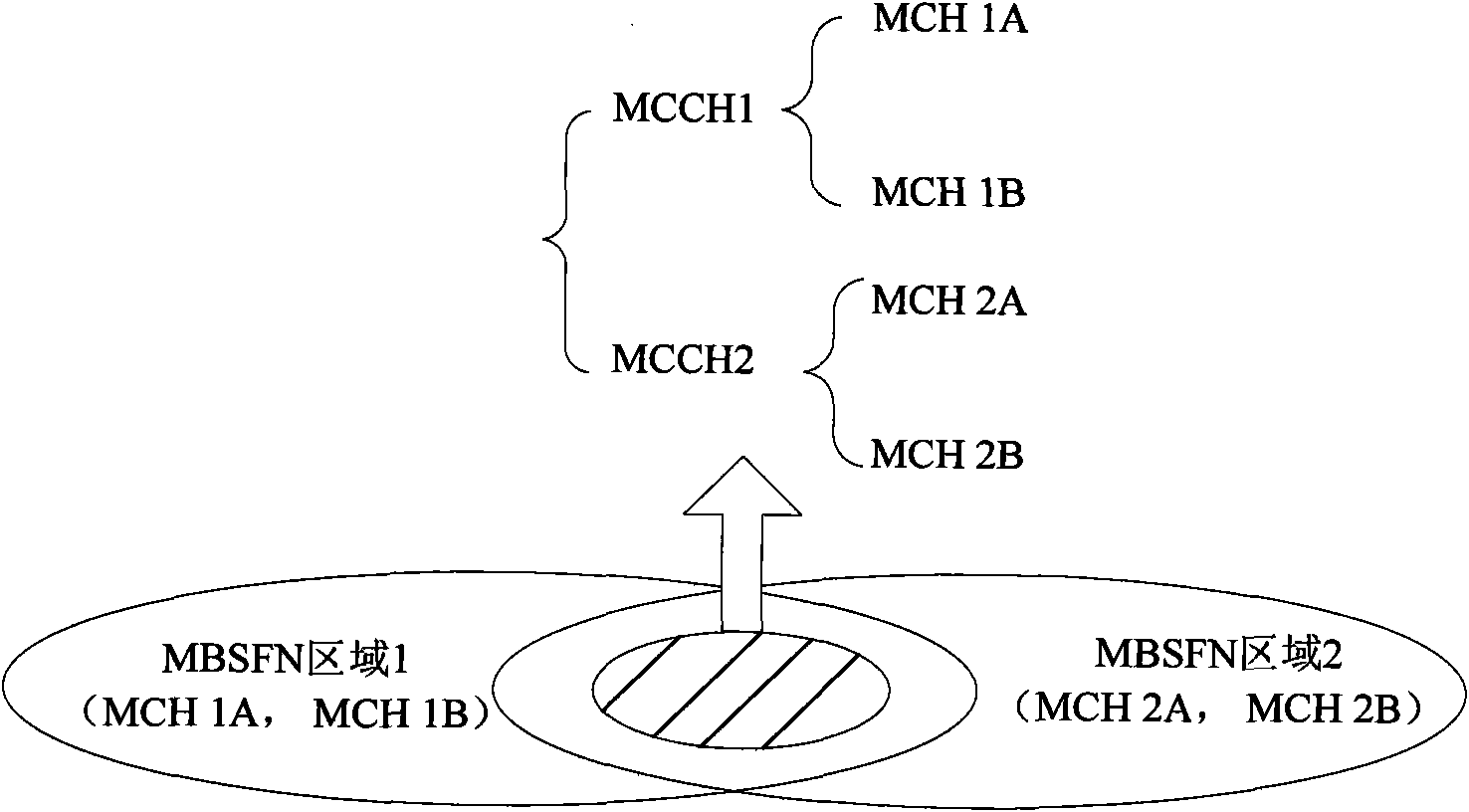

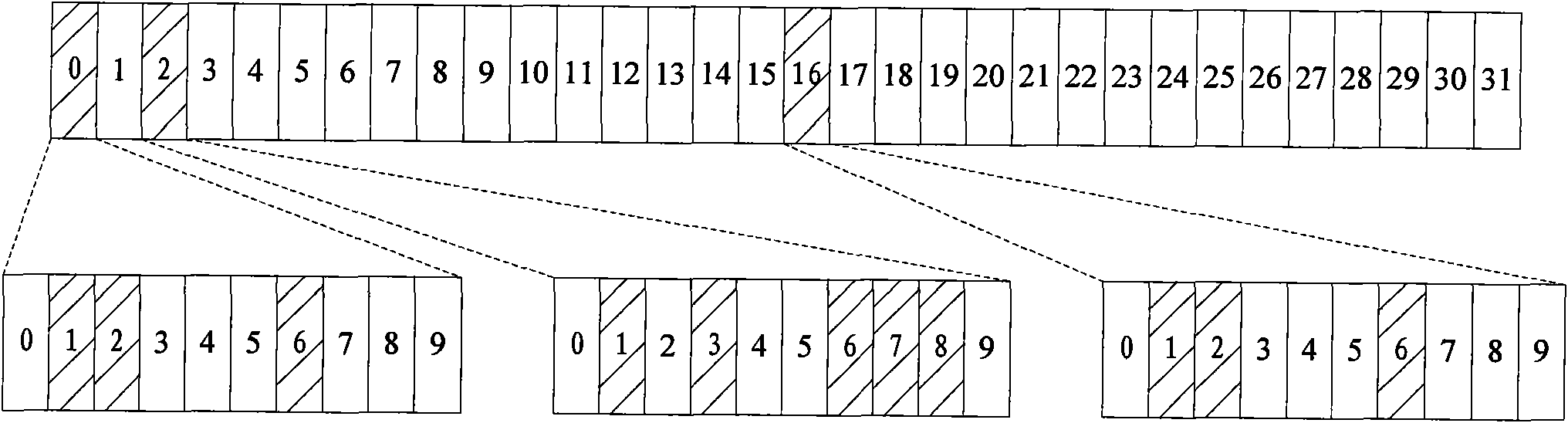

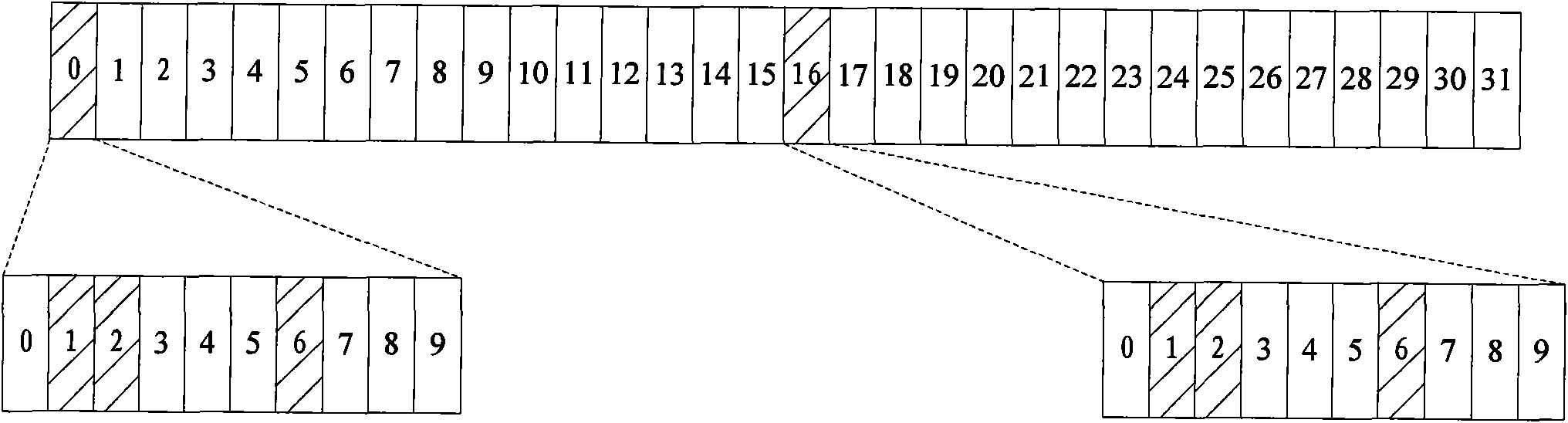

Method and device for notifying MBSFN (Multicast Broadcast Single Frequency Network) subframe position and application

ActiveCN101998264ADoes not affect schedulingSave resourcesAssess restrictionBroadcast service distributionMulticast-broadcast single-frequency networkComputer science

The embodiment of the invention provides a method and device for notifying MBSFN (Multicast Broadcast Single Frequency Network) subframe positions and applications, relating to the communication field, wherein an MBSFN subframe position occupied by each MCH (Multicast Channel) can be simply and flexibly notified, and the size of a transmission field is constant; all UE (User equipment) can also be flexibly notified that the applications of the MBSFN subframes are changed. The embodiment of the invention provides one method comprising the step of: transmitting a bitmap and the position of theMBSFN subframe occupied by each MCH in the bitmap, wherein the length of the bitmap is the number of the subframes which are indicated by reserved subframe arrays in system broadcast information and can be used for MBSFN transmission in the maximum period of the MBSFN subframes of the current MBSFN area transmission. The embodiment of the invention provides another method comprising the step of: transmitting a physical format indication channel (PCFICH), wherein the applications of the MBSFN subframes are indicated in the PCFICH.

