Patents

Literature

45results about How to "Structural Design Implementation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

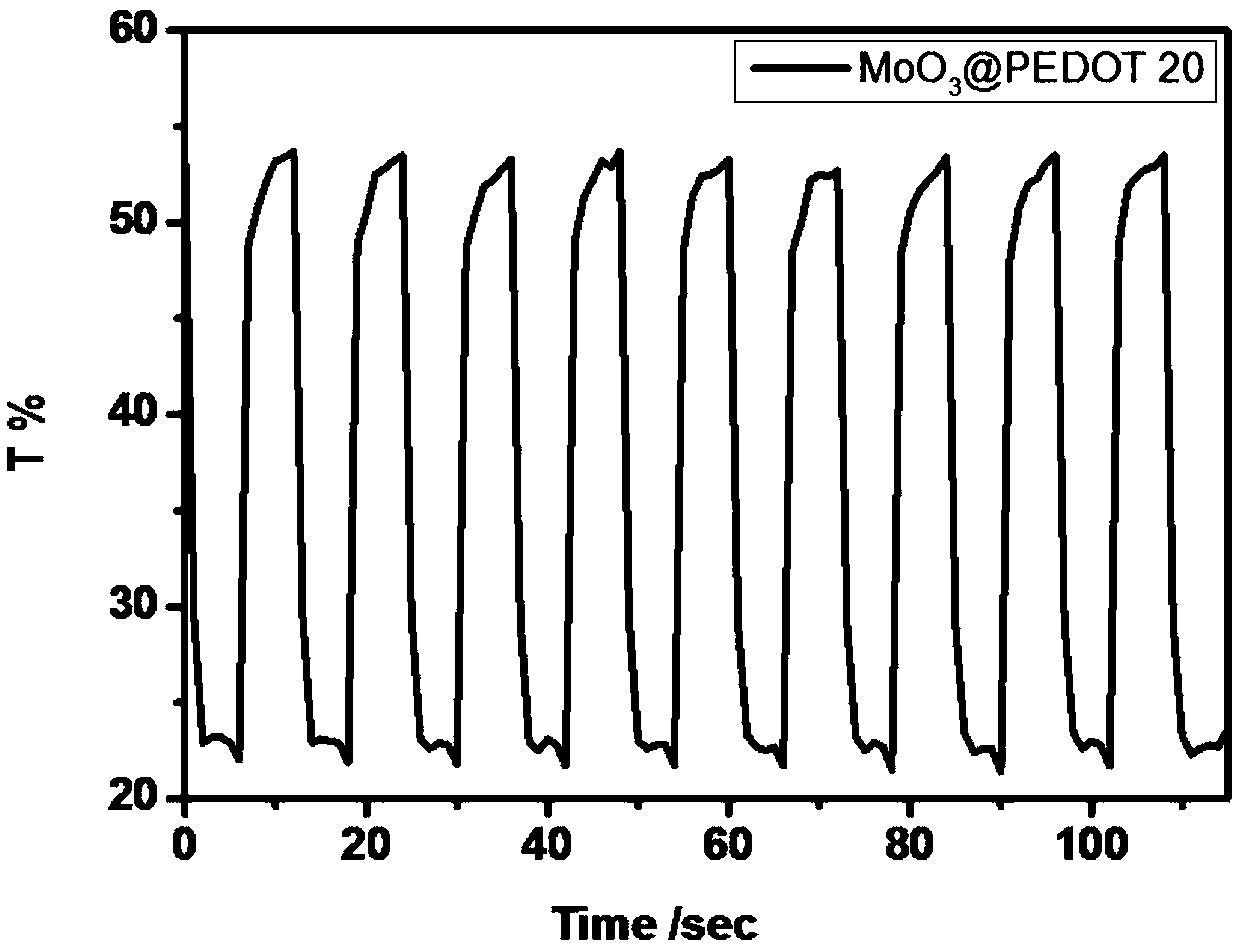

MoO3@PEDOT composite material, preparation method and applications thereof

ActiveCN110894343AStructural Design ImplementationImprove material performanceNon-linear opticsMicro nanoComposite film

The invention discloses a MoO3@PEDOT composite material, a preparation method and applications thereof, wherein the MoO3@PEDOT composite material comprises a MoO3 nanobelt and PEDOT coating the surface of the MoO3 nanobelt. The preparation method comprises the following steps: synthesizing a MoO3 nanobelt, and then polymerizing PEDOT on the surface of the MoO3 nanobelt by adopting an in-situ chemical oxidation reduction method to obtain the MoO3@PEDOT composite material with a coaxial nanobelt structure. The application of the composite material in the field of electrochromism is that a MoO3@PEDOT compound suspension is prepared, then MoO3@PEDOT composite films with different thicknesses are prepared by utilizing a film forming method, and the electrochromism performances of the MoO3@PEDOTcomposite films are researched. According to the material, the compounding of organic and inorganic electrochromic materials on a micro-nano level is realized, and a convenient channel can be provided for ion or electron transmission by utilizing the orderliness of a one-dimensional nanobelt, so that a film prepared from the material has good electrochromic performance, and has wide application prospects in the fields of intelligent windows, anti-glare glasses and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

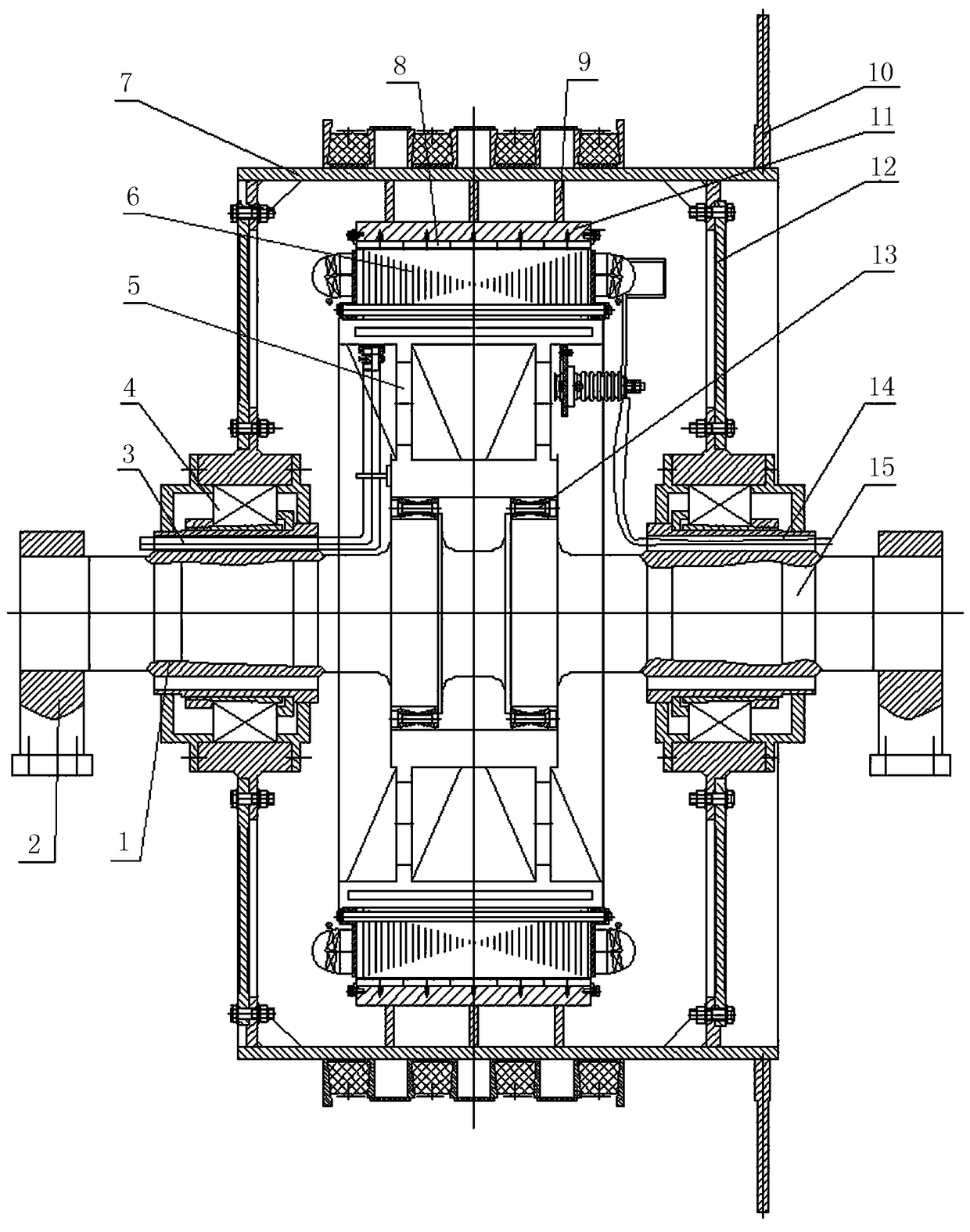

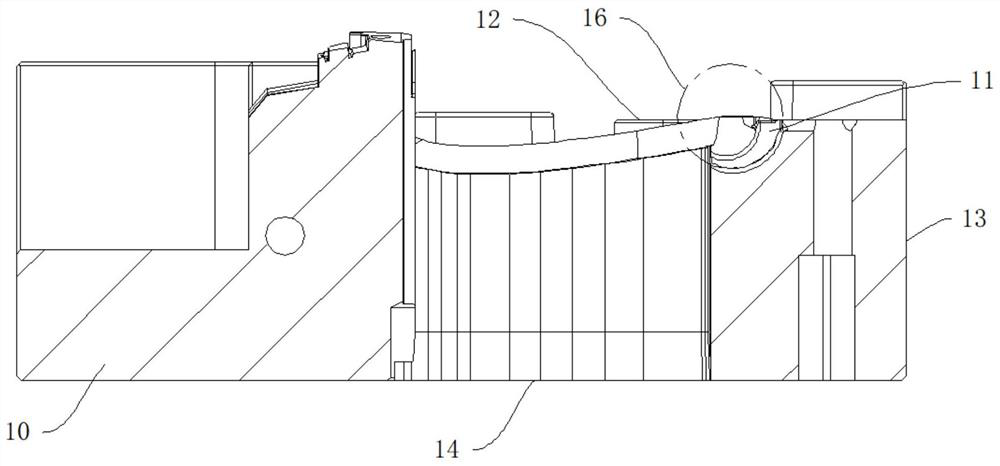

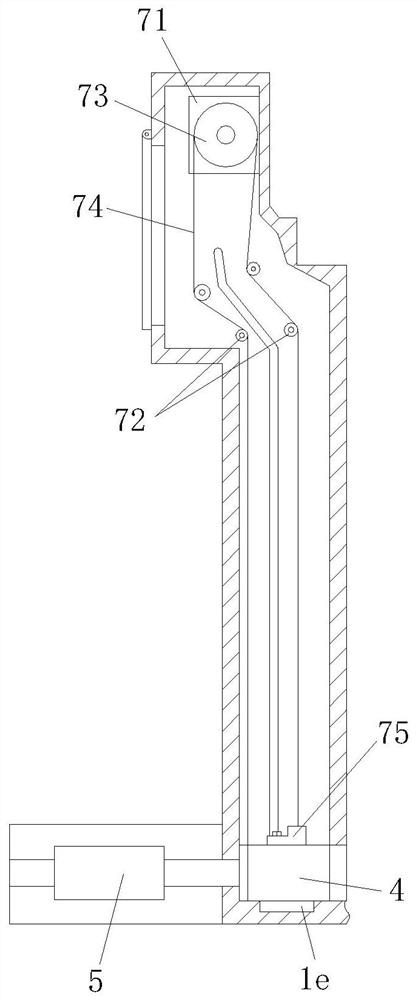

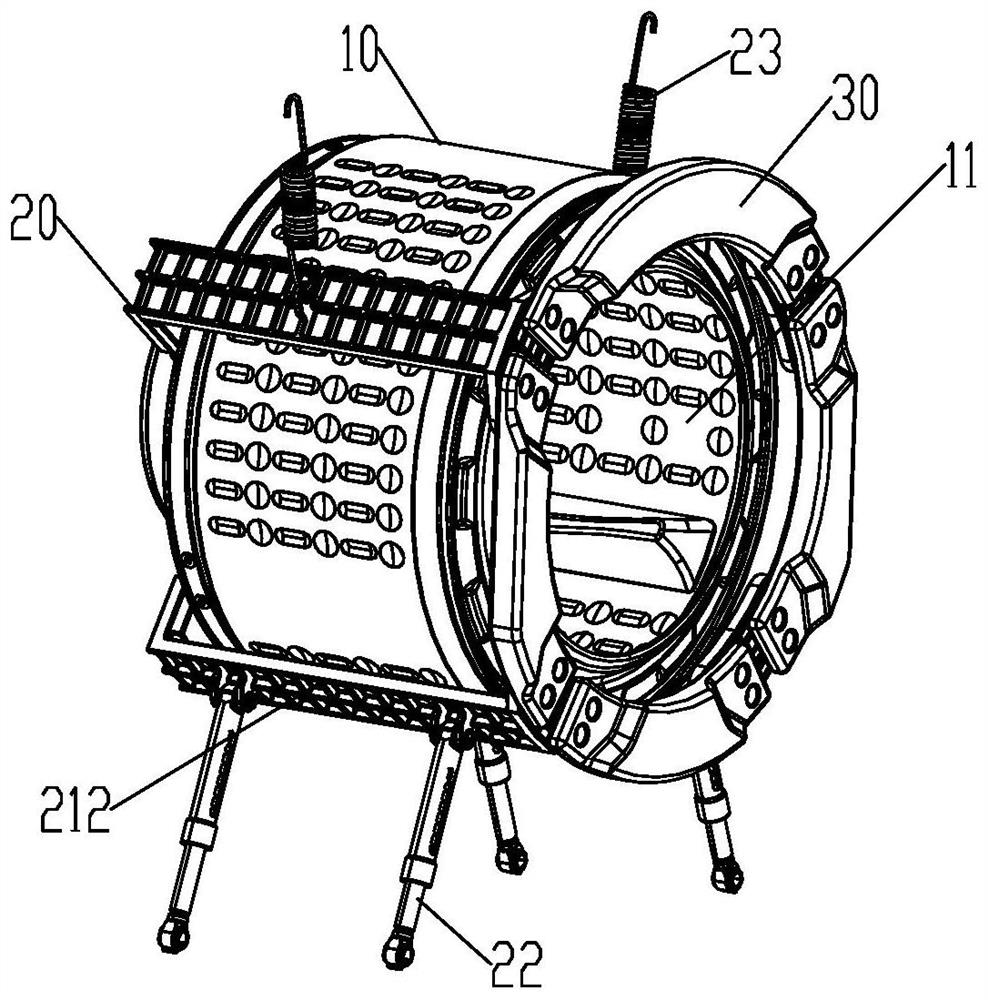

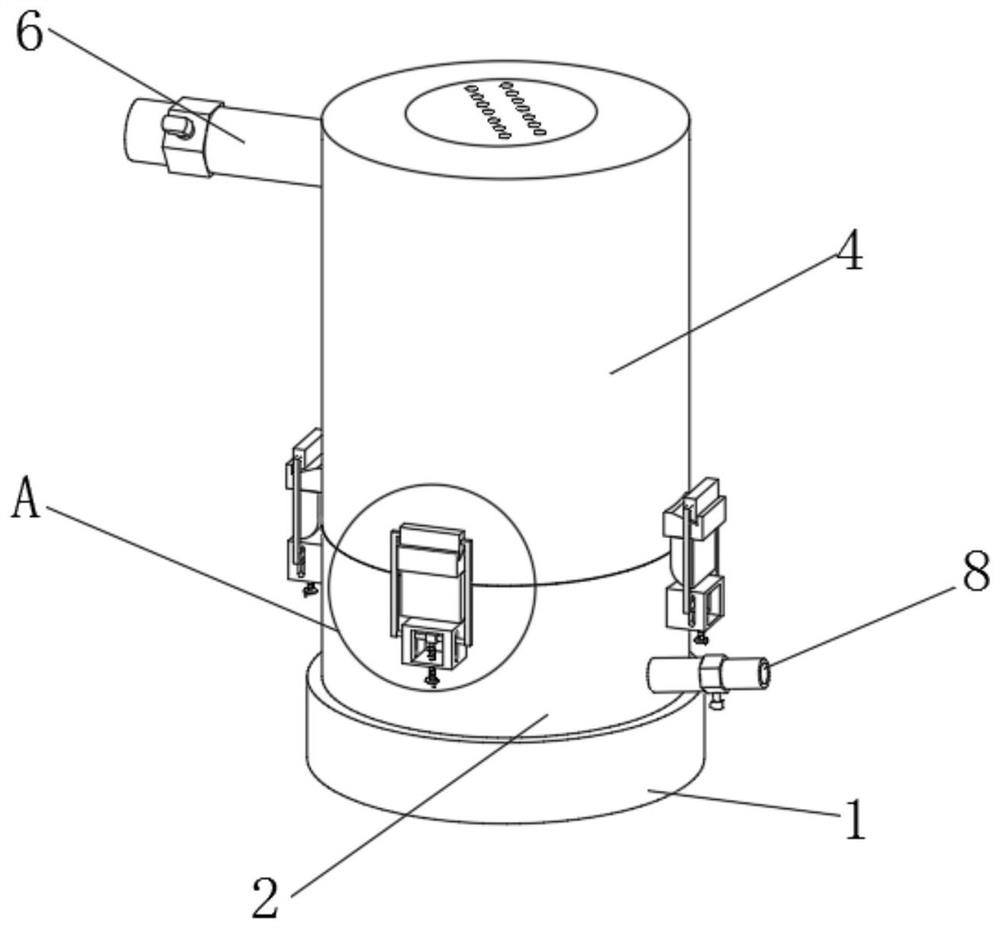

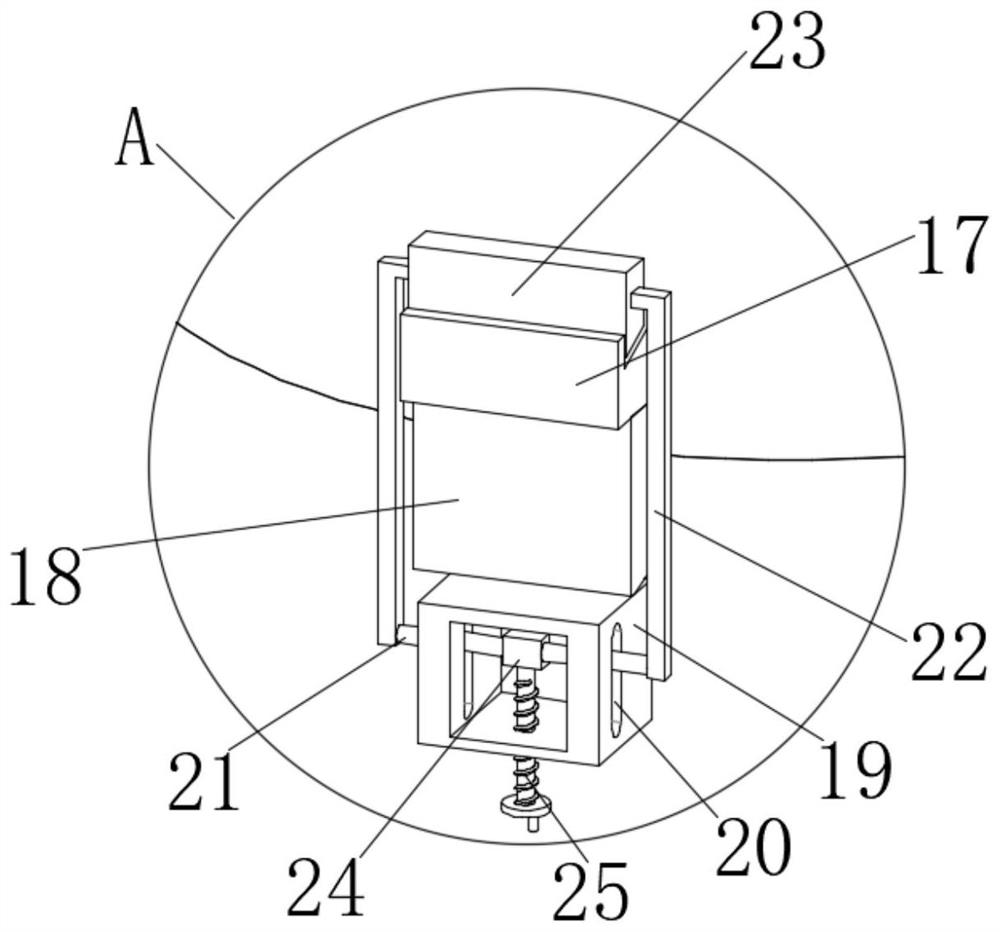

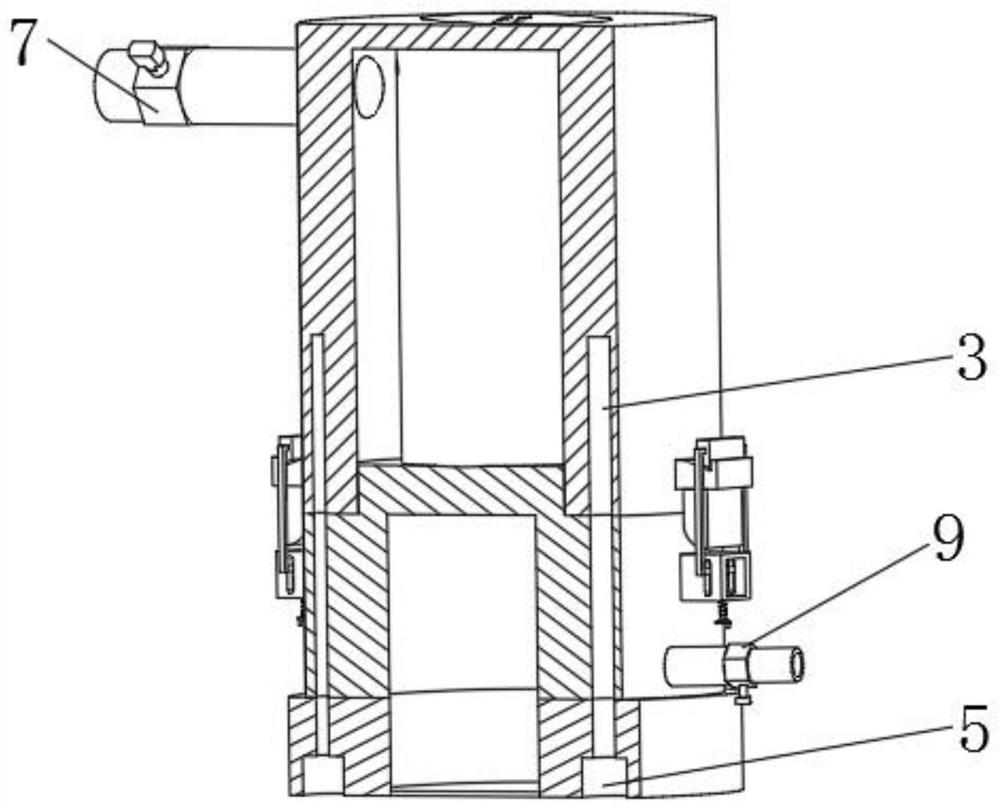

Permanent magnet direct-driven internally-mounted-type elevator

InactiveCN108313857AStructural Design ImplementationSave construction areaMine liftsElectricityPower factor

The invention relates to the field of mine elevators, in particular to a permanent magnet direct-driven internally-mounted-type elevator. The permanent magnet direct-driven internally-mounted-type elevator comprises a spindle and a winding drum rotatably arranged on the spindle. A stator coil is fixedly arranged on the position, corresponding to the winding drum, of the spindle along the outer circumference of the spindle, a permanent magnet used for being matched with the stator coil is arranged on the inner wall of the winding drum along the inner circumference of the winding drum, and the outer circumference of the winding drum is used for coiling of a steel wire rope of the elevator. The permanent magnet direct-driven internally-mounted-type elevator has the advantages that the efficiency is high, energy and electricity saving are achieved, the power factor is high, the motor structure is simple, reliability is high, the size is small, the power density is high, the starting torqueis large, noise is small, and the temperature is low.

