Bifocal positioning-free ellipsoidal reflector lighting device

A technology for ellipsoidal reflectors and lighting devices, applied in measuring devices, optical devices, instruments, etc., can solve problems such as complicated methods, low efficiency, and reduced complexity of ellipsoidal reflector systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

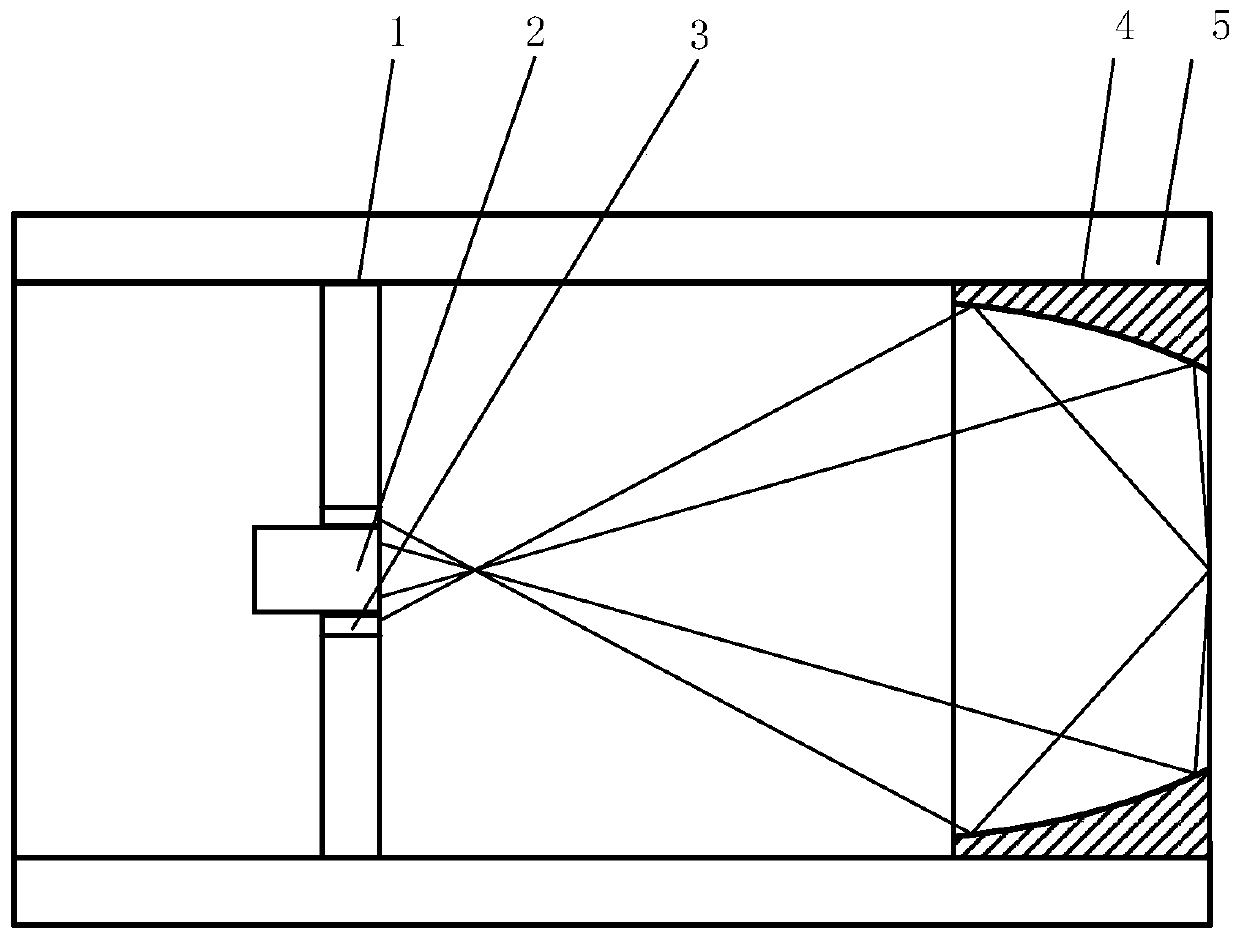

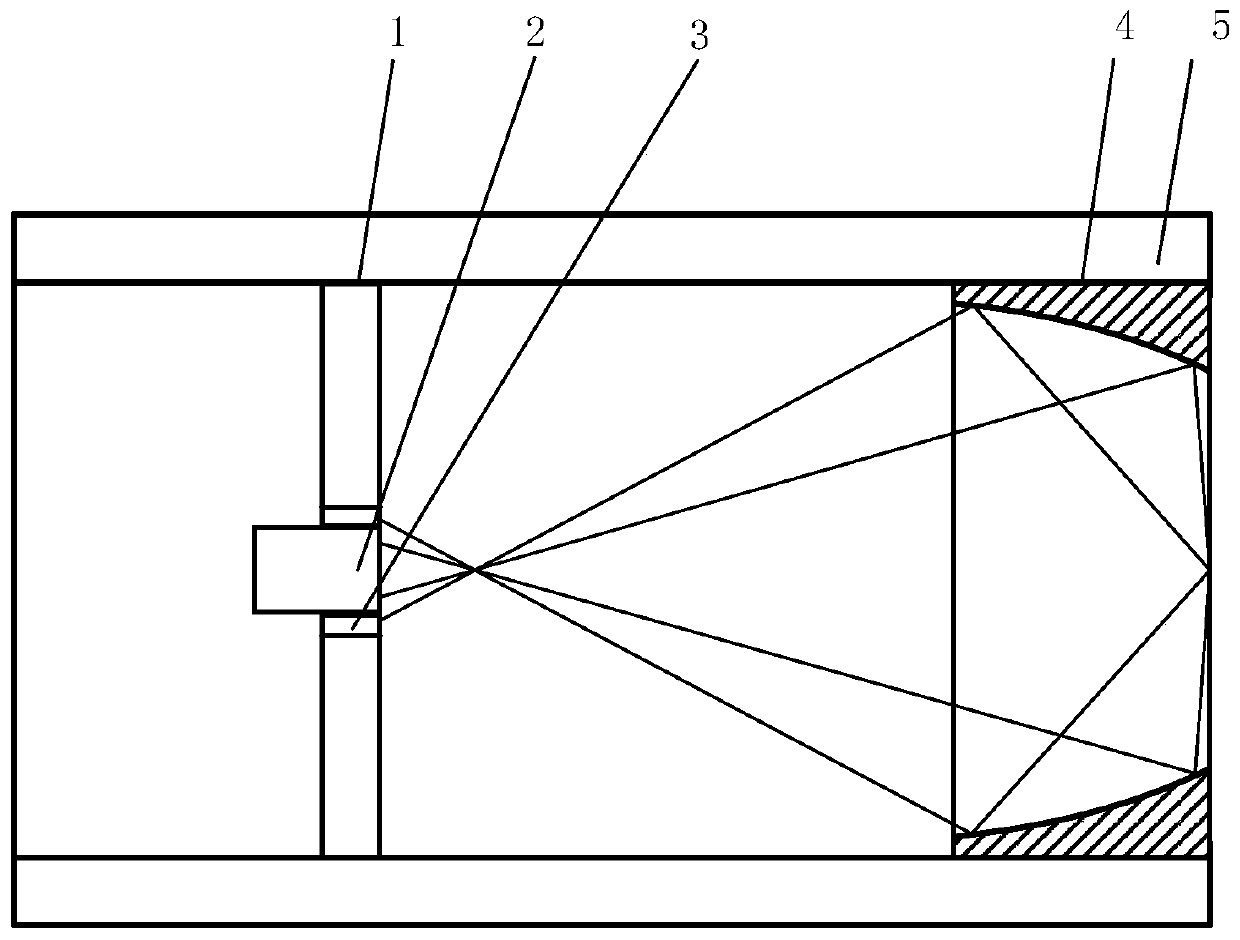

[0028] The structure schematic diagram of the bifocal positioning-free ellipsoid reflector lighting device of this embodiment is as follows figure 1 shown. The bifocal positioning-free ellipsoid reflector lighting device includes a coaxially arranged fixed disk 1, an objective lens 2, an objective lens adapter 3, an ellipsoid reflector 4 and a fixed sleeve 5;

[0029] The fixed disk 1 is installed inside the fixed sleeve 5, and the center of the fixed disk 1 has a threaded hole, and the objective lens adapter 3 for fixing the objective lens 2 is threadedly connected with the threaded hole, and the objective lens is realized by rotating in the threaded hole. 2. Move on the optical axis so that the focal point of the objective lens 2 coincides with the far focal point of the ellipsoidal reflector 4;

[0030] The near focal point of the ellipsoid reflector 4 is located on the end surface of the ellipsoid reflector 4 and the end surface of the fixed sleeve 5 at the same time.

specific Embodiment 2

[0032] The bifocal positioning-free ellipsoid reflector lighting device of the present embodiment, on the basis of the specific embodiment 1, further defines that the focal point of the objective lens 2 coincides with the far focus of the ellipsoid reflector 4, and the adjustment steps and judgment methods are as follows:

[0033] Step a, place a point light source at the near focal point of the ellipsoidal reflector 4, and place an observation screen or an imaging device behind the objective lens 2;

[0034] Step b, screwing the objective lens adapter 3 to move the objective lens 2 on the optical axis;

[0035] In step c, when the light intensity of the circular spot on the observation screen or the imaging device reaches the maximum value, the focal point of the objective lens 2 coincides with the far focal point of the ellipsoidal reflector 4 .

specific Embodiment 3

[0037] The bifocal positioning-free ellipsoid reflector lighting device of the present embodiment, on the basis of the specific embodiment 1, further defines that the focal point of the objective lens 2 coincides with the far focus of the ellipsoid reflector 4, and the adjustment steps and judgment methods are as follows:

[0038] Step a, place a point light source at the near focal point of the ellipsoidal reflector 4, and place an observation screen or an imaging device behind the objective lens 2;

[0039] Step b, screwing the objective lens adapter 3 to move the objective lens 2 on the optical axis;

[0040] Step c. Move the observation screen or imaging device on the optical axis. When the size of the circular light spot on the observation screen or imaging device remains unchanged, the focal point of the objective lens 2 coincides with the far focus of the ellipsoidal mirror 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com