Owner:HUAWEI TECH CO LTD

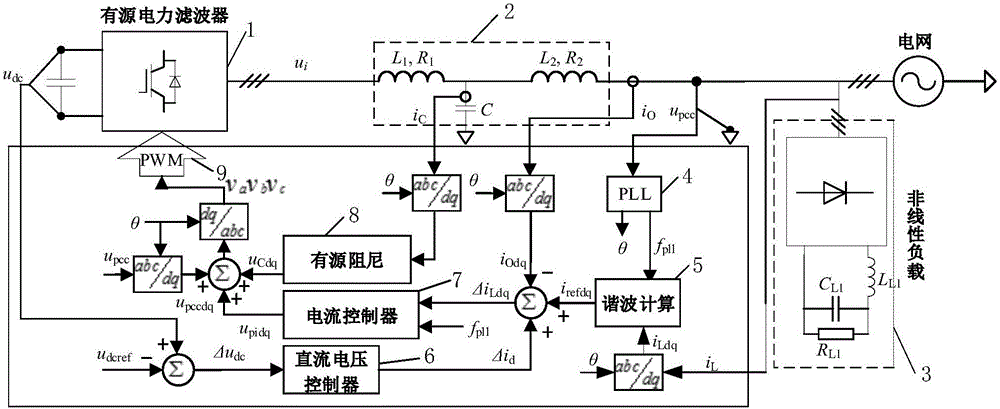

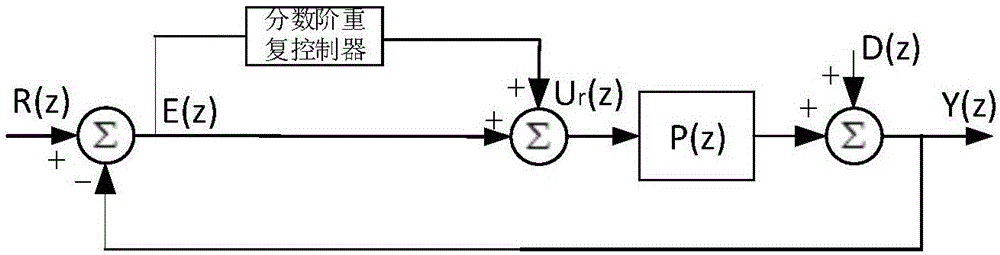

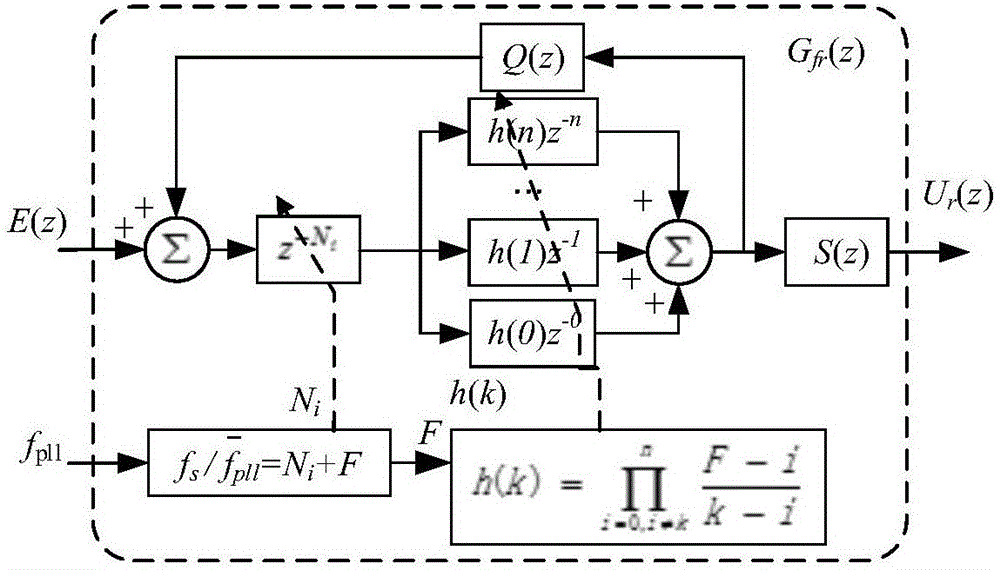

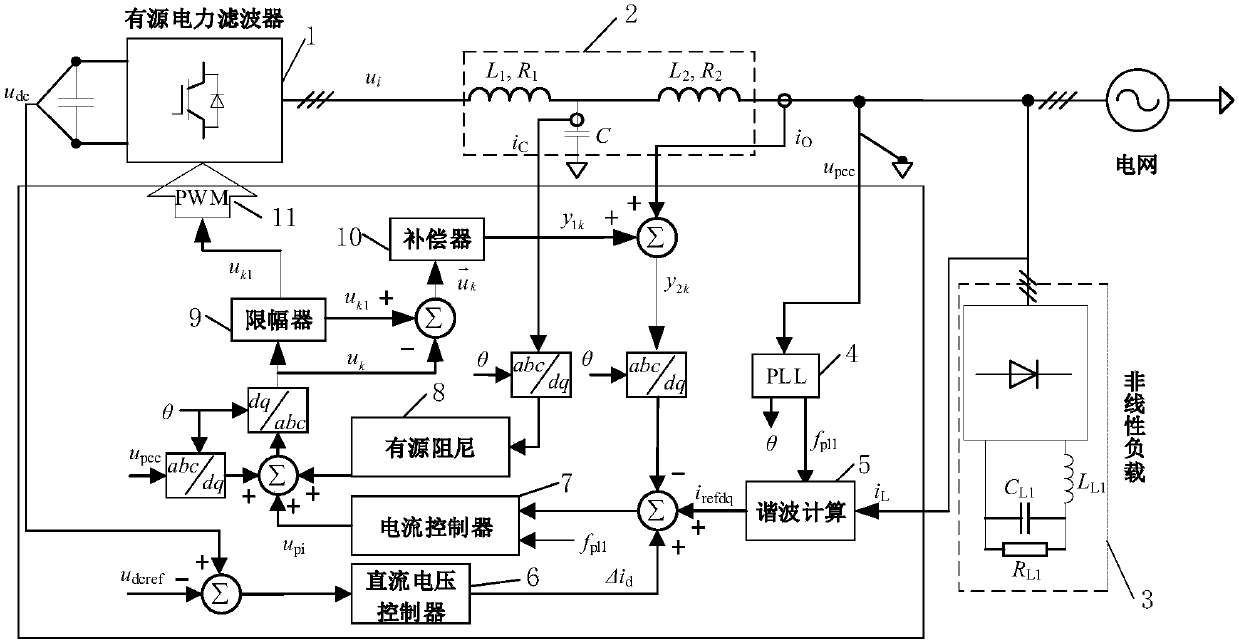

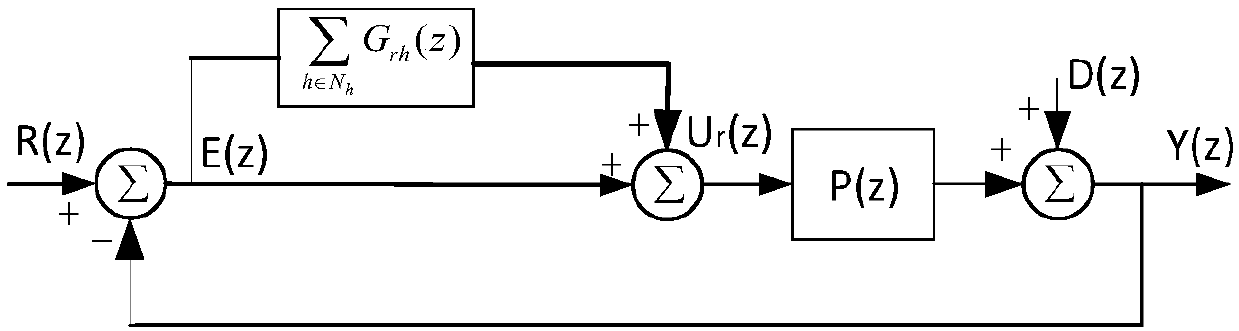

Improved broadband adaptive repetitive control method of active power filter

InactiveCN106532702AGood harmonic compensation effectHigh engineering realized valueActive power filteringAc network to reduce harmonics/ripplesBroadbandCapacitance

The invention discloses an improved broadband adaptive repetitive control method of an active power filter. The improved broadband adaptive repetitive control method comprises the steps of firstly collecting three-phase voltage of a common coupling point and obtaining a frequency fp11 and a phase theta of the voltage by using a phase-locked loop; extracting a harmonic signal instruction of nonlinear load current iL by a harmonic detection module, adding an active current output instruction obtained through a DC voltage controller and subtracting an output current feedback signal to obtain an input error signal of a current controller; obtaining an output control quantity through the current controller formed by a repetitive controller and a PI controller; and finally obtaining a PWM wave modulation instruction signal through addition of the output control quantity, a voltage feedforward quantity of the common coupling point and a capacitance current feedforward quantity of the filter passing through an active damping module.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

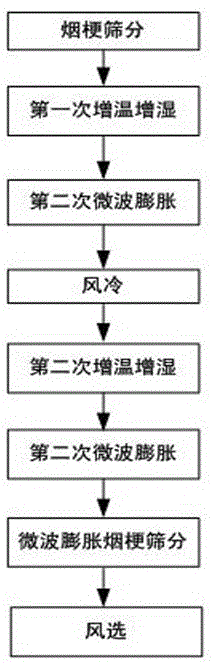

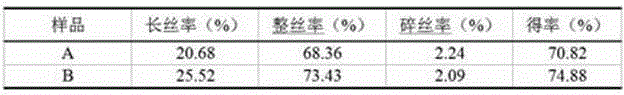

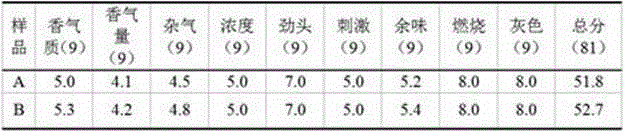

Two-section type tobacco stem microwave expansion processing method

The invention relates to a two-section type tobacco stem microwave expansion processing method and belongs to the technical field of tobacco processing. According to the method, two times of heating and humidification and two times of microwave expansion processing are performed on tobacco stems. The method includes the steps of tobacco stem screening, the first time of heating and humidification, the first time of microwave expansion, air cooling, the second time of heating and humidification, the second time of microwave expansion, microwave expansion tobacco stem screening and air separation. The two-section type tobacco stem microwave expansion processing method has the advantages that the average expansion rate of the tobacco stems can reach more than 200%, the power of the two times of microwave expansion is no higher than 50 KW, loss of natural tobacco fragrance is reduced, carbonization and fire striking of the microwave expansion tobacco stems are reduced, the uniformity of the microwave expansion tobacco stems is improved, the scorching smell of microwave expansion stem filaments is reduced, and the quality of the microwave expansion stem filaments is improved; the water content of the expanded tobacco stems is no lower than 6wt%, crush of the tobacco stems is reduced, and the filament rate and the yield of the microwave expansion stem filaments are increased.

Owner:CHINA TOBACCO YUNNAN IND

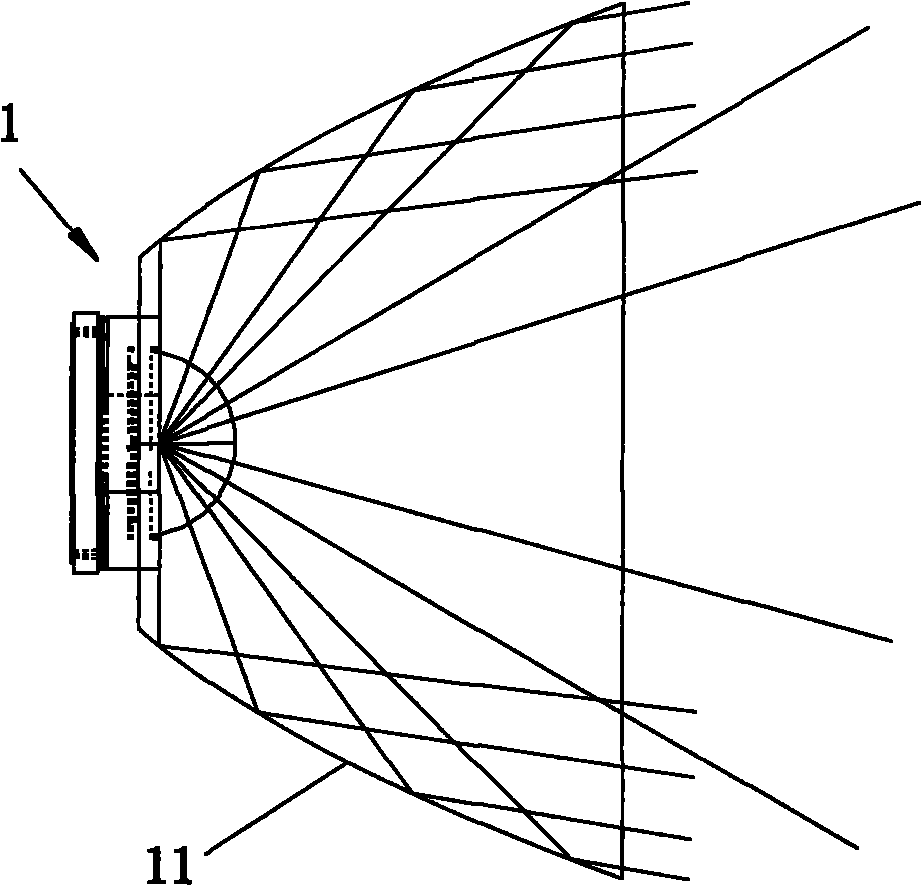

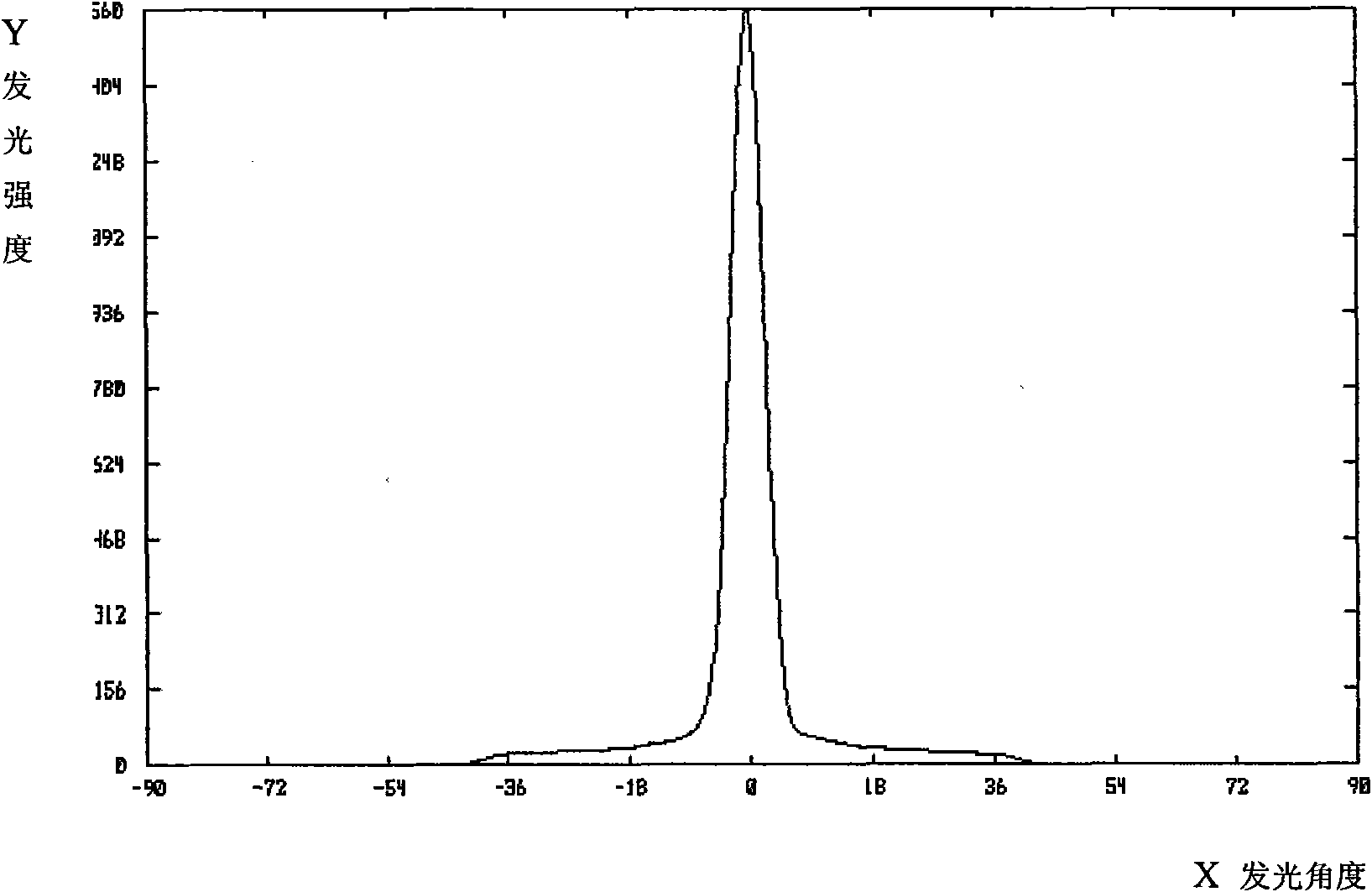

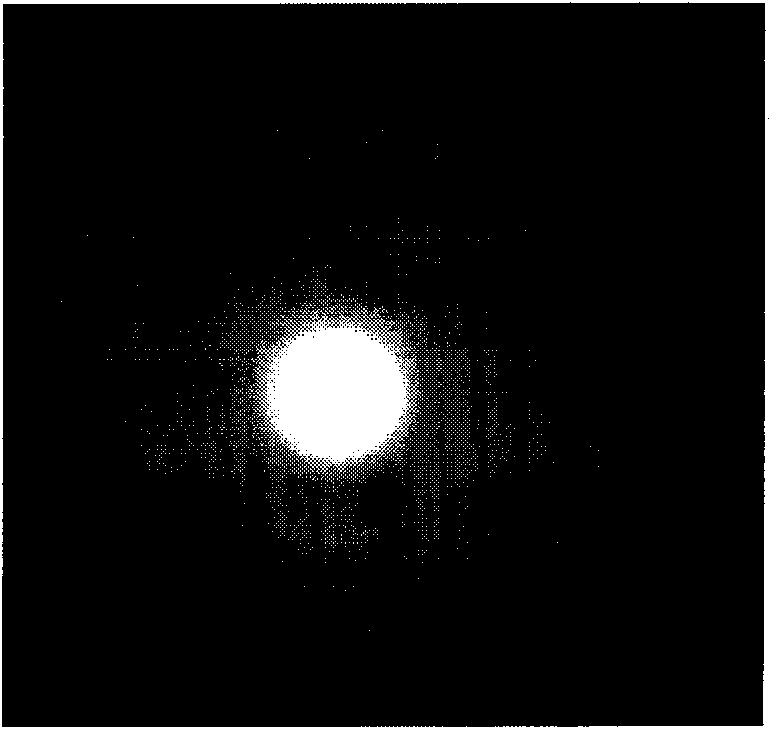

LED focusing optical system

InactiveCN101893205AIncrease brightnessLittle changePoint-like light sourceLighting device detailsLight spotLight beam