Owner:CITIC HEAVY INDUSTRIES CO LTD

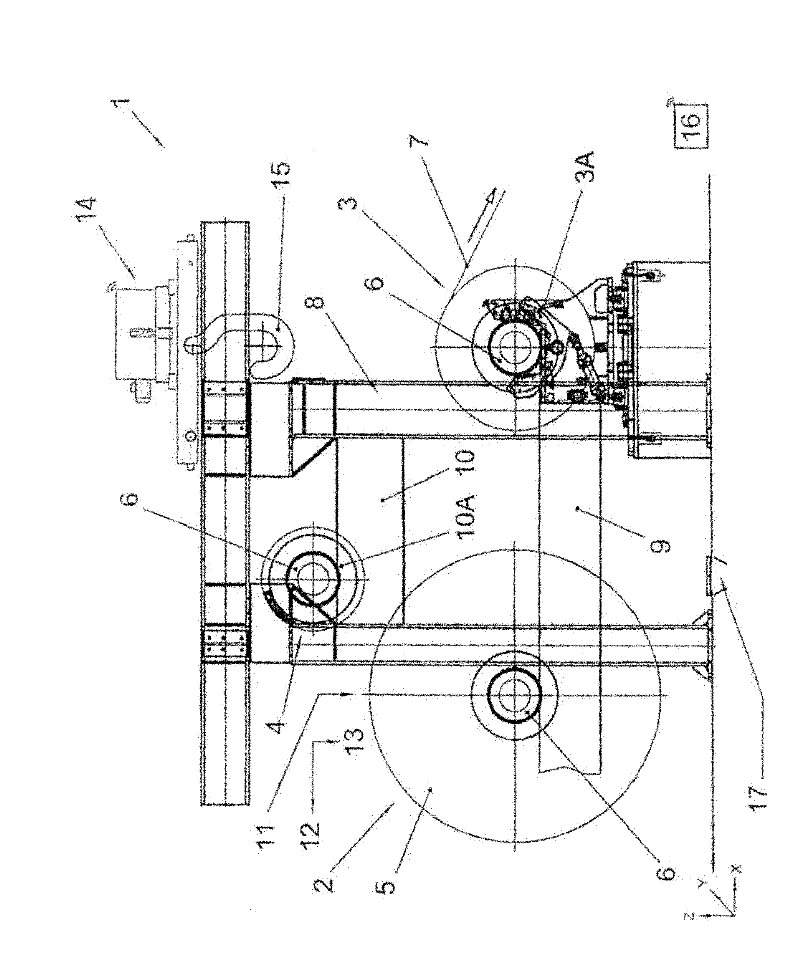

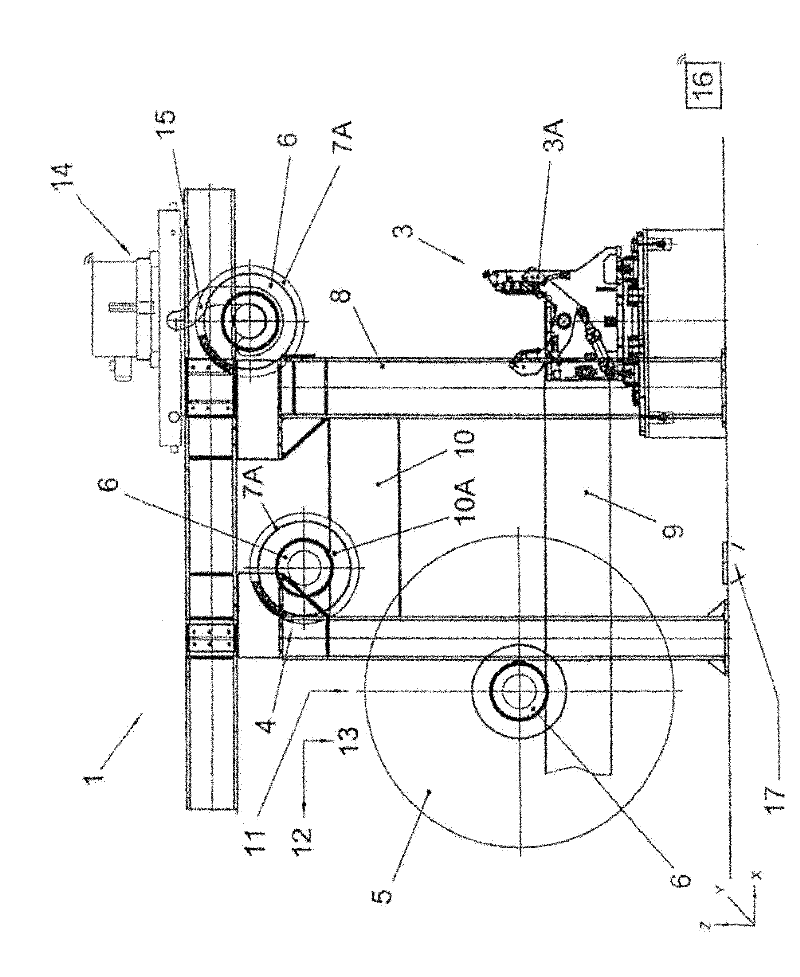

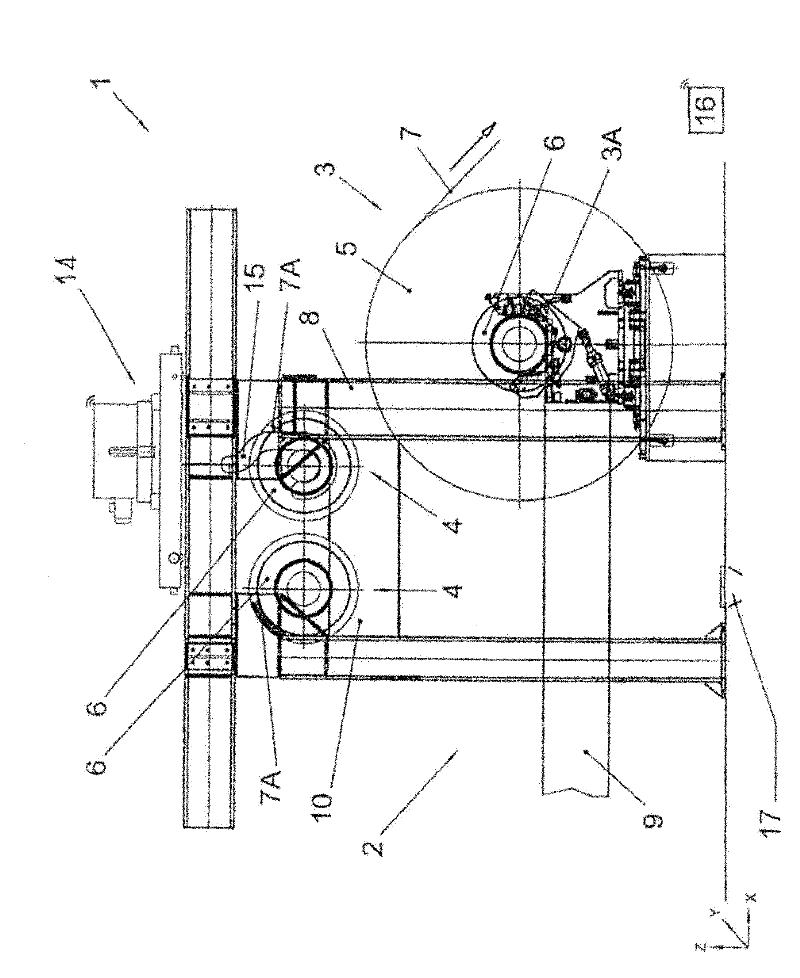

Coiling device and method for processing material web coil

The invention relates to a coiling device (1), which is provided with a preparing place and a coiling place for a material web coil, especially for a paper web or a cardboard web on a coil core, particularly on a roller; people wants to keep the space of the coil device small and improve the production rate, thus, the coil core, which is not coiled, can be moved to the preparing position from the coiling position according to the method.

Owner:VOITH PATENT GMBH

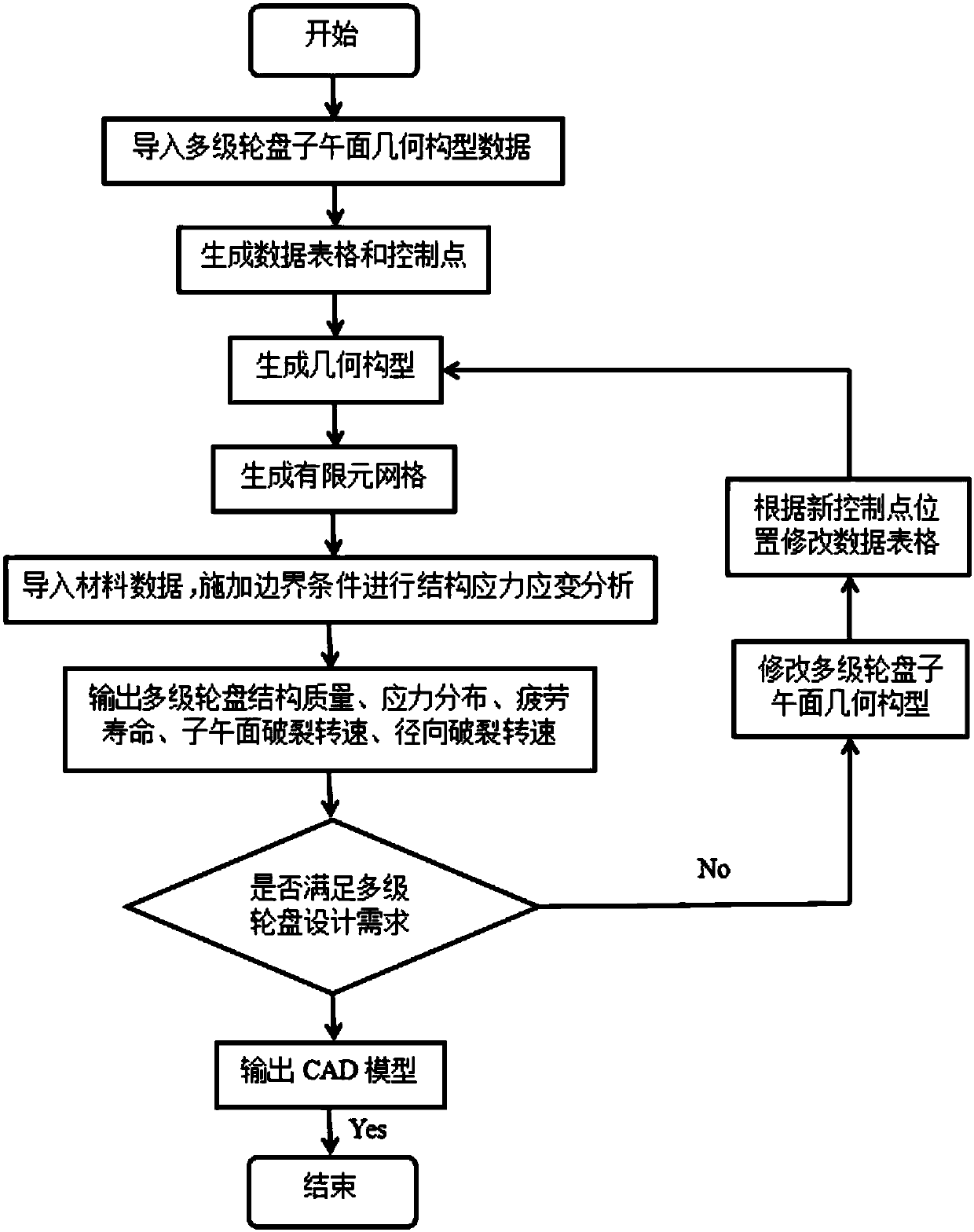

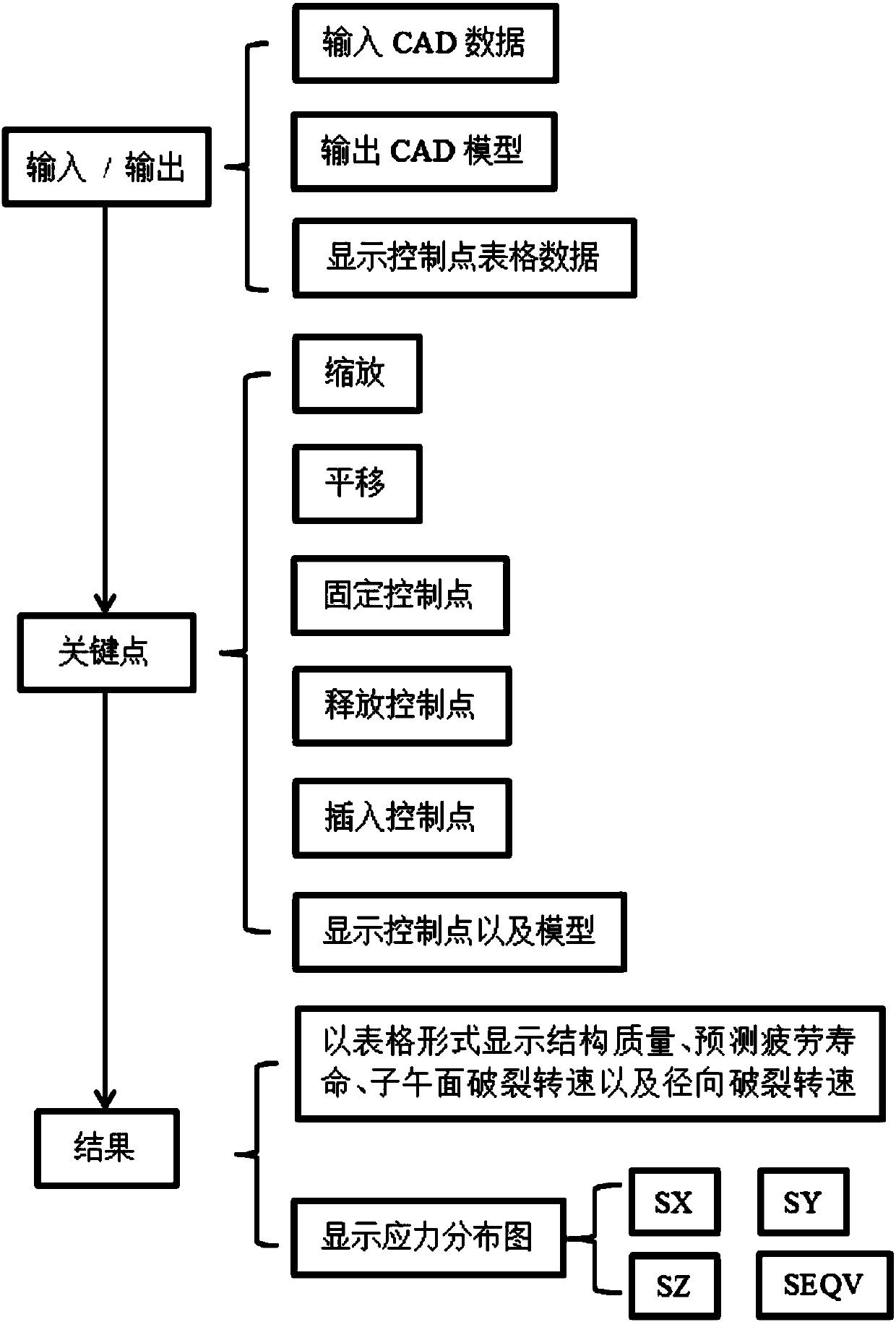

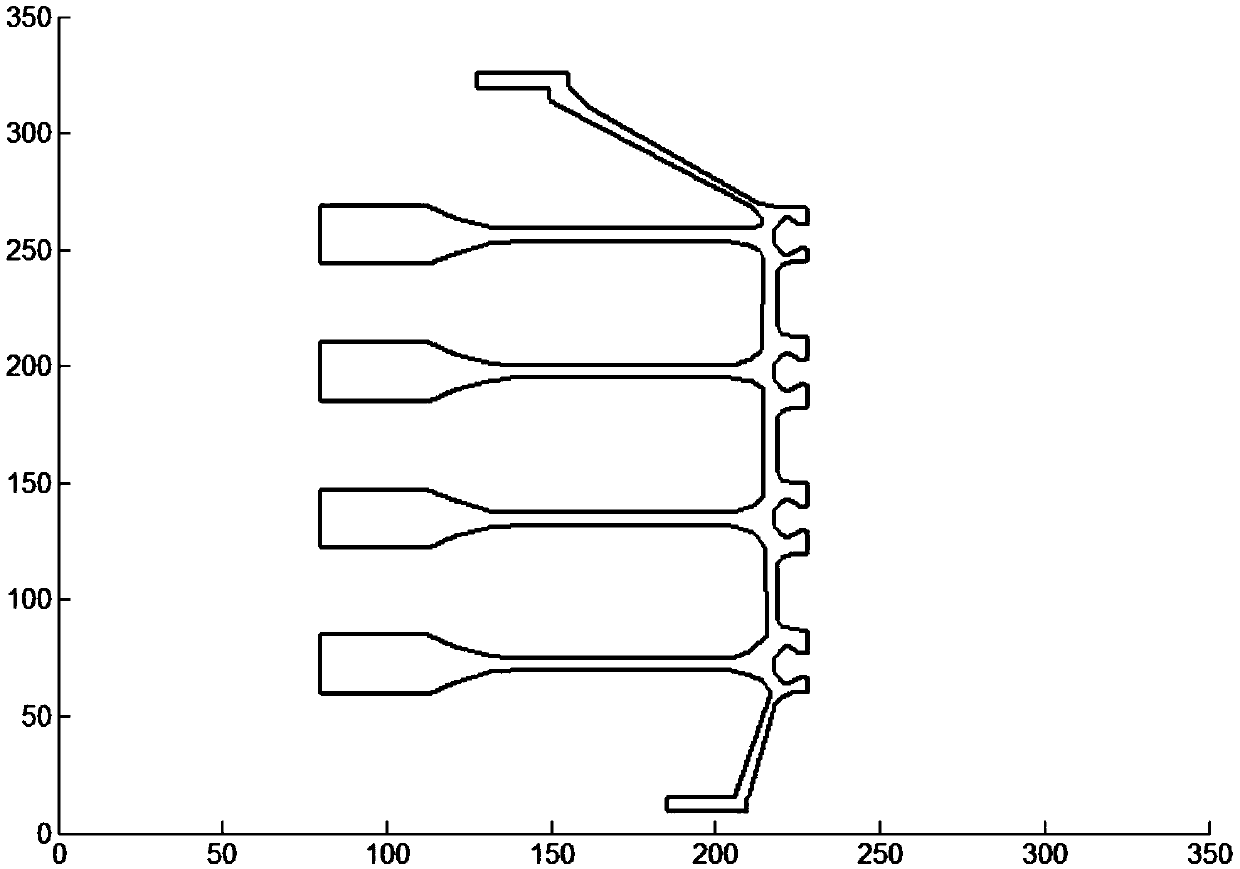

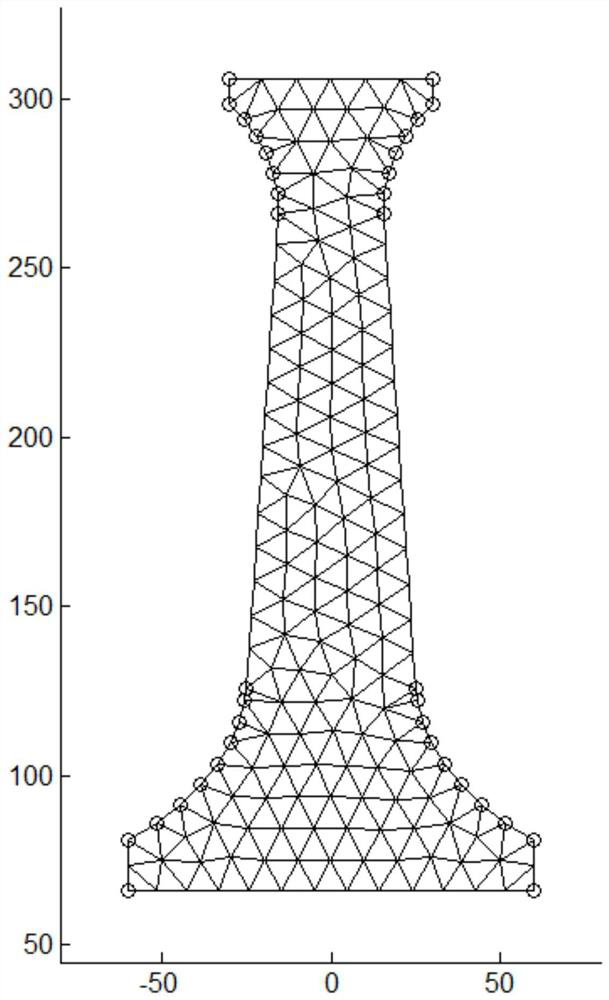

Multistage wheel disc rotor structure interactive design method driven by geometrical features

InactiveCN108280295AImprove design productivityImprove work efficiencyGeometric CADDesign optimisation/simulationElement modelInteractive design

The invention provides a multistage wheel disc rotor structure interactive design method driven by geometrical features and oriented to engineering requirements. The method comprises the following steps of 1, inputting control point coordinate values of a multistage wheel disc meridian plane geometrical structure; 2, building a multistage wheel disc structure axisymmetric finite element model forthe multistage wheel disc meridian plane geometrical structure; 3, analyzing the structure of the built multistage wheel disc structure axisymmetric finite element model; 4, obtaining the multistage wheel disc meridian plane geometrical structure which meets the design requirement and outputting a CAD model. Through the steps, the change of the control point coordinate values of the multistage wheel disc meridian plane geometrical structure can be automatically displayed, the working efficiency of designing a multistage wheel disc structure is improved to a great extent, the problems existingin the prior art during design that the time and labor cost are wasted when an optimizing algorithm is not steady, and artificial remodeling is needed once the scheme is changed during design in the prior art are solved, and finite element mesh dividing and multistage wheel disc structure design can be achieved.

Owner:BEIHANG UNIV

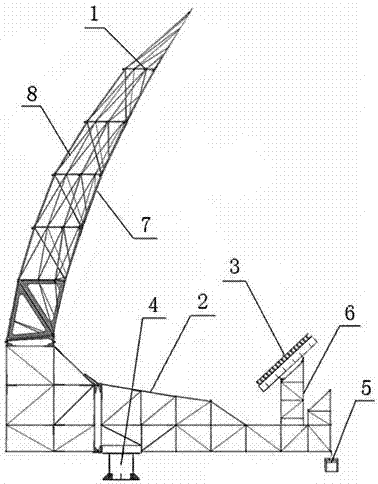

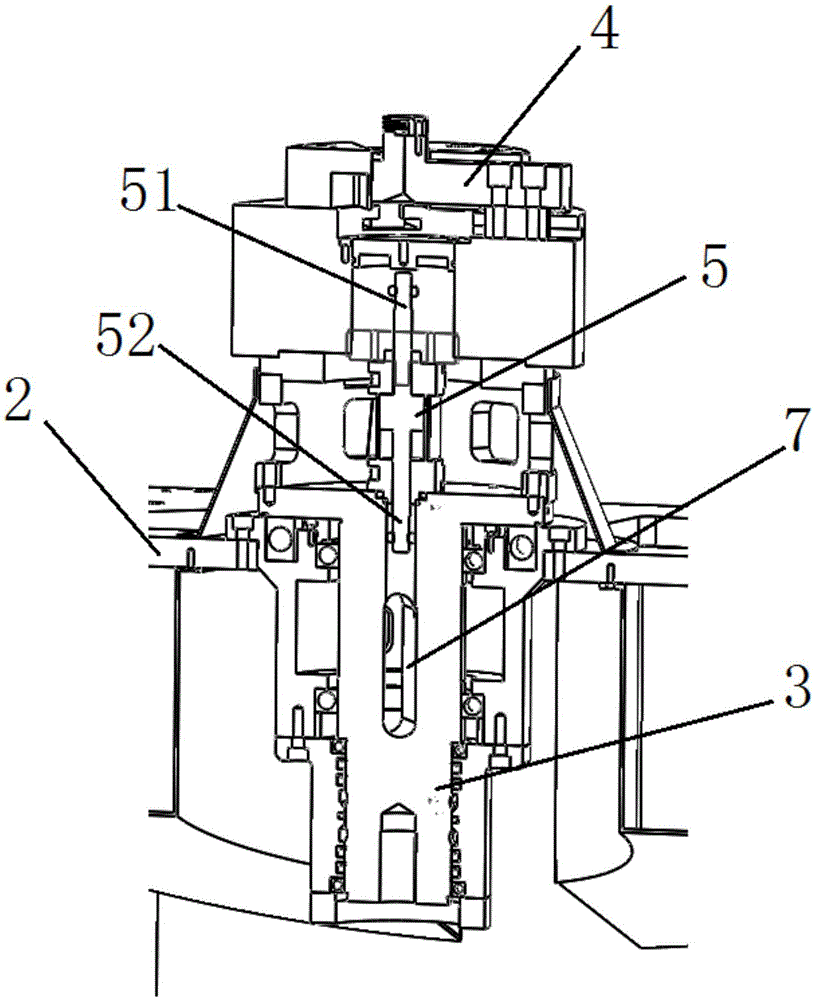

Large-scale high-accuracy parabolic offset antenna

InactiveCN102790257AControl manufacturing costsReduce manufacturing costAntenna arraysAntenna supports/mountingsThin shellsEngineering

The invention discloses a large-scale high-accuracy parabolic offset antenna which comprises an antenna body (1), a feed source array bracket (2), feed source arrays (3), a rotary table (4) and a counter weight device (5). The antenna body (1) is arranged at one end of the feed source array bracket (2); the other end of the feed source array bracket (2) is provided with at least one transition bracket mounting surface; the feed source arrays (3) are respectively arranged at the top ends of transition brackets (6); the rotary table (4) is arranged at the bottom of the feed source array bracket (2); and the counter weight device (5) is connected at the end of the feed source array bracket (2), which is close to the feed source arrays (3). According to the invention, a profile attachment technology is adopted and the manufacturing cost is reduced; a profile is riveted and cured and the problems of complex structure and control for the integral weight of a large-scale antenna are solved; a reflector skeleton adopts a truss structure, the feed source array bracket adopts a truss and thin shell beam mixed structure, and the structure design under a heavy load and under the complex boundary conditions of low weight, high stiffness requirement and the like is implemented.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

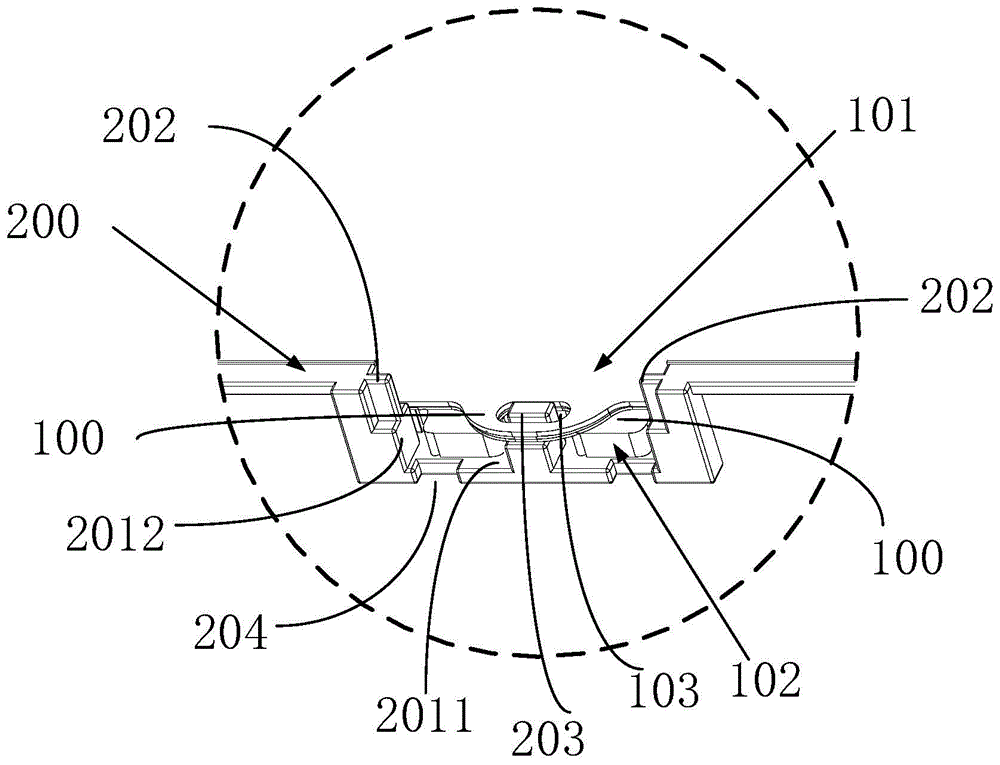

Television

ActiveCN107071319AReduce thicknessPrevent disengagementTelevision system detailsColor television detailsEngineeringMechanical engineering