The invention relates to an LED focusing optical system which comprises a reflector, an LED light source arranged at the focal point of the bottom of the reflector and also a thin lens arranged at the opening of the reflector, wherein the surface of the thin lens opposite to the LED light source is a convex surface. The LED focusing optical system realizes high collection of light beams of the LED light source through combination of the thin lens and the reflector to enable the brightness of central light spots to be strong, the influence on an luminescence angle of the system by adding the thin lens is small i.e. the variation of light spots at the outer ring of a lamp is not large, the height of the optical system is only 2-4 times of the size of the light source, and the optical system has the advantages of simple structure, small volume, strong light intensity and large radiation range, therefore, the LED focusing optical system can be widely applied to the field of focusing lamps such as flashlights, miner lamps, headband lamps and the like and fully satisfy the illumination requirement of people to the focusing lamps.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

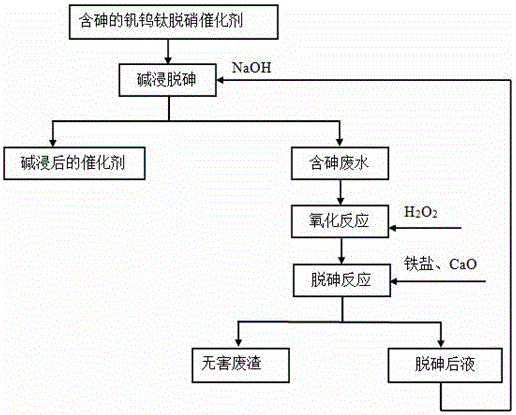

Method for dearsenization of arsenic containing waste water generated in regeneration process of vanadium, tungsten and titanium denitration catalyst

InactiveCN105668897AHigh removal rateSimple methodTreatment involving filtrationMultistage water/sewage treatmentPollutionSodium hydroxide

The invention relates to a method for removing arsenic from arsenic-containing wastewater produced in the regeneration process of a vanadium-tungsten-titanium denitrification catalyst, and belongs to the technical field of chemical engineering. The method is to carry out arsenic-containing catalyst and sodium hydroxide solution for alkali leaching dearsenic reaction. After the reaction, the catalyst and arsenic-containing wastewater after alkali leaching are obtained, and the arsenic-containing wastewater needs to be further treated for arsenic removal; Oxidation reaction is carried out by adding oxidizing agent hydrogen peroxide, then adding iron salt to adjust the pH of the solution>9, then adding CaO at 50-100° C., and continuing the reaction for 0.5-3 hours. After the reaction is finished, liquid-solid separation is carried out. The liquid phase is the liquid after de-arsenic, which can be prepared by adding sodium hydroxide to a solution containing sodium hydroxide, and then returns to participate in the alkali leaching de-arsenic reaction, which is recycled in the entire catalyst regeneration system; the solid phase It is harmless waste and can be piled up directly. The content of As in the waste water after arsenic removal treatment is less than or equal to 0.5 mg / l. This method not only reduces the cost, but also does not cause any pollution to the environment.

Owner:KUNMING METALLURGY INST

Cu/graphene delamination method based on femtosecond laser technology

The invention discloses a Cu / graphene delamination method based on the femtosecond laser technology, and belongs to the field of graphene preparation. The method comprises the following steps: (1) growing graphene on a copper foil; (2) bonding a transparent target substrate on graphene prepared in the step (1) to form transparent target substrate / graphene / Cu; (3) conducting scanning irradiation on one side of the upper surface of the transparent target substrate by adopting femtosecond laser, and removing the copper foil so as to obtain the graphene / transparent target substrate. The method has the advantages that the precision and the efficiency of laser delamination are improved; as a cold machining manner, the temperature of the graphene layer is uniform and small in change before and after femtosecond laser irradiation, the thermal stress of graphene and carrier substrate is effectively reduced, and the delamination quality is improved.

Owner:WUHAN FINEMEMS

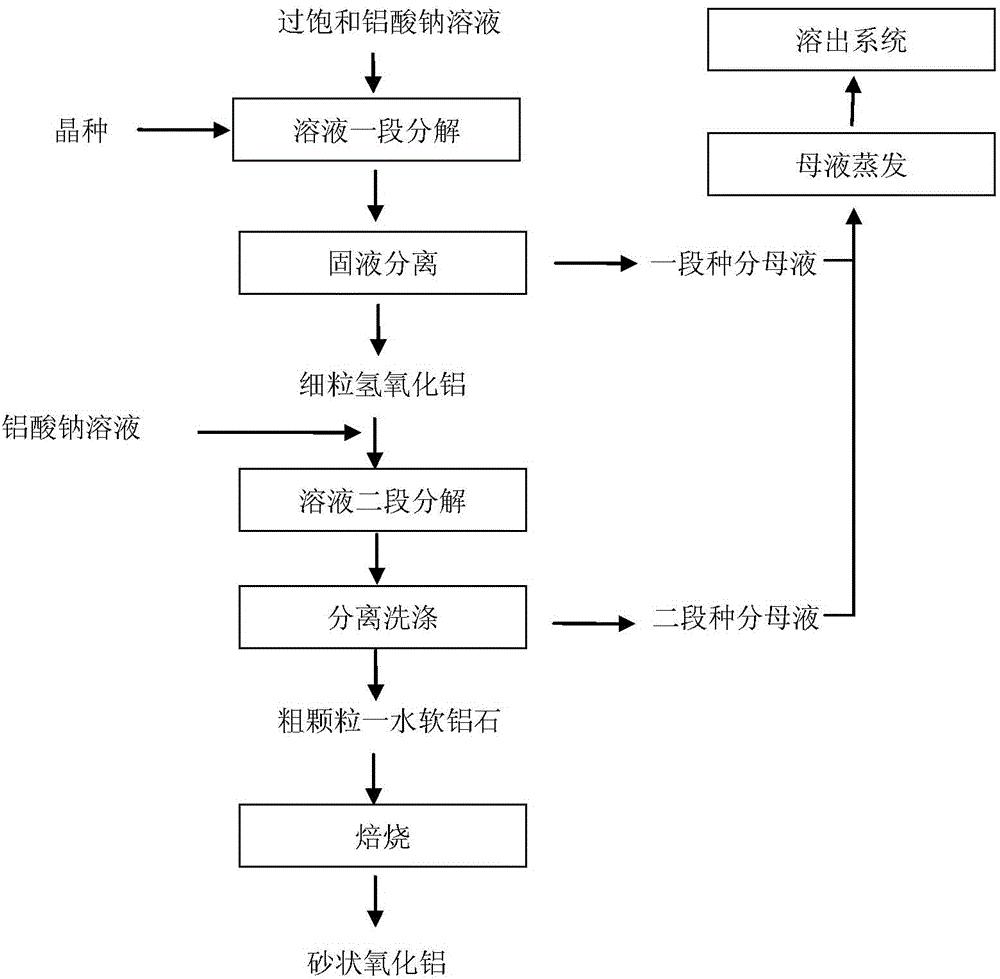

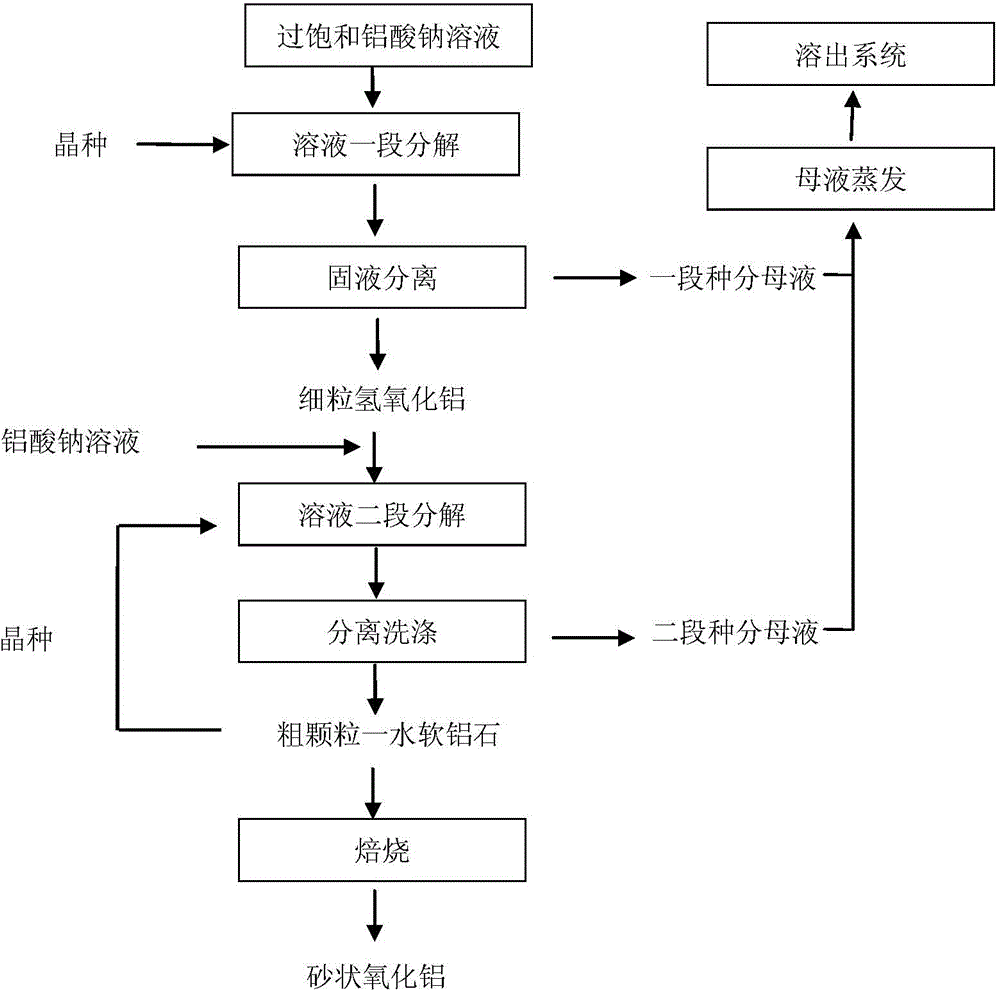

Method for preparing sand-shaped aluminum oxide

ActiveCN104817100AImprove product qualityLow impurity contentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationDecompositionAluminium hydroxide

The invention discloses a method for preparing sand-shaped aluminum oxide. The method for preparing the sand-shaped aluminum oxide includes steps that 1) using supersaturated sodium aluminate solution as decomposition stock solution, and adding seed crystal to perform primary seed precipitation to obtain primary seed precipitation mother liquor and primarily decomposed aluminum hydroxide; 2) taking the primarily decomposed aluminum hydroxide and sodium aluminate solution to perform secondary seed precipitation to obtain secondary seed precipitation mother liquor and boehmite; 3) washing the boehmite and roasting to obtain the sand-shaped aluminum oxide. The sand-shaped aluminum oxide prepared by the method is featured with high decomposition rate, less impurity content, high product quality and the like, and meanwhile, the alpha-Al2O3 in the product is less, and the aluminum electrolysis is facilitated.

Owner:CENT SOUTH UNIV

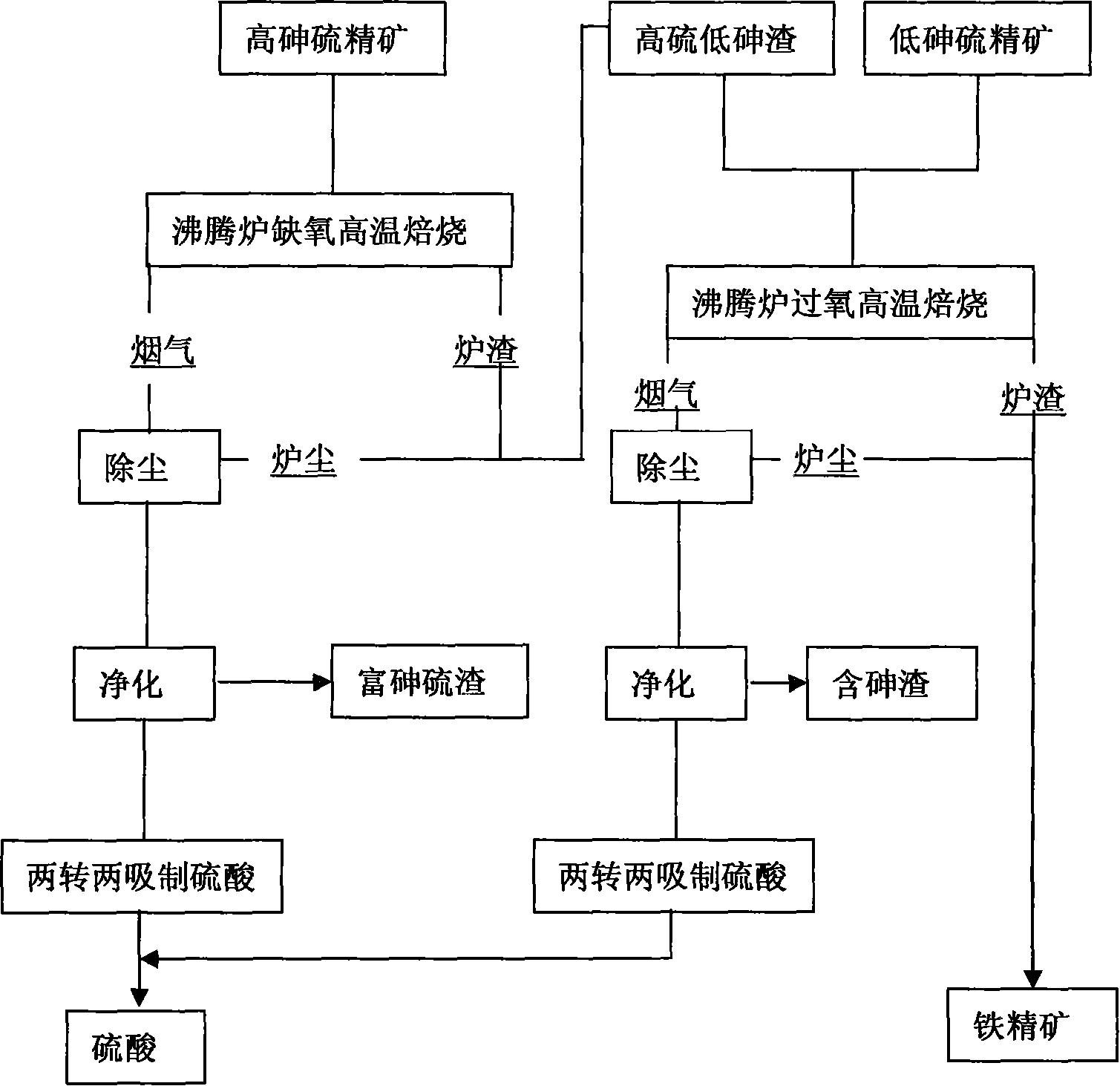

Method for producing iron ore concentrate with high arsenic ferro-sulphur ore concentrate

InactiveCN101245409ATake advantage ofMeet iron requirementProcess efficiency improvementSlagFlue gas

The invention relates to a method for producing iron ore concentrate with high arsenic-bearing pyrite concentrate. The invention comprises the steps that the arsenic-bearing pyrite concentrate is adopted as raw material used in a boiling furnace to be roasted with the excess air coefficient controlled at 0.7-0.9 and at the temperature of 850-1,000DEG C to remove arsenic; flue gas after being treated with dust removal enters into a purifying system in which the arsenic and sulfur are condensed and recycled to form arsenic and sulfur-rich slag; the purified flue gas is used for producing sulphuric acid and the cinder is the high-sulfur and low-arsenic cinder which is then mixed with low arsenic-bearing high-grade sulfur concentrate so as to form mixed material containing 24-30 percent of sulfur to be served as the material in the boiling furnace and roasted with high temperature of 900-1,000DEG C and the excess air coefficient controlled at 1.15-1.25. The flue gas after being treated with dust removal and purifying is then used for producing sulphuric acid and the mixed material is burnt into qualified iron ore concentrate. The technique of the invention can realize arsenic removal of high arsenic-bearing pyrite concentrate to obtain the qualified iron ore concentrate by merely changing technique parameters of the conventional system used for producing acid by the pyrite, which results in high utilization efficiency of iron ore resources in the high arsenic-bearing pyrite concentrate.

Owner:KUNMING UNIV OF SCI & TECH

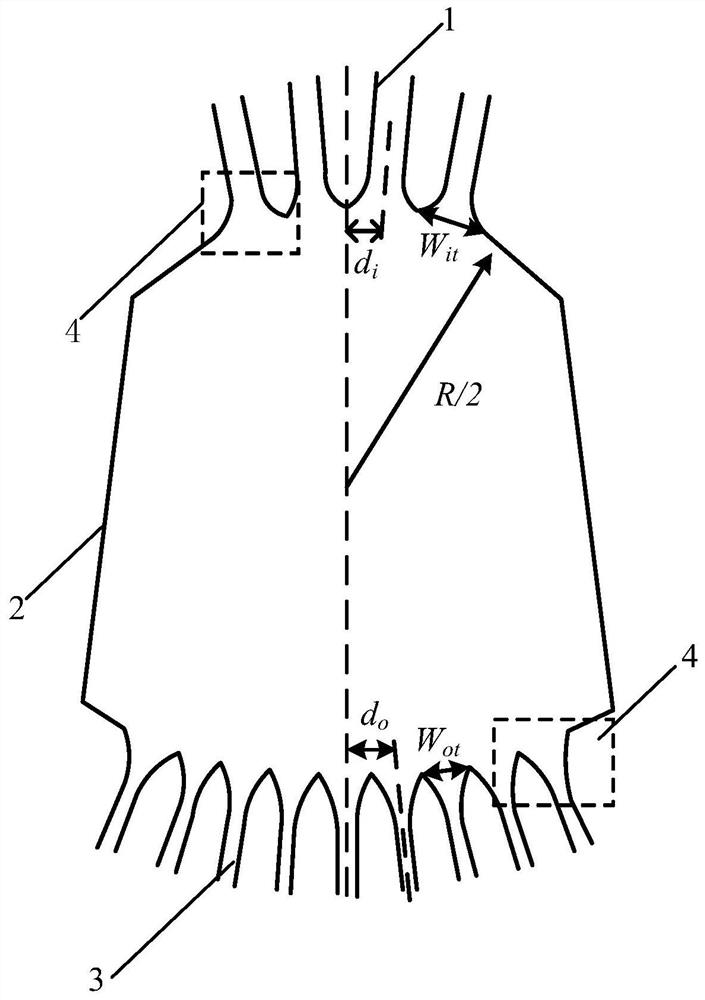

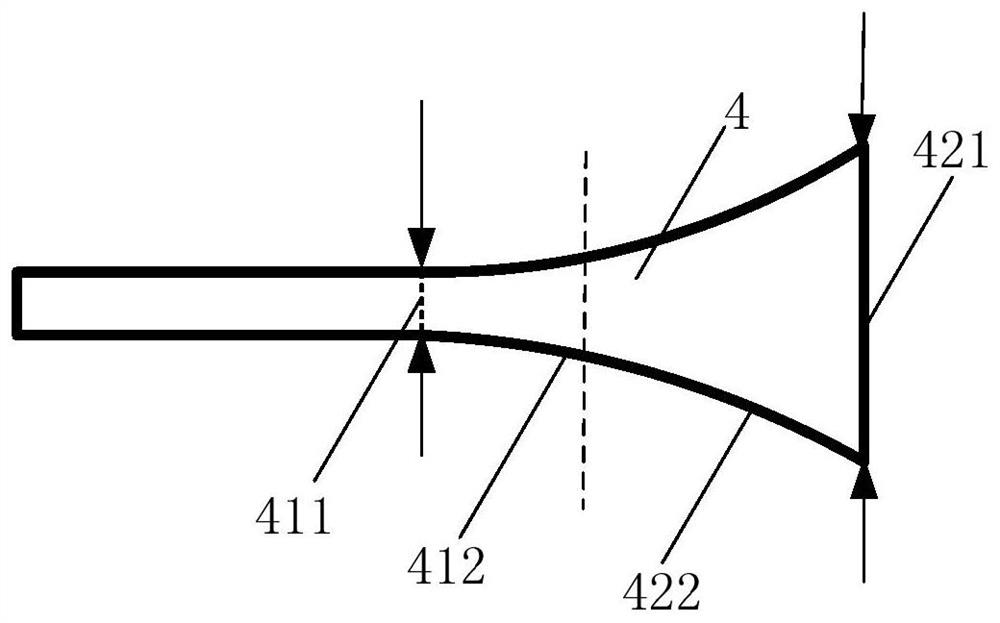

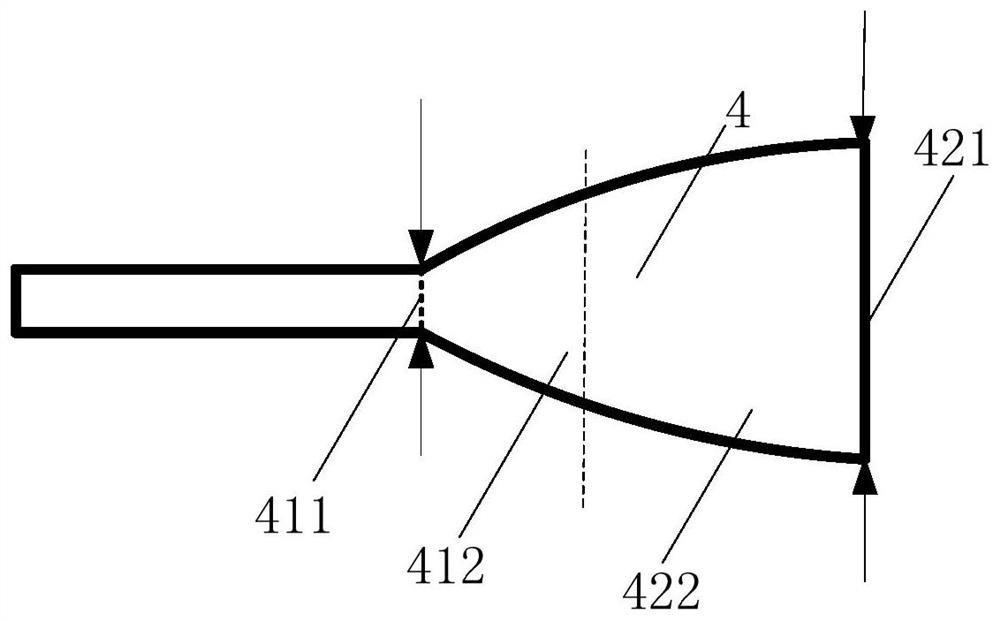

Four-channel silicon-based arrayed waveguide grating wavelength division multiplexer

The embodiment of the invention provides a four-channel silicon-based arrayed waveguide grating wavelength division multiplexer, which is characterized in that the proportion of a smaller part of thewidth of a second end transition section in a transition waveguide in an arrayed waveguide grating to the whole length of the transition waveguide is higher, so that the effective refractive index ischanged more slowly, and the insertion loss of a device can be effectively reduced; the ratio of the width of the first end transition section in the transition waveguide to the whole length of the transition waveguide is reduced to some extent, the effective refractive index of the transition waveguide is not changed greatly, the unnecessary length of the first end transition section can be reduced, the size is reduced, and the loss of the transition waveguide is lower than that of a linear transition mode.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Phase-change thermoregulation microcapsule and preparing method thereof

ActiveCN104001458AImprove performanceImprove thermal conductivityHeat-exchange elementsMicroballoon preparationPhysical chemistryGraphite

The invention provides a phase-change thermoregulation microcapsule and a preparing method of the phase-change thermoregulation microcapsule. A graphite adsorption method is adopted for preparation. The method comprises the steps that firstly, expansible graphite is processed to form wormlike porous graphite; then, a phase-change material is added, wherein the phase-change material is butyl stearate or n-octadecane; adsorption is accomplished by heating; cooling is conducted and a sample is obtained. The prepared microcapsule has good stability performance and has a circulation phase-change behavior within the temperature range between 15 DEG C and 31 DEG C; the performance of the microcapsule is stable within the circulation phase-change zone between 0 DEG C and 50 DEG C. The method is free of volatilized toxicity, facilitates environment protection and is simple in operation and small in number of procedures, direct adsorption is achieved, package is not needed, and the good industrial application value is achieved.

Owner:傅伟

Organic electrolysis solution purification process for lithium ionic cell

ActiveCN101453037AReduce concentrationLittle change in concentrationOrganic electrolyte cellsSecondary cellsElectrolysisPhysical chemistry

The invention provides a method for refining a lithium ion cell organic electrolytic solution. The method comprises a step of contacting a lithium ion exchange resin with an organic electrolytic solution, wherein the lithium ion exchange resin is the lithium ion exchange resin containing a -SO3Li active radical. Regarding the lithium cell organic electrolytic solution to be refined with the same lithium ion concentration of 1 mol / liter, the content of metal ion impurities in the organic electrolytic solution refined by the method of the invention and the prior method are reduced below 8ppm, but after the electrolytic solution is refined by the method of the invention, a lithium ion in the organic electrolytic solution is between 1.0 and 1.02 mol / liter, the lithium ion concentration is not greatly varied with variance ratio of between 0 and 2 percent; while after the electrolytic solution is refined by the prior method, the lithium ion in the organic electrolytic solution is 0.2 mol / liter, the lithium ion concentration is greatly reduced with reducing ratio as high as 80 percent. Therefore, the method of the invention is superior to the prior method.

Owner:BYD CO LTD

Newcastle disease virus double-antibody sandwich AlphaLISA detection kit and detection method thereof

InactiveCN105759046AStrong specificityHigh sensitivityBiological material analysisBiotin-streptavidin complexMicrosphere

The invention provides a Newcastle disease virus double-antibody sandwich AlphaLISA detection kit and a detection method thereof. The detection kit comprises a receptor microballoon coated with a Newcastle disease virus antibody, a biotin labeled Newcastle disease virus antibody and a donor microballoon coated with streptavidin. The detection method comprises the following steps of: successively adding a standard substance or a to-be-detected sample, the receptor microballoon coated with the Newcastle disease virus antibody and the biotin labeled Newcastle disease virus antibody into a porous plate and performing vibration incubation; adding the donor microballoon coated with streptavidin under a light shielding condition and then performing vibration incubation; and detecting a signal value on a AlphaScreen / Lisa detector. The detection kit provided by the invention has high stability and strong specificity. The influence of outside environment on the detection method is small. The detection method has higher sensitivity and specificity, can meet the requirements of high throughput and quick detection and has high popularization and application value.