Owner:QINGDAO HAIER MULTI MEDIA CO LTD +1

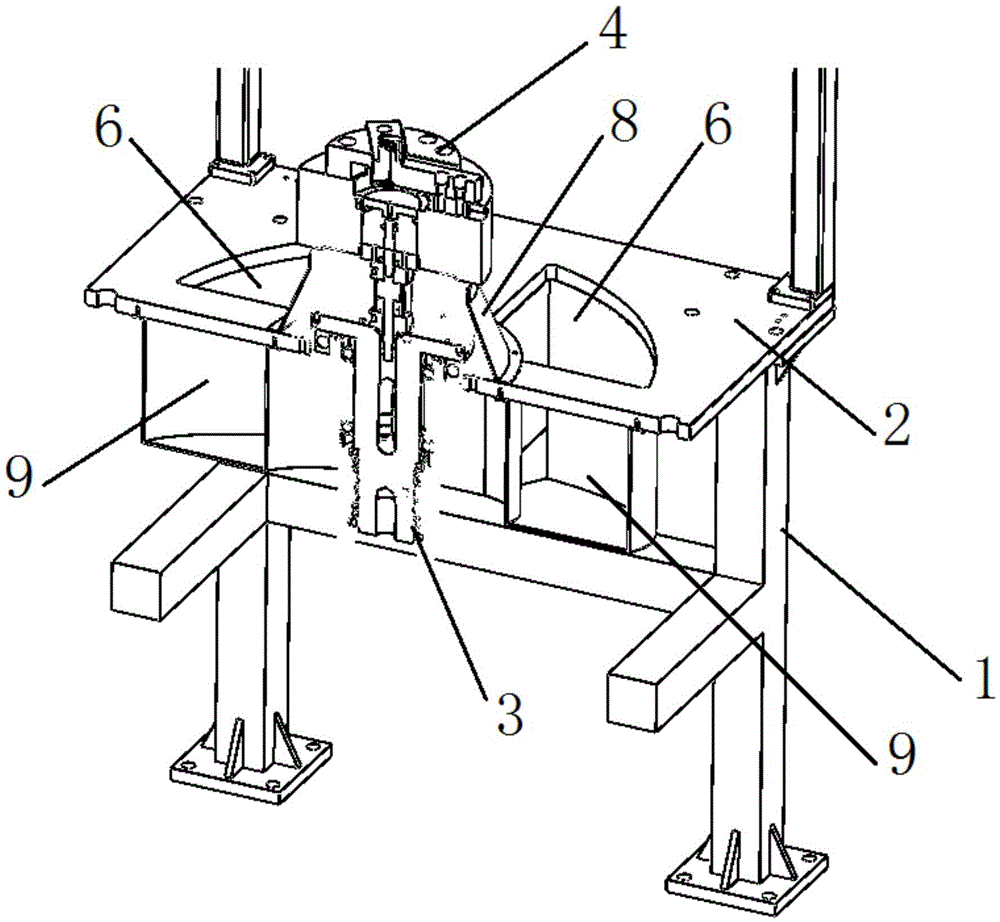

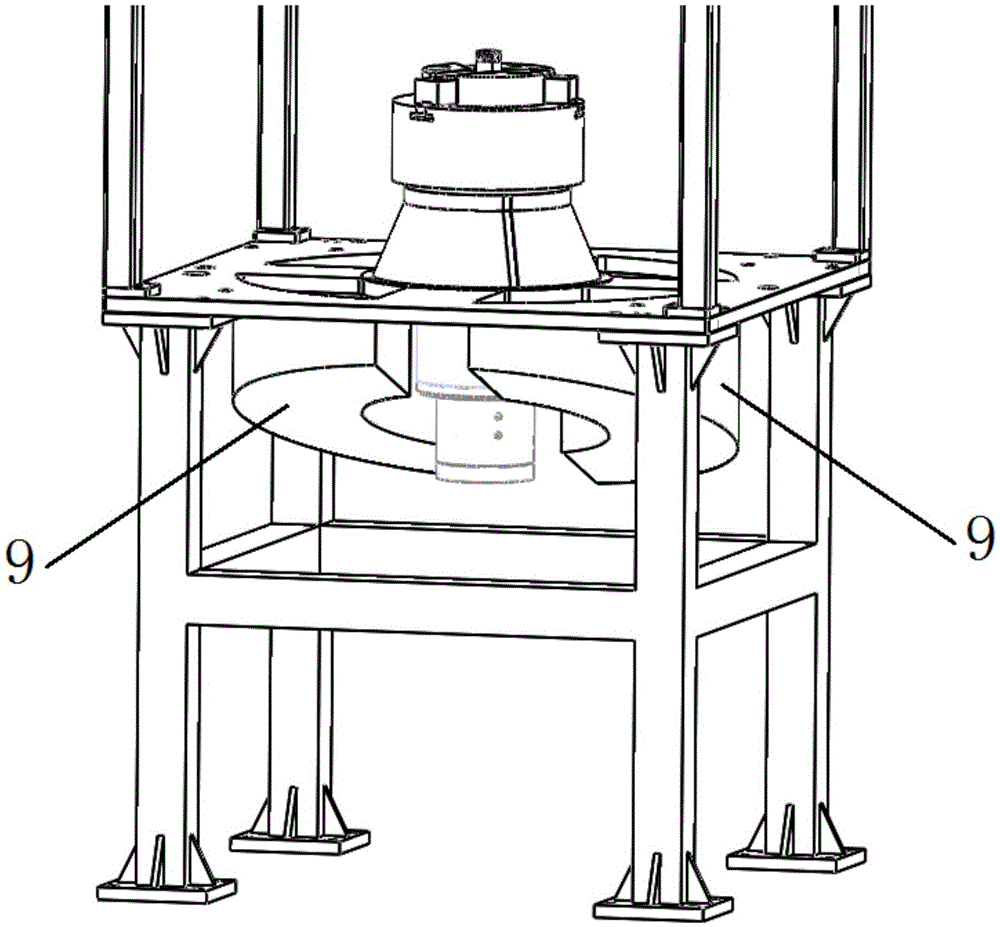

Intelligent hub positioning device

InactiveCN105538251AStructural Design ImplementationImprove the protective effectWork benchesElectrical and Electronics engineering

Owner:SHANGHAI FANUC ROBOTICS

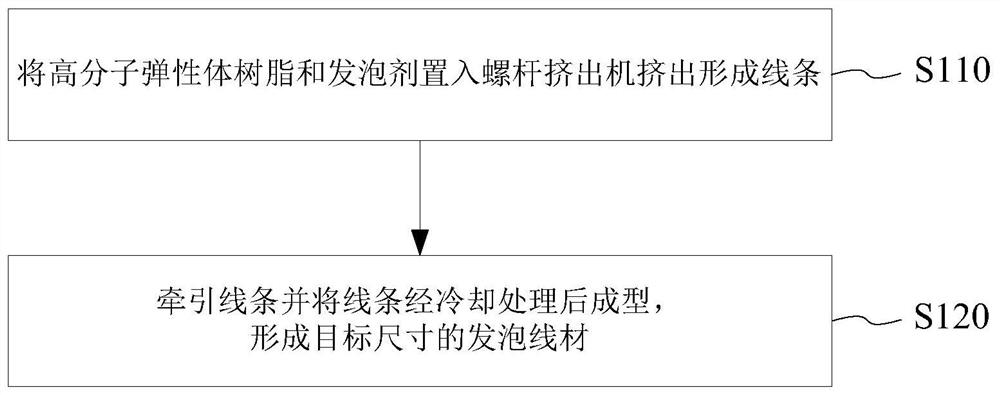

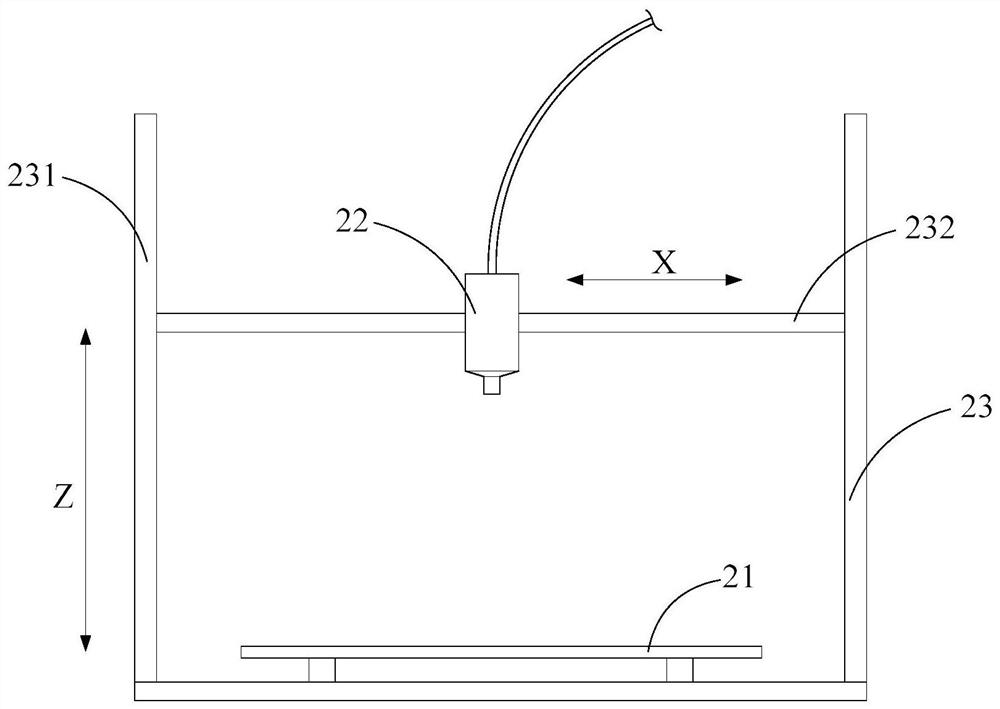

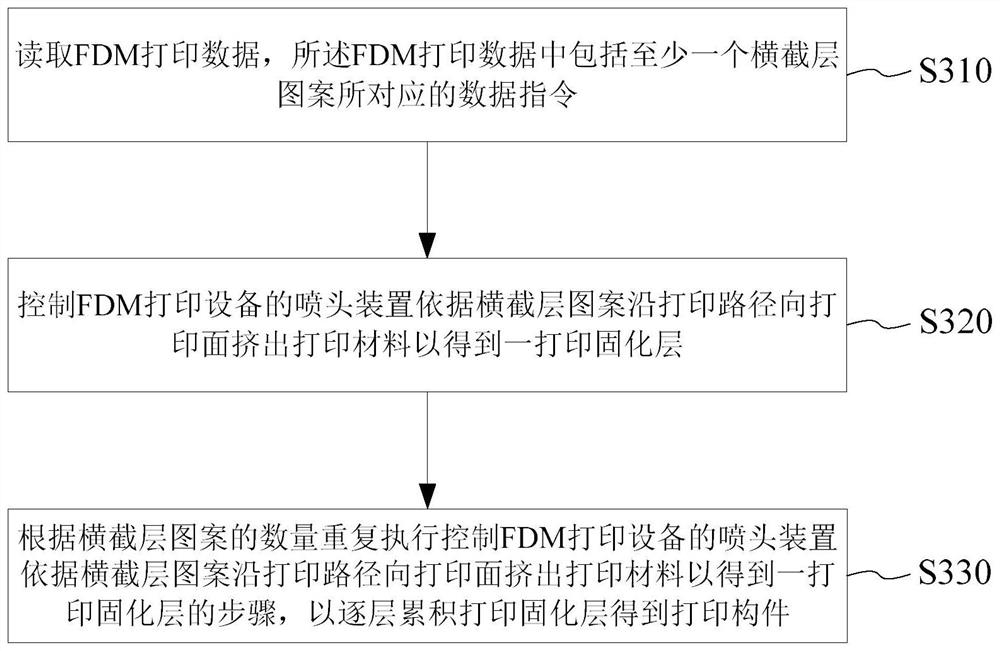

Foaming wire rod, preparation method, FDM printing method, printing equipment and storage medium

PendingCN113183455AIncreased Design FreedomStructural Design ImplementationAdditive manufacturing apparatus3D object support structuresWire rodElastomer

The invention discloses a foaming wire rod, a preparation method, an FDM printing method, printing equipment and a storage medium. The foaming wire rod is prepared from, by mass, 70%-99.5% of polymeric elastomer resin and 0.5%-30% of a foaming agent. The foaming wire rod has good foaming performance, and a printing component formed by printing of the foaming material has the advantages of frosted surface, light weight, softness and the like.

Owner:JF POLYMERS (SUZHOU) CO LTD

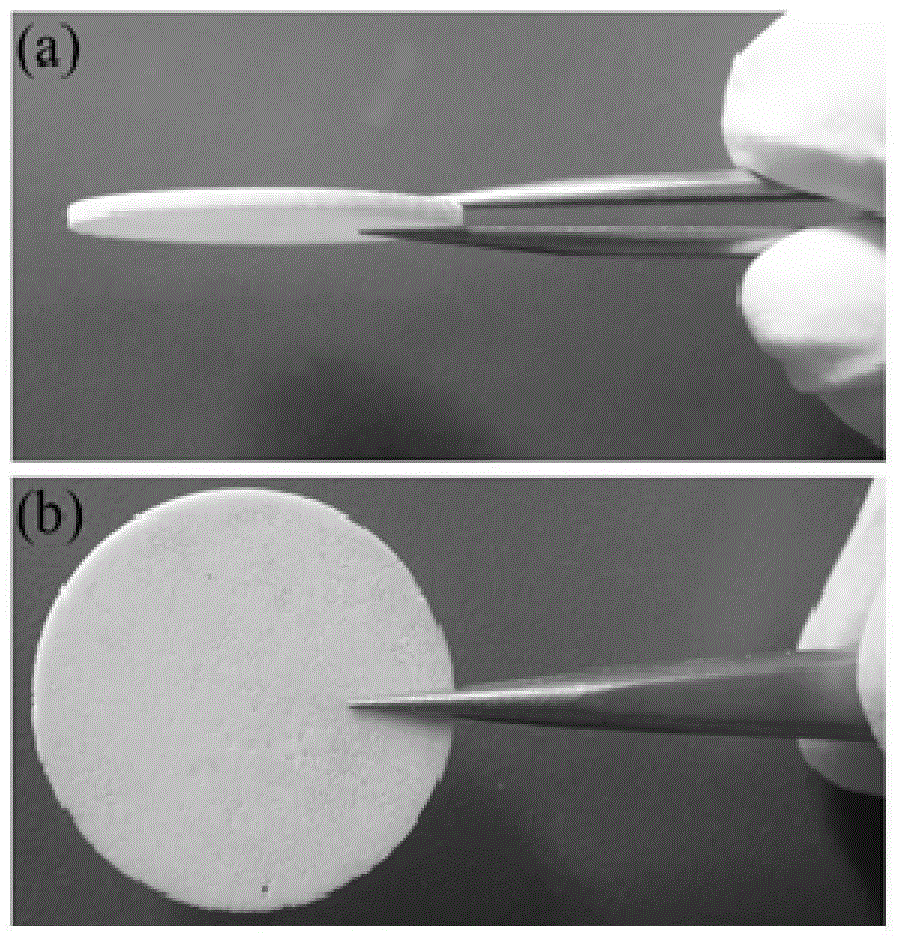

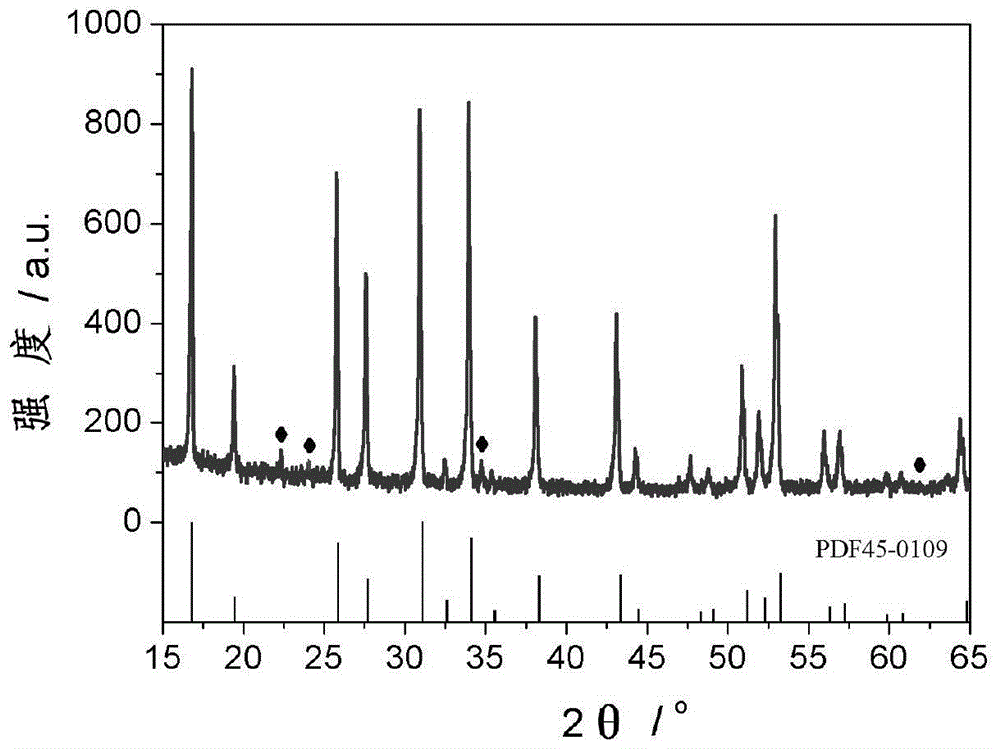

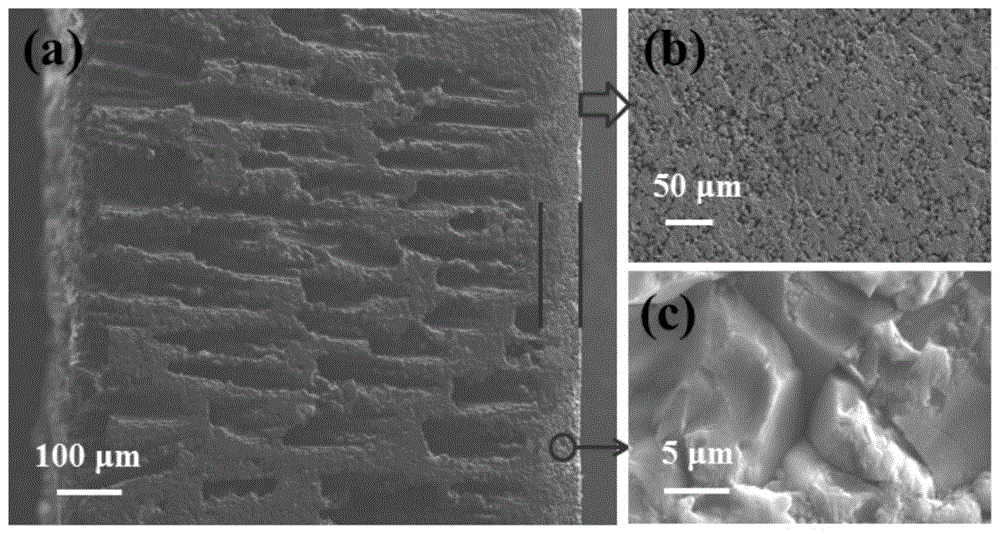

A kind of preparation method of composite electrolyte sheet

ActiveCN104638295BSolve the problem of lithium volatilizationHigh strengthElectrolyte accumulators manufactureComposite electrolyteAdhesive

The invention discloses a preparation method of a composite electrolyte sheet. The preparation method comprises the following steps: preparing a honeycomb alumina sheet, namely, mixing alumina powder, tert-butyl alcohol, an adhesive, a dispersant and deionized water, carrying out ball milling, injecting a mixture into a die, carrying out solidification, vacuum freeze-drying, sintering and cutting to obtain the honeycomb alumina sheet; then preparing LLZTO slurry, namely, weighing lithium carbonate, lanthanum oxide, zirconia and tantalum oxide, carrying out ball milling with ethanol, drying to obtain a premix, carrying out heat treatment on the premix to obtain preheated powder, mixing the preheated powder, ethyl glycol, the adhesive and triolein, and carrying out ball milling to obtain the LLZTO slurry; and finally, preparing the composite electrolyte sheet with a honeycomb alumina supported LLZTO membrane, namely, coating the LLZTO slurry on one surface of the honeycomb alumina sheet, naturally drying, putting on a crucible lid, and sintering to obtain the composite electrolyte sheet. According to the preparation method disclosed by the invention, the prepared composite electrolyte is excellent in performance and has wide application prospect in the field of lithium batteries.