Owner:CHONGQING UNIV OF TECH

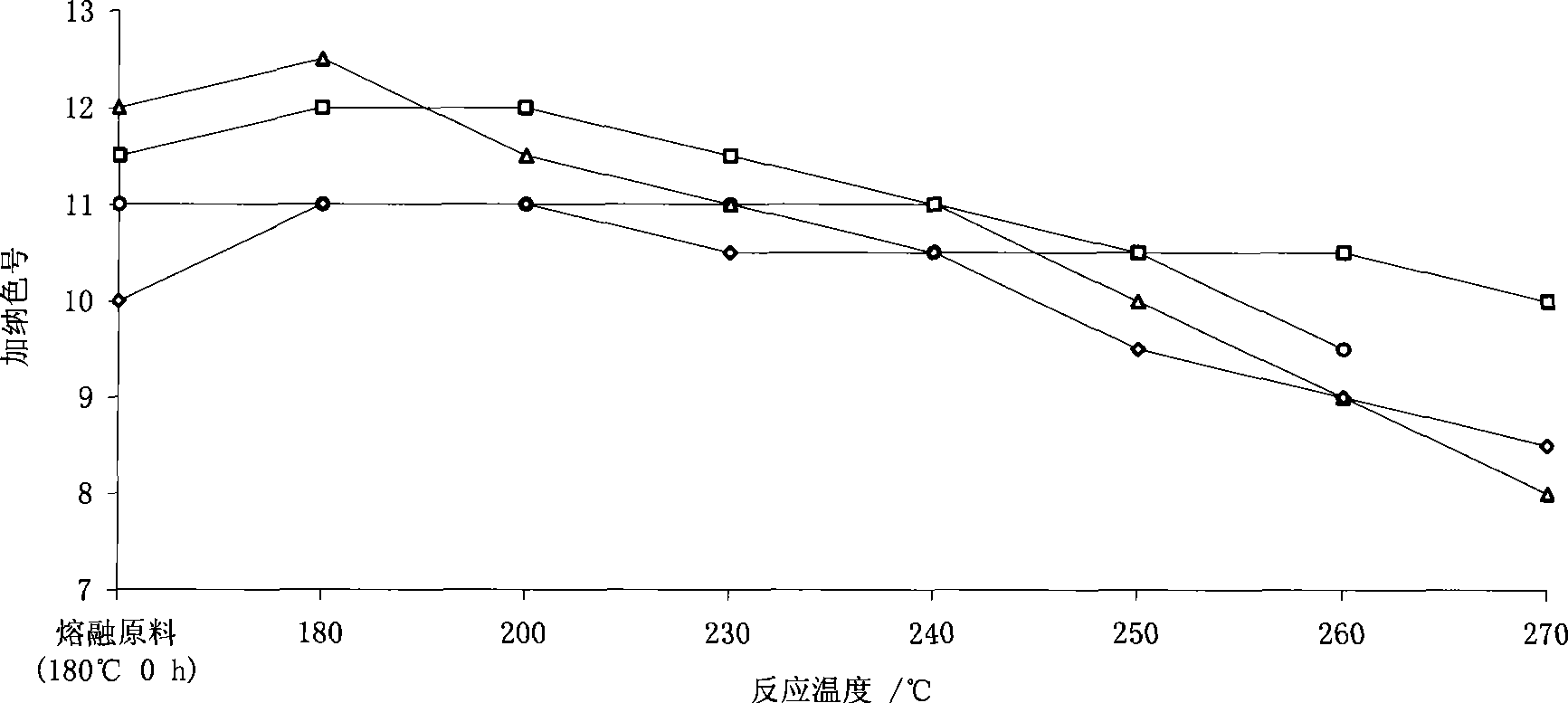

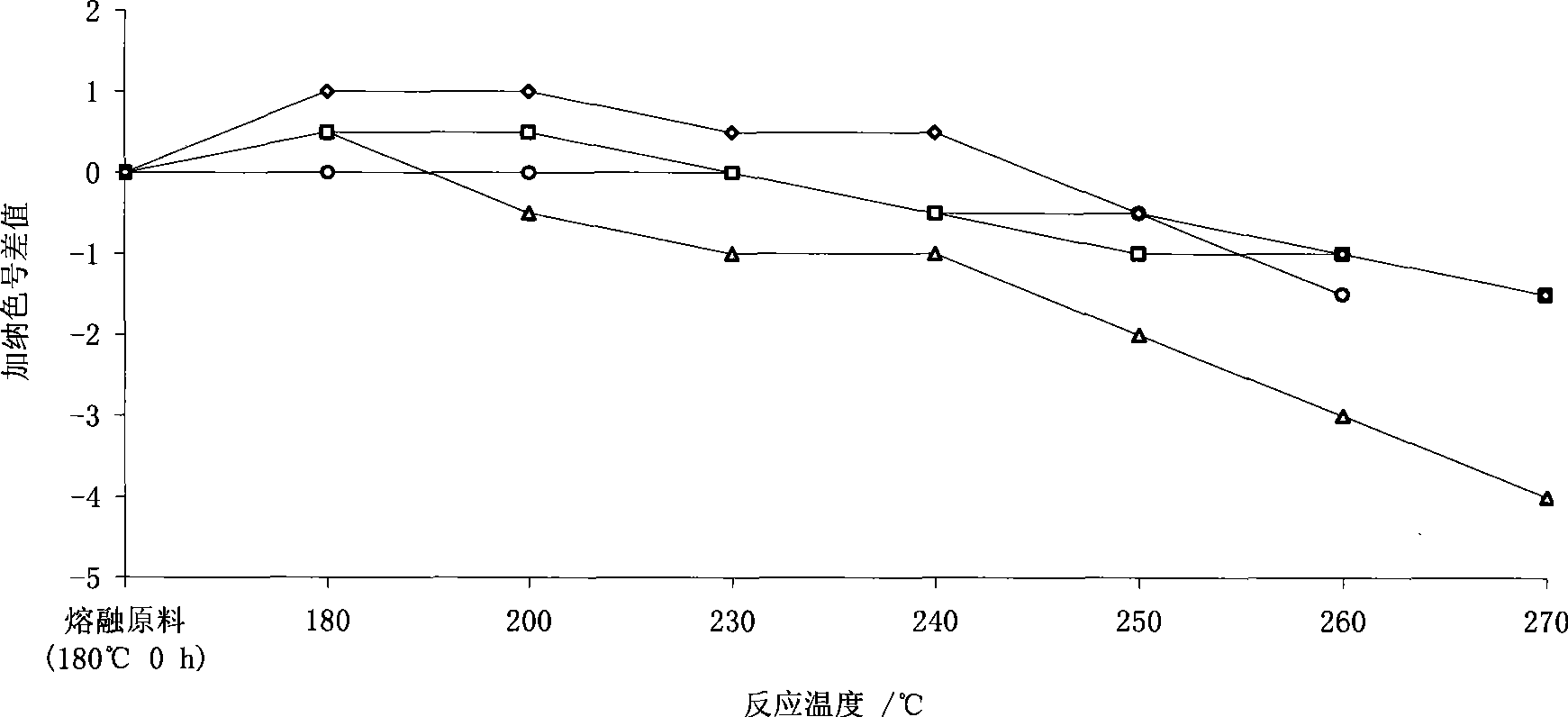

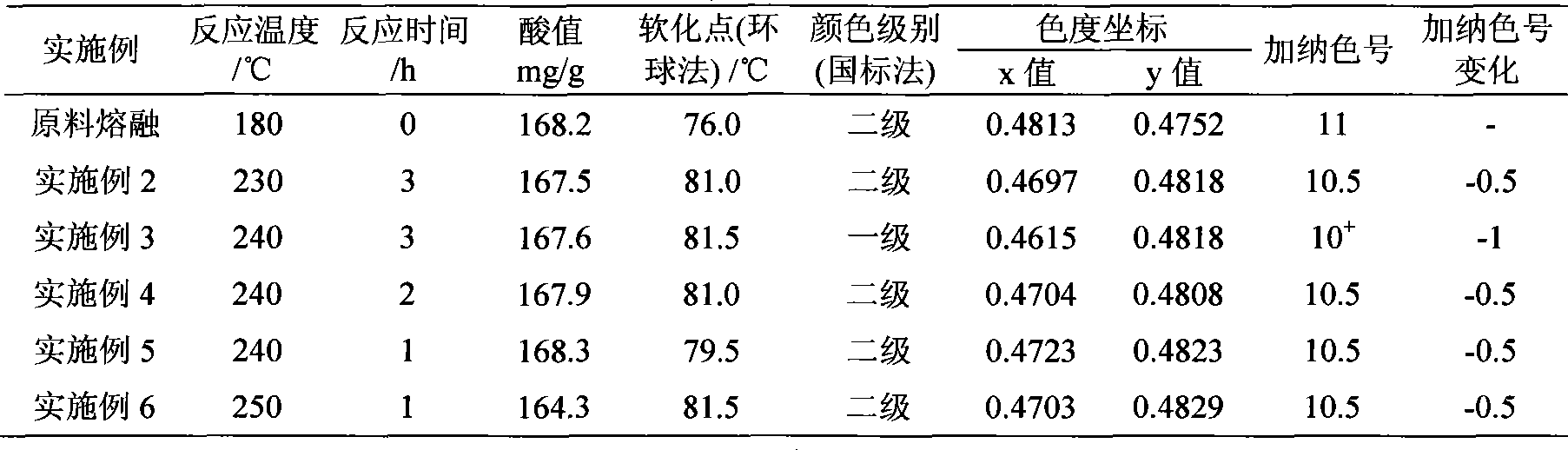

Method for decolorization preparation of pale rosin by rosin containing non-decoloring agent

The invention discloses a method used for preparing light-colored rosin by a rosin light-coloring way without adding decoloring agent, which is mainly characterized in that under the condition without the decoloring agent, colored composition in the rosin is decomposed by a thermo-chemical bleaching action, thus achieving the object of light-coloring decoloring of the rosin; namely, under the condition of protective gases such as nitrogen, and the like, the rosin keeps the temperature for a certain time at the temperature of 180-270 DEG C; after the reaction is finished, the rosin is cooled to the temperature below 180DEG C, and the light-colored rosin can be prepared by feeding. The color of the rosin prepared by the method is better than the raw material rosin; when being presented by Gardner color grade, the color of the product is shallower by 0.5-4 color grade than the initial color; the best color is equivalent to national standard special grade which is gained by lightening from national standard class 4; the light-colored rosin is not needed to be distilled in a high vacuum state, has simple and convenient operation, little energy consumption, low expense and high product yield, and has no adding of external additive composition; the gained light-colored rosin product is beneficial for the deep processing and utilization of the rosin, and is applicable to being directly taken as the raw material of various rosin resins.

Owner:湖南松本林业科技股份有限公司

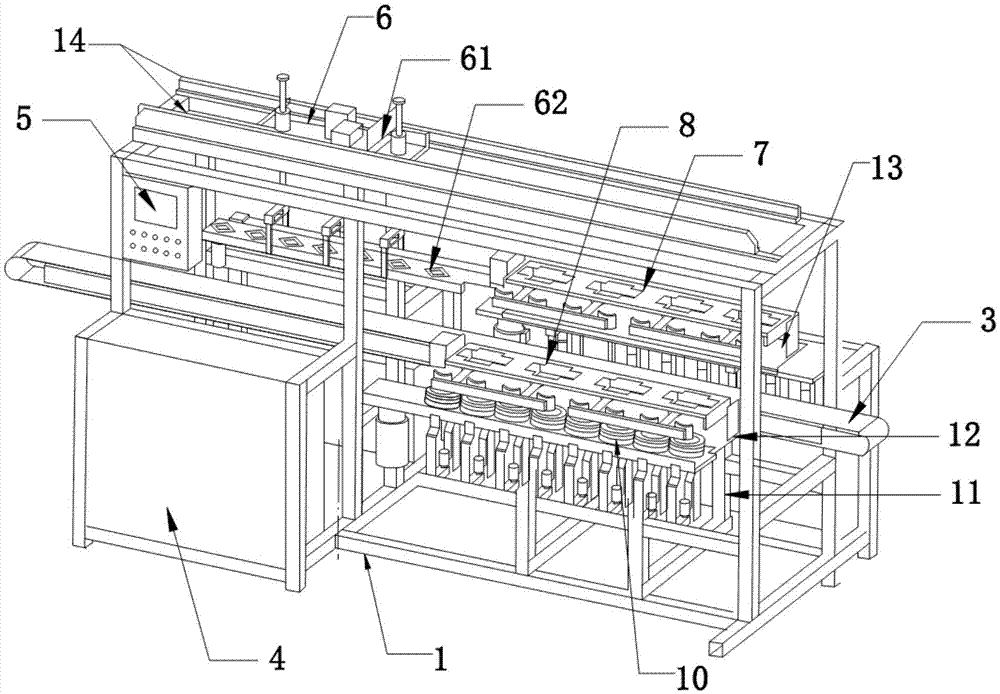

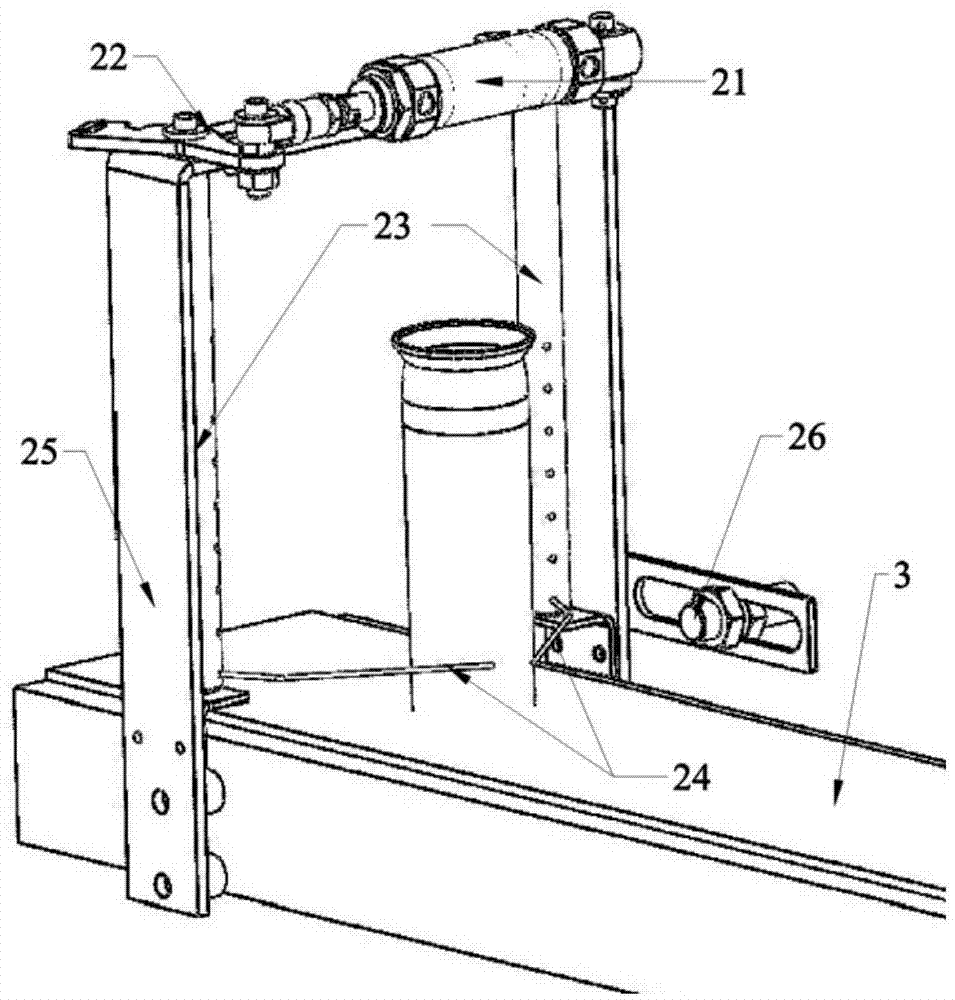

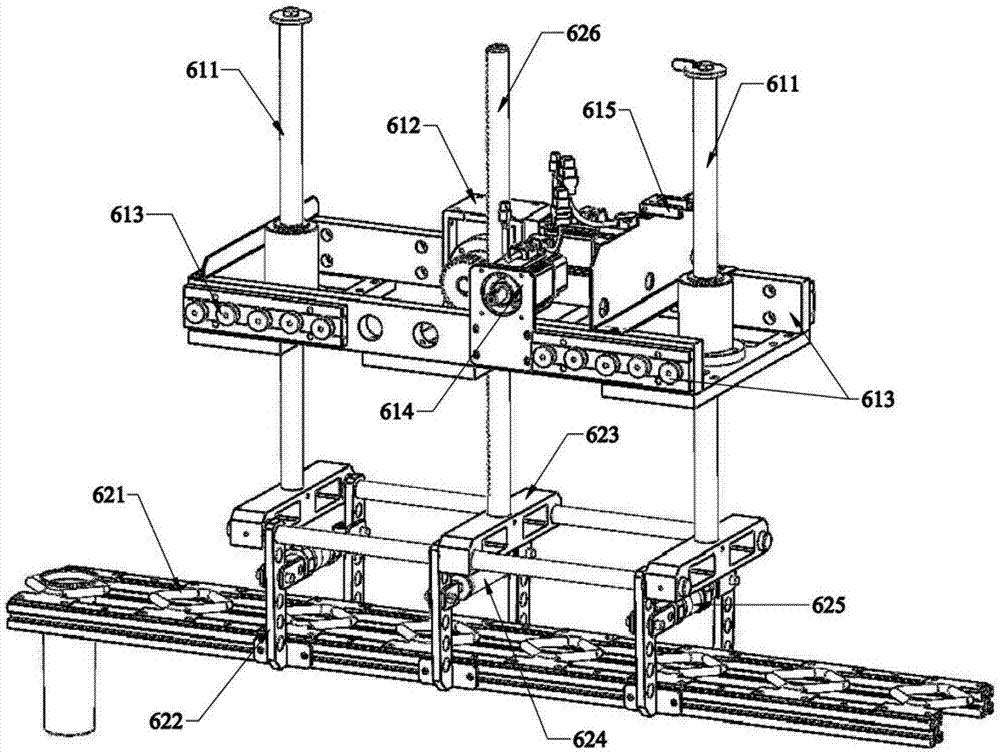

Fully automatic glass cracking-off machine

InactiveCN107021607AConvenient ArrangementAdapt to inhomogeneityGlass productionElectric controlFully automatic

The invention relates to a fully automatic glass cracking-off machine, which comprises a rack, a conveying belt and sliding rails, wherein the middle portion of the rack is provided with the conveying belt, the two sliding rails are arranged on the top portion of the rack, the fully automatic glass cracking-off machine further comprises a cup finishing device, a cup loading mechanical arm, a first cracking-off mechanical arm, a second cracking-off mechanical arm, an electric control box and an operation box, the cup finishing device is arranged on the front end of the rack, the cup loading mechanical arm is positioned behind the cup finishing device, is arranged on the upper portion of the rack through the sliding rail, and is positioned just above the conveying belt, and the first cracking-off mechanical arm and the second cracking-off mechanical arm are symmetrically arranged on both sides of the conveying belt and are positioned behind the cup loading mechanical arm. According to the present invention, the fully automatic glass cracking-off machine integrating the cup finishing device, the cup loading mechanical arm and the cracking-off mechanical arms is provided, the automated cup finishing, cup loading and cracking-off is achieved, the traditional manual operation processing is replaced, the processing quality is stable, the labor intensity is reduced, and the working efficiency is improved.

Owner:TIANJIN YIDIAN TECH

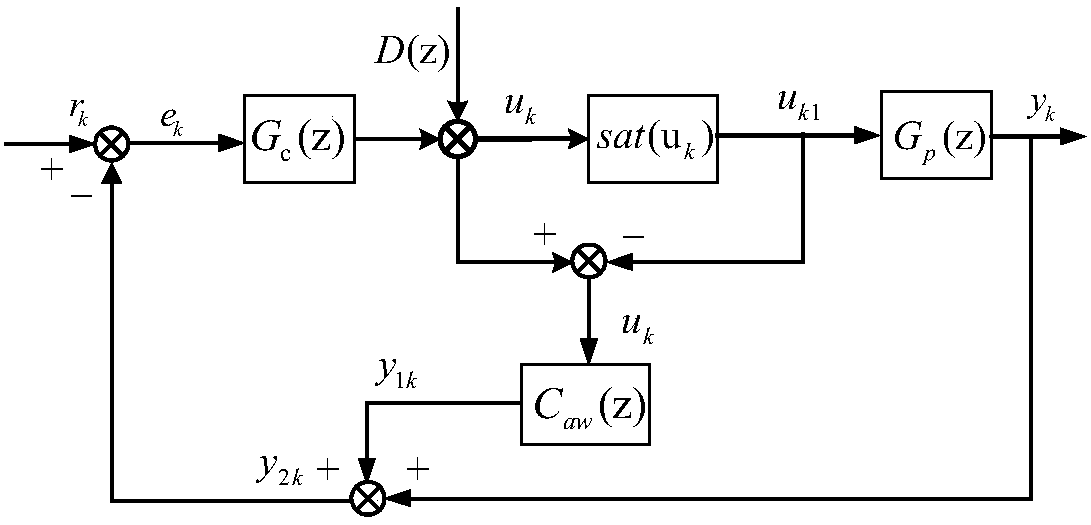

Anti-saturation frequency adaptive resonance control method for active power filter

ActiveCN108039706AAlgorithm structure is simpleHigh harmonic current compensation accuracyActive power filteringAc network to reduce harmonics/ripplesCapacitanceLimiter

The invention discloses an anti-saturation frequency adaptive resonance control method for an active power filter. The method comprises the steps that the three-phase voltage of a common coupling point is acquired, and the voltage frequency fpll and the phase theta are acquired by using a phase-locked loop; a harmonic detection module extracts the harmonic signal command of nolinear load current iL; the harmonic signal command is added with an output active current command acquired through a direct current voltage controller, and then is subtracted from the sum of an output current feedback signal and a compensator output signal to acquire the input error signal of a current controller; the current controller composed of a resonant controller and a PI controller is used to acquire the output control amount; and finally, after the output control amount, the voltage feedforward amount of the common coupling point, and the filter capacitor current feedforward amount through an active damping module are added together, a PWM wave modulation command signal is acquired through a limiter.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

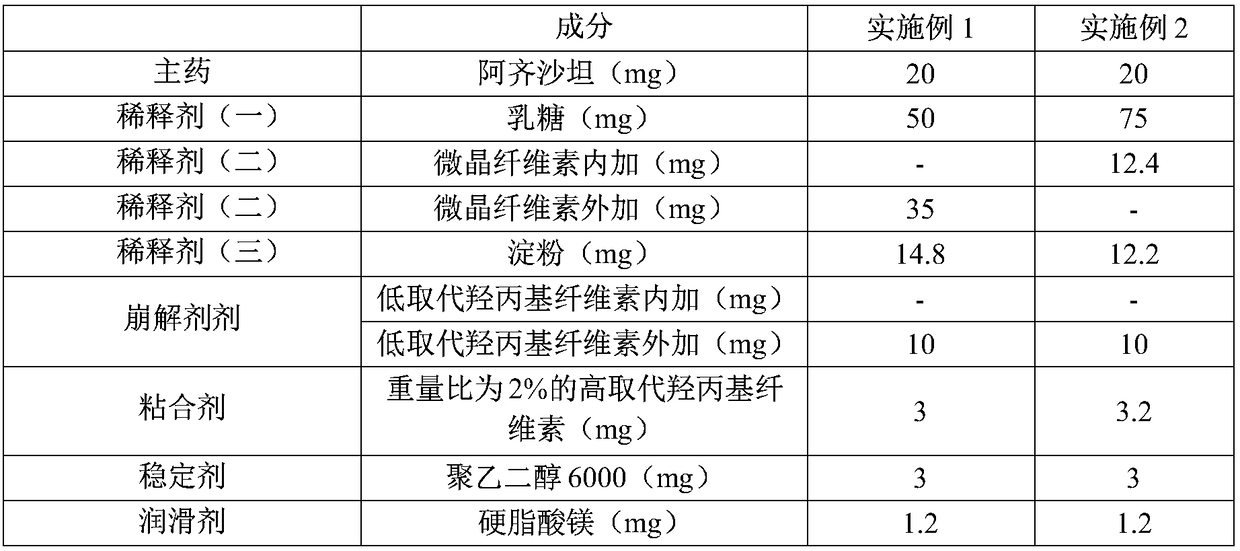

Azilsartan tablet and preparation method thereof

InactiveCN108553433ASmooth appearanceHigh hardnessOrganic active ingredientsPharmaceutical non-active ingredientsHardnessAzilsartan

The invention belongs to the technical field of pharmaceutic preparations, and particularly relates to an azilsartan tablet and a preparation method thereof. The provided azilsartan tablet comprises the following preparation raw materials in percentages by weight: 14-28% of azilsartan, 25-55% of a diluent (I), 8-26% of a diluent (II), 8-12% of a diluent (III), 1-4% of a stabilizer, 4-8% of a disintegrating agent, 0.4-2% of a lubricating agent and 1-3% of a binding agent. The prepared azilsartan tablet is smooth in appearance, good in hardness, small in tablet weight difference and uniform in content, and in-vitro dissolution behaviors of the azilsartan tablet are consistent to those of original drug. Through acceleration tests for six month, single impurity content is 0.14%, the sum of impurity contents is 0.54%, the quality is excellent, the stability is good, the process is simple, and commercialized production is facilitated.

Owner:YANGZIJIANG PHARMA GROUP SHANGHAI HAINI PHARMA

Pressure-controlling method of sterilizing kettle in sterilization cooling stage

The invention discloses a sterilizing method by adopting a sterilizing kettle, particularly to pressure-controlling method of a sterilizing kettle in sterilization cooling stage, which comprises the following steps of: introducing high-pressure air into the sterilizing tank until the pressure therein reaches the initial value; introducing cooling water into the sterilizing tank until the water level therein reaches the set value; introducing compressed air into the sterilizing tank continuously, opening a circulation pump at intervals according to the pressure in the sterilizing tank, wherein when the pressure in the sterilizing tank is greater than the set value, the circulation pump is opened, and when the pressure in the sterilizing tank is less than the set value, the circulation pump is stopped; when the cooling process is completed, emptying the cooling water, and reducing the sterilizing pressure in the tank to atmospheric pressure. By continuously air-intaking and opening, the pressure in the sterilizing tank can be continuously compensated; the circulation pump is opened at intervals according to the pressure in the sterilizing tank, the cooling operation can be conducted in the premise of ensuring the pressure in the tank, therefore great pressure drop occuring at the moment when the pump is opened for intruductino fo the cooling water and in the temperature dropping process can be effectively prevented. The method can be suitable for the sterilization operations of cans, flexible packages and other types of packaged food.