Owner:TSINGHUA UNIV

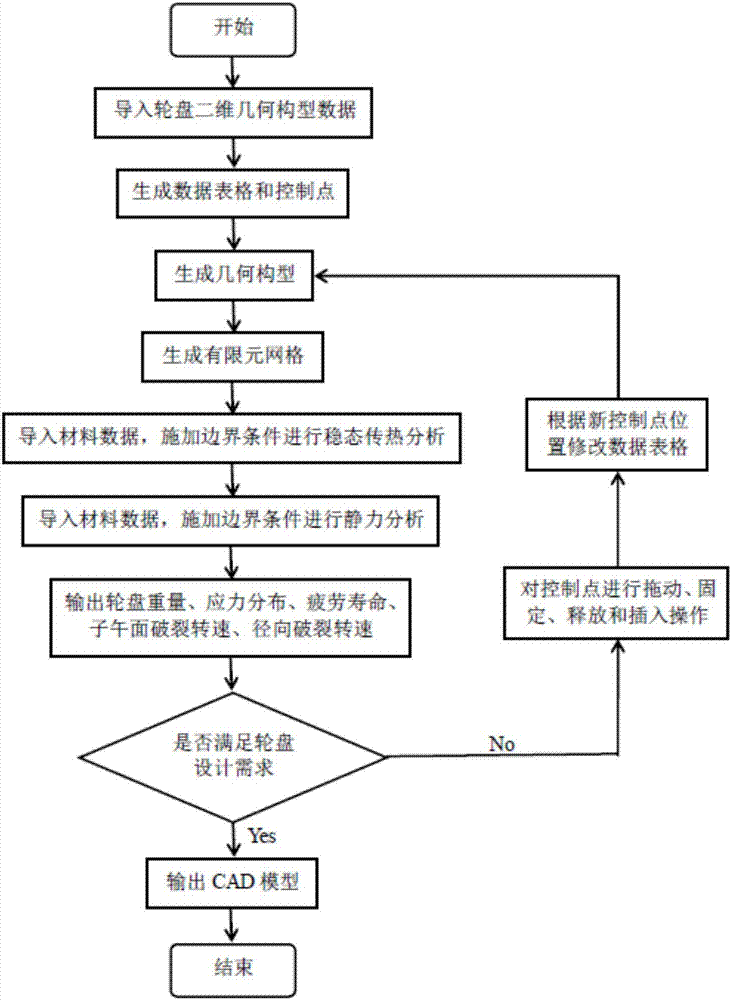

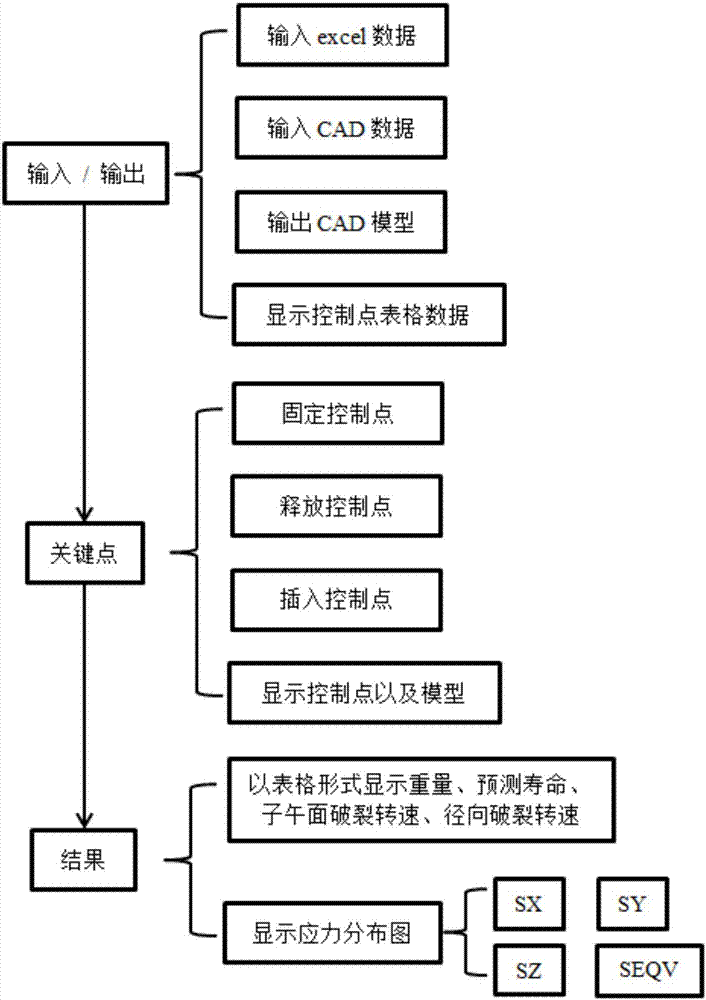

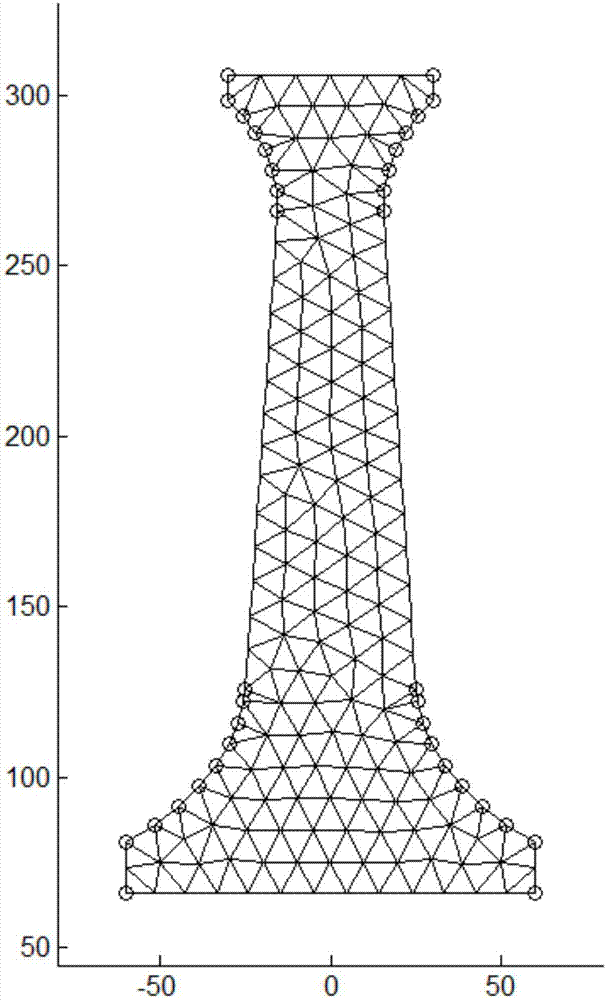

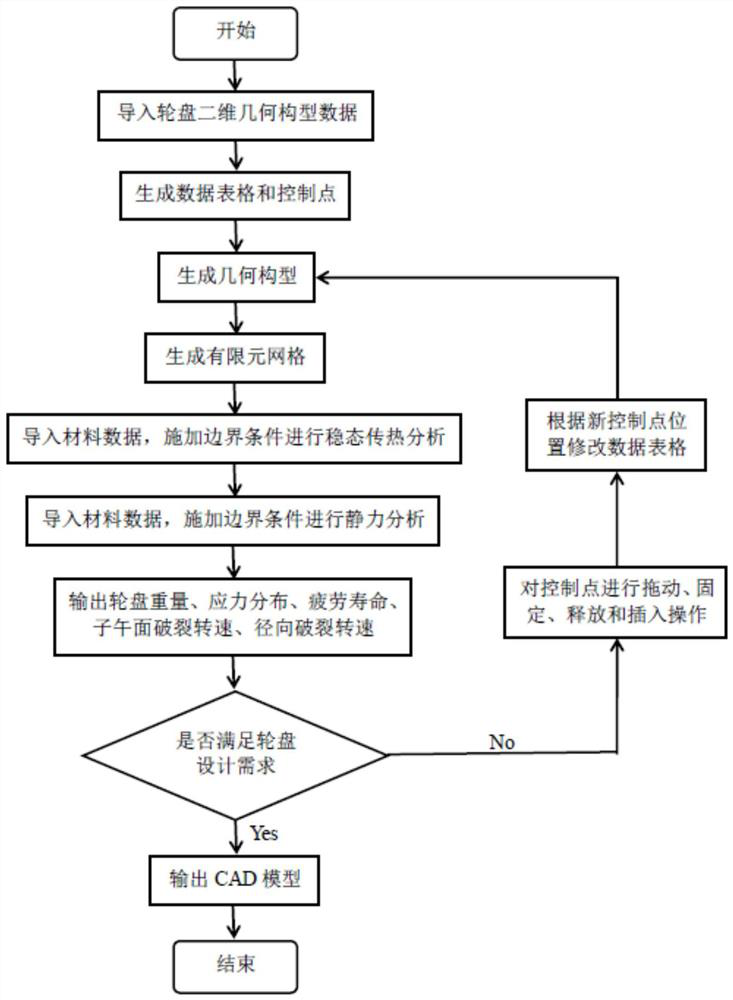

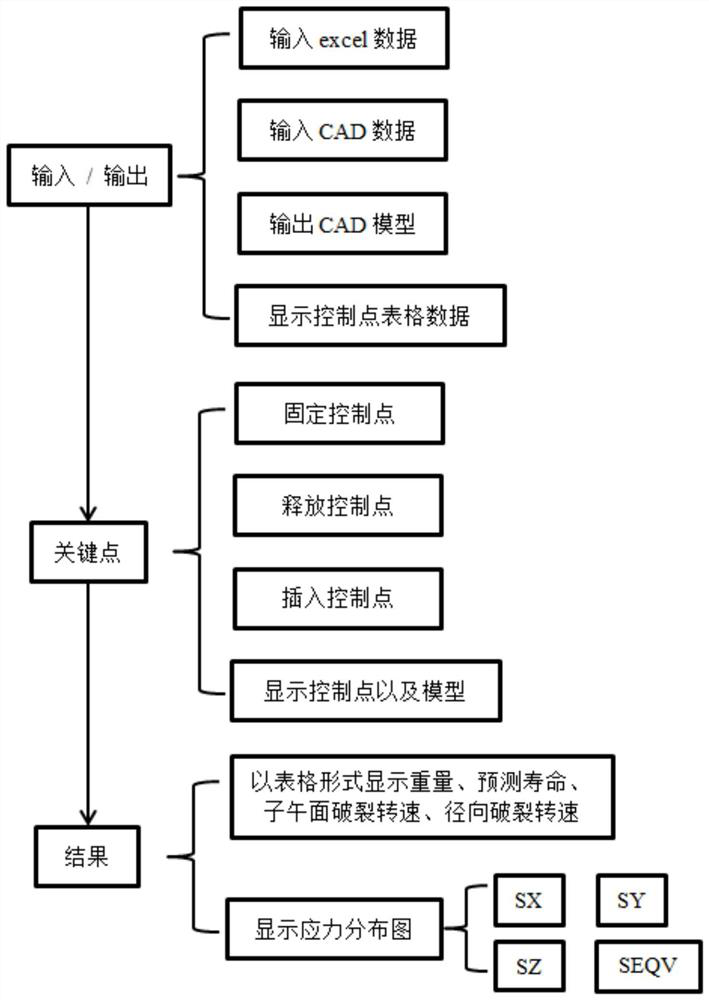

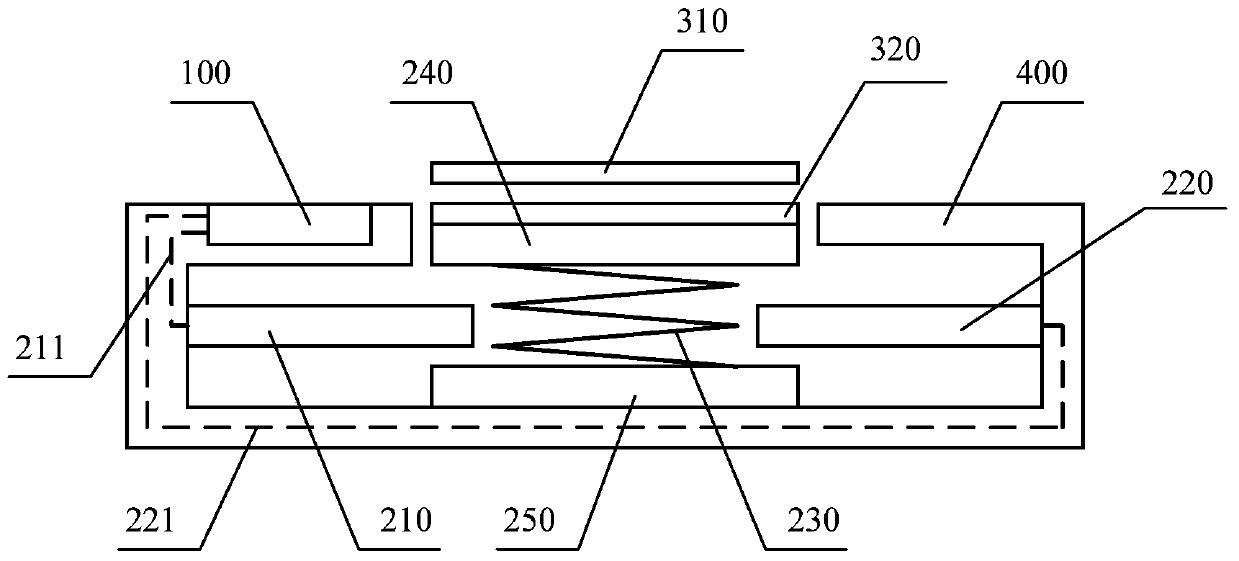

Demand-oriented geometric feature-driving turbine disc structure interactive design method

ActiveCN107229782AImprove efficiencySave human resourcesGeometric CADDesign optimisation/simulationEngineeringMeridian plane

The invention provides a demand-oriented geometric feature-driving turbine disc structure interactive design method. The interactive design method comprises following steps of 1, inputting coordinate values of control points of a turbine disc two-dimensional geometrical configuration; 2, establishing a turbine disc axisymmetric finite element model for the turbine disc two-dimensional geometrical configuration; 3, carrying out structural analysis on the established turbine disc axisymmetric finite element model; and 4, in dependence on the design demand, changing the turbine disc two-dimensional geometrical configuration, and automatically displaying the coordinate values of the control points of the turbine disc two-dimensional geometrical configuration, establishing the turbine disc axisymmetric finite element model and carrying out finite element calculation. Through the above steps, the control points of the turbine disc two-dimensional geometrical configuration can be dragged by a mouse, turbine disc weight calculation, stress-strain analysis, fatigue life prediction, meridian plane burst speed calculation and radial burst speed calculation are automatically carried out, the turbine disc structure design efficiency is improved, and the case that during the previous design process, once the scheme is changed, modeling needs to be carried out again manually, and therefore time and manpower are wasted is avoided.

Owner:BEIHANG UNIV

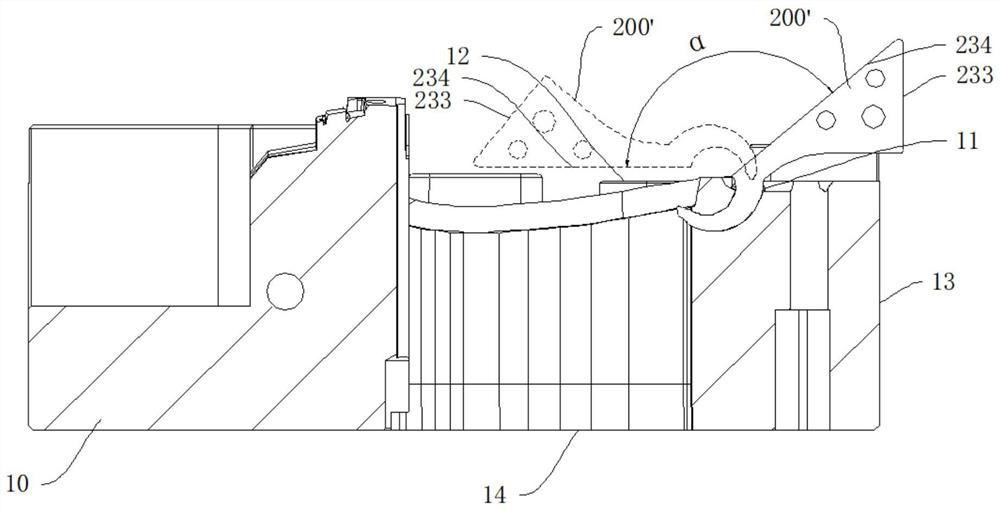

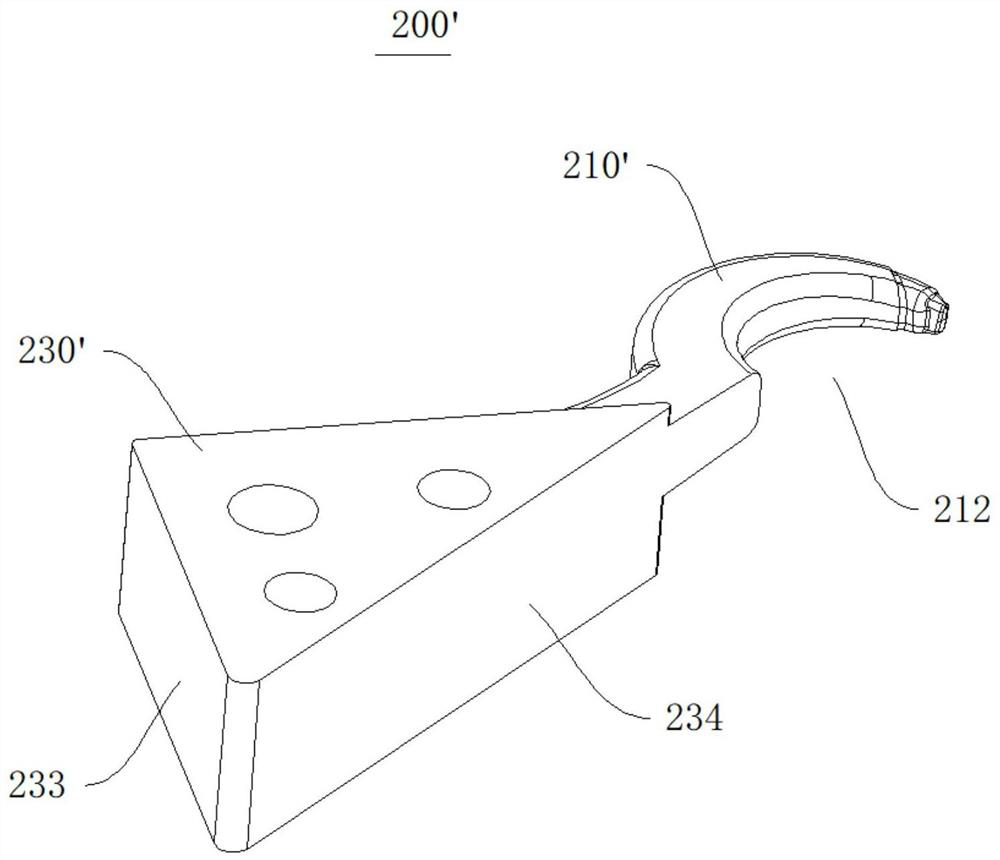

Tool electrode, manufacturing method of tool electrode and machining method of ox-horn-shaped pouring gate

ActiveCN113042835AStructural Design ImplementationAids in processabilityElectrical-based machining electrodesElectrical-based auxillary apparatusElectric dischargeMachining process

The invention relates to the field of material forming, and discloses a tool electrode and a manufacturing method of the tool electrode, and a machining method of an ox-horn-shaped gate. The tool electrode and the manufacturing method of the tool electrode not only realize the structural design and inspection of the tool electrode, but also can simulate the machining process through the rotation of the ox-horn-shaped electrode so as to determine the relative positions of the ox-horn-shaped electrode and a mold, and machining forming and assembling use of the tool electrode are facilitated. The tool electrode manufactured through the method can machine a mold to form a closed ox-horn-shaped pouring gate, so that the problem that a line is clamped by an insert is solved, the tool electrode is used for EDM electric discharge machining, the closed ox-horn-shaped pouring gate can be machined and formed on the mold, on one hand, the problem that the line is clamped by the insert of a product produced in a traditional mode is solved, and on the other hand, the machining cost of the insert and each section for manufacturing the insert is also saved.

Owner:惠州市盈旺精密技术股份有限公司

Lighting device

ActiveCN104595826AAchieve lightingStructural Design ImplementationLighting support devicesPoint-like light sourceControl switchFixed position

The invention provides a lighting device which comprises a lighting unit and a switch part, an installation part and an installation box of the lighting unit. The switch part is arranged in the installation box, the switch part is provided with a first fixed end, a second fixed end, an elastic piece, a connecting piece and a fixed position; the fixed position is arranged on one sides of the first fixed end and the second fixed end, the connecting piece is arranged on one sides of the first fixed end and the second fixed end, one end of the elastic piece is fixedly arranged on the fixed position, and the other end of the elastic piece is fixedly arranged on the connecting piece; the installation part comprises a pair of magnetic parts which comprise a first magnetic part and a second magnetic part, wherein the first magnetic part is arranged outside of the lighting device, and the second magnetic part is fixedly arranged on the connecting piece. According to the lighting device, indoor lighting and wardrobe lighting are achieved, the lighting device is also suitable for lighting of other dark positions with door instructures, the structure design of a magnetic control switch is achieved, the connecting control structure is simplified, the control of the magnetic control switch is easy and convenient, light is provided as long as a door is opened, wait and grope are not needed, and the experience of a user is enhanced greatly.

Owner:HUIZHOU UNIV

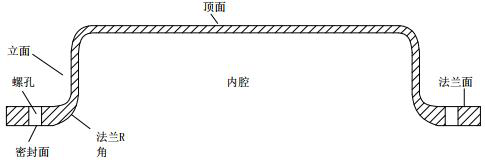

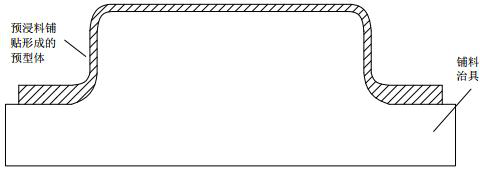

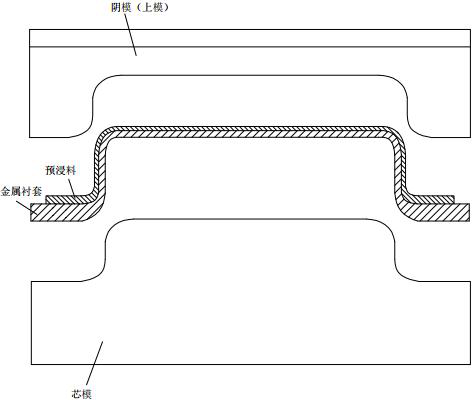

Manufacturing process of composite material battery box

ActiveCN112454941AIncreased mold entry accuracyStructural Design ImplementationCell component detailsDomestic articlesElectrical batterySand blasting

The invention relates to a manufacturing process of a composite material battery box. The manufacturing process of the composite material battery box comprises the following steps of: manufacturing abattery box framework, wherein the battery box framework comprises peripheral flanges, and the inner side of each flange is connected with a vertical surface R corner part through a flange R corner part with gradually changed thickness; carrying out sand blasting treatment on the prepared battery box framework, and then cleaning and airing for later use; preparing a material spreading jig; spreading large fabric on the material spreading jig, and then placing the battery box framework into the material spreading jig and pressing the battery box framework; spreading the remaining large fabric on the battery box framework, and pressing again to form a battery box preform; transferring the material spreading jig on which the materials are spread into a low-temperature refrigerator to be refrigerated for 2 to 15 minutes; completing demolding of the preform, rapidly placing the preform into a high-temperature product mold, and conducting curing molding of the product; and after opening themold and carrying out post-processing, obtaining a final battery box finished product. The process is not limited by the size of the battery box product, and is high in feasibility, high in universality and high in production efficiency; and the occurrence of the phenomena of local material shortage cavitation, performance weakening and the like after the product is formed is avoided.

Owner:许剑海

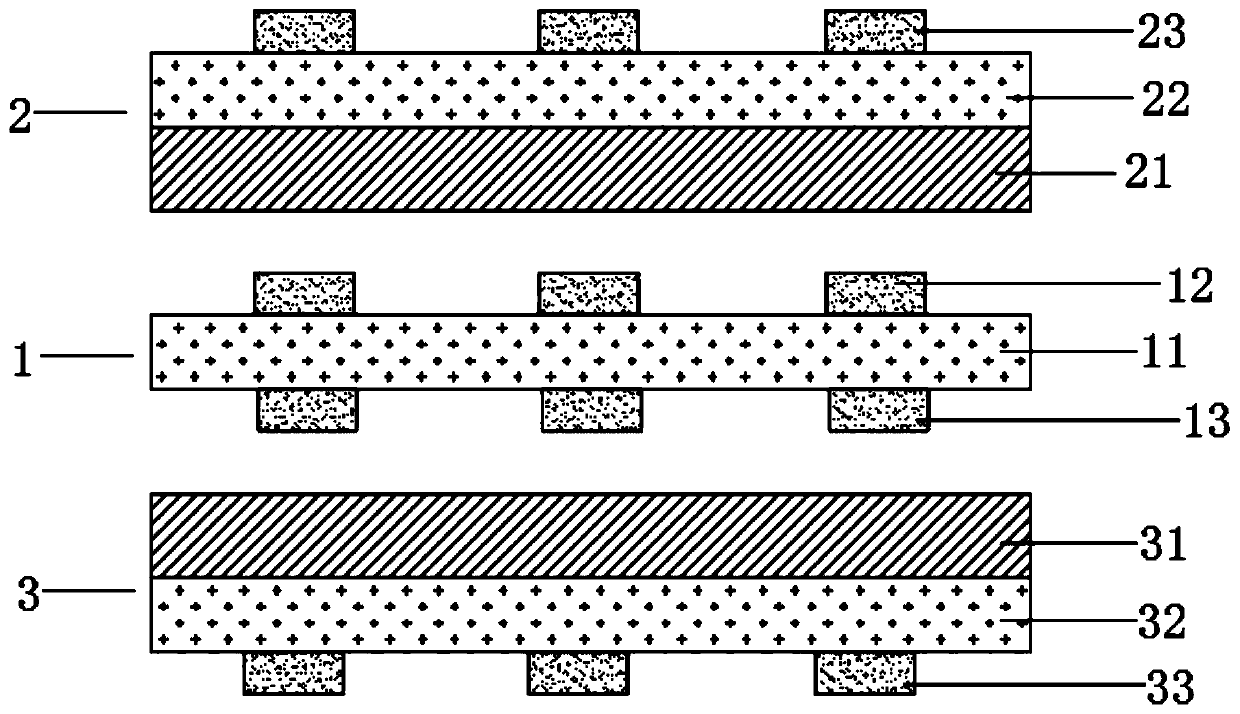

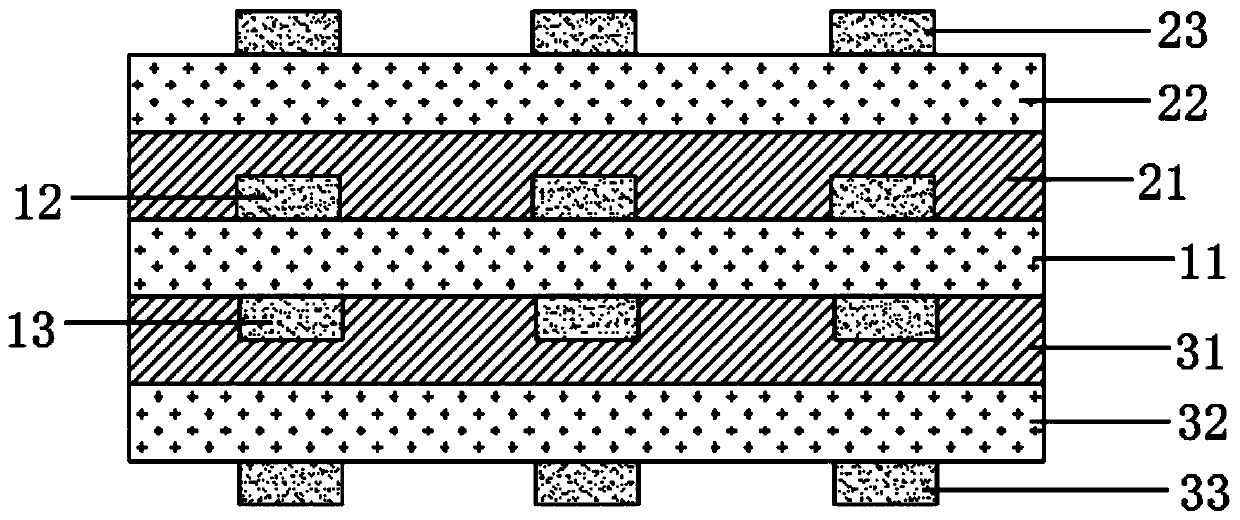

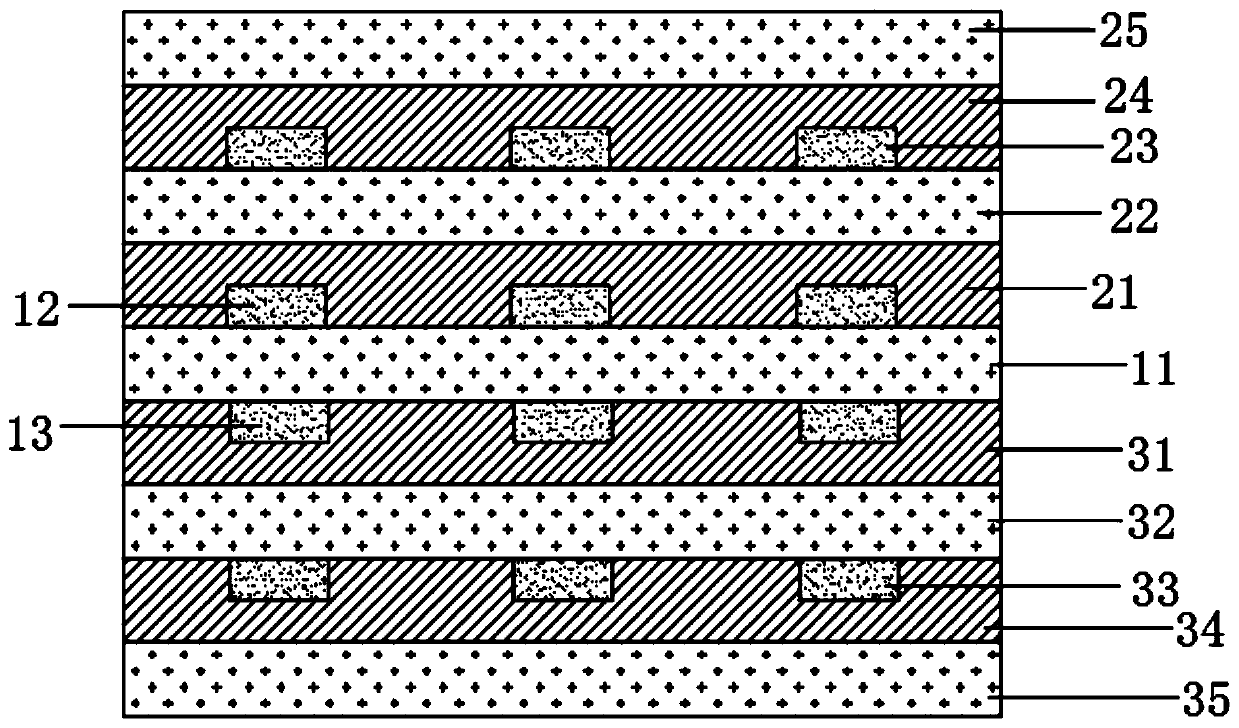

Manufacturing method of multilayer flexible circuit board and manufactured product

InactiveCN110678014AEasy to manufactureSimplify the manufacturing processCross-talk/noise/interference reductionPrinted circuit aspectsFlexible circuitsCopper ion transport

The invention discloses a manufacturing method of a multilayer flexible circuit board. The manufacturing method comprises the steps of (1) manufacturing a double-sided FPC flexible board; (2) manufacturing a novel material layer structure; (3) hot-pressing at least one group of novel material layer structures on the circuit on the upper surface and / or the lower surface of the double-sided FPC flexible board, and forming a protective layer on the circuit of the outermost novel material layer structure and / or the exposed circuit of the double-sided FPC flexible board to obtain the multi-layer flexible circuit board. The invention further discloses a multi-layer flexible circuit board manufactured by implementing the method. According to the invention, the manufacturing process is simplifiedand convenient, and the production efficiency is high; the manufactured multi-layer flexible circuit board not only greatly simplifies the novel material layer structure and reduces the overall thickness, but also has the function of transmitting high-frequency signals at a high speed, and is particularly suitable for novel 5G technological products; the protective and resistant effects on the copper ion migration phenomenon during the electrification between the circuits are achieved, and the safe and normal work of the circuits is guaranteed.