Owner:CHENGDU XIWANG FOOD

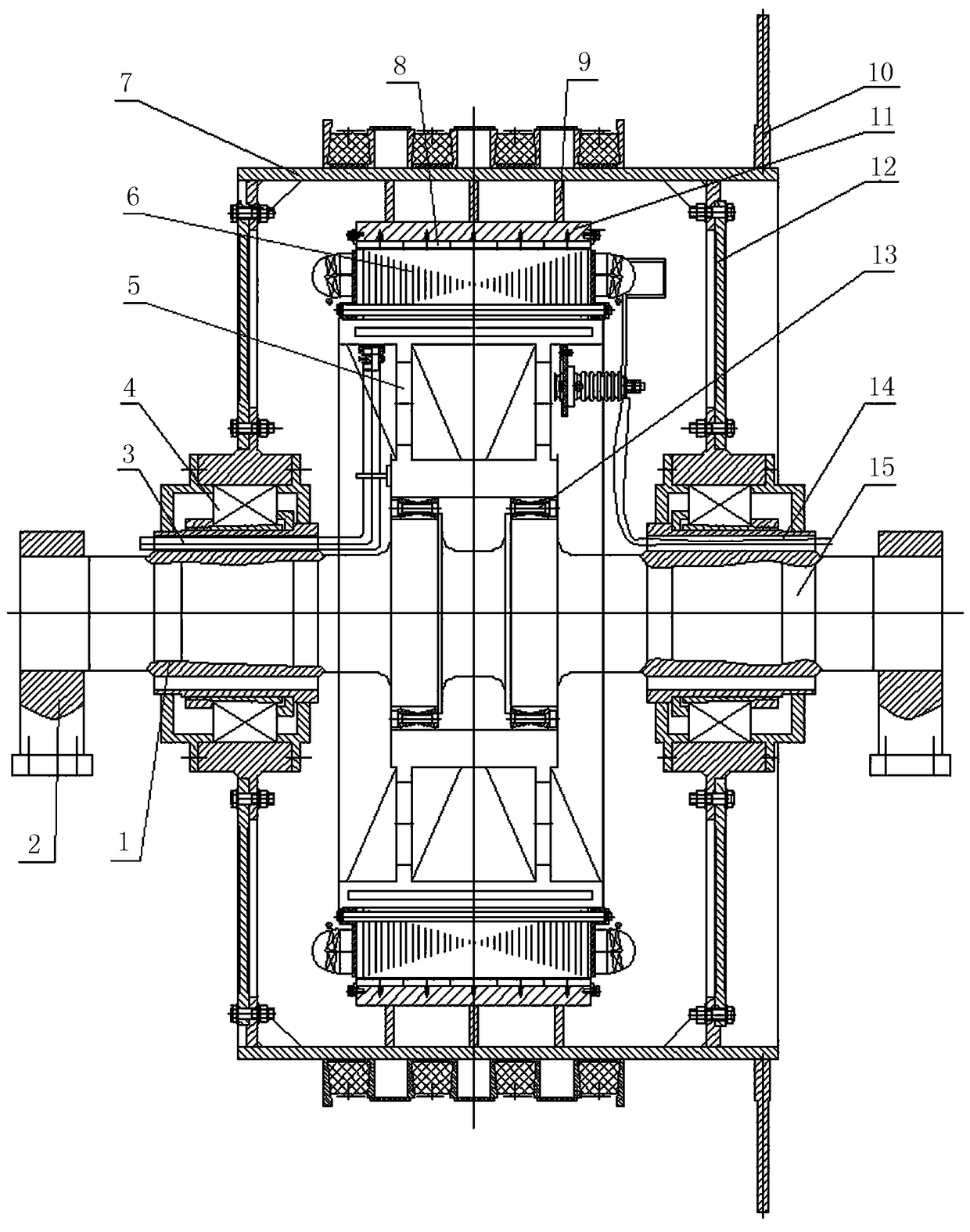

Permanent magnet direct-driven internally-mounted-type elevator

InactiveCN108313857AStructural Design ImplementationSave construction areaMine liftsElectricityPower factor

The invention relates to the field of mine elevators, in particular to a permanent magnet direct-driven internally-mounted-type elevator. The permanent magnet direct-driven internally-mounted-type elevator comprises a spindle and a winding drum rotatably arranged on the spindle. A stator coil is fixedly arranged on the position, corresponding to the winding drum, of the spindle along the outer circumference of the spindle, a permanent magnet used for being matched with the stator coil is arranged on the inner wall of the winding drum along the inner circumference of the winding drum, and the outer circumference of the winding drum is used for coiling of a steel wire rope of the elevator. The permanent magnet direct-driven internally-mounted-type elevator has the advantages that the efficiency is high, energy and electricity saving are achieved, the power factor is high, the motor structure is simple, reliability is high, the size is small, the power density is high, the starting torqueis large, noise is small, and the temperature is low.

Owner:CITIC HEAVY INDUSTRIES CO LTD

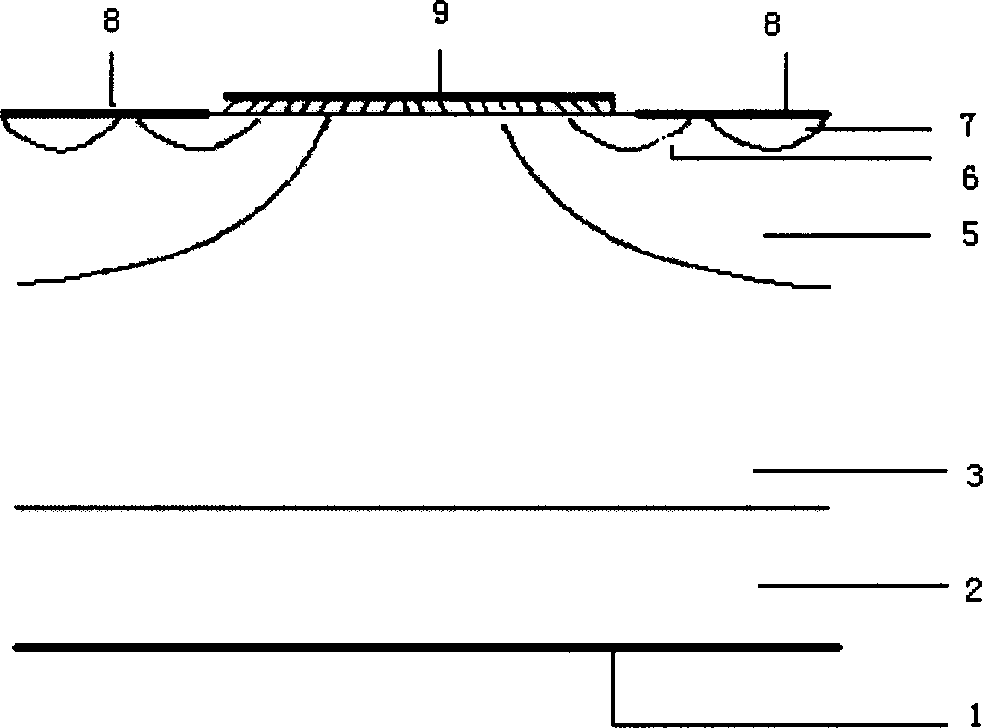

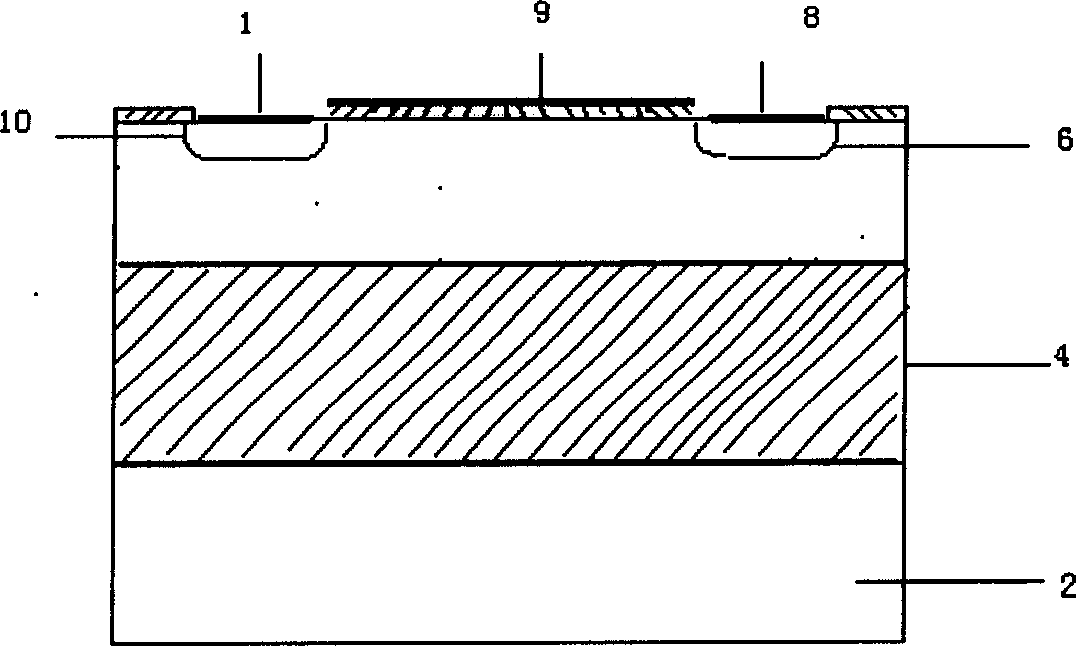

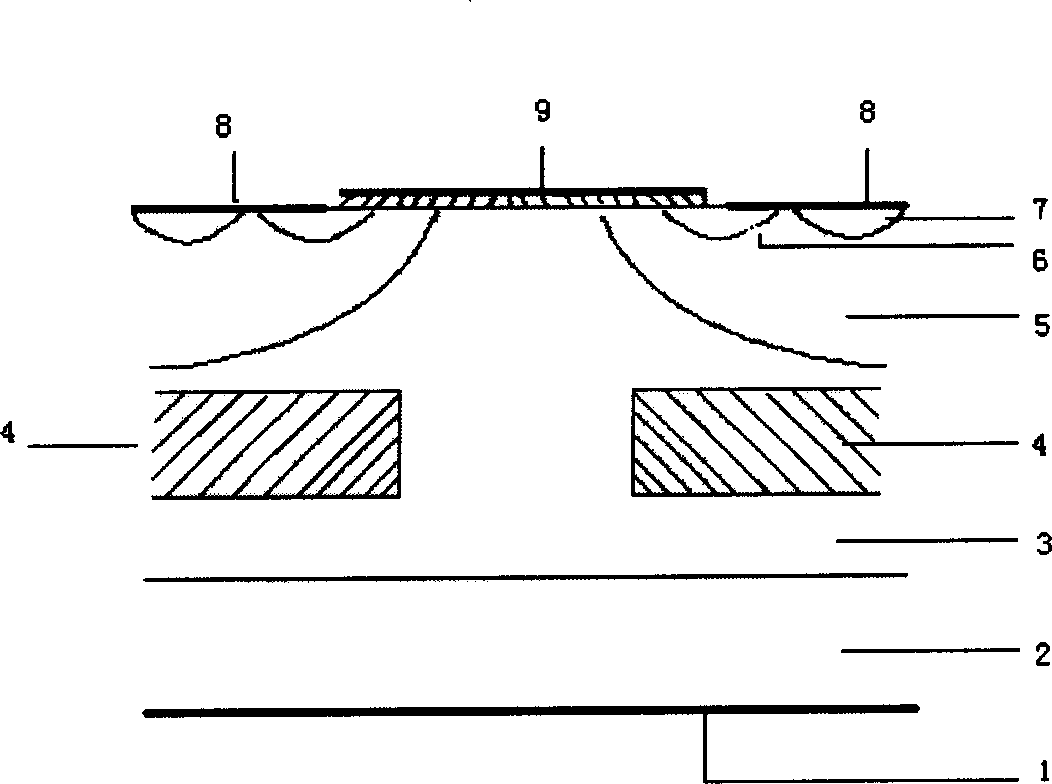

Vertical double diffusion metal oxide semiconductor power device

InactiveCN1822396AImprove radiation resistanceImprove pressure resistanceSemiconductor devicesDouble diffusionOxygen

A vertical double diffusion MOS power device belongs to semiconductor power device technology field. Present invention leads in part oxygen burying zone located both sides of device main vertical electrically conductive paths, said oxygen burying zone capable of being done on epitaxial layer, or simultaneously occupying substrate and part area of epitaxial layer, or simultaneously occupying epitaxial layer and P / N zone part area, also occupying simultaneously substrate, epitaxial layer and P / N zone part area, its shape capable of being rectangular, trapezia and ellipse etc, made from silicon dioxide or silicon nitride etc insulating material. Present invention raises voltage withstand and anti irradiation ability through part oxygen burying structure provided high voltage withstand, high electronic-hole pair recombination compound channel. Compared with traditional vertical DMOS, under same conduction resistance, said invention raises voltage withstand by more than 20 per cent, transient state irradiation ability by more than two times, and single particle fault threshold by almost one times. Present invention can make different kinds of high-speed vertical DMOS device with fine anti irradiation and high voltage performance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Immobilization treatment method of liquid-state polycarboxylate superplasticizer

The invention discloses an immobilization treatment method of liquid-state polycarboxylate superplasticizer, and belongs to the technical field of preparation and application of solid polycarboxylate superplasticizer. The method includes steps of evenly mixing mineral slag with liquid-state polycarboxylate superplasticizer; performing low-temperature drying treatment to preliminarily remove moisture in the liquid water reducer; then drying the evenly blended water reducer-mineral slag mixture; completely removing moisture in the liquid-state polycarboxylate superplasticizer; obtaining the solid water reducer product. After immobilization treatment on the liquid-state polycarboxylate superplasticizer, the water reducing rate is 34-38%; the compressive strength of concrete for 28d prepared by the treated polycarboxylate superplasticizer is 57.9 MPa above, thus every performance of original liquid-state polycarboxylate superplasticizer is not influenced; the method is advantageous of being simple in operation and convenient to practice. The method applies the mineral slag which is the one of industrial 'three wastes'; the raw material is easy to obtain, the cost is low; besides, the method is energy-saving and environmental-friendly, and complies with the green sustainable development principle vigorously advocated by our country.

Owner:山西奥瑞特建材科技有限公司

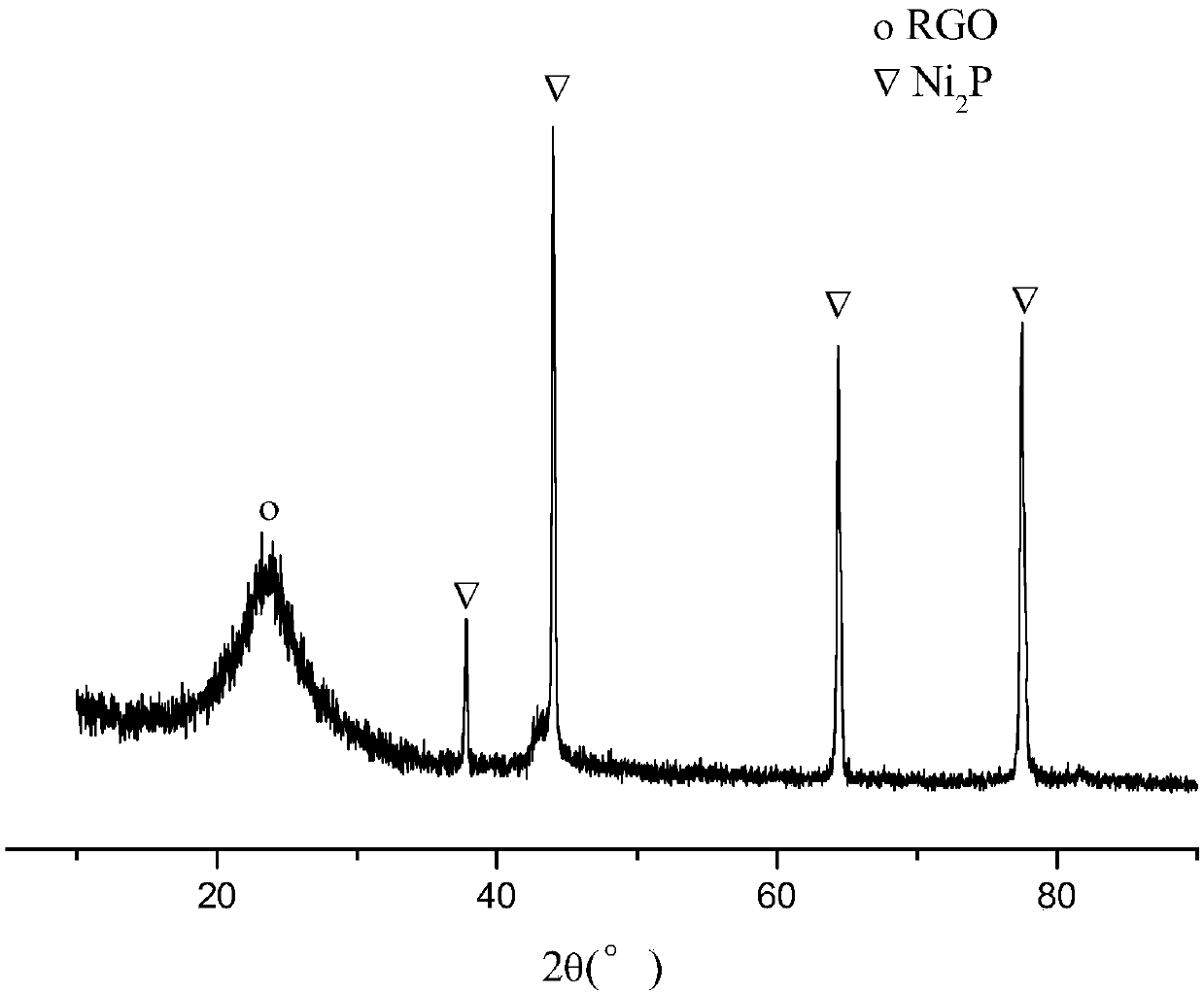

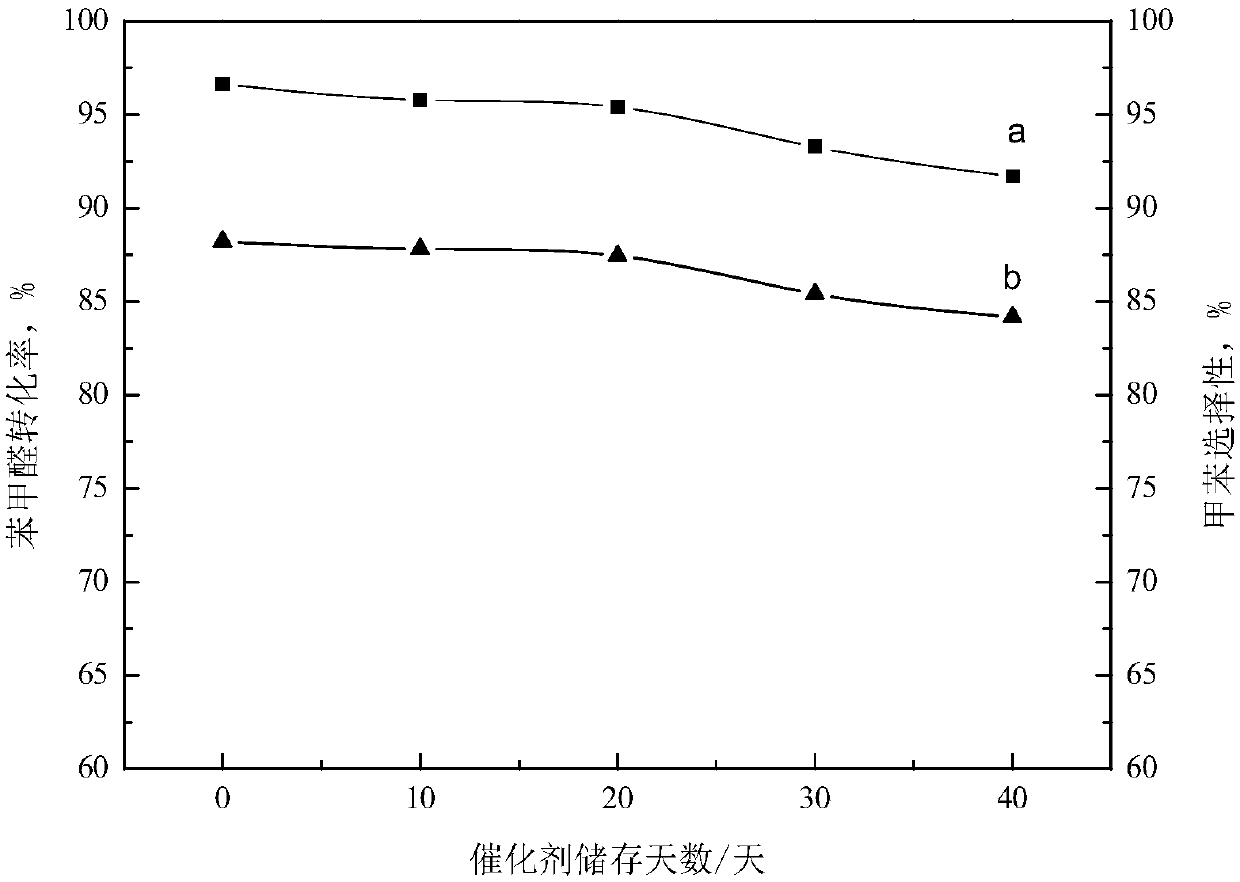

Ni2P/reduced graphene oxide catalyst for hydrodeoxygenation reaction of bio-oils and preparation method thereof

ActiveCN108671947AMild preparation conditionsIncrease surface areaPhysical/chemical process catalystsLiquid hydrocarbon mixture productionBenzaldehydeActive component

The invention discloses a Ni2P / reduced graphene oxide catalyst for hydrodeoxygenation reaction of bio-oils and a preparation method thereof. Reduced graphene oxide is used as a carrier, an active component Ni2P is loaded, and based on a catalyst, the load capacity of Ni2P is 10% to 25%. The preparation condition of the catalyst is relatively mild, and the catalyst is applied to the reaction systemfor preparing toluene by hydrodeoxygenation of benzaldehyde; the conversion rate of benzaldehyde reaches 96% or above, the selectivity of toluene is close to 90%, the catalyst activity is good, the selectivity is high, and the stability is good; the cost is much lower than the cost of precious metal catalysts, and the catalyst has very significant application value.

Owner:XI'AN PETROLEUM UNIVERSITY

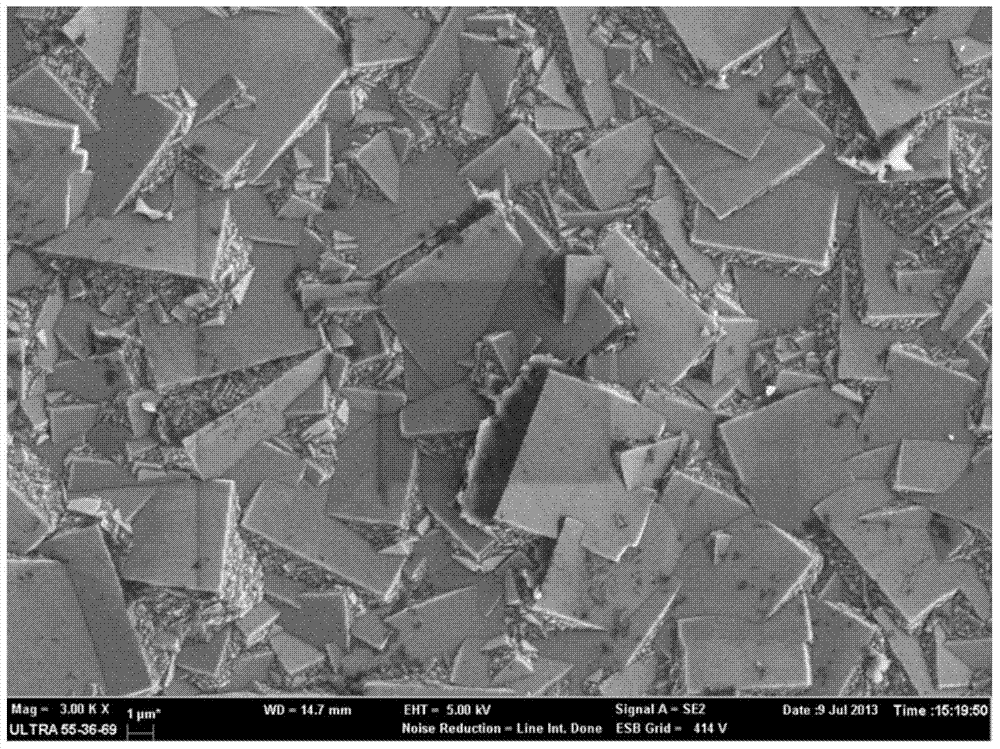

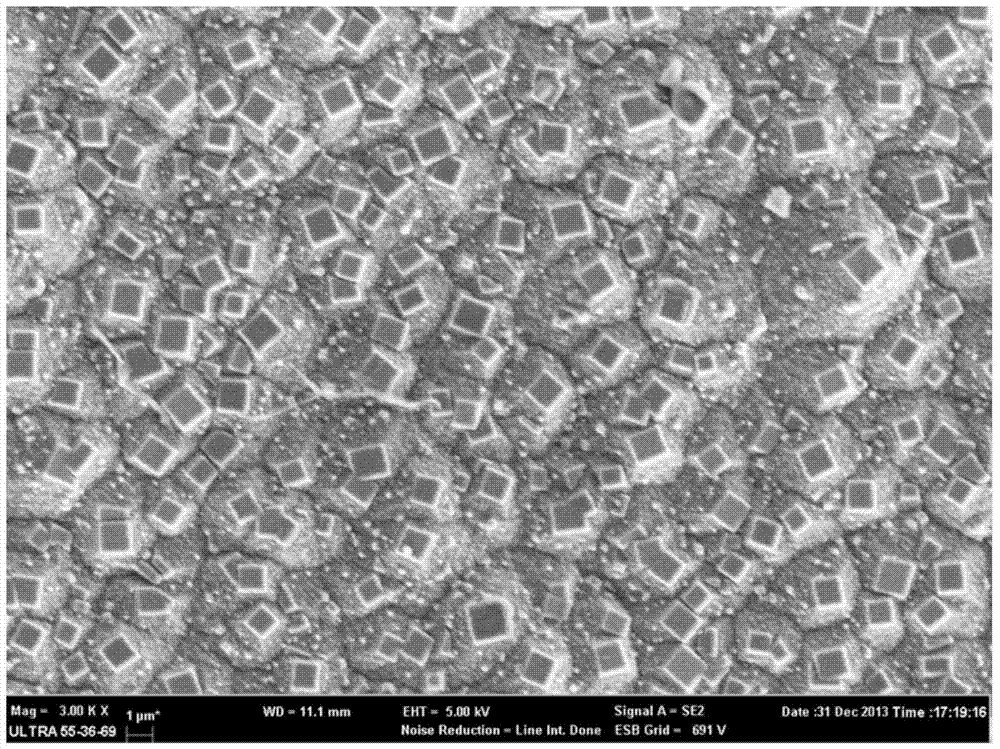

Preparation method of boron-nitrogen co-doped nano-based oriented diamond film

ActiveCN103938182ASimple preparation processUniform wear resistanceChemical vapor deposition coatingPolymer scienceHydrogen

The invention discloses a preparation method of a boron-nitrogen co-doped nano-based an oriented diamond film. The preparation method comprises the following steps: by taking a heater CVD (Chemical Vapor Deposition) device as deposition equipment, adding boron-nitrogen-containing compounds into a conventional hydrogen and acetone reaction system to form a co-doped system; adjusting the reaction technical parameters; preparing the film where diamond particle particles and oriented diamond particles co-exist. The method is simple in process flow. The obtained film has the characteristics that the film has the surface which is leveler than a randomly oriented micron order diamond film, high and uniform wear resistance, easiness in polishing, low internal stress, high adhesive force of the film base and the like.

Owner:SHANGHAI JIAO TONG UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com