Owner:李龙凯

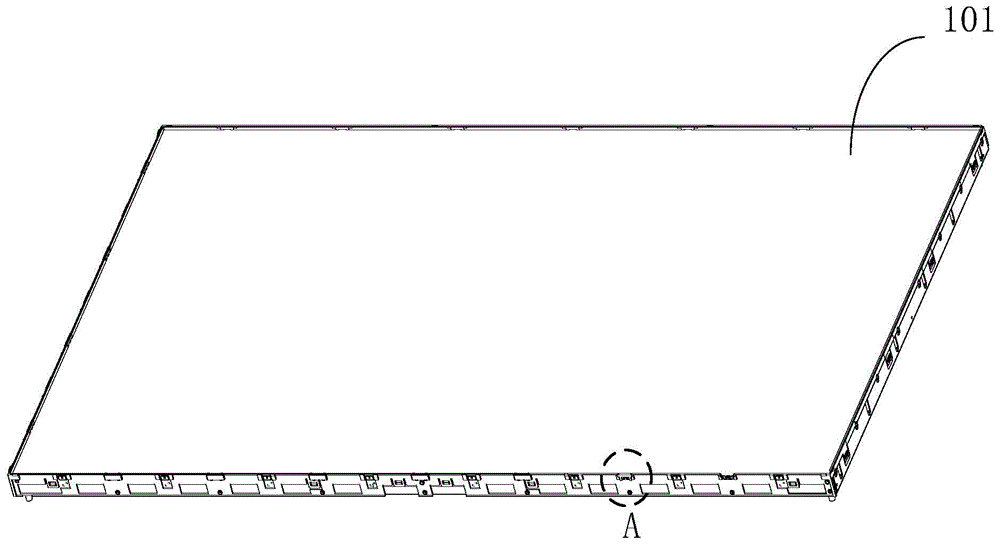

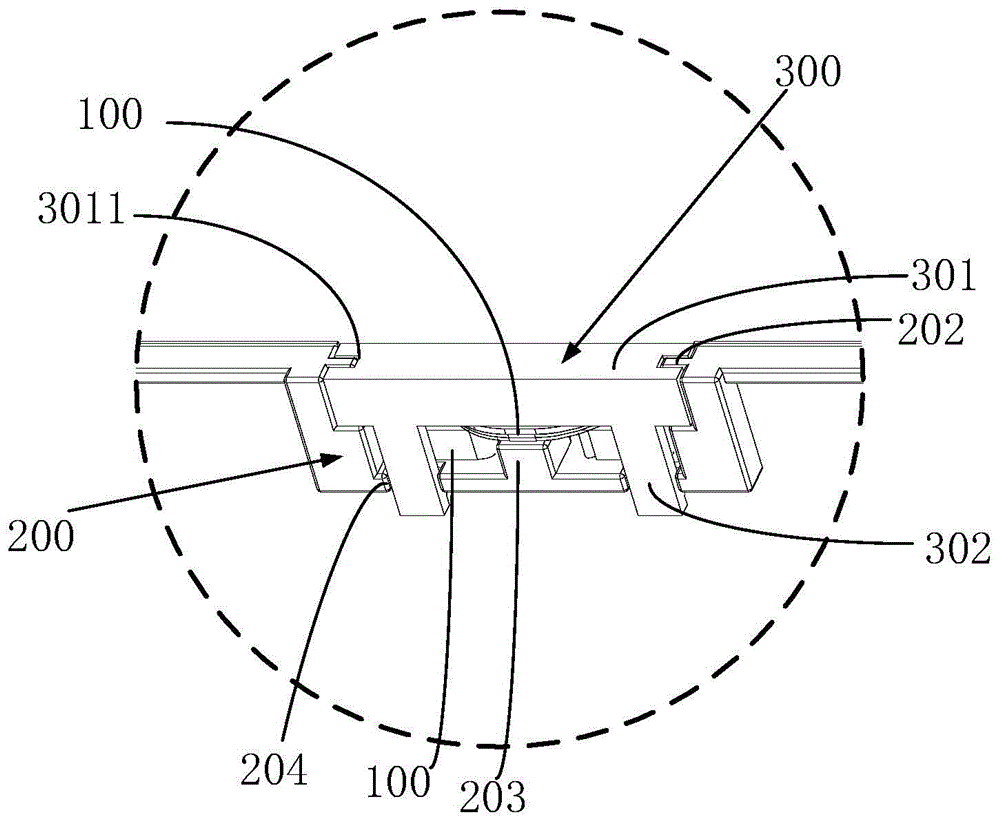

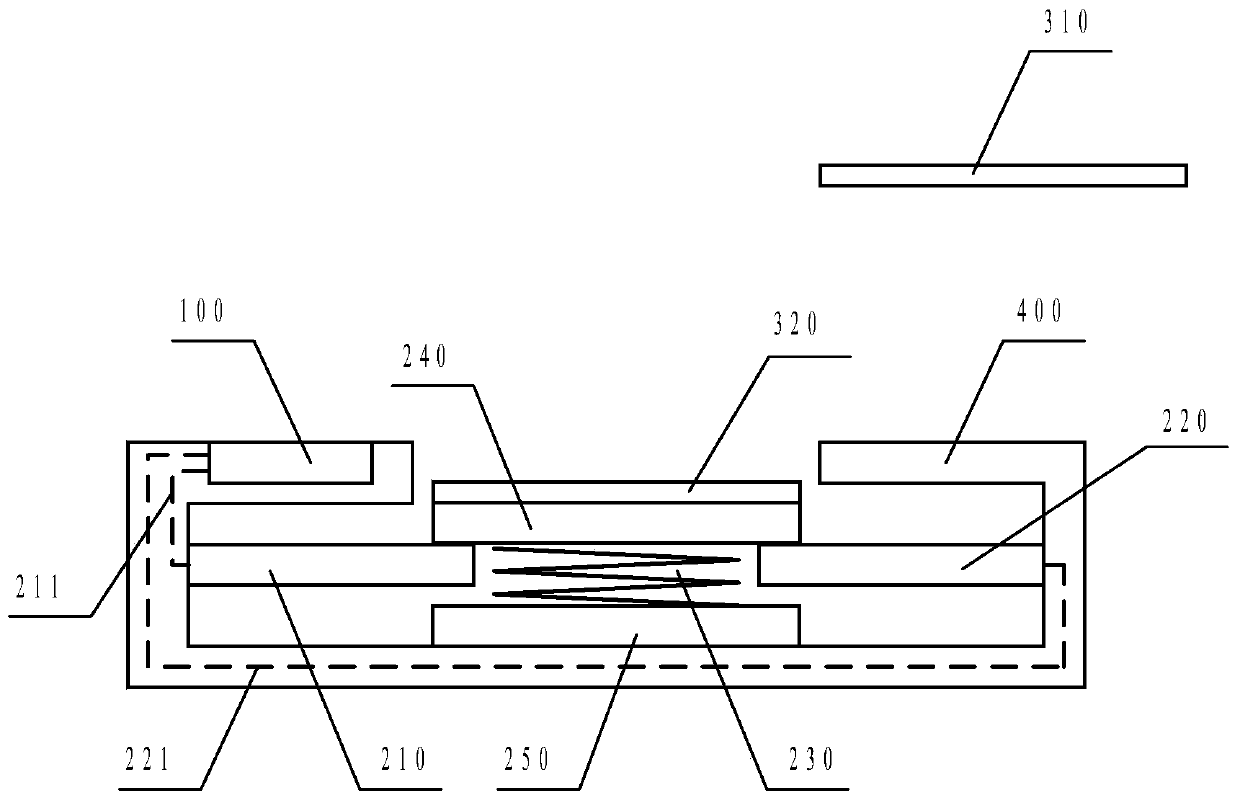

Backlight module and display device

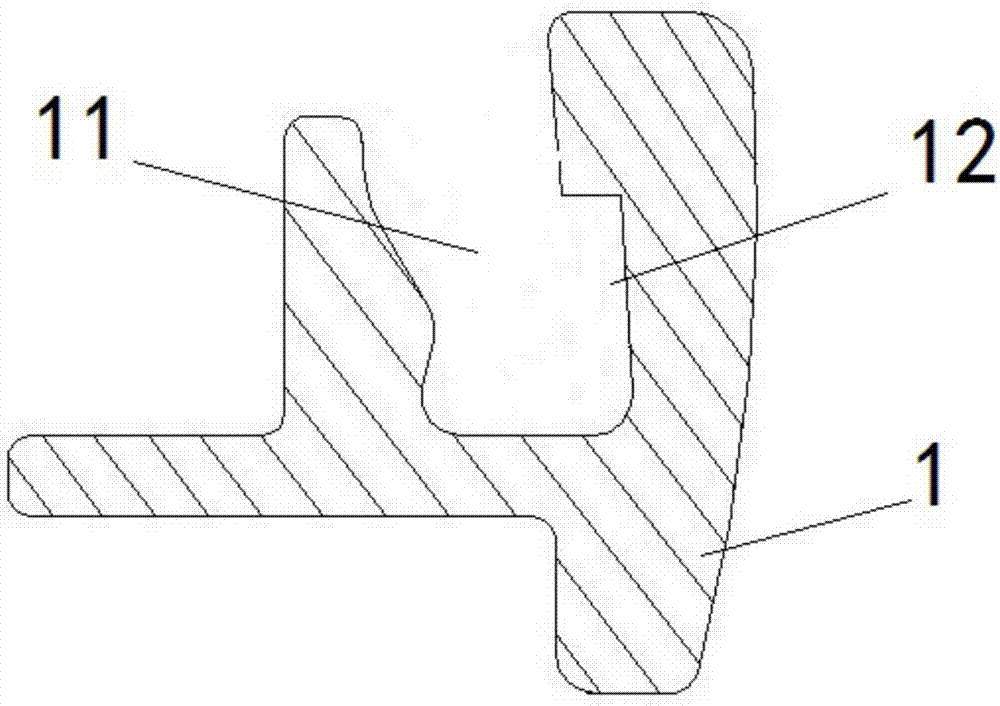

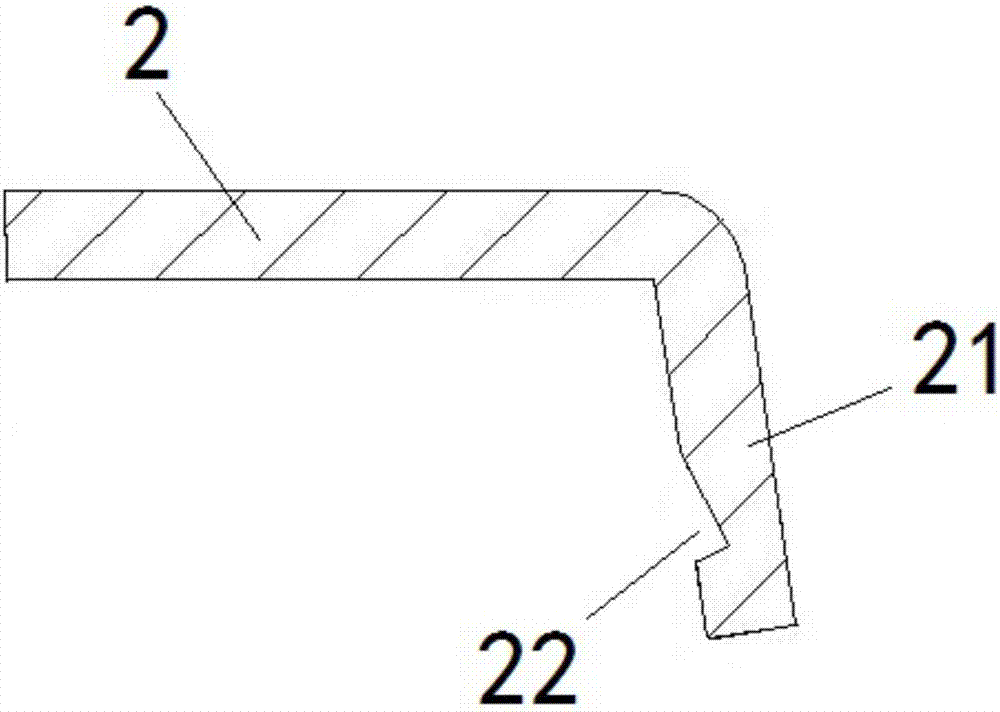

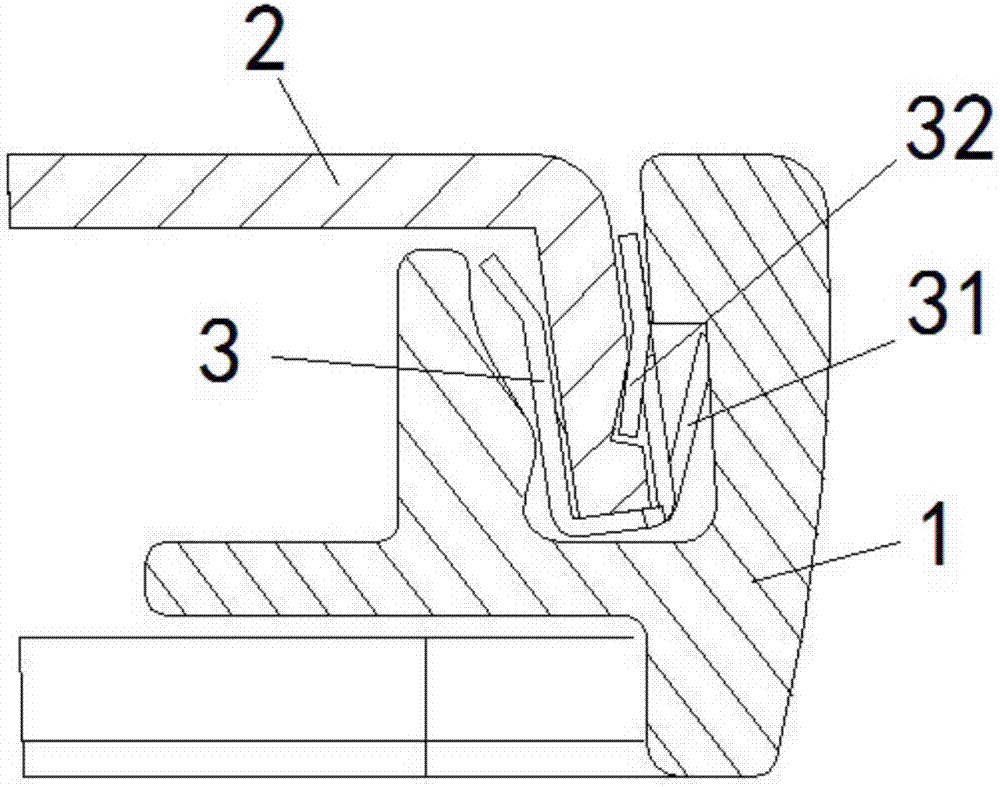

ActiveCN104197242BReduce widthStructural Design ImplementationNon-linear opticsLight fasteningsDisplay deviceEngineering

The invention provides a backlight module and a display device. The backlight module comprises at least two optical structures, a rubber frame and a fixing part, wherein a positioning convex lug which extends outwards is arranged at the edge positions of the at least two optical structures; the rubber frame is arranged on the peripheries of the at least two optical structures, a positioning notch is formed in the position, corresponding to the positioning convex lug, of the rubber frame, and the positioning convex lug is inserted into the positioning notch; the fixing part is arranged in the positioning notch and used for fixing the positioning convex lug into the positioning notch. The positioning notch is formed in the rubber frame, the positioning convex lug of the optical structures such as an optical film material and a diffuser plate is inserted and fixed into the positioning notch through the fixing part, fixation of the optical film material and the diffuser plate can be achieved without the need of a sheet guide in the fixing mode, the widths of the positioning convex lug on the optical film material and the diffuser plate can be reduced, and therefore the width of the frame of the backlight module is reduced and the structural design of a super-narrow frame is achieved.

Owner:BOE TECH GRP CO LTD +1

A postoperative suture removal nursing device for appendicitis in general surgery

ActiveCN111281691BStructural Design ImplementationPromote shakingNursing bedsAmbulance serviceAppendicitisNursing care

The invention discloses a postoperative suture removal nursing device for appendicitis surgery in general surgery, which includes a nursing bed; a number of shaking assemblies are fixedly connected between the left and right side walls of the nursing bed, and the shaking assemblies include a nursing bed fixedly connected to the nursing bed. The left side wall of the bed and the swaying connectors symmetrically on the right side; support rods are fixedly connected between the swaying connectors; the swaying connectors all include a first spherical shell fixedly connected to the side wall of the nursing bed, and the swaying connectors also include The second spherical shell fixedly connected to the support rod, the first spherical shell is rotatably connected with the first sphere, the first sphere is limited in the first spherical shell; the second spherical shell is rotatably connected with the second sphere, the second The sphere is limited in the second spherical shell; a connecting rod is fixedly connected between the first sphere and the second sphere; the above-mentioned device also includes a cylinder assembly; Significantly increased intestinal motility stability during the process.

Owner:江西省琪琪医疗器械有限公司

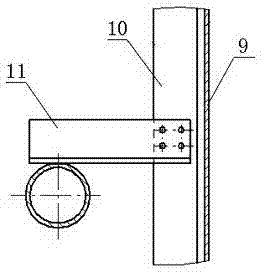

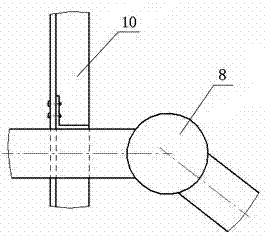

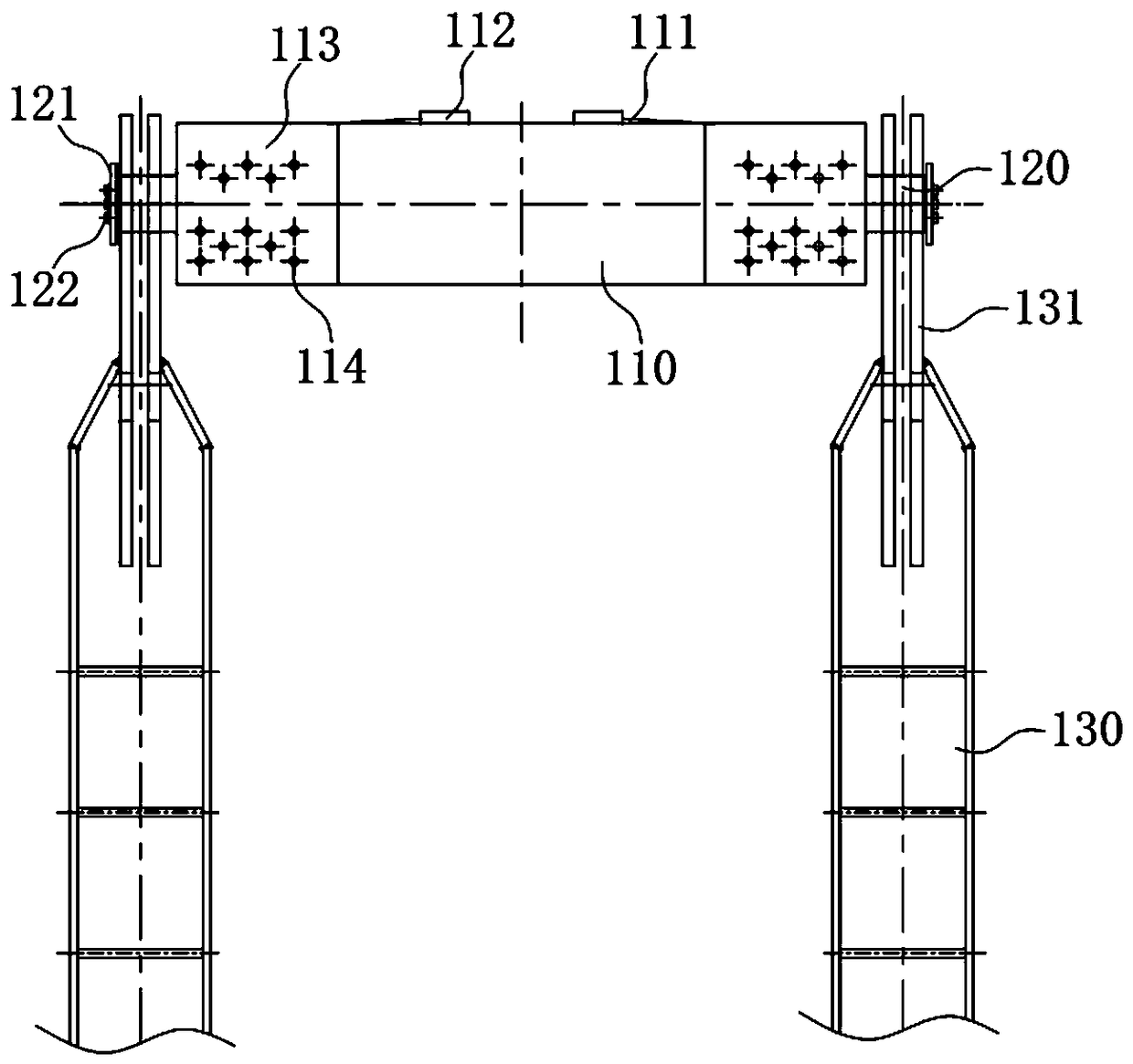

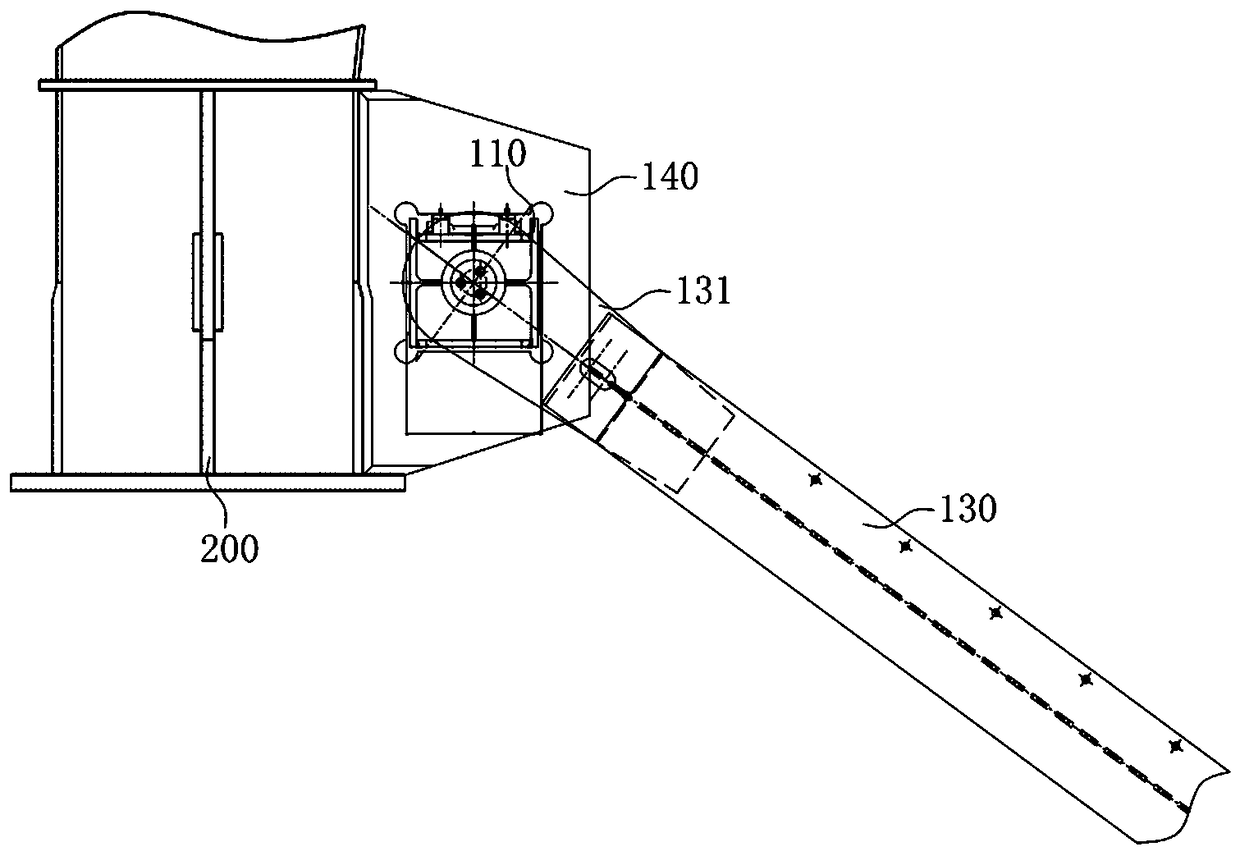

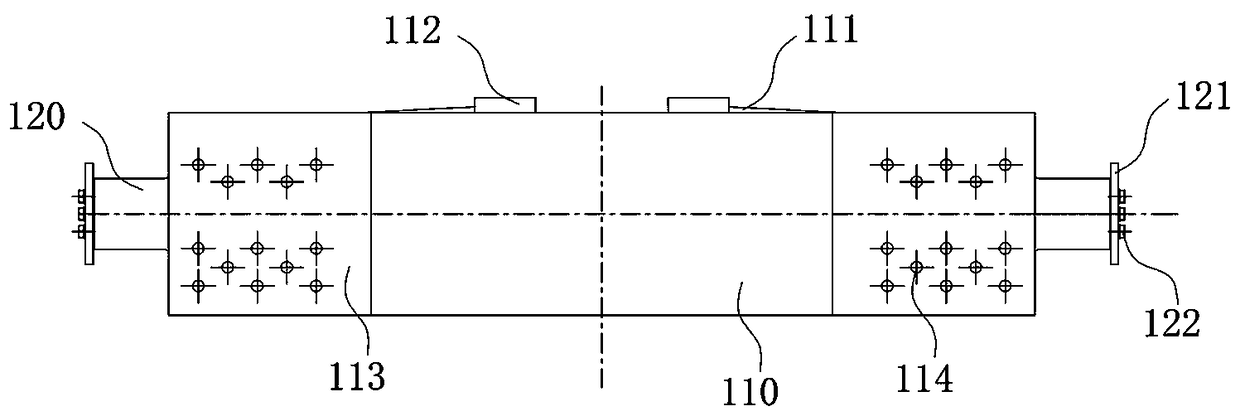

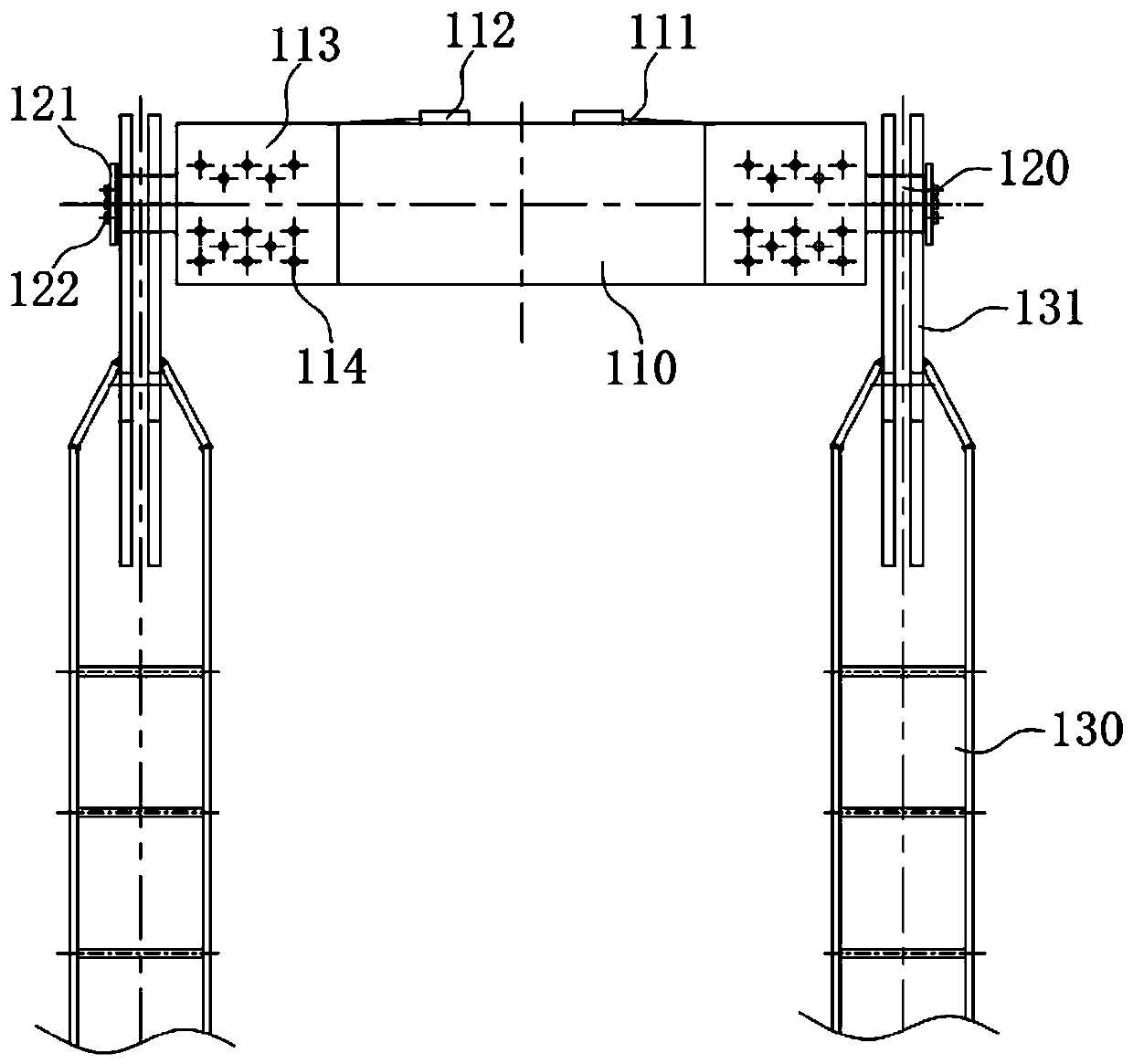

Sea tying carrying pole device and sea tying method for heavy equipment

ActiveCN108639251AEasy to assemble and disassembleSave spacePreventing unwanted cargo movementModularityHeavy equipment

The invention belongs to the technical field of waterway transportation of heavy equipment, and discloses a sea tying carrying pole device and a sea tying method for the heavy equipment. The sea tyingcarrying pole device comprises a carrying pole body, a hinge pin and supporting beams, wherein the hinge pin is disposed in the carrying pole body in a matched mode, and the end portion of the hingepin extends out of the carrying pole body. The upper ends of the supporting beams are arranged at the end portion of the hinge pin in a sleeving mode, and shaft end limiting assemblies are disposed atboth ends of the hinge pin. The shaft end limit assemblies and the carrying pole body limit the lateral sliding movement of the supporting beams. The sea tying carrying pole device realizes the modular design and standardized design of heavy equipment water transportation, and realizes the structural design of the sea tying carrying pole device for the heavy equipment and the characteristic property of the transport ship water transportation; targeted design is carried out from installation and disassembly, operation and construction, bearing performance and the like, and at the same time, the recycling and construction cost of the sea tying carrying pole device are considered and optimized, and breakthrough innovation in the whole equipment and construction method is achieved.

Owner:HUADIAN CAOFEIDIAN HEAVY IND

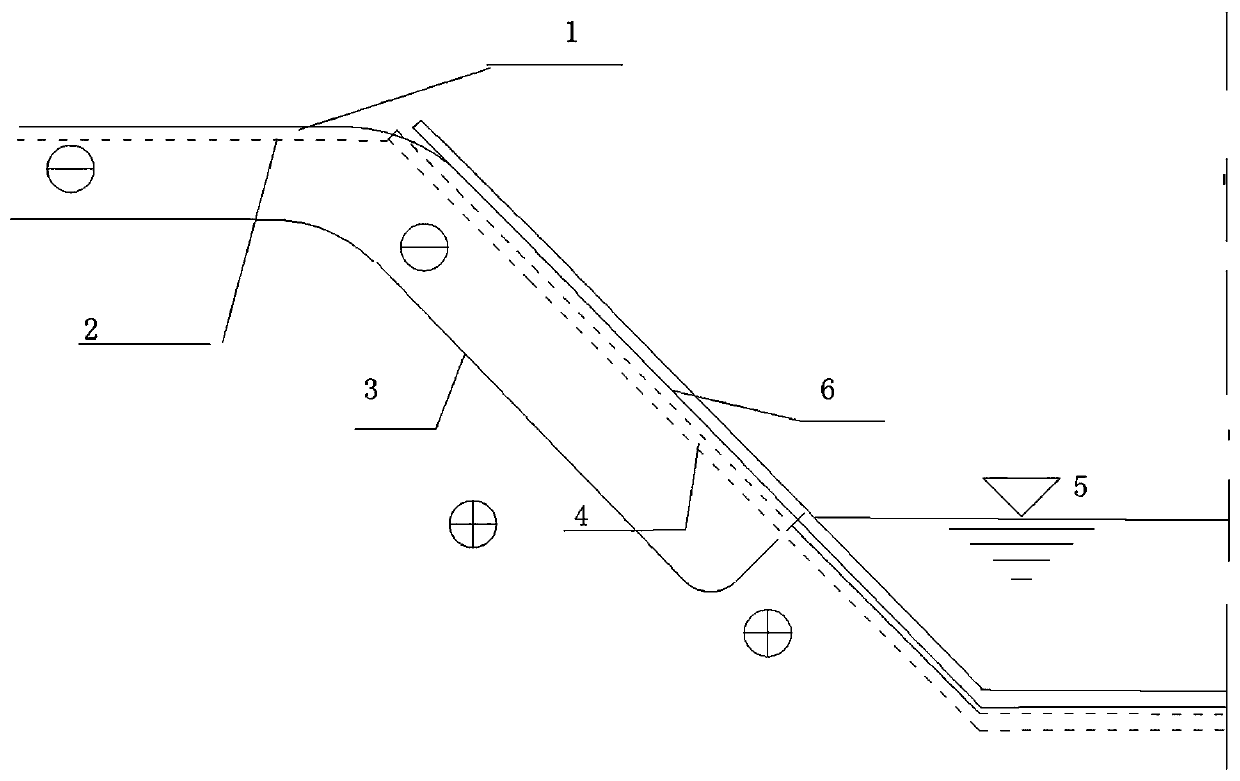

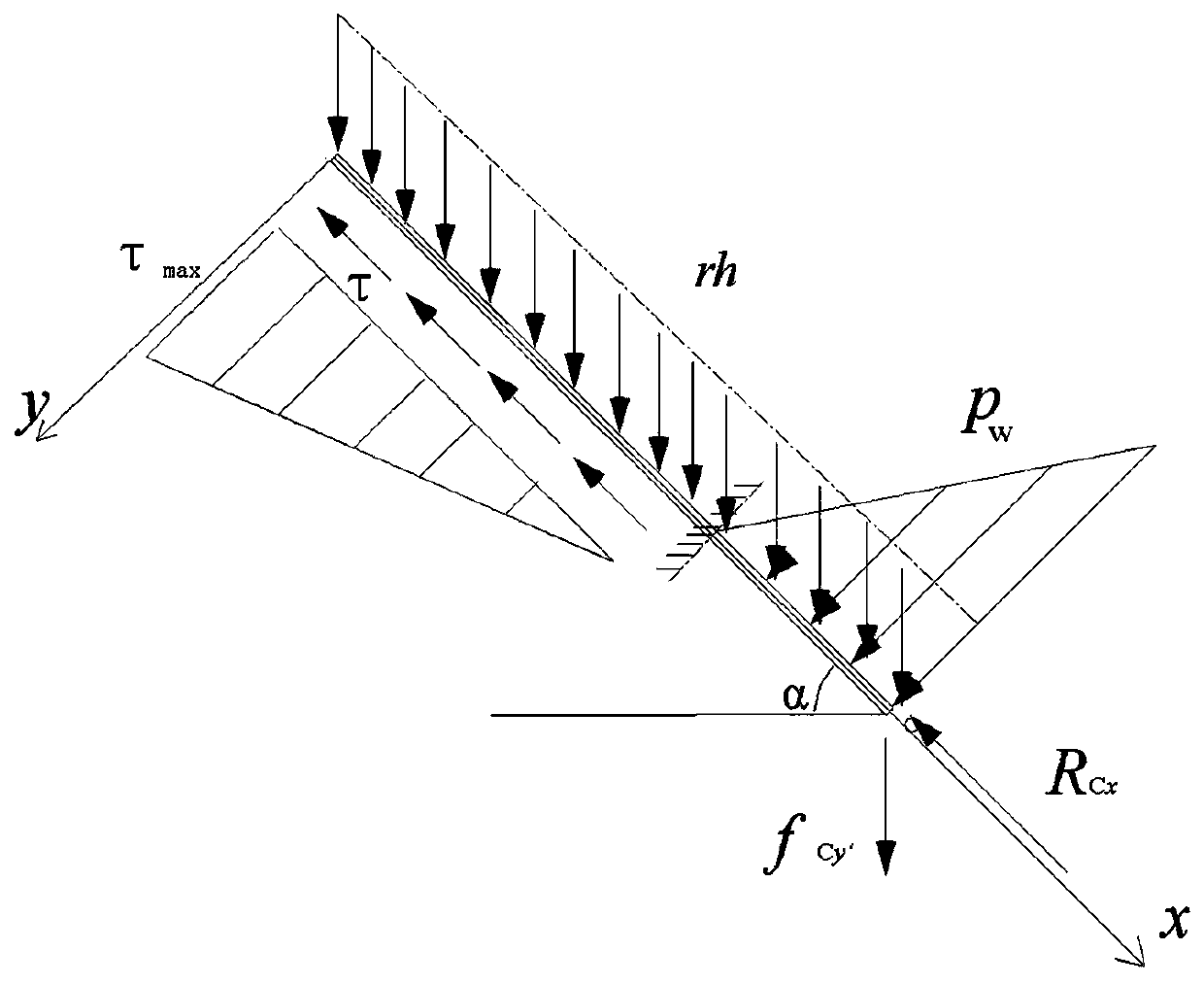

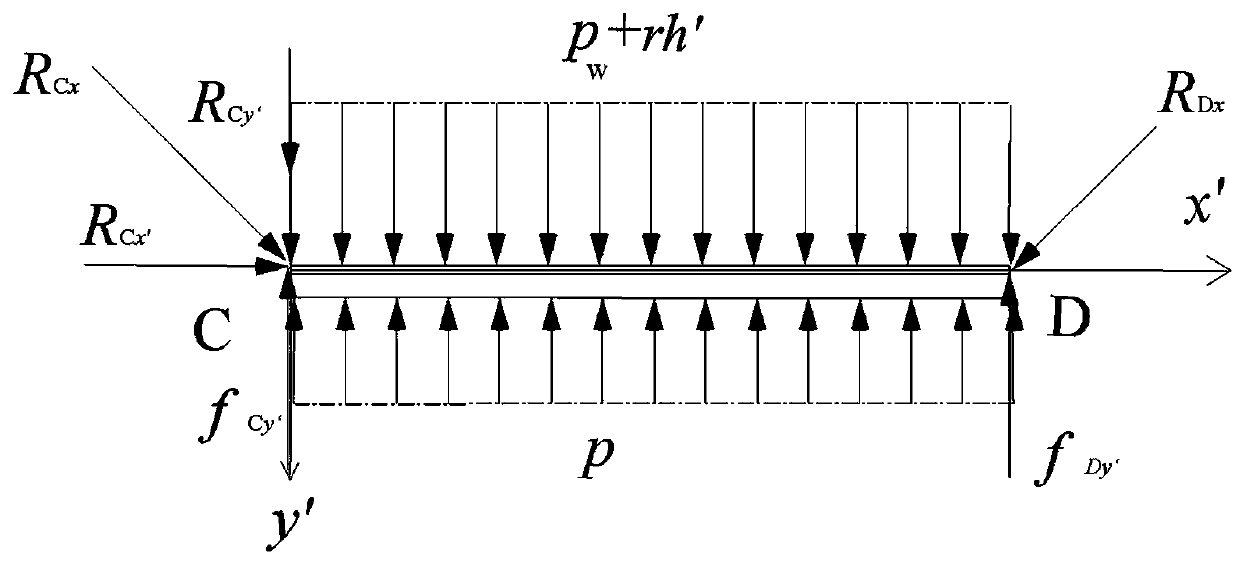

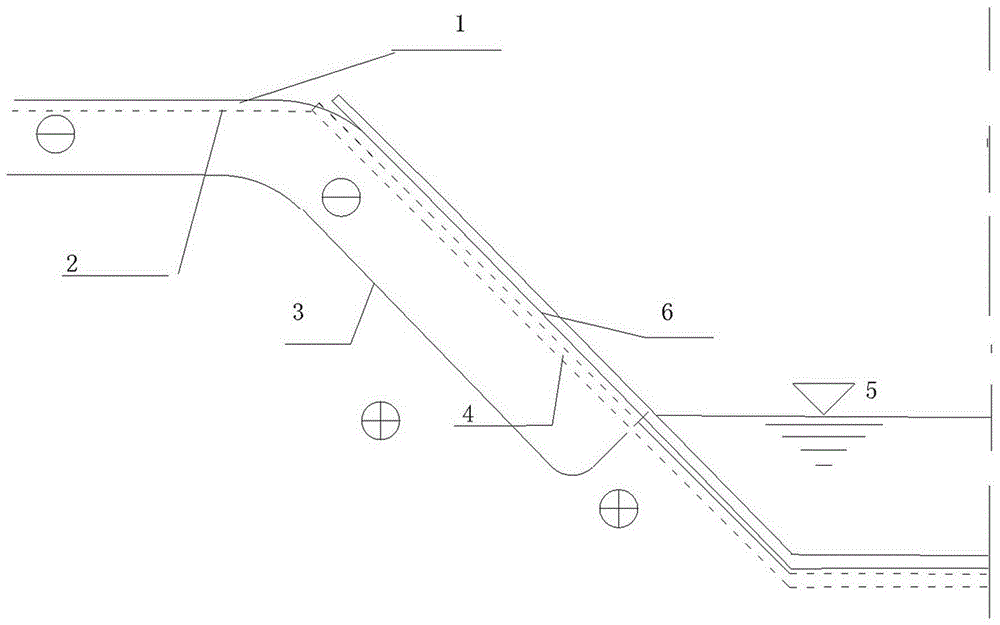

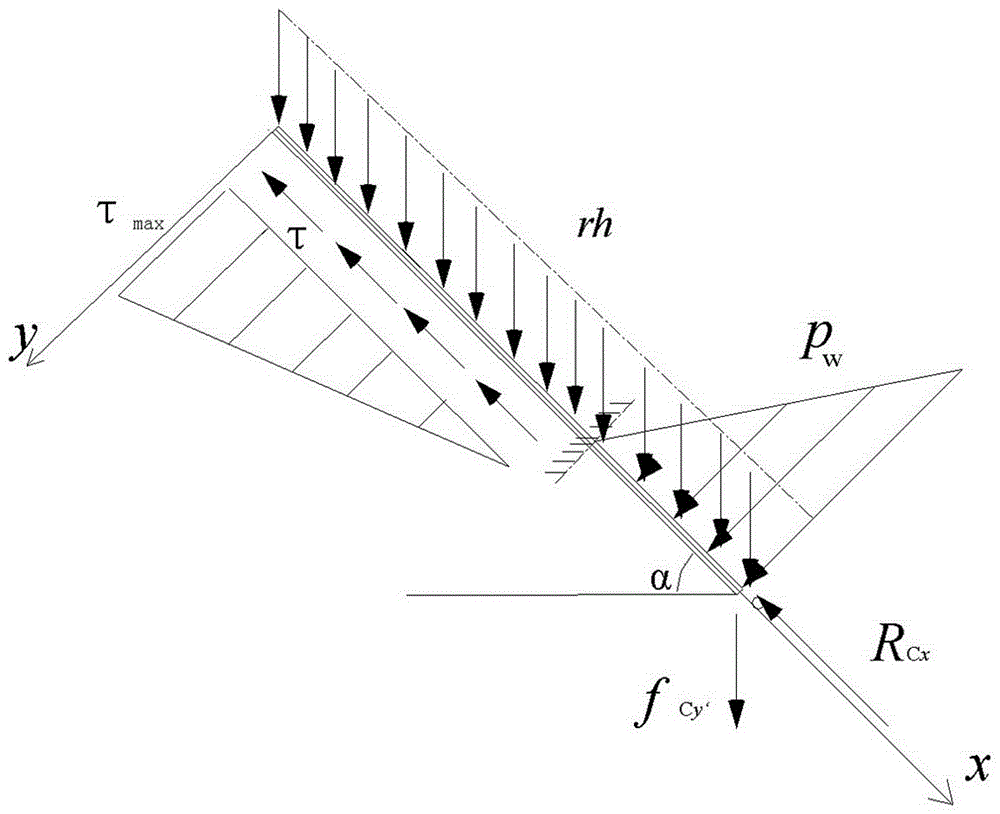

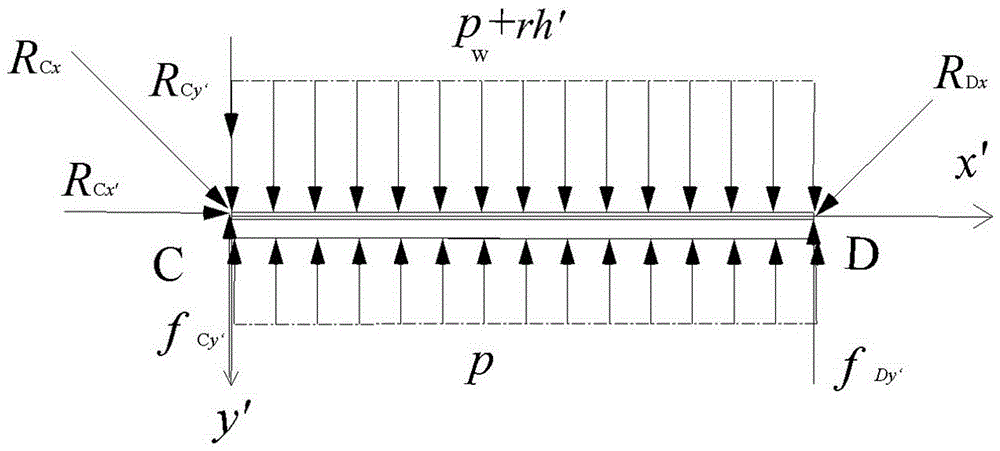

Frost-heave damage checking method of concrete trapezoidal channel during low water level operation in winter

ActiveCN106529046BSolve the anti-frost heave damage ability checkFrost heave damage checking resistanceGeometric CADDesign optimisation/simulationEngineeringFrost heaving

The invention discloses a frost heaving damage resistance checking method for a trapezoidal concrete channel during low water level operation in winter. The portion, above the water surface profile in the channel and frozen together with foundation soil, of a concrete side slope plate is regarded as restraint of the portion, below the water surface profile in the channel, of the concrete side slope plate, and the portion, below the water surface profile in the channel, of the concrete side slope plate is regarded as a cantilever structure under water pressure, self-weight and the restraint function of a bottom plate; the bottom plate is regarded as a stressed component under the water pressure and self-weight, the two ends of the bottom plate are restrained by the concrete side slope plate, and the bottom plate is horizontally placed on the foundation soil; the concrete side slope plate and the bottom plate are compared with concrete axial tension strength according to tensile stress generated by the tension bending combination action and tensile stress generated by the pressure bending combination action, and in this way, whether the concrete side slope plate and the bottom plate can resist the frost heaving damage function of the foundation soil of the channel or not is judged. By the adoption of the frost heaving damage resistance checking method to perform frost heaving damage resistance design on a lining layer of the concrete channel under a low water level condition, it can be ensured that the concrete channel has sufficient frost heaving damage resistance, and safe and reliable operation of the concrete channel is guaranteed.

Owner:SHIHEZI UNIVERSITY

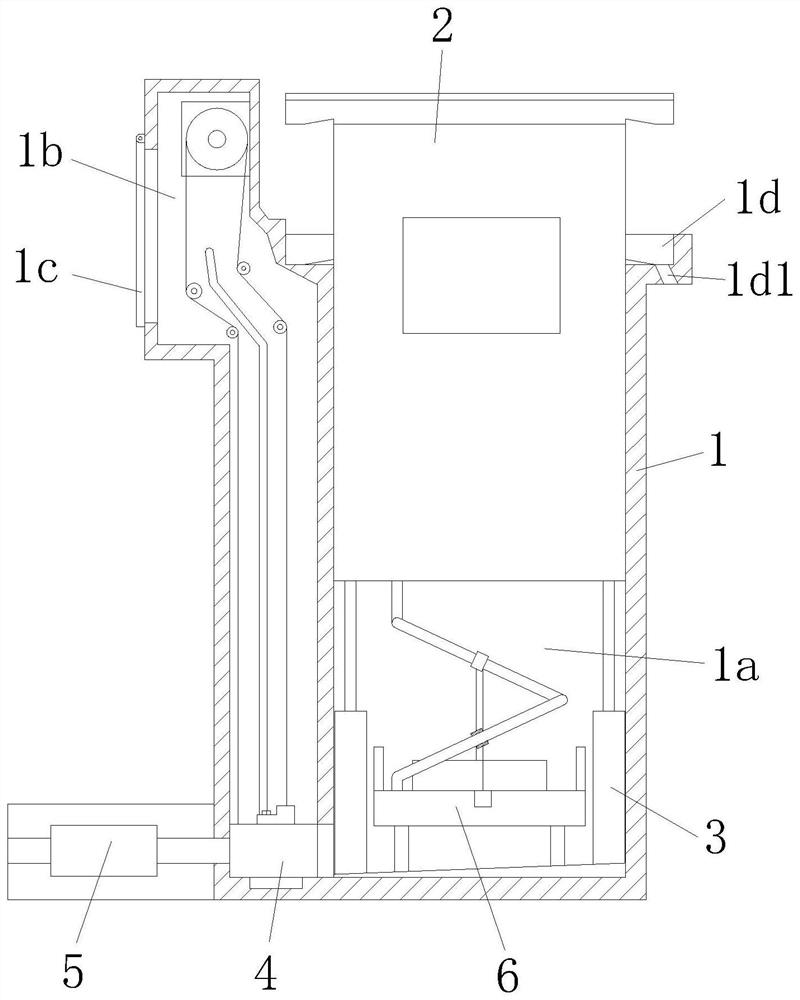

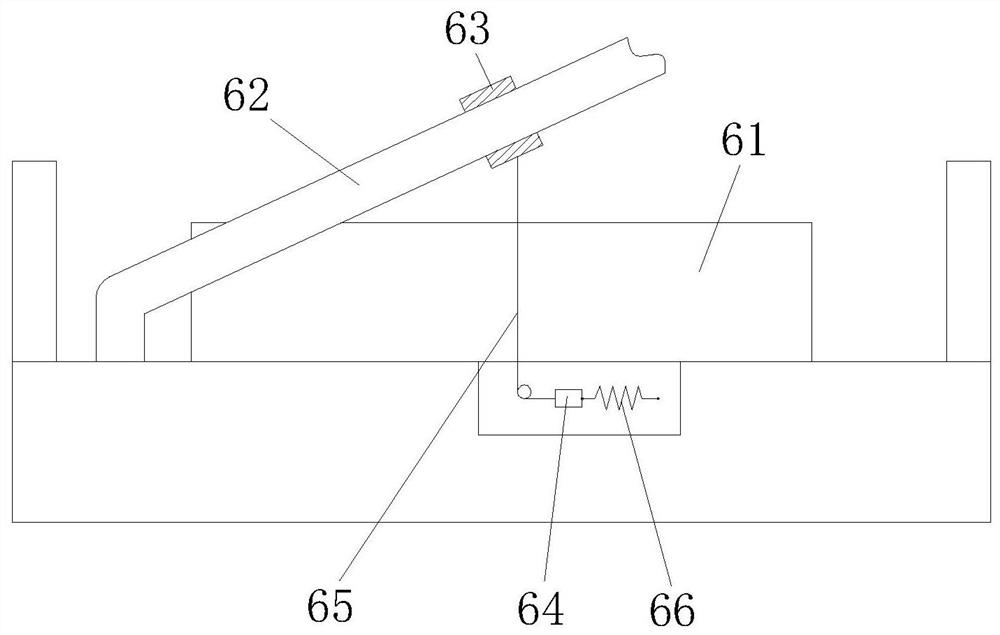

A lifting charging pile

ActiveCN110936838BStructural Design ImplementationEasy maintenanceCharging stationsElectric vehicle charging technologyHydraulic cylinderStructural engineering

The invention discloses a lifting type charging pile, which comprises an embedded part and a charging pile body. One side of the embedded part has an accommodation cavity, and the other side of the embedded part has an auxiliary cavity. A sliding groove is installed in the accommodation cavity for charging. The pile body is slidably installed in the sliding groove, the lower part of the charging pile body is equipped with a hydraulic cylinder, the auxiliary chamber is equipped with a guide groove, the guide groove is equipped with a filter assembly, the lower part of the auxiliary chamber is equipped with a pump, and the auxiliary chamber is installed. A moving component is provided, and a drain is provided in the accommodating chamber. The present invention realizes the structural design of the hidden charging pile through the cooperation of the embedded parts and the charging pile body. At the same time, the cooperation between the filter assembly and the pump is arranged in the embedded parts, so that the rainwater flowing into the embedded parts can be pumped out, and The mobile component can drive the filter component to move, which is convenient for the maintenance of the mobile component.

Owner:ANHUI KECHUANG NEWENERGY TECH CO LTD

A demand-oriented interactive design method for driving wheel structure based on geometric features

ActiveCN107229782BImprove design efficiencySave human resourcesGeometric CADDesign optimisation/simulationElement modelInteractive design

The invention provides a demand-oriented geometric feature-driving turbine disc structure interactive design method. The interactive design method comprises following steps of 1, inputting coordinate values of control points of a turbine disc two-dimensional geometrical configuration; 2, establishing a turbine disc axisymmetric finite element model for the turbine disc two-dimensional geometrical configuration; 3, carrying out structural analysis on the established turbine disc axisymmetric finite element model; and 4, in dependence on the design demand, changing the turbine disc two-dimensional geometrical configuration, and automatically displaying the coordinate values of the control points of the turbine disc two-dimensional geometrical configuration, establishing the turbine disc axisymmetric finite element model and carrying out finite element calculation. Through the above steps, the control points of the turbine disc two-dimensional geometrical configuration can be dragged by a mouse, turbine disc weight calculation, stress-strain analysis, fatigue life prediction, meridian plane burst speed calculation and radial burst speed calculation are automatically carried out, the turbine disc structure design efficiency is improved, and the case that during the previous design process, once the scheme is changed, modeling needs to be carried out again manually, and therefore time and manpower are wasted is avoided.

Owner:BEIHANG UNIV

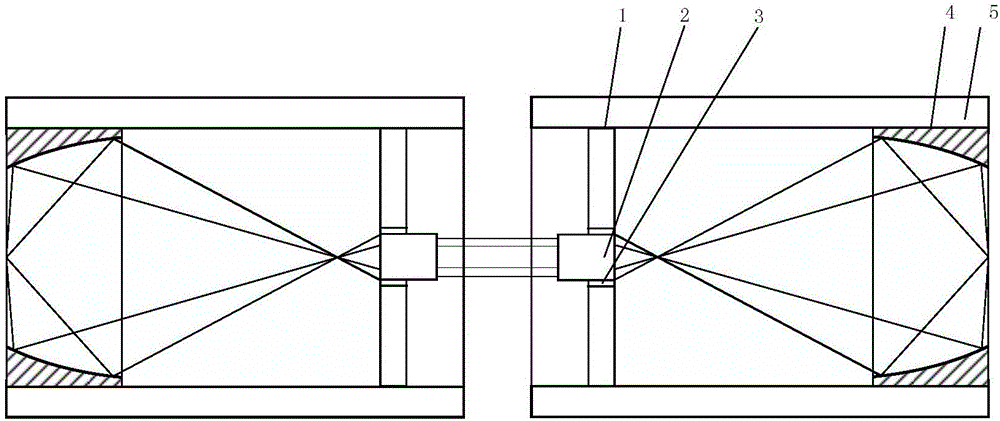

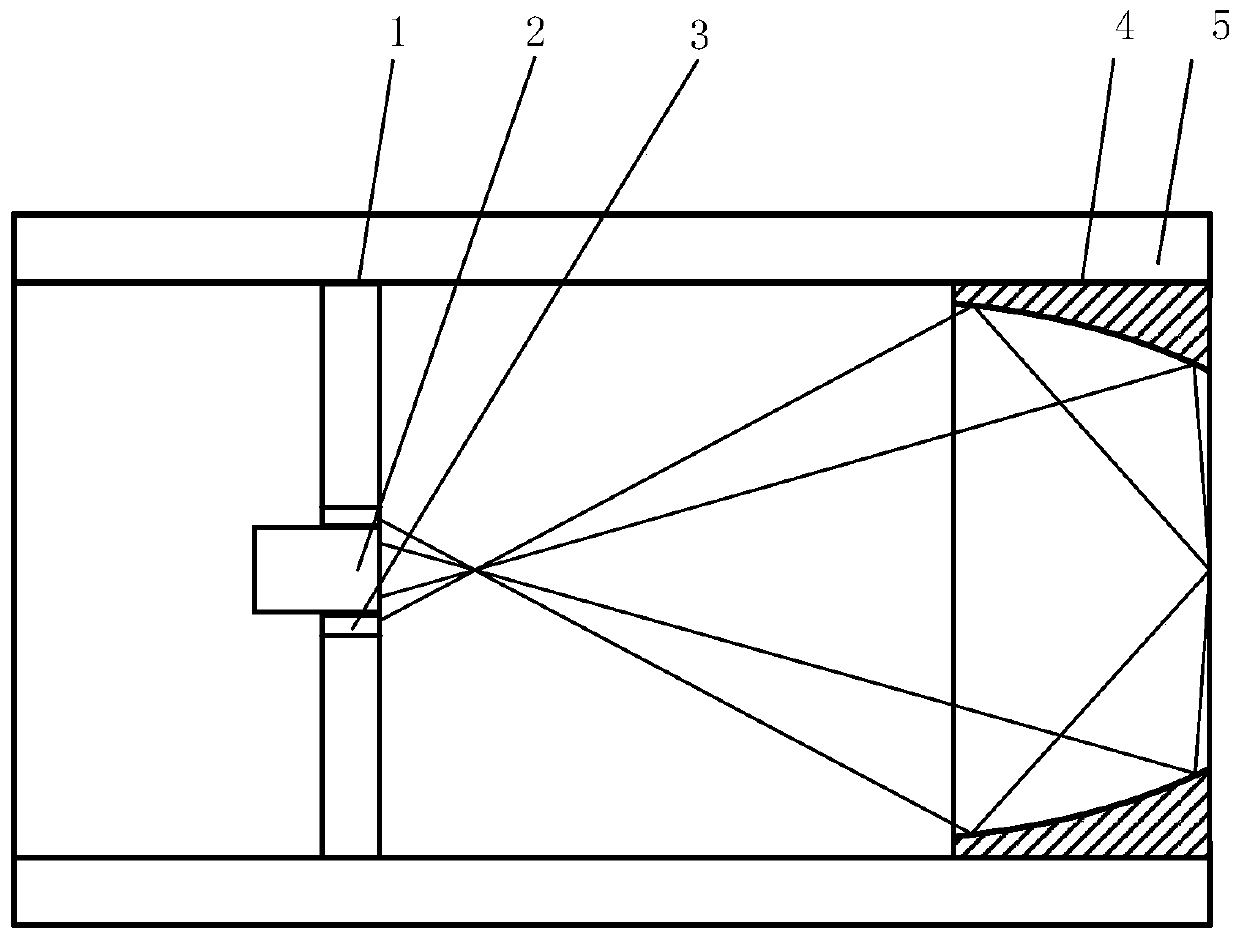

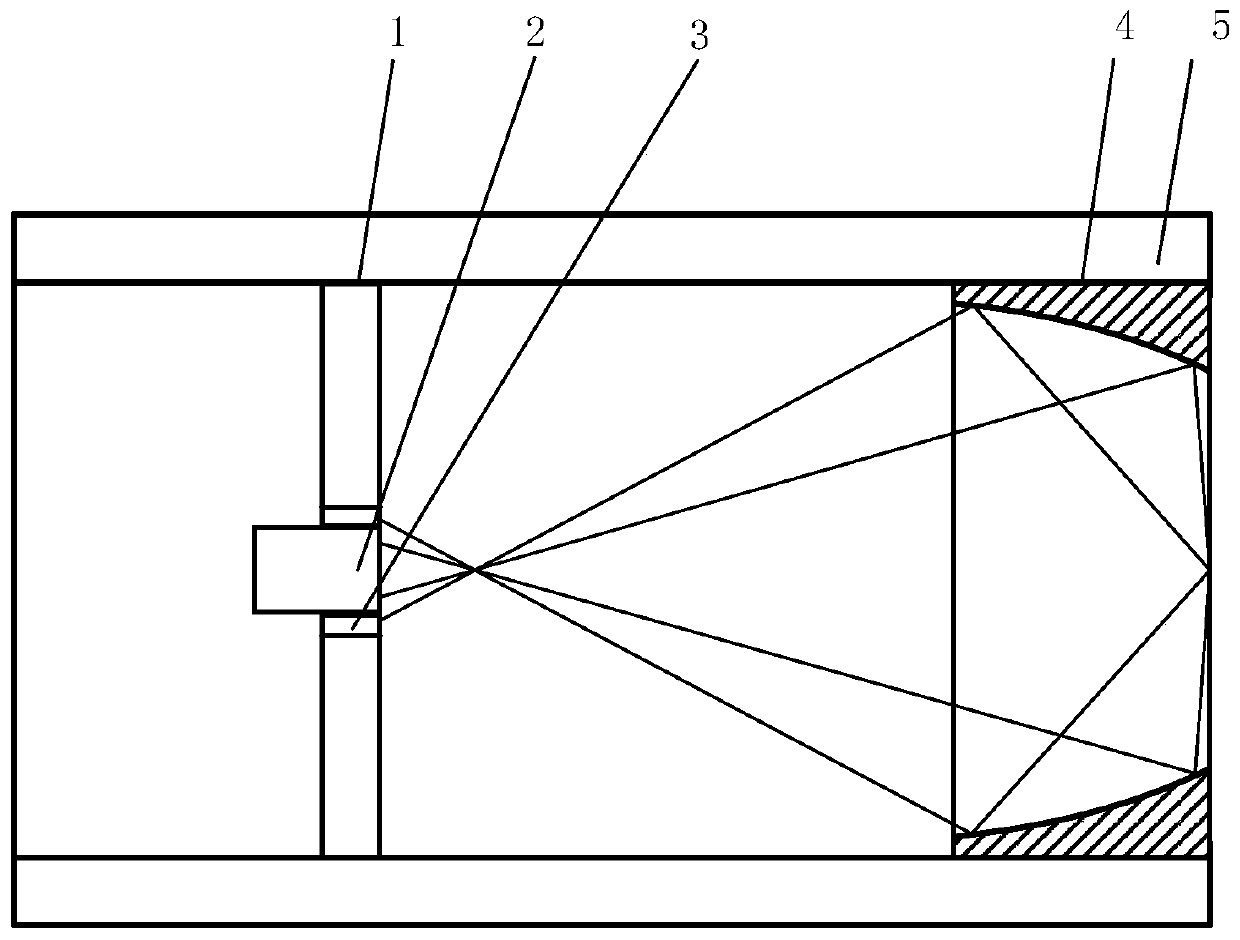

Diafocal point positioning-free type dual-ellipsoid imaging device

ActiveCN106501927ARealize free positioningStructural Design ImplementationOptical elementsOptical axisThree dimensional measurement

The invention provides a diafocal point positioning-free type dual-ellipsoid imaging device and belongs to the technical field of optical imaging. The imaging device comprises two sets of coaxially and oppositely arranged identical ellipsoidal reflecting systems. Each ellipsoidal reflecting system is composed of a fixed disc, an objective lens, an objective lens adaptor, an ellipsoidal reflecting mirror and a fixed sleeve, wherein the above parts are coaxially arranged. The fixed disc is arranged inside the fixed sleeve. The center of the fixed disc is provided with a threaded hole. The objective lens adaptor for fixing the objective lens is in threaded connection with the threaded hole. Through the rotation of the objective lens adaptor inside the threaded hole, the objective lens can move along an optical axis, so that the focal point of the objective lens coincides with the far focal point of the ellipsoidal reflecting mirror. The near focal point of the ellipsoidal reflecting mirror is simultaneously located on the end surface of the ellipsoidal reflecting mirror and the end surface of the fixed sleeve. According to the technical scheme of the invention, based on the design of a special mechanical structure, the spatial three-dimensional measurement step during the installing and adjusting process of the ellipsoidal reflecting mirror is avoided. meanwhile, the imaging device is simple to install and adjust, high in efficiency, and theoretically aberration-free.

Owner:HARBIN INST OF TECH

Bifocal positioning-free ellipsoidal reflector lighting device

ActiveCN106767392BRealize free positioningStructural Design ImplementationUsing optical meansOptical axisThree dimensional measurement

Owner:HARBIN INST OF TECH

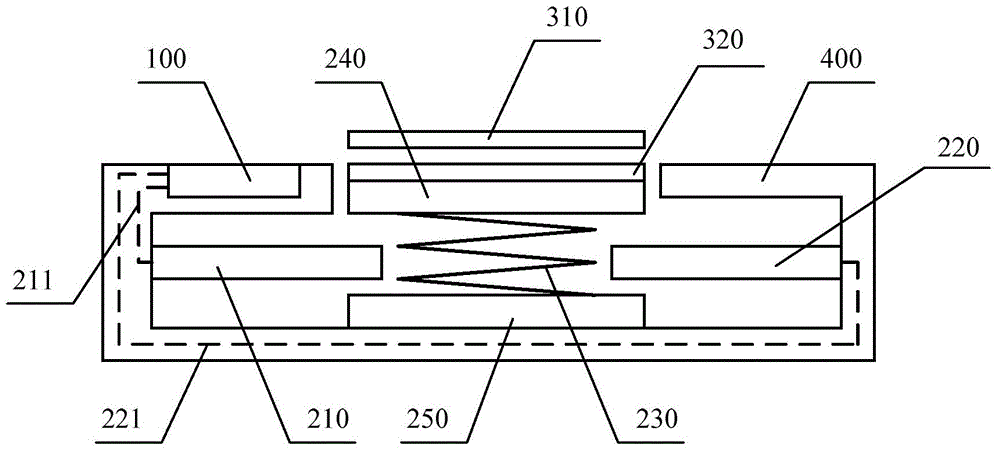

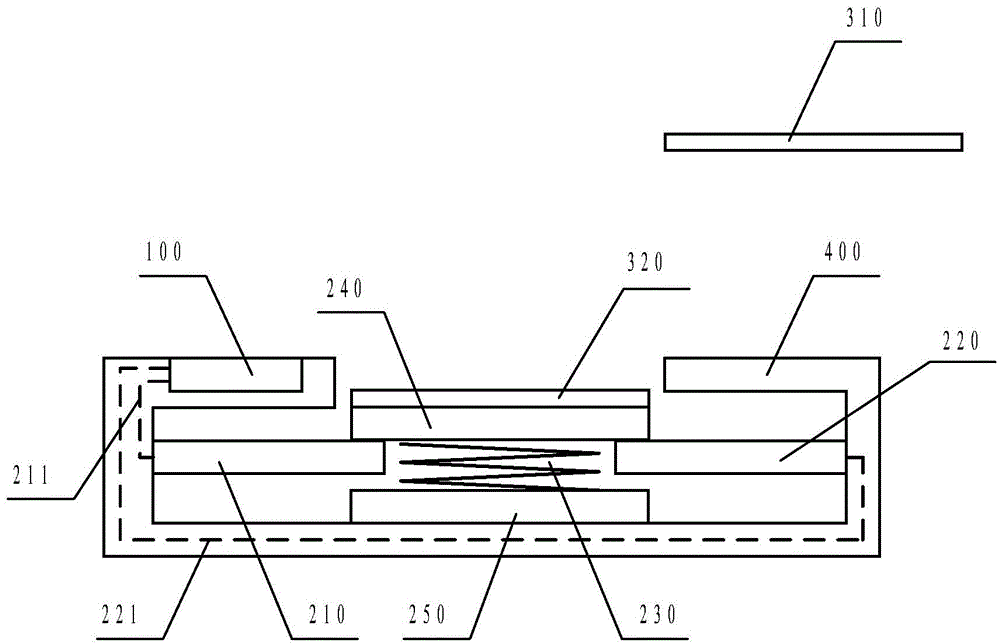

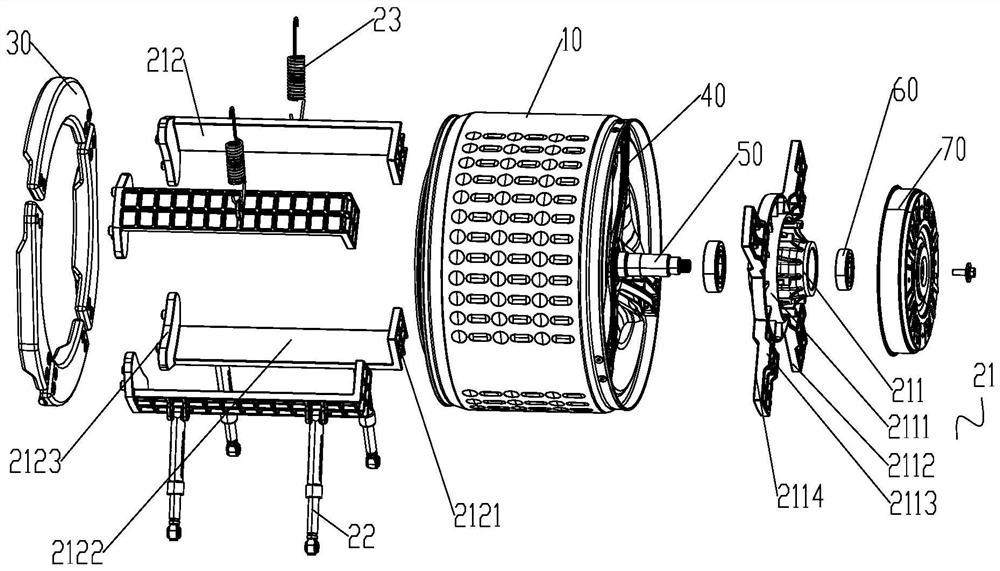

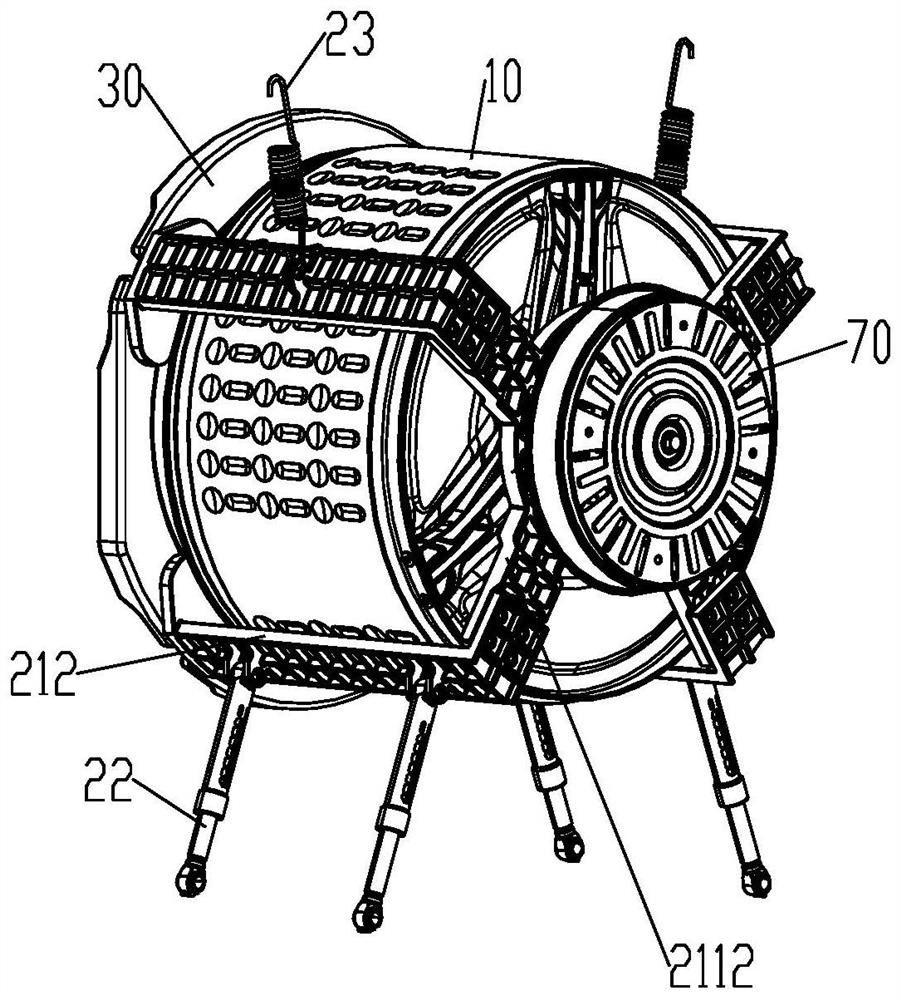

Roller washing machine without outer drum

InactiveCN113699736AStructural Design ImplementationQuality improvementOther washing machinesWashing machine with receptaclesLaundry washing machineEngineering

The invention provides a roller washing machine without an outer drum. The roller washing machine without the outer drum comprises a housing, a cylinder body, an elastic supporting assembly and a weight balancing block; a feeding opening is formed in one end of the cylinder body, and the cylinder body is arranged in the shell; the elastic supporting assembly comprises a damper and a hanging spring, the damper is located below the cylinder body, the hanging spring is located above the cylinder body, and the cylinder body is connected with the inner wall of the shell through the elastic supporting assembly; and the weight balancing block is arranged on the side, close to the feeding opening, of the elastic supporting assembly. The problem that in the prior art, the internal structure of a roller washing machine without an outer drum is difficult to arrange is solved.

Owner:GREE ELECTRIC APPLIANCES INC

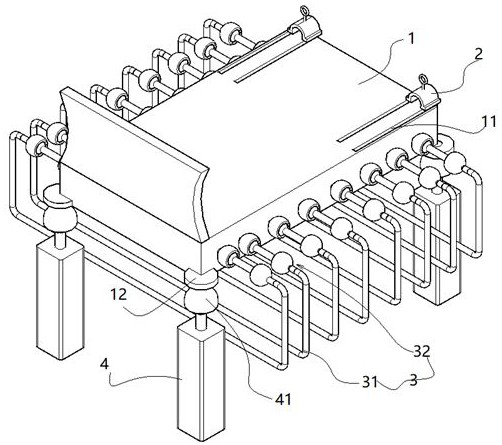

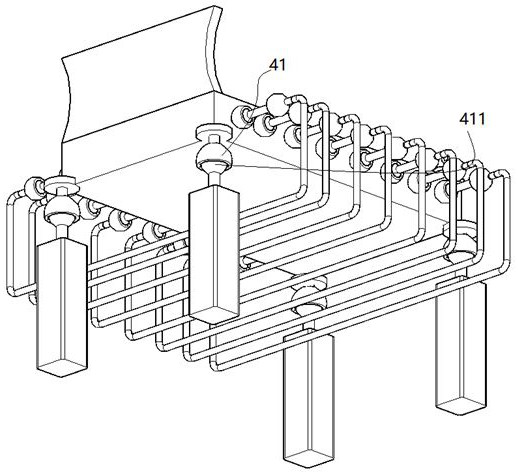

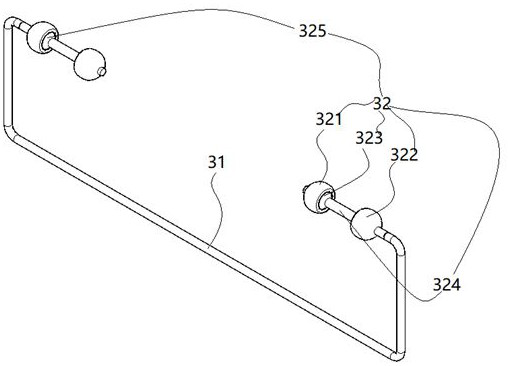

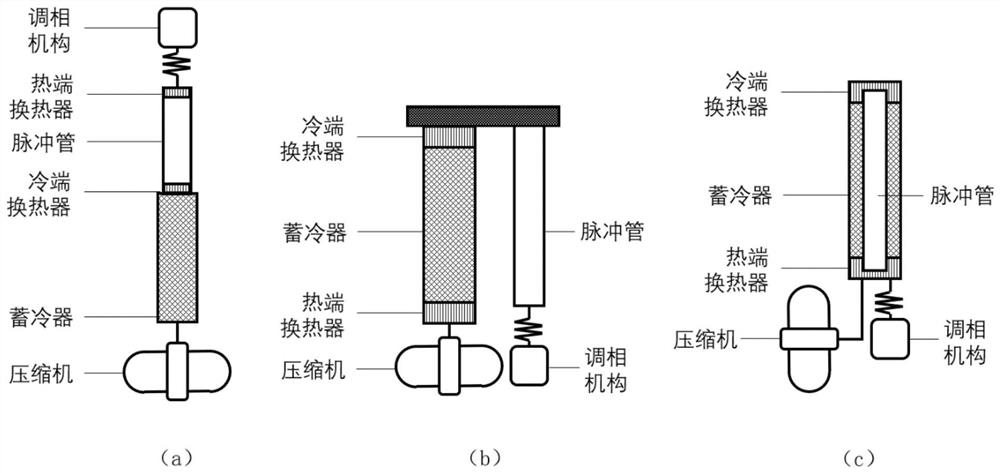

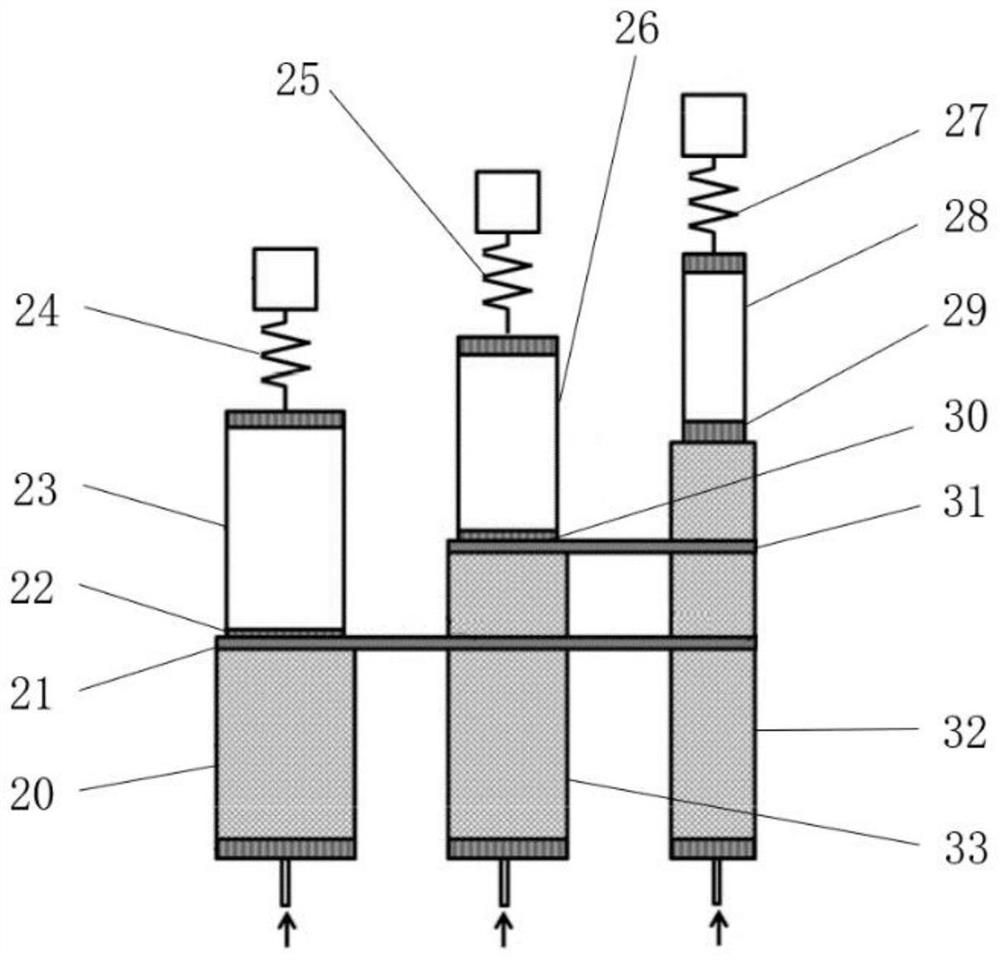

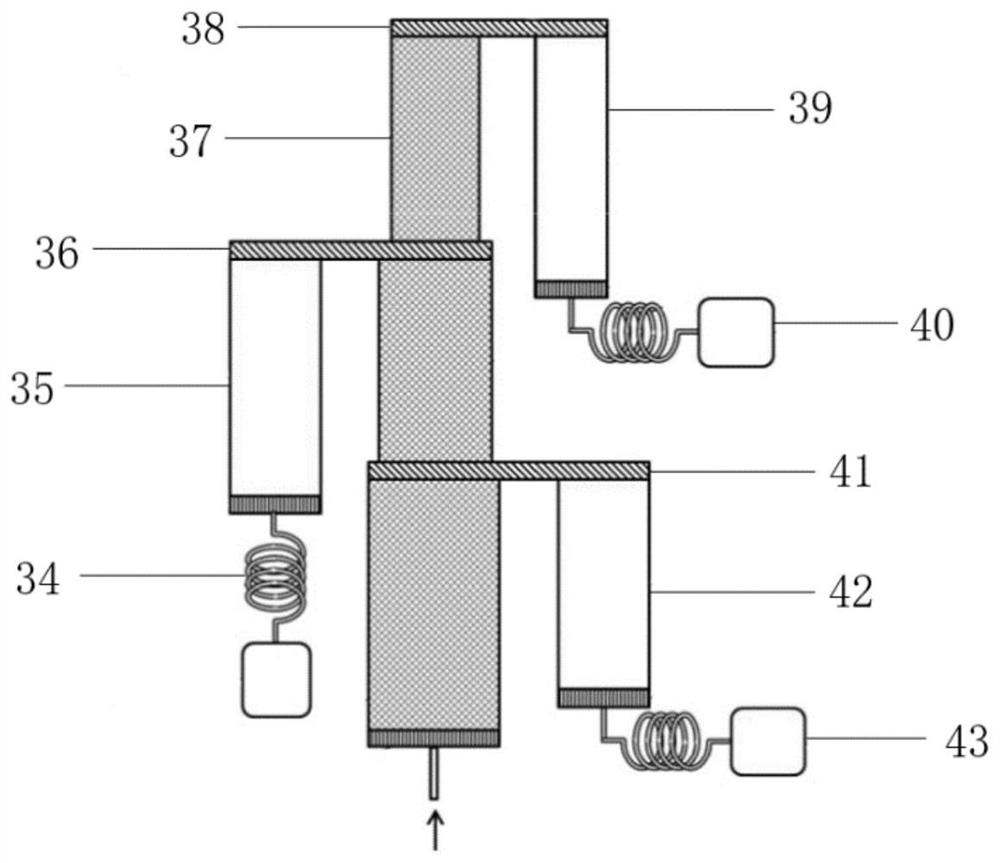

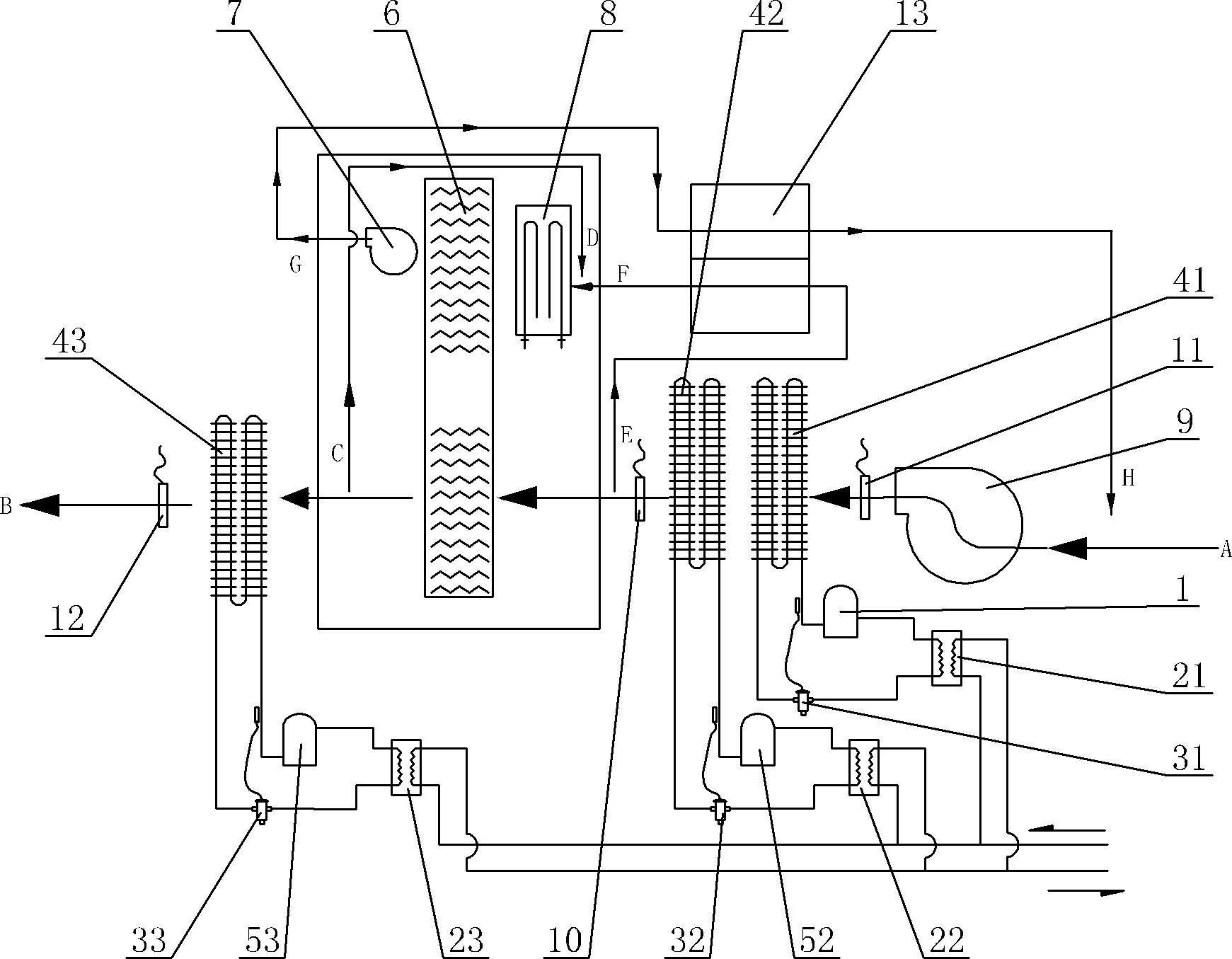

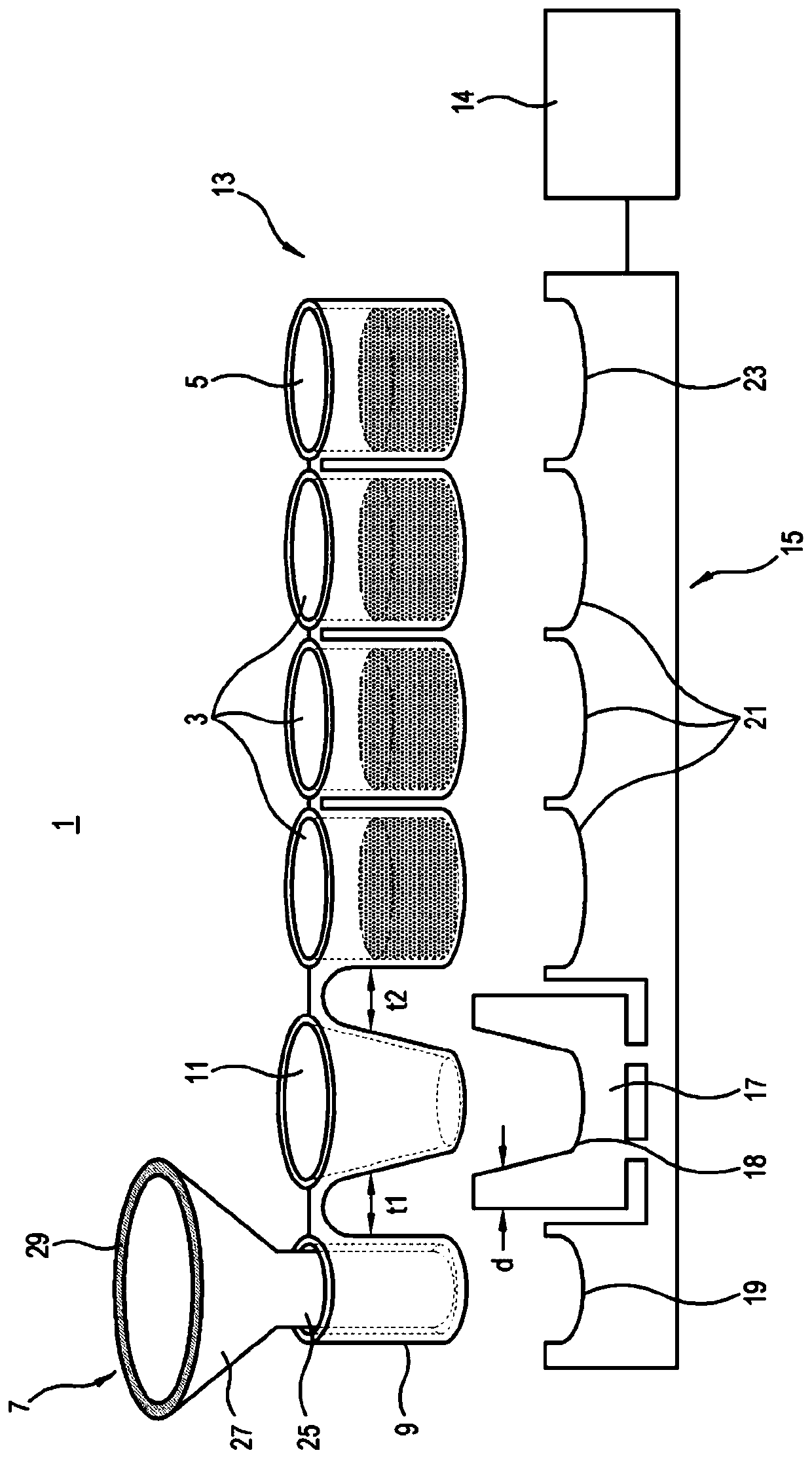

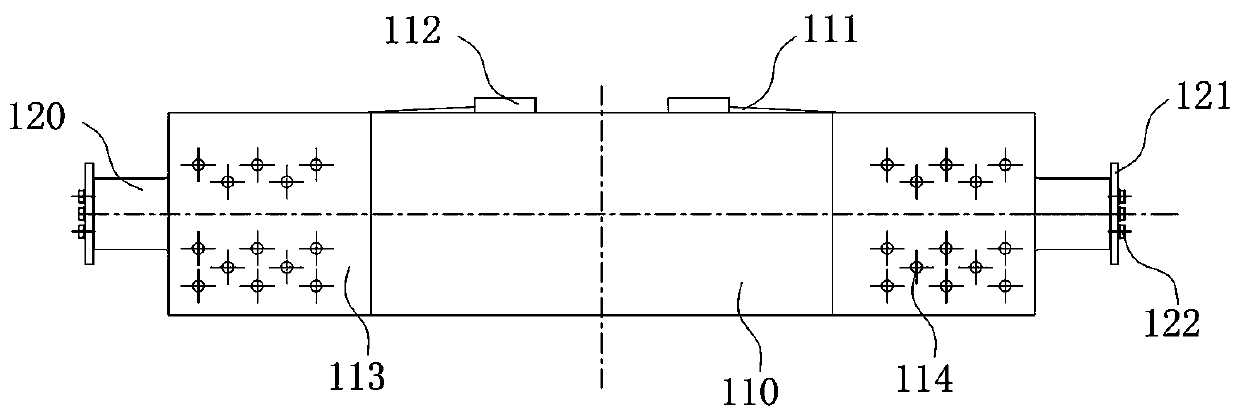

Multi-stage U-shaped gas-coupled pulse tube refrigerator connected-tube heat exchanger and its realization method

ActiveCN112880225BAvoid mixed flowPrevent backflowDomestic cooling apparatusEvaporators/condensersMixed flowPulse tube refrigerator

The invention discloses a tube-connected heat exchanger for a multi-stage U-shaped gas-coupling pulse tube refrigerator and a method for realizing the same. The cold-end heat exchanger comprises a heat exchanger shell, a connecting tube, a conical slit body, a The first through hole, the laminar flow element, the second conical slit body, and the second through hole. Conical slits are cut on the left and right sides of the heat exchanger shell respectively, and the two parts are connected by welding connecting pipes, and the connection of the first-stage regenerator, the second-stage regenerator and the first-stage pulse tube is realized at the same time. The invention maintains the advantages of high-efficiency heat exchange of traditional heat exchangers, and realizes high-efficiency matching between the front and rear stage cooling fingers of the pulse tube refrigerator, suppresses the backflow, mixed flow and turbulent disturbance of the gas working medium in the heat exchange channel, and ensures the uniformity of gas flow. sex. The invention will significantly improve the heat exchange efficiency and overall performance of the pulse tube refrigerator, and has very positive significance in realizing the compactness and practicality of the multi-stage pulse tube refrigerator and obtaining extremely low temperature.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Cone sintering device in optical fiber preform powder preparation and working method

PendingCN112028467AImprove sufficiencyStructural Design ImplementationGlass making apparatusMaterials scienceComposite material

The invention relates to the technical field of optical fiber preforms, and discloses a cone sintering device in optical fiber preform powder preparation and a working method thereof. The cone sintering device comprises a first-layer barrel, a second-layer barrel and a third-layer barrel; the first-layer barrel is located below the second-layer barrel; the second-layer barrel is located below thethird-layer barrel; and a limiting groove is formed in the bottom surface of the first-layer barrel. According to the cone sintering device in optical fiber preform powder preparation, hexagon socketscrew holes are formed and penetrate through the side wall of the first-layer barrel and the side wall of the second-layer barrel to extend into the side wall of the third-layer barrel, and the cone sintering device is designed in a multi-layer nested combination mode; the first-layer barrel, the second-layer barrel and the third-layer barrel are fixedly connected by inserting hexagon socket screws into the hexagon socket screw holes; when the hexagon socket screws are detached, the second-layer barrel and the third-layer barrel are fixedly connected through buckling connection of limiting blocks and clamping blocks, and the structural design that the device can be disassembled for maintenance is achieved.

Owner:QINGHAI ZHONGLI OPTICAL FIBER TECH CO LTD

Control method of ultra-low humidity compound dehumidifier

ActiveCN102095231BImprove utilization efficiencyReduce the amount of reheat compensationEnergy recovery in ventilation and heatingHeat recovery systemsTemperature controlDew

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Frost heaving damage resistance checking method for trapezoidal concrete channel during low water level operation in winter

ActiveCN106529046ASolve the anti-frost heave damage ability checkFrost heave damage checking resistanceGeometric CADDesign optimisation/simulationWater levelFrost heaving

The invention discloses a frost heaving damage resistance checking method for a trapezoidal concrete channel during low water level operation in winter. The portion, above the water surface profile in the channel and frozen together with foundation soil, of a concrete side slope plate is regarded as restraint of the portion, below the water surface profile in the channel, of the concrete side slope plate, and the portion, below the water surface profile in the channel, of the concrete side slope plate is regarded as a cantilever structure under water pressure, self-weight and the restraint function of a bottom plate; the bottom plate is regarded as a stressed component under the water pressure and self-weight, the two ends of the bottom plate are restrained by the concrete side slope plate, and the bottom plate is horizontally placed on the foundation soil; the concrete side slope plate and the bottom plate are compared with concrete axial tension strength according to tensile stress generated by the tension bending combination action and tensile stress generated by the pressure bending combination action, and in this way, whether the concrete side slope plate and the bottom plate can resist the frost heaving damage function of the foundation soil of the channel or not is judged. By the adoption of the frost heaving damage resistance checking method to perform frost heaving damage resistance design on a lining layer of the concrete channel under a low water level condition, it can be ensured that the concrete channel has sufficient frost heaving damage resistance, and safe and reliable operation of the concrete channel is guaranteed.

Owner:SHIHEZI UNIVERSITY

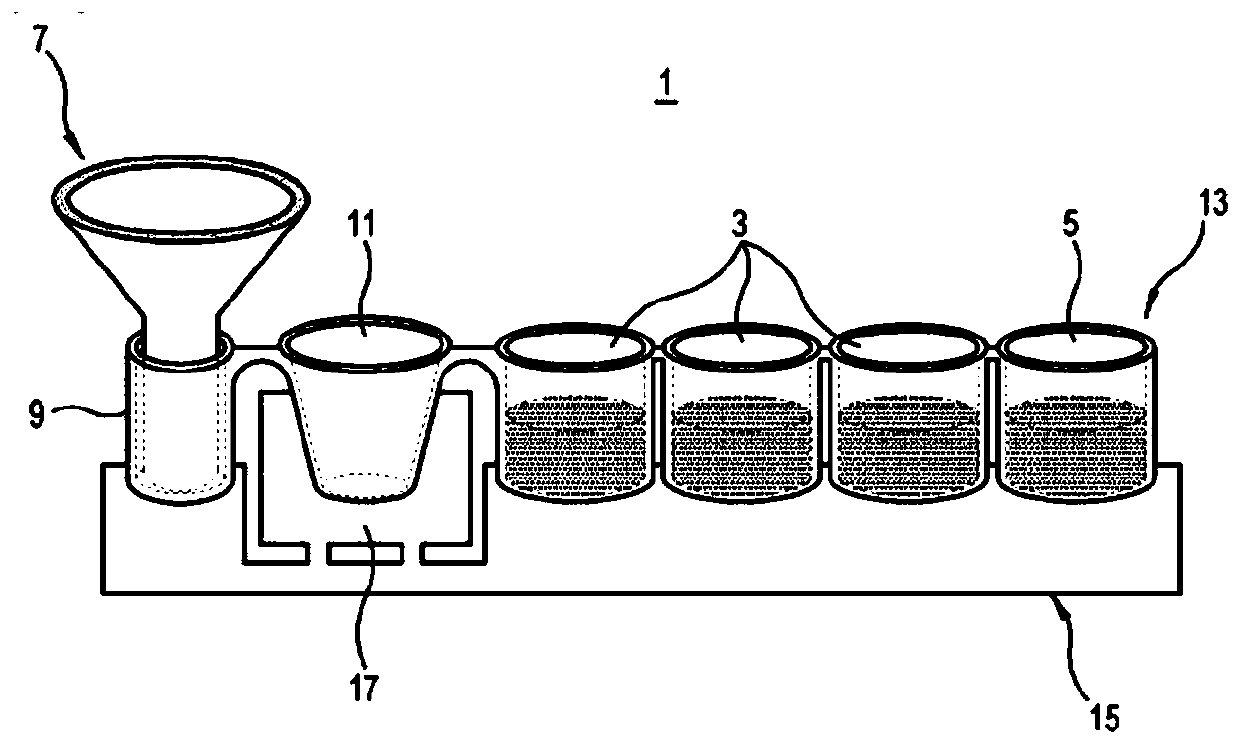

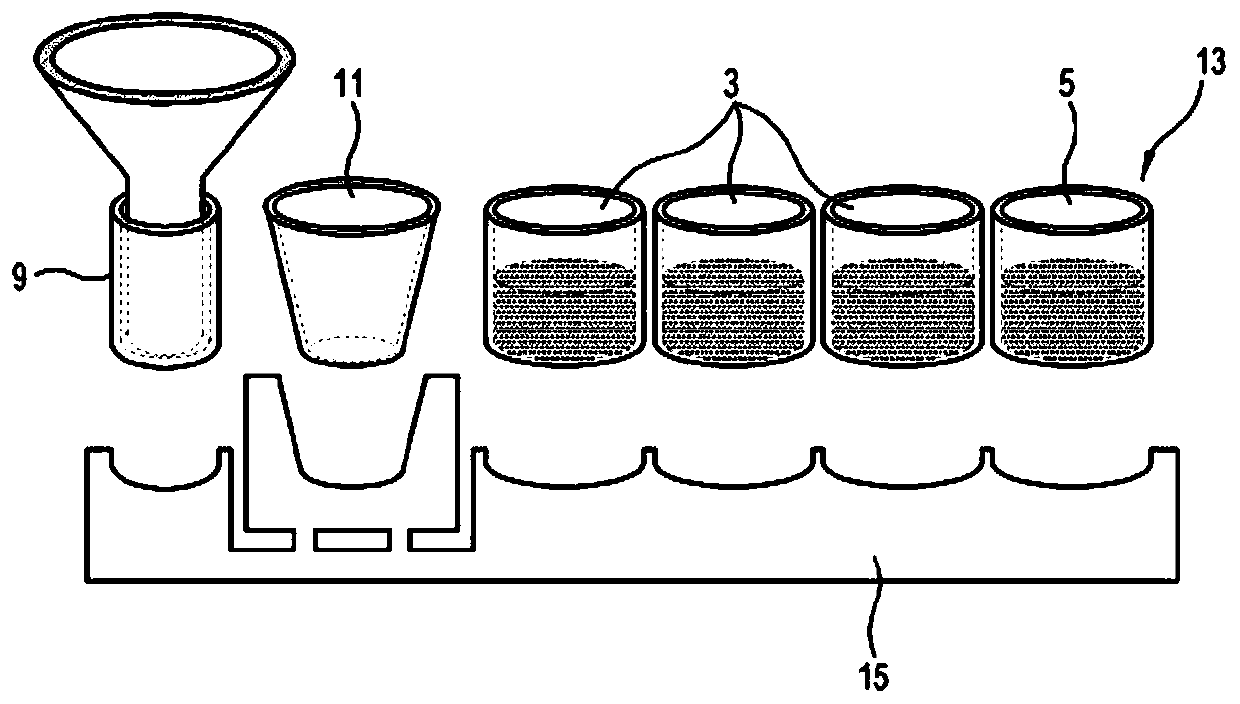

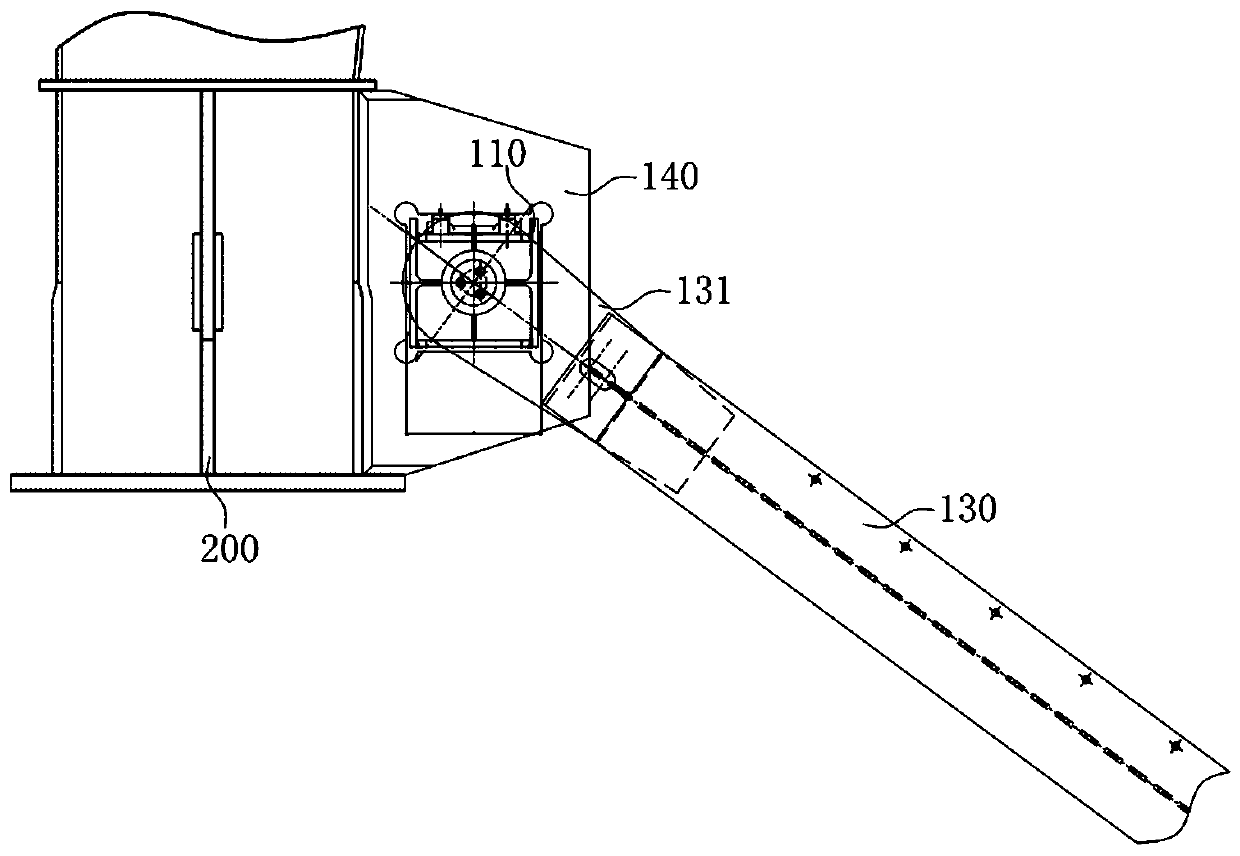

Automated immunoassay device and method using large magnetic particle complex

ActiveCN110573884AFast and easy immunoassayEasy to cleanLaboratory glasswaresMaterial analysisImmune profilingParticle physics

The present invention relates to an automated immunoassay device and method. The automated immunoassay device comprises: a cartridge (13) in which a T tip tube (9), a reactive tube (11), a washing tube (3), and a signal measuring tube (5) are integrally connected to one another or separately arranged; a T tip (7) and a magnetic rod (31) which enter the multiple tubes (3, 5) sequentially to allow the migration of large magnetic particles (m), a capturing material, a signal material, and an analysis material by magnetic force, with the concomitant performance of reactions and washing processes;a cartridge holder (15) on which the cartridge (13) is stably placed; and a heating member (17) disposed in an area in which the reactive tube (11) is stably placed on the cartridge holder (15) so asto generate heat, wherein the large magnetic particles (m) comprise morphologically identical or different magnetic particles to which a material capable of capturing only a specific analysis materialper each of the morphologically different magnetic particles is coupled.

Owner:EZDIA TECH INC

a lighting device

ActiveCN104595826BAchieve lightingStructural Design ImplementationLighting support devicesElectric circuit arrangementsEngineeringControl switch

The invention provides a lighting device which comprises a lighting unit and a switch part, an installation part and an installation box of the lighting unit. The switch part is arranged in the installation box, the switch part is provided with a first fixed end, a second fixed end, an elastic piece, a connecting piece and a fixed position; the fixed position is arranged on one sides of the first fixed end and the second fixed end, the connecting piece is arranged on one sides of the first fixed end and the second fixed end, one end of the elastic piece is fixedly arranged on the fixed position, and the other end of the elastic piece is fixedly arranged on the connecting piece; the installation part comprises a pair of magnetic parts which comprise a first magnetic part and a second magnetic part, wherein the first magnetic part is arranged outside of the lighting device, and the second magnetic part is fixedly arranged on the connecting piece. According to the lighting device, indoor lighting and wardrobe lighting are achieved, the lighting device is also suitable for lighting of other dark positions with door instructures, the structure design of a magnetic control switch is achieved, the connecting control structure is simplified, the control of the magnetic control switch is easy and convenient, light is provided as long as a door is opened, wait and grope are not needed, and the experience of a user is enhanced greatly.

Owner:HUIZHOU UNIV

Sea-tie pole device and sea-tie method for heavy equipment

ActiveCN108639251BStructural Design ImplementationReduce width requirementsPreventing unwanted cargo movementMarine engineeringModularity

The invention belongs to the technical field of waterway transportation of heavy equipment, and discloses a sea tying carrying pole device and a sea tying method for the heavy equipment. The sea tyingcarrying pole device comprises a carrying pole body, a hinge pin and supporting beams, wherein the hinge pin is disposed in the carrying pole body in a matched mode, and the end portion of the hingepin extends out of the carrying pole body. The upper ends of the supporting beams are arranged at the end portion of the hinge pin in a sleeving mode, and shaft end limiting assemblies are disposed atboth ends of the hinge pin. The shaft end limit assemblies and the carrying pole body limit the lateral sliding movement of the supporting beams. The sea tying carrying pole device realizes the modular design and standardized design of heavy equipment water transportation, and realizes the structural design of the sea tying carrying pole device for the heavy equipment and the characteristic property of the transport ship water transportation; targeted design is carried out from installation and disassembly, operation and construction, bearing performance and the like, and at the same time, the recycling and construction cost of the sea tying carrying pole device are considered and optimized, and breakthrough innovation in the whole equipment and construction method is achieved.

Owner:HUADIAN CAOFEIDIAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com